Page 1

Peeler Model

Technical Reference Guide

410019406

Rev. G

Page 2

Page 3

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Cautions

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson

Corporation.

❏ The contents of this document are subject to change without notice. Please contact us for the latest information.

❏ While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or abuse of this product or

unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to strictly comply with Seiko

Epson Corporation’s operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original Epson Products or Epson Approved Products by Seiko Epson

Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

All other trademarks are the property of their respective owners and used for identification purpose only.

ESC/POS® Command System

Epson ESC/POS is a proprietary POS printer command system that includes patented or patent-pending commands. ESC/POS is

compatible with most Epson POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises a set of highly

functional and efficient commands and also offers the flexibility to easily make future upgrades.

©Seiko Epson Corporation 2002-2019. All rights reserved.

3

Page 4

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the

following carefully before handling the product.

WARNING:

You must follow warnings carefully to avoid serious bodily injury.

CAUTION:

Provides information that must be observed to prevent damage to the equipment or loss of data.

❏

Possibility of sustaining physical injuries.

❏

Possibility of causing physical damage.

❏

Possibility of causing information loss.

Note:

Provides important information and useful tips on handling the equipment.

4

Page 5

Warnings

❏

❏

❏

❏

❏

❏

❏

TM-L90/TM-L90 Peeler Model Technical Reference Guide

WARNING:

Shut down your equipment immediately if it produces smoke, a strange odor, or unusual noise.

Continued use may lead to fire or electric shock. Immediately unplug the equipment.

Only disassemble this product as described in this manual. Do not make modifications to the unit.

Tampering with this product may result in injury, fire, or electric shock.

Do not install this product or handle cables during a thunderstorm in order to avoid risk of electric

shock.

Be sure to use the specified power source. Connection to an improper power source may cause fire or

shock.

Never insert or disconnect the power plug with wet hands. Doing so may result in severe shock.

Do not allow foreign matter to fall into the equipment. Penetration by foreign objects may lead to fire or

electric shock.

If water or other liquid spills into this equipment, turn off the power switch and unplug the power cord

immediately. Continued usage may lead to fire or electric shock.

❏

Do not place multiple loads on power outlet. Overloading the outlet may lead to fire. Always supply

power directly from a standard domestic power outlet.

❏

Handle the power cord with care. Improper handling may lead to fire or electric shock.

• Do not modify or attempt to repair the cord.

• Do not place any heavy object on top of the cord.

• Avoid excessive bending, twisting, and pulling.

• Do not place the cord near heating equipment.

• Check that the plug is clean before plugging it in.

• Be sure to push the plug all the way in.

5

Page 6

Cautions

❏

❏

❏

❏

❏

❏

CAUTION:

Do not connect cables in ways other than those mentioned in this manual. Different connections may

cause equipment damage and burning.

Be sure to set this equipment on a firm, stable horizontal surface. Product may break or cause injury if it

falls.

Do not use in locations subject to high humidity or dust levels. Excessive humidity and dust may cause

equipment damage, fire, or shock.

Do not place heavy objects on top of this equipment. Never stand or lean on this equipment. Equipment

may fall or collapse, causing breakage and possible injury.

To ensure safety, unplug this equipment prior to leaving it unused for an extended period.

Take care not to injure your fingers on the manual cutter

• When you remove printed paper

• When you perform other operations such as loading/replacing roll paper

❏

Do not open the roll paper cover without taking the necessary precautions, as this can result in injury

from the autocutter fixed blade.

❏

Do not use aerosol sprayers containing flammable gas inside or around this product. Doing so may

cause fire.

❏

Make sure to avoid bumping or otherwise exposing the printer to strong impact during operation.

Restriction of Use

When this product is used for applications requiring high reliability/safety such as transportation devices

related to aviation, rail, marine, automotive etc.; disaster prevention devices; various safety devices etc; or

functional/precision devices etc, you should use this product only after giving consideration to including

fail-safes and redundancies into your design to maintain safety and total system reliability. Because this

product was not intended for use in applications requiring extremely high reliability/safety such as

aerospace equipment, main communication equipment, nuclear power control equipment, or medical

equipment related to direct medical care etc, please make your own judgment on this product’s suitability

after a full evaluation.

Modular Connector

Use the modular connectors specifically designed for the cash drawer for this product. Do not connect

these connectors to an ordinary telephone line.

6

Page 7

TM-L90/TM-L90 Peeler Model Technical Reference Guide

About This Manual

Aim of the Manual

This manual was created to provide all information necessary for system planning, design, installations

and application of the printer for designers and developers of POS systems.

Manual Content

The manual is made up of the following sections:

Chapter 1 Product Overview

Chapter 2 Setup

Chapter 3 Connecting to the Host Computer and Options

Chapter 4 Setting/Checking Modes

Chapter 5 Application Development Information

Chapter 6 ESC/POS Command-Related Information

Chapter 7 Handling

Appendix Setting items for Memory Switch Setting Mode

Specifications

Character Code Table

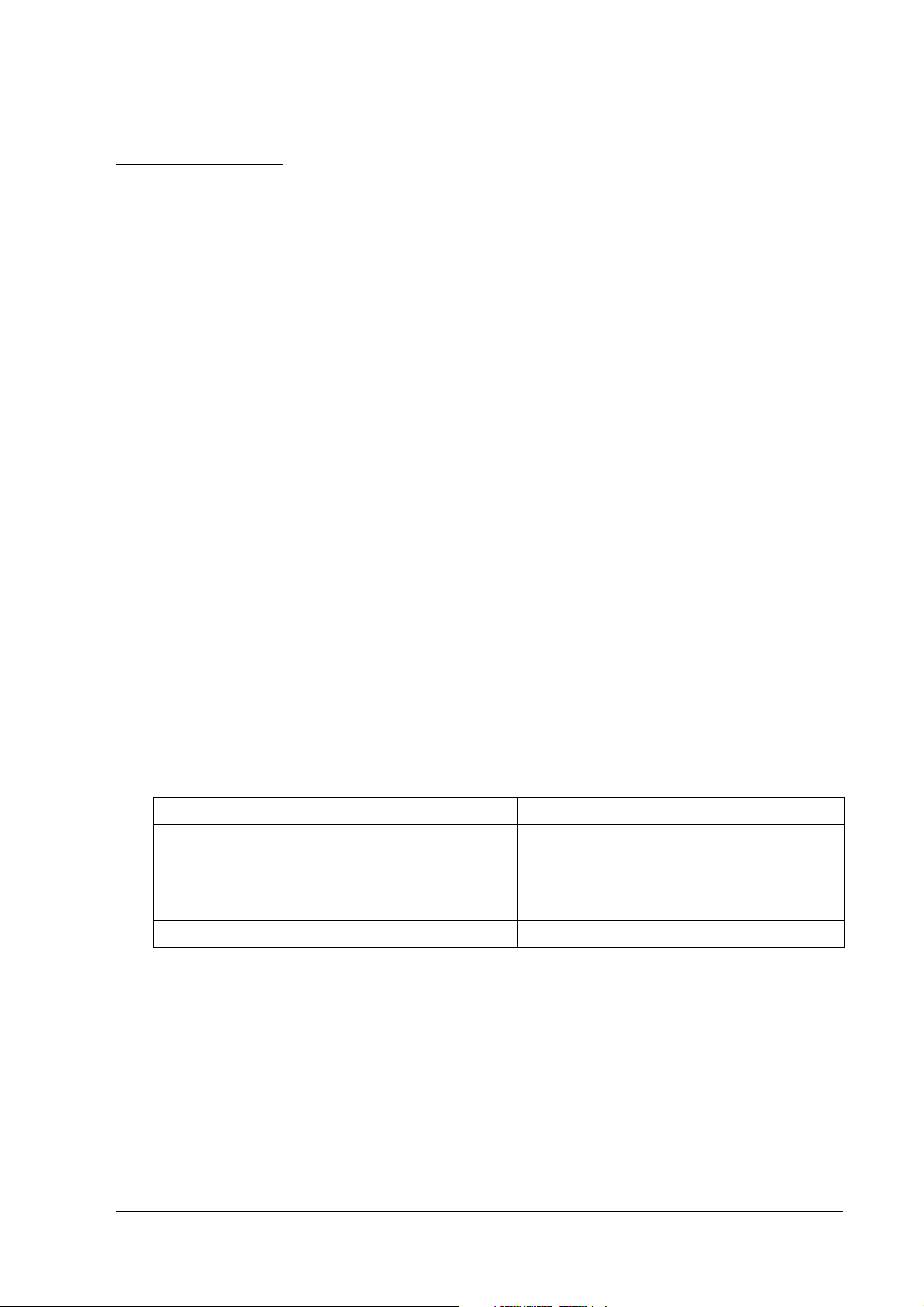

Related Documentation

The following documents also relate to the TM-L90 / TM-L90 Peeler Model.

Name of document Description

TM-L90 User's Manual (for TM-L90)

TM-L90 with Peeler User's Manual (for TM-L90 Peeler other

than 39* models)

TM-L90 Peeler Model User's Manual (for TM-L90 Peeler 39*

models)

ESC/POS Command Reference Provides detailed ESC/POS command information.

Comes with the printer.

Provides information to enable POS operators to use

the printer safely and correctly.

7

Page 8

For Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Key to Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Restriction of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Modular Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Aim of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Manual Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Product Overview

Product Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Name and Description of Each Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Part Names (TM-L90) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Part Names (TM-L90 Peeler Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Paper FEED button inside the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power Switch Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mode Switch (TM-L90 Peeler Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2 Setup

Setup Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Precaution For Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Instructions for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Adjusting Roll Paper Near-End Detection Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

With TM-L90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

With the TM-L90 Peeler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting AC adapter (PS-180) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Attaching AC adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Caution about AC adapter and Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Autocutter Settings (TM-L90 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cautions on the Lengths of the Receipts/Labels to Issue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setting Roll Paper Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Memory Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Memory switches of TM-L90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Memory switches of TM-L90 Peeler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Paper Loading Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

With TM-L90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

With the TM-L90 Peeler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setting Paper Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Clearing Paper Layout Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Connecting the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting to the Host Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Connecting to the Host Computer and Options

With the RS-232C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8

Page 9

TM-L90/TM-L90 Peeler Model Technical Reference Guide

With the Parallel (IEEE1284) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

With the USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

With the Ethernet Interface (TM-L90 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

With the Wireless LAN Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Connecting the Cash Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setting the internal buzzer (for models with an internal buzzer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Chapter 4 Setting/Checking Modes

Setting/Checking Modes of TM-L90 4** models, TM-L90 Peeler 39* models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Self-test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

NV Graphics Information Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Memory Switch Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Hexadecimal Dump Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Setting/Checking Modes of TM-L90 other than 4** models, TM-L90 Peeler other than 39* models . . . . . . . . . . . . . . . . . . . . . .80

Self-test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Memory Switch Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Hexadecimal Dump Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 5 Application Development Information

Introduction of Control Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Windows Driver (EPSON Advanced Printer Driver) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

EPSON OPOS ADK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

ESC/POS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Various Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Paper Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Printer Cover Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Label Peeling Sensor (Peeler Specification Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Barcode Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

CODE 128 Barcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Precautions for Two-Dimensional Code Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

NV Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

FAQ List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chapter 6 ESC/POS Command-Related Information

TM Printer Operation Performed When Power Switch is Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Power Switch-Related User Operation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Power Off Control by the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Head Divided Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Control After Paper Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

NV Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Customizing Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Printer Initial Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Changing Command Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Using the NV Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Printer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 7 Handling

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Cleaning the autocutter (TM-L90 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Print Head Cleaning

Cleaning the peeler (TM-L90 Peeler Model only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Panel LED and Error Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

The autocutter is jammed or the roll paper cover will not open (TM-L90 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9

Page 10

When a paper jam occurs (TM-L90 Peeler Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

The printer became inoperative after you change the interface reset signal in the memory switch setting mode . . . . . . . . 117

Shipping Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix Appendix

Setting items for Memory Switch Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Setting items of TM-L90 4** models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Setting items of TM-L90 other than 4** models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Setting items of TM-L90 Peeler 39* models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Setting items of TM-L90 Peeler other than 39* models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Print Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Character Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Paper Feed Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Printing Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Printing Position in Relation to Cutter Position (TM-L90) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Printing Position, Peeling Position, Manual Cutter Position (TM-L90 Peeler Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Overview of External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Interface And Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

RS-232 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

IEEE1284 Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Option Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

PS-180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Consumable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Specified Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Requirements for Receipt Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Requirements for Die-Cut Label Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Requirements for Continuous Label Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Notes on Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Character Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

10

Page 11

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Chapter 1

Product Overview

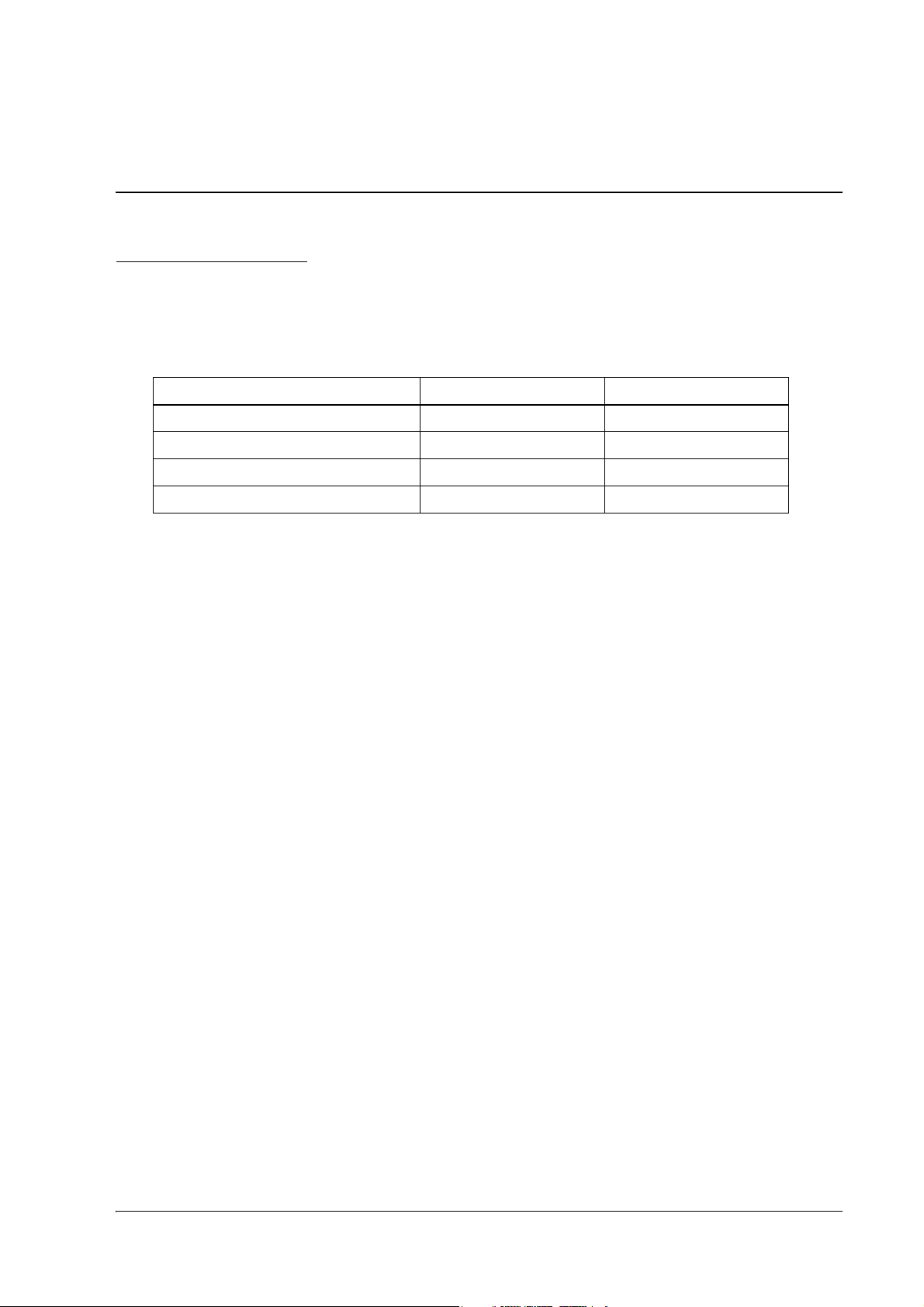

1.1 Product Structure

1.1.1 Models

❏

Model

Peeler unit Power switch

TM-L90 other than 4** models not mounted non-locking push button

TM-L90 4** models not mounted locker switch

TM-L90 Peeler other than 39* models mounted non-locking push button

TM-L90 Peeler 39* models mounted locker switch

❏

Interface

• Serial (RS-232C)

• Parallel (IEEE-1284 standard)

• USB (USB2.0)

• Ethernet (10BASE-T/100BASE-T)

• Wireless LAN (IEEE802.11a/b/g/n for TM-L90 4** models, TM-L90 Peeler 39* models)

• Wireless LAN (IEEE802.11b for the other models)

TM-L90 4** models and TM-L90 Peeler 39* models may have the build-in-USB.

1.1.2 Accessories

TM-L90

❏

Start Here

❏

Label roll paper

❏

Manual CD

❏

Power switch cover

❏

Control panel label used for horizontal installation

❏

Paper exit guide for horizontal installation

❏

Roll paper spacer

Product Overview 11

Page 12

❏

Screw for installation of the roll paper spacer

❏

Wire saddle*

❏

AC adapter*

❏

AC cable*

* May not be included depending on the printer model.

TM-L90 Peeler Model

❏

Start Here

❏

Label roll paper

❏

Manual CD

❏

Power switch cover

❏

Operation label (an instruction label for the peeler open lever and the cover open lever)

❏

Roll paper spacer

❏

Screw for installation of the roll paper spacer

❏

Wire saddle

❏

AC adapter *

❏

AC cable *

* May not be included depending on the printer model.

1.1.3 Option

❏

Affixing tapes (model: DF-10)

❏

Wall hanging bracket (model: WH-10)

❏

AC adapter PS-180 (PS-180 supports power-saving feature)

❏

Power cables

12 Product Overview

Page 13

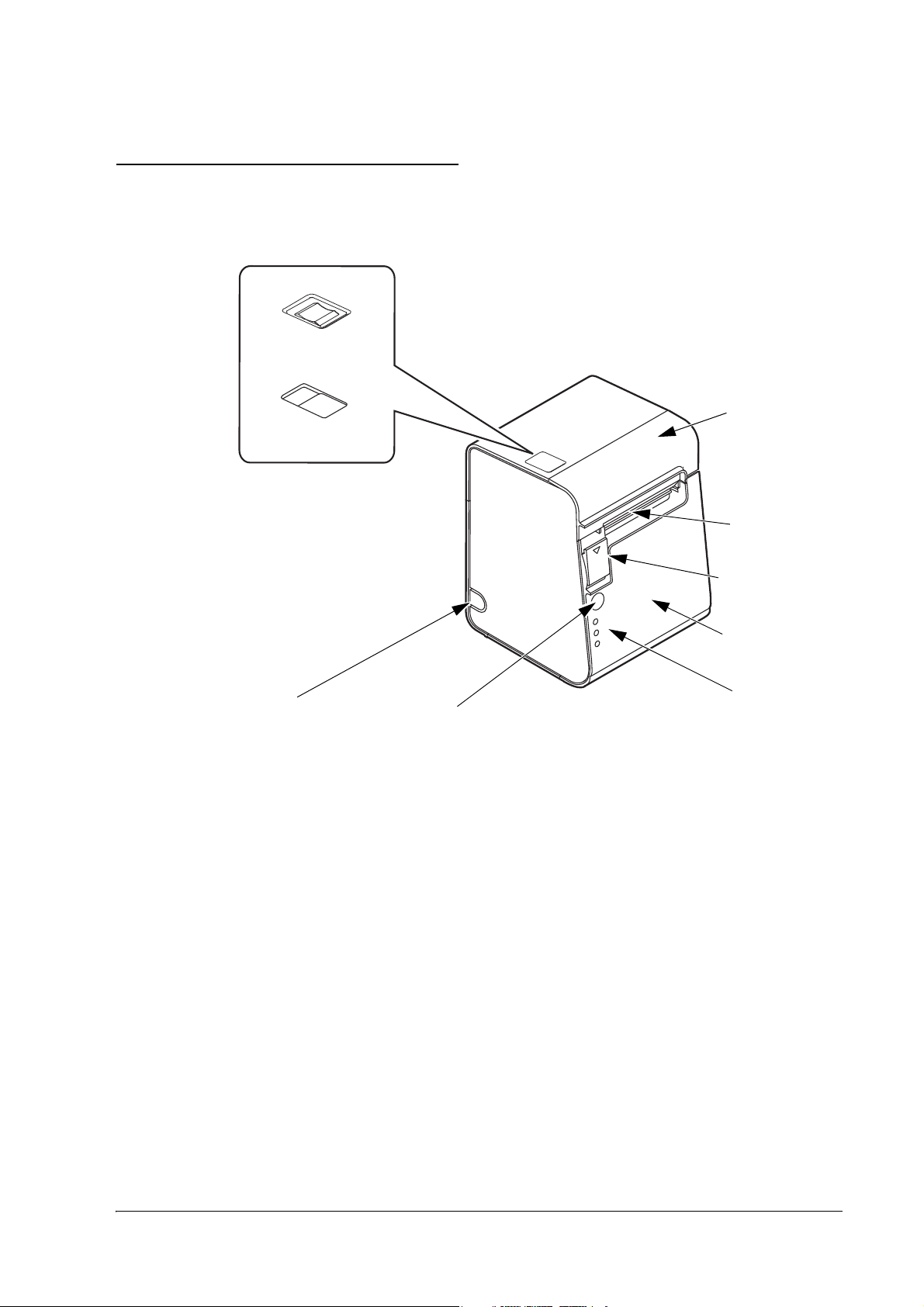

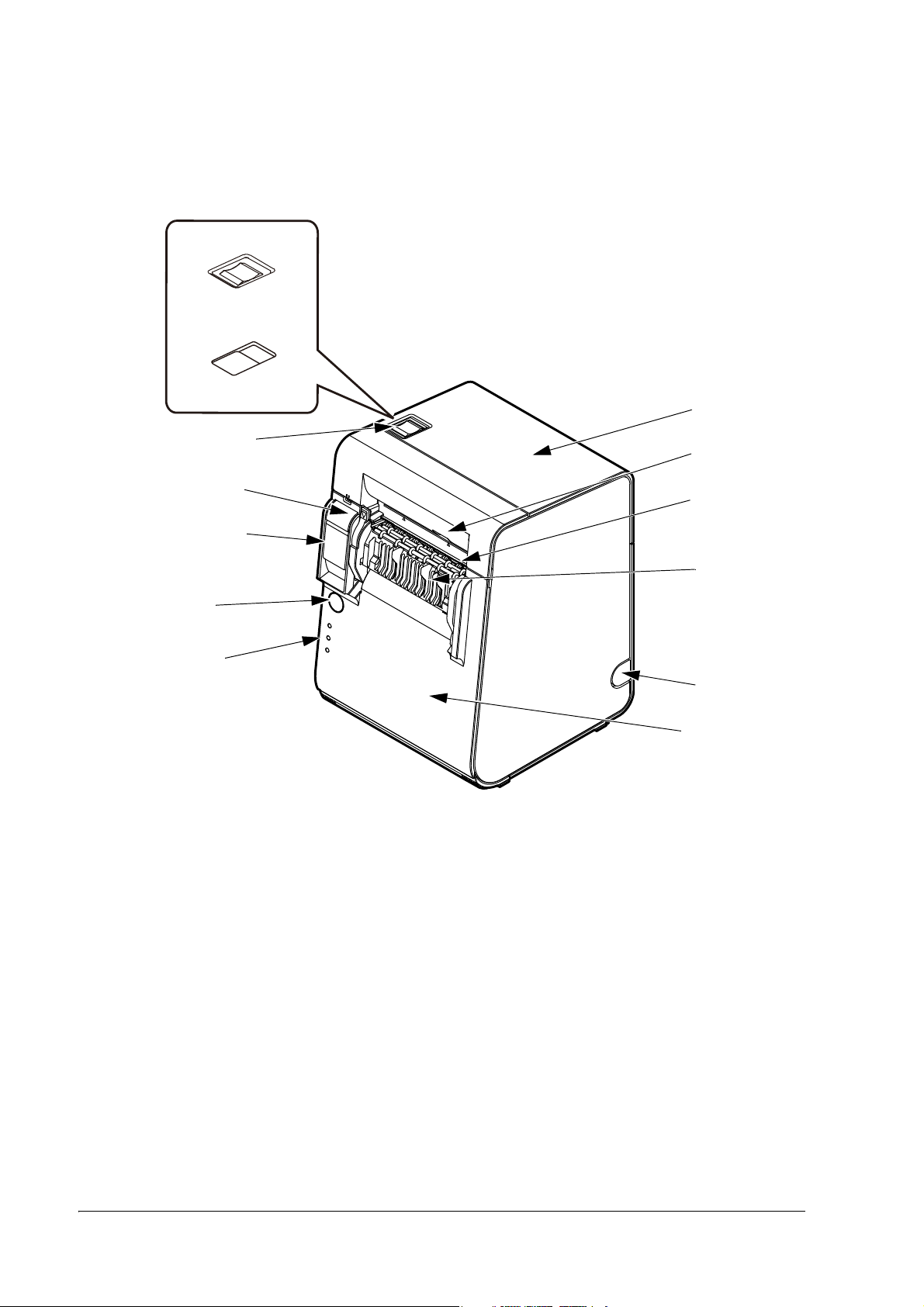

1.2 Name and Description of Each Part

Cutter cover

Control panel

Roll paper cover

Cover open lever

FEED Button

Perforation to pass the

cables through

Manual cutter

Rocker switch (with a

power switch soft cover)

or

Non-locking

push button

Power switch

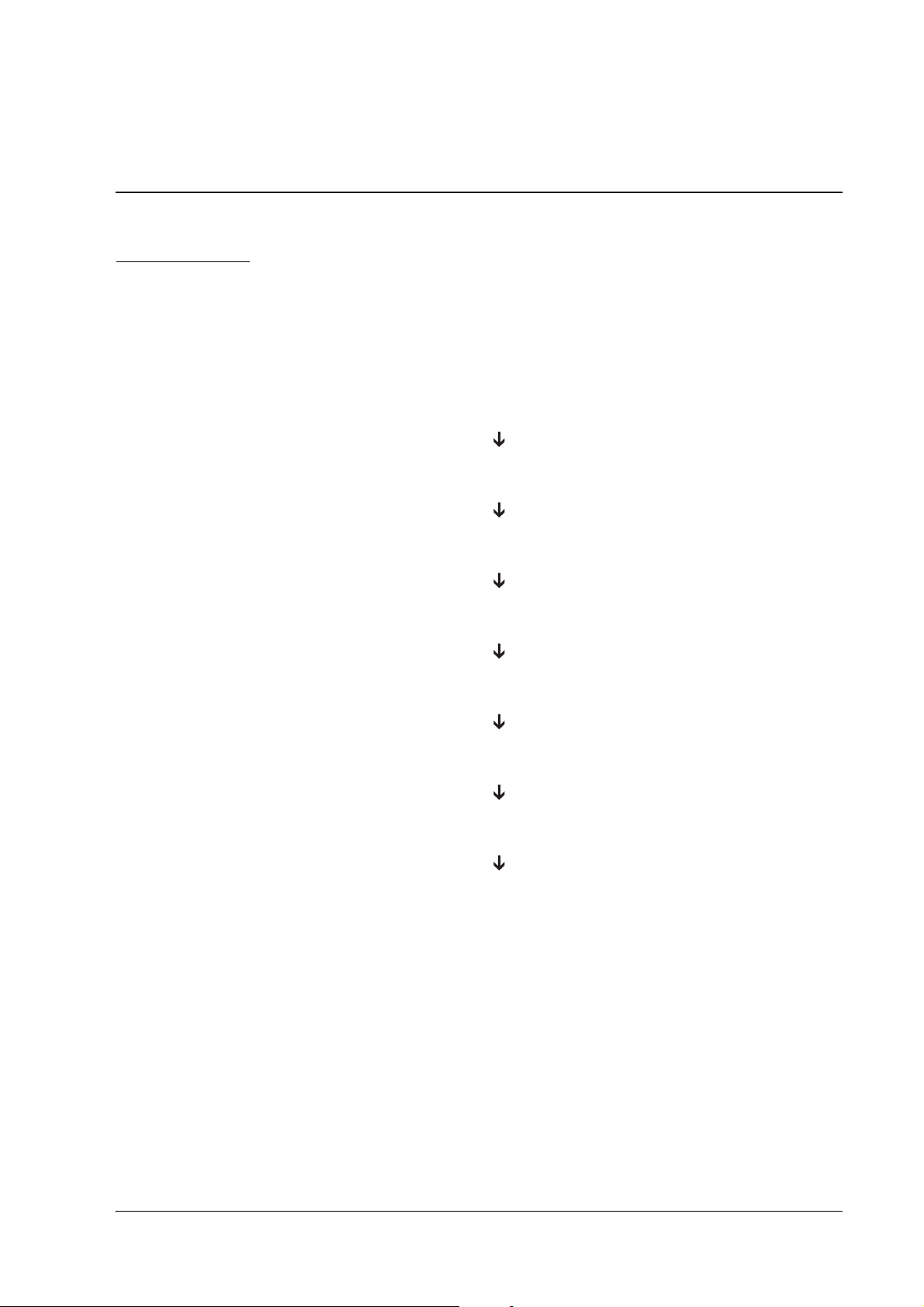

1.2.1 Part Names (TM-L90)

TM-L90/TM-L90 Peeler Model Technical Reference Guide

* Refer to page 42 for the location of the DIP switches (available only for TM-L90 other than 4** models).

Printer Part Names

Product Overview 13

Page 14

1.2.2 Part Names (TM-L90 Peeler Model)

Cutter cover

Control panel

Roll paper cover

Power switch

Peeler cover

FEED Button

Wiring knockout

Manual cutter

Peeler open lever

Cover open lever

Label peeling sensor

Rocker switch (with a

power switch soft cover)

or

Non-locking

push button

Power switch

* Refer to page 42 for the DIP switch positions. (available only for TM-L90 Peeler other than 39* models)

Part Names of TM-L90 Peeler Model

14 Product Overview

Page 15

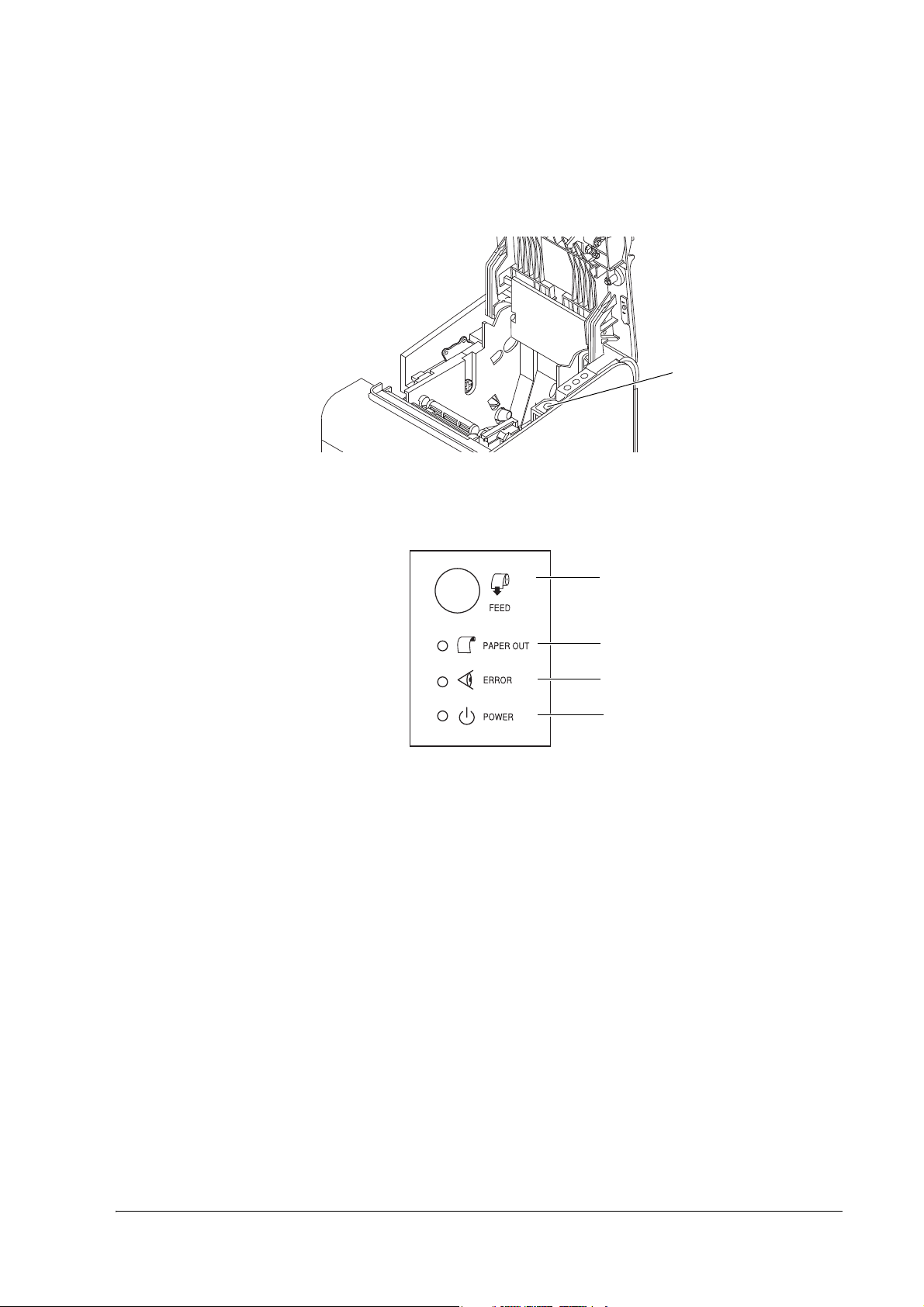

1.2.3 Paper FEED button inside the printer

Paper FEED button

(inside the printer)

ERROR LED

PAPER OUT LED

FEED Button

POWER LED

Another FEED button is located under the roll paper cover.

1.2.4 Control Panel

TM-L90/TM-L90 Peeler Model Technical Reference Guide

FEED button (with the TM-L90)

When using label paper or receipt paper with black mark:

❏

Pressing this button feeds paper to the next print starting position.

When using receipt paper:

❏

Pressing this button once feeds paper by one line. Holding this button down feeds paper continuously.

FEED button (with the TM-L90 Peeler Model)

When using label paper or receipt paper with black mark:

❏

Pressing this button feeds paper to the next print starting position.

❏

Pressing this button after opening/closing the roll paper cover initializes the mechanism. (After closing

the roll paper cover, the status changes to waiting to print when FEED button is pressed)

❏

When error recovery with FEED button is enabled by memory switch 8-1, if a paper layout error occurs,

pressing FEED button recovers from the error and performs automatic paper layout.

Product Overview 15

Page 16

When using receipt paper:

❏

Pressing this button once feeds paper by one line. Holding this button down feeds paper continuously.

PAPER OUT LED (with the TM-L90)

❏

Lights when there is no more roll paper or there is little remaining.

(Default setting. The LED condition varies according to the memory switch settings. Refer to "Memory

Switch Settings" on page 42 and "Error Code" on page 111 for details.)

❏

Off when there is a sufficient amount of roll paper remaining.

(Default setting. The LED condition varies according to the memory switch settings. Refer to "Memory

Switch Settings" on page 42 and "Error Code" on page 111 for details.)

❏

Flashes when a self test is in progress or when the printer waits for the macro execution switch to go on.

PAPER OUT LED (with the TM-L90 Peeler Model)

❏

Lights when there is no more roll paper or there is little remaining.

(Default setting. The LED condition varies according to the memory switch settings. Refer to "Memory

Switch Settings" on page 42 and "Error Code" on page 111 for details.)

❏

Off when there is a sufficient amount of roll paper remaining.

(Default setting. The LED condition varies according to the memory switch settings. Refer to "Memory

Switch Settings" on page 42 and "Error Code" on page 111 for details.)

❏

Flashes when a self test is in progress or when the printer waits for the macro execution switch to go on.

❏

When the roll paper is inserted and the roll paper cover is closed, one label is ejected and the LED starts

flashing. It flashes until FEED button is pressed.

❏

When a label is issued, flashing starts after it is issued. The LED flashes until the label is removed from

the peeler.

POWER LED

❏

Lights when the power supply is on.

❏

Off when the power supply is turned off.

❏

Flashes during execution of each operation.

ERROR LED

❏

Lights when the printer is offline.

❏

Off under normal conditions.

❏

Flashes when an error occurs. (Refer to "Error Code" on page 111 for details)

16 Product Overview

Page 17

TM-L90/TM-L90 Peeler Model Technical Reference Guide

1.2.5 Power Switch

Refer to "Printer Part Names" on page 13 for the power switch location. The type of the power switch

differs, depending on models and functions may differ, depending on the models. Therefore, be sure to

check the type of the power switch of your printer and a model number on the manufacturer’s plate of

your printer.

Rocker switch (TM-L90 4** models, TM-L90 Peeler 39* models):

Turns the printer on or off. The marks on the switch: ( / )

Non-locking push button (TM-L90 other than 4** models, TM-L90 Peeler other than 39* models):

Turn on the power by holding down the POWER button 1 second or longer. Turn off the power by

holding down the POWER button 3 seconds or longer.

The printer is normally turned on/off with this switch. You can select whether to enable or disable the

power switch using the DIP switches.

When the DIP switches are set to OFF (power switch enabled), the power switch controls the TM

printer as follows.

When the TM is turned off:

The TM printer is powered ON when the power switch is pressed more than 1 second.

When the TM is turned on:

The TM printer is powered OFF when the power switch is pressed more than 3 seconds.

If for some reason pressing the power switch even more than 10 seconds does not turn the power

off, the TM printer executes a forced power off.

Note:

When the DIP switches are set to ON (power switch disabled), use direct control of the printer with ESC/POS

commands. (For details, refer to "TM Printer Operation Performed When Power Switch is Disabled" on page

101.)

Note:

Make sure to check whether the AC adapter is connected to the power supply before turning on the power

switch of the printer.

Product Overview 17

Page 18

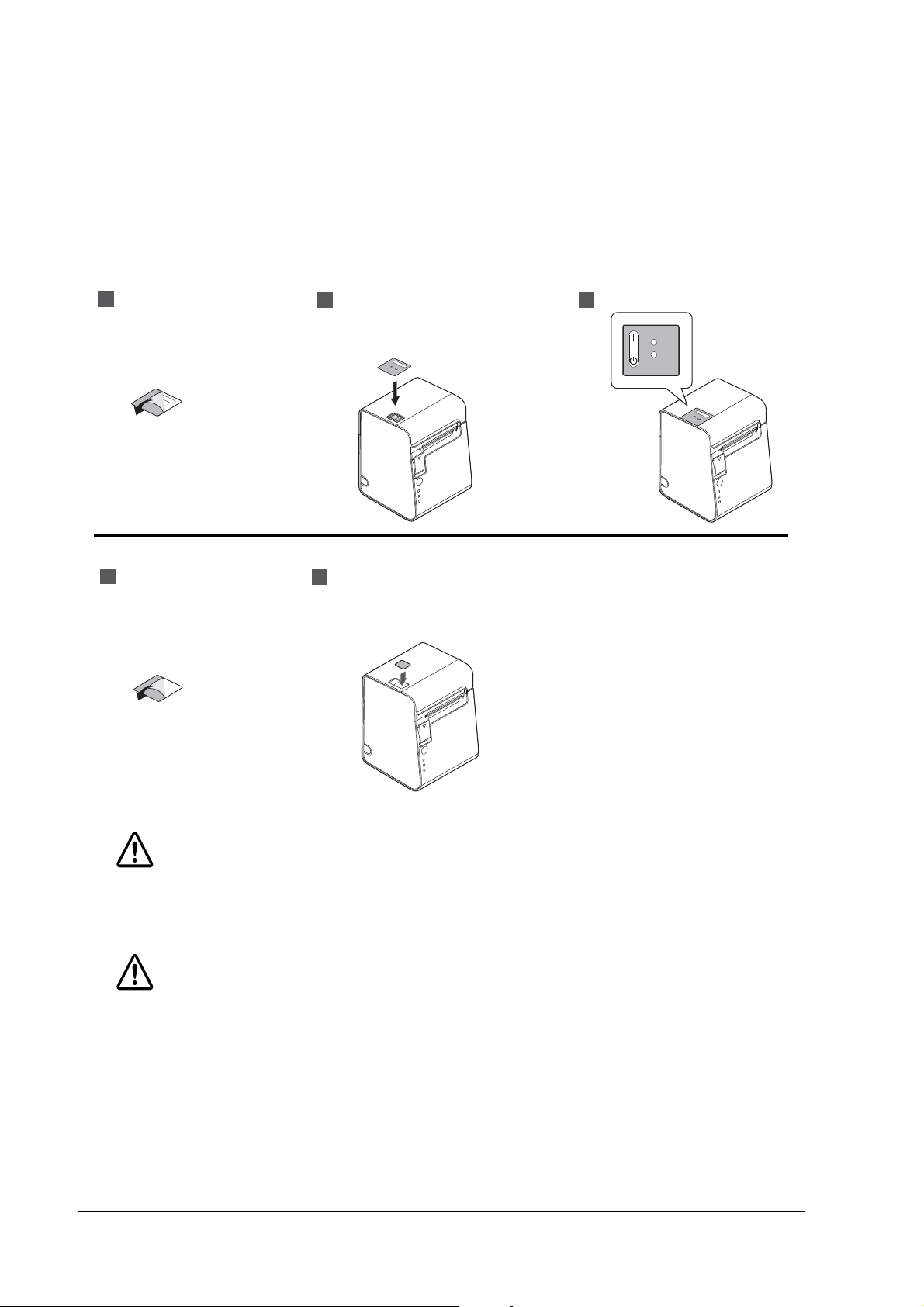

1.2.6 Power Switch Cover

2

3

1

2

1

TM-L90 4** models, TM-L90 Peeler 39* models

TM-L90 other than 4** models, TM-L90 Peeler other than 39* models

To prevent unintentional contact or improper changes and to improve the appearance, use a power switch

cover. When using the power switch cover, to turn on or off the TM printer, press the power switch

through the hole in the power switch cover. Attach the cover as shown in the illustrations below.

WARNING:

If an accident occurs with the power switch cover attached, unplug the power cord immediately. Continued

use may cause fire or shock.

CAUTION:

Do not remove the power switch soft cover. (only for TM-L90 4** models and TM-L90 Peeler 39* models)

18 Product Overview

Page 19

TM-L90/TM-L90 Peeler Model Technical Reference Guide

mode switch

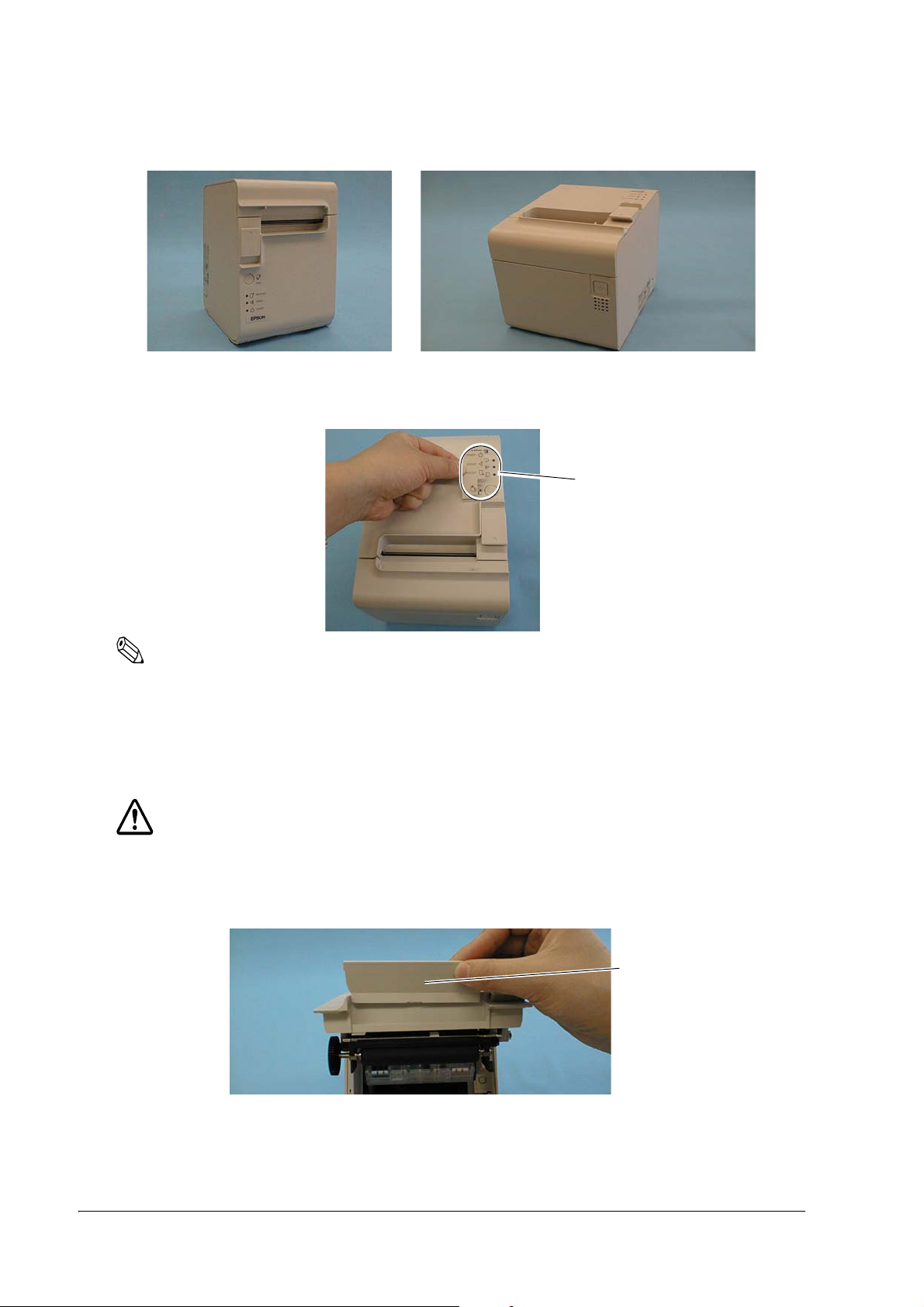

1.2.7 Mode Switch (TM-L90 Peeler Model Only)

With the TM-L90 Peeler Model, you can select the peeling issuing mode and continuous issuing mode

with the mode switch. The mode switch switches between the peeling issuing mode and continuous

issuing mode.

The mode switch is inside the top left of the printer when the roll paper cover is opened.

Note:

Be sure that the peeler cover and the roll paper cover are open when switching the modes. The setting is

effective when the power is turned on or the covers are closed. If the mode is switched with the covers

closed, the setting will not be changed.

Be sure not to use a ball point pen to switch the modes. A ball point pen can damage the switch.

To use the peeling issuing mode, move the mode switch to the right.

To use the continuous issuing mode, move the mode switch to the left.

Product Overview 19

Page 20

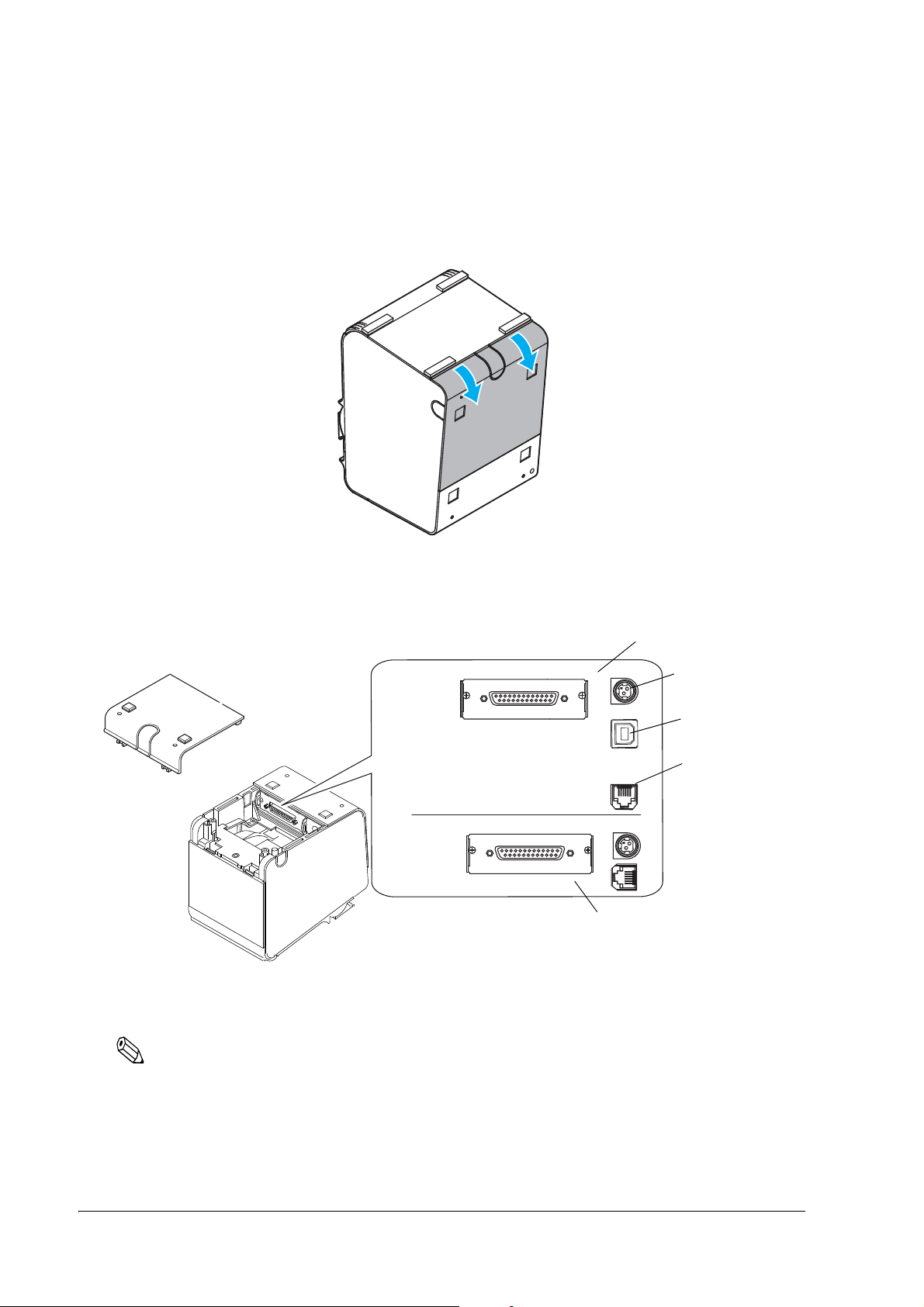

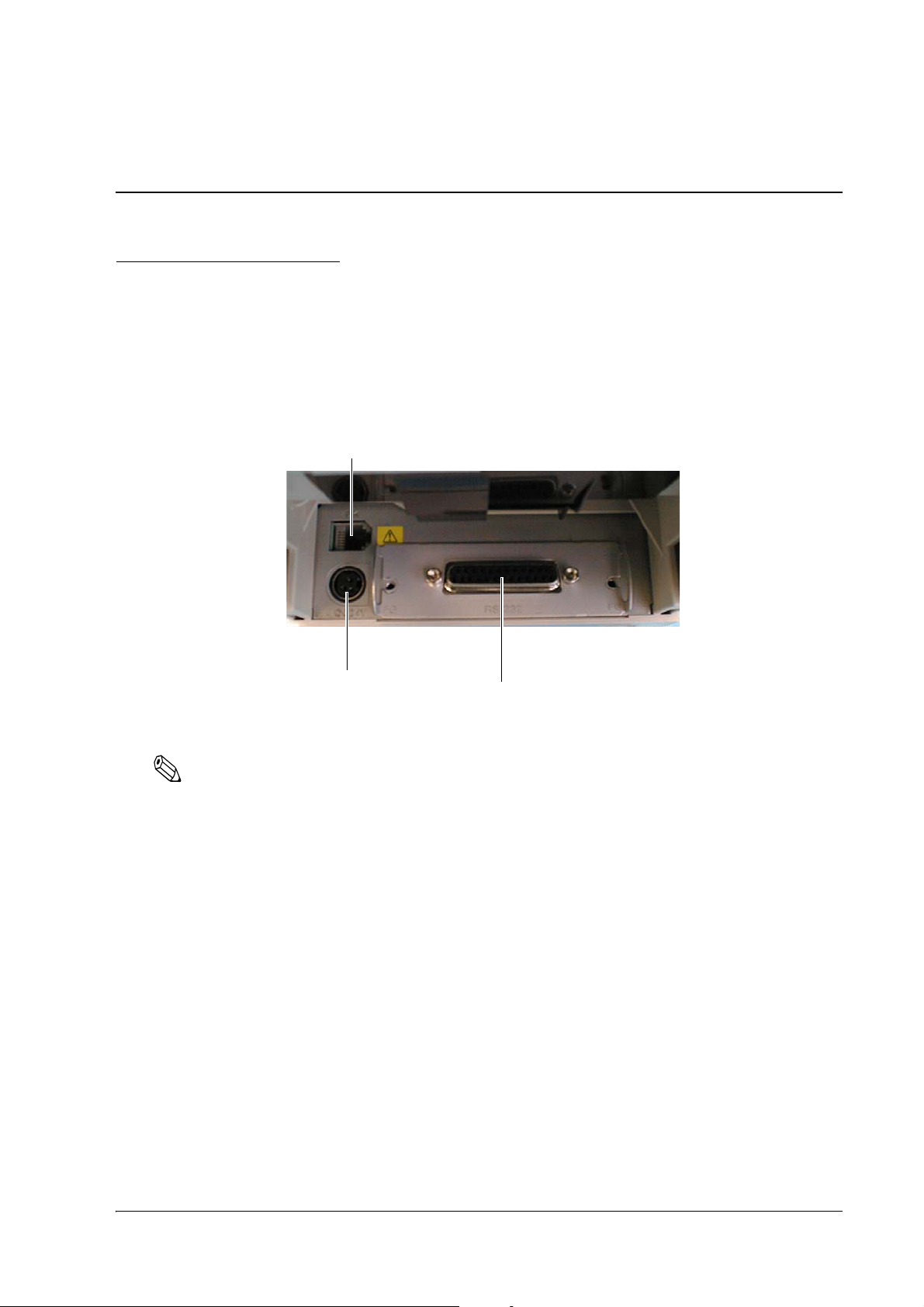

1.2.8 Connectors

Drawer kick

connector

power supply

connector

TM-L90 4** models,

TM-L90 Peeler 39* models

TM-L90 other than 4** models,

TM-L90 Peeler other than 39* models

USB interface

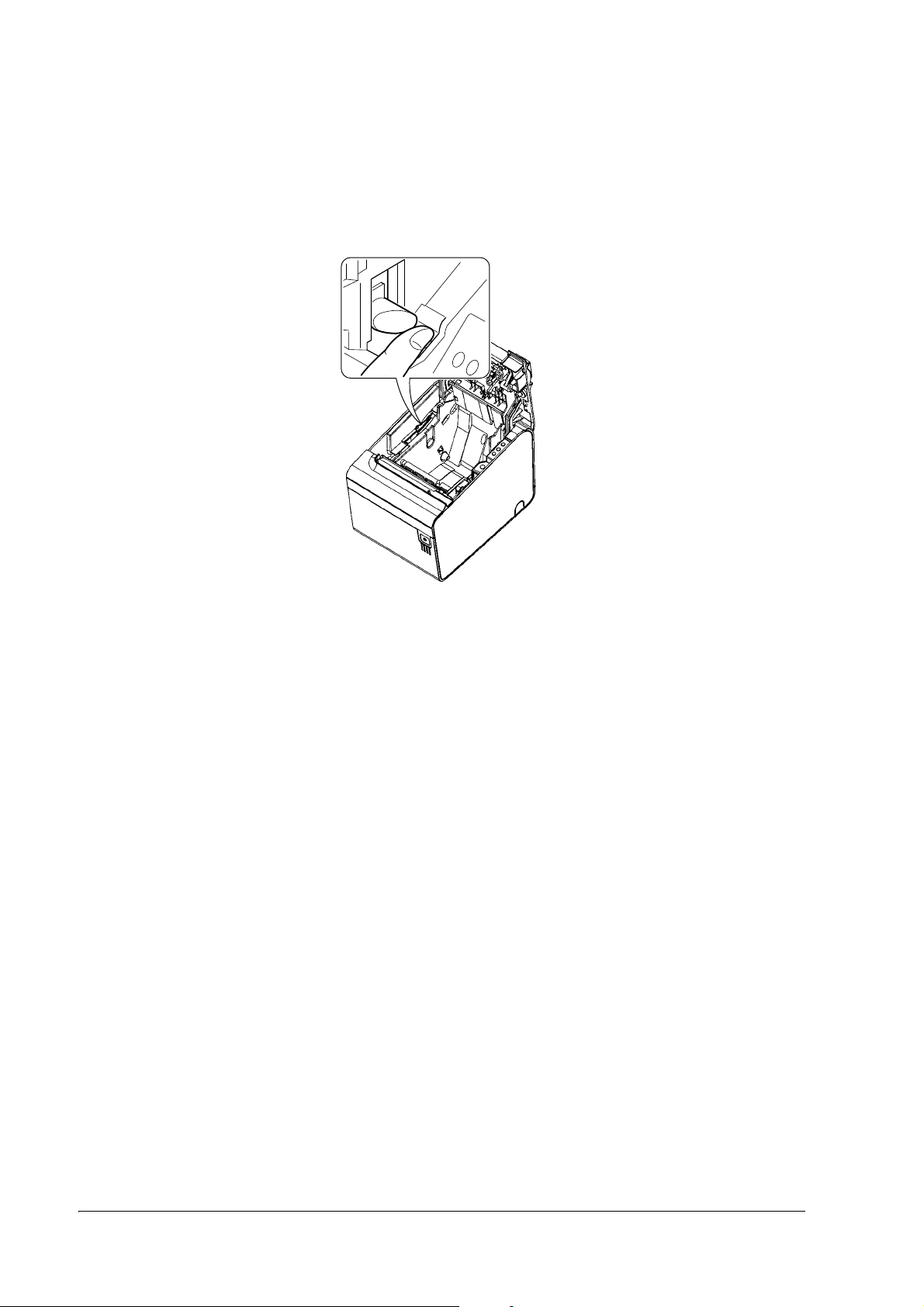

Remove the bottom of the cover as shown in the illustration below. All cables are connected to the

connector panel located on the lower rear side of the printer.

The connector panel differs, depending on the models.

Connector Panel

Note:

The model pictured is a serial interface model. For other information on interfaces and connectors, refer to

"Connecting the Cable" on page 63.

20 Product Overview

Page 21

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Chapter 2

Setup

2.1 Setup Flow

Before using the printer, you need to set various settings to increase the printer's functionality. Configure

the printer appropriately depending on the environment.

Determine how to install the printer (install it vertically or horizontally)

Set the Roll Paper Near-End Detector

Connect the AC adapter

Autocutter settings (TM-L90 only)

Set the Roll Paper width

DIP switch settings

Memory switch settings

Set the Paper layout

Setup 21

Page 22

2.2 Installation Procedures

2.2.1 Precaution For Installation

❏ TM-L90

• Locate the printer on a flat surface, whichever orientation you choose.

• Avoid locations susceptible to dust and other foreign matter.

• Avoid resting the printer on the power supply or other cables or other objects.

• Consider vibration during paper cutting and drawer usage. Take measures to prevent the printer

from moving.

❏ TM-L90 Peeler Model

• Locate the printer on a flat surface.

• Avoid locations susceptible to dust and other foreign matter.

• Avoid resting the printer on the power supply or other cables or other objects.

• Consider vibration during paper cutting and drawer usage. Take measures to prevent the printer

from moving.

• To prevent malfunction of the label peeling sensor, do not locate the printer in direct sunlight.

22 Setup

Page 23

TM-L90/TM-L90 Peeler Model Technical Reference Guide

2.2.2 Instructions for Installation

The TM-L90 can be placed vertically (paper outlet in front), horizontally (paper outlet at the top), or

attached to a wall (using the optional wall hanging set WH-10).

With the TM-L90 Peeler Model, you can use it vertically or wall mounted with either peeling issuing or

with continuous issuing (not using the peeler).

Note:

For the TM-L90 Peeler Model, horizontal installation is prohibited to avoid jams caused by re-sticking of

backing paper and a label.

The illustration below shows the vertical installation for the TM-L90 Peeler Model.

Note:

To hang the printer on the wall, see the Wall Hanging Bracket Set Installation Manual provided with the

WH-10 for instructions.

It is recommended to take some measures so that the printer will be stable when paper is being loaded or a

drawer is being used. The DF-10 (affixing tapes) for fixing the printer is provided as an option.

When using the printer with the peeling issuing mode, be sure to install the printer so that a peeled label will

not contact the used backing paper. Re-sticking of a peeled label to the backing paper will cause jams.

For the TM-L90, when changing the way of installation, you need to adjust the following items:

• Control panel label used for horizontal installation

• The location of the Roll Paper Near-End Detector

The following figure shows the TM-L90 placed both vertically and horizontally.

Setup 23

Page 24

When you install the printer horizontally, attach the control panel label as shown in the illustration below.

Control panel label

paper exit guide

Note:

To hang the printer on the wall, see the Wall Hanging Bracket Set Installation Manual provided with the

WH-10 for instructions.

When you use TM-L90 horizontally, peel off the backing sheet of the paper exit guide and attach it as

shown below to prevent cut paper from falling inside the printer after paper is cut by the autocutter.

CAUTION:

When using the paper exit guide, do not use roll paper with a core that is smaller than the specification

(inside diameter: 25.4 mm, outside diameter: 31.4 mm). Using a smaller one may cause a paper jam at the

attached paper exit guide.

24 Setup

Page 25

TM-L90/TM-L90 Peeler Model Technical Reference Guide

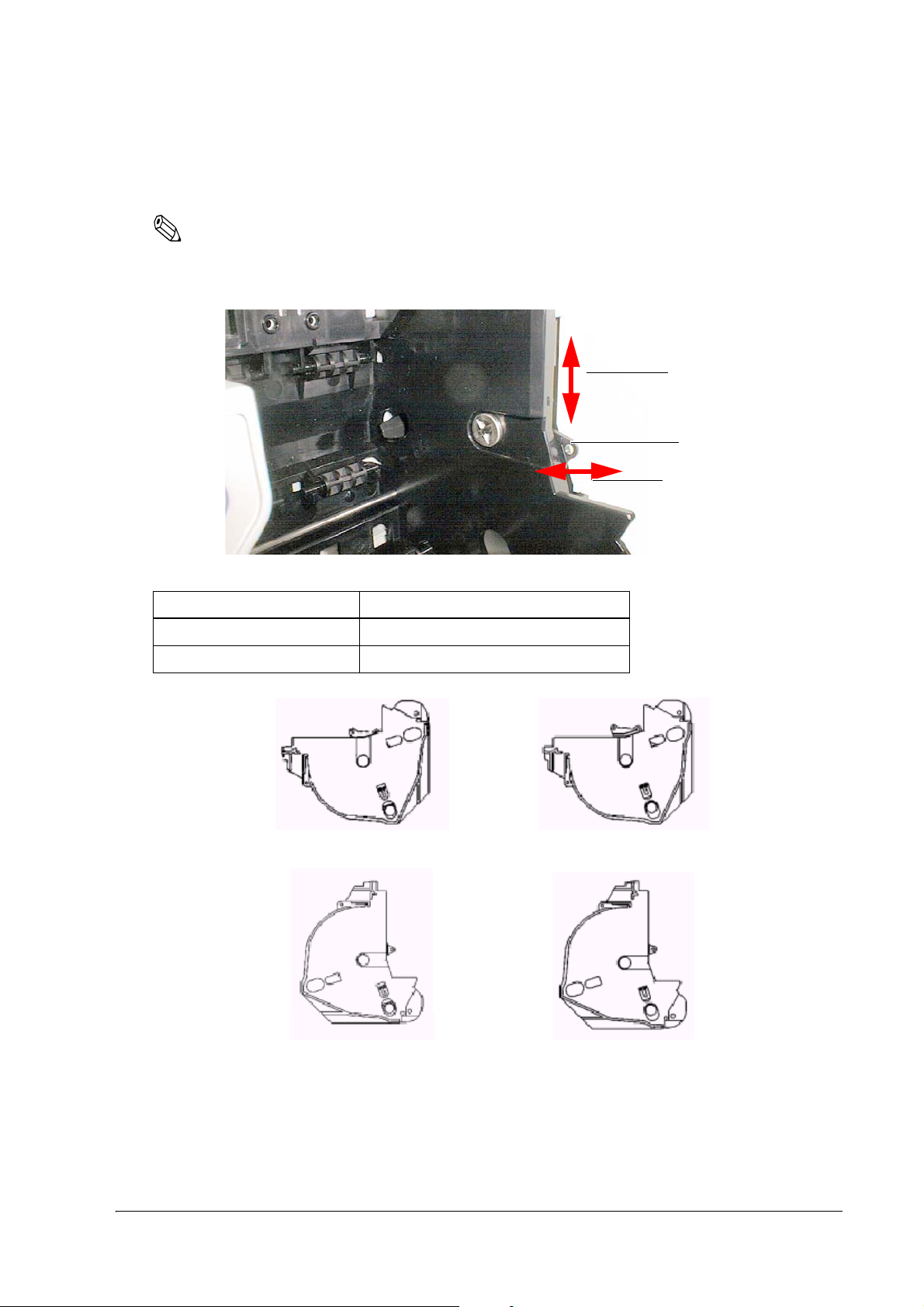

Detector adjustment screw

N.E. detector holder

N.E. detector

(location when installing

horizontally)

N.E. detector window

when installing vertically

2.3 Adjusting Roll Paper Near-End Detection Position

2.3.1 With TM-L90

Below are three situations when roll paper N.E. detector adjustment is required.

❏ When changing the way of installation. (Vertically ↔ Horizontally)

❏ To adjust the location of detection to suit the diameter of the roll paper core used.

❏ To adjust the amount of remaining paper desired.

Note:

Roll paper centers are manufactured according to various specifications, making it impossible to exactly

detect the remaining amount of paper.

1. Open the roll paper cover.

2. Remove the roll paper.

Part names and the locations of N.E. detector components

Setup 25

Page 26

3. Loosen the detector adjustment screw using a coin or similar tool.

Detector

adjustment

screw

Move the N.E. detector

holder in the direction of

the arrow to make the

detector come out from the

window for either vertical

or horizontal installation.

4. The adjustment position of the roll paper Near-End detector changes depending on the way of

installation. In either case (vertical or horizontal), adjust the detector so that its tab comes out from

the hole near the bottom of the printer. (Refer to "Adjusting Roll Paper Near-End Detection Position"

on page 25, "Adjustment Positions of N.E. Detector" on page 27.

Note:

When changing the position of the N.E. detector in accordance with the change of installation, move the roll

paper N.E. detector as the above arrow shows while holding down the detector.

26 Setup

Page 27

TM-L90/TM-L90 Peeler Model Technical Reference Guide

N.E. detector holder

Adjustment direction for

horizontal installation

Adjustment direction for vertical

installation

Holder Position #1 for horizontal Holder Position #2 for horizontal

Holder Position #1 for vertical Holder Position #2 for vertical

5. To fine tune the amount of remaining paper that is detected by the N.E. detector, move the N.E.

detector holder shown in the illustration "N.E. Detector Holder" on page 27 and adjust the position.

Note:

Note that the direction to move the roll paper N.E. detector varies depending on the method of printer

installation (vertical/horizontal).

N.E. Detector Holder

Adjustment Position Number Specified Thermal Paper Dimension

#1 Approximately 36 mm {1.42"}

#2 Approximately 41 mm {1.61"}

Adjustment Positions of N.E. Detector

Setup 27

Page 28

6. Tighten the detector adjustment screw using a coin or similar tool.

Check that the N.E. detect lever is

operating properly.

7. Move the N.E. detect lever by hand (finger) to confirm that it moves smoothly.

8. Load the roll paper.

9. Close the roll paper cover.

28 Setup

Page 29

TM-L90/TM-L90 Peeler Model Technical Reference Guide

sensor adjustment

screw

near end sensor holder

near end sensor window (the photo shows the

sensor projecting from the window)

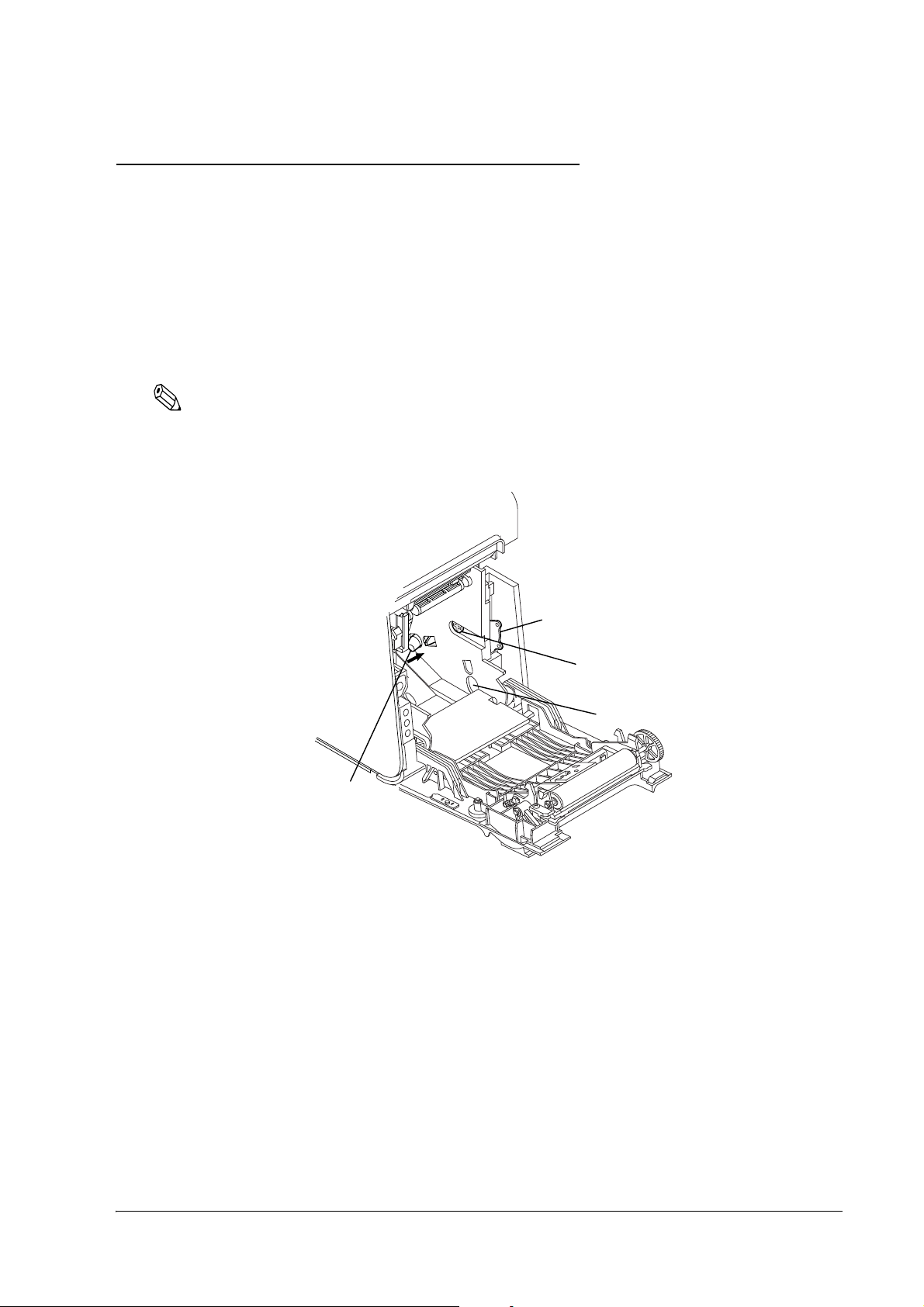

2.3.2 With the TM-L90 Peeler Model

In the following 2 cases, it is necessary to adjust the position of the roll paper near end sensor.

❏ When adjusting the detection position according to the thickness of the roll paper core

❏ When adjusting the amount remaining paper desired

Note:

Since the shape of the central part of the roll paper may differ slightly according to the specification, it is not

possible to detect near end exactly.

Part names and the locations of N.E. detector components

1. Open the peeler cover.

2. Open the roll paper cover.

3. Take out the roll paper.

Setup 29

Page 30

4. Using a coin or similar tool, loosen the sensor adjustment screw.

sensor

adjustment

screw

Adjust the sensor so that it projects

from the window.

5. Adjust the roll paper near end sensor so that the claw of the roll paper near end sensor projects from

the hole near the bottom of the device. (Refer to "Part names and the locations of N.E. detector

components" on page 25 and "Near end sensor adjustment position" on page 31.)

6. To make fine adjustments to the amount of paper remaining detected by the roll paper near end

sensor, finely adjust the position of the near end sensor holder by moving it in the direction of the

arrows as shown in the figure "N.E. Detector Holder" on page 27.

30 Setup

Page 31

TM-L90/TM-L90 Peeler Model Technical Reference Guide

N.E. detector holder

Adjustment direction

when the sensor holder position is #1

when placed vertically

when the sensor holder position is #2 when

placed vertically

Note:

Move the N.E. detector in the direction shown by arrow.

Near end sensor holder

Adjustment scale Outside diameter of specified thermal paper

#1 Approximately 36 mm {1.42"}

#2 Approximately 41 mm {1.61"}

Note:

Adjust the sensor while checking the position of the parts circled in the following figure.

Near end sensor adjustment position

Setup 31

Page 32

7. Using a coin or similar tool, tighten the sensor adjustment screw.

push the near end sensor with your

finger and check that it moves

smoothly

8. Push the near end sensor with your finger and check that it moves smoothly.

9. Set the roll paper.

10. Close the roll paper cover.

32 Setup

Page 33

TM-L90/TM-L90 Peeler Model Technical Reference Guide

2.4 Connecting AC adapter (PS-180)

Be sure to use the PS-180 or the equivalent product as the AC adapter.

CAUTION:

Be sure to remove the AC cable from the wall outlet whenever connecting or disconnecting the AC adapter

to the printer. Failure to do so may result in damage to the AC adapter or the printer.

Be sure to confirm that the wall outlet power supply satisfies the rated voltage requirements of the AC

adapter. Never insert the AC cable plug into a socket that does not meet the rated voltage requirements of

the AC adapter. Doing so may result in damage to both the AC adapter and the printer.

2.4.1 Attaching AC adapter

The following is an explanation of the procedure for attaching the power unit to the TM-L90.

1. Confirm that the printer's power supply is turned off and the AC adapter's AC cable has been removed

from the wall outlet.

2. To place cables, first break off by hand any of the three perforations to pass the cables through

indicated by circles in the illustration (the other one is on the right). Then put the cables through the

holes and replace the bottom of the cover.

Setup 33

Page 34

3. Remove the bottom of the cover as shown in the illustration below.

Power supply connector

4. Install the connector of the DC cable onto the DC connector (labeled DC24V).

Power Supply Connector

Note:

The connector panel varies depending on the models.

When removing the DC cable connector from the printer, first confirm that the AC cable has been

disconnected from the wall outlet; then grasp the arrow marked section of the connector and pull straight out.

2.4.2 Caution about AC adapter and Supply Voltage

❏ ERROR LED flashes when a high voltage or low voltage error occurs. In such cases, immediately turn

the power off.

Refer to "Unrecoverable errors" on page 114 for the LED flashing patterns.

34 Setup

Page 35

TM-L90/TM-L90 Peeler Model Technical Reference Guide

2.5 Autocutter Settings (TM-L90 only)

The TM-L90 has an autocutter attached for cutting the paper. The autocutter can perform 2 cuts, "partial

cut," in which a small part is left uncut on the left edge, and "full cut" (default setting), in which the paper is

cut completely. By adjusting the attachment position of the cutter unit, you can select between "partial cut"

and "full cut."

Note:

You can't configure the autocutter setting (Partial cut/Full cut) through a software command.

You can't change from partial cut setting to full cut setting after using the printer with partial cut setting.

Since the partial cut doesn't use the tip of the blade, it might have deteriorated. Contact the nearest Epson

service center if you'd like to do the above change.

To disable the autocutter, change the memory switch (MSW2-2) settings. (Refer to "Memory Switch Settings"

on page 42).

Performing full cut without the paper exit guide when the printer installed horizontally may cause a doublecut, paper jam or autocutter error because a cut sheet may drop in the paper path. Be sure to attach the paper

exit guide when performing a full cut in the horizontal installation. (Refer to "Instructions for Installation"

on page 23 for instructions on attaching the guide.)

2.5.1 Cautions on the Lengths of the Receipts/Labels to Issue

• To prevent the cut receipts or labels from getting stuck in the paper path, causing paper jams.

• To make the cut receipts or labels easy to remove

The lengths of the receipts and labels to issue is recommended as shown in the table below.

Use condition Recommended issuing length

Horizontal installation (full cut)*

Horizontal installation (partial cut)*

Vertical installation

Note 1: Install the paper exit guide packed in the box with the printer when the autocutter is used with a full cut, with the printer

positioned horizontally.

2: Partial cut (one point left uncut) is available only when using receipt paper or continuous label paper without black marks.

Also, do not perform cutting and reverse feed together.

1

2

Note:

If the lengths of receipts or labels are specified shorter than the recommended lengths, the issued receipts or

labels may be hard to remove. Users must make a thorough evaluation of the lengths to specify before using

the printer.

37.5 mm or more

25.4 mm or more

Setup 35

Page 36

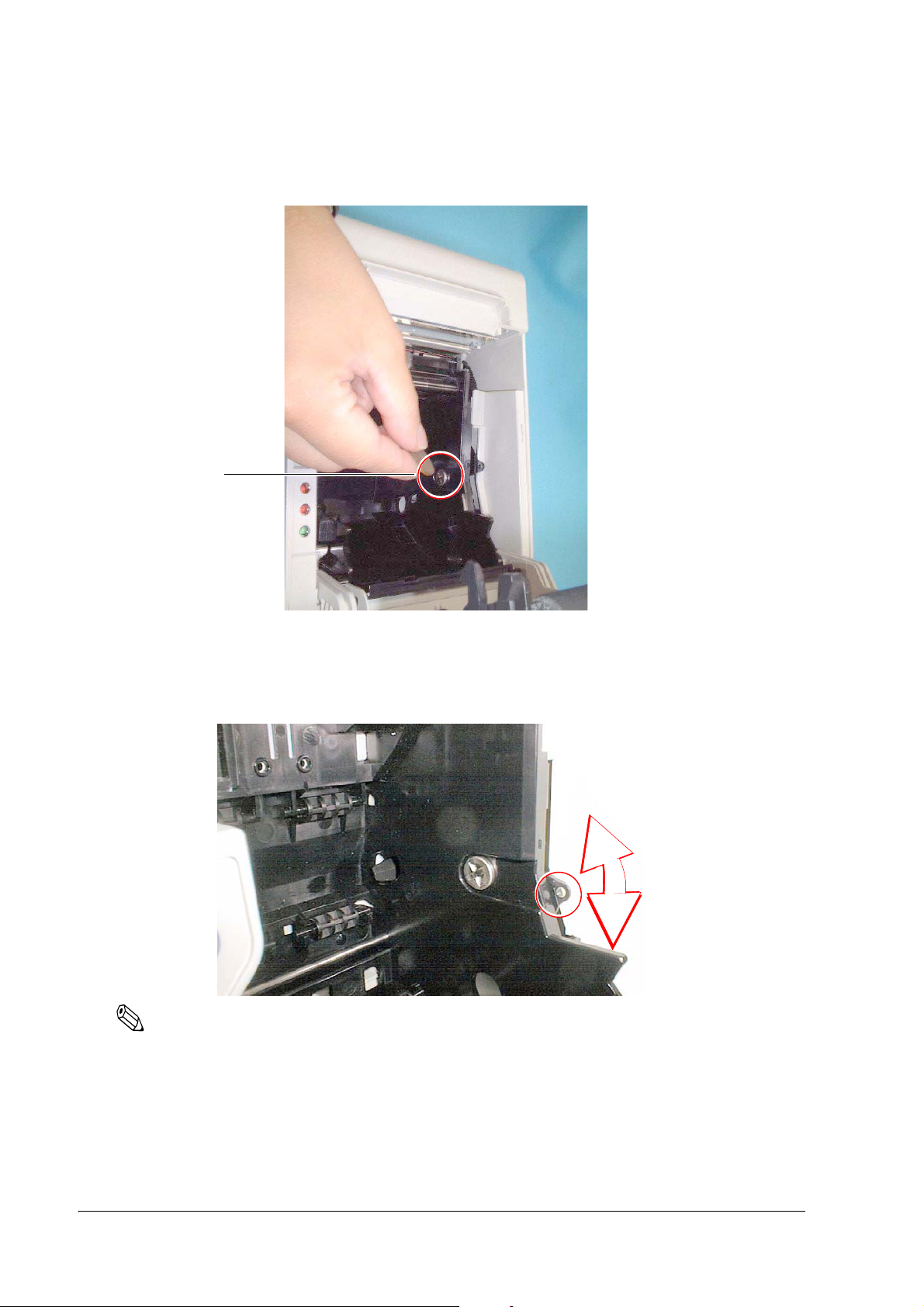

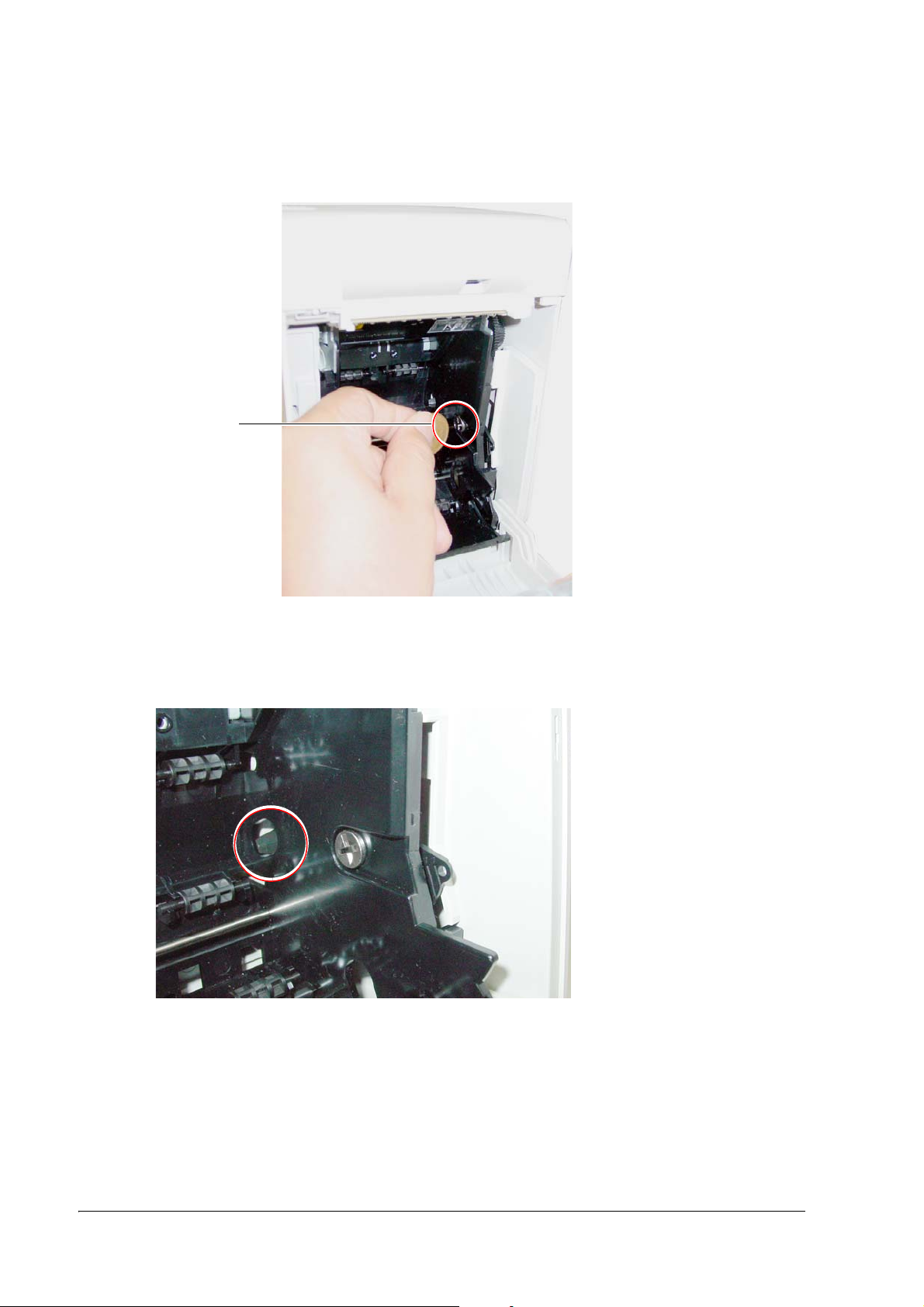

2.5.2 Setting Procedure

cutter cover

Remove this screw

Cutter unit

Loosen this screw

Lift upwards

1. Turn off the power.

2. Pull the cover open lever, and open the roll paper cover.

3. Push the body case outward (in the direction of the 2 arrows) and remove the cutter cover.

4. Remove the single screw retaining the cutter unit and loosen the screw indicated by the circle in the

illustration below.

36 Setup

5. Lift the top of the cutter unit upward and remove it.

Page 37

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Shift to dowel of

desired cut method

Partial cut Full cut

dowels

6. Moving the cutter unit in a lateral direction, shift to the dowel position of the desired cut method.

7. Secure the cutter unit again using the removed screw and the loosened screw.

8. Install the cutter cover.

9. Close the roll paper cover.

Setup 37

Page 38

2.6 Setting Roll Paper Width

tabs

front edge

shaft

notch

protrusion

The TM-L90 / TM-L90 Peeler Model uses a roll paper 80 mm wide in the default state. When using a roll

paper 38 to 70 mm wide with this printer, attach the roll paper spacer in accordance with the following

procedure.

Note:

If a printer has already been used, the paper width cannot be changed from narrow to wide. This is because

the part of the head that made direct contact with the platen may have been damaged when narrow roll

paper was used. The paperless part of the cutter blade may also have worn.

Only when the printer is not yet used can the paper width be changed from narrow to wide.

The following explains the procedure for setting the roll paper width for the TM-L90.

1. When using 61 mm to 70 mm roll paper, break off the two tabs of the roll paper spacer.

Note:

You can still use widths from 38 mm to 60 mm after breaking the tabs off.

38 Setup

2. Open the roll paper cover.

3. As shown below, insert the roll paper spacer so that the front edge goes through the notch in the

printer, and fit the protrusion of the roll paper spacer on the shaft.

Page 39

TM-L90/TM-L90 Peeler Model Technical Reference Guide

screw

measurement

4. Push the roll paper spacer until it clicks.

Note:

Check that the roll paper spacer slides smoothly from side to side.

5. Slide the roll paper spacer side-to-side and set it to the appropriate position. Use the measurement

lines if necessary.

Note:

Roll paper is placed on the tab-free side of the roll paper spacer.

When positioning the roll paper spacer, provide 0.5 mm of room for the maximum roll paper width.

6. Secure the roll paper spacer with the supplied screw. (See above.)

7. Make the setting for the paper width with the memory switch.

For information about the memory switch, see "Memory Switch Settings" on page 42.

Setup 39

Page 40

2.7 DIP Switch Settings

DIP switch cover

DIP switches

The following models have the DIP switches for settings.

❏ TM-L90 other than 4** models

❏ TM-L90 Peeler other than 39* models

The DIP switches are located inside the printer as shown the picture below.

Before setting DIP switches, remove the DIP switch cover.

Note:

Set the DIP switches after turning off the printer. The settings will not be enabled if they are set with the

power on.

40 Setup

Page 41

TM-L90/TM-L90 Peeler Model Technical Reference Guide

DIP switch settings (Serial interface model)

SW No. Function ON OFF Initial Setting

1 Enable/disable Power

switch.

2 Select for serial

communication condition.

3 Handshake XON/XOFF DTR/DSR OFF

4 Bit length 7 bits 8 bits OFF

5 Parity check Yes No OFF

6 Parity type Even Odd OFF

7 Baud rate (bps) 7 8

8 OFF

bps: Indicates the number of bits transferred per second.

DIP switches 2 to 8 are for serial communication. Not used in parallel communication.

Switches power supply On/

Off using commands. (Power

switch is disabled.)

Set using DIP switch 1-7, 1-8 Set using memory switches. ON

ON ON :2400

OFF ON :4800

ON OFF :9600

OFF OFF :19200

Power switch is used to

switch power On/Off.

OFF

OFF

Note:

When you set the baud rate with the memory switch, you can set faster communication than with the DIP

switch. (Refer to "Memory Switch Settings" on page 42, "Error Code" on page 111)

In serial communication, intermittent printing* may occur. This is because when the communication speed

is low, a data transmission waiting state occurs frequently since the printing mechanism speed is high.

Increasing the communication speed may reduce this symptom.

* Intermittent printing: White streaks as large as one or two hairs appear horizontally in a printing result.

DIP switch settings (Parallel, USB, Ethernet model)

SW No. Function ON OFF Initial Setting

1 Enable/disable Power

switch.

2 Reserved Fixed to on -- ON

3 Reserved -- Fixed to off OFF

4 Reserved -- Fixed to off OFF

5 Reserved -- Fixed to off OFF

6 Reserved -- Fixed to off OFF

7 Reserved -- Fixed to off OFF

8 Reserved -- Fixed to off OFF

bps: Indicates the number of bits transferred per second.

DIP switches 2 to 8 are for serial communication. Not used in parallel communication.

Switches power supply On/

Off using commands. (Power

switch is disabled.)

Power switch is used to

switch power On/Off.

OFF

Setup 41

Page 42

2.8 Memory Switch Settings

The printer has the following software switches, called memory switches, in the non-volatile memory.

❏ Msw1, Msw2, Msw5, Msw7, Msw8

❏ Customized values

❏ Serial communication conditions

❏ USB communication conditions

Note:

Msw5, Msw7, and USB communication conditions are available only for TM-L90 4** models or TML90 Peeler 39* models.

These settings can be made by the Memory Switch Setting Utility (see page 89), the Memory Switch Setting

Mode (see page 42), or ESC/POS commands.

For details of ESC/POS commands, refer to the “ESC/POS Command Reference”. For details on how to

obtain this manual, see "Introduction of Control Methods" on page 83.

For usage of the Memory Switch Setting Utility, refer to the user's manual of the utility.

For usage of the Memory Switch Setting Mode, see "Memory switches of TM-L90" on page 43 for TM-L90

4** models, TM-L90 Peeler 39* models, or "Memory switches of TM-L90 Peeler Model" on page 48 for

TM-L90 other than 4** models, TM-L90 Peeler other than 39* models.

42 Setup

Page 43

TM-L90/TM-L90 Peeler Model Technical Reference Guide

2.8.1 Memory switches of TM-L90

In the following tables, “✓” shows that the setting can be set by the utility or the setting mode.

Msw1

Initial

Msw Function Off On

1-1 Transmission of Power-on

notice

1-2 Receive buffer capacity 4K bytes 45 bytes Off ✓✓

1-3 BUSY condition Receive buffer

1-4 Data processing for receive

error

1-5 Automatic line feed Disabled Enabled Off ✓✓

1-6 (Reserved) Fixed to Off Off

1-7 #6 pin of RS-232 Not used Used for reset Off ✓✓

1-8 #25 pin of RS-232 Not used Used for reset Off ✓✓

[Msw1-4], [Msw1-7], [Msw1-8]: Valid only for serial interface

[Msw1-5]: Valid only for parallel interface

[Msw1-7], [Msw1-8]: Not available for TM-L90 4** models

Disabled Enabled Off ✓✓

Receive buffer

full or Offline

Replaced with

"?"

full

Ignored Off ✓✓

setting

Off ✓✓

Msw Setting

utility

Msw2

Msw Setting

Mode

Initial

Msw Function Off On

2-1 (Reserved) Fixed to On (Do not change) On

2-2 Autocutter function Disabled Enabled On ✓✓

2-3

(Reserved) - - Off

to

2-8

setting

Msw Setting

utility

Msw Setting

Mode

Setup 43

Page 44

Msw5 (only for 4** models)

Msw Function Off On

Initial

setting

Msw Setting

utility

5-1 USB power-saving function Enabled Disabled Off ✓✓

5-2 Recovery conditions from

256 bytes free 138 bytes free Off ✓✓

receive buffer BUSY

5-3 Paper sensor to output paper

end signals

Enabled both

Roll paper end

Disabled Off ✓

sensor and

Roll paper

near-end

sensor

5-4 Error signal output Enabled Disabled Off ✓✓

5-5

(Reserved) - - Off

to

5-8

[Msw5-1]: Valid only when the USB interface communication condition of the built-in USB is set to the Vendor-defined class and the

[Msw5-2]: Valid only when the receive buffer capacity is 4K bytes.

[Msw5-4]: Valid only for parallel interface

system configuration is set so that the USB driver can support the USB power-saving function.

Msw7 (only for 4** models)

Msw Setting

Mode

Msw Function Off On

7-1 Printer operation when print

position misalignment is

detected

7-2 Printer operation in recovery

from paper layout error

Print starting

position is not

changed

Automatic

paper layout

measurement

Print starting

position is

adjusted (*1)

Paper feed to

the next print

starting

Initial

setting

Off ✓✓

Off ✓✓

Msw Setting

utility

Msw Setting

Mode

position (*2)

7-3 Autocut after closing cover Disabled Enabled (*3) Off ✓✓

7-4 Paper feed length after closing

20 mm 40 mm Off ✓✓

cover

7-5

(Reserved) - - Off

to

7-8

(*1) When using label paper or paper with black mark, if print position misalignment is detected during reverse feeding, the printer

feeds the paper to the next print starting position.

(*2) When [Msw8-2] is OFF and the printer recovers from a paper layout error, the printer feeds the paper to the next print starting

position.

(*3) When using paper without black mark (excluding label roll paper), when the roll paper cover is closed, the printer feeds the paper

for the amount set with [Msw7-4], and cuts the paper. After the power is turned on, if printing is executed for the first time after a

cut command is executed, the printer starts printing after executing reverse feeding to the print starting position.

44 Setup

Page 45

Msw8

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Initial

Msw Function Off On

8-1 (Reserved) - - Off

8-2 User operation for recovery

from paper layout error

8-3 Paper out LED state in a paper

near-end

8-4 Maximum length of automatic

paper measurement

8-5 Space insertion at left and right

side of barcode print

8-6 Paper feed to the print starting

position when power is turned

on

8-7 (Reserved) - - Off

8-8 Printer cover open during

operation

Send the error

recovery

command or

open/close

the cover

LED On LED Off Off ✓✓

160 mm 300 mm Off ✓✓

Disabled Enabled Off ✓

Enabled Disabled Off ✓✓

Automatic

recoverable

error

Send the error

recovery

command

Recoverable

error

setting

Off ✓✓

Off ✓✓

Msw Setting

utility

Msw Setting

Mode

When [Msw 8-2] is Off, the paper layout is automatically measured and saved into the non-volatile

memory of the printer after recovery from the error.

If [Msw8-2] is On, the printer paper layout is not changed after error recovery. If the correct paper is not

inserted, the paper layout error will occur again.

The [Msw 8-4] setting influences initialization at power-on when “label paper” or “receipt paper with

black mark” is specified for the paper layout. Refer to "Setting Paper Layout" on page 57 for the paper

layout.

When [Msw 8-6] is set to "Feeding paper to the print starting position at power on is disabled", the printer

does not execute the operation of feeding paper to the print starting position at power on (the printer

executes the operation when its cover is opened and closed). Hence, the user should note the following

points since the printer operates on the assumption that the paper has already been fed to the print starting

position at power on.

a) Turn off the power supply after feeding of paper to the print starting position.

b) Do not open the cover while power is off.

c) If you have opened the cover while the power is off, open and close the cover once while the power is

on to feed the paper to the print starting position.

If printing is performed without the operation described above, the paper layout error (recoverable

error) may occur. If the error occurs, recover from the error by the operation selected with [Msw8-2].

If the print starting position has not been set at power-on, the printing position of the first sheet may shift,

or a paper layout error may occur.

Setup 45

Page 46

Customized values

Option

Item

NV user memory capacity 1KB

(underlined: initial setting)

, 64KB, 128KB, 192KB ✓

NV graphics memory capacity None, 64KB, 128KB, 192KB, 256KB, 320KB,

384KB

Print density 70%, 75%, 80%, 85%, 90%, 95%, 100%, 105%,

, 115%, 120%, 125%, 130%, 135%, 140%

110%

Print speed Level 1 (Slow) - Level 6

Default character code table

*1

Initial setting: Page 0: PC437 (USA, Standard

- Level 9 (Fast) ✓✓

Europe)

Default international character

Selection of the interface

*1

*1

Number of divisions of thermal head

Initial setting: USA ✓✓

Auto, UIB, Built-in USB ✓✓

, 2, 3, 4 ✓

1

energizing

*1

Automatic replacement of Font A

Automatic replacement of Font B

Paper selection

(monochrome or two-color)

Paper width 38 mm - 80 mm

Do not replace, Font B ✓✓

*1

*2

Do not replace, Font A ✓✓

Monochrome, two-color ✓✓

(1 mm pitches) ✓✓

Msw

Setting

utility

Msw

Setting

Mode

✓

✓✓

*1

✓✓

*3

Black-color density in two-color

printing

Buzzer control

*2

*1

Light, Medium, Dark ✓

Buzzer selection: Internal, Option, Disable

✓✓

Buzzer frequency: Continuous, 1 time, No

sound

Sound pattern: Pattern A, B, C, D, or E

(Refer to "Setting items of TM-L90 4** models"

on page 119, about the initial settings.)

*1: Not available for TM-L90 other than 4** models

*2: Not available for TM-L90 4** models

*3: Selectable 38, 58, 60, 70, 80 mm only

Note:

❏

The maximum print speed is available for only the one-part energizing mode. However, if the print duty

is too high in the one-part energizing mode, the printer will automatically reduce the printing speed.

❏

The four-part energizing mode reduces power consumption.

❏

The print width can be set in 43 ways with 1 mm pitches in the range from 38 mm to 80 mm. However, it

cannot be set in the range from 71 mm to 79 mm.

46 Setup

Page 47

❏

Depending on the paper type, it is recommended to set the print density as shown in the table below for

the best print quality.

Paper type Density level

Receipt P35024 90%

KF50 95%

F5041(55) 100%

Label 150PSMW 120%

DTM9502, KL80GT 130%

Serial communication conditions

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Option

Item

Baud rate 2400, 4800, 9600, 19200

Parity None

Flow control DTR/DSR, XON/XOFF ✓✓

Data length 7-bits, 8-bit

(underlined: initial setting)

, 38400, 57600,

115200 bps

, Odd, Even ✓✓

s ✓✓

Msw Setting

utility

✓✓

Note:

For models other than 4** models, these settings are valid only when the DIP switch 1-2 is Off.

USB communication conditions (only for 4** models)

This setting is valid for the built-in USB.

Option

Item

Class Vendor-defined class

(underlined: initial setting)

, Printer class ✓✓

Msw Setting

utility

Msw Setting

Mode

Msw Setting

Mode

Setup 47

Page 48

2.8.2 Memory switches of TM-L90 Peeler Model

In the following tables, “✓” shows that the setting can be set by the utility or the setting mode.

Msw1

Initial

Msw Function Off On

1-1 Transmission of Power-on

notice

1-2 Receive buffer capacity 4K bytes 45 bytes Off ✓✓

1-3 BUSY condition Receive buffer

1-4 Data processing for receive

error

1-5 Automatic line feed Disabled Enabled Off ✓✓

1-6 (Reserved) Fixed to Off Off

1-7 #6 pin of RS-232 Not used Used for reset Off ✓✓

1-8 #25 pin of RS-232 Not used Used for reset Off ✓✓

[Msw1-4], [Msw1-7], [Msw1-8]: Valid only for serial interface

[Msw1-5]: Valid only for parallel interface

[Msw1-7], [Msw1-8]: Not available for TM-L90 Peeler 39* models

Disabled Enabled Off ✓✓

Receive buffer

full or Offline

Replaced with

"?"

full

Ignored Off ✓✓

setting

Off ✓✓

Msw Setting

utility

Msw5 (only for 39* models)

Msw Function Off On

Initial

setting

Msw Setting

utility

Msw Setting

Mode

Msw Setting

Mode

5-1 USB power-saving function Enabled Disabled Off ✓✓

5-2 Recovery conditions from

receive buffer BUSY

5-3 Paper sensor to output paper

end signals

5-4 Error signal output Enabled Disabled Off ✓✓

5-5

(Reserved) - - Off

to

5-8

[Msw5-1]: Valid only when the USB interface communication condition of the built-in USB is set to the Vendor-defined class and the

[Msw5-2]: Valid only when the receive buffer capacity is 4K bytes.

[Msw5-4]: Valid only for parallel interface

system configuration is set so that the USB driver can support the USB power-saving function.

256 bytes free 138 bytes free Off ✓✓

Enabled both

Roll paper end

sensor and

Roll paper

near-end

sensor

Disabled Off ✓

48 Setup

Page 49

Msw7 (only for 39* models)

TM-L90/TM-L90 Peeler Model Technical Reference Guide

Msw Function Off On

7-1

(Reserved) - - Off

to

7-7

7-8 Function when FEED button is

pressed

Feed to the

next print

starting