Page 1

Technical Reference Guide

Describes the features of the product.

Describes the setup and installation of

the product and peripherals.

Describes the advanced usage of

the product.

Describes how to control the printer and gives

information useful for printer application development.

Describes the product specications,

interface specications, and character code.

Describes the basic handling of the printer.

Liner-Free Label Paper Model

Product Overview

Setup

Advanced Usage

Application Development

Information

Handling

Appendix

M00123002

Rev. C

Page 2

CAUTION

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson

Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to strictly

comply with Seiko Epson Corporation’s operating and maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original Epson Products or Epson Approved Products by Seiko

Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or other countries.

Android™ is a trademark of Google LLC.

IOS is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under license.

All other trademarks are the property of their respective owners and used for identification purpose only.

ESC/POS® Command System

EPSON ESC/POS is a proprietary POS printer command system that includes patented or patent-pending commands. ESC/

POS is compatible with most EPSON POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises a set of highly

functional and efficient commands and also offers the flexibility to easily make future upgrades.

©Seiko Epson Corporation 2019-2021.

Page 3

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the following

carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

!WARN ING

Provides information that must be observed to prevent damage to the equipment or

!CAUTION

loss of data.

• Possibility of sustaining physical injuries.

• Possibility of causing physical damage.

• Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

Warnings

!WARN ING

• Do not cover the printer with cloth or place it in a poorly ventilated location.

• The internal temperature may increase, leading to fire.

• Keep the printer away from volatile substances, such as alcohol and thinner, and

fire. Failure to do so may result in electrical shock or fire.

• Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise. Failure to do so may result in electrical shock or fire.

• If an accident occurs, turn off the power immediately and unplug the AC cable.

Then contact qualified service personnel.

• If foreign matter or liquid such as water spills into this equipment, do not continue

to use it. Continued use may result in electrical shock or fire.

• Immediately unplug the equipment and contact qualified service personnel.

• Do not disassemble the printer except for the locations indicated in the manual.

• Never attempt to repair this product yourself. Improper repair work can be

dangerous.

• Do not use the printer in a location where flammable gas, explosive gas, or similar

gas might exist in the air. Do not use aerosol sprayers containing flammable gas

inside or around this product. Doing so may cause fire.

• Do not connect cables in ways other than those indicated in this manual.

• Doing so may lead to fire. Doing so may also damage the connected equipment.

• Do not insert or drop metal or flammable objects into the printer from the

openings. Doing so may result in electrical shock or fire.

• Make sure to use this product at the specified voltage. Failure to do so may result in

fire or electrical shock.

3

Page 4

!WARN ING

• Check that the plug is clean before plugging it in. Failure to do so may result in

electrical shock or fire.

• Be sure to push the plug all the way in. Failure to do so may result in electrical

shock or fire.

• Do not use a damaged power cable. Doing so may result in electrical shock or fire.

• If the power cable is damaged, contact qualified service personnel.

• Do not place multiple loads on the power outlet. Overloading the outlet may lead

to fire.

• Be sure to disconnect the plug from the power outlet and clean the base of the

blades and the area between the blades. Leaving the plug inserted in the power

outlet for a long time may cause dust to stick to the base of blades, leading to fire.

• When you disconnect the plug from the power outlet, hold the plug and do not

pull the cable. Failure to do so may damage the cable or deform the plug, resulting

in electrical shock or fire.

• When handling the AC adapter, observe the instructions described below. Failure

to do so may result in electrical shock or fire.

* Avoid exposure to rain or water.

* Do not hang the adapter on the power cable.

* Avoid contact between a metal object such as a paper clip and the connector.

* Do not cover the adapter with a blanket or similar item.

• Do not insert a telephone line into the drawer kick connector. Doing so may

damage the telephone line or printer.

• Do not place the printer in a dusty or humid location. Doing so may result in

electrical shock or fire.

• Before relocating this product, turn off the power, disconnect the plug from the

power outlet, and make sure that all the cables are disconnected. Failure to do so

may result in electrical shock or fire.

4

Page 5

Cautions

!CAUTION

• Do not place/store the printer on an unsteady location or a location subject to the

vibration of other equipment. Otherwise, the product may break or cause injury if it

falls.

• Do not place heavy objects on top of this product. Never stand or lean on this

product. Otherwise, the product may fall or break and cause injury.

• When connecting cables or installing optional products, follow the procedures and

make sure that the cables and products are installed in the proper direction. Failure

to do so may cause injury.

• Follow the instructions in the manual for proper installation.

• While opening/closing the printer cover, keep your hands away from the joint

between the cover and the main body. Otherwise, your hand or finger may be

pinched and get injured.

• To ensure safety, unplug this product when leaving it unused for an extended

period.

• Do not touch the inside of the printer except for the locations indicated in the

manual. Doing so may result in electrical shock or burns.

• Observe the instructions below to prevent the power cable from being damaged.

• Do not modify or attempt to repair the cable

• Do not place any heavy object on top of the cable

• Avoid excessive bending, twisting, and pulling

• Do not place the cable near heating equipment

• Never insert or disconnect the power plug with wet hands. Doing so may result in

severe shock.

• Take care not to push your hand or finger against the manual cutter. Doing so may

injure your hand or finger.

* When you remove printed paper

* When you perform other operations such as loading/replacing roll paper

5

Page 6

Caution Labels

Thermal head

The caution labels on the product indicate the following precautions.

! K CAUTION:

Do not touch the thermal head during or immediately after use. After printing, the thermal head and its

surroundings can be very hot.

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices

related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc., you should use this product only after giving consideration to including

fail-safes and redundancies into your design to maintain safety and total system reliability.

Because this product was not intended for use in applications requiring extremely high reliability/safety,

such as aerospace equipment, main communication equipment, nuclear power control equipment, or

medical equipment related to direct medical care, etc., please make your own judgment on this product's

suitability after a full evaluation.

6

Page 7

About this Manual

Aim of the Manual

This manual provides developers/engineers with all the necessary information for design, development

and installation of a POS system, and also design and development of a printer application.

Manual Content

The manual is made up of the following sections:

Chapter 1 Product Overview

Chapter 2 Setup

Chapter 3 Advanced Usage

Chapter 4 Application Development Information

Chapter 5 Handling

Appendix Product Specifications

Specifications of Interfaces and Connectors

Character Code Tables

7

Page 8

Contents

■ For Safety ......................................................... 3

Key to Symbols..........................................................................3

Warnings......................................................................................3

Cautions.......................................................................................5

Caution Labels ...........................................................................6

■ Restriction of Use ............................................ 6

■ About this Manual........................................... 7

Aim of the Manual....................................................................7

Manual Content ........................................................................7

■ Contents........................................................... 8

Product Overview.......................11

■ Features ......................................................... 11

■ Product Configurations ................................ 12

Models....................................................................................... 12

Identification of LAN interface models.......................... 12

Accessories............................................................................... 13

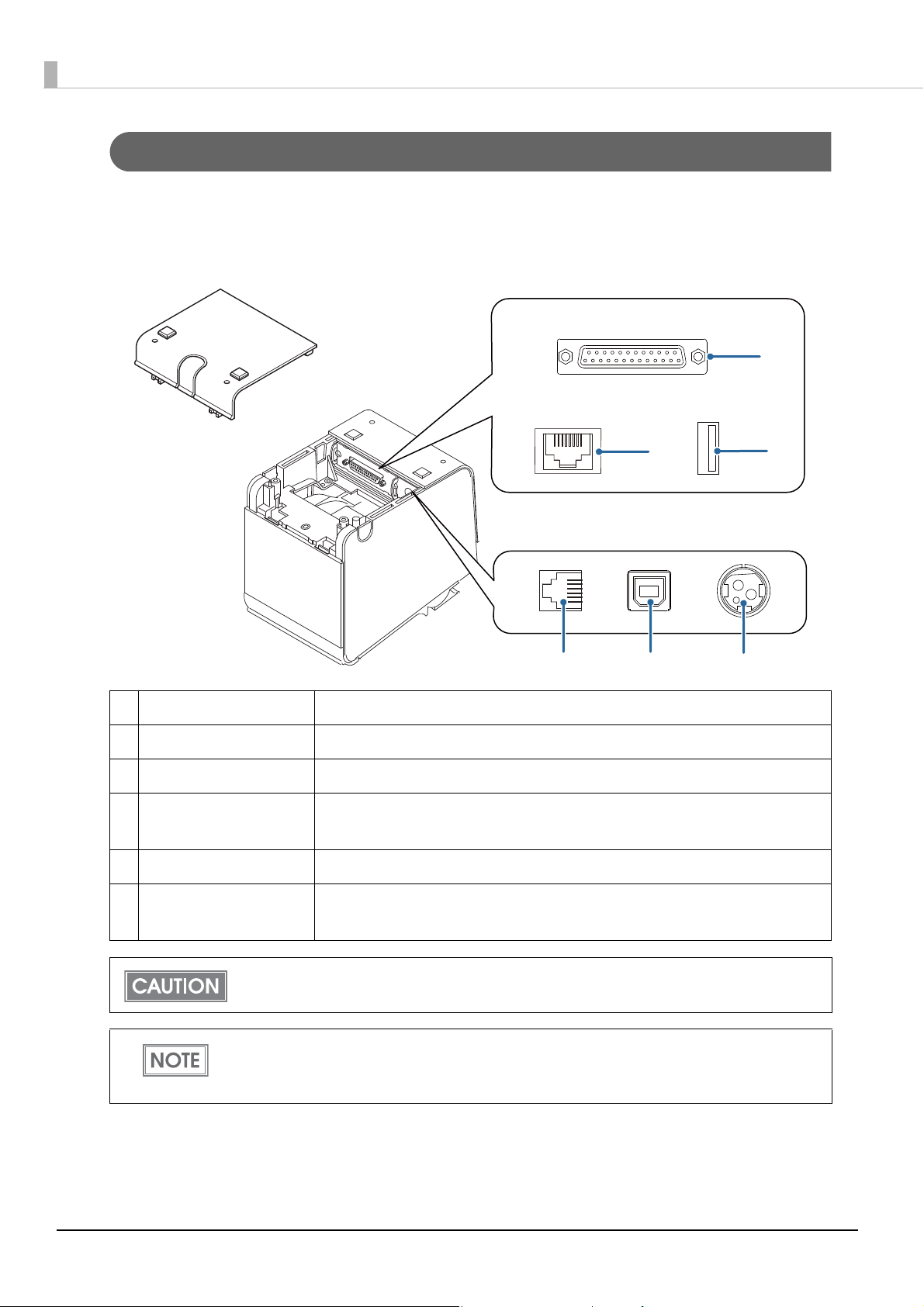

■ Part Names and Functions............................ 14

Front........................................................................................... 14

Control Panel........................................................................... 15

Connectors............................................................................... 16

Online and Offline ................................................................. 17

■ Status and Errors........................................... 18

Automatically Recoverable Errors.................................... 18

Recoverable Errors................................................................. 18

Unrecoverable Errors............................................................ 19

Status Display.......................................................................... 20

■ NV Memory.................................................... 21

NV Graphics Memory ........................................................... 21

User NV Memory.................................................................... 21

Memory Switches (Customized Value)......................... 21

User-defined page................................................................. 21

Maintenance Counter ..........................................................21

Setup ...........................................23

■ Flow of Setup ................................................. 23

■ Installing the Printer ..................................... 24

■ Changing the Paper Width ........................... 25

Removing the Roll Paper Guide .......................................26

Installing the Roll Paper Guide .........................................27

■ Connecting the AC Adapter.......................... 29

AC Adapter Connection Procedure .................................29

■ Connecting the Printer to the Host ............. 31

USB Interface ...........................................................................31

Ethernet Interface.................................................................. 31

For Serial Interface Models................................................. 32

■ Connecting the Cash Drawer ....................... 33

Cash Drawer Requirements................................................ 33

Connecting the Drawer Kick Cable..................................35

■ Connecting the Optional Wireless

LAN Unit........................................................ 36

Advanced Usage .........................37

■ Software Settings ......................................... 37

Memory Switch 1 ...................................................................39

Memory Switch 2 ...................................................................39

Memory Switch 6 ...................................................................40

Memory Switch 8 ...................................................................41

Customized value ..................................................................42

Communication condition of serial interface..............47

■ Setting/Checking Modes .............................. 48

Self-test Mode ......................................................................... 50

NV Graphics Information Print Mode..............................51

Software Setting Mode........................................................52

Starting Hexadecimal Dumping Mode .......................... 54

Application Development

Information.................................57

■ Controlling the Printer ................................. 57

ESC/POS..................................................................................... 57

■ Controlling the Cash Drawer........................ 58

■ Software ........................................................ 59

Development Kits ..................................................................59

Drivers........................................................................................ 60

Utilities....................................................................................... 60

Download .................................................................................61

Handling......................................63

■ Installing and Replacing Roll Paper ............ 63

■ Removing Jammed Paper ............................ 65

8

Page 9

■ Releasing a Stuck Roll Paper Cover ............. 67

■ Cleaning the Printer ..................................... 69

Cleaning the Printer Case................................................... 69

Cleaning the Inside of the Printer.................................... 69

■ Preparing for Transport ............................... 71

Appendix .................................... 73

■ Product Specifications ................................. 73

Printing Specifications......................................................... 75

Character Specifications ..................................................... 76

Details of Characters Per Line and Character

Specifications with Auto Scaling Enabled.................... 78

Paper Specifications ............................................................. 85

Printable Area ......................................................................... 90

Printing and Cutting Positions......................................... 92

Electrical Characteristics ..................................................... 93

Environmental Conditions .................................................94

External Dimensions and Mass......................................... 95

■ Printing and Cutting Positions With

Software Setting .......................................... 96

■ Specifications of Interfaces and

Connectors ................................................. 102

RS-232 Serial Interface.......................................................102

USB (Universal Serial Bus) Interface ..............................105

■ Character Code Tables................................ 106

9

Page 10

10

Page 11

Product Overview

This chapter describes features and specifications of the product.

Features

Printing

• Printing on liner-free label paper

Chapter 1 Product Overview

• High speed receipt printing (170 mm/s maximum).

• Supports the maximum paper width of 80 mm, and paper width of 40 mm or 58 mm by using the roll

paper guide*

∗ For 65* model, paper width of 80/40mm only supported

Handling

• Horizontal and vertical installation layouts are selectable.

• Easy drop-in paper loading

• Cable connectors can be stored inside the printer.

68* model only

• Paper taken sensor can detect that issued label is taken before issuing the next paper.

• The back-feed function has enabled top margin scaling.

Software

• Command protocol is based on the ESC/POS Proprietary Command System.

• Various layouts are available by using the page mode.

1

• A maintenance counter function is supported.

Environment

• Paper reduction function is available.

Others

• The interface is selectable.

• A built-in USB interface is also available.

11

Page 12

Product Configurations

The installed functions and the included accessories differ depending on the model.

Models

TM-L90 Liner-Free Label Paper Model has the following specifications with different functions.

• 65* model: Paper width of 40/80 mm supported

• 66* model: Paper of 40/58/80 mm supported

• 67* model (multilingual): Paper width of 40/58/80 mm supported

• 68* model (ANK/multilingual): Paper width of 40/58/80 mm supported, paper taken sensor installed,

back-feed function installed

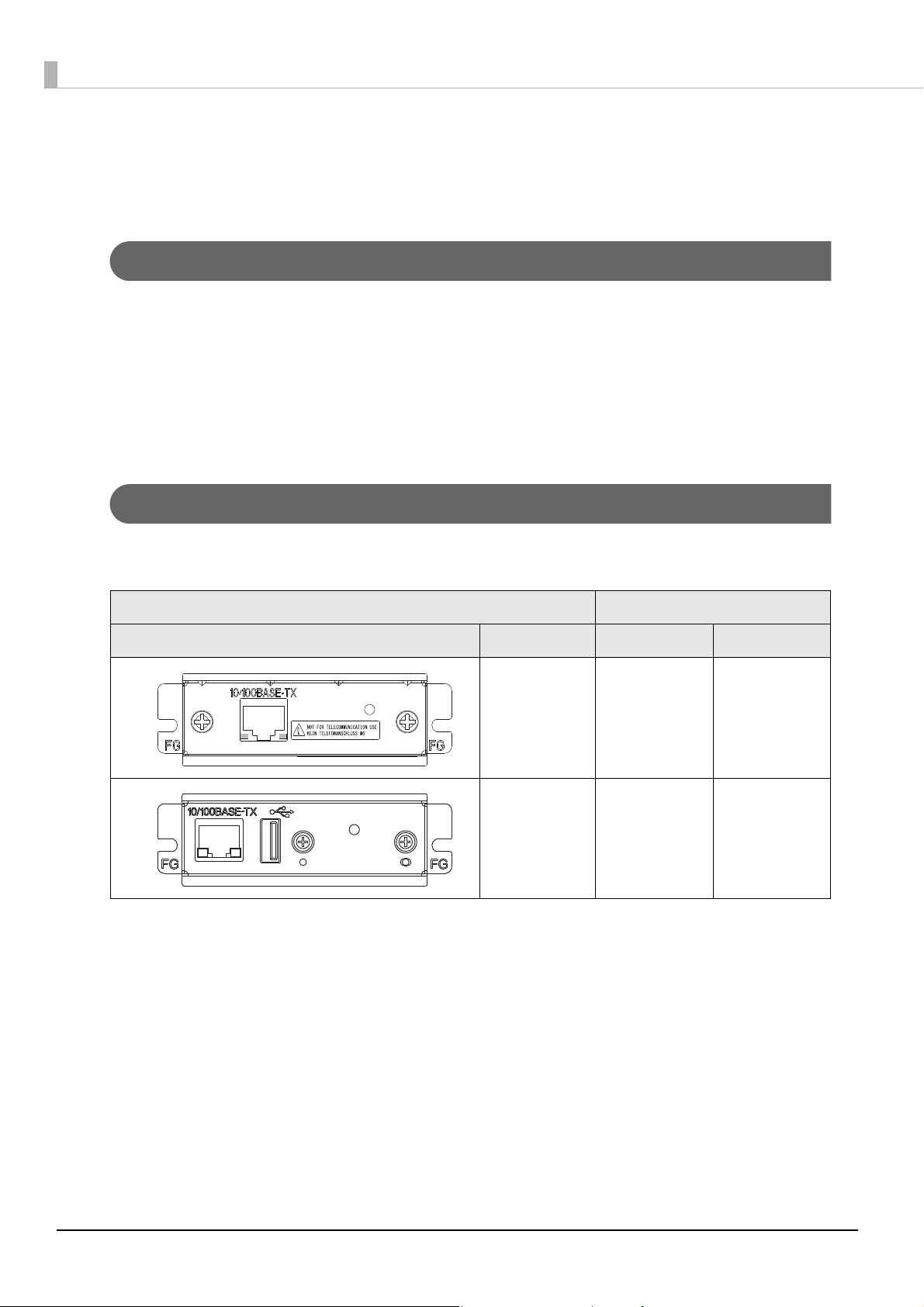

Identification of LAN interface models

TM-L90 has LAN interface models as shown below. To check the technical reference guide for the interface

board specifications and how to set the network, see the technical reference guide shown below.

Interface Board Interface

External View Name Ethernet Wireless LAN

*: For details, see the technical reference guide for the interface board.

UB-E03 ✔ -

UB-E04 ✔✔

*

12

Page 13

Accessories

Included

• Control panel label for vertical installation

• Roll paper spacer*

• AC adapter

•AC cable

• Manuals and documents

*

Not included with some models

*

*

*

Options

• Affixing tape for fixing the printer (Model: DF-10)

• Wall hanging bracket (Model: WH-10)

Chapter 1 Product Overview

1

• Wireless LAN Unit

13

Page 14

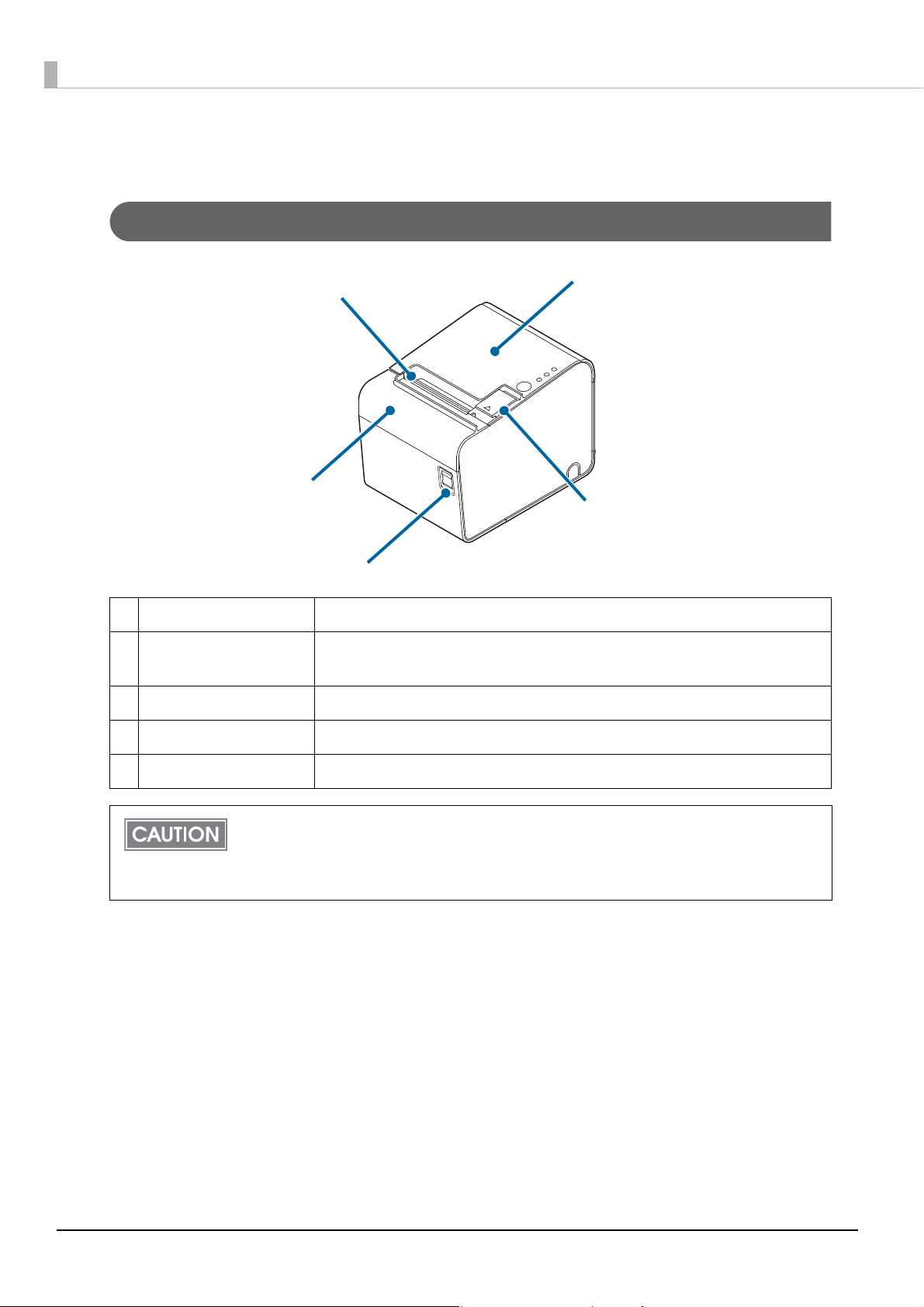

Part Names and Functions

1

2

3

4

5

Front

1 Manual cutter Use this cutter when you cut the roll paper manually.

2 Cutter cover If the roll paper cover will not open due a paper jam, open this cover and

unlock the autocutter blade.

3 Power switch Turn on/off the printer.

4 Cover open lever Operate this lever to open the roll paper cover.

5 Roll paper cover Open this cover to install/replace the roll paper.

Before turning the printer off, it is recommended to send a power-off command to the

printer. If you use the power-off sequence, the latest maintenance counter values are

saved. (Maintenance counter values are usually saved every two minutes.)

For information about ESC/POS commands, see the ESC/POS Command Reference.

14

Page 15

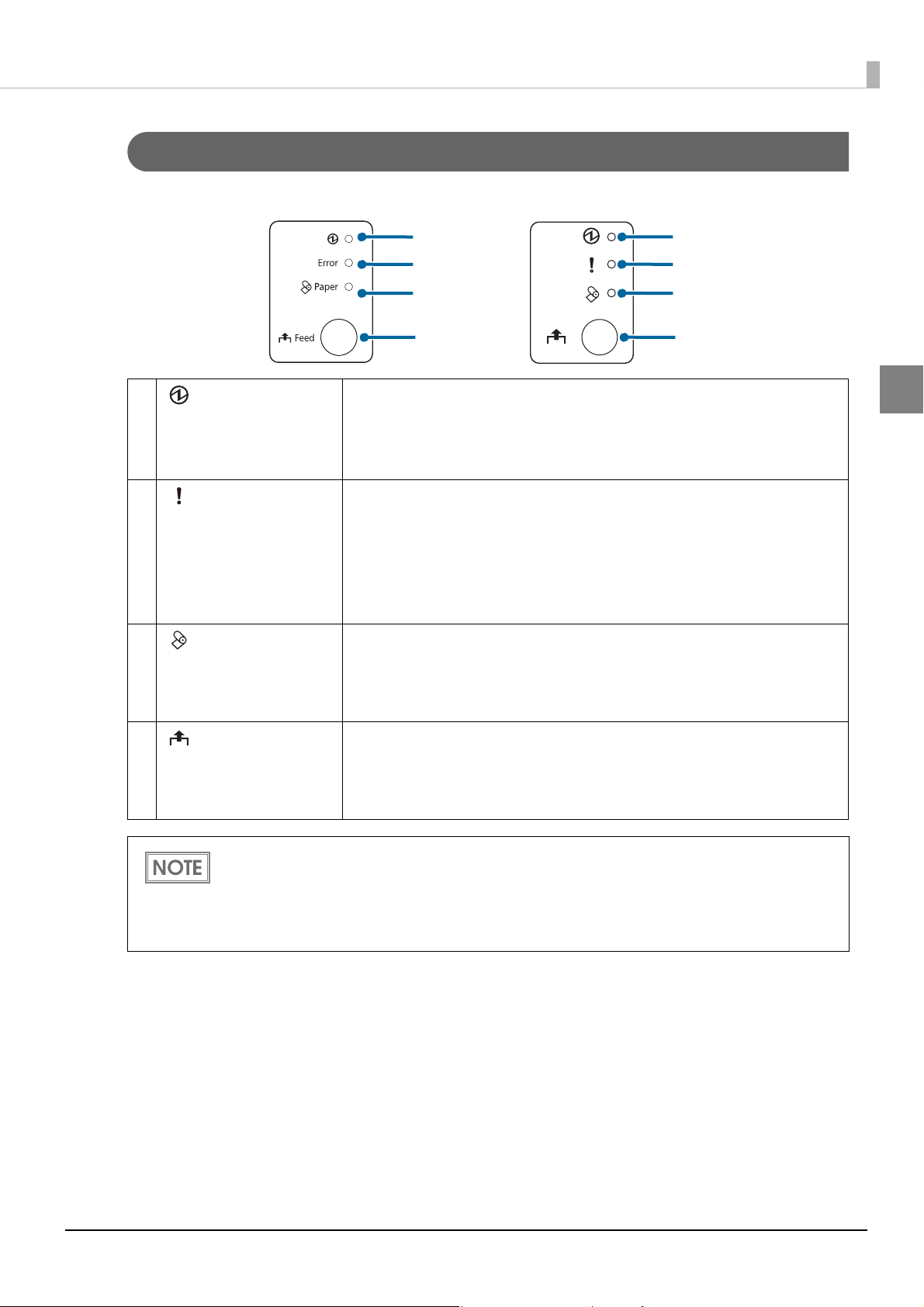

Control Panel

1

2

3

4

1

2

3

4

68* model

Chapter 1 Product Overview

1 LED • On when the power supply is on.

• Off when the power supply is off.

• Flashes during the network startup process after power-on and power-off

standby status, and while updating firmware.

2 (Error) LED • Lights or flashes when the printer is offline.

• Lights after the power is turned on or after a reset (offline). Automatically

goes out after a while to indicate that the printer is ready.

• Lights or flashes when an error occurs. (For information about the indication patterns, see

• Off when the printer is in standard mode (online).

3 (Paper) LED • Lights when there is no more roll paper.

• Flashes to prompt the user to operate the Feed button.

68* model only: Flashes to prompt the user to remove the issued paper

and to operate the Feed button.

4 (Feed) button Press this button to feed the roll paper by one line. Hold down this button to

feed the roll paper continuously.

When using liner-free label paper, and while waiting for the issued paper to

be removed (for 68* model only), the button operation is disabled.

"Status and Errors" on page 18.)

1

• Attach the control panel label for vertical installation when vertical installation is used. The

control panel label for vertical installation is upside down. (

)

24

• The Feed button is also located inside the roll paper cover. (See

page 52

)

"Installing the Printer" on page

"Software Setting Mode" on

15

Page 16

Connectors

1

23

4

5

6

All connectors are located on the bottom of the printer. Different interfaces are used depending on the

printer model to be used.

1 Serial interface Connects the serial cable for connecting to a computer.

2 LAN connector Connects the 10BASE-T/100BASE-TX Ethernet cable.

3 USB connector Used only for connecting optional Wireless LAN unit and customer display.

4 Drawer kick connector Connects the cash drawer or the optional external buzzer.

"Connecting the Cash Drawer" on page 33

5 USB connector Connects the USB cable for connecting to a computer.

6 Power supply connector Connects the AC adapter.

"Connecting the AC Adapter" on page 29

The USB (Type A) interface is used only for connecting the optional Wireless LAN unit.

For details about the connection procedures, see

page 31

page 33

, "Connecting the AC Adapter" on page 29, and "Connecting the Cash Drawer" on

.

"Connecting the Printer to the Host" on

16

Page 17

Chapter 1 Product Overview

Online and Offline

Online

The printer is online and ready for normal printing unless there is a reason to go offline.

Offline

The printer automatically goes offline under the following conditions:

• While the printer power is turning on/off

• While setting/checking mode is being executed (excluding hexadecimal dumping mode)

• While roll paper is fed using the Feed button

• When the printer stops printing due to a paper end (when the paper out detector detects that there is no

paper)

• During an operation standby state

1

• When an error has occurred (

• While the roll paper cover is open

"Status and Errors" on page 18)

17

Page 18

Status and Errors

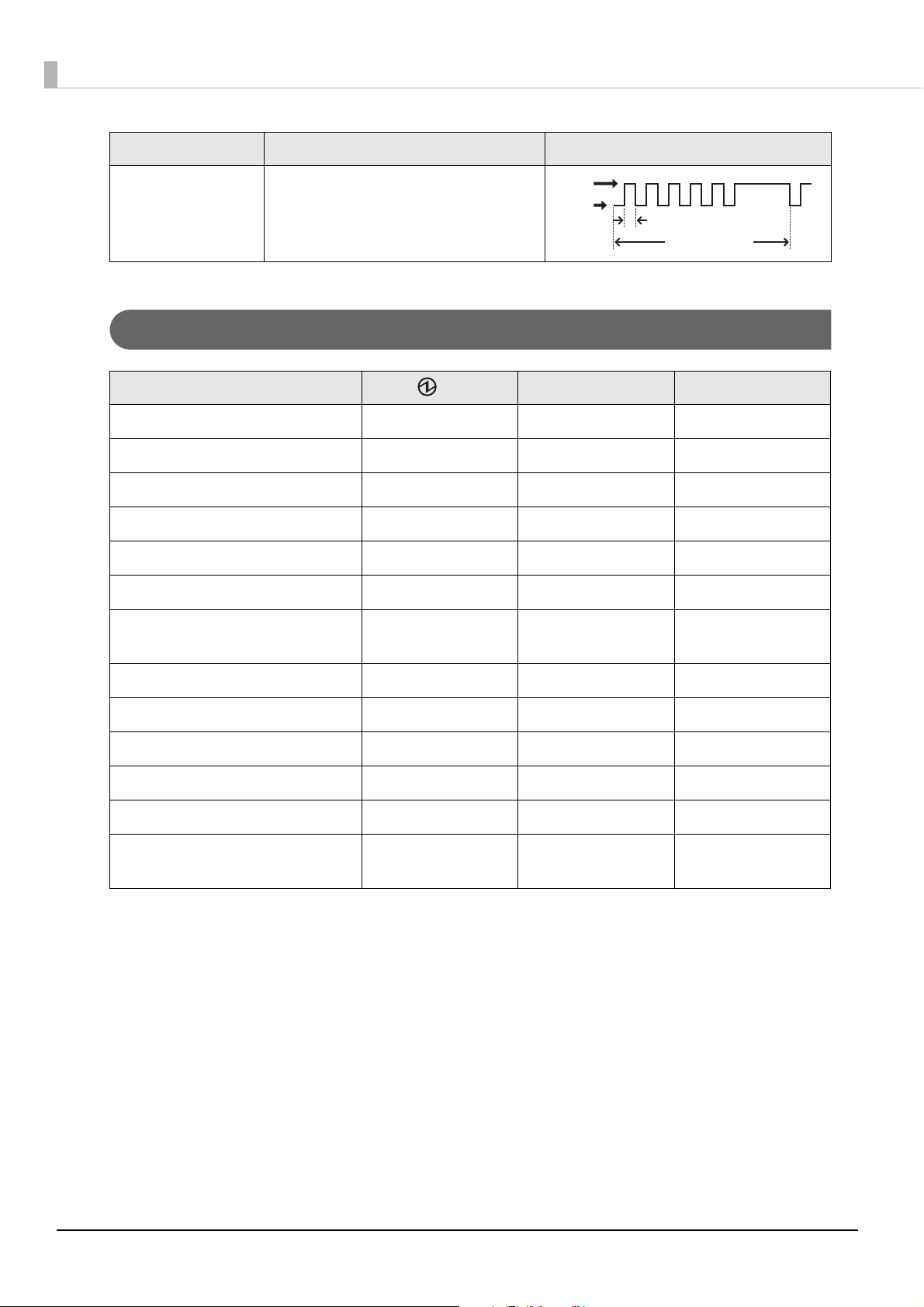

LED OFF

LED ON

Approx. 320 ms

LED OFF

LED ON

Approx. 320 ms

LED OFF

LED ON

Approx. 320 ms

The LEDs light or flash to indicate the printer status.

The printer cannot print while an error is left unresolved.

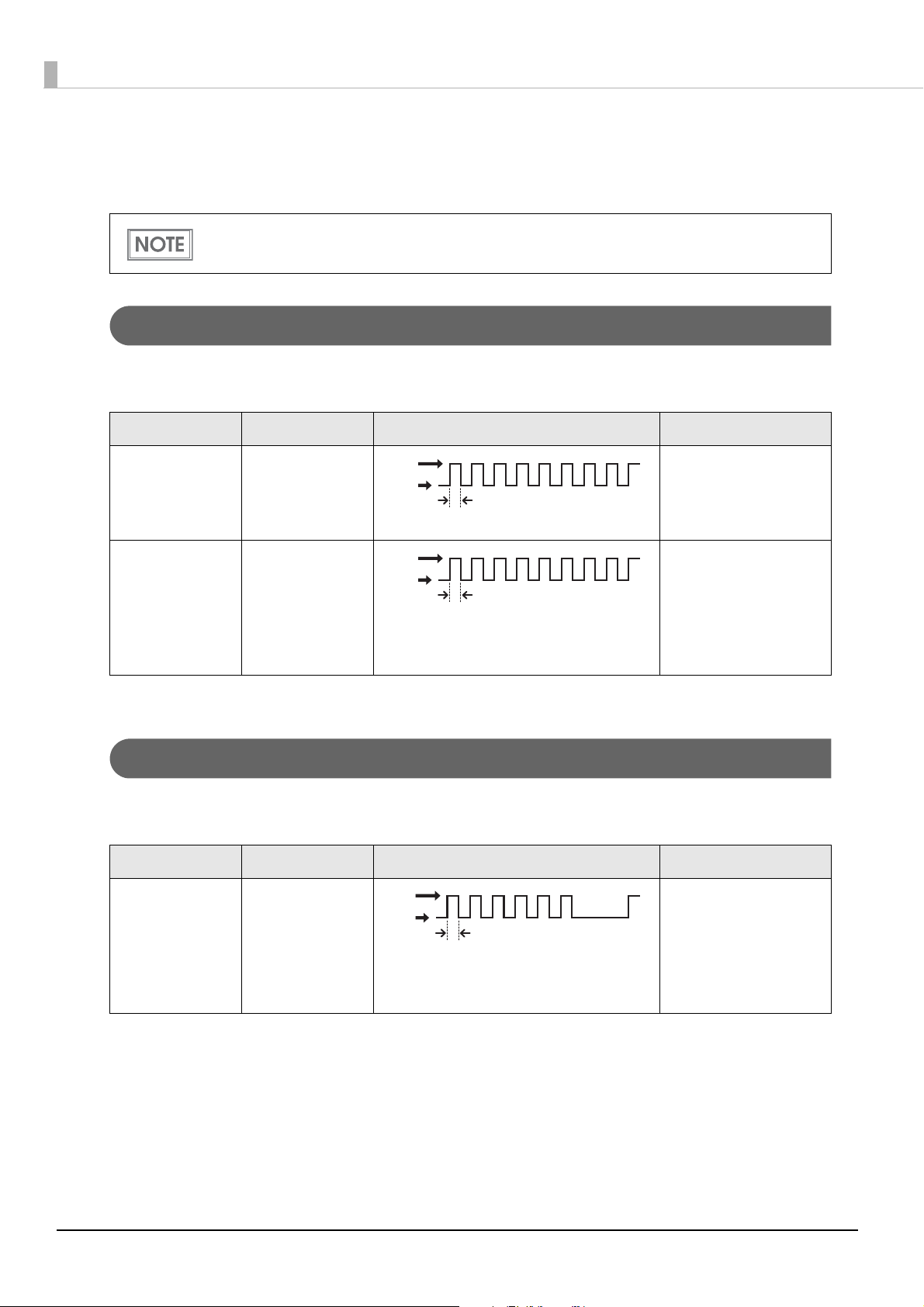

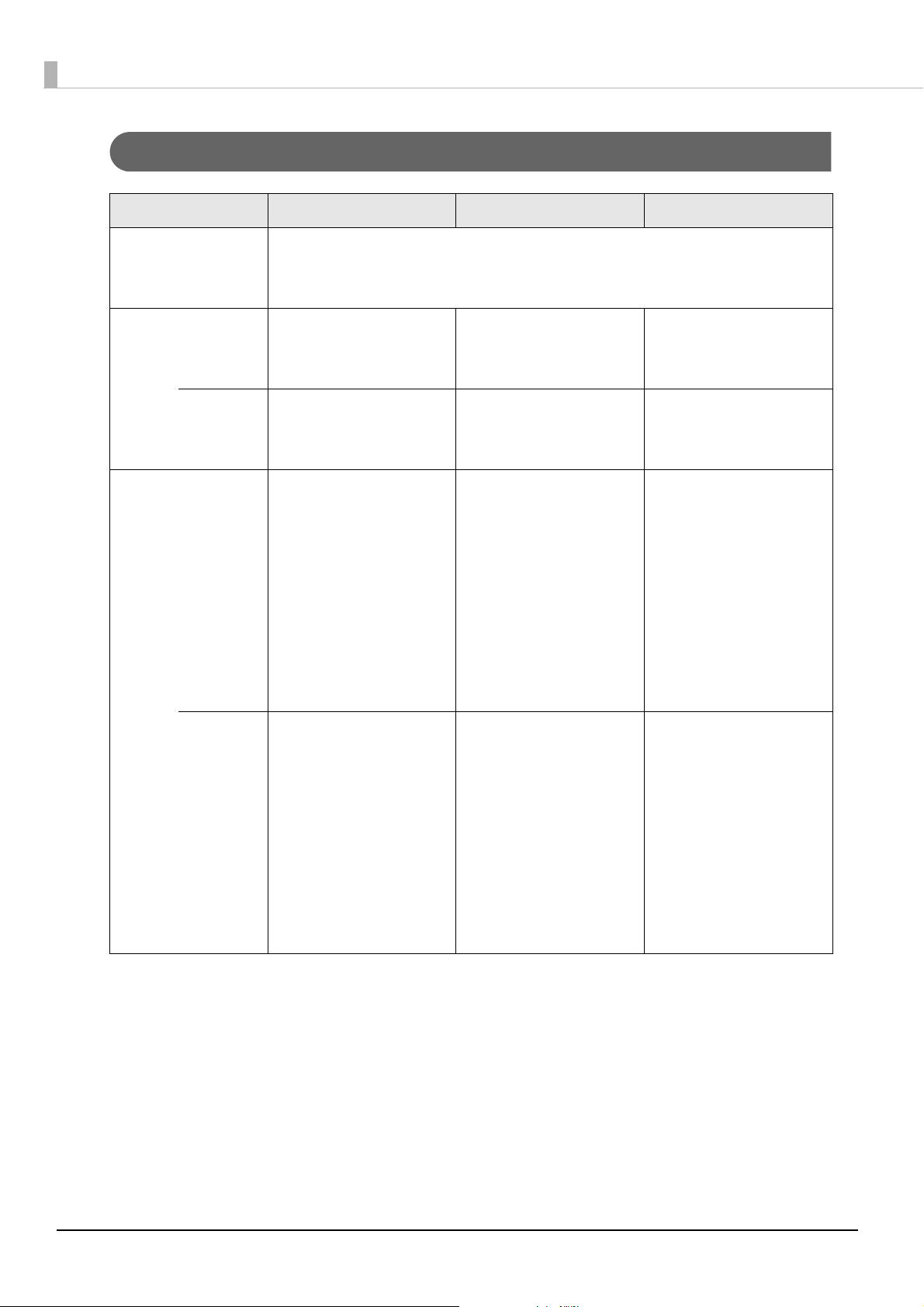

Automatically Recoverable Errors

The printer cannot print when automatically recoverable errors occur. It can be recovered as described

below.

Error Error description Error LED flash code Condition for Recovery

Roll paper cover

open error

*

The roll paper

cover was

opened while

Recovers automatically

when the roll paper

cover is closed.

printing.

Head

temperature

error

A high

temperature

outside the head

Recovers automatically

when the print head

cools.

drive operating

range was

detected.

*

: When the memory switch 8-8 is set to OFF (Roll paper cover open while the printer is printing: automatically recoverable error)

Recoverable Errors

The printer cannot print when a recoverable error occurs. It can be recovered easily by turning the power

on again or sending an error recovery command from the driver after eliminating the cause of the error.

Error Error description Error LED flash code Condition for Recovery

Roll paper cover

open error

*

The roll paper

cover was

opened while

printing.

Recovers when the roll

paper cover is closed

and the error recovery

command is executed

or the power is turned

on again.

18

Page 19

Chapter 1 Product Overview

LED OFF

LED ON

Approx. 320 ms

Approx. 5120 ms

LED OFF

LED ON

Approx. 320 ms

Approx. 5120 ms

LED OFF

LED ON

Approx. 320 ms

Approx. 5120 ms

LED OFF

LED ON

Approx. 320 ms

Approx. 5120 ms

LED OFF

LED ON

Approx. 5120 ms

Error Error description Error LED flash code Condition for Recovery

Autocutter error The Autocutter

does not work

correctly.

LED ON

LED OFF

Approx. 320 ms

Approx. 5120 ms

Recovers when the

jammed paper or

foreign matter is

removed and the roll

paper cover is closed,

and then the error

recovery command is

executed or the power

is turned on again.

*

: When the memory switch 8-8 is set to ON (Roll paper cover open while the printer is printing: recoverable error)

The error recovery command is valid only if a recoverable error (excluding automatically

recoverable errors) occurs.

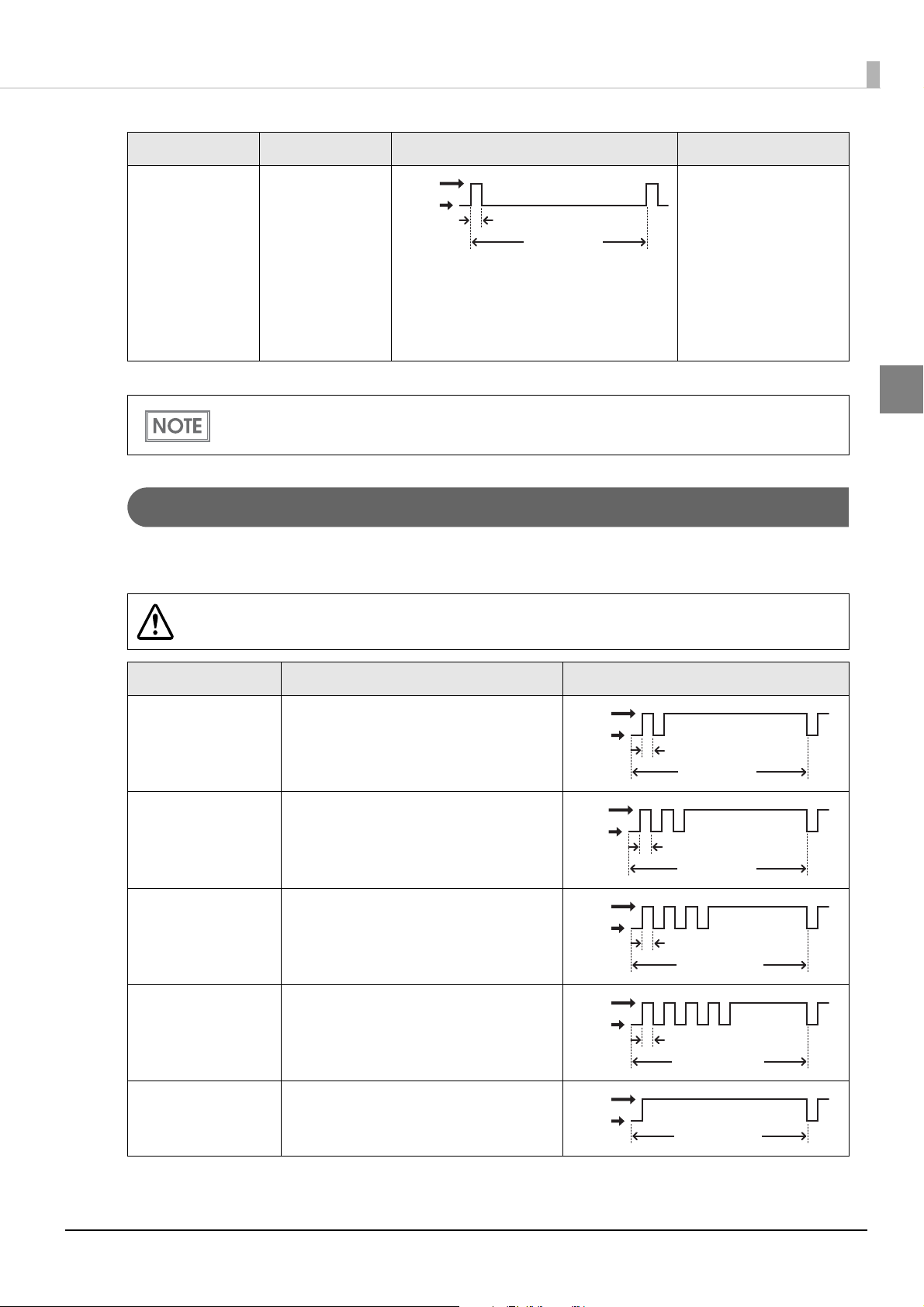

Unrecoverable Errors

1

The printer cannot print when an unrecoverable error occurs. If the error persists after turning the printer

off and then on again, the printer may be defective. Contact qualified service personnel.

Turn off the power immediately when an unrecoverable error occurs.

CAUTION

Error Error description Error LED flash code

R/W error in memory After R/W checking, the printer does not

work correctly.

High voltage error The power supply voltage is extremely

high.

Low voltage error The power supply voltage is extremely

low.

CPU execution error The CPU is executing an incorrect

address.

Internal circuit

connection error

Internal circuits are not connected

correctly.

19

Page 20

Error Error description Error LED flash code

LED OFF

LED ON

Approx. 320 ms

Approx. 5120 ms

Interface error Interface error

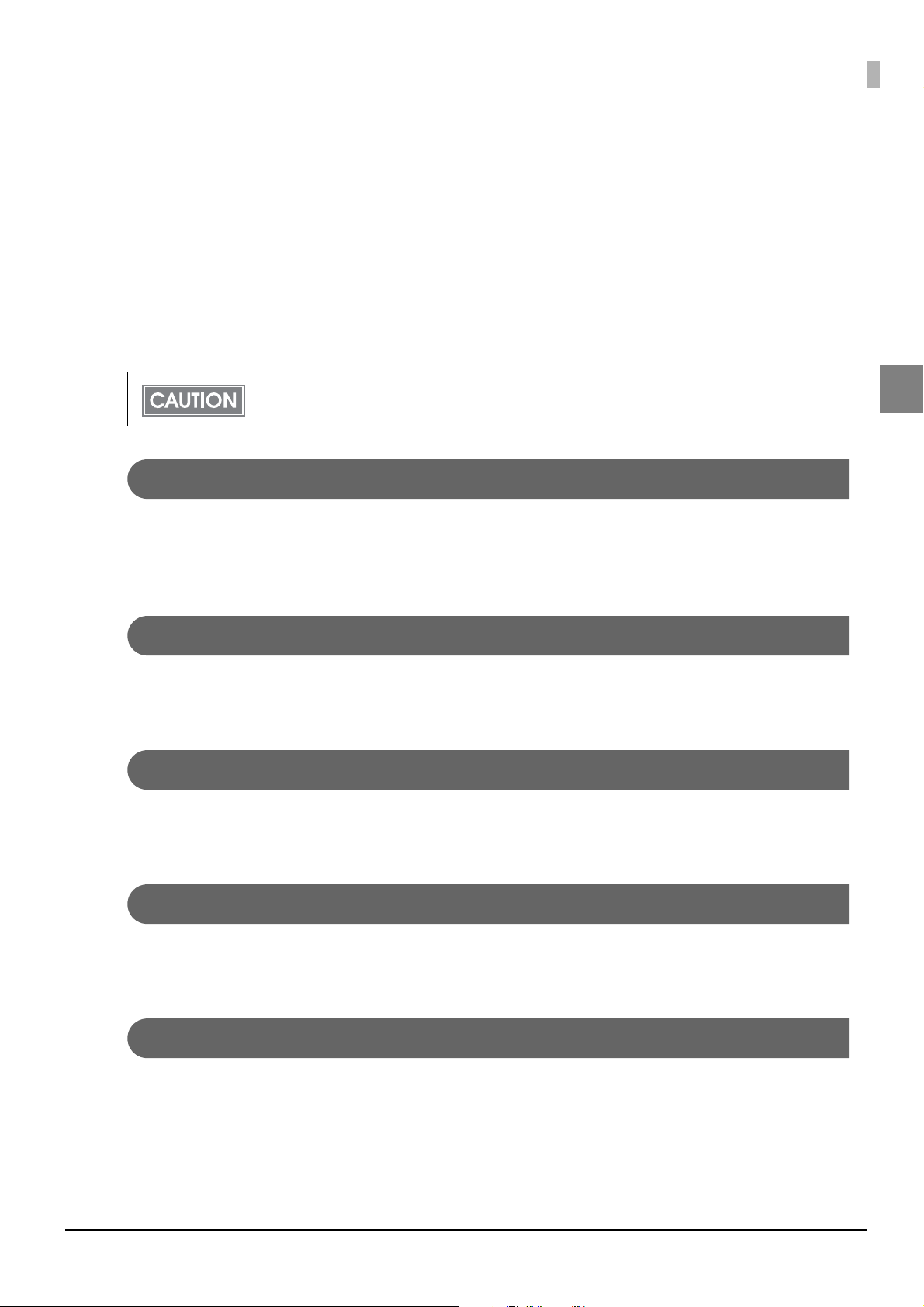

Status Display

LED Error LED PaperLED

Online ON OFF OFF

Initializing after power-on ON ON -

Running a self-test ON OFF -

Waiting to continue self-test ON OFF Flashing

Feeding using the Feed button ON OFF -

Waiting to execute a macro ON OFF Flashing

Roll paper cover open while the

ON ON -

printer is not printing

No paper ON ON ON

Near end ON OFF ON

While updating firmware Flashing OFF OFF

In power off standby status Flashing OFF OFF

Waiting to print status sheet ON ON Flashing

68* model only: Paper removal

ON OFF Flashing

standby

-: Changes depending on whether or not paper is detected.

20

Page 21

Chapter 1 Product Overview

NV Memory

The printer is equipped with NV memory (Nonvolatile Memory) to store data even after the printer power is

turned off. NV memory contains the following memory areas for the user:

•NV graphics memory

• User NV memory

• Memory switches

• User-defined page

• Maintenance counter

As a guide, NV memory rewriting should be 10 times or less a day when you program

applications.

NV Graphics Memory

Graphics, such as shop logos to be printed on receipts, can be stored. Even with a serial interface model

whose transmission speed is low, high speed graphic printing is possible.

Use the TMFlogo logo registration utility to register graphics.

User NV Memory

You can store and read text data for multiple purposes, such as for storing a note including customizing or

maintenance information of the printer.

Memory Switches (Customized Value)

You can configure the serial interface communication conditions and other various settings of the printer.

For more information, see

"Software Setting Mode" on page 52.

1

User-defined page

You can store character data in the user-defined page (character code table: page 255) so that you can also

print characters not resident in the printer.

Maintenance Counter

With this function, printer information, such as the number of lines printed, the number of autocuts, and

printer operation time after the printer starts working, is automatically stored in NV memory. You can read

the counter information with the Status API of the APD, OPOS ADK, or ESC/POS commands. You can use the

counter information for periodical checks or part replacement.

21

Page 22

22

Page 23

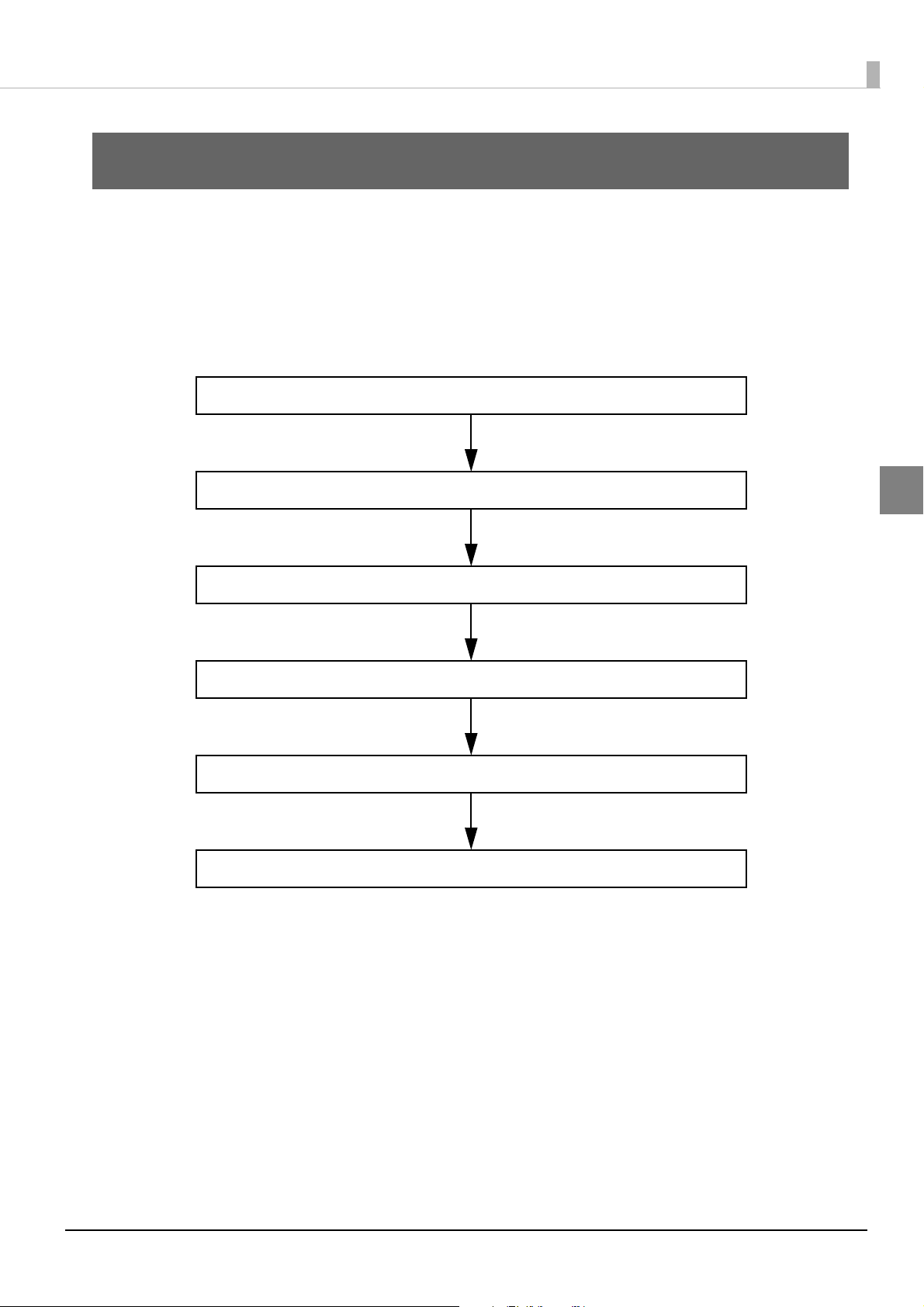

Chapter 2 Setup

3. Connecting the AC Adapter (29 page)

6. Connecting the Optional Wireless LAN Unit (36 page)

5. Connecting the Cash Drawer (33 page)

4. Connecting the Printer to the Host (31 page)

2. Changing the Paper Width (25 page)

1. Installing the Printer (24 page)

Setup

This chapter describes setup and installation of the product and peripherals.

Flow of Setup

This chapter consists of the following sections along with the setup flow of the product and peripherals.

2

23

Page 24

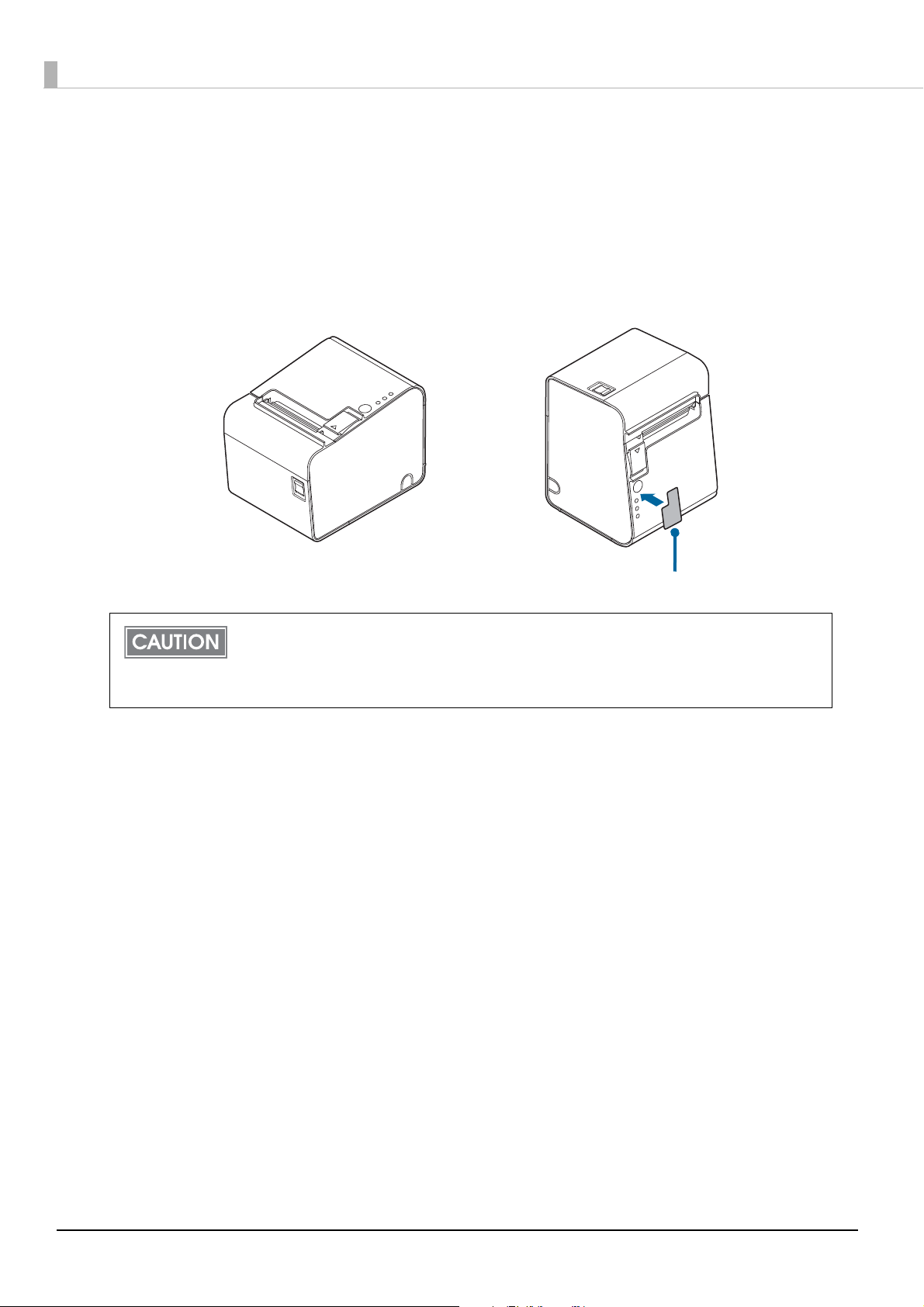

Installing the Printer

<Vertical installation>

<Horizontal installation>

Control panel for vertical installation

You can install the printer horizontally on a flat surface (with the paper exit on top) or vertically (with the

paper exit at the front). Also, you can hang it on a wall using the optional wall hanging bracket (WH-10).

Attach the control panel label for vertical installation when vertical installation (with the paper exit at the

front) is used.

• Do not place the printer in a dusty location.

• Do not knock or strike the printer. Doing so may cause defective printing.

• Be careful not to catch cables or place foreign matter under the printer during

installation.

24

Page 25

Changing the Paper Width

Install/remove the roll paper guide according to the roll paper width to be used.

The width of the installed roll paper guide differs according to the model by factory default.

❏ 65* model

Equipped with the 40 mm roll paper guide.

• When using 40 mm width roll paper, use this guide.

• When using 80 mm width roll paper, remove the installed guide.

❏ 66*/67*/68* models

Equipped with the 58 mm roll paper guide.

• When using 58 mm width roll paper, use this guide.

• When using 80 mm width roll paper, remove the installed guide.

• When using 40 mm width roll paper, remove the installed guide and install the guide for 40 mm paper supplied with the

product.

Chapter 2 Setup

• Because some parts of the print head and the autocutter blade may contact the platen and

become worn out, you cannot change a smaller paper width to a larger one once you start

using the product.

• The printable area is automatically defined by detecting the installed roll paper guide.

However, to change the paper width from 58 mm to 40 mm, using the memory switch is

required. (

"Memory Switch 6" on page 40)

2

25

Page 26

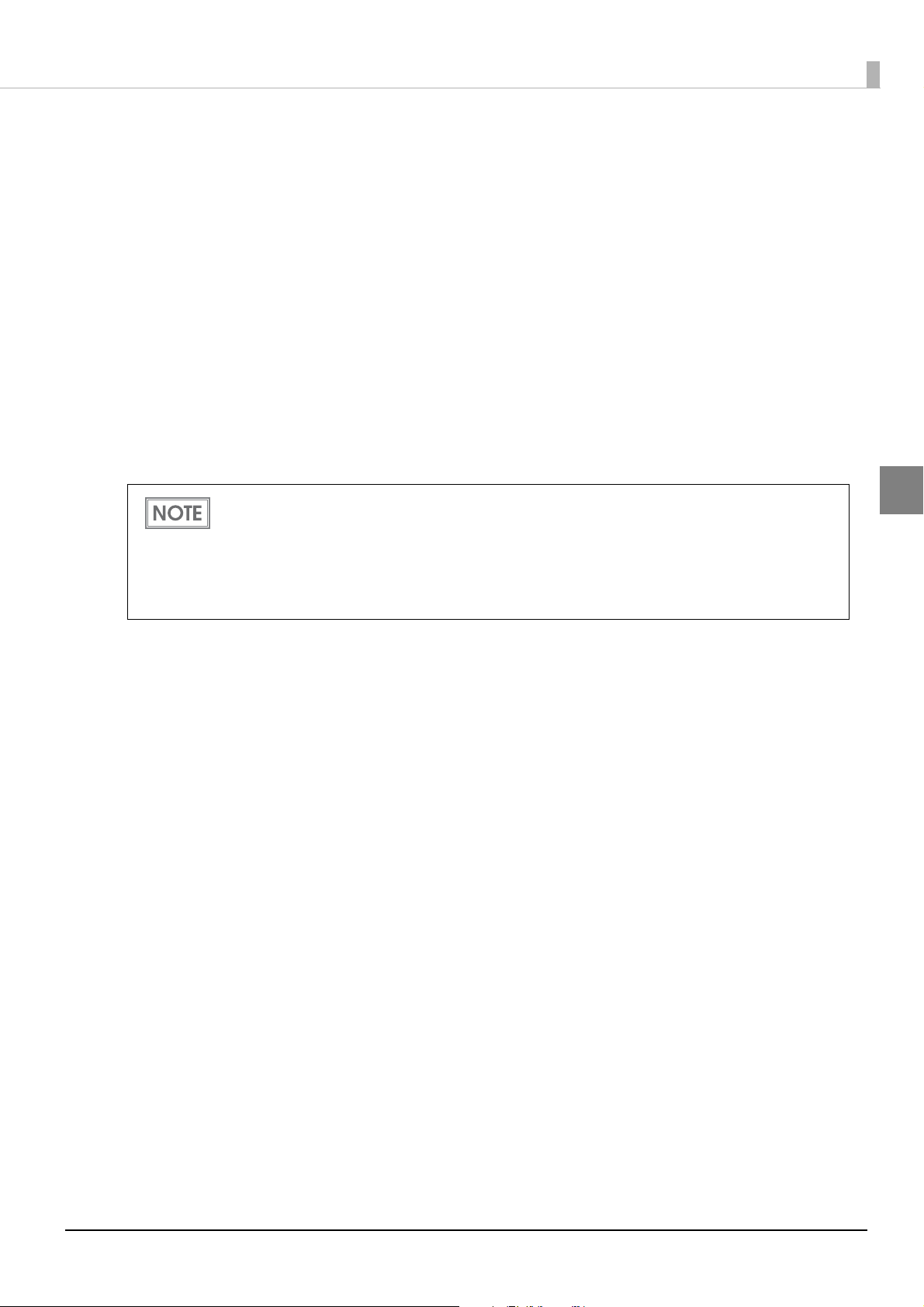

Removing the Roll Paper Guide

Press the cover open lever to open the roll paper cover.

1

While pushing down the roll paper guide lever in the arrow direction, lift the whole roll paper

2

guide to remove it.

26

Page 27

Chapter 2 Setup

40 mm

58 mm

58 mm

40 mm

Printer Front Side

Hole

Notch

Projection

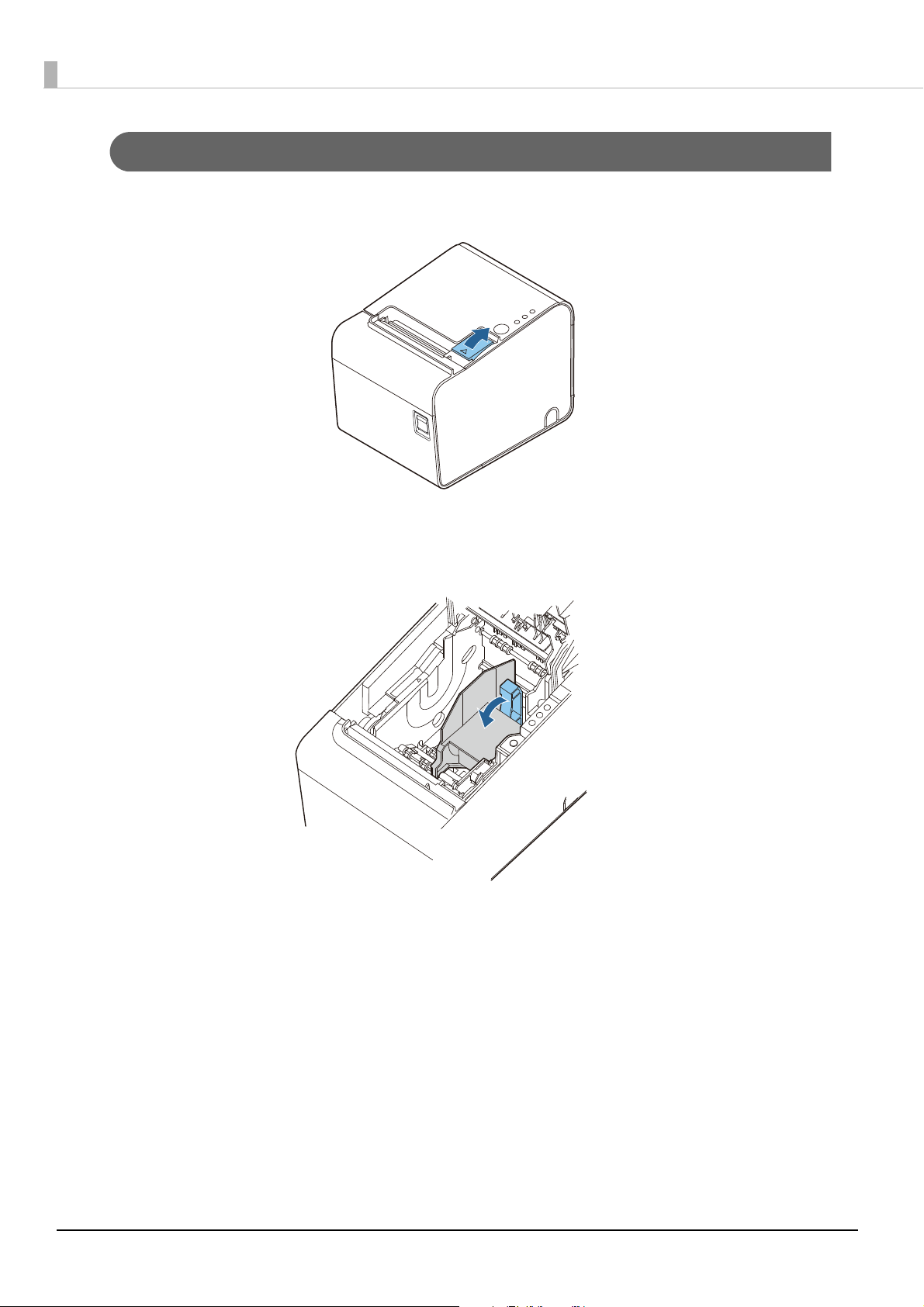

Installing the Roll Paper Guide

Press the cover open lever to open the roll paper cover.

1

Install the roll paper guide inside the printer.

2

Align the guide with the holes, cutouts, and protrusions in the printer as shown below. The installation position

of the roll paper guide is different depending on the width of the roll paper guide.

2

27

Page 28

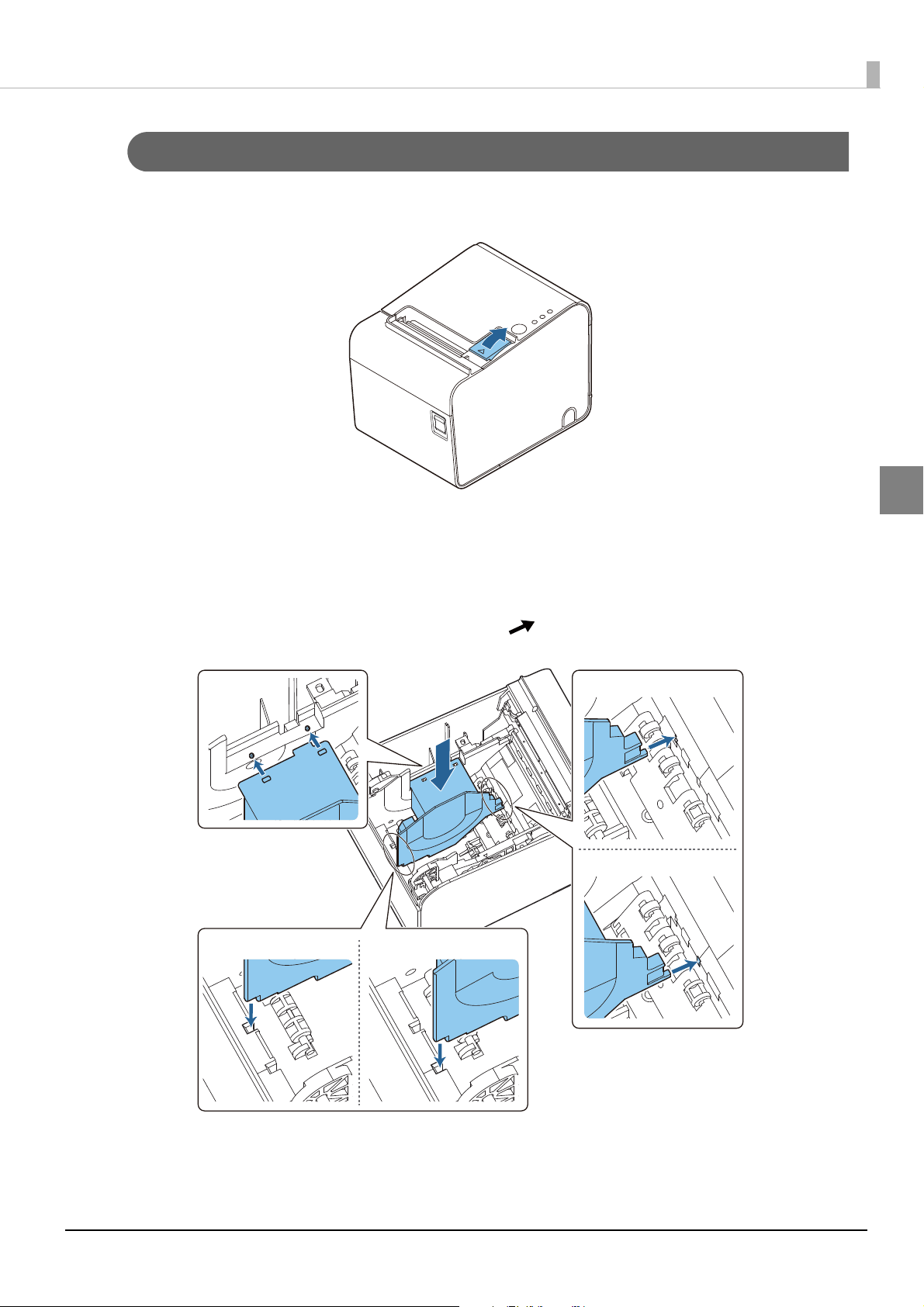

Push the lever of the roll paper guide down until the paper guide clicks into place.

3

28

Page 29

Connecting the AC Adapter

For the AC adapter, use PS-180 or the equivalent.

Use the AC cable supplied with the product.

• Use of an unspecified AC adapter may cause fire or electrical shock.

WARNING

AC Adapter Connection Procedure

Make sure the printer is turned off.

1

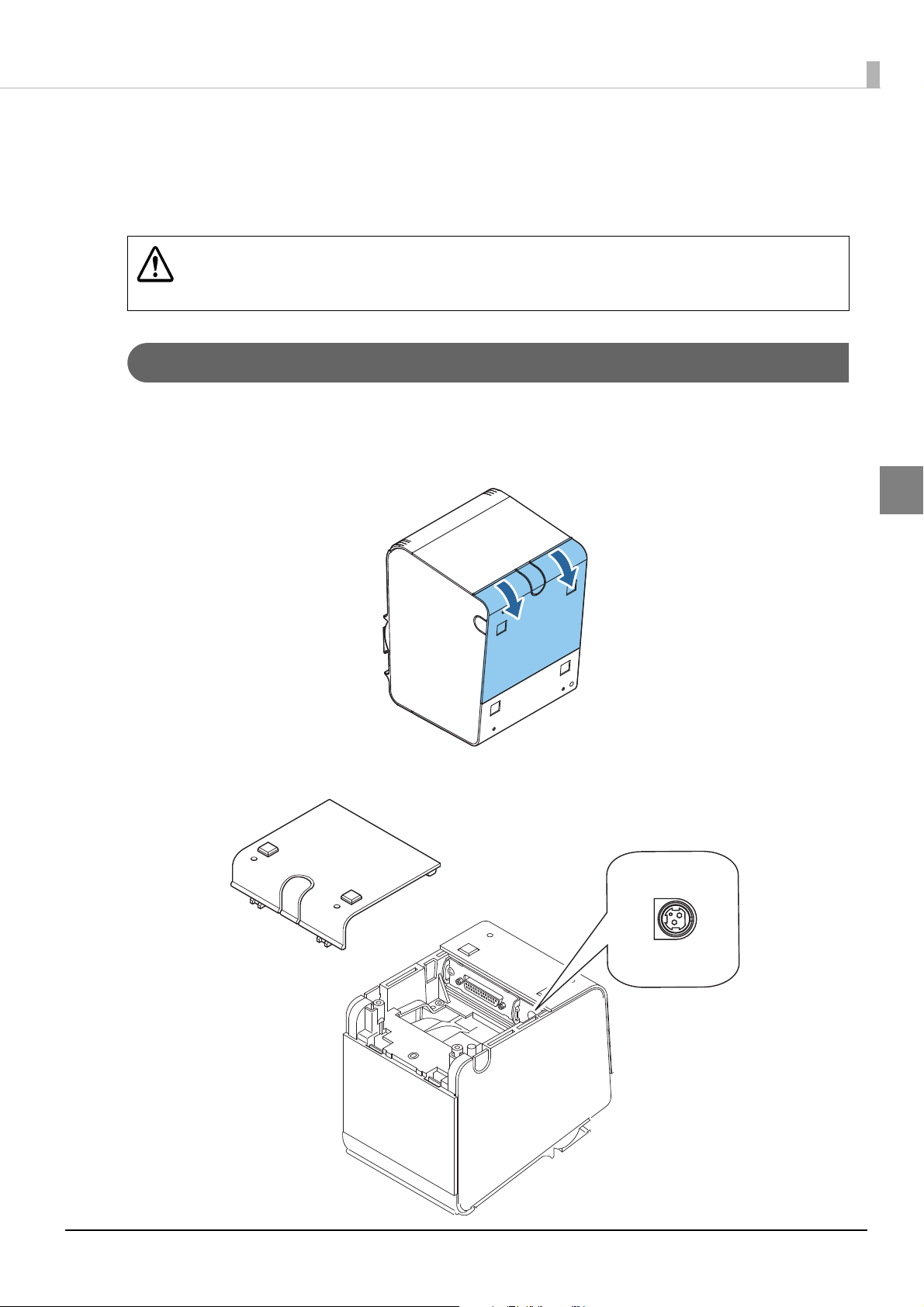

Remove the cover on the rear side of the printer.

2

• Should a fault ever occur, immediately turn off the power to the printer and unplug

the AC cable from the wall socket.

Chapter 2 Setup

2

Connect the DC cable of the AC adapter to the power supply connector (stamped DC 24V).

3

29

Page 30

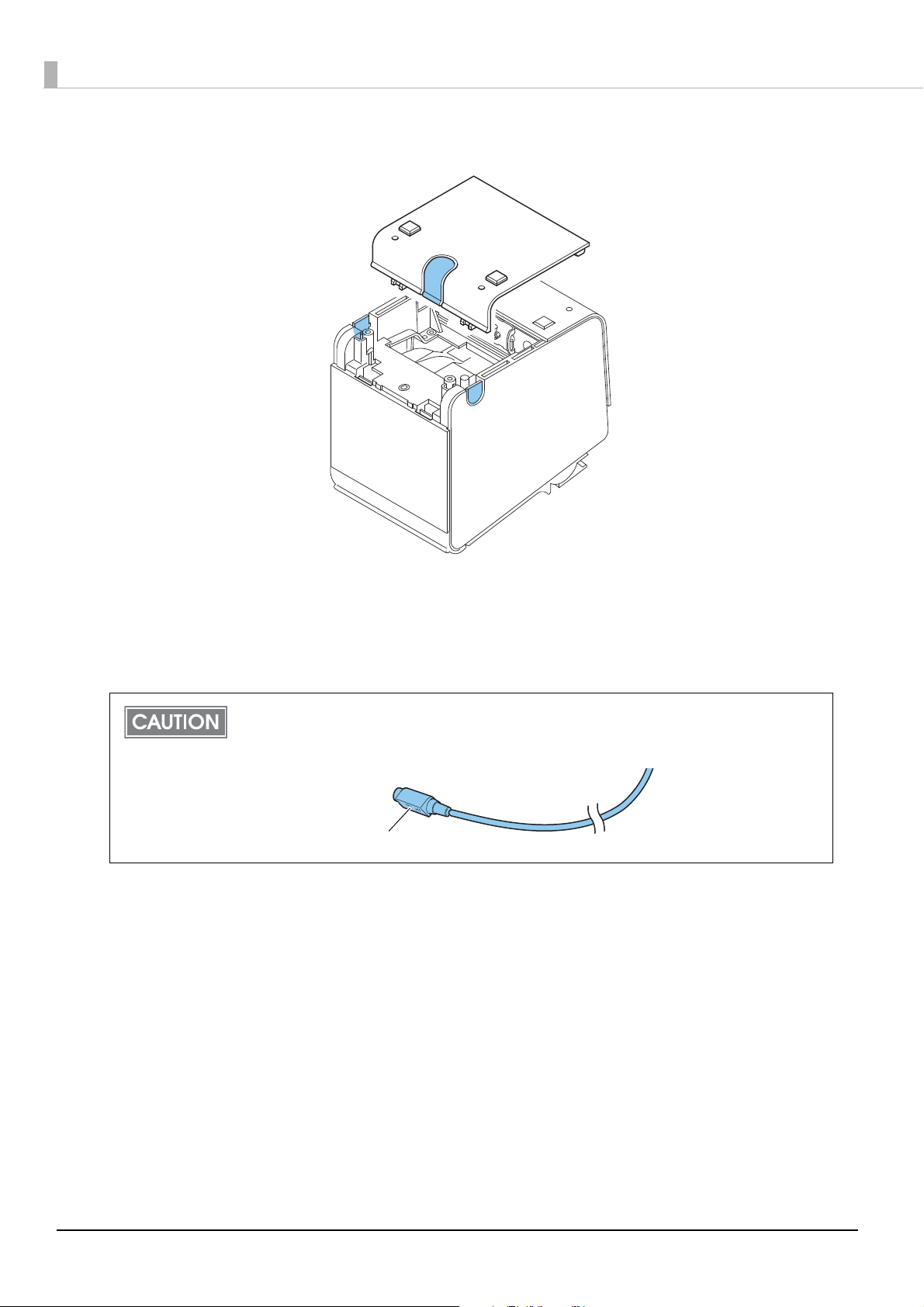

Remove any of the knockouts (at 3 locations) on the rear cover and pass the cable through.

Arrow part of connector

4

Close the rear cover.

5

Connect the AC cable to the AC adapter.

6

Connect the AC cable to the power outlet.

7

Before disconnecting the DC cable of the AC adapter from the printer, make sure that the

AC cable is disconnected. Then, hold the arrow part of the connector and pull out the

cable while keeping it straight.

30

Page 31

Chapter 2 Setup

Locking wire saddle

USB cable

USB connector

Connecting the Printer to the Host

The printer uses a modular connector specifically designed for the cash drawer or for the

customer display. Do not connect these connectors to an ordinary telephone line.

USB Interface

When using USB cable to connect with host device, connect the USB cable to the printer, and after starting

the host device, turn the printer on.

• Do not place any weight or stress on the cable when using. Doing so could damage

the cable and connectors.

• To prevent disconnection of the USB cable, secure the cable to the hook on the

locking wire saddle as shown below.

2

Ethernet Interface

Use an Ethernet cable to connect the printer to a network via a hub.

Use Epson EpsonNet Config to set network. For details about EpsonNet Config, refer to EpsonNet Config

Operations Guide.

• When LAN cables are installed outdoors, make sure they are connected through

devices that have surge protection.

Otherwise, the devices can be damaged by lightning.

• Never attempt to connect the customer display cable, the drawer kick cable, or a

telephone line cable to the LAN connector.

As same with Conventional models, you can use EpsonNet Config (Web version) in the

same way.

User name/password: epson

31

Page 32

For Serial Interface Models

Use Epson's optional cable or the equivalent.

• Crossover cable for RS-232C interface 2 m(model: OI-C01)

D-sub 9-pin (female) connector -D-sub 25-pin (male) connector

When connecting to the host computer through a serial interface (RS-232), connect a serial cable to the

printer, start the host computer, and then turn on the printer.

• When using connectors equipped with screws, tighten the screws on both sides to

secure the connectors firmly.

• When using interface cables equipped with a ground line, attach the ground line to

the screw hole marked “FG” on the printer.

32

Page 33

Chapter 2 Setup

With shielded

Drawer kick connector

Printer side User side (Drawer kick side)

Drawer open/

close switch

Drawer kick

solenoid

1

2

3

4

5

6

Connecting the Cash Drawer

• Two driver transistors cannot be energized simultaneously.

• Leave intervals longer than 4 times the drawer driving pulse when sending it

continuously.

Cash Drawer Requirements

Specifications of drawers greatly differ depending on manufacturers and models. When you use a drawer

other than specified, make sure its specification meets the following conditions.

Otherwise, devices may be damaged.

• The load, such as a drawer kick solenoid, must be connected between pins 4 and 2 or pins 4 and 5 of the

drawer kick connector.

• When the drawer open/close signal is used, a switch must be provided between drawer kick connector

pins 3 and 6.

2

• The resistance of the load, such as a drawer kick solenoid, must be 24 ohms or more or the input current

must be 1 A or less.

• Be sure to use the 24 V power output on drawer kick connector pin 4 for driving the equipment.

Drawer Connection Diagram

F.G

+24V

Connector

Modular connector RJ12

33

Page 34

Pin assignments

6 5 4 3 2 1

Pin

number

1Frame GND -

2Drawer kick drive signal 1Output

3 Drawer kick open/close signal Input

4+24 V -

5Drawer kick drive signal 2Output

6Signal GND -

Signal name Direction

34

Page 35

Chapter 2 Setup

DK

24V

Connecting the Drawer Kick Cable

• Use a shield cable for the drawer kick cable.

WARNING

Connect the drawer kick cable to the drawer kick connector by pressing firmly until the connector clicks

into place.

• When using cash drawer, make sure to use the power supply for printer (connector

pins 4).

• Do not insert a telephone line into the drawer kick connector.

• Doing so may damage the telephone line or printer.

2

35

Page 36

Connecting the Optional Wireless LAN Unit

The optional Wireless LAN cable set enables you to use the product with a Wi-Fi connection. For more

information, refer to User’s Manual of the Wireless LAN cable set.

• Be sure to turn off the printer when connecting the Wireless LAN unit.

• Depending on the installation conditions of the printer and the routing for cables

connected to it, the status of the radio waves for the Wireless LAN unit may decline. If

this does happen, use an extension cable.

36

Page 37

Chapter 3 Advanced Usage

Advanced Usage

Software Settings

With the functions such as the memory switches and customized values, which are software settings for

this printer, you can set the various functions.

For an outline of the functions, see the following pages. Use the software setting mode or the memory

switch setting utility for setting the functions.

• In the software setting mode, panel operations on the printer are used to configure

settings. For details about the panel operations, see

• For information about how to use the memory switch setting utility, see the User's Manual

for the memory switch setting utility.

• For information about ESC/POS commands, see the ESC/POS Command Reference.

• To check the setting status, use the self-test (

switch setting utility.

"Self-test Mode" on page 50) or the memory

"Software Setting Mode" on page 52.

Item/Method

Transmission of the power ON information

Capacity of receive buffer

1

Condition for BUSY

Data receive error

Automatic line feed

2 Autocutter operation

Autocutting position

Auto scaling for 40/58 mm width paper

Memory Switches

Auto top margin scaling

6

Selection of the characters per line for 80 mm

width paper

Selection of paper width

Enable left or right margin of bar code print

8

Roll paper cover open during operation

Software Setting

Mode

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

Memory Switch

Setting Utility

3

✔

37

Page 38

Item/Method

Software Setting

Mode

Memory Switch

Setting Utility

User NV memory capacity setting

NV graphics memory capacity setting

Selection of the energization parting

Selection of printing density

Selection of print speed

Automatic Paper Reduction

Auto image data scaling

Customized value

Selection of the media type detection method*

Amount of top margin by backfeed*

Stop position when Label cutting*

Selection of paper removal standby*

Serial interface communication condition setting

∗ *: 68* model only

✔

✔

✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

38

Page 39

Chapter 3 Advanced Usage

Memory Switch 1

SW Function ON OFF

1-1 Transmission of the power ON information Transmits Does not transmit

1-2 Capacity of receive buffer 45 bytes 4 KB

1-3 Condition for BUSY Receive buffer full

1-4 Data receive error Ignored Prints "?"

1-5 Automatic line feed Enabled Disabled

1-6 to 1-8 Reserved — —

• Regardless of the settings for memory switches 1-3, the printer enters the BUSY state

after the power is turned on (including the reset using the interface), and when a selftest is being run.

• If the memory switches 1-3 are set to ON, the printer will not become BUSY in the

following cases:

* When the roll paper cover is open

* When paper is fed by the FEED button

* When printing has stopped due to paper out

* When macro execution ready state

* When error has occurred

Receive buffer full or

Offline

Memory Switch 2

3

SW Function ON OFF

2-1 Reserved (Do not change the setting) Fixed to On

2-2 Autocutter operation Enabled Disabled

2-3 to

2-8

Reserved — —

39

Page 40

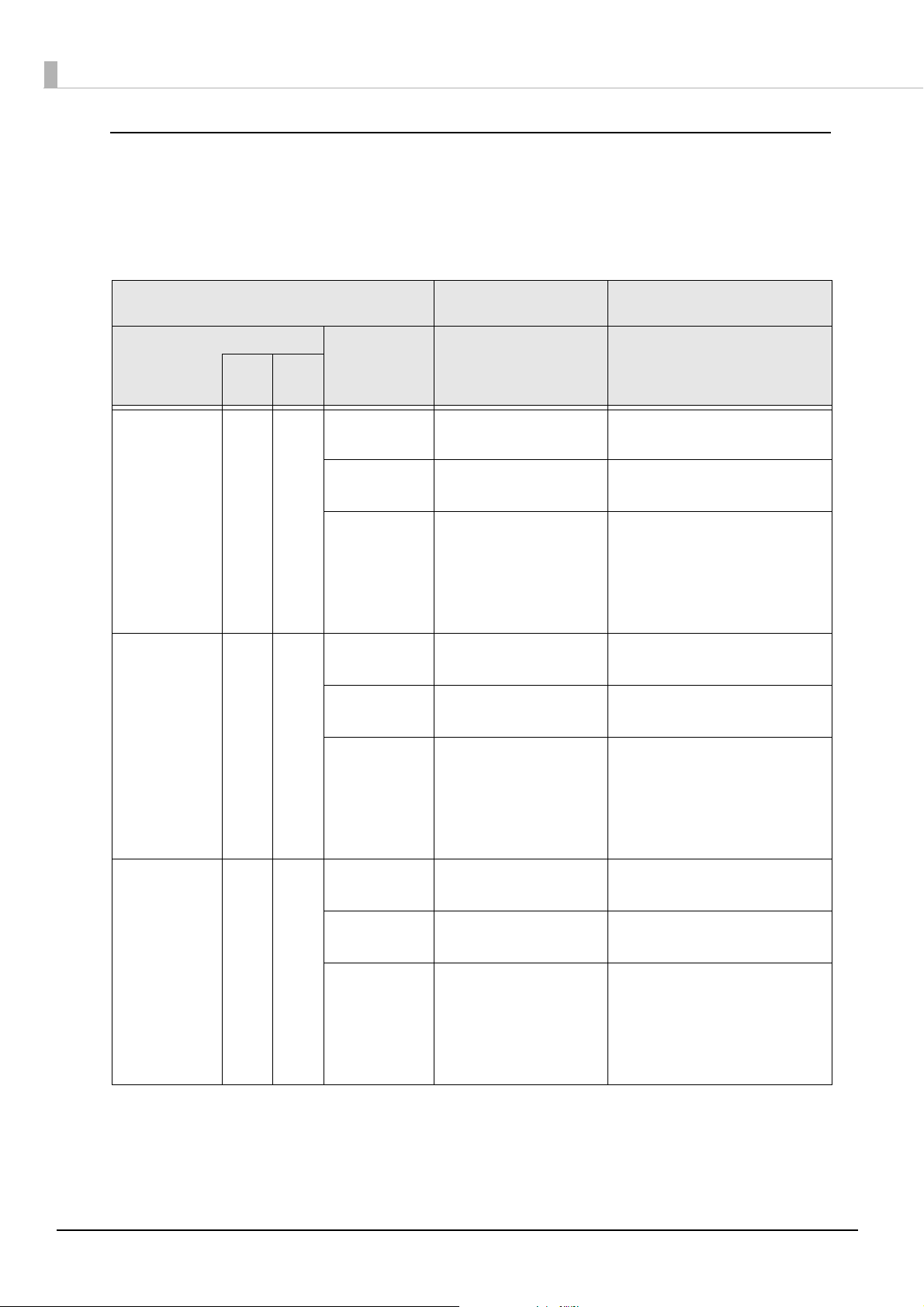

Memory Switch 6

SW Func tion ON OFF

6-1 Autocutting position

6-2 Auto scaling for 40/58 mm width paper

6-3 Auto top margin scaling

6-4

6-5

6-6 to

6-7

Selection of the characters per line for 80 mm

width paper

Reserved — —

6-8 Paper width selection

*1: For details about the characters per line and character specifications with this function enabled, see "Details of Characters Per Line and

Character Specifications with Auto Scaling Enabled" on page 78.

*2: Enabled when printing continues after autocutting.

To set the function using the software setting mode, select [11. Top margin reduction] - [11.2 when Paper removal standby is invalid].

*3: With the 67*/68*(multilingual) models, the functions for the memory switches 6-3/6-4/6-5 are reserved and unavailable.

*4: With the 65* model, the function for memory switch 6-8 is reserved and unavailable.

*2

*3

*4

*1

Cut at black mark

position

Enabled Disabled

Enabled Disabled

See the table below.

"Selection of the characters per line for 80 mm width paper

(compatible mode)" on page 40

58 mm/80 mm 40 mm/80 mm

Cut regardless of black

mark position

Selection of the characters per line for 80 mm width paper (compatible mode)

Compatible mode

TM-T88

compatible mode (1)

TM-T88

compatible mode (2)

TM-L90

compatible mode

Characters per line

Memory Switch 6

The printing and autocutting positions change depending on the software setting. For details,

see

Font A 42 44 48

Font B 55 57 64

6-4 ON ON OFF

6-5 ON OFF OFF

"Printing and Cutting Positions" on page 92.

40

Page 41

Chapter 3 Advanced Usage

Memory Switch 8

SW Func tion ON OFF

8-1 to

8-4

8-5 Enable left or right margin of bar code print Enables margin

8-6 Reserved — —

8-7 Reserved — —

8-8

Roll paper cover open while the printer is

Reserved — —

Does not enable

margin

Automatically

recoverable errors

printing

Recoverable errors

3

41

Page 42

Customized value

User NV memory capacity setting

•1 KB (default setting)

•64 KB

•128 KB

•192 KB

NV graphics memory capacity setting

The memory area for NV graphics data and the user NV memory area use a common area. Therefore, the

memory capacity that can be set for NV graphics changes depending on the user NV memory capacity

setting. If the specified memory capacity for NV graphics is out of the allowable range, the capacity is

automatically changed to a value that can be set.

Capacity of the user NV

memory

1 KB

64 KB

128 KB

192 KB • None

Capacity of the NVgraphics

•None

•64 KB

•128 KB

•192 KB

•256 KB

•320 KB

• 384 KB (default setting)

•None

•64 KB

•128 KB

•192 KB

•256 KB

•None

•64 KB

•128 KB

42

Page 43

Selection of the energization parting

• One-part energizing (default setting)

•Two-part energizing

• Three-part energizing

•Four-part energizing

· In normal operation, there is no need to change the energization parting.

· The maximum print speed is available only in the one-part energizing mode.

· Four-part energizing mode can reduce power consumption.

Selection of printing density

Models Media type Density setting Default setting

Chapter 3 Advanced Usage

Other than the 68*

model

68* model Thermal paper 100 - 130%

Depending on the paper type, it is recommended to set the print density as shown in the table below for

the best print quality.

Thermal paper (without black marks):

Original Paper type Density

P35524, P30523, P31523 120%

TF50KS-EY, F5041(55), KT55FA, KT48FA 115%

AF50KS-E 110%

KF50 100%

Thermal paper 100 - 130%

(in increments of 5%)

Liner-free label paper Fixed Fixed

(in increments of 5%)

Liner-free label paper 75 - 100% (in increments of 5%) 100%

120%

120%

3

Liner-free label paper (with black marks):

Density

Original Paper type

9023–1274, 9023–1253 (Lane coated: 80 mm) Fixed 100%

9023–1823, 9023–1397 (Lane coated: 58 mm) Fixed 100%

9023–1275, 9023–1257 (Lane coated: 40 mm) Fixed 100%

When the print density level is increased, print speed may be reduced.

Other than the

68* model

Density

68* model

43

Page 44

Selection of print speed

Selectable from levels 1 to 11 (Slow – Fast)

Default setting: level 11

• Printing speed may be slower, depending on items such as the print data, head

temperature, and energization parting.

• If white lines are caused by intermittent printing (printing sometimes stops) in graphics

printing, etc., set the print speed at low speed or, for serial interface models, set the

communication speed at high speed to prevent white lines.

Automatic Paper Reduction

Reduction of top margin

•Does not reduce

• Reduces

Reduction of bottom margin

•Does not reduce

• Reduces

Reduction of line spacing

•Does not reduce

• Reduces 25%

• Reduces 50%

• Reduces 75%

• Reduces the most (68* model only)

Reduction of line spacing where extra line feeds are included

•Does not reduce

• Reduces 25%

• Reduces 50%

• Reduces 75%

Reduction of bar code heights

•Does not reduce

• Reduces 25%

• Reduces 50%

• Reduces 75%

44

Page 45

Chapter 3 Advanced Usage

Reduction ratio of character height (68* model (ANK) only)

•Does not reduce

• Reduces 25%

• Reduces 50%

• Reduces 75%

• Reduces 75% and shortens character height

• Reduces the most and shortens character height

• The printing and autocutting positions change depending on the paper type or the

software setting. (

• Some selections are unavailable in the self-test mode. Use the memory switch setting

utility.

"Printing and Cutting Positions With Software Setting" on page 96)

Auto image data scaling

• Nearest neighbor interpolation: Shrink the image data by 82%, keeping the aspect ratio.

• Cut off both sides: Cut off 46 dots from the edge of both sides of the image data.

• Cut off the right side: Cut off 92 dots from the right side of the image data.

• Cut off the left side: Cut off 92 dots from the left side of the image data.

• None: Actual size image data is defined or printed

• This function has the following restrictions:

* The print-start time will be late.

* The print-result may have a blank line.

• This function is not available, if the data is less than 92 dots.

Selection of the media type detection method

• Auto detection (default setting)

• Fixed to liner-free label paper

• Fixed to continuous paper without black marks

Amount of top margin by backfeed

This function is enabled when the selection of paper removal standby is set to "Enabled".

3

Selectable from 4.0 to 14.0 mm (in increments of 0.5 mm)

Default setting: 4 mm

• The printing and autocutting positions change depending on the paper type or the

software setting. (

• To set the function using the software setting mode, select [11. Top margin reduction] -

[11.1 when Paper removal standby is invalid].

"Printing and Cutting Positions With Software Setting" on page 96)

45

Page 46

Stop position when Label cutting

• Arbitrary stop position (default setting)

• Specific stop position

The printing and autocutting positions change depending on the paper type or the software

setting. ("Printing and Cutting Positions With Software Setting" on page 96

Selection of paper removal standby

• Enabled (default setting)

•Disabled

)

46

Page 47

Communication condition of serial interface

Transmission speed

• 2400 bps

• 4800 bps

• 9600 bps

• 19200 bps (default setting)

• 38400 bps

• 57600 bps

• 115200 bps

[bps: bits per second]

Parity

Chapter 3 Advanced Usage

• No parity (default setting)

•Odd parity

•Even parity

Handshaking

• DSR/DTR (default setting)

•XON/XOFF

Bit length

•7 bits

• 8 bits (default setting)

3

47

Page 48

Setting/Checking Modes

Close the roll paper cover, and turn on the printer while pressing the Feed button.

Self-test

Close the roll paper cover, and turn on the printer while pressing the Feed button.

Release the Feed button when the Error LED turns on

+

Press the Feed button two times briefly

+

The roll paper cover is closed

Software setting

Release the Feed button when the LED turns on

+

The roll paper cover is closed

Hexadecimal dumping

1

Briefly press the Feed button

Continuing the self-test

Hold down the Feed button

Mode selection guidance

2

Press the Feed button once briefly and

then hold it down

NV graphics information print

Press the Feed button two times briefly

and then hold it down

Software setting

As well as print mode, the following modes are also provided for making various printer settings and

checking items.

• Self-test mode

• NV graphics information print mode

• Software setting mode

• Hexadecimal dumping mode

You can select the mode depending on the operation at power-on.

In (1) and (2), the following guidances are printed, the Paper LED flashes, and instructs the user's operations.

48

Page 49

1. Continuing self-test guidance

2. Mode selection guidance

Chapter 3 Advanced Usage

Mode Selection

Modes

0: Exit and Reboot Printer

1: NV Graphics Information

2: Customize Value Settings

3: or more: None

Select Modes by executing following

procedure.

step 1. Press the Feed button less

than 1 second as many times

as the selected mode number.

step 2. Press Feed button for 1

second or more.

3

49

Page 50

Self-test Mode

In the self-test mode, the printer prints the current printer status and a rolling pattern test print of resident

characters.

The current status print includes the following information:

•Control software version

• Serial number

• Interface type

• Receive buffer size

• BUSY condition

• Built-in fonts

• Auto line feed enabled/disabled

•Print density

• Power ON status transmission enabled/disabled

• Paper width to be set

• Media type detection

• Type of paper

• Stop position when Label cutting

• Setting status of paper removal standby

•Various sensor values

• Print speed to be set

• Top margin length

• Maintenance information

• Memory switch settings

Follow the procedures below.

Close the roll paper cover.

1

While pressing the Feed button on the control panel, turn on the printer. (Hold down the Feed

2

button until printing starts.)

After printing the current print status, a Continuing self-test guidance is printed, and the Power LED flashes.

Briefly press the Feed button (less than one second) to continue the self-test.

3

The printer prints a rolling pattern on the roll paper, using the built-in character set.

After “*** completed ***” is printed, the printer initializes and switches to standard mode.

50

Page 51

Chapter 3 Advanced Usage

NV Graphics Information Print Mode

Prints the following NV graphics information registered to the printer.

• Capacity of the NV graphics

• Used capacity of the NV graphics

• Unused capacity of the NV graphics

• Number of NV graphics that are registered

• Key code, number of dots in X direction, number of dots in Y direction to be defined.

• NV graphics data

For details on NV graphics, see "NV Graphics Memory" on page 21.

Follow the procedures below.

After running a self-test, hold down the Feed button for at least one second to enter the Mode

1

selection.

The Mode selection guidance is printed, and the Paper LED flashes.

After briefly (less than one second) pressing the Feed button once, hold it down for at least one

2

second, to print the NV graphics information.

After information printing, the Mode selection guidance is printed again.

To finish, turn off the power, or select “Exit and Reboot Printer”.

3

3

51

Page 52

Software Setting Mode

Feed button

This mode is used to set the memory switches and the customized values of the printer.

• For information about the memory switches, see "Software Settings" on page 37.

• The software setting mode can also be started from the self-test mode. (

on page 37

Follow the procedures below.

Make sure that the roll paper is properly installed and that the printer is turned off.

1

Open the roll paper cover.

2

While pressing the Feed button in the printer, turn on the printer.

3

Hold down the Feed button until the Error LED turns on.

)

"Advanced Usage"

Release the Feed button when the Error LED turns on.

4

52

Page 53

Press the Feed button two times and close the roll paper cover.

5

The operation guidance is printed.

Chapter 3 Advanced Usage

Press the Feed button in the printer the number of times indicated on the print result, and close

6

the roll paper cover.

When one setting has been completed, the printer stores the setting.

For details on setting items, see

To exit the software setting mode, turn off the printer.

7

• To select 0 as the item number, hold down the Feed button until printing starts.

• If the button is pressed a number of times that is not displayed by the Setup guidance, the

operation is invalid and the same guidance is printed.

"Software Settings" on page 37.

3

53

Page 54

Starting Hexadecimal Dumping Mode

Feed button

Hexadecimal Dump

To terminate hexadecimal dump,

press FEED button three times.

1B 21 00 1B 26 02 40 40 1B 69 .!..&.@@.i

1B 25 01 1B 63 34 00 1B 30 31 .%..c4..01

41 42 43 44 45 46 47 48 49 4A ABCDEFGHIJ

. ! . . & . @ @ . i

. % . . c 4 . . 0 1

ABCDEFGHIJ

In the hexadecimal dumping mode, the printer prints the data transmitted from a host device in

hexadecimal numbers and their corresponding characters. It enables you to check if data is transmitted to

the printer correctly.

• If there is no character corresponding to print data, “.” is printed.

• If you press the Feed button when there is less than one line of print data, one line is

printed.

• During hexadecimal dumping mode, applications that check the printer status may

not operate correctly. The printer only returns the status for the “Real-time

transmission status” command.

Follow the procedures below.

Open the roll paper cover.

1

While pressing the Feed button in the printer, turn on the printer.

2

Close the roll paper cover.

3

The printer starts printing data received from then on in hexadecimal numbers and their corresponding ASCII

characters.

Example of printing in hexadecimal dumping mode

54

*** completed ***

Page 55

Chapter 3 Advanced Usage

To close hexadecimal dumping mode, turn off the printer after printing is complete, or press the

4

Feed button for three times.

3

55

Page 56

56

Page 57

Chapter 4 Application Development

Application Development Information

This chapter describes how to control the printer and gives information useful for printer application

development.

Controlling the Printer

The printer supports the following command system:

•ESC/POS

Users can control the printer by using the aforementioned command, or the following development kits or

drivers.

• EPSON Advanced Printer Driver (APD)

• OPOS ADK

• OPOS ADK for .NET

• JavaPOS ADK

•Epson ePOS SDK for Android

• Epson ePOS SDK for iOS (models equipped with UB-E04 only)

ESC/POS

ESC/POS is the Epson original printer command system for POS printers and customer display.

With ESC/POS commands, you can directly control all the printer functions, but detailed knowledge of

printer specifications or combination of commands is required, compared to using drivers and applications.

For details of ESC/POS, see the ESC/POS Command Reference. The ESC/POS Command Reference can be

accessed at the following URL.

www.epson-biz.com/pos/reference/

4

57

Page 58

Controlling the Cash Drawer

A pulse output is sent to drawer kick connector pin 2 or pin 5, and you can open the drawer.

You can also check the open/close status of the drawer by checking the signal level of the drawer kick

connector pin 3.

These controls are executed by a driver or by commands.

ESC/POS Commands

The output command for the specified pulse and the status transmission command are provided.

For details, see the ESC/POS Command Reference.

For Windows Printer Drivers (APD)

You can set so that the drawer opens at the start/end of printing or start/end of a page. For details, see the

manual for drivers.

For details on control, see the manual for Status API of the driver.

OPOS (OCX Driver)

Register a cash drawer using the SetupPOS Utility, and control using the OpenDrawer method or the

DirectIO function.

For details, see the “EPSON OPOS ADK MANUAL APPLICATION DEVELOPMENT GUIDE Cash Drawer” and the

“UnifiedPOS Specification”.

OPOS for .NET

Register a cash drawer using the SetupPOS Utility, and control using the OpenDrawer method or the

DirectIO function.

For details, see the “EPSON OPOS ADK for .NET MANUAL Application Development Guide Cash Drawer

(EPSON Standard)” and the “UnifiedPOS Specification”.

Epson ePOS SDK

The output command for the drawer kick pulse and the status transmission command are provided in the

SDK library. For details, see the user's manuals provided with the SDK.

• Which drawer kick connector, pin 2 or pin 5, is used for operation depends on the

connected cash drawer.

• You can acquire documents regarding the UnifiedPOS from the following link.

https://www.omg.org/retail/unified-pos.htm

58

Page 59

Chapter 4 Application Development

Software

The following software is provided for application development.

Development Kits

Software Description

EPSON OPOS ADK This OCX driver can control POS peripherals using OLE technology *1.

Because controlling POS peripherals with original commands is not

required on the application side, efficient system development is possible.

EPSON OPOS ADK for .NET The OPOS ADK for .NET is a POS industry standard printer driver

compatible with Microsoft POS for .NET.

It allows you to develop applications that are compatible with the UPOS

(Unified POS) specification.

When developing applications, use a separate development environment

such as Microsoft Visual Studio .NET.

EPSON JavaPOS ADK

(Windows/Linux)

Epson ePOS SDK This is a development kit for controlling TM printers from native

for Android

for iOS

*1: OLE technology developed by Microsoft divides software into part blocks. The OPOS driver is presupposed to be used with a

development environment, such as Visual Basic, unlike ordinary Windows printer drivers. It is not a driver to be used for printing from

commercial applications.

You can acquire documents regarding the UnifiedPOS from the following link.

https://www.omg.org/retail/unified-pos.htm

JavaPOS is the standard specification which defines an architecture and

device interface (API) to access various POS devices from a Java based

system. Using JavaPOS standard API allows control with Java based

applications of functions inherent to each device. A flexible design with

Java language and JavaPOS enables many different types of computer

systems, such as stand alone or network configuration, to use a same

application. You can use JavaPOS to build applications and drivers

independently of platforms. This allows flexible configurations using thin

clients to meet the system requirements.

applications of smart devices. This includes libraries, manuals, and sample

programs.

4

59

Page 60

Drivers

Software Description

EPSON Advanced Printer Driver

(APD)

EPSON TM Virtual Port Driver This is a serial/parallel-USB/LAN conversion driver to

In addition to ordinary Windows printer driver functions,

this driver has controls specific to POS. The Status API

(Epson original DLL) that monitors printer status and

sends ESC/POS commands is also attached to this driver.

make an Epson TM/BA/EU printer connected via USB or

LAN accessible from a POS application through a virtual

serial or parallel port.

It allows you to directly control devices connected via

USB or LAN with ESC/POS commands without making

changes in the POS application that controls devices

connected via a serial or parallel interface.

Utilities

Software Description

Operating

environment

Windows

Windows

Operating

environment

TMFlogo Logo Setup Utility Used to register logos (for example, shop logos) to the

NV memory of the printer.

MSWUTL Memory Switch

Setting Utility

EpsonNet Config A network setting tool for Epson network products. Windows

Epson Deployment Tool Use to make network and printer settings

Epson Monitoring Tool Use to check a list of status for the Epson printers

EPSON TMUSB Identifier Utility A tool used to change the USB identification code (USB

Used to change the settings for the memory switches

and customized values of the printer.

simultaneously. Allows you to make settings efficiently at

the time of introducing TM printers for the first time, or

when configuring multiple TM printers at the same time.

connected to the network.

You can also update certificates for multiple printers

used for WPA2-Enterprise in a batch.

Serial No.). Using this tool makes replacement due to a

failure easier.

Windows

Windows

Mac

Windows

Windows

Windows

60

Page 61

Chapter 4 Application Development

Download

You can obtain software and manuals from one of the following URLs.

For customers in North America, go to the following web site:

www.epson.com/support/

For customers in other countries and regions, go to the following web site:

www.epson-biz.com/?service=pos

4

61

Page 62

62

Page 63

Handling

This chapter describes basic handling of the printer.

Installing and Replacing Roll Paper

• Do not open the roll paper cover while printing or autocutting.

CAUTION

The printer may be damaged.

• Do not touch the manual cutter with your hands when installing or replacing the

roll paper.

Doing so may injure your hand or finger.

• Use roll paper that meets the printer specification. For details about paper

specification, see

• Do not use a roll paper whose end is pasted to the paper core.

"Paper Specifications" on page 85.

Chapter 5 Handling

Press the cover open lever to open the roll paper cover.

1

Remove the used roll paper core, if any.

2

5

63

Page 64

Install the roll paper in the correct direction.

Horizontal installation Vertical/wall-hanging installation

Vertical/wall-hanging installation

Horizontal installation

3

Pull out some roll paper along the guide, and close the roll paper cover.

4

Close the roll paper cover firmly by pressing the center of the cover.

Cut the roll paper with the manual cutter.

5

When the printer power is on, the roll paper is automatically cut.

64

Page 65

Removing Jammed Paper

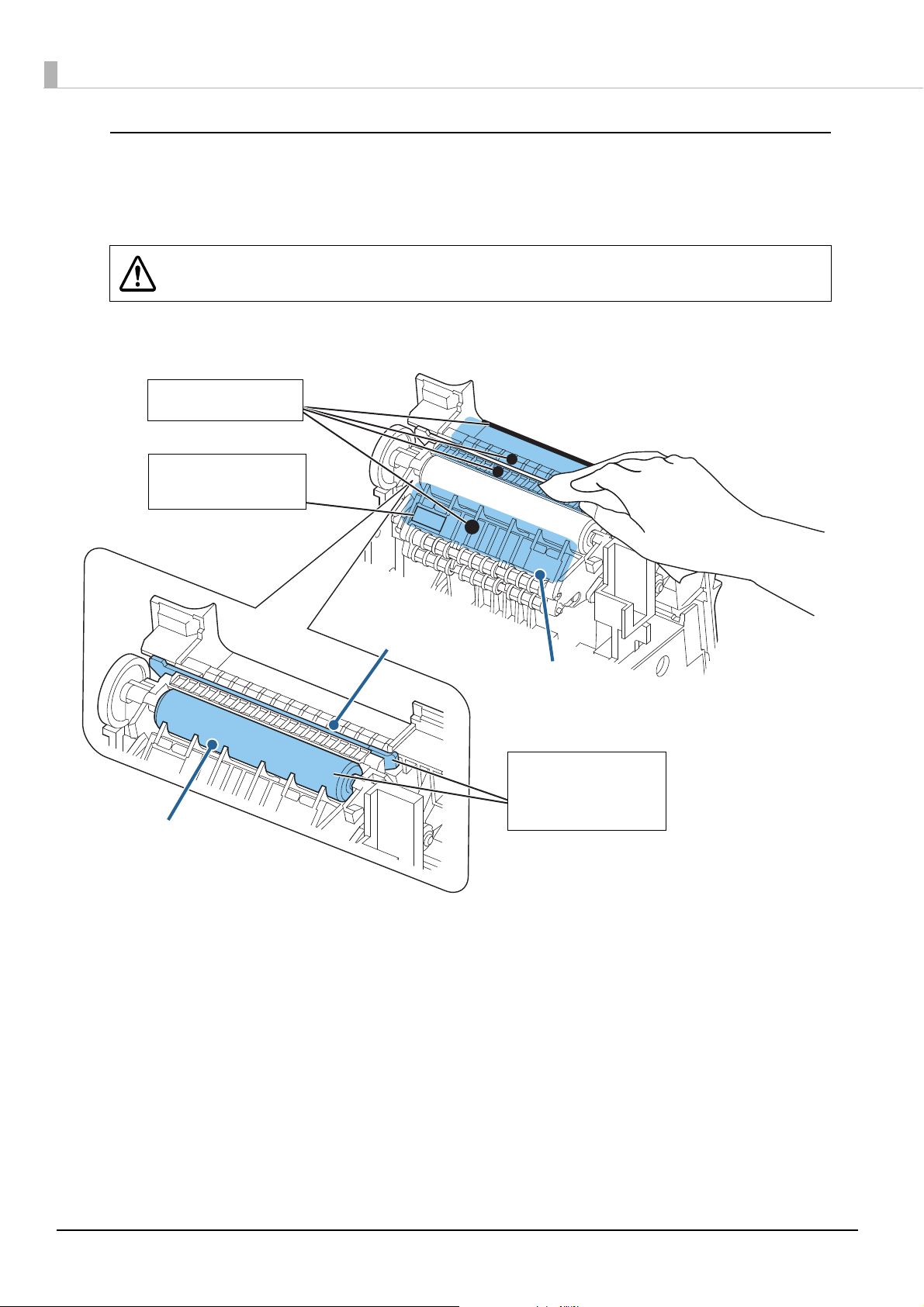

Do not touch the thermal head. (See "Cleaning the Printer" on page 69.)

CAUTION

Turn off the printer.

1

Press the cover open lever to open the roll paper cover.

2

After printing, the thermal head and its surroundings can be very hot.

Chapter 5 Handling

Remove the jammed paper.

3

Reinstall the roll paper and close the roll paper cover.

4

5

65

Page 66

If the printer is used for a long time, the platen roller may become worn out, allowing the linerfree label paper to stick to the platen roller easily. If you leave the liner-free label paper in the

printer for a long time, the liner-free label paper may stick to the platen roller, which may

cause paper jams.

If a paper jam occurs, clean the inside of the printer. ("Cleaning the Inside of the Printer" on

page 69

If paper jams occur frequently even after cleaning, replace the platen roller. Contact qualified

service personnel.

)

It may be possible to prevent paper jams in advance by reinstalling the roll paper. (

and Replacing Roll Paper" on page 63

If you leave the 68* model printer turned on for a long time (approx. 12 hours) without

printing, periodic paper feed is operated automatically in order to prevent the liner-free label

paper from sticking to the platen roller. During the next print after the paper feed operation,

the top margin is increased even when back feed is enabled. When back feed is disabled,

printing errors may occur.

)

"Installing

66

Page 67

Chapter 5 Handling

Releasing a Stuck Roll Paper Cover

If you cannot open the roll paper cover, a jammed auto cutter blade may be blocking it.

Try turning the printer off and on to return the blade to its home position. If you still cannot open the cover,

follow the steps below.

Turn the printer off.

1

Insert a spudger or a small flat-head screwdriver into the slot on either side of the auto cutter

2

cover.

Note: The printer shown may differ from your product, but the steps are the same.

Tilt the tool upwards until it is vertical. This will cause a slight separation between the side of the

3

printer and the auto cutter cover.

5

67

Page 68

Remove the auto cutter cover.

4

Use the tool or your finger to turn the auto cutter knob in the direction indicated by the arrow.

5

Once the triangle is visible in the opening, the blade is in its home position and you will be able

to open the roll paper cover.

Triangle

Knob

Note: You may need to rotate the knob several times. To reduce the possibility of future auto cutter jams, use

tweezers to remove any visible paper debris from the auto cutter.

Reattach the auto cutter cover.

6

68

Page 69

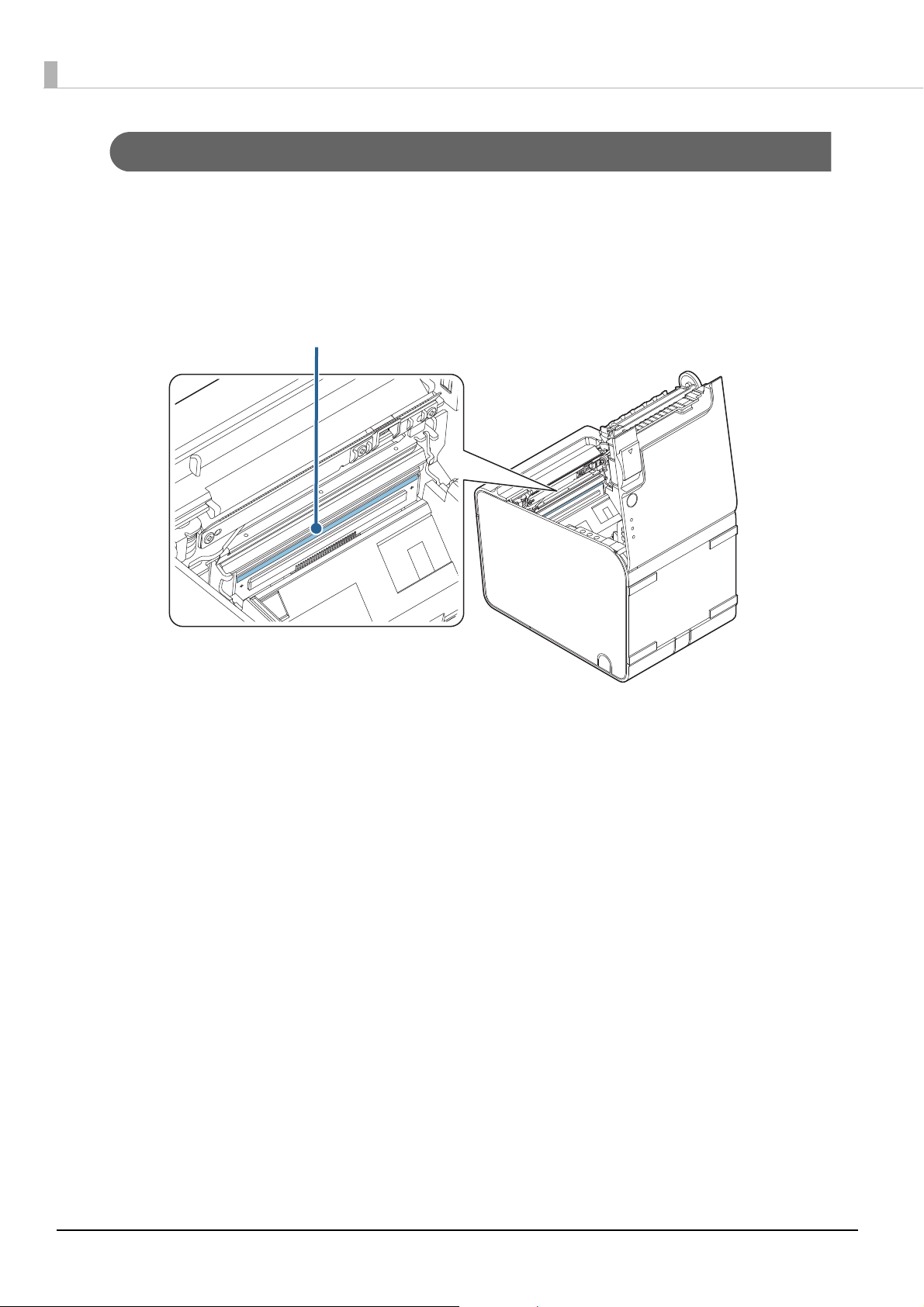

Chapter 5 Handling

Thermal head

Cleaning the Printer

Cleaning the Printer Case

Be sure to turn off the printer, and wipe the dirt off the printer case with a dry cloth or a damp cloth. Be sure

to unplug the AC cable while cleaning.

Never clean the product with alcohol, benzine, thinner, trichloroethylene, or ketone-

CAUTION

Cleaning the Inside of the Printer

Epson recommends cleaning the inside of the printer periodically (generally every 6 months) to maintain

print quality. Paper dust or glue from the label paper accumulated in the printer may cause an irregular

paper feed, improper cutting, or paper jams.

Turn on the printer power only after the cleaned area has completely dried.

based solvents.

Doing so may damage or break the parts made of plastic and rubber.

Thermal head and its surroundings

Turn off the printer and open the roll paper cover. Clean the thermal elements of the thermal head and its

surroundings with a cotton swab moistened with an alcohol solvent (ethanol or IPA).

• After printing, the thermal head can be very hot.

CAUTION

Let it cool before you clean it.

• Do not damage the thermal head by touching it with your fingers or any hard

object.

5

69

Page 70

Cleaning paper path/autocutter/platen roller

Wipe off all glue on the ribs

and edges.

Blow or wipe off the paper

dust around the black mark

sensor.

Wipe off all glue on the

touchable area of the

autocutter and the platen

roller.

Paper path

Autocutter

Platen roller

Turn off the printer and open the roll paper cover. Clean the paper dust and adhesive substance

accumulated in the printer with a cotton swab or nonwoven fabric moistened with an alcohol solvent

(ethanol or IPA).

Do not touch the edge of the autocutter blade directly with your finger. Doing so may

WARNING

injure your finger.

70

Page 71

Preparing for Transport

Follow the procedures below to transport the printer.

Turn off the printer by operating the power switch.

1

Ensure that the LED has turned off.

2

Disconnect the power supply connector.

3

Remove the roll paper.

4

Pack the printer upright.

5

Chapter 5 Handling

71

5

Page 72

72

Page 73

Appendix

Product Specifications

Appendix

Printing method

Cutting type

Roll paper

width

Interface

Buffers Receive buffer

65* model

Other than the 65* model

Downloaded buffer

Macro buffer

Thermal line printing

Partial cut (cutting with one point in left edge left uncut)

Width 40 mm

Width 80 mm

Width 40 mm

Width 58 mm

Width 80 mm

USB: USB 2.0 Full-speed (12 Mbps)

Ethernet: 10BASE-T/100BASE-TX

Serial: RS-232

Wireless LAN: Connecting an optional Wireless LAN unit to the

USB connector.

4 KB/45 bytes (selectable using memory switch 1-2)

Downloaded bit image: Approximately 12 KB

User-defined characters: Approximately 11 KB

2 KB

*1

*1

NV (Non-volatile)

graphics data area:

User NV memory

Page mode area

Barcode/two-dimensional symbol

printing

Power supply

0 to384 KB

1 to192 KB

106 KB

UPC-A, UPC-E, JAN 8 (EAN 8), JAN 13 (EAN 13), CODE 39, ITF,

CODABAR (NW-7), CODE 93, CODE 128, PDF417, MaxiCode,

QRCode

Power supplied by the PS-180 AC adapter

73

Page 74

Life

*2 *3

Printer mechanism

Thermal paper: 20,000,000 lines

Liner-free label paper: 10,000,000 lines

Thermal head

Autocutter

Platen roller

*4

MTBF

*5

MCBF

Temperature/humidity

Thermal paper:150 million pulses, 150 km

Liner-free label paper: 75 million pulses, 75 km

Thermal paper: 2,000,000 cuts

Liner-free label paper: 1,000,000 cuts (at the glued area cut rate =

50%)

Liner-free label paper:

• 80 mm width paper: 16 km

• 58 mm width paper: 16 km

• 40 mm width paper: 56 km

360,000 hours

Thermal paper: 70,000,000 lines

Liner-free label paper: 35,000,000 lines

Thermal paper

• Operating: 5 to 45°C {41 to 113°F}, 10 to 90% RH

• Storage: -10 to 50°C {14 to 122°F}, 10 to 90% RH

Liner-free label paper

• Operating: 5 to 35°C {41 to 95°F}, 20 to 80% RH

• Storage: -10 to 50°C {14 to 122°F}, 10 to 90% RH

External dimensions (H × W × D)

Mass

*1: Liner-free label paper only

*2: Changes depending on the paper type and model to be used.

*3: Indicates the point at which the wear-out failure period starts.