Describes how to control the printer and necessary information

when you develop applications.

Describes setup and installation of the product and peripherals.

Describes how to handle the product.

Describes character code tables.

Describes features and general specifications for the product.

Technical Reference Guide

Product Overview

Setup

Application Development Information

Handling

Appendix

M00059604

Rev. E

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained

herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating

and maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of

any options or any consumable products other than those designated as Original EPSON Products or

EPSON Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft

tion in the United States and other countries.

microSD is registered trademarks of SD Card Association.

Wi-Fi, WPATM, and WPA2TM are either registered trademarks or trademarks of Wi-Fi Alliance.

All other trademarks are the property of their respective owners and used for identification purpose

only.

and Internet Explorer are either registered trademarks or trademarks of Microsoft Corpora-

ESC/POS® Command System

EPSON has been taking industry’s initiatives with its own POS printer command system (ESC/POS).

ESC/POS has a large number of commands including patented ones. Its high scalability enables users

to build versatile POS systems. The system is compatible with all types of EPSON POS printers (excluding

the TM-C100) and displays. Moreover, its flexibility makes it easy to upgrade the future. The functionality

and the user-friendliness is valued around the world.

© Seiko Epson Corporation 2013-2015. All rights reserved.

2

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read

the following carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of

data.

CAUTION

Possibility of sustaining physical injuries.

Possibility of causing physical damage.

Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

3

Warnings

WARNING

To avoid risk of electric shock, do not set up this product or handle cables during

a thunderstorm

Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

Handle the power cable with care.

Improper handling may lead to fire or electric shock.

Do not modify or attempt to repair the cable.

Do not place any heavy object on top of the cable.

Avoid excessive bending, twisting, and pulling.

Do not place the cable near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the plug all the way in.

Be sure to use the specified power source.

Connection to an improper power source may cause fire or shock.

Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire.

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your

dealer or a Seiko Epson service center for advice.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact your

dealer or a Seiko Epson service center for advice.

If you open the DIP switch cover, be sure to close the cover and tighten the screw

after adjusting the DIP switch.

Using this product with the cover open may cause fire or electric shock.

Do not use aerosol sprayers containing flammable gas inside or around this

product.

Doing so may cause fire.

4

Cautions

CAUTION

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

Do not place heavy objects on top of this product. Never stand or lean on this

product.

Equipment may fall or collapse, causing breakage and possible injury.

Take care not to injure your fingers on the manual cutter

When you remove printed paper

When you perform other operations such as loading/replacing roll paper

Do not open the roll paper cover without taking the necessary precautions, as this

can result in injury from the autocutter fixed blade.

To ensure safety, unplug this product before leaving it unused for an extended

period.

When connecting external devices to the USB (including Micro-USB) connectors,

follow the precautions below.

Confirm the rated current of the external devices by checking the descriptions on the

devices or manuals. Do not use a device whose rated current is unclear.

Use the UL-approved external devices (only for North American users).

Connect the external devices only when those total rated current is less than 2.0A.

5

Wireless LAN (OT-WL01) Important Safety Information

May exert electromagnetic interference on, and cause malfunction of, cardiac

pacemakers.

WARNING

CAUTION

Before using this product, check that there is no one in the vicinity using a cardiac

pacemaker.

May exert electromagnetic interference on, and cause malfunction of, sensitive

medical equipment.

Before using this product, check that there is no sensitive medical equipment in the

vicinity.

Use of this product on aircraft may be restricted in some countries.

Before using this product, check that use of this product is not restricted on the aircraft.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

OT-WL01 is only for indoor use.

OT-WL01 should only be used for EPSON TM Intelligent Printers.

If it is installed on another device, it may result in computer failure, damage, or

malfunctions.

To comply with RF exposure compliance requirements, a distance of at least 20

cm must be maintained at all times between the antenna of OT-WL01 and people in

the vicinity.

Do not store in locations with high temperatures or high humidity.

It may in particular be damaged or deformed if left in a vehicle with the windows shut, or

placed in locations with unusually high temperatures for extended periods such as in

direct sunlight.

Do not get OT-WL01 wet.

This may cause malfunctions to occur.

Do not use near microwave ovens.

Wireless communication may be interrupted by electromagnetic interference generated

by microwave ovens.

Do not drop it, subject it to shocks, or place heavy objects on it.

Wireless LAN (OT-WL01) Usage Precautions

Wireless Telegraphy Act Regulations

The following acts are prohibited by the Wireless Telegraphy Act.

•Modifying and disassembling (including the antenna)

•Removing the label of conformance

6

Notes on Security when Using Wireless LAN

(Important information on customer rights (maintaining privacy)

The advantage of using a wireless LAN over a LAN cable is that, because information is

exchanged using radio signals, you can easily connect to the network if you are within range of

the radio signals. A disadva

signals can pass through barriers such as walls, so that if security countermeasures are not

implemented in some way, problems such as the following may occur.

•Communication data can be intercepted

A third party may be able t

could obtain personal information from these transmissions such as IDs, passwords, or credit

card numbers, or they could intercept the contents of personal e-mail messages.

•Unauthorized access to the network

third party could access an individual or intra-company network without permission and

A

carry out any of the following activities.

Retrieve personal data or other secret information (information leakage)

Pose as another user and send inappropriate data (impersonation)

Overwrite the contents of intercepted data and resend it (falsification)

Introduce a computer virus which could cause data loss or system crashes (damage)

Initially, the possibility that such problems could occur through settings concerning the

security of the wireless LAN product and by using the product are decreased, because the

wireless LAN card and the access point have security measures to deal with these problems.

We recom m e nd that you use this product

judgement and assuming full responsibility, a nd with your full understanding of problems

that may occur if you do not make any security settings.

ntage of this is that within a certain range, the electromagnetic

o receive wireless transmissions without authorization, and they

after making security settings using our own

Notes on Setting SSID (Service Set Identifier)

For protection of security, note the following precautions when setting the SSID.

•Change the SSID from the default setting.

•Do not set texts by which the owner can be identified as the SSID.

Notes on Setting Cryptographic Key

For protection of security, note the following precautions when setting the cryptographic key.

•Avoid using words on a dictionary as practicably as possible.

•Combine meaningless alphanumeric characters and symbols.

•Use texts consisted of at least 13 characters or more or of 20 characters or more if possible.

7

Restriction of Use

When this product is used for applications requiring high reliability/safety, s uch as

transportation devices related to aviation, rail, marine, automotive, etc.; disaster prevention

devices; various safety devices, etc.; or functional/precision

product only after giving consideration to including fail-safes and redundancies into your

design to maintain safety and total system reliability. B e c a use this product was not intended for

use in applications requiring extremely high reliability/safety, s uch as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment

related to direct medical care, etc., please make your own judgment on this product's suitability

after a f

ull evaluation.

devices, etc., you should use this

8

About this Manual

Aim of the Manual

This manual was created to provide information on development, design, and installation of

receipt issue systems and development and design of printer applications for developers.

Manual Content

The manual is made up of the following sections:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Appendix

Product Overview

Setup

Application Development Information

Handling

Character Code Tables

9

Contents

■ For Safety .............................................................................................................................. 3

Key to Symbols........................................................................................................................................3

Warnings..................................................................................................................................................4

Cautions ..................................................................................................................................................5

Wireless LAN (OT-WL01) Important Safety Information.......................................................................6

Wireless LAN (OT-WL01) Usage Precautions ........................................................................................6

■ Restriction of Use .................................................................................................................. 8

■ About this Manual................................................................................................................ 9

Aim of the Manual .................................................................................................................................9

Manual Content .....................................................................................................................................9

■ Contents.............................................................................................................................. 10

Product Overview ........................................................................15

■ Features............................................................................................................................... 15

■ Product Configurations...................................................................................................... 17

Autocutter............................................................................................................................................. 17

Colors.....................................................................................................................................................17

Accessories ...........................................................................................................................................17

■ Part Names and Functions ................................................................................................ 18

Power Switch.........................................................................................................................................18

Power Switch Cover .............................................................................................................................19

Control Panel ........................................................................................................................................19

Connectors ........................................................................................................................................... 21

Offline.....................................................................................................................................................23

■ Error Status........................................................................................................................... 24

Automatically Recoverable Errors ...................................................................................................... 24

Recoverable Errors ...............................................................................................................................25

Unrecoverable Errors............................................................................................................................26

No Connection to External Devices................................................................................................... 27

■ NV Memory (Non-Volatile Memory) ................................................................................ 28

NV Graphics Memory ..........................................................................................................................28

User NV Memory...................................................................................................................................28

Memory Switches .................................................................................................................................28

User-defined Page................................................................................................................................28

Maintenance Counter.........................................................................................................................29

Paper layout settings............................................................................................................................29

10

■ Product Specifications .......................................................................................................30

Software Specifications....................................................................................................................... 31

Intelligent Section Specifications ....................................................................................................... 32

Printing Specifications ......................................................................................................................... 33

Character Specifications.................................................................................................................... 34

Paper Specifications............................................................................................................................ 35

Printable Area ...................................................................................................................................... 45

Printing and Cutting Positions............................................................................................................. 47

Electrical Characteristics .................................................................................................................... 48

Environmental Conditions................................................................................................................... 49

External Dimensions and Mass ........................................................................................................... 50

TM-L90-i Dedicated AC Adapter ....................................................................................................... 50

■ Option Specifications.........................................................................................................51

Wireless LAN Cable Set (OT-WL01)..................................................................................................... 51

Setup .............................................................................................53

■ Flow of Setup.......................................................................................................................53

■ Installing the Printer ............................................................................................................55

Control panel label for horizontal use ............................................................................................... 56

Installing the paper discharge guide ................................................................................................ 56

■ Changing the Paper Width ................................................................................................57

■ Adjusting the position of the roll paper near end detector............................................59

Adjustment procedure........................................................................................................................ 60

■ Setting the DIP Switches.....................................................................................................62

Setting Procedure................................................................................................................................ 62

■ Connecting the Cash Drawer............................................................................................63

Connecting the Drawer Kick-out Cable ........................................................................................... 63

■ Connecting the Power Supply Unit ...................................................................................65

Connecting the Power Supply Unit.................................................................................................... 65

■ Connecting the Printer to the System ...............................................................................67

For Ethernet Interface ......................................................................................................................... 67

For Wireless LAN Interface................................................................................................................... 69

■ Network Setting...................................................................................................................72

Wired LAN Setting ................................................................................................................................ 72

Wireless LAN Setting............................................................................................................................. 74

Confirming Network Setting................................................................................................................ 78

Initializing the Network Setting ........................................................................................................... 83

■ Establishment of ePOS-Print System..................................................................................84

Examples of System Establishment .................................................................................................... 85

11

■ Setting for Connected Devices......................................................................................... 87

■ Registering Web Pages...................................................................................................... 89

How to Register..................................................................................................................................... 91

■ Paper Layout Settings ........................................................................................................ 92

Automatic paper layout settings........................................................................................................92

Paper layout settings by dismissing an error ...................................................................................... 94

Clearing paper layout settings ...........................................................................................................94

Auto paper determination..................................................................................................................95

■ Setting the Memory Switches............................................................................................ 96

Memory Switch 1..................................................................................................................................96

Memory Switch 2..................................................................................................................................96

Memory Switch 8..................................................................................................................................97

Customized value.................................................................................................................................97

■ Handling Cables .............................................................................................................. 101

Application Development Information....................................103

■ How to Control the Printer................................................................................................ 103

■ Software and Manuals..................................................................................................... 103

Utilities ..................................................................................................................................................103

How to Get Manuals and the Utility .................................................................................................104

■ EPSON TMNet WebConfig................................................................................................ 105

Starting EPSON TMNet WebConfig ................................................................................................... 105

General Information........................................................................................................................... 106

TCP/IP Information (Wired) ................................................................................................................ 108

TCP/IP Information (Wireless).............................................................................................................109

Web Contents Update Information..................................................................................................110

Time Information.................................................................................................................................111

Wired Setting....................................................................................................................................... 112

TCP/IP Setting (Wired) ........................................................................................................................ 113

Wireless Setting ................................................................................................................................... 114

TCP/IP Setting (Wireless)..................................................................................................................... 116

Device Settings...................................................................................................................................117

Web Contents Update Settings ........................................................................................................118

Server Direct Print Setting ..................................................................................................................120

Status Notification Setting .................................................................................................................121

Administrator Setting..........................................................................................................................122

Time Setting.........................................................................................................................................123

Password Setting.................................................................................................................................124

Reset ....................................................................................................................................................125

■ Settings Confirmation Mode ........................................................................................... 126

Self-test Mode.....................................................................................................................................126

Hexadecimal Dumping Mode..........................................................................................................127

Memory Switch Setting Mode .......................................................................................................... 128

12

Handling .....................................................................................131

■ Installing and Replacing Roll Paper................................................................................131

■ Removing Jammed Paper ...............................................................................................134

When the roll paper cover will not open ........................................................................................ 134

■ Cleaning the Thermal Head ............................................................................................136

■ Connecting to External Devices .....................................................................................137

■ Preparing for Transport .....................................................................................................138

Appendix....................................................................................139

■ Character Code Tables....................................................................................................139

Common to All Pages ....................................................................................................................... 139

Page 0 [PC437: USA, Standard Europe].......................................................................................... 140

Page 1 (Katakana)............................................................................................................................ 141

Page 2 (PC850: Multilingual) ............................................................................................................ 142

Page 3 (PC860: Portuguese)............................................................................................................. 143

Page 4 (PC863: Canadian-French)................................................................................................. 144

Page 5 (PC865: Nordic) .................................................................................................................... 145

Page 16 (WPC1252)........................................................................................................................... 146

Page 17 (PC866: Cyrillic #2).............................................................................................................. 147

Page 18 (PC852: Latin2).................................................................................................................... 148

Page 19 (PC858: Euro)..........................................................................................................

Page 255 (User-Defined Page) ......................................................................................................... 150

International Character Sets ............................................................................................................ 151

............. 149

13

14

Chapter 1 Product Overview

Product Overview

This chapter describes features and specifications of the product.

Features

The TM-L90-i is a supporting ePOS-Print XML, high-speed, power-saving thermal receipt

printer that can print on die-cut/full-surface labels and thick paper. Its compact size allows

installation in a variety of areas. It is a model of the TM-i series.

Printing

•Printing on die-cut labels (labels pre-cut to the desired size) is possible.

•Printing on full-surface labels (labels cut to the desired size with an auto cutter) is possible.

•Printing on thick paper (up to 145µm) is possible.

•Supports a maximum paper width of 80mm, and paper widths of 38mm to 70mm when using

a roll paper spacer.

• Roll paper wit

h a maximum 90mm diameter can be used.

Handling

•Can be installed horizontally or vertically.

•Easy drop-in paper loading

•Cable connectors can be stored inside the printer.

Intelligent functions

•Supports ePOS-Print.

•Direct server printing with data sent from a web server to the printer (supported by ePOS-

Print XML)

1

•Printer driver is not required.

15

Software

•Highly versatile through the adoption of control commands that conform with ESC/POS.

•In addition to a variety of bar codes, printing 2-dimensional symbols (PDF417, MaxiCode,

QRCode) is possible.

•A maintenance counter function is supported.

Interface

•Ethernet interface, USB host with 4 ports.

Others

• Development kits such as MSDN are not required for application development.

•Registering web pages on the TM-L90-i makes them accessible on the Web.

•Methods to efficiently construct multiple systems are included. For details, see the "TM-i

series Easy Setup Guide".

16

Product Configurations

Autocutter

•Full cut (cuts paper completely)

Colors

•ECW (Epson Cool White)

•EDG (Epson Dark Gray)

Accessories

Chapter 1 Product Overview

1

Included

•Dedicated AC adapter

•AC cable

•Power switch cover

• Paper roll spacer

•Screw for the paper roll spacer

•Panel label for horizontal installation

• Paper exit guide

• Label roll paper (for operation check)

• User’s manual

Options

•Wireless LAN cable set (Model: OT-WL01)

•Affixing Vel c ro tape (Model: DF-10)

17

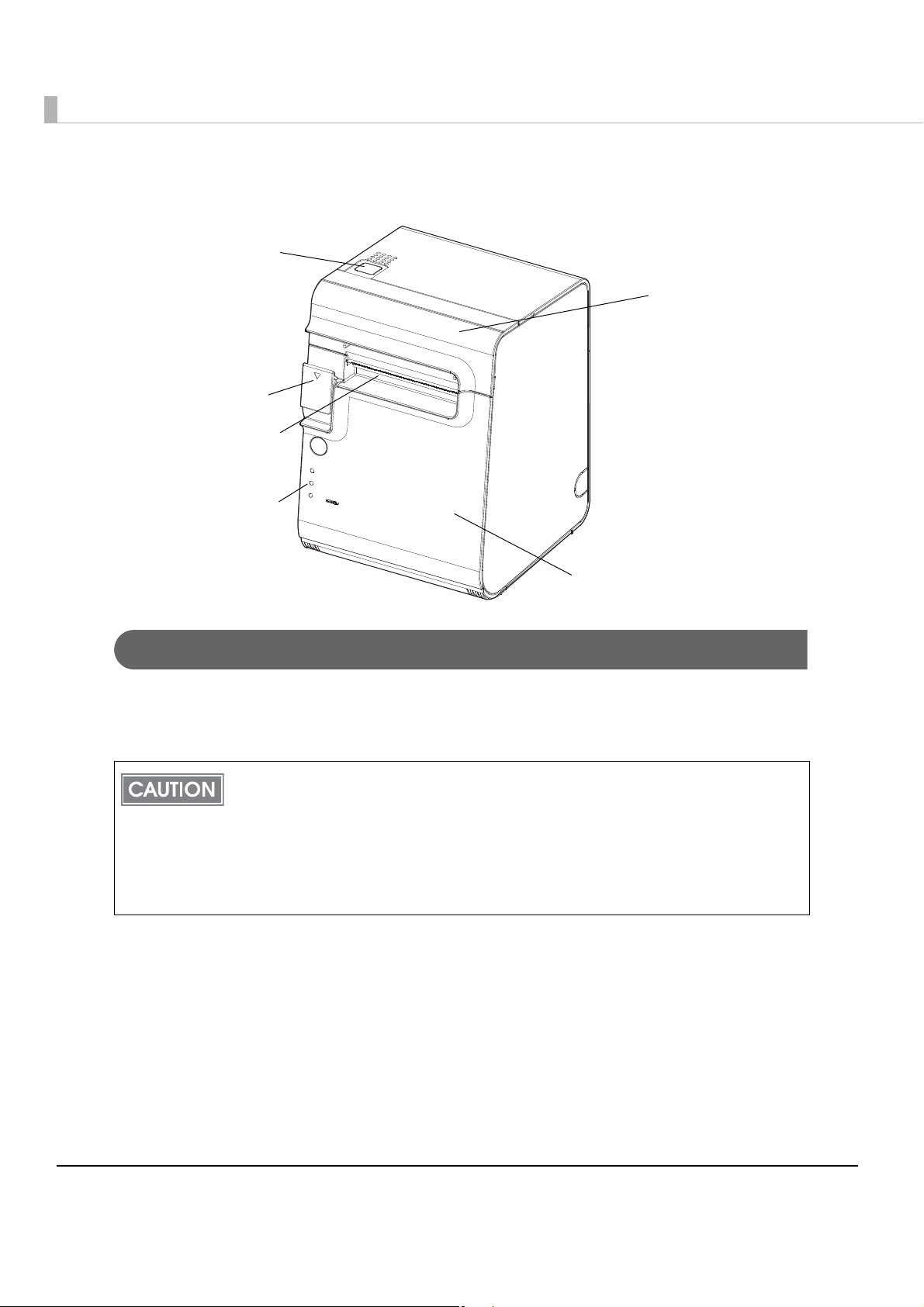

Part Names and Functions

Roll paper cover

Control panel

Cover open lever

Cutter cover

Powe r sw itch

Manual cutter

Power Switch

When DIP switch 1 is OFF (power switch: enabled), the power is turned ON/OFF. Press and

hold the switch for 1 second to turn the power on, and 3 seconds to turn the power off. After

turning the power on, approximately 30 seconds is required before printing is possible.

Before turning on the printer, be sure to check that the AC adapter is connected to the

power supply.

It is recommended that a power-off processing command be sent to the printer before

turning the power off. Doing so allows the latest maintenance counter value to be saved.

(Maintenance counter values are generally saved every two minutes.)

For more information about commands, see the "ESC/POS Application Programming

Guide".

18

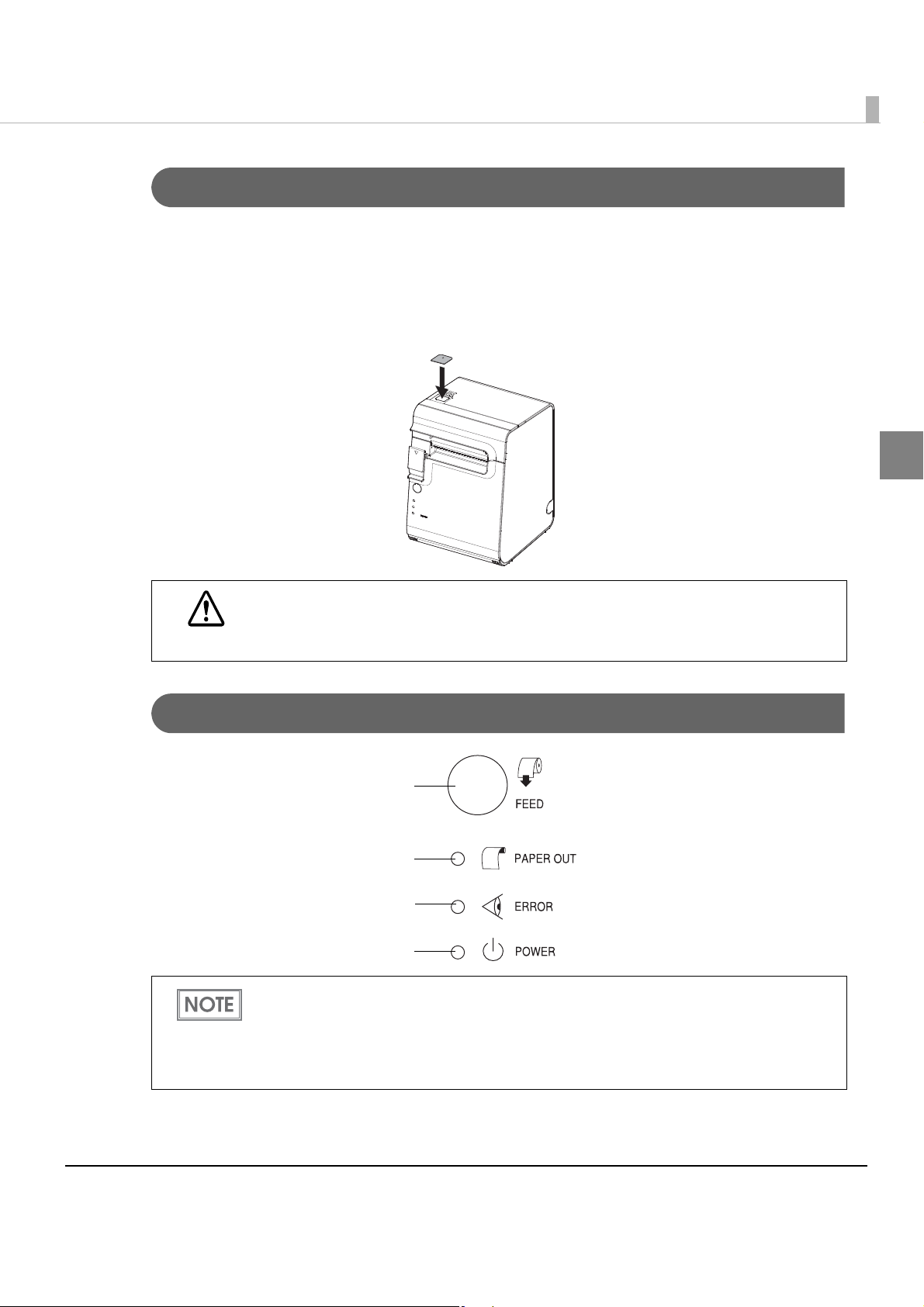

Chapter 1 Product Overview

FEED button

Paper roll end(PAPER OUT) LED

Error(ERROR) LED

Power(POWER) LED

Power Switch Cover

Install the power switch cover that comes with the TM-L90-i onto the printer to prevent

inadvertent changing of the power switch, to prevent tampering, and to improve the appearance

of the printer.

To reset the printer when the power switch cover is installed, insert a long, thin object (such as

the end of a paper cl

ip) into the hole in the power switch cover and press the power switch.

1

If a failure occurs while the power switch cover is attached, immediately remove the

connector cover and remove the power cord.

WARNING

Otherwise, using the printer in this condition could cause a fire.

Control Panel

If the printer is installed horizontally, affix the control panel label for horizontal use. The

A FEED button is also located on the inside of the roll paper cover.

control panel for horizontal use is reversed top to bottom compared to the normal installation.

"Memory Switch Setting Mode" on page 128)

(See

19

LEDs

Paper roll end(PAPER OUT) LED

•Lights when there is no more roll paper or there is little remaining.

•Off when there is a sufficient amount of roll paper remaining.

•Flashes when a self-test printing standby state and macro execution standby state.

You can use the memory switch (Msw8-3) to set whether the PAPER LED flashes when

there is little roll paper remaining.

"Setting the Memory Switches" on page 96)

(See

Error(ERROR) LED

•Lights when the end of the roll paper is detected, and when printing has stopped (offline). If

this happens, replace the roll paper.

•Goes out during regular operation (online).

•Flashes when an error occurs. (For details about the flash codes, see "Error Status" on page 24.)

Power(POWER) LED (green)

•Lights when the power supply is on.

•Goes out when the power supply is turned off.

FEED button

When this button is pressed for receipt paper, the receipt is fed only 1line; for label paper, the

entire sheet is fed.

Holding this button down feeds the roll paper continuously.

20

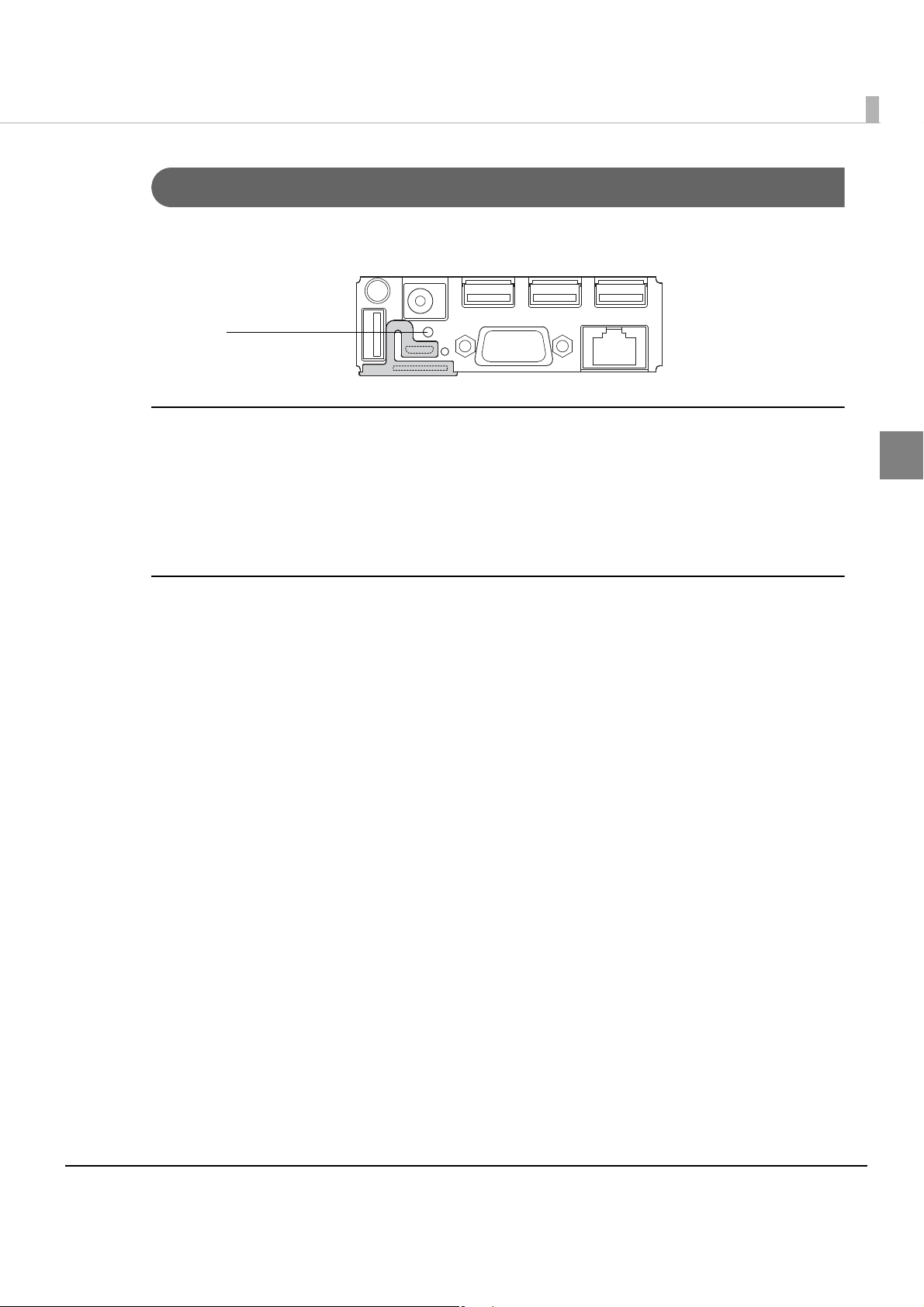

Chapter 1 Product Overview

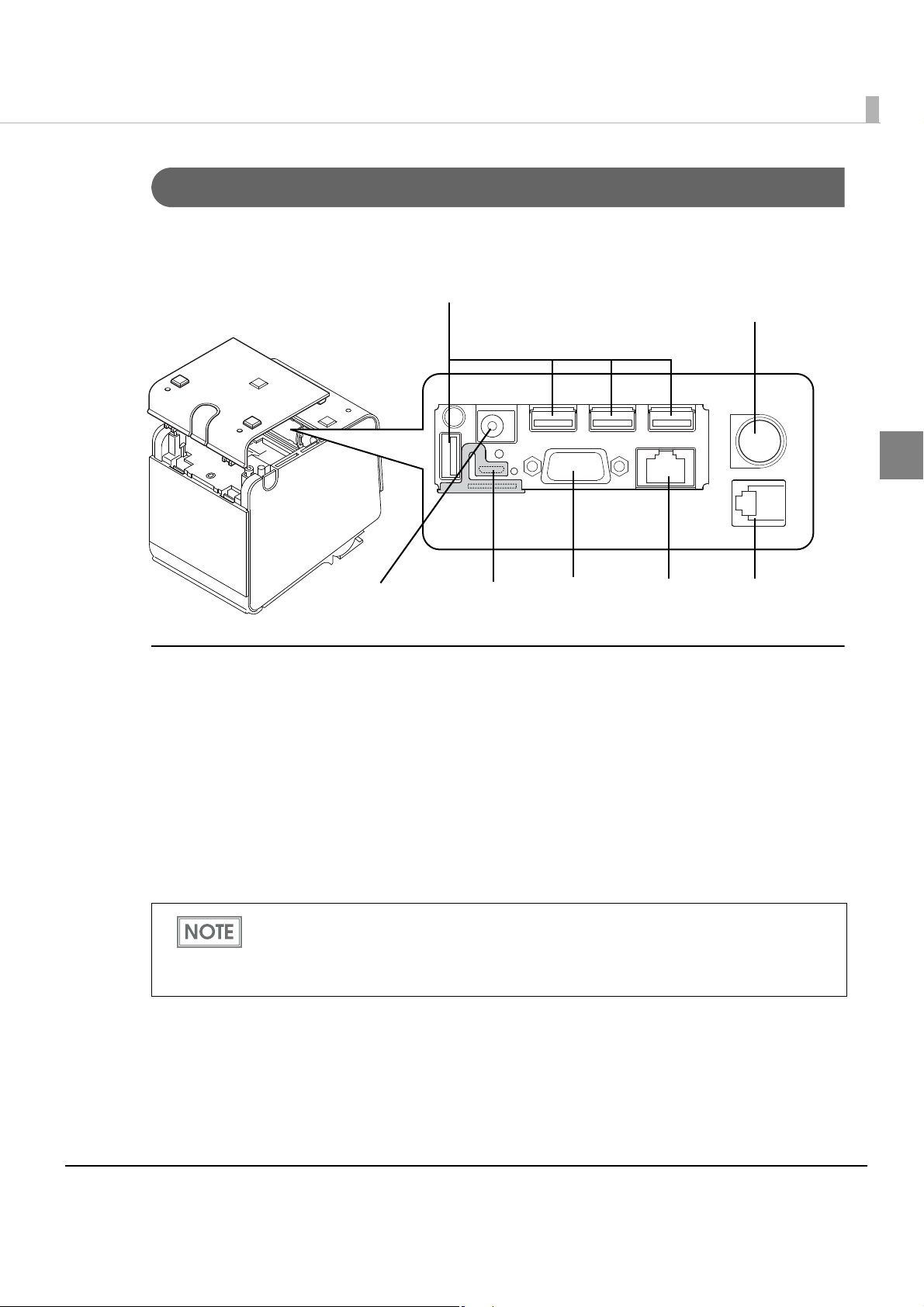

Power supply connector

(for DC 24V)

Ethernet

connector

Micro-USB

connector

Drawer kick-out

connector

*1

USB connectors

Power supply

connector for DC 5V

Connectors

When the connector cover is opened, you will see various connectors, a microSD card slot, and

push buttons.

1

Connector

•USB connector: Connects optional products.

•Power supply connector for DC 24V: Connects a power supply unit.

• Drawer kick-out connector: Connects a cash drawer or the optional buzzer unit.

•Ethernet connector: Connects the printer with a host computer.

•Micro-USB connector: Connect a micro USB (A-MicroB type) cable. This

cable is used only for configuration.

•Power supply connector for DC 5V: Connects a power supply unit.

*1: Analog RGB connector (Currently not available.)

For more information about connecting to a network, a power unit, a cache drawer, or other

external devices, see "Connecting the Printer to the System" on page 67, "Connecting the

Power Supply Unit" on page 65, "Connecting the Cash Drawer" on page 63, and

"Connecting to External Devices" on page 137.

21

microSD Card Slot

microSD card slot

Push button

Insert a microSD card. When PHP functionality is enabled.

For more information about how to set up the PHP environment, see the "TM-i series PHP

Setup Manual".

Push Button

The push button on the lower rear of the printer prints a status sheet or initializes the printer.

The push button has below function:

•Status sheet printing:

Make sure the printer is turned on, press the push button for approximately 3 seconds. When

you release the button, a status sheet on

(See "Confirming with a status sheet" on page 78

•Initialization:

Make sure the printer is turned on, press the push button for approximately 10 seconds. When

you release the button, all setting will be initialized. (See

page 83.)

which network parameters are printed will be ejected.

.)

"Initializing the Network Setting" on

22

Chapter 1 Product Overview

Offline

The printer automatically goes offline under the following conditions:

•During power on (including resetting with the interface) until the printer is ready

•During the self-test

•While paper is fed using the Feed button

•When the cover is open

•When there is no paper and printing is stopped

(when the roll paper end detector indicates there is no paper)

• Macro execution standby

•When an error has occurred

1

23

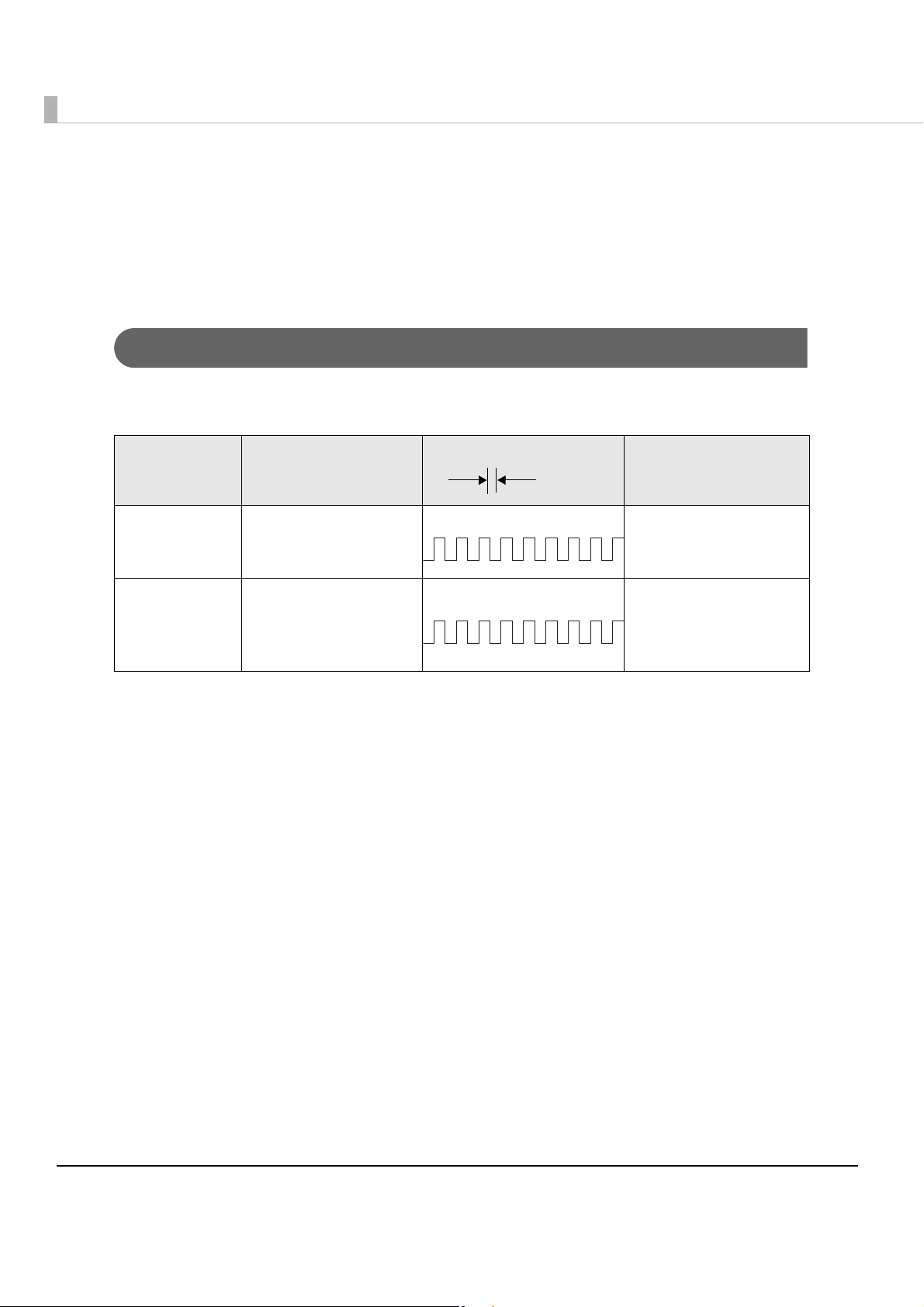

Error Status

Approx.

320 ms

There are three possible error types: automatically recoverable errors, recoverable errors, and

unrecoverable errors. Check the error LED flash code.

When connection to external devices fails, check the status LEDs at the lower rear of the printer.

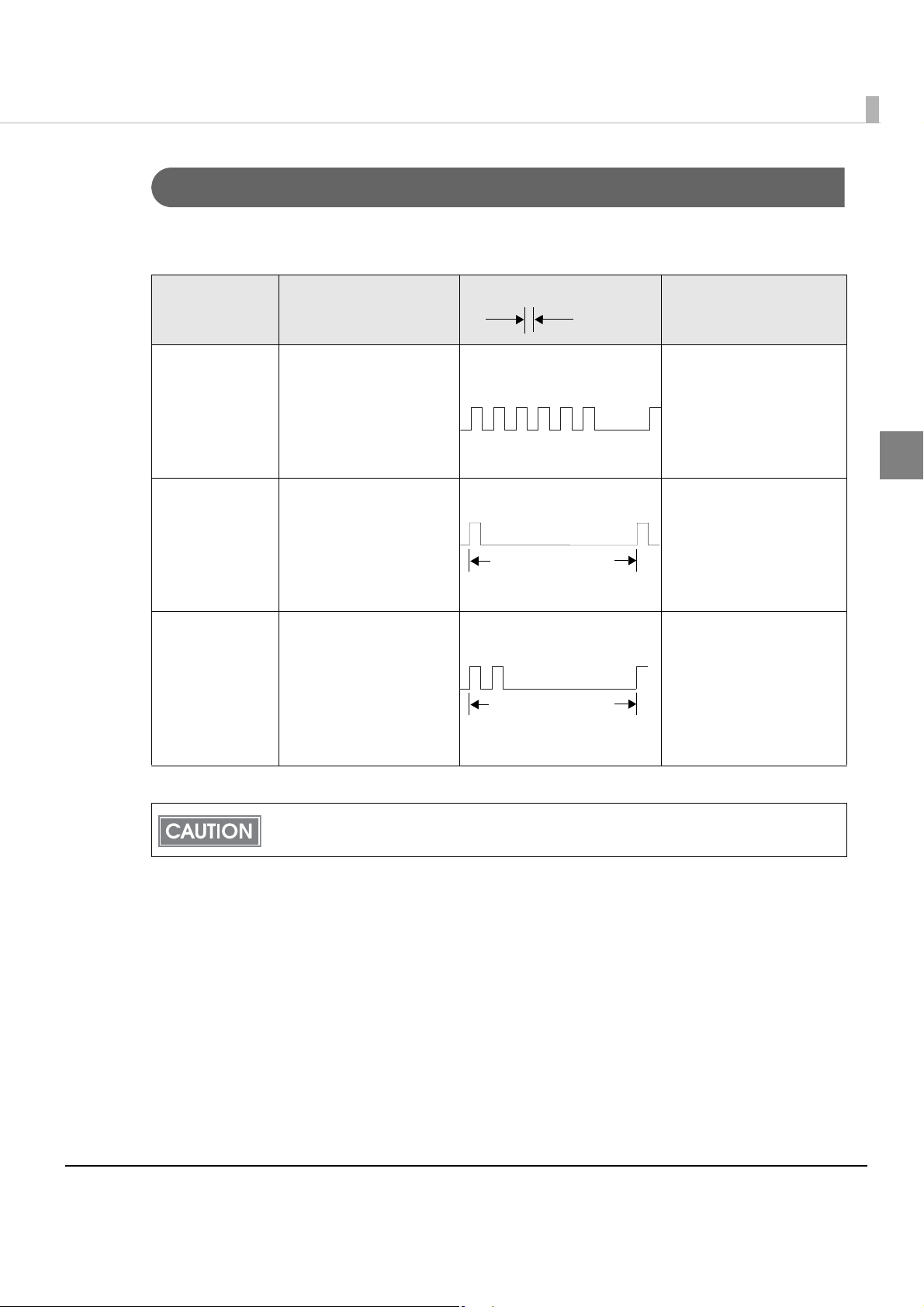

Automatically Recoverable Errors

Printing is no longer possible when automatically recoverable errors occur. They ca n be

recovered easily, as described below.

Error LED flash code

Error Error description

Recovery measure

Roll paper

cover open

error *

Print head

temperature

error

*: When memory switch 8-8 is set to OFF (roll paper cover open while printing: auto reset error)

The roll paper cover

was opened during

printing.

A high temperature

outside the head drive

operating range was

detected.

Recovers automatically

when the roll paper

cover is closed.

Recovers automatically

when the print head

cools.

24

Chapter 1 Product Overview

Approx.

320 ms

Approx. 5120 ms

Approx. 5120 ms

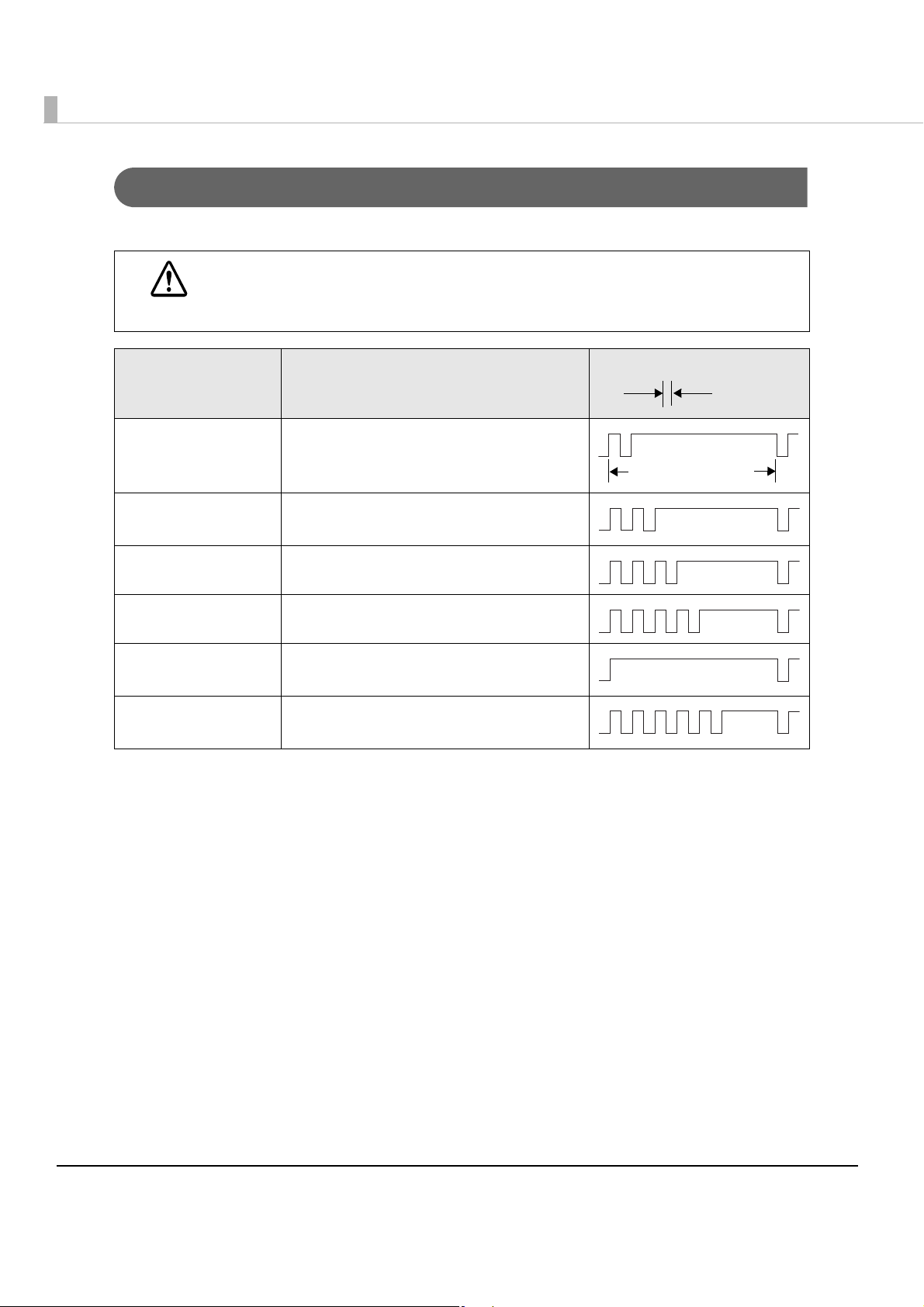

Recoverable Errors

Printing is no longer possible when recoverable errors occur. They c a n be recovered easily by

turning the power on again after eliminating the cause of the error.

Error LED flash code

Error Error description

Recovery measure

Roll paper

cover open

error *

Autocutter error The autocutter does not

Paper layout

error

*: When memory switch 8-8 is set to ON (roll paper cover open while printing: reset possible error)

The roll paper cover

was opened during

printing.

work correctly.

Cannot detect the

label or the black mark.

Close the roll paper

cover, and reset by

executing the error reset

command or turning the

power off and back on

again.

Remove the jammed

paper or foreign matter

in the printer, close the

roll paper cover, and

then turn the power on

to recover.

If the paper is jammed,

clear the jam, close the

roll paper cover, and

then execute the error

reset command or turn

the power off and back

on again.

1

The error reset command is enabled only when a reset possible error (not including auto

reset errors) occurs.

25

Unrecoverable Errors

Approx.

320 ms

Approx. 5120 ms

Printing is no longer possible when unrecoverable errors occur. The printer must be repaired.

Turn off the power immediately when unrecoverable errors occur.

CAUTION

Error LED flash code

Error Error description

Memory R/W error After R/W checking, the printer does not

work correctly.

High voltage error The power supply voltage is extremely

high.

Low voltage error The power supply voltage is extremely low.

CPU execution error The CPU is executing an incorrect address.

Internal circuit

connection error

Interface error An abnormal operation occurs in

Internal circuits are not connected

correctly.

interface.

26

Chapter 1 Product Overview

Status LED

Orange: Booting

Green: Operating normally

No Connection to External Devices

When connection to external devices is not possible, check the status LED at the back of the

printer.

When the status LED is lit in green

•Check whether the interface cable or the optional wireless LAN cable set is connected

correctly. (See

•Print the status sheet to check whether the network settings are correct. (See

Network Setting" on page 78

"Connecting to External Devices" on page 137.)

"Confirming

.)

When the status LED is lit in orange

When the status LED is off after turning on the printer or remains lit in orange even if 30 seconds

have passed after turning on the printer, the interface board needs repairing.

1

27

NV Memory (Non-Volatile Memory)

The printer's NV memory stores data even after the printer power is turned off. NV memory

contains the following memory areas for the user:

•NV graphics memory

• User NV memory

•Memory switches

•User-defined page

•Maintenance counter

•Paper layout settings

As a guide, NV memory rewriting should be 10 times or less a day when you program

applications.

NV Graphics Memory

Graphics, such as shop logos to be printed on receipts, can be stored.

Use the TM Flash Logo Setup Utility to register graphics.

User NV Memory

Yo u can store and read text data for multiple purposes, such as for storing a note including

customizing or maintenance information of the printer.

Memory Switches

Yo u can make a variety of printer settings, such as print density and printing speed.

For more information about memory switches, see

"Setting the Memory Switches" on page 96.

User-defined Page

Yo u can store character data in the user-defined page (character code table: page 255) so that you

can also print characters not resident in the printer.

28

Chapter 1 Product Overview

Maintenance Counter

With this function, printer information, such as the number of line feeds, the number of autocuts,

and printer operation time after the printer starts working, is automatically stored in NV

memory. Refer to the counter information when performing regular maintenance and replacing

s.

part

Paper layout settings

Paper layouts can be registered in this printer.

Registration is performed through panel operations or by executing commands.

If a paper layout is not registered, the printer will automatically determine the layout. The

results of this determination are temporarily saved in the printer. Whenever the printer is

turned on or the roll paper cover is closed, the paper is fed and the printer automatically

determines the paper layout.

(See "Auto paper determination" on page 95.)

1

29

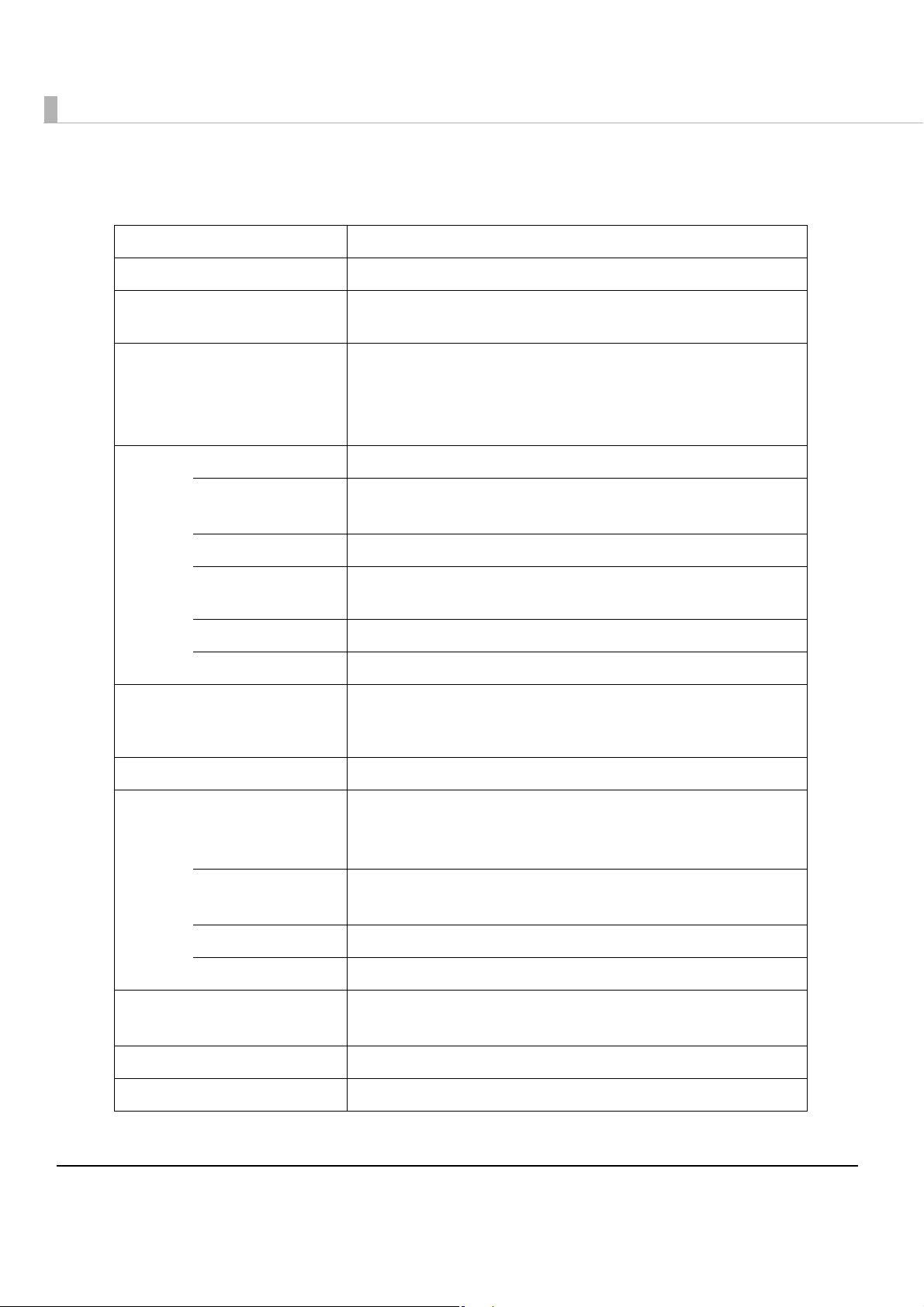

Product Specifications

Printing method Thermal line printing

Cutting method Full cut

Roll paper 79.5 ± 0.5 mm (3.13 ± 0.02") (Paper width: 80 mm)

(with the paper roll spacer: 38 to 70mm)

Interfaces Ethernet (10Base-T/100Base-TX)

Wireless LAN (IEEE802.11b/g/n)*

USB2.0 (for optional products)

Micro-USB (for setting)

Buffers Receive buffer 4 KB/45 bytes (selectable using DIP switch 1-2)

User-defined buffer Downloaded bit image: Approximately 12KB

User-defined characters: Approximately 11KB

Macro buffer 2KB

1

NV graphics data

area

NV user memory 1 to 192KB

Page mode area 106KB

Barcode/two-dimensional

symbol/printing

Power supply EPSON AC ADAPTER, RA (Model: M266A)

2

Life*

Temperature/humidity Operating: 5 to 45°C {41 to 113°F}, 10 to 90% RH

Mechanism Label: 1,000,000 labels issued

Thermal head 150 million pulses

MTBF 360,000 hours

MCBF 70,000,000 lines

0 to 384KB

JAN 8 (EAN 8), JAN 13 (EAN 13), UPC-A, UPC-E, CODE 39, ITF,

CODABAR (NW-7), CODE 93, CODE 128, PDF417, QR CODE,

MaxiCode

Receipt(thickness type):10,000,000 lines

Receipt: 20,000,000 lines

150 km

Storage: -10 to 50°C {14 to 122°F}, 10 to 90% RH

Overall dimensions 140 × 148 × 203 mm {5.51 × 5.83 × 7.99"} (W × D × H)

Weight (mass) Approx. 1.9 kg {4.18 lb} (roll paper excluded)

*1: When the optional wireless LAN cable set (OT-WL01) is used.

*2: This will vary according to the type and model of paper used.

30

Chapter 1 Product Overview

Software Specifications

Print control ePOS-Print API, ePOS-Print XML

(XML Web service is used. No printer driver is required.)

Utility EPSON TMNet WebConfig

Network setting (Ethernet/Wireless LAN)

Web contents registration

ePOS-Print setting

Controllable printer WW Model Following printers with the UB-E02 or UB-R03 embed-

ded

TM-T88V

TM-T88IV*

TM-T70

TM-T20*

TM-T90

TM-L90*

TM-U220*

TM-P60II*

*: Firmware Ver.3 or later

1

TC Model Following printers with the UB-E02 or UB-R03 embed-

ded

TM-T88V

TM-T88IV

TM-T70

TM-T90

TM-L90*

TM-U220*

*: Firmware Ver.3 or later

SA Model Following printers with the UB-E02 or UB-R03 embed-

ded

TM-T88V

TM-T88IV

TM-T70

TM-T90

TM-L90*

TM-U220*

*: Firmware Ver.3 or later

31

Controllable printer SC Model Following printers with the UB-E02 or UB-R03 embed-

ded

TM-T88IV

TM-T70*

TM-L90*

TM-U220*

*: Firmware Ver.3 or later

KO Model Following printers with the UB-E02 or UB-R03 embed-

ded

TM-T88IV

TM-L90*

TM-U220*

*: Firmware Ver.3 or later

Number of

printers

20 printers at maximum

Intelligent Section Specifications

CPU Arm9/360MHz

ROM 256MB

RAM 256MB

30MB at maximum for Web contents

OS Linux Ver. 2.6.30

32

Chapter 1 Product Overview

Printing Specifications

Printing method Thermal line printing

Dot density 203 × 203 dpi

Printing direction Unidirectional with friction feed (Reverse feed is not

supported.)

Printing width

(when the paper width is 80mm)

Characters per line

(when the paper

width is 80mm)

Maximum print speed*

Line spacing 3.75 mm {0.15"}

dpi: dots per inch

*1: When printing with the default print density level at 24V and 25°C {77°F}.

Font A (12 × 24) 48

Font B (9 × 17) 57

1

To change the paper width, you must install the roll paper spacer and change the mem-

ory switch. (See

Since it is possible for some areas of the printer head and the auto cutter blades to

become worn through direct contact with the platen, it is not possible to change from a

narrow width to a wider width once operation has started.

"Customized value" on page 97)

72.0 mm (2.83"), 576 dots

Normal printing : 120 mm/s

High-speed printing : 150 mm/s

(Programmable by control command.)

1

33

Character Specifications

Number of characters Alphanumeric characters: 95

Extended graphics: 128 × 11 pages (including one space page)

International characters: 37 sets

Character structure Font A (default): 12 × 24

Font B: 9 × 17

Character size Font A Standard: 1.50 × 3.0 mm

Double-height: 1.50 × 6.0 mm

Double-width: 3.0 × 3.0 mm

Double-width, double-height: 3.0 × 6.0 mm

Font B Standard: 1.13 × 2.13 mm

Double-height: 1.13 × 4.25 mm

Double-width: 2.25 × 2.13 mm

Double-width, double-height: 2.25 × 4.25 mm

Note:

1. The actual print character may be smaller than the size shown in the table above, because the above size

includes spaces in the font.

2. Characters can be scaled up to 64 times as large as the standard size.

3. Character size not including the horizontal spacing in the standard scale is as follows:

Font A(12 x 24): 1.25(W) x 3.0(H) mm

Font B(9 x 17): 0.88(W) x 2.13(H) mm

34

Paper Specifications

Paper types Specified thermal paper

Receipt paper, continuous label paper

(without black mark)

Receipt paper (with black mark)

Die-cut label paper (without black mark)

Die-cut label paper (with black mark)

Form Roll paper

Size Paper width 83 mm {3.27"} maximum

79.5 ± 0.5 mm {3.13 ± 0.02"}

37.5 ± 0.5 mm {1.48 ± 0.02"} to 69.5 ± 0.5 mm {2.74 ± 0.02"}

Paper thickness Thick receipt paper: 145μm or less

Receipt paper: 62 to 75μm

Roll diameter Maximum 90 mm {3.54"}

Chapter 1 Product Overview

1

Roll paper spool Receipt (paper thickness is 75μm or less)

Roll width when taken up 80 + 0.5/-1.0 mm {3.15+0.02"/-0.04"}

Specified original paper type

Receipt TF60KS-E* (paper thickness: 75μm)

Inside: 12 mm {0.47"} or more

Outside: 18 mm {0.71"} or more

Other than the above

Inside: 25.4 mm {1.00"}

Outside: 31.4 mm {1.24"}

38 + 0.5/-1.0 mm {3.15+0.02"/-0.04"}

to 70 + 0.5/-1.0 mm {2.72+0.02"/-0.04"}

(Nippon Paper Industries Co., Ltd.)

TF11KS-ET (paper thickness: 145μm)

(Nippon Paper Industries Co., Ltd.)

TF50KS-E* (paper thickness: 65μm)

(Nippon Paper Industries Co., Ltd.)

PD150R* (paper thickness: 75μm) (Oji Paper Mfg. Co., Ltd.)

PD160R* (paper thickness: 75μm) (Oji Paper Mfg. Co., Ltd.)

P350* (paper thickness: 62μm)

(Kanzaki Specialty Paper (USA))

F5041* (paper thickness: 60μm)

(Mitsubishi HiTec Paper Flensburg GmbH (Germany))

KF50* (paper thickness: 62μm)

(KANZAN Spezialpapiere GmbH (Germany))

35

Die-cut label paper/

Continuous label paper

*: Paper for high-speed printing. Depending on the memory switch (customized values) settings, this paper can

allow printing at the printer's maximum printing speed (Level 9: approximately 150mm/s).

Paper must not be pasted to the paper roll spool.

If a manual cutter is used to cut paper with a thickness of 100μm or greater, the paper

will slide out of position easily. Take special care when cutting the paper.

Using roll paper with an inside diameter of 25.4 mm {1"} or less may decrease the detec-

tion accuracy of the roll paper near-end sensor.

To ensure high printing quality and performance, it is recommended that you make

changes to the printing density settings ("Customized value" on page 97

the roll paper that is used.

HD-75* (Nippon Paper Industries Co., Ltd.)

HW76B* (Nippon Paper Industries Co., Ltd.)

HW76C* (Nippon Paper Industries Co., Ltd.

KL470* (NAKAGAWA MFG(USA).Inc.)

KL80GT* (NAKAGAWA MFG (Germany). GmbH.)

150HA* (Ricoh Co., Ltd.)

) according to

36

Chapter 1 Product Overview

Paper feed direction

[2]

[1]

Units: mmBack(non-printing side)

4 to 7.5

40 to 300

15 or

more

Preprintable area

Receipt Paper/Continuous Label Roll Paper

When using receipt paper/continuous label roll paper , be sure to use paper that meets the

following requirements.

Requirements for Black Mark

When using receipt paper/continuous label roll paper with black marks, be sure to use paper

that meets the following requirements.

Paper without intervals between labels, such as continuous label paper, paper with

perforated lines between labels, and paper with slits between labels, can also be used

under the same requirements.

• Black mark portions must be printed on the back of the paper (non-printing side).

•The reflecting rates of black mark portions [1] and non black mark portions [2] must meet the

combinations shown in t

(Reflecting rates are measured by the Macbeth PCM-II (Filter D) meter, using the back of the

paper.)

he table below :

1

Reflecting rate of black mark portion [1]

Reflecting rate of the portion where

the black mark does not exist [2]

17%

less

90%

more

16%

less

85%

more

15%

less

80%

more

14%

less

75%

more

13%

less

70%

more

37

Requirements for the Edge Cutoff of Continuous Label Roll Paper

Paper feed direction

[a]3.5 mm {0.14"}

or more

Face stock (printing side)

[b]0.3 mm {0.12"}

or more

To preve nt the print head from sticking to the adhesive agent, be sure to use continuous label

paper that edge cutoff(“Edge cutoff” is a method of cutting and removing the edge of the label in

advance so that the label can be peeled off easily from the backing paper.) has been done.

•When performing a full-cut, for the cutoff edge (a): 3.5 mm {0.14"} or more is n

ot necessary;

however, it is recommended that cutoff edges with approximately 2 mm {0.79"} width be

provided for both edges so that the label can be peeled off easily from the backing paper.

•When using a label with 80 mm {3.15"} paper width, the cutoff edge (b) is not necessary;

however, it is recommended that cutoff edges with approximately 2 mm {0.79"} wid

th be

provided for both edges so that the label can be peeled off easily from the backing paper.

•In consideration of the cutoff edges, allow the left and right margins of 2.8 mm or more

outside the printable area.

Requirements for thickness and adhesive agent of continuous label roll paper

Requirements if an original paper other than the specified original paper is used are as follows:

•Total amount of thickness of the thermal paper and backing paper: 145 μm or less (without

adhesive agent).

•Adhesive agent: Acrylic emulsion

38

Chapter 1 Product Overview

Thermal paper (label)

Thickness: 70 to 92μm

Adhesive agent (acrylic emulsion)

Thickness: 9 to 21μm

Adhesive agent (acrylic emulsion)

Thickness: 41 to 71μm

Label + Backing paper:

Transparency rate: 18% or less

Backing paper:

Transparency rate: 47% or more

Die-cut Label

Requirements for the thickness of the die-cut label paper, peeling strength against backing paper,

and the adhesive agent that can be used with the printer are shown in the figure below:

1) Paper Thickness, peeling strength, and adhesive agent

2) Requirements for transparency rate of die-cut label paper

1

39

Transparency rates are measured by the Macbeth TD-904 (with a filter for infrared) pho-

Units: mmFace (printed side)

Detection hole

Corner R2 or less

Corner R0.5 or less

0.5±0.3

0.5±0.3

8.0±0.1

6±0.5

1.75±0.5

5.0±0.5

tometer. The transparency rates are calculated as follows:

Use

Density = Log10 (Amount of irradiation / Amount of transparency)

Then,

Transparency rate (%) = (Amount of transparency / Amount of irradiation) x 100

If the transparency rates are out of the specified range (label + backing paper: 18% or

less, backing paper: 47% or more), the printer detects a layout error. However, paper

identified with a layout error may be used when the detection hole is prepared as follows.

The position to detect the label may be shifted by approximately 0.5 mm {0.02"}.

40

Chapter 1 Product Overview

Units: mmFace stock (printing face)

Paper feed

direction

2.8 or more 2.8 or more

Corner R2 or less

37.5±0.5 to 69.5±0.5 or 79.5±0.5

1.5 or more

1.5 or more

1.75±0.5 1.75±0.5

L2=3 to 10

L3

L4

(Label length: 25.4 ~ 101.6)

(Printable area)

Label interval L1:

(Label length +

L2)

Cutting position

Requirements for die-cut label size (without black marks)

Die-cut labels (without black marks) must satisfy the following requirements.

1

•Be sure to set the cutting position (L4) to 1.5 mm {0.059"} or more from the label edges at the

top and the bottom.

•Be sure that the distance from the cutting position to the print starting position (=L3-L4) is 2.75

mm {0.108"} or more. And the minimum label length must be 25.4 mm {1"}.

41

Requirements for die-cut label size (with black marks)

If die-cut label with black marks is used, there are two reflective rate requirements, depending

on the size and position of black marks. Be sure to use label paper that meets either black mark

position requirement I or II as follows.

Requirements for Black Mark Position I (when the black mark overlaps the adjacent label)

• Black mark portions must be printed on the back of the paper (non-printing side).

•The length of the black mark must cover the space between labels (backing paper between

labels) completely (overlapping labels by 0 to 1 mm).

•The reflective rates of the black mark portions [1] and label portions [2] must meet the

combinations shown in the table below (the reflective rate is measured using the back of the

paper, the non-printing side):

Reflecting rate for black mark portion [1]

Reflecting rate for label portion [2]

17%

less

90%

more

16%

less

85%

more

15%

less

80%

more

14%

less

75%

more

13%

less

70%

more

42

Chapter 1 Product Overview

Units: mmBack (non-printing side)

Paper feed direction

Preprintable area

15.0 or more

0.5±0.5

[2]

[1]

Cutting position

5.0±0.5

0.5±0.5

Reflective rates are measured by the Macbeth PCM-II (Filter D) meter.

1

Requirements for Black Mark Position II (when the black mark is between two labels)

• Black mark portions must be printed on the back of paper (non-printing side).

• If label paper meets Black Mark Position Requirement I, it is not necessary to consider Black

Mark Position Requirement II.

•The reflective rates of each portion [1], [2], and [3] must meet the combinations shown in the

table below (the reflective rate is measu

Reflective rate of black mark portion[1]

Reflective rate of the portion where the

black mark does not exist [2][3]

red using the back of the paper, the non-printing side):

17%

less

90%

more

16%

less

85%

more

15%

less

80%

more

14%

less

75%

more

13%

less

70%

more

43

Reflective rates are measured by the Macbeth PCM-II (Filter D) meter.

Units: mmBack (non-printing side)

Paper feed direction

Preprintable area

15.0 or more

[2]

[1]

5.0±0.54 to 5.5

[3]

44

Chapter 1 Product Overview

(2.65 mm)

(4.85 mm)

72 mm

0.125 mm

79.5 0.5 mm

576 dot

Printable Area

Receipt Paper/Continuous Label Roll Paper

The printable area may be out of alignment by 2 mm {0.08"} maximum (left or right), due to the

paper position or tolerance of parts. Please set by referring to the following.

Paper width (mm) 80 70 65 60 58 50 45 38

Printable area (mm) 72 64 59 54 52 44 39 32

Left margin (mm) 2.65 2.65 2.65 2.65 2.65 2.65 2.65 2.65

Right margin (mm) 4.85 2.85 2.85 2.85 2.85 2.85 2.85 2.85

Total number of dots 576 512 472 432 416 352 312 256

Example: 80mm paper width

1

Example: 58mm paper width

(2.65 mm)

57.5 0.5 mm

0.125 mm

52 mm

(2.85 mm)

416 dot

45

Die-cut Label

[Units: mm]

Liner width

Label (face stock) width

Printable area

1.5 or more

1.5 or more

2.8 or more2.8 or more

Make a margin of 2.8 mm {0.11"} or more from the label edges on both left and right sides and

also a margin of 1.5 mm {0.059"} or more from the label edges on top and bottom of the printable

area of the label (face stock).

Liner width (mm) 80 70 60 50 45 38

Label width (mm) 76 66 56 46 41 34

Printable area (mm) 70 60 50 40 35 28

Left margin (mm) 2.9 2.9 2.9 2.9 2.9 2.9

Right margin (mm) 3.1 3.1 3.1 3.1 3.1 3.1

Total number of dots 560 480 400 320 280 224

46

Printing and Cutting Positions

Autocutter blade position

Approx. 29

Approx. 14

Manual-cutter position

Center of the print dotline

Paper feed direction

Chapter 1 Product Overview

1

The values above may vary slightly as a result of paper slack or variations in the paper.

Take this into account when setting the cutting position of the autocutter.

Partial cuts (a portion of the left edge remains) can be made only on receipt paper with-

out black marks or full-surface label paper without black marks.

When making a partial cut (leaving a portion of the left edge), do not perform a back

feed.

Lengths of receipts/labels

To preve nt paper jams or to make it easier to remove printed receipts/labels, the following

lengths are recommended for printing receipts/labels.

Use condition Recommended issuing length

Horizontal installation (full cut) 37.5 mm or more

Horizontal installation (partial cut)

25.4 mm or more

Vertical installation

47

Electrical Characteristics

42 columns

Supply voltage DC 24V ± 7%

Current consumption

(at 24V, 25°C, normal

print density)

* When the supply current from the USB connectors is

•less than 600mA: Maximum 1.0A

•more than 600mA: Maximum 2.5A

Standby Mean: Approximately 0.1A

Maximum 1A for drawer kick-out driving.

Operating DC 24V Mean: Approximately 1.7A

DC 5V*: Maximum 1.0A/2.5A

Note: When print ratio is

approximately 18%

Continuous printing for 100

lines (repeating 20H-7FH)

Font A

42 columns

ASCII character

ABCDE

BCDE

6789

67890

48

Environmental Conditions

Relative humidity

Operating environment

range

90

65

10

5344045

Ambient temperature

[%RH]

[°C]

Chapter 1 Product Overview

Temperature/

Humidity

Acoustic noise (operating) Approximately 53 dB (bystander position)

Operating 5 to 45°C {41 to 113°F}, 10 to 90% RH

(See the operating temperature and humidity range below.)

Storage

(Factory packing)

-10 to 50°C {14 to 122°F}, 10 to 90% RH (except for paper)

Note:

The values above are measured in the Epson evaluation

condition.

Acoustic noise differs depending on the paper used, printing

contents, and the setting values, such as print speed or print

density.

1

49

External Dimensions and Mass

•Height: Approximately 203 mm {7.99"}

•Width: Approximately 140 mm {5.51"}

•Depth: Approximately 148 mm {5.83"}

• Mass: Approximately 1.9 kg {4.18 lb} (except for roll paper)

TM-L90-i Dedicated AC Adapter

Input conditions Input voltage: AC 100V to 240V

Frequency: 50/60 Hz

Input current (rating): 1.3A

Output conditions Output voltage (rating): DC 24V ± 5%

Output current (rating): 2.1A

50

Chapter 1 Product Overview

Option Specifications

Wireless LAN Cable Set (OT-WL01)

Wireless module ELPAP07: 802. 11b/g/n wireless LAN Module (EPSON)

Standard IEEE802.11b/g/n (Wi-Fi certificated)

SSID 1 to 32 one-byte alphabet and numbers

Connection mode Ad hoc mode, Infrastructure mode

Authentic method, Encryption algorithm Open+WEP, Shared+WEP, WPA-PSK+TKIP, WPA-PSK+AES,

WPA2-PSK+AES, WEP64, WEP128, TKIP, AES

Power voltage DC 4.5V to 5.5V

Current consumption 300mA at maximum

1

Frequency range 2.4 GHz band

Potential interference range 40 m

Overall dimensions Wireless LAN unit: Approx. 24 × 51 × 10 (W × D × H)

USB extension cable: 1 m (length)

51

52

Setup

2. Changing the Paper Width (page 57)

7. Connecting the Printer to the System (page 67)

5. Connecting the Cash Drawer (page 63)

4. Setting the DIP Switches (page 62)

6. Connecting the Power Supply Unit (page 65)

1. Installing the Printer (page 55)

3. Adjusting the position of the roll paper near end detector (page 59)

8. Network Setting (page 72)

9. Establishment of ePOS-Print System (page 84)

This chapter describes setup and installation of the product and peripherals, and setup for

ePOS-Print.

Flow of Setup

This chapter consists of the following sections along with the setup flow of the product and

peripherals.

In this setup flow, necessary items are in a frame with a solid line. Optional items are

explained in an frame with a dotted line.

Chapter 2 Setup

2

53

54

13. Setting the Memory Switches (page 96)

14. Handling Cables (page 101)

12. Paper Layout Settings (page 92)

10. Setting for Connected Devices (page 87)

11. Registering Web Pages (page 89)

Chapter 2 Setup

Horizontal position

Ver t i c a l posit i o n

Installing the Printer

Although this printer is normally installed and used vertically (with the paper discharged to the

front), it can also be installed and used horizontally (with the paper discharged to the top).

Do not place the printer in dusty locations.

Do not knock or strike the printer. This may cause defective print.

Do not catch cables or place foreign matter under the printer.

If you install the printer horizontally, affix the control panel labels for horizontal use.

(see "Control panel label for horizontal use" on page 56)

In addition, if the auto cutter is used to make full cuts with the printer installed horizontally, the

included paper discharge guide must also be installed.

"Installing the paper discharge guide" on page 56)

(see

2

55

Control panel label for horizontal use

When using the printer in the horizontal position, affix the control panel label for horizontal use

as shown in the figure.

Installing the paper discharge guide

If the auto cutter is used to make full cuts with the printer installed horizontally, the paper

discharge guide must be installed as shown in the figure.

This will prevent the cut paper from falling into the paper path, which could cause double cuts

and paper jams.

If roll paper with an inner diameter smaller than 25.4mm and an outer diameter smaller than

31.4mm is used, paper jams are likely to occur. Therefore, do not install the paper

discharge guide.

56

Chapter 2 Setup

Edge

Groove

Changing the Paper Width

This printer is shipped from the factory with the roll paper width set to 80mm. To use roll paper

with a width of 38mm to 70mm, install a roll paper spacer using the following procedure.

Since it is possible for some areas of the printer head and the auto cutter blades to

become worn through direct contact with the platen, it is not possible to change from a

narrow width to a wider width once operation has started.

To change the paper width, use the memory switch to change the paper width settings.

To use roll paper with a width of 61mm to 70mm, fold the tabs in two

1

locations on the roll paper spacer.

Even if the tabs are folded, you can still use roll paper with a width of 38mm to 60mm.

Open the roll paper cover.

2

Insert the roll paper spacers through the grooves on the inside edges of

3

the printer, and downward.

2

57

Press the spacers firmly into the spindle at the bottom surface.

Spindle

screw

4

Make sure the roll paper spacers slide smoothly to the left and right.

5

Move the roll paper spacers to the left and right, align them with the

6

position of the roll paper to be used, and fix them into place with the

included screws.

Set the roll paper spacers with an additional margin of 0.5mm over the maximum value for

the width of the roll paper. Use a ruler if necessary.

58

Chapter 2 Setup

Adjusting the position of the roll paper near end detector

The position of the roll paper near end detector must be adjusted in the following situations.

•When the installation direction of the printer is changed (from vertical to horizontal, or vice-

versa)

•When changing the remaining amount of roll paper detected by the near end detector

Since the center of the roll paper has a slightly different shape than the specifications

indicate, the near end cannot be detected precisely.

In order for the near end detector to correctly detect the amount of roll paper remaining,

use receipt paper with an inner diameter of 12mm or greater and an outer diameter of

18mm or greater; all other roll paper should have an inner diameter of 25.4mm and an

outer diameter of 31.4mm.

When shipped from the factory, this printer is adjusted for use in the vertical position.

2

59

Adjustment procedure

Horizontal position

Ver t i c a l posi t i o n

Adjustment

screw

Knob

Detection

lever

Adjustment

screw

Knob

Detection

lever

Open the roll paper cover.

1

Use a coin or similar object to loosen the adjustment screw on the

2

detector.

Push the detection lever all the way to the rear window, and then turn

3

the knob until the detection lever is set in the position shown in the figure

below.

Changing from horizontal to vertical : Turn the knob towards you.

Changing from vertical to horizontal : Turn the knob away from you.

60

Chapter 2 Setup

Horizontal position

Ver t i c a l posi t i o n

Knob

Knob

Move the knob forward/back or up/down, and align the line in the knob

4

with the position shown below.

Roll paper diameter for near end

detection

41 mm Top Left

36 mm Under (Default) Right

Vertical position Horizontal position

2

Tighten the adjustment screw on the detector.

5

Press the detection lever with your finger to check if it moves smoothly.

6

61

Setting the DIP Switches

Yo u can use the DIP switches to enable/disable the power switch. The initial setting is "Enabled".

Setting Procedure

Follow the steps below to change the DIP switch settings.

Be sure to turn the power off before setting the DIP switch.

Make sure the power supply for the printer is turned off.

1

Open the roll paper cover.

2

Remove the DIP switch cover.

3

62

Set the DIP switch 1, using the tip of a tool, such as a small screwdriver.

4

ON : Power switch is Disable

OFF : Power switch is Enable

Do not make any change to DIP switches other than DIP switch 1.

Install the DIP switch cover, and close the roll paper cover.

5

Connecting the Cash Drawer

DK

24V

Drawer kick-out connector

When using a cash drawer, connect the cash drawer.

Use the cash drawer handled by EPSON or your dealer.

Connecting the Drawer Kick-out Cable

Specifications of drawers differ depending on makers or models. When you use a

drawer other than specified, make sure its specification meets the following

WARNING

conditions.

Otherwise, devices may be damaged.

The load, such as a drawer kick-out solenoid, must be connected between pins 4 and

2 or pins 4 and 5 of the drawer kick-out connector.

When the drawer open/close signal is used, a switch must be provided between

drawer kick-out connector pins 3 and 6.

The resistance of the load, such as a drawer kick-out solenoid, must be 24

or the input current must be 1A or less.

Be sure to use the 24V power output on drawer-kick out connector pin 4 for driving the

equipment.

Use a shield cable for the drawer connector cable.

Two driver transistors cannot be energized simultaneously.

Leave intervals longer than 4 times the drawer driving pulse when sending it

continuously.

Be sure to use the printer power supply (connector pin 4) for the drawer power

source.

Do not insert a telephone line into the drawer kick-out connector.

Doing so may damage the telephone line or printer.

Chapter 2 Setup

or more

2

Connect the connector of the drawer kick-out cable to the printer.

63

Drawer Connection Circuitry

F. G

+24V

With shielded

Drawer kick-out connector

Printer side

User side [Drawer kick-out side]

Drawer open/close switch

Drawer kick-out solenoid

Control device

1

2

3

4

5

6

64

Connecting the Power Supply Unit

Use the TM-L90-i dedicated AC adapter and the AC cable included with the product as the

power supply unit.