Page 1

®

SERVICE MANUAL

Color Large Format Inkjet Printer

EPSON Stylus PRO 7500

SEIJ00005

Page 2

Notice:

n

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

n

The contents of this manual are subject to change without notice.

n

All efforts have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EP SON would greatly appre cia te

being informed of them.

n

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

EPSON disclaims any and all rights in those marks.

Copyright © 2000 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

About This Manual

This manual describes basic functi ons, theory of electrical and mechanical

operations, maintena nce and repair procedures of EPSON EPSON Stylus PRO

7500. The instructions and procedures included herein are intended for the

experienced repai r technicians, and attention shoul d be given to th e precautions

on the preceding page.

Contents

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specificati ons of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for the troubleshooting.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

CHAPTER 7. APPENDIX

Provides the following additional information for reference:

n Connector pin assignments

n Parts list

n Electric circuit boards components layout

n Exploded diagram

n Electrical circuit boards schematics

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

Page 5

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read WARNING, CAUTION or NOTE messages.

W ARNING

CAUTIO N

CHECK

PO IN T

Indicates an operating or maintenance procedure,

practice or condition that, if not strictly observe d, could

result in injury or loss of life.

Indicates an operating or maintenance procedure,

practice, or condition that, if not strictly observed,

could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessary to accomplish

a task efficiently. It may also provide additional

information that is related to a specific subject, or

comment on the results achieved through a previous

action.

Indicates a reassembly procedure, practice, or

condition that, if not strictly adhered to, could result

in damage to, or nonoperability of, the equipment.

Page 6

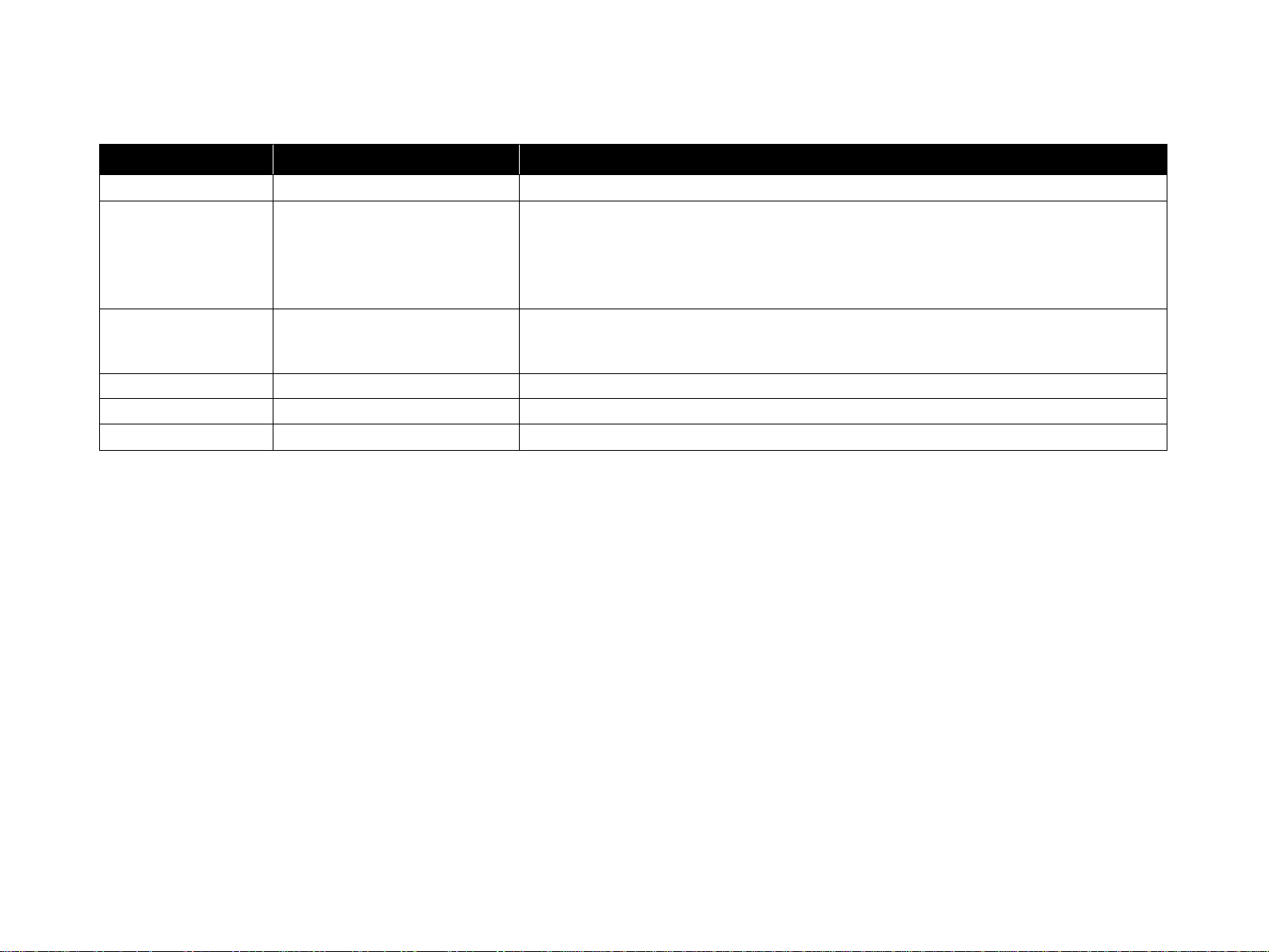

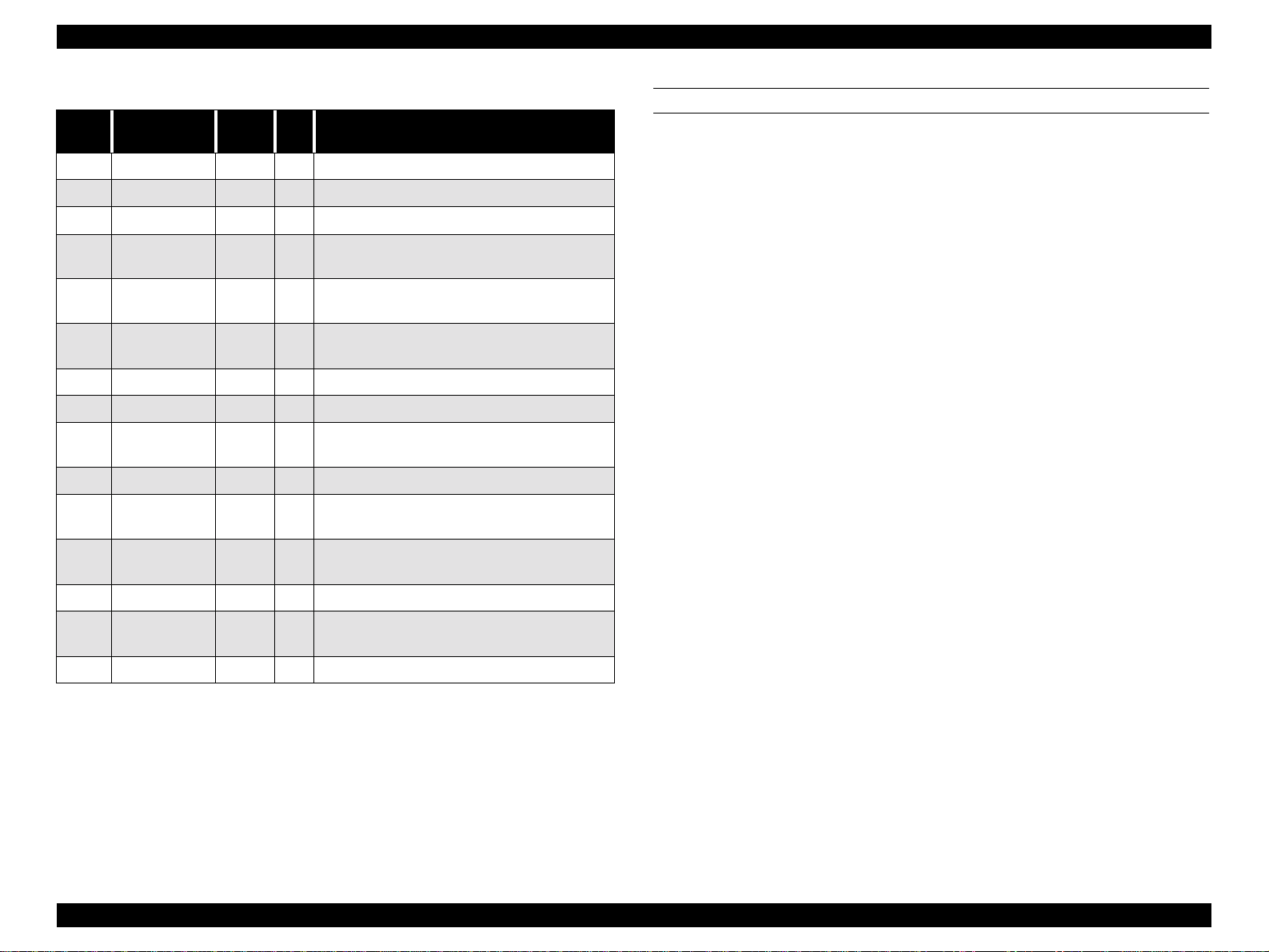

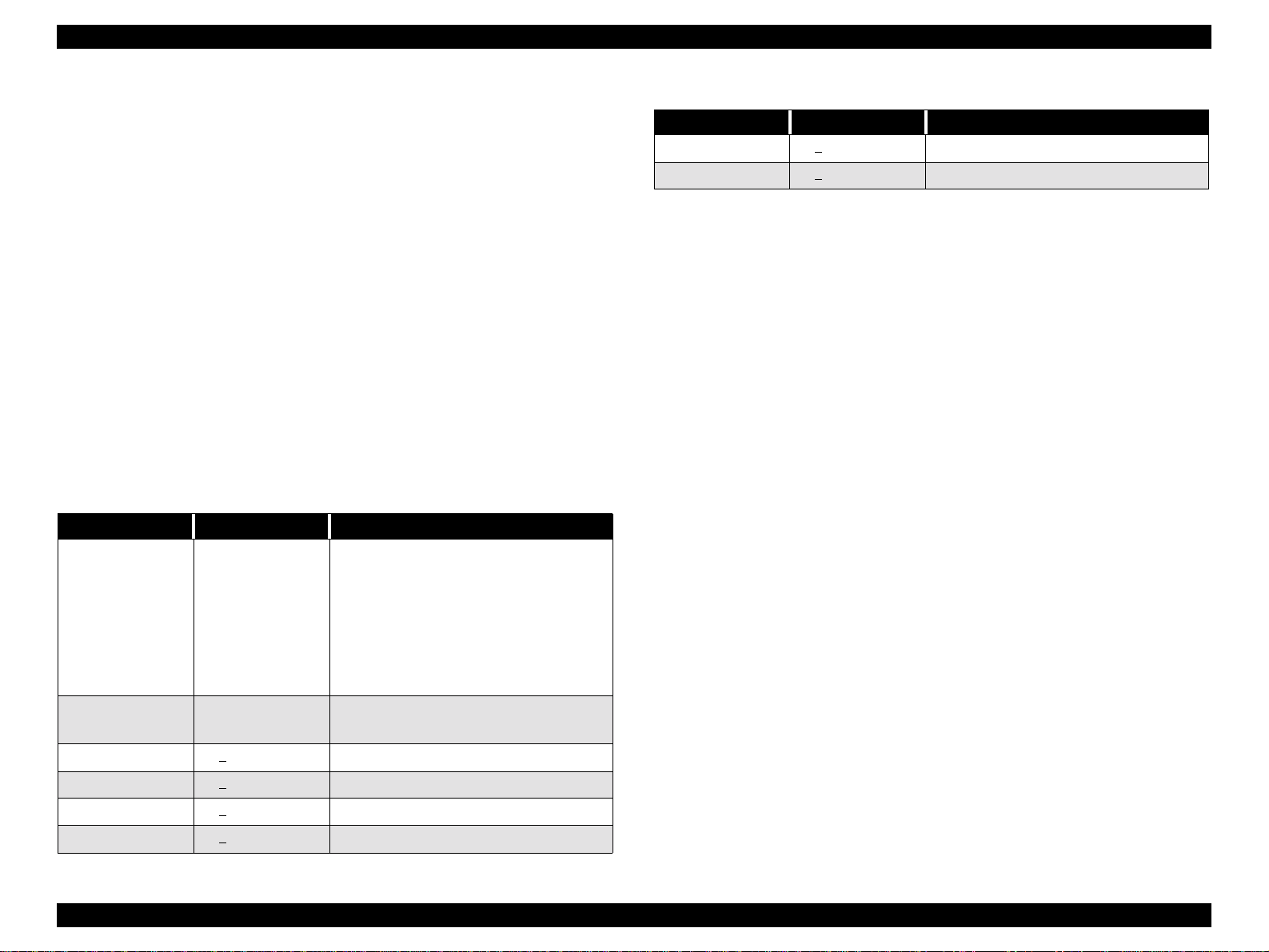

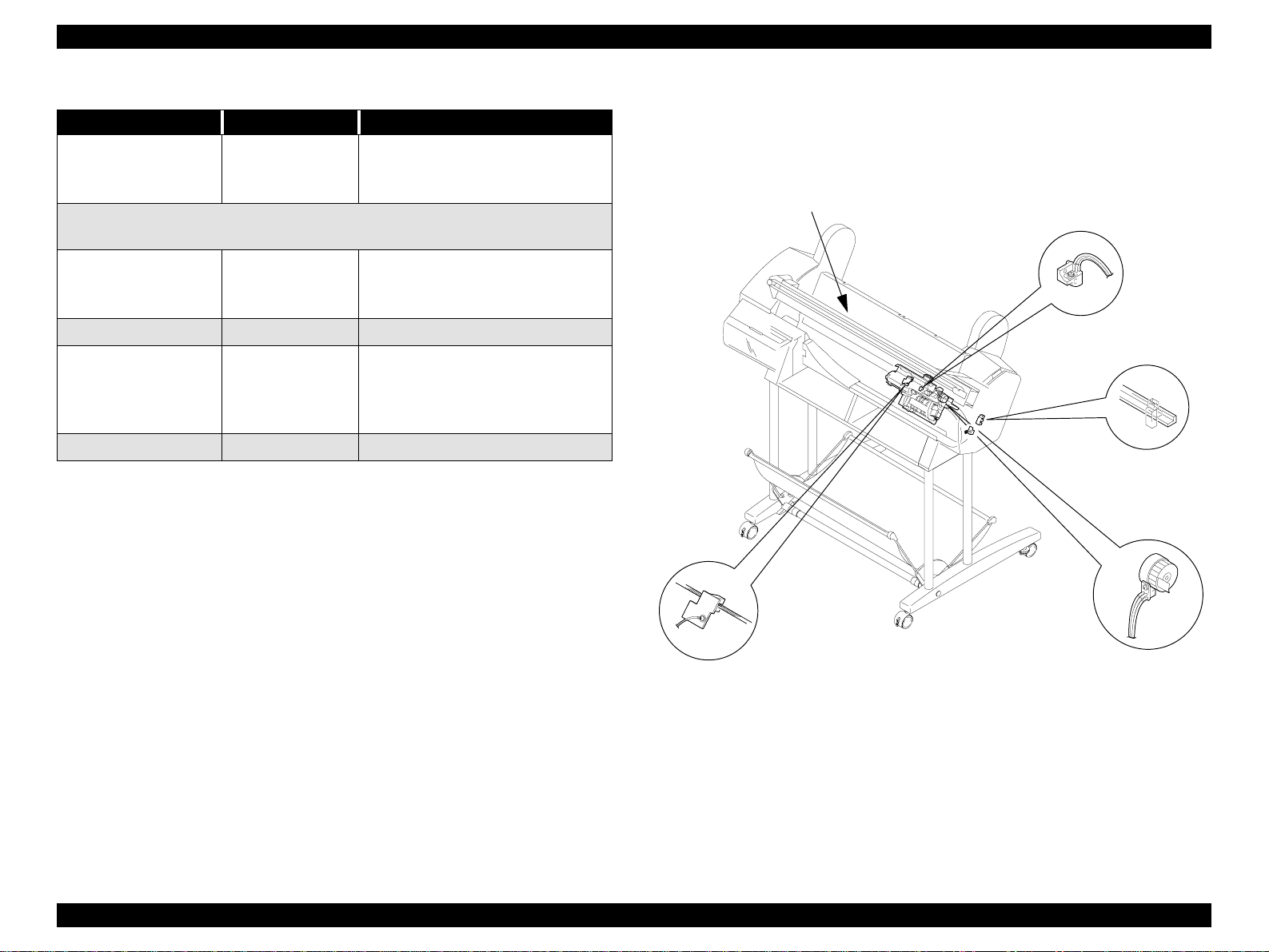

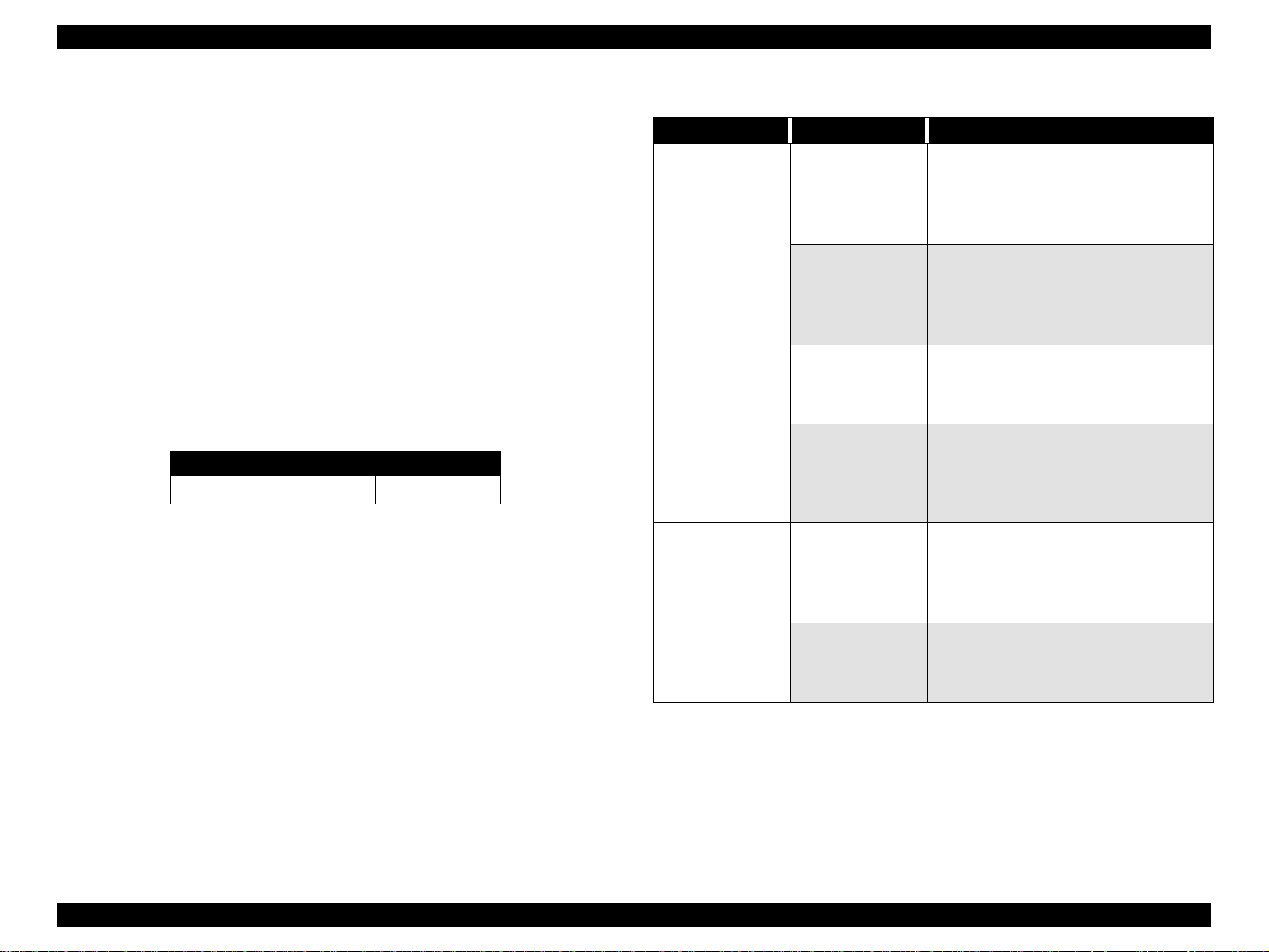

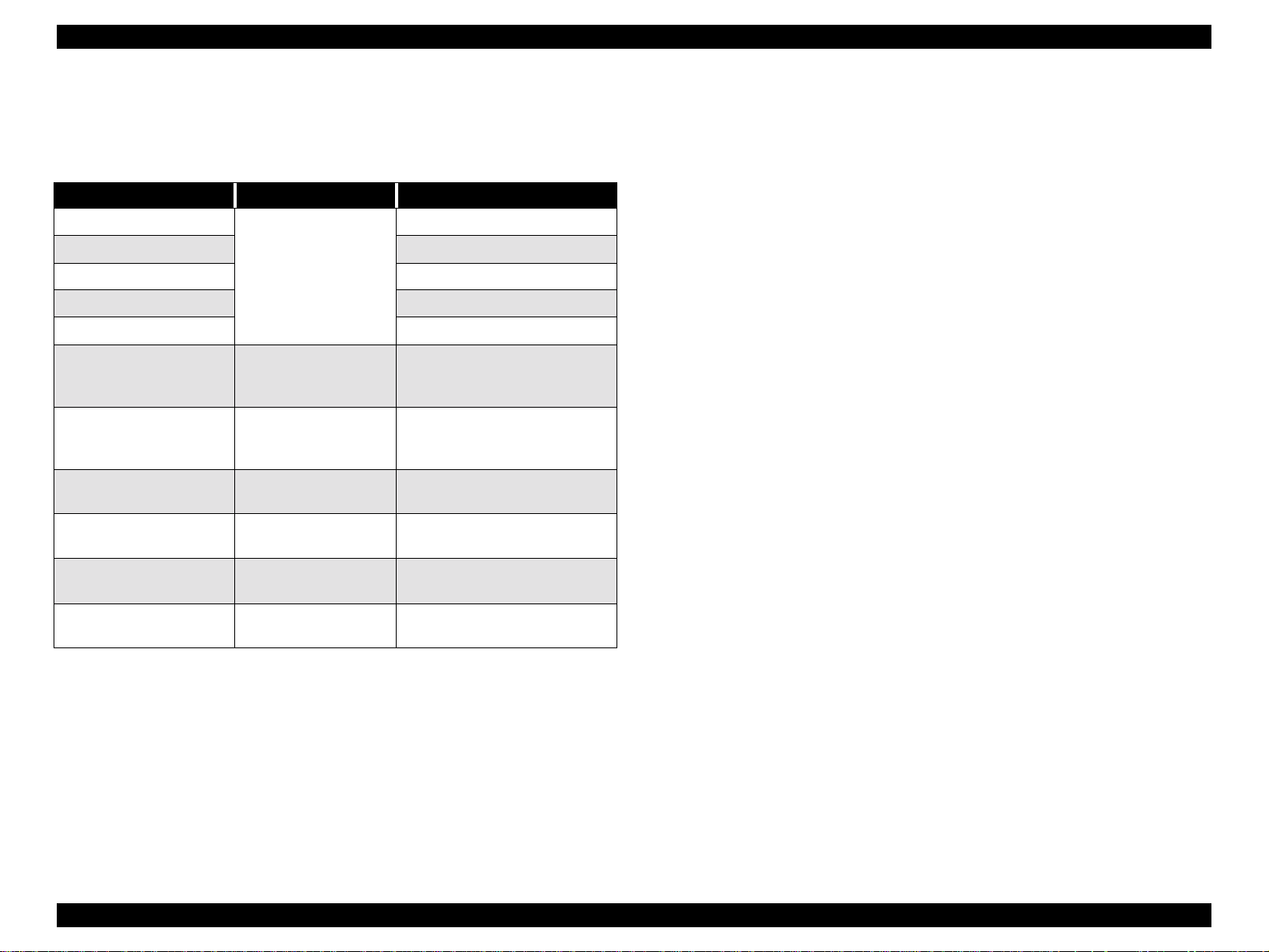

Revision Status

Revision Issued Date Description

Rev. A August 31, 2000 First Release

Rev. B September 7, 2000 Page 53 Ink ca rtridge size select mode can not use on SP7500.

Page 114 Dip SW setting for ASP Main bo a rd.

Page 130 Caution for the PF motor replacement

Page 172 Table 5-4 Main board replacement (Dip SW setting for ASP Mainboard)

Page 231 Dip SW setting for ASP Mainboard

Rev.C September 25,2000 Page 54 Model Name change mode

Page 163 Pigment firmware upload procedu re.

Th e pigment firmware must be uploaded before the pigment ink initial ink charge.

Page 7

Product Description

Features ....................................................................................................... 11

Consumable Products & Options............................................................ 12

Print Specifications....................................................................................... 13

Printing Specifications ...................................................................................13

Character Specifications .......................................... ...... ................................13

Paper Feeding .................................................................................................13

PAPER SPECIFICATION .............................................................................14

Ink (Dye Ink Cartridge) .................................................................................18

Electrical Specifications .................................................................................18

Conformity/Safety Approvals ........................................................................19

Reliability .......................................................................................................19

Environmental Conditions .............................................................................20

Controller Specifications ...............................................................................21

Cutting Specifications ....................................................................................21

External Dimensions / Installation Environment / Weight ............................22

Interfaces...................................................................................................... 23

Parallel Interface ........................ ...... ....... ...... ....... ...... ....... ...... ................ 23

Compatibility mode ............................................................ ...........................23

Nibble Mode ..................................................................................................26

ECP Mode ............................................... .......................................................27

USB Interface.......................................................................................... 29

TYPE-B Optional Type B Interface.......................................................... 30

Supplementary Items .............................................................................. 31

Receiving Buffer Operation ................................................ ...... ...... ...............31

Interface Selection .........................................................................................31

Initialization ................................................................................................... 31

Control Panel................................................................................................ 33

Buttons ........................................................................................................... 33

LED Indicators ...............................................................................................34

Panel Display................................................................................................ 36

Panel Setting Menu ...................................................................................... 37

Printer Setting Menus.............................................................................. 38

Test Print Menu....................................................................................... 40

Printer Status Menu................................................................................. 41

User Paper Setting Menu........................................................................ 44

Cutter Replacement Menu ...................................................................... 46

Gap Adjustment Menu............................................................................. 47

Maintenace Mode ..... ....... ............................................. ........................... 48

HEX Dump ....................................................................................................49

Panel Display Language Selection ................................................................49

M/W Mode Setting ........................................................................................49

Maintenance Mode 2............................................................................... 50

Ink Cartridge Size Select.............................................................................. 53

Inter-User Transport Mode........................................................................... 53

Firmware Reload.......................................................................................... 54

Model Name Change Mode ......................................................................... 54

Self-diagnostic Function Mode..................................................................... 55

Jumper Settings ........................................................................................... 55

Maintenance/ Service Calls.......................................................................... 56

Maintenance Call .................................................................................... 56

Service Call............................................................................................. 57

Operating Principles

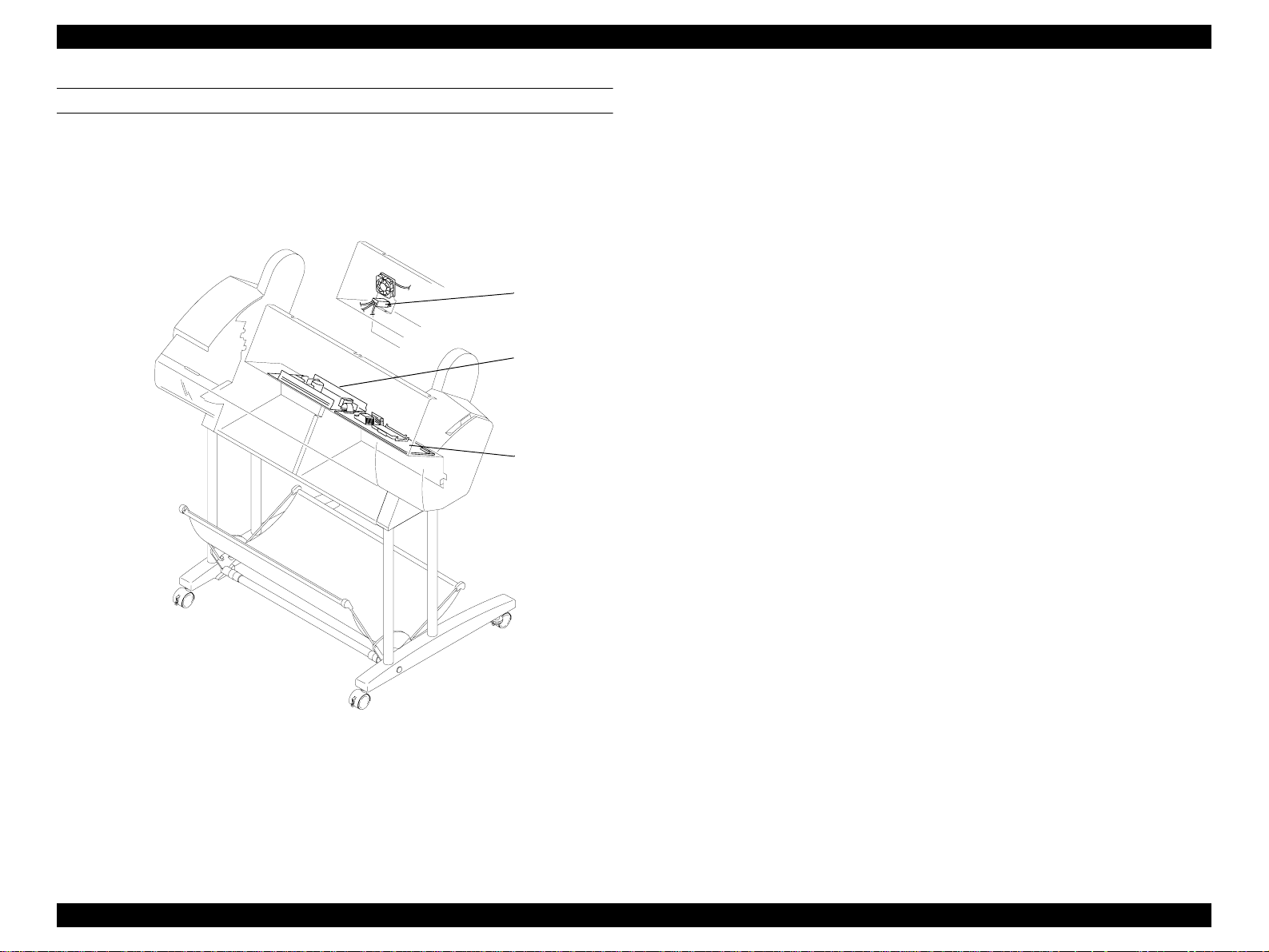

Component List & Illustrations...................................................................... 59

Print Mechanism Components ..................................................................... 60

Carriage (CR) Mechanism ..................................................................... 61

Carriage Moving Unit ................................................. ...................................62

Platen Gap Adjustment Unit ..........................................................................62

Paper Feed Assembly............................................................................. 66

Cleaning Mechanism............................................................................... 68

Ink Supply Mechanism ............................................................................ 70

Other ....................................................................................................... 71

Cover Sensor ..................................................................................................71

Circuit Board Placement ................................................................................72

Control Circuit (C299MAIN Board) Outline................................................... 73

Power Supply Board Summary.................................................................... 75

Troubleshooting

Outline.......................................................................................................... 77

Introduction ............................................................................................. 77

Troubleshooting Practice ........................................................................ 78

Troubleshooting Based on Error Display...................................................... 79

Page 8

Warnings ........................................................................................................81

Errors .............................................................................................................. 81

Fatal Errors .....................................................................................................86

Errors That Require a Service Technician.................................................... 88

Maintenance Call 0100 ..................................................................................88

Service Call 00000100 ...................................................................................88

Service Call 00000101 ...................................................................................88

Service Call 00010000 ...................................................................................88

Service Call 00010001 ...................................................................................89

Service Call 00010002 ...................................................................................89

Service Call 00010003 ...................................................................................89

Service Call 00010004 ...................................................................................90

Service Call 00010005 ...................................................................................90

Service Call 00010006 ...................................................................................90

Service Call 00010007 ...................................................................................90

Service Call 00010008 ...................................................................................90

Service Call 00010009 ...................................................................................91

Service Call 0001000A ............................................................. ...... ..... ..........91

Service Call 0001000C ................................. .................................................91

Service Call 0001000D

Service Call 0001000E ..................................................................................92

Service Call 0001000F ...................................................................................92

Service Call 00010010 ...................................................................................92

Service Call 00020000 (NVRAM error)

Service Call 00020001 (Internal RAM error)

Service Call 00020002 (SRAM error)

Service Call 00020003 (DRAM error) ..........................................................92

Service Call 10000004

(CPU Vector 4 / General improper command issued)

Service Call 10000006

(CPU Vector 6 / Slot improper command)

Service Call 10000009

(CPU Vector 9 / CPU address error)

Service Call 1000000A

(CPU Vector 10 / DMAC/DTC address error)

Service Call 1000000B

(CPU Vector 11 / WD timer out error)

Service Call 10000 ** ................................................(CPU Vector 32 ~ 63) 92

Troubleshooting Based on Your Printout...................................................... 93

Dot Missing ....................................................................................................93

Uneven Printing/Poor Resolution ..................................................................94

Smudged or Marred Printout (Front) .............................................................94

Smudged or Marred Printout (Reverse side) .................................................95

White or Black Banding ................................................................................95

Disassembly & Assembly

Summary...................................................................................................... 97

Warnings................................................................................................. 97

Tools ....................................................................................................... 99

Screw List.............................................................................................. 100

Disassembly Flow ...................................................................................... 101

Removing the Housing.......................................................................... 102

Circuit Board Removal .......................................................................... 111

Removing the Cooling Fan .........................................................................112

Disconnect the AC inlet ...............................................................................112

Changing the C299MAIN Board DIP-SW Settings ....................................114

Printer Mechanism Disassembly........................................................... 115

Conversion Kit Assembly Procedure..................................................... 146

Preparation before assembly ........................................................................148

Ink Discharge Procedure ..............................................................................148

Conversion Kit Parts Replacement Procedure .............................................149

Affixing Labels ............................................................................................162

Uploading Pigment Ink Firmware ...............................................................163

Pigment Ink Initial chARGE ........................................................................164

Required Adjustment Items .........................................................................164

Bi-D Adjustment (Round Trip Alignment) .................................................165

Head Gap Adjustment (Alignment Between Heads) ................................... 167

Final Check ..................................................................................................169

Adjustment

Adjustment Outline..................................................................................... 171

Cautions................................................................................................ 171

Adjustment Tools .................................................................................. 171

Adjustment Items .................................................................................. 173

Adjustment Steps ....................................................................................... 175

Parameter Backup ................................................................................ 175

Requirements for parameter Backup ...........................................................175

Backing up parameters From Main Board to PC card .................................176

Page 9

Downloading Parameters From PC Card to new Board ..............................176

Backup/Download Error Recovery ..............................................................177

Range of Backed Up Parameters .................................................................177

Firmware Update................................................................................... 178

Updating Firmware Via the PC ....................................................................178

Updating Firmware From a Memory Card ..................................................179

Self-diagnostic Function........................................................................ 180

Version ......................................................................................................... 183

Control Panel ...............................................................................................184

Sensors .........................................................................................................184

Adjustment the Paper Sensors .....................................................................185

Encoder ........................................................................................................189

Fan ................................................................................................................189

Elec. .............................................................................................................189

Adj Cap Position ..........................................................................................194

Adj Check Skew .......................................................................................... 195

Write D/A Value ..........................................................................................196

Adj Input Rank .............................................................................................196

Adj Check Nozzle ........................................................................................197

Adj x Head Slant (B/C heads) ......................................................................198

Adj B/C Head Height ...................................................................................200

Bi-D Printing Position Adjustment ..............................................................201

Head Gap Adjustment ................................... ...............................................204

Flush Point adjustment .................................................................................205

Feed Adjustment ..........................................................................................206

Adj Top & Bottom .......................................................................................207

Adj Rear Sensor Position .............................................................................208

Test Pattern Print ..........................................................................................209

Clean Head (drain ink) .................................................................................210

Counter Clear ...............................................................................................211

"Initialize" Items ..........................................................................................213

"Update" Items .............................................................................................213

Maintenance Mode................................................................................ 215

HEX Dump ..................................................................................................216

Panel Display Language Selection ...............................................................216

M/W Mode Setting ................................. ...... ...............................................216

Maintenance Mode 2............................................................................. 217

Mechanism Adjustment......................................................................... 220

Changing the C299MAIN Board DIP-SW Settings................................ 232

Writing the USB-ID............................................................................... 233

Required Materials .......................................................................................233

Operating Environment and Preliminary Preparations ................................233

Writing the USB ID .....................................................................................233

Bi-D #4 Adjustment Check Pattern ....................................................... 235

Required Materials .......................................................................................235

Operating Environment and Preliminary Preparations ................................235

Bi-D #4 Adjustment Check Pattern .............................................................235

Maintenance

General Maintenance Issues...................................................................... 238

Periodic Maintenance Items.................................................................. 239

Product Life Information ........................................................................ 240

Important Maintenance Items During Service Operations .................... 241

Lubrication and Glue .................................................................................. 242

Appendix

Wiring Diagrams......................................................................................... 244

Parts List .................................................................................................... 246

Exploded View Diagram............................................................................. 259

Component Layout.................................. ...... ....... ...... ....... ...... ....... ...... ...... 270

Circuit Diagrams......................................................................................... 273

Page 10

PRODUCT DESCRIPTION

CHAPTER

Page 11

EPSON Stylus Pro 7500 Revision c

1.1 Features

The EPSON Stylus Pro 7500 is an 24-inch wide, 6-color ink jet printer with professional

color output. It has the same printheads as the EPSON Stylus Pro 9000. The EPSON Stylus

Pro 7500 provides the follow ing major feat ure s and mor e.

o Large Format

A1, full size

24 inch-full size printing (A1+size supported)

o High-speed throughput

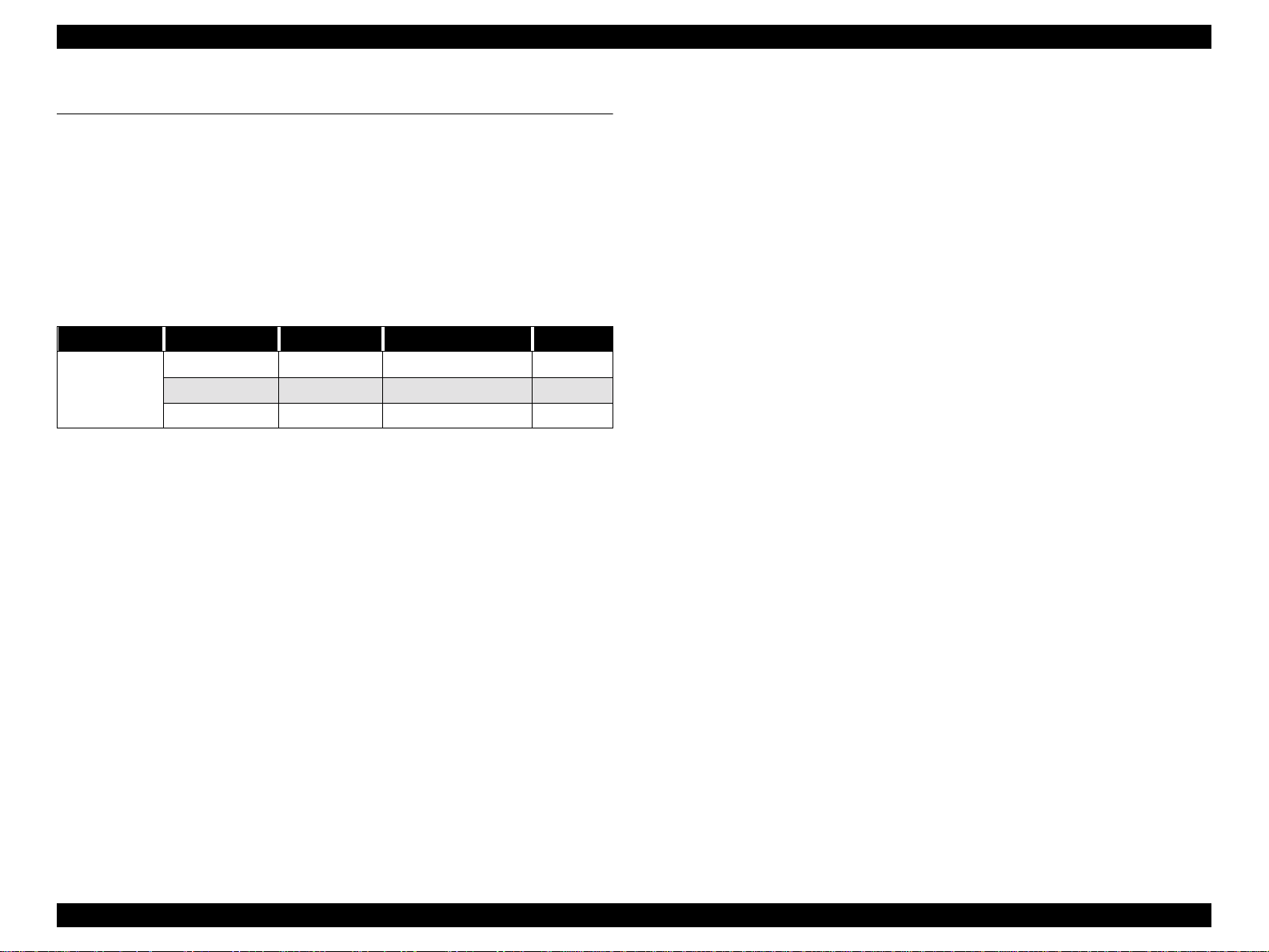

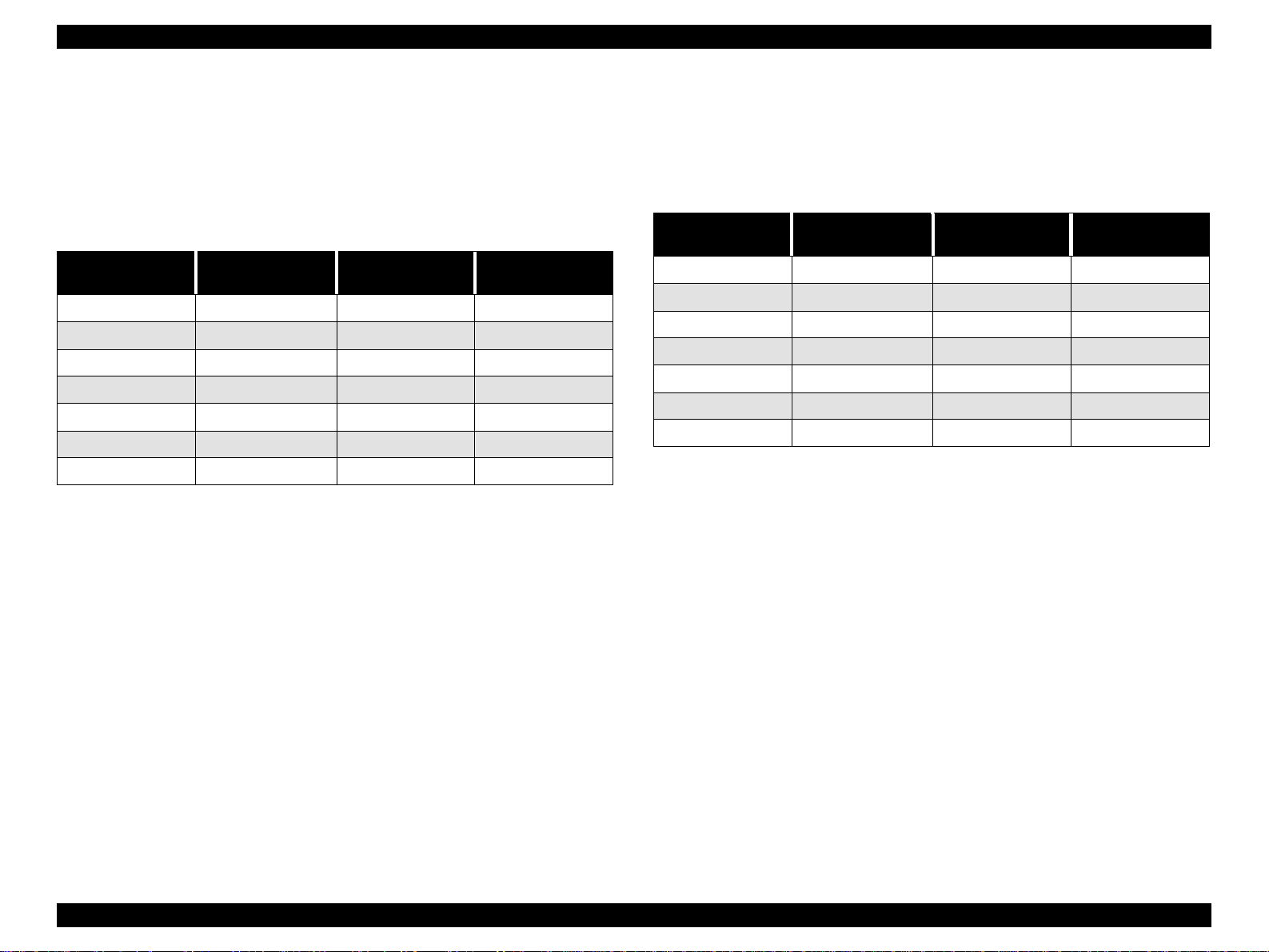

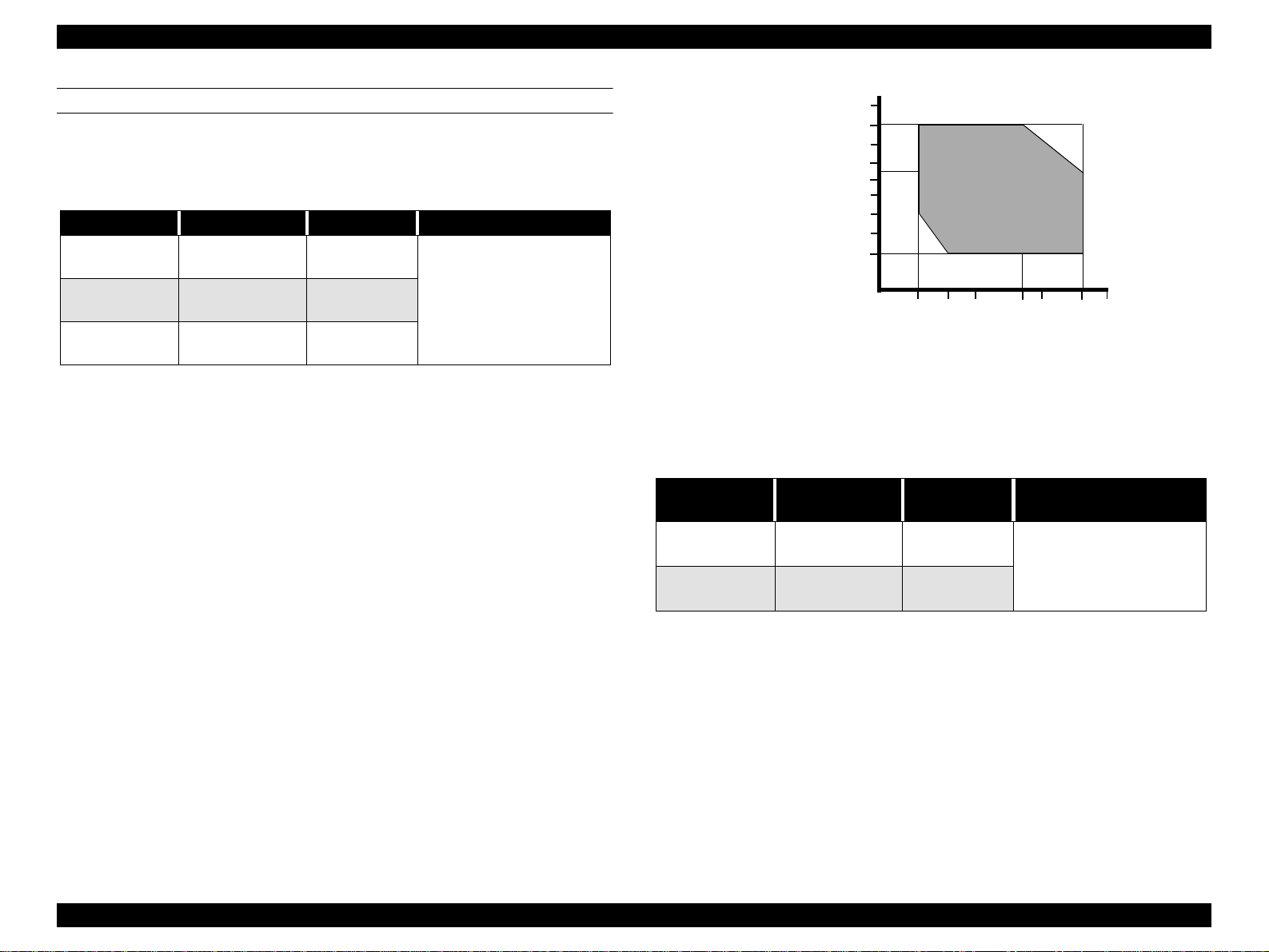

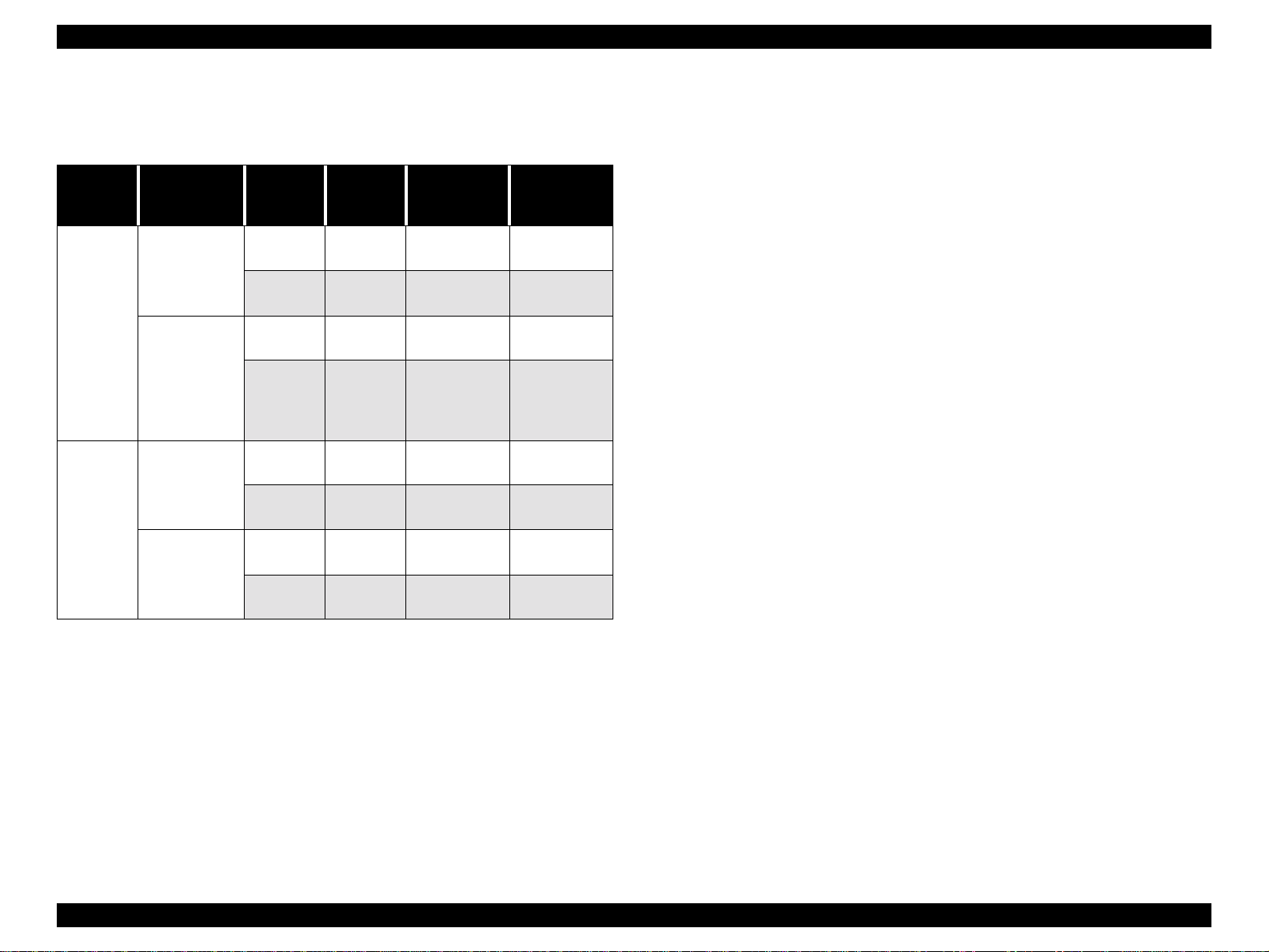

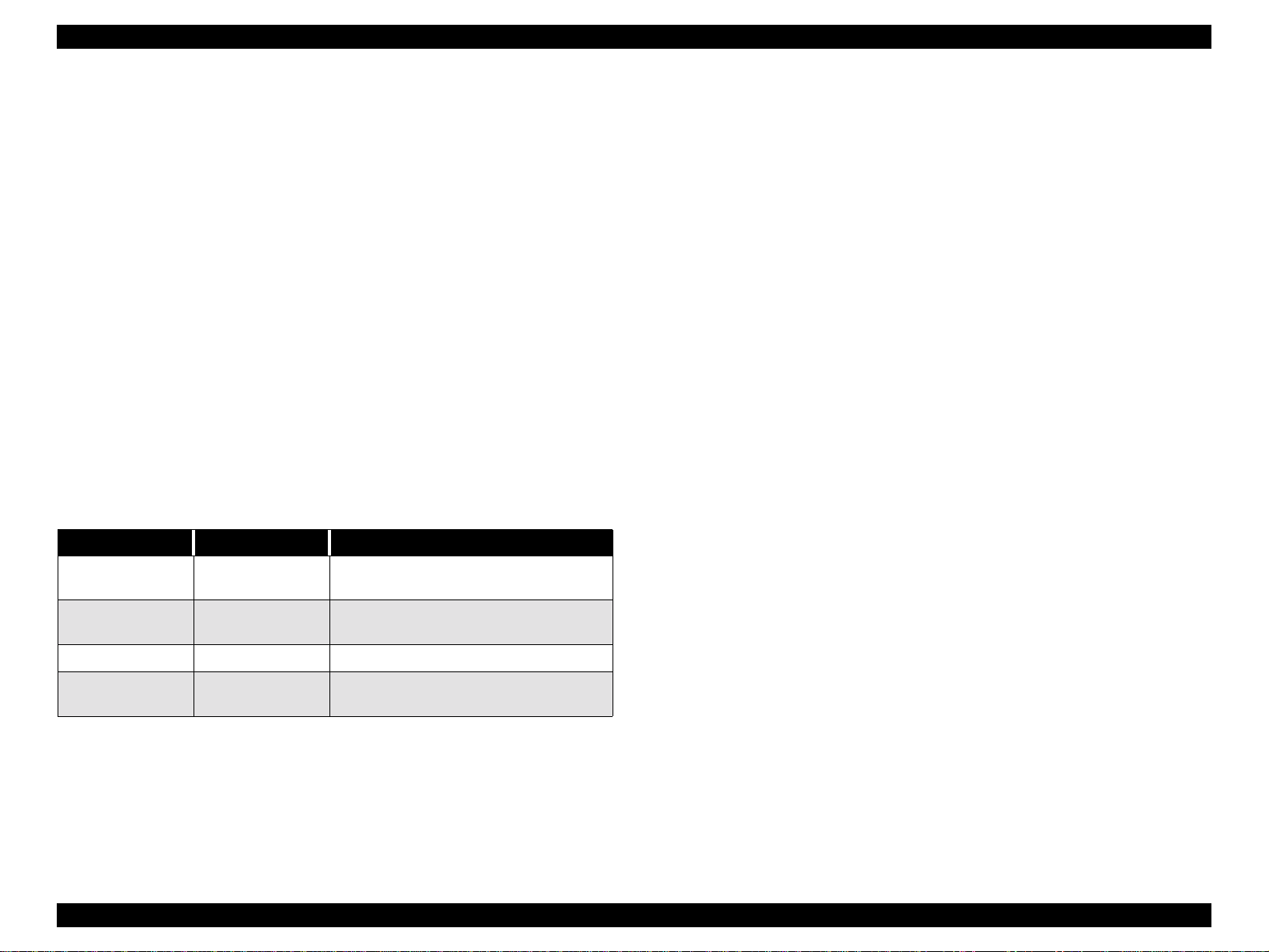

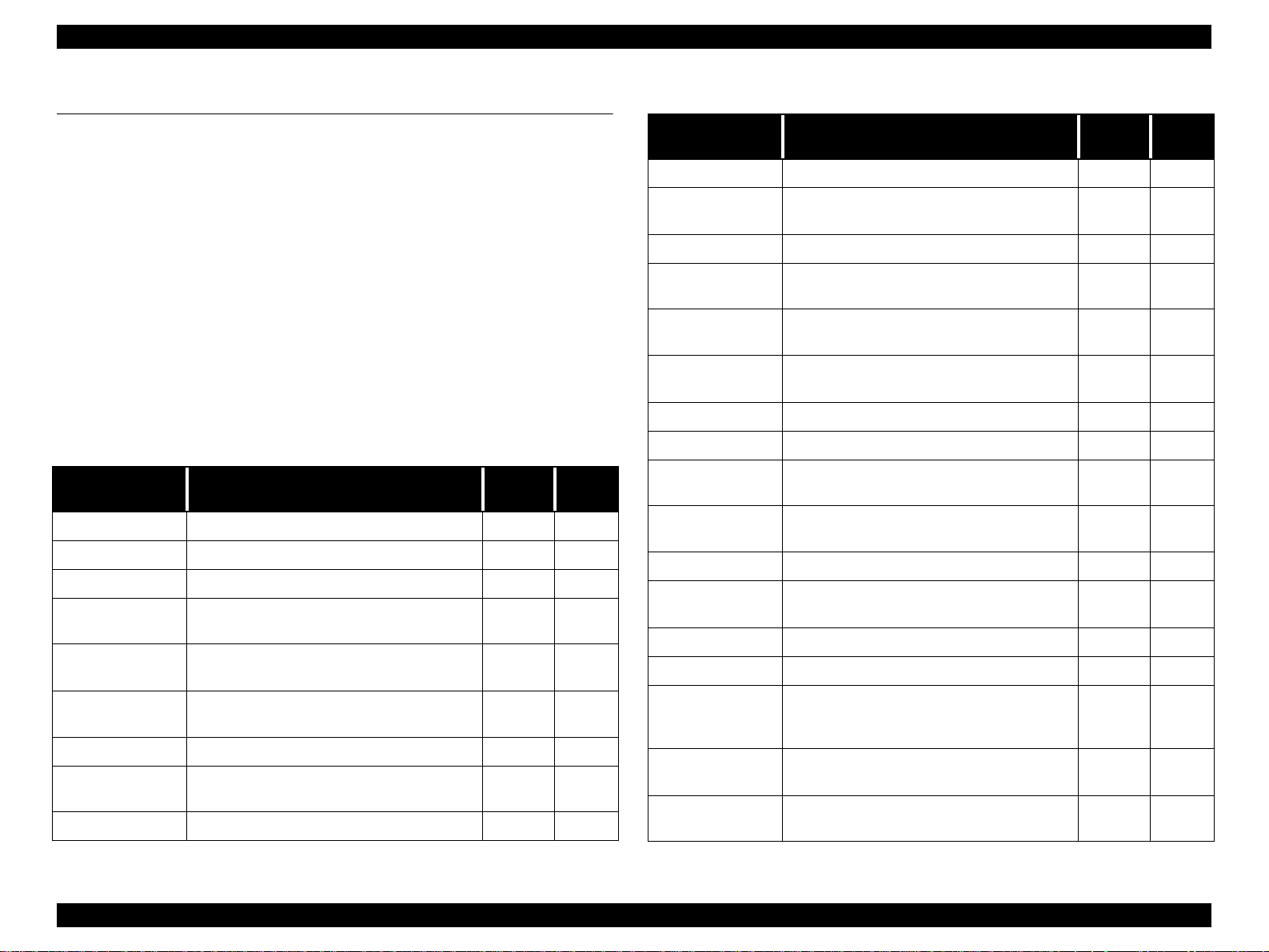

Table 1-1.

Paper Image Quality Resolution Mode Throughput

Fast 720x720dpi Bi-D MW/MF,240cps 9min

Medium Glossy

Paper

o High Image Quality

Pigment ink in 6 colors is used. Image quality and color reproduction are at the

same level as with the Stylus Pro 9500.

Beautiful 720x720dpi Bi-D FOL,333cps 14min

High Precision 1440x720dpi Bi-D FOL,4pss, 333cps 27min

o Low running c ost

Six separate ink cartridges so you only have to replace the empty ink cartridge

(each cartridge holds 100ml of ink)

o Applicable various media

Auto cutter provided in addition to the standard roll paper feeder.

o Complete Software Compatibility With EPSON Sty lu s Pro 9000

Stylus Pro 9000 commands and Stylus Pro 7000 commands are upward

compatible and can be interchanged with the Stylus Pro 9500 commands.

o Latest RIP Technology

CPSI Pro (software)

PS Server (Scheduled to go on sale in September, 2000)

o Compact, Low in Cost

Can be used on a desktop (The stand is an option)

Product Description Features 11

Page 12

EPSON Stylus Pro 7500 Revision c

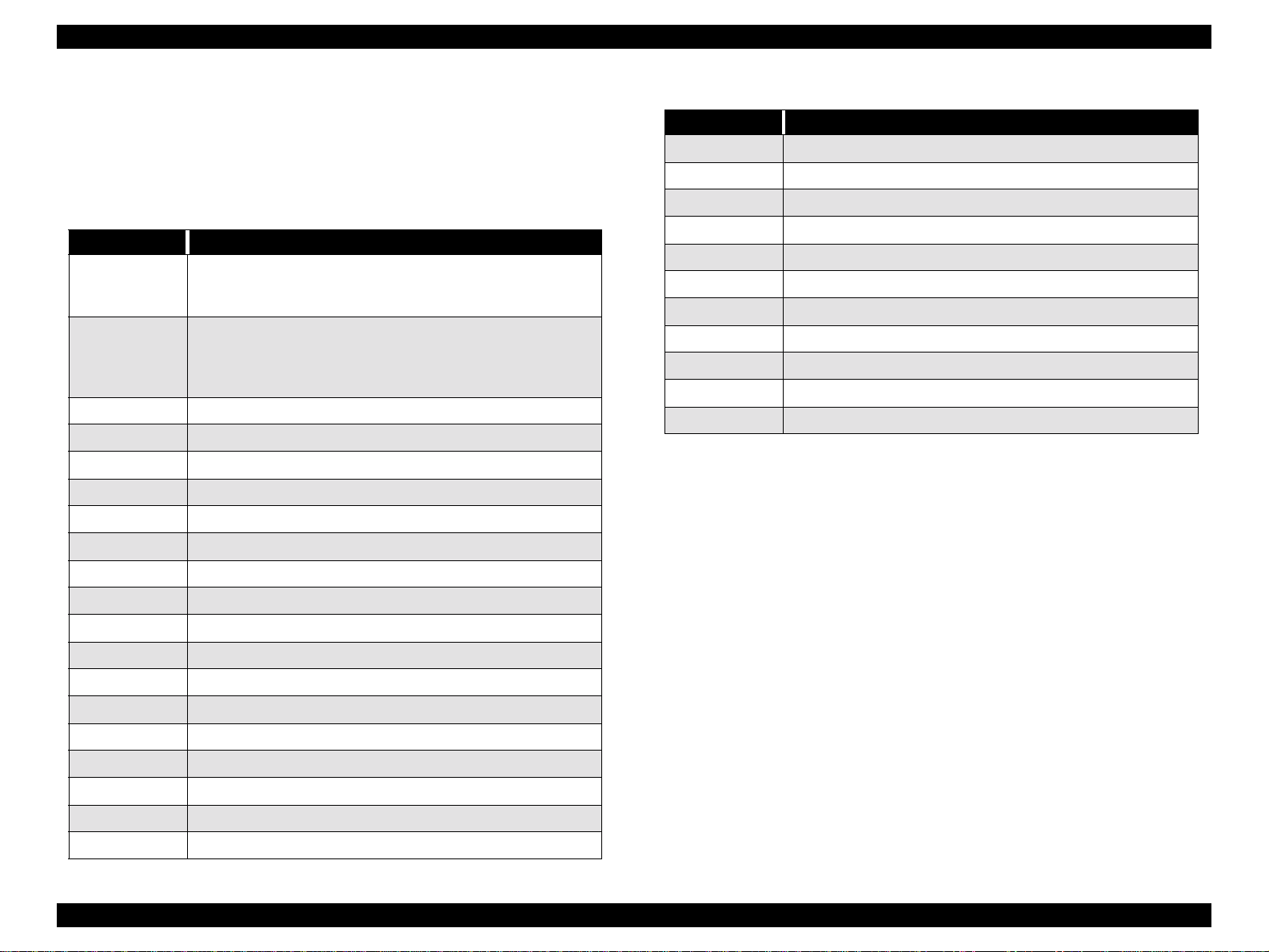

1.1.1 Consumable Products & Options

The consumables and options that can be used with the Stylus Pro 7500 are shown below.

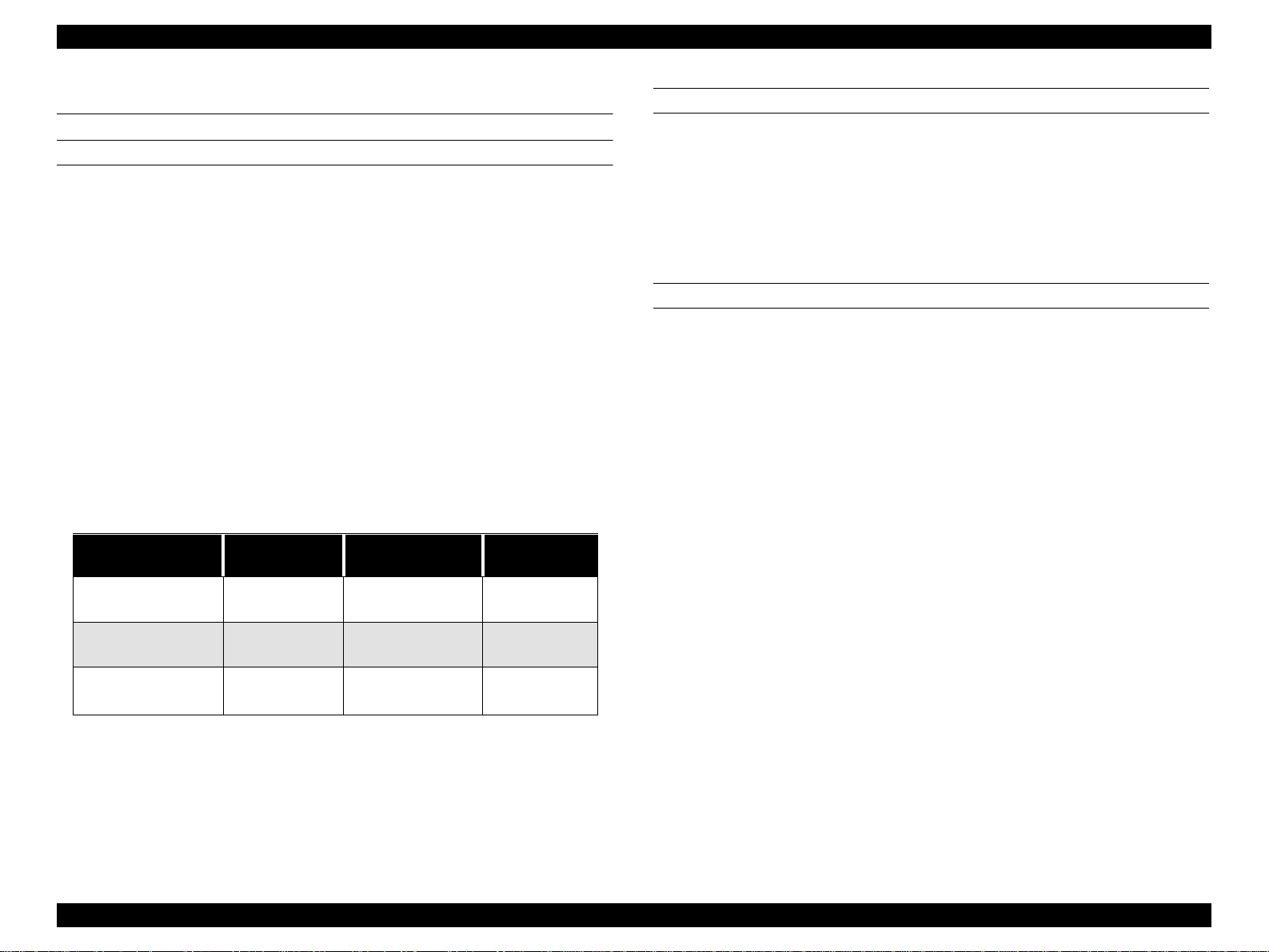

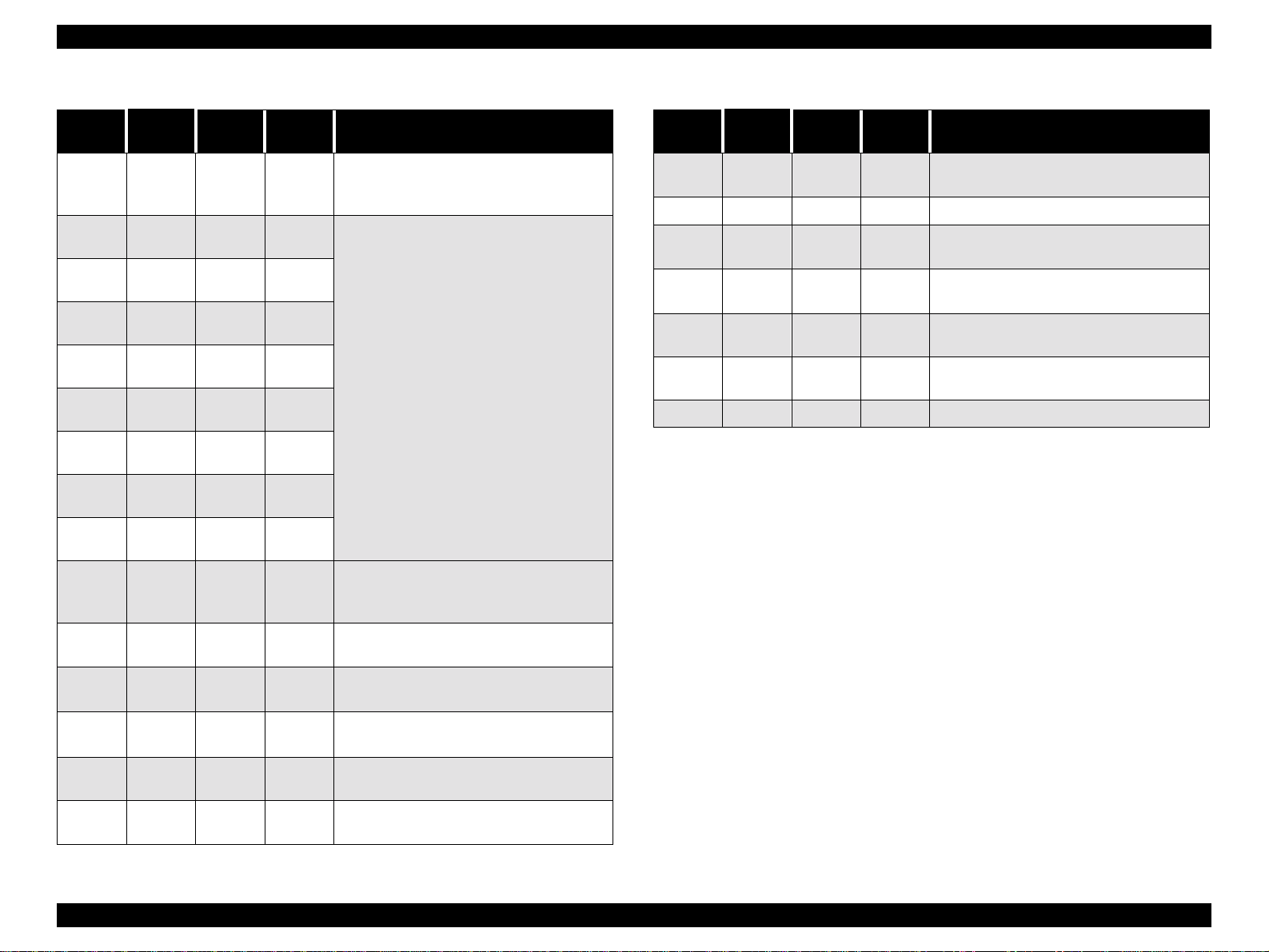

Table 1-2. Consumables & Options

Name Code Product

T460¬¬¬

T463¬¬¬

Ink cartridges

Stand

Paper cutter blade

Roll Feed Spindle 2”

Roll Feed Spindle 3”

Doubleweight Matte Paper

Glossy Pape - PhotoW eight

Premium Glossy Photo Pap e r

Premium Semium Semig los s Phot o

Watercolor Paper - Radiant White

Glossy Film

Synthetic Paper

Adhesive Synthetic Paper

Rip Station 5100 PS Server Series

II

Software RIP (CPSI Pro) Software RIP (CPSI Pro)

T462¬¬¬

T461¬¬¬

T465¬¬¬

T464¬¬¬

C844022

C815131

C811092

C811102

S041385

S041388

S041390

S041393

S041396

S041352

S041351

S041314

S041399

S041402

EAI - C850092

Other - C850093

Black Ink

Cyan Ink

Magenta Ink

Yellow Ink

Light Cyan Ink

Light Magenta Ink

Optional stand

Consumable item

For two-inch diameter roll paper

For three-inch diameter roll paper

24 in wide/25m long

22 in wide/20m long

24 in wide/30.5m long

24 in wide/30.5m long

24 in wide/18m long

A3 Wide / B

A3 Wide / B

610mm wide/20m long

24 in wide/45m long

24 in wide/30m long

Fiery Adobe® PostScript® 3™ Server

¬ Signifies a number that varies by market.

Multi-protocol Ethernet interface

card

100Mbps Multi-protocol Ethernet

interface card

IEEE 1394 interface card

C82362¬

C82363¬

C82372¬

Type-B 10Base-T

Type-B 100Base-T

IEEE 1394 interface card

Product Description Features 12

Page 13

EPSON Stylus Pro 7500 Revision c

1.2 Print Specifications

PRINTING SPECIFICATIONS

Printing System: Ink jet

o

o Head nozzle arrangement: black = 64 nozzles (32 nozzles x 2 rows)

Color = 320 nozzles (Cyan, magenta, yellow, light cyan and light magenta, 64

nozzles each (32 nozzles x 2 rows)

o Print direction = Bi-di rection (high-speed return, high-speed skip only)

o Print Speed and Printable Area

n

Character mode

Character Quality High Quality

Character pitch 10cpi (Pica)

Printable area 237 characters

Printing speed 240cps

n

Graphic mode

See the table below.

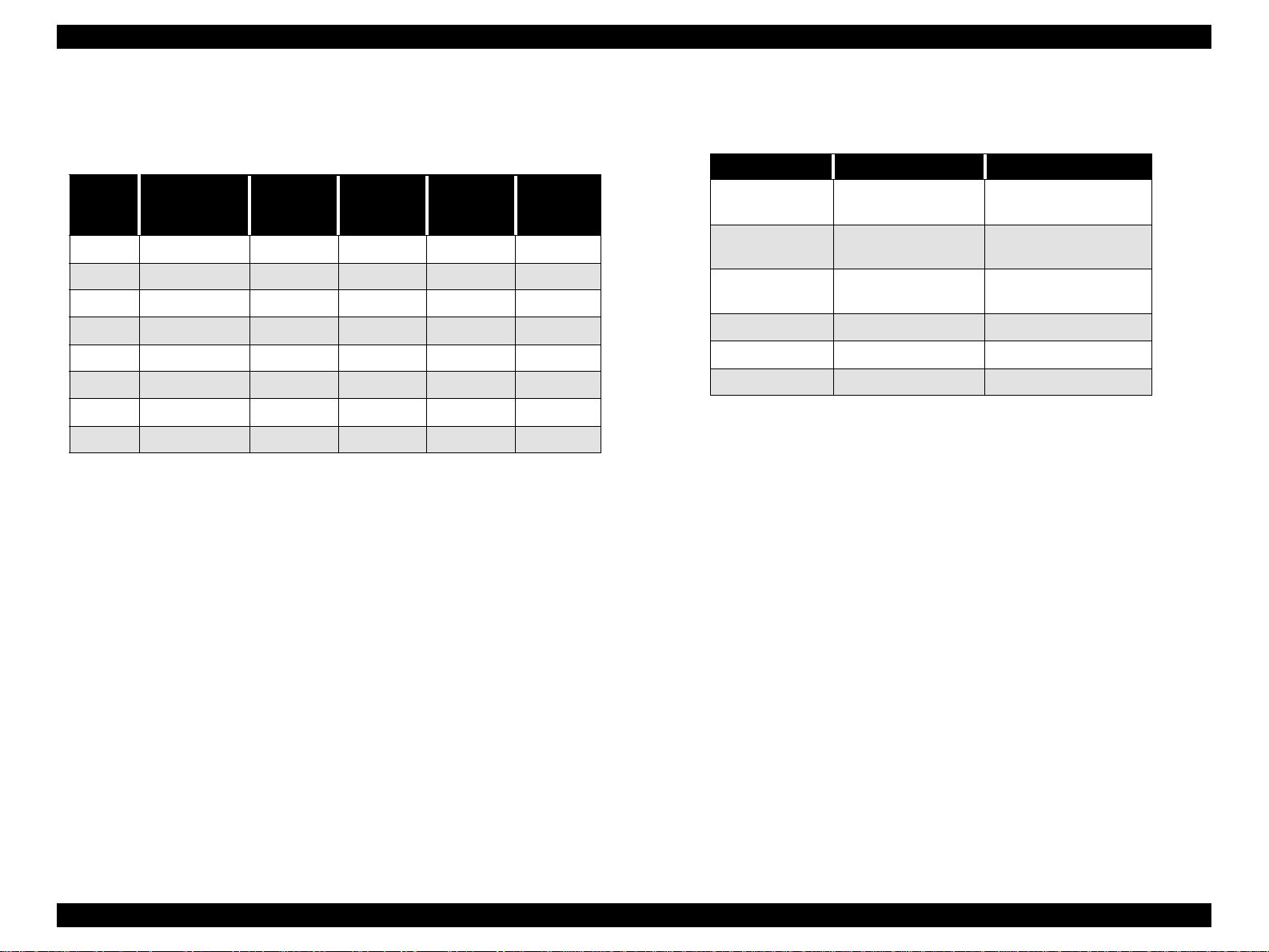

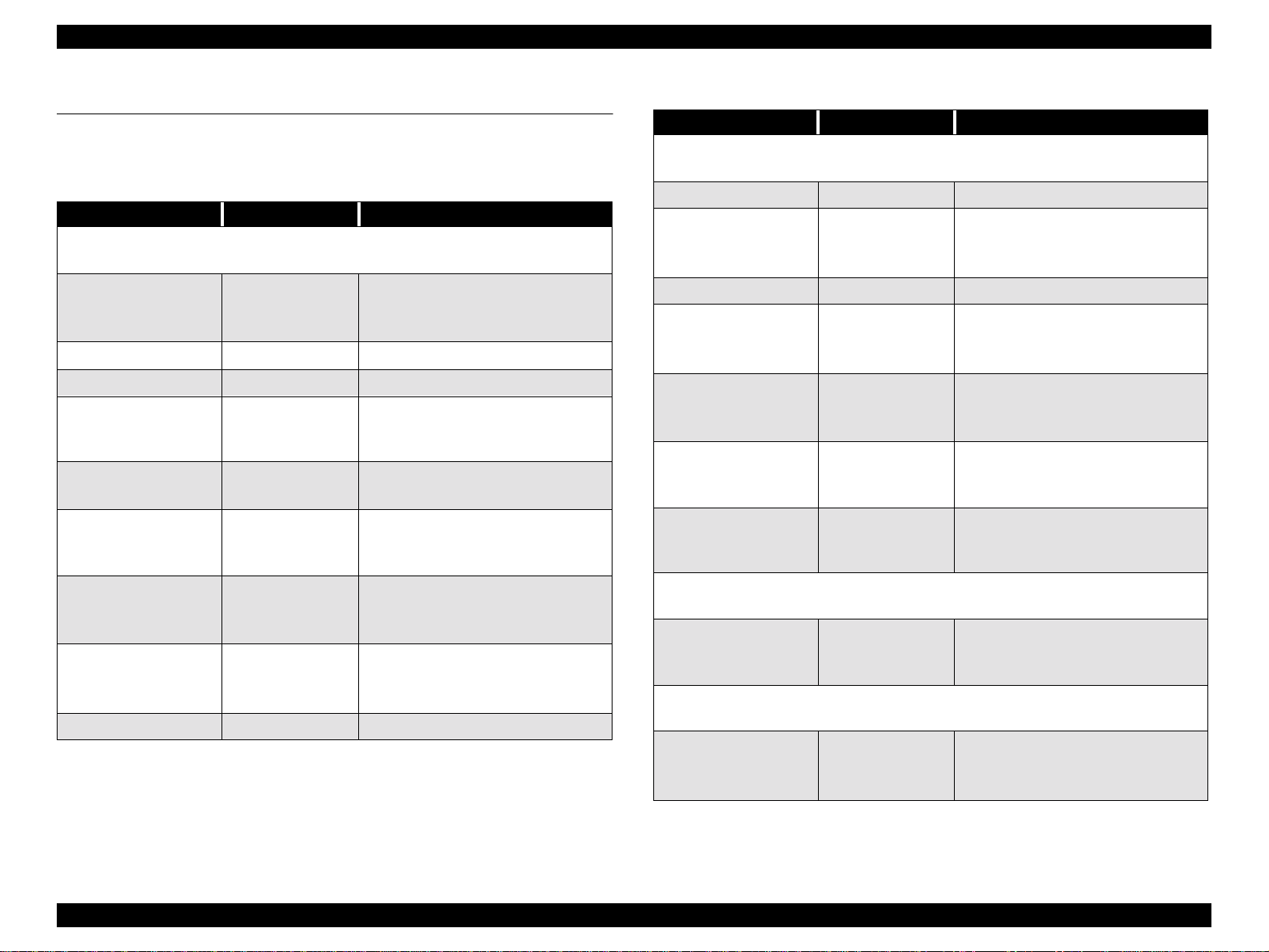

Table 1-3. Print Area and Speed

Horizontal resolution

(dpi)

360

Printable area Max. printable dots Speed

604mm

23.78 inches

8561 24 IPS

CHARACTER SPECIFICATIONS

Character Code:

o

PC437(US, Standerd Europe)

PC850(Multilingual)

o Type Faces:

Bitmap LQ fout : EPSON Courier 10 CPI

o Control Code: ESC/P Raster

PAPER FEEDING

Paper feeding method: Friction feed

Line spacing: 1/6” or programmable at 1/720”

Paper path: Roll paper/manual

±

Feed speed: 1/6” 200

Continuous 2.5” (63. 5mm ) /sec ond

10m seconds

720

1440

604mm

23.78 inches

604mm

23.78 inches

17,123

34,246

33.3 IPS/FOL

33.3 IPS/4pass

24 IPS/FOL

33.3 IPS/4pass

Product Description Print Specifications 13

Page 14

EPSON Stylus Pro 7500 Revision c

PAPER SPECIFICATION

Roll Paper: [Compatible papers]

The following papers can be loaded in this machine, but it

is not guaranteed that they will go through or that the print

quality will be good.

• Paper Size = Width: 210 ~ 610 mm

* However, it should be within the roll size.

• Roll size = 2” or 3” core

Outer diameter: within 150 mm

• Paper thickness = 0.08 ~ 0.05 mm

*1 There should be no wrin kles, fuzz, tearing or folding, of

the paper, etc.

*2 The exclusive option (3” roll paper spindle) is

necessary when using 3” core roll paper.

[Plain Paper]

Only paper feed operation is guaranteed for the following

papers.

• Paper Size = Width: 210 ~ 610 mm

* However, it should be within the roll size.

• Roll size = 2” or 3” core

Outer diameter: within 150 mm

• Paper thickness = 0.08 ~ 0.11 mm

• Paper weight = 64~90 gf/m

• Paper Quality =Plain paper, Recycled paper

*1 There should be no wrinkles, fuzz or tearing of the

paper, etc.

*2 The peel strength of the first part of the paper roll

should be within 300 ~ 500 gf.

*3 The exclusive option (3” roll paper spindle) is

necessary when using 3” core roll paper.

*4 This product should be used in a place with a normal

room temperature environment (Temperature: 15~25°C,

Relative humidity: 40~60%)

*5 The printable area for roll paper is from the core to the

point where it is cut off.

Length: 279 mm ~ 202 m

Length: 279 mm ~ 202 m

2

The remaining paper length when the paper is cut off from

the roll.

(Reference): approx. 30 cm.

[EPSON Special Paper]

The feed through characteristics and print quality of the

following genuine exclusive papers are guaranteed.

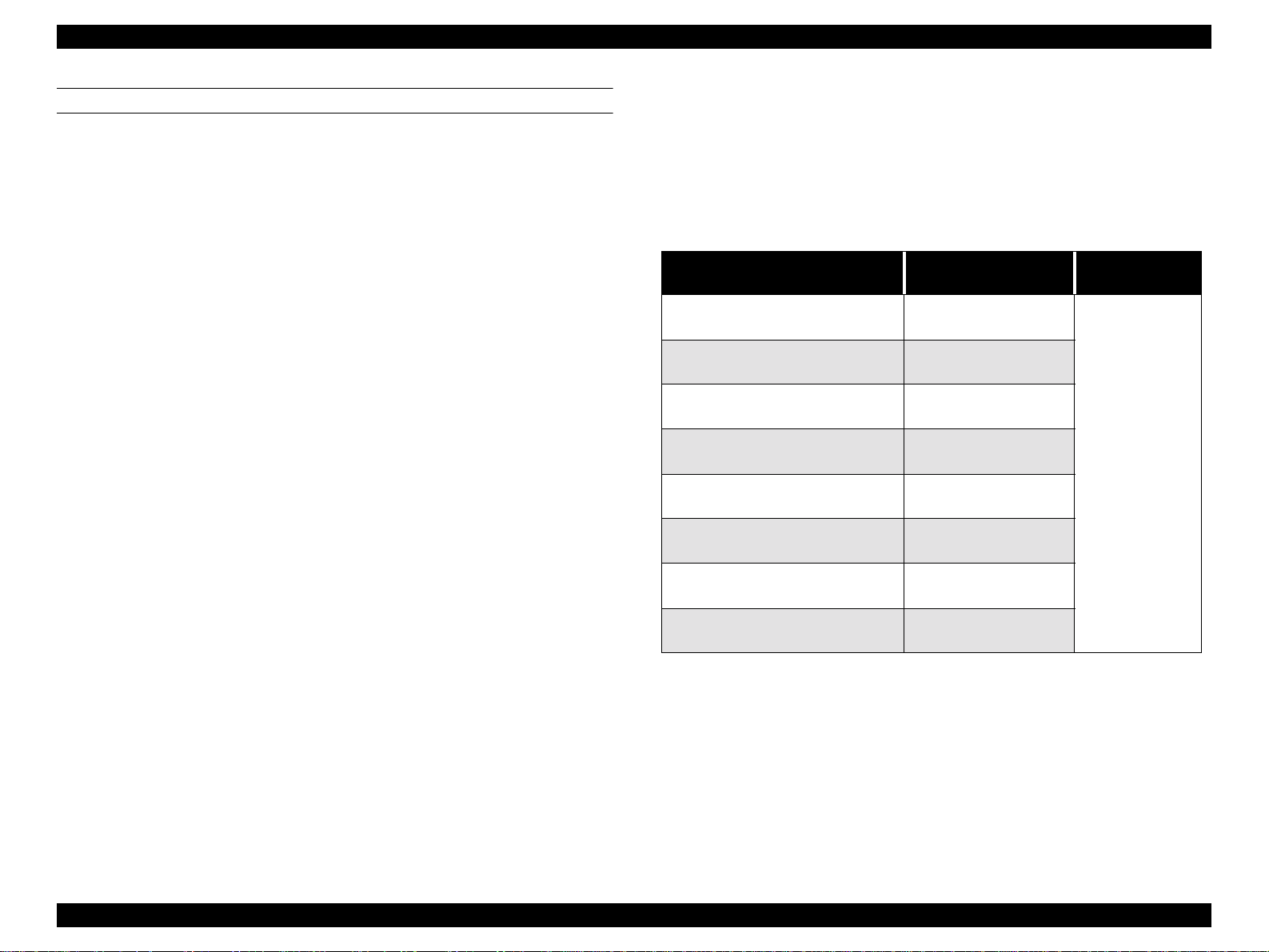

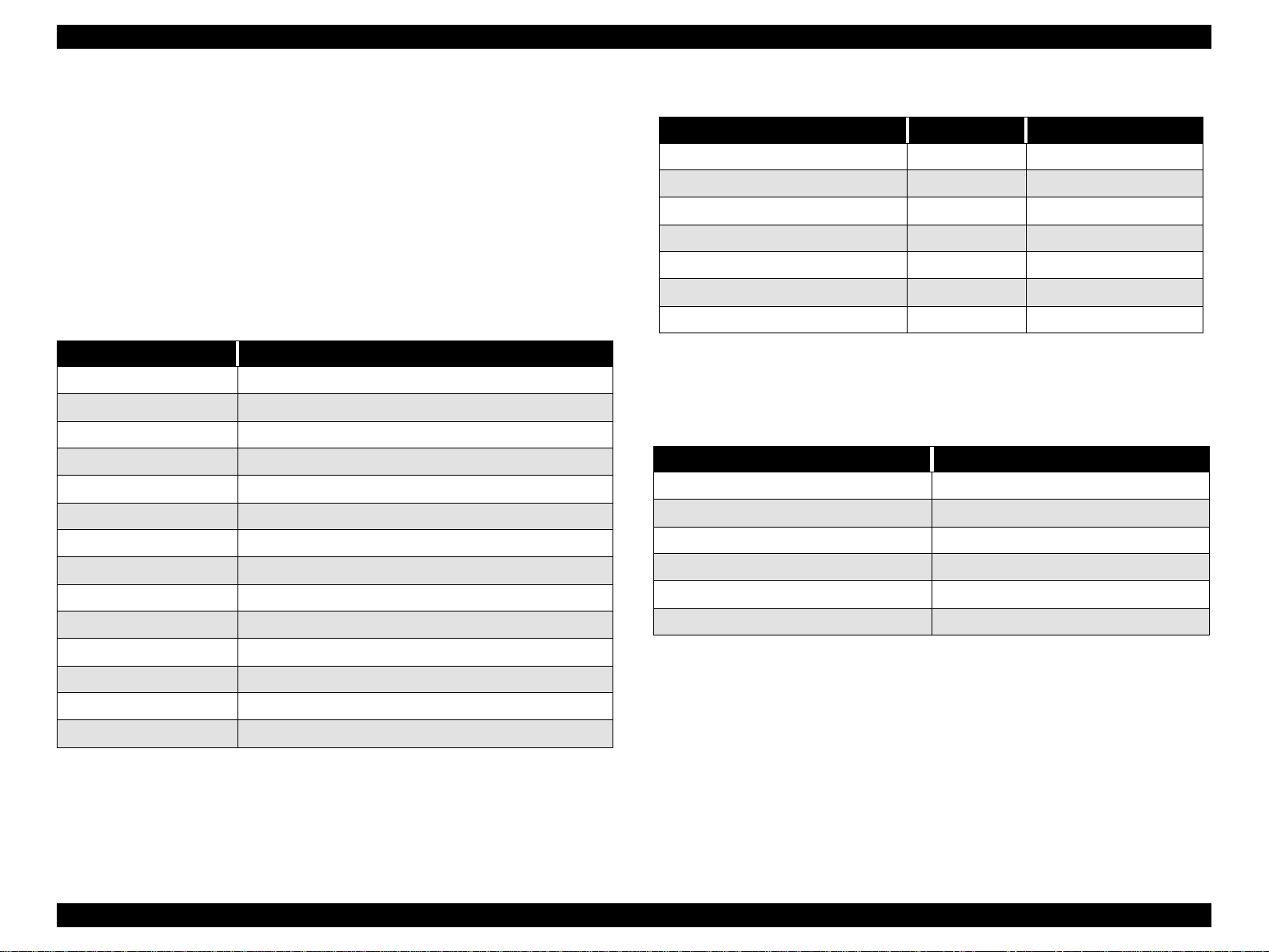

Table 1-4. EPSON Special Paper

Type (US)

Doubleweight Matte Paper

Glossy paper - Photo Wei ght

Premium Glossy Photo Paper

Premium Semigloss Photo paper

Watercolor Paper - Padiant White

Glossy Film

Synthetic Paper

Adhesive Syntheti c Paper

*1: Use at normal room te mperature (15~25°C (59~77°F) 40~60% humi dity)

*2: At the point where the rear edge comes fre e from th e core (app rox. last 3 0 cm.), pr int quality

is no longer guaranteed.

*3: The printable area for roll paper is from the core to the point where it is cut off.

The remaining paper length when the paper is cut off from the roll. (Reference): approx. 30

cm.

610mm x 25m

(24” x 83’)

559mm x 20m

(22” x66.4’)

610mm x 30.5m

(24” x 101.3’)

610mm x 30.5m

(24” x 101.3’)

610mm x 18m

(24” x 59.8’)

610mm x 20m

(24” x 66.1’)

610mm x 45m

(24” x 149.4’)

610mm x 30m

(24” x 99.6’)

Paper Size

(W x H)

Roll Size

2” core,

maximum103mm

external dia meter

Product Description Print Specifications 14

Page 15

EPSON Stylus Pro 7500 Revision c

Cut Sheet Paper: [Papers that can be loaded]

Loading of the following papers into this printer is

possible, but for papers other than the following plain

paper and exclusive paper, feed through characteristics

and print quality are not guaranteed.

• Paper Size: See the table below.

Table 1-5. Specifications of Papers which can be Loaded

Size Name

B2 515 x 728mm ????? 22” x 36”

A4 210 x 297mm ????? 20” x 24”

Super A1 24” x 36” ????? 18” x 22”

A1 594 x 841mm ANSI D 22” x 34”

A2 420 x 59 4mm ANSI C 17” x 22”

Super A3 329 x 483mm ANSI B 11” x 17”

A3 297 x 420mm Letter 8.5” x 11”

Dimensions

(H x W)

Size Name

• Paper Width: Paper length = 297 ~ 728 mm...

0.08 ~ 1.5 mm

Paper Length = 728 ~ 915 mm (36”) ...

0.08 ~ 0.5 mm

*1 There should be no wrinkles, fuzz, tearing or folding, of the paper, etc.

Dimensions

(H x W)

[Plain Paper]

For the following specifications, only the lack of

hindrance for paper feed through is guaranteed.

• Paper Size: See the table below.

Table 1-6. Specifications of Papers which can be Loaded

Size Name

B2 515 x 728mm ????? 22” x 36”

A4 210 x 297mm ????? 20” x 24”

Super A1 24” x 36” ????? 18” x 22”

A1 594 x 841mm ANSI D 22” x 34”

A2 420 x 594mm ANSI C 17” x 22”

Super A3 329 x 483mm ANSI B 11” x 17”

A3 297 x 420mm Letter 8.5” x 11”

Dimensions

(H x W)

Size Name

• Paper Thickness = 0.08 ~ 0.11 mm

• Paper Weight = 64 ~ 90 gf/m

2

• Paper Quality = Plain paper, recycled paper

*1 The paper should be loaded longitudinally.

*2 There should be no wrinkles, fuzz, or tearing, of the paper, etc.

*3 This product should be used in a place with a normal room temperature environment

(Temperature: 15~25°C, Relative humidity: 40~60%).

Dimensions

(H x W)

Product Description Print Specifications 15

Page 16

EPSON Stylus Pro 7500 Revision c

[EPSON Special Papers]

Shown below.

Table 1-7. Specifications of EPSON Special Papers

Size Name

A4 210 x 297mm ¡¡¡–

A3 297 x 420mm ¡ ¡ ¡

Super A3 329 x 483mm ¡¡¡–

A2 420 x 594mm ¡ – – –

LTR 216 x 279mm ¡¡¡–

B 279 x 432mm ¡

C 431 x 558mm ¡

B2 515 x 728mm – – – ¡

¡:Compatible Paper, –: Nonexistent Type of Paper

*1: Guaranteed for Uni-D printing.

*2: Paper that exists oversees only.

*3: The paper should be loaded long itudinally.

*4: There should be no wr inkles, fuzz or tearing of the paper, etc.

Dimensions

(H x W)

Super Fine

*1

*2

*2

Photo Print

Paper 2

*2

¡

–––

Photo

Quality

Glossy Film

*2

*2

¡

Art Board

–

–

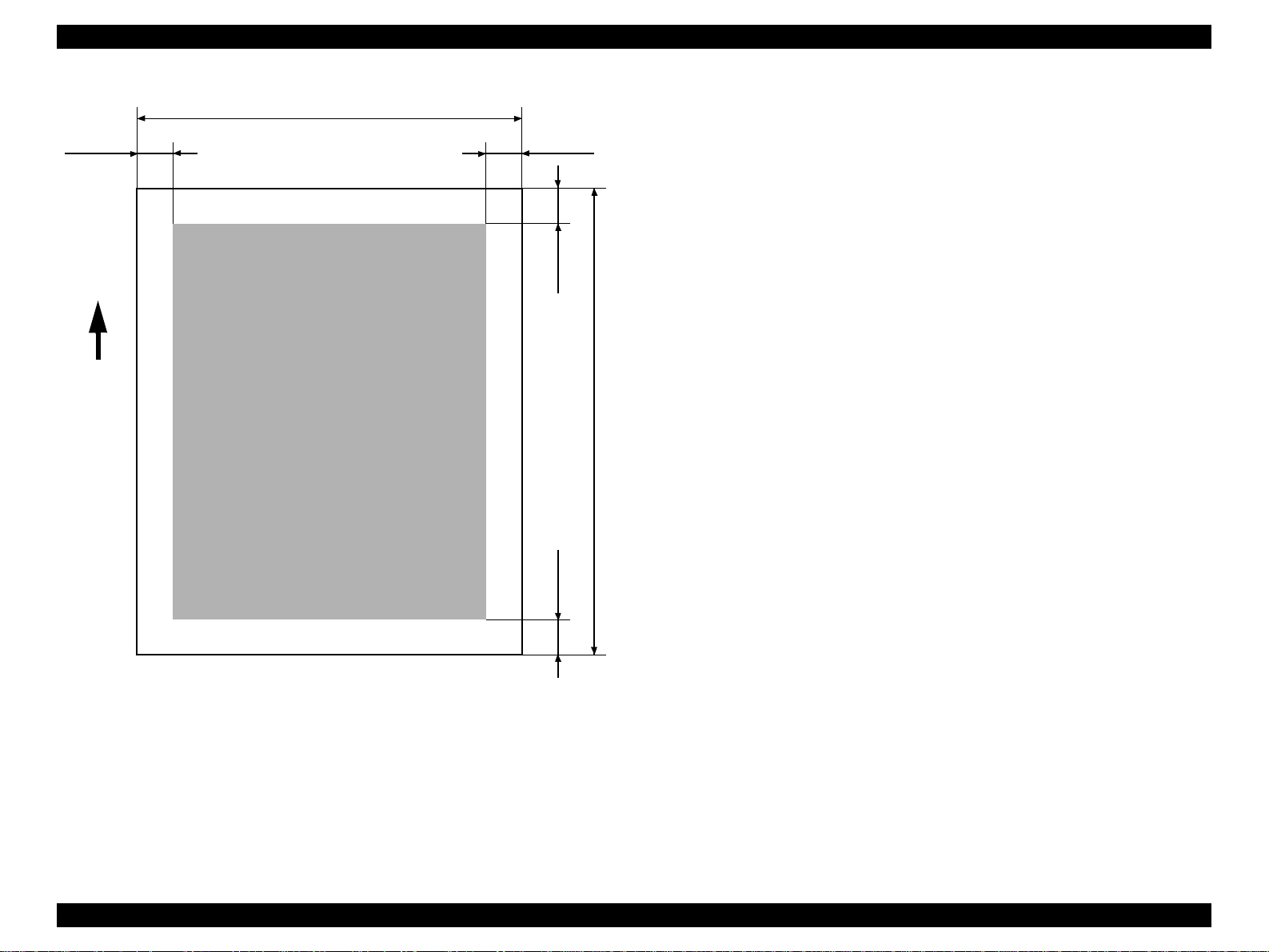

Printable Area: See the table and figure below.

Table 1-8. Printable Area

Heading Roll Paper Cut Sheets

PW (width)

PL (length)

LM (left margin)

TM (top) 3mm/15mm* 3mm

RM (right) 3mm/15mm* 3mm

BM (bottom) 3mm/15mm* 14mm

210 ~ 610mm

(8.27 ~ 24”)

Max. 90m

(298.8’)

3mm/15mm*

(0.12~0.59”)

• The printer detects the paper width when the paper is set.

• Any image that exceeds the detected paper width, or the printable area specified by

the paper size setting, is not printed.

• The size of the margin of roll paper can be changed from the panel as shown below.

Top and Bottom: 15 mm Left and Right: 3 mm / Top, Bottom, Left and Right: 3 mm

/ Top, Bottom, Left and Right: 15 mm.

210 ~ 610mm

(8.27 ~ 24”)

297~915mm

(11.8~36.4”)

3mm

*5: This product should be used in a place with a normal room temperature environment

(Temperature: 15~25°C, Relative humidity: 40~60%).

Product Description Print Specifications 16

Page 17

EPSON Stylus Pro 7500 Revision c

PW

LM

Paper

Feed

Printable Area

RM

TM

PL

BM

Figure 1-1. Printable Area

Paper Set Lever:

• By opening the paper Set lever, paper support is canceled and the paper can be set.

• By closing the paper Set lever, the set paper is held in place and printing is enabled.

• If the paper Set lever is opened during printer operation, the “SECURE PAPER

LEVER” error occurs.

Product Description Print Specifications 17

Page 18

EPSON Stylus Pro 7500 Revision c

INK (DYE INK CARTRIDGE)

Form: Exclusive Ink Cartridge

o

o Ink Colors: Black, Magenta, Light Magenta, Cyan, Light Cyan, Yellow

o Quantity: 110 ml

o Effective Ink Volume: 83.0g or more

o Life:

A1: Approx. 28 pages (720 dpi, when the printed share of the paper surface used

by each color is 40%.)

A1: Approx. 11 pages (720 dpi, when the printed share of the paper surface used

by each color is 100%.)

D Size: Approx. 26 pages (720 dpi, when the printed share of the paper surface

used by each color is 40%.)

A4: Approx. 3800 pages (360 dpi, when the printed share of the paper surface

used by each color is 5%.)

o Dimensions: 25.1 x 141.1 x 105.3 mm (Width x Depth x Height)

o Weight: Approx. 200 g

o Effective Period: Approx. 2 years from manufacture.

o Storage Temperature: See the table below.

.

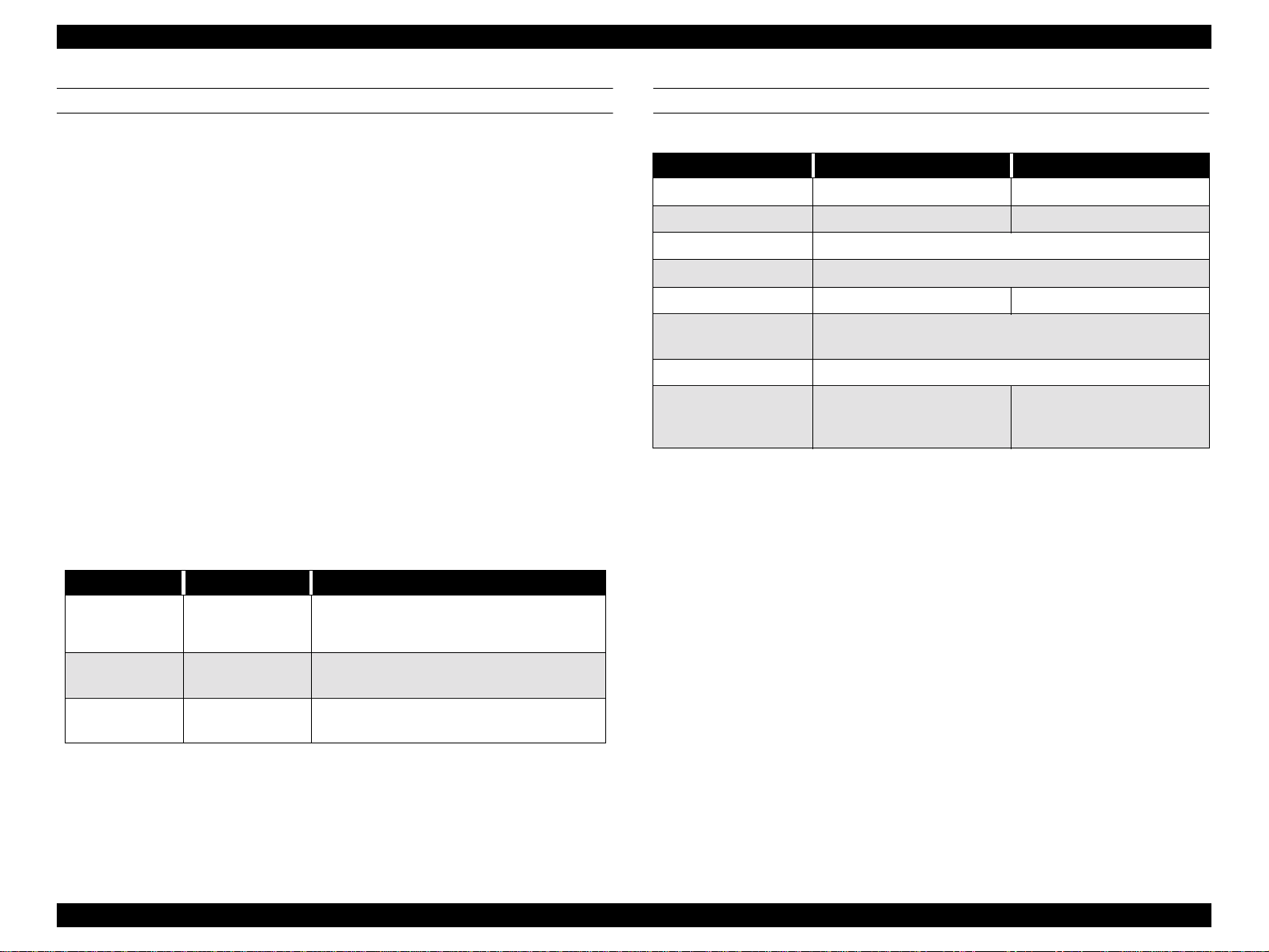

Table 1-9. Ink Cartridge Storage Environment

Condition Temperature Cautions

ELECTRICAL SPECIFICATIONS

Table 1-10. Electrical Specifications

120V Model 220-240V Model

Rated voltage range AC120V AC220~240V

Input voltage range AC90~132V AC198~264V

Rated frequency range

Input frequency range

Rated current 1.0A (Max. 1.6A) 0.5A (Max.0.8A)

Power consumption

Insulation resistance 10MΩ minimum (between AC line and chassis, DC 500 V)

Dielectric strength

standby mode = 15W or less

Energy Star Compliant

AC 1,000V rms per minute or

AC 1,200V rms per second

(between AC line and chassis)

50~60Hz

49.5~60.5Hz

AC 1,500V rms per minute

(between AC line and chassis)

During transport

when loaded

Storage when

packed

When load ed in the

printer

-30~60°C

-30~40°C If 40°C, within 1 month

-20~40°C If 40°C, within 1 m onth

• If 60°C, within 120 hrs.

• If 40°C, within 1 month

Usable ink cartridges: For Stylus Pro 7500 100 ml Ink Cartridge

For Stylus Pro 9500 200 ml Ink Cartridge *1

NOTE: If the above ink cartridge *1) uses, it is necessary to set it according to

1.9 “Ink C artridge Siz e Select.”

Product Description Print Specifications 18

Page 19

EPSON Stylus Pro 7500 Revision c

CONFORMITY/SAFETY APPROVALS

Safety Standards:

US Model UL 1950, CSA 22.2 No. 950

European Model EN60950 (VDE)

EMC:

US Model FCC part 15 subpart B class B

CSA C108.8 class B

European Model EN 55022 (CISPR Pub. 22) class B

EN 61000-3-2

EN 61000-3-3

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

Australian Model AS/NZS 3548 class B

International Energy Star Compliant

(EPA MOU2.1 Category Large Format Printer)

RELIABILITY

Life

o

[Body] 20,000 Pages (A1)

[Print Head] 2 billion dots/nozzle

[Cutter] 2,000 Sheets (A1)

o Periodic Replacement Parts

Maintenance Kit, Stylus Pro 7500 (No. 1054038)

This kit consists of the following parts.

Waste ink absorbent, pump assembly, cap assembly, flushing box assembly, head

cleaner (approximately 12,000 sheets (A1, criterion)

Product Description Print Specifications 19

Page 20

EPSON Stylus Pro 7500 Revision c

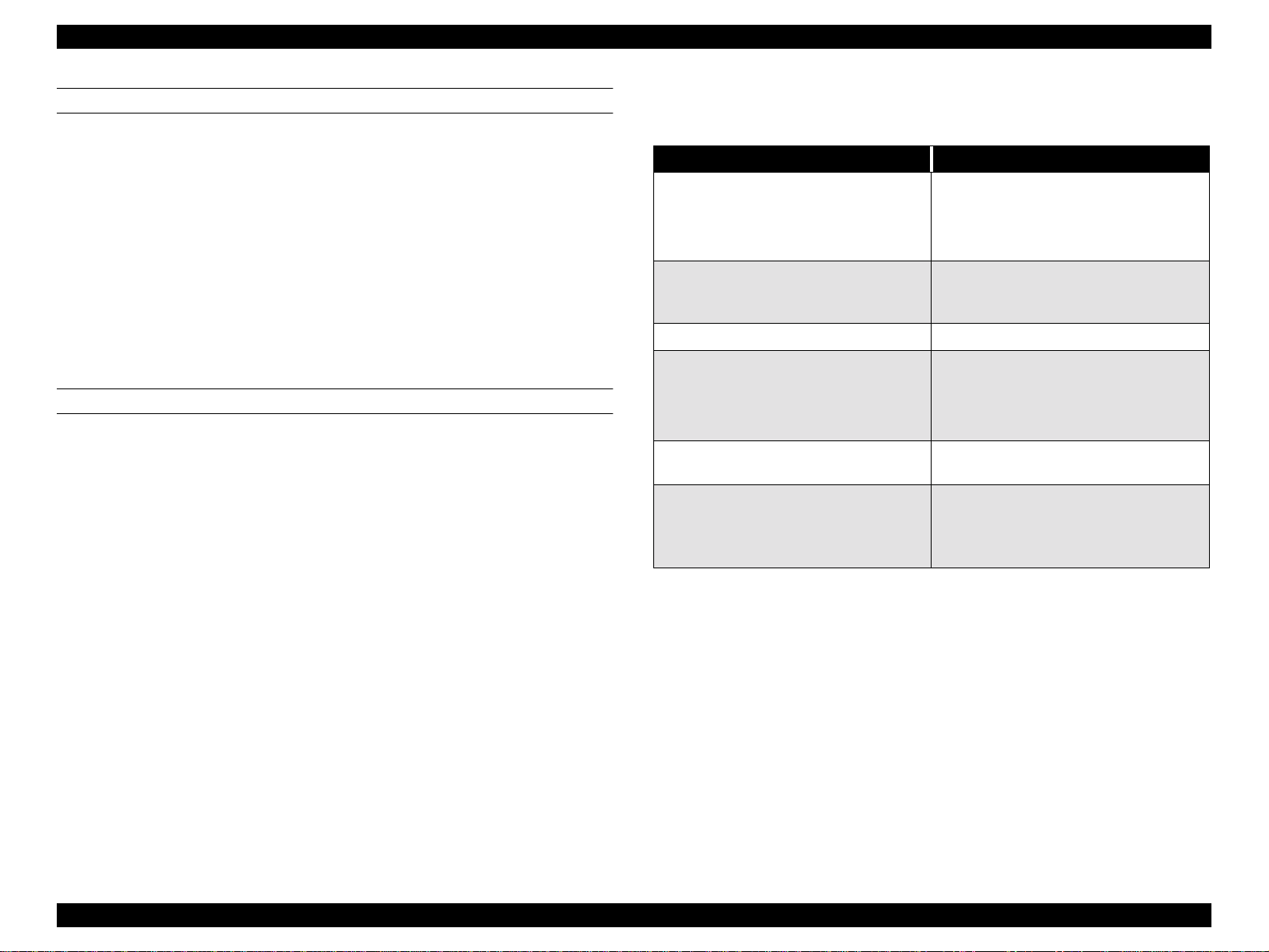

ENVIRONMENTAL CONDITIONS

Temperature&Humidity

o

See the following table.

Table 1-11. Environmental Conditions

Condition Temperature Humidity Notes

Operating

Storage

Transportation

*1 When storing the printer, make sure the printheads are in the home (capped) position. If

necessary switch power on, wait for the printheads to move to the home position, and then

switch power off.

*2 Before transporting the printer, remove the ink cartridges and turn the ink valves screws to

the closed position. Also make sure the printheads are in the home, capped, position. After

transporting the printer, install new ink cartridges.

*3 If the temperature drops below -15°C (5°F), the ink in the cartridges and printheads freezes.

The ink thaws completely after three hours at 25°C (77°F).

*4 If kept in an environment with a temperature of -15°C or lower, the ink inside the print head

and the ink cartridge will freeze. Once ink is frozen, a period of approximately 3 hours in a

25°C environment is required until the ink can be used again

10~35°C

(50~95°F)

-20~40°C

(-4~104°F)

-20~60°C

(-4~140°F)

20~80%

20~85%

5-85%

• Less than a month at 40°C

(104°F)

• Less than 120 hours at 60° C

(140°F)

• With no freezing

.

90

80

70

60

Humidity (%)

50

40

30

20

10

15

10

20

27 30 35

Temperature (°C)

Figure 1-2. Environmental Conditions: Temperature / Humidity

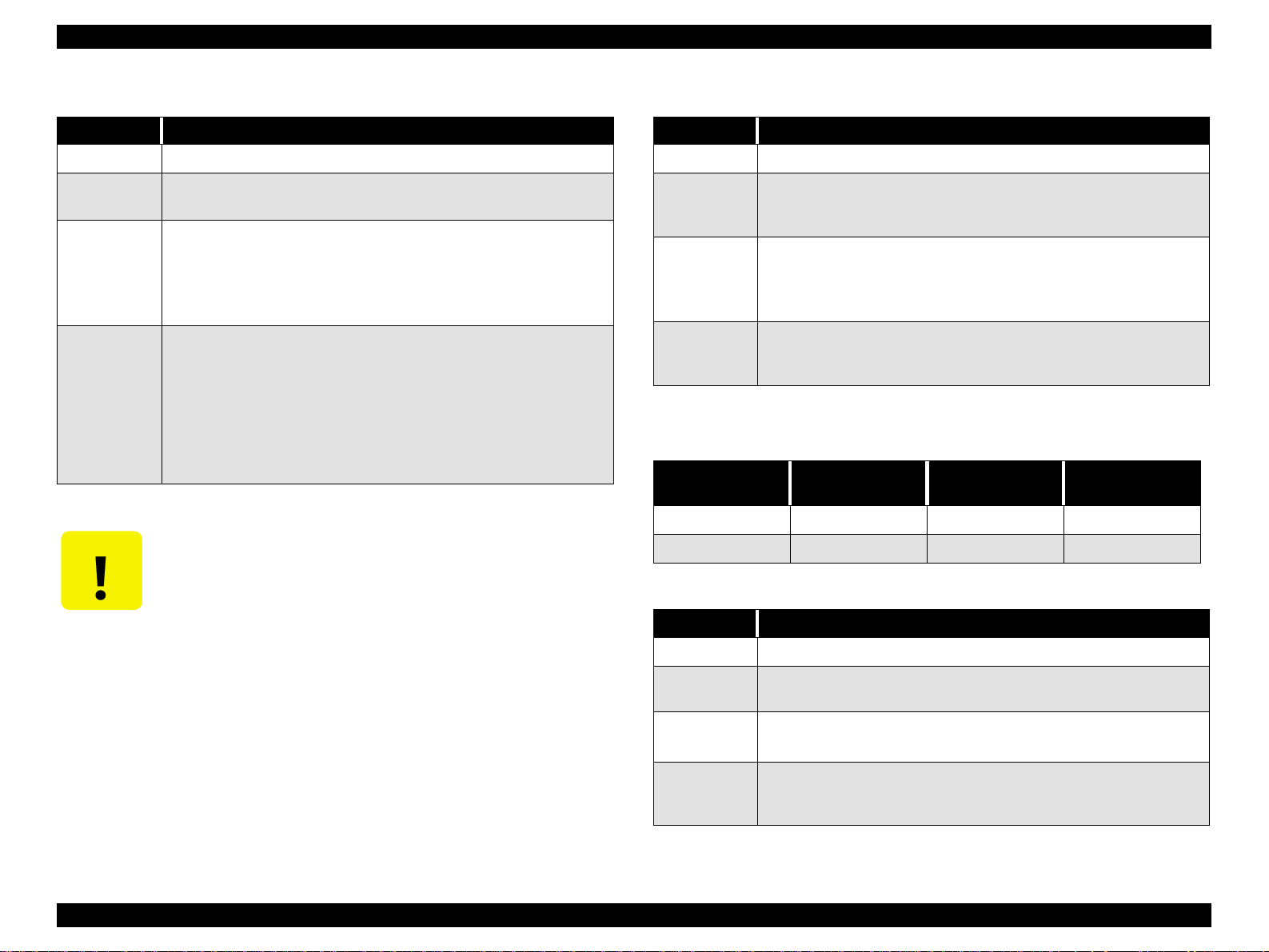

Vibration&Shock

o

See the following table.

Table 1-12. Vibration and Shock

Condition

Operating

Storage

Vibration

Resistance

0.15G

10~55Hz

0.5G

10~55Hz

Shock

Resistance

1G

maximum 1ms

X/Y/Z directions

2G

maximum 2ms

40

Notes

Product Description Print Specifications 20

Page 21

EPSON Stylus Pro 7500 Revision c

CONTROLLER SPECIFICATIONS

CPU

o

Hitachi SH7043 33 Mhz

o ROM

[Program]: CPU internal = 128 KB, External = 1 MB

[Fonts]: Not Loaded

o RAM

10 MB (Fixed)

o Interface

[Standard] IEEE 1284 Interface

USB Interface

Option Type B Interface Card Slot (x 1)

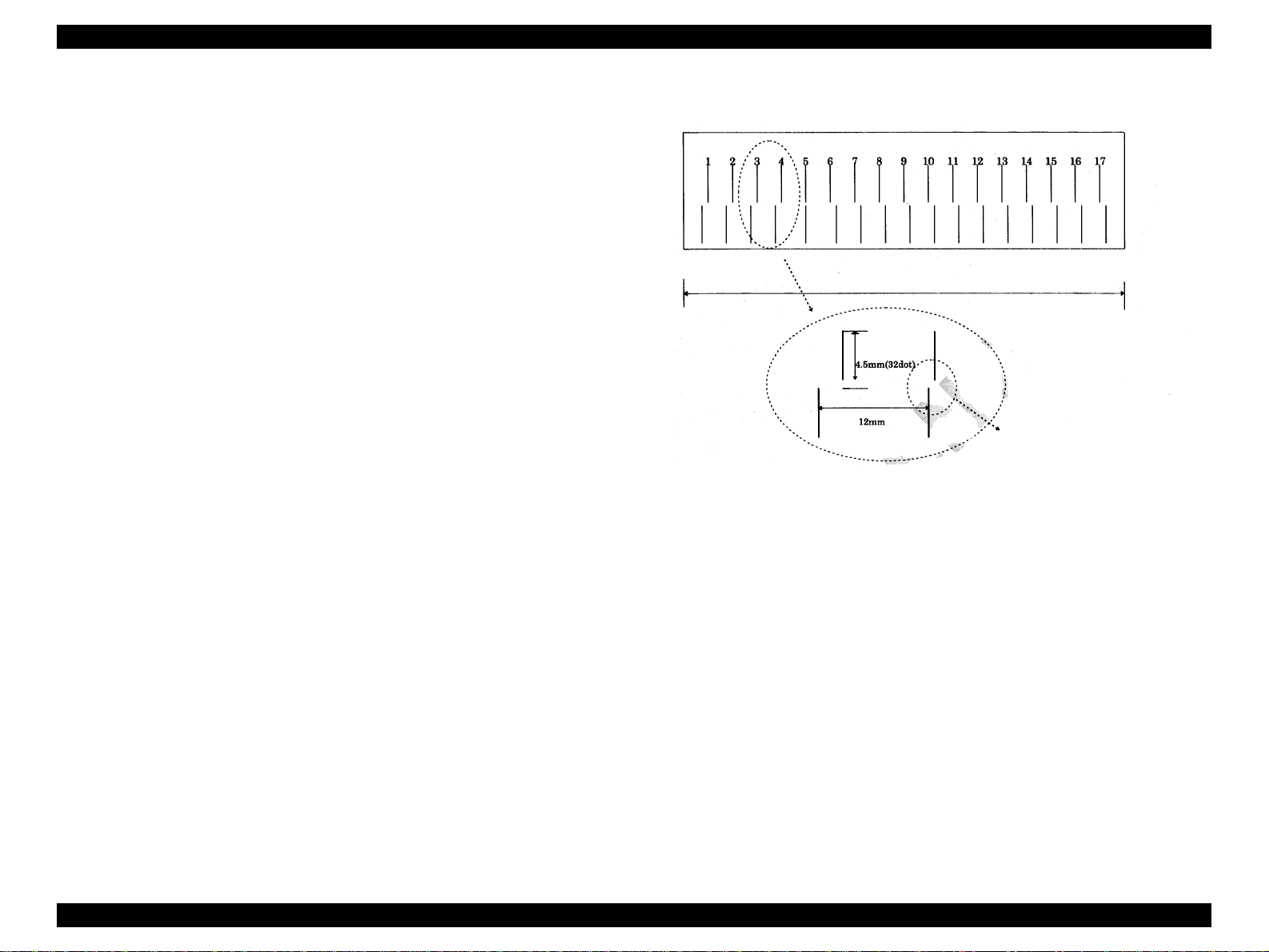

CUTTING SPECIFICATIONS

Mechanical Conditions

o

• Distance between Cutting Position and Cutter Marks

L1 = 47.5 mm

• Shortest cutting length L2 during 3-stage cutting = 100 mm

* (Paper width detection = OFF and) during manual cutting, L2 = 47.5 mm

• Shortest cutting length L3 = 20 mm

Cutting conditions and cutting system: See the table below.

Table 1-13. Cutting Conditions and Cutting System

Cutting Conditions Cutting System

Initial cut (Manual cutting when the paper is

on the top edge sensor an d the lever is down,

and the “Cut/Eject” button is pressed.)

Auto cutting after printing is finished and reset

is activated during printin g.

Manual cutting during printing. Same as above.

Manual cutting while in the normal standby

state.

Manual cutting after paper feed in the forward

paper feed direction.

Manual cutting after prin ting wit h Auto cutt ing

OFF and with Auto cutting ON.

When paper width sensor = ON.

4-stage cutting with the paper fed distance L1.

When paper width sensor = OFF.

3-stage cutting with the paper fed distance L2.

3-stage cutting. However, if (L+) is shorter

than L2, 3-stage cutting after feeding the paper

distance L2.

When paper width sensor = ON.

4-stage cutting with the paper fed distance L1.

When paper width sensor = OFF.

3-stage cutting with the paper fed distance L2.

Same as above.

If L1 + (L+) _ L2, 3-stage cutting with the

paper fed distance L1.

If L1 + (L+) < L2, 3-stage cutting with the

paper fed distance L2 – (L+).

• Let the distance the paper is pulled out from the cu t position by printing and paper

feed in the forward paper feed direction be (L+).

• Let the distance the paper is pulled back from the cut position by reverse paper

feed be (L–).

• L1 should be greater than L3.

Product Description Print Specifications 21

Page 22

EPSON Stylus Pro 7500 Revision c

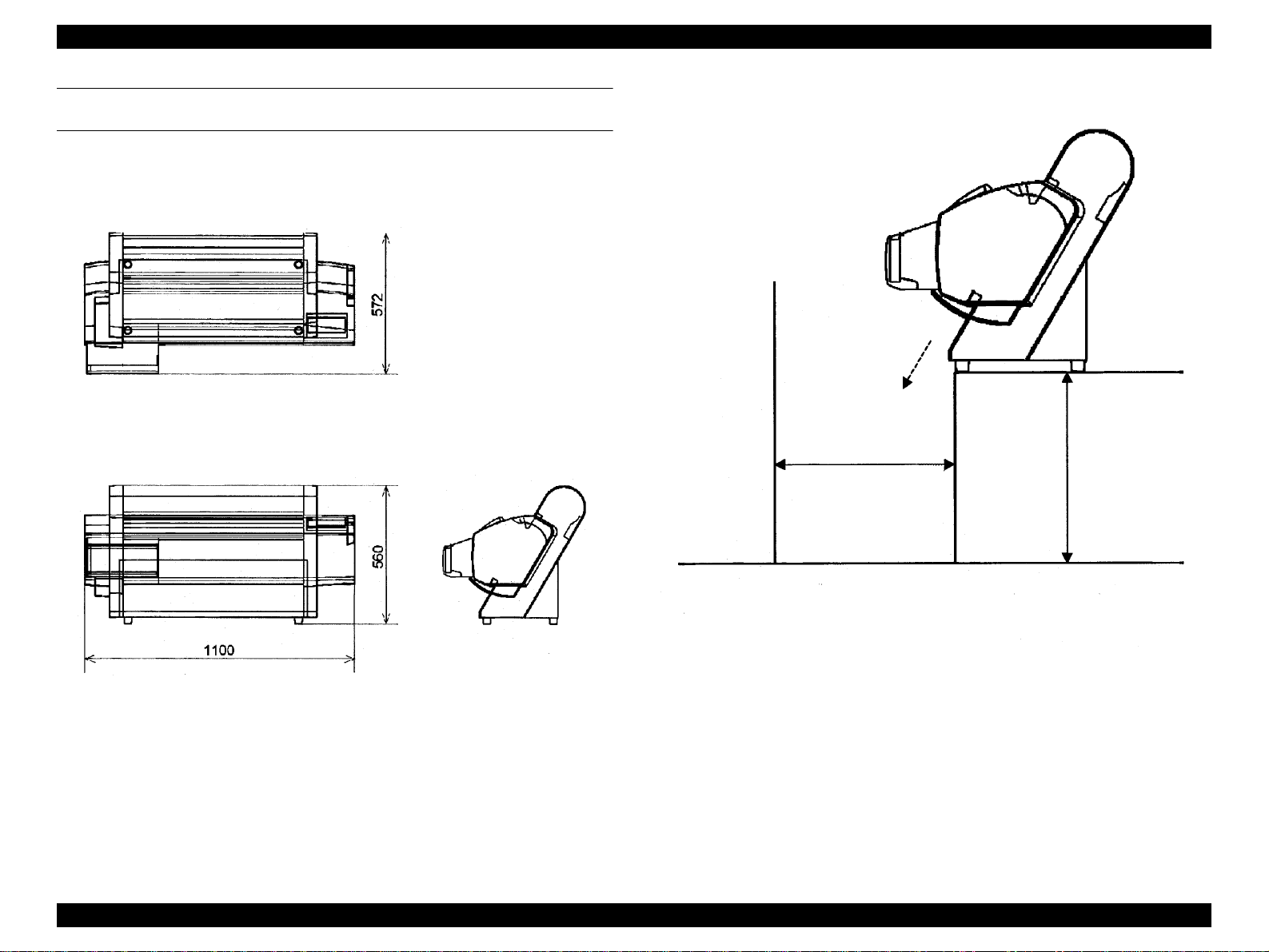

Installation Environment.

EXTERNAL DIMENSIONS / INSTALLATION ENVIRONMENT / WEIGHT

External Dimensions

o

1100 x 572 x 560 (Width x Depth x Height)

See the figure below.

o

See the figure below.

Other Obst acles

Paper Eject

Direction

Figure 1-3. External Dimensions

60 cm or more

Distance from

obstacles in front of

printer

(floor)

* Consideration should be given so that printed matter falling during paper

Eject is not damaged.

* The distance between the rubber feet on the front of the printer and the edge

of the desk should be insignificant.

60 ~ 80 cm

Height from floor.

Figure 1-4. Installation Environment

Weight

o

Approx. 43.5 kg (Not including consumables and the optional stand.

Product Description Print Specifications 22

Page 23

EPSON Stylus Pro 7500 Revision c

1.3 Interfaces

This printer is equipped with a parallel and a USB interface as standard equipment. As an

option, it can also be equipped with a Type B Interface.

1.3.1 Parallel Interface

COMPATIBILITY MODE

Data transfer format: 8-bit parallel, IEEE-1284 interchangeable

o

o Synchronization Method: External supply / by Strobe pulse.

o Handshake: By BUSY and /ACKNLG signals.

o Logic Level: TTL compatible level

(IEEE-P1284 Level 1 device)

o Applicable Connector: 57-30360 (Amphenol) 36-pin or comparable

product.

* It is recommended that the shortest possible

interface cable be used.

o Signal Arrangement and Signal Names: See the table below.

Product Description Interfaces 23

Page 24

EPSON Stylus Pro 7500 Revision c

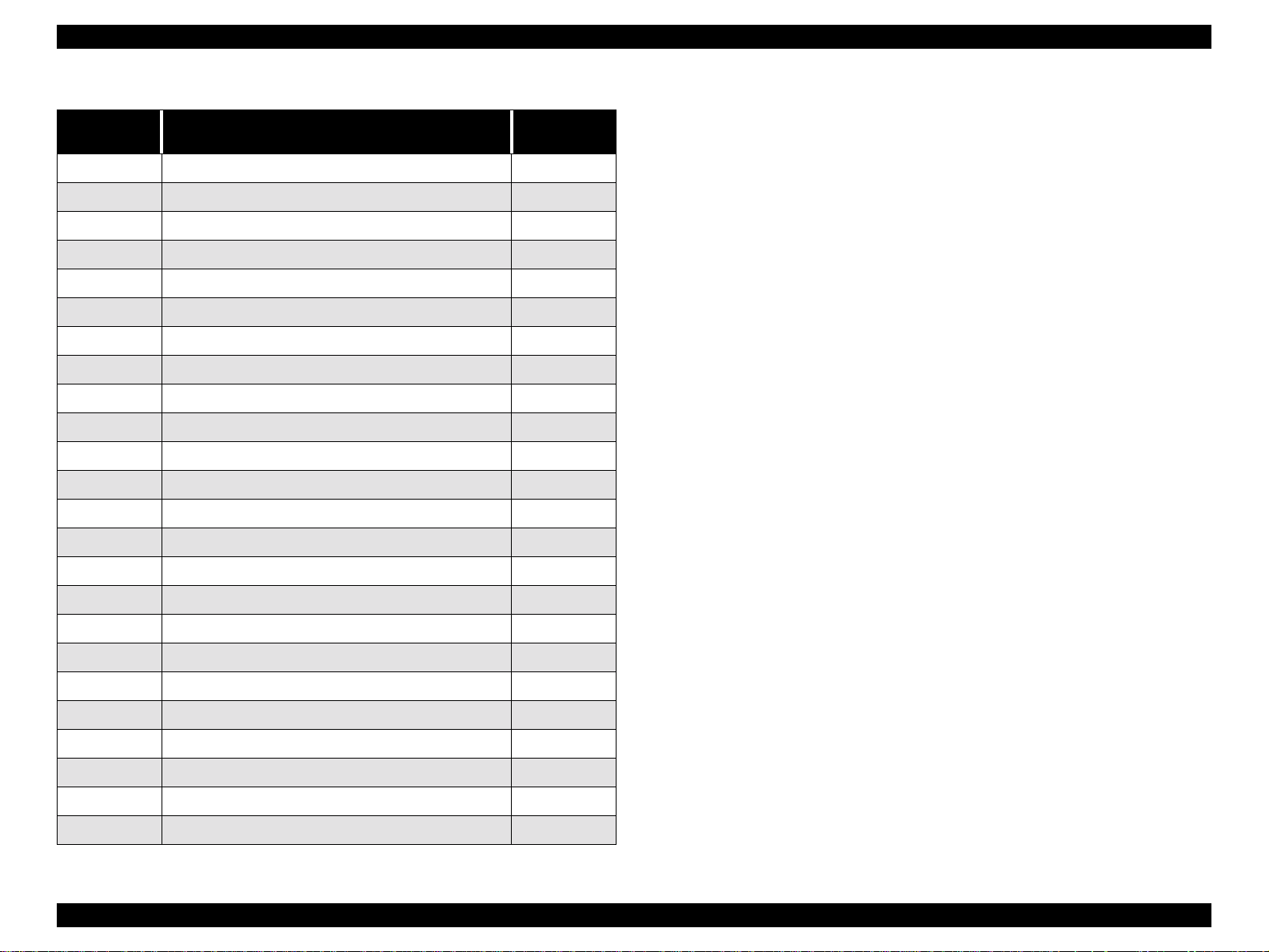

Table 1-14. Parallel Interface (Compatibility Mode)

Pin No.

1 /STROBE 19

2 DATA1 20

3 DATA2 21

4 DATA3 22

5 DATA4 23

6 DATA5 24

7 DATA6 25

8 DATA7 26

9 DATA8 27

10 /ACKNLG 28 Printer

Signal

Name

Return

Pin No.

Machine

Machine

Machine

Machine

Machine

Machine

Machine

Machine

Machine

Source Function

Center

Center

Center

Center

Center

Center

Center

Center

Center

Strobe puls e (When Low, data can be read.

When High, data cannot be received from the

PC.)

Data Signal

When Low, it indicates that data processing is

finished and preparation for reception of the

next data is completed.

Table 1-14. Parallel Interface (Compatibility Mode)

Pin No.

32 /ERROR 29

36 /SLIN 30 ----

18 Logic H ---- ----

35 +5V ---- ----

17

16,33,

19-30

15,34 NC ---- ----

Signal

Name

Chassis

GND

GND ---- ----

NOTE: If it is active in the Low state, a ” /” is included with the signal name.

Return

Pin No.

---- ----

Source Function

Center

Machine

When Low, it indicates that the printer is in an

error state.

Not used.

Normally High Level 3.9 K ohms, pulled up to

5 V.

Normally High Level 1.0 K ohms, pulled up to

5 V.

Chassis GND.

Signal GND.

Not connected.

11 BUSY 29 Printer

12 PE 28 Printer

13 SLAC 28 Printer

14 /AFXT 30

31 /INIT 30

Center

Machine

Center

Machine

When High, it indicat es th at the state is such

that data reception is impossible.

When High, it indicates that the printer has no

paper.

Normally High Level 1.0 K ohms, pulled up to

5 v.

Not used.

At a Low pulse with a pulse width of 50_ or

greater, it is set in the initialization state.

Product Description Interfaces 24

Page 25

EPSON Stylus Pro 7500 Revision c

-

*1 The return side means the twisted pair return and is conn ected to the signal grou nd level.

Furthermore, when interfacing, a twisted pair cable should definitely be used for each signal

and the return side should definitely connected. Also, use of a shielded cable and

connection to the chassis ground of the center machine and the printer, respectively are

effective countermeasures against noise.

*2 All the interface conditions are TTL level standard conditions. The rise and fall time of

each signal is 0.2 _s or less.

*3 For details on the timing of each signal, see the “Data Transmission Timing” diagram in

the figure below.

*4 There must not be any data transfer with disregard of the /ACKNLG or BUSY signals.

(Data transfer to this printer must be performed when/ACKNLG is confirmed or when

BUSY is in the “LOW” state.)

*5 If appropriate character codes are set for DATA 1~8 of the interface connector (as

opposed to “1” for GND open and “0” for short circuit), and BUSY and /STROBE are

connected, an external device is not used and a printing test can be performed, which

includes the interface circuits.

*6 The printer is in the following states when the PE signal line enters the A ssert state (“L”

Level).

• Out of paper error occurring (ST:00 ER:06 state)

• Other paper errors occurring (ST:00 ER:0E, 12, 13, 14, 15, 16 state)

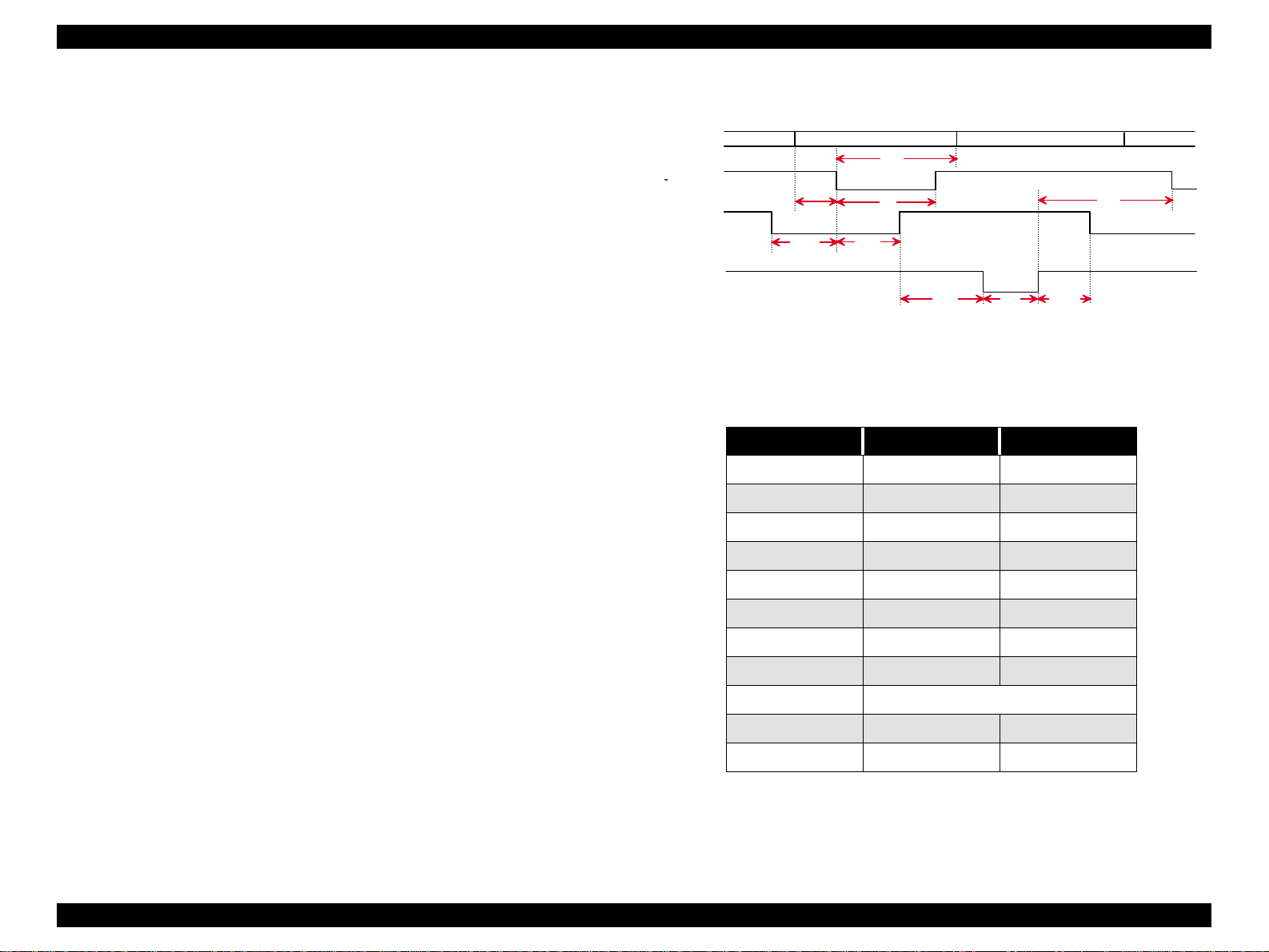

o Data Transmission Timing

DATA

STROBE

BUSY

-ACKNLG

tsetup

tready

Figure 1-5. Data Transmission Timing

Table 1-15. Timing Chart Parameter

Parameter Minimum Maximum

tsetup 500 ns thold 500 ns tstb 500 ns tready 0 -

data byte n

thold

ts tb

tbusy

tre p ly ta c k

data byte n+ 1

tnext

tnbusy

tbusy - 500 ns

tt-out* - 120 ns

tt-in** - 200 ns

treply 0 tack Typical 2 us

tnbusy 0 tnext 0 -

Product Description Interfaces 25

Page 26

EPSON Stylus Pro 7500 Revision c

NIBBLE MODE

Data Transfer Format: IEEE-1284 Nibble Mode

o

o Synchronization System: Compatible with IEEE-1284 Specifications

o Handshake: Compatible with IEEE-1284 Specifications

o Logic level: TTL level (IEE-P1284 Level 1 device)

o Data transfer timing: Compatible with IEEE-1284 Specifications

o Expansion Request Data: If the expansion request data value is 00H or 04H,

the request is received. The meanings of these

values are as shown below.

00H:Request to carry out reverse channel transfers

in the Nibble mode.

04H:Request to return the ID of the device using

the Nibble mode for reverse channel

transfers.

o Device ID: [00H] [47H]

MFG: EPSON

CMD: ESCPL2, BDC;

MDL:Stylus [SP] Pro [SP] 7500

CLS: PRINTER

DES: EPSON [SP] Stylus [SP] Pro [SP] 7500;

*: [SP] is code 20<H>.

o See the table below for the signal layout and signal names.

Product Description Interfaces 26

Page 27

EPSON Stylus Pro 7500 Revision c

Table 1-16. Parallel Interface-Nibble Mode

Pin

No.

1 HostClk 19 I Host side clock si gn a l.

2-9 Data1-8 20-27 I Data signal

10 PtrClk 28 O Printer side clock signal

11

12

13

14 HostBusy 30 I Host side BUSY signal.

31 -INIT 30 I Not used.

32

36 1284-Active 30 I 1284 Active signal.

18 Logic-H ---- O

35 +5V ---- O

Signal Name

PtrBusy/

DataBit-3,7

AckDataReq/

DataBit-2,6

Xflag/DataBit1,5

-DataAvail/

DataBit-0,4

Return

Pin

29 O

28 O

28 O

29 O

In/

Out

Printer side BUSY signal and data bit 3 or data bit

7 in the reverse channel.

ACK data request s ig na l and data bit 2 or 6 in the

reverse channel.

Xflag signal and data bit 1 or 5 in the reverse

channel.

Data available signal and data bit 0 or 4 in the

reverse channel.

Normally High Level 3.9 K ohms, pulled up to 5

V.

Normally High Level 1.0 K ohms, pulled up to 5

V.

Functional Description

ECP MODE

Data Transfer Format: IEEE-1284 ECP Mode

o

o Synchronization System: Compatible with IEEE-1284 Specifications

o Handshake: Compatible with IEEE-1284 Specifications

o Logic level: TTL level (IEE-P1284 Level 1 device)

o Data transfer timing: Compatible with IEEE-1284 Specifications

o Expansion Request Data: If the expansion request data value is 10H or 14H,

the request is received. The meanings of these

values are as shown below.

10H:Request to carry out transfers in the ECP

mode.

14H:Request to return the ID of the device using

the ECP mode.

o Device ID: [00H] [47H]

MFG: EPSON

CMD: ESCPL2, BDC;

MDL:Stylus [SP] Pro [SP] 7500

CLS: PRINTER

DES: EPSON [SP] Stylus [SP] Pro [SP] 7500;

*: [SP] is code 20<H>

o See the table below for the signal layout and signal names.

17 Chassis GND ---- ---- Printer chassis ground.

16,33,

9-30

15,34 NC ---- ---- Not used.

GND ---- ---- GND for twisted pair return.

NOTE: In (I) and Out (O) refer to the dirction of signal flow from the printer’s

point of view.

Product Description Interfaces 27

Page 28

EPSON Stylus Pro 7500 Revision c

Table 1-17. Parallel Interface (ECP Mode)

Pin

No.

1HostClk19

2 DATA1 20

3 DATA2 21

4 DATA3 22

5 DATA4 23

6 DATA5 24

7 DATA6 25

8 DATA7 26

9 DATA8 27

10 PeriphClk 28 Printer Transfers data from the printer to the host.

Signal

Name

Return

Pin

Source Function

Center

Machin

e

Center

Machin

e

Center

Machin

e

Center

Machin

e

Center

Machin

e

Center

Machin

e

Center

Machin

e

Center

Machin

e

Center

Machin

e

Transfers data or address information from the

host to the printer.

Each signal indicates parallel data information

from the first bit to the 8th bit. “HIGH” is shown

by a “1” in the data and “LOW” is shown by a “0”

in the data. These show the address from the host

to the printer or from printer to the host, or data.

Table 1-17. Parallel Interface (ECP Mode)

Pin

No.

12

13 Xflag 28 Printer

14 HostAck 30

31

32

18

35 +5V ---- Printer

17 Chassis ---- O Printer chassis ground.

16,33,

19-30

15,34 NC ---- ---- Not used.

36

NOTE: If it is active in the Low state, a ” /” is included with the signal name.

Signal

Name

nAckRever

se

nReverseR

equest

nPeriphRe

quest

PeriphLogi

c H

GND ---- ---- Ground for twisted pair return.

1284Active

Return

Pin

28 Printer

30

29 Printer This signal is used for generating host interr u pts.

29 Printer

30

Source Function

Drives the pr inter in the Low state and ap p r oves

nReverseRequest.

X-flag signal and data bit 1 or data bit 5 in the

reverse channel.

The printer uses this signal for reverse direction

Center

Machin

e

Center

Machin

e

Center

Machin

e

flow control. Also, this signal offers data bit 9,

used in judging whether the in forma tion out put in

the forward direction data signals contains

command information or data information.

Sets this signal “LOW” to switch the channel to

the reverse direction.

Normally High Level 3. 9 K ohms, pulled up to 5

V.

Normally High Level 1. 0 K ohms, pulled up to 5

V.

1284 active signal. “HIGH” while in the ECP

mode.

The printer uses this signal for forward direction

flow control. Also, this signal offers data bit 9,

11 PeriphAck 29 Printer

used in judging whether the info rmation out put in

the reverse direction data signals contains

command information or data information.

Product Description Interfaces 28

Page 29

EPSON Stylus Pro 7500 Revision c

1.3.2 USB Interface

o Standard :“Universal Serial Bus Specifications Revision

1.0”

“Universal Serial Bus Device Class Definition for

Printing Devices Version 1.0”

o Bit rate :12Mbps (Full speed device)

o Data encoding :NRZI

o Adaptable connector :USB series B

o Suggested cable length :2 meters

o Device ID <00H><4EH>

MFG: EPSON

CMD: ESCPL2, BDC

MDL: Stylus[SP] Pro[SP] 7500

CLS: PRINTER

DES: EPSON [SP] Stylus [SP] Pro [SP] 7500

o Signal Arrangement and Signal Names: See the table below.

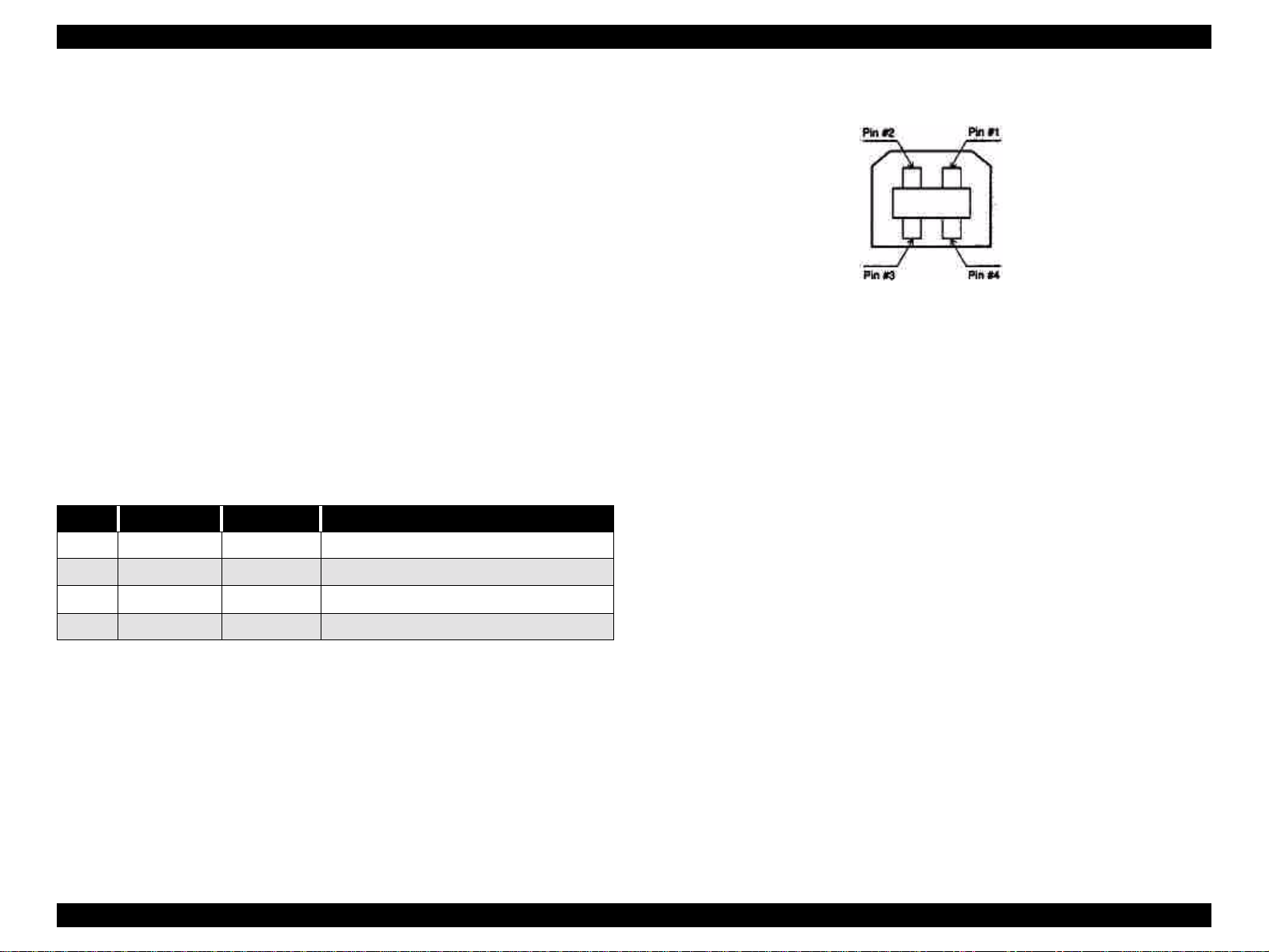

Table 1-18. USB Interface

Pin no. Signal name In/Out Description

1 VCC - Cable power, max. power consumption is 100mA

2 -Data bi-directional data

3 +Data bi-directional data, pull up to +3.3V via 1.5K Ω resistor

4 Ground - Cable ground

Figure 1-6. Pin Assignment

NOTE: When connecting to the USB interface, e sure to set the parallel interface

item in the printer’s settings menu on “PARA.I/F = COMPAT”

Product Description Interfaces 29

Page 30

EPSON Stylus Pro 7500 Revision c

1.3.3 TYPE-B Optional Type B Interface

o Installable Option: A Type B interface (Level 2, 1200 mA type) can be

used.

Product Description Interfaces 30

Page 31

EPSON Stylus Pro 7500 Revision c

1.3.4 Supplementary Items

RECEIVING BUFFER OPERATION

When receiving data via the parallel interface or Type B interface while in a state where no

error has occurred (including the Pause state), if the available capacity of the buffer drops to

4 KB or less, the printer receives at 1 byte/sec. and prevents the host from issuing a time

out.

If the available capacity of the buffer becomes 8 KB or higher, 1 byte/sec. reception is

canceled and reception stops when the available capacity is 32 bytes or less. When the

available capacity becomes 1K-byte or higher, reception at 1 byte/sec. is resumed.

INTERFACE SELECTION

It is possible to switch between the manual fixed selection function or auto selection

function to select the parallel, USB or optional interface.

However, if the USB interface is connected, it becomes impossible to use the parallel

interface, For this reason, only one of these interfaces, either the parallel interface or the

USB interface, can be connected to the host computer and they cannot be used in

combination.

o Manual Fixed Selection:

One interface, the Parallel/USB interface, or the optional interface, can be

selected.

o Auto Selection Function:

After the power is turned on, the interface from w hich data are first received is

selected. After that, if a predetermined period of time (fixed at 10 seconds) passes

during which the reception of data is stopped, the printer enters the idle state (a

state where no interface is selected), then selects the interface from which it first

receives data next.

o Concerning interface selection and interface state:

• When an interface other than the parallel/USB interface is selected, the parallel

interface enters the BUSY state. At this time, the LH signal goes “L.” The

meaning of LH = L is that the power is cut off. That is, it means that the 1284

interface cannot respond. Therefore, a hos t computer requesting reverse

transmission must first check LH. In addition, the USB interface is in a state where

it sends a NACK response and refuses to receive data.

• When an interface other than the optional interface is selected, the OFF-LINE bit

is set in the Main Status Register (MNSTS).

• After the printer has been initialized, or when in the idle state (with no interface

selected), with the parallel interface in the ready state, the USB interface in the

state where it does not send a NACK response, set the OFF-LINE bit of the Main

Status Register (MNSTS) for the optional interface.

• The interrupt signal, like the /INIT signal of the parallel interface, is disregarded

while that interface is not selected and while in the Nibble mode or ECP mode.

INITIALIZATION

This printer is initialized by the following three methods.

1. Hardware Initialization

This is the method of initialization that is carried out when the power is turned on.

<Initialization Operation>

• Printer mechanism initialization

• Input data buffer cleared.

• Print buffer cleared.

• Setting of default values.

2. Software Initialization

Initialization is performed by executing the Initialize command (ESC@).

<Initialization Operation>

• Print buffer cleared.

• Setting of default values.

3. Panel Initialization

This is the initialization operation when the Pause button is pressed for 2 seconds or

longer, or when the /INIT signal is input.

<Initialization Operation>

• Paper is ejected (in the case of roll paper, the printed portion is skipped and if the panel

setting’s paper select is set on Auto cut, the paper is cut, and if the cutter is OFF, the

Product Description Interfaces 31

Page 32

EPSON Stylus Pro 7500 Revision c

paper is not cut).

Print heads capped.

Input data buffer cleared.

Print buffer cleared.

Setting of default values.

4. Initial Settings

The initial settings which are set when the printer is first turned on are as shown below.

Also, as for panel settings, default settings and items which can be saved as remote

commands, the values for those items stored in memory become the default values.

Page Position:The current paper position is made the top of page position

Line Feed Amount::1/6 inch

Right Margin Positio:Column 237

Left Margin Position:Column 1

Character Pitch:10 CPI

Print Mode:Text Mode (Non-raster graphics mode)

Product Description Interfaces 32

Page 33

EPSON Stylus Pro 7500 Revision c

1.4 Control Panel

This section describes the control panel, the buttons, the lights, and the way you make

settings.

Figure 1-7. Control Panel

BUTTONS

The function of each button in the operation panel is as shown in the following table.

Table 1-19. Operation Panel Butt on Functions

Button (Operation

when pressed)

Power Turns the power on and off. – –

Pause(rESET)

SelecType

Cut/Eject (Enter)

Function (Single)

• Toggles between Print

Ready and Print Not Ready

• Reset (Press for 2 seconds.)

• Starts the panel setting

mode.

• Cutter replacement menu

(Press for 5 seconds.)

*3

• Cut sheet paper

Paper Eject.

• Roll paper auto cut

(Feeds paper from the cutter

mark to the cutter position

and cuts it.)

• Roll paper cutter OFF

(Feeds paper the height of

the head.)

Function (During panel

setting)

–

Selects Setting Menu

(Major category)

Fixes setting va lues and

stores them in memory.

Function (+

Power ON)

Starts the

Maintenance

Mode

Ink quantity

setting mode

–

Paper Feed (Paper

Feed +)

Paper Feed (Paper

Feed –)

Paper Source

(Setting Items)

Cleaning

Paper feed (Reverse) *1 Adds to the set value. –

Paper feed (Forward) *2

Selects the paper type.

Full head cleaning (press for 2

seconds).

Subtracts from the set

value.

Selects the setting item

(Minor category)

– –

–

–

Product Description Control Panel 33

Page 34

EPSON Stylus Pro 7500 Revision c

Table 1-19. Operation Panel Button Functions

Button (Operation

when pressed)

Paper Sourc e +

Eject + Paper Feed _-----

Paper Sourc e +

Eject + Cleaning

*1 For 2 seconds after the button is pressed, the paper is fed at 1.27 mm/sec. (5.0 cps). If the

button is pressed for 2 seconds longer, the paper is fed at 12.7 mm/sec. (50. 0 cps).

However, the paper can be reversed up to a maximum of 200 mm when the button is pressed

once.

*2 For 2 seconds after the button is pressed, the paper is fed at 1.27 mm/sec. (5.0 cps). If the

button is pressed for 2 seconds longer, the paper is fed at 12.7 mm/sec. (50. 0 cps).

*3 During the ink dry ing ti me, ink dryin g is inte rrupt ed and th e spec ified opera tion is perform ed.

Function (Single)

-----

Function (During pane l

setting)

Function (+

Power ON)

Starts

Maintenance

Mode 2.

Firmware

Reload Mode

LED INDICATORS

The functions of the LED’s located in the operation panel are as shown in the table below.

Table 1-20. Operation Panel LED

LED Display Status

Operate (Green)

Paper Out (Red)

Pause (Green)

Ink Out (Y) (Red)

Ink Out (LM)

(Red)

Ink Out (LC) (Red)

Ink Out (M) (Red)

Ink Out (C) (Red)

Ink Out (K) (Red)

•On

• Flashing

•On

• Flashing

•On

• Flashing

•Off

•On

• Flashing

•On

• Flashing

•On

• Flashing

•On

• Flashing

•On

• Flashing

•On

• Flashing

• Power On state, reset, timer IC reset / NVRAM Clear

• Processing data, processing power off, fatal error

• Out of paper, ro ll paper end, different roll paper/cut

sheet paper settings, cleaning impo ssible error, reset,

timer IC reset / NVRAM clear

• Paper jam, paper cutting error, p aper skew error, pape r

recognition error, cut sheet Eject failure, fatal error

• Pause state, reset timer IC reset / NVRAM clear

• Ink drying time, ink processing underway, fatal error

• Panel setting mode, pause state, other errors

• Ink out, no cartridge, reset, timer IC reset / NVRAM

clear

• Ink low (Y), fatal error

• Ink out, no cartridge, reset, timer IC reset / NVRAM

clear

• Ink low (LM), fatal error

• Ink out, no cartridge, reset, timer IC reset / NVRAM

clear

• Ink low (LC), fatal error

• Ink out, no cartridge, reset, timer IC reset / NVRAM

clear

• Ink low (M), fatal error

• Ink out, no cartridge, reset, timer IC reset / NVRAM

clear

• Ink low (C), fatal error

• Ink out, no cartridge, reset, timer IC reset / NVRAM

clear

• Ink low (K), fatal error

Product Description Control Panel 34

Page 35

EPSON Stylus Pro 7500 Revision c

Table 1-20. Operation Panel LED

LED Display Status

•On • Auto cut selected.

reset, timer IC reset/NVRAM clear

Roll Auto Cut

Roll Cutter Off

Sheet (Green)

• Flashing • Roll paper not set or roll paper and cut sheet sizes are

different.

Fatal error

•On • Cut off selected.

reset, timer IC reset/NVRAM clear

• Flashing • Roll paper not set or roll paper and cut sheet sizes are

different.

Fatal error

•On • Cut sheet paper printing mode.

reset, timer IC reset/NVRAM clear

• Flashing • Roll paper not set or roll paper and cut sheet sizes are

different.

Fatal error

Product Description Control Panel 35

Page 36

EPSON Stylus Pro 7500 Revision c

1.5 Panel Display

Messages corresponding to the printer status, error occurrence and other states are

displayed in the operation panel LCD. The messages displayed are shown in the following

table. Furthermore, the messages are shown in their display processing priority order, from

the highest priority messages to the lowest.

Table 1-21. List of Panel Display Messages

Display Content

SERVICE REQ nnnnnnnn *2 Fatal error occurrence state.

Indicates an error occurrence state that requires

MAINTENANCE REQ nnnn *3

WAIT *1

POWER OFF Executing power off processing.

INK OUT Ink out.

COVER OPEN Cover open state.

OPTION I/F ERROR A Type B interface error occurred.

TRANSPORT PREP

SECURE PAPER LEVER The paper support lever was released during operation.

LOAD xxx PAPER

maintenance by a service man (such as th e end of the

waste ink pad’s serv ice life).

Resetting the timer IC.

Clearing NVRAM.

Resetting.

Executing the ink sequence.

Executing initializatio n processing.

Processing paper initialization.

Executing ink discharge sequence for transport

between users.

The roll paper and cut sheet paper settings are

different.

Table 1-21. List of Panel Display Messages

Display Content

RELOAD PAPER

REMOVE PAPER Impossible to carry out cleaning.

NO INK CARTRIDGE The ink cartridge is not set.

PRESS PAUSE BUTTON

PAUSE Pause state (standby)

INK DRY xx MIN Ink is drying (“xx min.” = time remaining)

INK LOW

INK CHARGING nnn% Initial filling in progress *4

PRINTING *1 Processing data (printing operation in prog ress)

READY *1 Printer is ready to receive data

PAPER OUT

RESET Reset processing in progress

TURN PWR OFF AND ON

*1:If “Widen” is selected in the “Platen Gap” item in the panel settings, a “H ” is displaye d in the

20th column.

*2:See Chapter 3, “Troubleshooting”

*3: See Chapter 3, “Troubleshooting”

*4:“Initial filling in progress” displays the processing progress conditions. Initial filling ends at

the point when this value becomes 100%.

Paper Eject failed. (in the case of cut sheets)

Paper recognition error.

Waiting for the paper initialization processing start

trigger.

Remaining ink is low. (replacement preparations are

necessary)

Paper not set state

End of roll paper.

Instruction to turn the power on again. (Turn it off,

then turn it on again.)

PAPER JAM A paper jam occurred.

PAPER NOT CUT A paper cutting error with the auto cut settings.

PAPER NOT STRAIGHT Paper is being fed at a slant.

LOAD PAPER The paper support lever is released.

Product Description Panel Disp lay 36

Page 37

EPSON Stylus Pro 7500 Revision c

1.6 Panel Setting Menu

When the printer is not printing, pressing the “SelecType” button changes the pr inter to the

panel setting mode and automatically disables printing while the printer is being set. The

panel setting mode includes the fo llowing m enu items. Each time the “SelecTy pe” button is

pressed, the setting menu changes to the next menu in the sequence, which is then displayed

in the LCD.

To return to the Pause state, press the “SelecType” button until “Pause” is displayed in the

LCD panel or press the “Pause” button.

o Menu Selection: “SelecType” B utton

o Menu Item Setting: “Paper Source” Button

Mode End: “Pause” Button

Table 1-22. Panel Setting Menu Items

Menu Item Panel Display

Printer Setting Menu PRINTER SETTING MENU

Test Print Menu TEST PRINT MENU

Printer Status Menu PRINTER STATUS MENU

User Paper Sett ing Menu P AP ER CONFIG. MENU

Cutter Replacement Menu CUTTER REPLACE MENU

Gap Adjustment Menu HEAD ALIGNMENT MENU

Setting items for each of the above setting menus, with their contents, are shown below.

Product Description Panel Setting Menu 37

Page 38

EPSON Stylus Pro 7500 Revision c

1.6.1 Printer Setting Menus

In the printer setting menus, i t is possib le to chang e the s et values in th e settin g item s in the

following table. Each setting is made by operation of the following panel buttons.

o Printer setting menu selection: See the panel setting menu procedure.

o Printer setting item selection: “Paper Source” button

o Change the set value: “+” or “–” button

o Set the settings: “Enter” button

o Mode End: “Pause” button

A list of setting items in the printer setting menu is shown below.

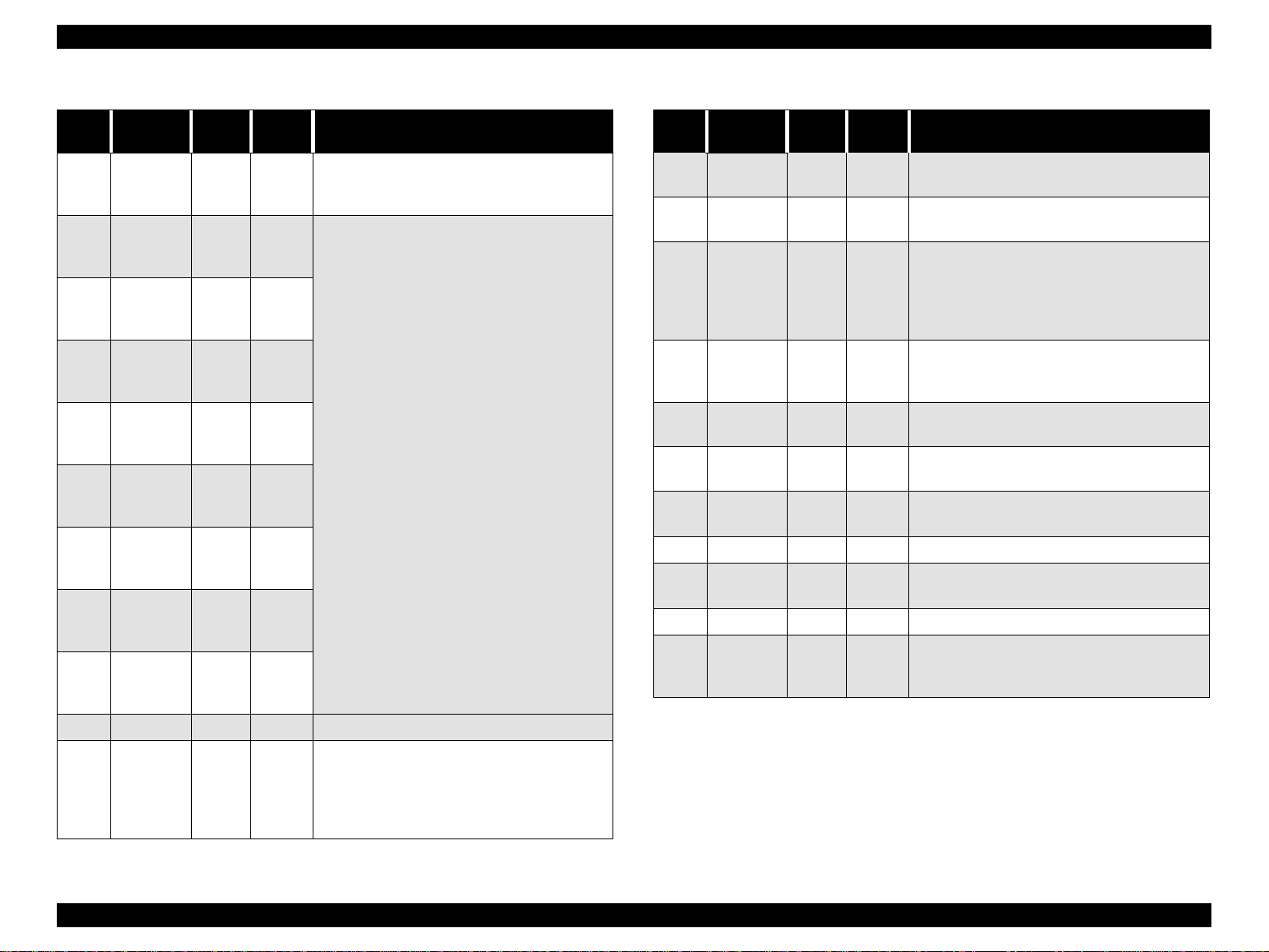

Table 1-23. List of Setting Items in the Printer Setting Menu

Display Setting Value Contents

PLATEN GAP

PAGE LINE

INTERFACE

PARA. I/F

CODE PAGE

AUTO *1

WIDE

ON*2

OFF

AUTO *3

PARA./USB

OPTION

COMPAT

ECP

RC437*5

PC850

Adjusts the platen gap. (Ordinarily, this is done

automatically.)

While in the “Roll Paper Cutter Off” selection

state, this sets whether or not to print a cutting

line (solid line) at the bottom edge of the sheet

when the roll paper is ejected.

Interface receiving setting (Auto select or fixed

on a single interface)

Sets the parallel interface receiving rate.

(Ordinarily, it is used with the “Compatible”

setting.)

Character code set selection.

(PC437: Expanded graphics / PC850: multi-

lingual.

Table 1-23. List of Setting Items in the Printer Setting Menu

Display Setting Value Contents

PAPER SIZE CHK

PAPER ALIGN CHK

INIT. PANEL EXEC.

ON*7

OFF

ON*8

OFF

Perform / Don’t perform automatic sensing of

the paper width.

Perform / Don’t perform automatic sensing of a

paper skew error.

Returns the panel setting co nte n ts to the ir initial

values.

Sets the margin on roll paper *2

Vertical 15 mm: Leaves 15 mm on the left and

right edges of the printable area, and a 3 mm

margin at the top and bottom. / Leaves a 3 mm

margin at the top, bottom, left and right. / 15