Page 1

ualPlateReader AF2200

E

Register your instrument!

www.eppendorf.com/myeppendorf

N)manual

Eppendorf® PlateReader AF2200

Software manual

Version 1.0.4

Page 2

©

Copyright

2013 Eppendorf AG, Hamburg. No part of this publication may be reproduced without the prior

permission of the copyright owner.

Trademarks

Eppendorf

Microsoft

®

and the Eppendorf Logo are registered trademarks of Eppendorf AG, Hamburg, Germany.

®

, Windows® and Excel® are registered trademarks of Microsoft Corporation, Redmond, WA,

USA.

Pentium

PicoGreen

®

is a registered trademark of Intel Corporation, Santa Clara, CA, USA.

®

, RiboGreen®, OliGreen® and NanoOrange® are registered trademarks of Molecular Probes,

Inc., Eugene, OR, USA.

®

Apo-ONE

Corning

Greiner

und CellTiter-Blue® are registered trademarks of Promega Corporation, Madison, WI, USA.

®

is a registered trademark of Corning Incorporated, New York, NY, USA.

®

and μClear® are registered trademarks of Greiner Labortechnik GmbH, Frickenhausen, Germany.

Lumox™ is a trademark of Greiner Bio-One GmbH, Frickenhausen, Germany.

Nunclon

®

is a registered trademark of Nunc A/S, Roskilde, Denmark.

LumiNunc™ und FluoroNunc™ are trademarks of, Nunc A/S, Roskilde, Denmark.

Trademarks are not marked in all cases with ™ or

6141 905.200-01/022013

®

in this manual.

Page 3

Table of contents

®

Eppendorf

PlateReader AF2200

English (EN)

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Danger symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Danger levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Area of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 CE Declaration for Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Install software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Starting PlateReader AF 2200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.1 Connected Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2 Simulated Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3

4 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Explorer bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Workflow Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4 Info bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.5 Menu Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.5.1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.5.2 Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.3 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5.4 Instrument Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5.5 Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.6 Plate List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Defining measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 Plate Size – Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2 Defining Endpoint Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3 Defining Multimode Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4 Defining Kinetic Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5 Indenting and Releasing Program Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page 4

Table of contents

®

4

Eppendorf

PlateReader AF2200

English (EN)

6 Predefined methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Method selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Method description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2.1 Nucleic acid quantification (UV 260 nm microvolume) . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2.2 Nucleic acid quantification (UV 260 nm with factor) . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2.3 Nucleic acid quantification (UV 260 nm with standards) . . . . . . . . . . . . . . . . . . . . . . . 56

6.2.4 Nucleic acid quantification (Fluorescence 485/535 nm with standards) . . . . . . . . . . . 59

6.2.5 Protein quantification BCA, Bradford, Lowry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.6 Protein quantification (NanoOrange 485/595 nm with standards) . . . . . . . . . . . . . . . . 63

6.2.7 Cell viability (CellTiter-Blue Assay). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.2.8 Cell viability (Apo-ONE Caspase-3/7 Assay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3 Method (measurement) parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4 Method results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4.1 Contents of the raw data sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4.2 Contents of the blanking sheet (factor methods only) . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.4.3 Content of the results sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1 General Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.2 Troubleshooting Absorbance mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.3 Troubleshooting Fluorescence mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.4 Save method scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.5 Save method results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8 Evaluation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.1 Nucleic acid quantification UV 260 nm with factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2 Nucleic acid and Protein quantification with standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.3 Protein quantification Nano Orange 485/595 nm with standards . . . . . . . . . . . . . . . . . . . . . . . 75

8.4 Cell viability CellTiter-Blue Assay, Cell viability Apo-ONE Caspase-3/7 Assay . . . . . . . . . . . . . 75

Page 5

Operating instructions

®

Eppendorf

PlateReader AF2200

English (EN)

1 Operating instructions

1.1 Using this manual

Read this operating manual completely before using the device for the first time. Please also note the

operating instructions for the accessories, if applicable.

This operating manual is part of the product. Thus, it must always be easily accessible.

Enclose this operating manual when transferring the device to third parties.

If this manual is lost, please request another one. For the current version, please refer to our webpage

www.eppendorf.com/worldwide

(international) or www.eppendorfna.com (North America).

1.2 Danger symbols and danger levels

The safety instructions in this manual appear with the following danger symbols and danger levels:

5

1.2.1 Danger symbols

Biohazard Explosion

Electric shock Toxic substances

Hazard point Material damage

1.2.2 Danger levels

DANGER Will lead to severe injuries or death.

WARN ING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

Page 6

Operating instructions

Eppendorf

6

English (EN)

®

PlateReader AF2200

1.3 Symbols used

Symbol Meaning

Handling

1.

2.

• List

Text Name of fields in the software

Actions in the specified order

Useful information

Page 7

Product description

®

Eppendorf

PlateReader AF2200

English (EN)

2 Product description

2.1 Area of Application

The Software is an easy-to-use and flexible tool, which gives the user complete control over the Eppendorf

PlateReader AF2200.

The Software presents the raw data for further use in Excel, offering excellent features for research

purposes.

2.2 System requirements

To install the software, the system must meet the following minimum requirements:

Component Minimum Recommended

7

Computer Windows XP (32-bit):

Windows-compatible computer

with a Pentium-compatible

processor, 1 GHz

Windows Vista (32-bit):

Windows-compatible computer

with a Pentium-compatible

processor, 1 GHz

Windows 7 (32- or 64-bit):

Windows-compatible computer

with a Pentium-compatible

processor, 1 GHz

Operating system Windows XP (32-bit) SP3

Windows Vista (32-bit)

Windows 7 (32-bit)

Windows 7 (64-bit)

Memory Windows XP: 512 MB RAM

Windows Vista (32-bit): 1 GB

RAM

Windows 7 (32-bit): 1 GB RAM

Windows 7 (64-bit): 2 GB RAM

2 GHz (dual-core)

2 GHz (dual-core)

2 GHz (dual-core)

Windows XP (32-bit) SP3

1 GB RAM

2 GB RAM

2 GB RAM

3 GB RAM

Memory requirements 700 MB RAM 1 GB RAM

Monitor Super VGA Graphics 1280 x 1024

Screen resolution 1024 x 768 -

Color depth 256 -

Mouse Microsoft-compatible mouse or

similar device

-

Page 8

Product description

Eppendorf

8

English (EN)

Component Minimum Recommended

Communication 1x USB 2.0 2x USB 2.0

®

PlateReader AF2200

1x RS232 (serial)

Drive, graphic card 1xCD-ROM drive

Windows Vista:

DirectX 9 graphic and 32 MB

graphics memory (for Home Basic

version)

DirectX 9 graphic and 128 MB

graphics memory with WDDM

support for all other versions.

Windows 7:

DirectX 9 graphic with WDDM

driver 1.0 or higher.

.NET Microsoft .NET Framework 2.0

If this version is not available, it

will be installed by the installation

and update program using any

available installation of the .NET

Framework.

Windows Installer 3.1

If this version is not available, it

will be installed by the installation

and update program.

Microsoft Excel Excel 2002 (only compatible for

script-based messages without

data reduction). Excel 2002 is not

compatible for methods.

Excel 2003, 2007 and 2010

(32-bit)

The Starter Edition is not

supported.

-

-

-

-

2.3 CE Declaration for Europe

PlateReader AF2200 Software is not a CE-marked product. Therefore no CE declaration for Europe is

available.

Page 9

3 Installation

3.1 Install software

You must have administrator rights to install the software.

Install the software before connecting the PlateReader AF2200 to the computer.

®

Eppendorf

1. Insert the CD with the software into the CD-ROM

drive.

2. Start the installation by executing the Setup file.

PlateReader AF2200

Installation

English (EN)

9

3. Press the OK button to continue the installation.

4. Press the Next button to continue the installation.

The Next button can be used to confirm the current installation step and continue the

installation.

The Back button brings you back to the previous installation step.

The Cancel button can be used to abort the installation.

Page 10

10

Installation

Eppendorf

®

English (EN)

PlateReader AF2200

5. Define the user.

6. Select language.

7. Define the installation directory.

Page 11

®

Eppendorf

PlateReader AF2200

English (EN)

8. Press the Install button to confirm the settings

and start the installation.

9. Press the Finish button to complete the

installation.

Installation

11

The PlateReader AF2200 can now be connected to the computer.

Page 12

12

Installation

Eppendorf

English (EN)

®

PlateReader AF2200

3.2 Starting PlateReader AF 2200

The Software can be used either with a connected instrument or in simulation mode.

3.2.1 Connected Instrument

Install the software before connecting the instrument to the computer.

1. Connect the instrument to your computer and switch the instrument on.

2. Start the program by selecting Programs > Eppendorf > PlateReader AF2200 from the Windows Start

menu.

3. The following dialog box appears:

4. Select the instrument name in the dialog box.

5. Click the Button OK to start the software.

3.2.2 Simulated Instrument

1. Start the program by selecting Programs > Eppendorf > PlateReader AF2200 from the Windows Start

menu.

2. The following dialog box appears:

3. Select the checkbox Show simulated instruments.

4. Select the demo instrument to connect to from the Instrument Name list.

5. Click the Button OK to start the software.

Page 13

Overview

1

2

3

456

English (EN)

Eppendorf

®

PlateReader AF2200

4Overview

4.1 Main Window

The main window of the software is used to set up workflows. Each workflow is easily created by dragging

and dropping the process steps into a sequence according to the application. The application workflow is

then visible to the user in the workflow pane and can be saved for future use.

Each process step, that is each program element, can be copied and pasted and moved to the desired

position in the workflow.

Data can be exported easily to Windows compatible formats (Excel).

Start the software and connect an instrument as described in the previous chapter or select the simulation

mode. The Software main window appears.

13

1Menu bar

2Workflow pane

3Info bar

4 Controls

5 Status bar

6Explorer bar

Page 14

14

Overview

Eppendorf

English (EN)

®

PlateReader AF2200

4.2 Explorer bar

The Explorer bar is divided into different sections. Each section contains program elements used to create

an individual workflow.

1. Create a workflow either by double-clicking the selected program element or by dragging and dropping

it into the workflow pane.

The following program elements are available:

Methods Eppendorf prdefined methods

Labware Plate

Pattern

Well

Mode Absorbance

Fluorescence Intensity

Actions Temperature

Shaking

Move Plate

Kinetic Kinetic Cycle

Kinetic Condition

Miscellaneous Comment

User Intervention

Wait for Temperature

Wait Time

Incubation

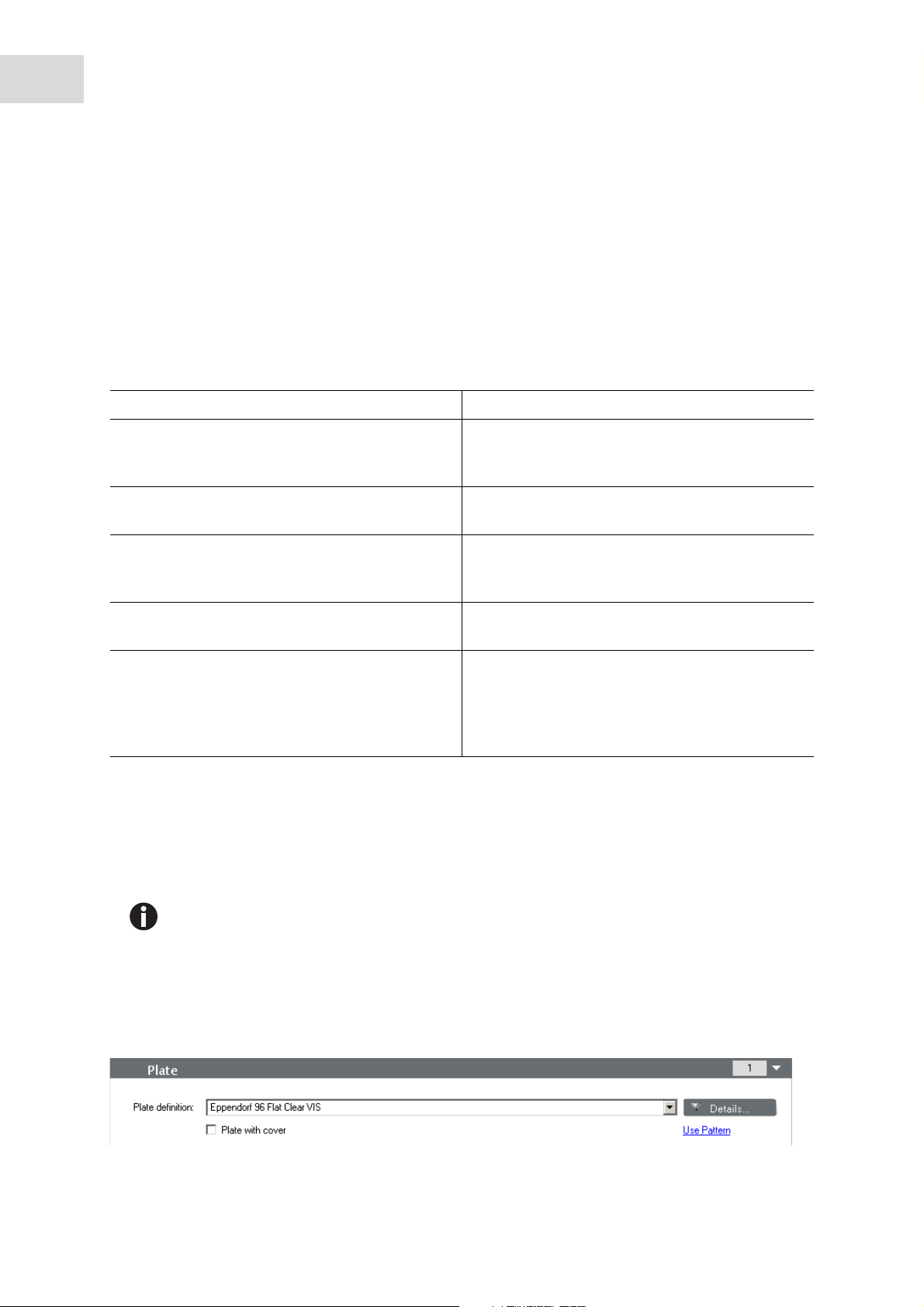

4.2.1 Labware

Plate

The Plate program element is used to select a plate format from the Plate definition drop-down list.

For accurate measurements it is essential that plate and pattern selected in the software

correspond to the plate and the pattern you use for measuring.

1. Click Details to see further information on the selected plate.

2. If a plate with cover is used, select the Plate with cover checkbox.

3. The measurement will automatically measure all selected wells of the plate. If you want to measure a

specific well or a range of wells, click the link Pattern in the lower right corner.

Page 15

®

Eppendorf

PlateReader AF2200

English (EN)

4. Under Details it is possible to apply a filter so that only certain plate definition files are shown.

Pattern

The Pattern program element is displayed according to the selected plate format (number of wells).

1. To measure individual wells, click the desired well or to measure a range of wells drag a frame around

the desired range.

Overview

15

Independent Pattern

1. Clicking on Zoom, the plate preview can be zoomed and independent parts of the plate can be selected

2. A second range of wells can be selected by pressing the Control key on the keyboard and dragging a

frame over the wells to be selected.

Page 16

16

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

Well

Use the Well program element to perform measurements well by well. Without this program element, all

measurement steps are done plate-wise.

4.2.2 Mode

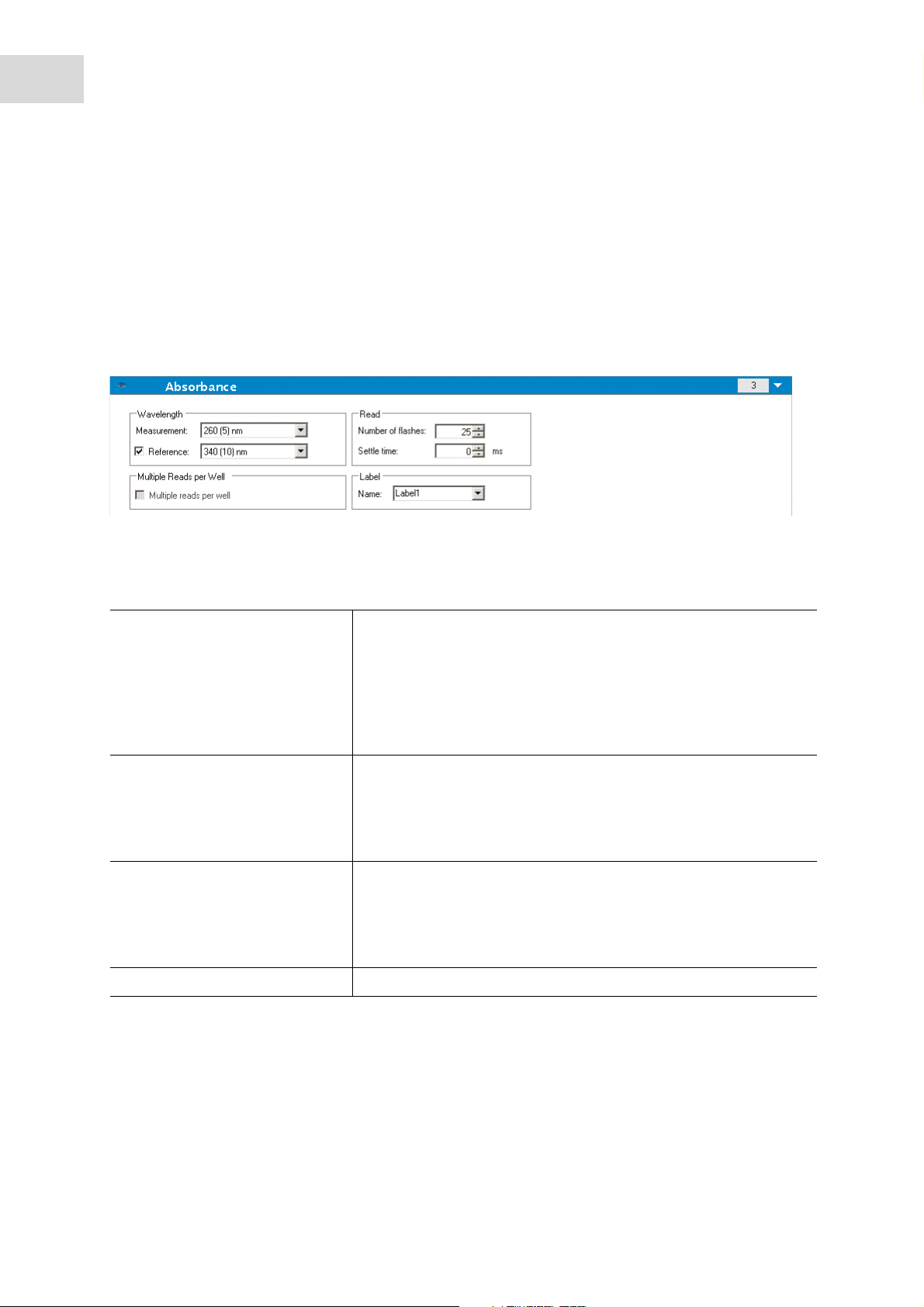

Absorbance

The Absorbance program element is used to perform absorbance measurements.

1. Enter or select the respective parameters:

Wavelength Specify a measurement wavelength.

The Reference wavelength may be selected to correct for flash

variations.

Two drop-down lists display the available measurement and

reference filter wavelengths, according to the inserted absorbance

filter slide. If the drop-down lists are empty, the absorbance filter

either has not been inserted into the reader or has not been defined.

Read Specify a certain Number of flashes and, if required, a Settle time

before the next measurement. The number of flashes is selectable

from 1 – 100.

Settle time: Enter a value to specify the time between the movement

of the plate carrier to the measurement position and the first flash.

Flashes In order to obtain a good measurement precision it is recommended

to perform absorbance measurements with the number of flashes

that is set as a default value for the respective instrument. On-the-fly

measurements with one flash per well are possible with all plate

types.

Measurement Enter a measurement name.

Page 17

®

Eppendorf

PlateReader AF2200

English (EN)

Fluorescence Intensity

The Fluorescence Intensity program element contains fields for the selection of excitation and emission

wavelength, top or bottom reading mode, integration and lag time, flash number and gain settings. A

checkbox for multiple reads per well gives access to additional function.

Overview

17

The following are the Fluorescence Intensity parameters:

Wavelength and Bandwidth Specify an Excitation and an Emission wavelength.

Two drop-down lists display the available measurement filter

wavelengths.

If the spin box of fixed values is empty, the excitation and emission

filters have not been inserted into the reader or have not been

defined.

The bandwidth is specific for every used filter and needs to be

defined together with the central filter wavelength.

Read Specify a certain Number of flashes and, if required, a Settle time

before the next measurement. The number of flashes is selectable

from 1 – 100.

Settle time: Enter a value to specify the time between the movement

of the plate carrier to the measurement position and the first flash.

Flashes In order to obtain a good measurement precision it is recommended

to perform fluorescence measurements with the number of flashes

that is set as a default value for the respective instrument. On-the-fly

measurements with one flash per well are possible with all plate

types.

Mode Select Top or Bottom.

Measurement Enter a measurement name

Page 18

18

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

Gain The gain is an amplification factor for the photomultiplier tube (PMT)

and may be set by selecting one of the following modes:

Manual gain: user-defined gain value (valid range: 1-255)

Optimal gain: calculated automatically by the instrument according

to the highest signal within the selected well range in order to avoid

OVER. Optimal gain determination is performed in a

pre-measurement. It is recommended to use the optimal gain

function for all applications that produce results with unknown RFU

values.

Calculated from well: determines the optimal gain for the selected

well. The resulting gain value is applied to all other wells within the

selected well range.

Extended dynamic range: The extended dynamic range option is an

automatic gain function that serves to optimally adjust the gain

setting for both very high and very low signals on a microplate within

one single measurement. By selecting "extended dynamic range",

the measurement is done in two consecutive parts, one with a high

and one with a low gain. The results of both measurements are

automatically correlated and displayed within one single data set.

For measurements in combination with the Extended dynamic range function, a very high gain

value in the first measurement can result in OVER values in the second measurement. When

only very high and very low signal intensities are detected within the measured well range, the

new gain value is calculated on the basis of the very low values, in certain cases this can lead

to OVER for the entire second measurement.

Integration/Lag time Integration time: duration of signal recording per well (valid range:

20-2000 μs).

Lag time: time between flash and the start of signal integration.

While lag time is an optional function, the integration time is a

mandatory parameter for defining the duration of signal recording.

The default values for standard fluorescence intensity measurements

are 0 μs lag time and 20 μs integration time.

Page 19

®

Eppendorf

PlateReader AF2200

English (EN)

Multiple Reads per Well

The software allows the user to define multiple reads per well (MRW) in Absorbance, Fluorescence top and

Fluorescence bottom mode.

The MRW feature is not available for well wise measurements.

The Reference wavelength on the absorbance program element is not selectable in combination with

multiple reads per well.

The multiple reads per well function can be activated on an absorbance or fluorescence intensity program

element by selecting the Multiple reads per well check box.

Overview

19

More details on defining parameters for multiple reads per well, are available in the Operating

Manual of the Eppendorf PlateReader AF2200.

The multiple reads per well function is available for plate formats with up to 384 wells.

4.2.3 Actions

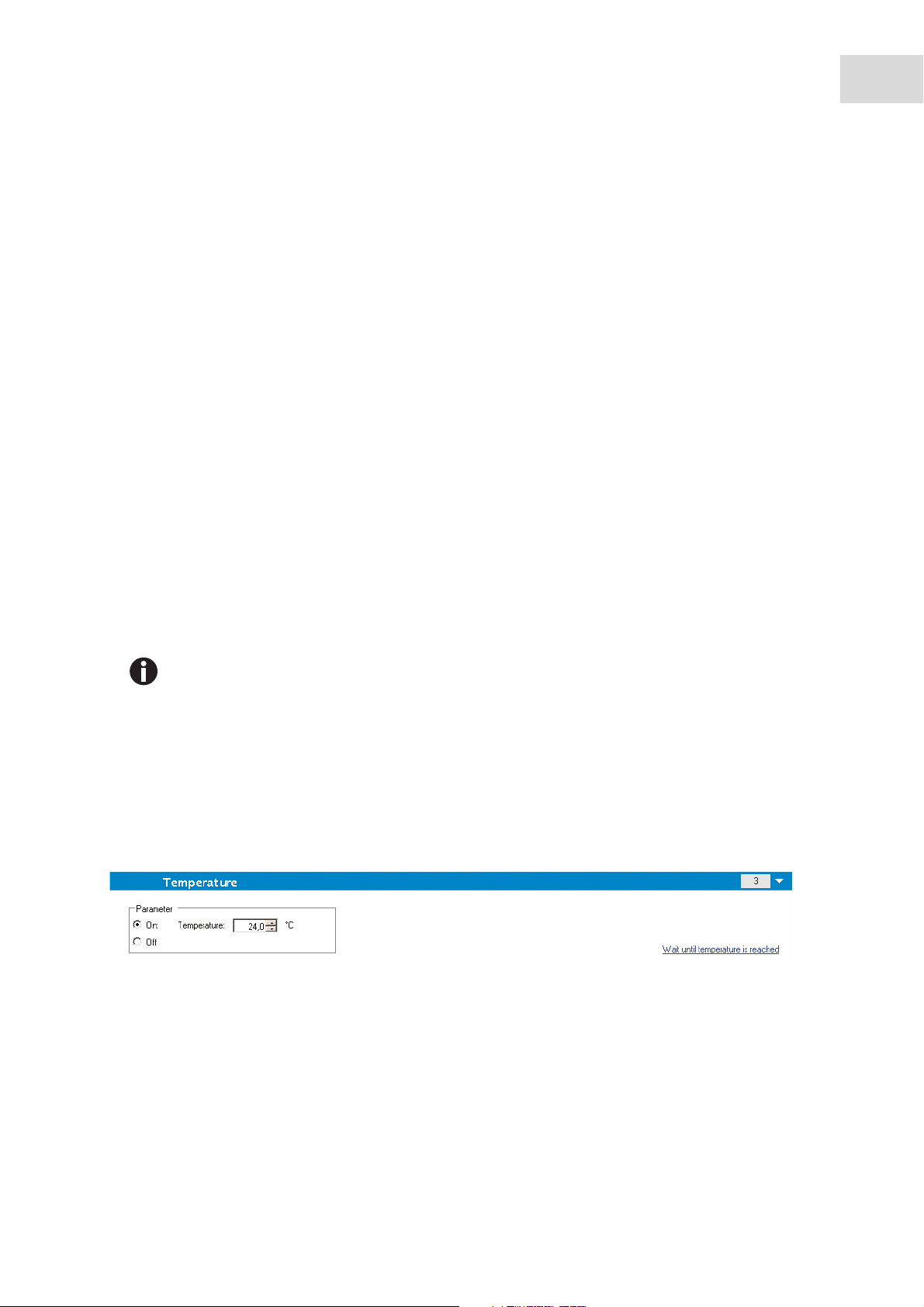

Tem perature

1. Select the Temperature program element to enter a certain target temperature.

2. Select On to enter a target temperature value.

3. Click on the link Wait until temperature is reached to define the Minimum and/or Maximum temperature

values. The heating of the instrument starts when clicking the Start button.

4. For pre-heating the instrument, select Heating in the Instrument menu and click the On button.

The measurement only starts if the current instrument temperature is within the specified range (see

Miscellaneous on p. 21).

Page 20

20

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

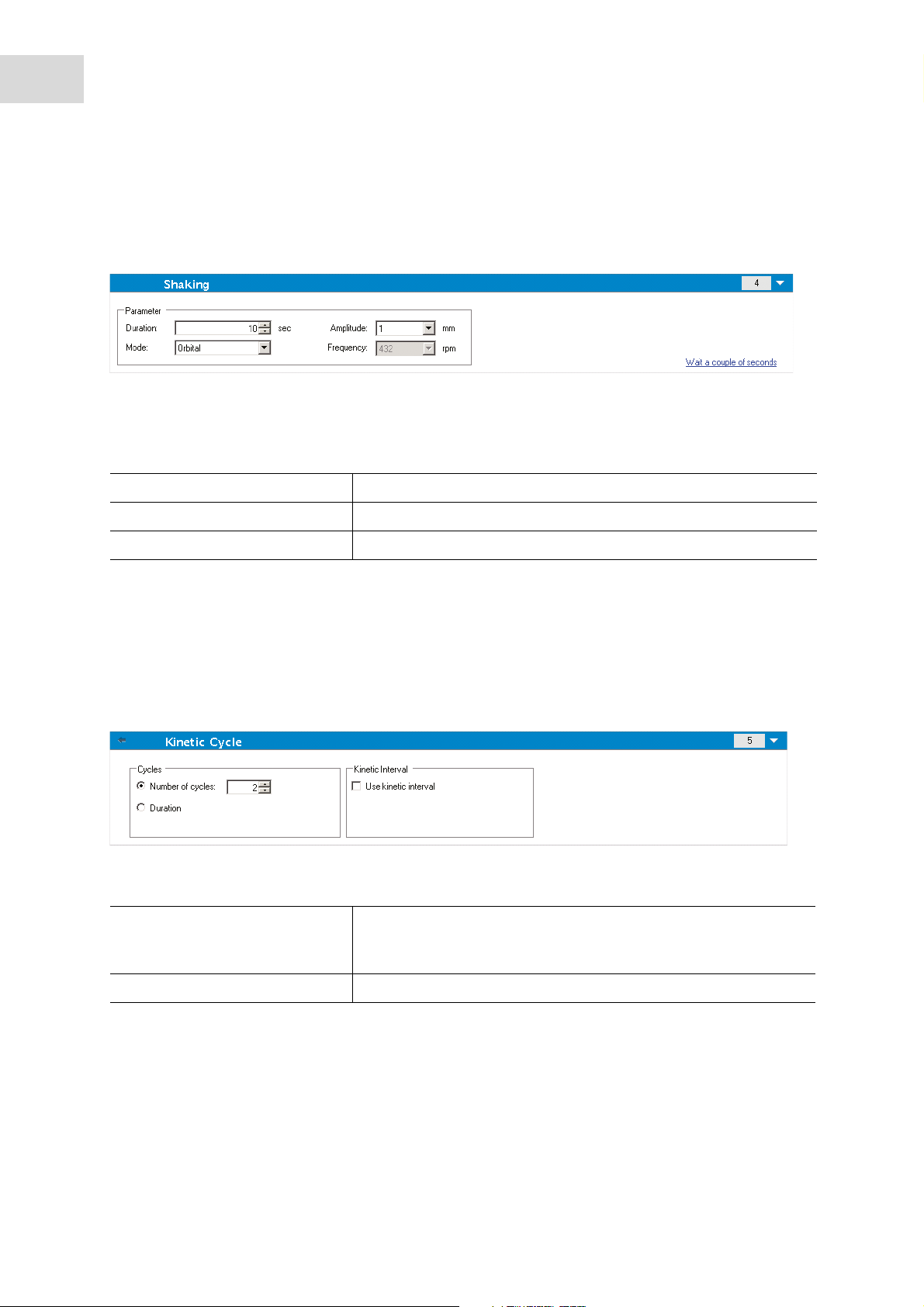

Shaking

1. Select the Shaking program element if the plate is to be shaken, either before the measurement or

between kinetic cycles.

2. Enter the respective parameters (see Parameter list).

3. Clicking the link Wait a couple of seconds inserts a new program element (see Miscellaneous on p. 21).

Tab. 4-1: Parameter list

Duration Enter the duration of the shaking process.

Mode Select between the options Linear and Orbital.

Amplitude Enter the required Amplitude value from the drop-down list.

4.2.4 Kinetic

Kinetic Cycle

Use the program element Kinetic Cycle to perform several consecutive measurements, which may be

executed in certain intervals.

1. Enter the respective parameters:

Cycles Number of cycles: Enter a number or click the up or down arrows for

the number of actual measurement steps (2 – 1000 cycles)

Duration: Enter the duration, format hh:mm:ss.

Kinetic Interval Use kinetic interval: Enter the time interval (hh:mm:ss or ms).

Plate-wise kinetic measurements

Each cycle of the kinetic measurement is performed on all selected wells. Plate-wise kinetic measurements

may contain a maximum of ten independent measurement stripes that do not need to be of the same

measurement type.

Page 21

®

Eppendorf

PlateReader AF2200

English (EN)

Well-wise kinetic measurements

All cycles of the kinetic measurement are first performed in one well before continuing to the next well.

Well-wise kinetic measurements may be composed of a maximum of four measurement stripes of the same

type, e.g., four absorbance stripes.

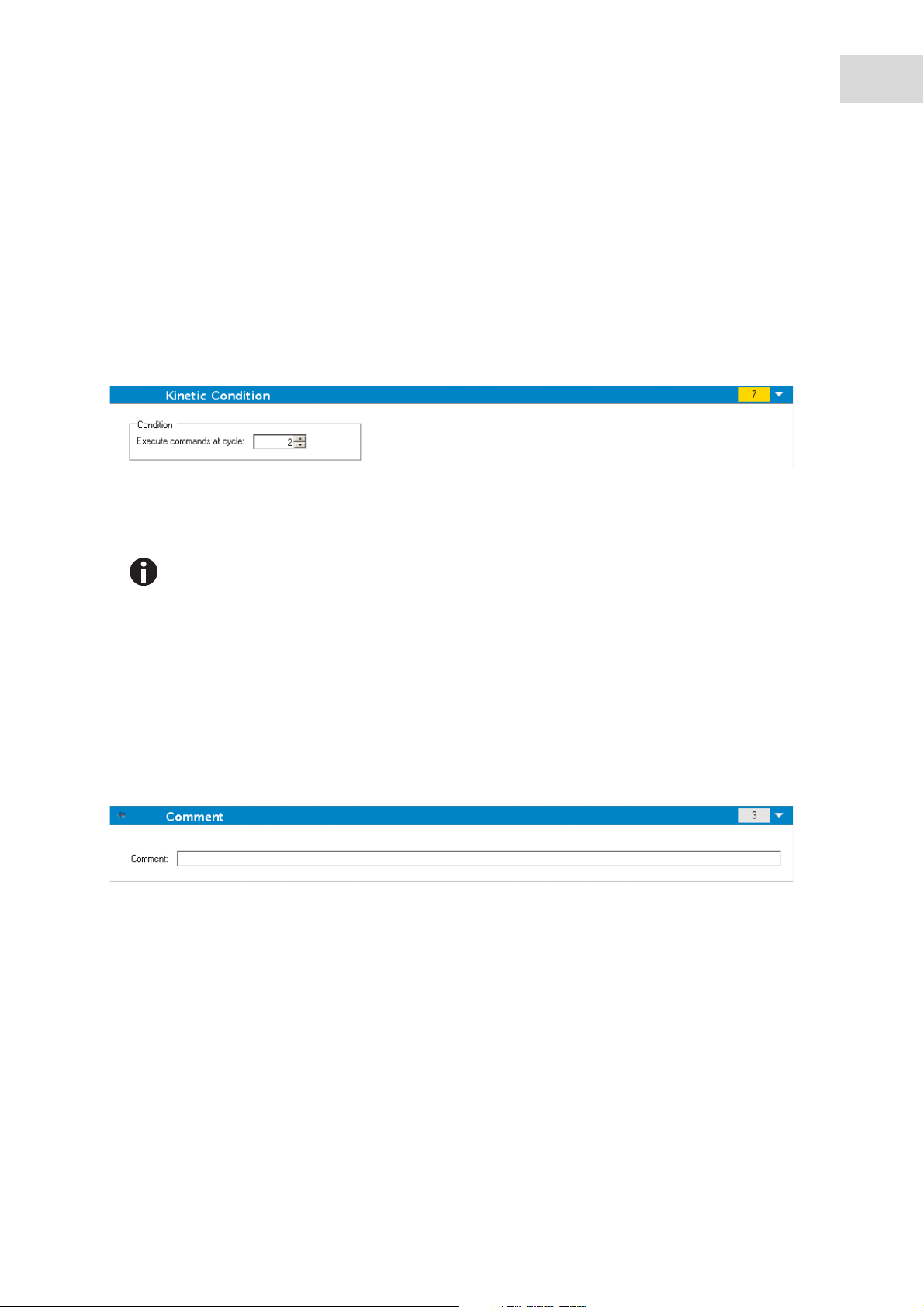

Kinetic Condition

Use the Kinetic Condition program element to define which actions should be executed at a certain cycle.

If 3 is entered for Execute command at cycle within a kinetic measurement containing, e.g. a Shake step,

shaking is performed only at cycle 3.

Overview

21

Kinetic conditions should be inserted right after a Kinetic Cycle program element in order to

ensure optimal result reproducibility.

Users are advised to set up suitable scripts prior to the measurements and to use the same

script for all similar kinetic measurements in order to obtain comparable results.

4.2.5 Miscellaneous

Comment

Use the program element Comment to enter a remark or statement for the current measurement in the text

field. This text is shown together with the measurement in the Excel output sheet.

Page 22

22

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

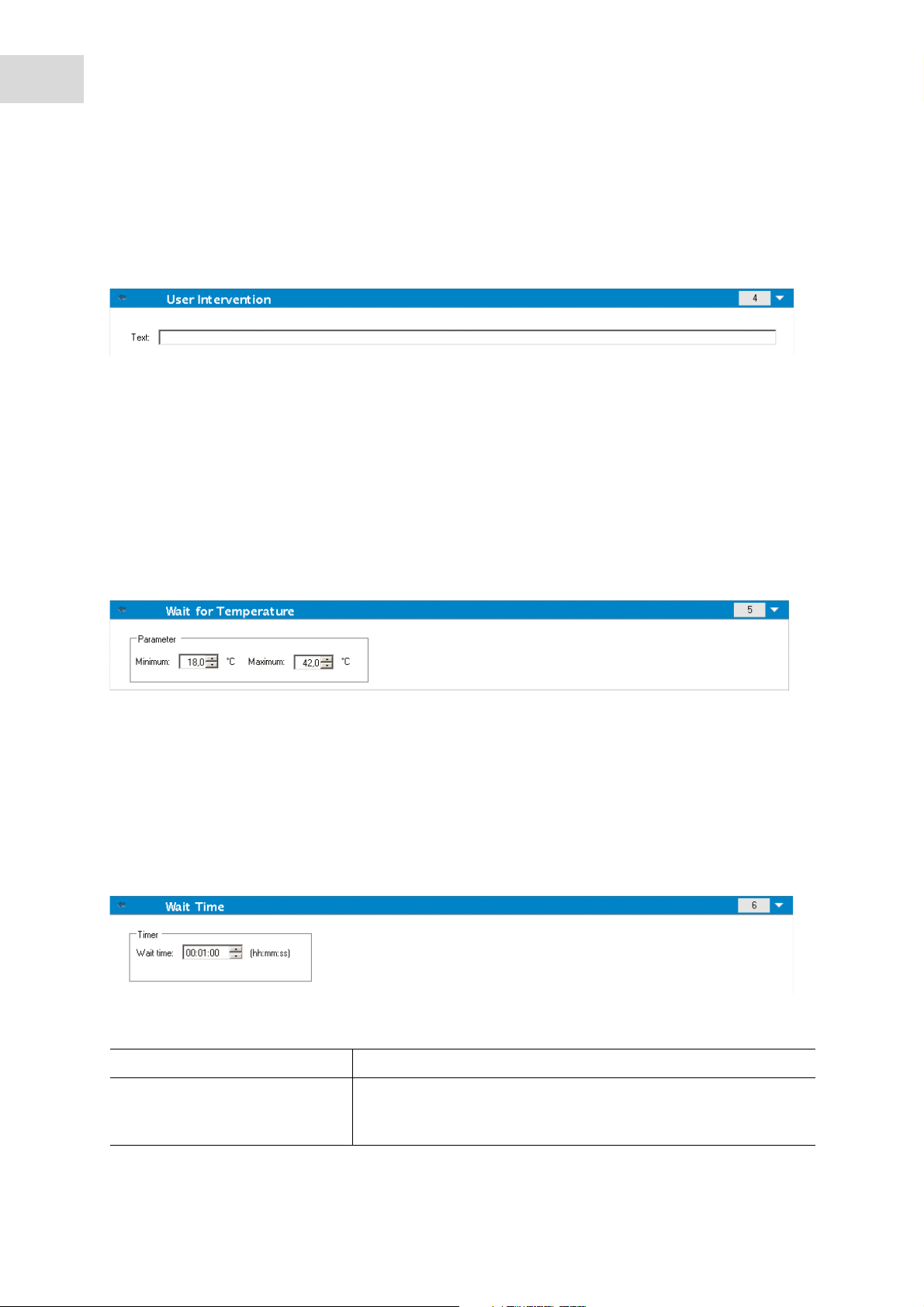

User Intervention

The User Intervention program element informs the operator of the instrument to execute a definite action

during the workflow at a certain time.

If for example the Move Plate program element is used to move the plate out to perform a certain action,

then the entered text should inform the operator to perform these actions. A dialog box shows the message

and the measurement process stops until OK is clicked.

If the plate should be moved in after pipetting for example, then the text Move Plate In informs the operator

to move the plate in after pipetting to continue the workflow.

Wait for Temperature

Use the program element Wait for Temperature to define a valid temperature range for the assay.

This is typically used after a Temperature program element

Wait Time

Use the Wait Time program element to define a certain waiting period before the next step within a

workflow is executed.

In the Wait time field enter the required time.

1. Enter the respective parameters:

Timer Enter the Wait time (hh:mm:ss)

Options Ignore wait at last kinetic cycle: When the program step Wait Time is

the last action within a kinetic run, the wait time will be ignored in

the last cycle.

Page 23

®

Eppendorf

PlateReader AF2200

English (EN)

Incubation

Incubation is always done at the heating position to ensure inside the instrument proper temperature

distribution.

Incubation can consist of shaking and waiting steps (up to 2 shaking steps and up to 2 waiting steps are

allowed in any combination).

The Remaining Wait step waits until the overall incubation time is over (including shaking and waiting

times).

The incubation program element is typically used to perform shaking and waiting at a certain temperature

for a certain time.

Overview

23

1. Enter the appropriate parameters for incubation:

Incubation time Enter the total time (min. 5 s)

Actions Available actions: Shaking, Wait Time

2 wait and 2 shaking actions are allowed. Select actions by

double-clicking or use the arrow keys.

Organize actions by using the up/down keys.

Remaining Wait Time: mandatory, cannot be deleted or edited

(duration 3 s)

Page 24

24

Overview

Eppendorf

English (EN)

®

PlateReader AF2200

4.3 Workflow Pane

The main window in the software is the Workflow pane, where the measurement script is visible and where

parameters are defined and edited.

There are two ways to insert a program element from the Explorer bar into the Workflow pane.

1. Select a program element from the Explorer bar; by double-clicking it, it is inserted into the Workflow

pane directly after the previous program element.

2. Click the program element in the Explorer bar and drag it into the Workflow pane to the respective

position.

The program elements are numbered according to their sequence.

Once a program element has been inserted into the Workflow pane, settings and parameters for this

element can be entered or edited.

Single program elements inside the Workflow pane can be collapsed to display the most important

information or expanded to access all editable functions.

3. Click one of the triangles next to the title of the program element, or , to switch between the two view

modes.

By default, the software starts with the Plate element in the Workflow pane. This can be modified in the

Settings menu > User Settings.

Currently selected program elements within the Workflow pane are displayed with a blue heading.

If a program element contains errors or is invalid within the current workflow, the element will

be flagged with an error mark and the number of the element is highlighted in red. In the

Status bar, the number of Errors appears in red. In the Info bar detailed information on the

error is displayed. If the workflow contains errors, the measurement script can neither be

saved nor started.

It is recommended to always save the workflow before starting a measurement. You can define this feature

as default in the Settings menu > User Settings > Options.

Select Save the script before it is started.

Page 25

®

Eppendorf

PlateReader AF2200

English (EN)

4.3.1 Hierarchy of Elements

The hierarchy of elements in the Workflow pane is as follows:

•Plate

•Pattern

•Well

Any desired measurement step can be inserted directly after a plate, a pattern or a well element.

Arrows placed on the left side of the program elements header to release or indent it.

Other elements from the Explorer bar can be inserted into the hierarchy of a workflow as follows:

Overview

25

The first Pattern element is inserted directly after the Plate element; then all subsequent Pattern elements

can be inserted.

Well elements can only be inserted directly after a Pattern or a Plate element.

Only measurement steps of the same mode (e.g. absorbance only with different wavelengths) are allowed

within one well element.

Kinetic steps are possible within a Plate, Pattern or Well element.

User Intervention, Comment, Wait Time and Wait until temperature is reached steps are possible within a

Plate, Pattern or Well element.

4.4 Info bar

The Info bar on the right side of the screen displays information that is relevant for the currently selected

program element. Any warnings and errors are shown.

Page 26

26

Overview

Eppendorf

English (EN)

®

PlateReader AF2200

4.5 Menu Bar

4.5.1 File Menu

New This command opens a new measurement workflow. If an empty

document is to be opened, you will be asked to save the current

workflow.

• Click Yes to save the current workflow.

• Click No to create a new workflow without saving the previous

one.

• Click Cancel to leave the dialog box.

Open This command opens an existing PlateReader AF2200 Software

workflow (*.mdfx) from the selected folder. If you want to open an

existing workflow while another one is still open, you will be asked if

you want to save the workflow.

• Click Yes to save the current workflow to a certain destination.

• Click No to create a new workflow without saving the previous

one.

• Click Cancel to leave the dialog box.

Open from Method By default this file is empty. The user could save Eppendorf

predefined methods in this file.

Open from Template Templates are predefined scripts that are similar to common

PlateReader AF2200 Software scripts, but contain some additional

information, e.g. a short description of the measurement parameters.

Templates may be assigned to distinct groups and may be annotated

individually.

The User settings dialog contains a checkbox that can be used to

open the Open from template dialog directly after starting the

software by default or hide it by default.

Open from Template

All templates are designed as example scripts for common applications.

It is the responsibility of the user to validate all parameters for the purpose of the particular

application before using a template.

Page 27

Properties

®

Eppendorf

PlateReader AF2200

Possibilty to save information for a script or a method.

Overview

27

English (EN)

Save This command saves the current script.

Save As… This command saves the current workflow under a different name.

List of most recently used script

files

A list of the most recently saved workflow files is displayed. Define

how many files are to be included in this list in the Settings menu >

User settings.

Exit This command exits and closes the program. If you are still

connected to an instrument, you will be asked if you want to

disconnect and to close the program.

• Click Yes if you want to exit or click No if you want to return to

the program.

4.5.2 Edit Menu

Cut This command cuts the selected program element, which can be

pasted again.

Copy This command copies the selected program element.

Paste This command pastes the selected program element.

Delete This command deletes the selected program element.

Release Strip This command releases the selected program element.

Indent Strip This command indents the selected program element.

Select All This command selects all program elements in the workflow pane.

Page 28

28

Overview

Eppendorf

English (EN)

®

PlateReader AF2200

4.5.3 View Menu

Status bar This command shows or hides the status bar (located at the bottom of

the window).

Collapse All This command collapses all program elements in the workflow pane

to view only one line of text.

Expand All This command expands all program elements in the workflow pane

to extended view and shows all visible parameters.

4.5.4 Instrument Menu

Disconnect / Connect This toggle command connects or disconnects an instrument to or

from the PlateReader AF2200 Software. To connect to an instrument

select the instrument name from the list.

Start This command starts the measurement process. If the measurement

is started, a small window informs that the measurement is in

progress. Excel opens automatically and the results are displayed in

a worksheet.

Movements

Plate: Move Plate in and out

Filterslide: Move Filter out

Page 29

®

Eppendorf

PlateReader AF2200

English (EN)

Heating This command is used to set the target temperature of the

instrument manually.

• Select or enter the Target temperature and click Set and On to

start instrument heating.

•Click the Read button to display the current temperature inside

the instrument or click the Auto check box to have it read

automatically.

•Click Off to stop heating.

• Click the down button to display the heating graph and

click the up button to hide it.

• Click the close button to exit the Heating dialog box.

Overview

29

Properties Select Properties to set a new alias name for the instrument.

Enter a new name in the New Alias field and click Set Alias to

confirm.

These settings take effect after restarting the software.

4.5.5 Settings Menu

Filter Definitions

Measurement Mode Select the appropriate filter position and enter the new wavelength,

bandwidth, and measurement mode for each new filter.

Choose from the dropdown list:

• FI for fluorescence intensity,

• ABS for absorbance measurements, and

• Empty for filter-free positions.

Wavelength Enter the filter wavelength.

For fluorescence intensity measurements, set the filter wavelength

within the allowed range of the instrument.

Absorbance filters are definable between 230 and 1000 nm

(Excitation only).

Bandwidth Enter the bandwidth (nm) of the filter.

Description This field can be used for individual user remarks about the filter,

e.g. filter name, application, etc.

Page 30

30

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

Filter Definitions

Purchase Date This option enables the user to enter the purchase or installation

date of the filter.

Flash Counter The flash counter monitors the number of flashes through a filter.

The flash counter number provides the user only with additional

information about the filter in use.

• For a new filter, set the counter to 0.

• For a previously used filter, enter the last collected flash number

if the number is available.

The flash counter number is saved together with other information

about the filter on the filter slide microchip. If you replace a filter,

this information will be lost unless the last filter flash number is

manually documented by the user.

• Confirm the new filter values by clicking Save.

• Close the Filter Definition dialog and the system is ready to

perform measurements with the new filters.

Refer to the Operating Manual of the connected instrument for

further details and examples.

Page 31

®

Eppendorf

PlateReader AF2200

English (EN)

Plate Definition

This command allows you to choose a plate file from the drop-down list of available plates. The plate

definition files contain all relevant parameters of a specific plate type, e.g. coordinates of measurement

points, number of columns, number of rows, well form, well diameter, plate height, plate height with

cover…).

A graphic element at the bottom of the dialog visualizes the parameter which is currently defined.

Plate Definition Menu

Overview

31

Define a new Plate:

To create a custom plate definition file, you need the technical data of your plate. These are provided by the

manufacturer of the plate. Open the plate definition menu and choose one plate from the list as a template.

Enter general data, plate geometry data and well geometry data of the new plate.

Click Save As to save the selected plate definition as a *.pdfx-file.

Plate list (see Plate List on p. 36)

Page 32

32

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

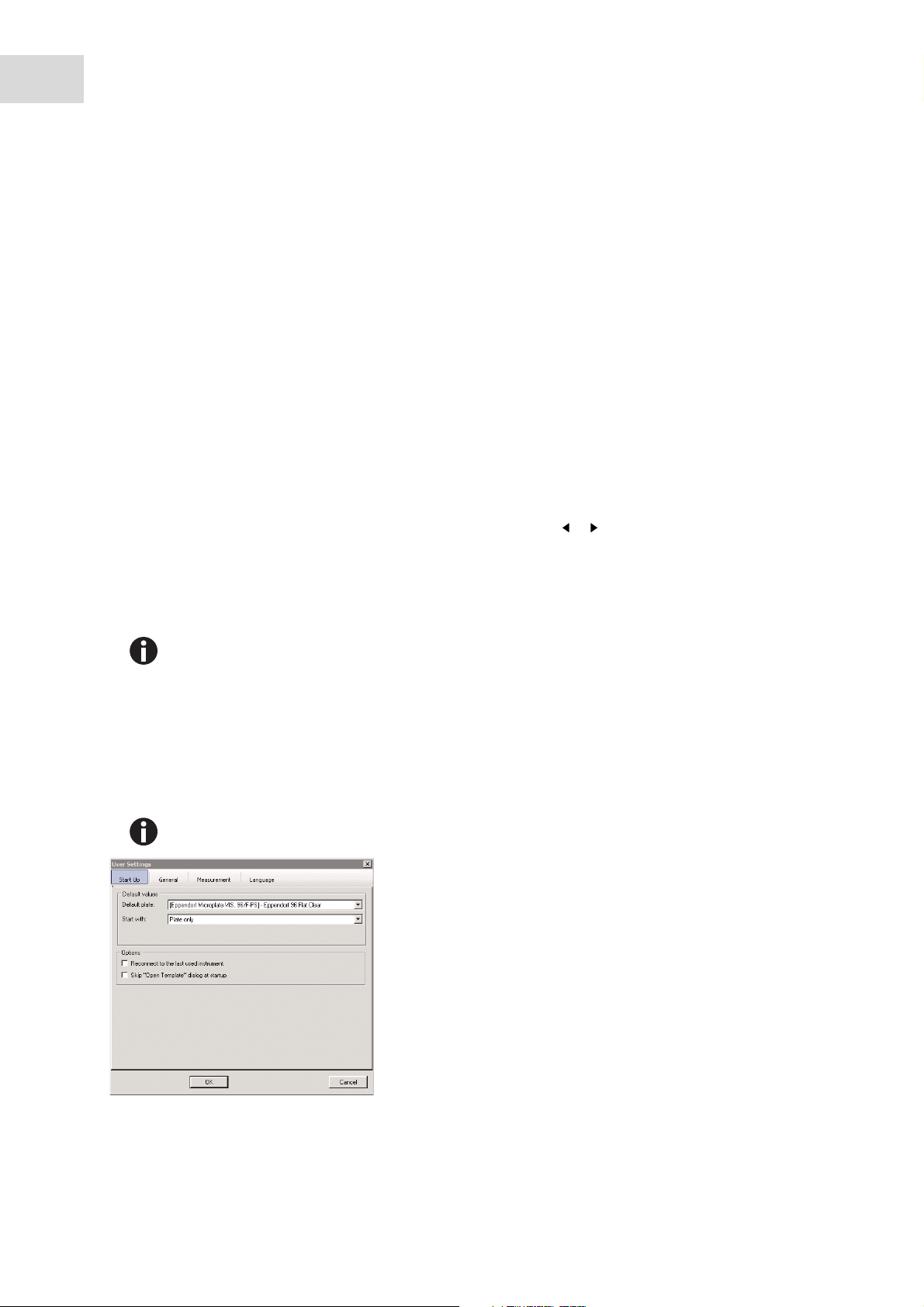

User Settings

User Settings - Tab Start Up

Behavior at start up can be set.

1. Select a default plate.

2. Determine if the workflow pane should start with an empty workflow, plate only, or plate and part of

plate.

3. Select whether the last used instrument should be reconnected

4. Select whether the Open Template dialog at startup should be skipped.

User Settings - Tab General

General options can be set.

1. Ask to save the workflow (when changed) before the measurement starts.

2. Determine if the software window should be minimized while the measurement is performed.

3. Determine the length of the list of recently used plate files (combo box for plate selection in the plate

program element).

4. Determine how many recently used workflow files are to be listed in the file menu.

User Settings - Tab Measurement

1. Certain measurement settings can be saved as default settings.

2. Absorbance: Select default number of flashes.

3. Fluorescence: Select default number of flashes and default value for manual gain.

4. Regressionskoefficient predefined methods: Set required value for R2.

Page 33

®

Eppendorf

PlateReader AF2200

English (EN)

User Settings - Tab Language

1. Select the language of the PlateReader AF2200 Software

2. Click OK to save your settings or click Cancel to leave the dialog box without saving any changes

Data Presentation

This command offers the following tabs to determine the output settings of the measured results in Excel.

Overview

33

Data Presentation - General

Destination: Select between New workbook, New worksheet, Use previous worksheet, Use existing

workbook or Use XML Output.

• If New workbook is selected, a new workbook is opened every time a measurement script is performed.

•If New worksheet is selected, a new worksheet of the existing workbook is created. If no workbook is

open a new one is created.

•If Use existing workbook is selected, a workbook and a worksheet must be selected. First select the

workbook (an Excel file), and then select the sheet the results should be placed into.

•If Use previous worksheet is selected, data are written in the same worksheet underneath the previous

measured data.

•If Use XML Output is selected, Data are put out in XML. You have to define the XML-path.

The default output of Eppendorf predefined methods is New Workbook. This cannot be

changed.

Page 34

34

Overview

®

Eppendorf

PlateReader AF2200

English (EN)

View Mode: Select between Matrix and List.

•If Matrix is selected, the data alignment corresponds to a microplate; times per well cannot be

displayed. Not relevant for kinetic result presentation.

•If List is selected, choose between: Align, Rotation, Display Times.

Show: Select between All and Measured.

•If All is selected, the whole plate geometry, including all possible rows and columns, is displayed.

•If Measured is selected, only the results of the measured wells are displayed.

Align: Select between A1A2 or A1B1.

•If A1A2 is selected, the results are arranged in rows (of the microplate).

•If A1B1 is selected, the results are arranged in columns (of the microplate).

Rotation: Select between Columnwise or Rowwise.

•If Columnwise is selected, the results are displayed in a column (in the Excel sheet).

•If Rowwise is selected, the results are displayed in a row (in the Excel sheet).

Display Times: Select between No time or Time per well.

If No Time is selected, only the values are displayed.

If Time per well is selected, a timespan for each value is displayed.

Data Presentation - Kinetic

Rotation: Select between Columnwise or Rowwise.

If Columnwise is selected, the results are displayed in a column (in the Excel sheet). •

If Rowwise is selected, the results are displayed in a row (in the Excel sheet).

Align: Select between A1A2 and A1B1.

If A1A2 is selected, the results are arranged in rows (of the microplate).

If A1B1 is selected, the results are arranged in columns (of the microplate).

Display Times: Select between Time per cycle and Time per well.

If Time per cycle

If Ti

me per well is selected, a timespan for every well is displayed.

is selected, a timespan per cycle is displayed.

Page 35

®

Eppendorf

PlateReader AF2200

English (EN)

Data Presentation - Eppendorf μPlate G 0.5

Show Raw Data: Select the Show Raw Data box to display the raw measurement values of a Nucleic Acid

Quantification measurement.

Exception History

The Exception History dialog box shows a list of exceptions (instrument errors, software failures) with date

and time.

Every time an exception occurs and an error box is displayed, all relevant information is collected and

saved in a zip-file. Each of these zip-files leads to an entry in this list.

Relevant information is: The error message and number, communication log-files and system information

(like operating system version, free amount of disc space).

Every entry (which corresponds with a zip-file) can be saved as a separate file to a user-defined location

using the floppy disc symbol at the lower left corner of the dialog box.

Overview

35

This information is helpful to the customer support or help desk to track problems.

Save Error Log

Warnings or Errors could be saved as logfiles.

Page 36

36

Overview

Eppendorf

English (EN)

®

PlateReader AF2200

4.6 Plate List

Order No. Manufacturer Number of

Wells

351155,

351156,

351157, 351158

351161,

351162,

351163, 351164

3631 Corning 96 Flat Black Clear Bottom

3880 Corning 96 Flat Black Half Area / Clear

3694 Corning 96 Flat Black Half Area

3679 Corning 96 Flat Clear Half Area / UV

3635 Corning 96 Flat Clear UV

3632 Corning 96 Flat White Clear Bottom

3883 Corning 96 Flat White Half Area / Clear

3693 Corning 96 Flat White Half Area

BD Falcon 24 Flat Clear/ Black FluoroBlok

BD Falcon 96 Flat Clear/ Black HTS FluoroBlok

Bottom Shape Color Additional

Information

Bottom

Bottom

3711 Corning 384 Flat Black Clear Bottom

3675 Corning 384 Flat Clear UV

3706 Corning 384 Flat White Clear Bottom

3335, 3506,

3516, 3471

3336, 3512,

3513

3337, 3524,

3526, 3527,

3473

3548 Corning 48 Flat Clear -

3650, 3915,

3916, 3925,

3991

Corning 6 Flat Clear -

Corning 12 Flat Clear -

Corning 24 Flat Clear -

Corning 96 Flat Black -

Page 37

Eppendorf

®

PlateReader AF2200

English (EN)

Overview

37

Order No. Manufacturer Number of

Bottom Shape Color Additional

Wells

2503, 2507,

Corning 96 Flat Clear 2509, 3300,

3361, 3370,

3474, 3585,

3590, 3591,

3595, 3598,

3599, 3628,

3641, 9017,

9018

3690, 3695,

Corning 96 Flat Clear Half Area

3696, 3697

3362, 3596,

Corning 96 Flat White 3600, 3912,

3917, 3922

3359, 3365 Corning 96 Round Clear -

3655, 3711 Corning 384 Flat Black -

3540, 3544,

Corning 384 Flat Black Low Volume

3820, 3821,

3821BC

Information

3640, 3680,

Corning 384 Flat Clear 3700, 3701,

3702

3576, 3653,

Corning 384 Flat White 3703

3824, 3824BC Corning 384 Flat White Low Volume

3677, 3676,

Corning 384 Round Black 3678

3673, 3674 Corning 384 Round White -

657 160, 657

Greiner 6 Flat Clear 185

665 180, 665

Greiner 12 Flat Clear 102

662 160, 662

Greiner 24 Flat Clear 102

677 180, 677

Greiner 48 Flat Clear 102

655 079, 655

Greiner 96 Flat Black Chimney

086, 655 077,

655 076

Page 38

38

Overview

Eppendorf

®

English (EN)

PlateReader AF2200

Order No. Manufacturer Number of

Wells

685 077, 675

Greiner 96 Flat Black Half Area

076, 675 097,

675 096

655 101, 655

Greiner 96 Flat Clear 161

675 161, 675

Greiner 96 Flat Clear Half Area

101, 675 801

655 073, 655

Greiner 96 Flat White Chimney

083, 655 074,

655 075

675 074, 675

Greiner 96 Flat White Half Area

075, 675 094,

675 095

650 101, 650

Greiner 96 U Clear 161, 650 160,

650 180, 650

185

651 101, 651

Greiner 96 V Clear 161, 651 160,

651 180

Bottom Shape Color Additional

Information

781 079, 781

Greiner 384 Flat Black 086, 781 077,

781 076, 781

094, 781 095

781 062, 781

Greiner 384 Flat Clear 101, 781 162,

781 185, 781

186, 781 165,

781 182

781 073, 781

Greiner 384 Flat White 080, 781 074,

781 075, 781

097, 781 096

784 209 Greiner 384 V Black Small Volume

784 201 Greiner 384 V Clear Small Volume

784 207 Greiner 384 V White Small Volume

96000014,

96110024

96000024,

96120096

Greiner 24 Flat Black Lumox

Multiwell

Greiner 96 Flat Black Lumox

Multiwell

Page 39

Eppendorf

®

PlateReader AF2200

English (EN)

Overview

39

Order No. Manufacturer Number of

Wells

96000034,

Greiner 384 Flat Black Lumox

96130384

137 101, 137

Nunclon 96 Flat Black 103, 237 105,

237 107, 237

108, 437 111,

437 112

137 101, 137

Nunclon 96 Flat Black Luminunc

103, 237 105,

237 107, 237

108, 437 111,

437 112

439 454, 442

Nunclon 96 Flat Clear 404, 475 094,

269 620, 269

787

136 101, 136

Nunclon 96 Flat White 102, 236 105,

236 107, 236

108, 436 110,

436 111

Bottom Shape Color Additional

Information

Multiwell

FluoroNunc

136 101, 136

Nunclon 96 Flat White Luminunc

102, 236 105,

236 107, 236

108, 436 110,

436 111

143 761, 163

Nunclon 96 U Clear 320, 262 170,

262 162, 475

434, 449 824

264 556, 164

Nunclon 384 Flat Black 564, 460 518

242 765, 242

Nunclon 384 Flat Clear 757, 164 688,

464 718, 265

196

264 572, 164

Nunclon 384 Flat White 610, 460 372

0030 601.700 Eppendorf 96 Flat Black -

0030 601.807 Eppendorf 96 U Black -

0030 601.904 Eppendorf 96 V Black -

FluoroNunc

Page 40

40

Overview

Eppendorf

®

English (EN)

PlateReader AF2200

Order No. Manufacturer Number of

Wells

Bottom Shape Color Additional

Information

0030 621.905 Eppendorf 384 V Black -

0030 601.475 Eppendorf 96 Flat White -

0030 601.572 Eppendorf 96 U White -

0030 601.670 Eppendorf 96 V White -

0030 621.670 Eppendorf 384 V White -

0030 730.020 Eppendorf 96 F Clear VIS

0030 741.048 Eppendorf 96 F Clear UV-VIS

0030 730.119 Eppendorf 96 F Clear Cell Culture

0030 741.013 Eppendorf 96 F Black Clear Bottom,

CellCulture

0030 128.800 Eppendorf 96 V Black Wells twin.tec PCR

0030 128.818 Eppendorf 384 V Black Wells twin.tec PCR

0030 132505 Eppendorf 96 V White Wells twin.tec PCR

0030 132.734 Eppendorf 384 V White Wells twin.tec PCR

Page 41

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

5 Defining measurements

The following chapter describes some examples to illustrate the definition of different measurements.

5.1 Plate Size – Pattern

1. Use the Plate program element in the workflow pane to choose a plate format.

2. Select the desired plate format from the Plate definition drop-down list (e.g. Eppendorf 96 Flat Clear

UV-VIS)

3. To measure a particular well or a range of wells on the plate click the link Pattern.

4. In the Pattern program element click the desired well or drag a frame over the range of desired wells

(e.g. A1 to E6). The selected wells are displayed in blue; unselected appear in grey.

41

Wells can be selected by dragging a frame over the plate. Further ranges can be selected by holding

down the Ctrl key on the keyboard and dragging another frame around the wells to be selected.

5. By clicking on Zoom the plate is zoomed in; well selection can be done also in the zoomed window.

Page 42

42

Defining measurements

Eppendorf

English (EN)

®

PlateReader AF2200

5.2 Defining Endpoint Measurements

The following example describes an Absorbance Endpoint Measurement in all wells of a 96 well plate.

Select a 96 well plate (e.g. Eppendorf 96 Flat Clear UV-VIS) from the Plate definition drop-down list. If

the Pattern program element is not visible, click the link Pattern. It is recommended to use the Pattern

program element in every workflow, even if all wells are measured.

Double-click the Absorbance program element from the Explorer bar, and define the Workflow as

follows:

• Wavelength/Measurement: 462 nm

•Read/Number of reads/flashes: 25 (per well)

• Settle time (time between moving the plate and starting the measurement): 0 ms

Page 43

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

If the plate shall be moved out of the instrument after measurement, insert a Move Plate program

element and select the Out radio button.

43

If a Move Plate program element is not defined after the measurement, the plate will stay inside the

instrument until Move Plate Out is clicked.

After finishing the definition as described above start the measurement by clicking the Start button on

the right side beneath the Info bar.

When clicking the Start button, Excel opens automatically and the results are displayed in a worksheet.

Page 44

44

Defining measurements

Eppendorf

English (EN)

®

PlateReader AF2200

5.3 Defining Multimode Measurements

Multimode measurements are measurements with multiple consecutive reading modes, e.g. with multiple

absorbance and fluorescence measurements or with mixed measurements.

The following example describes the definition of a Multimode measurement in a 96 well plate.

Measurement 1 – Absorbance 462 nm in all wells

1. Select a 96 well plate (e.g. Eppendorf 96 Flat Clear UV-VIS) from the Plate definition drop-down list.

2. Select all wells in the Pattern.

3. Insert the Absorbance program element from the Explorer bar, and define as follows:

• Wavelength/Measurement: 462 nm

• Read/Number of reads: 25

Page 45

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

Measurement 2 – Fluorescence 485/535 nm in all wells

1. Insert the Fluorescence Intensity program element from the Explorer bar and define as follows:

• Wavelength/Excitation: 485 nm

• Wavelength/Emission: 535 nm

• Read/Number of reads: 25

•Gain: Optimal

45

Page 46

46

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

Measurement 3 – Fluorescence 360/465 nm in all wells

1. Insert a second Fluorescence Intensity program element from the Explorer bar and define as follows:

• Wavelength/Excitation: 360 nm

• Wavelength/Emission: 465 nm

• Read/Number of reads: 25

•Gain: Optimal

2. After finishing the definition as described above start the measurement by clicking the Start button on

the right side beneath the Info bar.

When clicking the Start button, Excel opens automatically and the raw data are displayed in a

worksheet.

Page 47

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

5.4 Defining Kinetic Measurements

The following example describes a kinetic measurement of a 96 well plate.

Select the 96 well plate (e.g. Eppendorf 96 Flat Clear UV-VIS) from the Plate definition drop-down list,

and select all wells in the Pattern program element.

47

Double-click the Kinetic Cycle program element and define as follows:

• Cycles/Number of cycles: 50

• Kinetic Interval (intervals between measurements): Select Use kinetic interval and enter: 2 minutes

30 seconds.

Double-click the Absorbance program element and define as follows:

• Wavelength/Measurement: 462 nm

• Read/Number of reads: 25

Page 48

48

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

After finishing the definition as described above start the measurement by clicking the Start button on

the right side beneath the Info bar.

When clicking the Start button, Excel opens automatically and the raw data are displayed in a

worksheet.

Page 49

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

5.5 Indenting and Releasing Program Elements

The decision to indent or release a program element will modify the workflow of the instrument during

measurements.

The actions of all program elements with the same indentation are performed sequentially. The only

dependence between these program elements is that the next action starts directly after the previous action

is finished.

A program element that is indented more than the previous program element shows dependence between

the two program elements. This means the parameters defined in the first program element are also active

for the second (indented) program element.

The following is an example of how to define a Multimode kinetic with two Absorbance measurements. The

example shows that the two Absorbance program elements depend on the Kinetic Cycle program element,

which depends on the Pattern program element, which depends on the Plate program element.

49

Define the parameters for an example as follows:

• Plate: 96 well plate, e.g. Eppendorf 96 Flat Clear UV-VIS

• Kinetik Cycle/Number of cycles: 50

• Absorbance/Wavelength: 260 nm

•Number of reads: 25

• Measurement Name: 260

• Second Absorbance/Wavelength: 280 nm

•Number of reads: 25

• Measurement Name: 280

Page 50

50

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

The Workflow pane appears as shown in the screenshot.

The above definition results in the following workflow.

The Absorbance of all wells of a 96 well plate is first measured at 260 nm and then at 280 nm. Both

Absorbance measurements are performed in 5 kinetic cycles.

Indenting the second Absorbance program elements on a level with Kinetic Cycle item changes the

workflow.

Select the second Absorbance program element and click on the arrow in the left side of the program

element header.

Page 51

Defining measurements

Eppendorf

®

PlateReader AF2200

English (EN)

51

In this workflow, an Absorbance Kinetic measurement with 5 cycles is done first at 260 nm; finished this

loop, Absorbance Endpoint measurement at 280 nm is performed.

Ways to Indent or Release Script Elements

Select a program element from the Workflow pane.

Click Edit and Indent Stripe/Release Stripe

Use the arrow buttons in the header of the program element to release or indent the selected element.

Click the right mouse button and click Release or Indent.

Page 52

52

Defining measurements

®

Eppendorf

PlateReader AF2200

English (EN)

Page 53

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

6 Predefined methods

6.1 Method selection

Frequently-used methods in molecular and cell biology are provided as predefined methods. To load a

method, select the required method from the upper left "Methods" section of the Explorer bar either by

double-clicking the method or by dragging and dropping the method into the Workflow pane.

Abb. 6-1: Overview of predefined methods

53

Fig. 6-1: Overview of predefined methods

The following predefined methods are provided:

Nucleic acid quantification

• UV 260 nm microvolume

• UV 260 nm with factor

• UV 260 nm with standards

• Fluorescence 485/535 nm with standards

Protein quantification

• BCA 562 (600) nm with standards

• Bradford 595 (600) nm with standards

• Lowry 750 (600) nm with standards

• Nano Orange 485/595 nm with standards

Cell viability

• CellTiter-Blue Assay

• Apo-ONE Caspase-3/7 Assay

Page 54

54

Predefined methods

Eppendorf

English (EN)

®

PlateReader AF2200

6.2 Method description

6.2.1 Nucleic acid quantification (UV 260 nm microvolume)

This method is restricted to the Eppendorf μPlate G0.5.

For microvolume measurements with the μPlate G0.5 please refer to the dedicated manual.

6.2.2 Nucleic acid quantification (UV 260 nm with factor)

Introduction

The most common technique for measuring nucleic acid concentration is based on measuring the

absorbance at 260 nm. According to the Lambert-Beer law, the amount of absorbed light is proportional to

the concentration of the sample and to the path length of the light passing through a sample.

A = ε * d * c

AAbsorbance, OD

ε Extinction Coefficient

d Distance (path length in cm)

c Concentration

Wavelength 260 nm

Sample Type dsDNA ssDNA RNA

average extinction

coefficient ε [μg/mL]

concentration [μg/ml] at

A =1,0 and d = 1,0

For the Eppendorf Microplate UV-VIS, 96/F the path lengths of 100, 150, 200, 250 and 300 μL per well have

been determined. Thus, the nucleic acid concentration can easily be calculated.

To assess the purity of the nucleic acid sample, an additional "Ratio" measurement at 280 nm may be

performed to indicate the presence of proteins or organic compounds in the sample. For pure DNA, a 260/

280 ratio between 1.8 - 1.9 is acceptable; for pure RNA, a 260/280 ratio of approximately 2.0 is acceptable.

0,02 0,027 0,025

50 33 40

Page 55

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

Default measurement parameters

• Measurement wavelength: 260 (5) nm

• Ratio wavelength (for purity check with 260/280 ratio): 280 (5) nm, optional

• Background wavelength (for correction of turbidity): 340 (10) nm, optional

•Number of flashes: 25

• Settle time: 0 ms

• Plate definition: Eppendorf Microplate UV-VIS, 96/F

The method is restricted to Eppendorf Microplate UV-VIS, 96/F. The pathlengths are

determined for aquaeus buffer. For accurate results the meniscus of the sample has to be flat.

This method does not work for samples solved or diluted in detergent.

User defined method parameters

• The measurement is performed at 260 nm with default measurement parameters.

• For a ratio measurement, select the Ratio wavelength 280 nm check box.

• For a background measurement, select the Background wavelength 340 nm check box.

• Ratio wavelength and background wavelength may also be combined.

• Define the number of blank replicates (possible number: 1–8).

• Define the number of samples (max. 95, depends on number of blank replicates).

• Select the type of sample under Sample type (possible selection: dsDNA, ssDNA, RNA).

• Select your sample volume under Sample volume (possible selection: 100; 150; 200; 250; 300 μL).

• Define the unit (possible selection: μg/mL or ng/μL).

• Check if entered parameters are correct.

• Required plate layout: Pipette in a vertical order, starting with blanks at position A1. Samples are

pipetted in subsequent wells.

• Press Start.

• For method results and data evaluation principle see chapter method results and evaluation procedure.

55

Page 56

56

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

Plate layout

Abb. 6-2: Method strip: Nuclei c acid quantif ication (UV 2 60 nm with fac tor)

Fig. 6-2: Method strip: Nucleic acid quantification (UV 260 nm with factor)

The selected number of blanks and samples are shown in the plate view on the right side of the method

strip.

6.2.3 Nucleic acid quantification (UV 260 nm with standards)

Introduction

The most common technique for determining the concentration of a nucleic acid sample is based on

measuring the absorbance at 260 nm. By using two or more nucleic acid standards of known

concentrations, the nucleic acid concentrations of unknown samples can be obtained.

Default measurement parameters

• Measurement wavelength: 260 (5) nm

•Number of flashes: 25

• Settle time: 0 ms

• Plate definition: Eppendorf Microplate UV-VIS, 96/F or comparable plates

The method is restricted to 96-well UV transparent microplates.

Page 57

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

User defined method parameters

• The measurement is performed at 260 nm with default measurement parameters.

• Define the number of blank replicates (possible number: 1 – 8).

• Define the number of standards (possible number: 2 – 12).

• Define number of standard replicates (possible number: 1 – 8).

• Define the concentrations of each standard (Press triangle button to open the menu).

• Define the number of samples (max. 93, depends on number of blanks and standards).

• Define the unit of your concentration.

• Check if entered parameters are correct.

• Required plate layout: Pipette in a vertical order, starting with blanks at position A1. Standards are

pipetted in subsequent wells, samples must be placed in the following wells.

• Press Start.

• For method results and data evaluation principle see chapter method results and evaluation procedure

57

Page 58

58

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

Plate layout

Abb. 6-3: Method strip: Nucleic acid quantification (UV 260 nm with standards)

Fig. 6-3: Method strip: Nucleic acid quantification (UV 260 nm with standards)

The selected number of blanks, standards and samples are shown in the plate view on the right side of the

method strip.

Page 59

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

6.2.4 Nucleic acid quantification (Fluorescence 485/535 nm with standards)

Introduction

PicoGreen is a highly sensitive fluorescent nucleic acid stain for the quantitation of double-stranded

(ds)DNA in solution. The measured fluorescence intensity signal is directly proportional to the amount of

dsDNA present in the sample.

RiboGreen is one of the most sensitive stains for the detection and quantitation of RNA in solution. The

measured fluorescence intensity signal is directly proportional to the amount of RNA present in the sample.

By using two or more nucleic acid standards of known concentrations, the nucleic acid concentrations of

unknown samples can be obtained.

Default measurement parameters

• Excitation wavelength: 485 (20) nm

• Emission wavelength: 535 (25) nm

•Number of flashes: 25

• Settle time: 0 ms

•Mode: Top

• Lag time: 0 μs

• Integration: 20 μs

• Gain: ‘optimal’

• Plate definition: Eppendorf Microplate 96/U-PP, black or comparable plates

59

The method is restricted to 96-well microplates.

User defined method parameters

• The measurement is performed at 485/535 nm with default measurement parameters.

• Define the number of blank replicates (possible number: 1 – 8).

• Define the number of standards (possible number: 2 – 12).

• Define number of standard replicates (possible number: 1 – 8).

• Define the concentrations of each standard (Press triangle button to open the menu).

• Define the number of samples (max. 93, depends on number of blanks and standards).

• Define the unit of your concentration.

• Check if entered parameters are correct.

• Required plate layout: Pipette in a vertical order, starting with blanks at position A1. Standards are

pipetted in subsequent wells, samples must be placed in the following wells.

• Press Start.

• For method results and data evaluation principle see chapter method results and evaluation procedure.

Page 60

60

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

Plate layout

Abb. 6-4: Method strip: Nu cleic acid quantif ication (Fluorescence 485/535 nm with st andards)

Fig. 6-4: Method strip: Nucleic acid quantification (Fluorescence 485/535 nm with standards)

The selected number of blanks, standards and samples are shown in the plate view on the right side of the

method strip.

Page 61

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

6.2.5 Protein quantification BCA, Bradford, Lowry

BCA 562 (600) nm with standards, Bradford 595 (600) nm with standards, Lowry 750 (600) nm with

standards

Introduction

The BCA Protein Assay uses bicinchoninic acid (BCA) for colorimetric quantification of total protein in a

sample. The method is based on the reduction of Cu2+ to Cu1+ by protein in an alkaline medium. Cu1+

complexes with BCA, forming a colored water-soluble chelate with an absorption maximum at 562 nm.

The Bradford assay is a colorimetric assay based on an absorbance shift of the Coomassie Brilliant Blue

G-250 dye. Under acidic conditions, the green form of the dye is converted into its blue form, which binds

to the protein being assayed. In this process, the absorbance maximum of the dye is shifted from 465 nm to

595 nm.

The Lowry Assay is a colorimetric assay for the quantification of soluble protein. The protein complexes

with cupric sulfate and tartrate in an alkaline solution and reduces the Folin-Ciocalteu reagent. The reaction

product is blue-colored and water-soluble, with an absorption maximum between 500 and 800 nm.

61

By using two or more protein standards of known concentrations, the protein concentrations of unknown

samples can be obtained.

Using the Eppendorf preconfigured UV/Vis filter slide these methods are measured at 600nm.

As for BCA the absorbance at 600nm is merely half as big as in the BCA absorbance maximum

at 562nm the results of the lower concentrations are slightly inaccurate in comparison to a

measurement at 562nm. The absorbance maxima of Lowry and Bradford are close to 600nm.

Therefore the results of these methods are not restricted by a measurement wavelength of

600nm.

Default measurement parameters

• Measurement wavelength BCA: 562 (600) (10) nm

• Measurement wavelength Bradford: 595 (600) (10) nm

• Measurement wavelength Lowry: 750 (600) (10) nm

•Number of flashes: 25

• Settle time: 0 ms

• Plate definition: Eppendorf Microplate VIS, 96/F-PS or comparable plates

The method is restricted to transparent 96-well microplates.

Page 62

62

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

User defined method parameters

• Using the predefined UV/Vis filter slide the measurement is performed at 600 nm with default

measurement parameters.

• Define the number of blank replicates (possible number: 1 – 8).

• Define the number of standards (possible number: 2 – 12).

• Define number of standard replicates (possible number: 1 – 8).

• Define the concentrations of each standard (Press triangle button to open the menu).

• Define the number of samples (max. 93, depends on number of blanks and standards).

• Define the unit of your concentration.

• Check if entered parameters are correct.

• Required plate layout: Pipette in a vertical order, starting with blanks at position A1. Standards are

pipetted in subsequent wells, samples must be placed in the following wells.

• Press Start.

• For method results and data evaluation principle see chapter method results and evaluation procedure.

Plate layout

Abb. 6-5: Method strip: Protein quant ification (BCA 562 (600) nm wit h standards)

Fig. 6-5: Method strip: Protein quantification (BCA 562 (600) nm with standards)

The selected number of blanks, standards and samples are shown in the plate view.

Page 63

Predefined methods

®

Eppendorf

PlateReader AF2200

English (EN)

6.2.6 Protein quantification (NanoOrange 485/595 nm with standards)

Introduction

NanoOrange (Molecular Probes) is a highly sensitive fluorescent stain for protein quantification in solution.

The reagent is virtually non-fluorescent in aqueous solution, but when bound to proteins undergoes a

strong fluorescence enhancement with a broad excitation peak centered at app. 470 nm and a broad

emission peak centered at app. 570 nm.

By using three or more protein standards of known concentrations, the protein concentrations of unknown

samples can be obtained.

Default measurement parameters

• Excitation wavelength: 485 (20) nm

• Emission wavelength: 595 (25) nm

•Number of flashes: 25

• Settle time: 0 ms

•Mode: Top

• Lag time: 0 μs

• Integration: 20 μs

• Gain: "optimal"

• Plate definition: Eppendorf Microplate 96/U-PP, black" or comparable plates

63