Endress+Hauser S TAF11, S TAF12S, S TAF16 Specifications

TI00251T/09/en/14.13

71214661

Products Solutions Services

Technical Information

Omnigrad S

TAF11, TAF12x, TAF16

High temperature assemblies

With metal or ceramic protection tubes

Adjustable process connection

Thermocouple sensor types J, K, N, R, S, B

Application

TAF11

• Applicable for steel treatment (annealing), concrete furnaces and primaries.

It contains a single or double TC insert and a ceramic protection tube.

TAF12x

• The versions S/D/T are assemblies with single/double/triple ceramic protection

tubes, designed specifically for applications such as ceramic baking ovens,

brickworks, porcelain production and glass industries. They contain a single or

double TC insert in ceramic insulators.

TAF16

• Applicable for cement production, steel treatment, incinerators and fluidized bed

furnaces. The TAF16 contains a single or double TC insert and a metal or ceramic

protection tube.

Process temperatures:

• TAF11 up to +1600 °C (+2912 °F)

• TAF12 up to +1700 °C (+3092 °F)

• TAF16 up to +1700 °C (+3092 °F)

Your benefits

• Long lifetime by usage of innovative protection tube materials with increased wear

and chemical resistance

• Long term stable measurement due to sensor protection with non-porous materials

• Flexible product selection by modular design

• Optimized life cycle costs by means of replaceable spare parts

TAF11, TAF12x, TAF16

ENDRESS+HAUSER

TMT 122

B

°C

C D

A

Function and system design

Measuring principle Thermocouples are comparatively simple, robust temperature sensors which use the Seebeck effect for

temperature measurement: if two electrical conductors made of different materials are connected at a

point, a weak electrical voltage can be measured between the two open conductor ends if the

conductors are subjected to a thermal gradient. This voltage is called thermoelectric voltage or

electromotive force (emf.). Its magnitude depends on the type of conducting materials and the

temperature difference between the "measuring point" (the junction of the two conductors) and the

"cold junction" (the open conductor ends). Accordingly, thermocouples primarily only measure

differences in temperature. The absolute temperature at the measuring point can be determined from

these if the associated temperature at the cold junction is known or is measured separately and

compensated for. The material combinations and associated thermoelectric voltage/temperature

characteristics of the most common types of thermocouple are standardized in the IEC 60584 and

ASTM E230/ANSI MC96.1 standards.

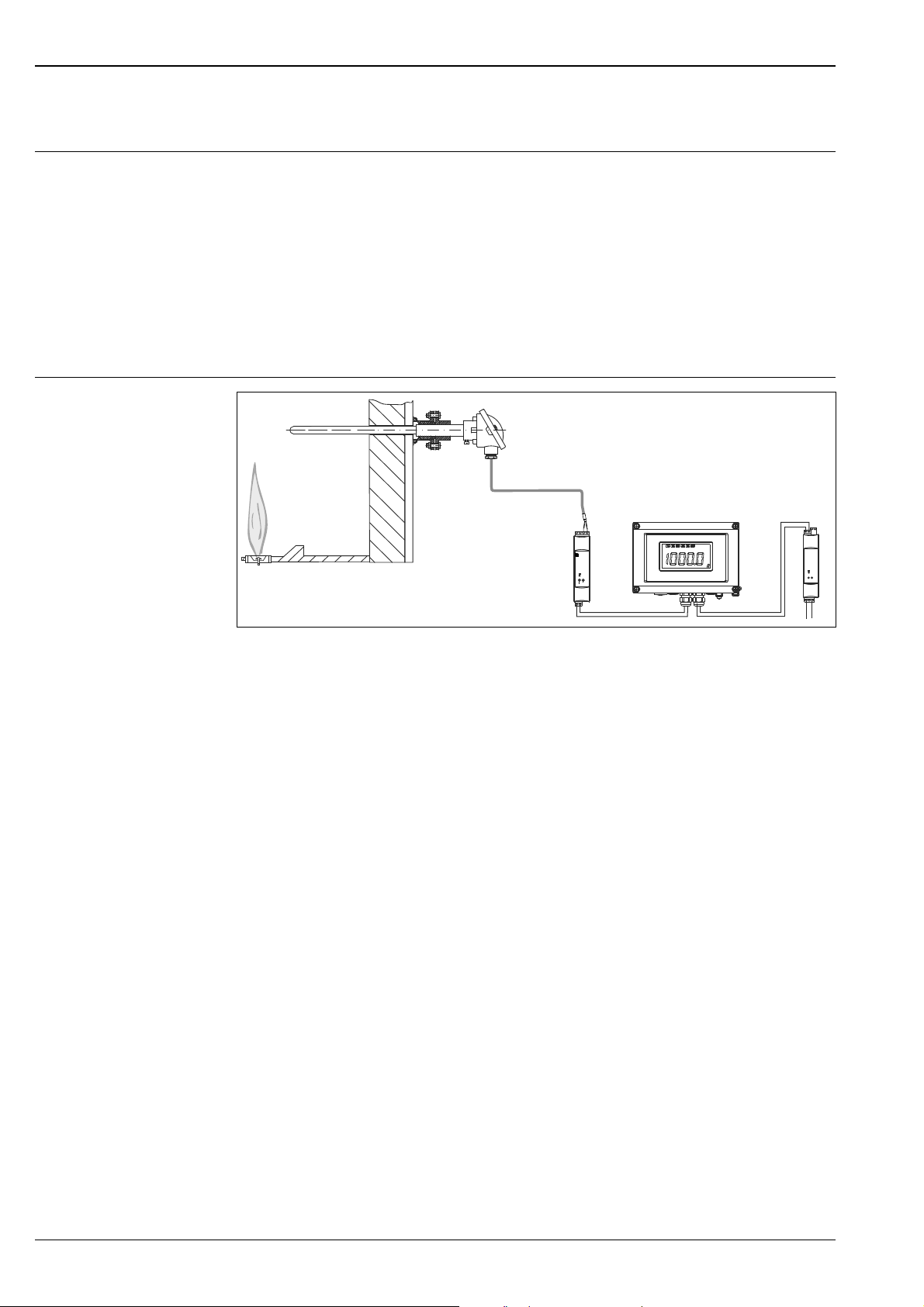

Measuring system

Example of an application

A Thermometer of the TAF series, installed in the reactor wall of a furnace

B Temperature transmitter iTEMP

of the

thermocouple thermometer and converts them into an analog 4 to 20 mA measurement signal.

C RIA16 field display unit

– The display unit records the analog measuring signal from the head transmitter and shows this on the

display. The LC display shows the current measured value in digital form and as a bar graph indicating a limit

value violation. The display unit is looped into the 4 to 20 mA circuit and gets the required energy from there.

More information on this can be found in the Technical Information (see "Documentation").

D Active barrier RN221N

– The RN221N active barrier (24 V DC, 30 mA) has an galvanically isolated output for supplying voltage to

loop powered transmitters. The universal power supply works with an input supply voltage of 20 to

250 V DC/AC, 50/60 Hz, which means that it can be used in all international power grids. More information

on this can be found in the Technical Information (see "Documentation").

®

DIN rail TMT12x. The two-wire transmitter detects the measurement signals

a0015182

2 Endress+Hauser

TAF11, TAF12x, TAF16

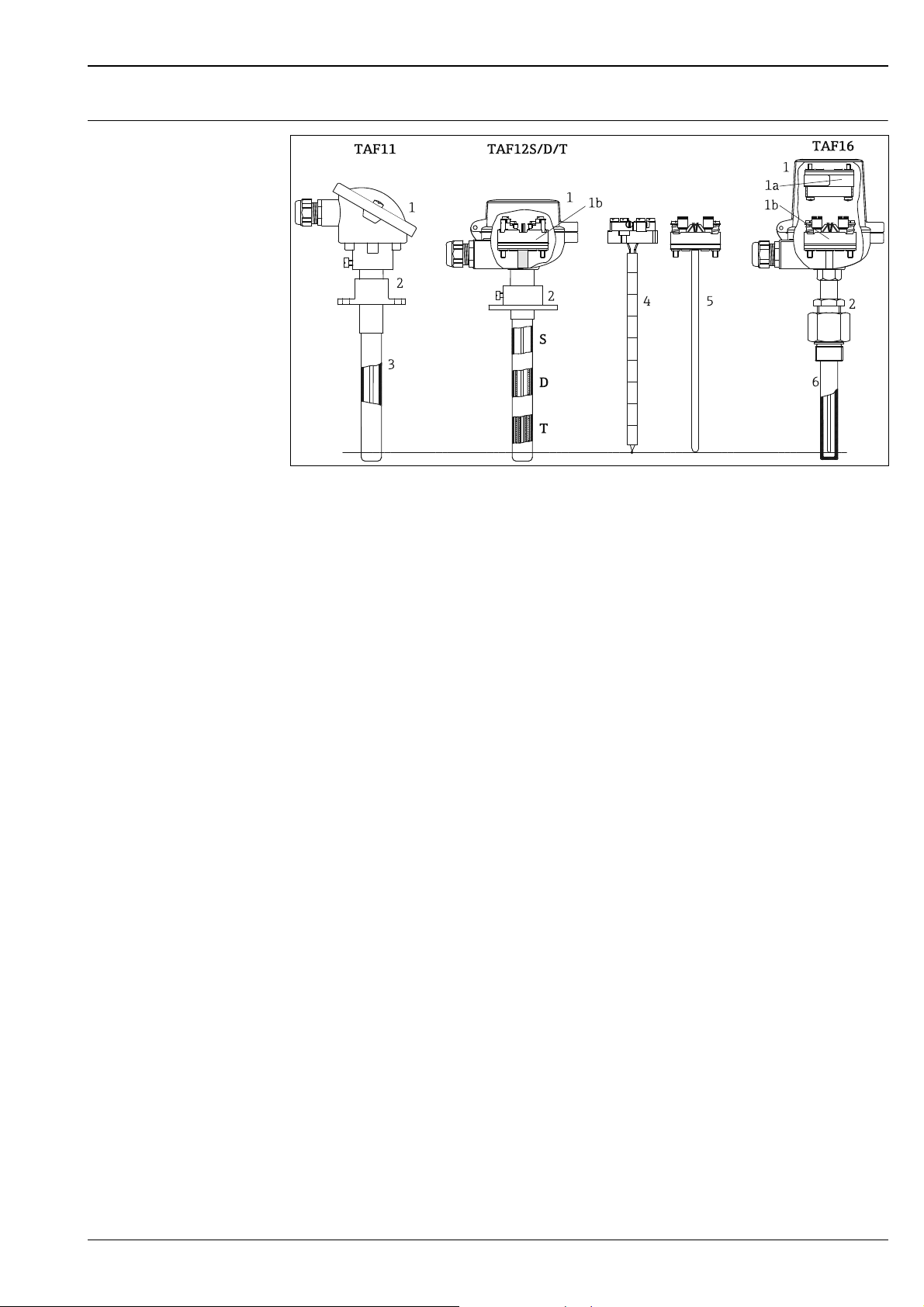

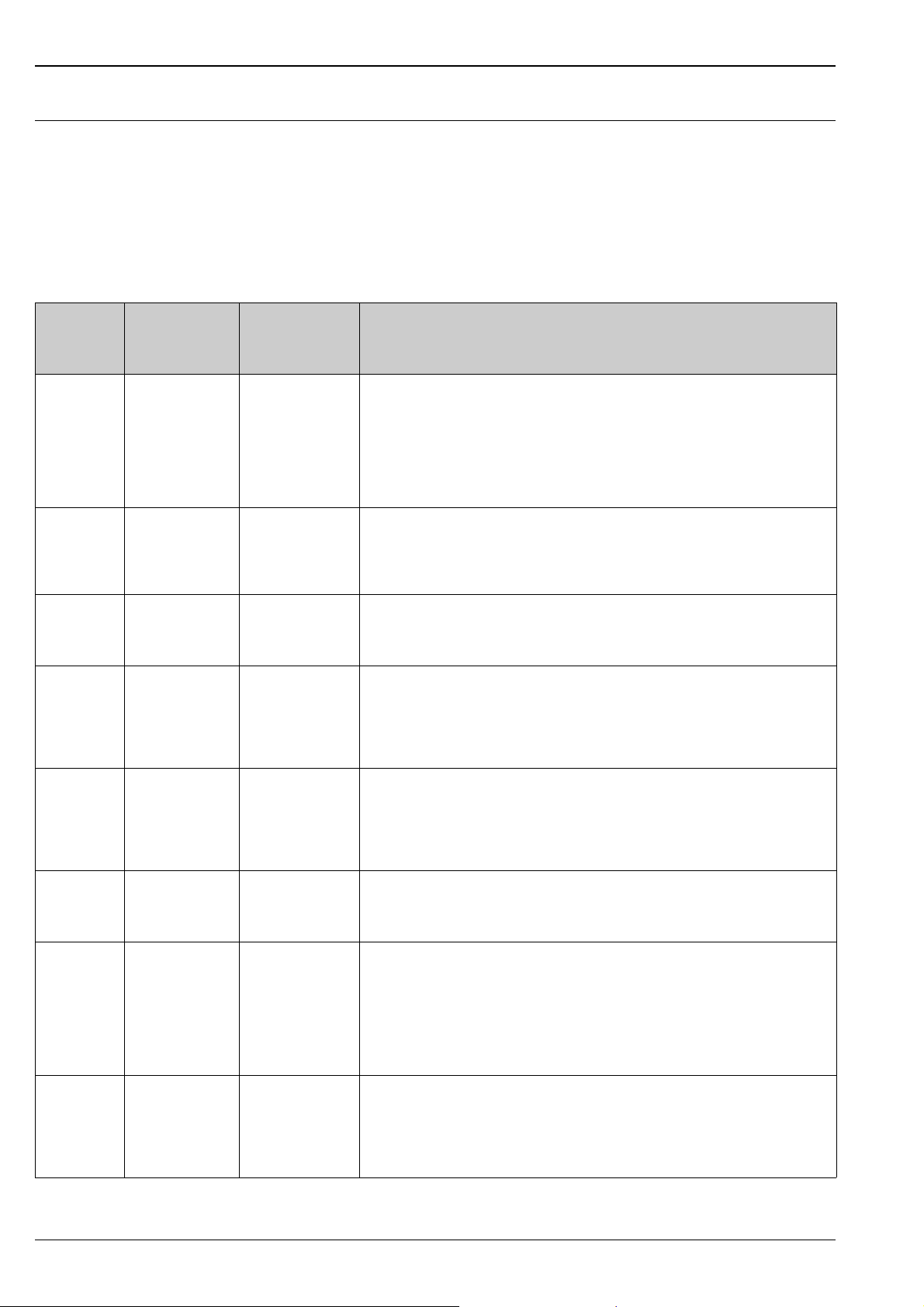

Equipment architecture

a0015181

High temperature assemblies design

1

Terminal head DIN A (see left side) or DIN B (e.g.

see right side) with following available electrical

connections:

1a

– Terminal block DIN B with head transmitter

(only in high cover terminal head)

1b

–Terminal block (DIN B) or

– Flying leads, only with MgO insulated insert

2 Available process connections:

Stop flange according to DIN EN 50446,

adjustable flange, or gas-tight compression fitting

3 Ceramic protection tube (external sheath for

TAF11)

S

(Single) ceramic protection tube external sheath for

TAF12

D

(Double) ceramic protection tube external and middle

sheath for TAF12

T

(Triple) ceramic protection tube external, middle and

internal sheath for TAF12

45Measuring insert TPC200 with ceramic isolation

Measuring insert TPC100 with MgO insulation and

metallic sheath, selectable for TAF11 and TAF16

6 Metal or ceramic protection tube for TAF16

TAF series high temperature assemblies are manufactured according to international DIN EN 50446

standards. These products consist of a measuring insert, a protection tube, a metal sleeve (only TAF11/

TAF12x) and a terminal head, which contains a transmitter or terminal block as electrical connection.

Measuring insert

The measuring point of the thermocouple is located close to the tip of the insert. The operating

temperature ranges (→ ä 4) and permissible deviation limits of the thermoelectric voltages from the

standard characteristic (→ ä 5) vary according to the type of thermocouple used. The thermocouple

wires are inserted in appropriate high-temperature-resistant ceramic isolators or in a mineral

insulated insert.

Protection tube

Two types are commonly used in this type of assembly:

• Metallic protection tube, usually machined from tubes or bars.

• Ceramic protection tube.

The selection of the protection tube materials majorly depends on the following material properties,

which will directly influence the lifetime of the sensor:

•Hardness

• Chemical resistance

• Maximum operating temperature

• Wear/abrasion resistance

•Brittleness

• Porosity for process gases

• Creep resistance

Ceramic materials are commonly used for highest temperatures and, due to their hardness, for

applications with high abrasion rates. Attention has to be paid regarding the brittleness of these

materials when exposed to high mechanical loads inside the process. When using porous ceramics as

Endress+Hauser 3

TAF11, TAF12x, TAF16

external protection sheath, an additional, non-porous inner protection sheath has to be used in order

to protect the noble sensor elements from contamination leading to temperature drift.

Metal alloys generally show higher mechanical resistance but lower maximum temperature limits and

less abrasion resistance. All metal alloys are non-porous and usually there is no need for an additional

inner protection sheath.

Metal sleeve and process connection

The TAF11 and TAF12 ceramic protection tubes are mounted into a metal sleeve which connects them

towards the terminal head. Also the process connection is fitted on the metal sleeve due to its higher

mechanical strength. The dimensions and material type for the sleeve are related to the process

temperatures and insertion length of the ceramic protection tubes.

All high temperature assemblies are available with an adjustable flange, stop flanges or gas tight

compression fittings.

Measuring range

Input Designation Measuring range limits

Thermocouples (TC)

as per IEC 60584,

part 1 - using an

Endress+Hauser -

®

iTEMP

temperature

head transmitter

Thermocouples (TC)

- flying leads - as per

IEC 60584

1) For definite ranges see respective Technical Information (→ ä 18) of the head transmitters.

2) Typical sensitivity above 0 °C (+32 °F)

Type J (Fe-CuNi)

Type K (NiCr-NiAl)

Type N (NiCrSi-NiSi)

Type S (PtRh10-Pt)

Type R (PtRh13-Pt)

Type B (PtRh30PtRh6)

• Internal cold junction (Pt100)

• Cold junction accuracy: ± 1 K

• Max. sensor resistance 10 kΩ

2)

Type J (Fe-CuNi)

Type K (NiCr-NiAl)

Type N (NiCrSi-NiSi)

Type S (PtRh10-Pt)

Type R (PtRh13-Pt)

Type B (PtRh30PtRh6)

typ. -200… +1200 °C (-328… +2192 °F)

typ. -200… +1372 °C (-328… +2502 °F)

typ. -270... +1300 °C (-454... +2372 °F)

typ. -50… +1768 °C (-58… +3214 °F)

typ. -50… +1768 °C (-58... +3214 °F)

typ. +40… +1820 °C (+104... + 3308 °F)

-210… +1200 °C (-346… +2192 °F), typical sensitivity ≈ 55 μV/K

-270… +1372 °C (-454… +2502 °F), typical sensitivity ≈ 40 μV/K

-270… +1300 °C (-454… +2372 °F), typical sensitivity ≈ 40 μV/K

-50… +1768 °C (-58… +3214 °F), typical sensitivity ≈ 11 μV/K

-50… +1768 °C (-58… +3214 °F), typical sensitivity ≈ 13 μV/K

0… +1820 °C (+32... +3308 °F), typical sensitivity ≈ 9 μV/K

1)

Min. span

50 K

50 K

50 K

500 K

500 K

500 K

Performance characteristics

Operating conditions Ambient temperature

Terminal head Temperature in °C (°F)

Without mounted head transmitter Depends on the terminal head and cable gland used, see 'Terminal

With mounted head transmitter -40 to +85 °C (-40 to +185 °F)

heads' section, → ä 8

Process pressure

Depends on material.

High temperature assemblies are generally designed for use in pressureless processes. Available

process connections can be gas tight up to 1 bar, details → ä 12.

Permitted flow rate as a function of immersion length

Depends on material and application. For process pressures ≥ 1 bar and a flow rate ≥ 1 m/s it is

recommended to order a protection tube stress calculation, please contact your nearest

Endress+Hauser sales organisation.

Shock and vibration resistance

Valid for MgO insulated inserts: 4g / 2 to 150 Hz as per IEC 60068-2-6

4 Endress+Hauser

TAF11, TAF12x, TAF16

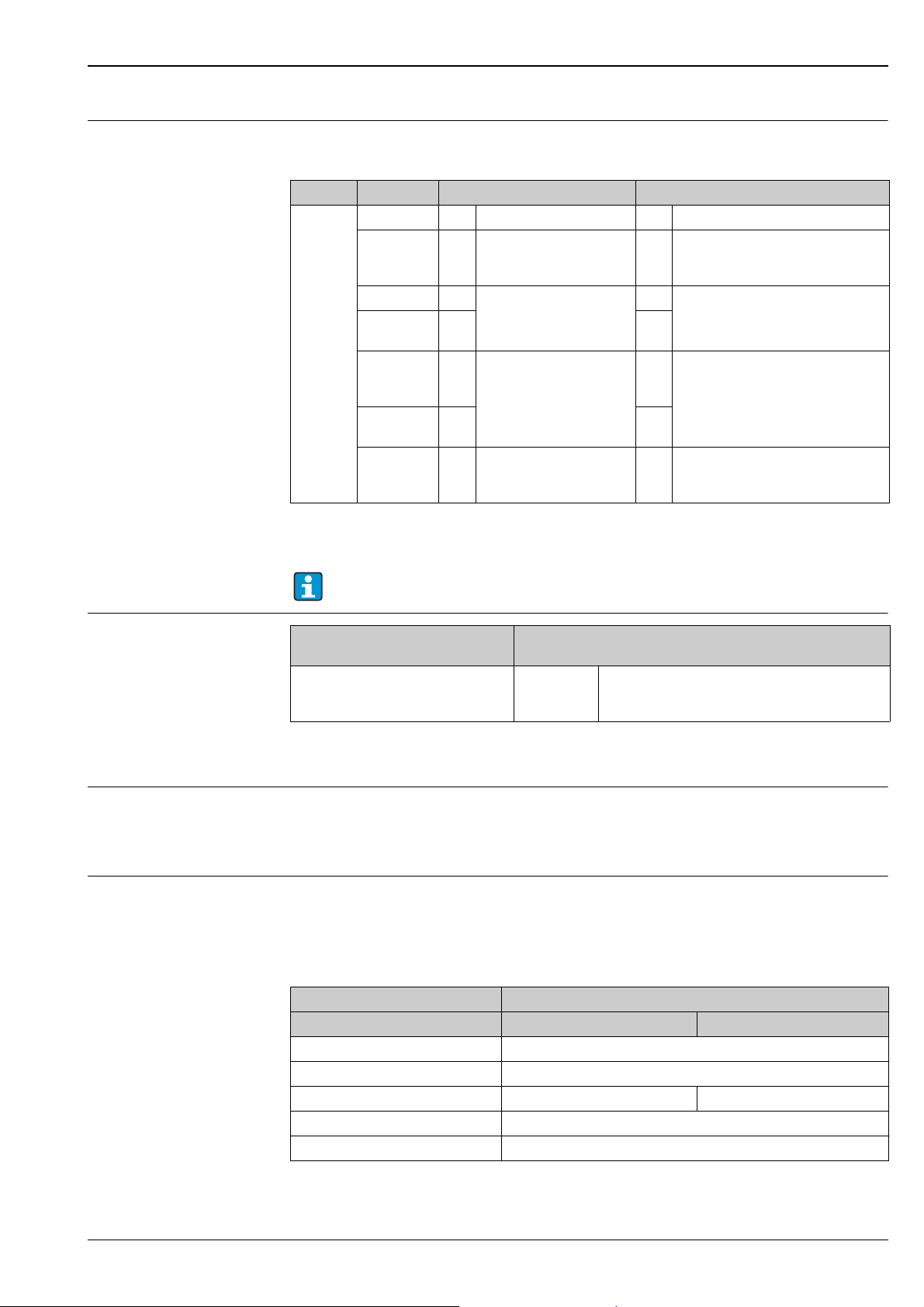

Accuracy Permissible deviation limits of thermoelectric voltages from standard characteristic for thermocouples

as per IEC 60584:

Standard Type Standard tolerance Special tolerance

Class Deviation Class Deviation

IEC 60584

J (Fe-CuNi) 2 ±2.5 °C (-40 to 333 °C)

±0.0075 |t|

750 °C)

K (NiCr-NiAl) 2

N (NiCrSiNiSi)

R (PtRh13Pt) and S

(PtRh10-Pt)

S (PtRh13Pt)

B (PtRh30PtRh6)

±2.5 °C (-40 to 333 °C)

±0.0075 |t|

21

1200 °C)

2

±1.5 °C (0 to 600 °C)

±0.0025 |t|

1600 °C)

21

2 ±1.5 °C or

±0.0025 |t|

1700 °C)

1)

(333 to

1)

(333 to

1)

(600 to

1)

(600 to

1 ±1.5 °C (-40 to 375 °C)

±0.004 |t|1) (375 to 750 °C)

1

±1.5 °C (-40 to 375 °C)

±0.004 |t|

1

±1 °C (0 to 1100 °C)

±[1 + 0.003(|t|1) -1100)]

(1100 °C to 1600 °C)

--

1)

(375 to 1000 °C)

1) |t| = Absolute temperature value in °C

In order to obtain the maximum tolerances in °F, the results in °C must be multiplied by a factor

of 1.8.

Response time

Assembly probe Response time1) for fast temperature change from 1000 °C

TAF12T with Ø26/Ø14/Ø9 mm triple

ceramic protection tube (material

C530+C610)

1) For the assembly without transmitter

(1832 °F) to room temperature in stationary air

t

50

t

90

195 s

500 s

Insulation resistance Insulation resistance between each terminal and the sheath is measured with a voltage of 500 V DC.

Insulation resistance ≥ 1000 MΩ at ambient temperature 25 °C (77 °F).

Insulation resistance ≥ 5 MΩ at temperature 500 °C (932 °F).

For TAF16 with 6 mm (0.24 in) mineral insulated insert versions, standard DIN EN 61515 is applied.

Calibration specifications Endress+Hauser provides comparison temperature calibration from -80 to +1400 °C (-110 °F to 2552

°F) based on the International Temperature Scale (ITS90). Calibrations are traceable to national and

international standards. The calibration report is referenced to the serial number of the thermometer.

Only the measurement insert is calibrated. In the case of thermometers without a replaceable insert,

the entire thermometer - from the process connection to the tip of the thermometer - is calibrated.

Minimum insertion length IL in mm (in)

Temperature range without head transmitter with head transmitter

-80 °C to -40 °C (-110 °F to -40 °F) 200 (7.87)

-40 °C to 0 °C (-40 °F to 32 °F) 160 (6.3)

0 °C to 250 °C (32 °F to 480 °F) 120 (4.72) 150 (5.9)

250 °C to 550 °C (480 °F to 1020 °F) 300 (11.81)

550 °C to 1400 °C (1020 °F to 2552 °F) 450 (17.75)

Endress+Hauser 5

Material Sheath and protection tube.

The temperatures for continuous operation specified in the following table are only intended as

reference values for use of the various materials in air and without any significant compressive load.

The maximum operation temperatures are reduced considerably in some cases where abnormal

conditions such as high mechanical load occur or in aggressive media.

Endress+Hauser supplies DIN/EN threaded process connections and flanges made of stainless steel

according to AISI 316L (DIN/EN material number 1.4404 or 1.4435). With regard to their

temperature stability properties, the materials 1.4404 and 1.4435 are grouped under 13E0 in EN

1092-1 Tab. 18. The chemical composition of the two materials can be identical.

TAF11, TAF12x, TAF16

Material

name

AISI 316L/

1.4404

1.4435

AISI 310/

1.4841

AISI 304/

1.4301

AISI 446/

~1.4762/

~1.4749

INCONEL

/ 2.4816

INCONEL

/ 2.4851

INCOLOY

HT / 1.4959

Kanthal AF FeCrAl 1300 °C (2372 °F) • A high-temperature ferritic iron/chromium/aluminum alloy

Short form Recommended

X2CrNiMo17-12-2

X2CrNiMo18-14-3

X15CrNiSi25-20 1100 °C (2012 °F) • Austenitic, stainless steel

X5CrNi18-10 850 °C (1562 °F) • Austenitic, stainless steel

X10CrAl24 /

X18CrNi24

®

600

NiCr15Fe 1100 °C (2012 °F) • A nickel/chromium alloy with very good resistance to aggressive, oxidizing and

®

601

NiCr23Fe 1200 °C (2192 °F) • High temperature corrosion resistance enhanced by aluminum content

®

800

X8NiCrAlTi32-21 1100 °C (2012 °F) • A nickel/chromium/iron alloy that has the same basic composition as INCOLOY®800,

max. temperature

for continuous use

in air

650 °C (1200 °F)

1100 °C (2012 °F) • A ferritic, heat resistant, high-chromium stainless steel

Properties

1)

• Austenitic, stainless steel

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorine-based and acidic, non-oxidizing

atmospheres through the addition of molybdenum (e.g. phosphoric and sulfuric acids,

acetic and tartaric acids with a low concentration)

• Increased resistance to intergranular corrosion and pitting

• Compared to 1.4404, 1.4435 has even higher corrosion resistance and a lower delta

ferrite content

• Good resistance to oxidizing and reducing atmospheres

• Due to the higher chromium content well resistant to oxidizing aqueous solution and

neutral salts melting at higher temperatures

• Only weakly resistant to sulphurous gases

• Well usable in water and lowly pollute waste water

• Only at relatively low temperatures resistant to organic acids, saline solutions,

sulphates, alkaline solutions, etc.

• Very high resistance to reducing sulphurous gases and salts with low content of

oxygen

• Very good resistance to constant as well as cyclical thermal stress, to incineration ash-

corrosion and to melts of copper, lead and tin

• Poorly resistant to gases containing nitrogen

reducing atmospheres, even at high temperatures

• Resistant to corrosion caused by chlorine gas and chlorinated media as well as many

oxidizing mineral and organic acids, sea water etc.

• Corrodible by ultrapure water

• Not to be used in a sulfur-containing atmosphere

• Resistance to oxide spalling and carburization under thermal cycling

• Good resistance against molten salt corrosion

• Particularly susceptible to sulfidation

but has significantly higher creep rupture strength, resultant from the close control of

the carbon, aluminum and titanium contents.

• Good strength and excellent resistance to oxidation and carburization at high

temperature environments.

• Good resistance to stress corrosion cracking, attack by sulfur, internal oxidation,

scaling and corrosion in a multitude of industrial environments. Suitable for sulfurous

environments.

• High resistance to sulfurous, carburizing and oxidising environments

• Good hardness and weldability

• Good form stability at high temperature

• Not to be used in a chloride-containing atmosphere and in nitrogenous gases (cracked

ammonia)

6 Endress+Hauser

Loading...

Loading...