TI01040F/00/EN/09.18

71394703

2018-04-12

Products

Solutions Services

Technical Information

Micropilot FMR51, FMR52

Free space radar

Level measurement in liquids

Application

• Continuous, non-contact level measurement of liquids, pastes and slurries

• Horn antenna (FMR51); flush mounted, completely filled PTFE horn antenna

(FMR52)

• Maximum measuring range: 70 m (230 ft)

• Process temperature: –196 to +450 °C (–321 to +842 °F)

• Process pressure: –1 to +160 bar (–14.5 to +2 320 psi)

• Accuracy: ± 2 mm

• International explosion protection certificates; WHG; marine approvals

• Linearity protocol (3-point, 5-point)

Your benefits

• Reliable measurement even for changing product and process conditions

• HistoROM data management for easy commissioning, maintenance and

diagnostics

• Highest reliability due to Multi-Echo Tracking

• SIL2 according to IEC 61508, SIL3 in case of homogeneous or heterogeneous

redundancy

• Seamless integration into control or asset management systems

• Intuitive user interface in national languages

• Bluetooth® wireless technology for commissioning, operation and maintenance via

free iOS / Android app SmartBlue

• Easy proof test for SIL and WHG

• Heartbeat Technology™

Table of contents

Micropilot FMR51, FMR52

Wichtige Hinweise zum Dokument .............. 4

Symbols .................................... 4

Terms and abbreviations ........................ 6

Registered trademarks .......................... 7

Function and system design ................... 8

Measuring principle ............................ 8

Input .................................... 10

Measured variable ............................ 10

Measuring range ............................. 10

Operating frequency .......................... 15

Transmitting power ........................... 15

Output .................................. 16

Output signal ............................... 16

Signal on alarm .............................. 17

Linearization ............................... 17

Galvanic isolation ............................ 17

Protocol-specific data .......................... 17

Power supply ............................. 22

Terminal assignment .......................... 22

Device plug connectors ......................... 30

Supply voltage .............................. 31

Power consumption ........................... 33

Current consumption .......................... 33

Power supply failure .......................... 34

Potential equalization ......................... 34

Terminals ................................. 34

Cable entries ............................... 34

Cable specification ............................ 34

Overvoltage protection ......................... 35

Performance characteristics .................. 36

Reference operating conditions ................... 36

Maximum measured error ....................... 36

Measured value resolution ...................... 37

Reaction time ............................... 37

Influence of ambient temperature ................. 37

Influence of gas layer .......................... 37

Gas phase compensation with external pressure sensor

(PROFIBUS PA, FOUNDATION Fieldbus) ............. 38

Installation ............................... 39

Installation conditions ......................... 39

Measuring conditions .......................... 43

Mounting cladded flanges ....................... 44

Installation in vessel (free space) .................. 44

Installation in stilling well ....................... 48

Installation in bypass .......................... 50

Container with heat insulation .................... 52

Environment .............................. 53

Ambient temperature range ..................... 53

Ambient temperature limits ..................... 53

Storage temperature .......................... 61

Climate class ............................... 62

Altitude according to IEC61010-1 Ed.3 .............. 62

Degree of protection .......................... 62

Vibration resistance ........................... 62

Cleaning the antenna .......................... 62

Electromagnetic compatibility (EMC) ............... 62

Process .................................. 63

Process temperature, Process pressure .............. 63

Dielectric constant ............................ 65

Mechanical construction .................... 66

Dimensions ................................ 66

Weight ................................... 76

Materials: GT18 housing (stainless steel, corrosion-

resistant) .................................. 77

Materials: GT19 housing (plastic) .................. 78

Materials: GT20 housing (die-cast aluminum, powder-

coated) ................................... 79

Materials: Antenna and process connection ........... 80

Materials: Weather protection cover ................ 82

Operability ............................... 83

Operating concept ............................ 83

Local operation .............................. 84

Operation with remote display and operating module

FHX50 ................................... 84

Operation via Bluetooth® wireless technology .......... 85

Remote operation ............................ 86

Integration in tank gauging system ................. 89

SupplyCare inventory management software .......... 90

Certificates and approvals ................... 93

CE mark ................................... 93

RoHS ..................................... 93

RCM-Tick marking ............................ 93

Ex approval ................................ 93

Dual seal according to ANSI/ISA 12.27.01 ............ 93

Functional safety ............................. 93

WHG ..................................... 93

Sanitary compatibility ......................... 93

NACE MR 0175 / ISO 15156 ..................... 94

NACE MR 0103 ............................. 94

Pressure equipment with allowable pressure

≤ 200 bar (2 900 psi) .......................... 94

Marine certificate ............................ 94

Radio standard EN302729-1/2 ................... 94

Radio standard EN302372-1/2 ................... 95

FCC / Industry Canada ......................... 95

Japanese radio approval ........................ 96

CRN approval ............................... 96

Track record ................................ 97

Test, Certificate .............................. 98

Hard-copy product documentation ................. 98

Other standards and guidelines ................... 99

Ordering information ...................... 100

Ordering information ......................... 100

2 Endress+Hauser

Micropilot FMR51, FMR52

3-point linearity protocol ...................... 101

5-point linearity protocol ...................... 102

Customized parametrization .................... 103

Tagging (TAG) ............................. 103

Services .................................. 103

Application Packages ...................... 104

Heartbeat Diagnostics ........................ 104

Heartbeat Verification ........................ 105

Heartbeat Monitoring ......................... 106

Accessories .............................. 107

Device-specific accessories ...................... 107

Communication-specific accessories ............... 113

Service-specific accessories ..................... 114

System components .......................... 114

Documentation ........................... 115

Standard documentation ....................... 115

Supplementary documentation ................... 115

Safety Instructions (XA) ....................... 115

Endress+Hauser 3

Wichtige Hinweise zum Dokument

DANGER

WARNING

CAUTION

NOTICE

A

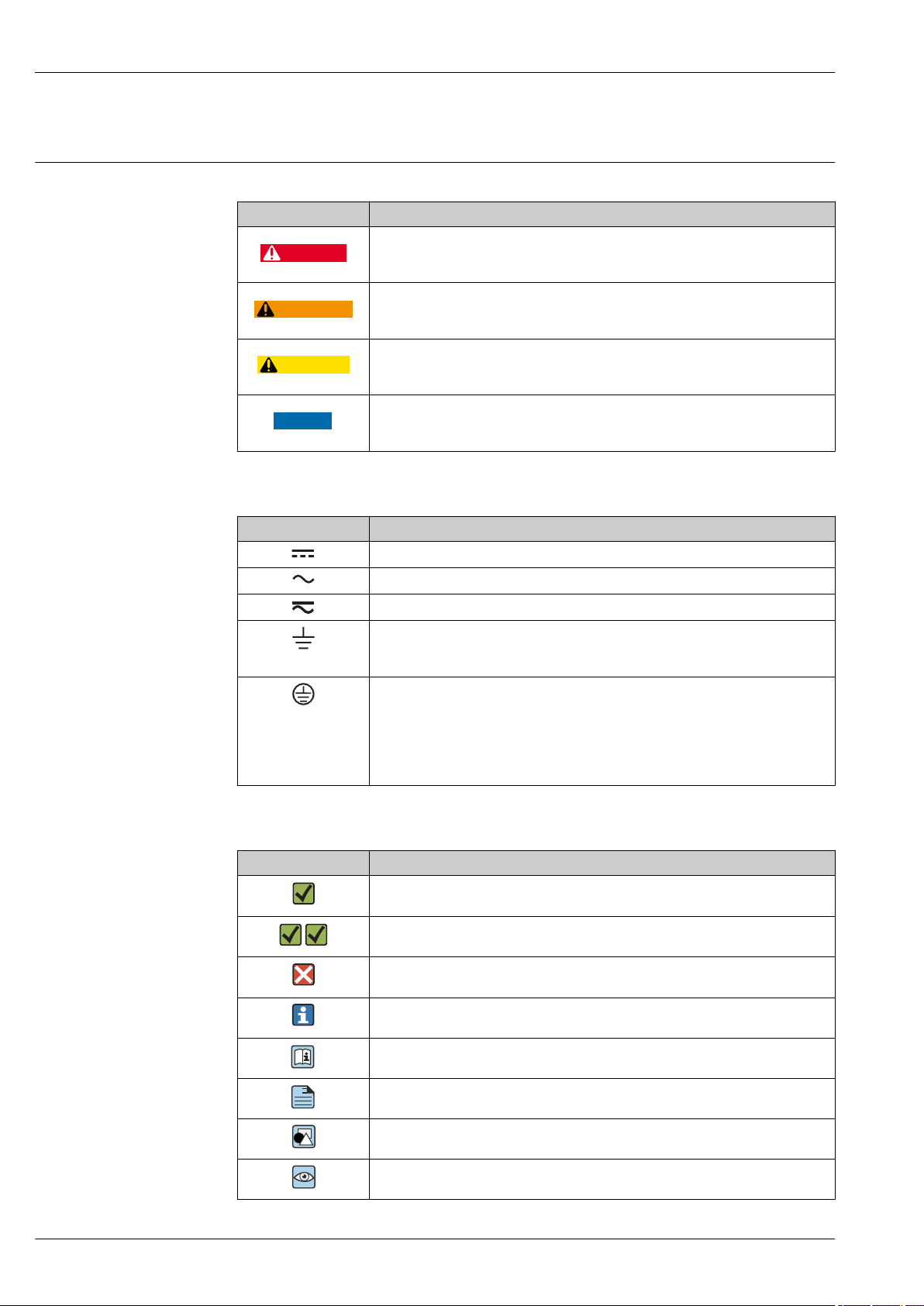

Symbols Safety symbols

Symbol Meaning

Electrical symbols

Micropilot FMR51, FMR52

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

Reference to page.

Reference to graphic.

Visual inspection.

4 Endress+Hauser

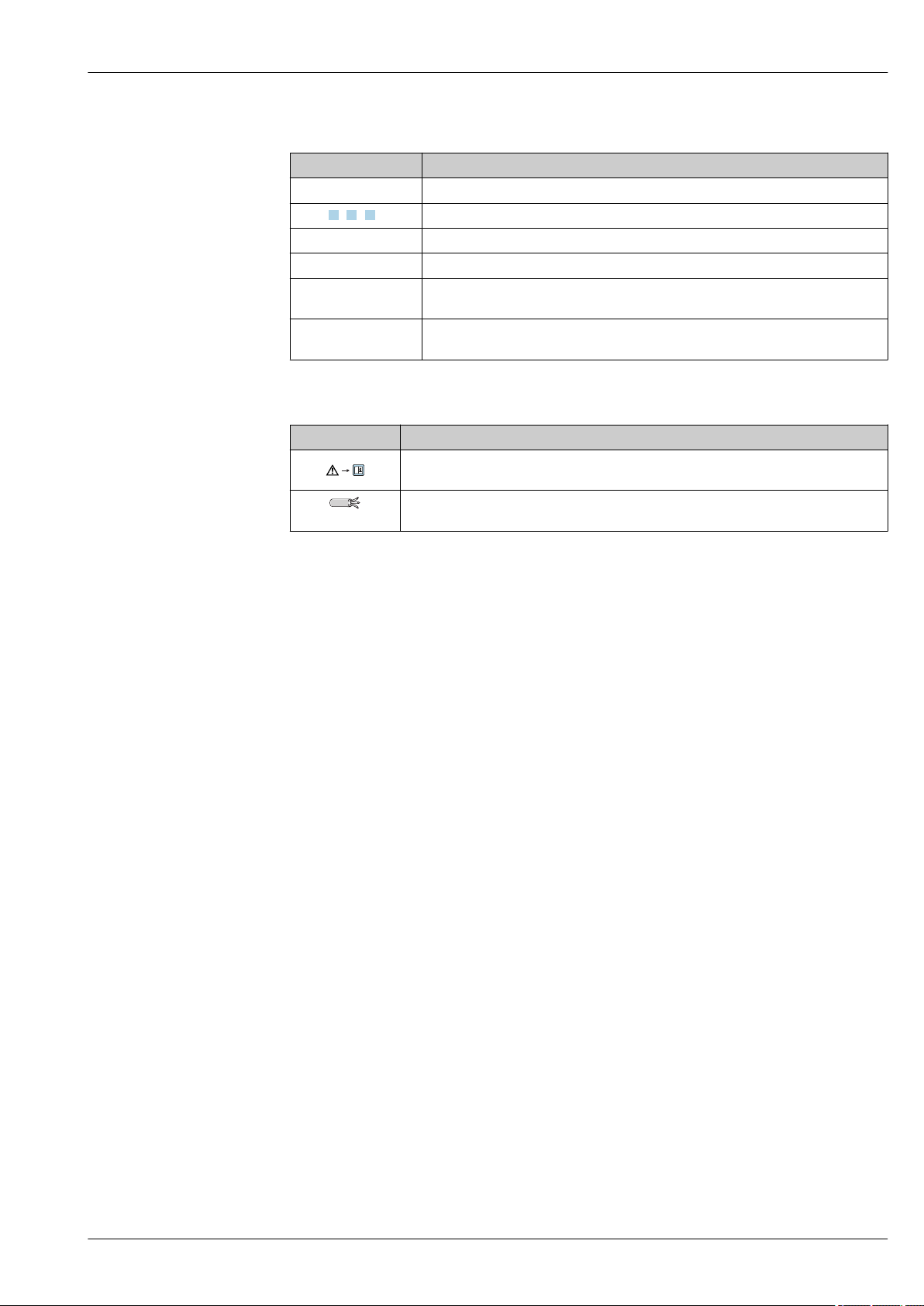

Micropilot FMR51, FMR52

1.

-

.

Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

Endress+Hauser 5

Micropilot FMR51, FMR52

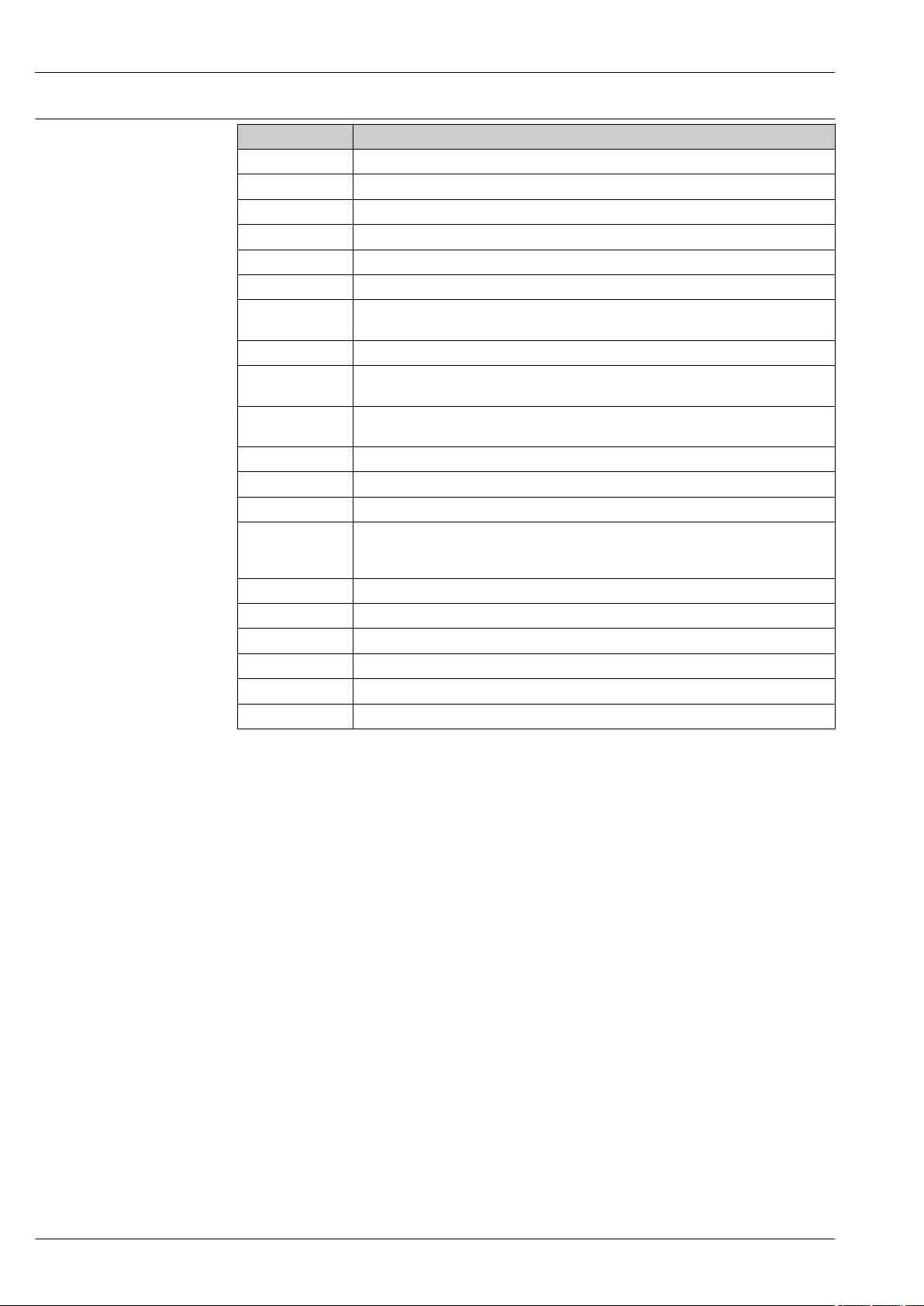

Terms and abbreviations

Term/abbreviation Explanation

BA Document type "Operating Instructions"

KA Document type "Brief Operating Instructions"

TI Document type "Technical Information"

SD Document type "Special Documentation"

XA Document type "Safety Instructions"

PN Nominal pressure

MWP Maximum Working Pressure

The MWP can also be found on the nameplate.

ToF Time of Flight

FieldCare Scalable software tool for device configuration and integrated plant asset management

solutions

DeviceCare Universal configuration software for Endress+Hauser HART, PROFIBUS,

FOUNDATION Fieldbus and Ethernet field devices

DTM Device Type Manager

DD Device Description for HART communication protocol

εr (DC value) Relative dielectric constant

Operating tool The term "operating tool" is used in place of the following operating software:

• FieldCare / DeviceCare, for operation via HART communication and PC

• SmartBlue (app), for operation using an Android or iOS smartphone or tablet.

BD Blocking Distance; no signals are analyzed within the BD.

PLC Programmable Logic Controller

CDI Common Data Interface

PFS Pulse Frequence Status (Switching output)

MBP Manchester Bus Powered

PDU Protocol Data Unit

6 Endress+Hauser

Micropilot FMR51, FMR52

Registered trademarks

®

HART

Registered trademark of the FieldComm Group, Austin, USA

PROFIBUS

®

Registered trademark of the PROFIBUS User Organization, Karlsruhe, Germany

FOUNDATIONTM Fieldbus

Registered trademark of the FieldComm Group, Austin, Texas, USA

Bluetooth®

The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc. and

any use of such marks by Endress+Hauser is under license. Other trademarks and trade names are

those of their respective owners.

Apple®

Apple, the Apple logo, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S.and

other countries. App Store is a service mark of Apple Inc.

Android®

Android, Google Play and the Google Play logo are trademarks of Google Inc.

KALREZ®, VITON

®

Registered trademark of DuPont Performance Elastomers L.L.C., Wilmington, USA

TEFLON

®

Registered trademark of E.I. DuPont de Nemours & Co., Wilmington, USA

TRI CLAMP

®

Registered trademark of Alfa Laval Inc., Kenosha, USA

Endress+Hauser 7

Function and system design

F

L

D

E

R

0%

100%

Micropilot FMR51, FMR52

Measuring principle

The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight

method (ToF). It measures the distance from the reference point (process connection) to the product

surface. Radar impulses are emitted by an antenna, reflected off the product surface and received

again by the radar system.

A0017871

1 Setup parameters of the Micropilot

R Reference point of the measurement (lower edge of the flange or threaded connection)

E Empty calibration ( = zero)

F Full calibration (= span)

D Measured distance

L Level (L = E - D)

Input

The reflected radar impulses are received by the antenna and transmitted into the electronics. A

microprocessor evaluates the signal and identifies the level echo caused by the reflection of the radar

impulse at the product surface. The unambiguous signal identification is accomplished by the

PulseMaster® eXact software together with the Multi-echo tracking algorithms, based on many

years of experience with time-of-flight technology.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c · t/2,

with c being the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

The reference point R of the measurement is located at the process connection. For details see the

dimensional drawing:

• FMR51: → 67

• FMR52: → 73

The Micropilot is equipped with functions to suppress interference echoes. The user can activate

these functions. Together with the multi-echo tracking algorithms they ensure that interference

echoes (i.e. from edges and weld seams) are not interpreted as level echo.

8 Endress+Hauser

Micropilot FMR51, FMR52

Output

The Micropilot is commissioned by entering an empty distance "E" (=zero), a full distance "F" (=span)

and application parameters which automatically adapt the instrument to the process conditions. For

models with a current output, the factory adjustment for zero point "E" and span "F" is 4 mA and 20

mA. For digital outputs and the display module, the factory adjustment for zero point "E" and span "F"

is 0 % and 100 %.

A linearization with max. 32 points, based on a table entered either manually or semi-automatically,

can be activated locally or remotely. This function provides a measurement in engineering units and

a linear output signal for spheres, horizontal cylindrical tanks and vessels with conical outlet.

Life cycle of the product

Engineering

• Universal measuring principle

• Measurement unaffected by medium properties

• Hardware and software developed according to SIL IEC 61508

Procurement

• Endress+Hauser being the world market leader in level measurement guarantees asset protection

• Worldwide support and service

Installation

• Special tools are not required

• Reverse polarity protection

• Modern, detachable terminals

• Main electronics protected by a separate connection compartment

Commissioning

• Fast, menu-guided commissioning in only a few steps on site or from the control room

• Plain text display in national languages reduces the risk of error or confusion

• Direct local access of all parameters

• Short instruction manual at the device

Operation

• Multi-echo tracking: Reliable measurement through self-learning echo-search algorithms taking

into account the short-term and long-term history in order to check the found echoes for

plausibility and to suppress interference echoes.

• Diagnostics in accordance with NAMUR NE107

Maintenance

• HistoROM: Data backup for instrument settings and measured values

• Exact instrument and process diagnosis to assist fast decisions with clear details concerning

remedies

• Intuitive, menu-guided operating concept in national languages saves costs for training,

maintenance and operation

• Cover of the electronics compartment can be opened in hazardous areas

Retirement

• Order code translation for subsequent models

• RoHS-conforming (Restriction of certain Hazardous Substances), unleaded soldering of electronic

components

• Environmentally sound recycling concept

Endress+Hauser 9

Input

Micropilot FMR51, FMR52

Measured variable

The measured variable is the distance between the reference point and the product surface.

The level is calculated from this distance, taking into account the empty distance "E" entered by the

user.

If required, the level can be converted into other variables (volume, mass) by means of a linearization

(up to 32 points).

Measuring range Maximum measuring range

Device Maximum measuring range

FMR51 - standard version 40 m (131 ft)

FMR51 - with "Advanced dynamics" application package 70 m (230 ft)

FMR52 - standard version 40 m (131 ft)

FMR52 - with "Advanced dynamics" application package 60 m (197 ft)

Usable measuring range

The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the

mounting location and eventual interference reflections.

The following tables describe the groups of media as well as the achievable measuring range as a

function of application and media group. If the dielectric constant of a medium is unknown, it is

recommended to assume media group B to ensure a reliable measurement.

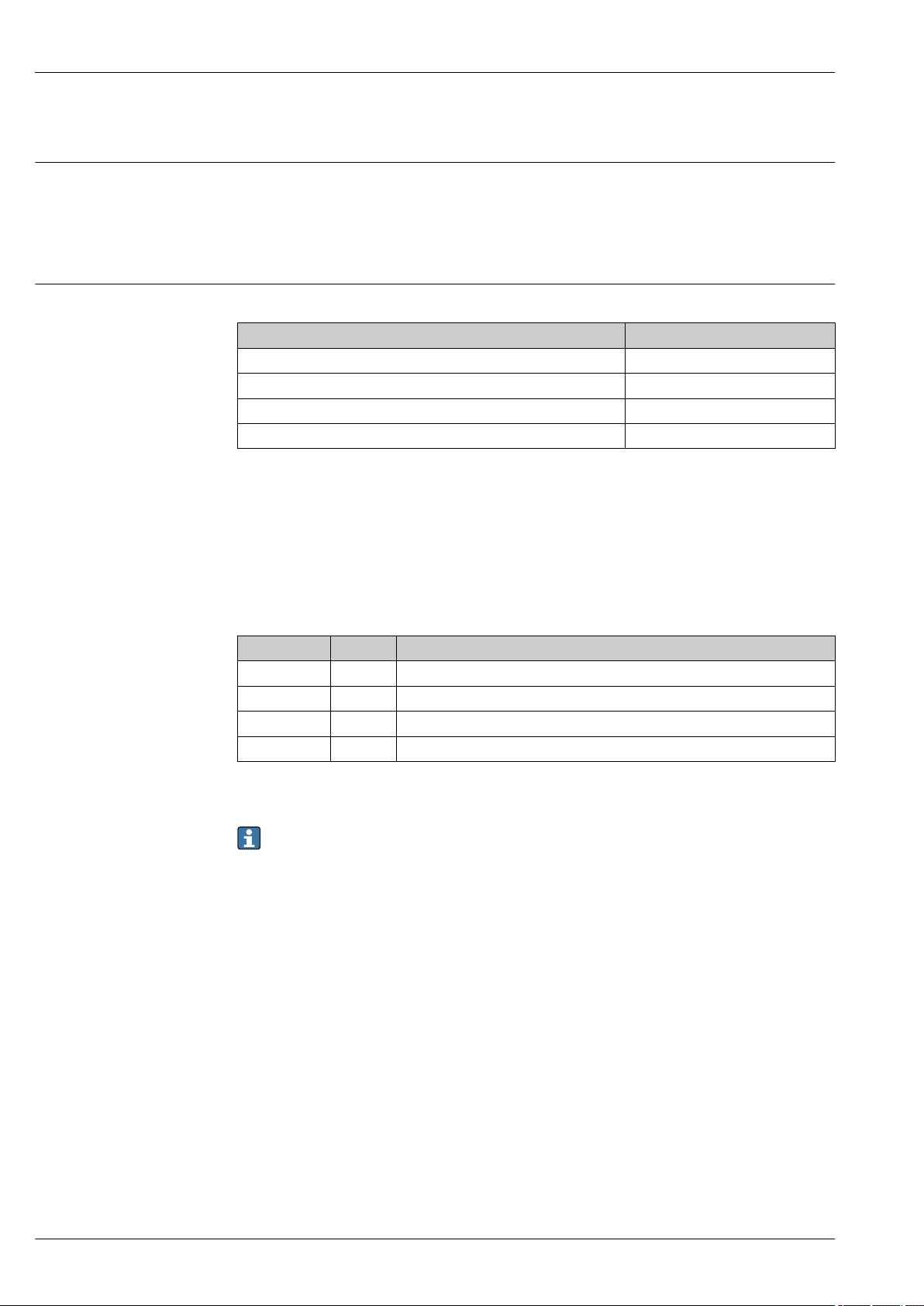

Media groups

Media groups DC (εr) Example

A 1.4 to 1.9 non-conducting liquids, e.g. liquefied gas

B 1.9 to 4 non-conducting liquids, e.g. benzene, oil, toluene, …

C 4 to 10 e.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, …

D > 10 conducting liquids, e.g. aqueous solutions, dilute acids and alkalis

1) Treat Ammonia NH3 as a medium of group A.

1)

For dielectric constants (DC values) of many media commonly used in various industries refer

to:

• the Endress+Hauser DC manual (CP01076F)

• the Endress+Hauser "DC Values App" (available for Android and iOS)

10 Endress+Hauser

Micropilot FMR51, FMR52

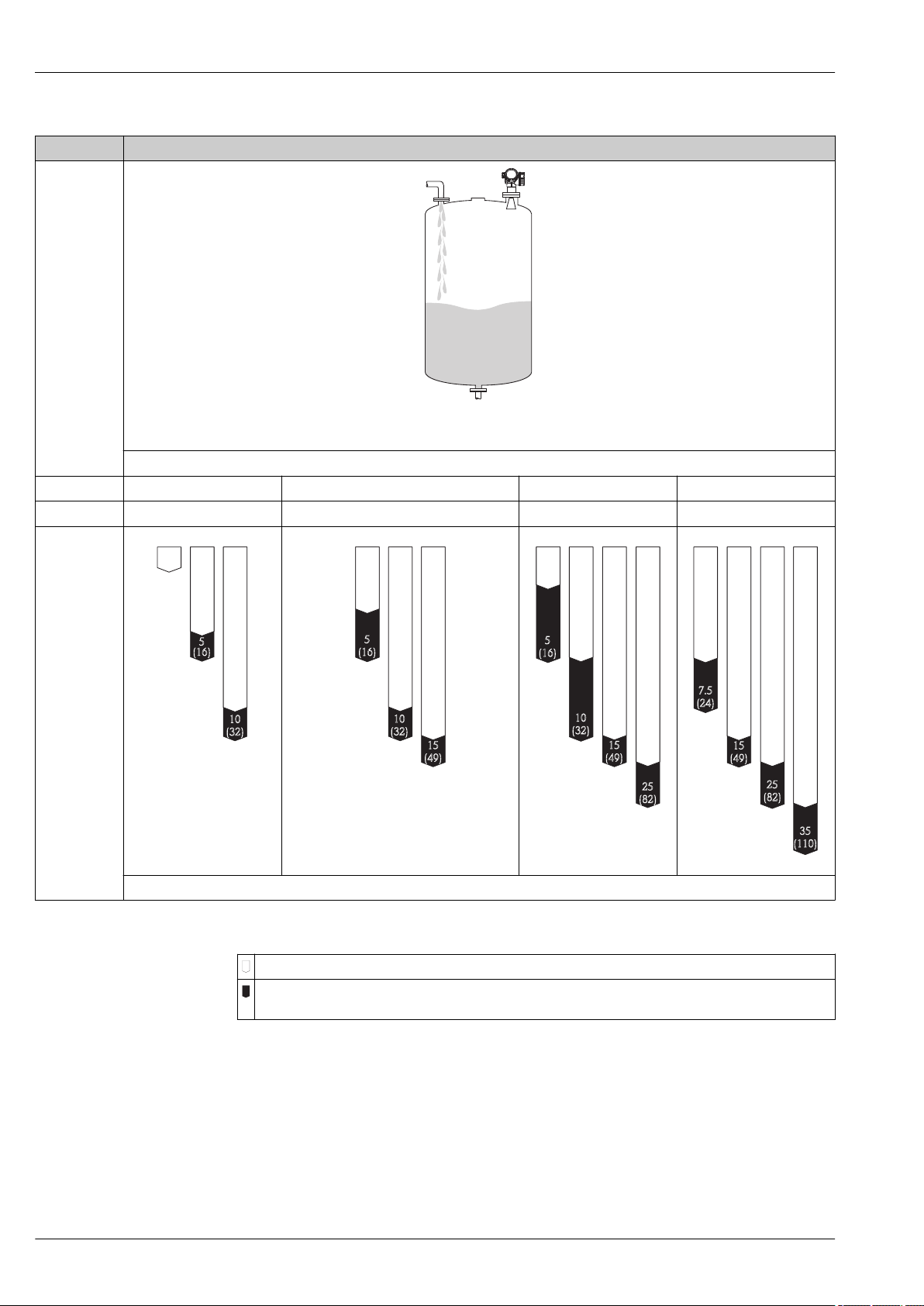

A B

25

(82)

15

(49)

C D

3

(9.9)

10

(32)

15

(49)

5

(16)

8

(26)

5

(16)

A B C D

4

(13)

8

(26)

8

(26)

15

(49)

12

(39)

25

(82)

35

(110)

40

(131)

A B C D

8

(26)

15

(49)

30

(98)

40

(131)

10

(32)

20

(65)

40

(131)

60

(197)

A B C D

10

(32)

25

(82)

40

(131)

40

(131)

15

(49)

30

(99)

45

(148)

70

(229)

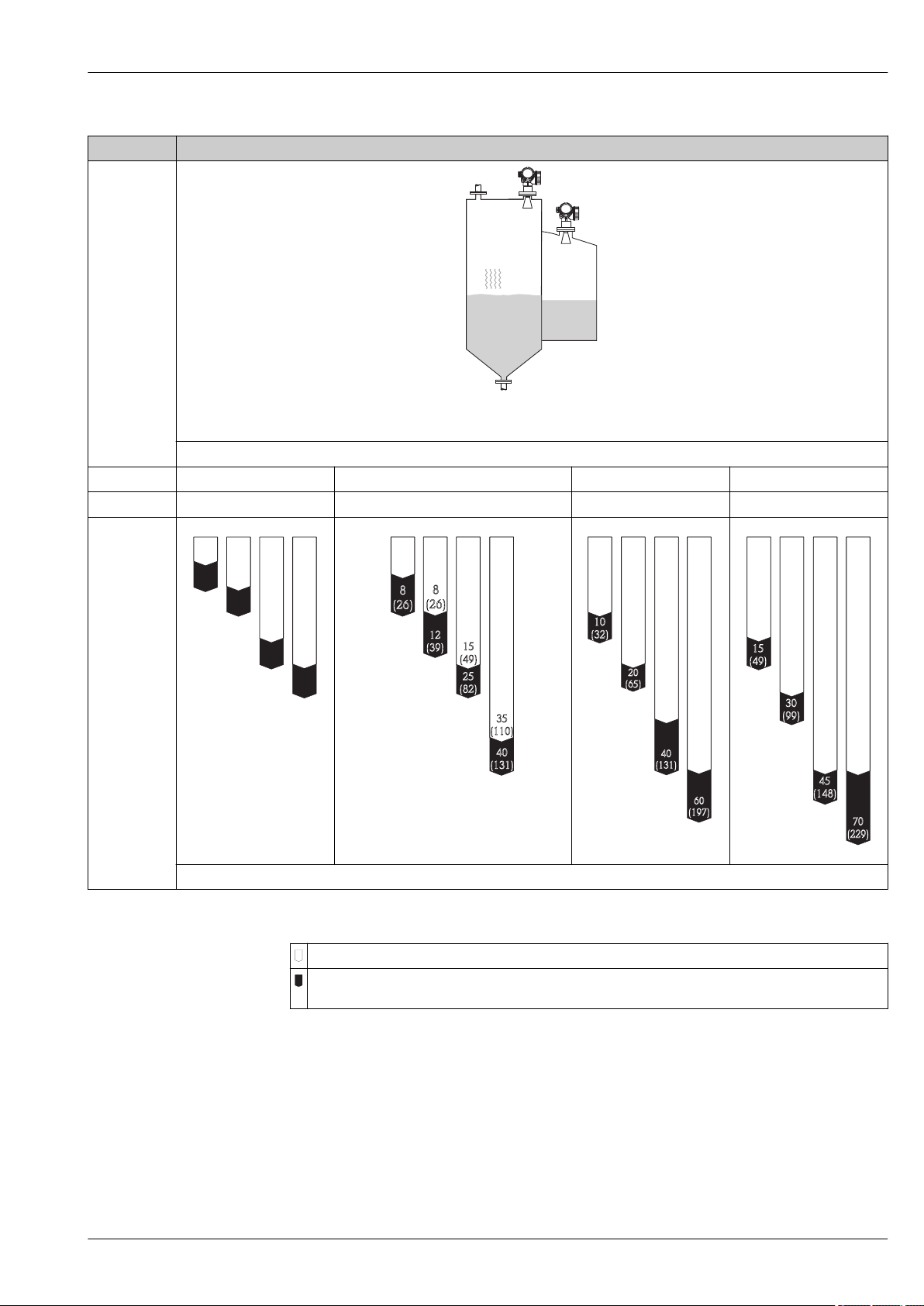

Device Storage tank

Calm product surface (e.g. intermittent filling, filling from bottom, immersion tubes)

Antenna size

FMR51 40 mm (1½ in) 50 mm (2 in) 80 mm (3 in) 100 mm (4 in)

FMR52 - 50 mm (2 in) 80 mm (3 in) -

A0018833

Endress+Hauser 11

A0018858

A0018859

A0018860

A0018862

Measuring range [m (ft)]

Legend

Measuring range of the standard version

Measuring range for the "Advanced dynamics" application package (product structure: feature 540:

"Application Package", Option EM: "Advanced dynamics")

Micropilot FMR51, FMR52

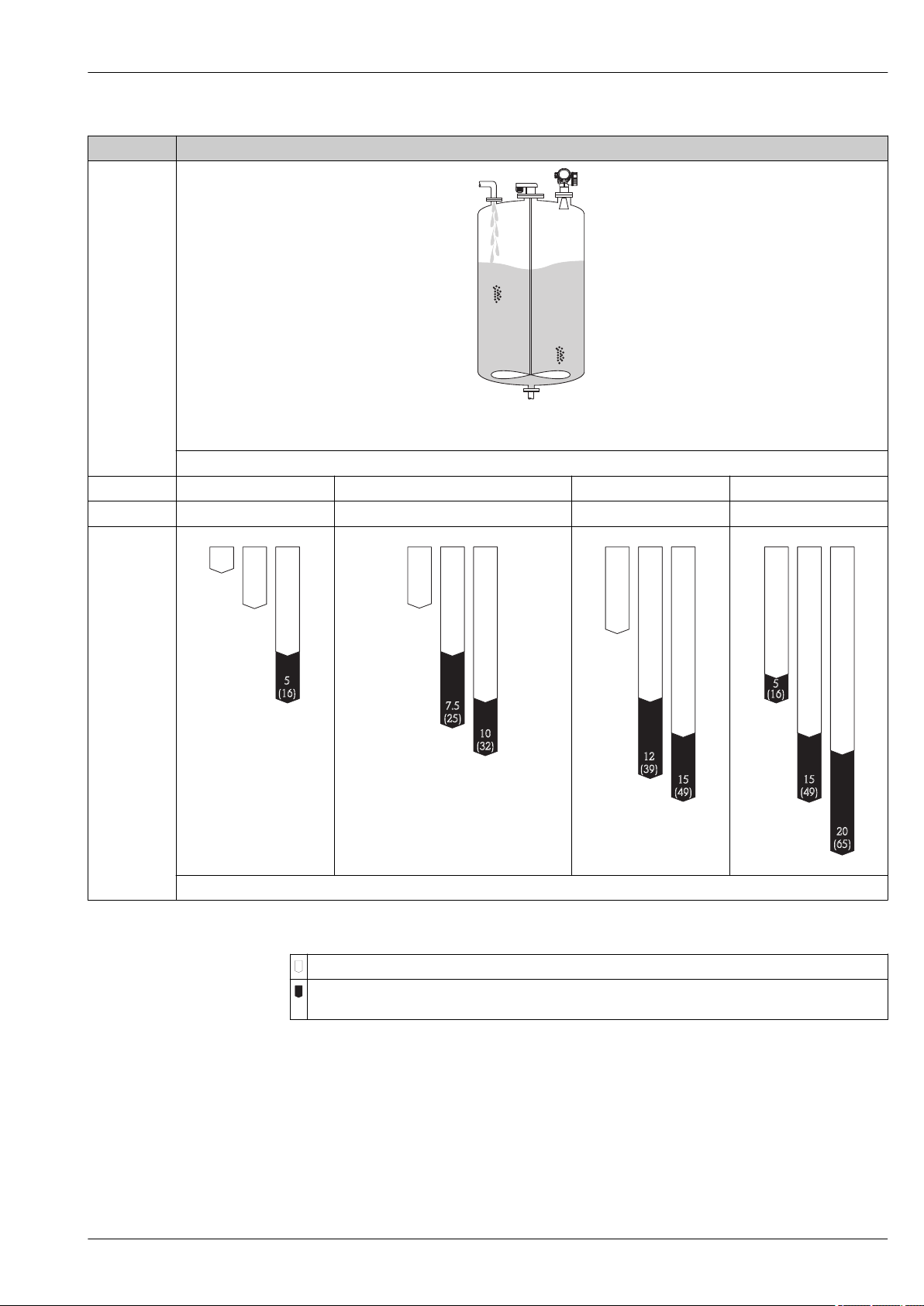

B C D

(6.6)

4

(13)

7.5

(24)

10

(32)

(16)

5

2

BB CC DD

3

(9.9)

7.5

(24)

10

(32)

5

(16)

10

(32)

15

(49)

A B C D

2.5

(8)

5

(16)

10

(32)

15

(49)

5

(16)

10

(32)

15

(49)

25

(82)

A B C D

5

(16)

10

(32)

15

(49)

25

(82)

7.5

(24)

15

(49)

25

(82)

35

(110)

Device Buffer tank

Moving surfaces (e.g. continuous filling, from above, mixing jets)

Antenna size

FMR51 40 mm (1½ in) 50 mm (2 in) 80 mm (3 in) 100 mm (4 in)

FMR52 - 50 mm (2 in) 80 mm (3 in) -

A0018835

A0018863

A0018864

A0018865

Measuring range [m (ft)]

Legend

Measuring range of the standard version

Measuring range for the "Advanced dynamics" application package (product structure: feature 540:

"Application Package", Option EM: "Advanced dynamics")

12 Endress+Hauser

A0018866

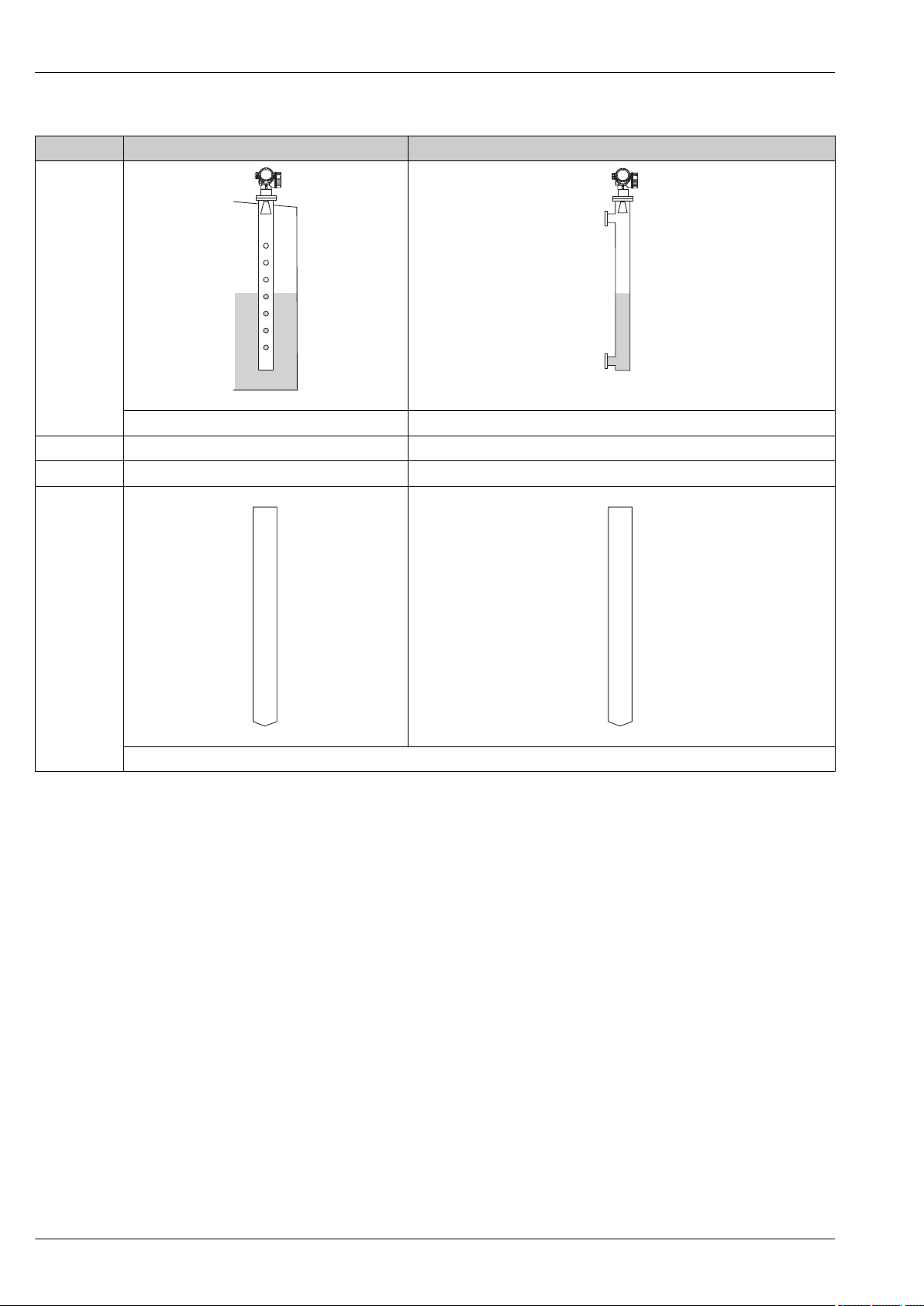

Micropilot FMR51, FMR52

B C D

1

(3.2)

2

(6.6)

3

(9.8)

5

(16)

B C D

2

(6.6)

3

(9.8)

5

(16)

7.5

(25)

10

(32)

B C D

2.5

(8.2)

5

(16)

12

(39)

15

(49)

8

(26)

B C D

4

(13)

(16)

5

8

(26)

15

(49)

20

(65)

10

(32)

Device Process tank with agitator

Turbulent surface (e.g. filling from above, agitators, baffles)

Antenna size

FMR51 40 mm (1½ in) 50 mm (2 in) 80 mm (3 in) 100 mm (4 in)

FMR52 - 50 mm (2 in) 80 mm (3 in) -

A0018837

A0018867

A0018868

A0018869

Measuring range [m (ft)]

Legend

Measuring range of the standard version

Measuring range for the "Advanced dynamics" application package (product structure: feature 540:

"Application Package", Option EM: "Advanced dynamics")

Endress+Hauser 13

A0018870

Micropilot FMR51, FMR52

20

(66)

A, B, C, D

20

(66)

C, D

Device Stilling well Bypass

A0018842

Antenna size Antenna size

FMR51 40 ... 100 mm ( 1½ ... 4 in) 40 ... 100 mm ( 1½ ... 4 in)

FMR52 50 ... 80 mm ( 2 ... 3 in) 50 ... 80 mm ( 2 ... 3 in)

A0018840

A0018851

Measuring range [m (ft)]

A0018852

14 Endress+Hauser

Micropilot FMR51, FMR52

Operating frequency

Transmitting power

K-band (~ 26 GHz)

Up to 8 Micropilot transmitters can be installed in the same tank because the transmitter pulses are

statistically coded.

Distance Average energy density in beam direction

Standard version With "Advanced dynamics" application

1 m (3.3 ft) < 12 nW/cm

5 m (16 ft) < 0.4 nW/cm

2

2

1) Product structure, feature 540: "Application package", option EM: "Advanced dynamics"

1)

package

< 64 nW/cm

< 2.5 nW/cm

2

2

Endress+Hauser 15

Output

Output signal HART

Signal coding FSK ±0.5 mA over current signal

Data transmission rate 1 200 Bit/s

Galvanic isolation Yes

Bluetooth® wireless technology

Device version Ordering feature 610 "Accessory mounted", option NF "Bluetooth"

Operation / configuration By the SmartBlue app.

Range under reference conditions > 10 m (33 ft)

Encryption Encrypted communication and password encryption prevent incorrect

PROFIBUS PA

Micropilot FMR51, FMR52

operation by unauthorized persons.

Signal coding Manchester Bus Powered (MBP)

Data transmission rate 31.25 kBit/s, voltage mode

Galvanic isolation Yes

FOUNDATION Fieldbus

Signal coding Manchester Bus Powered (MBP)

Data transmission rate 31.25 kBit/s, voltage mode

Galvanic isolation Yes

Switch output

For HART devices, the switch output is available as an option. See product structure, feature 20:

"Power Supply, Output", option B: "2-wire; 4-20mA HART, switch output"

Devices with PROFIBUS PA and FOUNDATION Fieldbus always have a switch output.

16 Endress+Hauser

Micropilot FMR51, FMR52

Switch output

Function Open collector switching output

Switching behavior Binary (conductive or non-conductive), switches when the programmable switch

point is reached

Failure mode non-conductive

Electrical connection values U = 16 to 35 VDC, I = 0 to 40 mA

Internal resistance RI < 880 Ω

The voltage drop at this internal resistance has to be taken into account on

planning the configuration. For example, the resulting voltage at a connected

relay must be sufficient to switch the relay.

Insulation voltage floating, Insulation voltage 1 350 VDC to power supply aund 500 VAC to ground

Switch point freely programmable, separately for switch-on and switch-off point

Switching delay freely programmable from 0 to 100 s, separately for switch-on and switch-off

point

Number of switching cycles corresponds to the measuring cycle

Signal source

device variables

Number of switching cycles unlimited

• Level linearized

• Distance

• Terminal voltage

• Electronic temperature

• Relative echo amplitude

• Diagnostic values, Advanced diagnostics

Signal on alarm

Depending on the interface, failure information is displayed as follows:

• Current output (for HART devices)

– Failsafe mode selectable (in accordance with NAMUR Recommendation NE 43):

– Failsafe mode with user-selectable value: 3.59 to 22.5 mA

• Local display

– Status signal (in accordance with NAMUR Recommendation NE 107)

– Plain text display

• Operating tool via digital communication (HART, PROFIBUS PA, FOUNDATION Fieldbus) or

service interface (CDI)

– Status signal (in accordance with NAMUR Recommendation NE 107)

– Plain text display

Linearization

The linearization function of the device allows the conversion of the measured value into any unit of

length or volume. Linearization tables for calculating the volume in cylindrical tanks are preprogrammed. Other linearization tables of up to 32 value pairs can be entered manually or semiautomatically.

Galvanic isolation

All circuits for the outputs are galvanically isolated from each other.

Protocol-specific data HART

Manufacturer ID 17 (0x11)

Device type ID 0x1128

HART specification 7.0

Device description files (DTM, DD) Information and files under:

HART load min. 250 Ω

Minimum alarm: 3.6 mA

Maximum alarm (= factory setting): 22 mA

• www.endress.com

• www.fieldcommgroup.org

Endress+Hauser 17

Micropilot FMR51, FMR52

HART device variables The measured values can be freely assigned to the device variables.

Measured values for PV (primary variable)

• Level linearized

• Distance

• Electronic temperature

• Relative echo amplitude

• Area of incoupling

• Analog output adv. diagnostics 1

• Analog output adv. diagnostics 2

Measured values for SV, TV, FV (second, third and fourth variable)

• Level linearized

• Distance

• Electronic temperature

• Terminal voltage

• Relative echo amplitude

• Absolute echo amplitude

• Area of incoupling

• Analog output adv. diagnostics 1

• Analog output adv. diagnostics 2

Supported functions • Burst mode

• Additional transmitter status

Wireless HART data

Minimum start-up voltage 16 V

Start-up current 3.6 mA

Start-up time 65 s

Minimum operating voltage 14.0 V

Multidrop current 4.0 mA

Set-up time 15 s

PROFIBUS PA

Manufacturer ID 17 (0x11)

Ident number 0x1559

Profile version 3.02

GSD file Information and files under:

GSD file version

Output values Analog Input:

• www.endress.com

• www.profibus.org

• Level linearized

• Distance

• Terminal voltage

• Electronic temperature

• Absolute echo amplitude

• Relative echo amplitude

• Analog output adv. diagnostics 1

• Analog output adv. diagnostics 2

Digital Input:

• Digital output AD 1

• Digital output AD 2

• Switch output

18 Endress+Hauser

Micropilot FMR51, FMR52

Input values Analog Output:

• Analog value from PLC (for sensor block external pressure to compensate gas phase

effects)

• Analog value from PLC to be indicated on the display

Digital Output:

• Extended diagnostic block

• Level limiter

• Sensor block measurement on

• Sensor block save history on

• Status output

Supported functions • Identification & Maintenance

Einfachste Geräteidentifizierung seitens des Leitsystems und des Typenschildes

• Automatic Ident Number Adoption

GSD compatibility mode with respect to the preceding product Micropilot M FMR2xx

• Physical Layer Diagnostics

Installation check of the PRFIBUS segment and the Micropilot FMR5x via the terminal

voltage and telegram surveillance.

• PROFIBUS Up-/Download

Up to 10 times faster writing and reading of parameters via PROFIBUS up-/download

• Condensed Status

Simple and self-explanatory diagnostic information by categorization of occurring

diagnostic messages.

FOUNDATION Fieldbus

Manufacturer ID 0x452B48

Device type 0x1028

Device Revision 0x01

DD Revision Information and files can be found:

CFF Revision

Device Tester Version (ITK Version) 6.0.1

ITK Test Campaign Number IT085300

Link Master (LAS) capable yes

Link Master / Basic Device selectable yes; default: Basic Device

Node address Default: 247 (0xF7)

Features supported Following methods are supported:

Virtual Communication Relationships (VCRs)

Number of VCRs 44

Number of Link Objects in VFD 50

Permanent entries 1

Client VCRs 0

Server VCRs 10

Source VCRs 43

Sink VCRs 0

Subscriber VCRs 43

Publisher VCRs 43

Device Link Capabilities

Slot time 4

• www.endress.com

• www.fieldcommgroup.org

• Restart

• ENP Restart

• Setup

• Linearization

• Self Check

Endress+Hauser 19

Micropilot FMR51, FMR52

Min. inter PDU delay 8

Max. response delay 20

Transducer Blocks

Block Content Output values

Setup Transducer Block Contains all parameters for a standard commissioning

procedure

Advanced Setup

Transducer Block

Display Transducer Block Contains all parameters for the configuration of the

Diagnostic Transducer

Block

Advanced Diagnostic

Transducer Block

Expert Configuration

Transducer Block

Expert Information

Transducer Block

Service Sensor Transducer

Block

Service Information

Transducer Block

Data Transfer Transducer

Block

Contains all parameters for a more detailed

configuration of the device

display module

Contains diagnostic information no output values

Contains parameters for the Advanced Diagnostic no output values

Contains parameters which require detailed knowledge

of the functionalities of the device

Contains information about the state of the device no output values

Contains parameters which can only be operated by

Endress+Hauser service personnel

Contains information on the state of device which is

relevant for service operations

Contains parameters which allow to backup the device

configuration in the display module and to restore it

into the device. Access to these parameters is restricted

to the Endress+Hauser service.

• Level or volume

(Channel 1)

• Distance (Channel 2)

no output values

no output values

no output values

no output values

no output values

no output values

1)

1) depending on the configuration of the block

Function Blocks

Block Content Number of

permanent

blocks

Resource Block The Resource Block contains all the

data that uniquely identifies the

field device. It is an electronic

version of a nameplate of the

device.

Analog Input

Block

Discrete Input

Block

Mutiple

Analog Output

Block

Mutiple

Discrete

Output Block

The AI block takes the

manufacturer's input data, selected

by channel number, and makes it

available to other function blocks at

its output.

The DI block takes a discrete input

value (e.g. indication of an level

limit), and makes it available to

other function blocks at its output.

This block is used to transfer analog

data from the bus into the device

This block is used to transfer

discrete data from the bus to the

device.

1 0 - enhanced

2 3 25 ms enhanced

1 2 20 ms standard

1 0 20 ms standard

1 0 20 ms standard

Number of

instantiable

blocks

Execution

time

Functionality

20 Endress+Hauser

Micropilot FMR51, FMR52

Block Content Number of

permanent

blocks

PID Block The PID block serves as

proportional-integralderivative

controller and is used almost

universally to do closed-loopcontrol in the field including

cascade and feedforward.

Arithmetic

Block

Signal

Characterizer

Block

Input Selector

Block

Integrator

Block

Analog Alarm

Block

This block is designed to permit

simple use of popular measurement

math functions. The user does not

have to know how to write

equations. The math algorithm is

selected by name, chosen by the

user for the function to be done.

The signal characterizer block has

two sections, each with an output

that is a non-linear function of the

respective input. The non-linear

function is determined by a single

look-up table with 21 arbitrary x-y

pairs.

The input selector block provides

selection of up to four inputs and

generates an output based on the

configured action. This block

normally receives its inputs from AI

blocks. The block performs

maximum, minimum, middle,

average and ‘first good’ signal

selection.

The Integrator Function Block

integrates a variable as a function

of the time or accumulates the

counts from a Pulse Input block.

The block may be used as a

totalizer that counts up until reset

or as a batch totalizer that has a

setpoint, where the integrated or

accumulated value is compared to

pre-trip and trip settings,

generating discrete signals when

these settings are reached.

1 1 25 ms standard

1 1 25 ms standard

1 1 25 ms standard

1 1 25 ms standard

1 1 25 ms standard

1 1 25 ms standard

Number of

instantiable

blocks

Execution

time

Functionality

Up to 20 blocks can be instantiated in the device altogether, including the blocks already

instantiated on delivery.

Endress+Hauser 21

Terminal assignment

1

+

2

-

A

1

+

2

-

B

1

2

3

5

4

1

2

3

++

--

Y

I

6

1

2

Micropilot FMR51, FMR52

Power supply

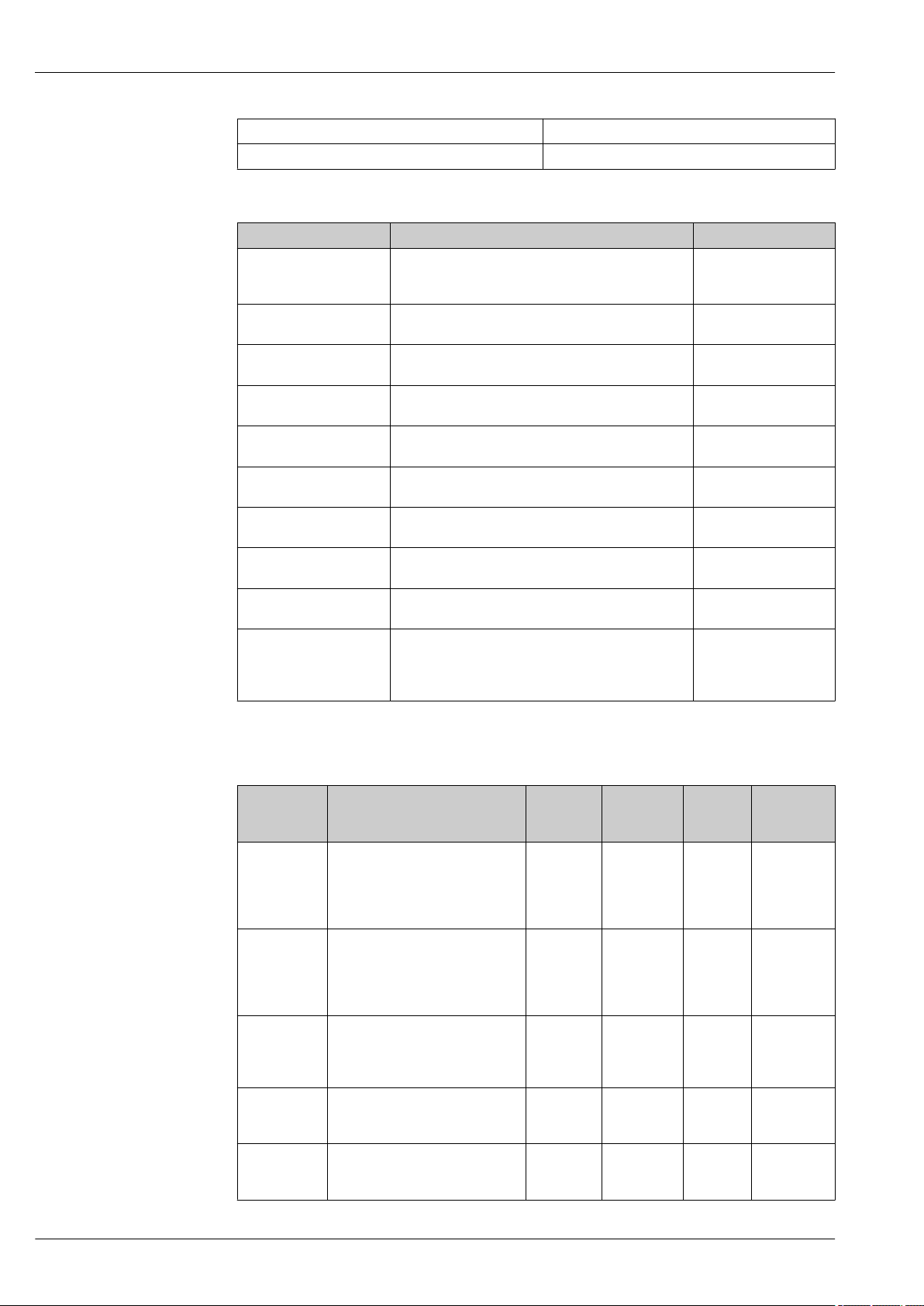

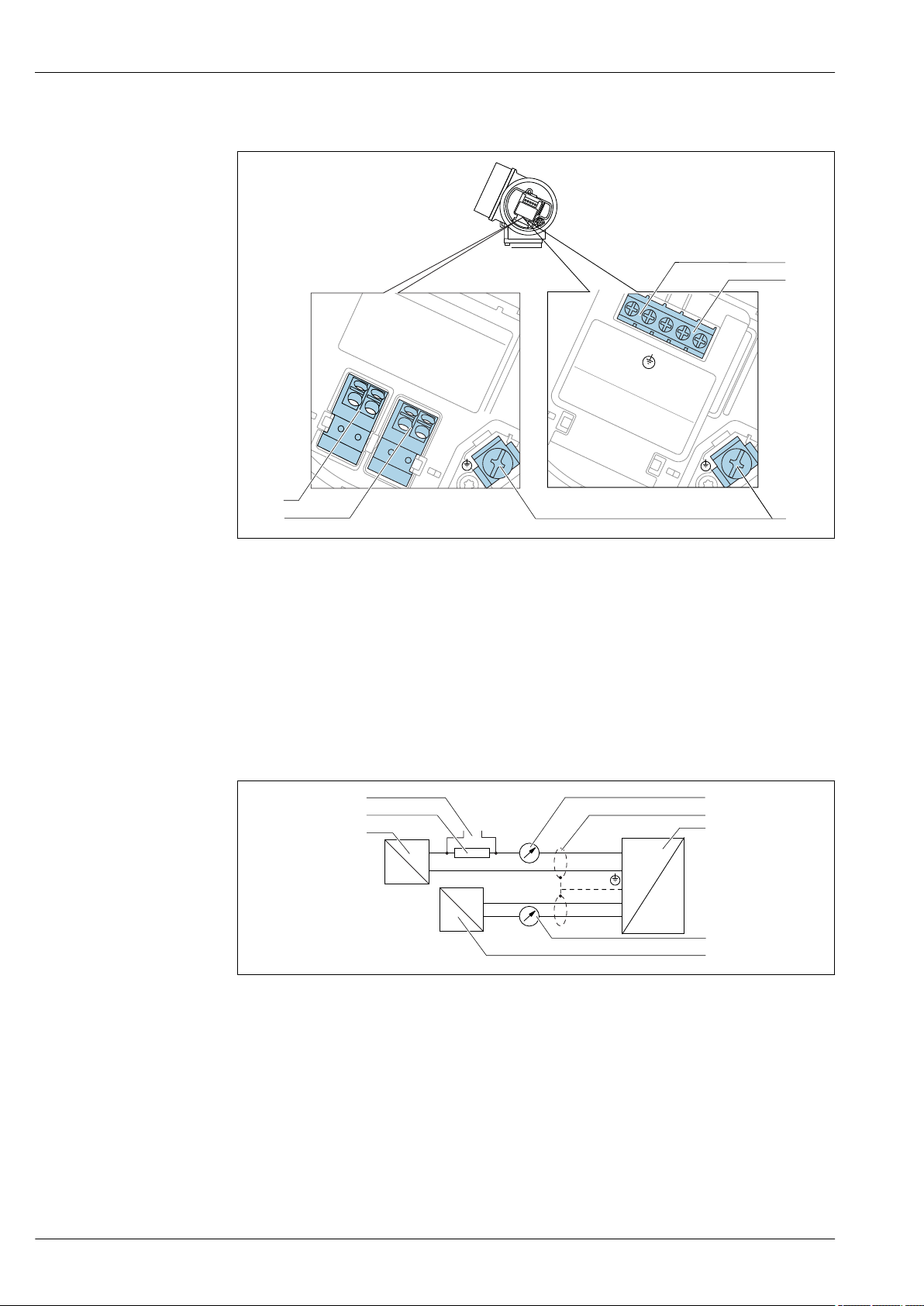

Terminal assignment 2-wire: 4-20 mA HART

2 Terminal assignment 2-wire: 4-20 mA HART

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Connection 4-20 mA HART passive: terminals 1 and 2, without integrated overvoltage protection

2 Connection 4-20 mA HART passive: terminals 1 and 2, with integrated overvoltage protection

3 Terminal for cable screen

Block diagram 2-wire: 4-20 mA HART

3 Block diagram 2-wire: 4-20 mA HART

1 Active barrier with power supply (e.g. RN221N); observe terminal voltage

2 HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6 Measuring device

A0036498

A0036499

22 Endress+Hauser

Micropilot FMR51, FMR52

1

3

+

+

2

4

-

-

A

1

3

+

+

2

4

-

-

B

1

4

5

2

3

5

4

1

2

3

+

+

+

-

-

-

Y

I

6

7

1

2

3

4

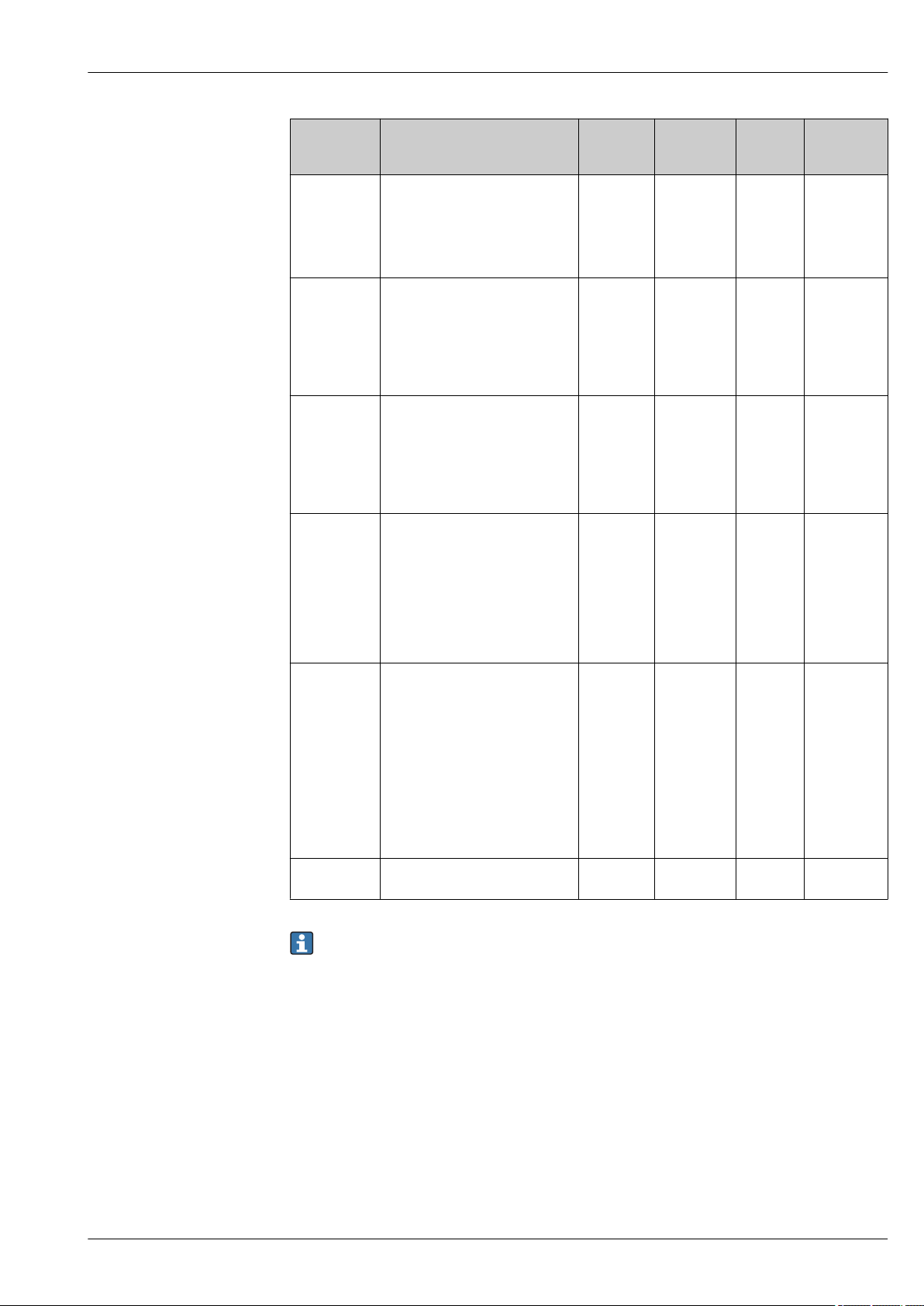

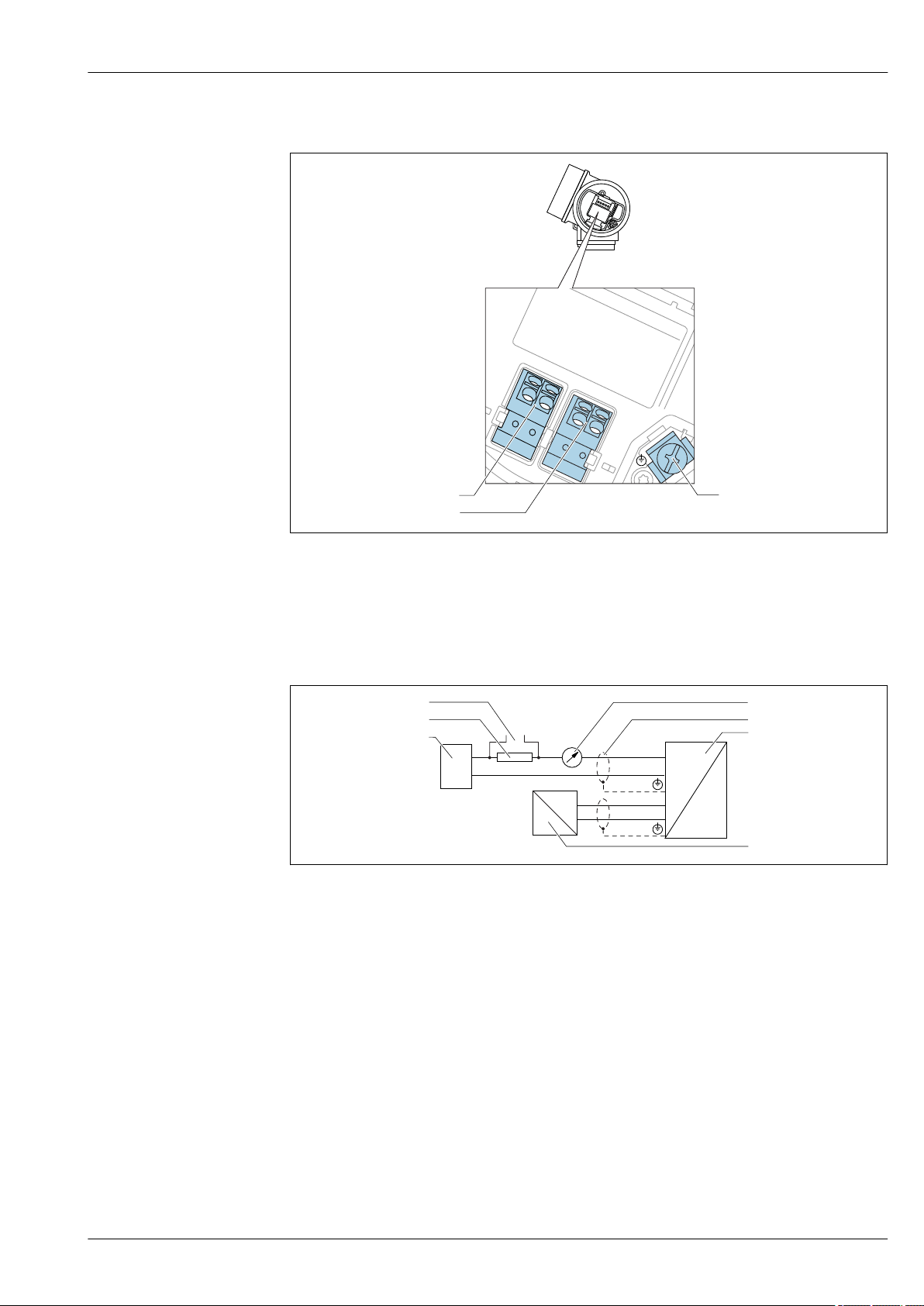

Terminal assignment 2-wire: 4-20 mA HART, switch output

4 Terminal assignment 2-wire: 4-20 mA HART, switch output

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Connection 4-20 mA HART passive: terminals 1 and 2, without integrated overvoltage protection

2 Connection switch output (Open Collector): terminals 3 and 4, without integrated overvoltage protection

3 Connection switch output (Open Collector): terminals 3 and 4, with integrated overvoltage protection

4 Connection 4-20 mA HART passive: terminals 1 and 2, with integrated overvoltage protection

5 Terminal for cable screen

Block diagram 2-wire: 4-20 mA HART, switch output

5 Block diagram 2-wire: 4-20 mA HART, switch output

1 Active barrier with power supply (e.g. RN221N); observe terminal voltage

2 HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6 Measuring device

7 Switch output (Open Collector)

A0036500

A0036501

Endress+Hauser 23

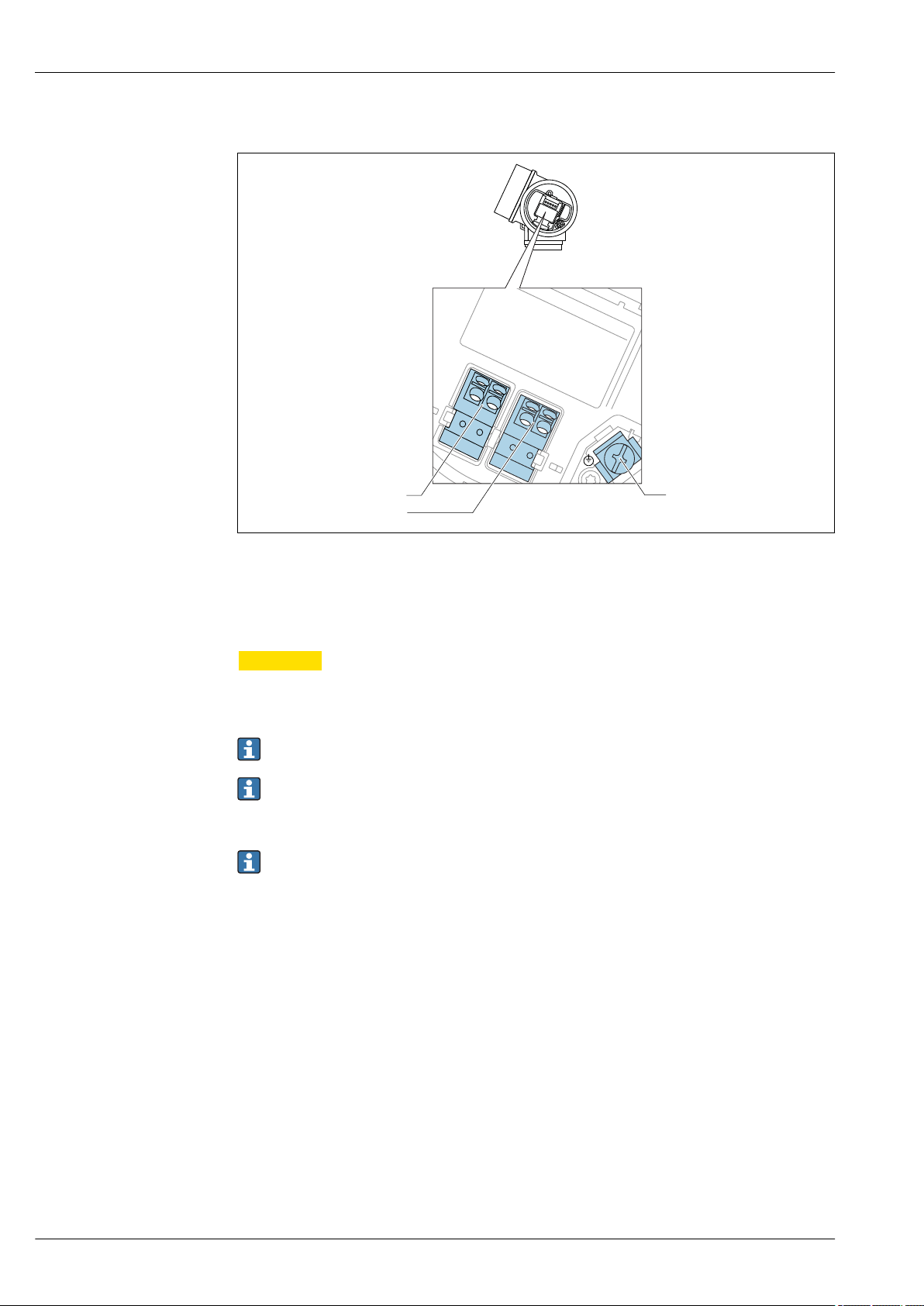

Terminal assignment 2-wire: 4-20 mA HART, 4-20 mA

1

3

+

+

2

4

-

-

A

1

3

+

+

2

4

-

-

B

1

4

5

2

3

5

4

1

2

3

+

+

+

+

-

-

-

-

Y

I

6

7

8

1

2

3

4

Micropilot FMR51, FMR52

A0036500

6 Terminal assignment 2-wire: 4-20 mA HART, 4-20 mA

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Connection current output 1, 4-20 mA HART passive: terminals 1 and 2, without integrated overvoltage

protection

2 Connection current output 2, 4-20 mA: terminals 3 and 4, without integrated overvoltage protection

3 Connection current output 2, 4-20 mA: terminals 3 and 4, with integrated overvoltage protection

4 Connection current output 1, 4-20 mA HART passive: terminals 1 and 2, with integrated overvoltage

protection

5 Terminal for cable screen

Block diagram 2-wire: 4-20 mA HART, 4-20 mA

A0036502

7 Block diagram 2-wire: 4-20 mA HART, 4-20 mA

1 Active barrier with power supply (e.g. RN221N); observe terminal voltage

2 HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6 Measuring device

7 Analog display device; observe maximum load

8 Active barrier with power supply (e.g. RN221N), current output 2; observe terminal voltage

24 Endress+Hauser

Micropilot FMR51, FMR52

3

1

+

L+

4

2

-

L-

1

3

2

5

4

+

L+

-

L-

Y

I

6

7

3

4

1

2

Terminal assignment 4-wire: 4-20 mA HART (10.4 to 48 VDC)

8 Terminal assignment 4-wire: 4-20 mA HART (10.4 to 48 VDC)

1 Connection 4-20 mA HART (active): terminals 3 and 4

2 Connection supply voltage: terminals 1 and 2

3 Terminal for cable screen

Block diagram 4-wire: 4-20 mA HART (10.4 to 48 VDC)

9 Block diagram 4-wire: 4-20 mA HART (10.4 to 48 VDC)

1 Evaluation unit, e.g. PLC

2 HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6 Measuring device

7 Supply voltage; observe terminal voltage, observe cable specification

A0036516

A0036526

Endress+Hauser 25

Terminal assignment 4-wire: 4-20 mA HART (90 to 253 VAC)

3

1

+

L

4

2

-

N

3

2

Micropilot FMR51, FMR52

10 Terminal assignment 4-wire: 4-20 mA HART (90 to 253 VAC)

1 Connection 4-20 mA HART (active): terminals 3 and 4

2 Connection supply voltage: terminals 1 and 2

3 Terminal for cable screen

CAUTION

L

To ensure electrical safety:

Do not disconnect the protective connection.

‣

Disconnect the supply voltage before disconnecting the protective earth.

‣

Connect protective earth to the internal ground terminal (3) before connecting the supply

voltage. If necessary, connect the potential matching line to the external ground terminal.

In order to ensure electromagnetic compatibility (EMC): Do not only ground the device via the

protective earth conductor of the supply cable. Instead, the functional grounding must also be

connected to the process connection (flange or threaded connection) or to the external ground

terminal.

An easily accessible power switch must be installed in the proximity of the device. The power

switch must be marked as a disconnector for the device (IEC/EN61010).

A0036519

26 Endress+Hauser

Micropilot FMR51, FMR52

5

4

+

L

-

N

Y

I

6

7

3

4

1

2

1

3

+

+

2

4

-

-

A

1

3

+

+

2

4

-

-

B

4

5

2

3

Block diagram 4-wire: 4-20 mA HART (90 to 253 VAC)

A0036527

11 Block diagram 4-wire: 4-20 mA HART (90 to 253 VAC)

1 Evaluation unit, e.g. PLC

2 HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device; observe maximum load

5 Cable scree; observe cable specification

6 Measuring device

7 Supply voltage; observe terminal voltage, observe cable specification

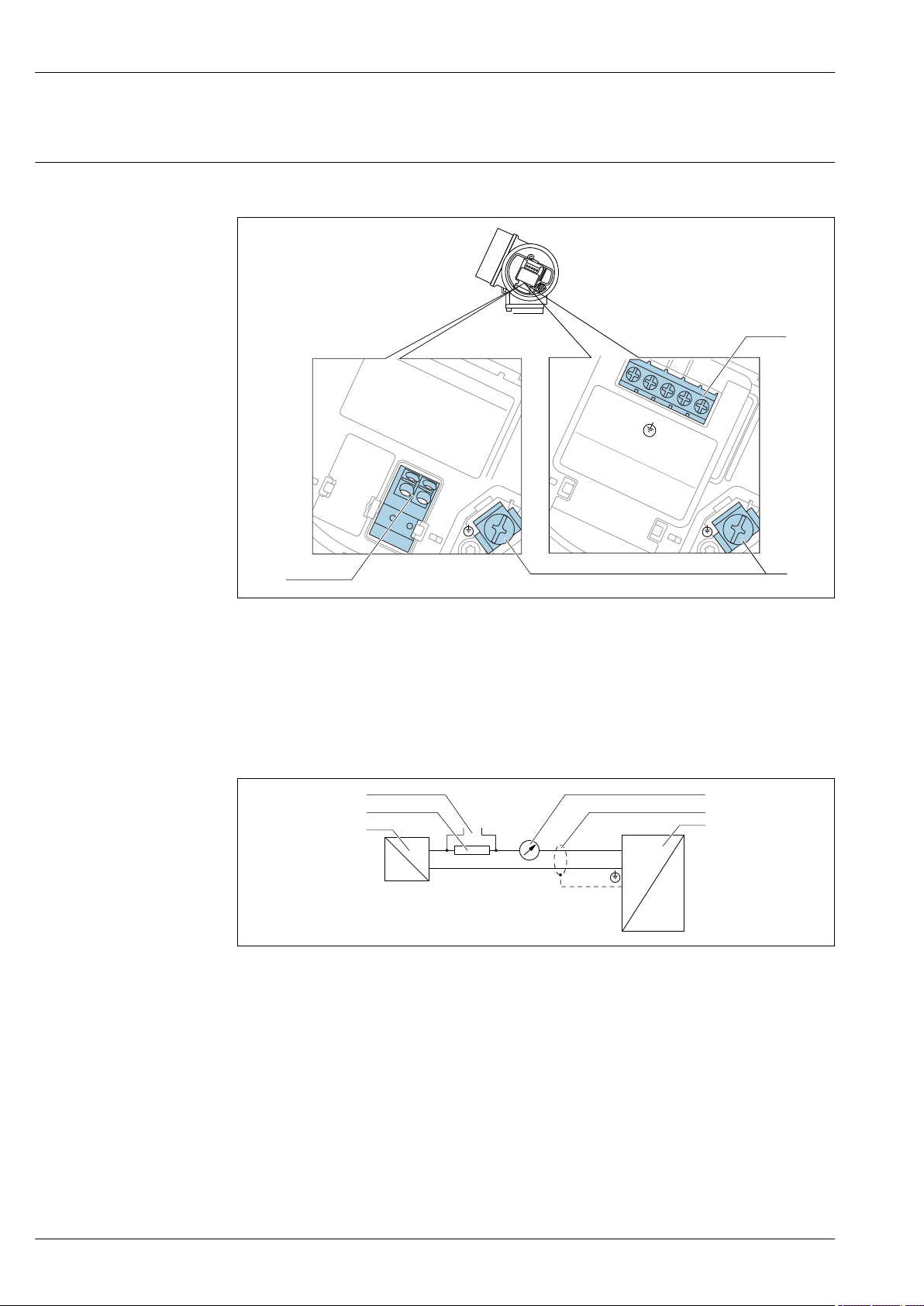

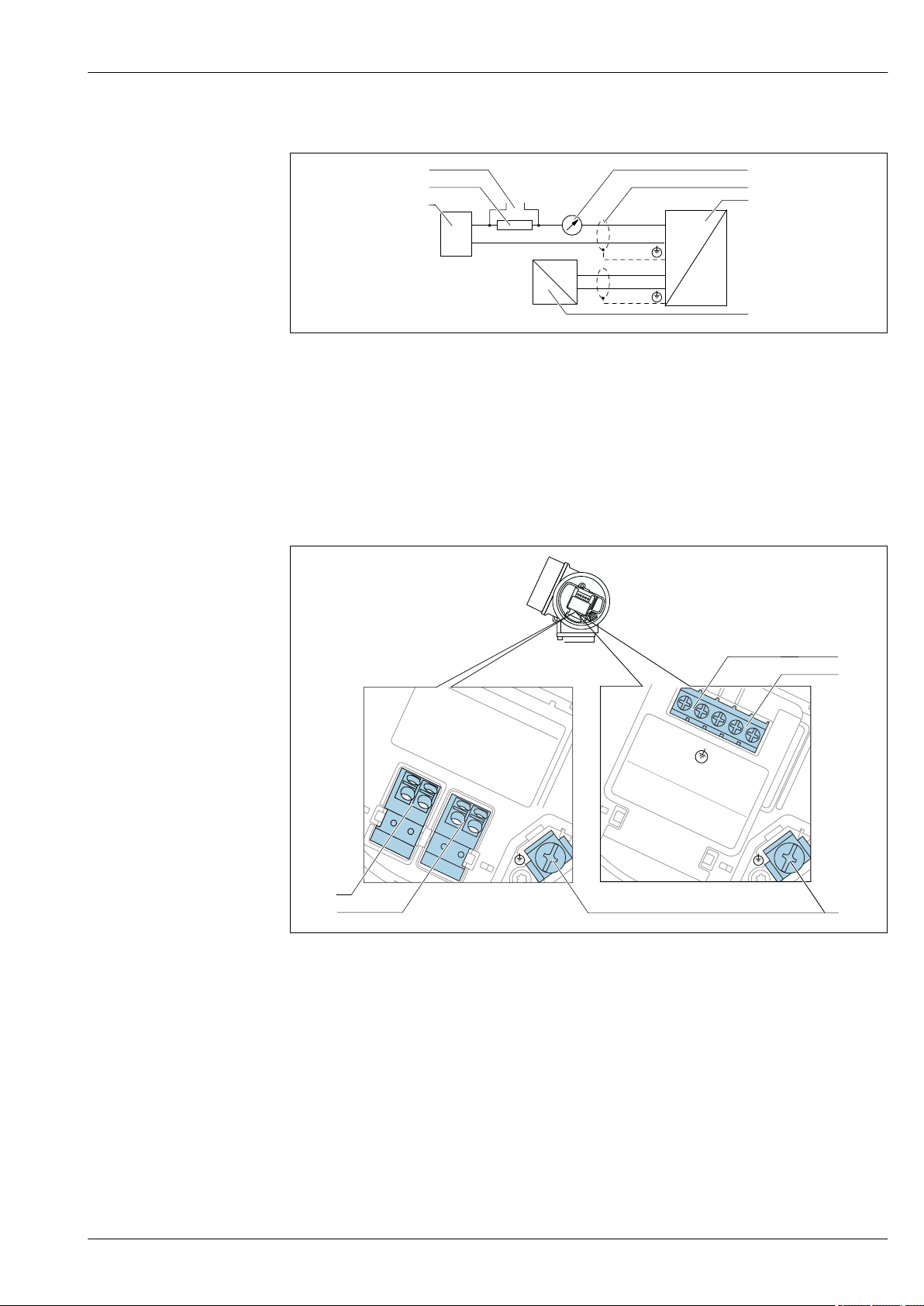

Terminal assignment PROFIBUS PA / FOUNDATION Fieldbus

A0036500

12 Terminal assignment PROFIBUS PA / FOUNDATION Fieldbus

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Connection PROFIBUS PA / FOUNDATION Fieldbus: terminals 1 and 2, without integrated overvoltage

protection

2 Connection switch output (Open Collector): terminals 3 and 4, without integrated overvoltage protection

3 Connection switch output (Open Collector): terminals 3 and 4, with integrated overvoltage protection

4 Connection PROFIBUS PA / FOUNDATION Fieldbus: terminals 1 and 2, with integrated overvoltage protection

5 Terminal for cable screen

Endress+Hauser 27

Block diagram PROFIBUS PA / FOUNDATION Fieldbus

+

+

-

-

Y

I

2

3

1

2

3

4

4

13 Block diagram PROFIBUS PA / FOUNDATION Fieldbus

1 Cable screen; observe cable specifications

2 Connection PROFIBUS PA / FOUNDATION Fieldbus

3 Measuring device

4 Switch output (open collector)

Micropilot FMR51, FMR52

A0036530

28 Endress+Hauser

Micropilot FMR51, FMR52

3+

+

-

4-

R

i

3+

2

1

+

4-

R

i

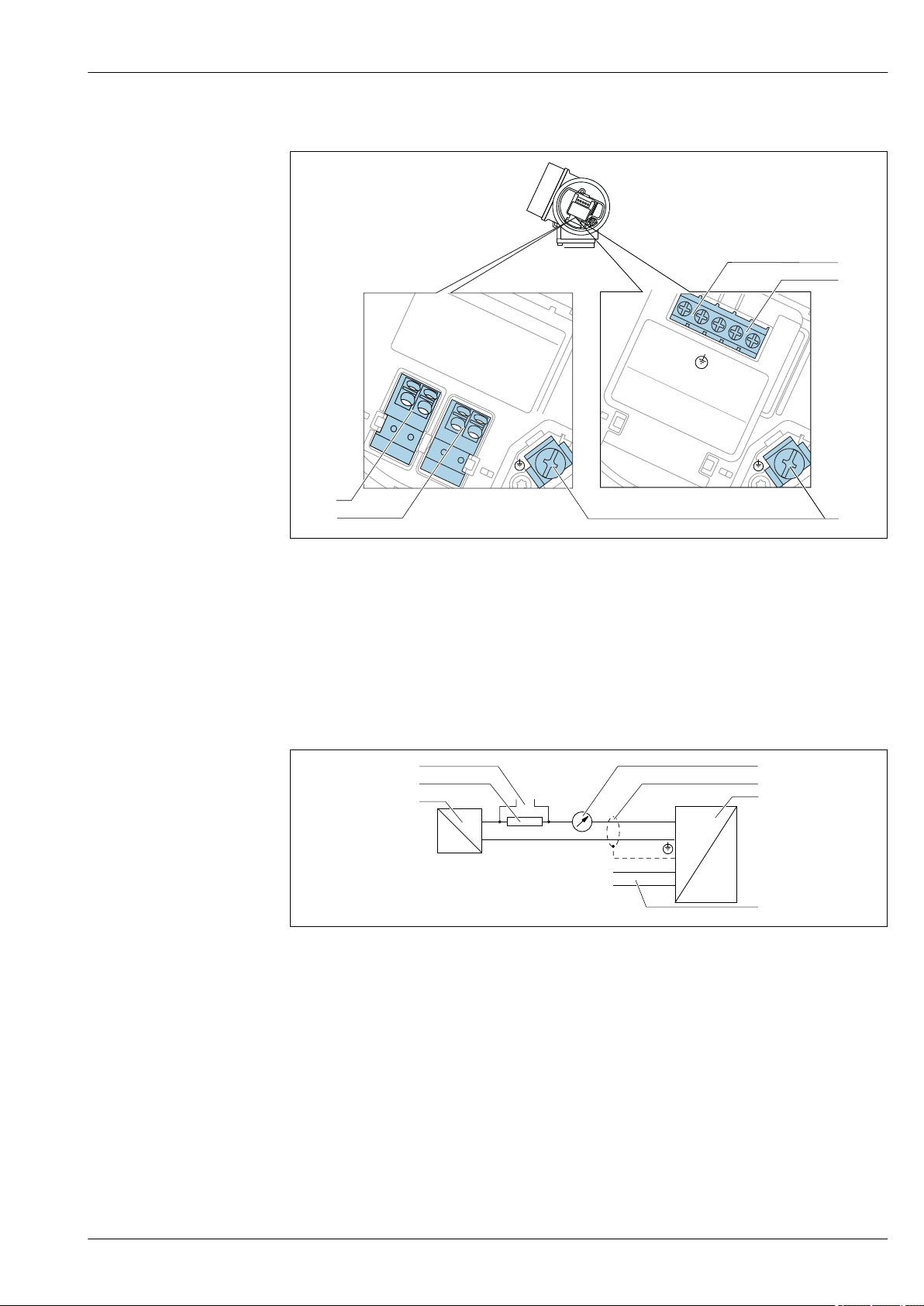

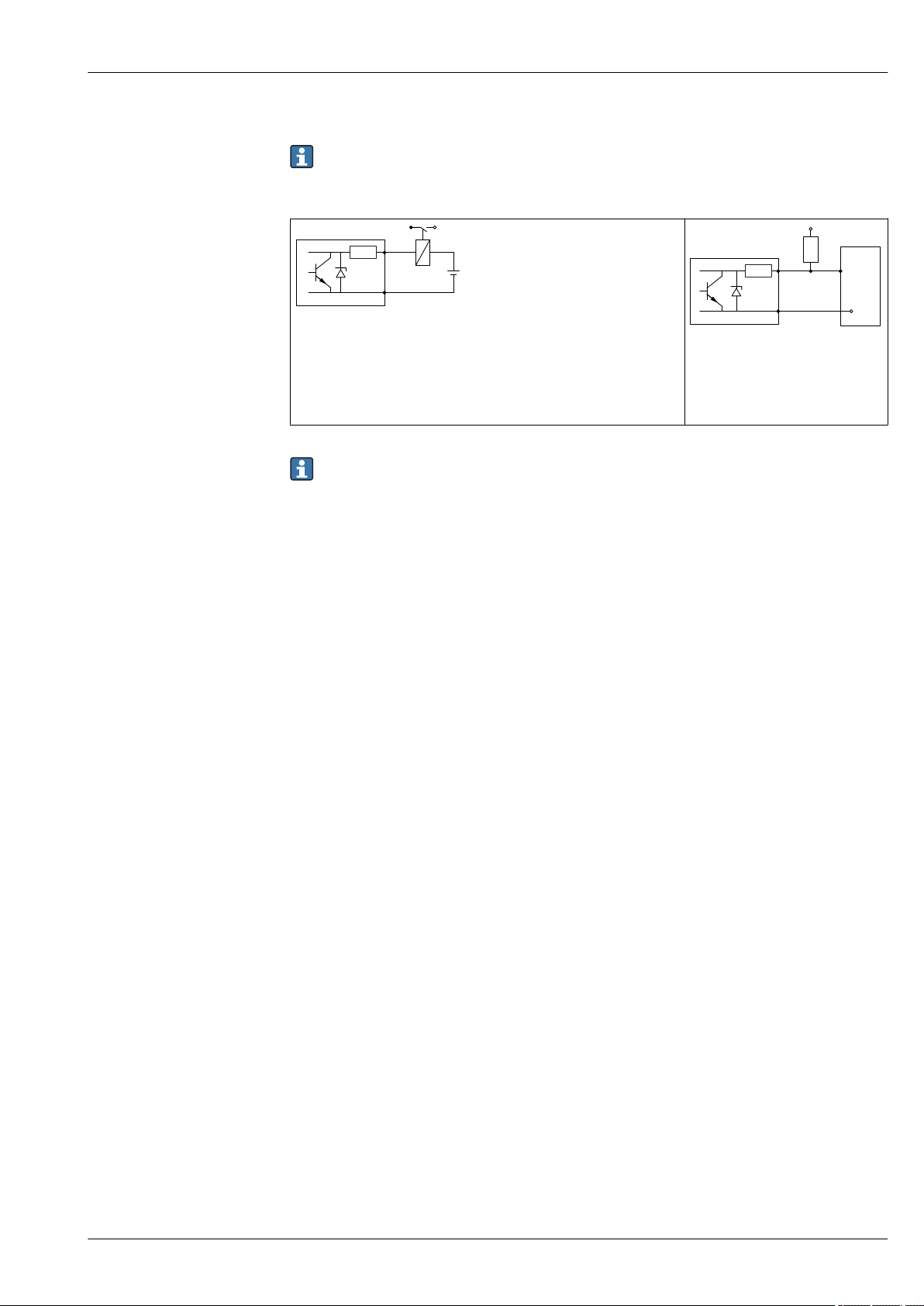

Connection examples for the switch output

For HART devices, the switch output is available as an option. See product structure, feature 20:

"Power Supply, Output", option B: "2-wire; 4-20 mA HART, switch output"

Devices with PROFIBUS PA and FOUNDATION Fieldbus always have a switch output.

A0015909

14 Connection of a relay

Suitable relays (examples):

• Solid-state relay: Phoenix Contact OV-24DC/480AC/5 with mounting

rail connector UMK-1 OM-R/AMS

• Electromechanical relay: Phoenix Contact PLC-RSC-12DC/21

15 Connection of a digital input

1 Pull-up resistor

2 Digital input

For optimum interference immunity we recommend to connect an external resistor (internal

resistance of the relay or Pull-up resistor) of < 1 000 Ω.

A0015910

Endress+Hauser 29

Micropilot FMR51, FMR52

2

1

3

4

4

2

3

1

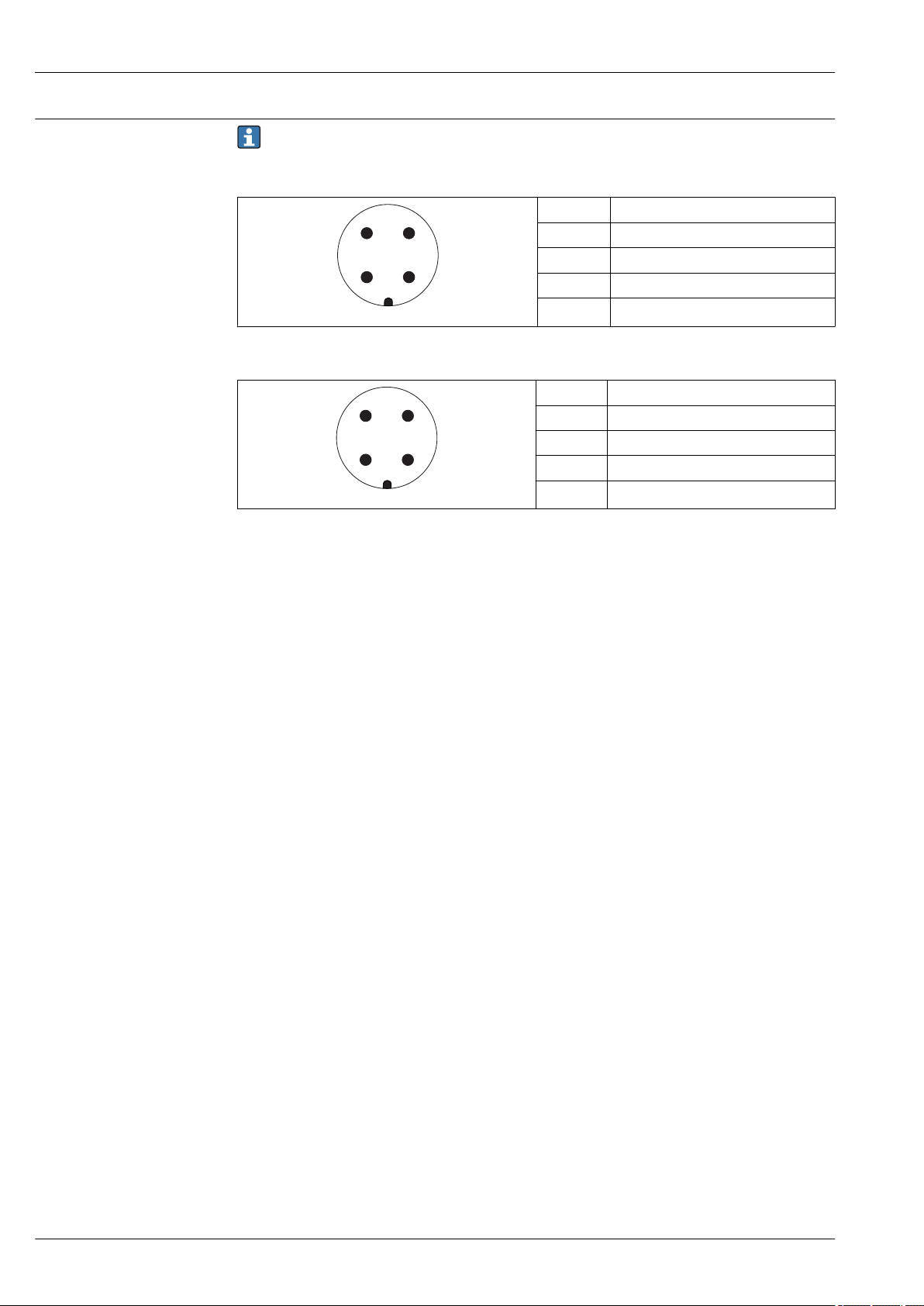

Device plug connectors

For the versions with fieldbus plug connector (M12 or 7/8"), the signal line can be connected

without opening the housing.

Pin assignment of the M12 plug connector

Pin Meaning

1 Signal +

2 not connected

3 Signal -

4 Ground

A0011175

Pin assignment of the 7/8" plug connector

Pin Meaning

1 Signal -

2 Signal +

3 Not connected

4 Screen

A0011176

30 Endress+Hauser

Micropilot FMR51, FMR52

R [ ]?

U0[V]

10

10.4 21.4

20 30 35

0

500

U0[V]

10

13 24

20 30 35

0

500

R [ ]Ω

Supply voltage

"Power Supply,

1)

Output"

A: 2-wire; 4-20mA

HART

An external power supply is required.

Various supply units can be ordered from Endress+Hauser: see "Accessories" section→ 114

2-wire, 4-20mA HART, passive

"Approval"

• Non-Ex

• Ex nA

• Ex ic

• CSA GP

Ex ia / IS 10.4 to 30 V

• Ex d(ia) / XP

• Ex ic(ia)

• Ex nA(ia)

• Ex ta / DIP

Ex ia + Ex d(ia) / IS + XP 13 to 30 V

2)

Terminal voltage U at

the device

10.4 to 35 V

13 to 35 V

Maximum load R, depending on the supply voltage U0 at the supply unit

3) 4) 5)

3) 4) 5)

A0017140

5) 6)

5) 6)

A0034771

1) Feature 020 of the product structure

2) Feature 010 of the product structure

3) For ambient temperatures Ta≤ -20 °C (-4 °F) a minimum voltage of 15 V is required for the sartup of the device at the minimum error current (3,6

mA). The startup current can be parametrized. If the device is operated with a fixed current I ≥ 5,5 mA (HART multidrop mode), a voltage of U ≥

10,4 V is sufficient throughout the entire range of ambient temperatures.

4) In the current simulation mode a voltage U ≥ 12.5 V is required.

5) If the Bluetooth modem is used, the minimum supply voltage increases by 3 V.

6) For ambient temperatures Ta≤ -20 °C (-4 °F) a minimum voltage of 16 V is required for the startup of the device at the minimum error current

(3.6 mA).

Endress+Hauser 31

Micropilot FMR51, FMR52

U0[V]

10

13 24

20 30 35

0

500

R [ ]Ω

R [ ]W

U0[V]

10

13 24

20 28

0

500

"Power Supply,

1)

Output"

B: 2-wire; 4-20 mA

HART, switch output

"Approval"

• Non-Ex

• Ex nA

2)

Terminal voltage

Maximum load R, depending on the supply voltage U0 at the supply unit

U at the device

13 to 35 V

3) 4)

• Ex nA(ia)

• Ex ic

• Ex ic(ia)

• Ex d(ia) / XP

• Ex ta / DIP

• CSA GP

• Ex ia / IS

13 to 30 V

3) 4)

• Ex ia + Ex d(ia) / IS + XP

A0034771

1) Feature 020 of the product structure

2) Feature 010 of the product structure

3) For ambient temperatures Ta≤ -30 °C (-22 °F) a minimum voltage of 16 V is required for the startup of the device at the minimum error current

(3.6 mA).

4) If the Bluetooth modem is used, the minimum supply voltage increases by 3 V.

"Power Supply, Output"

1)

"Approval"

2)

Terminal voltage U at the

Maximum load R, depending on the supply voltage U0 at the supply unit

device

C: 2-wire; 4-20mA HART,

any 13 to 28 V

3) 4)

4-20mA

1) Feature 020 of the product structure

2) Feature 010 of the product structure

3) For ambient temperatures Ta≤ -30 °C (-22 °F) a minimum voltage of 16 V is required for the startup of the device at the minimum error current

(3.6 mA).

4) If the Bluetooth modem is used, the minimum supply voltage increases by 3 V.

Polarity reversal

Yes

protection

Admissible residual ripple

USS < 1 V

at f = 0 to 100 Hz

Admissible residual ripple

USS < 10 mV

at f = 100 to 10000 Hz

A0034841

32 Endress+Hauser

Micropilot FMR51, FMR52

4-wire, 4-20mA HART, active

"Power supply; Output"

1)

Terminal voltage Maximum load

K: 4-wire 90-253VAC; 4-20mA HART 90 to 253 VAC (50 to 60 Hz),

overvoltage category II

L: 4-wire 10,4-48VDC; 4-20mA HART 10.4 to 48 V

DC

1) Feature 020 of the product structure

PROFIBUS PA, FOUNDATION Fieldbus

"Power supply; Output"

1)

E: 2-wire; FOUNDATION Fieldbus, switch output

G: 2-wire; PROFIBUS PA, switch output

1) Feature 020 of the product structure

2) Feature 010 of the product structure

3) Input voltages up to 35 V will not spoil the device.

"Approval"

• Non-Ex

• Ex nA

• Ex nA(ia)

• Ex ic

• Ex ic(ia)

• Ex d(ia) / XP

• Ex ta / DIP

• CSA GP

• Ex ia / IS

• Ex ia + Ex d(ia) / IS + XP

2)

R

max

500 Ω

Terminal voltage

9 to 32 V

9 to 30 V

3)

3)

Polarity sensitive No

FISCO/FNICO compliant

according to IEC 60079-27

Power consumption

"Power supply; Output"

A: 2-wire; 4-20mA HART < 0.9 W

B: 2-wire; 4-20mA HART, switch output < 0.9 W

C: 2-wire; 4-20mA HART, 4-20mA < 2 x 0.7 W

K: 4-wire 90-253VAC; 4-20mA HART 6 VA

L: 4-wire 10,4-48VDC; 4-20mA HART 1.3 W

1) Feature 020 of the product structure

Current consumption HART

Nominal current 3.6 to 22 mA, the start-up current for multidrop mode can be parametrized (is

Breakdown signal

(NAMUR NE43)

PROFIBUS PA

Yes

1)

set to 3.6 mA on delivery)

adjustable: 3.59 to 22.5 mA

Power consumption

Nominal current 14 mA

Failure current FDE (Fault

0 mA

Disconnection Electronic)

Endress+Hauser 33

FOUNDATION Fieldbus

Device basic current 15 mA

Failure current FDE (Fault

Disconnection Electronic)

0 mA

FISCO

Micropilot FMR51, FMR52

Power supply failure

U

i

I

i

P

i

C

i

L

i

• Configuration is retained in the HistoROM (EEPROM).

17.5 V

550 mA

5.5 W

5 nF

10 μH

• Error messages (incl. value of operated hours counter) are stored.

Potential equalization

No special measures for potential equalization are required.

If the device is designed for hazardous areas, observe the information in the documentation

"Safety Instructions" (XA).

Terminals

• Without integrated overvoltage protection

Plug-in spring terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• With integrated overvoltage protection

Screw terminals for wire cross-sections 0.2 to 2.5 mm2 (24 to 14 AWG)

Cable entries Connection of power supply and signal line

To be selected in feature 050 "Electrical connection"

• Gland M20; Material dependent on the approval:

– For Non-Ex, ATEX, IECEx, NEPSI Ex ia/ic:

Plastics M20x1.5 for cable ⌀5 to 10 mm (0.2 to 0.39 in)

– For Dust-Ex, FM IS, CSA IS, CSA GP, Ex nA:

– For Ex d:

No gland available

• Thread

– ½" NPT

– G ½"

– M20 × 1.5

• Plug M12 / Plug 7/8"

Only available for Non-Ex, Ex ic, Ex ia

Connection of remote display FHX50

Feature 030 "Display, Operation" Cable entry for FHX50 connection

L: "Prepared for display FHX50 + M12 connection" M12 socket

M: "Prepared for display FHX50 + M16 gland, custom connection" M12 cable gland

N: "Prepared for display FHX50 + NPT1/2 thread, custom connection" NPT1/2 thread

Cable specification

• Devices without integrated overvoltage protection

Pluggable spring-force terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Devices with integrated overvoltage protection

Screw terminals for wire cross-sections 0.2 to 2.5 mm2 (24 to 14 AWG)

• For ambient temperature TU≥60 °C (140 °F): use cable for temperature TU +20 K.

34 Endress+Hauser

Micropilot FMR51, FMR52

HART

• A normal device cable suffices if only the analog signal is used.

• A shielded cable is recommended if using the HART protocol. Observe grounding concept of the

plant.

• For 4-wire devices: Standard device cable is sufficient for the power line.

PROFIBUS

Use a twisted, screened two-wire cable, preferably cable type A.

For further information on the cable specifications, see Operating Instructions BA00034S

"PROFIBUS DP/PA: Guidelines for planning and commissioning", PNO Guideline 2.092

"PROFIBUS PA User and Installation Guideline" and IEC 61158-2 (MBP).

FOUNDATION Fieldbus

Endress+Hauser recommends using twisted, shielded two-wire cables.

For further information on the cable specifications, see Operating Instructions BA00013S

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2 (MBP).

Overvoltage protection

If the measuring device is used for level measurement in flammable liquids which requires the use of

overvoltage protection according to DIN EN 60079-14, standard for

test procedures 60060-1 (10 kA, pulse 8/20 μs), an overvoltage protection module has to be

installed.

Integrated overvoltage protection module

An integrated overvoltage protection module is available for 2-wire HART as well as PROFIBUS PA

and FOUNDATION Fieldbus devices.

Product structure: Feature 610 "Accessory mounted", option NA "Overvoltage protection".

Technical data

Resistance per channel 2 × 0.5 Ω max.

Threshold DC voltage 400 to 700 V

Threshold impulse voltage < 800 V

Capacitance at 1 MHz < 1.5 pF

Nominal arrest impulse voltage (8/20 μs) 10 kA

External overvoltage protection module

HAW562 or HAW569 from Endress+Hauser are suited as external overvoltage protection.

Endress+Hauser 35

Performance characteristics

2 (0.08)

0

-2 (-0.08)

A 1 (3.3)

4 (0.16)

-4 (-0.16)

R

D [mm] ([in])

D [m] ([ft])

Micropilot FMR51, FMR52

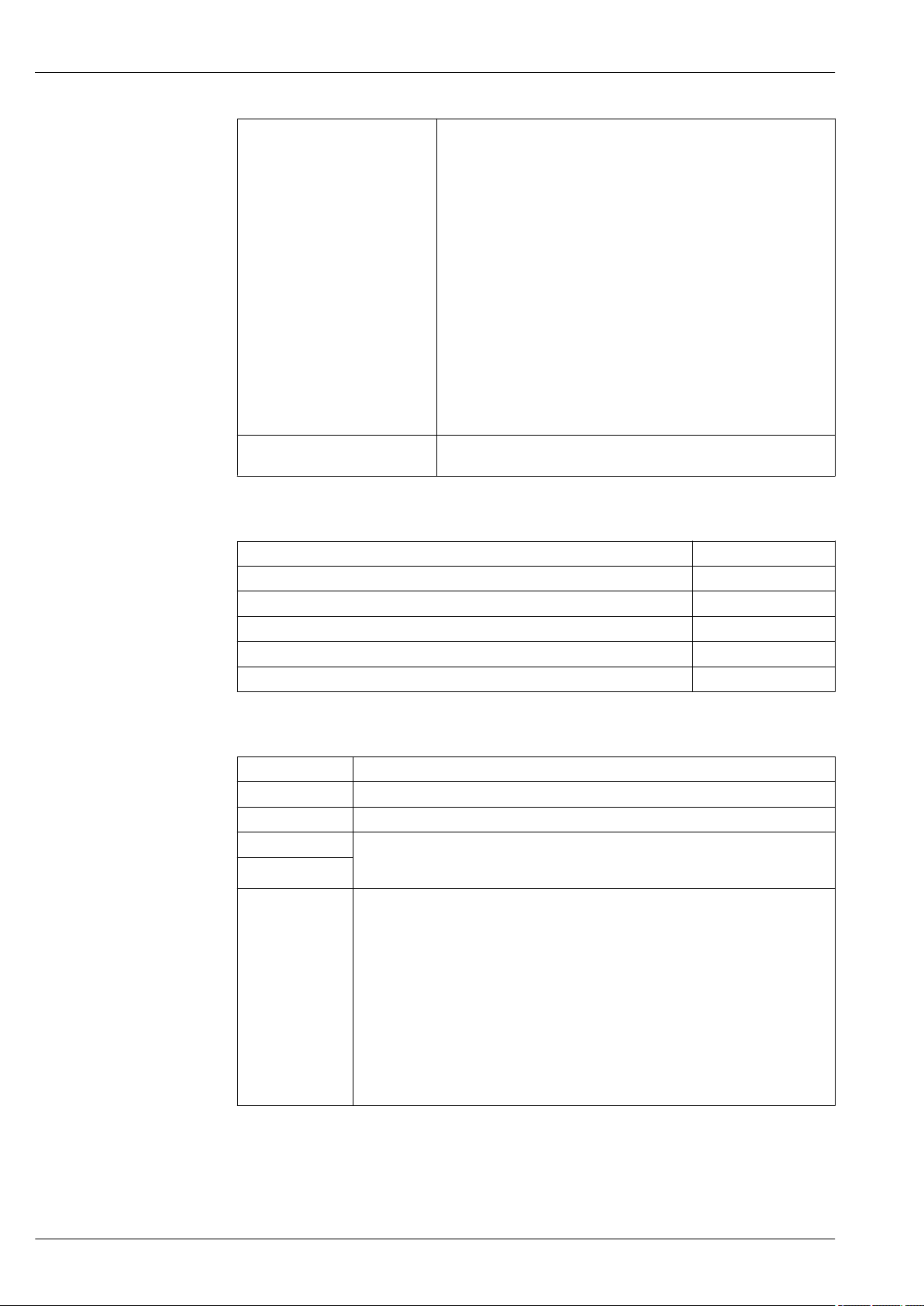

Reference operating conditions

Maximum measured error

• Temperature = +24 °C (+75 °F) ±5 °C (±9 °F)

• Pressure = 960 mbar abs. (14 psia) ±100 mbar (±1.45 psi)

• Humidity = 60 % ±15 %

• Reflector: metal plate with a minimum diameter of 1 m (40 in)

• No major interference reflections inside the signal beam

Typical data under reference operating conditions: DIN EN IEC 61298-2 / DIN EN IEC 60770-1;

percentage values in relation to the span.

Device Value Output

digital analog

FMR51/FMR52

Standard version

FMR51/FMR52

Version with application package

"Advanced dynamics"

1) Only relevant for 4-20mA current output; add error of the analog value to the digital value.

2) Product structure: Feature 540 "Application Package", Option EM "Advanced dynamics"

2)

Sum of nonlinearity,

nonrepeatability and

hysteresis

Offset/Zero ± 4 mm (0.2 in) ± 0.03 %

Sum of nonlinearity,

nonrepeatability and

hysteresis

Offset/Zero ± 4 mm (0.2 in) ± 0.03 %

± 2 mm (0.08 in) ± 0.02 %

± 3 mm (0.12 in) ± 0.02 %

1)

Differing values in near-range applications

A0019035

16 Maximum measured error in near-range applications; values for standard version

Δ Maximum measured error

A Lower edge of the antenna

D Distance from the lower edge A of the antenna

R Reference point of the distance measurement

36 Endress+Hauser

Micropilot FMR51, FMR52

3 (0.12)

0

-3 (-12)

A 2 (6.6) D [m] ([ft])

20 (0.79)

-20 (-0.79)

R

D [mm] ([in])

A0019034

17 Maximum measured error in near-range applications; values for version with the "Advanced dynamics"

application package

Δ Maximum measured error

A Lower edge of the antenna

D Distance from the lower edge A of the antenna

R Reference point of the distance measurement

Measured value resolution

Reaction time

Influence of ambient temperature

Influence of gas layer

Dead band according to DIN EN IEC 61298-2 / DIN EN IEC 60770-1:

• digital: 1 mm

• analog: 1 μA

The reaction time can be parametrized. The following step response times (as per DIN EN IEC

61298-2 / DIN EN IEC 60770-1)

Tank height Sampling rate Step response time

< 10 m (33 ft) ≥ 3.6 s

< 70 m (230 ft) ≥ 2.2 s

1)

are valid if the damping is switched off:

–1

–1

< 0.8 s

< 1 s

The measurements are carried out in accordance with DIN EN IEC 61298-3 / DIN EN IEC

60770-1

• Digital (HART, PROFIBUS PA, FOUNDATION Fieldbus):

– Standard version: average TK = 2 mm/10 K

– Version with advanced dynamics

2)

: average TK = 3 mm/10 K

• Analog (current output):

– zero point (4 mA): average TK = 0.02 %/10 K

– span (20 mA): average TK = 0.05 %/10 K

High pressures reduce the propagation velocity of the measuring signals in the gas/vapor above the

fluid. This effect depends on the kind of gas/vapor and of its temperature. This results in a

systematic measuring error that gets bigger as the distance increases between the reference point of

the measurement (flange) and the product surface. The following table illustrates this measured

1) According to DIN EN IEC 61298-2 / DIN EN IEC 60770-1 the response time is the time which passes after a sudden change of the input signal

until the output signal for the first time assumes 90% of the steady-state value.

2) Feature 540 "Application Package", option EM

Endress+Hauser 37

Micropilot FMR51, FMR52

error for a few typical gases/vapors (with regard to distance; a positive value means that too large a

distance is being measured):

Gas layer Temperature Pressure

°C °F 1 bar (14,5 psi) 10 bar (145 psi) 50 bar (725 psi) 100 bar (1450 psi) 160 bar (2320 psi)

Air/

Nitrogen

Hydrogen 20 68 –0.01 % 0.10 % 0.61 % 1.2 % 2.00 %

Water

(saturated

steam)

20 68 0.00 % 0.22 % 1.2 % 2.4 % 3.89 %

200 392 –0.01 % 0.13 % 0.74 % 1.5 % 2.42 %

400 752 –0.02 % 0.08 % 0.52 % 1.1 % 1.70 %

200 392 –0.02 % 0.05 % 0.37 % 0.76 % 1.23 %

400 752 –0.02 % 0.03 % 0.25 % 0.53 % 0.86 %

100 212 0.02 % - - - -

180 356 - 2.1 % - - -

263 505,4 - - 8.6 % - -

310 590 - - - 22 % -

364 687 - - - - 41.8 %

Gas phase compensation with external pressure sensor (PROFIBUS PA, FOUNDATION Fieldbus)

When the pressure is known and constant, this measured error can, for example, be

compensated by means of a linearization.

PROFIBUS devices can receive the signal of an external pressure sensor through the bus and use it to

perform a pressure dependent time-of-flight correction. In the case of saturated steam in the

temperature range from 100 to 350 °C (212 to 662 °f), for example, the measuring error of the

distance measurement can be reduced by this method from up to 29 % (without compensation) to

less than 3 % (with compensation).

38 Endress+Hauser

Micropilot FMR51, FMR52

A

1 2 3

Installation

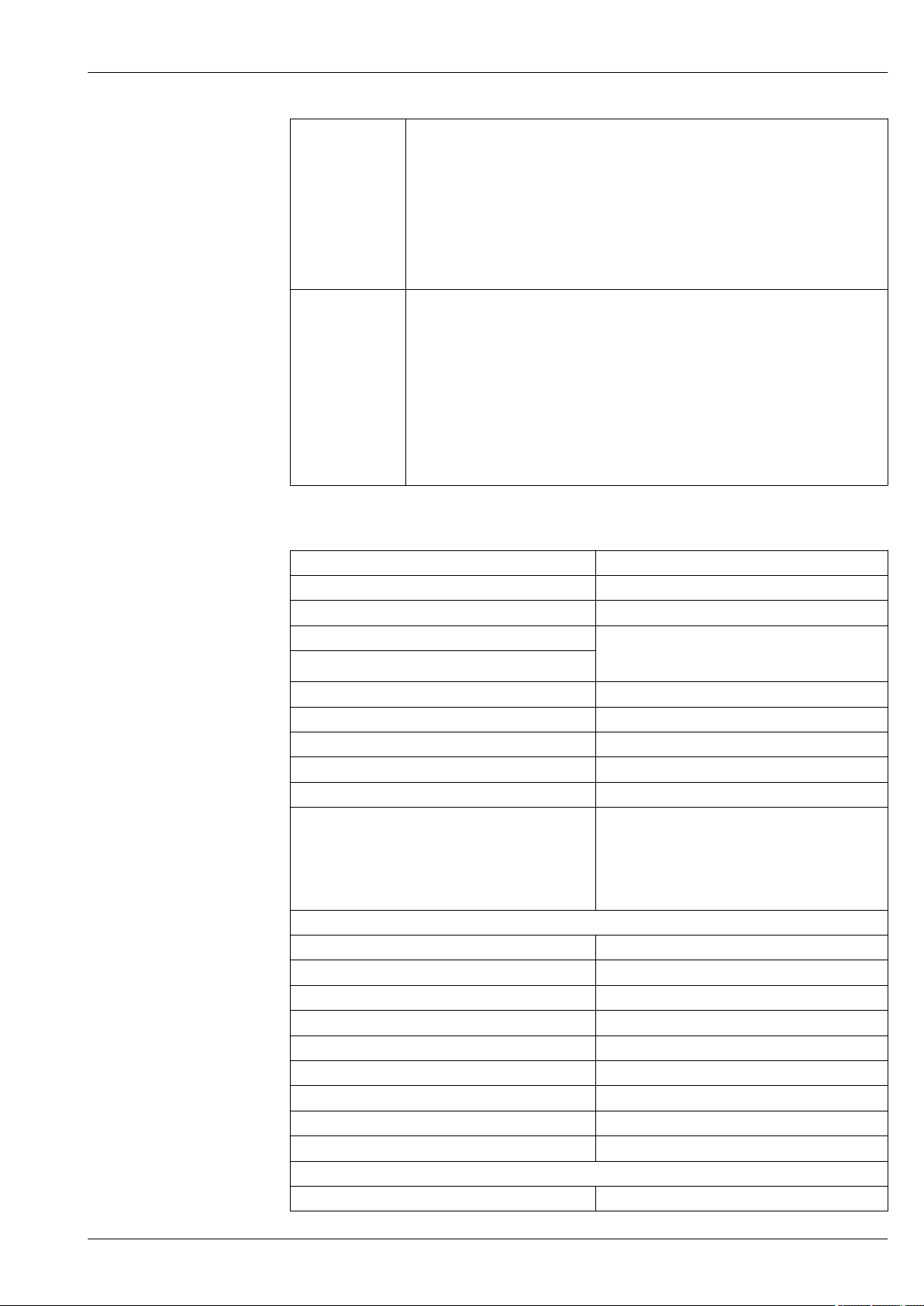

Installation conditions Mounting position

• Recommended distance A from wall to outer

edge of nozzle: ~ 1/6 of tank diameter.

Nevertheless the device should not be

installed closer than 15 cm (5.91 in) to the

tank wall.

• Not in the center (2), as interference can

cause signal loss.

• Not above the fill stream (3).

• It is recommended to us a weather protection

cover (1) in order to protect the device from

direct sun or rain.

A0016882

Vessel installations

Avoid any installations (point level switches,

temperature sensors, braces, vacuum rings,

heating coils, baffles etc.) inside the signal

beam. Take into account the beam angle

→ 41.

A0018944

Endress+Hauser 39

Reduction of interference echoes

2

3

1

Micropilot FMR51, FMR52

Metallic screens mounted at a slope spread the

radar signal and can, therefore, reduce

interference echoes.

A0016890

Measurement in a plastic vessel

If the outer wall of the vessel is made of a non-conductive material (e.g. GRP), microwaves can also

be reflected off interfering installations outside the vessel (e.g. metallic pipes (1), ladders (2), grates

(3), ...). Therefore, there should be no such interfering installations in the signal beam. Please

contact Endress+Hauser for further information.

A0017123

40 Endress+Hauser

Micropilot FMR51, FMR52

a

D

W

a

D

_

=

2

2

. .

tan

W

Optimization options

• Antenna size

The bigger the antenna, the smaller the beam angle α and the fewer interference echoes

→ 41.

• Mapping

The measurement can be optimized by means of electronic suppression of interference echoes.

• Antenna alignment

Take into account the marker on the flange or threaded connection .

• Stilling well

A stilling well can be applied to avoid interferences → 48.

• Metallic screens mounted at a slope

They spread the radar signals and can, therefore, reduce interference echoes.

Beam angle

A0016891

18 Relationship between beam angle α, distance D and beamwidth diameter W

The beam angle is defined as the angle α where the energy density of the radar waves reaches half

the value of the maximum energy density (3-dB-width). Microwaves are also emitted outside the

signal beam and can be reflected off interfering installations.

Endress+Hauser 41

Micropilot FMR51, FMR52

Beam diameter W as a function of beam angle α and measuring distance D:

FMR51

Antenna size 40 mm (1½ in) 50 mm (2 in) 80 mm (3 in) 100 mm (4 in)

Beam angle α 23° 18° 10° 8°

Measuring

distance (D)

3 m (9.8 ft) 1.22 m (4 ft) 0.95 m (3.1 ft) 0.53 m (1.7 ft) 0.42 m (1.4 ft)

6 m (20 ft) 2.44 m (8 ft) 1.9 m (6.2 ft) 1.05 m (3.4 ft) 0.84 m (2.8 ft)

9 m (30 ft) 3.66 m (12 ft) 2.85 m (9.4 ft) 1.58 m (5.2 ft) 1.26 m (4.1 ft)

12 m (39 ft) 4.88 m (16 ft) 3.80 m (12 ft) 2.1 m (6.9 ft) 1.68 m (5.5 ft)

15 m (49 ft) 6.1 m (20 ft) 4.75 m (16 ft) 2.63 m (8.6 ft) 2.10 m (6.9 ft)

20 m (66 ft) 8.14 m (27 ft) 6.34 m (21 ft) 3.50 m (11 ft) 2.80 m (9.2 ft)

25 m (82 ft) 10.17 m (33 ft) 7.92 m (26 ft) 4.37 m (14 ft) 3.50 m (11 ft)

30 m (98 ft) - 9.50 m (31 ft) 5.25 m (17 ft) 4.20 m (14 ft)

35 m (115 ft) - 11.09 m (36 ft) 6.12 m (20 ft) 4.89 m (16 ft)

40 m (131 ft) - 12.67 m (42 ft) 7.00 m (23 ft) 5.59 m (18 ft)

45 m (148 ft) - - 7.87 m (26 ft) 6.29 m (21 ft)

60 m (197 ft) - - 10.50 m (34 ft) 8.39 m (28 ft)

70 m (230 ft) - - - 9.79 m (32 ft)

Antenna size 50 mm (2 in) 80 mm (3 in)

Beam angle α 18° 10°

Beamwidth diameter W

FMR52

Measuring distance (D) Beamwidth diameter W

3 m (9.8 ft) 0.95 m (3.1 ft) 0.53 m (1.7 ft)

6 m (20 ft) 1.9 m (6.2 ft) 1.05 m (3.4 ft)

9 m (30 ft) 2.85 m (9.4 ft) 1.58 m (5.2 ft)

12 m (39 ft) 3.80 m (12 ft) 2.1 m (6.9 ft)

15 m (49 ft) 4.75 m (16 ft) 2.63 m (8.6 ft)

20 m (66 ft) 6.34 m (21 ft) 3.50 m (11 ft)

25 m (82 ft) 7.92 m (26 ft) 4.37 m (14 ft)

30 m (98 ft) 9.50 m (31 ft) 5.25 m (17 ft)

35 m (115 ft) 11.09 m (36 ft) 6.12 m (20 ft)

40 m (131 ft) 12.67 m (42 ft) 7.00 m (23 ft)

45 m (148 ft) - 7.87 m (26 ft)

60 m (197 ft) - 10.50 m (34 ft)

42 Endress+Hauser

Micropilot FMR51, FMR52

100%

0%

B

A

C

H

øD

Measuring conditions

• In case of boiling surfaces, bubbling or tendency for foaming use FMR53 or FMR54. Depending

on its consistence, foam can either absorb microwaves or reflect them off the foam surface.

Measurement is possible under certain conditions. For FMR50, FMR51 and FMR52, the additional

option "Advanced dynamics" is recommended in these cases (feature 540: "Application Package",

option EM).

• In case of heavy steam development or condensate, the maximum measuring range of FMR50,

FMR51 and FMR52 may decrease depending on density, temperature and composition of the

steam → use FMR53 or FMR54.

• For the measurement of absorbing gases such as ammonia NH3 or some fluorocarbons

3)

, please

use Levelflex or Micropilot FMR54 in a stilling well.

• The measuring range begins, where the beam hits the tank bottom. Particularly with dish bottoms

or conical outlets the level cannot be detected below this point.

• In stilling well applications, the electromagnetic waves do not propagate completely outside the

tube. It must be taken into account that the accuracy may be reduced in the area C. In order to

guarantee the required accuracy in these cases, it is recommended to position the zero-point at a

distance C above the end of the tube (see figure).

• In case of media with a low dielectric constant (εr = 1.5 to 4)

4)

the tank bottom can be visible

through the medium at low levels (low height C). Reduced accuracy has to be expected in this

range. If this is not acceptable, we recommend positioning the zero point at a distance C (see

figure) above the tank bottom in these applications.

• In principle it is possible to measure up to the tip of the antenna with FMR51, FMR53 and FMR54.

However, due to considerations regarding corrosion and build-up, the end of the measuring range

should not be chosen any closer than A (see figure) to the tip of the antenna.

• When using FMR54 with planar antenna, especially for media with low dielectric constants, the

end of the measuring range should not be closer than A: 1 m (3.28 ft) to the flange.

• The smallest possible measuring range B depends on the antenna version (see figure).

• The tank height should be at least H (see table).

Device A [mm (in)] B [m (ft)] C [mm (in)] H [m (ft)]

FMR51 50(1.97)

FMR52 200(7.87)

3) Affected compounds are e.g. R134a, R227, Dymel 152a.

4) Dielectric constants of important media commonly used in various industries are summarized in the DC manual (CP01076F) and in the Endress

+Hauser "DC Values App" (available for Android and iOS).

Endress+Hauser 43

> 0.2 (0.7) 50 to 250 (1.97 to 9.84) > 0.3 (1.0)

A0018872

Micropilot FMR51, FMR52

Mounting cladded flanges

• Use flange screws according to the number of flange holes.

• Tighten the screws with the required torque (see table).

• Retighten the screws after 24 hours or after the first temperature cycle.

• Depending on process pressure and process temperature check and retighten the screws at

regular intervals.

Usually, the PTFE flange cladding also serves as a seal between the nozzle and the device

flange.

Flange size Number of screws Recommended torque [Nm]

minimum maximum

EN

DN50/PN16 4 45 65

DN80/PN16 8 40 55

DN100/PN16 8 40 60

DN150/PN16 8 75 115

ASME

2"/150lbs 4 40 55

3"/150lbs 4 65 95

4"/150lbs 8 45 70

6"/150lbs 8 85 125

JIS

10K 50A 4 40 60

10K 80A 8 25 35

10K 100A 8 35 55

10K 100A 8 75 115

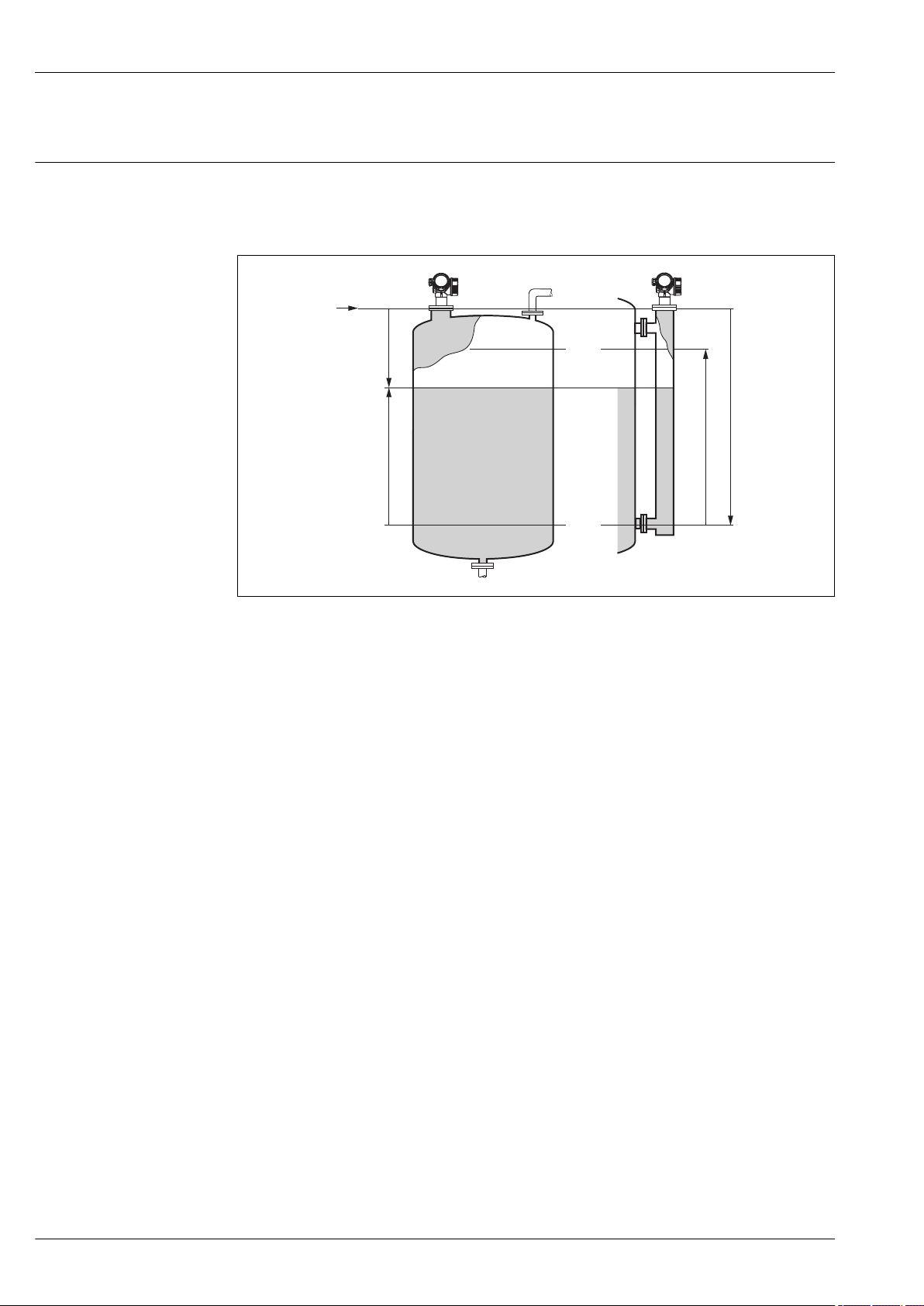

Installation in vessel (free space)

Horn antenna (FMR51)

Alignment

• Align the antenna vertically to the product surface.

The maximum range may be reduced if the horn antenna is not vertically aligned.

• A marking at the flange (somewhere between the flange holes) or the boss enables alignment of

the antenna. This marking must be aligned towards the tank wall as well as possible.

44 Endress+Hauser

Micropilot FMR51, FMR52

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

A

B

H

max

A0018974

Depending on the device version the marking may be a circle or two short parallel lines.

Nozzle mounting

For optimum measurement, the tip of the antenna should extend below the nozzle. Depending on

the antenna size this is achieved by the following maximum nozzle heights:

19 Nozzle height for horn antenna (FMR51)

Antenna

BA: Horn 40mm/1-1/2" 86 mm (3.39 in)

BB: Horn 50mm/2" 115 mm (4.53 in)

BC: Horn 80mm/3" 211 mm (8.31 in)

BD Horn 100mm/4" 282 mm (11.1 in)

1)

Maximum nozzle height H

max

A0016820

1) Feature 070 of the product structure

Conditions for longer nozzles

If the medium has good reflective properties, higher nozzles can be accepted. In this case the

maximum nozzle height, H

Endress+Hauser 45

, is dependent on the nozzle diameter, D:

max

Micropilot FMR51, FMR52

H

max

øD

A0023611

Nozzle diameter D Maximum nozzle height

H

max

40 mm (1.5 in) 100 mm (3.9 in) BA: Horn 40mm/1-1/2"

50 mm (2 in) 150 mm (5.9 in) BB: Horn 50mm/2"

80 mm (3 in) 250 mm (9.8 in) BC: Horn 80mm/3"

100 mm (4 in) 500 mm (19.7 in) BD: Horn 100mm/4"

150 mm (6 in) 800 mm (31.5 in) BD: Horn 100mm/4"

1) Feature 070 of the product structure

Recommended antenna

1)

If the antenna doesn't extend below the nozzle, observe the following:

• The nozzle end must be smooth and free of burrs. If possible its edge should be rounded.

• An interference echo suppression must be performed.

• Please contact Endress+Hauser for applications with higher nozzles than those indicated in

the table.

• For mounting in heigh nozzles the device is available in a version with an antenna extension

of up to 1 000 mm (39.4 in)

5)

• The antenna extension may cause interference echoes in the near range. In this case it may

occur that the maximum measurable level is reduced.

Threaded connection

For devices with a threaded connection it may be necessary - depending on the antenna size to unmount the horn before fastening the device and to mount it again afterwards.

• Tighten with the hexagonal nut only.

• Tool : 55 mm hexagonal wrench

• Maximum permissible torque: 60 Nm (44 lbf ft)

Measurement from the outside through plastic walls (FMR50/FMR51)

• Dielectric constant of the medium: εr > 10

• If possible, use an antenna 100 mm (4 in).

• The distance from the lower edge of the antenna to the tank ceiling should be about

100 mm (4 in).

• If possible, avoid mounting locations where condensation or build-up might occur.

• In case of outdoor mounting, the space between antenna and vessel has to be protected from the

elements.

• Do not mount any potential reflectors (e.g. pipes) outside the tank in the signal beam.

5) Feature 610 "Accessory mounted" of the product structure.

46 Endress+Hauser

Micropilot FMR51, FMR52

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

A

B

H

max

Suitable thickness of the tank ceiling:

Penetrated material PE PTFE PP Perspex

DK / ε

r

Optimum thickness

1) Other possible values for the thickness are multiples of the values listed (e.g. for PE: 7,6 mm (0.3 in), 11,4

mm (0.45 in)

1)

2.3 2.1 2.3 3.1

3.8 mm (0.15 in) 4.0 mm (0.16 in) 3.8 mm (0.15 in) 3.3 mm (0.13 in)

Horn antenna, flush mount (FMR52)

Alignment

• Align the antenna vertically to the product surface.

The maximum range may be reduced if the horn antenna is not vertically aligned.

• A marking at the flange (somwhere between the flange holes) or the boss enables alignment of

the antenna. This marking must be aligned towards the tank wall as well as possible.

A0018974

Depending on the device version the marking may be a circle or two short parallel lines.

Nozzle mounting

20 Nozzle height for horn antenna, flush mount (FMR52)

A0016819

Endress+Hauser 47

Micropilot FMR51, FMR52

1

90°

Installation in stilling well

Antenna

BO: Horn 50mm/2" 500 mm (19.7 in)

BP: Horn 80mm/3" 500 mm (19.7 in)

1) Feature 070 of the product structure

1)

Maximum nozzle height H

max

Please contact Endress+Hauser for applications with higher nozzle.

• For flanges with PTFE cladding: Observe the notes on the mounting of cladded flanges

→ 44.

• Usually, the PTFE flange cladding also serves as a seal between the nozzle and the device

flange.

A0016841

21 Installation in stilling well

1 Marking for antenna alignment

• For horn antenna: Align the marking towards the slots of the stilling well.

• Measurements can be performed through an open full bore ball valve without any problems.

• After mounting, the housing can be turned 350° in order to facilitate access to the display and the

terminal compartment.

Recommendations for the stilling well

• Metal (no enamel coating; plastic on request).

• Constant diameter.

• Diameter of stilling well not larger than antenna diameter.

• Diameter difference between horn antenna and inner diameter of the stilling well as small as

possible.

• Weld seam as smooth as possible and on the same axis as the slots.

• Slots offset 180° (not 90°).

• Slot width or diameter of holes max. 1/10 of pipe diameter, de-burred. Length and number do not

have any influence on the measurement.

• Select horn antenna as big as possible. For intermedaite sizes (e.g. 180 mm (7 in)) select next

larger antenna and adapt it mechanically (for horn antennas)

• At any transition (i.e. when using a ball valve or mending pipe segments), no gap may be left

exceeding 1 mm (0.04 in).

• The stilling well must be smooth on the inside (average roughness Rz ≤ 6.3 μm (248 μin)). Use

extruded or parallel welded metal pipe. An extension of the pipe is possible with welded flanges or

pipe sleeves. Flange and pipe have to be properly aligned at the inside.

• Do not weld through the pipe wall. The inside of the stilling well must remain smooth. In case of

unintentional welding through the pipe, the weld seam and any unevenness on the inside need to

be carefully removed and smoothened. Otherwise, strong interference echoes will be generated