Page 1

TI00354F/00/EN/13.16

71310307

Products Solutions Services

Technical Information

Liquiphant S FTL70, FTL71

Vibronic

High-temperature point level switch for all types

of liquids

Application

The Liquiphant S is a point level switch for use in all types of liquids

– for process temperatures between –60 °C and 280 °C (–76 °F to 540 °F)

(300 °C (572 °C) for max. 50 cumulative hours; without thermal shock restriction)

– for pressures up to 100 bar (1450 psi)

– for viscosities up to 10,000 mPa*s (cSt)

– for density 0.5 g/cm

– Foam detection on request

The function is not affected by flow, turbulence, bubbles, foam, vibration, solids

content or buildup, making the Liquiphant an ideal substitute for float switches.

FTL70: Compact design, for pipes also

FTL71: Extension pipe up to 3 m (9.8 ft) and up to 6 m (20 ft) on request

For use in very aggressive liquids, the fork and process connection are available in the

highly corrosion-resistant material AlloyC22 (2.4602).

EEx ia, EEx de and EEx d protection enable it to be used in hazardous areas.

Your benefits

• Use in safety systems requiring functional safety to SIL2 in accordance with IEC

61508/IEC 61511-1

• Welded, gas-tight feed-through ensures maximum safety, even in the event of

damage to sensor

• With process connections from ¾" and small fork dimensions, it is also suitable

where space is tight.

• A wide range of process connections allows for universal application.

• The right connection for every process control system: e.g. NAMUR, relay, DC-PMP,

•PROFIBUS PA interface

• No adjustment: quick, low-cost startup

• No mechanical moving parts: maintenance-free

(SGU) or 0.7 g/cm(SGU), other configurations on request

Page 2

Table of contents

Liquiphant S FTL70, 71

Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Point level detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Function and system design . . . . . . . . . . . . . . . . . . . . . .4

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Modularity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electronic versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measuring range (detection range) . . . . . . . . . . . . . . . . . . . . . . 5

Process density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electronic insert FEL51 (AC 2-wire) . . . . . . . . . . . . . . .6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electronic insert FEL52 (DC PNP). . . . . . . . . . . . . . . . . .8

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electronic insert FEL57 (PFM) . . . . . . . . . . . . . . . . . . 13

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electronic insert FEL50A (PROFIBUS PA) . . . . . . . . . 15

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connection and function . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Safety mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switching time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch-on behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Influence of process temperature . . . . . . . . . . . . . . . . . . . . . . . 17

Influence of process density . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Influence of process pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Switching delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electronic insert FEL54 (AC/DC with relay output). . .9

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electronic insert FEL55 (8/16 mA) . . . . . . . . . . . . . . 10

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electronic insert FEL56 (NAMUR L-H edge). . . . . . . 11

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electronic insert FEL58 (NAMUR H-L edge). . . . . . . 12

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connectable load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Examples of mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation height as per IEC61010-1 Ed.3 . . . . . . . . . . . . . . 20

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Process conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Process temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Thermal shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Process pressure pe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

State of aggregation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Solids content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lateral loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Medium conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2

Page 3

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 22

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electronic inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 28

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RCM-tick mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Other certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

EAC conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CRN approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Process seal according to ANSI/ISA 12.27.01 . . . . . . . . . . . . . 29

Pressure Equipment Directive 2014/68/EU (PED) . . . . . . . . . 29

Use in hazardous zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ASME B 31.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Combinations of housing and electronic inserts . . . . . . . . . . . 30

Liquiphant S FTL70, 71

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ordering information Liquiphant S FTL70, FTL71 . . . . . . . . . 31

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lap joint flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lap joint flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Sliding sleeves for unpressurized operation . . . . . . . . . . . . . . . 35

High pressure sliding sleeves . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cover with sight glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cover with sight glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Functional safety (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Safety Instructions (ATEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Safety Instructions (NEPSI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Control Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3

Page 4

Liquiphant S FTL70, 71

FEL51/52/54

…

FEL55/56/57/58/50A

Ex i

…

E

X

E

X

Switching unit

PLC

Isolating

amplifier

Segment

coupler

Application

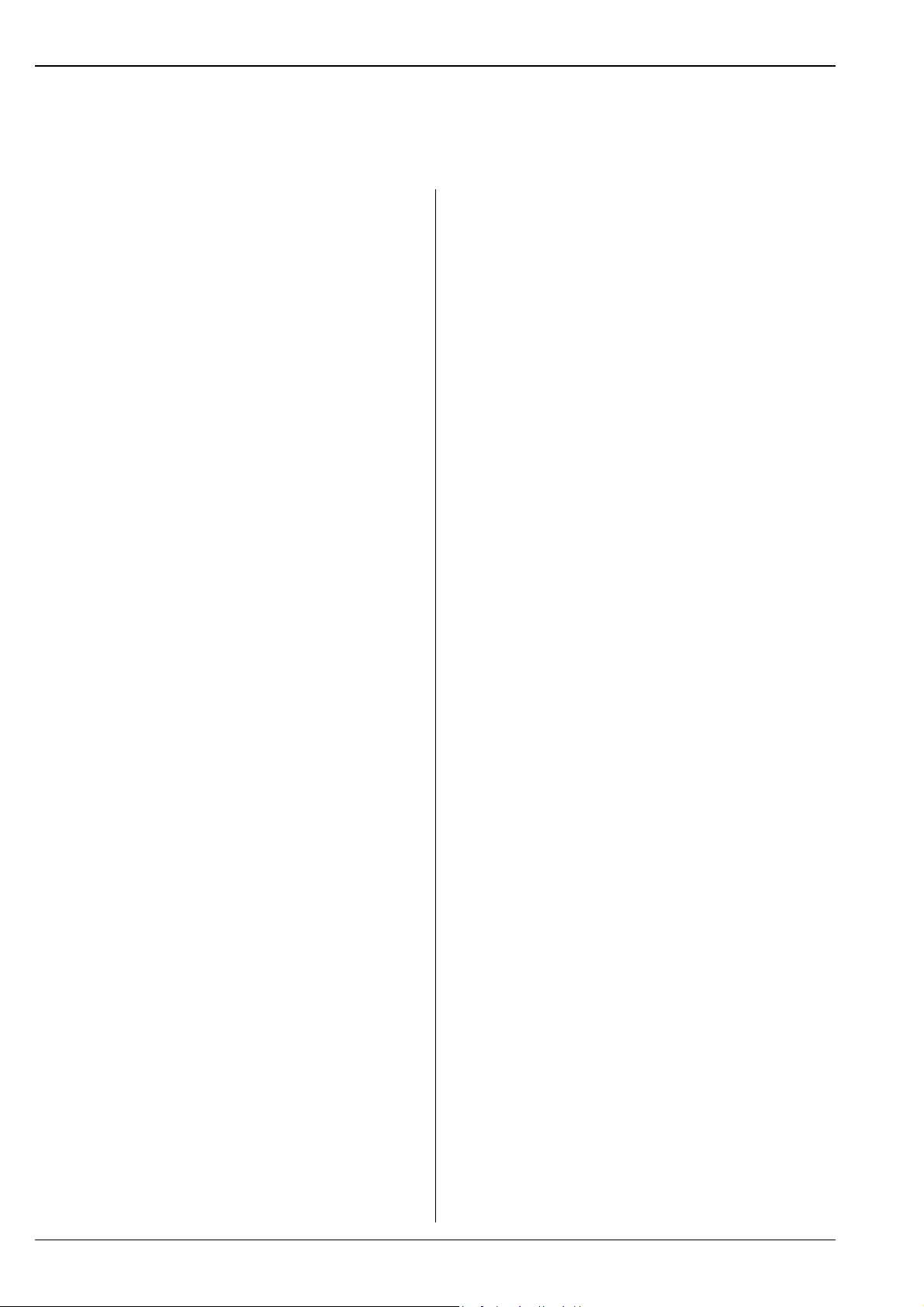

Point level detection Maximum or minimum detection in tanks or pipes with all types of cold to very hot liquids. The devices

are also suitable for use in hazardous areas and for applications involving high pressure.

L00-FTL7xxxx-11-05-xx-xx-001

Function and system design

Measuring principle The sensor's fork vibrates at its intrinsic frequency. This frequency is reduced when covered with liquid.

This change in frequency causes the point level switch to switch.

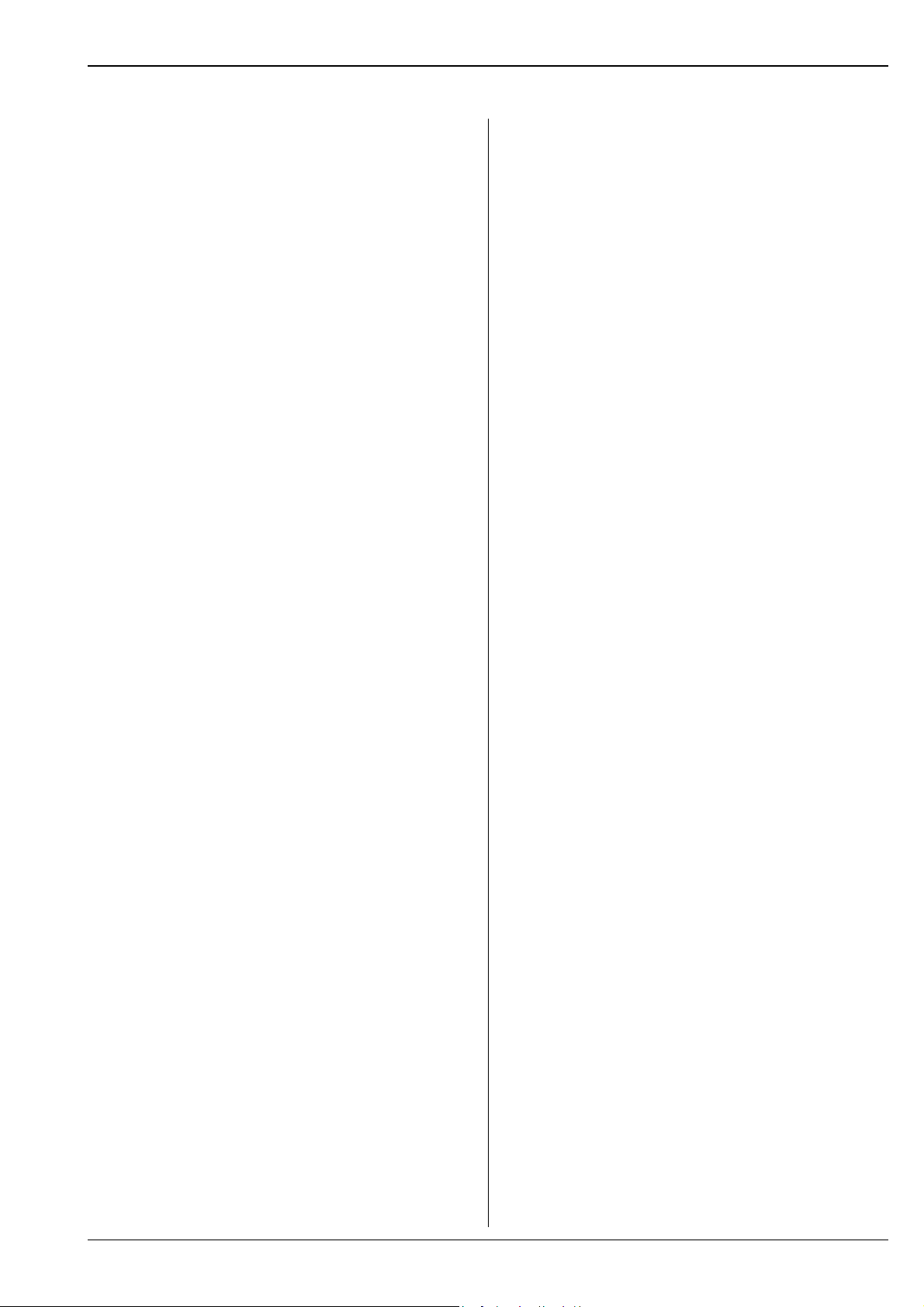

Modularity

Point level switch

Liquiphant S FTL7x with electronic inserts

FEL51, FEL52, FEL54

L00-FTL7xxxx-15-05-xx-xx-000

Point level switch

Liquiphant S FTL7x with electronic inserts

FEL55, FEL56, FEL57, FEL58, FEL50A

for connecting to a separate switching unit,

an isolating amplifier or for connecting

to a PROFIBUS PA segment coupler

4

L00-FTL7xxxx-15-05-xx-en-000

Page 5

Liquiphant S FTL70, 71

Electronic versions FEL51:

Two-wire AC version;

Switches the load directly into the power supply circuit via an electronic switch.

FEL52:

Three-wire DC version;

Switches the load via the transistor (PNP) and separate connection e.g. in conjunction with

programmable logic controllers (PLCs), DI modules as per EN 61131-2.

FEL54:

Universal current version with relay output;

Switches the loads via 2 floating change-over contacts.

FEL55:

Signal transmission 16/8 mA on two-wire cabling e.g. in conjunction with programmable logic

controllers (PLCs), AI modules 4 to 20 mA as per EN 61131-2.

FEL56:

For separate switching unit; signal transmission L-H edge 0.6 to 1.0 / 2.2 to 2.8 mA

to EN 50227 (NAMUR) on two-wire cabling.

FEL58:

For separate switching unit; signal transmission H-L edge 2.2 to 3.5 / 0.6 to 1.0 mA

to EN 50227 (NAMUR) on two-wire cabling.

Checking of connecting cabling and other devices by pressing a key on the electronic insert.

FEL57:

For separate switching unit; PFM signal transmission;

Current pulses superposed on the power supply along the two-wire cabling.

Proof test from the switching unit without changing levels.

FEL50A:

For connecting to PROFIBUS PA;

Cyclic and acyclic data exchange acc. to PROFIBUS-PA Profile 3.0

Discrete Input

Galvanic isolation FEL51, FEL52, FEL50A: between sensor and power supply

FEL54: between sensor and power supply and load

FEL55, FEL56, FEL57, FEL58, FEL50D: see connected switching unit

Design FTL70: Compact

FTL71: With extension pipe

Input

Measured variable Level (limit value)

Measuring range (detection range)

Process density Setting on the electronic insert > 0.5 g/cm

FTL70: dependent on mounting point

FTL71: dependent on mounting point and the extension pipe ordered.

Standard extension pipe up to 3 m (9.8 ft) and up to 6 m (20 ft) on request.

(SGU) or > 0.7 g/cm (SGU) (others on request)

5

Page 6

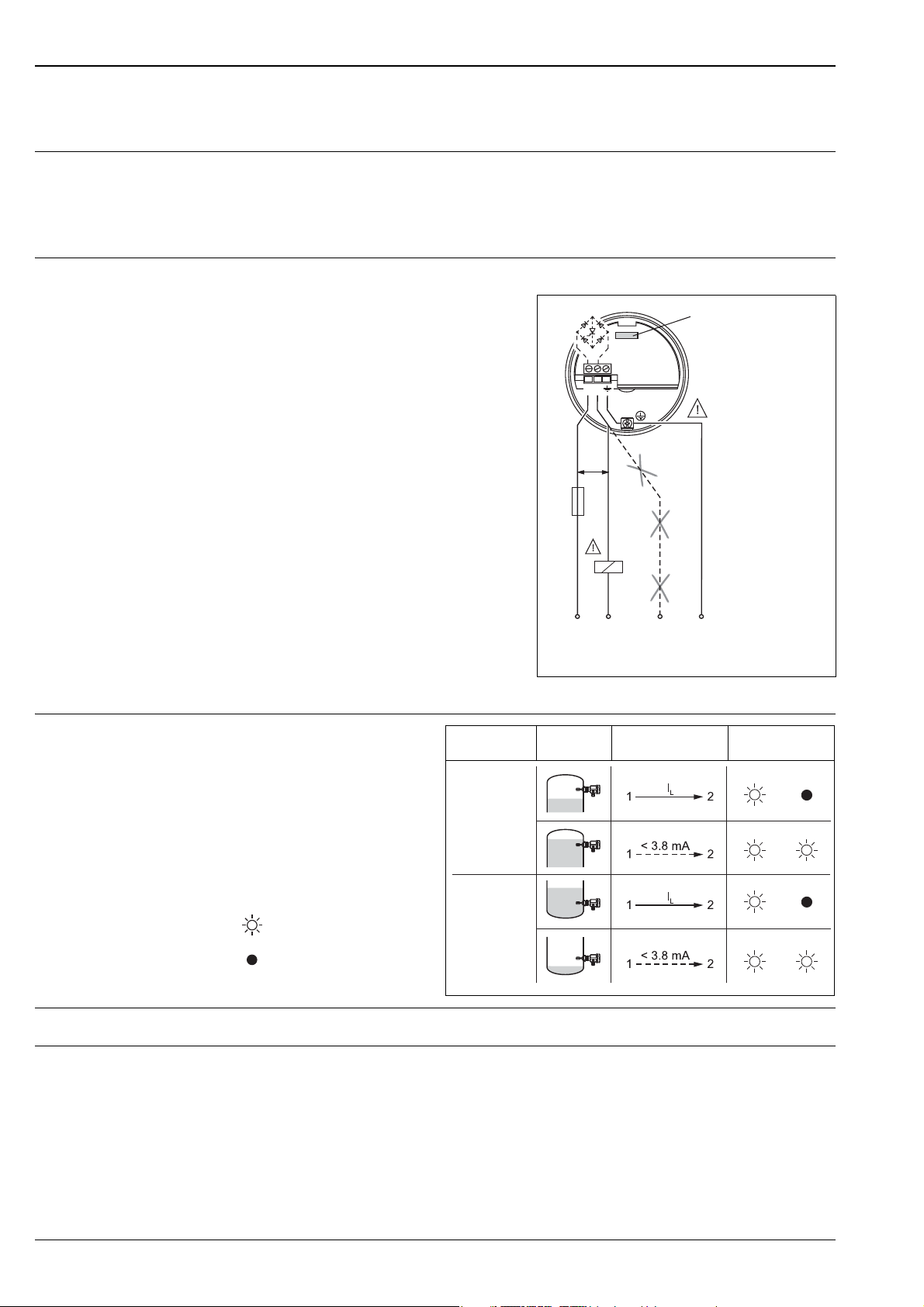

Electronic insert FEL51 (AC 2-wire)

L1

U~ max. 253 V AC

50/60 Hz

NNPE

(Ground)

1A

min.

19 V

12

FEL51

*

R

*

External load R

be connectedmust

MAX

MIN

Power supply Supply voltage: AC 19 to 253 V

Power consumption: < 0.83 W

Residual current consumption: < 3.8 mA

Short-circuit protection

Overvoltage protection FEL51: overvoltage category III

Electrical connection Two-wire AC connection

Switches the load directly into the power supply

circuit via an electronic switch.

Always connect in series with a load!

Check the following:

• The residual current in blocked state

(up to 3.8 mA)

• That for low voltage

– the voltage drop across the load is such that

the minimum terminal voltage at the

electronic insert (19 V)

when blocked is not undershot.

– the voltage drop across the electronics when

switched through is observed (up to 12 V)

• That a relay cannot de-energize with holding

power below 3.8 mA.

If this is the case, a resistor should be

connected parallel to the relay. An RC module is

available under the part number: 71107226

• When selecting the relay, pay attention to the

holding power

/ rated power

(see "Connectable load")

Liquiphant S FTL70, 71

L00-FTL5xxxx-04-05-xx-en-007

Output signal

I

L

= load current

Safety mode Level Output signal LEDs

(switched through)

< 3.8 mA

= residual current

(blocked)

= lit

L00-FTL2xxxx-07-05-

Signal on alarm Output signal on power failure or in the event of damaged sensor: < 3.8 mA

Connectable load • Voltage drop via FEL51

• Residual current if electrical switch is blocked:

• Load switched directly into the power supply circuit via the thyristor.

Transient (40 ms)

The load is switched via an electronic switch directly in the power circuit.

= unlit

xx-xx-000

12 V

3.8 mA

1.5 A, 375 VA at 253 V or 36 VA at 24 V (not short-circuit-proof)

Always connect in series with a load!

Not suitable for connection to low-voltage PLC inputs!

green red

L00-FTL5xxxx-04-05-xx-xx-001

6

Page 7

Liquiphant S FTL70, 71

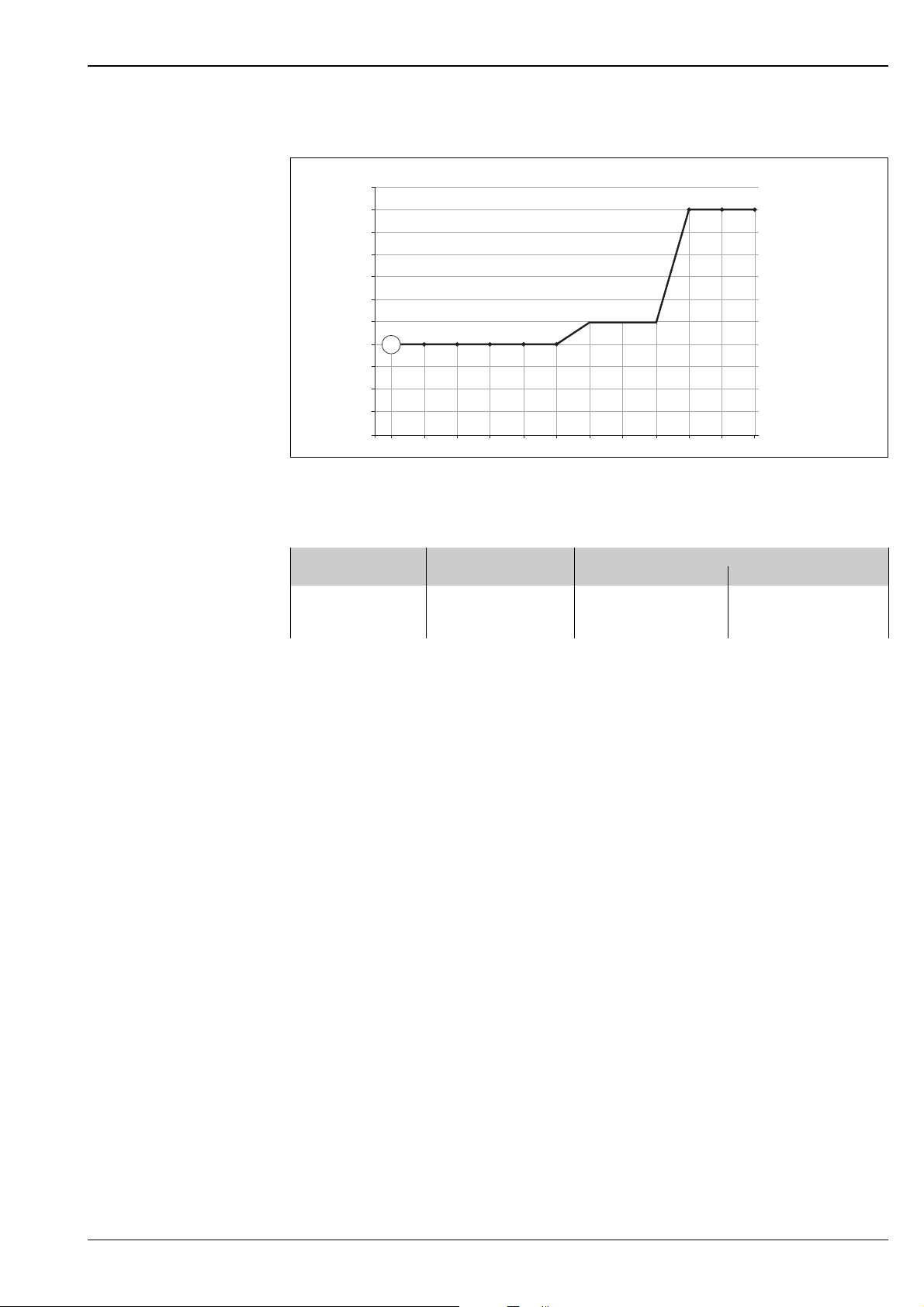

2.7

2.5

2.3

2.1

1.9

1.7

1.5

1.3

1.1

0.9

0.7

0.5

20 24 27 43 48 53 60 110 121 207 230 253

P/S

U

P1

Selection guide for relays

TI00328F_001

Minimum nominal power of load

P/S nominal power in [W] / [VA]

U operating voltage in [V]

Position Operating voltage Nominal power

min. max.

P1

AC operation

24 V

110 V

230 V

> 1.3 VA

> 1.5 VA

> 2.5 VA

< 8.4 VA

< 38.5 VA

< 80.5 VA

Relays with less nominal power can be operated via an RC module connected in parallel (optional).

7

Page 8

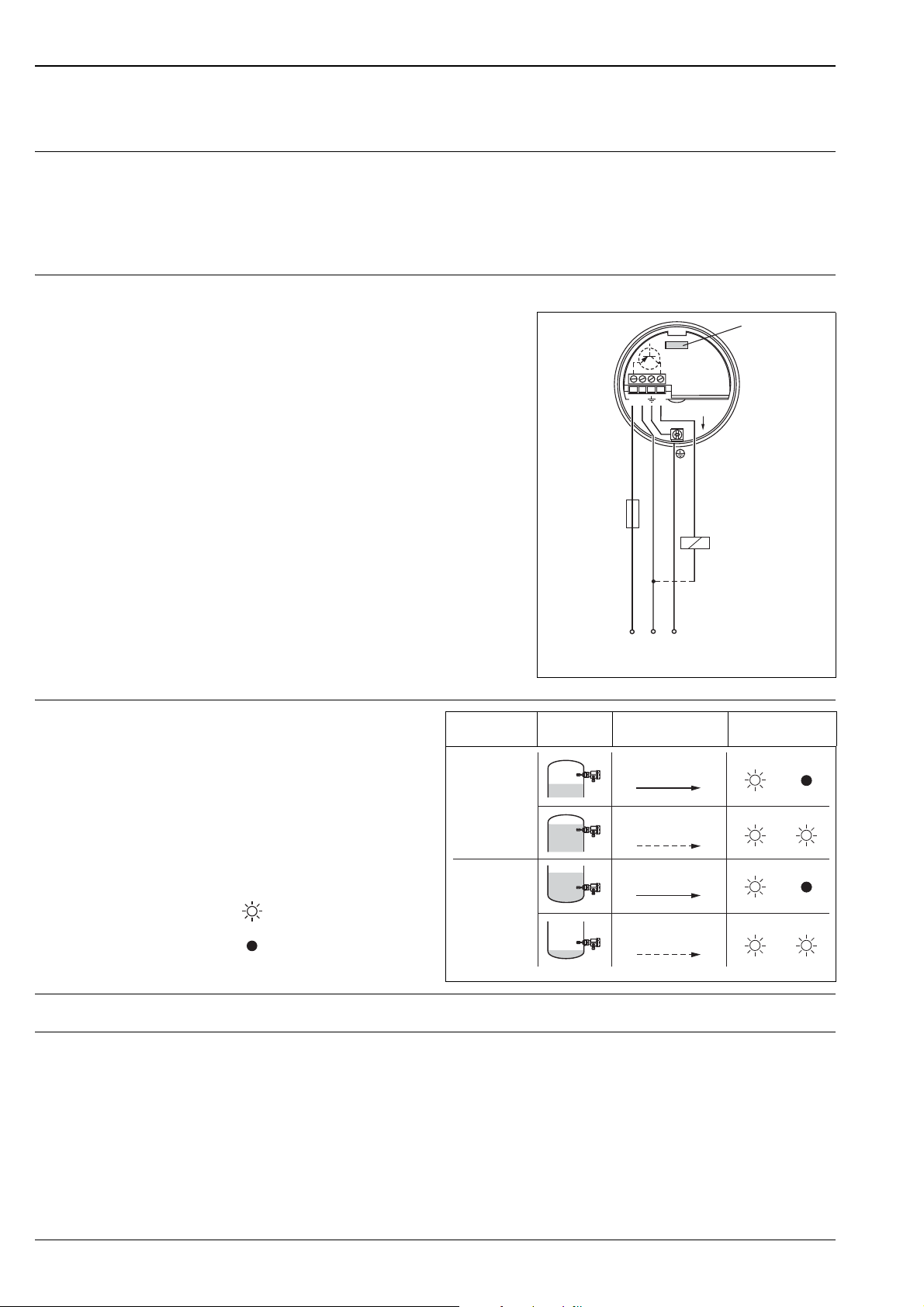

Electronic insert FEL52 (DC PNP)

1 2 3

(+)

FEL52

L+

L–

–

0.5 A

U– 10…55 V DC

...

Relais,

PLC, ...

PE

(Ground)

R

MAX

MIN

L+ +

1 3

L+ +

1 3

1 3

1 3

I

L

I

L

< 100 μA

< 100 μA

Power supply Supply voltage: DC 10 to 55 V

1.7 V, 0 to 400 Hz

Ripple:

Current consumption: 15 mA

Power consumption: 0.83 W

Reverse polarity protection

Overvoltage protection FEL52: overvoltage category III

Electrical connection Three-wire DC connection

Switches the load via the transistor (PNP) and

separate connection.

Preferably used with programmable logic

controllers (PLC),

DI modules as per EN 61131-2.

Positive signal at switching output of the

electronics (PNP); Output blocked on reaching

point level.

Liquiphant S FTL70, 71

Output signal

I

L

= load current

Safety mode Level Output signal LEDs

(switched through)

< 100 μA

= residual current

(blocked)

= lit

= unlit

L00-FTL2xxxx-07-05-

xx-xx-000

Signal on alarm Output signal on power failure or in the event of damaged sensor: < 100 μA

Connectable load • Load switched via transistor and separate PNP connection,

•Load current

DC 55 V

350 mA (pulsed overload and short-circuit protection)

• Residual current < 100 μA (with transistor blocked)

• Capacitance load 0.5 μF at 55 V, 1.0 μF at 24 V

8

• Residual voltage < 3 V (with transistor switched through);

L00-FTL5xxxx-04-05-xx-xx-030

green red

L00-FTL5xxxx-04-05-xx-xx-004

Page 9

Liquiphant S FTL70, 71

L1

L+

a

NO

a

NO

u

C

u

C

N

L–

r

NC

r

NC

0.5 A

PE

(Ground)

*

** **

12 678345

FEL54

U~ 19…253 V AC, 50/60 Hz

U– 19… 55 V DC

...

MAX

MIN

354

354

687

687

354

354

687

687

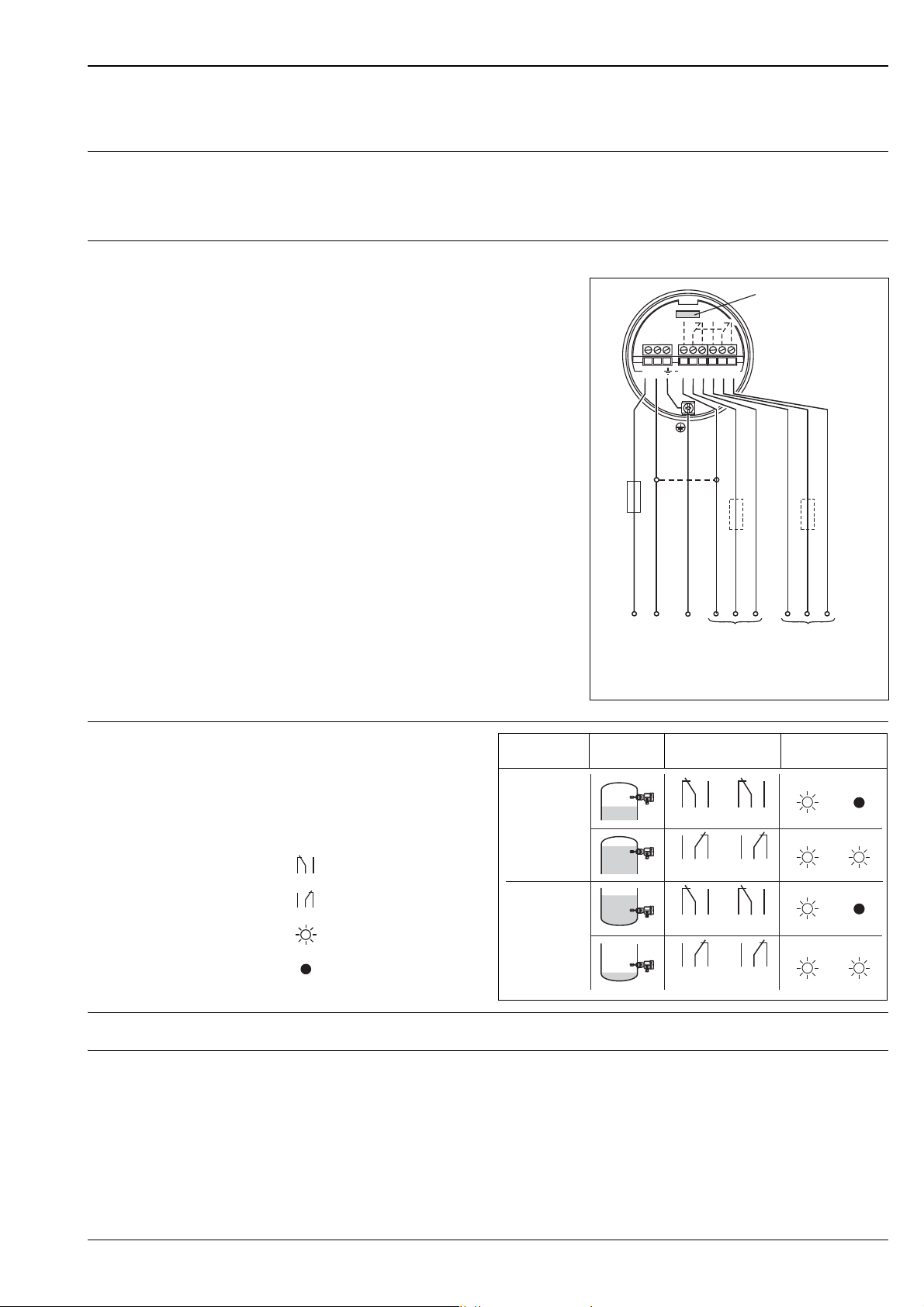

Electronic insert FEL54 (AC/DC with relay output)

Power supply Supply voltage: AC 19 to 253 V, 50/60 Hz or DC 19 to 55 V

Power consumption:

Reverse polarity protection

Overvoltage protection FEL54: overvoltage category III

Electrical connection Universal current connection with relay output

Power supply:

Please note the different

voltage ranges for AC and DC.

Output:

When connecting an instrument with

high inductance, provide a spark arrester

to protect the relay contact.

A fine-wire fuse (depending on the

load connected) protects the relay

contact on short-circuiting.

Both relay contacts switch simultaneously.

1.3 W

Output signal

* When jumpered, the relay

output works with NPN logic.

** See "Connectable load"

= relay energized

= relay de-energized

= lit

= unlit

L00-FTL2xxxx-07-05-

xx-xx-001

L00-FTL5xxxx-04-05-xx-xx-002

Safety mode Level Output signal LEDs

green red

L00-FTL5xxxx-04-05-xx-xx-005

Signal on alarm Output signal on power failure or in the event of damaged sensor: relay de-energized

Connectable load • Loads switched via 2 floating change-over contacts (DPDT).

6 A (Ex de 4 A), U~ AC 253 V; P~ 1500 VA, cos = 1, P~ 750 VA, cos > 0.7

•I~

6 A (Ex de 4 A) to DC 30 V , I% 0.2 A to 125 V

•I%

• When connecting a low-voltage circuit with double insulation according to IEC 1010, the following

applies: the sum of the voltages of the relay output and power supply is 300 V

• The electronic insert FEL52 DC-PNP is preferred for low DC load currents (e.g. when connecting to

a PLC)

• Relay contact material: silver/nickel AgNi 90/10

9

Page 10

Electronic insert FEL55 (8/16 mA)

1 2

FEL55

–

Ex ia

+

E

X

E

X

U 11...36 V DC

–

+

–

+

R

R =

max

U–11 V

16.8 mA

PLC/SPS,

AI-Modules, ...

F=T50mA

MMAX

MIN

+

2 1

+

2 1

+

2 1

+

2 1

~16 mA

~8 mA

~8 mA

~16 mA

Power supply Supply voltage: DC 11 to 36 V

Power consumption: < 600 mW

Reverse polarity protection

Overvoltage protection FEL55: overvoltage category III

Electrical connection Two-wire connection for separate switching unit

For separate switching unit.

Signal transmission 16/8 mA on two-wire cabling.

For connection to programmable logic controllers

(PLC) for example, AI modules 4 to 20 mA to

EN 61131-2.

Output signal jump from high to low current on

point level.

Fuse required for non-Ex applications!

Only use power units with safe galvanic isolation (e.g.

SELV).

Liquiphant S FTL70, 71

Output signal

~ 16 mA

~8 mA

= 16 mA ± 5 %

= 8 mA ± 6 %

Safety mode Level Output signal LEDs

= lit

= unlit

L00-FTL2xxxx-07-05-

xx-xx-000

Signal on alarm Output signal on power failure or in the event of damaged sensor: < 3.6 mA

Connectable load • R = (U - 11 V) : 16.8 mA

• U = connection voltage: DC 11 to 36 V (in wet environments DC 11 to 35 V)

Example: PLC with 250 with 2-wire version

250 = (U – 11V) / 16.8 mA

4.2 [/] = U – 11 V

U = 15.2 V

L00-FTL5xxxx-04-05-xx-en-000

green red

L00-FTL5xxxx-04-05-xx-xx-006

10

Page 11

Liquiphant S FTL70, 71

12

FEL56

–

EEx ia

H

L

+

E

X

E

X

I

Isolating amplifier

to

(NAMUR)

IEC 60947-5-6

MAX

MIN

+

2 1

+

2 1

+

2 1

+

2 1

0.6 …

1.0 mA

0.6 …

1.0 mA

2.2 …

2.8 mA

2.2 …

2.8 mA

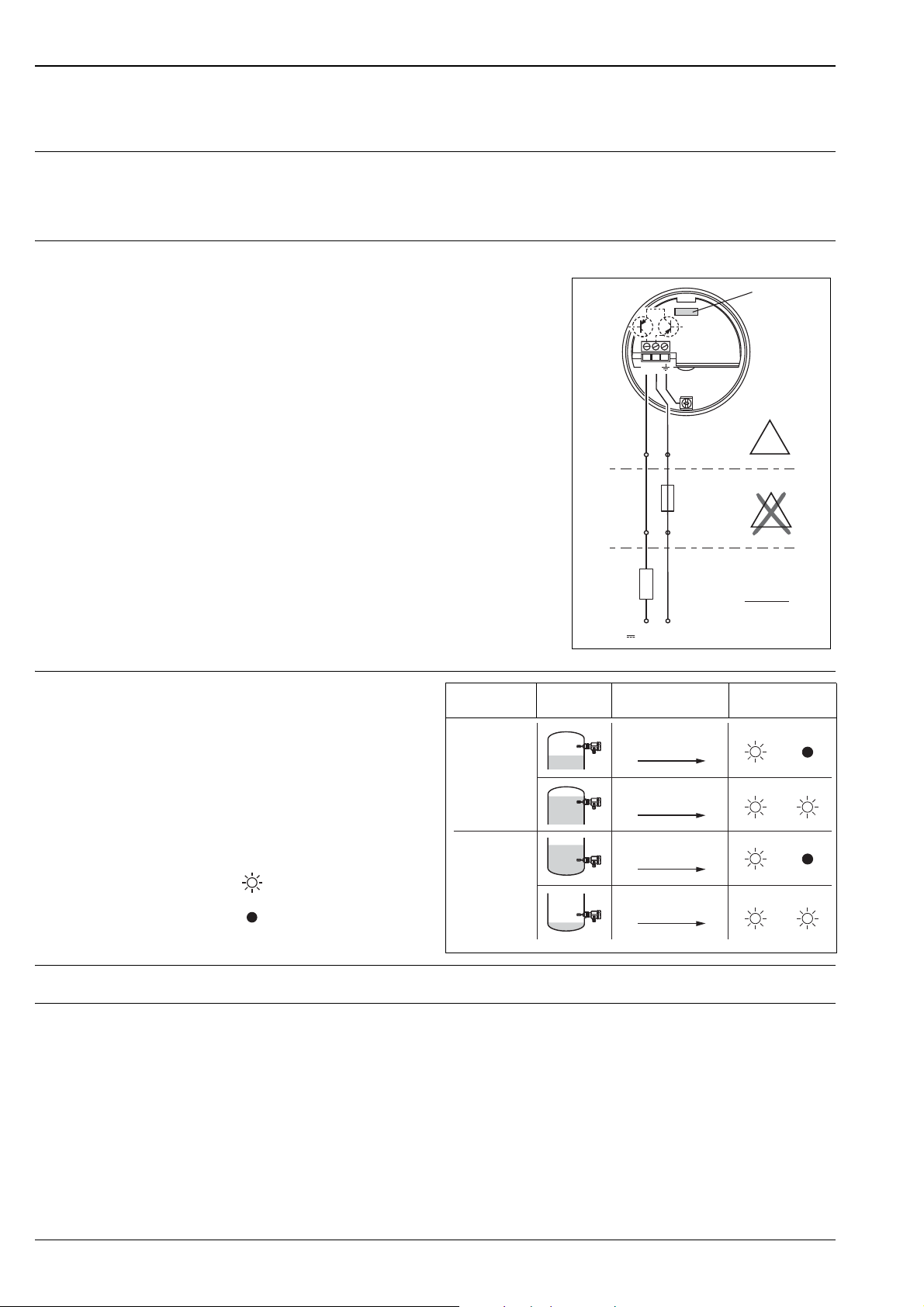

Electronic insert FEL56 (NAMUR L-H edge)

Power supply Supply voltage: DC 8.2 V ±20 %

Power consumption: < 6 mW at I < 1 mA; < 38 mW at I = 2.8 mA

Connection data interface: IEC 60947-5-6

Electrical connection Two-wire connection for separate switching unit

For connecting to isolating amplifiers according to

NAMUR (IEC 60947-5-6), e.g. FTL325N from

Endress+Hauser.

Output signal jump from low to high current on

point level.

(L–H edge)

Connecting to multiplexer:

Set clock time to min. 2 s.

Output signal

Safety mode Level Output signal LEDs

= lit

= flashes

= unlit

L00-FTL5xxxx-07-05-

xx-xx-002

Signal on alarm Output signal in the event of damaged sensor: > 2.2 mA

Connectable load • See Technical Data of the isolating amplifier connected according to IEC 60947–5–6 (NAMUR)

L00-FTL5xxxx-04-05-xx-en-004

green red

L00-FTL5xxxx-04-05-xx-xx-003

11

Page 12

Electronic insert FEL58 (NAMUR H-L edge)

12

FEL58

–

EEx ia

H

L

+

E

X

E

X

I

Isolating amplifier

to

(NAMUR)

IEC 60947-5-6

MAX

MIN

+

2 1

+

2 1

+

2 1

+

2 1

2.2 …

3.5 mA

2.2 …

3.5 mA

0.6 …

1.0 mA

0.6 …

1.0 mA

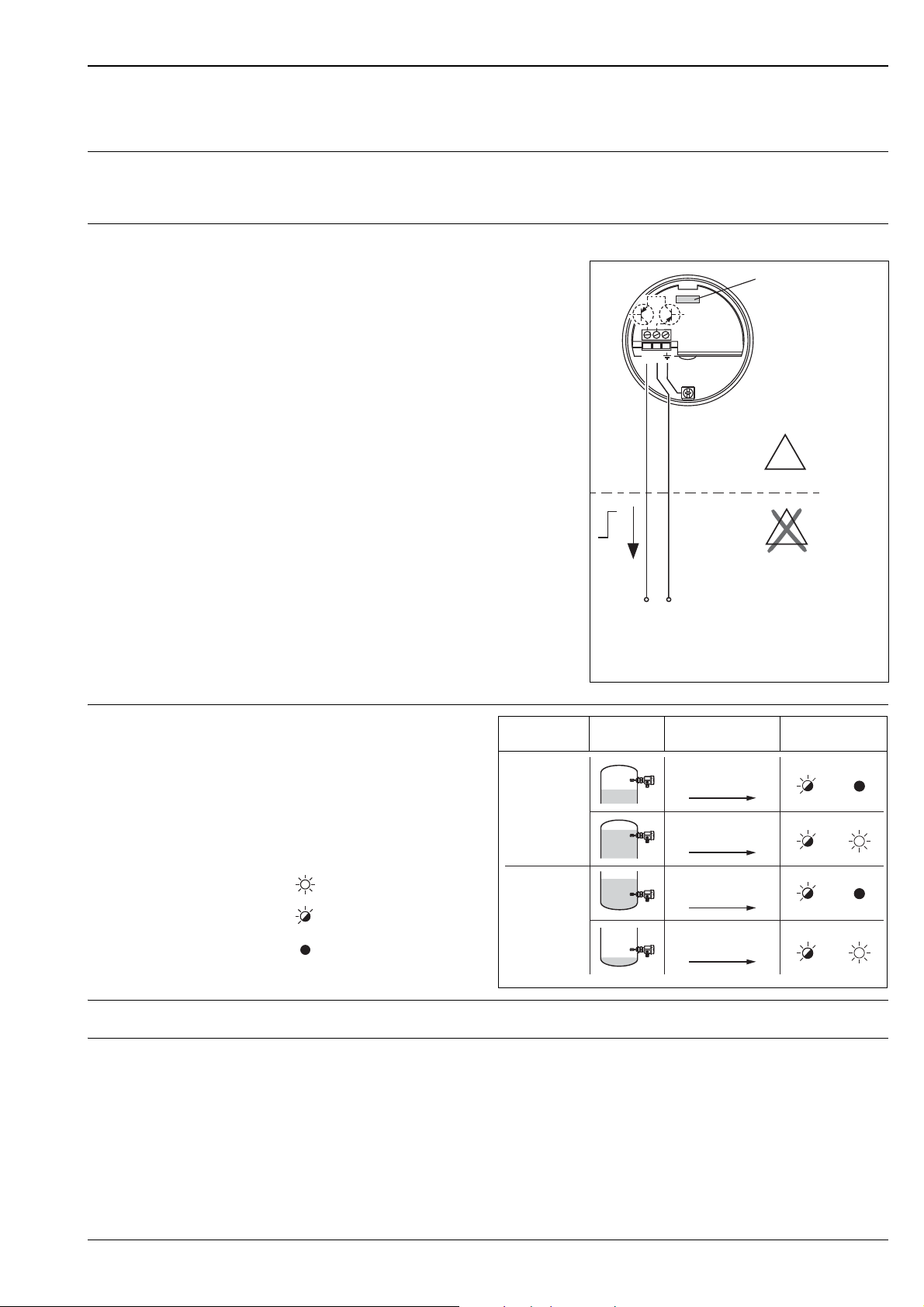

Power supply Supply voltage: DC 8.2 V ±20 %

Power consumption: < 6 mW at I < 1 mA; < 38 mW at I = 3.5 mA

Connection data interface: IEC 60947-5-6

Electrical connection Two-wire connection for separate switching unit

For connecting to isolating amplifiers

as per NAMUR (IEC 60947-5-6), e.g. FTL325N,

FTL375N from Endress+Hauser.

Output signal jump from high to low current on

point level.

(H–L edge)

Additional function:

Test key on the electronic insert.

Pressing the key breaks the connection to the

isolating amplifier.

Note!

!

In Ex–d applications, the additional function

can only be used if the housing is not exposed

to an explosive atmosphere.

Liquiphant S FTL70, 71

Output signal

Connecting to multiplexer:

Set clock time to min. 2 s.

= lit

= flashes

= unlit

L00-FTL5xxxx-07-05-

xx-xx-002

L00-FTL5xxxx-04-05-xx-en-002

Safety mode Level Output signal LEDs

green

yellow

L00-FTL5xxxx-04-05-xx-xx-007

Signal on alarm Output signal in the event of damaged sensor: < 1.0 mA

Connectable load • See Technical Data of the isolating amplifier connected according to IEC 60947–5–6 (NAMUR)

12

• Connection also to isolating amplifiers which have special safety circuits (I > 3.0 mA)

Page 13

– +

78

33 34

37 38

d4 d2

z6d6

z4 z2

PFM

50 /

150 Hz

E

X

E

X

12

FEL57

EEx ia

Nivotester

FTL320

FTL325P 1CH

FTL325P 3CH

FTL370/372

FTL375P 1CH

Input 1

FTL372

FTL375P 2CH

Input 2

FTL375P 3CH

Input 3

Liquiphant S FTL70, 71

Electronic insert FEL57 (PFM)

Power supply Supply voltage: DC 9.5 to 12.5 V

Current consumption: 10 to 13 mA

Power consumption: < 150 mW

Reverse polarity protection

Electrical connection Two-wire connection for separate switching unit

For connecting to Endress+Hauser switching units

Nivotester FTL320, FTL325P, FTL370, FTL372,

FTL375P (also with proof test).

Output signal jump of the PFM signal from high to

low frequency when sensor is covered. Switching

between minimum/maximum safety in the

Nivotester.

Additional function “proof test”:

After interruption of the power supply,

a test cycle is activated

which checks the sensor and electronics

without any change in level.

Approved for overfill protection acc. to WHG

(German Water Resources Act).

The following can be switched at the electronic

insert:

– Standard

(STD):

Corrosion of the fork unlikely;

simulation approx. 8 s

tuning fork exposed – covered – exposed.

For proof testing, the Nivotester tests the

sensor's level notification function.

– Extended (EXT):

Corrosion of the fork possible;

Simulation approx. 41 s: tuning fork exposed –

covered – corroded – exposed.

For proof testing, the Nivotester tests the

sensor's level notification function and fault

notification (alarm) function.

The check is activated and monitored at the switching unit.

The twin-core connecting cable (instrument cable) with a cable resistance of

connected to the screw terminals (conductor cross-sections 0.5 to 2.5 mm / 0.02 to 0.1 in) in the

connection compartment. Protective circuits against reverse polarity, HF influences and overvoltage

peaks are installed.

Maximum cable length up to 1000 m (3281 ft).

A shielded connecting cable is recommended in the event of strong electromagnetic interference. Here

the shielding must be connected to the sensor and the power supply.

L00-FTL5xxxx-04-05-xx-en-003

25 per core is

13

Page 14

Switching behavior of the connected device:

Fail-safe mode

set at

switching unit

MAX

MAX

MAX

MAX

MIN

MIN

MIN

MIN

Setting

at FEL57

STD

EXT

STD

EXT

STD

EXT

STD

EXT

Fork

free

free

covered

covered

free

free

covered

covered

Switching status of relay in switching unit

on = energised off = de-energised

Te st start End of t

est start

(power off) (power on)

> 3 s

on

on

off

off

off

off

on

on

off

off

off

off

~ 3 s on

~ 3 s on

~ 3 s on

~ 3 s on

~ 5 s off

~ 5 s off

off

off

~ 5 s off

~ 7 s off

~ 5 s off

~ 5 s off

~ 2 s on

~ 2 s on

~ 3 s on

on

~ 35 s on

~ 3 s off

~ 2 s off

~ 35 s off

off

~ 30 s on

on

on

on

off

150 Hz

50 Hz

Liquiphant S FTL70, 71

* De-energized on power supply failure

Please note this switching response and function of the plant especially when replacing a Liquiphant

incorporating electronic insert EL17Z or FEL37 with a Liquiphant M incorporating electronic insert

FEL57.

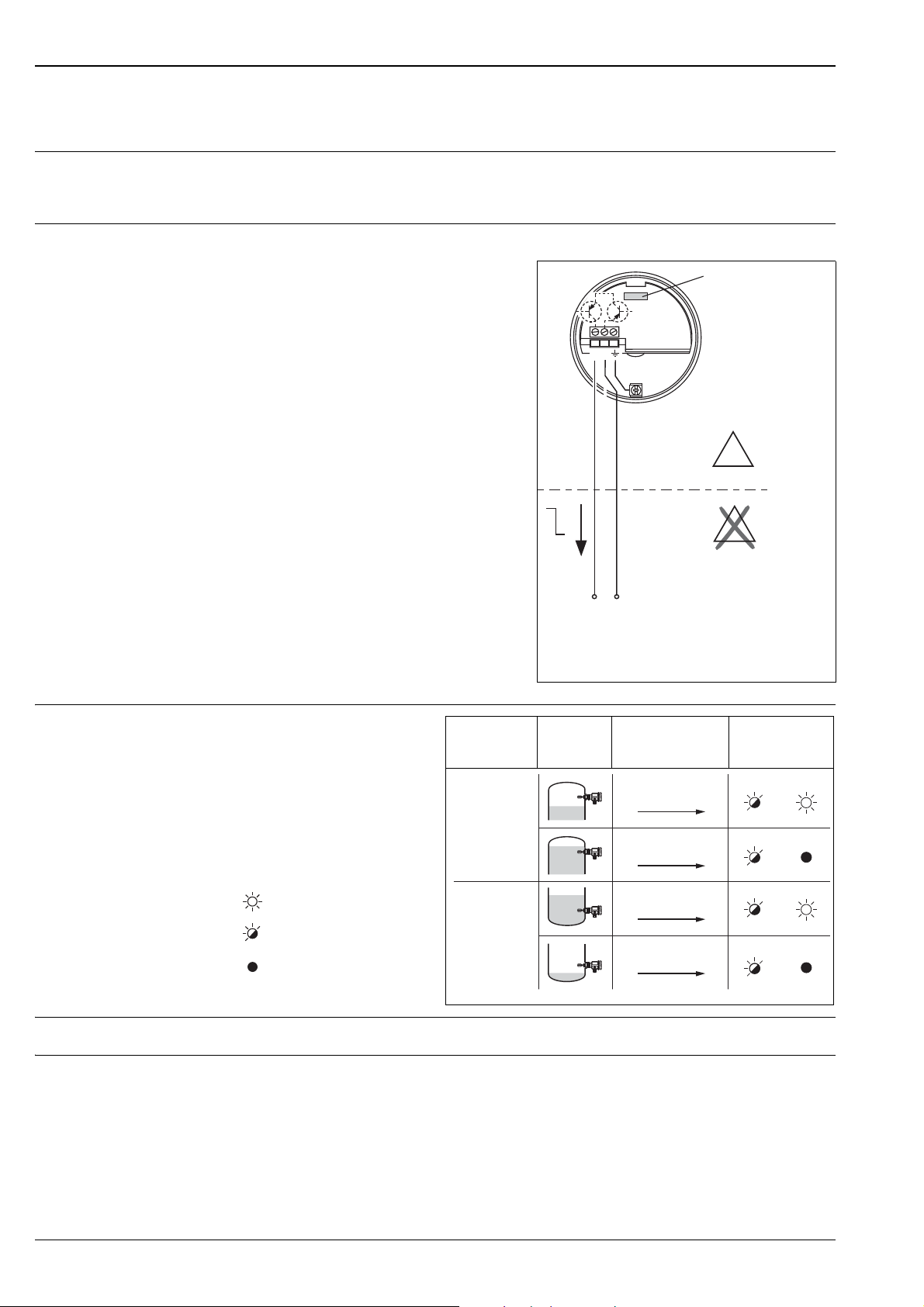

Output signal

Safety mode Level Output signal

(PFM)

LEDs

green yellow

= lit

= unlit

L00-FTL2xxxx-07-05-

xx-xx-000

L00-FTL5xxxx-04-05-xx-xx-008

Signal on alarm Output signal on power failure or in the event of damaged sensor: 0 Hz

Connectable load • Floating relay contacts in the connected switching unit Nivotester FTL325P, FTL375P

• For contact load, see the Technical Data of the switching unit.

L00-FTL5xxxx-05-05-xx-en-000

14

Page 15

Liquiphant S FTL70, 71

PA– PA+

PROFIBUS PA

–

–

–

–

E

X

E

X

U– 9…32 V DC

...

12

FEL50A

Segment coupler

PLC

PROFIBUS DP

PROFIBUS PA

E

X

E

X

PC

Proficard Profiboard/

Segment plercou

Electronic insert FEL50A (PROFIBUS PA)

Power supply Bus voltage: DC 9 to 32 V

Bus current:

• 12.5 mA +/– 1.0

mA (software version: 01.03.00, hardware version: 02.00)

• 10.5 mA +/– 1.0

mA (software version: 01.03.00, hardware version: 01.00)

Electrical connection Two-wire connection for power supply and data transfer

For connecting to PROFIBUS PA

Additional functions:

– Digital communication enables the

representation, reading and editing

of the following parameters:

Fork frequency, switch-on frequency,

switch-off frequency, switch-on time and

switch-off time, status, measured value, density

change

– Matrix locking possible

– Switch to WHG mode possible

(WHG approval)

– For a detailed description, see BA00198F

L00-FTL5xxxx-04-05-xx-en-005

L00-FTL5xxxx-04-05-xx-xx-100

15

Page 16

Liquiphant S FTL70, 71

13

(0,51)

mm (in)

*

Output signal

Setting Level LEDs

FEL50A

green yellow

OUT_D = 0

PA bus signal

not

inverted

OUT_D = 1

PA bus signal

OUT_D = 0

PA bus signal

= lit inverted

OUT_D = 1

L00-FTL2xxxx-07-05-

xx-xx-000

= unlit

L00-FTL5xxxx-04-05-xx-xx-009

PA bus signal

Signal on alarm • Failure information can be opened using the following interfaces:

Yellow LED flashing, status code, diagnostic code; see BA00198F

Connection and function

Connecting cables • Electronic inserts: cross-section 2.5 mm (14 AWG); strand in ferrule as per DIN 46228

• Protective ground in housing: cross-section

2.5 mm

• External equipotential bonding connection on housing: cross-section 4 mm(12 AWG)

(14 AWG)

Safety mode Minimum/maximum residual current safety selectable on electronic insert

(with FEL57 on Nivotester only)

MAX = maximum safety:

The output switches to the power fail response when the fork is covered

For use with overfill protection for example

MIN = minimum safety:

The output switches to the power fail response when the fork is exposed

For use with dry running protection for example

Switching time When fork is covered: approx. 0.5 s

When fork is exposed: approx. 1.0 s

Additionally configurable for PROFIBUS PA:

0.5 to 60 s

Other switching times available on request.

Switch-on behavior When switching on the power supply, the output assumes the alarm signal.

3 s it assumes the correct switching mode (exception: FEL57)

After

Accuracy

Reference operating conditions

16

Ambient temperature: 23 °C (73 °F)

Medium temperature: 23 °C (73 °F)

Medium density (water): 1 g/cm (SGU)

Medium viscosity: 1 mm

/s (cSt)

Medium pressure pe: 0 bar (0 psi)

Sensor mounting: vertical from above

Density switch: to > 0.7 g/cm³ (SGU)

* Switch point under reference operating conditions

L00-FTL5xxxx-06-05-xx-xx-031

Page 17

Liquiphant S FTL70, 71

13

(0.51)

mm (in)

*

13

(0.51)

4

(0.16)

4

( 0.16)

mm (in)

Maximum measured error Under reference operating conditions: max. +/–1 mm (0.04 in)

Repeatability 0.1 mm (0.004 in)

Hysteresis approx. 2 mm (0.08 in)

Influence of process temperature

Influence of process density max. +4.8 to –3.5 mm ((0.5 to 1.5 g/cm

max. +1.4 to –5.5 mm (–60 to +280 °C)

max. +0.06 to -0.22 in

(SGU))

max. +0.19 to -0.14 in

Influence of process pressure max. 0 to –3.9 mm (–1 to 100 bar (-14.5 to 1450 psi))

max. 0 to -0.15 in

Switching delay • When fork is covered: 0.5 s

• When fork is exposed: 1.0 s

• Available on request: 0.2 s; 1.5 s or 5 s (when the tuning fork is covered or exposed)

Operating conditions

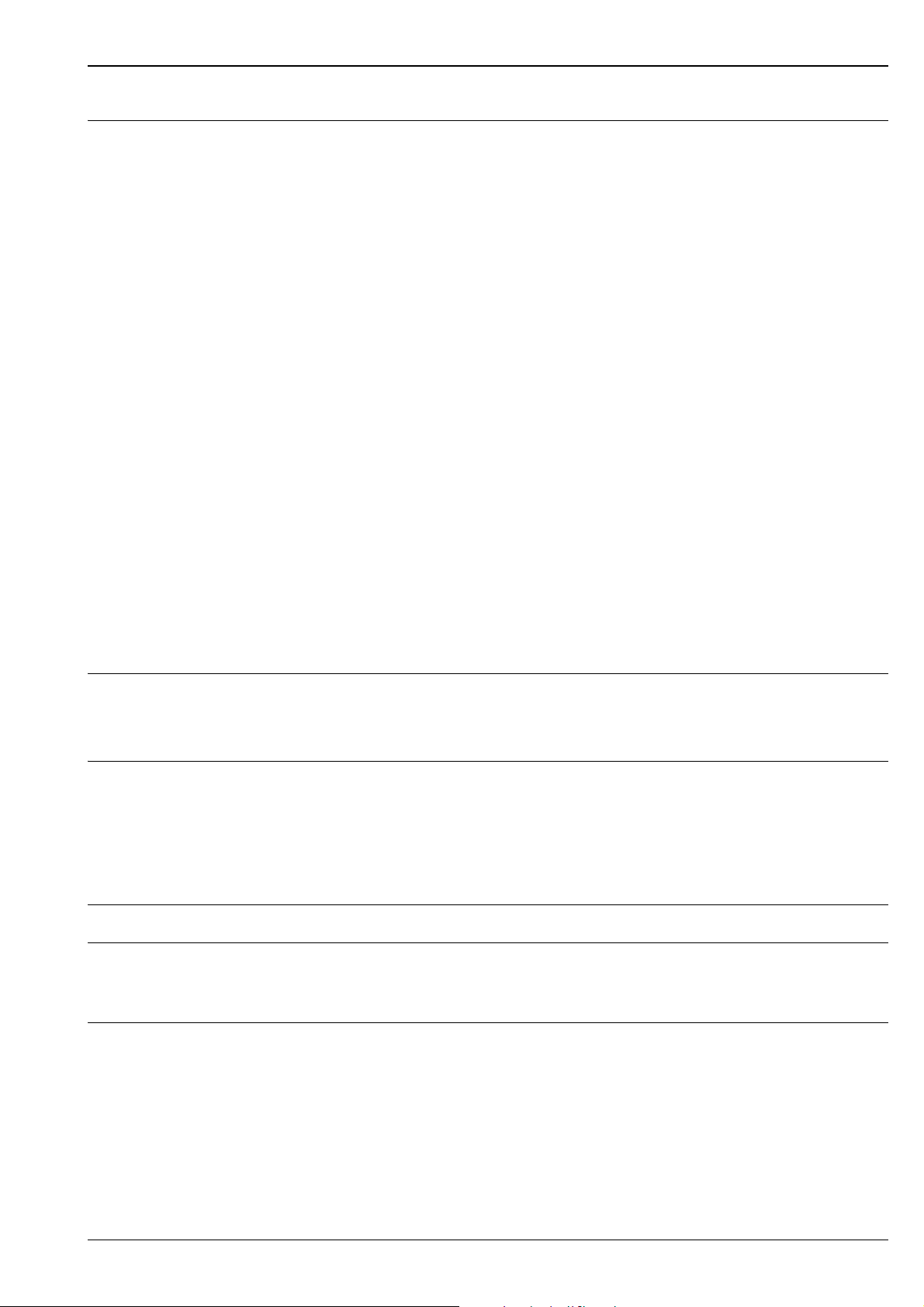

Installation Installation instructions

Switch points on the sensor depend on the mounting position, with reference to water,

Density 1 g/cm

(SGU), 23 °C (73 °F), pe 0 bar (0 psi).

Mounting from above Mounting from below Mounting from the side

Examples of mounting Depending on the viscosity of the liquid and the tendency to form buildup

Optimum mounting, without problem even with high viscosity:

Position the fork so that the narrow edge of the tines is vertical to ensure that the liquid can run off

easily.

Vertical from above Flush-mounted from the side

L00-FTL5xxxx-06-05-xx-xx-051

L00-FTL7xxxx-11-05-xx-xx-002

17

Page 18

Liquiphant S FTL70, 71

*

*

(min. 1 in)

(min. 2")

min. 25

min. DN 50

*

*

With buildup on the tank walls:

* Ensure that there is sufficient distance between the buildup expected on the tank wall and

the fork.

L00-FTL7xxxx-11-05-xx-xx-003

Vertical from above Protruding into the tank from the side

Mounting positions in the case of low viscosity (up to 2000 mm/s (cSt)):

* Deburr the nozzle surfaces

L00-FTL7xxxx-11-05-xx-xx-004

Installation in pipes from 2":

Flow velocities up to 5 m/s (16.4 ft/s) for viscosity of 1 mm/s (cSt) and density 1 g/cm (SGU).

(Check the function for other medium conditions.)

L00-FTL7xxxx-11-05-xx-xx-005

18

Page 19

Liquiphant S FTL70, 71

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..

Dynamic load

Support the Liquiphant S FTL71 in the event of a severe dynamic load.

L00-FTL7xxxx-11-05-xx-xx-006

Space outside the tank

Ensure that there is adequate space outside the tank for mounting, connection and configuration.

Orientation FTL70, and FTL71 with short pipe up to approx. 500 mm (19.7 in): in any position,

FTL71 with long pipe: vertical

L00-FTL7xxxx-11-05-xx-xx-007

19

Page 20

Liquiphant S FTL70, 71

T

a

T

a

T

p

FTL70/71

FTL70/71

T

p

0

T

a

T

p

°C (°F)

°C (°F)

0

(158)

0

0

FTL70/71- L##########

FTL70/71- N##########

FTL70/71- L##########

FTL70/71- N##########

300*

230

(440)

–60**

(–76)

–50

(–58)

–50

(–58)

109

(3 )74

280

(5 )72(540)

(122)

70

FEL50A

–60**

(–76)

–50

(–58)

–50

(–58)

300*

230

(440)

280

(5 )72(540)

(158)

70

60

(140)

***

FEL50A

***

T

a

°C (°F)

T

p

°C (°F)

50

Environment

Ambient temperature range Permitted ambient temperature Ta at the housing depending on the process temperature Tp in the

vessel:

* Maximum of 50 cumulative hours

** –60 °C for ATEX and CSA certificates only

*** FEL50A maximum +60 °C ambient temperature (T

) in hazardous areas

a

Ambient temperature limits –50 to +70 °C (-58 to 158 °F)

Storage temperature –50 to +80 °C (-58 to 176 °F)

Installation height as per

Up to 2000 m (6600 ft) above sea level.

IEC61010-1 Ed.3

Can be extended up to 3000 m (9800 ft) above sea level if overvoltage protection is used, for example

HAW562 or HAW569.

Climate class Climate protection to IEC 68, Part 2-38,

Fig. 2a

Degree of protection

Types of housing IP65 IP66* IP67* IP68* IP69 NEMA4X**

Polyester housing F16 – X X – – X

Stainless steel housing F15 – X X – – X

Aluminum housing F17 X X X – – X

Aluminum housing F13**** X X – X*** – X

Stainless steel housing F27 – X – X – 4X/6P

Aluminum housing T13

with separate connection compartment

(EEx d)

* As per EN60529

** As per NEMA 250

*** Only with M20 cable entry or G1/2 thread

**** F13 housing only in conjunction with XP or Ex d approval

Vibration resistance As per IEC 68, parts 2-6 (10 to 55 Hz, 0.15 mm (0.01 in), 100 cycles)

X X – X*** – 4X/6P

L00-FTL7xxxx-05-05-xx-xx-025

20

Page 21

Liquiphant S FTL70, 71

p

e

bar

(psi)

100

(1450)

63

(9 )14

(–76)

280

(540)

0

(32)

–1

(–14.5)

T

p

°C

(°F)

0

(32)

206

()500

–60

Electromagnetic compatibility

Interference emission to EN 61326, Electrical Equipment Class B

Interference immunity to EN 61326; Annex A (Industrial) and NAMUR Recommendation NE 21

(EMC)

Process conditions

Process temperature –60 to +280 °C (-76 to 536 °F) and 300 °C (572 °C) for max. 50 cumulative hours

Thermal shock Without restriction within the process temperature range.

Process pressure p

e

L00-FTL7xxxx-05-05-xx-xx-010

For the pressure values permitted for the flanges in the case of higher temperatures, please refer to the

following standards:

• pR EN 1092-1: 2005

With regard to their stability-temperature property, the materials 1.4435 and 1.4404 are identical

and are grouped together in EN1092-1 Tab. 18 under 13E0. The chemical composition of the two

materials can be identical.

• ASME B 16.5a - 1998 Tab. 2-2.2 F316

• ASME B 16.5a - 1998 Tab. 2.3.8 N10276

• JIS B 2220

The lowest value from the derating curves of the device and selected flange applies in each case.

Test pressure max. 150 bar (2175 psi) at 20 °C (68 °F). The function is not available during test pressure.

Burst pressure of diaphragm 400 bar (5800 psi)

State of aggregation Liquid

3

Density 0.7 g/cm

(SGU) = delivery status

0.5 g/cm3 (SGU) can be adjusted via switches

Viscosity 10,000 mm2/s (cSt)

Solids content

ø5 mm (0.2 in)

Lateral loading 75 Nm

Medium conditions The service life of the device can be affected in applications involving an increased h level of hydrogen

diffusion through the metal process isolating diaphragm of the sensor.

Typical conditions: temperature >180 °C (>356 °F) and pressure >64 bar (>928 psi)

21

Page 22

Mechanical construction

+ 140

(5.51)

Isolation

!

Design Summary of all electrical and mechanical versions

Note!

2D and 3D drawings containing individual dimensions can be generated and downloaded in the

Configurator on the product pages of the Liquiphant FTL7x at www.endress.com.

Plug-in electronic inserts to mount in the housing

Liquiphant S FTL70, 71

Two-wire AC connection

Three-wire DC connection PNP

Universal current connection, 2 relay outputs

Output 16/8 mA for separate switching unit

Output 0.6 to 1.0 / 2.2 to 2.8 mA for separate switching unit (NAMUR)

Output 2.2 to 3.5 / 0.6 to 1.0 mA for separate switching unit (NAMUR)

Output 150/50 Hz, PFM, for separate switching unit (Nivotester)

Digital communication PROFIBUS PA

L00-FTL5xxxx-03-05-xx-xx-000

FEL51:

FEL52:

FEL54:

FEL55:

FEL56:

FEL58:

FEL57:

FEL50A:

Housing

L00-FTL5xxxx-03-05-xx-xx-001 L00-FTL5xxxx-03-05-xx-xx-002 L00-FTL5xxxx-03-05-xx-xx-003 L00-FTL5xxxx-03-05-xx-xx-004

F16

Polyester (PBT)

F15

Stainless steel

(316L)

F13

Aluminum, coated

(also for Ex d)

F17

Aluminum, coated

F27

Stainless steel (316L),

(also for Ex d)

T13

Aluminum with separate

connection compartment (also

Ex de and Ex d), coated

22

Temperature spacer and pressure-tight feedthrough

Temperature spacer with gas-tight, welded feedthrough (standard version)

approx. 160 mm (6.3 in) to 230 °C (446 °F)

Order code ("L")

approx. 200 mm (7.87 in) to 280 °C (536 °F)

Order code ("N")

L00-FTL7xxxx-03-05-xx-xx-002

Pressure-tight feedthrough (optional)

Protects the housing from pressures up to 100 bar

(1450 psi) if the sensor is damaged. Provides

sealed insulation for the vessel and normal

ambient temperatures for the housing.

L00-FTL5xxxx-06-05-xx-xx-091

Page 23

Liquiphant S FTL70, 71

*

ø85

≤76

"L" 230 °C: 280≤mm**

"N" 280 °C: 320≤mm

17.5

≤ 40.7

( 3.35)ø

(≤ 2.99)

(≤ 1.6)

(0 69).

"L" :446 °F ≤ 11 in**

"N" ° :F536 ≤ 12,6 in

*

~25

ø 76

( 2.99)ø

≤46

(≤ 2.52)

( 0.98)~

"L" 230 °C: ≤ 275 mm**

"N" 280 °C: ≤ 315 mm

"L" :446 °F ≤ 10.8 in**

"N" ° :F536 ≤ 12,4 in

Process connections

L00-FTL5xxxx-03-05-xx-xx-006 L00-FTL5xxxx-03-05-xx-xx-007 L00-FTL5xxxx-03-05-xx-xx-009

G ¾, DIN ISO 228/I

R ¾, DIN 2999

NPT ¾, ANSI B 1.20.1

(AF 32)

G 1, DIN ISO 228/I

R 1, DIN 2999

NPT 1, ANSI B 1.20.1

(AF 41)

Sensors

Compact or with extension pipe up to 3 m (9.8 in)

(6 m (20 in) on request)

Flanges according to DIN, ANSI, JIS

from DN 25 / 1"

Dimensions Dimensions in mm (in)!

Housing and sensor FTL70/71

Polyester housing F16

Stainless steel housing F15

L00-FTL5xxxx-03-05-xx-xx-018

L00-FTL7xxxx-06-05-xx-xx-001

L00-FTL5xxxx-06-05-xx-xx-005

* See process connections

** "L" = version FTL70/71 - # # # # # # # # # # L for 230 °C (446 °F)

"N" = version FTL70/71 - # # # # # # # # # # N for 280 °C (536 °F)

23

Page 24

Aluminum housing F17/F13

*

"L" 230 °C: F17 285≤ ** (11.2**)

"N" 280 °C: F17 325≤ (12.8)

F13 300≤ (11.8)

(0.39)

ø21.5

ø80

( 3.15)ø

≤96

(≤ 2.72)

≤06

(≤ 2.36)

F13 340≤ (13.4)

"N" °446 F

"L" ° :536 F

( 8.85)ø

10

*

≤69

≤97

"L" 230 °C: 315≤**

"N" 280 °C: 355≤

"L" ° :446 F ≤ 12.4**

"N" ° :536 F ≤ 14

~25

( 0.98)~

(≤ 2.72)

(≤ 3.82)

50.5

(2.19)

66.5

(2.62)

SW/AF

32

69

(2.72)

50.5

(1.99)

SW/AF

41

Stainless steel housing (316L) F27

(F13 also for Ex d)

Aluminum housing T13

with separate connection

compartment

Liquiphant S FTL70, 71

L00-FTL7xxxx-06-05-xx-xx-002

24

* See process connections

** "L" = version FTL70/71 - # # # # # # # # # # L for 230 °C (446 °F)

"N" = version FTL70/71 - # # # # # # # # # # N for 280 °C (536 °F)

The dimensions apply to process connections with G, R, NPT threads;

for versions with flanges, the dimensions may be up to 30 mm (1.18 in) greater.

Process connections

Process connection Dimensions Accessories Pressure

G ¾

DIN ISO 228/I

G 1

DIN ISO 228/I

GQ2

GQ6

GR2

GR6

Flat seal as per

DIN 7603;

installed on site

L00-FTL5xxxx-06-05-xx-xx-092

Flat seal as per

DIN 7603;

installed on site

L00-FTL5xxxx-06-05-xx-xx-094

L00-FTL7xxxx-06-05-xx-xx-003

Temperature

100 bar

( 1450 psi)

280 °C

(536 °F)

100 bar

( 1450 psi)

280 °C

(536 °F)

Page 25

Liquiphant S FTL70, 71

R: 66.5

(2.62)

50.5

(1.99)

NPT: 71.5

(2.81)

SW/AF

32

NPT: 75.5

(2.97)

50.5

(1.99)

R: 69

(2.72)

SW/AF

41

66.5

(2.62)

Process connection Dimensions Accessories Pressure

Temperature

NPT ¾

ANSI B 1.20.1

GM2

GM6

100 bar

( 1450 psi)

or

R ¾

DIN 2999

NPT1

ANSI B 1.20.1

or

R 1

DIN 2999

Flanges

ANSI B 16.5

EN 1092-1

(DIN 2527 B)

JIS B2220

280 °C

(536 °F)

GE2

GE6

L00-FTL5xxxx-06-05-xx-xx-096

GN2

GN6

100 bar

( 1450 psi)

280 °C

(536 °F)

GF2

GF6

L00-FTL5xxxx-06-05-xx-xx-097

See nominal

pressure of flange,

however

100 bar

( 1450 psi)

A##

B##

C##

K##

Seal depending on

design;

installed on site

280 °C

(536 °F)

At high

temperatures, note

L00-FTL5xxxx-06-05-xx-xx-098

pressure loading

capacity of flange

depending on

temperature!

For higher chemical-resistance, AlloyC22-plated flanges are available. The flange

carrier material is made of 316L and is welded with a 2 to 3 mm (0.08 to 0.12 in)

thick AlloyC22 disk.

25

Page 26

Sensor length L for FTL71

L

ø21.5

( 0.85)ø

L

L

The sensor length L depends on the process connection.

Liquiphant S FTL70, 71

Thread: G ¾

G 1

L00-FTL5xxxx-06-05-xx-xx-016

From seal surface of

thread

Any length L:

148 mm to 3000 mm (6 to 115 in); special version (TSP) on request up to 6000 mm (235 in)

Weights See ordering information: ä 31

Thread: NPT ¾

NPT1

R ¾

R 1

L00-FTL5xxxx-06-05-xx-xx-017 L00-FTL5xxxx-06-05-xx-xx-018

From lower edge of

thread

Flanges and

flange-like process connections

Materials Material specifications as per AISI and DIN-EN.

Parts in contact with process

• Process connection and extension pipe: 316L (1.4435) optional 2.4602 (AlloyC22)

• Tuning fork: S31803 (1.4462) optional 2.4602 (AlloyC22)

• Flanges: 316L (1.4404)

• Flange plating: AlloyC22

Parts with no process contact

• Tuning fork/housing seal: EPDM

• Temperature spacer: 316 L (1.4435)

• Pressure-tight feedthrough: 316L (1.4435)

• Ground terminals at housing (external): 304 (1.4301)

• Nameplate on housing (external): 304 (1.4301)

• Cable glands

– Housing F13, F15, F16, F17: polyamide (PA)

With B or C approval ( ä 31 ordering information): nickel-plated brass

– Housing F27: 316L (1.4435)

– Housing T13: nickel-plated brass

• Polyester housing F16: PBT-FR with PBT-FR cover or with PA12 transparent cover,

– Cover seal: EPDM

– Nameplate glued: polyester film (PET)

– Pressure compensation filter: PBT-GF20

• Stainless steel housing F15: 316L (1.4404)

– Cover seal: silicone

– Safety claw: 304 (1.4301)

– Pressure compensation filter: PBT-GF20, PA

• Aluminum housing F17/F13: EN-AC-AlSi10Mg, plastic-coated,

– Cover seal: EPDM

– Safety claw: nickel-plated brass

– Pressure compensation filter: silicone

• Stainless steel housing F27: 316L (1.4435)

– Cover seal: FVMQ (optional: EPDM seal available as spare part)

– Safety claw: 316L (1.4435)

26

Page 27

Liquiphant S FTL70, 71

Min

Max1

2

>0,7

>0,5

FEL51

12

L1 N U~

19...253V AC

50/60Hz

I max : 350mA

Connecting terminal LEDs Switches

• Aluminum housing T13: EN-AC-AlSi10Mg, plastic-coated,

– Cover seal: EPDM

– Safety claw: nickel-plated brass

Process connections – Parallel thread G ¾, G 1 as per DIN ISO 228/I, flat seal as per DIN 7603, installed on site

– Tapered thread R ¾, R 1 as per DIN 2999 Part 1

– Tapered thread ¾ -14 NPT, 1 - 11½ NPT as per ANSI B 1.20.1

– Flanges (for standards, see also Ordering information ä 31+):

– as per EN/DIN from DN 25

– as per ANSI B16.5 from 1"

– as per JIS B2220 (RF)

Operability

Electronic inserts

With FEL51, FEL52, FEL54, FEL55:

• 2 switches for fail-safe circuit and

density change,

• green LED to indicate

operational status,

• red LED to indicate switching status, flashes in

the event of corrosion damage on sensor or if the

electronics are defective

With FEL56:

• 2 switches for fail-safe circuit and

density change,

• green LED flashes to indicate

operational status,

• red LED to indicate switching status, flashes in

the event of corrosion damage on sensor or if the

electronics are defective

With FEL57:

• 2 switches for density change and

proof testing,

• green LED to indicate

operational status,

• yellow LED to indicate covered status, flashes in

the event of corrosion damage on sensor or if the

electronics are defective

L00-FTL5xxxx-03-05-xx-en-001

With FEL58:

L00-FTL5xxxx-03-05-xx-xx-013

• 2 switches for fail-safe circuit and

density change,

•green LED

– flashes quickly to indicate

operational status

– flashes slowly in the event of corrosion

damage on sensor or if the electronics are

defective,

• yellow LED to indicate switching status, test key

– breaks cable connection

27

Page 28

Liquiphant S FTL70, 71

HW

OFF

ON

Address

SW

12345678

FEL50A

12

PA– PA +

Connecting terminal LEDs Switches

With FEL50A:

• 8 switches for configuring device address

• green LED to indicate

operational status,

pulsing to indicate communication;

• yellow LED to indicate

switching status,

flashes in the event of corrosion damage on

sensor

or if the electronics are defective

L00-FTL5xxxx-03-05-xx-en-002

Operating concept Onsite configuration

Certificates and approvals

CE mark The measuring system meets the legal requirements of the applicable EC Directives. These are listed in

the corresponding EC Declaration of Conformity along with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

RoHS The measuring system complies with the substance restrictions of the EU Directive on the restriction

of the use of certain hazardous substances 2011/65/EU (RoHS 2).

RCM-tick mark The product or measuring system supplied complies with the regulations of the Australian

Communications and Media Authority (ACMA) for network integrity, performance characteristics and

health and safety requirements. The specifications for electromagnetic compatibility, in particular, are

observed. The products bear the RCM-tick mark on their nameplate.

A0029561

Other certificates • See Ordering informationLiquiphant S FTL70 FTL71 ä 31

• Leak-detection system in conjunction with WHG approval

Approval number: Z–65.40–446

(See also "Ordering information" ä 31)

• TSE Certificate of Suitability

The following applies to wetted device components:

– They do not contain any materials derived from animals.

– No additives or operating materials derived from animals are used in production or processing.

Note!

!

Wetted device components are listed in the "Mechanical construction“ ( ä 22+) and “Ordering

information“ ( ä 31) sections.

EAC conformity The measuring system meets the legal requirements of the applicable EAC Directives.

These are listed in the corresponding EAC Declaration of Conformity along with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the EAC mark.

CRN approval Device versions available with CRN approval: 0F10904.5C (Canadian Registration Number) are

marked with a "*" in feature 20 "Process connection" under Ordering information( ä 31+).

Further details on maximum pressure values are available in the Download area of the product pages

under www.endress.com.

28

Page 29

Liquiphant S FTL70, 71

Process seal according to ANSI/ISA 12.27.01

Practice in North America for the installation of process seals

Endress+Hauser devices are designed as either single seal or dual seal devices with an alarm in

accordance with ANSI/ISA 12.27.01. This means that the user does need to install for an external

secondary process seal in the thermowell which is required in ANSI/NFPA 70 (NEC) and CSA 22.1

(CEC). These devices comply with installation practice in North America and enable very safe, low-cost

installation in pressurized applications with hazardous media.

Further information is provided in the Safety Instructions (XA) for the specific device ä 39 ff.

Product Listing Type Max. process pressure Marking

Pressure Equipment Directive 2014/68/EU (PED)

Liquiphant M CSA

FM

CSA

FM

Pressure instruments with permitted pressure ≤ 200 bar (2 900 psi)

Pressure instruments with permitted pressure ≤ 200 bar (2 900 psi) Pressure instruments with a

FTL70-S/T##...

FTL70-P/Q/R##...

FTL71-S/T##...

FTL71-P/Q/R##...

64/100 bar

(928/1450 psi)

64/100 bar

(928/1450 psi)

Single Seal

Single Seal

flange and threaded boss that do not have a pressure-bearing housing do not fall within the scope of

the Pressure Equipment Directive, irrespective of the maximum permitted pressure.

Reason:

According to Article 2, point 5 of EU Directive 2014/68/EU, pressure accessories are defined as

"devices with an operational function and having pressure-bearing housings".

If a pressure instrument does not have a pressure-bearing housing (no identifiable pressure chamber

of its own), there is no pressure accessory present within the meaning of the Directive.

Use in hazardous zones Pay particular attention to the information provided in the documentation: Safety Instructions, Control

Drawings etc. ä 39

ASME B 31.3 Design and materials in accordance with ASME B31.3 The welding seals are through-penetration

welded and comply with ASME Boiler and Pressure Vessel Code Section IX and EN ISO 15614-1.

29

Page 30

Liquiphant S FTL70, 71

Combinations of housing and electronic inserts

!

For permitted combinations of housing versions and electronic inserts, see the safety instructions for

ATEX, NEPSI etc.. A list of available documents can be found on ä 39+. The actual documents are

available on the product pages at www.endress.com.

Abbreviations used:

Housing Electronic inserts

Polyester housing F16

Aluminum housing F17 (plug-in)

Aluminum housing F13 (thread)

Aluminum housing T13 (separate connection

compartment)

Stainless steel housing F15 (for hygiene applications)

Stainless steel housing F27 (precision casting)

A: Non-hazardous area F16, F17, F13, T13, F15, F27 FEL51/52/54

B: ATEX/NEPSI II 3G EEx nC II T6,

WHG

C: ATEX/NEPSI II 3G EEx nA II T6,

WHG

D: Non-hazardous area, WHG F16, F17, F13, T13, F15, F27 FEL51/52/54

E: ATEX II 1/2G EEx de IIC T6, WHG/

IEC Zone 0/1

F: ATEX II 1/2GD Ex ia IIC T6, WHG/

IEC

L: ATEX II 1/2G EEx d IIC T6, WHG/

IECE Zone 0/1

M: NEPSI Ex ia IIC T6 F16, F17, F13, T13, F15, F27 FEL50A/55/56/57/58

N: NEPSI Ex d IIC T6 F13, T13, F27 FEL51/52/54

P: FM IS Cl.I, II ,III Div.1 Gr.A-G, Zone 0,

1, 2, 20, 21, 22

Q: FM XP Cl.I, II, III Div.1 Gr.A-G, Zone

1, 2, 21, 22

R: FM NI Cl.I Div.2 Gr.A-D, Zone 2 F16, F17, F13, T13, F15, F27 FEL51/52/54

S: CSA IS Cl I, II, III Div.1 Gr.A-G, Zone

0, 1, 2

T: CSA XP Cl I, II, III Div.1 Gr.A-G, Zone

1, 2

U: CSA General Purpose F16, F17, F13, T13, F15, F27 FEL51/52/54

V: TIIS Ex ia IIC T2 F16, F17, F13, T13, F15, F27 FEL50A/55/56/57/58

W: TIIS Ex d IIC T2 F13, T13, F27 FEL51/52/54

Y: Other certificate

(for non-hazardous areas)

Note! Polyester housing F16 (PBT)

Electrical connecting cables run in pipes:

• Do not screw cable entries firmly to the piping. Use flexible connections (e.g. with armored hose).

• If piping is used for grounding, ensure that there is a continuous electrical connection.

F16, F17, F13, T13, F15, F27 FEL54

F16, F17, F13, T13, F15, F27 FEL51/52

T13 FEL51/52/54

F17, F13, T13, F15, F27 FEL50A/55/56/57/58

F13, T13, F27 FEL51/52/54

F16, F17, F13, T13, F15, F27

(with NPT cable entry)

F13, T13, F27 FEL51/52/54

F16, F17, F13, T13, F15, F27

(with NPT cable entry)

F13, T13, F27 FEL51/52/54

FEL50A Profibus PA

FEL51 SIL 2-wire 19-253VDC

FEL52 3-wire PNP

FEL54 relay DPDT 19-253VAC/19-55VDC

FEL55 8/16mA, 11-36VDC

FEL56 NAMUR (L-H signal)

FEL57 2-wire PFM

FEL58 NAMUR+test key (H-L signal)

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

FEL50A/55/56/57/58

30

Page 31

Liquiphant S FTL70, 71

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com → Click "Corporate"

→ Select your country → Click "Products" → Select the product using the filters and search mask →

Open the product page → The "Configuration" button to the right of the product image opens the

Product Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: direct input of information specific to measuring point, such as measuring

range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly from the Endress+Hauser online shop

Versions that are mutually exclusive are not indicated in this table.

Ordering information Liquiphant S FTL70 FTL71

Design: Basic weight

FTL70 Compact 0.7 kg

FTL71 With extension pipe 0.7 kg

10 Approval:

A Non-hazardous area

B ATEX/NEPSI II 3 G EEx nC II T6 Overfill protection as per WHG

C ATEX/NEPSI II 3 G EEx nA II T6 Overfill protection as per WHG

D Non-hazardous area Overfill protection as per WHG

E ATEX II 1/2 G EEx de IIC T6 Overfill protection as per WHG, IEC Ex Zone 0/1

F ATEX II 1/2 G EEx ia IIC T6 Overfill protection as per WHG, IEC Ex Zone 0/1

ATEX II 1/2 D T 80°C*

L ATEX II 1/2 G EEx d IIC T6 Overfill protection as per WHG, IEC Ex Zone 0/1

MNEPSI Ex ia IIC T6

N NEPSI Ex d IIC T6

P FM IS, Class I, II, III Division 1, Group A-G

Q FM XP, Class I, II, III Division 1, Group B-G, for E5 housing Group A-G

R FM NI, Class I Division 2, Group A-D

S CSA IS, Class I, II, III Division 1, Group A-G

T CSA XP, Class I, II, III Division 1, Group A-G

U CSA General Purpose

V TIIS Ex ia IIC T2

W TIIS Ex d IIC T2

Y Special version

*) not for PBT

20 Process connection: Additional

weight

Threaded connection

GQ2 G ¾ 316L Thread ISO 228

GQ6 G ¾ AlloyC22 Thread ISO 228

GR2 G 1 316L Thread ISO 228 0.2 kg

GR6 G 1 AlloyC22 Thread ISO 228 0.2 kg

GE2 R ¾ 316L Thread DIN 2999

GE6 R ¾ AlloyC22 Thread DIN 2999

GF2 R 1 316L Thread DIN 2999 0.2 kg

GF6 R 1 AlloyC22 Thread DIN 2999 0.2 kg

GM2* NPT ¾ 316L Thread ANSI

GM6 NPT ¾ AlloyC22 Thread ANSI

GN2* NPT1 316L Thread ANSI 0.2 kg

GN6 NPT1 AlloyC22 Thread ANSI 0.2 kg

EN flanges

B82 DN25 PN25/40 A 316L Flange EN 1092-1

C82 DN25 PN25/40 B1 316L Flange EN 1092-1

(DIN 2527 B)

(DIN 2527 C)

1.4 kg

1.3 kg

31

Page 32

Liquiphant S FTL70, 71

20 Process connection: Additional

weight

C86 DN25 PN25/40 B1 AlloyC22 >1.4462 Flange EN 1092-1

D82 DN25 PN40 B1 316L Flange EN 1092-1

BB2 DN32 PN25/40 A 316L Flange EN 1092-1

BD2 DN40 PN25/40 A 316L Flange EN 1092-1

CF2 DN50 PN10/16 B1 316L Flange EN 1092-1

BG2 DN50 PN25/40 A 316L Flange EN 1092-1

CG2 DN50 PN25/40 B1 316L Flange EN 1092-1

DG2 DN50 PN40 B1 316L Flange EN 1092-1

CG6 DN50 PN25/40 B1 AlloyC22 >1.4462 Flange EN 1092-1

BI2 DN50 PN63 A 316L Flange EN 1092-1

CI2 DN50 PN63 B2 316L Flange EN 1092-1

CI6 DN50 PN63 B1 AlloyC22 >1.4462 Flange EN 1092-1

BJ2 DN50 PN100 A 316L Flange EN 1092-1 5.5 kg

CJ2 DN50 PN100 B2 316L Flange EN 1092-1 5.5 kg

BK2 DN65 PN25/40 A 316L Flange EN 1092-1

CM2 DN80 PN10/16 B1 316L Flange EN 1092-1

BN2 DN80 PN25/40 A 316L Flange EN 1092-1

CN2 DN80 PN25/40 B1 316L Flange EN 1092-1

DN2 DN80 PN40 B1 316L Flange EN 1092-1

CN6 DN80 PN25/40 B1 AlloyC22 >1.4462 Flange EN 1092-1

B02 DN80 PN63 A 316Ti Flange EN 1092-1

C02 DN80 PN63 B2 316L Flange EN 1092-1

C06 DN80 PN63 B1 AlloyC22 >1.4462 Flange EN 1092-1

B12 DN80 PN100 A 316L Flange EN 1092-1 8.0 kg

C12 DN80 PN100 B2 316L Flange EN 1092-1 8.0 kg

CQ2 DN100 PN10/16 B1 316L Flange EN 1092-1

BR2 DN100 PN25/40 A 316L Flange EN 1092-1

BU2 DN100 PN63 A 316L Flange EN 1092-1

CU2 DN100 PN63 B2 316L Flange EN 1092-1

CU6 DN100 PN63 B1 AlloyC22 >1.4462 Flange EN 1092-1

(DIN 2527)

(DIN 2526 D)

(DIN 2527 B)

(DIN 2527 B)

(DIN 2527 C)

(DIN 2527 B)

(DIN 2527 C)

(DIN 2526 D)

(DIN 2527)

(DIN 2527 B)

(DIN 2527 E)

(DIN 2527)

(DIN 2527 B)

(DIN 2527 C)

(DIN 2527 B)

(DIN 2527 C)

(DIN 2526 D)

(DIN 2527)

(DIN 2527 B)

(DIN 2527 E)

(DIN 2527)

(DIN 2527 C)

(DIN 2527 B)

(DIN 2527 B)

(DIN 2527 E)

(DIN 2527)

1.3 kg

1.4 kg

2.0 kg

2.4 kg

2.5 kg

3.2 kg

2.9 kg

2.9 kg

2.9 kg

4.5 kg

4.5 kg

4.5 kg

4.3 kg

4.8 kg

5.9 kg

5.2 kg

5.2 kg

5.2 kg

6.9 kg

6.9 kg

6.9 kg

5.3 kg

7.5 kg

10.1 kg

10.1 kg

10.1 kg

32

ANSI flanges

A82* 1" 150 lbs RF 316/316L Flange ANSI B16.5 1.0 kg

AB2* 1¼" 300 lbs RF 316/316L Flange ANSI B16.5 2.0 kg

AC2* 1½" 150 lbs RF 316/316L Flange ANSI B16.5 1.5 kg

AD2* 1½" 300 lbs RF 316/316L Flange ANSI B16.5 2.7 kg

AE2* 2" 150 lbs RF 316/316L Flange ANSI B16.5 2.4 kg

AE6 2" 150 lbs RF AlloyC22 >1.4462 Flange ANSI B16.5 2.4 kg

AF2* 2" 300 lbs RF 316/316L Flange ANSI B16.5 3.2 kg

AF6 2" 300 lbs RF AlloyC22 >1.4462 Flange ANSI B16.5 3.2 kg

AG2* 2" 600 lbs RF 316/316L Flange ANSI B16.5 4.2 kg

AG6 2" 600 lbs RF AlloyC22 >1.4462 Flange ANSI B16.5 4.2 kg

AL2* 3" 150 lbs RF 316/316L Flange ANSI B16.5 4.9 kg

AM2* 3" 300 lbs RF 316/316L Flange ANSI B16.5 6.8 kg

AN2* 3" 600 lbs RF 316/316L Flange ANSI B16.5 8.5 kg

AN6 3" 600 lbs RF AlloyC22 >1.4462 Flange ANSI B16.5 8.5 kg

AP2* 4" 150 lbs RF 316/316L Flange ANSI B16.5 7.0 kg

Page 33

Liquiphant S FTL70, 71

20 Process connection: Additional

weight

AQ2* 4" 300 lbs RF 316/316L Flange ANSI B16.5 11.5 kg

AR2* 4" 600 lbs RF 316/316L Flange ANSI B16.5 17.3 kg

JIS flanges

KF2 20 K 50 RF 316L Flange JIS B2220 1.9 kg

KF6 20 K 50 RF AlloyC22 >316L Flange JIS B2220 1.9 kg

YY9 Special version

* With CRN approval.

30 Probe length:

FTL70

AB Compact version Ra < 3.2 μm/80 grit, 316L

Fork: 318L

AE Compact version Ra < 3.2 μm/80 grit, Alloy

FTL71

BB ....... mm L Ra < 3.2 μm/80 grit, 316L

Fork: 318L 0.9 kg/m

BE ....... mm L Ra < 3.2 μm/80 grit, Alloy 0.9 kg/m

CB ....... inch L Ra < 3.2 μm/80 grit, 316L

Fork: 318L 2.3 kg/100 in

CE ....... inch L Ra < 3.2 μm/80 grit, Alloy 2.3 kg/100 in

YY Special version

40 Electronics; output:

A FEL50A; PROFIBUS PA

1 FEL51; SIL 2–wire 19 to 253 V AC

2 FEL52; SIL 3–wire PNP 10 to 55 V DC

4 FEL54; SIL relay DPDT 19 to 253 V AC/19 to 55 V DC

5 FEL55; SIL 8/16 mA 11 to 36 V DC

6 FEL56; SIL NAMUR (L-H signal)

7 FEL57; SIL 2-wire PFM

8 FEL58; SIL NAMUR + test keys (H-L signal)

9 Special version

50 Housing; cable entry:

E1* F27 316L NEMA6P; Thread NPT ¾

E4 F16 Polyester NEMA4X; Thread NPT ½

E5 F17 Alu NEMA4X; Thread NPT ¾ 0.5 kg

E7 T13 Alu coated IP66; Thread NPT ¾

Separate connection compartment 1.1 kg

E8 F13 Alu NEMA4X; Thread NPT ¾

suitable for EEx d/XP 0.5 kg

F1* F27 316L IP68 Thread G1/2

F4 F16 Polyester IP66; Thread G ½

F5 F17 Alu IP66; Thread G ½ 0.5 kg

F7 T13 Alu coated IP66; Thread G ½

Separate connection compartment 1.1 kg

F8 F13 Alu IP68; Thread G ½

suitable for EEx d/XP 0.5 kg

G1* F27 316L IP68; M20 threaded joint

G4 F16 Polyester IP66; M20 threaded joint

G5 F17 Alu IP66; M20 threaded joint 0.5 kg

G7 T13 Alu coated IP66; M20 threaded joint

separate connection compartment (EEx d > M20 thread) 1.1 kg

G8 F13 Alu IP68; M20 threaded joint

suitable for EEx d/XP 0.5 kg

N4 F16 Polyester IP66; M12 connector

N4 F16 Polyester IP66; M12 connector

N5 F17 Alu IP66; M12 connector

Y9 Special version

* F27 housing under development.

33

Page 34

!

14

(0.55)

G1 12

(0.47)

2

(0.08)

92

(3.62)

92

(3.62)

60 Additional option:

A Basic version

C EN 10204 - 3.1 material (316L/318L wetted)

Inspection certificate

N EN 10204 - 3.1 material, NACE MR0175 (316L wetted)

inspection certificate

S GL/ABS marine certificate

Y Special version

70 Application:

L 230 °C, gas-tight feed-through

N 280 °C, gas-tight feed-through 0.2 kg

Y Special version

FTL7x- Complete product designation

Note!

The basic weight comprises:

•Sensor (compact)

•Thread G ¾

• Electronic insert

• Polyester housing

Liquiphant S FTL70, 71

Lap joint flange

Lap joint flanges

Accessories

Order number: 918158-0000

with G 1 thread for mounting a

Liquiphant 51 with GR2 process connection

Pressure up to 40 bar (580 psi)

Material: corrosion-resistant steel

1.4301 (AISI 304)

Weight: 0.54 kg (1.19 lbs)

With G 1 thread for mounting

a Liquiphant S FTL70/71

with GR2 process connection.

Material: corrosion-resistant steel

1.4571 (AISI 113Ti)

– Order number: 918143-0000

Flange DN50 PN40, EN 1092-1

Weight: 3.11 kg (6.86 lbs)

– Order number: 918144-0000

Flange ASME 2", 150 psi, RF

Weight: 2.38 kg (5.25 lbs)

L00-FTL5xxxx-06-05-xx-xx-108

L00-FTL5xxxx-03-05-xx-xx-015

34

Page 35

Liquiphant S FTL70, 71

ø110 (4.33)

114 (4.49)

140 (5.51)

140 (5.51)

mm (in)

102 (4.02)

162 (6.38)

mm (in)

112 (4.41)

22

(0.87)

M6 (3x)

18

(0.71)

G 1 A

(1 NPT)

G 1½A

(1½ NPT)

19

(0.75)

M6 (3x)

p =

0 bar (psi)

e

FTL51/71

SW/AF 41

SW/AF 55

19

(0.75)

Weather protection cover For F16 housing

Material Order No. Weight

PBT, gray 71127760 240 g (8.46 oz)

A0018225

Sliding sleeves for unpressurized operation

For F13, F17 and F27 housing

A0018226

Material Order No. Weight

PA6, gray 71040497 300 g (10.58 oz)

Switch point infinitely variable for

Liquiphant MFTL71

Material: corrosion-resistant steel

1.4435 (AISI 316 L)

Weight for G 1, NPT 1: 0.21 kg (0.46 lbs)

Weight for G 1½, NPT 1½: 0.54 kg (1.19 lbs)

L00-FTL5xxxx-06-05-xx-xx-109

35

Page 36

Liquiphant S FTL70, 71

G 1 A

(1 NPT)

G 1½A

(1½ NPT)

18

(0.71)

2

(0.08)

~70

(2.76)

ø60 (2.36)

~72

(2.83)

SW/AF 50

SW/AF 50

FTL51/71

22

(0.87)

2

(0.08)

ø60 (2.36)

Thread Standard Material Order number Approval

G 1 DIN ISO 228/I 1.4435 (AISI 316 L) 52003978

G 1 DIN ISO 228/I 1.4435 (AISI 316 L) 52011888 With inspection

certificate EN 10204 -

3.1 material

NPT1 ASME B 1.20.1 1.4435 (AISI 316 L) 52003979

NPT1 ASME B 1.20.1 1.4435 (AISI 316 L) 52011889 With inspection

certificate EN 10204 -

3.1 material

G 1½ DIN ISO 228/I 1.4435 (AISI 316 L) 52003980

G 1½ DIN ISO 228/I 1.4435 (AISI 316 L) 52011890 With inspection

NPT1½ ASME B 1.20.1 1.4435 (AISI 316 L) 52003981

NPT1½ ASME B 1.20.1 1.4435 (AISI 316 L) 52011891 With inspection

certificate EN 10204 -

3.1 material

certificate EN 10204 -

3.1 material

High pressure sliding sleeves

For continuous adjustment of the switch point of a

Liquiphant M FTL71.

Also for use in hazardous areas. For further

information ä 39ff. (ATEX, NEPSI).

Material: corrosion-resistant steel

1.4435 (AISI 316L) or AlloyC22

Weight for G 1, NPT 1: 1.13 kg (2.49 lbs)

Weight for G 1½, NPT 1½: 1.32 kg (2.91 lbs)

Seal package made of graphite.

For G1, G 1½:

Seal is included in the delivery.

Note!

For process pressures up to 100 bar (1450 psi).

Thread Standard Material Order number Approval

G 1 DIN ISO 228/1 1.4435 (AISI 316 L) 52003663

G 1 DIN ISO 228/1 1.4435 (AISI 316 L) 52011880 With inspection certificate EN

G 1 DIN ISO 228/1 AlloyC22 71118691 With inspection certificate EN

NPT1 ASME B 1.20.1 1.4435 (AISI 316 L) 52003667

NPT1 ASME B 1.20.1 1.4435 (AISI 316 L) 52011881 With inspection certificate EN

NPT1 ASME B 1.20.1 AlloyC22 71118694 With inspection certificate EN