Page 1

BA01894F/00/EN/02.19

71440978

2019-06-28

Valid as of version

01.00.zz

Products Solutions Services

Operating Instructions

Liquiphant FTL51B

Vibronic

Limit switch for liquids

Page 2

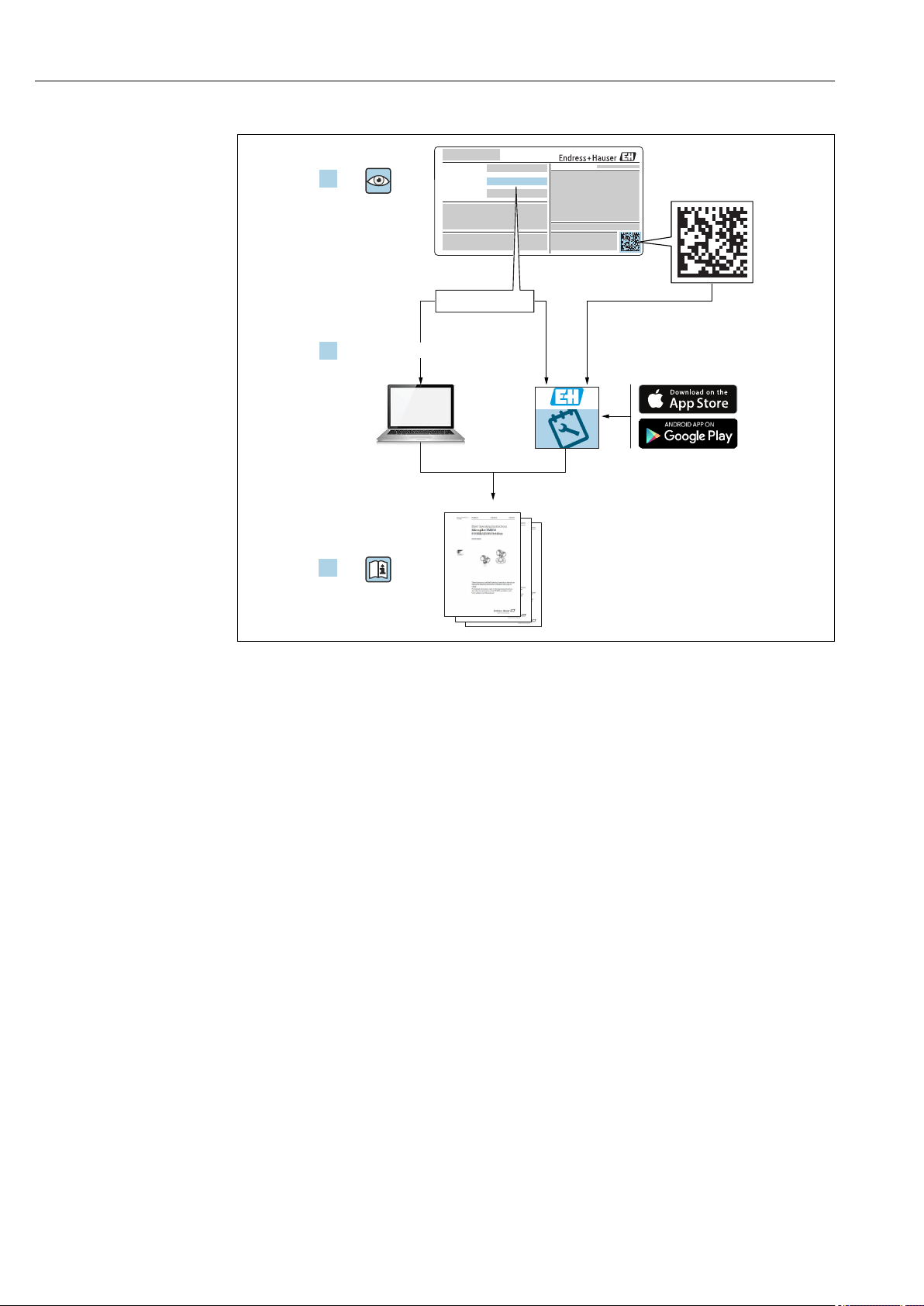

Liquiphant FTL51B

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

2 Endress+Hauser

Page 3

Liquiphant FTL51B Table of contents

Table of contents

1 About this document ................ 5

1.1 Symbols ............................. 5

1.1.1 Safety symbols .................. 5

1.1.2 Electrical symbols ................ 5

1.1.3 Symbols for certain types of

information .................... 5

1.1.4 Symbols in graphics ............... 5

2 Basic safety instructions ............ 6

2.1 Requirements for the personnel ............ 6

2.2 Designated use ........................ 6

2.2.1 Incorrect use .................... 6

2.3 Workplace safety ....................... 6

2.4 Operational safety ...................... 6

2.5 Product safety ......................... 7

2.6 IT security ............................ 7

3 Product description ................. 7

3.1 Product design ........................ 8

4 Incoming acceptance and product

identification ....................... 9

4.1 Incoming acceptance .................... 9

4.2 Product identification .................... 9

4.2.1 Nameplate ..................... 9

4.2.2 Manufacturer address ............. 9

4.3 Storage and transport .................. 10

4.3.1 Storage conditions ............... 10

4.3.2 Transporting the device ........... 10

6.2 Connecting the measuring device .......... 17

6.2.1 2-wire AC (electronic insert

FEL61) ....................... 17

6.2.2 3-wire DC-PNP (electronic insert

FEL62) ....................... 19

6.2.3 Universal current connection with

relay output (electronic insert

FEL64) ....................... 21

6.2.4 DC connection, relay output

(electronic insert FEL64 DC) ....... 23

6.2.5 PFM output (electronic insert

FEL67) ....................... 25

6.2.6 2-wire NAMUR > 2.2 mA/< 1.0 mA

(electronic insert FEL68) .......... 27

6.2.7 Bluetooth module VU121

(optional) ..................... 29

6.2.8 LED module VU120 (optional) ...... 30

6.2.9 Cable entry .................... 30

6.3 Post-connection check .................. 31

7 Operation options ................. 32

7.1 Overview of operation options ............ 32

7.1.1 Operating concept .............. 32

7.1.2 Functional test using the button on

the electronic insert .............. 32

7.1.3 Functional test of the electronic

switch with a test magnet ......... 35

7.1.4 Heartbeat diagnostics and

verification with Bluetooth® wireless

technology .................... 36

7.2 LED module VU120 (optional) ............ 37

7.2.1 Configuration and sensor status ..... 37

5 Installation ....................... 11

5.1 Mounting conditions ................... 11

5.1.1 Taking the switch point into

consideration .................. 11

5.1.2 Take viscosity into consideration .... 12

5.1.3 Avoiding buildup ................ 13

5.1.4 Take clearance into consideration ... 13

5.1.5 Support the device ............... 14

5.1.6 Weld-in adapter with leakage hole .. 14

5.2 Mounting the measuring device ........... 14

5.2.1 Required tools .................. 14

5.2.2 Installation .................... 15

5.3 Sliding sleeves ....................... 16

5.4 Post-installation check .................. 16

6 Electrical connection .............. 17

6.1 Connection conditions .................. 17

6.1.1 Cover with securing screw ......... 17

6.1.2 Connecting protective earth (PE) .... 17

Endress+Hauser 3

8 Commissioning .................... 37

8.1 Function check ....................... 37

8.2 Switching on the measuring device ......... 38

8.3 Establishing a connection via SmartBlue

(app) .............................. 38

8.3.1 SmartBlue (app) ................ 38

9 Operation ......................... 40

9.1 Diagnostics menu ..................... 40

9.1.1 "Diagnostics" menu ............... 40

9.1.2 "Application" menu .............. 40

9.1.3 "System" menu .................. 41

9.2 Heartbeat Verification .................. 42

9.3 Recurrent testing for SIL/WHG (German

Water Resources Act) devices ............. 42

10 Diagnostics and troubleshooting ... 42

10.1 Diagnostic information via light emitting

diodes .............................. 43

10.1.1 LED at electronic insert ........... 43

Page 4

Table of contents Liquiphant FTL51B

10.1.2 SmartBlue ..................... 43

11 Maintenance ...................... 44

11.1 Maintenance tasks .................... 44

11.1.1 Cleaning ...................... 44

12 Repair ............................ 45

12.1 General information ................... 45

12.1.1 Repair concept ................. 45

12.1.2 Repair of Ex-certified devices ....... 45

12.2 Spare parts .......................... 45

12.3 Return .............................. 45

12.4 Disposal ............................ 46

13 Accessories ....................... 47

13.1 Device-specific accessories ............... 47

13.1.1 Test magnet ................... 47

13.1.2 Weather protection cover for dualcompartment housing, aluminum ... 47

13.1.3 Weather protection cover for single-

compartment housing, metal ....... 47

13.1.4 Plug-in jack .................... 48

13.1.5 Additional modules .............. 48

13.1.6 Sliding sleeves for unpressurized

operation ..................... 49

13.1.7 High pressure sliding sleeves ....... 50

14 Technical data .................... 52

14.1 Input ............................... 52

14.1.1 Measured variable .............. 52

14.1.2 Measuring range ............... 52

14.2 Output ............................. 52

14.2.1 Output and input variants ......... 52

14.2.2 Output signal .................. 53

14.2.3 Ex connection data .............. 53

14.3 Environment ......................... 53

14.3.1 Ambient temperature range ....... 53

14.3.2 Storage temperature ............. 54

14.3.3 Humidity ..................... 54

14.3.4 Operating altitude ............... 55

14.3.5 Climate class .................. 55

14.3.6 Degree of protection ............. 55

14.3.7 Vibration resistance ............. 55

14.3.8 Shock resistance ................ 55

14.3.9 Mechanical load ................ 56

14.3.10 Electromagnetic compatibility ...... 56

14.4 Process ............................. 56

14.4.1 Process temperature range ........ 56

14.4.2 Thermal shock ................. 56

14.4.3 Process pressure range ........... 56

14.4.4 Test pressure .................. 57

14.4.5 Density ...................... 57

14.4.6 Pressure tightness .............. 58

14.5 Additional technical data ................ 58

Index .................................. 59

4 Endress+Hauser

Page 5

Liquiphant FTL51B About this document

DANGER

WARNING

CAUTION

NOTICE

A

1.

-

.

1 About this document

1.1 Symbols

1.1.1 Safety symbols

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.1.2 Electrical symbols

Ground connection

Grounded clamp, which is grounded via a grounding system.

Protective earth (PE)

Ground terminals, which must be grounded prior to establishing any other connections.

The ground terminals are located on the inside and outside of the device.

1.1.3 Symbols for certain types of information

Permitted

Procedures, processes or actions that are permitted.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information

Reference to documentation

Reference to another section

, 2., 3. Series of steps

1.1.4 Symbols in graphics

A, B, C ... View

1, 2, 3 ... Item numbers

Hazardous area

Safe area (non-hazardous area)

Endress+Hauser 5

Page 6

Basic safety instructions Liquiphant FTL51B

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel must fulfill the following requirements to carry out the necessary tasks,

e. g., commissioning and maintenance:

Trained, qualified specialists must have a relevant qualification for the specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Must have read and understood the instructions in the manual and supplementary

‣

documentation

Follow instructions and comply with conditions

‣

2.2 Designated use

• Only use the measuring device as a limit switch for liquids

• Improper use can pose hazards

• Ensure that the measuring device is free of defects while it is in operation

• Use the measuring device only for media to which the process-wetted materials have an

adequate level of resistance

• Do not exceed or drop below the limit values for the measuring device

TI01403F/00/EN

2.2.1 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Residual risks

Due to heat transfer from the process, the temperature of the electronics housing and the

assemblies contained therein may rise to 80 °C (176 °F) during operation.

Danger of burns from contact with surfaces!

If necessary, ensure protection against contact to prevent burns.

‣

For requirements concerning functional safety in accordance with IEC 61508, the

associated SIL documentation must be observed.

2.3 Workplace safety

For work on and with the device:

Wear the required protective equipment according to federal/national regulations.

‣

2.4 Operational safety

Risk of injury!

Operate the device only if it is in proper technical condition, free from errors and faults.

‣

The operator is responsible for ensuring failure-free operation of the device.

‣

Modifications to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

6 Endress+Hauser

Page 7

Liquiphant FTL51B Product description

Repair

To ensure continued operational safety and reliability:

Only perform repair work on the device if this is expressly permitted.

‣

Observe federal/national regulations pertaining to the repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

‣

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

2.6 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device has safety mechanisms integrated to prevent users

from inadvertently changing settings.

Provide additional protection for the device and data transfer to/from the device

IT security measures defined in the plant owner/operator's own security policy must be

‣

implemented by plant owners/operators themselves.

3 Product description

Point level switch for minimum or maximum detection.

Endress+Hauser 7

Page 8

Product description Liquiphant FTL51B

1

2

3

4

5

Contains

FCC ID:

IC:

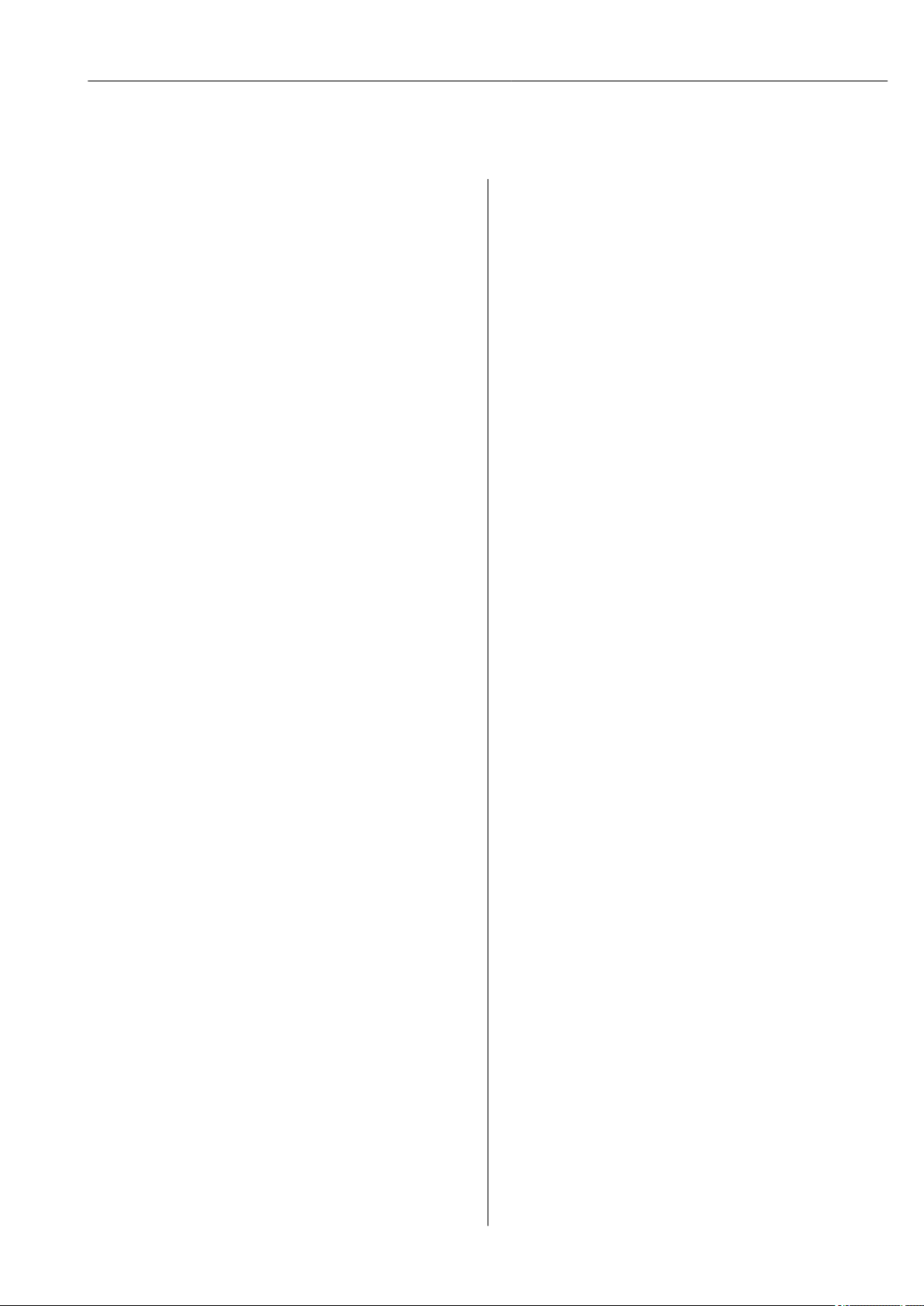

3.1 Product design

A0036953

1 Product design

1 Housing with electronic insert and cover, optional Bluetooth module or LED module

2 Optional spacer (temperature spacer or pressure-tight feedthrough (second line of defense))

3 Compact probe design

4 Probe design with pipe extension

5 Probe design with short pipe

Identify the electronic insert via the order code on the nameplate.

Optional: Bluetooth module VU121 or LED module VU120

A0039257

2 Bluetooth module

3 LED module

8 Endress+Hauser

A0039258

Page 9

Liquiphant FTL51B Incoming acceptance and product identification

Order code: Ser. no.:

Ext. ord. cd.:

L:

FW:

Dev.Rev.:

Pmax:

0.83 W PNP

2

3

5

1

4

4

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Check the following during goods acceptance:

Are the order codes on the delivery note and the product sticker identical?

Are the goods undamaged?

Do the nameplate data match the ordering information on the delivery note?

If required (see nameplate): Are the Safety Instructions, e. g. XA, provided?

Is the device properly secured?

If one of these conditions is not met, please contact the manufacturer's sales office.

4.2 Product identification

The measuring device can be identified in the following ways:

• Nameplate data

• Extended order code with breakdown of the device features on the delivery note

• Enter serial number from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All of the information on the measuring device is

displayed along with an overview of the scope of technical documentation provided

• Enter the serial number on the nameplate into the Endress+Hauser Operations App or

use the Endress+Hauser Operations App to scan the 2-D matrix code (QR Code) on the

nameplate

4.2.1 Nameplate

4 Nameplate specifications

1 Manufacturer name and device name

2 Manufacturer address

3 Order number, external order code, serial number

4 Technical data

5 Approval-specific information

4.2.2 Manufacturer address

Endress+Hauser SE+Co. KG

Hauptstraße 1

79689 Maulburg, Germany

Address of the manufacturing plant: See nameplate.

A0038187

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Liquiphant FTL51B

4.3 Storage and transport

4.3.1 Storage conditions

Use original packaging.

Storage temperature

–40 to +80 °C (–40 to +176 °F)

optional: –52 °C (–62 °F), –60 °C (–76 °F)

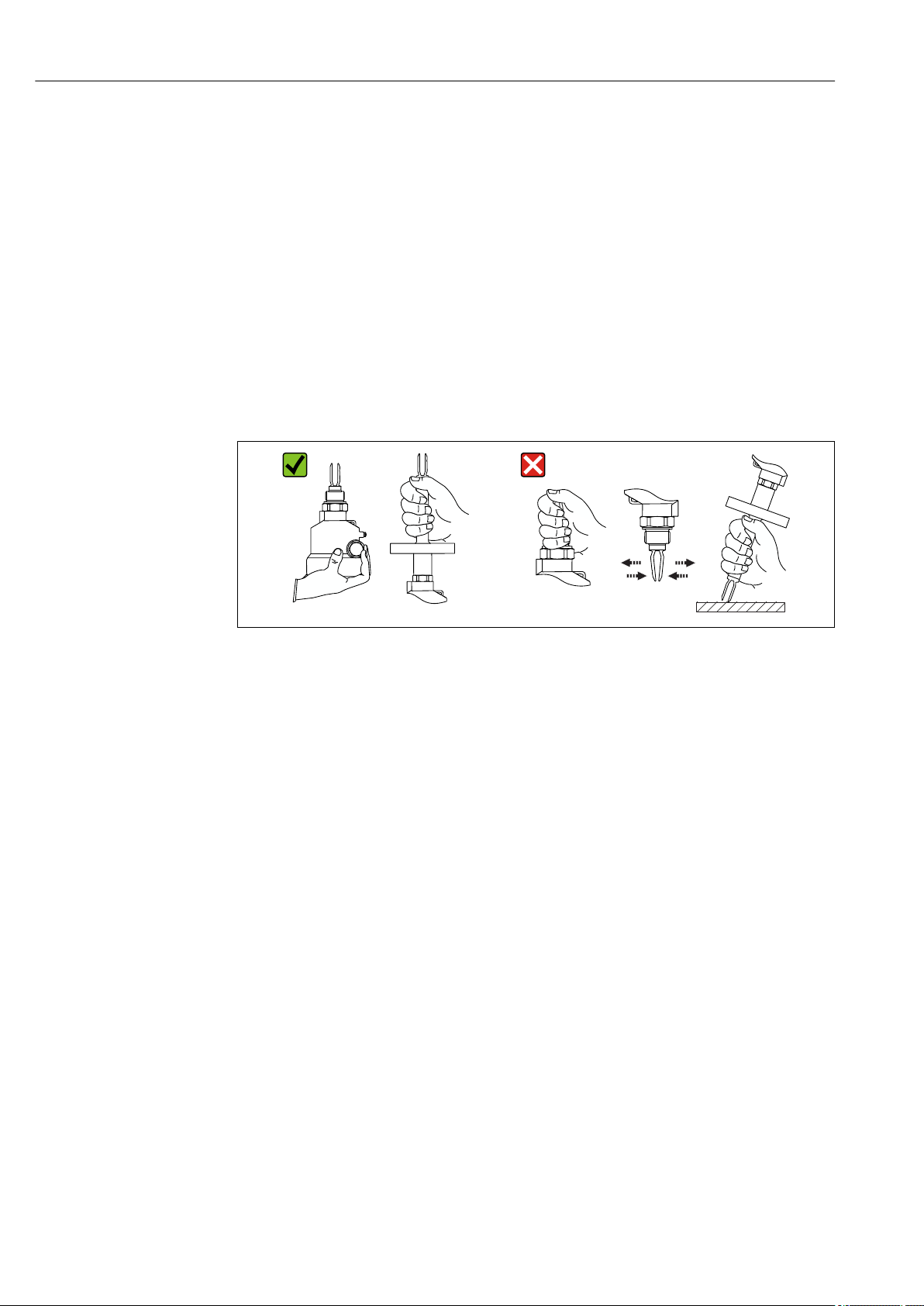

4.3.2 Transporting the device

• Transport the device to the measuring point in the original packaging

• Hold the device by the housing, temperature spacer, flange or extension pipe

• Do not bend, shorten or extend the tuning fork

5 Handling the device during transportation

A0034846

10 Endress+Hauser

Page 11

Liquiphant FTL51B Installation

1

~13 (0.5)

~4 (0.16)

~12.5 (0.49)

D

A B C

D

D

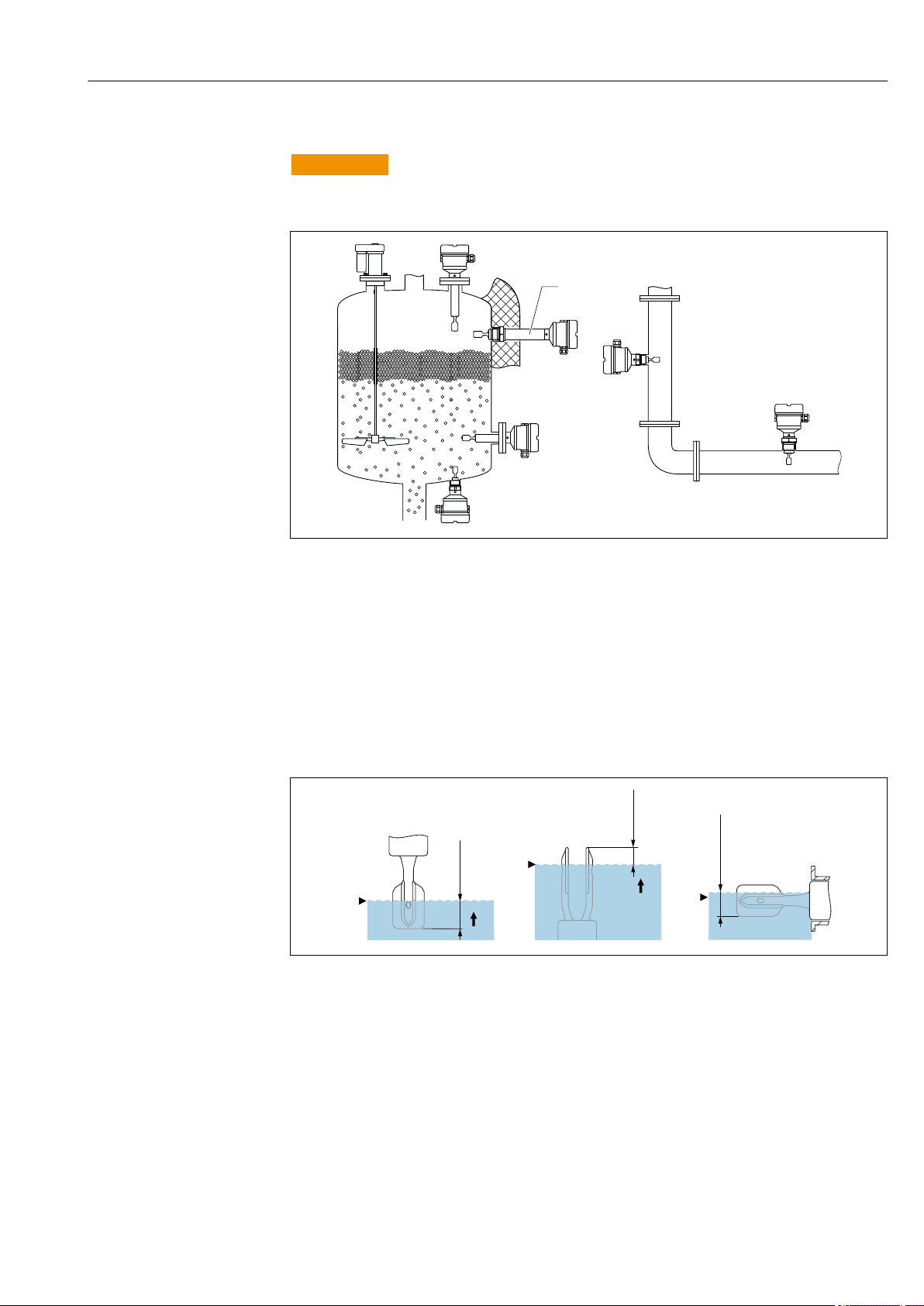

5 Installation

WARNING

L

Loss of protection rating if the device is opened in a wet environment.

Only open the device in a dry environment!

‣

A0037879

6 Installation in any position in a vessel, pipe or tank

1 Temperature spacer for tank with insulation and/or high process temperatures

5.1 Mounting conditions

5.1.1 Taking the switch point into consideration

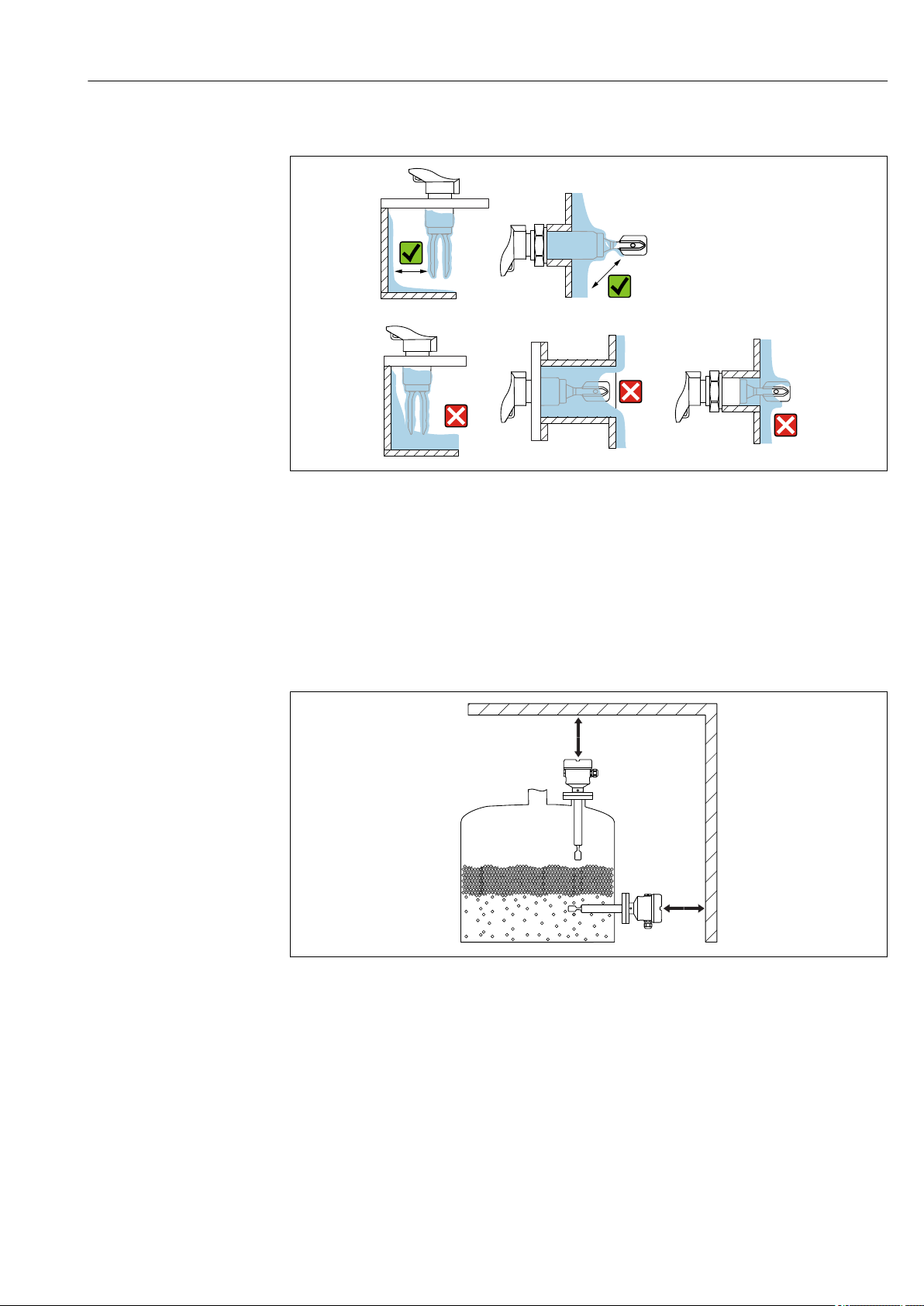

Typical switch points, depending on the orientation of the point level switch

(water +23 °C (+73 °F))

A0037915

7 Typical switch points. Unit of measurement mm (in)

A Installation from above

B Installation from below

C Installation from the side

D Switch point

Endress+Hauser 11

Page 12

Installation Liquiphant FTL51B

> 25 (0.98)

D

> 40 (1.57)

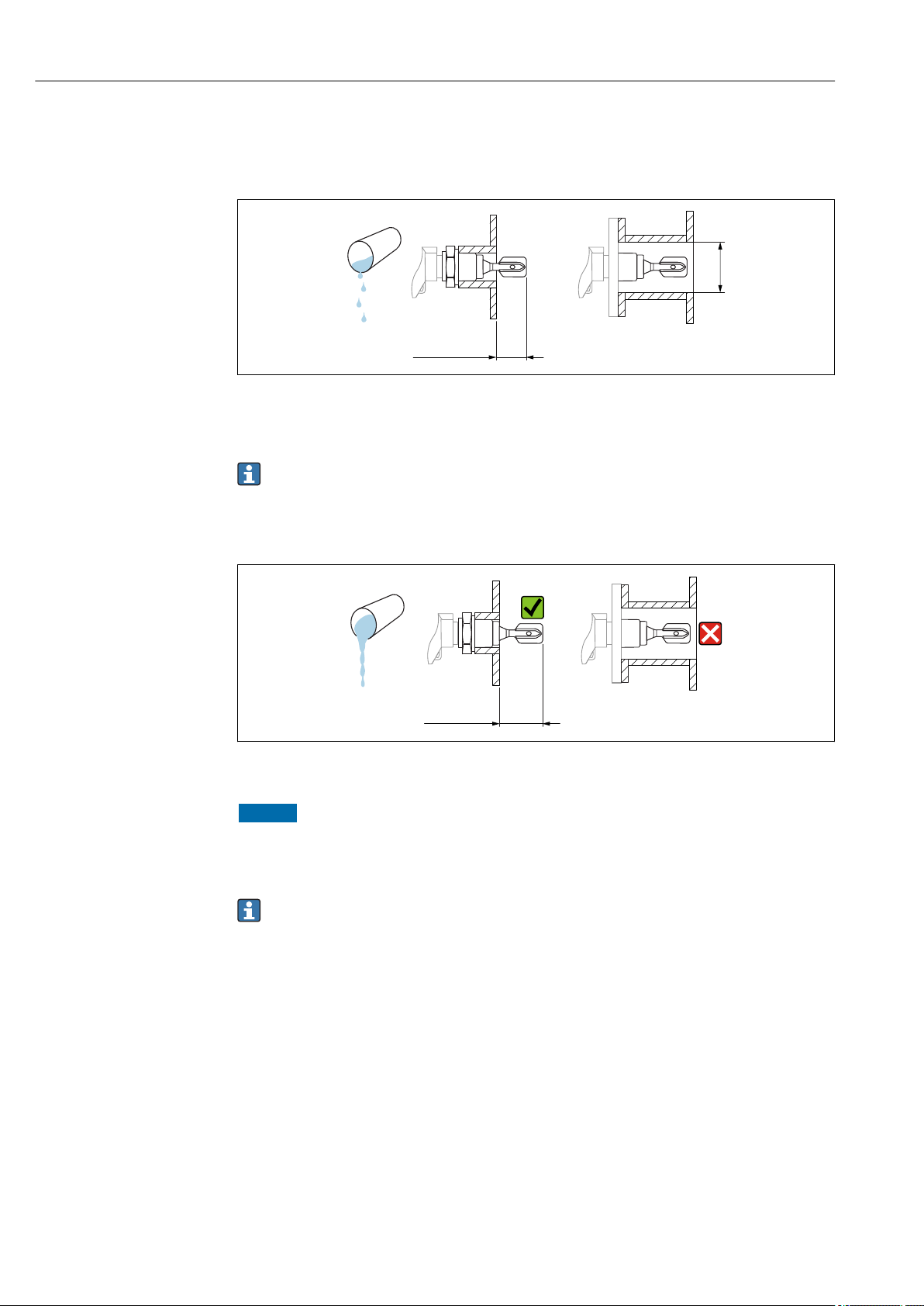

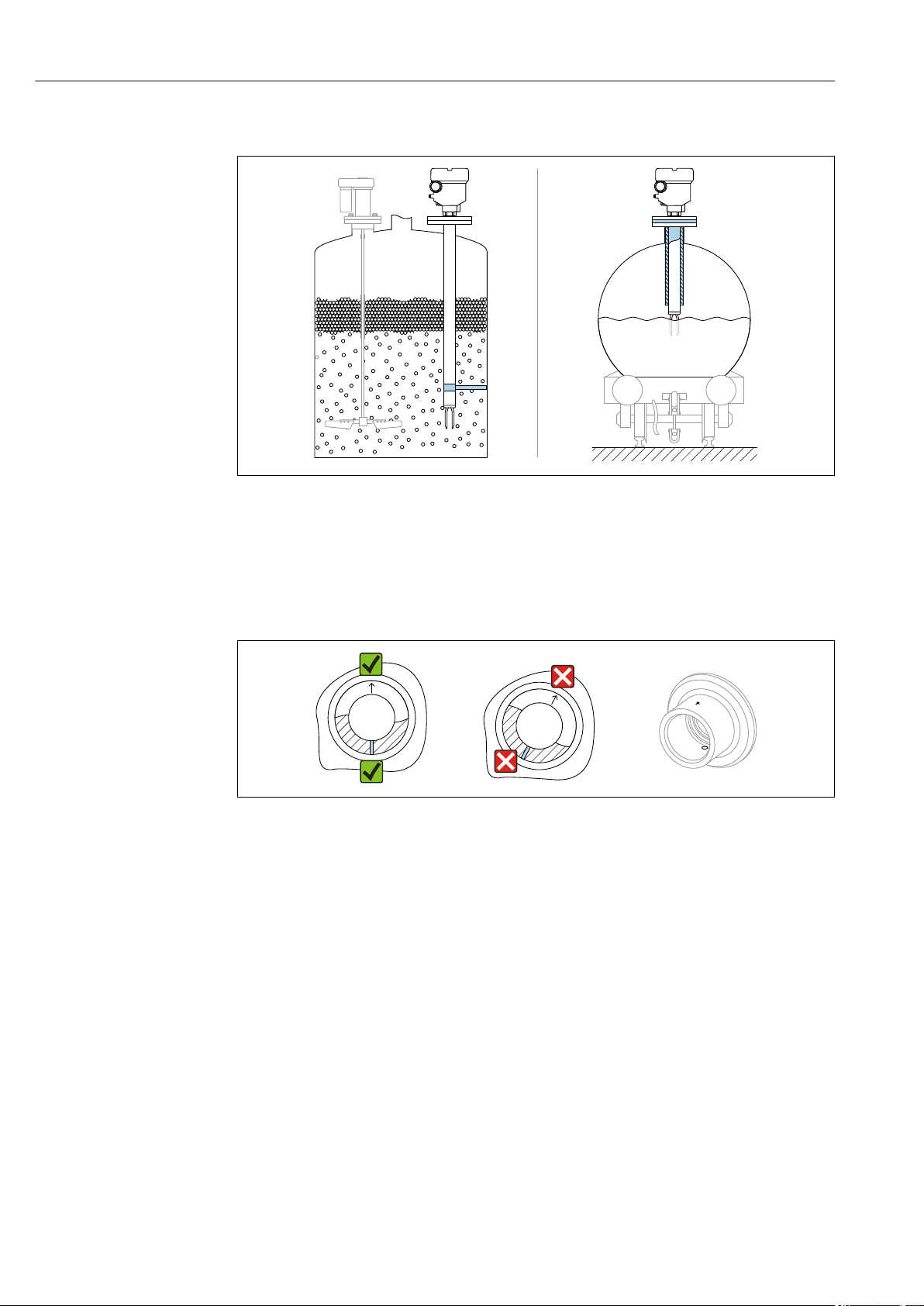

5.1.2 Take viscosity into consideration

Low viscosity

A0033297

8 Installation example for low-viscosity liquids. Unit of measurement mm (in)

D Diameter of installation socket: at least 50 mm (2.0 in)

Low viscosity, e. g. water: < 2 000 mPa⋅s

It is permitted to position the tuning fork within the installation socket.

High viscosity

9 Installation example for a highly viscous liquid. Unit of measurement mm (in)

NOTICE

Highly viscous liquids may cause switching delays.

Make sure that the liquid can run off the tuning fork easily.

‣

Deburr the socket surface.

‣

High viscosity, e. g. viscous oils: < 10 000 mPa⋅s

The tuning fork must be located outside the installation socket!

A0037348

12 Endress+Hauser

Page 13

Liquiphant FTL51B Installation

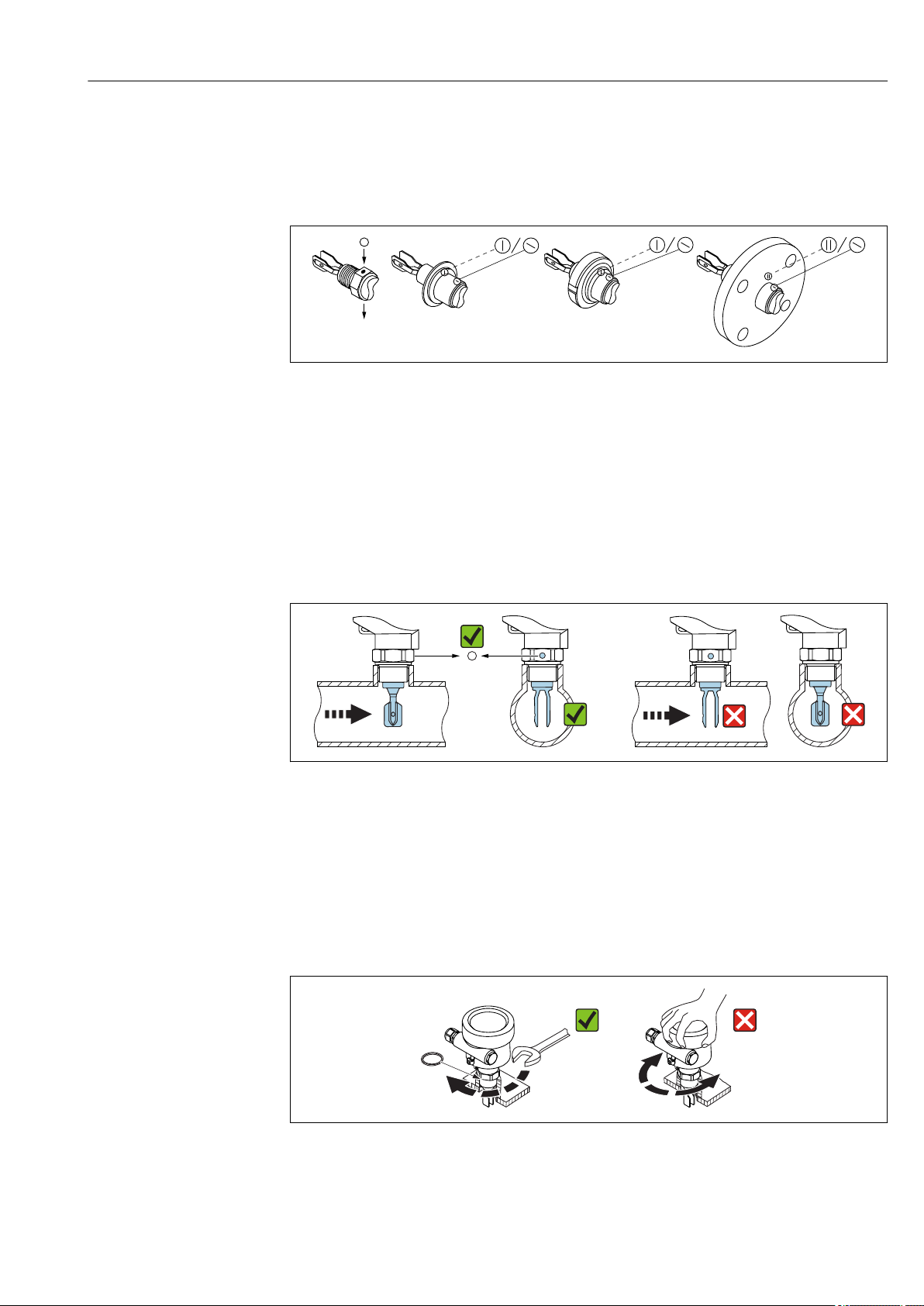

5.1.3 Avoiding buildup

A0033239

10 Installation examples for a highly viscous process medium

• Use short installation sockets to ensure that the turning fork can project freely into the

vessel.

• Install preferably flush-mounted on vessels or in pipes.

• Leave sufficient distance between the buildup expected on the tank wall and the tuning

fork.

5.1.4 Take clearance into consideration

A0033236

11 Take clearance into consideration

Allow sufficient space outside the tank for mounting, connection and settings involving

the electronic insert.

Endress+Hauser 13

Page 14

Installation Liquiphant FTL51B

316L

5.1.5 Support the device

A0031874

12 Support in the event of dynamic load

Support the device in the event of severe dynamic load. Maximum lateral loading capacity

of the pipe extensions and sensors: 75 Nm (55 lbf ft).

5.1.6 Weld-in adapter with leakage hole

A0039230

13 Weld-in adapter with leakage hole

Weld in the welding neck in such a way that the leakage hole is pointing downwards. This

enables any leaks to be detected quickly.

5.2 Mounting the measuring device

5.2.1 Required tools

• Open-ended wrench for sensor installation

• Screwdriver for electrical connection

14 Endress+Hauser

Page 15

Liquiphant FTL51B Installation

316L/G1

5.2.2 Installation

Horizontal installation in vessels

Align the tuning fork with the marking

A0039125

14 Marking to align the tuning fork

Use the marking to align the tuning fork in such a way that medium can run off easily and

deposit buildup is avoided.

The following can be used as the marking:

• Material specification, thread description or circle on the hexagonal nut or on the weldin adapter

• The II symbol on the back of the flange or Tri-Clamp

Installing in pipes

15 Marking and fork position

• Flow velocity up to 5 m/s with viscosity 1 mm2/s (cSt) and density 1 g/cm3 (SGU)

Check for correct functioning in the event of other process medium conditions

• The marking on the adapter points in the flow direction; the flow is thus not severely

obstructed

• The marking can be identified while the device is installed

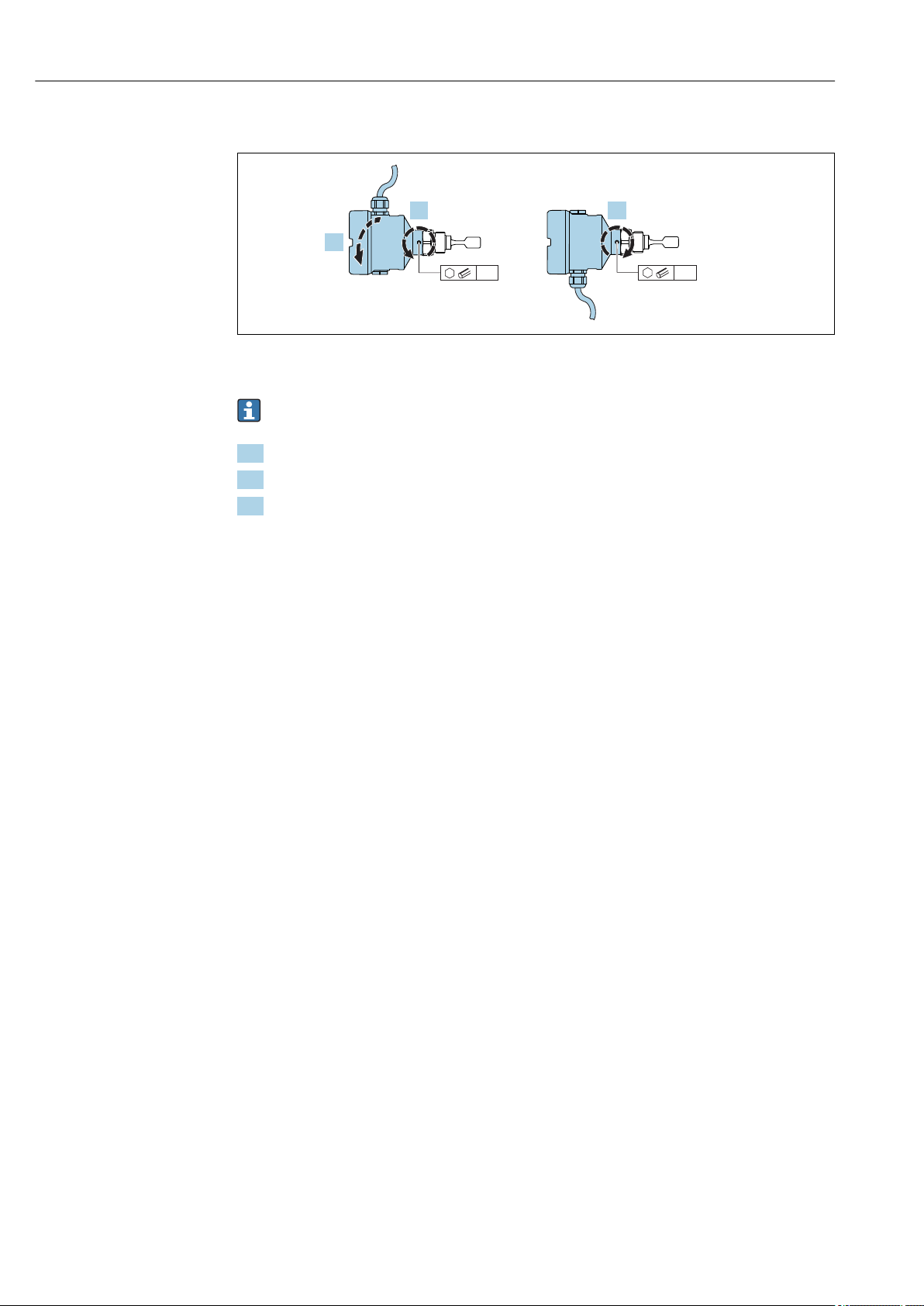

Screwing in the device

A0034851

A0034852

16 Screwing in the device

• Turn by the hex bolt only, 15 to 30 Nm (11 to 22 lbf ft)

• Do not turn at the housing!

Endress+Hauser 15

Page 16

Installation Liquiphant FTL51B

1.

2.

3

0.7 Nm

3

3.

Aligning the cable entry

A0037347

17 Housing with external locking screw

The locking screw is not tightened when the device is delivered.

1. Release the external locking screw.

2. Turn the housing, align the cable entry.

3. Tighten the external locking screw.

5.3 Sliding sleeves

See the "Accessories" section.

5.4 Post-installation check

Is the measuring device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature

• Process pressure

• Ambient temperature range

• Measuring range

Are the measuring point number and labeling correct (visual inspection)?

Is the measuring device adequately protected against precipitation and direct sunlight?

Is the device properly secured?

16 Endress+Hauser

Page 17

Liquiphant FTL51B Electrical connection

6 Electrical connection

6.1 Connection conditions

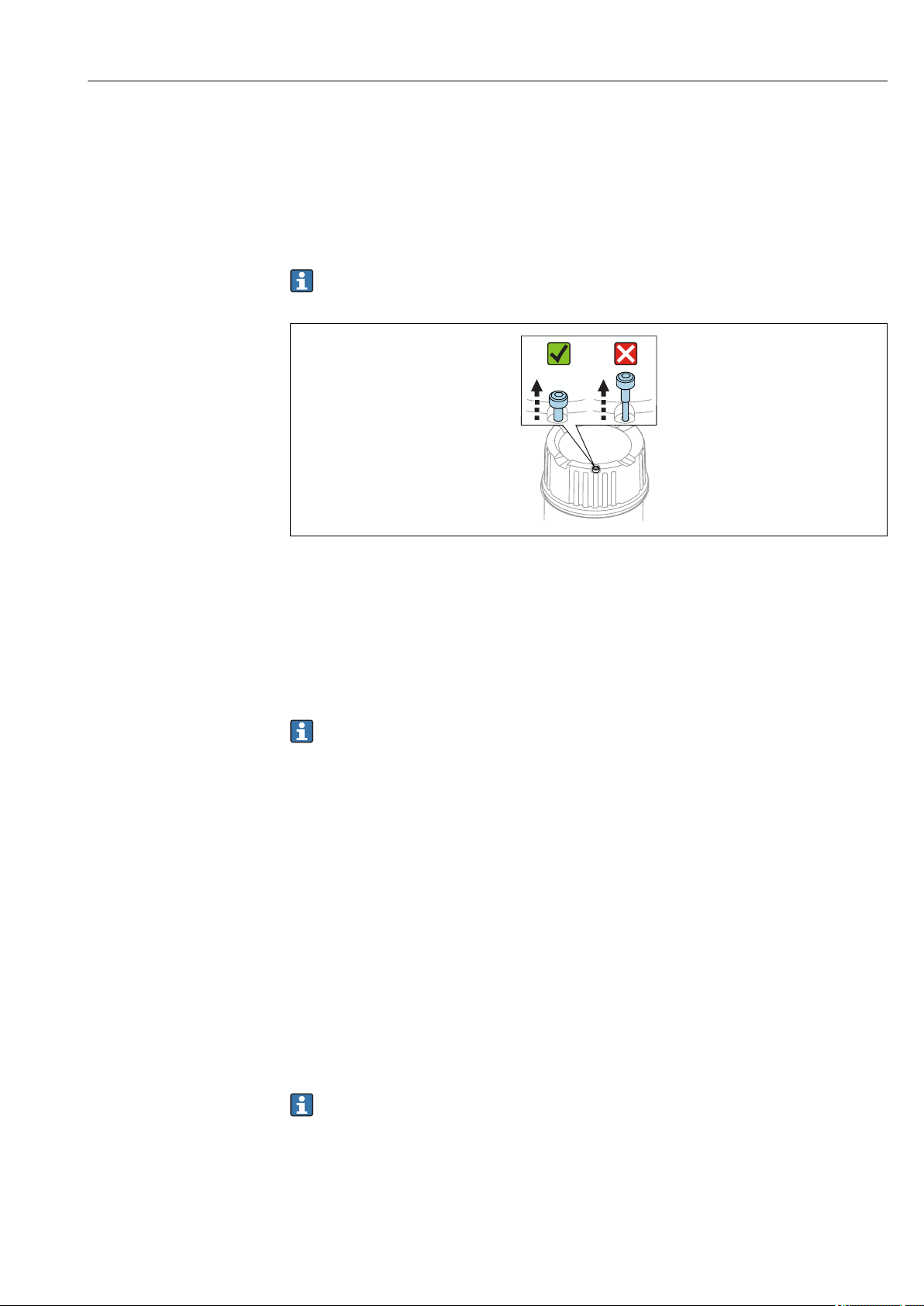

6.1.1 Cover with securing screw

Covers with a securing screw are available for devices for use in hazardous areas. Do

not release the screw fully.

A0039520

18 Cover with securing screw

6.1.2 Connecting protective earth (PE)

The protective earth conductor at the device must only be connected if the device's

operating voltage is ≥ 35 VDC or ≥ 16 VACeff.

When the device is used in hazardous areas, it must always be included in the potential

equalization of the system, irrespective of the operating voltage.

The plastic housing is available with or without an external protective earth

connection (PE).

6.2 Connecting the measuring device

6.2.1 2-wire AC (electronic insert FEL61)

• Two-wire AC version

• Switches the load directly into the power supply circuit via an electronic switch; always

connect in series with a load.

• Functional testing without level change

A functional test can be performed on the device using the test button on the electronic

insert.

Supply voltage

U = 19 to 253 V

Residual voltage when switched through: maximum 12 V

Pay attention to the following as per IEC/EN61010-1: Provide a suitable circuit

breaker for the device, and limit the current to 1 A, e. g. by installing a 1 A fuse (slowblow) in the line (not the neutral wire) of the supply circuit.

Power consumption

P ≤ 2 VA

Endress+Hauser 17

AC

Page 18

Electrical connection Liquiphant FTL51B

!

>0,5

COM

NL1

1

2

MIN

MAX

>0,7

U 19...253 V AC

I max: 350 mA

~

~

1 A

L1 NPE

K

1 2

Current consumption

Residual current when blocked: I ≤ 3.8 mA

The red LED flashes in the event of an overload or short-circuit. Check for an overload or

short-circuit every 5 seconds. The test is deactivated after 60 seconds.

Power output and load current

• Max 89 VA/253 V (350 mA); max 8.4 VA/24 V (350 mA)

• Min 2.5 VA/253 V (10 mA); min ≥ 0.5 VA/24 V (20 mA)

• With overload and short-circuit protection.

Behavior of output signal

• OK status: load on (switched through)

• Demand mode: load off (blocked)

• Alarm: load off (blocked)

Terminal assignment

Always connect an external load. The electronic insert has integrated short-circuit

protection.

A0036060

19 2-wire AC, electronic insert FEL61

18 Endress+Hauser

Page 19

Liquiphant FTL51B Electrical connection

MAX

RD YE GN

MIN

K

K

K

K

K

(N)

(N)

(N)

(N)

(N)

I

L

I

L

<3.8 mA

<3.8 mA

<3.8 mA

2

2

2

2

2

1

1

1

1

1

L1

L1

L1

L1

L1

ΔU

ΔU

Behavior of switch output and signaling

A0031901

20 Behavior of switch output and signaling, electronic insert FEL61

MAXDIP switch for setting MAX safety mode

MIN DIP switch for setting MIN safety mode

RD LED, red, for warning or alarm

YE LED, yellow, switch status

GN LED, green, operational status, device on

ILLoad current switched through

6.2.2 3-wire DC-PNP (electronic insert FEL62)

• Three-wire DC version

• Preferably in conjunction with programmable logic controllers (PLC), DI modules as per

EN 61131-2. Positive signal at switch output of electronics module (PNP)

• Functional testing without level change

A functional test can be performed on the device using the test button on the electronic

insert or using the test magnet with the housing closed.

Supply voltage

WARNING

L

Failure to use the prescribed power unit.

Risk of fatal injury due to electric shock!

The FEL62 may only be powered by devices with safe galvanic isolation, as per

‣

IEC 61010-1.

U =10 to 55 V

Pay attention to the following as per IEC/EN61010-1: Provide a suitable circuit

breaker for the device, and limit the current to 500 mA, e. g. by installing a 0.5 A fuse

(slow-blow) in the line (not the neutral wire) of the supply circuit.

Power consumption

P ≤ 0.5 W

DC

Current consumption

I ≤ 10 mA (without load)

The red LED flashes in the event of an overload or short-circuit.

Endress+Hauser 19

Page 20

Electrical connection Liquiphant FTL51B

!

U = 10...55 V DC

I max: 350 mA

1

3

L-L+

COM

MIN

MAX

>0,7

>0,5

1

3

0.5 A

L+ L-

I 350 mA

max

U 55 V

max

K

K

I

L

PE

4

3

1

2

1

3

4

M12

1 2 3

B

A

L+ L-

K

Load current

I ≤ 350 mA with overload and short-circuit protection

Capacitance load

C ≤ 0.5 µF at 55 V, C ≤ 1.0 µF at 24 V

Residual current

I < 100 µA (with transistor blocked)

Residual voltage

U < 3 V (with transistor switched through)

Behavior of output signal

• OK status: switched through

• Demand mode: blocked

• Alarm: blocked

Terminal assignment

21 3-wire DC-PNP, electronic insert FEL62

A Connection wiring with terminals

B Connection wiring with M12 connector in housing as per EN61131-2 standard

20 Endress+Hauser

A0036061

Page 21

Liquiphant FTL51B Electrical connection

MAX

RD YE GN

MIN

K

K

K

(L–)

(L–)

(L–)

I

L

<100 µA

I

L

3

3

3

1

1

1

L+

L+

L+

ΔU

ΔU

K

(L–)

<100 µA

3

1

L+

(L–)

<100 µA

3

1

L+

K

Behavior of switch output and signaling

A0033508

22 Behavior of switch output and signaling, electronic insert FEL62

MAXDIP switch for setting MAX safety mode

MIN DIP switch for setting MIN safety mode

RD LED, red, for warning or alarm

YE LED, yellow, switch status

GN LED, green, operational status, device on

ILLoad current switched through

6.2.3 Universal current connection with relay output (electronic

insert FEL64)

• Switches the loads via 2 potential-free changeover contacts

• Two galvanically isolated change-over contacts (DPDT), both change-over contacts

switch simultaneously

• Functional testing without level change. A functional test can be performed on the

device using the test button on the electronic insert or using the test magnet with the

housing closed.

WARNING

L

In the event of an error, the electronic insert can exceed the limit temperature for

touchable surfaces, resulting in a risk of burns.

Do not touch the electronics in the event of an error!

‣

Supply voltage

U = 19 to 253 VAC/19 to 55 V

Pay attention to the following as per IEC/EN61010-1: Provide a suitable circuit

breaker for the device, and limit the current to 500 mA, e. g. by installing a 0.5 A fuse

(slow-blow) in the line (not the neutral wire) of the supply circuit.

Power consumption

P < 25 VA,< 1.3 W

DC

Connectable load

Loads switched via 2 potential-free changeover contacts (DPDT)

• IAC ≤ 6 A (Ex de 4 A), U~ ≤ AC 253 V; P~ ≤ 1 500 VA, cos φ = 1, P~ ≤ 750 VA, cos φ > 0.7

• IDC ≤ 6 A (Ex de 4 A) to DC 30 V, I DC ≤ 0.2 A to 125 V

Endress+Hauser 21

Page 22

Electrical connection Liquiphant FTL51B

L1 N

4

3 5

876

U = 19...55 V DC

U 19...253 V AC

~

~

!

0.5 A

1

2 2

L1

L+

NO NONC NCC CNL-PE

1 2 3 64 75 8

MIN

>0,7

MAX

>0,5

COM

According to IEC 61010: the sum of the voltages of the relay outputs and power supply

≤ 300 V

Preferably use electronic insert FEL62 DC PNP for low DC current loads, e. g. connection to

a PLC.

Relay contact material: silver/nickel AgNi 90/10

When connecting a device with high inductance, fit a spark suppressor to protect the relay

contact. Depending on the connected load, a fine-wire fuse protects the relay contact in

the event of a short-circuit.

Both relay contacts switch simultaneously.

Behavior of output signal

• OK status: relay energized

• Demand mode: relay de-energized

• Alarm: relay de-energized

Terminal assignment

23 Universal current connection with relay output, electronic insert FEL64

1 When bridged, the relay output works using NPN logic.

2 Connectable load

22 Endress+Hauser

A0036062

Page 23

Liquiphant FTL51B Electrical connection

3 54

3 54

6 87

6 87

3 54

33554

4

6 87

66887

7

MAX

RD YE GN

MIN

Behavior of switch output and signaling

A0033513

24 Behavior of switch output and signaling, electronic insert FEL64

MAXDIP switch for setting MAX safety mode

MIN DIP switch for setting MIN safety mode

RD LED, red, for alarm

YE LED, yellow, switch status

GN LED, green, operational status, device on

6.2.4 DC connection, relay output (electronic insert FEL64 DC)

• Switches the loads via 2 potential-free changeover contacts

• Two galvanically isolated change-over contacts (DPDT), both change-over contacts

switch simultaneously

• Functional testing without level change. Functional testing of the entire device can be

performed using the test button on the electronic insert or with the test magnet with the

housing closed.

Supply voltage

U = 9 to 20 V

Pay attention to the following as per IEC/EN61010-1: Provide a suitable circuit

breaker for the device, and limit the current to 500 mA, e. g. by installing a 0.5 A fuse

(slow-blow) in the power circuit.

Power consumption

P < 1.0 W

Connectable load

Loads switched via 2 potential-free changeover contacts (DPDT)

• IAC ≤ 6 A (Ex de 4 A), U~ ≤ AC 253 V; P~ ≤ 1 500 VA, cos φ = 1, P~ ≤ 750 VA, cos φ > 0.7

• IDC ≤ 6 A (Ex de 4 A) to DC 30 V, I DC ≤ 0.2 A to 125 V

According to IEC 61010: the sum of the voltages of the relay outputs and power supply

≤ 300 V

Preferably use electronic insert FEL62 DC PNP for low DC current loads, e. g. connection to

a PLC.

Relay contact material: silver/nickel AgNi 90/10

DC

Endress+Hauser 23

Page 24

Electrical connection Liquiphant FTL51B

L1 N

4

3 5

876

U = 9...20 V DC

!

0.5 A

1

2 2

L1

L+

NO NONC NCC CNL-PE

1 2 3 64 75 8

MIN

>0,7

MAX

>0,5

COM

When connecting a device with high inductance, fit a spark suppressor to protect the relay

contact. Depending on the connected load, a fine-wire fuse protects the relay contact in

the event of a short-circuit.

Behavior of output signal

• OK status: relay energized

• Demand mode: relay de-energized

• Alarm: relay de-energized

Terminal assignment

A0037685

25 DC connection with relay output, electronic insert FEL64 DC

1 When bridged, the relay output works using NPN logic.

2 Connectable load

24 Endress+Hauser

Page 25

Liquiphant FTL51B Electrical connection

3 54

3 54

6 87

6 87

3 54

33554

4

6 87

66887

7

MAX

RD YE GN

MIN

Behavior of switch output and signaling

A0033513

26 Behavior of switch output and signaling, electronic insert FEL64 DC

MAXDIP switch for setting MAX safety mode

MIN DIP switch for setting MIN safety mode

RD LED, red, for alarm

YE LED, yellow, switch status

GN LED, green, operational status, device on

6.2.5 PFM output (electronic insert FEL67)

• For connecting to the Nivotester FTL325P and FTL375P switching units from Endress

+Hauser

• PFM signal transmission; pulse frequency modulation, superimposed on the power

supply along the two-wire cabling

• Functional testing without level change:

• A functional test can be performed on the device using the test button on the

electronic insert.

• The functional test can also be prompted by disconnecting the supply voltage or

triggered directly by the Nivotester FTL325P and FTL375P switching unit.

Supply voltage

U = 9.5 to 12.5 V

Pay attention to the following as per IEC/EN61010-1: Provide a suitable circuit

breaker for the device.

Power consumption

P ≤ 150 mW with Nivotester FTL325P or FTL375P

Behavior of output signal

• OK status: MAX mode 150 Hz, MIN mode 50 Hz

• Demand mode: MAX mode 50 Hz, MIN mode 150 Hz

• Alarm: MAX/MIN mode 0 Hz

DC

Endress+Hauser 25

Page 26

Electrical connection Liquiphant FTL51B

>0,5

COM

MIN

MAX

>0,7

– +

1

2

L- L+

!

!

7

33

37

d4

z4

8

34

38

d2

z2

z6 d6

.

-

1 2

Terminal assignment

A0036065

27 PFM output, electronic insert FEL67

7/ 8: Nivotester FTL325P 1 CH, FTL325P 3 CH input 1

33/ 34: Nivotester FTL325P 3 CH input 2

37/ 38: NivotesterFTL325P 3 CH input 3

d4/ d2: Nivotester FTL375P input 1

z4/ z2: Nivotester FTL375P input 2

z6/ d6: Nivotester FTL375P input 3

Connection cable

• Maximum cable resistance: 25 Ω per core

• Maximum cable capacitance: < 100 nF

• Maximum cable length: 1 000 m (3 281 ft)

26 Endress+Hauser

Page 27

Liquiphant FTL51B Electrical connection

MAX

RD YE GN

MIN

1

1

1

1

1

2

2

2

2

2

L+

L+

L+

L+

L+

150 Hz

50 Hz

50 Hz

150 Hz

0 Hz

L-

L-

L-

L-

L-

Behavior of switch output and signaling

A0037696

28 Switching behaviour and signaling, electronic insert FEL67

MAXDIP switch for setting MAX safety mode

MIN DIP switch for setting MIN safety mode

RD LED, red, for alarm

YE LED, yellow, switch status

GN LED, green, operational status, device on

The MAX/MIN switch must be set in accordance with the application. Only then is it

possible to perform the functional test correctly.

6.2.6 2-wire NAMUR > 2.2 mA/< 1.0 mA (electronic insert FEL68)

• For connecting to isolating amplifier as per NAMUR (IEC 60947-5-6), e. g. the

Nivotester FTL325N from Endress+Hauser

• Signal transmission H-L edge 2.2 to 3.8 mA/ 0.4 to 3.8 mA as per IEC 60947-5-6

(NAMUR) on two-wire cable

• Functional testing without level change. A functional test can be performed on the

device using the test button on the electronic insert or using the test magnet with the

housing closed.

The functional test can also be triggered by interrupting the supply voltage or activated

directly from the Nivotester FTL325N.

Supply voltage

U = 8.2 V

Power consumption

NAMUR IEC 60947-5-6

Behavior of output signal

• OK status: output current 2.2 to 3.8 mA

• Demand mode: output current 0.4 to 1.0 mA

• Alarm: output current 0.4 to 1.0 mA

DC

Pay attention to the following as per IEC/EN61010-1: Provide a suitable circuit

breaker for the device.

Endress+Hauser 27

Page 28

Electrical connection Liquiphant FTL51B

>0,5

COM

– +

MIN

MAX

>0,7

IEC 60947-5-6

8,2 V DC NAMUR

1

2

L- L+

.

-

1 2

!

!

MAX

RD YE GN

MIN

1

1

1

1

1

2

2

2

2

2

L+

L+

L+

L+

L+

2.2...3.8 mA

0.4...1.0 mA

2.2...3.8 mA

0.4...1.0 mA

< 1.0 mA

L-

L-

L-

L-

L-

Terminal assignment

A0036066

29 2-wire NAMUR > 2.2 mA/< 1.0 mA, electronic insert FEL68

Behavior of switch output and signaling

30 Behavior of switch output and signaling, electronic insert FEL68

MAXDIP switch for setting MAX safety mode

MIN DIP switch for setting MIN safety mode

RD LED, red, for alarm

YE LED, yellow, switch status

GN LED, green, operational status, device on

A0037694

When using the device with the electronic insert FEL68 (2-wire NAMUR), the

Bluetooth module must be ordered separately, including the required battery.

Product Configurator, order code for "Accessory mounted", option NG "Prepared for

Heartbeat Verification + Monitoring + Bluetooth".

28 Endress+Hauser

Page 29

Liquiphant FTL51B Electrical connection

Contains

FCC ID:

IC:

1.

2.

6.2.7 Bluetooth module VU121 (optional)

A0039257

31 Bluetooth module VU121

• The Bluetooth module can be connected via the COM interface to the following

electronic inserts: FEL61, FEL62, FEL64, FEL64 DC, FEL67, FEL68 (2-wire NAMUR).

• The Bluetooth module with battery is suitable for use in hazardous areas.

• For energy-related reasons, the Bluetooth module requires a special battery when

operated with the 2-wire NAMUR electronics.

When using the device with the electronic insert FEL68 (2-wire NAMUR), the

Bluetooth module must be ordered separately, including the required battery.

Product Configurator, order code for "Accessory mounted", option NG "Prepared for

Heartbeat Verification + Monitoring + Bluetooth".

Batteries

The battery is categorized as dangerous goods when transported by air and may not

be installed in the device when shipped.

Replacement batteries can be purchased from a specialist retailer. Only the following

types of AA 3.6 V lithium batteries made by the manufacturers listed below are

suitable as replacement batteries:

• SAFT LS14500

• TADIRAN SL-360/s

• XENOENERGY XL-060F

Connecting the module

A0039242

32 Connecting the module

Connect the Bluetooth module with the COM interface in the electronic insert.

Endress+Hauser 29

Page 30

Electrical connection Liquiphant FTL51B

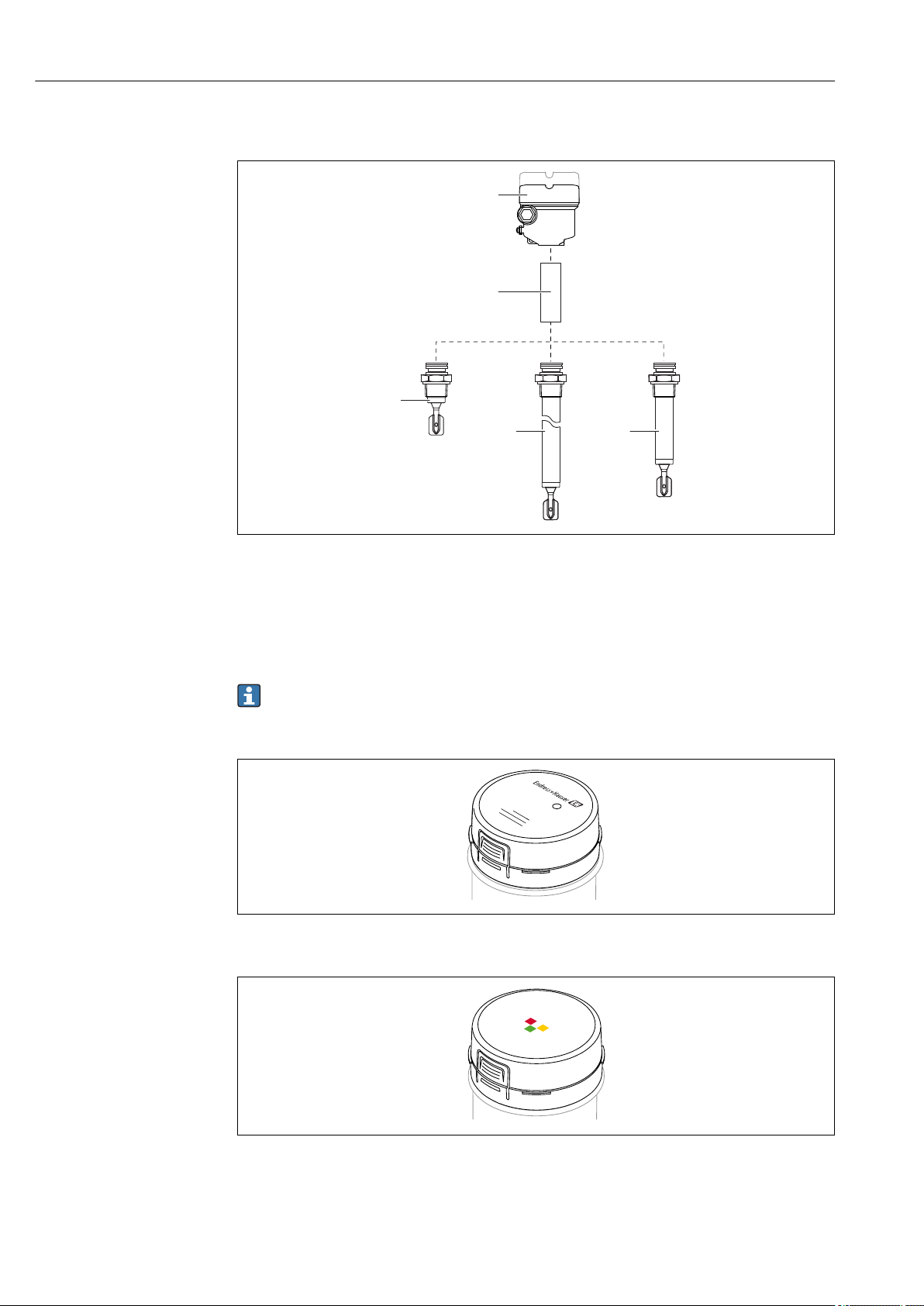

6.2.8 LED module VU120 (optional)

A0039258

33 LED module

The bright LED display indicates the switch status or the alarm condition and can be

connected to the following electronic inserts: FEL62, FEL64, FEL64DC

Supply voltage

U = 12 to 55 VDC, 19 to 253 V

AC

Power consumption

U ≤ 0.7 W, < 6 VA

Current consumption

I

= 0.4 A

max

Connecting the module

34 Connecting the LED module

A0033542

1. Attach the connecting cable of the LED module to the connecting cables of the supply

voltage. Use the wire end ferrules supplied.

2. Connect the wire end ferrules to the terminals of the measuring device.

3. Connect the LED module with the COM interface in the electronic insert.

6.2.9 Cable entry

Required tools

• Flat-blade screwdriver (0.6 x 3.5 mm) for terminals

• Torque spanner (8 Nm) for M20 cable gland

30 Endress+Hauser

Page 31

Liquiphant FTL51B Electrical connection

1

2

3

!

ød

3.5

A0018023

35 Cable entry, electronic insert

1 M20 cable gland

2

Conductor cross-section, 2.5 mm2 maximum (AWG14)

3

Conductor cross-section, 4.0 mm2 maximum (AWG12)

ød Nickel-plated brass 7 to 10.5 mm (0.28 to 0.41 in)

ød Plastic 5 to 10 mm (0.2 to 0.38 in)

ød Stainless steel 7 to 12 mm (0.28 to 0.47 in)

Secure the cable gland and tighten the union nut of the cable gland, 8 Nm (5.9 lbf ft)

torque. Screw the enclosed cable glands into the housing with a torque of

3.75 Nm (2.76 lbf ft).

6.3 Post-connection check

Is the device or cable undamaged (visual inspection)?

Do the cables used comply with the requirements?

Do the mounted cables have adequate strain relief?

Are the cable glands mounted and firmly tightened?

Does the supply voltage match the specifications on the nameplate?

No reverse polarity, is terminal assignment correct?

If supply voltage is present, is the green LED lit?

Are all the housing covers installed and tightened?

Optional: Is the cover with securing screw tightened?

Endress+Hauser 31

Page 32

Operation options Liquiphant FTL51B

>0,5

COM

NL1

1

2

MIN

MAX

>0,7

>0,5

1

2

MIN

MAX

>0,7

7 Operation options

7.1 Overview of operation options

7.1.1 Operating concept

• Operation with button and DIP switches on the electronic insert

• Display with optional Bluetooth module and SmartBlue (app) via Bluetooth® wireless

technology

• Indication of switching status and operational status with optional LED module (lights

visible from the outside)

• For plastic housing and aluminum housing (standard and Ex d) in conjunction with the

DC-PNP and relay electronics

• Ordering information: Product Configurator, order code for "Display; operation" option

"B"

7.1.2 Functional test using the button on the electronic insert

A0037132

36 Position of button for functional test

The functional test must be performed when the device status is OK.

Status OK: MAX safety and sensor free or MIN safety and sensor covered.

• Press the test button for at least 1 second (FEL61/62/64/64DC/67/68 electronic

inserts)

• The output changes to the safety-oriented state - the functional test of the device takes

place

• Test duration at least 10 s or until the button is released if the button is pressed for

> 10 s

• The device returns to normal operation if the internal test is successful

The LEDs flash one after another as a chaser light during the functional test.

If the housing cannot be opened during operation due to explosion protection

requirements, e. g., EX d/XP), the functional test can also be performed from the outside

using the test magnet (FEL62, FEL64 DC, FEL68). The functional test of the PFM

electronics (FEL67) and NAMUR electronics (FEL68) can be started at the Nivotester

FTL325P/N.

Pay attention to the information in the Safety Manual for proof testing safety

equipment in accordance with SIL or WHG (German Water Resources Act).

1. Make sure no undesired switching processes are triggered!

2. Press the button "T" on the electronic insert for at least 1 s (e. g., with a screwdriver).

The output changes from the OK status to demand mode.

32 Endress+Hauser

Page 33

Liquiphant FTL51B Operation options

YE YE

GNRD GN

RD

1.

2.

>1 s

3.

MAX

MIN

K

(N)

<3.8 mA

2

1

L

K

(N)

<3.8 mA

2

1

L

K

(N)

2

1

L

ΔU

I

L

K

(N)

<3.8 mA

2

1

L

K

(N)

<3.8 mA

2

1

L

K

(N)

A

2

1

L

YE YE

GNRD GN

RD

1.

2.

>1 s

3.

MAX

MIN

K

(L-)

<100 µA

3

1

L+

K

(L-)

3

1

L+

ΔU

I

L

K

(L-)

A

3

1

L+

K

(L-)

3

1

L+

<100 µA

K

(L-)

3

1

L+

<100 µA

K

(L-)

3

1

L+

<100 µA

FEL61 switching behavior and signaling

A0039210

37 FEL61 switching behavior and signaling

A After the test button is pressed, the load is switched off for at least 10 seconds (I < 3.8 mA) even if the button

is pressed for < 10 seconds. If the button is pressed for > 10 seconds, the load remains switched off

(I < 3.8 mA) until the test button is released. The load is then switched on again.

FEL62 switching behaviour and signaling

A0039211

38 FEL62 switching behaviour and signaling

A After the test button is pressed, the DC-PNP output is switched off for at least 10 seconds (I < 100 µA) even if

the button is pressed for < 10 seconds. If the button is pressed for > 10 seconds, the DC-PNP output remains

switched off ((I < 100 µA) until the test button is released. The DC-PNP output is then switched on again.

Endress+Hauser 33

Page 34

Operation options Liquiphant FTL51B

1.

2.

>1 s

3.

MAX

MIN

YE

GNRD

YE

GN

RD

3

4

5

678

3

4

5

678

3

4

5

678

3

4

5

678

3

4

5

678

3

4

5

678

A

1.

2.

>1 s

3.

MAX

YE

GNRD

YE

GN

RD

150 Hz

1

2

L+ L-

50 Hz

1

2

L+

L-

50 Hz

1

2

L+

L-

50 Hz

1

2

L+

L-

50 Hz

1

2

L+ L-

A

1

2

L+ L-

FEL64, FEL64DC switching behavior and signaling

A0039212

39 FEL64, FEL64DC switching behavior and signaling

A After the test button is pressed, the relay is de-energized for at least 10 seconds even if the button is pressed

for < 10 seconds. If the test button is pressed for > 10 seconds, the relay remains de-energized until the test

button is released. The relay is then energized again.

FEL67 switching behaviour and signaling

A distinction must be made between MAX and MIN operating modes in the case of

the FEL67 electronic insert!

A0039213

40 FEL67 MAX switching behaviour and signaling

A After the test button is pressed, the output frequency is switched off for at least 10 seconds, 50 Hz, even if the

button is pressed for < 10 seconds. If the button is pressed for > 10 seconds, the output frequency remains at

50 Hz until the test button is released. The output frequency then returns to 150 Hz once again.

34 Endress+Hauser

Page 35

Liquiphant FTL51B Operation options

1.

2.

>1 s

3.

YE

GNRD

YE

GN

RD

50 Hz

1

2

L+ L-

150 Hz

1

2

L+

L-

150 Hz

1

2

L+

L-

150 Hz

1

2

L+

L-

150 Hz

1

2

L+ L-

A

1

2

L+ L-

MIN

YE YE

GNRD GN

RD

1.

2.

>1 s

3.

MAX

MIN

2.2 ... 3.5 mA 0.6 ... 1 mA

0.6 ... 1 mA

0.6 ... 1 mA

A

0.4 … 1 mA

1 1

1 1

1 1

2

2

2

L+

L+

L+

2

2

2

L+

L+

L+

A0039214

41 FEL67 MIN switching behaviour and signaling

A After the test button is pressed, the output frequency is switched off for at least 10 seconds, 150 Hz, even if

the button is pressed for < 10 seconds. If the button is pressed for > 10 seconds, the output frequency remains

at 150 Hz until the test button is released. The output frequency then returns to 50 Hz once again.

The PFM frequency cannot be measured on site. It is therefore recommended to proof

test the functionality at the Nivotester FTL325P/FTL375P.

FEL68 switching behaviour and signaling

A0033543

42 NAMUR electronics switching behaviour and signaling

A After the test button is pressed, the current is 0.6 to 1 mA for at least 10 seconds even if the button is pressed

for < 10 seconds. If the button is pressed for > 10 seconds, the current remains at 0.6 to 1 mA until the test

button is released. The current then returns to 2.2 to 3.5 mA.

7.1.3 Functional test of the electronic switch with a test magnet

Perform functional test of the electronic switch without opening the device

• Hold the test magnet against the marking on the nameplate on the outside

• Simulation is possible in the case of the FEL62, FEL64, FEL64DC, FEL68 electronic

inserts

The functional test with the test magnet acts in the same way as pressing the test button

on the electronic insert.

Endress+Hauser 35

Page 36

Operation options Liquiphant FTL51B

Ser. no.:

Order code:

Ext. ord. cd.:

1

2

A0033419

43 Functional test with test magnet

7.1.4 Heartbeat diagnostics and verification with Bluetooth® wireless technology

Access via Bluetooth® wireless technology

A0033411

44 Remote operation via Bluetooth® wireless technology

1 Smartphone or tablet with SmartBlue (app)

2 Device with optional Bluetooth module

Bluetooth module VU121 (optional)

Functions

• Connection via COM interface: Bluetooth module for device diagnostics via a smartphone

app or tablet app

• Display the battery status via app when used with electronic insert FEL68 (NAMUR)

• User guidance (wizard) for SIL/WHG proof testing

• Visible in the livelist 10 seconds after the Bluetooth search commences

• Data can be read from the Bluetooth module 60 seconds after the supply voltage is

switched on

• Display of the current vibration frequency and the switching state of the device

The yellow LED flashes when the Bluetooth module is connected to another Bluetooth

device, e. g. mobile phone.

Heartbeat Technology

Heartbeat Technology module

Heartbeat Diagnostics

Continuously monitors and evaluates the device status and process conditions. Generates

diagnostic messages when certain events occur and provides troubleshooting measures in

accordance with NAMUR NE 107.

Heartbeat Verification

Performs a verification of the current device status upon request and generates a

Heartbeat Technology verification report showing the result of the verification.

Heartbeat Monitoring

Continuously provides device and/or process data for an external system. Analysis of this

data forms the basis for process optimization and predictive maintenance.

36 Endress+Hauser

Page 37

Liquiphant FTL51B Commissioning

Technical data

• Approval: intrinsically safe Ex ia, IS or ec/ic

• NAMUR electronics (electronic insert FEL68):

For energy-related reasons, the Bluetooth module VU121 requires a special battery

when operated with the 2-wire NAMUR electronics. The service life of the Bluetooth

module without replacing the battery is at least 5 years with a maximum of 60

downloads of complete datasets (at ambient temperatures between

10 to 40 °C (50 to 104 °F)).

• Maximum free-field range 50 m (165 ft)

• Operation radius with intervisibility 10 m (33 ft) around the device

For documentation on radio approvals, see the Endress+Hauser website:

www.endress.com → Downloads.

7.2 LED module VU120 (optional)

The LED module lights up very brightly and can be easily identified from a distance. It can

be connected to the following electronic inserts: FEL62, FEL64, FEL64 DC

Depending on either the MAX/MIN setting, the sensor status can be identified from the

LEDs; displayed in the colors green, yellow and red.

The three colors of the LEDs flash one after another as a chaser light during the functional

test.

7.2.1 Configuration and sensor status

LED shows a green light

• MAX, sensor status: Not covered

• MIN, sensor status: Covered

LED shows a yellow light

• MAX, sensor status: Covered

• MIN, sensor status: Not covered

LED shows a red light

Alarm

LED flashes red

• Warning

• FEL62 overload/short-circuit or no communication

The three colors of the LEDs flash one after another as a chaser light during the functional

test.

8 Commissioning

8.1 Function check

Before commissioning the measuring point, check whether the post-installation and postconnection checks have been performed:

• "Post-installation check" checklist → 16

• "Post-connection check" checklist → 31

Endress+Hauser 37

Page 38

Commissioning Liquiphant FTL51B

ID:

_____________

_________

____________

XXX-XXXXXX

8.2 Switching on the measuring device

During the power-up time, the device output is in the safe state, or in the alarm state if

available.

FEL61, FEL62, FEL64, FEL64DC electronic inserts: The output is in the correct state for a

maximum of 3 seconds after the device is switched on.

NAMUR FEL68 and PFM FEL67 electronic inserts: A functional test is always carried out

when the device is switched on. The output is in the correct state after a maximum of 10

seconds.

8.3 Establishing a connection via SmartBlue (app)

8.3.1 SmartBlue (app)

Requirements

Device requirements

Commissioning via SmartBlue is only possible if a Bluetooth module is installed in the

device.

System requirements

SmartBlue is available as a download from the Google Play Store for Android devices and

from the iTunes Store for iOS devices

• iOS devices: iPhone 4S or higher from iOS9.0; iPad2 or higher from iOS9.0; iPod Touch

5th generation or higher from iOS9.0

• Devices with Android: from Android 4.4 KitKat and Bluetooth® 4.0

Initial password

The ID number (serial number) on the nameplate of the Bluetooth module is used as the

initial password when establishing the connection for the first time.

It is important to note the following if the Bluetooth module is removed from one

device and installed in another device: all log-in data are only stored in the Bluetooth

module and not in the device. This also applies to the password changed by the user.

Preparatory steps

Note down the ID number of the Bluetooth module. The ID number on the nameplate of

the Bluetooth module is used as the initial password when establishing the connection for

the first time.

The high cover with the window must be used for devices that are operated with the

Bluetooth module.

A0039040

38 Endress+Hauser

Page 39

Liquiphant FTL51B Commissioning

Establishing a connection via SmartBlue (app)

1. Scan the QR code or enter "SmartBlue" in the search field.

A0039186

45 Download link

2. Start SmartBlue.

3. Select device from livelist displayed.

4. Log-in:

User name: admin

Password: ID number on the Bluetooth module

5. Tap the icons for more information.

After logging in for the first time, change the password!

Saving PDF reports

The PDF reports generated in the SmartBlue app are not automatically saved and

must therefore be actively saved on the smartphone or tablet.

Endress+Hauser 39

Page 40

Operation Liquiphant FTL51B

9 Operation

9.1 Diagnostics menu

The following data can be read out via the optional Bluetooth module and the associated

Endress+Hauser SmartBlue app.

9.1.1 "Diagnostics" menu

Diagnostics

Actual diagnostics

‣

Actual diagnostics

Timestamp

Event logbook

‣

Diagnostics 1

Timestamp

Diagnostics 2

Timestamp

Diagnostics 3

Timestamp

Diagnostics 4

Timestamp

Diagnostics 5

Timestamp

9.1.2 "Application" menu

Application

Operating mode

‣

MIN/MAX setting

Density setting

40 Endress+Hauser

Page 41

Liquiphant FTL51B Operation

Switching delay uncovered to covered

Switching delay covered to uncovered

Output

‣

Digital Output-Status

9.1.3 "System" menu

System

Electronic type

Bluetooth configuration

‣

BLE HW revision

Information

‣

Device tag

Serial number

Firmware version

Device name

Order code

Manufacturer

Manufacturer ID

ENP version

Operating time

Number of system starts

Time stamp of last proof test

Date of last proof test

Frequency at delivery status

Current frequency

Endress+Hauser 41

Page 42

Diagnostics and troubleshooting Liquiphant FTL51B

Upper alarm frequency

Upper warning frequency

Lower alarm frequency

Battery status

Temperature

Min. electronics temperature

Max. electronics temperature

9.2 Heartbeat Verification

The "Heartbeat Verification" module contains the Heartbeat Verification wizard which

carries out the verification of the current device status and creates the Heartbeat

Technology verification report:

• The wizard can be used via the SmartBlue app.

• The wizard takes the user through the entire process of creating the verification report.

• Displays the operating hours counter and the temperature drag indicator.

• If the vibration frequency of the fork increases, a corrosion warning appears.

• The order configuration of the air's vibration frequency is shown on the verification

report. An increased vibration frequency indicates corrosion. A reduced vibration

frequency signals deposits or that the medium is covering the sensor. Deviations

between the current vibration frequency and the vibration frequency upon delivery can

be caused by the process temperature and process pressure.

9.3 Recurrent testing for SIL/WHG (German Water

Resources Act) devices

The "SIL Prooftest", "WHG Prooftest" and "SIL/WHG Prooftest" modules contain a wizard for

recurrent testing. This is required at appropriate intervals for the following applications:

SIL (IEC61508/IEC61511), WHG (German Water Resources Act):

• The wizard can be used via the SmartBlue app.

• The wizard takes the user through the entire process of creating the verification report.

• The verification report can be saved as a PDF file.

10 Diagnostics and troubleshooting

The device indicates warnings and faults via Bluetooth in the SmartBlue app and via the

LEDs on the electronic insert. All the device warnings and faults are for information

purposes only and do not have a safety function. The faults diagnosed by the device are

displayed in the SmartBlue app in accordance with NE107. Depending on the diagnostic

message, the device behaves as per a warning or fault condition.

The device behaves in accordance with NAMUR Recommendation NE131 "NAMUR

standard device requirements for field devices for standard applications".

1) Only available for devices with SIL or WHG approval

1)

42 Endress+Hauser

Page 43

Liquiphant FTL51B Diagnostics and troubleshooting

If using NAMUR electronics, change or insert the battery in the Bluetooth module.

10.1 Diagnostic information via light emitting diodes

10.1.1 LED at electronic insert

LED green not lit

Possible cause: No power supply

Troubleshooting: Check plug, cable and power supply

LED flashes red

Possible cause: Overload or short-circuit in load circuit

Troubleshooting: Clear the short-circuit

Reduce maximum load current to below 350 mA

LED red continuously lit

Possible cause: Internal sensor error or electronic fault

Troubleshooting: Replace device

10.1.2 SmartBlue

Device is not visible in the live list

Possible cause: No Bluetooth connection available

The device is already connected to another smartphone or tablet

No cable is connected to the Bluetooth module

Troubleshooting:

• Connect the Bluetooth module to the COM interface

• Enable Bluetooth function on smartphone or tablet

• If using NAMUR electronics, change or insert the battery in the Bluetooth module

Device is visible in the live list but cannot be accessed via SmartBlue

• Possible cause on Android end device

Troubleshooting:

• Check whether the location function is enabled for the app

• Check whether the location function for the app was approved the first time

• GPS or positioning function must be activated for certain Android versions in

conjunction with Bluetooth®

• Activate GPS, close the app fully and restart, enable the positioning function for the

app

• Possible cause on Apple end device

Troubleshooting:

• Log in as normal

• Enter the user name: admin

• Enter initial password (serial number of Bluetooth module), paying attention to lower/

upper case

Login via SmartBlue not possible

Possible cause: Device is being put into operation for the first time

Troubleshooting: Enter initial password (ID number of Bluetooth module) and change it,

paying attention to lower/upper case.

No communication with device via SmartBlue

• Possible cause: Incorrect password entered

Troubleshooting: Enter correct password

• Possible cause: Forgotten password

Troubleshooting: Contact Endress+Hauser Service

Endress+Hauser 43

Page 44

Maintenance Liquiphant FTL51B

11 Maintenance

No special maintenance work is required.

11.1 Maintenance tasks

11.1.1 Cleaning

It is not permitted to use the device with abrasive media. Material abrasion on the tuning

fork can result in the device malfunctioning.

• Clean the tuning fork as necessary

• Cleaning is also possible in the installed state, e. g. CIP Cleaning in Place and SIP

Sterilization in Place

44 Endress+Hauser

Page 45

Liquiphant FTL51B Repair

12 Repair

12.1 General information

12.1.1 Repair concept

Endress+Hauser repair concept

• Measuring devices have a modular design

• Customers can carry out repairs

For more information on service and spare parts, please contact your Endress+Hauser

sales representative.

12.1.2 Repair of Ex-certified devices

WARNING

L

Limitation of electrical safety due to incorrect connection!

Risk of explosion!

Only specialist personnel or the Endress+Hauser service team may carry out repairs on

‣

Ex-certified devices.

Relevant standards and national regulations on hazardous areas, safety instructions

‣

and certificates must be observed.

Use only original Endress+Hauser spare parts.

‣

Please note the device designation on the nameplate. Only identical parts may be used

‣

as replacements.

Carry out repairs according to the instructions. On completion of repair work, carry out

‣

the routine test specified for the device.

Only the Endress+Hauser service team is permitted to modify a certified device and

‣

convert it to another certified version.

All repairs and modifications must be documented.

‣

12.2 Spare parts

• Some replaceable measuring device components are identified by means of a spare part

nameplate. This contains information about the spare part.

• All the spare parts for the measuring device along with the order code are listed in the

W@M Device Viewer (www.endress.com/deviceviewer) and can be ordered. If available,

users can also download the associated Installation Instructions.

Measuring device serial number or QR code:

Located on the device and spare part nameplate.

12.3 Return

The measuring device must be returned if the wrong device has been ordered or delivered.

As an ISO-certified company and also due to legal regulations, Endress+Hauser is obliged

to follow certain procedures when handling any returned products that have been in

contact with medium. To ensure safe, swift and professional device returns, please refer to

the procedure and conditions for returning devices provided on the Endress+Hauser

website at http://www.endress.com/support/return-material

Endress+Hauser 45

Page 46

Repair Liquiphant FTL51B

12.4 Disposal

If required by the Directive 2012/19/EU on waste electrical and electronic equipment

(WEEE), our products are marked with the depicted symbol in order to minimize the

disposal of WEEE as unsorted municipal waste. Such products may not be disposed of as

unsorted municipal waste and can be returned to Endress+Hauser for disposal at

conditions stipulated in our General Terms and Conditions or as individually agreed.

46 Endress+Hauser

Page 47

Liquiphant FTL51B Accessories

81 (3.19)

103 (4.06)

102.5 (4.04)

73.5 (2.89)

135 (5.31)

229.4 (9.03)

136.7 (5.38)

Ø

65 (2.56)

140 (5.51) 32 (1.26)

115 (4.53)

122 (4.8)

13 Accessories

13.1 Device-specific accessories

13.1.1 Test magnet

Order number: 71437508

A0039209

46 Test magnet

13.1.2 Weather protection cover for dual-compartment housing,

aluminum

• Material: stainless steel 316L

• Order number: 71438303

47 Weather protection cover for dual-compartment housing, aluminum. Unit of measurement mm (in)

13.1.3 Weather protection cover for single-compartment housing,

metal

• Material: plastic

• Order number: 71438291

A0039231

A0038280

48 Weather protection cover for single-compartment housing, metal. Unit of measurement mm (in)

Endress+Hauser 47

Page 48

Accessories Liquiphant FTL51B

27.5

(1.08)

40³

(1.57)

27.5

(1.08)

40³

(1.57)

13.1.4 Plug-in jack

The plug-in jacks listed are suitable for use in the temperature range

–25 to +70 °C (–13 to +158 °F).

Plug-in jack M12 IP69

• Terminated at one end

• Elbowed 90°

• 5 m (16 ft) PVC cable (orange)

• Slotted nut 316L (1.4435)

• Body: PVC (orange)

• Order number: 52024216

49 Plug-in jack M12 IP69. Unit of measurement mm (in)

Plug-in jack M12 IP67

• Elbowed 90°

• 5 m (16 ft)PVC cable (gray)

• Slotted nut Cu Sn/Ni

• Body: PUR (blue)

• Order number: 52010285

50 Plug-in jack M12 IP67. Unit of measurement mm (in)

13.1.5 Additional modules

A0023713

A0022292

If the Liquiphant is retrofitted with the Bluetooth module or the LED module, it is also

necessary to order a tall housing cover with sight glass. The cover depends on the

housing and approval of the device.

More detailed information is available:

• Product Configurator on the Endress+Hauser webpage: www.endress.com

• Endress+Hauser Sales Center www.addresses.endress.com

48 Endress+Hauser

Page 49

Liquiphant FTL51B Accessories

Contains

FCC ID:

IC:

Bluetooth module VU121 (optional)

A0039257

51 Bluetooth module VU121

The Bluetooth module can be connected to the following electronic inserts via the COM

interface: FEL61, FEL62, FEL64, FEL64DC, FEL67, FEL68 (NAMUR 2-wire).

• Bluetooth module with battery for use in conjunction with NAMUR electronics FEL68

electronic insert

Order number: 71437381

• Bluetooth module without battery for use in conjunction with FEL61, FEL62, FEL64,

FEL64DC and FEL67 electronic inserts

Order number: 71437383

When using the device with the electronic insert FEL68 (2-wire NAMUR), the

Bluetooth module must be ordered separately, including the required battery.

Product Configurator, order code for "Accessory mounted", option NG "Prepared for

Heartbeat Verification + Monitoring + Bluetooth".

LED module VU120 (optional)

52 LED module

The bright LED display indicates the switch status or the alarm condition and can be

connected to the following electronic inserts: FEL62, FEL64, FEL64DC

Order number: 71437382

13.1.6 Sliding sleeves for unpressurized operation

Switch point, infinitely adjustable.

A0039258

Endress+Hauser 49

Page 50

Accessories Liquiphant FTL51B

22 (0.87)

18 (0.71)

G 1 A

(1 NPT)

G 1½ A

(1½ NPT)

M6 (3x)

1

M6 (3x)

19 (0.75)

19 (0.75)

55

55

A0037666

53 Sliding sleeves for unpressurized operation. Unit of measurement mm (in)

1 pe = 0 bar (0 psi)

G 1, DIN ISO 228/I

• Material: 1.4435 (AISI 316L)

• Weight: 0.21 kg (0.46 lb)

• Order number: 52003978

• Order number: 52011888, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 0.21 kg (0.46 lb)

• Order number: 52003979

• Order number: 52011889, approval: with inspection certificate EN 10204 - 3.1 material

G 1½, DIN ISO 228/I

• Material: 1.4435 (AISI 316L)

• Weight: 0.54 kg (1.19 lb)

• Order number: 52003980

• Order number: 52011890, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1½, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 0.54 kg (1.19 lb)

• Order number: 52003981

• Order number: 52011891, approval: with inspection certificate EN 10204 - 3.1 material

13.1.7 High pressure sliding sleeves

• Switch point, infinitely adjustable

• For use in hazardous areas,

• Seal package made of graphite

• For G 1, G 1½: seal included in delivery

50 Endress+Hauser

Page 51

G 1 A

(1 NPT)

G 1½A

(1½ NPT)

ø60 (2.36)

~72 (2.83)

~70 76(2. )

2 (0.08)

2 (0.08)

ø60 (2.36)

18 71(0. )

5050

Liquiphant FTL51B Accessories

54 High pressure sliding sleeves. Unit of measurement mm (in)

G 1, DIN ISO 228/I

• Material: 1.4435 (AISI 316L)

• Weight: 1.13 kg (2.49 lb)

• Order number: 52003663

• Order number: 52011880, approval: with inspection certificate EN 10204 - 3.1 material

G 1, DIN ISO 228/I

• Material: AlloyC22

• Weight: 1.13 kg (2.49 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

• Order number: 71118691

NPT 1, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 1.13 kg (2.49 lb)

• Order number: 52003667

• Order number: 52011881, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1, ASME B 1.20.1

• Material: AlloyC22

• Weight: 1.13 kg (2.49 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

• Order number: 71118694

G 1½, DIN ISO 228/1

• Material: 1.4435 (AISI 316L)

• Weight: 1.32 kg (2.91 lb)

• Order number: 52003665

• Order number: 52011882, approval: with inspection certificate EN 10204 - 3.1 material

G 1½, DIN ISO 228/1

• Material: AlloyC22

• Weight: 1.32 kg (2.91 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

NPT 1½, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 1.32 kg (2.91 lb)

• Order number: 52003669

• Order number: 52011883, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1½, ASME B 1.20.1

• Material: AlloyC22

• Weight: 1.32 kg (2.91 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

• Order number: 71118695

A0037667

Endress+Hauser 51

Page 52

Technical data Liquiphant FTL51B

14 Technical data

14.1 Input

14.1.1 Measured variable

Level (point level), MAX or MIN safety

14.1.2 Measuring range

Depends on the installation location and the pipe extension ordered

Maximum sensor length 6 m (20 ft)

14.2 Output

14.2.1 Output and input variants

Electronic inserts

2-wire AC (FEL61)

• Two-wire AC version

• Switches the load directly into the power supply circuit via an electronic switch.

3-wire DC-PNP (FEL62)

• Three-wire DC version

• Switches the load via the transistor (PNP) and separate connection, e. g. in conjunction

with programmable logical controllers (PLC)

• Ambient temperature –60 °C (–76 °F), optionally available for order

Low-temperature electronic inserts are marked LT.

Universal current connection, relay output (FEL64)

• Switches the loads via 2 potential-free changeover contacts

• Ambient temperature –60 °C (–76 °F), optionally available for order

Low-temperature electronic inserts are marked LT.

Direct current connection, relay output (FEL64DC)

• Switches the load via 2 potential-free changeover contacts

• Ambient temperature –60 °C (–76 °F), optionally available for order

Low-temperature electronic inserts are marked LT.

PFM output (FEL67)

• For separate switching device (Nivotester FTL325P, FTL375P)

• PFM signal transmission; current pulses are superimposed on the power supply along

the two-wire cabling

• Ambient temperature –52 °C (–62 °F), optionally available for order

The low-temperature electronic inserts are marked LT

2-wire NAMUR > 2.2 mA/< 1.0 mA (FEL68)

• For separate switching device, e. g. Nivotester FTL325N

• Signal transmission H-L edge 2.2 to 3.8/0.4 to 1.0 mA as per IEC 60917-5-6 (NAMUR)

on two-wire cable

• Ambient temperature –52 °C (–62 °F), optionally available for order

Low-temperature electronic inserts are marked LT.

2-wire density (FEL60D) for density measurement

Connection to Density Computer FML621

For more information, see the Technical Information for density measuring

technology.

52 Endress+Hauser

Page 53

Liquiphant FTL51B Technical data

14.2.2 Output signal

Switch output

Preset switching times can be ordered. The following ranges can be ordered for point level

switches without communication (AC two-wire, relays, DC-PNP, PFM, NAMUR):

• 0.5 seconds when the fork is covered and 1.0 seconds when it is uncovered (factory

setting)

• 0.25 seconds when the fork is covered and 0.25 seconds when it is uncovered (fastest

setting)

• 1.5 seconds when the fork is covered and 1.5 seconds when it is uncovered

• 5 seconds when the fork is covered and 5 seconds when it is uncovered

COM interface

For connecting to modules VU120 or VU121 (no modifying effect)

Bluetooth® wireless technology (optional)

The device has a Bluetooth® wireless technology interface. Device data and diagnostic data

can be read out using the free "SmartBlue" app.

14.2.3 Ex connection data

See safety instructions (XA): All data relating to explosion protection are provided in

separate Ex documentation and are available from the Downloads Area of the

Endress+Hauser-website. The Ex documentation is supplied as standard with all Ex

devices.

14.3 Environment

14.3.1 Ambient temperature range

–40 to +70 °C (–40 to +158 °F)