Page 1

TI01402F/00/EN/02.19

71440553

2019-06-29

Products Solutions Services

Technical Information

Liquiphant FTL41

Vibronic

Limit switch for liquids

Application

• Limit switch for minimum or maximum detection in tanks, containers and piping

with all types of liquids, even in hazardous areas

• Process temperature range: –40 to +150 °C (–40 to +302 °F)

• Pressures up to 40 bar (580 psi)

• Viscosities up to 10 000 mPa⋅s

• Ideal substitute for float switches, as reliable function is not affected by flow,

turbulence, air bubbles, foam, vibration, solids content or buildup.

Advantages

• No calibration needed: Quick, low-cost commissioning

• Design in accordance with ASME B31.3 and CRN approval

• No mechanically moving parts: No maintenance, no wear, long operating life

• Functional safety: Monitoring of vibration frequency of the tuning fork

• RFID TAG – easy measuring point identification and simplified data access

Page 2

Table of contents

Liquiphant FTL41

About this document ........................ 4

Symbols ................................... 4

Function and system design ................... 5

point level detection ........................... 5

Measuring principle ........................... 5

Measuring system ............................ 5

Input ..................................... 5

Measured variable ............................ 5

Measuring range ............................. 5

Output ................................... 5

Output and input variants ........................ 5

Output signal ................................ 6

Ex connection data ............................ 6

3-wire DC-PNP (electronic insert FEL42) ......... 6

Supply voltage ............................... 6

Power consumption ............................ 6

Current consumption ........................... 6

Load current ................................. 6

Residual current .............................. 6

Residual voltage .............................. 6

Behavior output signal .......................... 6

Terminal assignment ........................... 7

Behavior of the switch output and signaling ............ 7

Mounting ................................ 12

Mounting location, orientation ................... 12

Installation instructions ........................ 12

Taking marking into account ..................... 14

Weld-in adapter with leakage hole ................ 15

Sliding sleeves .............................. 15

Aligning the cable entry ........................ 15

Special mounting instructions .................... 15

Environment .............................. 16

Ambient temperature range ..................... 16

Storage temperature .......................... 16

Humidity .................................. 16

Operating altitude ............................ 16

Climate class ............................... 16

Degree of protection .......................... 16

Vibration resistance .......................... 17

Shock resistance ............................. 17

Mechanical load ............................. 17

Electromagnetic compatibility .................... 17

Process .................................. 17

Process temperature range ...................... 17

Thermal shock .............................. 17

Process pressure range ........................ 17

Test pressure ............................... 18

Density ................................... 18

Pressure tightness ........................... 18

Universal current connection with relay output

(electronic insert FEL44) ..................... 7

Supply voltage ............................... 8

Power consumption ............................ 8

Connectable load .............................. 8

Behavior output signal .......................... 8

Terminal assignment ........................... 8

Behavior of the switch output and signaling ............ 9

2-wire NAMUR > 2.2 mA/< 1.0 mA (electronic

insert FEL48) .............................. 9

Supply voltage ............................... 9

Power consumption ............................ 9

Behavior output signal .......................... 9

Terminal assignment .......................... 10

Behavior of the switch output and signaling ........... 10

Performance characteristics .................. 10

Reference operating conditions ................... 10

Maximum measured error ...................... 11

Hysteresis ................................. 11

Non-repeatability ............................ 11

Influence of the process temperature ............... 11

Influence of the process pressure .................. 11

Influence of the density of the process medium (at room

temperature and normal pressure) ................. 11

Mechanical construction .................... 18

Design, dimensions ........................... 18

Dimensions ................................ 19

Weight ................................... 25

Materials ................................. 25

Surface roughness ........................... 25

Operability ............................... 25

Operation concept ............................ 25

Elements on the electronic insert .................. 26

Terminals ................................. 26

Local operation ............................. 26

Certificates and approvals ................... 27

CE mark .................................. 27

RCM-Tick marking ............................ 27

Ex approval ................................ 27

Overfill protection ............................ 27

Marine approvals ............................ 27

CRN approval ............................... 27

Test reports ................................ 27

Pressure Equipment Directive .................... 28

Process seal as per ANSI/ISA 12.27.01 .............. 28

China RoHS symbol ........................... 28

RoHS ..................................... 28

Additional certification ......................... 28

ASME B 31.3 ............................... 28

2 Endress+Hauser

Page 3

Liquiphant FTL41

Ordering information ....................... 29

TAG ..................................... 29

Accessories ............................... 29

Device-specific accessories ...................... 29

Sliding sleeves for unpressurized operation ........... 30

High pressure sliding sleeves ..................... 31

Supplementary documentation ............... 33

Special documentation ......................... 33

Device-dependent supplementary documentation ....... 33

Endress+Hauser 3

Page 4

About this document

DANGER

WARNING

CAUTION

NOTICE

A

1.

-

.

Symbols Safety symbols

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in serious or

fatal injury.

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious or

fatal injury.

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in minor or

medium injury.

This symbol contains information on procedures and other facts which do not result in personal

injury.

Electrical symbols

Ground connection

Grounded clamp, which is grounded via a grounding system.

Protective earth (PE)

Ground terminals, which must be grounded prior to establishing any other connections. The ground

terminals are located on the inside and outside of the device.

Liquiphant FTL41

Symbols for certain types of information

Permitted

Procedures, processes or actions that are permitted.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information

Reference to documentation

Reference to another section

, 2., 3. Series of steps

Symbols in graphics

A, B, C ... View

1, 2, 3 ... Item numbers

Hazardous area

Safe area (non-hazardous area)

4 Endress+Hauser

Page 5

Liquiphant FTL41

A B

Function and system design

point level detection

Measuring principle

Measuring system

Maximum or minimum detection for liquids in tanks or pipes in all industries. Suitable for leakage

monitoring, dry-running protection, pump protection or overfill protection, for example .

Specific versions are suitable for use in hazardous areas.

The point level switch differentiates between the "covered" and "not covered" conditions.

Depending on the MIN (minimum detection) or MAX (maximum detection) modes, there are two

possibilities in each case: OK status and demand mode

OK status

• In MIN mode, the fork is covered, e. g. pump protection

• In MAX mode, the fork is not covered e. g. overfill protection

Demand mode

• In MIN mode, the fork is not covered e. g. pump protection

• In MAX mode, the fork is covered e. g. overfill protection

The sensor's tuning fork vibrates at its intrinsic frequency. As soon as the liquid covers the tuning

fork, the vibration resistance decreases. The change in frequency causes the point level switch to

switch.

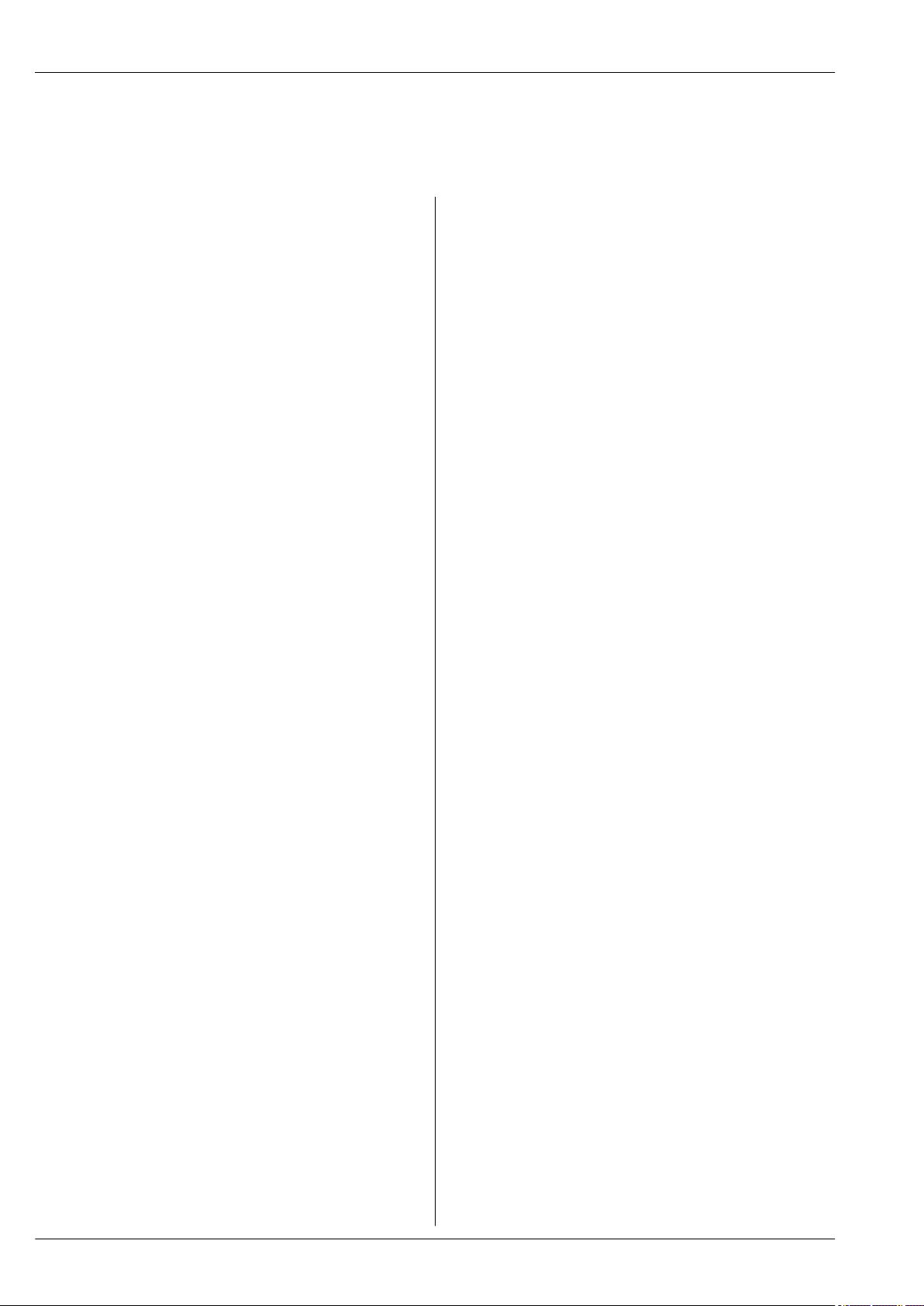

1 Example of a measuring system

A Device for direct connection of a load

B Device for connection to a separate switching unit or PLC

Input

Measured variable

Measuring range

Level (point level), MAX or MIN safety

Depends on the installation location and the pipe extension ordered

Output

Output and input variants Electronic inserts

3-wire DC-PNP (FEL42)

• Three-wire direct current version

• Switches the load via the transistor (PNP) and separate connection, e. g. in conjunction with

programmable logic controllers (PLC)

Universal current connection, relay output (FEL44)

Switches the loads via 2 floating change-over contacts

A0035308

Endress+Hauser 5

Page 6

2-wire NAMUR > 2.2 mA/< 1.0 mA (FEL48)

• For separate switching unit

• Signal transmission H-L edge 2.2 to 3.8/0.4 to 1.0 mA as per EN 60947-5-6 (NAMUR) on twowire cabling

Output signal Switch output

Preset switching times for the limit switches can be ordered for the following areas:

• 0.5 seconds when the tuning fork is covered and 1 second when it is uncovered (factory setting)

• 0.25 seconds when the tuning fork is covered and 0.25 seconds when it is uncovered (fastest

setting)

• 1.5 seconds when the tuning fork is covered and 1.5 seconds when it is uncovered

• 5 seconds when the tuning fork is covered and 5 seconds when it is uncovered

Liquiphant FTL41

Ex connection data

Supply voltage

Power consumption

See safety instructions (XA): All data relating to explosion protection are provided in separate Ex

documentation and are available from the Downloads Area of the Endress+Hauser-website. The Ex

documentation is supplied as standard with all Ex devices.

3-wire DC-PNP (electronic insert FEL42)

• Three-wire direct current version

• Switches the load via the transistor (PNP) and separate connection, e. g. in conjunction with

programmable logic controllers (PLC), DI modules as per EN 61131-2

WARNING

L

Failure to use the prescribed power unit.

Risk of potentially life-threatening electric shock!

The FEL42 may only be powered by power supply units with secure galvanic isolation in

‣

accordance with IEC 61010-1.

U = 10 to 55 V

Observe the following in accordance with IEC/EN61010-1: Provide a suitable circuit breaker for

the device and limit the current to 500 mA, e. g. through the installation of a 0.5 A fuse (slowblow) in the power supply circuit.

P < 0.5 W

DC

Current consumption

Load current

Residual current

Residual voltage

Behavior output signal

I ≤ 10 mA (without load)

The red LED flashes in the event of an overload or short-circuit. Check for an overload or shortcircuit every five seconds.

I ≤ 350 mA

I < 100 µA (for blocked transistor)

U < 3 V (for switched through transistor)

• OK status: switched through

• Demand mode: blocked

• Alarm: blocked

6 Endress+Hauser

Page 7

Liquiphant FTL41

0.5 A

L+ L-

1

3

MIN

MAX

>0,7

L-L+

U = 10...55 V DC

I max: 350 mA

>0,5

1

3

!

K

PE

1 2 3

B

4 3 1

2

1

34

M12

I 350 mA

max

U 55 V

max

K

I

L

A

L+L-

K

MAX

RD YE GN

MIN

K

K

K

(L–)

(L–)

(L–)

I

L

<100 µA

I

L

3

3

3

1

1

1

L+

L+

L+

ΔU

ΔU

K

(L–)

<100 µA

3

1

L+

(L–)

<100 µA

3

1

L+

K

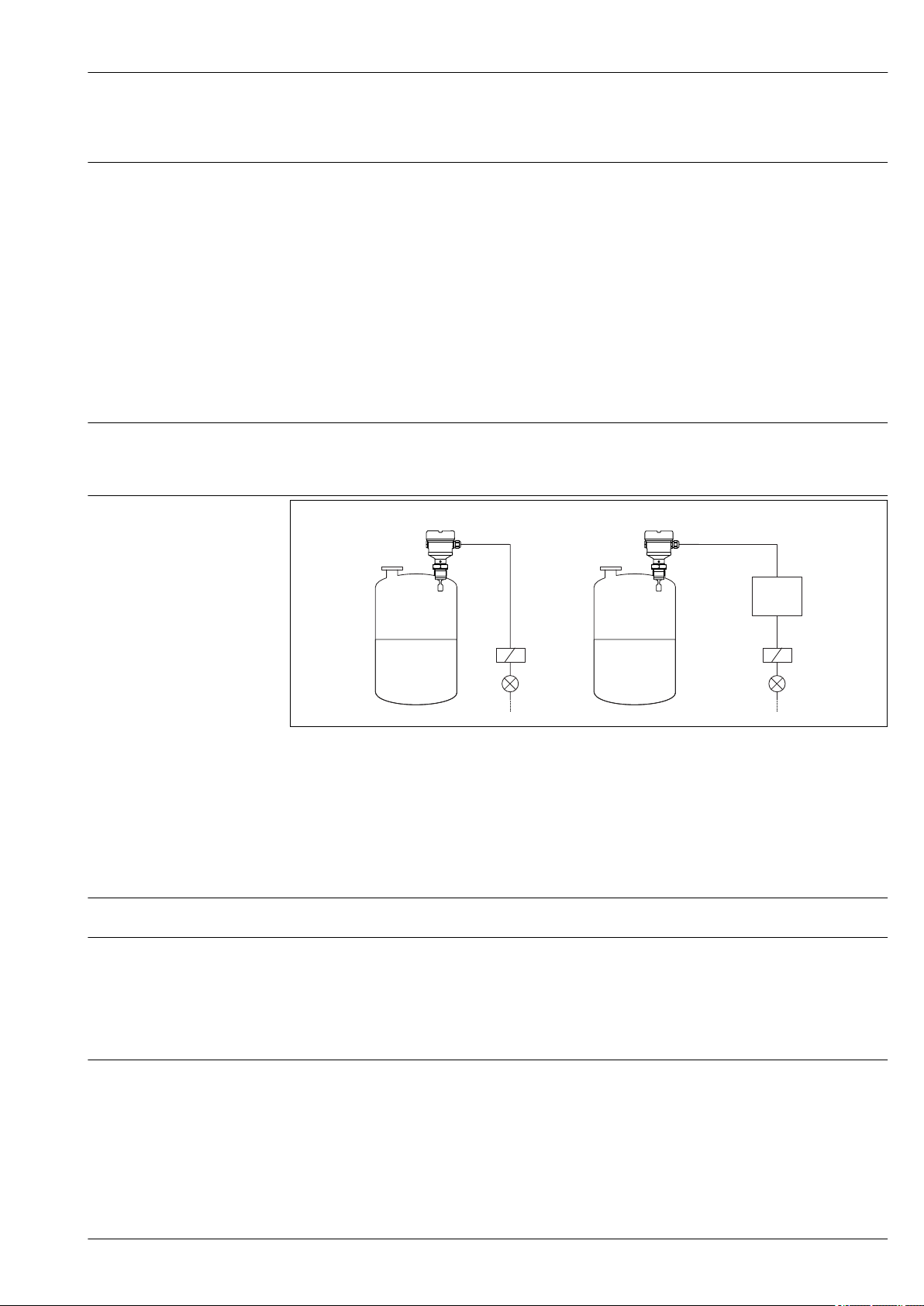

Terminal assignment

A0036056

2 Terminal assignment FEL42

A Terminal assignment at electronic insert

B Terminal assignment on connector M12

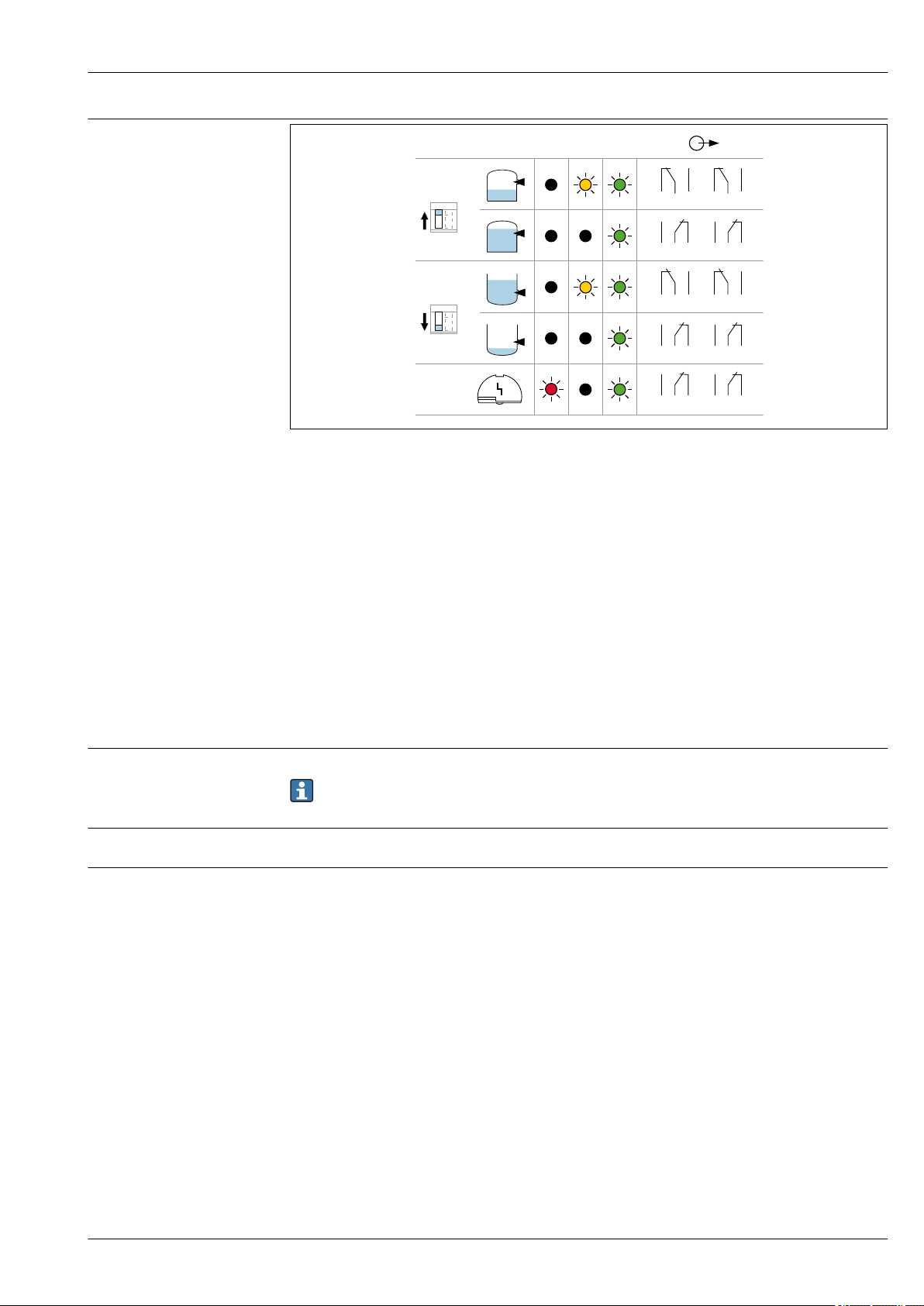

Behavior of the switch output and signaling

A0033508

3 FEL42 switching behavior, signaling LED

MAXDIP switch for setting the MAX safety

MIN DIP switch for setting the MIN safety

RD LED red for warning or alarm

YE LED yellow switch status

GN LED green operational status, device on

ILLoad current switched through

Endress+Hauser 7

Universal current connection with relay output (electronic insert FEL44)

• Switches the loads via 2 floating change-over contacts

• Two separate change-over contacts (DPDT)

Page 8

Liquiphant FTL41

L1

MIN

>0,7

MAX

>0,5

N

4

3 5

876

U = 19...55 V DC

U 19...253 V AC

~

~

!

0.5 A

1

2 2

L1

L+

NO NONC NCC CNL-PE

1 2 3 64 75 8

WARNING

L

In the event of an error, the electronic insert can exceed the limit temperature for touchable

surfaces, posing the risk of burns.

Do not touch the electronics in the event of an error!

‣

Supply voltage

Power consumption

Connectable load

Behavior output signal

U= 19 to 253 VAC / 19 to 55 V

DC

Observe the following in accordance with IEC/EN61010-1: Provide a suitable circuit breaker for

the device and limit the current to 500 mA, e. g. with the installation of a 0.5 A fuse (slowblow) in the phase (not the neutral conductor) of the power supply circuit.

P < 25 VA,< 1.3 W

Loads switched via 2 floating change-over contacts (DPDT)

• IAC ≤ 6 A (Ex de 4 A), U~ ≤ AC 253 V; P~ ≤ 1 500 VA, cos φ = 1, P~ ≤ 750 VA, cos φ > 0.7

• IDC ≤ 6 A (Ex de 4 A) to DC 30 V, IDC ≤ 0.2 A to 125 V

According to IEC 61010, the following applies: Total voltage from relay outputs and power supply

≤ 300 V

Electronic insert FEL42 DC PNP preferred for small DC load currents, e. g. for connection to a PLC.

Relay contact material: silver/nickel AgNi 90/10

When connecting a device with high inductivity, provide spark quenching to protect the relay

contact. A fine-wire fuse (depending on the connected load) protects the relay contact in the event of

a short-circuit.

Both relay contacts switch simultaneously.

• OK state: Relay energized

• Demand mode: Relay de-energized

• Alarm: Relay de-energized

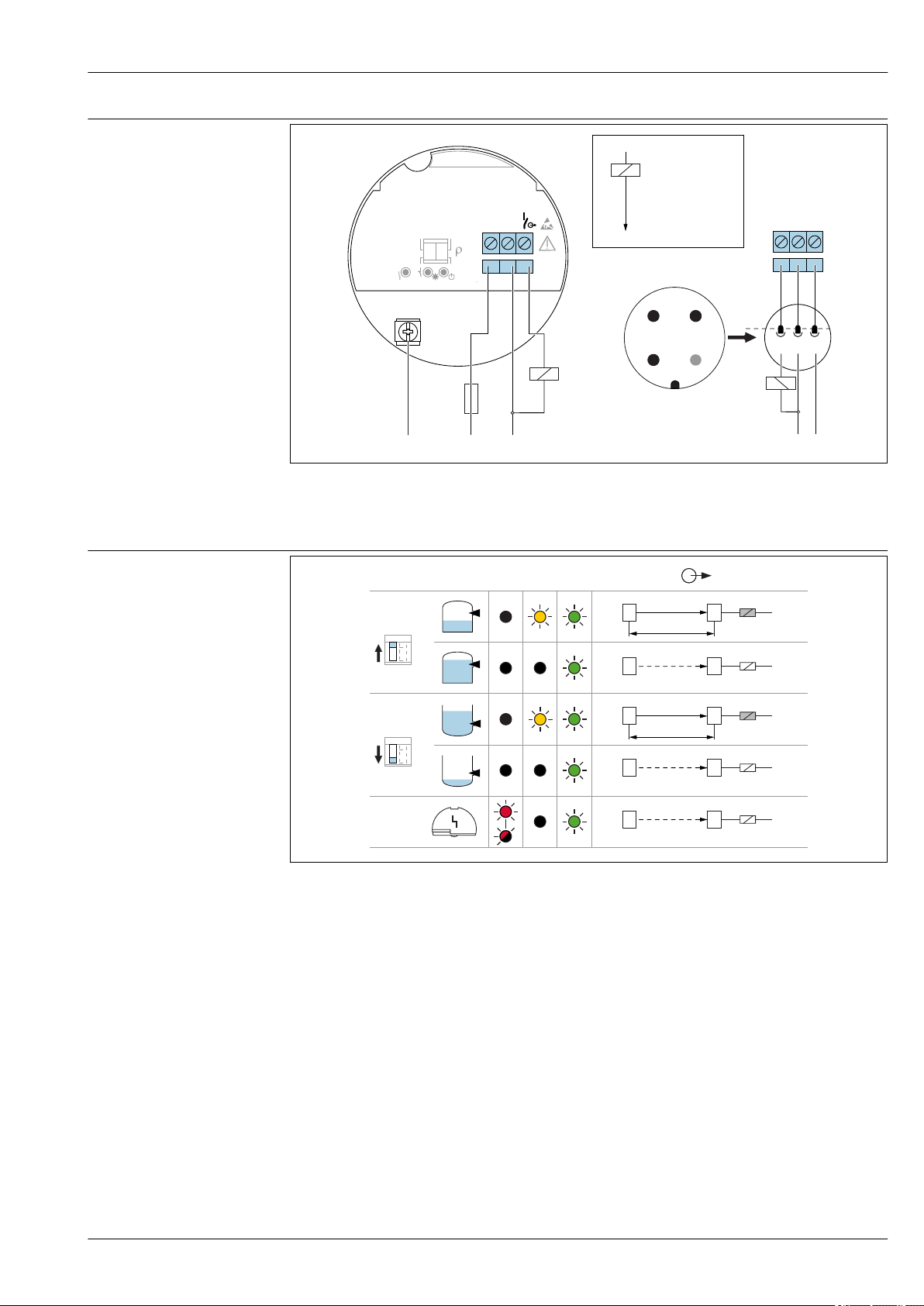

Terminal assignment

A0036057

4 Universal current connection with relay output, electronic insert FEL44

1 When bridged, the relay output works with NPN logic

2 Connectable load

8 Endress+Hauser

Page 9

Liquiphant FTL41

3 54

3 54

6 87

6 87

3 54

33554

4

6 87

66887

7

MAX

RD YE GN

MIN

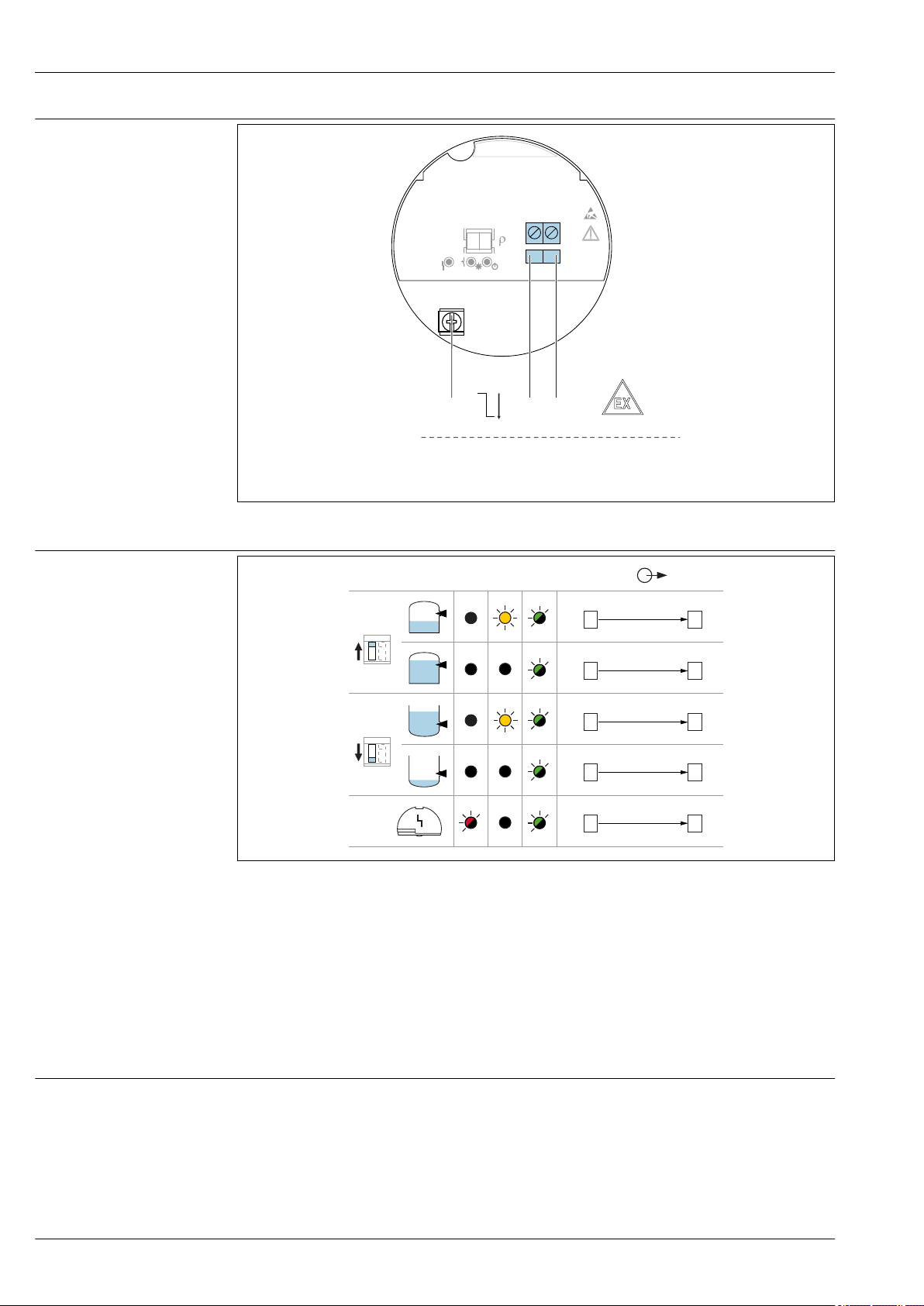

Behavior of the switch output and signaling

A0033513

5 FEL44 switching behavior, signaling LED

MAXDIP switch for setting the MAX safety

MIN DIP switch for setting the MIN safety

RD LED red for alarm

YE LED yellow switch status

GN LED green operational status, device on

Supply voltage

Power consumption

Behavior output signal

2-wire NAMUR > 2.2 mA/< 1.0 mA (electronic insert FEL48)

• For connection to the isolating switch repeater as per NAMUR (IEC 60947-5-6), e. g. Nivotester

FTL325N from Endress+Hauser

• Signal transmission H-L edge 2.2 to 3.8 mA/0.4 to 1.0 mA as per IEC 60947-5-6 (NAMUR) on

two-wire cabling

U = 8.2 V

P < 50 mW

• OK state: Current 2.2 to 3.8 mA

• Demand mode: Current 0.4 to 1.0 mA

• Alarm: Current 0.4 to 1.0 mA

DC

Observe the following in accordance with IEC/EN61010-1: Provide a suitable circuit breaker for

the device.

Endress+Hauser 9

Page 10

Terminal assignment

"

– +

MIN

MAX

>0,7

IEC 60947-5-6

8,2 V DC NAMUR

>0,5

1

2

!

L-

I

H

L

L+

.

-

1 2

MAX

RD YE GN

MIN

1

1

1

1

1

2

2

2

2

2

L+

L+

L+

L+

L+

2.2...3.8 mA

0.4...1.0 mA

2.2...3.8 mA

0.4...1.0 mA

< 1.0 mA

L-

L-

L-

L-

L-

Liquiphant FTL41

A0036058

6 2-wire NAMUR > 2.2 mA/< 1.0 mA, electronic insert FEL48

Behavior of the switch output and signaling

7 FEL48 switching behavior and signaling

MAXDIP switch for setting the MAX safety

MIN DIP switch for setting the MIN safety

RD LED red for alarm

YE LED yellow switch status

GN LED green operational status, device on

Reference operating conditions

Performance characteristics

• Ambient temperature: 23 °C (73 °F)

• Process temperature: 23 °C (73 °F)

• Density (water): 1 g/cm

• Medium viscosity: 1 mPa⋅s

3

• Process pressure: ambient pressure/unpressurized

• Sensor installation: vertically from above

• Density selection switch: > 0.7 g/cm3 (SGU)

• Switch direction of sensor: uncovered to covered

10 Endress+Hauser

A0037694

Page 11

Liquiphant FTL41

~13 (0.5)

~4 (0.16)

~12.5 (0.49)

D

A B C

D

D

0.5

1

1.5

2

-8

-6

-4

-2

0

2

4

6

[in]

[g/cm!]

C

A ( )ρ

B1

A1

-0.3

-0.2

-0.2

-0.1

0

0.2

0.2

[mm]

0.1

B ( )ρ

[ ]ρ

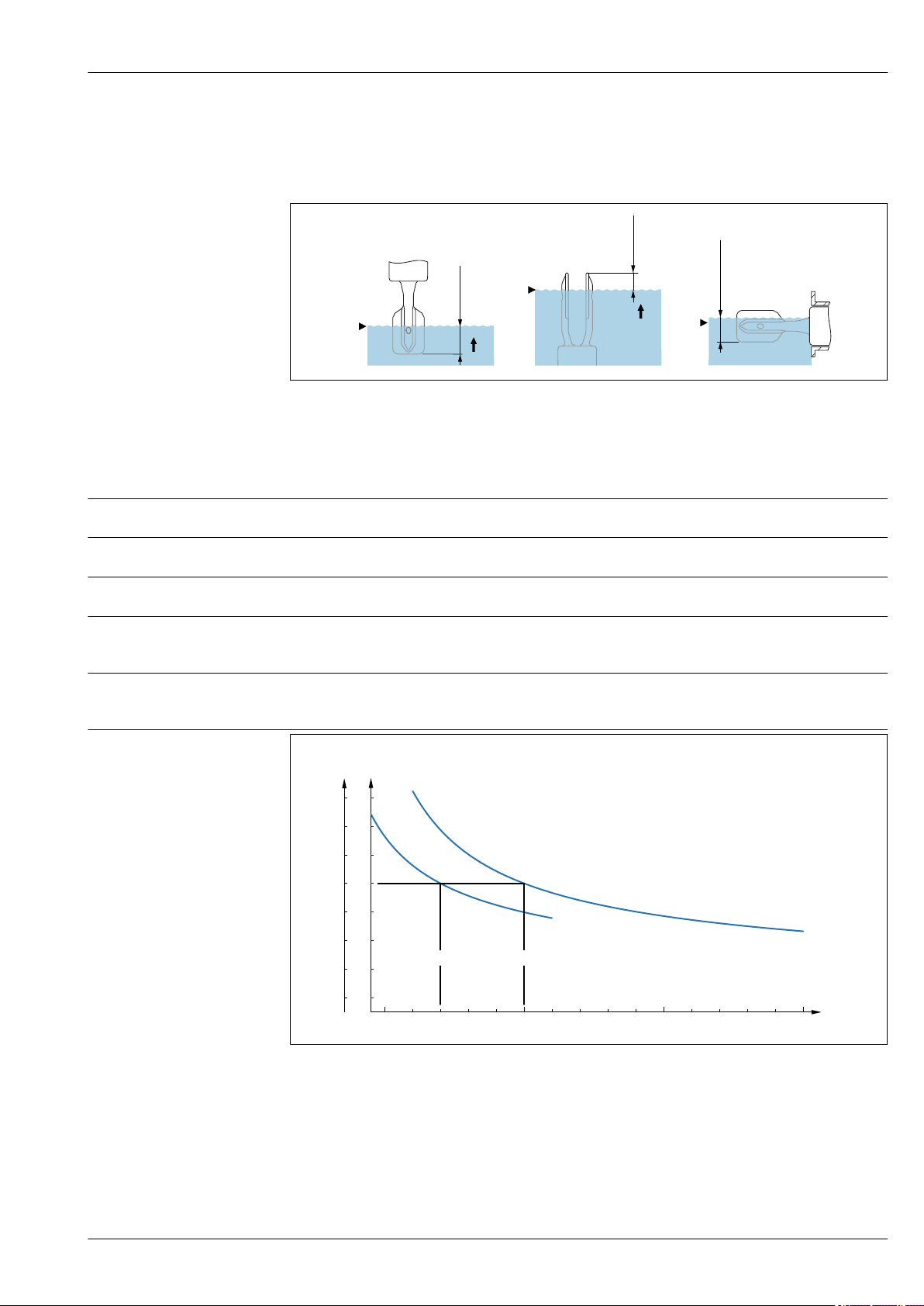

Taking the switch point into consideration

Typical switch points, depending on the orientation of the point level switch

(water +23 °C (+73 °F))

A0037915

8 Typical switch points. Unit of measurement mm (in)

A Installation from above

B Installation from below

C Installation from the side

D Switch point

Maximum measured error

Hysteresis

Non-repeatability

Influence of the process temperature

Influence of the process pressure

Influence of the density of the process medium (at room temperature and normal pressure)

At reference operating conditions: max. ±1 mm (0.04 in)

Typically 2.5 mm (0.1 in)

2 mm (0.08 in)

The switch point moves between +1.4 to –2.6 mm (+0.06 to –0.1 in) in the temperature range from

–50 to +150 °C (–58 to +302 °F)

The switch point moves between 0 to 2.6 mm (0 to 0.1 in) in the pressure range from

–1 to +64 bar (14.5 to 928 psi)

9 Switch point deviation over density

A Density switch setting (ρ) > 0.7

A1

B Density switch setting (ρ) > 0.5

B1

C Switch point deviation

Endress+Hauser 11

reference operating condition ρ = 1 g/cm

Reference operating condition ρ = 0.7 g/cm

3

A0037669

3

Page 12

Mounting location,

> 25 (0.98)

D

orientation

Density setting

• TK

, [mm/10 k]

type

• ρ > 0.7: –0.2

• ρ > 0.5: –0.2

• Pressure

, [mm/10 bar]

type

• ρ > 0.7: –0.3

• ρ > 0.5: –0.4

Mounting

Open the device only in a dry environment!

Liquiphant FTL41

10 Installation in any position in container, pipe or tank

Installation instructions Take viscosity into consideration

Low viscosity

11 Installation example for low-viscosity liquids. Unit of measurement mm (in)

D Diameter of installation socket: at least 50 mm (2.0 in)

Low viscosity, e. g. water: < 2 000 mPa⋅s

It is permitted to position the tuning fork within the installation socket.

A0036954

A0033297

12 Endress+Hauser

Page 13

Liquiphant FTL41

> 40 (1.57)

High viscosity

12 Installation example for a highly viscous liquid. Unit of measurement mm (in)

NOTICE

Highly viscous liquids may cause switching delays.

Make sure that the liquid can run off the tuning fork easily.

‣

Deburr the socket surface.

‣

High viscosity, e. g. viscous oils: < 10 000 mPa⋅s

The tuning fork must be located outside the installation socket!

A0037348

Avoiding buildup

13 Installation examples for a highly viscous process medium

• Use short installation sockets to ensure that the turning fork can project freely into the vessel.

• Install preferably flush-mounted on vessels or in pipes.

• Leave sufficient distance between the buildup expected on the tank wall and the tuning fork.

A0033239

Endress+Hauser 13

Page 14

Liquiphant FTL41

316L/G1

Take clearance into consideration

14 Take clearance into consideration

Allow sufficient space outside the tank for mounting, connection and settings involving the

electronic insert.

A0033236

Taking marking into account Align the tuning fork in accordance with the marking.

15 Markings for aligning the tuning fork

Using the marking, the tuning fork can be aligned in such a way that medium can run off easily and

buildup is avoided.

Markings may include the following:

• material specification, thread description or circle on hexagonal nut or welding neck

• Symbol II on rear of flange or Tri-Clamp

Installing in pipes

A0039125

A0034851

16 Installation in pipes

Flow velocities up to 5 m/s at a viscosity of 1 mPa⋅s and density of 1 g/cm3 (SGU)

Check the function in the event of other process medium conditions.

The flow will not be significantly impeded if the tuning fork is correctly aligned and the marking on

the adapter is pointing in the direction of flow.

The marking is visible when installed.

14 Endress+Hauser

Page 15

Liquiphant FTL41

316L

1.

2.

3

0.7 Nm

3

3.

Weld-in adapter with leakage hole

A0039230

17 Weld-in adapter with leakage hole

Weld in the welding neck in such a way that the leakage hole is pointing downwards. This enables

any leaks to be detected quickly.

Sliding sleeves

Aligning the cable entry

Special mounting instructions

See the "Accessories" section.

A0037347

18 Housing with external locking screw

Support the device

A0031874

19 Support in the event of dynamic load

Support the device in the event of severe dynamic load. Maximum lateral loading capacity of the pipe

extensions and sensors: 75 Nm (55 lbf ft).

Endress+Hauser 15

Page 16

Environment

T

a

T

p

+150

+302

+120

+248

+90

+194

+60

+140

+30

+86

0

32

-30

-22

-60

-76

70158

60140

50122

40104

3086

20

68

1050

032

[°C]

[°C]

[°F]

[°F]

Liquiphant FTL41

Ambient temperature range

–40 to +70 °C (–40 to +158 °F)

In the hazardous area, the permitted ambient temperature can be limited depending on the zones

and gas groups. Pay attention to the information in the Ex documentation (XA).

The minimum permitted ambient temperature of the plastic housing is limited to –20 °C (–4 °F); for

North America, "indoor use" applies.

Storage temperature

Humidity

Operating altitude

Climate class

Degree of protection

A0038718

20 For process temperature and FEL44 Tp > 90° max. load current 4 A

For outdoor operation in strong sunlight:

• Mount the device in the shade

• Avoid direct sunlight, particularly in warmer climatic regions

• Use a protective cover, which can be ordered as an accessory

–40 to +80 °C (–40 to +176 °F)

optional: –52 °C (–62 °F), –60 °C (–76 °F)

Operate up to 100 %. Do not open in a condensing atmosphere.

As per IEC 61010-1 Ed.3:

• Up to 2 000 m (6 600 ft) above sea level

• Can be extended to 3 000 m (9 800 ft) above sea level if overvoltage protection is used

As per IEC 60068-2-38 test Z/AD

For housing with electrical connection

Coupling M20, plastic

• Single-chamber plastic: IP66/67 NEMA Type 4X

• Single-chamber aluminum: IP66/68 NEMA Type 4X/6P

Coupling M20, nickel-plated brass

Single-chamber aluminum: IP66/68 NEMA Type 4X/6P

Coupling M20, 316L

Single-chamber aluminum: IP66/68 NEMA Type 4X/6P

16 Endress+Hauser

Page 17

Liquiphant FTL41

p

e

T

p

+150

+302

0

32

-40

-40

40580

032

[bar]

[°C]

[psi]

[°F]

Thread M20

• Single-chamber plastic: IP66/67 NEMA Type 4X

• Single-chamber aluminum: IP66/68 NEMA Type 4X/6P

Thread G ½

• Single-chamber plastic: IP66/67 NEMA Type 4X

• Single-chamber aluminum: IP66/68 NEMA Type 4X/6P

Thread NPT ½

Single-chamber plastic: IP66/67 NEMA Type 4X

Thread NPT ¾

Single-chamber aluminum: IP66/68 NEMA Type 4X/6P

M12 plug

• Single-chamber plastic: IP66/67 NEMA Type 4X

• Single-chamber aluminum: IP66/67 NEMA Type 4X

Vibration resistance

As per IEC60068-2-64-2009

a(RMS) = 50 m/s², f = 5 to 2 000 Hz , t = 3 axes x 2 h

Shock resistance

As per IEC60068-2-27-2008: 300 m/s² [=30 gn] + 18ms

Mechanical load Lateral loading capacity

Special mounting instructions

Electromagnetic compatibility

• Electromagnetic compatibility as per EN 61326 series and NAMUR recommendation EMC (NE21).

• The requirements of EN 61326-3-1 are fulfilled.

Process

Process temperature range

Thermal shock

Process pressure range

Pay attention to the pressure and temperature dependence (see the "Sensor process pressure range"

section )

–40 to +150 °C (–40 to +302 °F)

≤ 120 K/s

21 Process temperature FTL41

Endress+Hauser 17

A0038719

Page 18

WARNING

L

The maximum pressure for the measuring device is dependent on the lowest-rated element,

with regard to pressure, of the selected components. This means that it is necessary to pay

attention to the process connection as well as the sensor.

For pressure specifications, see the "Mechanical construction" section.

‣

The measuring device must be operated only within the specified limits!

‣

The Pressure Equipment Directive (2014/68/EU) uses the abbreviation "PS". The abbreviation "PS"

‣

corresponds to the MWP (maximum working pressure) of the measuring device.

Approved pressure values of the flanges at higher temperatures, taken from the following standards:

• pR EN 1092-1: 2005 With regard to its stability-temperature property, the material 1.4435 is

identical to 1.4404, which is classed as 13E0 in EN 1092-1 Tab. 18. The chemical composition of

the two materials can be identical.

• ASME B 16.5

• JIS B 2220

In each case, the lowest value from the derating curves of the device and the selected flange applies.

Process pressure range of the sensors

PN: 40 bar (580 psi)

Test pressure Overpressure

PN = 40 bar (580 psi): Test pressure = 1.5 · PN max. 60 bar (870 psi) dependent on the process

connection selected

The device function is limited during the pressure test.

The mechanical integrity is guaranteed at pressures up to 1.5 times the process nominal pressure

PN.

Liquiphant FTL41

Density

Pressure tightness

• Switch position > 0.7 g/cm3 = order configuration

Standard setting for liquids with a density > 0.7 g/cm

• Switch position > 0.5 g/cm3 = can be set via DIP switch

For liquids with a density > 0.5 g/cm3 to < 0.8 g/cm

• Order option: 0.4 g/cm

For liquids with a density > 0.4 g/cm3 to < 0.6 g/cm

If this option has been selected, the density setting is then always set to 0.4 g/cm3. The setting can

no longer be changed.

Up to vacuum

In vacuum evaporation systems, the density of the liquids can drop to a very low value: select

density setting 0.4.

Mechanical construction

For the dimensions, see the Product Configurator: www.endress.com

Search for product → click "Configuration" to the right of the product image → after

configuration click "CAD"

The following dimensions are rounded values. For this reason, they may deviate slightly from

the dimensions given on www.endress.com.

Design, dimensions Device height

The device height is made up of the following components:

• Housing including cover

• Pipe extension, short pipe or compact version

• Process connection

The individual heights of the components can be found in the following sections:

• Calculate device height and add the individual heights of the components

• Take the installation clearance into consideration (space that is required to install the device)

3

3

3

3

18 Endress+Hauser

Page 19

Liquiphant FTL41

C

B

B

B

A

F

D

E

!94 (3.7)

101 (3.98)

!101 (3.98)

103 (4.06)

A0036789

22 Components for calculating the device height

A Housing

B Process connections

C Process connections

D Pipe extension

E Short pipe

F Installation clearance

Dimensions Housing

All housings can be aligned. On metal housings, the alignment of the housing can also be fixed by

means of the locking screw.

23 Single chamber housing, plastic

A0038712

24 Single chamber housing, aluminum, coated

Endress+Hauser 19

A0038713

Page 20

Liquiphant FTL41

!101 (3.98)

118 (4.65)

L

25 Single chamber housing, aluminum, coated, suitable for Ex d/XP zone

Ground terminal

• Ground terminal inside the housing, max. conductor cross-section 2.5 mm2 (14 AWG)

• Ground terminal outside the housing, max. conductor cross-section 4 mm2 (12 AWG)

• Safety extra-low voltage used to supply power to electronic inserts; do not connect protective

ground.

Cable glands

Cable diameter

• Nickel-plated brass: dia. 7 to 10.5 mm (0.28 to 0.41 in)

• Plastic: dia. 5 to 10 mm (0.2 to 0.38 in)

At delivery

• One fitted cable gland

• One cable gland sealed with dummy plug

The relay electronics additionally include a second cable gland (not fitted) with delivery.

Exceptions: For Ex d/XP, only threaded insertions are permitted.

For Japanese Ex d approval, a special cable gland is enclosed.

A0035590

Probe design

Compact

• Material: 316L

• Sensor length L: Dependent on process connection

See section on process connections: Thread G, ASME B1.20.3 MNPT, EN10226 R, tri-clamp

26 Compact, sensor length L

Version: Probe design pipe extension

Material: 316L, sensor lengths L: 117 to 2 000 mm or 4.6 to 78.7 in

A0036848

20 Endress+Hauser

Page 21

Liquiphant FTL41

L

3

L

L

1 2

L

3

L

L

1 2

40 (1.57)

17 (0.67)

17.2 (0.68)

1.5 (0.06)

14 (0.55)

A0036860

27 Pipe extension, sensor length L

1 G ¾, G 1

2 NPT ¾, NPT 1, R ¾, R 1

3 Flange, tri-clamp

Version: Probe design short pipe

Material: 316L, sensor length L: Dependent on process connection

• Flange = 115 mm (4.53 in)

• Thread G ¾ = 115 mm (4.53 in)

• Thread G 1 = 118 mm (4.65 in)

• Thread NPT, R = 99 mm (3.9 in)

• Tri-clamp = 115 mm (4.53 in)

Endress+Hauser 21

A0036861

28 Short pipe, sensor length L

1 G ¾, G 1

2 NPT ¾, NPT 1, R ¾, R 1

3 Flange, tri-clamp

Tuning fork

A0038269

29 Tuning fork. Unit of measurement mm (in)

Page 22

Process connections

50.5 (2.19)

32

66.5 (2.62)

41

80 (3.15)

61.3 (2.41)

50.5 (2.19)

32

66.5 (2.62)

41

69 (2.72)

50.5 (1.99)

32

50.5 (2.19)

71.5 (2.81)

50.5 (2.19)

69 (2.72)

41

Thread ISO228 G for installing in weld-in adapter

G ¾, G 1 suitable for installation in weld-in adapter

• Material: 316L

• Pressure rating, temperature: ≤ 40 bar (580 psi), ≤ 100 °C (212 °F)

• Pressure rating, temperature: ≤ 25 bar (363 psi), ≤ 150 °C (302 °F)

• Weight: 0.2 kg (0.44 lb)

• Accessory: weld-in adapter

The weld-in adapter is not included in the scope of delivery.

Liquiphant FTL41

30 Thread ISO228 G ¾. Unit of

measurement mm (in)

Thread ISO228 G with flat seal

32 Thread ISO228 G ¾. Unit of

measurement mm (in)

Thread ASME B1.20.3, MNPT

A0035549

31 Thread ISO228 G 1. Unit of

measurement mm (in)

A0035549

33 Thread ISO228 G 1. Unit of

measurement mm (in)

A0035551

A0037756

A0038274

34 Thread ASME B1.20.3, MNPT ¾. Unit of

measurement mm (in)

35 Thread ASME B1.20.3, MNPT 1. Unit of

measurement mm (in)

22 Endress+Hauser

A0038275

Page 23

Liquiphant FTL41

32

50.5 (2.19)

66 (2.62)

50.5 (2.19)

69 (2.72)

41

50.5 (1.99)

66.5 (2.62)

64 (2.52)

66.5 (2.62)

66.5 (2.62)

Thread EN10226, R

A0038272

36 Thread EN10226, R ¾. Unit of

measurement mm (in)

37 Thread EN10226, R 1. Unit of

measurement mm (in)

Tri-Clamp

Version ISO2852 DN25-38 (1 to 1-½), DIN32676 DN25-40

• Material: 316L

• Pressure rating: ≤ 25 bar (363 psi)

• Temperature: ≤ 150 °C (302 °F)

• Weight: 0.1 (0.22)

The maximum temperature and the maximum pressure are dependent on the clamping ring

and the seal used. The lowest value applies in each case.

A0035555

38 Tri-Clamp 1 to 1-½. Unit of

measurement mm (in)

39 Tri-Clamp 2. Unit of measurement mm (in)

A0038273

A0037671

Sensor dimensions in the case of flanges

A0035554

40 Example with flange. Unit of measurement mm (in)

ASME B16.5 flanges, RJF

Pressure rating Type Material Weight

kg (lb)

Cl.300 NPS 2" 316/316L 3.2 (7.06)

Cl.300 NPS 4" 316/316L 11.5 (25.6)

Endress+Hauser 23

Page 24

Liquiphant FTL41

EN flanges EN 1092-1, A

Pressure rating Type Material Weight

kg (lb)

PN6 DN32 316L (1.4404) 1.2 (2.65)

PN6 DN40 316L (1.4404) 1.4 (3.09)

PN6 DN50 316L (1.4404) 1.6 (3.53)

PN10/16 DN80 316L (1.4404) 4.8 (10.58)

PN10/16 DN100 316L (1.4404) 5.6 (12.35)

PN25/40 DN25 316L (1.4404) 1.3 (2.87)

PN25/40 DN32 316L (1.4404) 2.0 (4.41)

PN25/40 DN40 316L (1.4404) 2.4 (5.29)

PN25/40 DN50 316L (1.4404) 3.2 (7.06)

PN25/40 DN65 316L (1.4404) 4.3 (9.48)

PN25/40 DN80 316L (1.4404) 5.9 (13.01)

PN25/40 DN100 316L (1.4404) 7.5 (16.54)

PN40 DN50 316L (1.4404) 3.2 (7.06)

EN flanges EN 1092-1, B1

Pressure rating Type Material Weight

kg (lb)

PN6 DN32 316L (1.4404) 1.2 (2.65)

PN6 DN50 316L (1.4404) 1.6 (3.53)

PN10/16 DN100 316L (1.4404) 5.6 (12.35)

PN25/40 DN25 316L (1.4404) 1.4 (3.09)

PN25/40 DN50 316L (1.4404) 3.2 (7.06)

PN25/40 DN80 316L (1.4404) 5.9 (13.01)

JIS flanges B2220

Pressure rating Type Material Weight

kg (lb)

10K 10K 25A 316L (1.4404) 1.3 (2.87)

10K 10K 40A 316L (1.4404) 1.5 (3.31)

10K 10K 50A 316L (1.4404) 1.7 (3.75)

Process connection, sealing surface

• Thread ISO228, G

• Thread ASME, MNPT

• Thread EN10226, R

• Flange ASME B16.5, RF (Raised Face)

• Flange EN1092-1, Form A

• Flange EN1092-1, Form B1

• Flange JIS B2220, RF (Raised Face)

• Flange HG/T20592, RF (Raised Face), pending

• Flange HG/T20615, RF (Raised Face), pending

Other

24 Endress+Hauser

Page 25

Liquiphant FTL41

Weight

Materials Materials in contact with process

See the specific section.

• Process connection: 316L (1.4404 or 1.4435)

• Pipe extension: 316L (1.4404 or 1.4435)

• Flat seal for process connection G ¾ or G 1: Fiber-reinforced elastomer seal, asbestos-free as per

DIN 7603

• Flanges, mechanical construction

• Tuning fork: 316L (1.4435)

Seals

Seal included in delivery:

Metrical threads G ¾, G 1 standard, flat seal as per DIN7603

Seal not included in delivery:

• Tri-Clamp

• Flanges

• R and NPT thread

• Metrical threads G ¾, G 1 for installation in weld-in adapter

Materials not in contact with process

Aluminum housing

• Housing: Alu-EN AC 44300

• Blind cover: Alu-EN AC 44300

• Cover sealing materials: HNBR

• TAG plate: Plastic film, stainless steel or provided by the customer

• Cable glands M20: Select material (stainless steel, nickel-plated brass, polyamide)

Plastic housing

• Housing: PBT/PC

• Blind cover: PBT/PC

• Cover seal: EPDM

• Potential equalization: 316L

• Seal under potential equalization: EPDM

• Plug: PBT-GF30-FR

• M20 cable gland: PA

• Seal on plug and cable gland: EPDM

• Adapter as replacement for cable glands: 316L

• TAG plate: Plastic film, metal or provided by the customer

Surface roughness

The roughness of the surface in contact with the process is Ra < 3.2 µm (126 μin).

Operability

Operation concept

Endress+Hauser 25

Operation with DIP switches on the electronic insert

Page 26

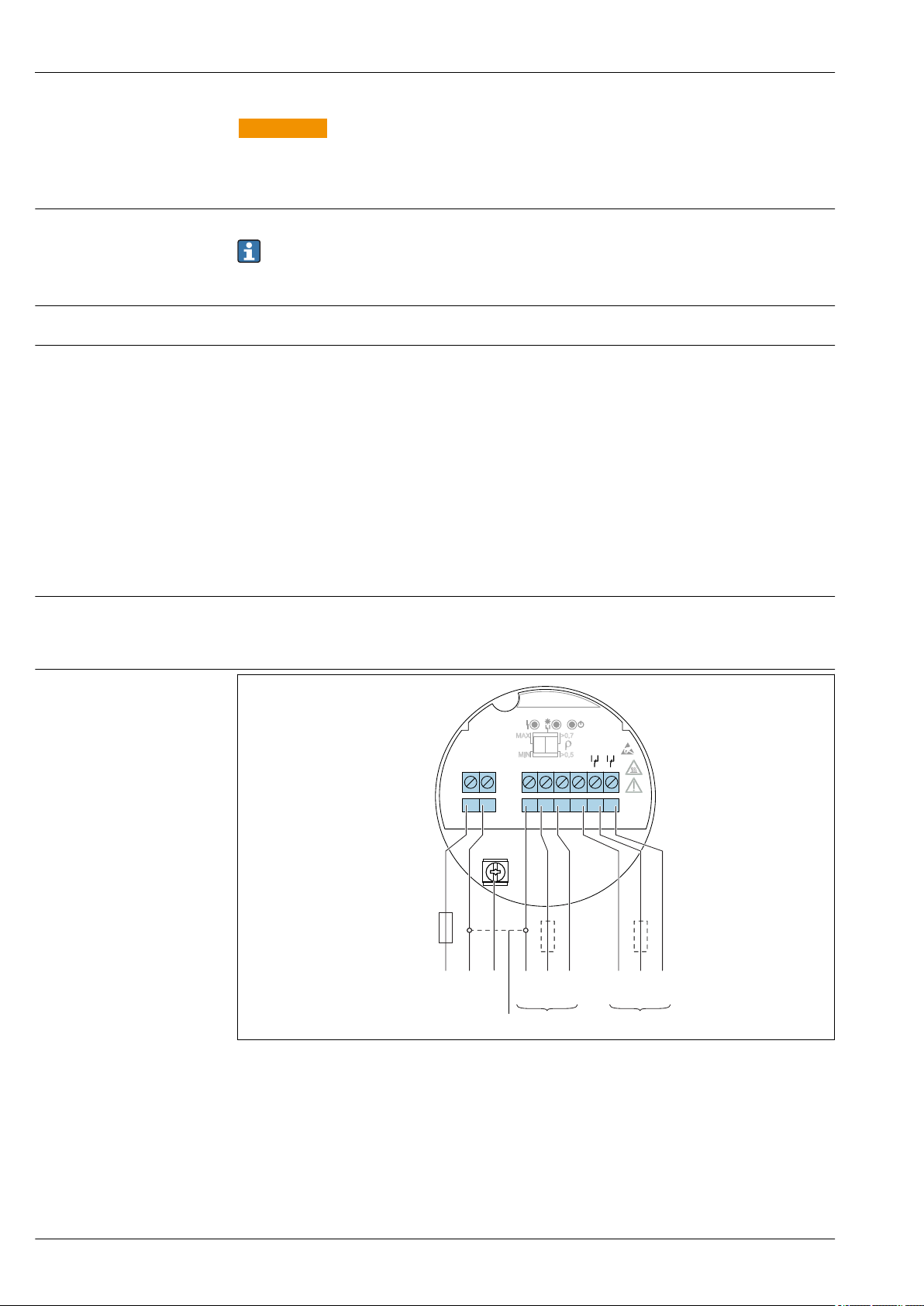

Elements on the electronic

L1

MIN

>0,7

MAX

>0,5

N

4

3 5 876

U = 19...55 V DC

U 19...253 V AC

~

~

1 2 3 64 75 8

1

2

3

4

5

6

7

A B

MAX

MIN

ρ > 0.7

ρ > 0.5

insert

Liquiphant FTL41

A0039317

41 Example electronic insert FEL44

1 LED red, for warning or alarm

2 LED yellow, switch status

3 LED green, operational status (LED green lights up = device on)

4 DIP switch to set the density to 0.7 or 0.5

5 Relay contact terminals

6 Power supply terminals

7 DIP switch for setting MAX/MIN safety

Terminals

Terminals for cable cross-section up to 2.5 mm2 (14 AWG). Use ferrules for the wires.

Local operation Operation at electronic insert

MAX/MIN fail-safe mode

42 Switch position on the electronic insert for fail-safe mode MAX/MIN

A MAX (maximum fail-safe mode)

B MIN (minimum fail-safe mode)

• Minimum/maximum quiescent current safety can be switched at the electronic insert

• MAX = maximum safety: The output switches to demand mode when the tuning fork is covered,

used e. g. for overfill protection

• MIN = minimum safety: The output switches to demand mode when the tuning fork is uncovered,

used e. g. to prevent pumps from running dry

Density switchover

A0033470

43 Switch position on the electronic insert for density

Factory setting density: 0.7

26 Endress+Hauser

A0033471

Page 27

Liquiphant FTL41

CE mark

RCM-Tick marking

• Switch position > 0.7 g/cm3 = order configuration

Standard configuration for liquids with a density > 0.7 g/cm

3

• Switch position > 0.5 g/cm3 = can be adjusted via DIP switch

For liquids with a density > 0.5 g/cm3 to < 0.8 g/cm

• Order option: 0.4 g/cm

3

For liquids with a density > 0.4 g/cm3 to density < 0.6 g/cm

3

3

If the option has been selected, the density setting is then always set to 0.4 g/cm3. The setting can

no longer be changed.

Certificates and approvals

The certificates and approvals currently available can be accessed via the

• Product Configurator

• Endress+Hauser website: www.endress.com → Downloads.

The measuring system complies with the statutory requirements of the applicable EC Directives.

These are listed in the corresponding EC Declaration of Conformity along with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

The supplied product or measuring system meets the ACMA (Australian Communications and Media

Authority) requirements for network integrity, interoperability, performance characteristics as well

as health and safety regulations. Here, especially the regulatory arrangements for electromagnetic

compatibility are met. The products are labelled with the RCM- Tick marking on the name plate.

Ex approval

Overfill protection

Marine approvals

CRN approval

A0029561

All explosion protection data is listed in separate documentation which is available from the

download area. The Ex documentation is supplied as standard with all Ex-systems.

Before mounting the device, observe the documentation from the WHG approvals (German Federal

Water Act).

Approved for overfill protection and leakage detection.

Ordering information: Product Configurator, order code for "Additional approval", option "LD"

• ABS (American Bureau of Shipping), option "LF"

• GL (Germanischer Lloyd)/DNV (Det Norske Veritas), option "LJ"

• LR (Lloyd's Register) marine approval, option "LG"

• BV (Bureau Veritas) marine approval, option "LH"

Ordering information: Product Configurator, order code for "Additional approval", for option see

items listed

Versions with a CRN approval (Canadian Registration Number) are listed in the corresponding

registration documents. CRN-approved devices are marked with a registration number.

Any restrictions regarding the maximum process pressure values are listed on the CRN certificate.

Ordering information: Product Configurator, order code for "Service", option "17"

Test reports Test, report, declaration

The following documentation can be ordered:

Endress+Hauser 27

Page 28

Liquiphant FTL41

• Inspection certificate 3.1, EN10204 (material certificate, wetted parts)

• ASME B31.3 Process Piping, declaration

• Pressure test, internal procedure, test report

• Helium leak test, internal procedure, test report

• Material identification check (PMI), internal procedure (wetted parts), test report

Service

• Cleaned of oil+grease (wetted)

• PWIS-free (paint-wetting impairment substances)

• Switching delay setting to be spec.

• Setting for MIN safety mode

• Default density setting > 0.4 g/cm

• Default density setting > 0.5 g/cm

• Product documentation on paper (test, certificate, declaration available for selection)

3

3

Pressure Equipment Directive

Process seal as per ANSI/ISA

12.27.01

China RoHS symbol

RoHS

Pressure equipment with allowable pressure ≤ 200 bar (2 900 psi)

Pressure instruments with a flange and threaded boss that do not have a pressurized housing do not

fall within the scope of the Pressure Equipment Directive, irrespective of the maximum allowable

pressure.

Reasons:

According to Article 2, point 5 of EU Directive 2014/68/EU, pressure accessories are defined as

"devices with an operational function and having pressure-bearing housings".

If a pressure instrument does not have a pressure-bearing housing (no identifiable pressure chamber

of its own), there is no pressure accessory present within the meaning of the Directive.

North American practice for the installation of process seals. In accordance with ANSI/ISA 12.27.01,

Endress+Hauser devices are designed as either single seal or dual seal devices with a warning

message. This allows the user to waive the use of – and save the cost of installing – an external

secondary process seal in the protective conduit as required in ANSI/NFPA 70 (NEC) and CSA 22.1

(CEC). These devices comply with the North-American installation practice and provide a very safe

and cost-effective installation for pressurized applications with hazardous process media. More

information is provided in the Safety Instructions (XA) for the relevant device.

Aluminum and plastic housings are approved as single-seal devices.

China RoHS 1, law SJ/T 11363-2006: The measuring system complies with the substance

restrictions of the Restriction on Hazardous Substances Directive (RoHS).

The measuring system complies with the substance restrictions of the Restriction on Hazardous

Substances Directive 2011/65/EU (RoHS 2).

Additional certification EAC conformity

The measuring system meets the legal requirements of the applicable EAC guidelines. These are

listed in the corresponding EAC Declaration of Conformity together with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the EAC mark.

ASME B 31.3

Design and materials in accordance with ASME B31.3. The welds are through-penetration welded

and meet the requirements of the ASME Boiler and Pressure Vessel Code, Section IX and EN ISO

15614-1.

28 Endress+Hauser

Page 29

Liquiphant FTL41

140 (5.51) 32 (1.26)

115 (4.53)

122 (4.8)

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com → Click "Corporate"

→ Select your country → Click "Products" → Select the product using the filters and search field →

Open product page → The "Configure" button to the right of the product image opens the Product

Configurator.

• Endress+Hauser sales center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

TAG Measuring point (tag)

The device can be ordered with a tag name.

Position of the tag name

In the additional specification, select:

• Tag plate, stainless steel

• Plastic film

• Supplied plate

Definition of the tag name

In the additional specification, specify:

3 lines, each containing up to maximum 18 characters

The specified tag name appears on the selected label and/or the RFID TAG.

Accessories

Device-specific accessories Weather protection cover for single-compartment housing, metal

• Material: plastic

• Order number: 71438291

44 Weather protection cover for single-compartment housing, metal. Unit of measurement mm (in)

Plug-in jack

The plug-in jacks listed are suitable for use in the temperature range

–25 to +70 °C (–13 to +158 °F).

Plug-in jack M12 IP69

• Terminated at one end

• Elbowed 90°

• 5 m (16 ft) PVC cable (orange)

• Slotted nut 316L (1.4435)

• Body: PVC (orange)

• Order number: 52024216

A0038280

Endress+Hauser 29

Page 30

27.5

(1.08)

40³

(1.57)

45 Plug-in jack M12 IP69. Unit of measurement mm (in)

27.5

(1.08)

40³

(1.57)

22 (0.87)

18 (0.71)

G 1 A

(1 NPT)

G 1½ A

(1½ NPT)

M6 (3x)

1

M6 (3x)

19 (0.75)

19 (0.75)

55

55

Plug-in jack M12 IP67

• Elbowed 90°

• 5 m (16 ft)PVC cable (gray)

• Slotted nut Cu Sn/Ni

• Body: PUR (blue)

• Order number: 52010285

Liquiphant FTL41

A0023713

Sliding sleeves for unpressurized operation

46 Plug-in jack M12 IP67. Unit of measurement mm (in)

Switch point, infinitely adjustable.

47 Sliding sleeves for unpressurized operation. Unit of measurement mm (in)

1 pe = 0 bar (0 psi)

G 1, DIN ISO 228/I

• Material: 1.4435 (AISI 316L)

• Weight: 0.21 kg (0.46 lb)

• Order number: 52003978

• Order number: 52011888, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 0.21 kg (0.46 lb)

• Order number: 52003979

• Order number: 52011889, approval: with inspection certificate EN 10204 - 3.1 material

A0022292

A0037666

30 Endress+Hauser

Page 31

Liquiphant FTL41

G 1 A

(1 NPT)

G 1½A

(1½ NPT)

ø60 (2.36)

~72 (2.83)

~70 76(2. )

2 (0.08)

2 (0.08)

ø60 (2.36)

18 71(0. )

5050

G 1½, DIN ISO 228/I

• Material: 1.4435 (AISI 316L)

• Weight: 0.54 kg (1.19 lb)

• Order number: 52003980

• Order number: 52011890, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1½, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 0.54 kg (1.19 lb)

• Order number: 52003981

• Order number: 52011891, approval: with inspection certificate EN 10204 - 3.1 material

High pressure sliding sleeves

• Switch point, infinitely adjustable

• For use in hazardous areas,

• Seal package made of graphite

• For G 1, G 1½: seal included in delivery

48 High pressure sliding sleeves. Unit of measurement mm (in)

G 1, DIN ISO 228/I

• Material: 1.4435 (AISI 316L)

• Weight: 1.13 kg (2.49 lb)

• Order number: 52003663

• Order number: 52011880, approval: with inspection certificate EN 10204 - 3.1 material

G 1, DIN ISO 228/I

• Material: AlloyC22

• Weight: 1.13 kg (2.49 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

• Order number: 71118691

NPT 1, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 1.13 kg (2.49 lb)

• Order number: 52003667

• Order number: 52011881, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1, ASME B 1.20.1

• Material: AlloyC22

• Weight: 1.13 kg (2.49 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

• Order number: 71118694

G 1½, DIN ISO 228/1

• Material: 1.4435 (AISI 316L)

• Weight: 1.32 kg (2.91 lb)

• Order number: 52003665

• Order number: 52011882, approval: with inspection certificate EN 10204 - 3.1 material

A0037667

Endress+Hauser 31

Page 32

Liquiphant FTL41

G 1½, DIN ISO 228/1

• Material: AlloyC22

• Weight: 1.32 kg (2.91 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

NPT 1½, ASME B 1.20.1

• Material: 1.4435 (AISI 316L)

• Weight: 1.32 kg (2.91 lb)

• Order number: 52003669

• Order number: 52011883, approval: with inspection certificate EN 10204 - 3.1 material

NPT 1½, ASME B 1.20.1

• Material: AlloyC22

• Weight: 1.32 kg (2.91 lb)

• Approval: with inspection certificate EN 10204 - 3.1 material

• Order number: 71118695

32 Endress+Hauser

Page 33

Liquiphant FTL41

Supplementary documentation

The certificates and approvals currently available can be accessed via the

• Product Configurator

• Endress+Hauser website: www.endress.com → Downloads.

Special documentation

Device-dependent supplementary documentation

• TI00426F: Welding neck and flanges (overview)

• SD01622F: Welding neck (assembly manual)

Document type: Operating Instructions (BA)

Installation and initial commissioning ‒ contains all functions in the operating menu that are

required for a typical measuring task. Functions beyond this scope are not included.

BA01893F

Document type: Brief Operating Instructions (KA)

Quick guide to the first measured value ‒ includes all essential information from the incoming

acceptance to the electrical connection.

KA01411F

Document type: Safety Instructions, certificates

Depending on the approval, Safety Instructions are also supplied with the device, e. g. XA. This

documentation is an integral part of the Operating Instructions.

The nameplate indicates the Safety Instructions (XA) that are relevant to the device.

Endress+Hauser 33

Page 34

Page 35

Page 36

*71440553*

71440553

www.addresses.endress.com

Loading...

Loading...