Page 1

TI01147F/00/EN/03.16

71325891

Products Solutions Services

Technical Information

Liquiphant FTL31

Vibronic

Point level switch for liquids

Application

The Liquiphant FTL31 is a point level switch for liquids and is used in tanks, vessels

and pipes.

It is used for overfill prevention or pump protection in cleaning and filter systems as

well as in cooling and lubrication vessels, for instance.

Ideal for applications in which float switches or conductive, capacitance and optical

sensors have been used up to now. The Liquiphant FTL31 also works in areas where

these measuring principles are not suitable due to conductivity, buildup, turbulence,

flow conditions or air bubbles.

The Liquiphant FTL31 can be used for process temperatures up to:

• 100 °C (212 °F)

• 150 °C (302 °F)

Not suitable for hazardous areas.

The use of the Liquiphant FTL33 is recommended for hygiene areas.

Your benefits

• Operational safety, reliability and universal application thanks to the tuning fork

measuring principle

• Robust stainless steel housing (316L)

• External function test with test magnet

• Onsite function check possible thanks to LED indication

• Compact design for easy installation even in confined conditions or hard-to-access

areas

Page 2

Table of contents

Liquiphant FTL31

Document information ....................... 3

Document conventions .......................... 3

Function and system design ................... 4

Measuring principle ............................ 4

Measuring system ............................. 4

Input ..................................... 5

Measured variable ............................. 5

Measuring range .............................. 5

Output ................................... 5

Switch output ................................ 5

Operating modes .............................. 5

Power supply .............................. 5

Supply voltage ............................... 5

Power consumption ............................ 5

Current consumption ........................... 5

Residual ripple ............................... 5

Electrical connection ........................... 5

Cable entry ................................. 9

Cable specification ............................ 10

Overvoltage protection ......................... 10

Performance characteristics .................. 11

Reference operating conditions ................... 11

Switch point ................................ 11

Hysteresis ................................. 11

Non-repeatability ............................ 11

Influence of ambient temperature ................. 11

Influence of medium temperature .................. 11

Influence of medium pressure .................... 11

Switching delay .............................. 11

Switch-on delay ............................. 11

Measuring frequency .......................... 11

Measured error .............................. 11

Process .................................. 17

Process temperature range ...................... 17

Process pressure range ......................... 17

Density ................................... 17

State of aggregation ........................... 17

Viscosity .................................. 17

Solids contents .............................. 17

Lateral loading capacity ........................ 17

Mechanical construction .................... 18

Design .................................... 18

Connector ................................. 19

Tuning fork ................................ 19

Sensor type ................................ 20

Weight ................................... 23

Materials .................................. 23

Surface roughness ............................ 24

Operability ............................... 25

LED display ................................ 25

Function test with test magnet .................... 25

Certificates and approvals ................... 26

CE mark ................................... 26

EAC conformity .............................. 26

RCM-Tick marking ............................ 26

Approval .................................. 26

Overfill prevention ............................ 26

Marine approvals ............................ 26

CRN approval ............................... 26

Inspection certificates .......................... 26

Manufacturer declarations ...................... 26

Pressure Equipment Directive .................... 26

Other standards and guidelines ................... 26

Ordering information ...................... 27

Ordering information .......................... 27

Services (optional) ............................ 27

Installation ............................... 12

Orientation ................................ 12

Installation instructions ........................ 12

Length of connecting cable ...................... 14

Environment .............................. 15

Ambient temperature range ..................... 15

Storage temperature .......................... 15

Climate class ............................... 15

Altitude ................................... 15

Degree of protection .......................... 16

Shock resistance ............................. 16

Vibration resistance ........................... 16

Electromagnetic compatibility .................... 16

Reverse polarity protection ...................... 16

Short-circuit protection ........................ 16

Accessories ............................... 27

Weld-in adapter ............................. 27

Plug-in jack, cable ............................ 27

Additional accessories ......................... 28

Supplementary documentation ............... 29

Operating Instructions ......................... 29

Additional documentation ...................... 29

Certificates ................................. 29

2 Endress+Hauser

Page 3

Liquiphant FTL31

DANGER

WARNING

CAUTION

NOTICE

Document information

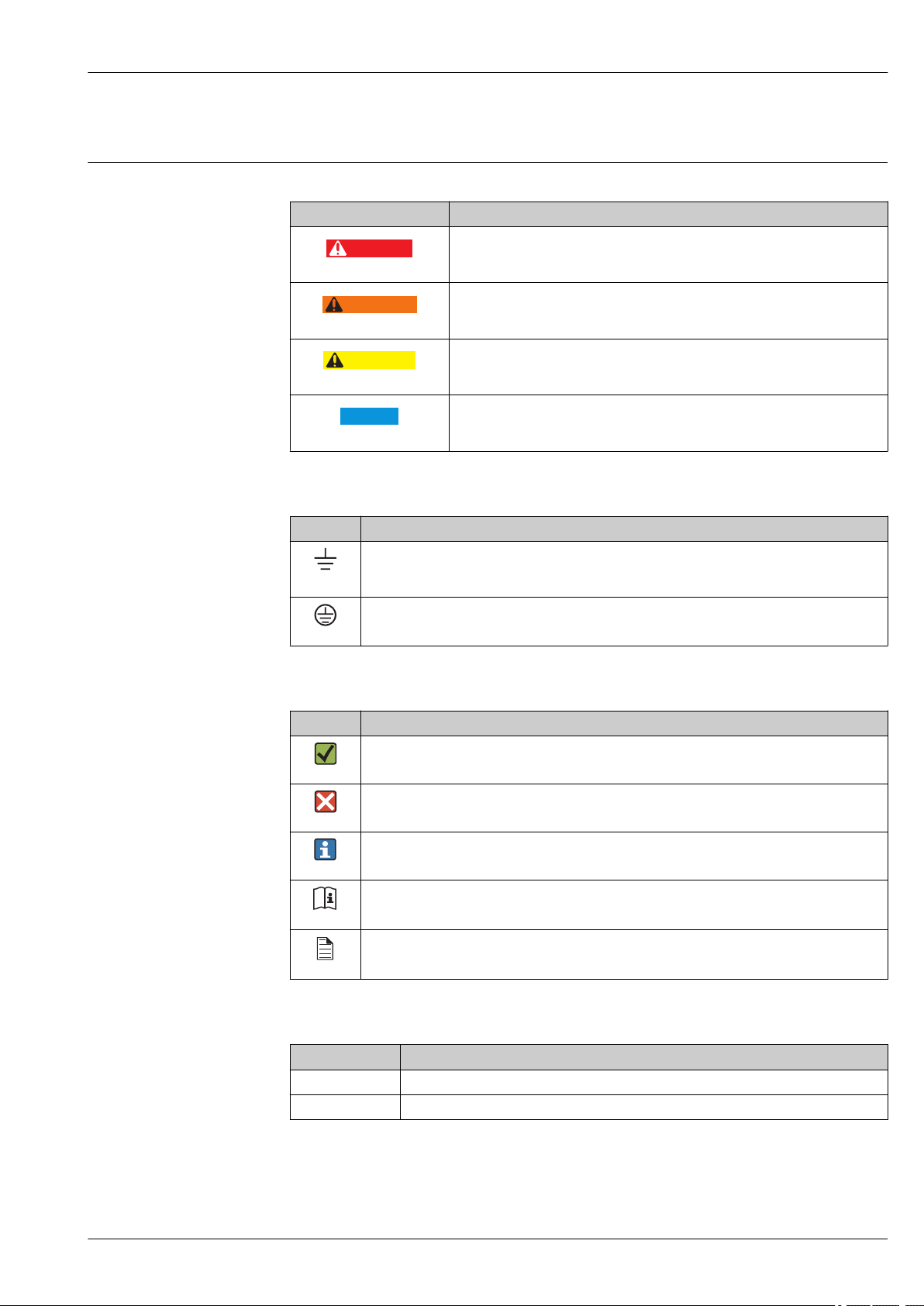

Document conventions Safety symbols

Symbol Meaning

Electrical symbols

A0011189-EN

A0011190-EN

A0011191-EN

A0011192-EN

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

will result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not

result in personal injury.

Symbol Meaning

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

A0011200

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

A, B, C, ... Views

Endress+Hauser 3

Page 4

Function and system design

2

1

3

Liquiphant FTL31

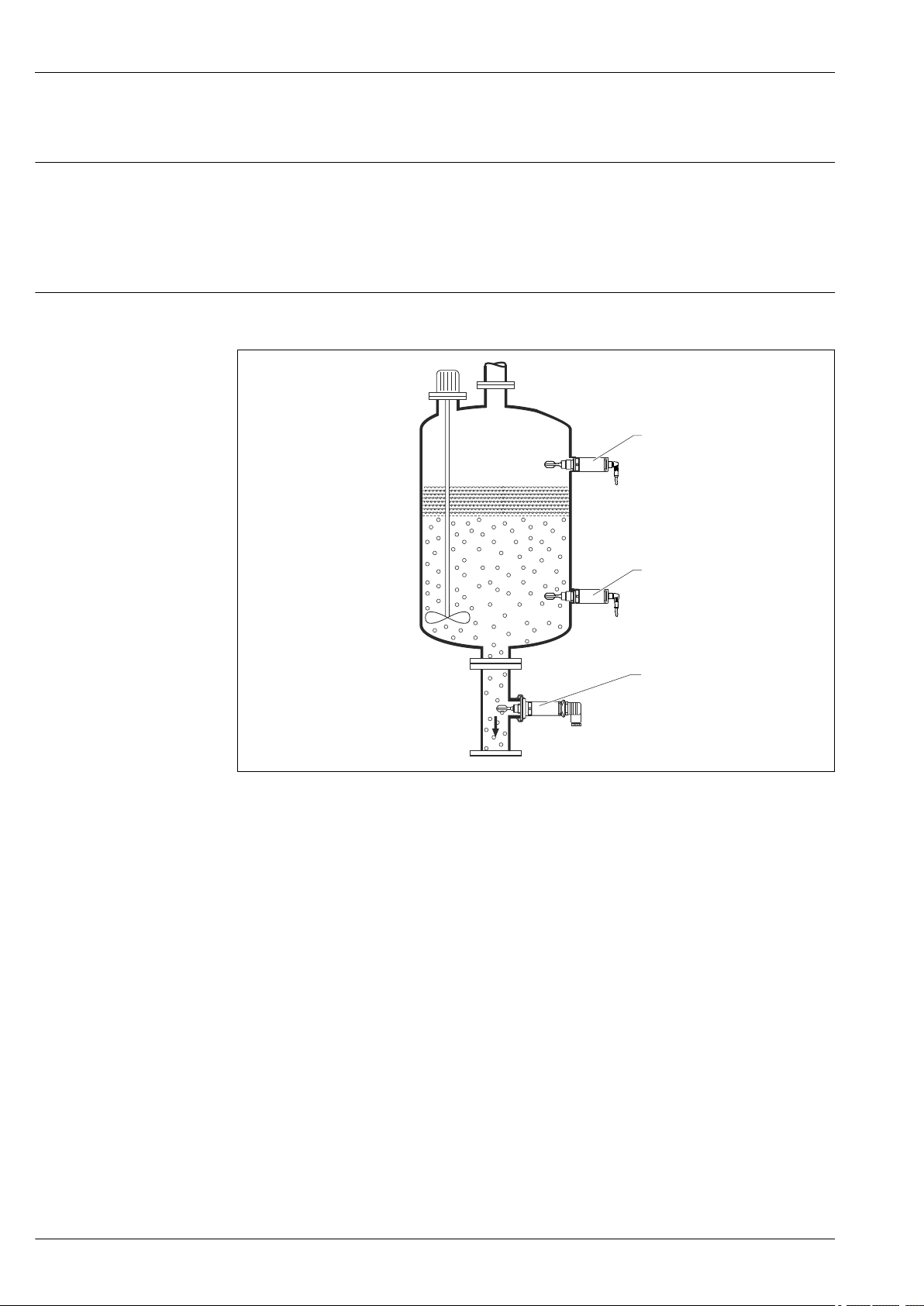

Measuring principle

Measuring system

A piezoelectric drive causes the tuning fork of the Liquiphant FTL31 to vibrate at its resonance

frequency. When the tuning fork is immersed in a liquid, its intrinsic frequency changes due to the

change in density of the surrounding medium. The electronics system in the point level switch

monitors the resonance frequency and indicates whether the tuning fork is vibrating in air or is

covered by liquid.

A signal is output via the DC-PNP or AC/DC electrical connection.

The measuring system consists of a Liquiphant FTL31 point level switch, e.g. for connection to

programmable logic controllers (PLC), a mini-contactor or solenoid valve.

1 Overfill prevention or upper level detection MAX (maximum safety)

2 Lower level detection MIN (minimum safety)

3 Lower level detection MIN, e.g. dry running protection for pump

A0020911

4 Endress+Hauser

Page 5

Liquiphant FTL31

Input

Measured variable

Measuring range

Switch output

Operating modes

Density

> 0.7 g/cm³ (optionally available: > 0.5 g/cm³)

Output

Switching behavior: On/Off

Function

3-wire DC-PNP:

Positive voltage signal at the switch output of the electronics (PNP), switching capacity 200 mA

2-wire AC/DC:

Load switching in the power supply line, switching capacity 250 mA

The device has two operating modes: maximum safety (MAX) and minimum safety (MIN).

By choosing the corresponding operating mode, the user ensures that the device also switches in a

safety-oriented manner even in an alarm condition, e.g. if the power supply line is disconnected.

• Maximum safety (MAX)

The device keeps the electronic switch closed as long as the liquid level is below the fork. Sample

application: overfill prevention

• Minimum safety (MIN)

The device keeps the electronic switch closed as long as the fork is immersed in liquid. Sample

application: Dry running protection for pumps

The electronic switch opens if the limit is reached, if a fault occurs or the power fails (quiescent

current principle).

Supply voltage

Power consumption

Current consumption

Residual ripple

Electrical connection

Power supply

DC-PNP:

AC/DC:

DC-PNP:

AC/DC:

DC-PNP:

AC/DC:

DC-PNP:

AC/DC:

Two electronic versions and three different connections are available for the device.

• Electronic version 3-wire DC-PNP with connection; M12 plug, valve plug or cable

• Electronic version 2-wire AC/DC with connection; valve plug or cable

A fine-wire fuse is necessary for operation: 500 mA slow-blow.

Electronic version 3-wire DC-PNP

3-wire DC-PNP is preferably used in conjunction with programmable logic controllers (PLC), DI

modules as per EN 61131-2. Positive signal at the switch output of the electronics (PNP).

Voltage source: non-hazardous contact voltage or Class 2 circuit (North America).

10 to 30 V DC, 3-wire

20 to 253 V AC/DC, 2-wire

< 975 mW

< 850 mW

< 15 mA

< 3.8 mA

5 Vss 0 to 400 Hz

—

Endress+Hauser 5

Page 6

Liquiphant FTL31

0.5A

L– L+

2

1

3

4

K

0.5A

L–

L+

2

1

3

4

K

1

21

2

1

41

4

0.5A

L– L+

2

1

3

4

K1

K2

1

2

1

4

4

1

1 2

21

41

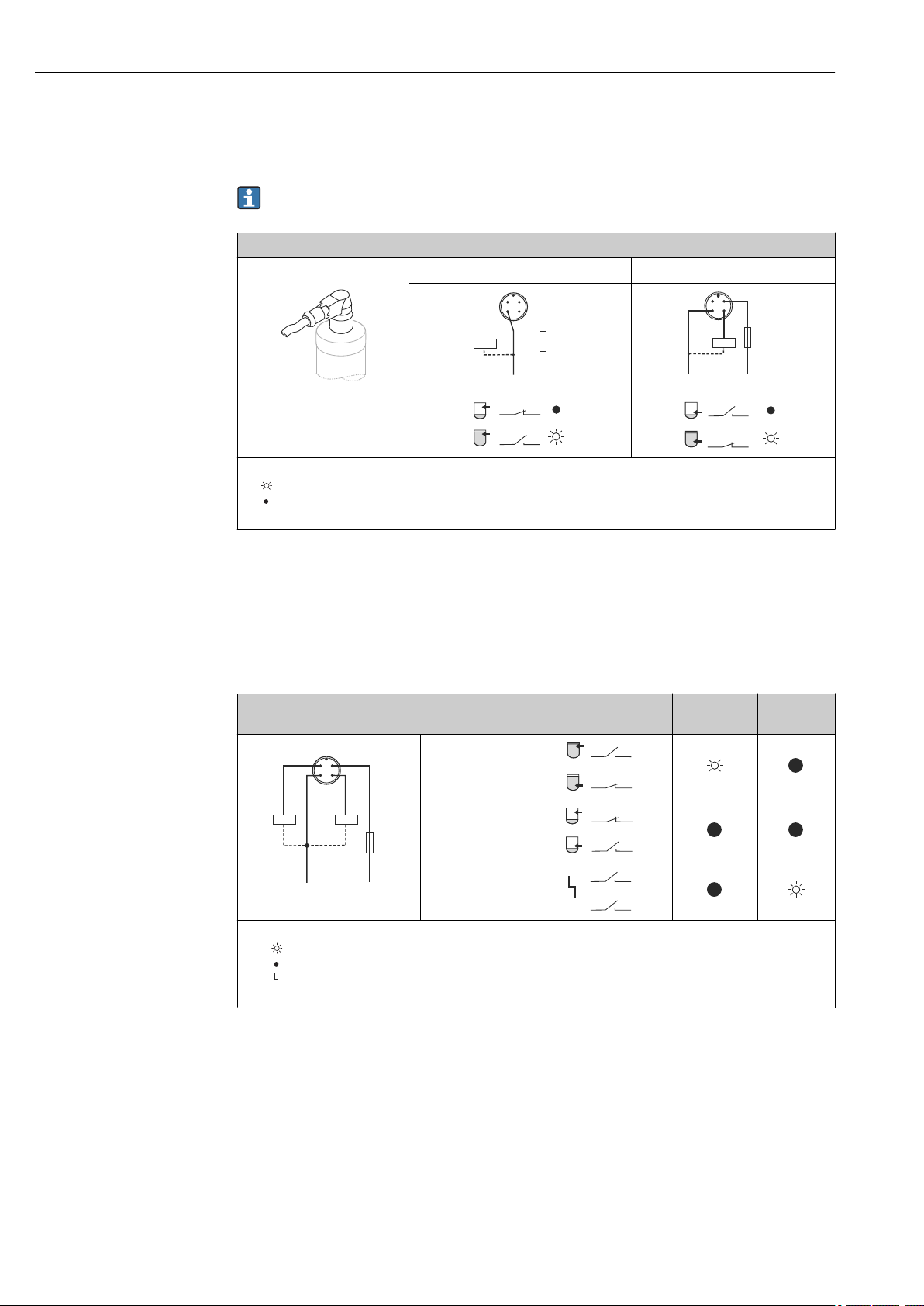

Connection with M12 plug

Depending on the analysis of the switch outputs, the device works in the MAX (maximum safety) or

MIN (minimum safety) mode.

A cable is optionally available for order, see "Accessories" section → 27.

3-wire DC-PNP Operating mode

M12 connector MAX MIN

A0022901

SymbolsKDescription

Yellow LED (ye) lit

Yellow LED (ye) not lit

external load

Function monitoring with M12 connector

Using a two-channel analysis, function monitoring of the sensor can be implemented in addition to

level monitoring, e.g. per relay switch, PLC, AS-i Bus I/O module, …).

When both outputs are connected, the MIN and MAX outputs assume opposite states when the

device is operating fault-free (XOR). In the event of an alarm condition or a line break, both outputs

are deenergized.

Connection with 3-wire DC-PNP for function monitoring based on XOR logic

Sensor covered

Sensor exposed

Fault

A0022917

Symbols

K1 / K2

Description

LED lit

LED not lit

Fault or warning

external load

Yellow LED

(ye)

Red LED

(rd)

6 Endress+Hauser

Page 7

Liquiphant FTL31

1

3

0.5A

L–

L+

2

K

+

–

L–

L+

3

0.5A

1

2

K

+

–

3

23

2

2323

0.5A

1

2

3

L–

L+

K

+

L+

0.5A

K

1

2

3

L–

+

3

23

2

2323

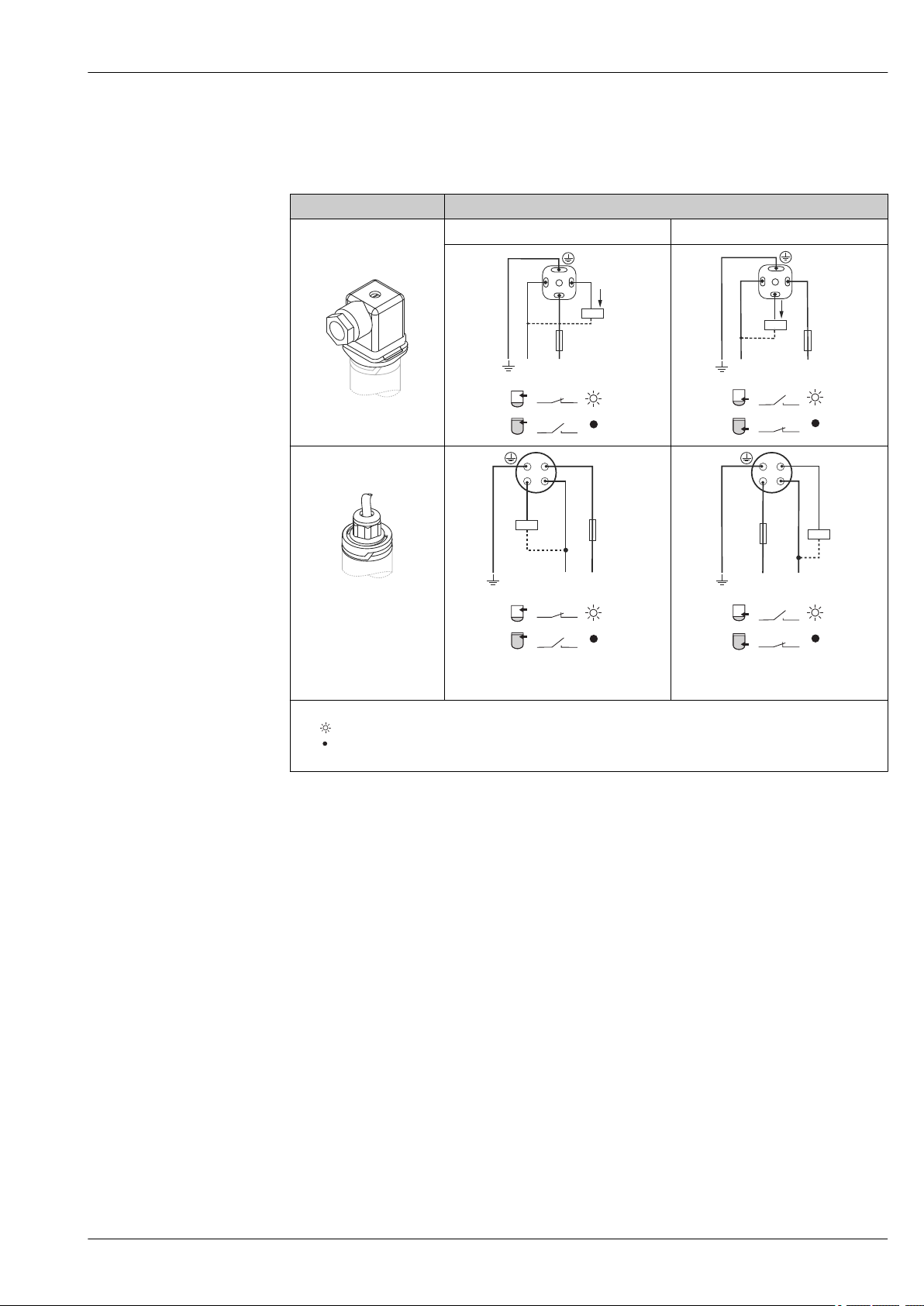

Connection with valve plug or cable

Depending on the assignment of the connector or the wiring of the cable, the device works in either

the MAX or MIN operating mode.

3-wire DC-PNP Operating mode

Valve plug MAX MIN

A0022900

Cable (cannot be

dismantled)

Core colors:

1 = BK (black)

2 = GR (gray)

3 = BN (brown)

Ground = GNYE (greenyellow)

SymbolsKDescription

Yellow LED (ye) lit

Yellow LED (ye) not lit

external load

A0022902

Endress+Hauser 7

Page 8

Liquiphant FTL31

2.7

2.5

2.3

2.1

1.9

1.7

1.5

1.3

1.1

0.9

0.7

0.5

20 24 27 43 48 53 60 110 121 207 230 253

P/S

U

P1

P2

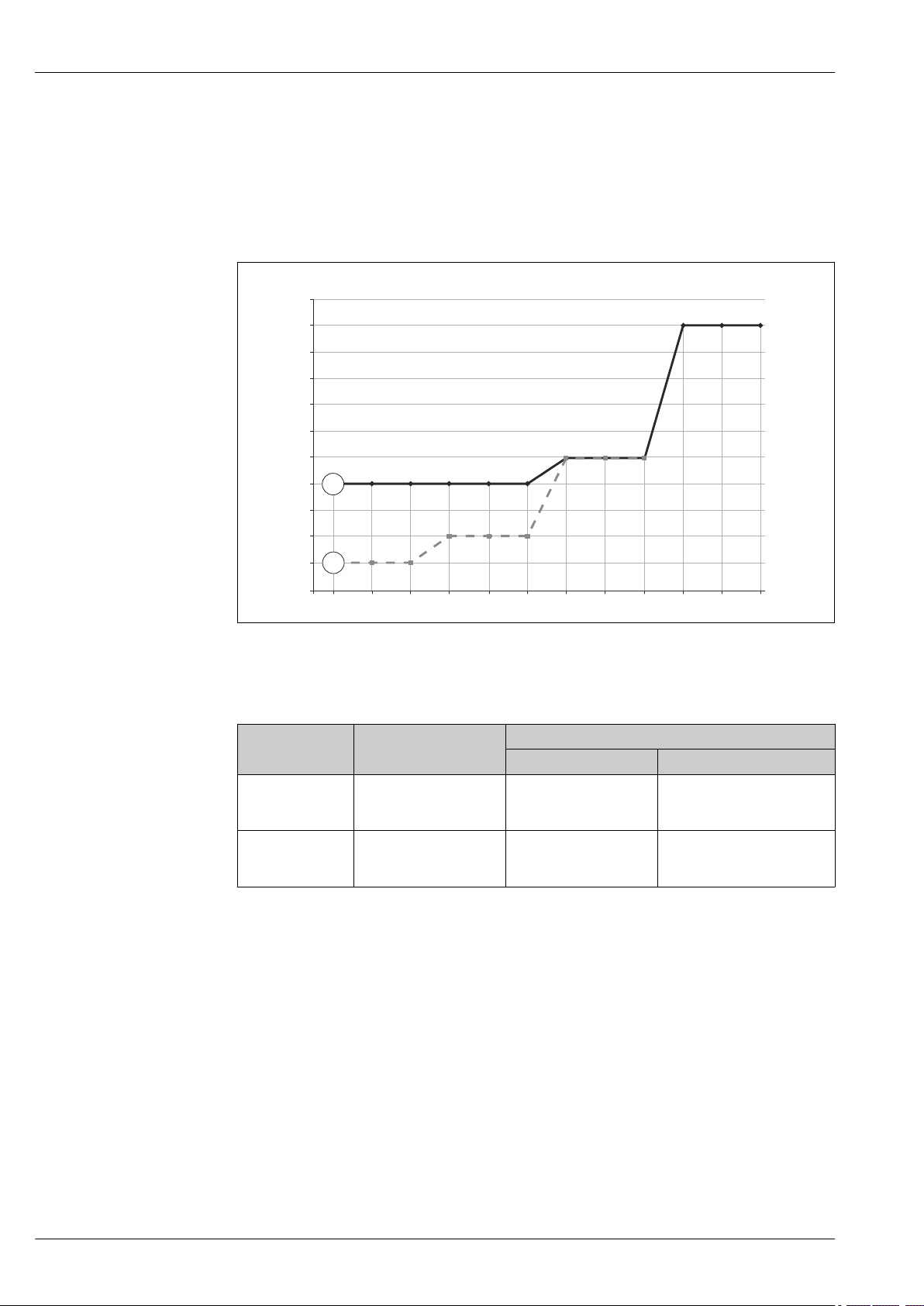

Electronic version 2-wire AC/DC

The load is switched via an electronic switch directly in the power supply circuit. Always connect in

series with a load!

Not suitable for connection to low-voltage PLC inputs!

Selection tool for relays

1 Minimum rated power of the load

P/S Rated power in [W] / [VA]

U Operating voltage in [V]

Item Supply voltage

P1

AC mode

P2

DC mode

24 V

110 V

230 V

24 V

48 V

60 V

min max

> 1.3 VA

> 1.5 VA

> 2.5 VA

> 0.7 W

> 0.9 W

> 1.5 W

Rated power

< 6 VA

< 27.5 VA

< 57.5 VA

< 6 W

< 12 W

< 15 W

Relays with a lower rated power can be operated by means of an RC module connected in parallel

(optional).

A0023486

8 Endress+Hauser

Page 9

Liquiphant FTL31

3

0.5A

1

K

>20 V

L1/L+ N/L–

2

0.5A

1

K

>20 V

L1/L+ N/L–

1313

1

21

2

3

L1/L+

0.5A

K

>20 V

1

2

N/L–

1

L1/L+

0.5A

K

2

3

N/L–

>20 V

1313

1

21

2

A

B

C

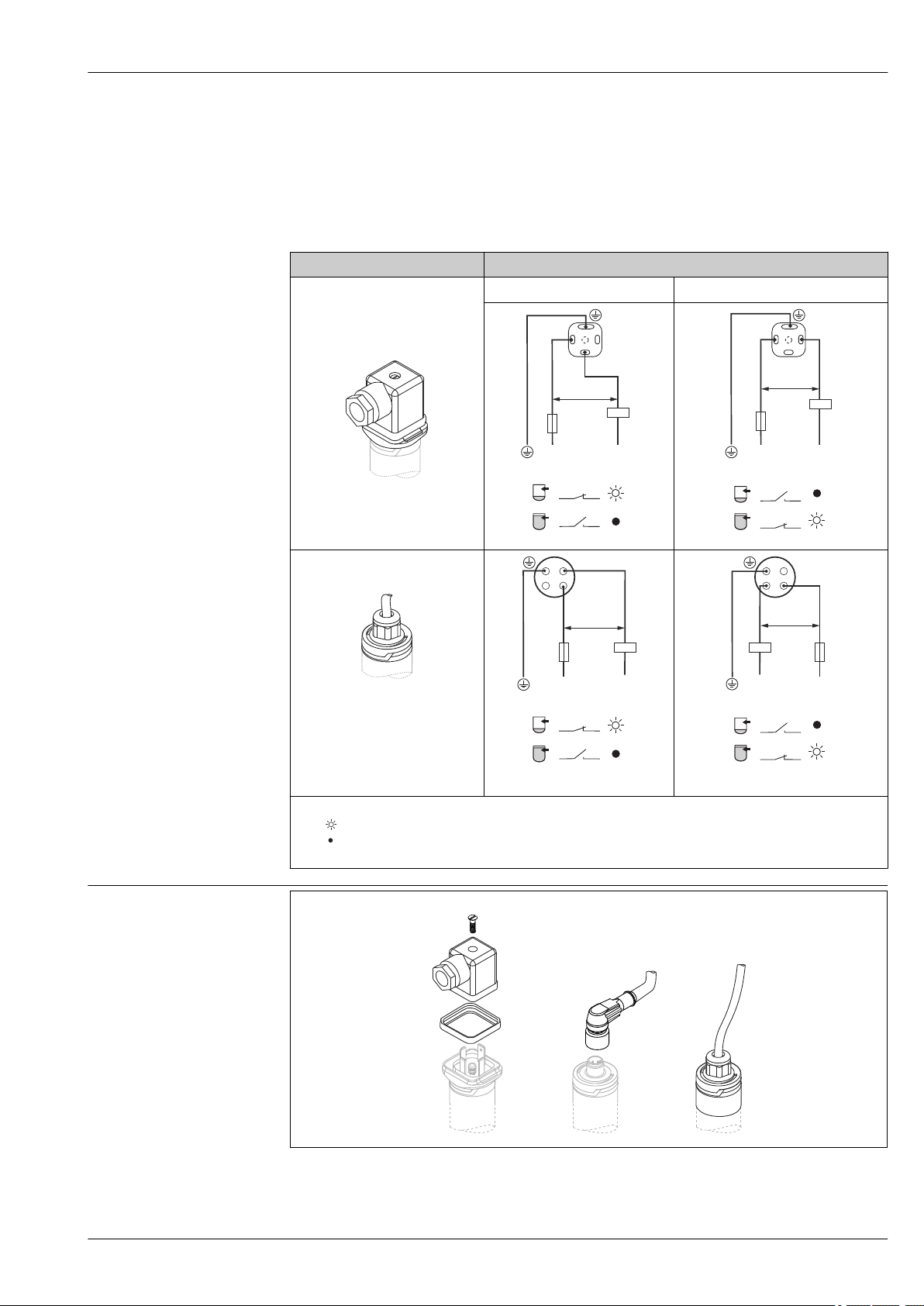

Connection with valve plug or cable

Depending on the assignment of the connector or the wiring of the cable, the device works in either

the MAX or MIN operating mode.

When the cable is wired, one wire of the cable does not have any function in each of the operating

modes (brown in the case of MIN, and gray in the case of MAX). The cable with no function must be

secured against inadvertent contact.

2-wire AC/DC Operating mode

Valve plug MAX MIN

Cable entry

Cable (cannot be dismantled)

Core colors:

1 = BK (black)

2 = GR (gray)

3 = BN (brown)

Ground = GNYE (green-yellow)

SymbolsKDescription

Yellow LED (ye) lit

Yellow LED (ye) not lit

external load

A0022900

A0022902

A0021219

A0021418

A0022161

A0021418

A0021220

A0021420

A0022225

A0021420

Endress+Hauser 9

A0020928

A Valve plug (M16x1.5; NPT ½"; QUICKON)

B M12 connector

C Cable 5 m (16 ft); secured in place on delivery and cannot be disassembled

Page 10

Liquiphant FTL31

Cable specification

Overvoltage protection

• Valve plug

– Cable cross-section: max. 1.5 mm2 (AWG 16)

– Ø 3.5 to 8 mm (0.14 to 0.26 in)

• M12 connector: IEC 60947-5-2

• Cable (3LPE)

– Cable cross-section: 0.75 mm2 (AWG 20)

– Ø 6 to 8 mm (0.24 to 0.31 in)

– Material: PUR

Overvoltage category II

10 Endress+Hauser

Page 11

Liquiphant FTL31

Performance characteristics

Reference operating conditions

Switch point

Hysteresis

Non-repeatability

Influence of ambient temperature

Influence of medium temperature

Influence of medium pressure

Ambient temperature: +25 °C (+77 °F)

Process pressure: 1 bar (14.5 psi)

Fluid: Water (density: approx. 1 g/cm³, viscosity 1 mm2/s)

Medium temperature: 25 °C (77 °F)

Density setting: > 0.7 g/cm³

Switching time delay: Standard (0.5 s, 1 s)

13 mm (0.51 in)±1 mm

max. 3 mm (0.12 in)

±1 mm (0.04 in) in accordance with DIN 61298-2

Negligible

–25 µm (984 µin)/°C

–20 µm (787 µin)/bar

Switching delay

Switch-on delay

Measuring frequency

Measured error

• 0.5 s when tuning fork is covered

• 1.0 s when tuning fork is uncovered

• Optionally available: 0.2 s; 1.5 s or 5 s (when the tuning fork is covered and uncovered)

max. 3 s

approx. 1 100 Hz in air

In event of device change: ±2 mm (0.08 in) as per DIN 61298-2

Endress+Hauser 11

Page 12

Installation

1

2

2

3

A

~30 (1.2)

A

A

~10.5(0.4)

~13 (0.5)

Liquiphant FTL31

Orientation

The point level switch can be installed in any position in a vessel, pipe or tank. Foam formation does

not affect the function.

2 Installation options

1 Overfill prevention or upper level detection

2 Lower level detection

3 Dry running protection for pump

Installation instructions Switch point

The switch point (A) on the sensor depends on the orientation of the point level switch (water

+25 °C (+77 °F), 1 bar (14.5 psi).

3 Vertical and horizontal orientation, dimensions in mm (in)

A0023118

A0020734

12 Endress+Hauser

Page 13

Liquiphant FTL31

A

B

116.8 (4.6)

13 (0.51)

25 (0.98)

128 (5.04)

C

C

ø >50 (2.0)

<5 m/s (16 ft/s)

ø >10 (0.4)

Short tube version

The use of the short tube ensures that the switch point is at the same level as in the previous

Liquiphant FTL260 model when an identical thread is selected. In this way, the device can be

replaced quickly and easily. (Applies for process connections G 1" weld-in adapter for flush-mounted

installation, MNPT 1" and R 1")

A0022122

Dimensions mm (in)

A Liquiphant FTL31 with short tube

B Liquiphant FTL260

C Switch point

Installation in pipes

During installation, pay attention to the position of the fork in order to minimize turbulence in the

pipe.

A0021357

Dimensions mm (in)

Endress+Hauser 13

A0022268

Page 14

Liquiphant FTL31

G1/2

316L

Installation in vessels

If installed horizontally, pay attention to the position of the tuning fork to ensure that the liquid can

drip off easily.

The electrical connection, e.g. M12 connector, should be pointing down with the cable. This can

prevent moisture from penetrating.

Length of connecting cable

A0021034

4 Position of the fork in the case of horizontal installation in a vessel

Distance from wall

Ensure that there is sufficient distance between the expected buildup on the tank wall and the fork.

Recommended distance from wall ≥10 mm (0.39 in).

A0022272

• to1 000 m (3 281 ft)

• max. 25 Ω/wire, total capacitance < 100 nF

14 Endress+Hauser

Page 15

Liquiphant FTL31

0 +50

+80

+100

–40

+32 +122

+176

+212

–40

–40

+70

[°C]

+158

[°F]

0

+32

[°C]

[°F]

+50

+122

T

a

T

P

T

a

T

p

1

2

–40

0 +50 +100 +150

–40

+32 +122 +212 +302

–40

–40

+70

[°C]

–40

+158

[°F]

0

+32

[°C]

[°F]

+50

+122

T

a

T

P

1

2

T

a

T

p

+90

+194

Environment

Ambient temperature range

–40 to +70 °C (–40 to +158 °F)

5 Derating curve: 100 °C (212 °F)

1 I

2 I

Ta Ambient temperature range

Tp Process temperature

: 200 mA (DC-PNP), 250 mA (AC/DC)

max

: 150 mA (DC-PNP), 150 mA (AC/DC)

max

A0022002

A0020869

6 Derating curve: 150 °C (302 °F)

1 I

Storage temperature

Climate class

Altitude

2 I

Ta Ambient temperature range

Tp Process temperature

–40 to +85 °C (–40 to +185 °F)

DIN EN 60068-2-38/IEC 68-2-38: test Z/AD

Up to 2 000 m (6 600 ft) above sea level

Endress+Hauser 15

: 200 mA (DC-PNP), 250 mA (AC/DC)

max

: 150 mA (DC-PNP), 150 mA (AC/DC)

max

Page 16

Liquiphant FTL31

Degree of protection

Shock resistance

Vibration resistance

Electromagnetic compatibility

Reverse polarity protection

Short-circuit protection

• IP65/67 NEMA Type 4X Enclosure (M12 connector)

• IP65 NEMA Type 4X Enclosure (valve plug)

• IP66/68 NEMA Type 4X/6P Enclosure (cable)

a = 300 m/s² = 30 g, 3 planes x 2 directions x 3 shocks x 18 ms,

as per test Ea, prEN 60068-2-27:2007

a(RMS) = 50 m/s², ASD = 1.25 (m/s²)²/Hz, f = 5 to 2000 Hz, t = 3 x 2 h,

as per test Fh, EN 60068-2-64:2008

Electromagnetic compatibility in accordance with all relevant requirements of the EN 61326 series

and NAMUR recommendation EMC (NE21). For details, refer to the EC Declaration of Conformity.

The EC Declaration of Conformity is available in the Download Area of the Endress+Hauser website:

www.endress.com → Downloads.

2-wire AC/DC

• AC mode: the device has reverse polarity protection.

• DC mode: in the event of reverse polarity the maximum safety mode is always detected. Check the

wiring and perform a function check before commissioning. The device is not damaged in the

event of reverse polarity.

3-wire DC-PNP

Integrated. In the event of reverse polarity, the device is deactivated automatically.

2-wire AC/DC

During switching the sensor checks whether a load, e.g. relay or contactor, is present (load check). If

an error occurs, the sensor is not damaged.

Smart monitoring: normal operation is resumed once the error is fixed.

3-wire DC-PNP

Overload protection/short-circuit protection at I > 250 mA; the sensor is not destroyed.

Intelligent monitoring: Testing for overload at intervals of approx. 1.5 s; normal operation resumes

once the overload/short-circuit has been rectified.

16 Endress+Hauser

Page 17

Liquiphant FTL31

Process

Process temperature range

Process pressure range

Density

State of aggregation

Viscosity

Solids contents

Lateral loading capacity

–40 to +100 °C (–40 to +212 °F)

–40 to +150 °C (–40 to +302 °F)

Max. –1 to +40 bar (–14.5 to +580 psi)

> 0.7 g/cm³ (optionally available: > 0.5 g/cm³)

Liquid

1 to 10 000 mPa·s, dynamic viscosity

ø < 5 mm (0.2 in)

Lateral loading capacity of the tuning fork: maximum 200 N

Endress+Hauser 17

Page 18

Mechanical construction

A

C

D

B

Liquiphant FTL31

Design

Various versions of the point level switch are available, the features of which can be selected to suit

your user needs.

The versions can be selected via the product structure in the Product Configurator, see the "Ordering

information" section → 27. Examples can be seen in the following diagram:

A0022228

Cable

Examples

M12 connector M12 connector

Versions

Electrical connection Valve plug

Housing (sensor design)

for process temperatures up

to:

Sensor type Compact version Short tube version Compact version Short tube version

A B C D

(cannot be dismantled)

100 °C (212 °F) 100 °C (212 °F) 150 °C (302 °F) 150 °C (302 °F)

Detailed information on the process connections is provided in the "Sensor type" section

→ 20.

Information on the short tube version is provided in the "Installation instructions" section

→ 13.

18 Endress+Hauser

Page 19

Liquiphant FTL31

40 (1.6)

51.5 (2.0)

45 (1.8)

45.5 (1.8)

27.5 (1.1)

25 (1.0)

39 (1.5)

27.8 (1.1)

45.3 (1.8)

8 (0.31)

13.7 (0.54)

38 (1.5)

14 (0.55)

3 (0.12)

ø17.1 (0.67)

Connector

Dimensions

Dimensions mm (in)

The following graphics illustrate the connectors together with the suitable housing covers on the

housing of the point level switch.

Electrical connection with housing cover Designation

A

A0021859

B

A:

Valve plug M16, NPT ½"

for housing cover: PPSU plastic

B:

Valve plug QUICKON

for housing cover: PPSU plastic

A0021860

M12 connector

for housing cover: PPSU plastic (IP65/67)

A0021857

Captive cable

with housing cover: PPSU plastic

Tuning fork

A0021692

Dimensions

Dimensions mm (in)

A0022250

Endress+Hauser 19

Page 20

Liquiphant FTL31

16 (0.63)

63.9 (2.52)

112 (4.41)*

136.6 (5.38)**

38 (1.5)

ø31.5

(1.24)

32

16 (0.63)

103.3 (4.07)

151.4 (5.96)*

176 (6.93)**

ø17.1

(0.7)

ø31.5

(1.24)

38 (1.5)

32

Sensor type

Dimensions

Dimensions mm (in)

The total dimensions of the device can vary depending on the connector selected. To determine the

total dimensions, please refer also to the "Electrical connection" section → 19.

Information on the following tables

• Meaning of symbols:

* Dimension for process temperature max. 100 °C (212 °F)

** Dimension for process temperature max. 150 °C (302 °F)

• If several versions have the same dimensions, one example of the compact version and one

example of the short tube version is given.

• The versions in the second column refer to the process connections in the product structure.

Information on weld-in adapters can be found in the "Weld-in adapters, process adapters and

flanges" documentation, TI00426F/00.→ 29.

Dimensions Version Description

WBJ

Thread ISO 228 G ½"

WCJ

Thread ISO 228 G ¾"

• Material: 316L

• Scope of delivery: flat seal (FA)

• Pressure and temperature (maximum):

+40 bar (+580 psi) at +150 °C (+302 °F)

W5J Thread ISO 228 G ¾" for flush-mounted installation

in weld-in adapter

• Material: 316L

• Scope of delivery: flat seal (FA)

A0021787

7 Compact version, example G ½"

Accessory: weld-in adapter

– Scope of delivery: seal (VMQ)

– Pressure and temperature (maximum):

+25 bar (+352 psi) at +150 °C (+302 °F)

+40 bar (+580 psi) at +100 °C (+212 °F)

The dimensions apply for G ½"; G ¾" and G ¾" for flushmounted installation.

A0021883

8 Short tube version, example G ½"

20 Endress+Hauser

Page 21

Liquiphant FTL31

66.4 (2.6)

112 (4.41)*

136.6 (5.38)**

38 (1.5)

18.5 (0.73)

ø31.5

(1.24)

32

105.8 (4.17)

151.4 (5.96)*

176 (6.93)**

38 (1.5)

ø17.1

(0.7)

ø31.5

(1.24)

32

18.5 (0.73)

47.9 (1.89)

77.4 (3.05)

136.6 (5.38)*

151.4 (5.96)**

38 (1.5)

ø31.5

(1.24)

32

87.3 (3.44)

116.8 (4.6)

176 (6.93)*

190.8 (7.51)**

ø17.1

(0.7)

38 (1.5)

ø31.5

(1.24)

32

Dimensions Version Description

WDJ Thread ISO 228 G 1"

• Material: 316L

• Scope of delivery: flat seal (FA)

• Pressure and temperature (maximum):

+40 bar (+580 psi) at +150 °C (+302 °F)

A0022232

9 Compact version

A0022231

10 Short tube version

Dimensions Version Description

WSJ Thread ISO 228 G 1"

for flush-mounted installation in weld-in adapter

• Material: 316L

• Scope of delivery: flat seal (FA)

Accessory: weld-in adapter

– Scope of delivery: seal (VMQ)

– Pressure and temperature (maximum):

+25 bar (+362 psi) at +150 °C (+302 °F)

+40 bar (+580 psi) at +100 °C (+212 °F)

A0022008

11 Compact version

12 Short tube version

Endress+Hauser 21

A0022007

Page 22

Dimensions Version Description

63.9 (2.52)

112 (4.41)*

136.6 (5.38)**

38 (1.5)

ø31.5

(1.24)

32

47.9 (1.89)

103.3 (4.07)

151.4 (5.96)*

176 (6.93)**

38 (1.5)

ø17.1

(0.7)

ø31.5

(1.24)

32

87.3 (3.44)

VAJ Thread ASME MNPT ½"

VBJ Thread ASME MNPT ¾"

XBJ Thread EN10226 R ½"

XCJ Thread EN10226 R ¾"

Pressure and temperature (maximum):

+40 bar (+580 psi) at +150 °C (+302 °F)

The dimensions apply for MNPT ½", MNPT ¾"; R ½"

and R ¾".

A0021788

13 Compact version, example MNPT ¾"

Liquiphant FTL31

14 Short tube version, example MNPT ¾"

A0021895

22 Endress+Hauser

Page 23

Liquiphant FTL31

66.4 (2.61)

47.9 (1.89)

112 (5.38)*

136.6 (5.38)**

38 (1.5)

ø31.5

(1.24)

32

98.3 (3.87)

116.8 (4.57)

176 (6.93)*

190.8 (7.51)**

ø17.1

(0.7)

38 (1.5)

ø31.5

(1.24)

32

Dimensions Version Description

VCJ Thread ASME MNPT 1"

XDJ Thread EN10226 R 1"

Pressure and temperature (maximum):

+40 bar (+580 psi) at +150 °C (+302 °F)

The dimensions apply for MNPT 1" and R 1".

A0022330

15 Compact version, example MNPT 1"

16 Short tube version, example MNPT 1"

Weight

Materials

Sensor type Weight

Compact version with process adapter G ½" and valve plug

for process temperature up to 100 °C (212 °F)

Short tube version with process adapter G ½" and valve plug

for process temperature up to 150 °C (302 °F)

Material specifications in accordance with AISI and DIN EN.

Materials in contact with process

Component part Material

Tuning fork 316L

Process adapter 316L (1.4404/1.4435)

Short tube 316L (1.4404/1.4435)

Seal for weld-in adapter with G ¾", G 1" VMQ

Flat seal FA (composite material based on aramid fibers

A0022331

Pay attention to the temperature and pressure specifications for seals used at the customer site.

Endress+Hauser supplies DIN/EN process connections with threaded connection in stainless

steel in accordance with AISI 316L (DIN/EN material number 1.4404 or 14435). With regard

to their stability-temperature property, the materials 1.4404 and 1.4435 are grouped together

under 13E0 in EN 1092-1, Tab. 18. The chemical composition of the two materials can be

identical.

Approx. 140 g (4.938 oz)

Approx. 169 g (5.961 oz)

combined with NBR)

Endress+Hauser 23

Page 24

Materials not in contact with process

Component part Material

Housing cover with M12 connector (IP65/67)

PPSUHousing cover with valve plug (IP65)

Housing cover with cable (IP66/68)

Cable gland PVDF

Design ring PBT/PC

Housing 316L (1.4404/1.4435)

Nameplate Plastic foil (attached to housing)

Liquiphant FTL31

Surface roughness

Metallic surface in contact with process:

Ra ≤3.2 µm (126 µin)

The surface is not defined in the area of the welding seam.

24 Endress+Hauser

Page 25

Liquiphant FTL31

A

B

1

2

3

4

12

3

2

3

1

1

2

3

TEST

N

Ser. no.:

Order code:

Ext. ord. cd.:

LED display

Operability

A M12 connector, (cable without graphic)

B Valve plug

Item Function Description

Green LED (gn)

1

2

3

Lit

Yellow LED (ye)

Lit

Red LED (rd)

Flashing

Lit

Device is operational

M12 connector

Indicates the sensor state: tuning fork is covered by liquid

Valve plug / cable

Indicates the switching state:

• MAX operating mode (overfill prevention): sensor is not covered by liquid

• MIN operating mode (dry running protection): the sensor is covered by liquid

Warning/maintenance required: Fault can be remedied, e.g. incorrect wiring;

protective function if test magnet is held against the sensor for longer than 30 s

Fault/device failure: error cannot be rectified, e.g. electronic error

A0016856

Function test with test magnet

Carry out a function test while the device is in operation.

Hold the test magnet against the marking on the housing for at least 2 seconds.

‣

This inverts the current switch status, and the yellow LED changes state. When the magnet

is removed, the switching status valid at that time is adopted.

If the test magnet is held against the marking for longer than 30 seconds, the red LED will flash: The

device returns automatically to the current switch status.

The test magnet is not included in the scope of delivery. It can be ordered as an optional

accessory → 27.

A0020960

17 Position for test magnet on housing

Endress+Hauser 25

Page 26

Liquiphant FTL31

Certificates and approvals

The following documents are also available in the Download Area of the Endress+Hauser

website:www.endress.com → Downloads.

CE mark

EAC conformity

RCM-Tick marking

Approval

Overfill prevention

The measuring system is in conformity with the statutory requirements of the applicable EC

Directives. These are listed in the corresponding EC Declaration of Conformity along with the

standards applied. Endress+Hauser confirms successful testing of the device by affixing to it the CE

mark.

The measuring system meets the legal requirements of the applicable EAC guidelines. These are

listed in the corresponding EAC Declaration of Conformity together with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the EAC mark.

The supplied product or measuring system meets the ACMA (Australian Communications and Media

Authority) requirements for network integrity, interoperability, performance characteristics as well

as health and safety regulations. Here, especially the regulatory arrangements for electromagnetic

compatibility are met. The products are labelled with the RCM- Tick marking on the name plate.

A0029561

CSA C/US General Purpose

Prior to mounting the device, pay attention to the WHG approval documents which can be

found on the Endress+Hauser web site: www.endress.com → Downloads.

WHG

• Overfill detection system: Z-65.11-531

• Leak detection system: Z-65.40-532

Marine approvals

CRN approval

Inspection certificates

Manufacturer declarations

Pressure Equipment Directive

Other standards and guidelines

• GL (German Lloyd)

• ABS (American Bureau of Shipping)

• LR (Lloyds Register)

• BV (Bureau Veritas)

• DNV (Det Norske Veritas)

Versions with a CRN approval (Canadian Registration Number) are listed in the corresponding

registration documents. CRN-approved devices are labeled with registration number 0F16950.5C on

the nameplate. You can find further details on the maximum pressure values in the Download Area

of the Endress+Hauser website.

The following documents can be ordered with the device (optional):

• Acceptance test certificate as per EN 10204-3.1

• Final inspection report

The following manufacturer declarations can be ordered (optional):

• FDA conformity

• TSE-free, materials free from animal origin

• ROHS-compliant in accordance with Endress+Hauser regulation

The device does not fall within the scope of Pressure Equipment Directive 97/23/EC as it does not

have a pressurized housing as defined in Article 1, Section 2.1.4 of the directive.

The applicable European guidelines and standards can be found in the relevant EU Declarations of

Conformity.

26 Endress+Hauser

Page 27

Liquiphant FTL31

1

Ordering information

Ordering information

Services (optional)

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

In addition, the following services can be selected via the product structure in the Product

Configurator:

• Cleaned of oil+grease

• PWIS-free (PWIS = paint-wetting impairment substances)

• Density setting > 0.5 g/cm³

• Switching delay setting → 11

Accessories

Weld-in adapter

Plug-in jack, cable

Various weld-in adapters are available for installation in vessels or pipes.

The adapters are optionally available with inspection certificate 3.1 EN10204.

View (example) Description

G ¾" ø29 pipe installation

ø50 vessel installation

FDA-listed materials as per 21 CFR Part 175-178

G 1" ø53 pipe installation

ø60 vessel installation

A0023557

1 Leakage hole

If installed horizontally and weld-in adapters with a leakage hole are used, ensure that the leakage

hole is pointing down. This allows leaks to be detected as quickly as possible.

Detailed information can be found in TI00426F/00/EN "Weld-in adapters, process adapters

and flanges" and in the supplementary documentation → 29.

The plug-in jacks listed are suitable for use in the temperature range

–25 to +70 °C (–13 to +158 °F).

Endress+Hauser 27

Page 28

Liquiphant FTL31

27.5

(1.08)

40

(1.57)

³

~52.5 (2.07)

ø20

(0.8)

32

TEST

N

Engineering unit mm (in)

Plug-in jack M12 IP67 Description Order number

• elbowed 90°

• 5 m (16 ft)PVC cable (gray)

• Slotted nut Cu Sn/Ni

• Body: PUR (blue)

A0022292

Plug-in jack M12 IP67 Description Order number

• Self-terminated connection to M12

connector

• Slotted nut Cu Sn/Ni

• Body: PBT

A0022293

52010285

52006263

Additional accessories

Wire colors for M12 connector: 1 = BN (brown), 2 = WT (white), 3 = BU (blue), 4 = BK (black)

Socket wrench for mounting Description Order number

• Hexagonal

• Size across flats AF32

A0022273

Test magnet Description Order number

Information in section on Operation

→ 25

A0021732

52010156

71267011

28 Endress+Hauser

Page 29

Liquiphant FTL31

Supplementary documentation

The following document types are available in the Download Area of the Endress+Hauser

website: www.endress.com → Downloads.

Operating Instructions

Additional documentation

Certificates

Liquiphant FTL31 → BA01285F/00

TI00426F/00 → Weld-in adapters, process adapters and flanges (overview)

SD01622Z/00 → Weld-in adapter (installation instructions)

SD00356F/00→ Valve plug (installation instructions)

ZE01010F/00→ Overfill protection

ZE01011F/00→ Leaks

Endress+Hauser 29

Page 30

Page 31

Page 32

*71325891*

71325891

www.addresses.endress.com

Loading...

Loading...