Page 1

silometer

FMX 570

Level Measurement

Operating Instructions

BA 119F/00/en/06.03

016338-1000

Software Version 1.x

FMX 570

Hauser+Endress

The Power of Know How

Page 2

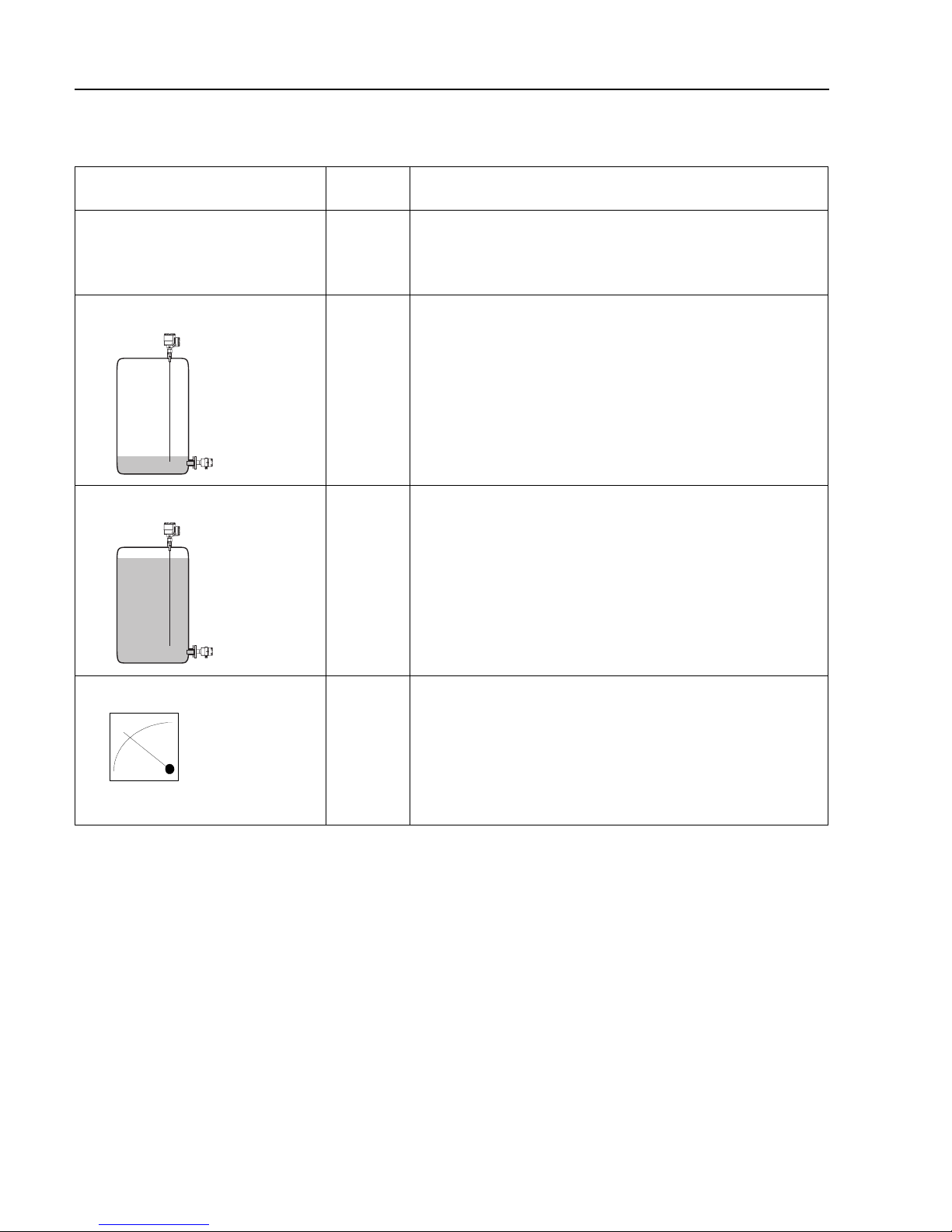

Level Measurement at a Glance

*Can be performed in reverse order

Function Matrix Action

1 Reset transmitter V9H5 ●Enter 671: »+« and »-« keys, ⇒ changes digit

Press »E« to register entry

- Omit if commissioned as in Section 4.1

2 »Empty« calibration* V0H1 ●Fill vessel 0…40% full (probe covered)

Enter level in %, m, ft, etc.

Press »E« to register entry

3 »Full« calibration* V0H2 ●Fill vessel 60…100% full

Enter level in %, m, ft, etc.

Press »E« to register entry

4 0/4 mA signal V0H3

V0H5

V0H6

●Enter 0 for 0…20 mA signal, 1 for 4…20 mA signal

Press »E« to register entry

●Enter level for 0/4 mA signal (if not 0)

Press »E« to register entry

●Enter level for 20 mA signal (if not 100)

Press »E« to register entry

Silometer FMX 570 Measurement at a Glance

Page 3

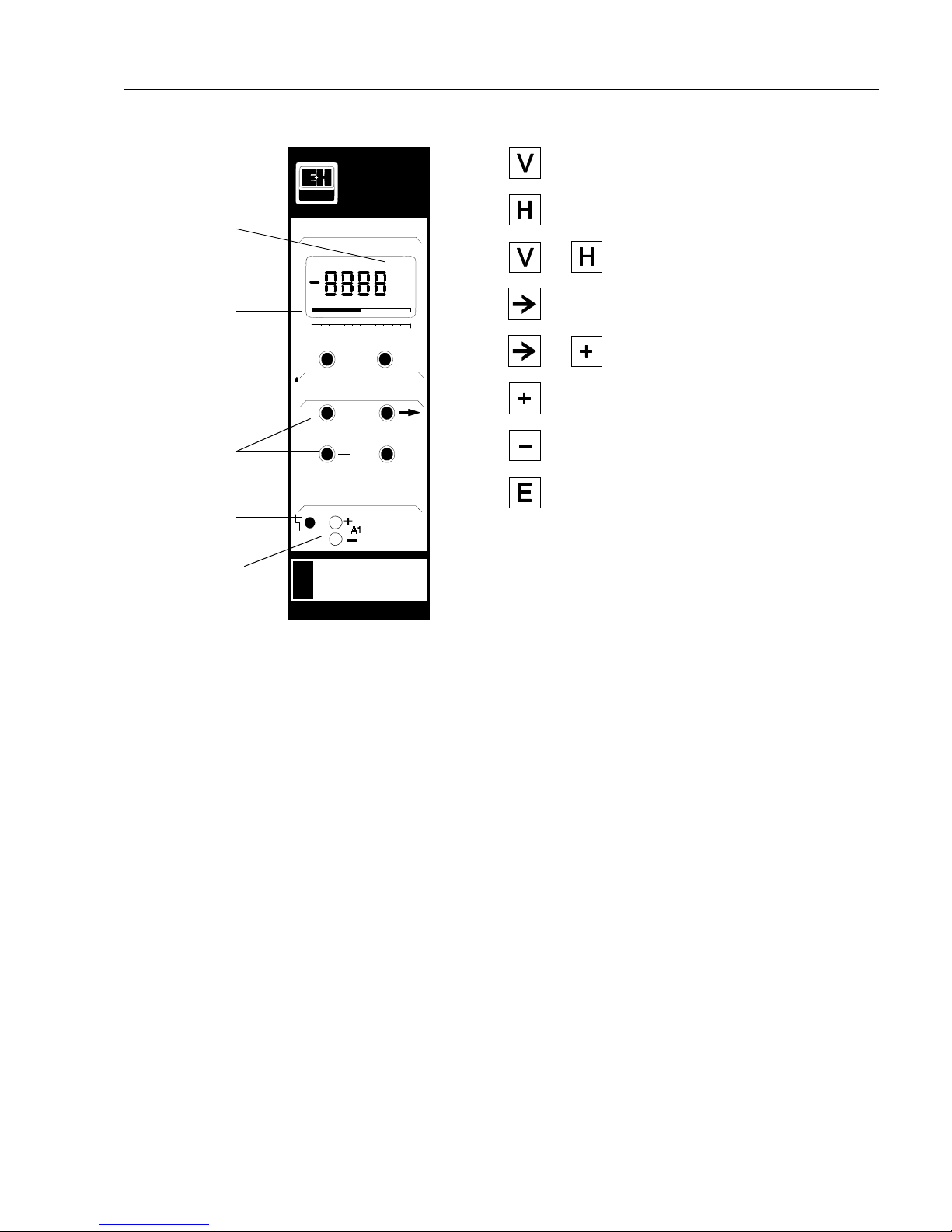

Silometer FMX 570

Selects vertical matrix position

Selects horizontal matrix position

Select position V0H0

Selects next digit

Move decimal point

Increases value of digit

Decreases value of digit

Registers entry

0 100

VH

00

VH

+

E

FMX 570

m

Measured

value

Bar chart

Matrix

selection

Parameter entry

Alarm relay

lit: fault

Matrix position

Test sockets for

0/4…20 mA output

+

+

See also »Controls«, Chapter 3

Measurement at a Glance Silometer FMX 570

1

Page 4

Table of Contents

Measurement at a Glance

Notes on Safety . . . . . . . . . . . . 3

1 Introduction . . . . . . . . . . . . . 5

1.1 Application . . . . . . . . . . . . . . . 6

1.2 Measuring principle . . . . . . . . . . . 7

2 Installation . . . . . . . . . . . . . . 8

2.1 Probes and sensors . . . . . . . . . . . 8

2.2 Silometer installation . . . . . . . . . . . 9

2.3 Transmitter wiring . . . . . . . . . . . . 11

2.4 Sensor connection . . . . . . . . . . . . 13

2.5 Technical data: Silometer FMX 570 transmitter . 14

3 Controls . . . . . . . . . . . . . . . 15

3.1 Commutec operating matrix . . . . . . . . 15

3.2 Configuration and display . . . . . . . . . 16

4 Calibration and Operation . . . . . . . 17

4.1 Commissioning . . . . . . . . . . . . . 17

4.2 Calibration for level measurement . . . . . . 18

4.3 Calibration for linear volume or weight

measurement . . . . . . . . . . . . . . 19

4.4 »Dry calibration« for open vessels . . . . . 20

4.5 Level offset value . . . . . . . . . . . . 22

4.6 Measured value display . . . . . . . . . 23

4.7 Locking the parameter matrix . . . . . . . 23

5 Linearization . . . . . . . . . . . . . 24

5.1 Linearization for a horizontal cylindrical tank . 25

5.2 Linearization for a tank with conical outlet . . 26

5.3 Other modes . . . . . . . . . . . . . . 29

6 Analogue Outputs . . . . . . . . . . 30

6.1 Analogue output settings . . . . . . . . . 31

7 Trouble-Shooting . . . . . . . . . . . 33

7.1 Trouble-shooting tables . . . . . . . . . 33

7.2 Simulated operating mode . . . . . . . . 35

7.3 Exchanging transmitters, probes and electronic

inserts . . . . . . . . . . . . . . . . 36

7.4 Repairs . . . . . . . . . . . . . . . . 37

8 Quick programming guide . . . . . . . 38

8.1 Level measurement . . . . . . . . . . . 38

8.2 Continuous volume measurement (linearization) 39

Index . . . . . . . . . . . . . . . . 40

Operating matrix

Silometer FMX 570 Table of Contents

2

Page 5

Notes on Safety

The Silometer FMX 570 is a level measurement transmitter which can be used with a

variety of probes and sensors. It must be installed by qualified personnel according to

the instructions in this manual.

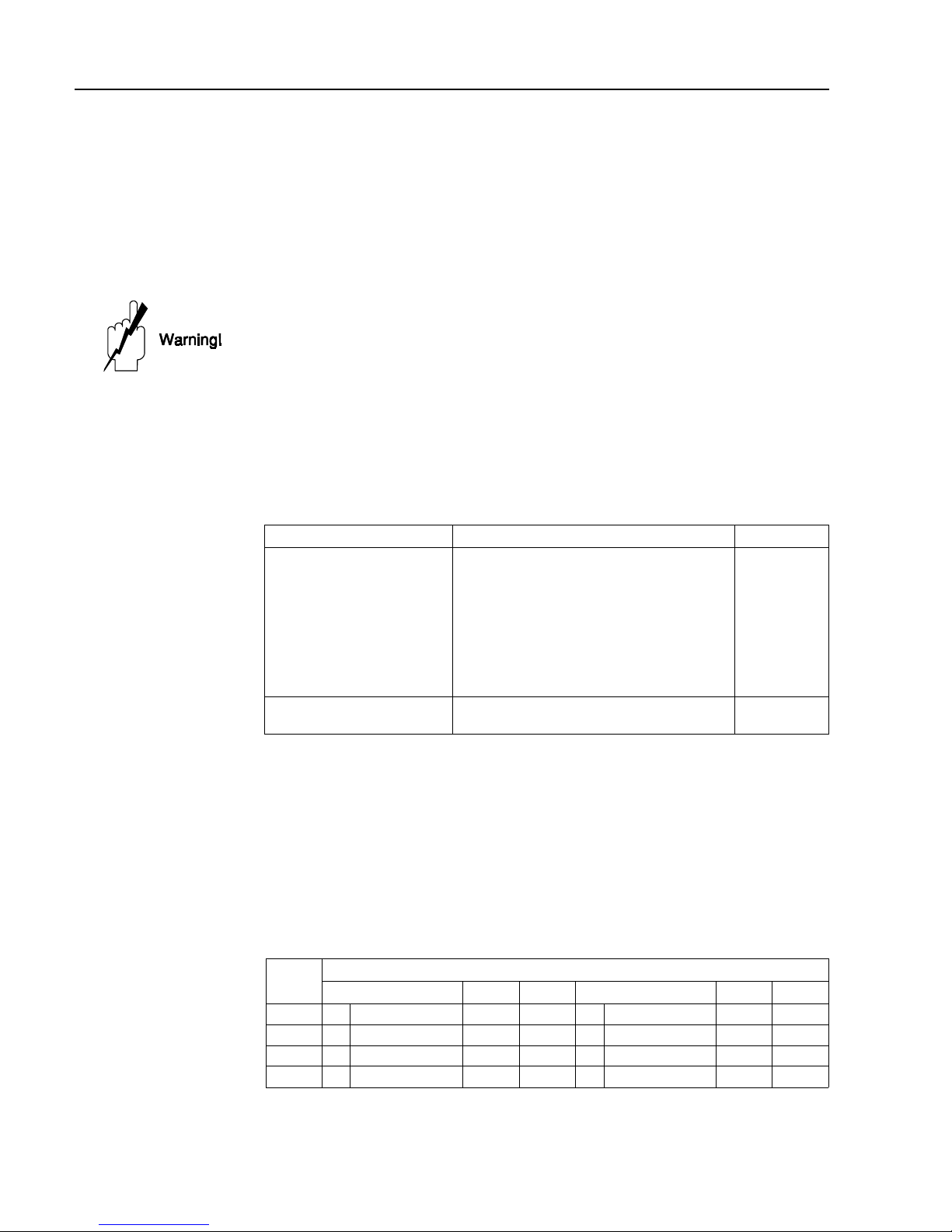

CertificatesThe Silometer FMX 570 transmitter is available with certificate. The Table below indicates

the combinations available and conditions for installation. Full details can be taken from

the certificates. Please note that where quoted technical data differs from that listed in

Section 2.5, that in the certificate applies.

Certificate Instruments Notes

TÜV 00 ATEX 1640 Silometer FMC 671 Z/676 Z II (1) GD,

[EEx ia] IIC/IIB,

install outside Ex-area

PTB 98 ATEX 2215 X DC 12 TE, DC .. TE .,

DC .. E ., DC ..

Capacitance probes

11500 Z(M), 11961 (Z),

21561 (Z)

with electronic insert

EC 16/17/27/37/47 Z,

FEC 12,

HTC 16/17/27 Z, HTC 10 E,

HMC 37/47 Z

II 1/2 G, II 2 G,

EEx ia IIC/IIB T6

PTB 98 ATEX 2215 X DC 12 TE, DC .. TE .,

DC .. E ., DC ..

Capacitance probes

11500 Z(M), 11961 Z,

21561 Z

with electronic insert

EC 17/37/47 Z, FEC 12

II 1 G,

EEx ia IIC/IIB T6

PTB 98 ATEX 2094 DB 50, DB 50 L,

DB 51, DB 52, DB 53

II 1/2 G, II 2 G,

EEx ia IIC T4…T6

DIBt No. Z-65.11-29 Silometer FMX 570,

DB 50…52

with electronic insert

FEB 17 / FEB (17) P

Continuous level measurement

for overspill protection in stationary

vessels

(for storage of non-combustible,

water-polluting liquids)

Silometer FMX 570 Notes on Safety

3

Page 6

Safety conventions

In order to highlight safety-relevant or alternate operation procedures in the manual the

following conventions have been used, each indicated by a corresponding icon in the

margin.

Note!

• A note highlights actions or procedures which, if not performed correctly, may

indirectly affect operation or may lead to an instrument response which is not

planned.

Caution!

• Caution indicates actions or procedures which, if not performed correctly, may lead

to personal injury or incorrect functioning of the instrument.

Warning!

• A warning indicates actions or procedures which, if not performed correctly, will

lead to personal injury, a safety hazard or destruction of the instrument.

Notes on Safety Silometer FMX 570

4

Page 7

1 Introduction

Quick Operating GuidesThe front cover contains short instructions for continuous level measurement with the

default parameters.

In this manualUsers unfamiliar with the Silometer FMX 570 must read the operating instructions, which

are structured as follows:

• Chapter 1: Introduction;

contains general information including application, measurement

principle and functional description.

• Chapter 2: Installation;

contains hardware configuration, installation instructions.

connection diagrams and technical data for the plug-in card.

• Chapter 3: Controls;

describes the front panel keys and operating matrix.

• Chapter 4: Calibration and Operation;

tells you how to commission the Silometer for level measurement.

• Chapter 5: Linearization;

tells you how to calibrate the Silometer to measure volume in a

horizontal cylindrical tank or a tank with a conical outlet.

• Chapter 6: Analogue Outputs;

describes in detail the setting of the 0/4…20 mA signal line.

• Chapter 7: Trouble-Shooting;

contains a description of the self-checking system with error

messages, the simulation feature as well as instructions for

configuration on replacement of the transmitter, probe or electronic

insert.

• Chapter 8: Short Operating Guide

contains a flowcharts for level and volume measurements

• Chapter 9: Index;

lists key words to help you find information quickly.

• Chapter 10: Operating Matrix

contains the operating matrix, the default parameters and a table to

enter your operating parameters,

Further documentationInstallation of the probes, electronic inserts and accessories are described in the

documentation accompanying these articles - see text for references. When installing

probes in explosion hazardous areas the instructions included in the accompanying

probe certification must also be observed.

Silometer FMX 570 Chapter 1: Introduction

5

Page 8

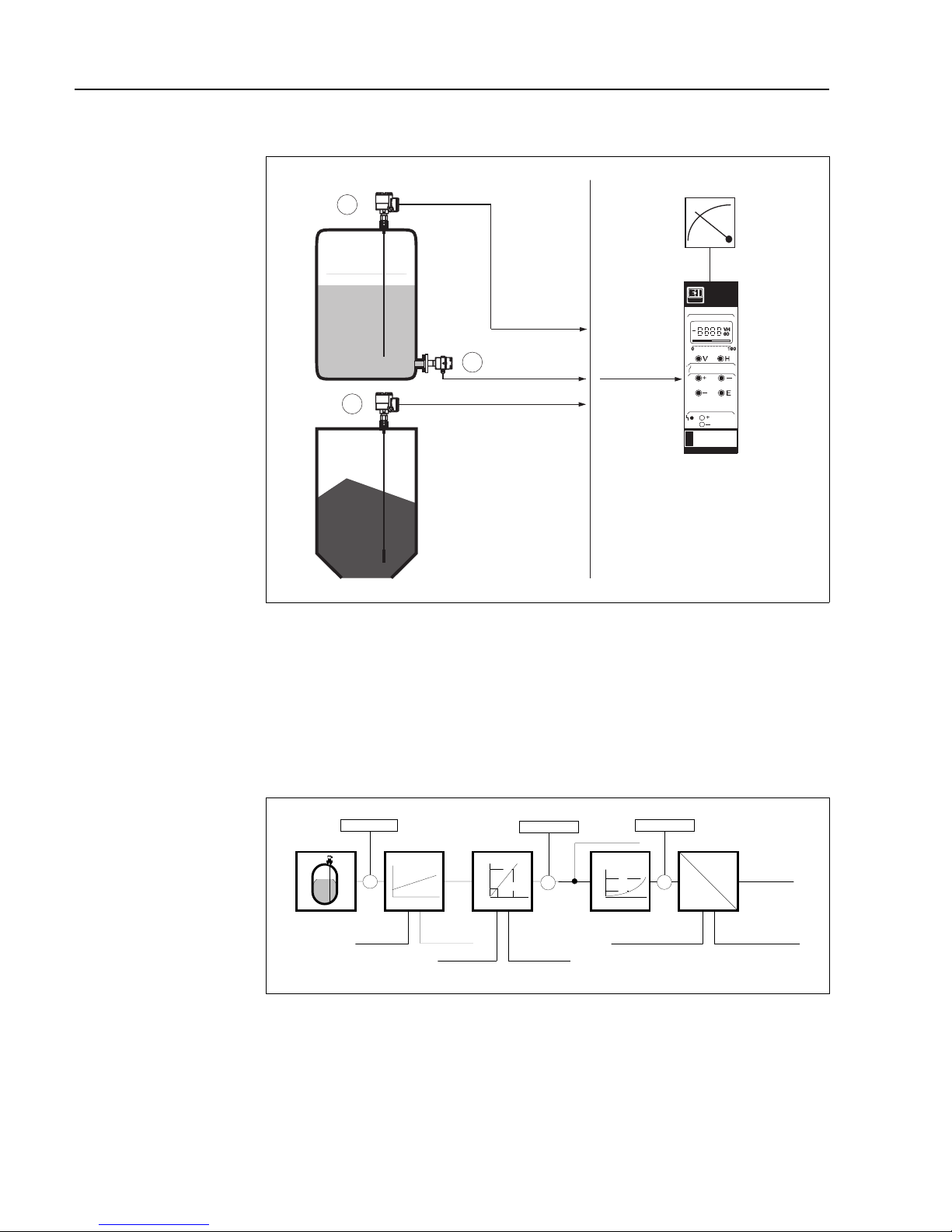

1.1 Application

The Silometer FMX 570 is designed for level measurement with a capacitance or

hydrostatic pressure probe in safe or explosion hazardous areas. It possesses an

intrinsically-safe sensor circuit conforming to EEx ia IIC and IIB. A list of certificated

combinations is to be found in »Notes on Safety« preceding this chapter. A working

system for level measurement comprises:

• Silometer FMX 570 transmitter,

• Capacitance, Multicap or Deltapilot S probe

• Electronic insert

Silometer function The capacitance or pressure measured by the sensor is converted into a frequency

signal by the electronic insert located in its head. The Silometer FMX 570 supplies the

power and receives a level-proportional frequency signal over a two-core cable. The

signal is then processed to provide a level or volume measurement.

Fail-safe operation If a fault condition is detected, e.g. a break in sensor - transmitter cable, the analogue

signal switches to -10 % or +110 % level or holds the last measured value. In addition,

the alarm relay de-energises.

2

1

1

FMX 570

mA1

0/4...20 mA,

0/2...10V

output

Silometer

FMX 570

transmitter

Liquids

Bulk solids

Channel 1

Ex non-Ex

or

or

BA119Y01

Fig. 1.1:

Standard application showing

Silometer FMX 570 controlling

level measurement

➀

Capacitance probe

➁

Deltapilot

frequency

analog

digital

current

voltage

sens. [Hz/pF]offset [Hz]

offset [pF] sens. [pF/cm]

range upper limit

V2

range lower limit

V1

frequency

electronicinsert

electronicinsert

capacit./

pressure

volume

V2

V1

level

volume

H2

H1

level

cap./press.

level

zero point shift

BA119E08

Fig. 1.2

Signal processing in the

Silometer FMX 570

Chapter 1: Introduction Silometer FMX 570

6

Page 9

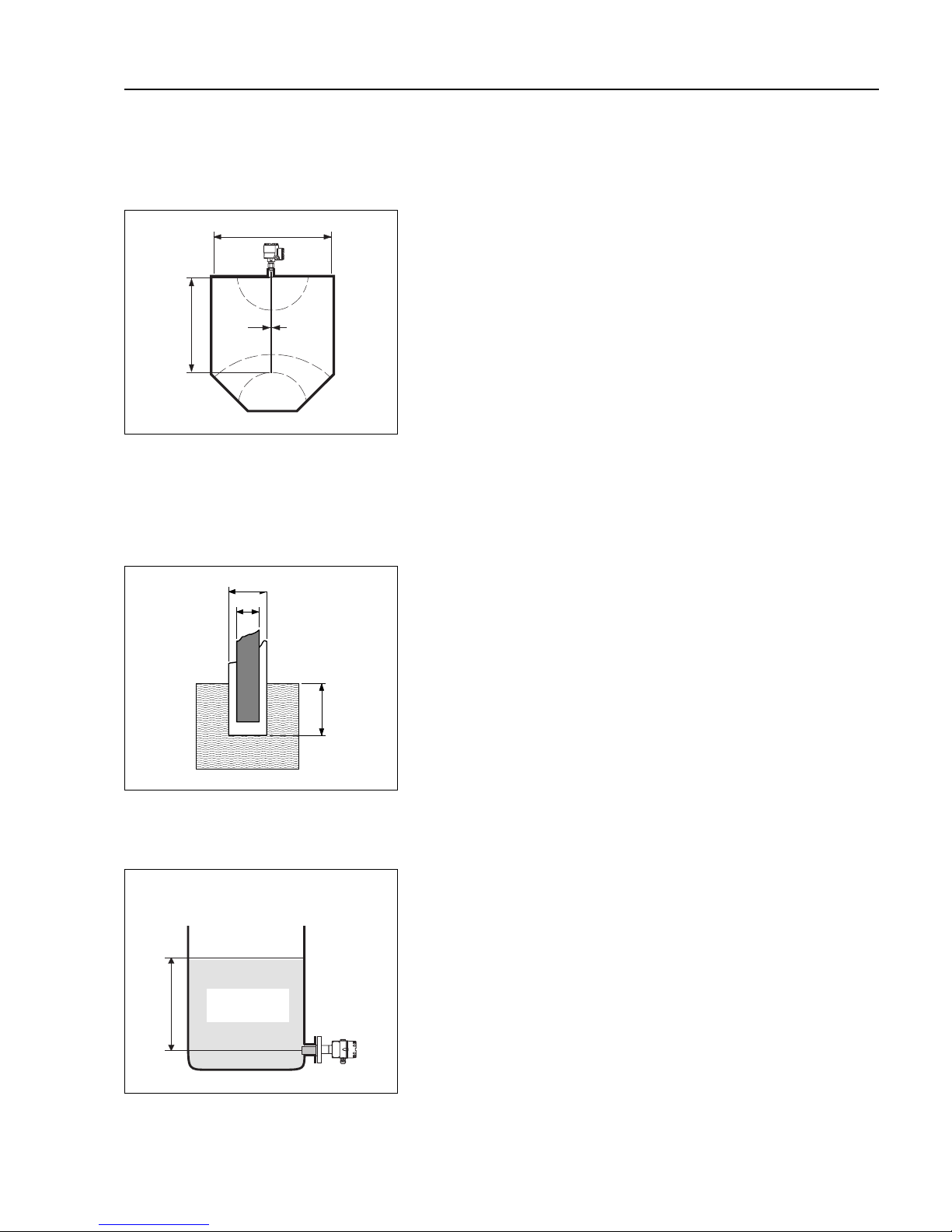

1.2 Measuring principle

The Silometer FMX 570 measures level on the basis of the capacitance and hydrostatic

measurement principles. In both cases the measured value is processed by the

electronic insert and passed on as a frequency signal.

The probe and vessel form the two plates

of a capacitor, the total capacitance of

which can then be calculated from the

formula:

C

tot

=C

1

+ 2πε0ε

r

x L pF (1)

--------------------------------

ln (D/d)

whereby

C

tot

= total capacitance

C

1

= capacitance or feed through

ε

0

= dielectric constant of air

ε

r

= rel. dielectric constant of product

D= diameter of vessel

d= diameter of probe

L= length of probe immersed in

product in meters

If the product conducts, the capacitance is

determined by the thickness and

properties of the insulating material

surrounding the probe. Equation (1)

applies, whereby the variable D is now the

diameter of the probe with insulation. In this

case the capacitance varies by approx.

300 pF/m.

Measurement is independent of dielectric

constant and not affected by changes in

this variable.

In an open vessel, the level is derived from

the hydrostatic pressure exerted by a

column of liquid on a probe placed at its

foot. The pressure exerted is:

p

1

= ρ x g x h (2)

whereby

p

1

= hydrostatic pressure

ρ = density of the liquid

g = acceleration due to gravity

h = height of the liquid column.

Assuming a constant density, the level of

the liquid can be calculated from the

pressure measured by the Deltapilot.

BA119Y05

d

L

D

C

1

Fig. 1.3

Capacitance measurement principle

BA119E06

d

Conducting

product

L

D

Fig. 1.4

Measurement in conducting media

BA119Y07

p1 = ρ x g x h

h

atmospheric

pressure

p

1

Fig. 1.5

Hydrostatic measurement principle

Capacitance

measurement

Hydrostatic

measurement

Measurement in

conducting media

Silometer FMX 570 Chapter 1: Introduction

7

Page 10

2 Installation

This Chapter describes:

• The probes for use with the Silometer FMX 570

• Silometer installation in a rack or Monorack housing

• Transmitter wiring

• Sensor connection.

• Technical data.

Warning!

• The Silometer FMX 570 transmitter must be installed outside explosion hazardous

areas.

2.1 Probes and sensors

Table 2.1 lists the probes most frequently used with the Silometer FMX 570 transmitter.

In addition to those listed, all probes which can be used with an EC 37 Z or EC 47 Z

electronic insert can be connected to the transmitter. Installation hints can be taken from

the appropriate Technical Information Sheet.

Sensor constants Deltapilot S sensors and EC 37 Z/47 Z inserts for capacitance probes are supplied with

the sensor constants zero frequency »fo« and sensitivity »∆f« or »S«. For Deltapilot S

sensors the constants are printed on a label stuck inside the sensor head, for inserts

they are printed on the name plate, see Fig. 7.1, Section 7.3.

Note these constants and enter them into fields V3H5 and V3H6 during commissioning,

Section 4.1. This dispenses with the need for a recalibration of the transmitter on

replacement of the sensor or insert.

Principle Probe TI sheet Insert

Capacitance,

Multicap

11 500 Z TI 161F

Multicap DC 11 TI 169F

Multicap DC 16 TI 096F

Multicap DC 21 TI 208F

Multicap DC 26 TI 209F

Multicap TA TI 239F

Multicap TE TI 240F

Multicap E TI 242F

Multicap A TI 243F

EC 37 Z

EC 47 Z

FEC 12

Hydrostatic pressure Deltapilot S TI 031F

DB 50...53 TI 257P

FEB 17 (P)

Table 2.1:

Selection of probes suitable for

use with the Silometer FMX 570

Cell

type

Electronic insert FEB 17/FEB 17 P

Range f

0

∆

fRange f

0

∆

f

0.1 bar BA 0…100 mbar 200 10 DA -100…100 mbar 200 5

0.4 bar BB 0…400 mbar 200 2.5 DB -400…400 mbar 200 1.25

1.2 bar BC 0…1200 mbar 200 0.833 DC -900…1200 mbar 200 0.476

4.0 bar BD 0…4000 mbar 200 0.25 DD -900…4000 mbar 200 0.204

Table 2.2:

Measuring ranges and sensor

constants of the

Deltapilot S DB 5x

Silometer FMX 570 Chapter 2: Installation

8

Page 11

2.2 Silometer installation

There are three possibilities for installing Silometer transmitters:

• Standard 19" rack with space for 12 7HP cards,

• Field housing with space for up to 6 7HP cards,

• Monorack housings for single transmitters.

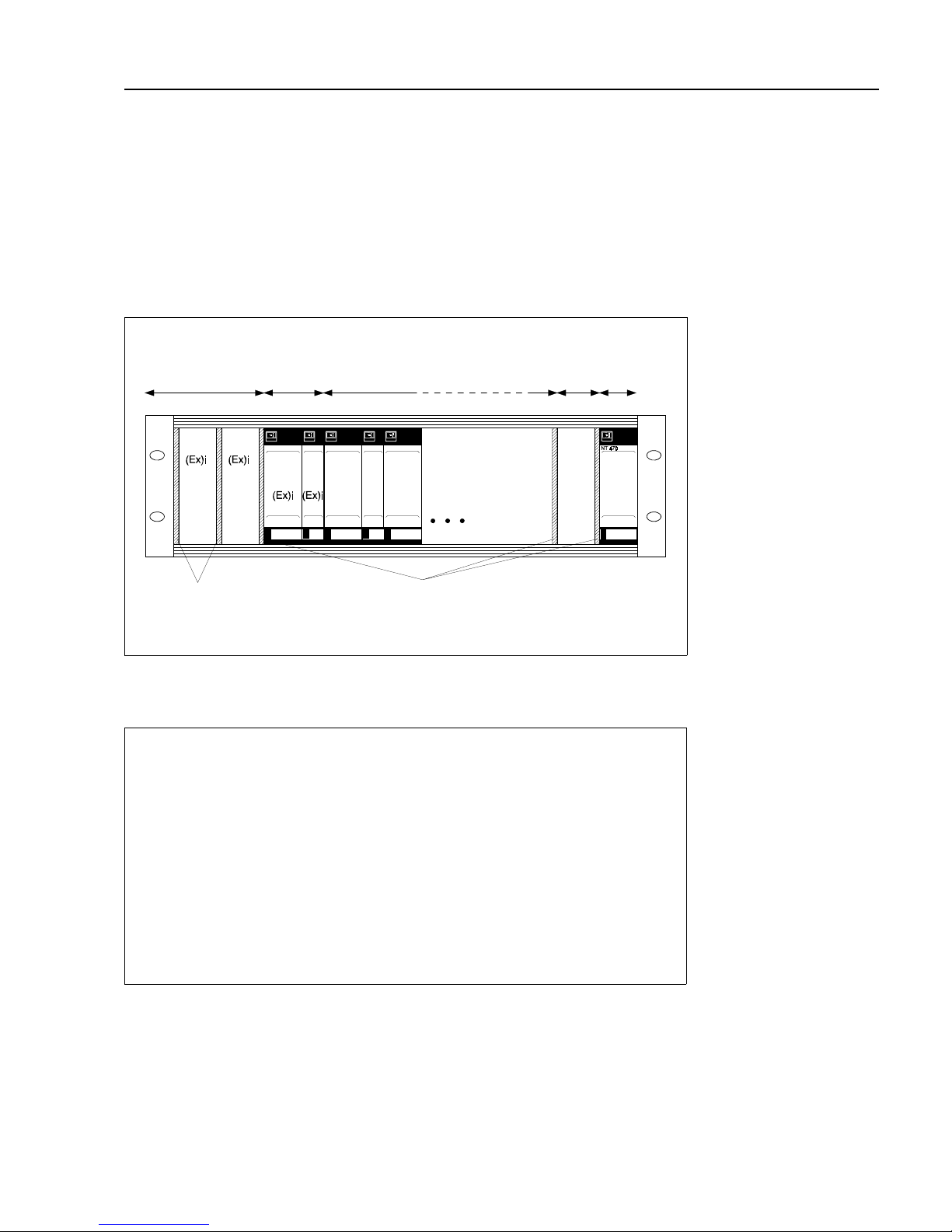

Rack installationA Racksyst system can be ordered fully wired, in which case the sensors and the external

power supply only need to be wired. Planning hints can be found in Publication

SD 041/00/e, »Racksyst Assembly Racks« .

For non-Racksyst installations and for installations including non-Racksyst cards, fill the

rack as follows (see also Fig. 2.1):

Rack arrangement

Step Procedure

1 Allocate the power supply (NT 470) at the rightmost position.

- If two NT 470s are used, install a 2 HP dummy panel between them.

2 Install non-intrinsically safe transmitters next to the power supply.

- Install a 2 HP dummy panel between all foreign transmitters and between

Racksyst cards and foreign transmitters

3 Install intrinsically safe transmitters to the left of the rack.

- Install foreign cards first.

- Install dummy panels between all foreign transmitters and between Racksyst

cards and foreign transmitters in accordance with the instructions on the

Ex-Certificate.

- No spacer is required between Racksyst cards.

Racksyst field housingInstructions for installing Commutec transmitters in the Racksyst field housing with half

19" rack are to be found in Publication PI 003.

• Check that the field housing is not installed in direct sunlight.

- If appropriate fit a protective sun cover.

• The maximum permissible ambient temperature for the field housing varies

between +50…+60 °C according to the power consumption of the cards

(0…20 W)

BA119E09

Non-E+H

(Ex)i devices

E+H (Ex)i

devices

E+H devices Non-E+H

devices

NT power

supply

Spacing between

non-E+H (Ex)i devices

as per certificate

2 HP dummy panel between

E+H and non-E+H devices

Fig. 2.1:

Recommended arrangement for

Racksyst rack assemblies

Chapter 2: Installation Silometer FMX 570

9

Page 12

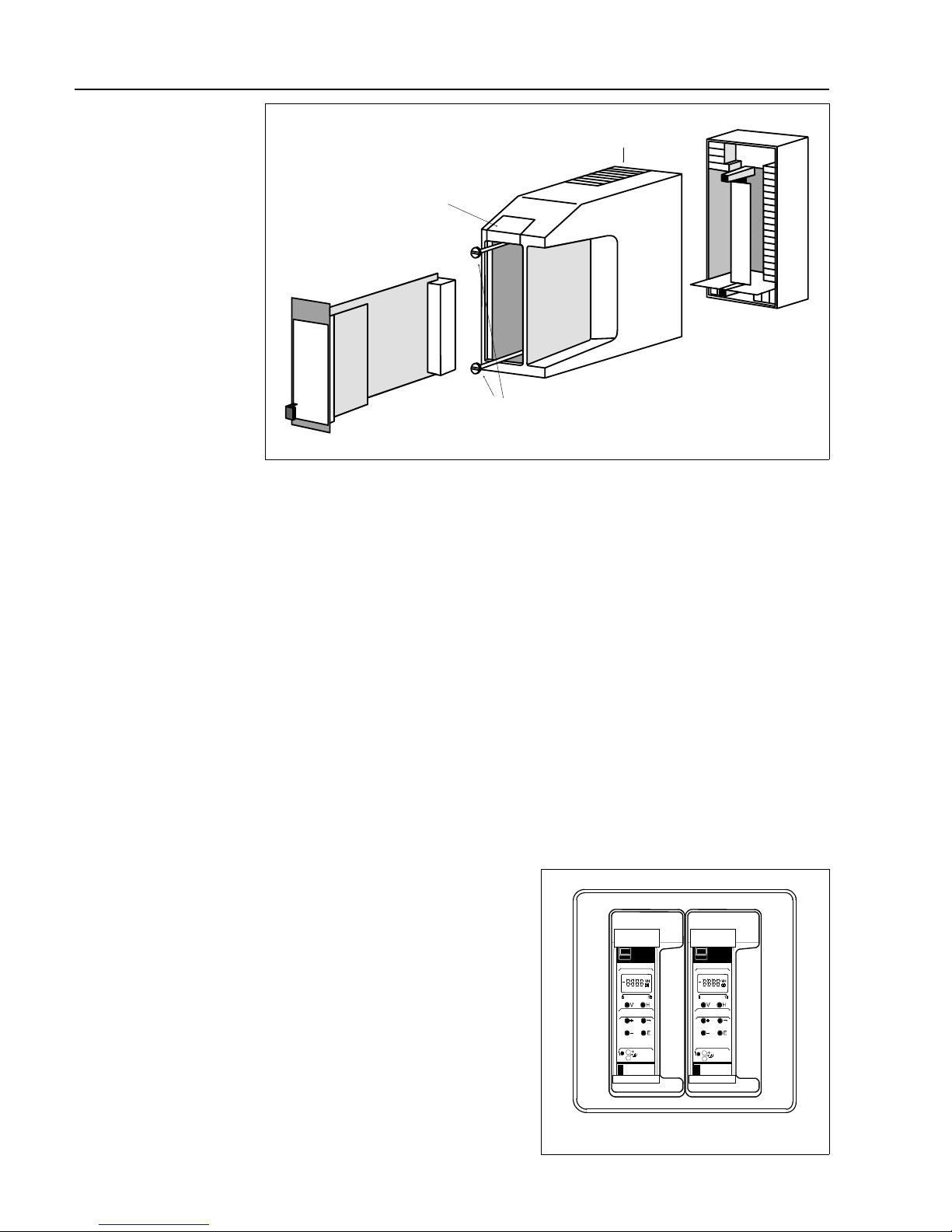

Monorack housing The Silometer FMX 570 transmitter and Monorack housing are supplied separately. The

system must be assembled as shown in Fig. 2.2 before use.

• The Monorack is prepared for wall-mounting, degree of protection IP 40.

• The site must be chosen such that the operating temperature of

-20°C…+60°C for one Monorack and -20°C…+50°C for Monorack banks is

not exceeded.

Full details of the Monorack installation procedure can be taken from the manual supplied

with it.

Monorack protective

housing

If the Silometer FMX 570 transmitter and Monorack housing are to be mounted at an

exposed site, then it is recommended that they be installed in the protective housing,

degree of protection IP 55, which is available as an accessory.

• The protective housing accomodates two Silometer FMX 570 transmitters.

• The permissible ambient temperature is -20°C…+50°C for one Monorack and

-20°C…+40°C for two.

Dimensions and instructions for installation are to be found in the Technical Information

sheet TI 099/00/e.

BA119E10

Plug-in card

Monorack

housing

Monorack base

(terminal block)

Retaining

screws

Retaining

flap

Fig. 2.2:

Assembly and disassembly of

the Monorack housing

Power

pack

Fig. 2.3:

Monorack protective housing

BA119E60

Silometer FMX 570 Chapter 2: Installation

10

Page 13

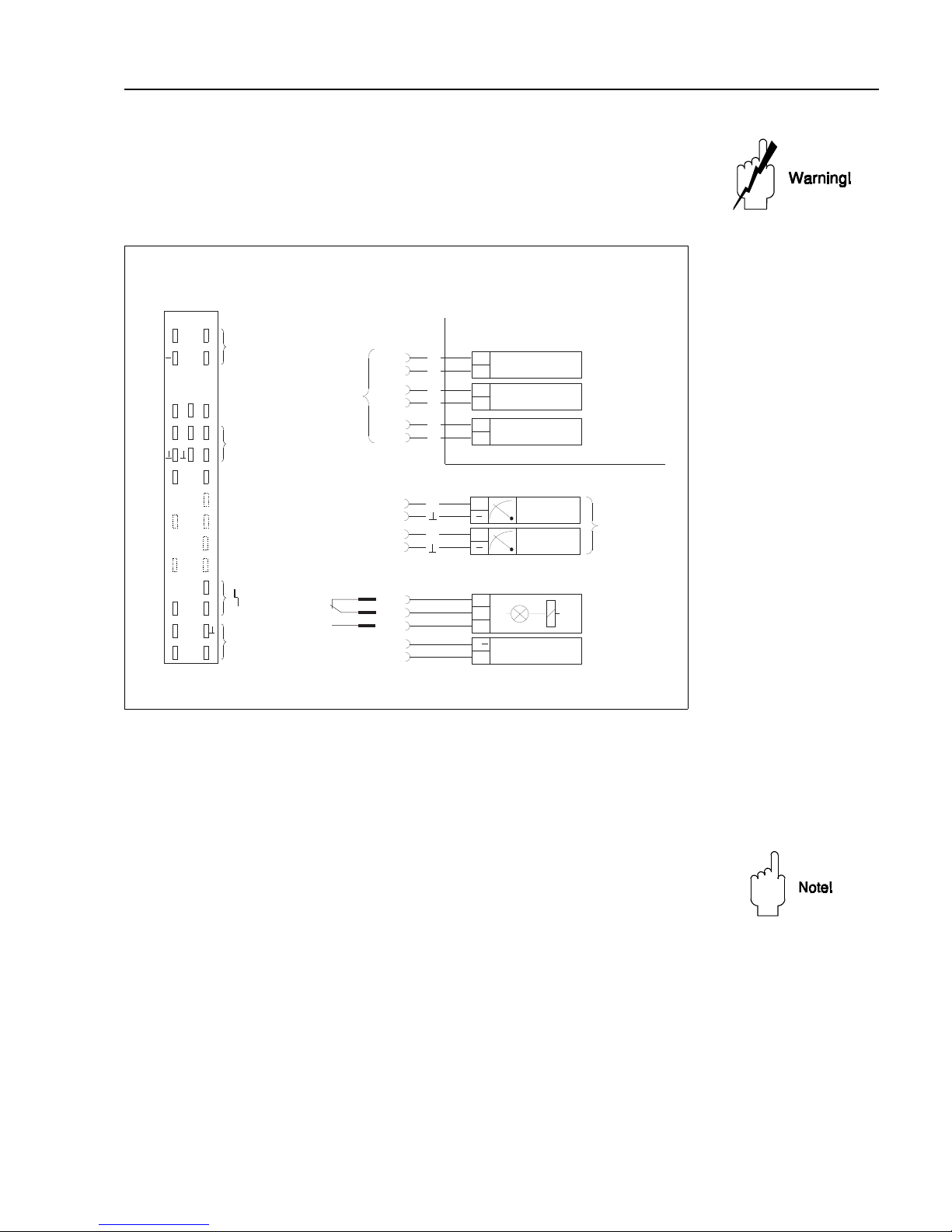

2.3 Transmitter wiring

Warning!

• Make electrical connections with the power supply switched off!

• When wiring up probes and sensors in explosion hazardous areas, observe the

instructions on the certificate and other appropriate regulations.

Rack wiringFig. 2.4 is a pin assignment diagram for the Silometer FMX 570.

• Terminals z 30, b 14 and d 14 are connected internally

• Inputs d2, d4 are electrically isolated from the circuit and each other.

• The circuit zero of the unit ( ⊥ ) is connected to the negative terminal of the

supply voltage.

Note!

• Two indexing pins, at positions 2 and 9 in the rack connector ensure that Silometer

FMX 570 transmitters only can be inserted at these points. The pins must be

inserted if the rack is not custom built by Endress+Hauser.

Analogue outputsThe negative terminal of the current output, of the voltage output and of the supply voltage

are connected to the circuit zero of the Silometer FMX 570 module.

• Any number of measurement and control units can be connected in parallel to

the voltage output, provided that all potentials are related to negative terminal

of the 24 V supply (R

L

≥ 10 kOhm).

- There is no limit to the number of floating devices, apart from that imposed

by considerations of maximum or minimum load.

• Only one non-floating device can be connected to each of the current

outputs.

d b z

+

2

4

6

8

2

1

+

-

EC 47 Z

d2

d4

3

2

+

-

FEB 17 (P)

d2

d4

2

1

+

-

EC 37 Z

d2

d4

L

L+

20 V...30 V

z30

d32

+

+

d12

d14

0/4...20 mA

+

+

b12

b14

0/2...10 V

r

z26

d28

z28

u

a

10

12 + +

14

16

32 L+

18

20

22

24

26 r

28 u a

30 -L

Analogue

outputs

Alarm relay

Power supply

Level,

volume

BA119Y11

Alarm relay

FMX 570

Non-Ex- area

Input

DC supply

Deltapilot S

Ex-area

Current

Voltage

Capacitance/

Multicap probe

Capacitance/

Multicap probe

Input

Fig. 2.4:

Pin assignment diagram for

Silometer FMX 570

Chapter 2: Installation Silometer FMX 570

11

Page 14

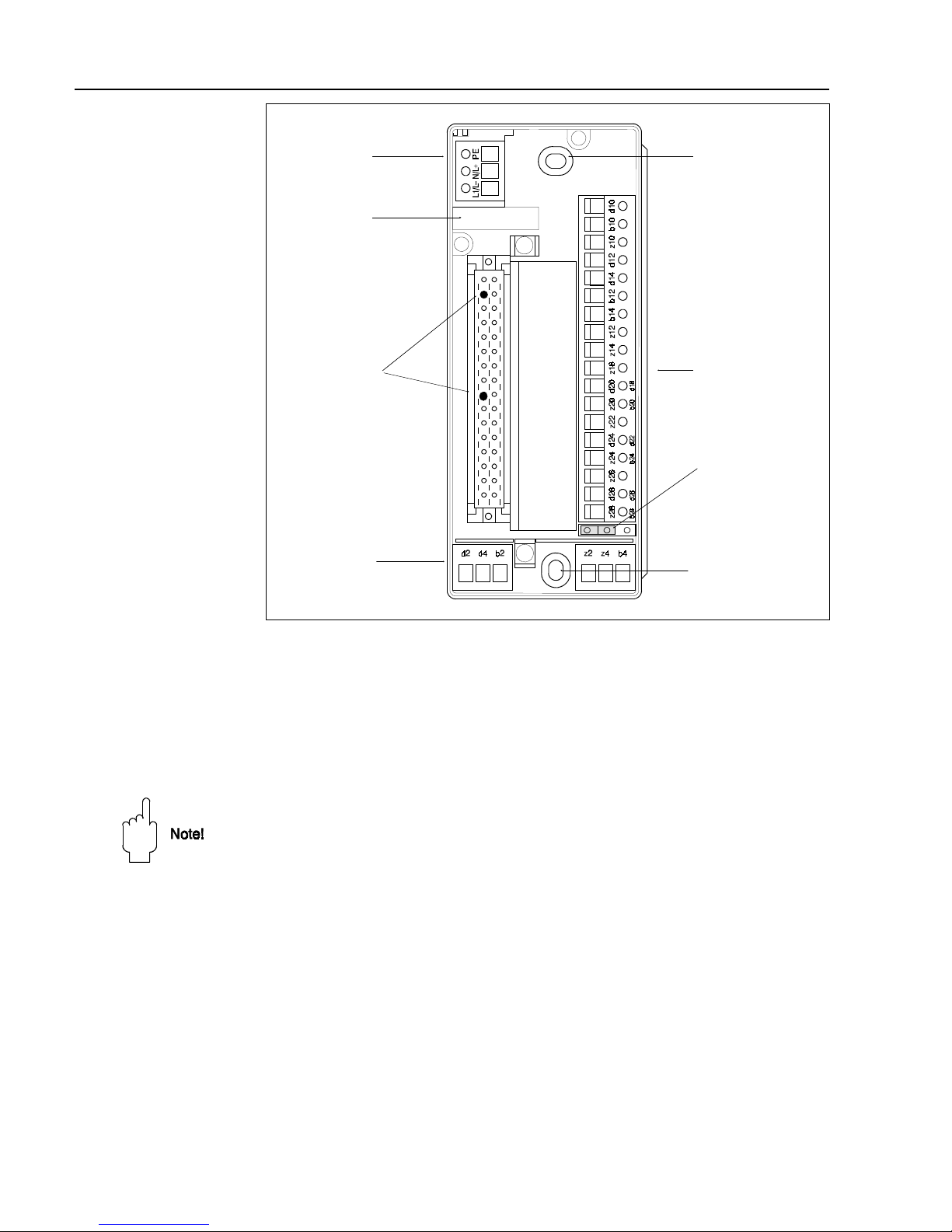

Monorack wiring Fig. 2.5 shows the layout in the base of the Monorack II housing, the pin assignments

correspond to those in Fig. 2.4. When connecting together several Monoracks, follow

the instructions supplied with the housing.

• Set the jumper to position "Racksyst I"

• Insert the coding pins supplied at positions 2 and 9 in the female connector

at the base of the housing.

• The pin assignments printed in black are valid for the Silometer FMX 570.

Note!

If you are installing the Silometer FMX in a Monorack I housing, please note that there is

no jumper switch. In addition, for the 24 VDC version, the dummy card in the power

control slot must be replaced by the 24 V card supplied.

PC board

slot

BA119E14

Power

Outputs

see Fig. 2.4

Input, d2, d4

Insert coding pins

for Z-version at

Positions

2 and 9

Hole for mounting

screw

Hole for mounting

screw

Jumper positioned

for Racksyst I card

Fig. 2.5:

Layout of Monorack terminal

blocks

Silometer FMX 570 Chapter 2: Installation

12

Page 15

2.4 Sensor connection

The Silometer FMX 570 can be operated with a variety of sensor types, each requiring

a different electronic insert, e.g.:

• EC 37 Z or EC 47 Z for capacitance and Multicap probes

• EB 17 Z or EB 27 Z for Deltapilots

Sensor cableUse commercial 2-core installation cable, max. line resistance 25 Ω/core, for the sensor/

transmitter cable. If electromagnetic interference is to be expected, we recommend

• that the PFM negative line be grounded at the sensor (check Ex-regulations)

• in case of heavy interference, that shielded cable be used, grounded at both

ends.

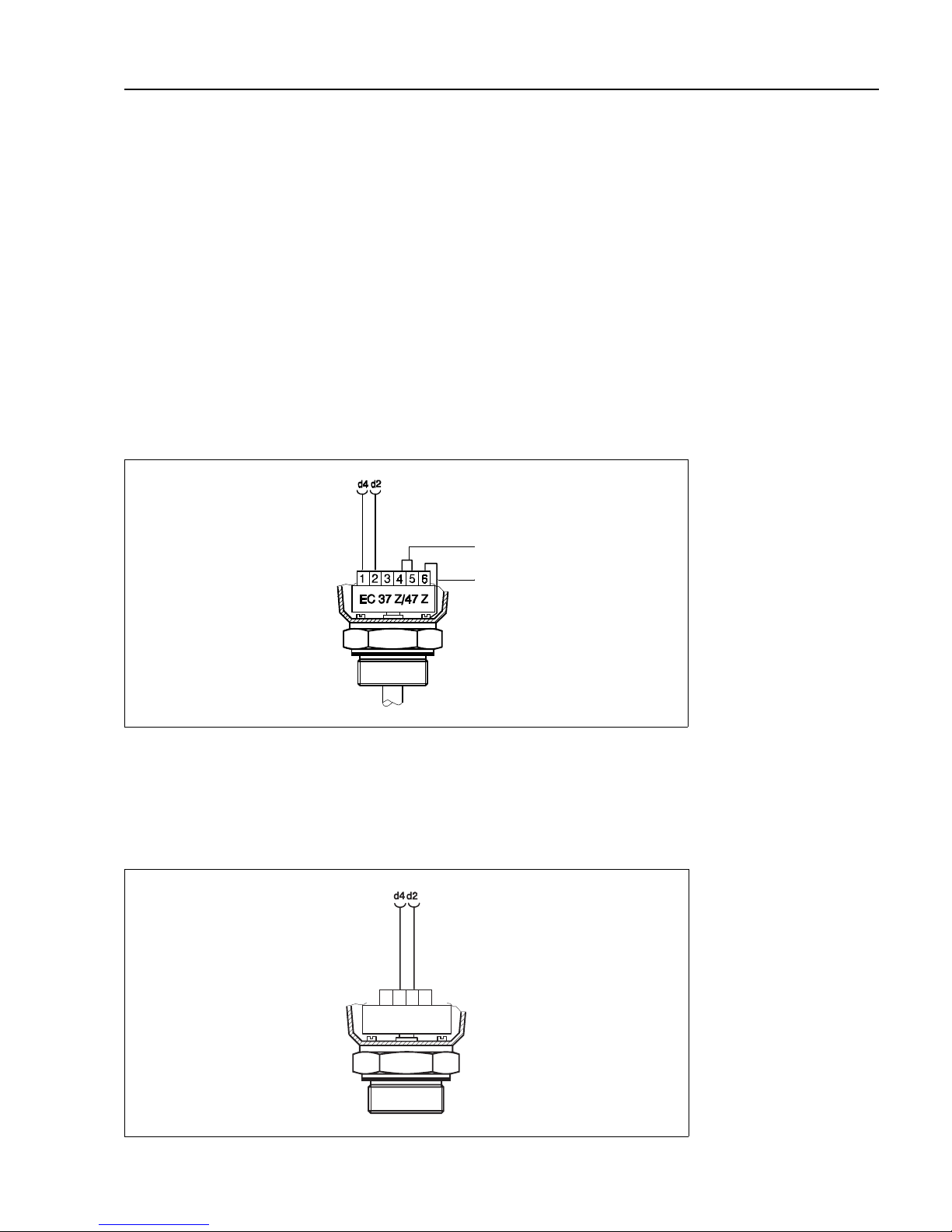

EC 37 Z and EC 47 ZThe electronic inserts EC 37 Z and EC 47 Z have two measuring ranges which can be

selected by inserting a bridge between terminals 4 and 5 of the insert, see Fig 2.6. Full

instructions on the selection of the insert are to be found in Publication E 07.80.06/1c.

• Note the zero frequency f

o

____ and sensitivity S_____on the insert.

FEB 17 (P)The FEB 17 (P) electronic insert can be used with Deltapilot S sensors to measure level

and volume in open vessels.

• Note the zero frequency f

o

_____ and sensitivity ∆f _____ of the probe

(see Table 2.2 on page 8)

BA119E15

Insert bridge for

Range II (standard)

Remove for Range I

Ground

connection

FMX 570 input

Fig. 2.6:

Connection diagram for

electronic inserts

EC 37 Z/EC 47 Z

FEB 17/FEB 17 P

1234

BA119Y18

FMX 570 input

Fig. 2.7:

Connection diagram for

electronic insert

FEB 17 (P)

Chapter 2: Installation Silometer FMX 570

13

Page 16

2.5 Technical data: Silometer FMX 570 transmitter

Construction

• Design: 19", 7 HP, plug-in card

• Front panel: black synthetic with blue field inlay, grip and markings,

Protection: IP 20 (DIN 40050)

• Dimensions: see diagram

• Weight: approx. 0.3 kg/11 oz

• Operating temperature: -0 °C...+70 °C/+32 °F..158 °F

Storage temperature: -20 °C...+85 °C/-4 °F...185 °F

Electrical connection

• Multipoint plug: conforming to DIN 41612, Part 3, Type F (28-pole)

Coding pins in positions 2 and 9

• Power supply: 24 V DC (+6 V…-4 V); residual ripple 2 V, within tolerance

• Supply current: approx. 90 mA, max. 125 mA

• Signal inputs: Electrically isolated from the rest of the circuitry.

Protection [EEx ia] IIC or IIB

• Probes: Capitance probes, impedance probes

with EC 37 Z or EC 47 Z electronic insert

Deltapilot S with electronic insert FEB 17 / FEB 17 P

• Electromagnetic Interference Emission to EN 61326, Electrical Equipment Class A

compatibility: Interference Immunity to EN 61326

Outputs

• Analogue output: 0...20 mA/4...20 mA selectable, R

L

max. 500 Ω

0...10 V/2...10 V selectable, R

L

min. 10 k Ω

• Alarm relay relay with a potential-free change-over contact

Max. switching capacity:

2.5 A, 250 VAC, 300 VA at cos ϕ > 0.7 or

100 VDC, 90 W

Certificates

• Silometer FMX 570 Intrinsically safe circuit to [EEx ia] IIC and IIB

(PTB certification in preparation)

see also »Safety Notes«.

BA119E22

Fig. 2.8

Silometer FMX 570 plug-in card

Silometer FMX 570 Chapter 2: Installation

14

Page 17

3 Controls

This Chapter describes how the Silometer FMX 570 transmitters are operated. It is

divided into the following sections:

• Commutec operating matrix

• Configuration and display: Silometer FMX 570

3.1 Commutec operating matrix

All functions, including the analogue outputs and relay switch points are configured via

the operating matrix, see Fig. 3.1:

• Each field in the matrix is accessed by a vertical (V) and horizontal (H)

position which can be entered at the front panel of the FMX 570 with the

V and H keys

• The parameters are entered with the plus, minus, arrow and enter keys.

Parameter at current matrix

position

Pressed together

Move to V0H0

Move H0 …H9, H0

Move V0…V9, V0

BA119E25

Current matrix position

Fig. 3.1:

Silometer FMX 570 display

Parameter matrix operation with

function of V and H keys.

The complete matrix has 10 x 10

fields, although not all are used

Silometer FMX 570 Chapter 3: Controls

15

Page 18

3.2 Configuration and display

Fig. 3.1 shows the LC-display with matrix of the Silometer FMX 570, Fig. 3.2 its front panel.

Table 3.1 below describes the function of the operating keys.

• Changes are not possible if the matrix has been locked (Section 4.7).

• Non-flashing parameters are either read-only indications or locked entry fields.

0 100

VH

00

VH

+

E

FMX 570

m

Measured value display with

10-step bar chart showing

percentage 0/4 …20 mA signal

Parameter entry keys

Alarm relay LED

•

Lights on fault condition,

relay de-energises

•

Flashes on warning,

relay remains energised

Matrix selection keys

Matrix position indicator

BA119E23

Test sockets for

0/4…20 mA current output

Fig. 3.2:

Front panel of the

Silometer FMX 570 transmitter

Keys Function

Matrix selectio n

•

Press V to select the vertical position.

•

Press H to select the horizontal position

•

Press simultaneously to select the measured value field, V0H0

Parameter entry

•

Select the digit to be changed.

The digit at the extreme left is selected and flashes.

•

Move to the next digit by pressing »⇒« again. When the last digit

is reached »⇒« selects the leftmost digit again.

•

To change the position of the

decimal point

, press down both

»⇒« and »+«. The decimal point moves 1 space to the right.

•

Increases the value of the flashing digit

•

Decreases the value of the flashing digit

•

To enter a

negative number

decrease the leftmost digit until a

minus sign appears in front of it

•

Press »E« to register entry.

•

Unregistered entries remain ineffective and the instrument will

operate with the old value.

+

+

Table 3.1:

Silometer FMX 570

Parameter entry and display keys

Chapter 3: Controls Silometer FMX 570

16

Page 19

4 Calibration and Operation

This chapter is concerned with the basic settings of the Silometer FMX 570 which allow

it to operate for continuous level measurement. The principle sections describe:

• Commissioning

• Calibration for level measurement

• Calibration for linear volume or weight measurement

• Dry calibration for Deltapilot probes

• Level offset

• Display of measured values

• Locking the parameter matrix.

The linearization for volume or weight measurements is described in Chapter 5, the

setting of the analogue outputs in Chapter 6 and the controls in Chapter 3.

Note your settings!When configuring, note your parameters in the Table in the rear cover.

• If the transmitter is ever replaced, these parameters can be entered at the

front panel. The transmitter will then measure correctly without the need for

another calibration.

4.1 Commissioning

If programming the module for the first time, reset the module to the factory based

parameters, see Table in back cover. Then enter the probe constants fo and S (∆f). This

ensures that the EC 37 Z/EC 47 Z electronic insert or Deltapilot can be replaced without

the need for recalibration, see Section 7.3.

Step Matrix Entry Significance

1 V9H5 e.g. 672 Enter any number 670…679 to reset transmitter

2 - »E« Register change

3 V3H5 e.g. 475.3 Enter zero frequency f

o

(offset) of electronic insert or sensor

4 - »E« Register change

5 V3H6 e.g. 0.652 Enter sensitivity, S or ∆f, of electronic insert or sensor

6 - »E« Register change

Operating modeThe operating mode is set at V8H0. Since the default value corresponds to level

measurement, this step can be omitted if the transmitter has been reset.

For a recalibration without reset check that mode 1, is on display:

• 1 = continuous level measurement, Sections 4.2, 4.3, 4.4.

• 6 = simulation, see Chapter 7, Section 7.2.

Step Matrix Entry Significance

1 V8H0 e.g. 1 Mode 1, continuous level measurement

2 - »E« Register entry

Chapter 4: Calibration and Operation Silometer FMX 570

17

Page 20

4.2 Calibration for level measurement

This calibration requires the determination of two parameters,

• an »empty« level at V0H1,

• a »full« level at V0H2.

After calibration If the level is entered in %, after the calibration:

• % level is displayed at V0H0

• the 0/4…20 mA signal range corresponds to 0…100% level

• the parameters »offset« and »sensitivity« are calculated and stored at

V3H1/V3H2.

If the level is entered in m, ft. etc. the analogue outputs must be set in the same units,

see Chapter 6.

Procedure

Step Matrix Entry Significance

1 V0H1 e.g. 10% Fill the vessel until the probe is covered (ca. 0…40%) and

enter the level you wish to have displayed.

2 - »E« Register entry

3 V0H2 e.g. 95% Fill the vessel as far as possible (ca. 60…100%) and

enter the level you wish to have displayed.

4 - »E« Register entry

5 V0H0 The measured value is shown in the units selected.

Note!

• The calibration can be performed in reverse order

• For bulk solids, the probe measures the depth of emersion in the product only.

Account for any filling mound or outflow depression by the entered levels.

• For the Deltapilot S (liquids only), a »dry calibration« can be made see Section 4.4.

• If appropriate, a linearization can now be carried out, see Chapter 5.

»Full« V0H2

e.g. 95% or 5 m

BA119Y27

Capacitance probe

Capacitance probe

»Empty«, V0H1

e.g. 10% or 0.5 m

Fig. 4.1:

Parameters required for

calibration of the Silometer

FMX 570 for level measurement

shown for bulk solid

measurement.

Any filling mound or outflow

depression can be accounted for

by the parameters entered.

Silometer FMX 570 Chapter 4: Calibration and Operation

18

Page 21

4.3 Calibration for linear volume or weight measurement

The Silometer FMX 570 can also be calibrated in volume or weight units, e.g. in litres,

hectolitres, gallons, %vol, tonnes or kg. After calibration volume (or weight) is displayed

at V0H0. The analogue output must be set in the same units, as described in Chapter 6.

If the level/volume relationship is not linear, i.e. the tank is a horizontal cylinder or has a

conical outlet, the volume calibration is performed as part of the linearization procedure.

In this case, before proceding further, turn to Chapter 5, Section 5.1 or 5.2 to determine

the correct order of parameter entry.

Procedure

Step Matrix Entry Significance

1 V0H1 e.g. 50 hl Fill the vessel until the probe is covered (ca. 0…40%) and

enter the volume (or weight) you wish to have displayed.

2 - »E« Register entry

3 V0H2 e.g. 450 hl Fill the vessel as far as possible (ca. 60…100%) and

enter the volume (or weight) you wish to have displayed.

4 - »E« Register entry

5 V0H0 The measured value is shown in the units selected.

Note!

•

The calibration can be performed in the reverse order.

•

If the level/volume relationship for the vessel is not linear, first see Chapter 5.

BA119Y28

Volume » E mp ty«

V0H1, e.g. 50 hl

e.g. Deltapilot S

e.g. Capacitance

probe

Volume »full«

V0H2, e.g. 450 hl

Fig. 4.2:

Parameters required for

calibration of the

Silometer FMX 570.

Example for volume

measurement of liquids with

capacitance probe or hydrostatic

pressure sensor

Chapter 4: Calibration and Operation Silometer FMX 570

19

Page 22

4.4 »Dry calibration« for open vessels (Deltapilot)

It may not always be possible to fill and empty the vessel for the calibrations as described

in Sections 4.2 and 4.3. To cover this eventuality the Silometer FMX 570 can be calibrated

»dry« by using the sensor constants. For this alternative calibration you need:

• the »zero frequency« and »sensitivity« of the sensors,

• the »empty« level or offset at which the measurement should start

• the maximum height of the liquid column and

• the density of the liquid.

Caution!

• Check the calibration during the first filling of the tank! If your calculations are

incorrect the levels measured will be incorrect also!

Sensor constants f

o

, ∆f

V3H5/V3H6

The sensor constants »f

o

« and »∆f«, see Section 2.1, are to be found in Table 2.2 on

page 9. For the theoretical calibration, however, it is recommended that the zero

frequency of the installed Deltapilot S at atmospheric pressure is read from V0H8.

Step Matrix Entry Significance

1 V3H5 e.g. 99.5 Enter »f

o

« value (read from V0H8)

2 - »E« Register entry

3 V3H6 e.g. 1.02 Enter »∆f« value

4 - »E« Register entry

Note!

• The zero frequency of the sensor is in fact dependent upon the sensor orientation,

so that there may be a slight difference between the value read from Table 2.2 and

that of the factory calibration which is printed in the sensor housing. This effect is

compensated during the standard calibration, where the factory values are used.

VH

00

VH

00

2000

50

BA119Y61

Sensitivity V3H2

measurement span

display span

Offset V3H1

P = ρ x g x ∆h

Empty, e.g. 50 hl

Max. level e.g. 10 m

= 980.7 mbar

Max. display, e.g. 2000 hl

Fig. 4.3:

Parameters for dry calibration

with Deltapilot probes

Silometer FMX 570 Chapter 4: Calibration and Operation

20

Page 23

Offset and sensitivity of

the display, V3H1/V3H2

The entry of values in V3H5/V3H6 adapts

the Silometer to the application. It now

knows which pressure is associated with a

particular frequency. The next step is to

adapt the display, i.e. the measuring range

is fixed. This requires the entry of:

• the offset in

mbar

in V3H1

The offset is the pressure in mbar

which acts on the sensor when the

display reads »0«, i.e.

V3H1 = p

zero

• the sensitivity in

mbar/digit

in V3H2

The sensitivity determines the change

in the measured value ∆h in V0H0 per

mbar change at the sensor, i.e.

V3H2 = ∆p/∆h = (p

2

- p1)/(h2 - h1)

• the pressures: p

mbar

= 10 x ρ (kg/dm

3

) x g (m/s

2

) x ∆h (m)

Example 1:Example: For 0.45 m water display = 0%, for 10 m water, display = 100%

• Maximum display = 100%

• Determine pressures

p

zero

= 10 x 1.0 x 9.807 x 0.45 = 44.13 mbar

p

100%

= 19 x 1.0 x 9.807 x 10 = 980.7

• Sensitivity = ∆p/∆h

= (980.7 - 44.13)/(100 - 0) = 936.6/100 = 9.366 mbar/%

• Offset, V3H1 = 44.13 mbar

Sensitivity, V3H2 = 9.366 mbar/%

Example 2:Example: For 0.45 m water display = 50 hl, for 10 m water, display = 2000 hl

• Maximum display = 2000 hl

• Determine pressures

p

50 hl

= 10 x 1.0 x 9.807 x 0.45 = 44.13 mbar

p

2000 hl

= 19 x 1.0 x 9.807 x 10 = 980.7

• Sensitivity = ∆p/∆h

= (980.7 - 44.13)/(2000 - 50) = 936.6/1950 = 0.4803 mbar/hl

• Since 50 hl is displayed for 0.45 m water,

p

zero

has to be calculated

p

zero

= p

50 hl

- h1 x sensitivity

= 44.14 - 50 x 0.4803 = 44.13 - 24.01 = 20.12

• Offset, V3H1 = 20.12 mbar

Sensitivity, V3H2 = 0.480 mbar/hl

»Dry calibration«,

Sensor adjustment

Step Matrix Entry Significance

1 V3H1 e.g. 20.12 Enter offset (V0H0 displays 50 for 45 cm water)

2 - »E« Register entry

3 V3H2 e.g. 0.480 Enter sensitivity

4 - »E« Register entry

5 V0H0 The measured value is displayed in the units selected

Probe sensitivity ∆F,

V3H6

P/mbar

level

measurement span

display span

Offset

V3H1

Zero frequency

f/Hz

BA119E62

Fig. 4.4:

Parameters for dry calibration with Deltapilot probe

Chapter 4: Calibration and Operation Silometer FMX 570

21

Page 24

4.5 Level offset value

The calibration determines the level displayed at V0H0 for a particular head of liquid. By

entering a level offset at V3H4 the displayed value can be corrected by the value entered.

• The offset is

subtracted

from the true measured value

• It must be entered in the units you have used for calibration

• The analog output settings must be changed to follow the corrected

measurement.

For example, the Silometer FMX has been calibrated to display 0.0 at the level shown in

Fig. 4.5. Sometime later it is decided that the true volume measured from the bottom of

the tank is to be measured, i.e. when the liquid reaches the calibrated zero level, the

display must indicate say 250 m

3

. The value -250 is entered:

Step Matrix Entry Significance

1 V3H4 e.g -250 Enter amount by which the display is to be corrected in

the units used for calibration

2 - »E« Register entry

3V0H0

…

The corrected value is displayed (+250 instead of 0 at 0)

Note!

• The offset can also be used if a linearization has been performed. In this case, the

offset is first subtracted from the »level« displayed at V0H9 and the result converted

to the volume to be displayed at V0H0.

BA119Y59

After offset = -250

Volume 250 m

3

Display 250 m

3

Before offset

Volume 250 m

3

Display 0.000

Fig. 4.5:

Effect of level offset on display at

V0H0 for level measurement

without linearization

Silometer FMX 570 Chapter 4: Calibration and Operation

22

Page 25

4.6 Measured value display

During normal operation the measured value can be read at V0H0 In addition to this,

several other fields contain system information which might be needed, e.g., for

trouble-shooting. Table 4.1 summarizes the measured value displays.

4.7 Locking the parameter matrix

When all parameter entries have been made (see also Chapters 5…6) the matrix can be

locked by entering a code number.

Step Matrix Entry Significance

1 V8H9 e.g. 888 Enter any code from 100 - 669 or from 680 - 999

2 - »E« Register entry

In this mode, all entries can be displayed but not changed.

• The lock is released when a number between 670 and 679, e.g. 672, is

entered into the matrix at the same position.

Channel 1 Measured value Remarks

V0H0 Level or volume Display in %, m, ft, hl, m

3

, ft3, t etc. according to

calibration and/or linearization.

The entries for the 0/4 mA and 20 mA value at V0H5

and V0H6 control the 10-step LCD bar diagram.

V0H8 Current measuring

frequency

Displays the frequency which is actually measured

by the probe. Can be used as a fault check (must

change as level changes)

V0H9 Measured value before

linearization

Indicates level in the units used for calibration or

before linearization

V9H0 Current error code Error code of fault with highest priority appears on

fault condition, alarm LED lights or blinks

V9H1 Last error code The previous (corrected) error code can be read and

deleted here - press »E« to delete

V9H3 Software version with

instrument code

The first two figures indicate the instrument, the last,

the software version; 33 = Version 3.3

Table 4.1:

Matrix positions of measured

value displays

Chapter 4: Calibration and Operation Silometer FMX 570

23

Page 26

5 Linearization

For tanks in which volume is not directly proportional to level, e.g. for horizontal cylinders

or tanks with conical outlets, the linearization converts the level measurement into a

measurement of capacity.

Parameters for linearization are selected and entered at fields V2H0…V2H8. In addition,

the field V3H0 determines whether the associated calibration is to be performed in level

or volume units (0 = level …default, 1 = volume). The following linearization modes can

be entered at V2H0:

0 = linear, default value

1 = horizontal cylinder

3 = manual entry

4 = cancel current setting

The modes horizontal cylinder and manual entry for conical outlets are described in

Sections 5.1 and 5.2, all others in Section 5.3.

Two important rules must be observed when performing a linearization:

• All level (or volume) entries must be made in the units you have chosen for

calibration at V0H1 and V0H2.

• The levels for linearization and calibration must be referenced to the same

datum point.

After linearization After linearization:

• The volume of liquid currently in the tank can be read from V0H0.

• The level before linearization can be read from V0H9.

• The 0/4…20 mA signal range must be set in the volume units entered,

see Chapter 6.

30.00

VH

00

133.0

VH

00

7.000

VH

00

VH

00

120.0

BA119Y63

»Empty« = 10%

»Full« = 90%

»Empty« = 35 hl

»Full« = 500 hl

»Empty« = 0.5 ft

»Full« = 9 ft

»Empty« = 20 gal

»Full« = 150 gal

Fig. 5.1:

Linearization for a vessel with a

conical outlet

Chapter 5: Linearization Silometer FMX 570

24

Page 27

5.1 Linearization for a horizontal cylindrical tank

Use this mode if you have a cylindrical tank which lies horizontally. The Silometer

FMX 570 transmitter uses a stored linearization table which requires the entry of the tank

diameter, tank volume for its volume calculations.

Procedure

Step Matrix Entry Significance

1 V9H5 e.g. 672 Reset, see Section 4.1 (default = operating mode 1)

- Enter sensor constants at V3H5 and V3H6

2 - »E« Register entry

3 V3H0 e.g. 0 Select units to be used for calibration: 0 = level, 1 = volume

4 - »E« Register entry

5 V2H7 e.g. 10 Enter tank dia. (for level, in units to be used for calibration)

6 - »E« Register entry

7 V2H8 e.g. 200 Enter tank volume in the units you require

- If 100 is entered, the system measures in % vol.

8 - »E« Register entry

9 V2H0 1 Select horizontal cylinder mode

10 - »E« Press »E« to activate linearization

11 V0H1/V0H2 - Calibrate for level or volume , see Section 4.2 or 4.3.

12 V0H0/V0H9 - V0H0 indicates volume, V0H9 level before linearization

Note!

• For capacitance or Multicap probes a ground tube is necessary or the liquid must

be conducting.

• If a level calibration is made, V3H0 = 0, the calibration can preceed the linearization.

• If the calibration is to be in

volume units

(V3H0 = 1),

the sequence of steps must be

exactly as shown above.

• When V3H0 = 1, the entry at V2H7 fixes the end value for the level display at V0H9.

BA119Y41

Units must correspond to

those used for calibration

Diameter: V2H7

Volume V2H8

Max. measuring range

0%

»Empty«

V0H1, e.g.

20%

10%

80%

100%

level

(V0H9)

volume (V0H0)

»Full«

V0H2, e.g.

80%

Fig. 5.2:

Parameters required for

linearization of the Silometer

FMX 570 for a horizontal cylinder

Silometer FMX 570 Chapter 5: Linearization

25

Page 28

5.2 Linearization for a tank with conical outlet

Manual entry

V2H0 = 3

This option allows you to enter your own characteristic, whereby two possibilities exist

for entering the level values:

• By hand: in this case both level and volume/weight parameters should be

calculated and entered in a table prior to configuration. A level calibration can

always be performed.

• Automatically: the tank is filled or emptied in known volume increments and

the measured level is written into V2H4 by the system. This method can be

used when the level/volume relationship is not known.

The automatic mode can also be used if you can calibrate in volume units only: perform

the volume calibration first, e.g. when filling the tank, followed by the linearization with

»level registration« e.g. when emptying the tank. In this case, however, the »level« values

displayed at V0H9 have no significance. The entry mode is selected at V2H1:

• 0 = manual,

• 1 = automatic.

At the end of the linearization the system measures in the volume/weight units selected,

e.g. m

3

, ft3, t, %. Use the Table overleaf to enter your values.

Note!

• You must enter at least two points:

- The first level point should be below or at the level of the sensor. If it is not and the

level drops below the first point, the linearization will extrapolate back!

- The last level point should be greater than or equal to the maximum level to be

measured.

- The maximum value is 9998; 9999 cancels the entry.

• The maximum number of points is 30

• When all points have been entered and the linearization is activated, the points are

sorted in rising volume and subjected to a plausibility check!

level (m)

V0H9

Datum level for

calibration and

linearization

units of volume V0H0

Max. level = 4.75 m

10 m 0

20.5 m 2

31.0 m 10

41.5 m 27

5 4.25 m 220

6 4.75 m 260

BA119Y40

0.0

1.0

2.0

3.0

4.0

50 100 150 200 250

»Empty« = 1m

»Full« = 4.25 m

Fig. 5.3:

Linearization for a vessel with a

conical outlet

Chapter 5: Linearization Silometer FMX 570

26

Page 29

No.

V2H2

Volume

V2H3

Level

V2H4

No.

V2H2

Volume

V2H3

Level

V2H4

116

217

318

419

520

621

722

823

924

10 25

11 26

12 27

13 28

14 29

15 30

Procedure

Step Matrix Entry Significance

1 V9H5 e.g. 672 Reset transmitter (default = operating mode 1)

- Enter sensor constants at V3H5 and V3H6

2 - »E« Register entry

3 V0H1/V0H2 - Calibrate as described in e.g. Section 4.2

4 V2H1 0 Select manual entry of values

5 - »E« Register entry

6V2H21…30 Enter table entry number

7 - »E« Register entry

8 V2H3 e.g. 0 Enter volume in required units

9 - »E« Register entry

10 V2H4 00.00 Enter level in units used in calibration

11 - »E« Register entry

12 V2H5 2…30 Enter next table entry number

13 - »E« Register entry.

- The system jumps to V2H3, V2H2 is incremented

14 V2H3 Repeat steps 8 to 13 until all points are entered

15 V2H0 3 Select manual linearization table

16 - »E« Press »E« to activate linearization

Note!

•

Set analogue output in units used for linearization

Manual linearization

with tabular values

Silometer FMX 570 Chapter 5: Linearization

27

Page 30

Manual linearization with

automatic level

registration

Step Matrix Entry Significance

1 V9H5 e.g. 672 Reset transmitter (default = operating mode 1)

- Enter sensor constants at V3H5 and V3H6

2 - »E« Register entry

3 V0H1/V0H2 - Calibrate as described in e.g Section 4.2

4 V2H1 1 Select automatic entry of level

5 - »E« Register entry

6V2H21…30 Enter table entry number

7 - »E« Register entry

8 V2H3 e.g. 0 Fill vessel, enter volume in required units

9 - »E« Register entry

10 V2H4 - Select level entry field

11 - »E« Press »E« to write measured level in matrix

12 V2H5 2…30 Enter next table entry number

13 - »E« Register entry

- The system jumps to V2H3, V2H2 is incremented

14 V2H3 Repeat steps 8 to 13 until all points are entered

15 V2H0 3 Select manual linearization table

16 - »E« Press »E« to activate linearization

Note!

•

For this procedure the tank can be filled for calibration then emptied for linearization.

•

If a volume calibration is performed, Section 4.3, then the value displayed at field

V2H4 is a »volume« not a level.

•

Set analogue output in same units as used for linearization

Corrections to manual

linearization

An incorrect entry can be overwritten by selecting the appropriate table number at V2H2

and entering the new value at V2H3 or V2H4.

•

If 9999 is entered, the entire point is deleted from the characteristic.

•

On activation the linearization is resorted and subjected to a plausibility check.

Step Matrix Entry Significance

1V2H21…30 Enter table entry number where correction is to be made

2 - »E« Register entry

3 V2H3/H4 e.g. 10 Correct volume or level

4 - »E« Register entry

5 - Make further correction as in steps 1 to 4

6 V2H0 3 Select manual linearization table

7 - »E« Press »E« to activate linearization

Chapter 5: Linearization Silometer FMX 570

28

Page 31

5.3 Other modes

Linear

V2H0 = 0

This mode (default) is selected when the Silometer FMX 570 transmitter is to revert to

measurement of level after being used for volume measurement.

• If the volume is proportional to level, e.g. standing cylinder, a volume

measurement is obtained by entering the »empty« and »full« volumes at

V0H1 and V0H2 respectively, see Section 4.3.

Step Matrix Entry Significance

1 V2H0 0 Select linear characteristic

2 - »E« Press »E« to activate linearization

Cancel current setting

V2H0 = 4

Use this option if you wish to enter an entirely new manual characteristic without a

transmitter reset. All values in the linearization table are cancelled and can be entered

anew. The function does not affect the horizontal cylinder characteristic or any factory

characteristic stored in the transmitter.

Step Matrix Entry Significance

1 V2H0 4 Cancel all previous entries in the manual linearization table

2 - »E« Press E to register

Silometer FMX 570 Chapter 5: Linearization

29

Page 32

6 Analogue Outputs

This Chapter deals with the analogue output settings. The FMX 570 transmitter is

designed for continuous measurement with control of:

• one voltage output 0/2 ... 10 V

• one current output 0/4 ... 20 mA

by the level or volume indication at V0H0. Table 6.1 and Fig. 6.1 summarize the

parameters which control the analogue outputs and 10-step LCD display.

Units When defining the analogue range at V0H5/V0H6, the entries must be made in the units

used for calibration or if performed, linearization.

Channel 1 Significance Default value

V0H3 Analogue range

0 = 0...20 mA / 0...10 V

1 = 4...20 mA / 2...10 V

1

V0H4 Output damping in seconds 1

V0H5 0/4 mA value (in units used for calibration or linearization) 0.0

V0H6 20 mA value (in units used for calibration or linearization) 100.0

V0H7 Output on fault condition (safety alarm)

0 = -10 %

1 = +110 %

2 = hold last value

0

Table 6.1:

Control parameters for analogue

outputs

+22

+20

Output

current mA

controlled range

V0H6

20 mA fu ll-scale

V0H7

fail to 110 %

V0H7

fail to hold

V0H5

0/4 mA

V0H7

fail to -10 %

0

-2

0/4

…

20 mA output

BA119Y29

Volume or level V0H0

Max. measuring range

V0H6

V0H5

Fig. 6.1:

Control parameters for analogue

outputs (0…20 mA)

Chapter 6: Analogue Outputs Silometer FMX 570

30

Page 33

6.1 Analogue output settings

Analogue output rangeOne of two analogue ranges can be set at V0H3:

• 0 = 0 ... 20 mA/ 0...10 V

• 1 = 4 ... 20 mA/ 2...10 V (default setting.).

Current and voltage outputs are switched together.

Step Matrix Entry Significance

1 V0H3 0 Selects 0... 20 mA/0 ...10 V range

2 - »E« Register entry

Output dampingA filter, set at V0H4, acts to smooth the analogue output. Using it results in a steady

display and analogue output less affected by sudden changes in level e.g. due to

turbulence. The effect may be modified by changing the integration factor for output

damping between 0 ... 100s.

• 0 = without filter.

• 1…100 = with filter (default value = 1 s).

Step Matrix Entry Significance

1 V0H4 e.g. 5 Sets output damping = 5s

2 - »E« Register entry

0/4…20 mA signal

parameters

These parameters, entered in the units used for calibration or linearization, indicate the

start and end of range values of the analogue signal output and also control the 10-step

LCD display. The parameters to be entered are:

• 0/4 mA value: V0H5

• 20 mA value: V0H6.

Step Matrix Entry Significance

1 V0H5 e.g. 100 Start-point level or volume for analogue output

2 - »E« Registers entry

3 V0H6 e.g. 1100 Full scale level or volume for analogue output

4 - »E« Register entry

Turn-down scale:

Practically any start or end value can be entered, allowing the 0/4…20 mA signal to be

assigned to any section of the measuring range.

Reverse scale:

If V0H5> V0H6 a warning E 608 appears at V9H0 and the alarm LEDs blink, however,

the instrument continues to operate. The warning and alarm can be eliminated by

swapping the values contained in the fields V3H8 and V3H9, D/A calibration, which are

normally used for service purposes only. The bar chart, however, still operates in the

same direction

• Enter the smaller value in V0H5, the larger in V0H6

• Select operating mode 6 in field V8H0 (simulation). Note the parameters in

V3H8 and V3H9

• Enter the V3H8 parameters in V3H9 and vica versa

• Select operating mode 1 in field V8H0.

Silometer FMX 570 Chapter 6: Analogue Outputs

31

Page 34

Output at fault The current and voltage outputs can be set to take on distinctive values if the self-

monitoring circuit of the Silometer FMX 570 transmitter triggers on finding a fault. The

choice is made at V0H7, whereby:

• 0 = -10% of full scale ≤ -2 mA, -1V (default value)

• 1 = +110% of full scale ≥ +22 mA, +11V

• 2 = hold = value at fault held

Proceed as follows:

Step Matrix Entry Significance

1 V0H7 e.g. 0 Analogue output drops to -2 mA/-1V on fault

2 - »E« Registers entry

Caution!

• Selecting option 2 effectively disables any fault recognition safeguards on the

analogue lines. Although the self-checking system functions, the alarm relay trips

and the red alarm LED lights on the transmitter, all analogue devices connected to

the Silometer appear to indicate correct measurements.

Chapter 6: Analogue Outputs Silometer FMX 570

32

Page 35

7 Trouble-Shooting

When the instructions in the manual have been followed correctly, the system must now

function. Should this not be the case, the Silometer FMX 570 transmitter provides a

number of aids for setting up and operating the module correctly. This Chapter contains

the following:

• Trouble-shooting tables, with error messages, meaning and response

• Description of simulation operating mode for service and commissioning

purposes

• Instructions for commissioning replacement electronic inserts, probes and

transmitters.

• Repairs

7.1 Trouble-shooting tables

Fault conditionWhen the FMX 570 transmitter recognizes a fault condition:

• the red fault LED lights and the alarm relay trips.

• the output current (with the exception of operating mode 2) reverts to the

status selected in field V0H7, i.e. to -10%, +110% of the selected measuring

range or last measured value (hold) - see Chapter 6.

A diagnostic message is given in Field V9H0:

• If the cause of the fault has been rectified, the last diagnostic message is

retained in V9H1.

• This message can be cleared by pressing the »E« key.

If the power fails, all relays de-energise.

WarningsWhen the FMX 570 transmitter has detected a warning:

• the red fault LED flashes but the Silometer continues to measure

• the alarm relay remains energised

• the appropriate message is to be found in V9H0.

The error messages are listed in Table 7.1 in the order of their priority. If one fault is on

display and a fault of higher priority occurs, the latter will appear at V9H0. The preceding

message can be called by pressing the "plus" key.

Table 7.2, trouble-shooting, indicates possible configuration errors for the Silometer

FMX 570.

Chapter 7: Trouble-Shooting Silometer FMX 570

33

Page 36

Code Type Cause and Remedy

E 101-106 Alarm Fault in instrument electronics

- Call Endress+Hauser Service

E 107 Alarm Battery voltage too low

- Make back-up of entered parameters immediately

- Have battery changed at once by trained personel or ring for service

E 201-202 Alarm Fault in probe (f < 35 Hz; f > 3000 Hz)

- Check probe and electronic insert

E 401 Alarm Fault in probe or wiring

- Check probe, electronic insert and wiring

E 601 Warning PFM transmission internal code check

- can be ignored if it appears only briefly

E 602 Warning Linearization does not rise monotonously (volume does not increase

with level)

- Check and re-enter correct values, reactivate linearization

E 604 Warning Linearization has less than two sets of values

- Enter more values, reactivate linearization

E 608 Warning Value in V0H5 greater than that in V0H6

- Check input

E 610 Warning Calibration fault (»empty« level > »full« level)

- Repeat calibration

E 613 Warning Instrument in simulation mode

- Switch back when finished

Table 7.1:

Error messages

Sensor/

channel

Fault Cause and remedy

Capacitance Measured value wrong • Incorrect calibration? Check measured

value before linearisation, V0H9

- if not correct, check whether full and empty

calibration correct V0H1/V0H2

- if correct, check linearization parameters

- check operating mode, V8H0

• Change in product

- recalibrate for new product

• Build-up on probe

- wire electronic insert for build-up, see

Section 2.4

- clean probe

• Probe damaged, bent or pressed to side of

vessel

- check and remedy

• Condensation in connection compartment

Deltapilot S Measured value wrong • Incorrect calibration? Check measured

value before linearisation, V0H9

- if not correct, check whether full and empty

calibration correct V0H1/V0H2

- If correct, check linearization parameters

- check operating mode, V8H0

• Change in density of product

- recalibrate

-• Sensor damaged

- check and remedy

Table 7.2:

Trouble shooting table for

incorrect function without error

message

Silometer FMX 570 Chapter 7: Trouble-Shooting

34

Page 37

7.2 Simulated operating mode

This function is intended primarily for checking the correct function of the system and is

selected and terminated at V8H0:

• Enter 6 to simulate frequency, level, volume or current

• Enter an operating mode to terminate simulation and resume normal

measurements.

Start and stop simulation

Step Matrix Entry Significance

1 V8H0 e.g. 6 Selects simulation mode channel 1, entries can be made at

fields V9H6…V9H9

or

e.g. 0 Selects two channel measurement and ends simulation

2 - »E« Registers entry

Four modes are possible:

• Simulation of frequency, V9H6

• Simulation of level, V9H7

• Simulation of volume, V9H8

• Simulation of current, V9H9.

When a value is entered at the appropriate matrix, the analog outputs are fed with the

appropriate current and voltage and the other 3 simulation values are recalculated.

Throughout the simulation the red alarm LED flashes to indicate that the instrument is no

longer measuring, the alarm relay does not, however, trip.

Frequency simulation

Step Matrix Entry Significance

1 V9H6 e.g. 100 Depending upon the calibration and linearization, a value

corresponding to 100 Hz is displayed

2 - »E« Registers entry

Level simulation

Step Matrix Entry Significance

1 V9H7 e.g. 10 Depending upon the calibration and linearization, the

analogue output is fed with a current corresponding to

e.g.10 m, 10 ft, 10% level.

2 - »E« Registers entry

Volume simulation

Step Matrix Entry Significance

1 V9H8 e.g. 100 Depending upon the calibration and linearization, the

analogue outputs are fed with the current corresponding

to 100 hl, 100 gallons, 100%

2 - »E« Registers entry

Current simulation

Step Matrix Entry Significance

1 V9H9 e.g. 16 The analogue output is fed with a current of 16 mA and

the corresponding measured value displayed at V0H0

2 - »E« Registers entry

Chapter 7: Trouble-Shooting Silometer FMX 570

35

Page 38

7.3 Exchanging transmitters, probes and electronic inserts

Transmitter If the Silometer has to be exchanged, the replacement need not be recalibrated. Instead

it is usually sufficient to enter all the matrix values from the old into the new transmitter.

The replacement will then measure correctly.

• Where a special order has to be maintained, e.g. activation of linearization

after entry of parameters, this should be accounted for during re-entry or the

steps must be performed separately.

For probes and electronic inserts, the procedure to be followed depends upon the type

used.

Capacitance probes

with EC 37 Z/EC 47 Z

For level measurement, provided the sensor constants were entered before calibration,

it is not necessary to recalibrate the instrument when the electronic insert is replaced by

one of the same type. On replacement:

• the zero frequency (or offset) f

o

and

• sensitivity S

for the range selected (default Range II) must be entered at V3H5 and V3H6 respectively.

Fig. 7.1 shows where the information is to be found on the EC 37 Z and EC 47 Z inserts.

• If a different range is selected, the transmitter must be recalibrated.

• If the constants were not entered a recalibration is necessary.

Procedure

Step Matrix Entry Significance

1 V3H5 e.g. 57.2 Enter zero frequency (offset)

2 - »E« Register entry

3 V3H6 e.g. 0.652 Enter sensitivity

4 - »E« Register entry

1 3 6542

+

I

II

CA (pF)

C(S)(pF)

17

d4

d4 / z4

7

18

d2

d2 / z2

8

FMC 480 Z

FMC 470 Z / FMX 570

FMC 671 / 672 / 676 / 677 Z

HAA 420 Z

1 MHz

EC 47 Z

Ex

0,6526,805S

III

f

o

475,3 57,2

EC10015EP 8

Fig. 7.1:

Electronic insert EC 37 Z/

EC 47 Z showing location of

probe constants

Silometer FMX 570 Chapter 7: Trouble-Shooting

36

Page 39

DeltapilotProvided a »dry« calibration was made or the sensor constants were entered before

calibration, it is not necessary to recalibrate the instrument when the electronic insert is

replaced. The measurement can be taken up again as soon as the new constants have

been entered in the matrix.

• If the old sensor constants were not entered, the system must be recalibrated.

For new sensor constants see table 2.2.

• f

o

is the zero frequency (or offset)

•∆f is the sensitivity

For the Deltapilot, the zero frequency may also be read from V0H8 when the probe is

unpressurized. This value gives slightly better accuracy, since it accounts for the

orientation of the probe.

Procedure

Step Matrix Entry Significance

1 V3H5 e.g. 101 Enter zero frequency (from probe head or V0H8)

2 - »E« Register entry

3 V3H6 e.g. 1.052 Enter sensitivity

4 - »E« Register entry

7.4 Repairs

Check the condition of the probes during regular maintenance inspections. If necessary,

free them of build-up. Remember that all probes are sensitive instruments and must be

treated accordingly.

Should the Silometer FMX 570 transmitter or its probes need to be repaired by

Endress+Hauser, please send it to your nearest Service Centre with a note containing

the following information:

• An exact description of the application for which it was used.

• The physical and chemical properties of the product measured.

• A short description of the fault.

Caution!

• Special precautions must be observed when sending probes for repair:

• Remove all visible traces of product from the probe.

• If the product can impair health, i.e. is corrosive, poisonous, carcinogenic,

radioactive etc., please check that the probe is thoroughly decontaminated.

• If the last traces of dangerous products cannot be removed, e.g. product has

penetrated into fissures or diffused into plastic parts, we kindly ask you not to

send the probe for repair.

Chapter 7: Trouble-Shooting Silometer FMX 570

37

Page 40

8 Quick programming guide

8.1 Level measurement

Start

Chapter 4, Section 4.1

- Constants for EC 37 Z/EC 47 Z or

FEB 17 / FEB 17 P

- level is displayed at V0H0

Calibration

Chapter 4, Section 4.2 or 4.3

- After calibration level/volume is

displayed at V0H0

Set analogue output signal (optional)

Chapter 6

- Enter settings in the units selected

during calibration or linearization

Lock parameter matrix (optional)

Chapter 4, Section 4.7

Reset parameters: V9H5

Enter sensor constants

- Zero frequency V3H5

- Sensitivity V3H6

Select mode V8H0

1= Level measurement

Level or volume V3H0

»Empty« calibration V0H1

»Full« calibration V0H2

Select output range V0H3

0 = 0…20 mA/0…10 V,

1 = 4…20 mA/2…10V

Set output damping V0H4

Set 0/4 mA value V0H5

Set 20 mA value V0H6

Set output at fault V0H7

0 = -10% (-2 mA/-1 V)

1 = +110% (+22 mA/11V)

2 = last measurement

Lock parameter matrix V8H9

Silometer FMX 570 Chapter 8: Quick programming guide

38

Page 41

8.2 Continuous volume measurement (linearization)

Start

Chapter 4, Section 4.1

- Constants for EC 37 Z/EC 47 Z or

FEB 17 / FEB 17 P

- level is displayed at V0H0

Calibration

Chapter 4, Section 4.3

- After calibration level is

displayed at V0H0

Linearization

Chapter 5

- V0H0 displays volume

- Analogue output must be set

in volume units

Set analogue output signal (optional)

Chapter 6

- Enter settings in the units selected

Lock parameter matrix (optional)

Chapter 4, Section 4.6

Reset parameters: V9H5

Enter sensor constants

zero frequency V3H5

sensitivity V3H6

Select mode V8H0

1 = Level measurement

»Empty« calibration V0H1

»Full« calibration V0H2

For vessel linearization

Set linearization type V2H0

1 = horizontal cylinder*

3 = manual characteristic

For Option 1,

Enter tank diameter V2H7

Enter tank volume V2H8

For Option 3

Enter mode V2H1

0 = manual

1 = automatic level (E)

Enter volume V2H3

Enter level V2H4

Select output range V0H3

0 = 0…20 mA/0…10 V,

1 = 4…20 mA/2…10V

Set output damping V0H4

Set 0/4 mA value V0H5

Set 20 mA value V0H6

Set output at fault V0H7

0 = -10% (-2 mA/-1 V)

1 = +110% (+22 mA/11V)

2 = last measurement

Lock parameter matrix V8H9

* If you have calibrated in volume units,

turn to Section 5.1 to check the correct

order of entry of the paramters

Chapter 8: Quick programming guide Silometer FMX 570

39

Page 42

Index

!

0/4…20 mA signal 31

A

Analogue outputs 11, 14, 30 - 32

Analogue range 31

Application 6

C

Calibration 18 - 19

»Dry« for Deltapilot 20

Level 18

Volume measurement 39

Volume or weight 19

Capacitance probes 36

Certificates 3, 14

Construction 14

Controls 15 - 16

D

Deltapilot sensors 37

E

Electrical connections 11, 13

Electronic inserts 13

Error messages 34

F

Fault condition 33

I

Indexing pins 11

Indicators 12

Installation 8 - 14

L

Level offset 22

Linearization 24 - 29

Cancel settings 29

Horizontal tank 25

Linear characteristic 25

Manual entry of characteristic 29

Tank with conical outlet 26

M

Measured value 23

Measured value display 23

Monorack installation 10

Monorack wiring 12

O

Offset 21

Operating matrix 15

Operating mode 17

Operating parameters vii

Output at fault 32

Output damping 31

P

Parameter matrix lock 23

Pin assignment

Monorack housing 12

Silometer FMX 570 11

Probes 8

Q

Quick programming guide 38 - 39

R

Rack wiring 11

Racksyst installation 9

S

Sensor constants 8, 20, 36 - 37

Simulated operation 35

T

Technical data 14

Transmitter reset 17

Trouble-shooting 33 - 37

V

Vibration sensors 37

W

Warnings 33

Silometer FMX 570 Index

40

Page 43

Operating Matrix

Operating and default parameters

Enter your operating parameters in the matrix below.

H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

V0

V1

V2

V3

V4

V5

V6

V7

V8

V9

Display field

The default parameters are as indicated below.

H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

V0 0.0 100.0 0 1 0.0 100.0 1

V1

V20010.00.01 100100

V3 0 0.0 10.0 0.0 0.0 1.0

V4

V5

V6

V7

V8 1 670

V9 E E 1020 0 0.0 0.0 0.0 0.0

Display field

Silometer FMX 570 Operating matrix

41

Page 44

H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

V0

Calibration

Channel 1

Measured

value

Empty

calibration

Full

calibration

Select

current

0=0…20mA

1=4…20mA

Output

damping

(s)

Value for

0/4 mA

Value for

20 mA

Safety

alarm

0 = -10%

1=+110%

2=Hold

Actual

measuring

frequency

channel 1

Measured

value

before

linearization

V1

V2

Linearisation

Channel 1

Linearizat ion

0=linear

1= hor. cylinder

2=factory

3=manual

4=clear 3

Level input

mode

0=manual

1=auto.

Tab l e N o .

(1…30)

Input

Volum e

Input

Level

Next

Tab l e N o .

Diameter

for

horizontal

cylinder

Volum e

for

horizontal

cylinder

V3

Extended

Calibration

Channel 1

Calibration

mode

0=level

1= volume

Offset Sensitivity Zero offset

value

Offset

of device

(zero

frequency)

Sensitivity

of device

For Service

only

(0 mA D/A

calibration)

For Service

only

20 mA D/A

calibration)

V4

V5

V6

.

V7

V8

Operating

mode

1= level

6 = simulation

Security

locking

< 670 or

> 679

V9

Service

and

Simulation

Current

diagnostic

code

Last

diagnostic

code

E=clear

Instrument

and

Software

version

Reset to

default

values

670…679

Simulation

frequency

Simulation

level

Simulation

volume

Simulation

current

Display field

Parameter Matrix

Operating matrix Silometer FMX 570

42

Page 45

Page 46

Page 47

Page 48

Europe

Austria

❑ Endress+Hauser Ges.m.b . H.

Wien

Tel. (01) 88 056-0, F ax (01 ) 88056- 35

Belarus

Belorgsintez

Minsk

Tel. (01 72) 508473, Fax (0172) 508583

Belgium / Luxemburg

❑ Endress+Hauser N.V.

Brussels

Tel. (02) 24 80600, Fax (02) 2480553

Bulgaria

INTERTECH-A UTOMA TION

Sofia

Tel. (02) 664869, Fax (02) 963 13 89

Croatia

❑ Endress+Hauser GmbH+Co.

Zagreb

Tel. (01) 66 37785, Fax (01) 6637823

Cyprus

I+G Electrical Services Co. Ltd.

Nicosia

Tel. (02) 484788, Fax (02) 4846 90

Czech Republic