Endress+Hauser FMU 40, FMU 41, FMU 43 User Manual

Technical

Information

TI 365F/24/ae

Ultrasonic Level Measurement

prosonic M FMU 40/41/43

Compact transmitters for non-contact level

measurement of fluids, pastes and coarse

bulk materials

FMU 41

FMU 40

Application

The compact Prosonic M transmitters are

used for continuous, non-contact level

measurement in fluids and coarse bulk

materials.

Additionally, the sensors can be used for

flow measurement in open channels and

measuring weirs.

The following interfaces are available for

system integration:

• HART

• PROFIBUS-PA

• Foundation Fieldbus

The maximum measuring range for

Prosonic M sensors are:

• FMU 40:

• FMU 41:

• FMU 43:

®

(standard), 4 to 20 mA

– Fluids, 16 feet (5 m)

– Bulk solids, 6 feet (2 m)

– Fluids, 26 feet (8 m)

– Bulk solids, 12 feet (3.5 m)

– Fluids, 50 feet (15 m)

– Bulk solids, 23 feet (7 m)

FMU 43

Features and benefits

• Simple, menu-guided on-site

operation with four-line plain text

display

• Envelope curves on the on-site

display for simple diagnosis

• Easy operation, diagnosis and

measuring point documentation with

the supplied ToF Tool operating

program

• Alignable NEMA 6P (IP 68) aluminum

housing

• Optional remote display and operation

• Installation via 1-1/2” NPT, 2” NPT

or 4” universal slip-on flange

• Integrated temperature sensor for

Time-of-Flight correction provides

accurate measurements, even with

temperature changes

• Linearization function (up to 32 points)

for measured value output in any unit

of length, volume, or flow rate

• Non-contact measurement method,

therefore almost independent of

product properties

The Power of Know How

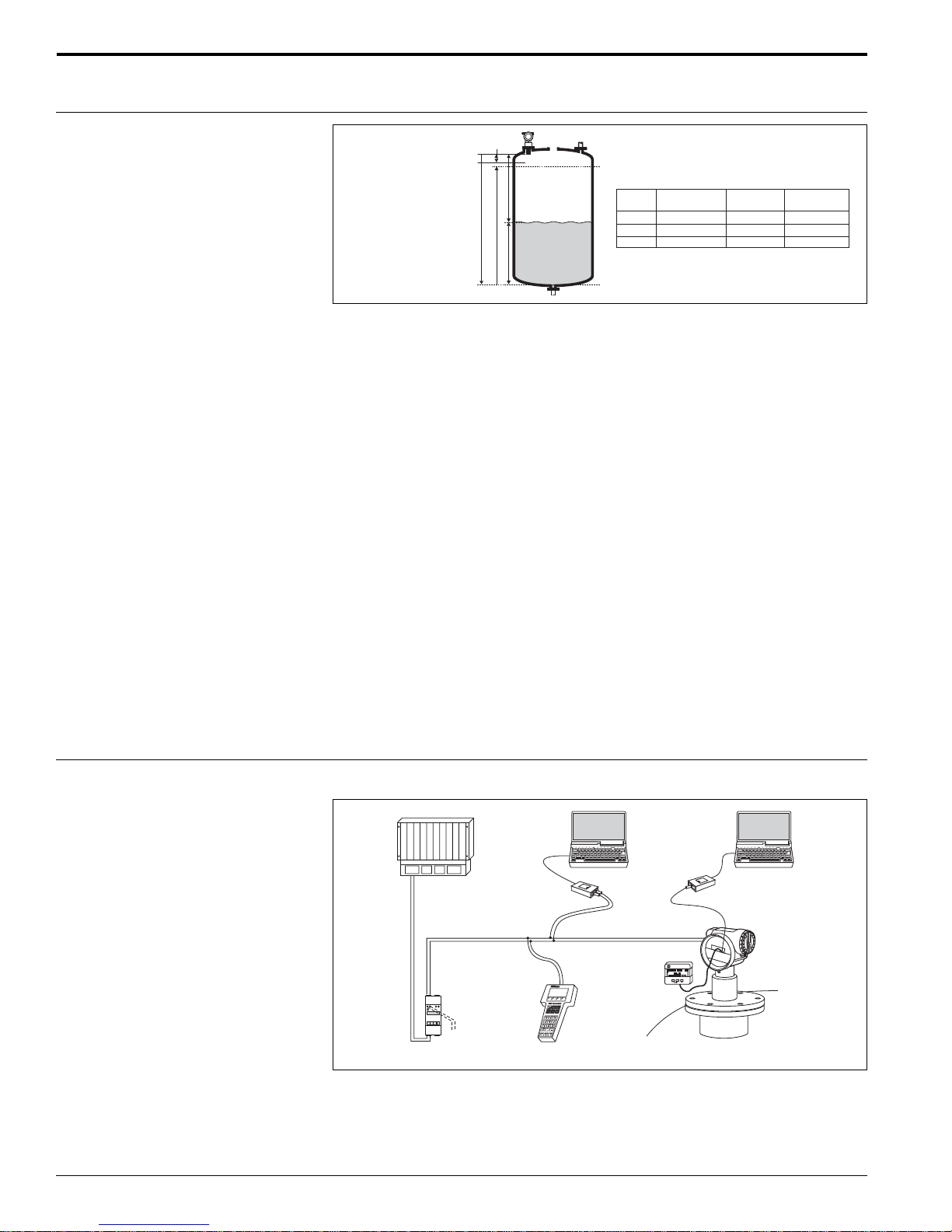

Function and system design

Prosonic M

Measuring principle

BD

20 mA

100%

BD: Blocking Distance

E: Empty calibration

F: Full calibration (span)

D: Distance from sensor

membrane to product level

L: Level

D

E

F

L

4 mA

0%

Sensor

FMU 40

FMU 41

FMU 43

BD

9.84" (250 mm)

15.7" (400 mm)

23.6" (600 mm)

Max. range

in liquids

16 ft (5 m)

26 ft (8 m)

50 ft (15 m)

Max. range

in solids

6.5 ft (2 m)

11.5 ft (3.5 m)

23 ft (7 m)

Time-of-Flight method

The Prosonic M sensor transmits ultrasonic pulses in the direction of the product

surface. The ultrasonic pulse is reflected back and received by the sensor. The

Prosonic M electronics measures the time t between pulse transmission and reception. Using the time t (and the velocity of sound c), the system calculates the distance

D between the sensor membrane and the product surface

D = c x t/2

As the device knows the empty distance E from the user entry, it can calculate the

level as follows:

L = E - D

An integrated temperature sensor compensates for changes in the velocity of sound

caused by temperature changes.

Interference echo suppression

The interference echo suppression feature ensures that interference echos (such as

welded joints, internal ladder steps, edges and installations) are not interpreted as a

level echo.

Equipment architecture

Calibration

Enter the empty distance E and the span F to calibrate the system.

Blocking distance

Span F may not extend into the blocking distance BD. Level echos within the blocking

distance cannot be evaluated due to the transient characteristics of the sensor.

4 to 20 mA ouput with HART

PLC

Transmitter power

supply unit

RMA 422

or RN 221 N

(communication resistor

included)

FXA 191

or

DXR 275

®

protocol

- COMMUWIN II

- ToF Tool

Commubox

FXA 191

Operating and

display module

VU 331

HART handheld

DXR 275

- ToF Tool

Service adapter

FXA 193

2

The Prosonic M can be operated on-site using either the display module VU 331 or

the supplied ToF Tool program. The system can also be operated remotely using the

HART® handheld terminal DXR 275 or using the ToF Tool.

®

NOTE: If a HART

communication resistor is not built into the power supply device, a

250Ω communication resistor in the 2-wire line must be inserted.

Endress+Hauser

Prosonic M

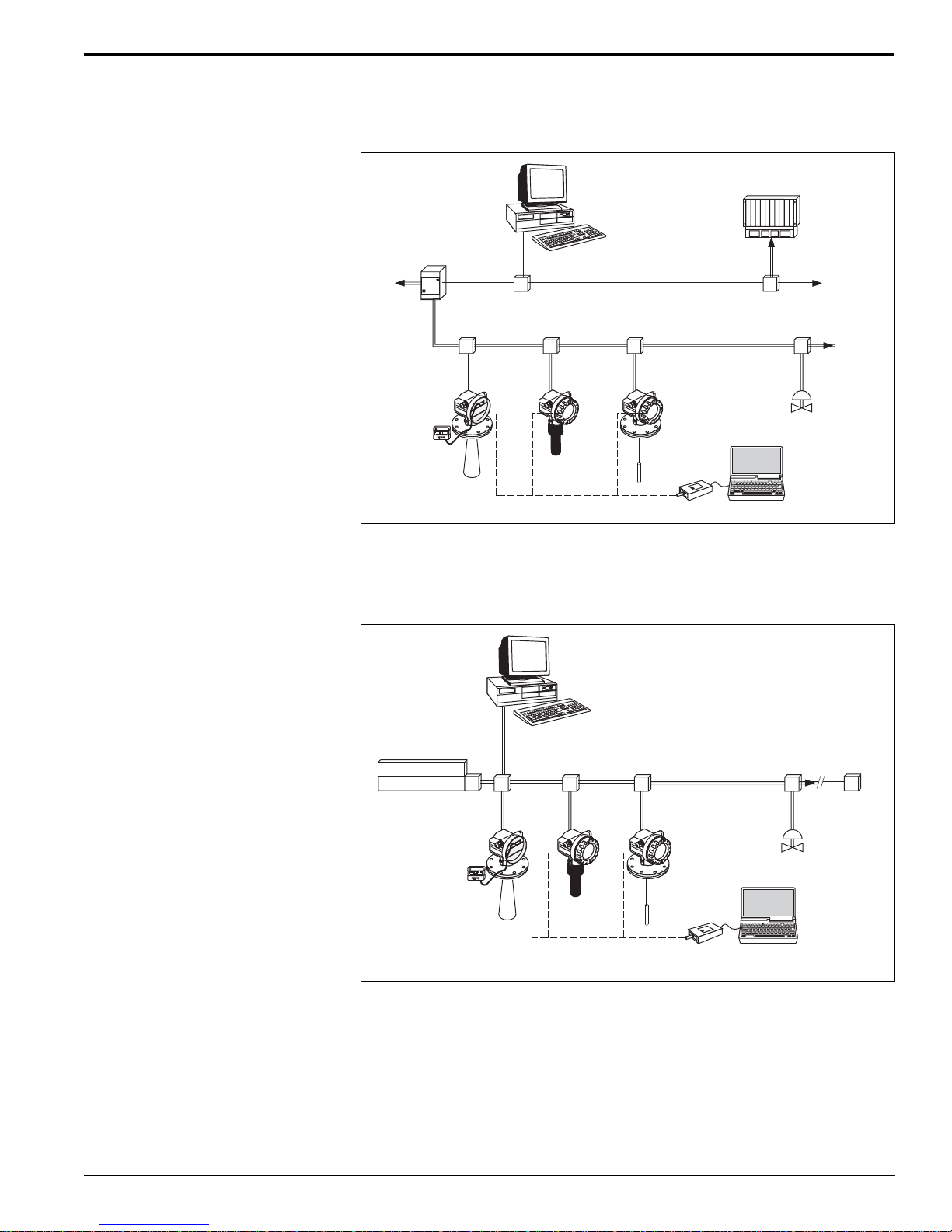

Profibus-PA protocol

Segment coupler

PROFIBUS-PA

Personal computer

e.t.with Commuwin II

or ToFTool and

Profibard (Proficard)

PROFIBUS-DP

PLC

Operating and

display module

VaU 331

Micropilot

Prosonic

Levelflex

FXA 193

ToF Tool

Additional

functions

(valves, etc.)

A maximum of 32 transmitters (8 if mounted in an explosion hazardous area) can be

connected to the bus. Both on-site as well as remote operation are possible.

Foundation Fieldbus (FF) protocol

Personal computer

e.g.with

NI-FBUS configurator

Power supply

Power conditioner

Operating and

display module

VaU 331

T

Levelflex

T

Additional

functions

(valves, etc.)

Endress+Hauser 3

Prosonic

Micropilot

FXA 193

ToF Tool

A maximum of 32 transmitters (standard or hazardous) can be connected to the bus.

For intrinsically safe circuits, the maximum number of transmitters depends on the

established rules and standards for intrinsically safe circuits (EN 60070-14) and proof

of instrinsic safety. Both on-site and remote operation are possible.

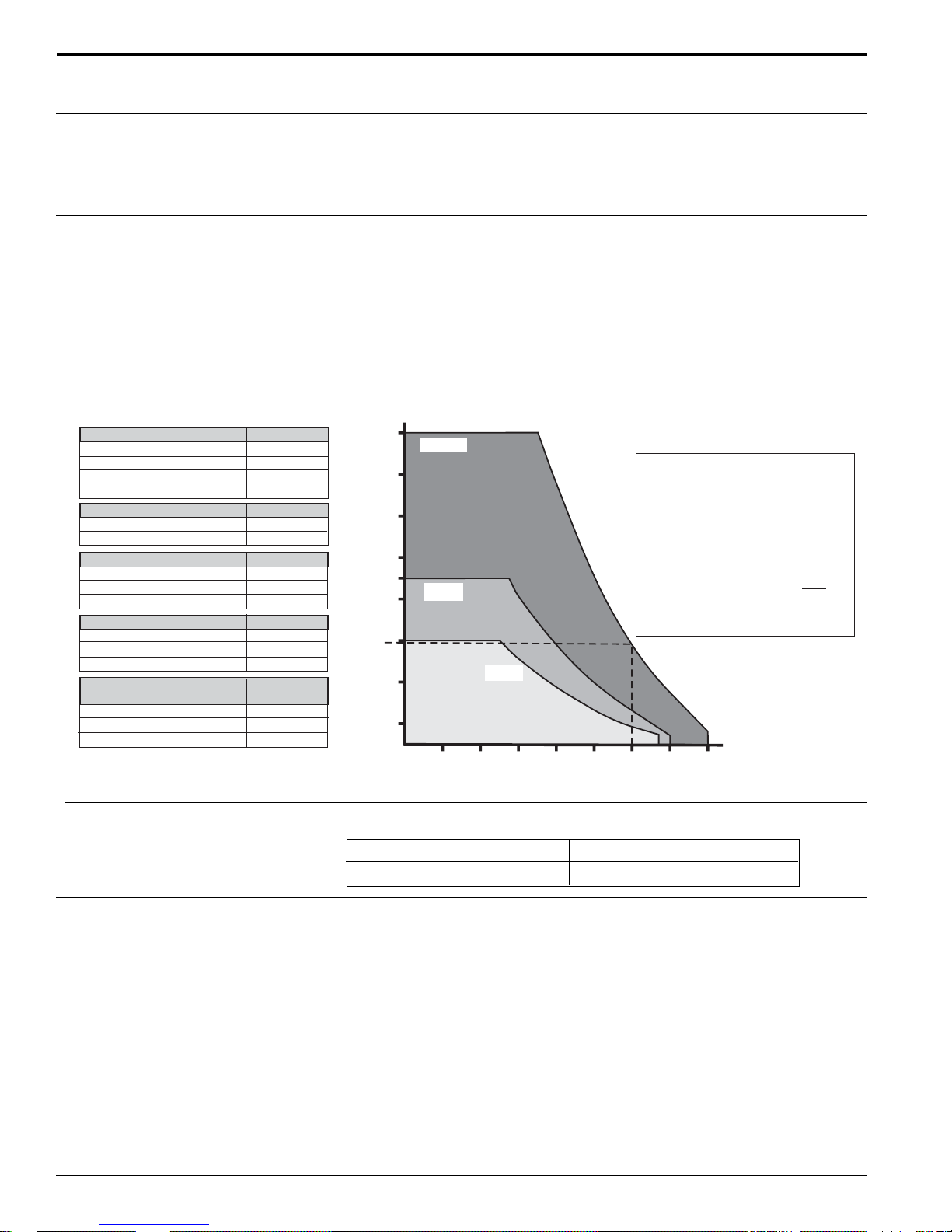

Input

Prosonic M

Measured variable

Measuring range

Fluid surface

Calm

Waves

Strong turbulence (agitators, etc.)

Foaming

Bulk material surface

Hard, rough (e.g.rubble)

Soft (e.g.peat, dust-covered clinker)

Dust

No dust formation

Little dust formation

Heavy dust formation

Filling curtain in detection range

None

Smalll quantities

Large quantities

Temperature difference between

sensor and surface

To 68°F (20°C)

To 104°F (40°C)

To 176°F (80°C)

Attenuation

0 dB

5 to 10 dB

10 to 20 dB

Consult factory

Attenuation

40 dB

40 to 60 dB

Attenuation

0 dB

5 dB

5 to 20 dB

Attenuation

0 dB

5 to 10 dB

10 to 40 dB

Attenuation

0 dB

5 to 10 dB

10 to 20 dB

The distance D between the sensor membrane and the product surface is measured

(page 2). Using the linearization function, the device uses D to calculate:

• Level L in any units

• Volume V in any units

• Flow Q across measuring weirs or open channels in any units

The measuring range is limited by the range of a sensor. The sensor range is, in turn,

dependent on operating conditions. The diagram below defines the effect that echo

attenuation has on the sensor’s measuring range. The ideal echo attenuation curves

for each sensor are shown in the diagram. A number of echo attenuation sources that

affect proper sensor selection are shown in the table.

1. Determine which of the influences shown are appropriate for your process.

2. Add the corresponding attenuation values.

3. From the total attenuation, use the diagram to calculate the sensor range.

50

FMU 43

Example (for FMU 43)

Dust-covered rubble

Medium dust development

Not in filling curtain

Temperature differential < 68°F

Approximate range = 15.5 ft.

Approximate dB

50

10

0

0

60 dB

range in feet

15.5

26

16

43

36

30

FMU 41

23

10

3

10 20 30 40 50 60 70 80

FMU 40

Attenuation / dB

Operating frequency

Pulse frequency

4

Sensor FMU 40 FMU 41 FMU 43

Frequency approx. 70 kHz approx. 50 kHz approx. 35 kHz

• 2-wire devices, maximum 0.5 Hz

• 4-wire devices, maximum 2 Hz

The exact values are dependent on the type of device and supply voltage.

Endress+Hauser

Prosonic M

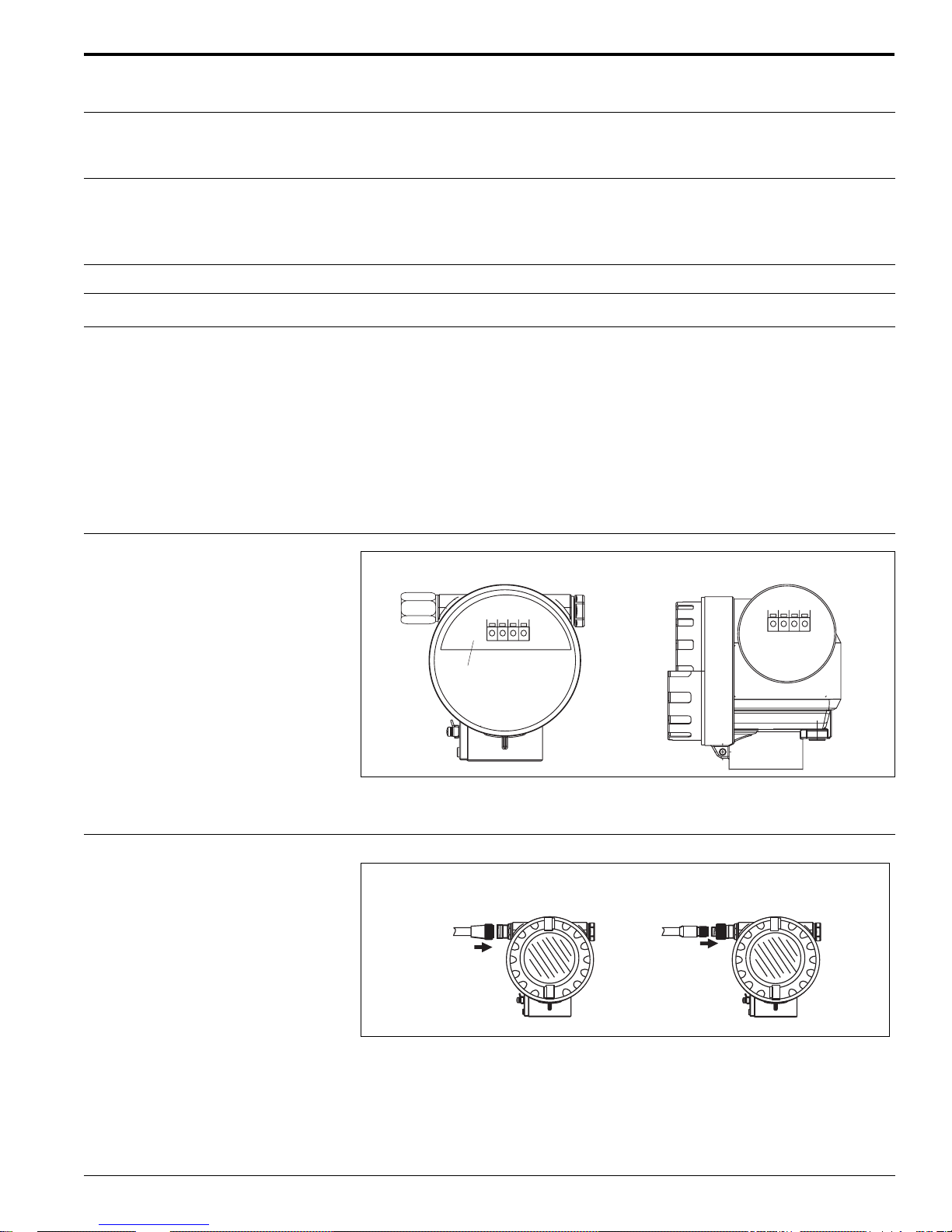

1 234

1 234

Sealed terminal

compartment

F 12 Housing T 12 Housing

Output signal

Output

®

• 4 to 20 mA with HART

• Profibus-PA

• Foundation Fieldbus (FF)

protocol

Signal on alarm

Load HART

®

Output damping

Linearization

Terminal compartment

Error information can be accessed via the following interfaces:

• On-site display (error symbol, error code and plain text description)

• Current output (configurable)

• Digital interface

Minimum load for HART

®

communication, 250Ω

Freely selectable, 0 to 255 seconds

The linearization function of the Prosonic M allows conversion of the measured value

into any unit of length or volume. In open channels or measuring weirs, it is also

possible to linearize the flow. Linearization tables for calculating volume in horizontal

cylindrical tanks are preprogrammed. You can also enter any number of other tables

containing up to 32 value pairs either manually or semi-automatically (by filling the

vessel under controlled conditions). You can use the ToF Tool operating program to

calculate the table automatically for any tank form and then enter it into the device.

Power supply

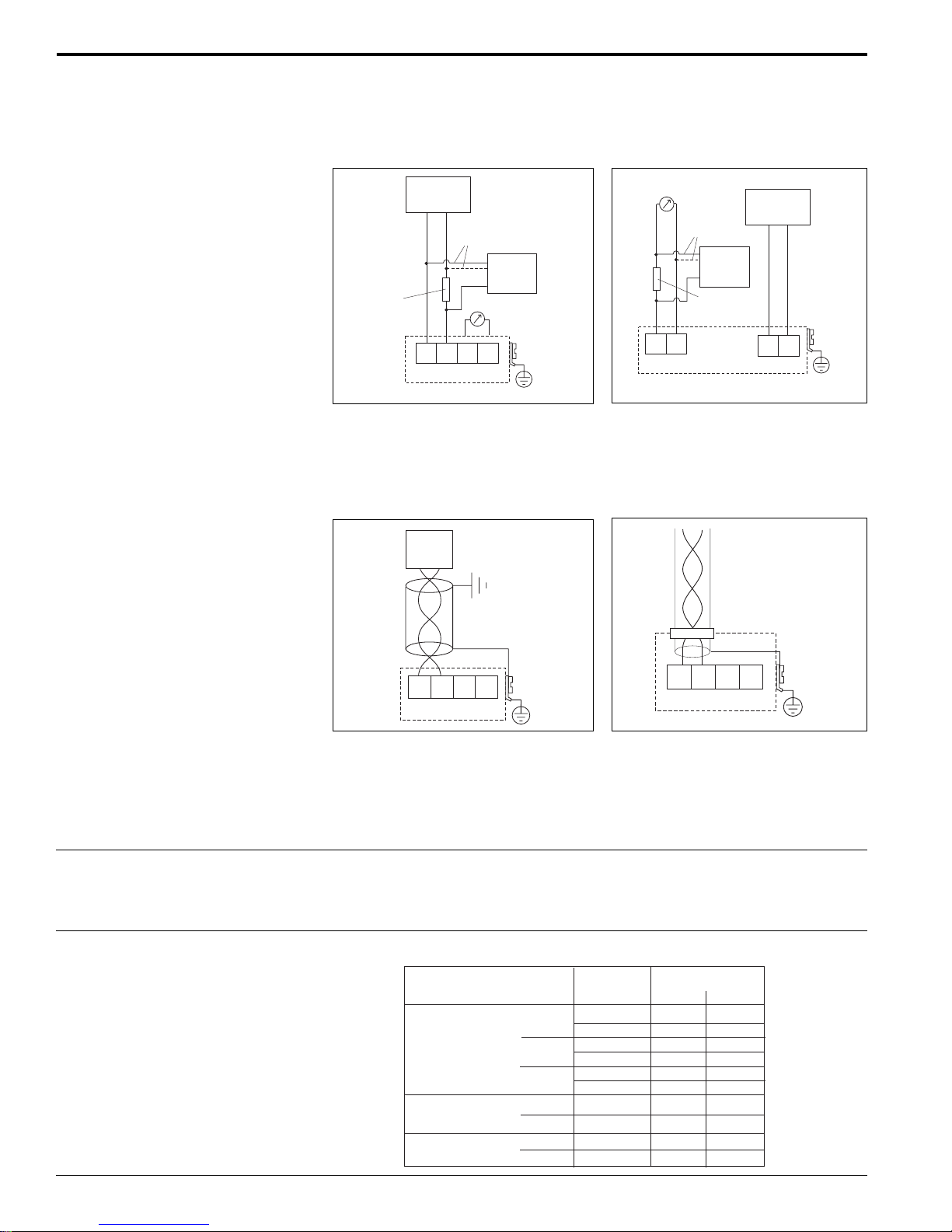

Fieldbus plug connector

Endress+Hauser

In the F 12 housing, the terminals are located underneath the housing cover. In the

T 12 housing, they are under the cover of the separate terminal compartment.

Foundation Fieldbus 7/8" plug

Profibus M 12 plug

• For the Foundation Fieldbus version, a 7/8” plug connector is available.

• For the Profibus-PA version, an M12 plug connector is available

Both versions are supplied fully wired.

5

Terminal assignment 4 to 20 mA with HART

FF+ FF-

1234

Plant

ground

Prosonic M

®

, 2-wire 4 to 20 mA with HART®, active,

4-wire

AC / DC

Auxiliary

power

12

L1/L+

N/L-

Plant

ground

Communication

resistor

(> 250 )Ω

Power:

4 to 20 mA

alternative

Test sockets

(via interlock diode)

1234

L- L+ I+ I-

Commubox

FXA 191

DXR 275

Plant

ground

0 to 20 mA

56

I-

I+

alternative

Commubox

FXA 191

DXR 275

Communication

resistor

(> 250 )Ω

• Connect the connecting line to the screw terminals (up to 18 AWG) in the terminal

compartment

• Use 2-wire twisted pair cable with shield for the connection

• Units are internally protected against reverse polarity, RFI and over-voltage peaks

PROFIBUS-PA Foundation Fieldbus

T-Box

3 412

PA+ PA-

Plant

ground

The digital communication signal is transmitted to the bus via a 2-wire connection.

The bus also provides the auxiliary power. Please use 2-wire twisted pair cable with

shield. Refer to the following operating manuals for information on cable types, and

how to set and ground the network:

• BA 198F/00/en “PROFIBUS-DP/-PA: Guidelines for planning and commissioning”

• BA 013S/04/en “Foundation Fieldbus, Installation and Commissioning Guidelines”

Cable entry

• Cable gland: M20x1.5, recommended cable diameter 0.23” to 0.39” (6 to 10 mm)

• Cable entry 1/2” NPT or G 1/2

• PROFIBUS-PA M12 plug

• Foundation Fieldbus 7/8” plug

Power supply The following values are the voltages across the terminals directly at the instrument.

Version

2-wire HART

Fixed current

(measured value

transmitted by HART)

4-wire

Standard

XP

Standard

DC

AC

consumption

IS

IS

Current

4 mA

20 mA

4 mA

20 mA

4 mA

20 mA

11 mA

11 mA

Terminal voltage

Min. Max.

14 V

8V

14 V

8V

14 V

11 V

10 V

10 V

10.5 VDC

90 VAC 253 VAC

36 V

36 V

30 V

30 V

30 V

30 V

36 V

30 V

32 VDC

6

Endress+Hauser

Loading...

Loading...