Page 1

Technical

Information

TI 365F/24/ae

Ultrasonic Level Measurement

prosonic M FMU 40/41/43

Compact transmitters for non-contact level

measurement of fluids, pastes and coarse

bulk materials

FMU 41

FMU 40

Application

The compact Prosonic M transmitters are

used for continuous, non-contact level

measurement in fluids and coarse bulk

materials.

Additionally, the sensors can be used for

flow measurement in open channels and

measuring weirs.

The following interfaces are available for

system integration:

• HART

• PROFIBUS-PA

• Foundation Fieldbus

The maximum measuring range for

Prosonic M sensors are:

• FMU 40:

• FMU 41:

• FMU 43:

®

(standard), 4 to 20 mA

– Fluids, 16 feet (5 m)

– Bulk solids, 6 feet (2 m)

– Fluids, 26 feet (8 m)

– Bulk solids, 12 feet (3.5 m)

– Fluids, 50 feet (15 m)

– Bulk solids, 23 feet (7 m)

FMU 43

Features and benefits

• Simple, menu-guided on-site

operation with four-line plain text

display

• Envelope curves on the on-site

display for simple diagnosis

• Easy operation, diagnosis and

measuring point documentation with

the supplied ToF Tool operating

program

• Alignable NEMA 6P (IP 68) aluminum

housing

• Optional remote display and operation

• Installation via 1-1/2” NPT, 2” NPT

or 4” universal slip-on flange

• Integrated temperature sensor for

Time-of-Flight correction provides

accurate measurements, even with

temperature changes

• Linearization function (up to 32 points)

for measured value output in any unit

of length, volume, or flow rate

• Non-contact measurement method,

therefore almost independent of

product properties

The Power of Know How

Page 2

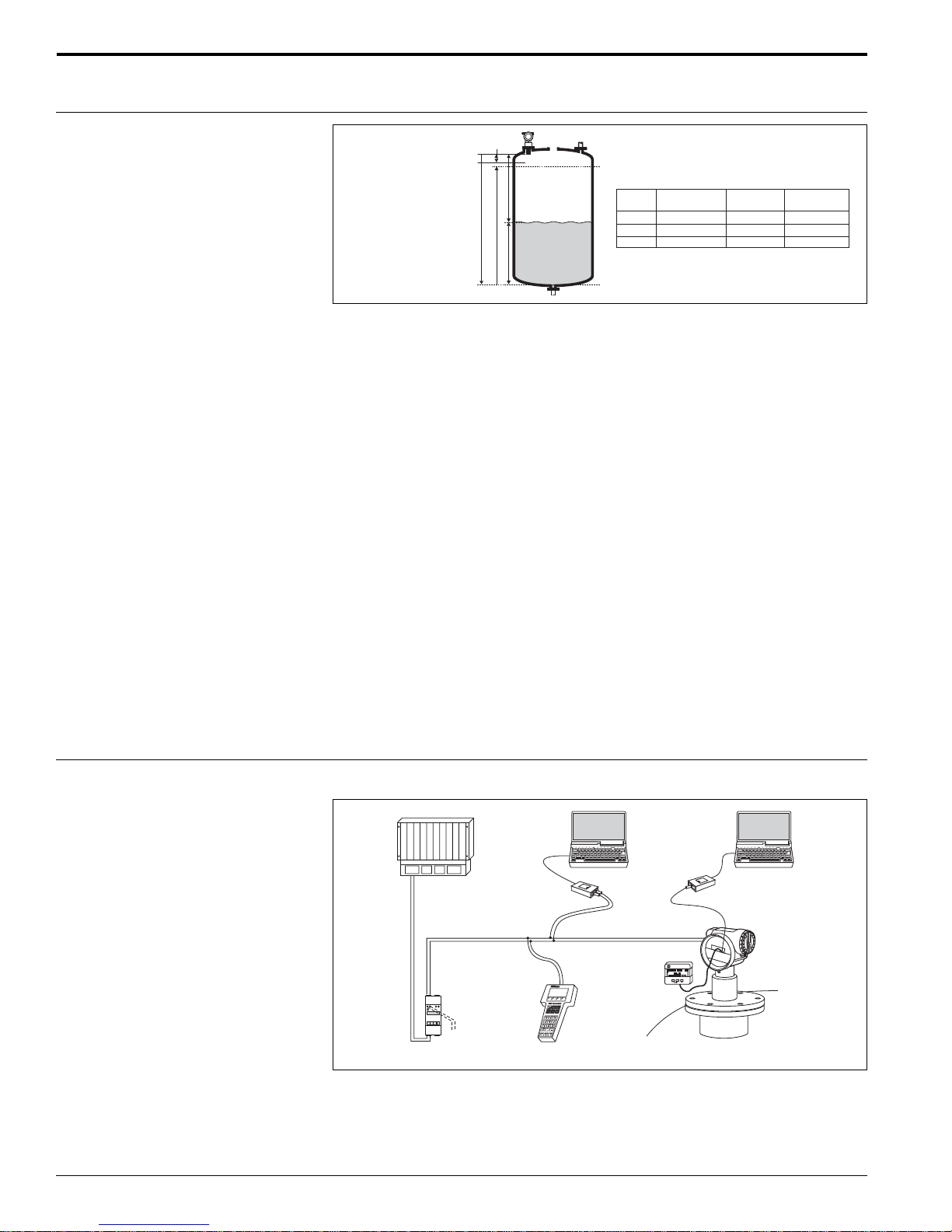

Function and system design

Prosonic M

Measuring principle

BD

20 mA

100%

BD: Blocking Distance

E: Empty calibration

F: Full calibration (span)

D: Distance from sensor

membrane to product level

L: Level

D

E

F

L

4 mA

0%

Sensor

FMU 40

FMU 41

FMU 43

BD

9.84" (250 mm)

15.7" (400 mm)

23.6" (600 mm)

Max. range

in liquids

16 ft (5 m)

26 ft (8 m)

50 ft (15 m)

Max. range

in solids

6.5 ft (2 m)

11.5 ft (3.5 m)

23 ft (7 m)

Time-of-Flight method

The Prosonic M sensor transmits ultrasonic pulses in the direction of the product

surface. The ultrasonic pulse is reflected back and received by the sensor. The

Prosonic M electronics measures the time t between pulse transmission and reception. Using the time t (and the velocity of sound c), the system calculates the distance

D between the sensor membrane and the product surface

D = c x t/2

As the device knows the empty distance E from the user entry, it can calculate the

level as follows:

L = E - D

An integrated temperature sensor compensates for changes in the velocity of sound

caused by temperature changes.

Interference echo suppression

The interference echo suppression feature ensures that interference echos (such as

welded joints, internal ladder steps, edges and installations) are not interpreted as a

level echo.

Equipment architecture

Calibration

Enter the empty distance E and the span F to calibrate the system.

Blocking distance

Span F may not extend into the blocking distance BD. Level echos within the blocking

distance cannot be evaluated due to the transient characteristics of the sensor.

4 to 20 mA ouput with HART

PLC

Transmitter power

supply unit

RMA 422

or RN 221 N

(communication resistor

included)

FXA 191

or

DXR 275

®

protocol

- COMMUWIN II

- ToF Tool

Commubox

FXA 191

Operating and

display module

VU 331

HART handheld

DXR 275

- ToF Tool

Service adapter

FXA 193

2

The Prosonic M can be operated on-site using either the display module VU 331 or

the supplied ToF Tool program. The system can also be operated remotely using the

HART® handheld terminal DXR 275 or using the ToF Tool.

®

NOTE: If a HART

communication resistor is not built into the power supply device, a

250Ω communication resistor in the 2-wire line must be inserted.

Endress+Hauser

Page 3

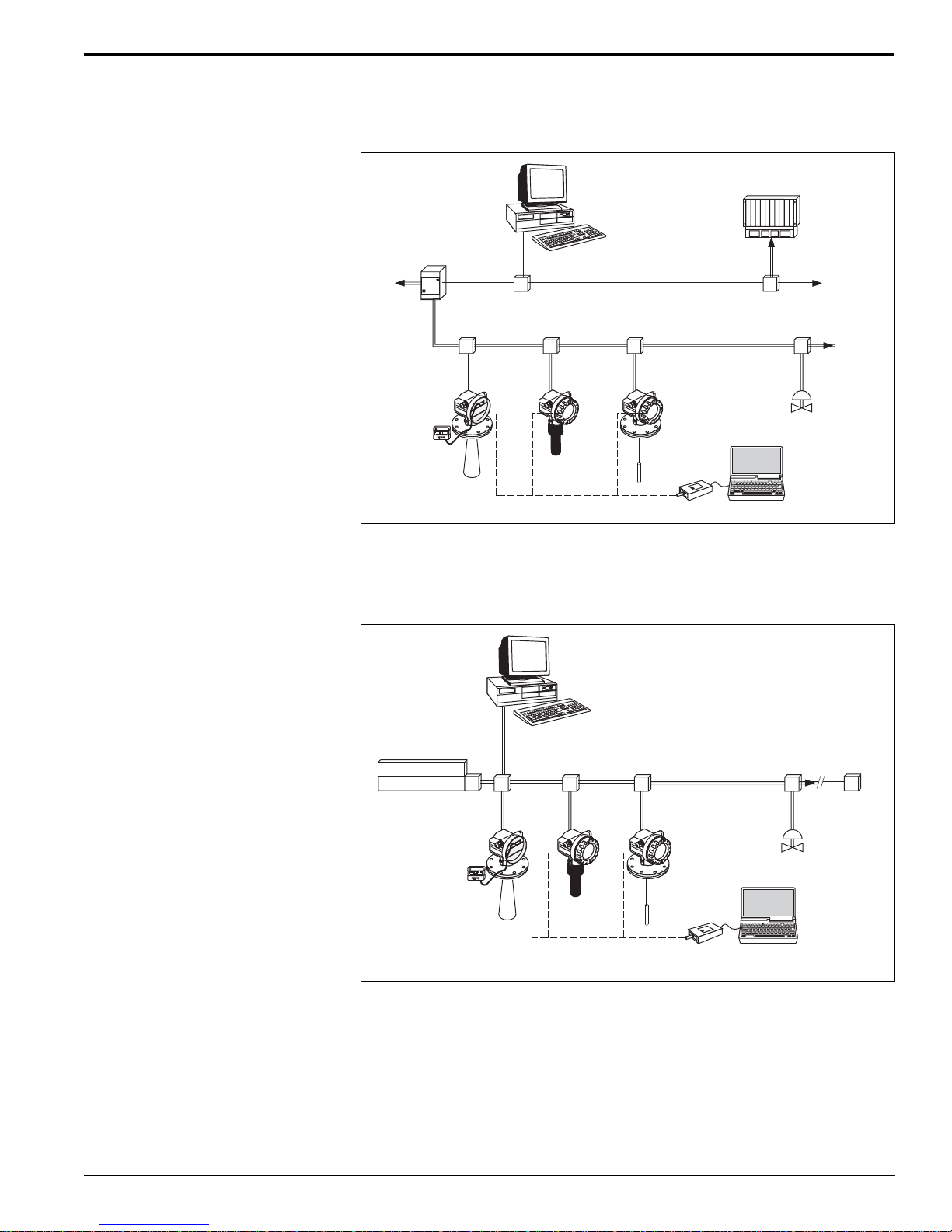

Prosonic M

Profibus-PA protocol

Segment coupler

PROFIBUS-PA

Personal computer

e.t.with Commuwin II

or ToFTool and

Profibard (Proficard)

PROFIBUS-DP

PLC

Operating and

display module

VaU 331

Micropilot

Prosonic

Levelflex

FXA 193

ToF Tool

Additional

functions

(valves, etc.)

A maximum of 32 transmitters (8 if mounted in an explosion hazardous area) can be

connected to the bus. Both on-site as well as remote operation are possible.

Foundation Fieldbus (FF) protocol

Personal computer

e.g.with

NI-FBUS configurator

Power supply

Power conditioner

Operating and

display module

VaU 331

T

Levelflex

T

Additional

functions

(valves, etc.)

Endress+Hauser 3

Prosonic

Micropilot

FXA 193

ToF Tool

A maximum of 32 transmitters (standard or hazardous) can be connected to the bus.

For intrinsically safe circuits, the maximum number of transmitters depends on the

established rules and standards for intrinsically safe circuits (EN 60070-14) and proof

of instrinsic safety. Both on-site and remote operation are possible.

Page 4

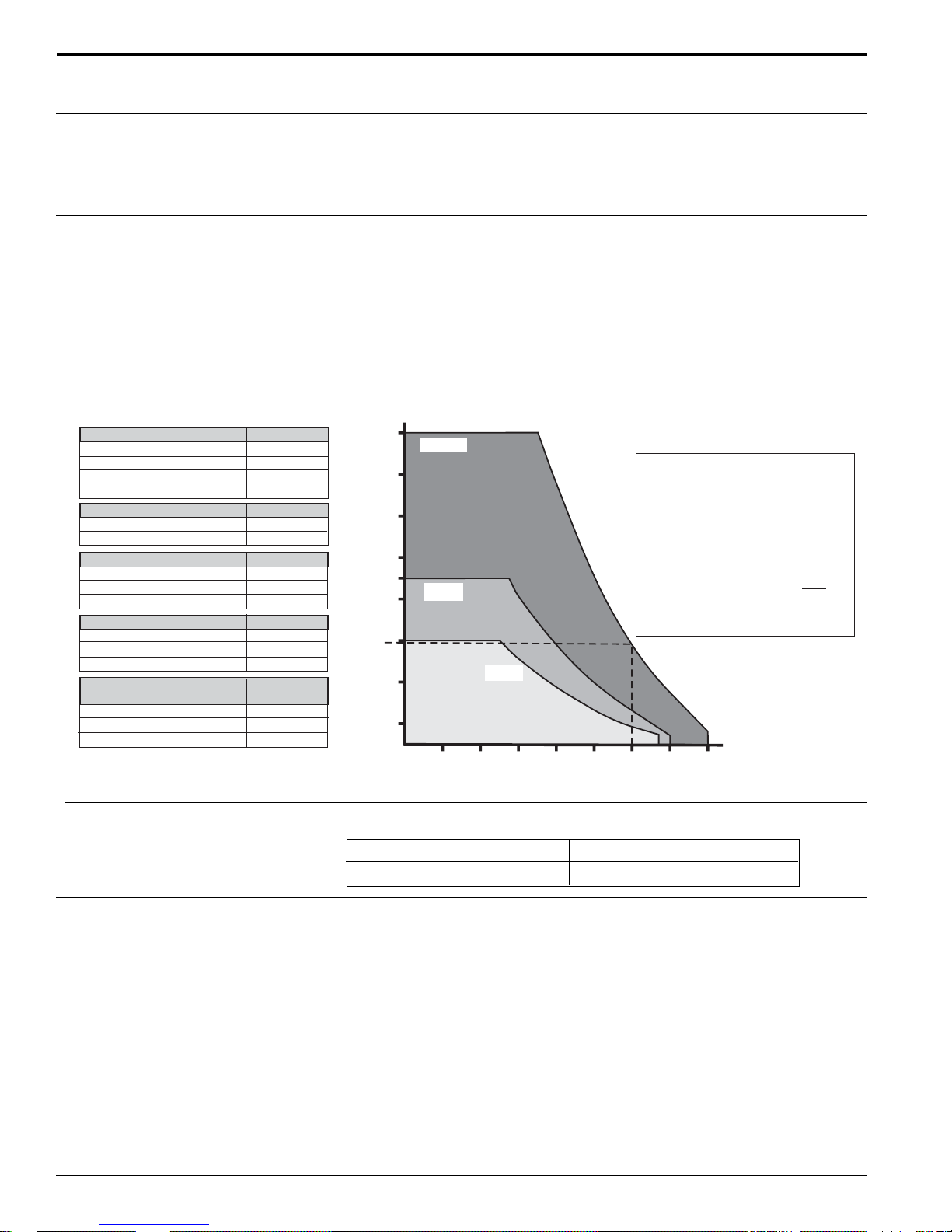

Input

Prosonic M

Measured variable

Measuring range

Fluid surface

Calm

Waves

Strong turbulence (agitators, etc.)

Foaming

Bulk material surface

Hard, rough (e.g.rubble)

Soft (e.g.peat, dust-covered clinker)

Dust

No dust formation

Little dust formation

Heavy dust formation

Filling curtain in detection range

None

Smalll quantities

Large quantities

Temperature difference between

sensor and surface

To 68°F (20°C)

To 104°F (40°C)

To 176°F (80°C)

Attenuation

0 dB

5 to 10 dB

10 to 20 dB

Consult factory

Attenuation

40 dB

40 to 60 dB

Attenuation

0 dB

5 dB

5 to 20 dB

Attenuation

0 dB

5 to 10 dB

10 to 40 dB

Attenuation

0 dB

5 to 10 dB

10 to 20 dB

The distance D between the sensor membrane and the product surface is measured

(page 2). Using the linearization function, the device uses D to calculate:

• Level L in any units

• Volume V in any units

• Flow Q across measuring weirs or open channels in any units

The measuring range is limited by the range of a sensor. The sensor range is, in turn,

dependent on operating conditions. The diagram below defines the effect that echo

attenuation has on the sensor’s measuring range. The ideal echo attenuation curves

for each sensor are shown in the diagram. A number of echo attenuation sources that

affect proper sensor selection are shown in the table.

1. Determine which of the influences shown are appropriate for your process.

2. Add the corresponding attenuation values.

3. From the total attenuation, use the diagram to calculate the sensor range.

50

FMU 43

Example (for FMU 43)

Dust-covered rubble

Medium dust development

Not in filling curtain

Temperature differential < 68°F

Approximate range = 15.5 ft.

Approximate dB

50

10

0

0

60 dB

range in feet

15.5

26

16

43

36

30

FMU 41

23

10

3

10 20 30 40 50 60 70 80

FMU 40

Attenuation / dB

Operating frequency

Pulse frequency

4

Sensor FMU 40 FMU 41 FMU 43

Frequency approx. 70 kHz approx. 50 kHz approx. 35 kHz

• 2-wire devices, maximum 0.5 Hz

• 4-wire devices, maximum 2 Hz

The exact values are dependent on the type of device and supply voltage.

Endress+Hauser

Page 5

Prosonic M

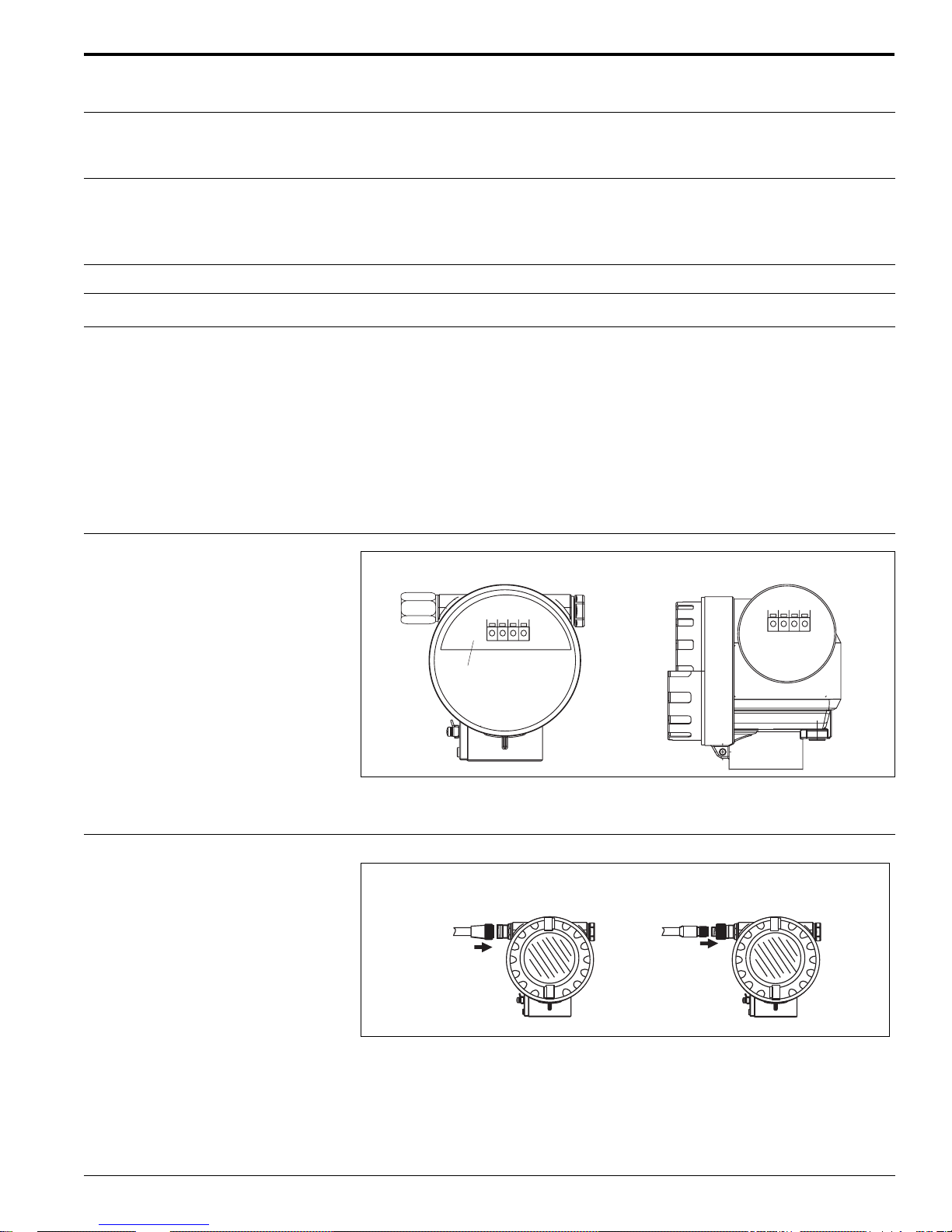

1 234

1 234

Sealed terminal

compartment

F 12 Housing T 12 Housing

Output signal

Output

®

• 4 to 20 mA with HART

• Profibus-PA

• Foundation Fieldbus (FF)

protocol

Signal on alarm

Load HART

®

Output damping

Linearization

Terminal compartment

Error information can be accessed via the following interfaces:

• On-site display (error symbol, error code and plain text description)

• Current output (configurable)

• Digital interface

Minimum load for HART

®

communication, 250Ω

Freely selectable, 0 to 255 seconds

The linearization function of the Prosonic M allows conversion of the measured value

into any unit of length or volume. In open channels or measuring weirs, it is also

possible to linearize the flow. Linearization tables for calculating volume in horizontal

cylindrical tanks are preprogrammed. You can also enter any number of other tables

containing up to 32 value pairs either manually or semi-automatically (by filling the

vessel under controlled conditions). You can use the ToF Tool operating program to

calculate the table automatically for any tank form and then enter it into the device.

Power supply

Fieldbus plug connector

Endress+Hauser

In the F 12 housing, the terminals are located underneath the housing cover. In the

T 12 housing, they are under the cover of the separate terminal compartment.

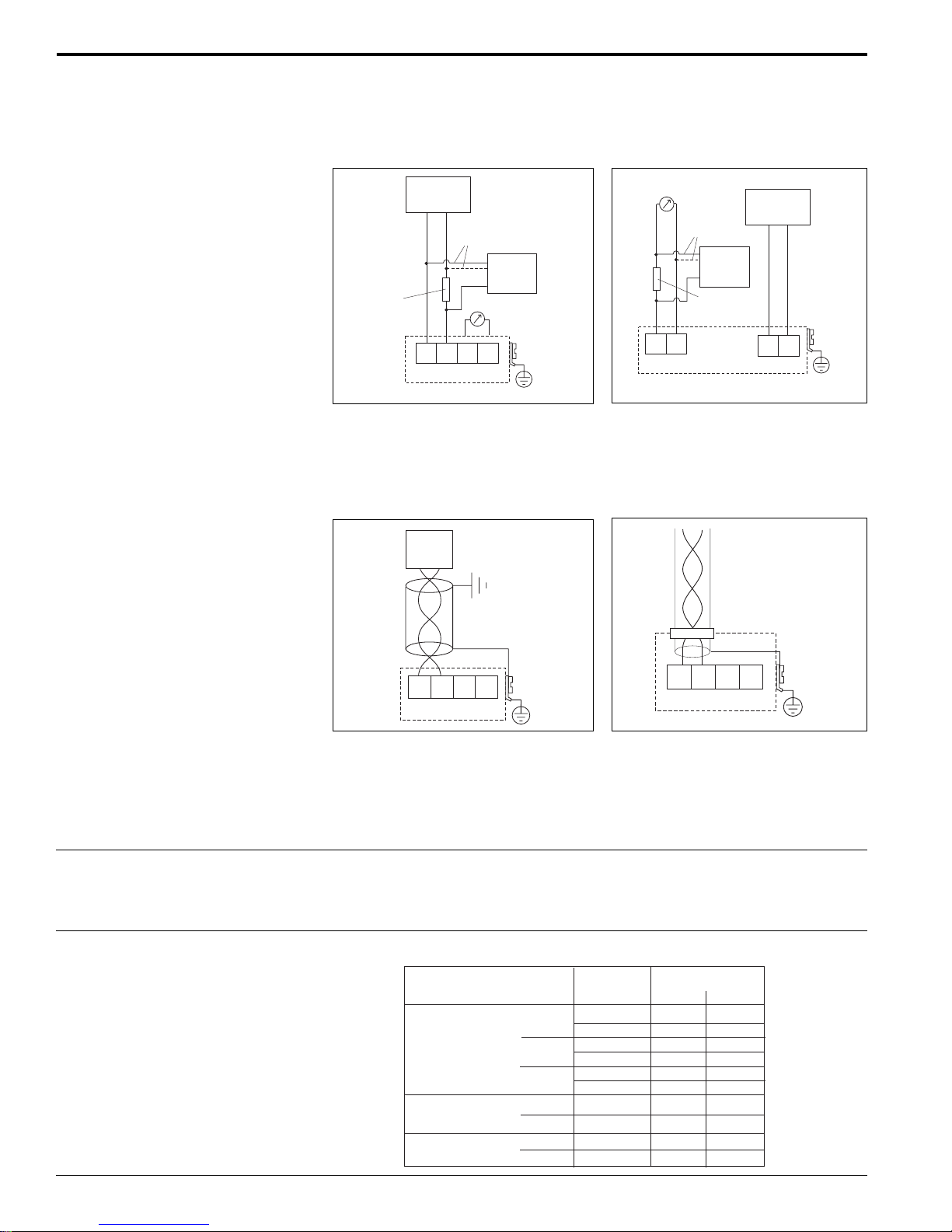

Foundation Fieldbus 7/8" plug

Profibus M 12 plug

• For the Foundation Fieldbus version, a 7/8” plug connector is available.

• For the Profibus-PA version, an M12 plug connector is available

Both versions are supplied fully wired.

5

Page 6

Terminal assignment 4 to 20 mA with HART

FF+ FF-

1234

Plant

ground

Prosonic M

®

, 2-wire 4 to 20 mA with HART®, active,

4-wire

AC / DC

Auxiliary

power

12

L1/L+

N/L-

Plant

ground

Communication

resistor

(> 250 )Ω

Power:

4 to 20 mA

alternative

Test sockets

(via interlock diode)

1234

L- L+ I+ I-

Commubox

FXA 191

DXR 275

Plant

ground

0 to 20 mA

56

I-

I+

alternative

Commubox

FXA 191

DXR 275

Communication

resistor

(> 250 )Ω

• Connect the connecting line to the screw terminals (up to 18 AWG) in the terminal

compartment

• Use 2-wire twisted pair cable with shield for the connection

• Units are internally protected against reverse polarity, RFI and over-voltage peaks

PROFIBUS-PA Foundation Fieldbus

T-Box

3 412

PA+ PA-

Plant

ground

The digital communication signal is transmitted to the bus via a 2-wire connection.

The bus also provides the auxiliary power. Please use 2-wire twisted pair cable with

shield. Refer to the following operating manuals for information on cable types, and

how to set and ground the network:

• BA 198F/00/en “PROFIBUS-DP/-PA: Guidelines for planning and commissioning”

• BA 013S/04/en “Foundation Fieldbus, Installation and Commissioning Guidelines”

Cable entry

• Cable gland: M20x1.5, recommended cable diameter 0.23” to 0.39” (6 to 10 mm)

• Cable entry 1/2” NPT or G 1/2

• PROFIBUS-PA M12 plug

• Foundation Fieldbus 7/8” plug

Power supply The following values are the voltages across the terminals directly at the instrument.

Version

2-wire HART

Fixed current

(measured value

transmitted by HART)

4-wire

Standard

XP

Standard

DC

AC

consumption

IS

IS

Current

4 mA

20 mA

4 mA

20 mA

4 mA

20 mA

11 mA

11 mA

Terminal voltage

Min. Max.

14 V

8V

14 V

8V

14 V

11 V

10 V

10 V

10.5 VDC

90 VAC 253 VAC

36 V

36 V

30 V

30 V

30 V

30 V

36 V

30 V

32 VDC

6

Endress+Hauser

Page 7

Prosonic M

Power consumption 2-wire, 51 mW to 800 mW

4-wire AC, maximum 7W

4-wire DC FMU 40/41, 330 mW to 830 mW

4-wire DC FMU 43, 600 mW to 1 W

®

, 3.6 to 22 mA

Current consumption (2-wire units)

HART

PROFIBUS-PA, maximum 13 mA

Foundation Fieldbus, maximum 15 mA

HART® ripple

Maximum noise HART

®

Galvanic isolation

Reference operating conditions

Measuring error

Measured value resolution

47 to 125 Hz: Vpp = 200 mV (measured at 500 W)

500 Hz to 10 kHz: Vrms = 2.2 mV (measured at 500 W)

With 4-wire units, the evaluation electronics and power supply voltage are

galvanically isolated from each other

Performance characteristics

• Temperature = 68°F (20°C)

• Pressure = 14.7 psia (1013 mbar abs.)

• Humidity = 50%

• Ideal reflective surface (calm, smooth fluid surface)

• No interference reflections within signal beam area

• Set application parameters:

Tank shape = flat ceiling

Medium property = liquid

Process conditions = calm surface

Typical specifications for reference operating conditions (include linearity,

repeatability, and hysteresis):

FMU 40 / 41: ± 0.08” (2 mm) or 0.2% of set measuring range, which ever is greater

FMU 43: ± 0.15” (4 mm) or 0.2% of set measuring range, which ever is greater

FMU 40 / 41: 0.04” (1 mm)

FMU 43: 0.08” (2 mm)

Reaction time

The reaction time depends on the parameter settings (minimum 0.5 seconds for

4-wire devices, minimum 2 seconds for 2-wire devices)

Endress+Hauser

7

Page 8

Installation conditions

Prosonic M

FMU 40/41 installation variants

Installation with counter nut

Counter nut supplied

for G 1-1/2 and G2

instruments

Installation with extension bracket

ENDRESS+HAUSER

Prosonic M

Installation with sleeve

Installation with adapter flange

Adapter flange

EPDM sealing

ring supplied

EPDM sealing

ring supplied

FMU 43 installation variants

Slip-on flange

Nozzle

Installation with

universal slip-on flange

Sensor

Hazardous area or non-hazardous

Sensor

Installation with

mounting bracket

R

E

S

U

A

H

+

S

S

E

R

D

N

E

M

ic

n

o

s

ro

P

Non-hazardous area

Nozzle

8

Endress+Hauser

Page 9

Prosonic M

ENDRESS+HAUSER

Prosonic MProsonic M

ENDRESS+HAENDRESS+HAUSERUSER

Prosonic MProsonic M

Venting

hole

Installation conditions for level

measurement

• Do not install the sensor in the middle of the tank (3). Mounting distance between

• Use a protective cover (see accessories, page 18), to protect the sensor from rain

• Avoid measurements in the filling stream area (4).

• Make sure that equipment (5) such as limits swtiches, temperature sensors, etc.

• Align the sensor so that it is vertical to the product surface (7).

• Never install two ultrasonic measuring devices in the same vessel, as the two

• To estimate the transmitted echo beam and its detection range, use the 3 dB

234

1

1/6D

D

5

6

FMU 40

FMU 41

FMU 43

α

r

r = L tan

α

11°

11°

6°

L

α

2

LSensor

16 ft (5 m)

26 ft (8 m)

50 ft (15 m)

18.9" (480 mm)

30.3" (770 mm)

31.1" (790 mm)

7

r

vessel wall and sensor (1) should be 1/6 of the tank diameter.

or direct sunlight (2).

are not located in the beam angle α. In particular, symmetrical equipment (6) such

as heating coils, baffles, stationary ladder rungs etc. can influence measurement.

signals may affect each other.

emitting angle α (see Figure above).

Installation in narrow shafts In narrow shafts with strong interference

Endress+Hauser

echoes, we recommend using an

ultrasound guide pipe (e.g. PE or PVC

wastewater pipe) with a minimum

diameter of 4” (100 mm). Make sure that

the pipe does not accumulate dirt, clean

pipe at regular intervals.

9

Page 10

Prosonic M

Installation conditions for flow

measurements

• Install the Prosonic M at the inflow side, as close above the maximum water

level H

• Position the Prosonic M in the middle of the channel or weir.

as possible, plus the blocking distance BD.

max

• Align the sensor membrane parallel to the water surface.

• Keep to the installation distance of the channel or weir.

• The “Flow to Level” linearization curve (“Q/h curve”) can be entered using the

ToF Tool or manually via the on-site display.

Example: Khafagi-Venturi flume

Khafagi -Venturi - flume

BD

inflow

o

b

o

direction of flow

H

max

1 x b

outflow

Blocking distance with nozzle

installation

BD

SD

E

F

BD: Blocking Distance

SD: Safety Distance

E: Empty calibration

F: Full calibration (span)

FMU 40/41

L

D

Sensor

FMU 40

FMU 41

FMU 43

FMU 43

L

D

BD Max. range

9.84" (250)

15.7" (400)

23.6" (600)

16 ft (5 m)

26 ft (8 m)

50 ft (15 m)

in liquids

1.97" (50)

3.15" (80)

3.94" (100)

3.15" (80)

3.94" (100)

FMU 40

D (mm) max. L (mm)

approx.3.15" (80)

approx.7.87" (200)

approx.9.84 (250)

FMU 41

D (mm) max. L (mm)

D > approx.3.94" (100)

L < approx.11.8" (300)

approx.7.87" (200)

approx.9.84 (250)

FMU 43

Max. range

in solids

6.5 ft (2 m)

11.5 ft (3.5 m)

23 ft (7 m)

Install the Prosonic M at a height so that the blocking distance BD is not interferred

with, even at the maximum fill level. Usa a pipe nozzle if you cannot maintain the

sensor blocking distance in any other way. The interior of the nozzle must be smooth

and cannot contain any edges or welded joints. In particular, remove any burr on the

inside of the tank side nozzle end. Note the specified limits for nozzle diameter to

length. Nozzles which extend into the vessel should be cut at an angle of 45° to

minimize echo disturbances.

10

Caution !

The sensor may malfunction if the blocking distance is not above the maximum level.

NOTE: In order to prevent the level from entering the blocking distance, a safety

distance (SD) can be specified. If the level is within the safety distance, the Prosonic

outputs a warning or alarm message.

Endress+Hauser

Page 11

Prosonic M

Ambient conditions

Ambient temperature

Storage temperature

Resistance to alternating

temperature cycles

Climate class

Ingress protection

Vibration resistance

Electromagnetic compatibility (EMC)

-40° to + 176°F (-40° to + 80°C)

The function of the LCD becomes restricted at T

and 60°C). If the device is operated outdoors in strong sunlight, a protective cover

< -5°F and T

amb

> 140°F (-20°C

amb

should be used.

-40° to +176°F (-40° to +80°C)

To DIN EN 60068-2-14; Nb test: 176°F / -40°F (+80°C / -40°C), 1 K/min, 100 cycles

DIN EN 60068-2-38 (Test Z/AD) EIN/IEC 68 T2-30Db

• With closed housing, tested according to NEMA 6P (IP 68), 24 hours at 6 feet

(1.83 m) under water surface.

NEMA 4X (IP 66)

• With open housing, NEMA 1 (IP 20)

DIN EN 60068-2-64 / IEC 68-2-64: 20 to 2000 Hz, 1 (m/x

2)2

/Hz; 3 x 100 min

• Interference emission to EN 61326, Equipment Class B

• Interference immunity to EN 61326, Appendix A (Industrial) and NAMUR

Recommendation NE 21 (EMC)

• A standard installation cable is sufficient if only the analog signal is used. Use

shielded cable when working with a superimposed communication signal (HART

Process conditions

®

)

Process temperature -40° to +176°F (-40° to +80°C)

A temperature sensor is integrated in the sensor for temperature-dependent

time-of-flight correction.

Process pressure

• FMU 40/41: 44 psia (3 bar abs.)

• FMU 43: 36 psia (2.5 bar ads.)

Mechanical construction

FMU 40 / 41 dimensions

Dimensions are in inches (mm)

3.38"

(86)

1-1/2" NPT

(G 1-1/2)

F12 housing

2.26"

3.07"

(65)

(78)

3.35"

(85)

FMU 40 FMU 41

60 AF

3.43"

(87)

0.87"

(22)

∅ 1.54"

(39)

5.83"

(148)

∅ 5.08"

(129)

5.91"

(150)

2" NPT

(G 2)

2.68"

(68)

60 AF

∅ 1.97"

(50)

T12 housing

3.70"

(94)

0.87"

(22)

3.27"

(83)

2.26"

(65)

1.26"

(32)

5.83"

(148)

3.07"

(78)

3.35"

(85)

∅ 5.08"

(129)

6.38"

(162)

Endress+Hauser

11

Page 12

FMU 43 dimensions

Prosonic M

3.39"

(80)

2 x M8

2.56"

(65)

∅ 9.05"

(230)

3.07"

(78)

∅ 5.08"

(129)

Dimensions are in inches (mm)

Weight • FMU 40: Approximately 5.5 lb (2.5 kg)

• FMU 41: Approximately 6 lb (2.6 kg)

• FMU 43: Approximately 8 lb (3.5 kg)

Housing

Types of housings:

• F 12 housing with sealed terminal compartment for standard or hazardous areas

• T 12 housing with separate terminal compartment for explosion proof areas

Material:

• Aluminum, chromed, powder-coated, seawater resistant

Cover:

• Aluminum, for version without on-site display

• Inspection glass for version with on-site display (this version cannot be specified

with the ATEX II 1/2 D certificate)

3.35"

(85)

5.90"

(150)

9.76"

(248)

4.72"

(120)

1.57"

(40)

4.68"

(119)

0.08"

1.57"

(40)

(2)

0.43"

(11)

3.50"

(89)

0.98"

(25)

0.98"

(25)

4.84"

(123)

Process connection and sensor

material

12

FMU 40: 1-1/2” NPT or G1-1/2, PVDF sensor material with EPDM seal

FMU 41: 2” NPT or G 2, PVDF sensor material with EPDM seal

FMU 43: Universal slip-on flange, 4” ANSI or mounting bracket, PVDF sensor

material, 316 Ti SS diaphragm

Endress+Hauser

Page 13

Prosonic M

E

+–

E

N

D

R

E

S

S

+

H

A

U

S

E

R

M

I

C

R

O

P

I

L

O

T

I

I

I

P

6

5

O

r

d

e

r

C

o

d

e

:

Se

r

.-

N

o

.

:

M

e

s

s

be

re

ic

h

M

e

a

s

u

r

i

n

g

r

a

n

ge

U

16

.

..

3

6

V

D

C

4

.

..

2

0

m

A

m

a

x

.

2

0

m

Made i

n Germ

any

M

aulburg

T

>

7

0

°

C

:

A

t

>

8

5

°

C

Symbols

3 keys

ENDRESS+HAUSER

LCD

Human interface

Display elements The LCD module VU 331 for display and operation is located beneath the housing

cover. The measured value is legible through the glass in the cover. Open the cover

to operate the device.

Displayed

Symbol

Meaning

ALARM symbol

Symbol appears when the instrument is in an alarm state. Flashing indicates

warning, steady ON indicates alarm.

LOCK symbol

The lock symbol appears when the instrument is locked;input is not possible

during the locked state.

COMMUNICATION symbol

Communication symbol appears when data transmission via HART, PROFIBUS,

or Foundation Fieldbus is in progress.

Key (s)

+

-

Esc

-

E

+

-

Or

Or

+

Or

and

or

and

Or

Meaning

Navigate upwards in the selection list

Edit numeric value within a function

Navigate downwards in the selection list

Edit numeric value within a function

Navigate to the left within a function group

Navigate to the right within a function group, confirmation

E

E

Contrast settings of the LCD

E

Hardware lock / unlock

After a hardware lock, an operation via the display or

+

and and

-

communication is not possible.

E

The hardware can only be unlocked via the display. An

unlock parameter must be entered to do so.

Endress+Hauser

13

Page 14

On-site operation Operation with VU 331

The LC-Display VU 331 allows configuration via 3 keys directly at the instrument. All

device functions can be set through a menu system. The menu consists of function

groups and functions. Within a function, application parameters can be read or

adjusted. The user is guided through a complete configuration procedure.

ENDRESS + HAUSER

Prosonic M

Headline Position indicator

+–

E

Function groups -> Functions

HOME

+

-

E

+

-

FG00

FG01

FG02

FG03

FG04

FG05

FG06

FG07

...

Esc

+

F000 F001 F002 F003 F004 ...

-

E

E

+

Esc

-

Operation with DXR 275 HART

E

Esc

-

+

®

terminal

Selection list

+

Envelope

curve

Symbol

Help text

Main value

Bar graph

Unit

On units with HART® communication, access to the programming matrix can be done

using a handheld DXR 275 terminal.

FMU43: LIC0001

FMR 231:LIC0001

Online

1 >Group Select

2 PV 8.7 m

HELP

I

O

Online

1->Group Select

2 PV 8.7m

HELP

F1 F4F2 F3

FMU43 : LIC0001

Group Select

1->Calibration

2 Safety settings

3 Temperature

4 Linearization

5 Extended calibr.

F1 F4F2 F3

HOME

FMU43: LIC0001

Calibration

1 Measured Value

2->Tank shape

3 Medium property

4 Process cond.

5 Empty calibr.

HOME

F1 F4F2 F3

13

14

Endress+Hauser

Page 15

Prosonic M

Remote operation

Operation with ToF Tool

The ToF Tool is a graphical operation software for instruments from Endress+Hauser

that operate based on the time-of-flight principle. It is used to support commissioning,

securing of data, signal analysis and documentation of the instruments. It is compatible with the f ollo wing operating systems: Win95, Win98, WinNT4.0 and Win2000.

The ToF Tool suppor ts the following functions:

• Online configuration of transmitters

• Signal analysis via envelope curve

• Loading and saving of instrument data (Upload/Download)

• Documentation of measuring point

Menu-guided commissioning

Functions

Function

groups

Navigation bar

Main window

Help pages

Device

list

Signal analysis via envelope curve

Envelope

curve

Data at

cursor position

Evaluated echo

Device data

Parameter list

Envelope

list

Curve

data

Endress+Hauser

Connection options (page 2 and 3):

®

• HART

with Commubox FXA 191 (available as accessory)

• PROFIBUS-PA

• Service-interface with adapter FXA 193 (available as accessory)

15

Page 16

Prosonic M

Operation with Commuwin II (for communication versions HART

®

or

PROFIBUS-PA)

Commuwin II is an operating software with graphical support (MS Windows) for

intelligent transmitters with the communication protocols Rackbus, Rackbus RS-485,

HART® and PROFIBUS-PA.

Commuwin II supports the following functions:

• Online configuration of transmitters

• Loading and saving of instrument data (Upload/Download)

• Orderly visulization of measured values and limit values

• Display and recording of measured values with a line recorder

NOTE: It is not possible to display envelope curves with Commuwin II. To display

curves, use the ToF Tool program supplied.

Connections (page 3):

• HART® with Commubox FXA 191 (available as accessory)

• PROFIBUS-PA

Operation with NI-FBUS Configurator (only with Foundation Fieldbus)

The NI-FBUS Configurator is an easy-to-use graphical environment for creating

linkages, loops, and a schedule based on the fieldbus concepts.

The NI-FBUS Configurator is used to configure a fieldbus network as follows:

• Set block and device tags

• Set device addresses

• Create and edit function block control strategies (function block applications)

• Configure vendor-defined function and transducer blocks

• Create and edit schedules

• Read and write to function block control strategies (function block applications)

• Invoke Device Description (DD) methods

• Download a configuration

• Verify a configuration and compare it to a saved configuration

• Monitor a downloaded configuration

• Replace devices

• Save and print a configuration

Endress+Hauser16

Page 17

Prosonic M

Certificates and Approvals

CE mark By attaching the CE mark, Endress+Hauser confirms that the instrument fulfills all the

requirements of the relevant EC directives.

Hazardous areas

FMU 40

1 2 3 4 5 6

FMU 40 -

1 Certificate

A Non-hazardous version

S FM IS Cl. I, II, III; Div. 1, Grps. A-G

FM NI Cl. I, Div. 2

T FM XP Cl. I, II, III; Div . 1, Grps. A-G

U CSA IS Cl. I, II, III; Div. 1, Grps. A-G

CSA NI Cl. I, Div. 2

V CSA XP Cl. I, II, III; Div. 1, Grps. A-G

N CSA General purpose

2 Process connection

R G 1-1/2, ISO 228

N 1-1/2” NPT

3 Power supply / communication

B 2-wire, 4 to 20 mA loop-powered / HART

H 4-wire, 10.5 to 32 VDC / 4 to 20 mA HART

G 4-wire, 90 to 253 VAC / 4 to 20 mA HART

D 2-wire PROFIBUS-PA

F 2-wire Foundation Fieldbus

4 Display / operation

1 Without LCD

2 With LCD VU 331 / on-site operation

5 Housing

A F12 aluminum housing, coated, NEMA 6P

C T12 aluminum housing with separate

terminal

compartment, coated, NEMA 6P

6 Cable entry

2 M 20 x 1.5

3 G 1/2

4 1/2” NPT

5 M 12 PROFIBUS-PA plug-in connector

6 7/8” Foundation Fieldbus plug-in connnector

FMU 40 / 41:

• FM approved Intrinsically safe Class I, II, III; Division 1, Groups A-G / Nonincendive Class I, Division 2

• FM approved explosion proof Class I, II, III; Division 1, Groups A-G

• CSA approved Intrinsically safe Class I, II, III; Division 1, Groups A-G / Nonincendive Class I, Division 2

• CSA approved explosion proof Class I, II, III; Division 1, Groups A-G

FMU 43:

• FM approved dust-ignition proof Class I, Division 2, Groups E-G, non-incendive

• CSA approved dust-ignition proof Class I, Division 2, Groups E-G, non-incendive

Ordering Information

FMU 41

1 2 3 4 5 6

FMU 41 -

1 Certificate

A Non-hazardous version

S FM IS Cl. I, II, III; Div. 1, Grps. A-G

FM NI Cl. I, Div. 2

T FM XP Cl. I, II, III; Div . 1, Grps. A-G

U CSA IS Cl. I, II, III; Div . 1, Grps. A-G

CSA NI Cl. I, Div. 2

V CSA XP Cl. I, II, III; Div. 1, Grps. A-G

N CSA General purpose

2 Process connection

R G 2, ISO 228

N 2” NPT

3 Power supply / communication

®

®

®

B 2-wire, 4 to 20 mA loop-powered / HART

H 4-wire, 10.5 to 32 VDC / 4 to 20 mA HART

G 4-wire, 90 to 253 VAC / 4 to 20 mA HART

D 2-wire PROFIBUS-PA

F 2-wire Foundation Fieldbus

4 Display / operation

1 Without LCD

2 With LCD VU 331 / on-site operation

5 Housing

A F12 aluminum housing, coated, NEMA 6P

C T12 aluminum housing with separate

terminal compartment, coated, NEMA 6P

6 Cable entry

2 M 20 x 1.5

3 G 1/2

4 1/2” NPT

5 M 12 PROFIBUS-PA plug-in connector

6 7/8” Foundation Fieldbus plug-in connnector

FMU 43

1 2 3 4 5 6

FMU 43 -

1 Certificate

M FM DIP CI. 1, Div. 2, Grps. E-G, NI

N CSA General purpose

P CSA DIP CI. 1, Div. 2, Grps. E-G, NI

2 Process connection

P 4” ANSI flange, PP (universal slip-on

flange included)

S 4” ANSI flange, 316Ti SS (universal slip-on

flange included)

3 Power supply / communication

H 4-wire, 10.5 to 32 VDC / 4 to 20 mA HART

G 4-wire, 90 to 253 VAC / 4 to 20 mA HART

®

®

®

D 2-wire PROFIBUS-PA

F 2-wire Foundation Fieldbus

4 Display / operation

1 Without LCD

2 With LCD VU 331 / on-site operation

5 Housing

A F12 aluminum housing, coated, NEMA 6P

6 Cable entry

2 M 20 x 1.5

3 G 1/2

4 1/2” NPT

5 M 12 PROFIBUS-PA plug-in connector

6 7/8” Foundation Fieldbus plug-in connnector

®

®

Endress+Hauser 17

Page 18

Prosonic M

Accessories

Protective cover A protective cover made of stainless steel is available for outdoor installation. Cover,

mounting ring and hardware inlcuded.

Part Number: 543199-0001

F12 / T 12 housing

E

N

D

R

M

E

Order Code:

I

S

C

S

R

+

O

Ser

H

P

A

.-No

I

L

U

O

S

.:

T

E

I

R

I

Messbereich

Measur

ing r

ange

U 16...36

max.

4...20 mA

20 m

V DC

I

P

6

5

T

A

>70°C

:

t

>

8

5

°C

Made in Germany Maulburg

FHX 40 remote display and operating

unit

F 12 housing

E

N

D

R

E

O

S

r

d

S

e

r

C

+

S

H

o

e

d

A

r

e

.-

:

U

N

o

S

.

:

E

R

M

e

s

s

M

b

e

e

re

a

s

i

c

u

h

r

in

g

r

a

n

g

e

U

m

1

a

6

x

.

.

.

.

4

2

3

..

0

6

.2

m

V

0

D

m

C

A

Maulburg

I

P

6

5

T

A

>

7

0

°

C

:

t

>

8

5

°

C

Made in Germany

FHX 40 separate housing

5.9"

(150)

4.8"

(122)

3.15"

(80)

Cable

The FHX 40 provides remote display and operation for the FMU 40/41/43 units. The

display unit must be specified when ordering the Prosonic M sensors, it cannot be

retrofited due to the preinstallation of the plug connectors. Maximum cable length is

65 feet (20 m).

• Temperature range: -22° to +158°F (-30° to +70°C)

• Protection: NEMA 4 (IP 65)

• Material: Aluminium alloy AL Si 12

• Maximum cable length: 65 ft. (20 m)

Consult factory for ordering information.

Installation bracket for FMU 40/41

ENDRESS+HAUSER

Prosonic M

15.7"

(400)

0.12"

(3)

9.84"

(250)

4.72"

(120)

4.72"

(120)

1.18"

(30)

∅ 0.63"

(16)

For FMU 40, order no.942669-0000

For FMU 41, order no.942669-0001

Endress+Hauser18

Page 19

Prosonic M

Adapter flange for FMU 40/41

FXA 191 commubox

FXA 193 service adapter

Adapter flange for the FMU 40/41 threaded Prosonic M units for mounting on existing

nozzles or applications requiring a nozzle mount.

1 2 3

FAU 70 A -

1 Version

12 2” ANSI, Class 150

14 3” ANSI, Class 150

15 4” ANSI, Class 150

2 Thread

3 1-1/2” NPT

4 2” NPT

3 Material

2 317L SS

7 PPS (Polypropylene)

For intrinsically safe communication between HART

Sealing ring

EPDM

(supplied)

Sensor

®

protocol and Personal Computer

Nozzle

Adapter

flange

(refer to page 2). The Prosonic M can be operated either with the ToF Tool or the

Commuwin II program. The commubox coverts HART® protocol signals into

RS 232C signals.

Additional information is available in Technical Information TI 237F/00/en.

For comunication with ToF Tool via the display connector (refer to page 3).

Order No.: 50095566

Endress+Hauser 19

Page 20

Supplemental documentation

Device function description

Operating manual

BA 240F/00/en

This document contains detailed descriptions of all Prosonic M functions and is valid

for all communication variants

Communication operating manuals

The following operating manuals are supplied with the unit depending on the communication version ordered.

4 to 20 mA, HART

®

BA 237F/00/en

PROFIBUS-PA BA 238F/00/en

Foundation Fieldbus BA 239F/00/en

These manuals describe the installation and initial commissioning of the Prosonic M.

From the operating menu, all functions are included, which are required for standard

measurement tasks. Additional functions are not contained in the manual.

For application and selection assistance, in the U.S.

call 888-ENDRESS

For total support of your installed base, 24 hours

a day, in the U.S. call 800-642-8737

Visit us on our web site, www.us.endress.com

United States

Endress+Hauser, Inc.

2350 Endress Place

Greenwood, IN 46143

Phone: (317) 535-7138

888-ENDRESS

FAX: (317) 535-8498

TI 365F/24/ae/03.02

© 2002 Endress+Hauser, Inc.

Canada

Endress+Hauser

Canada Ltd.

1440 Graham’s Lane

Unit 1, Burlington

ON, L7S 1W3

Phone: (905) 681-9292

800-668-3199

FAX: (905) 681-9444

Mexico

Endress+Hauser

Paseo del Pedregal No. 610

Col. Jardines del P edregal

01900, Mexico D .F.

Mexico

Phone: (525) 568-2405

FAX: (525) 568-7459

Endress+Hauser

The Power of Know How

Loading...

Loading...