Page 1

TI00365F/00/EN/17.14

71275861

Products Solutions Services

Technical Information

Prosonic M

FMU40, FMU41, FMU42,

FMU43, FMU44

Ultrasonic Level Measurement

Compact transmitters for non-contact level

measurement

Application

• Continuous, non-contact level measurement in fluids, pastes, sullages and coarse

bulk materials

• Flow measurement in open channels and measuring weirs

• System integration via:

– HART (standard), 4 to 20mA

–PROFIBUS PA

–FOUNDATION Fieldbus

• Maximum measuring range:

– FMU40: 5 m (16 ft) in fluids, 2 m (6.6 ft) in bulk materials

– FMU41: 8 m (26 ft) in fluids, 3,5 m (11 ft) in bulk materials

– FMU42: 10 m (33 ft) in fluids, 5 m (16 ft) in bulk materials

– FMU43: 15 m (49 ft) in fluids, 7 m (23 ft) in bulk materials

– FMU44: 20 m (66 ft) in fluids, 10 m (33 ft) in bulk materials

Features and benefits

• Quick and simple commissioning via menu-guided on-site operation with four-line,

multilingual plain text display

• Envelope curves on the on-site display for simple diagnosis

• Easy remote operation, diagnosis and measuring point documentation with the free

operating program FieldCare supplied.

• Suitable for explosion hazardous areas

(Gas-Ex, Dust-Ex)

• Linearization function (up to 32 points) for conversion of the measured value into

any unit of length, volume or flow rate

• Non-contact measurement method minimizes service requirements

• Optional remote display and operation (up to 20 m (66 ft) from transmitter)

• Installation possible from thread G 1½“ or 1½“ NPT upwards

• Integrated temperature sensor for automatic correction of the temperature

dependent sound velocity

Page 2

Table of contents

Prosonic M

Function and system design . . . . . . . . . . . . . . . . . . . . . .3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Load HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terminal compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fieldbus plug connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Current consumption (2 wire instruments) . . . . . . . . . . . . . . 14

HART ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Max. noise HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance characteristics . . . . . . . . . . . . . . . . . . . . 15

Reaction time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . 15

Measured value resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pulse frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maximum measuring error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical measuring error

Influence of the vapor pressure . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

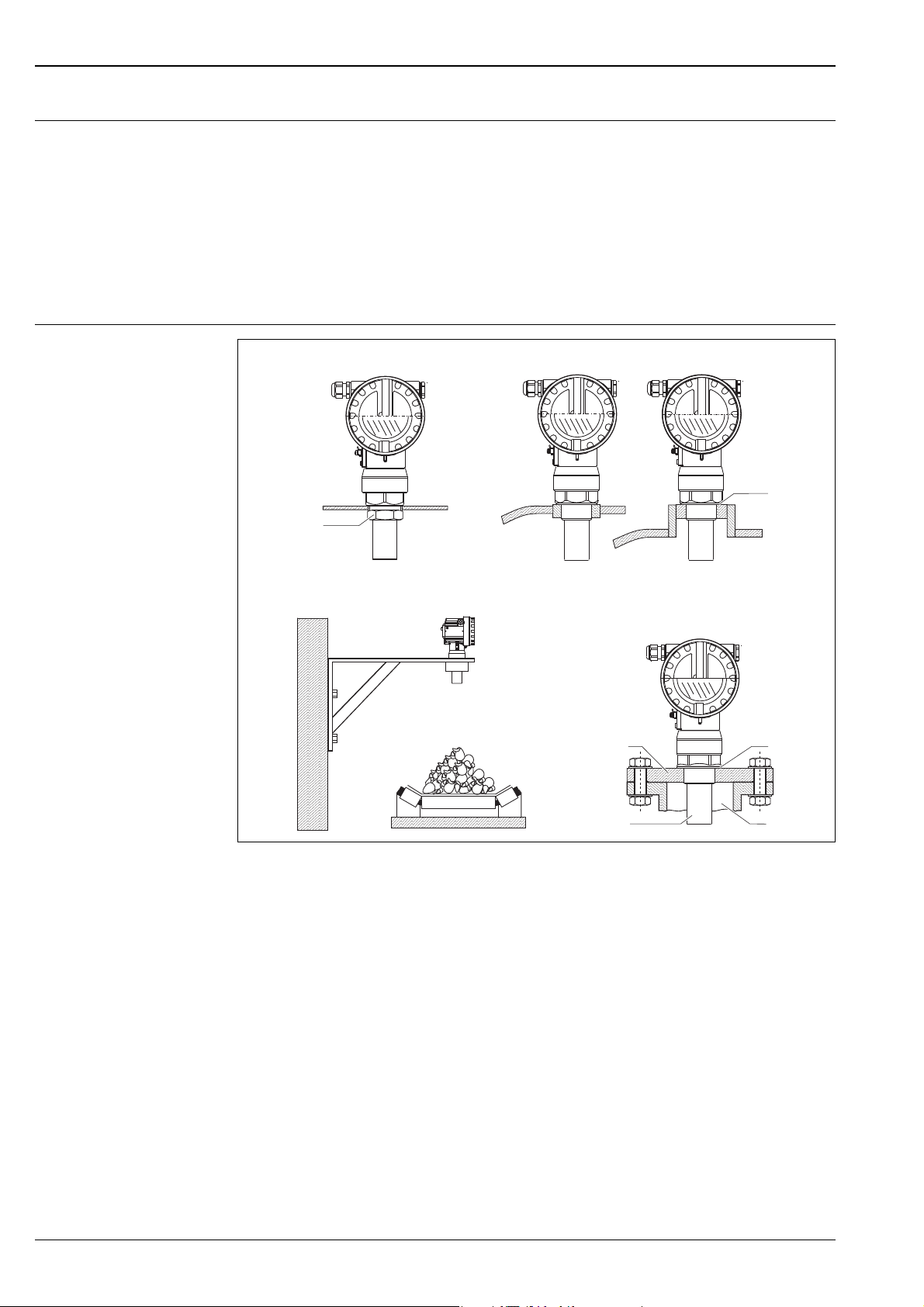

Installation variants FMU40, FMU41 . . . . . . . . . . . . . . . . . . . . 16

Installation variants FMU42, FMU44 . . . . . . . . . . . . . . . . . . . . 17

Installation variants FMU43 . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation conditions for level measurements . . . . . . . . . . . . 17

Installation in narrow shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation conditions for flow measurements . . . . . . . . . . . . 18

Blocking distance, nozzle installation . . . . . . . . . . . . . . . . . . . . 20

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Resistance to alternating temperature cycles . . . . . . . . . . . . . 21

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . 21

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Process temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Process pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 22

Design; dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Housing design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Process connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Material (not in contact with process) . . . . . . . . . . . . . . . . . . . 26

Material (in contact with process) . . . . . . . . . . . . . . . . . . . . . . 27

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Display and operating elements . . . . . . . . . . . . . . . . . . . . . . . . 28

On-site operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Certificates and Approvals. . . . . . . . . . . . . . . . . . . . . . 31

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

External standards and guidelines . . . . . . . . . . . . . . . . . . . . . . 31

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Product structure FMU40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Product structure FMU41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Product structure FMU42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Product structure FMU43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Product structure FMU44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installation bracket for FMU40, FMU41 . . . . . . . . . . . . . . . . . 43

Screw in flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cantilever with mounting frame or wall bracket . . . . . . . . . . . 45

Commubox FXA195 HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ToF Adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Remote display FHX40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Description of device functions . . . . . . . . . . . . . . . . . . . . . . . . . 51

Short instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Safety Instructions ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Safety Instructions NEPSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Safety Instructions

INMETRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Control drawings Installation drawings . . . . . . . . . . . . . . . . . . 55

2 Endress+Hauser

Page 3

Prosonic M

20 mA

100%

4 mA

0%

D

L

F

E

BD

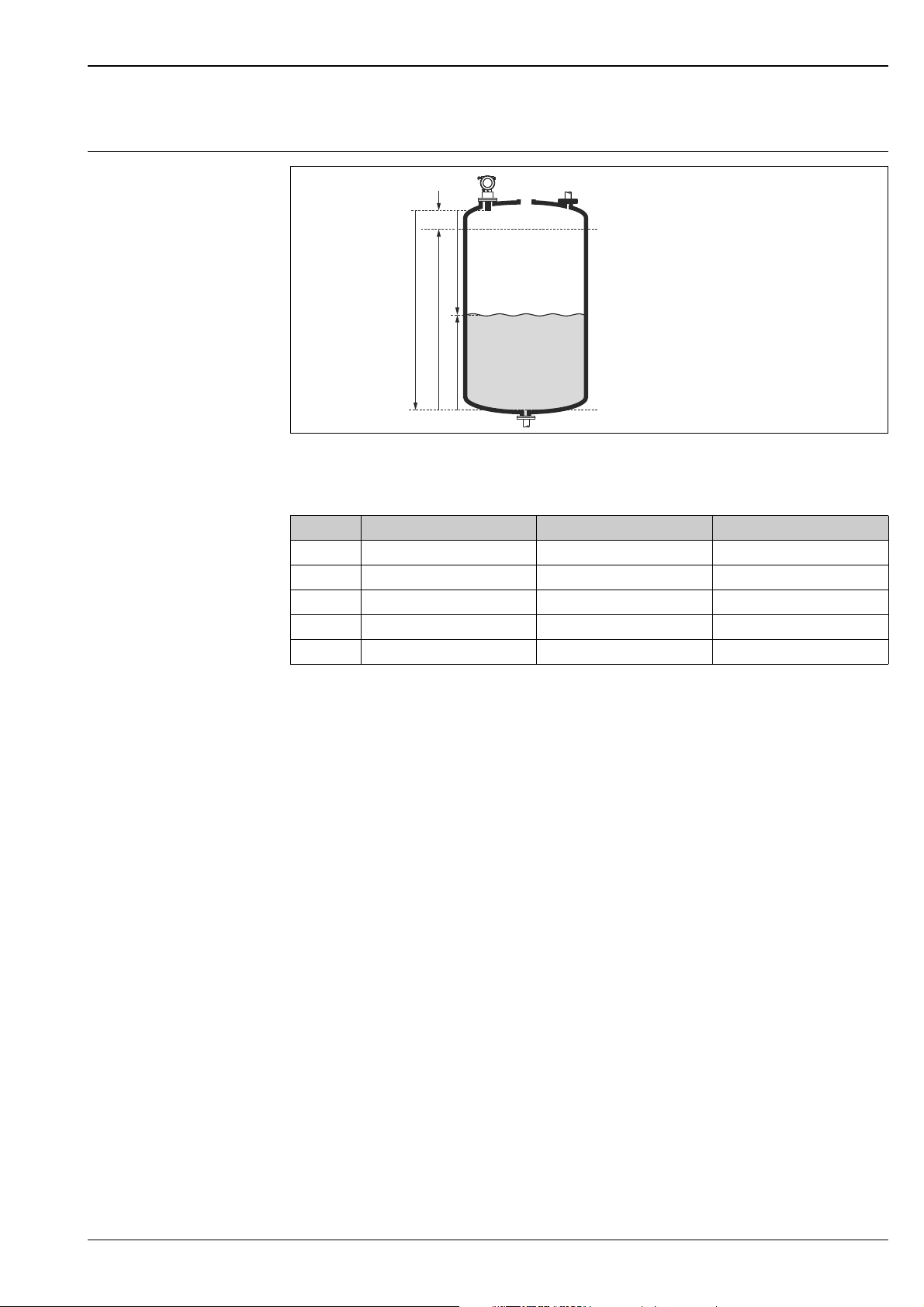

Measuring principle

Function and system design

BD Blocking distance D Distance from sensor membrane - product surface

E Empty distance F Span (full distance)

L Level

A0019264

Sensor BD Max. range fluids Max. range bulk materials

FMU40 0.25 (0.8) 5 (16) 2 (6.6)

FMU41 0.35 (1.1) 8 (26) 3.5 (11)

FMU42 0.4 (1.3) 10 (33) 5 (16)

FMU43 0.6 (2.0) 15 (49) 7 (23)

FMU44 0.5 (1.6) 20 (66) 10 (33)

Dimensions m (ft)

Time-of-flight method

The sensor of the Prosonic M transmits ultrasonic pulses in the direction of the product surface. There,

they are reflected back and received by the sensor. The Prosonic M measures the time t between pulse

transmission and reception. The instrument uses the time t (and the velocity of sound c) to calculate

the distance D between the sensor membrane and the product surface:

D = c t/2

As the device knows the empty distance E from a user entry, it can calculate the level as follows:

L = E - D

An integrated temperature sensor (NTC) compensates for changes in the velocity of sound caused by

temperature changes.

Interference echo suppression

The interference echo suppression feature on the Prosonic M ensures that interference echos (e.g.

from edges, welded joints and installations) are not interpreted as a level echo.

Calibration

Enter the empty distance E and the span F to calibrate the device.

Blocking distance

Span F may not extend into the blocking distance BD. Level echos within the blocking distance cannot

be evaluated due to the transient characteristics of the sensor.

Endress+Hauser 3

Page 4

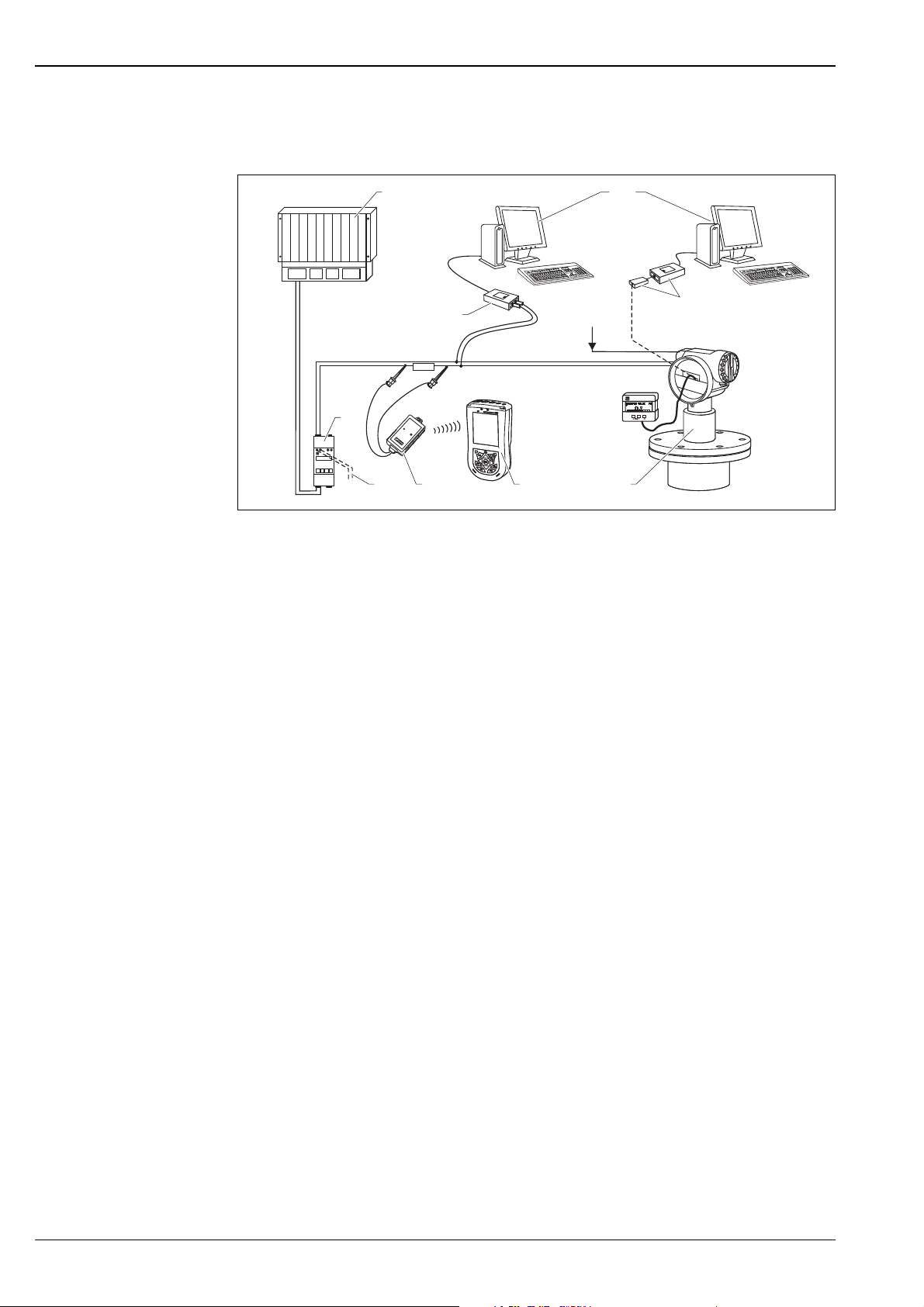

Equipment architecture 4…20 mA output with HART protocol

ENDRESS + HAUSER

E

+–

%

ENDRESS + HAUSER

RMA422

2

4

6789

10

5

1

3

The complete measuring system consists of:

Prosonic M

A0019266

1 PLC (programmable logic controller)

2 Commubox FXA191 (RS232) or FXA195 (USB)

3 Computer with operating tool (e.g. FieldCare)

4 Commubox FXA291 with ToF Adapter FXA291

5 Power supply (for 4-wire)

6 Prosonic with display and operating modul

7 Field Xpert

8 VIATOR Bluetooth modem with connection cable

9 Connection for Commubox FXA191, FXA195 or Field Xpert

10 Transmitter supply unit RMA422 or RN221N (communication resistor included)

If the HART communication resistor is not built into the supply unit, it is necessary to insert a

communication resistor of 250 into the 2-wire line.

On-site operation

• With display and operating module,

• With a Personal Computer, FXA291 with ToF Adapter FXA291 (USB) and the operating software

"FieldCare". FieldCare is a graphical operating software for instruments (radar, ultrasonic, guided

microimpulse). It assists with commissioning, securing data, signal analysis and documentation of

the measuring point.

Remote operation

•With Field Xpert

• With a Personal Computer, Commubox FXA195 and the operating software "FieldCare"

4 Endress+Hauser

Page 5

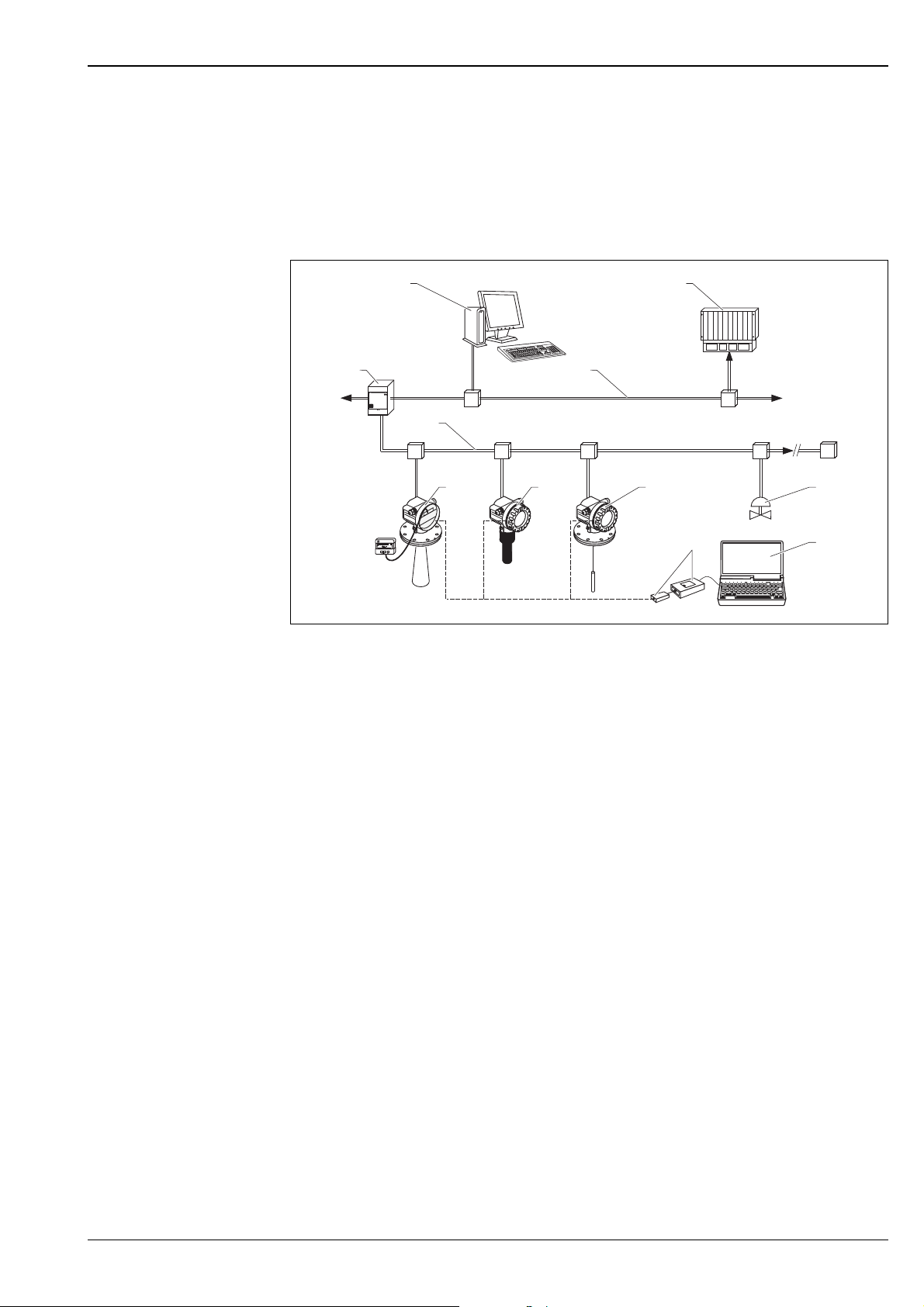

Prosonic M

ENDRESS + HAUSERENDRESS + HAUSER

T

1 3

211

10

4

5

6

7

89

ENDRESS + HAUSER

E+–

%

System integration using PROFIBUS PA

A maximum of 32 transmitters (8 if mounted in an explosion hazardous location Ex ia IIC according to

FISCO-model) can be connected to the bus.The segment coupler provides the operating voltage to the

bus. Both on-site as well as remote operation are possible. For further information on the cable

specifications, see Operating Instructions BA00034S/04/ENGuidelines for planning and

commissioning PROFIBUS DP/PA", PNO Guideline 2.092 "PROFIBUS PA User and Installation

Guideline" and IEC61158-2 (MBP).

1 Computer with Profiboard/Proficard and operating tool (FieldCare)

2PROFIBUS DP

3 PLC (programmable logic controller)

4 More functions (valves etc.)

5 Computer with operating tool (FieldCare)

6 Commubox FXA291 with ToF Adapter FXA291

7 Levelflex M

8Prosonic M

9 Micropilot M with display and operating modul

10 PROFIBUS PA

11 Segment coupler

A0019308

Endress+Hauser 5

Page 6

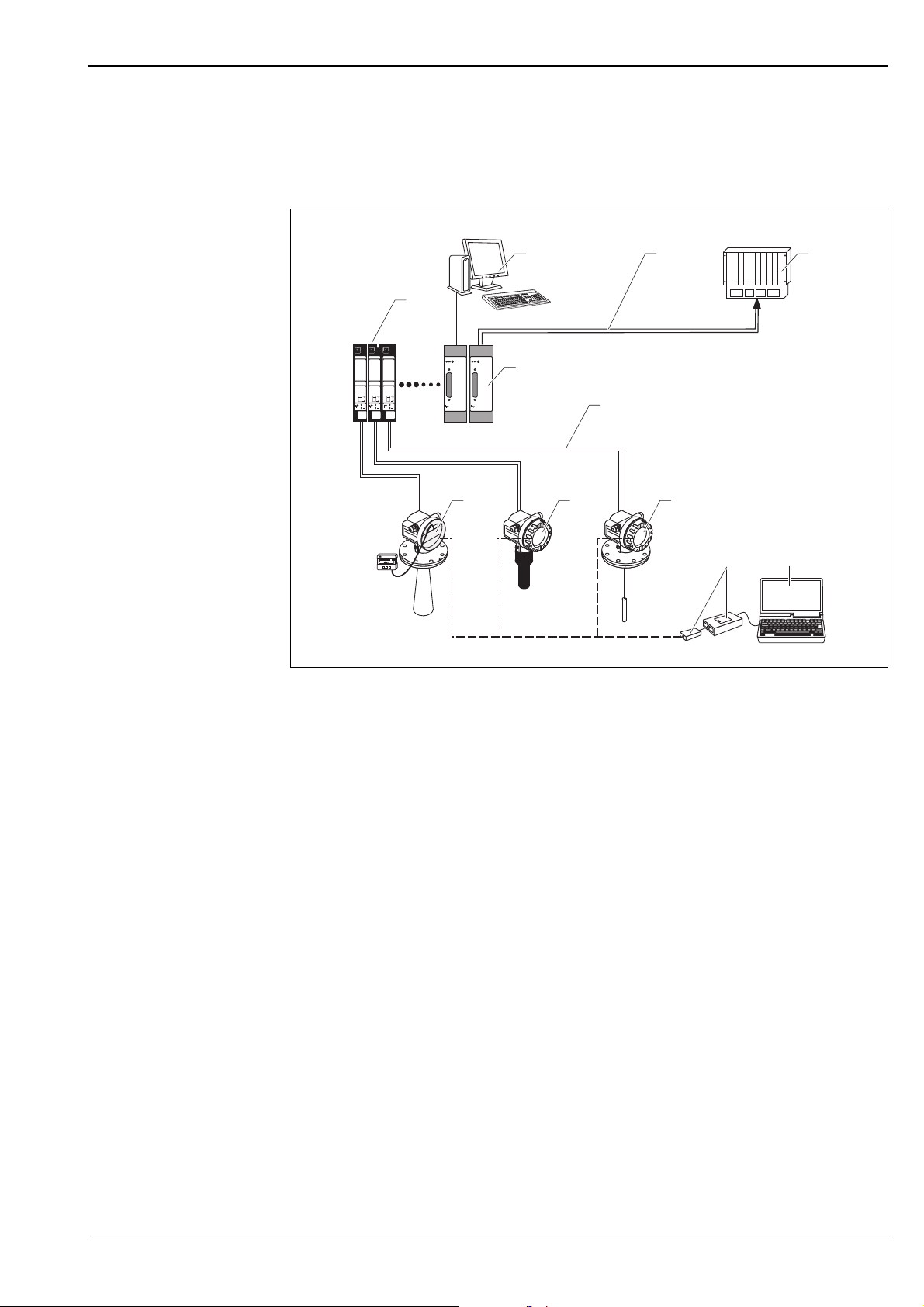

Prosonic M

T

T

15

13

14

1

6

5

7

11

12

3

4

8910

2

System integration using FOUNDATION Fieldbus

A maximum of 32 transmitters (standard or Ex d) can be connected to the bus. For protection class

Ex ia: the maximum number of transmitters depends on the established rules and standards for

intrinsically safe circuits (EN 60070-14) and proof of instrinsic safety. Both on-site and remote

operation are possible.

A0019309

1 SPS, PLC, API

2 Personal computer, e.g. with NI-FBUS configurator

3 VIATOR Bluetooth modem with connection cable

4 Field Xpert

5 More functions (valves etc.)

6 FieldCare

7 Commubox FXA291 with ToF Adapter FXA291

8 Levelflex M

9Prosonic M

10 Micropilot M

11 Power conditioner

12 Power supply

13 FF link

14 FOUNDATION Fieldbus

15 Ethernet

6 Endress+Hauser

Page 7

Prosonic M

FXN 671

mA1

+

FXN 671

mA1

+

FXN 671

mA1

+

ENDRESS + HAUSER

E+–

%

3

9

2

4

1

7

1011

8

5

6

System integration using Endress+Hauser Rackbus

You can interconnect a maximum of 64 2-wire devices with HART protocol to a Rackbus. Use an

FXN672 interface module for each device. You can integrate this bus into a higher-level bus by using

gateway.

A0019307

1 Interface FXN672

2 Personal computer with communication software

3Bus

4PLC

5 Gateway to MODBUS, FIP, PROFIBUS, INTERBUS etc.

6 4-20 mA HART

7 FieldCare

8 Commubox FXA291 with ToF Adapter FXA291

9 Levelflex M

10 Prosonic M

11 Micropilot M with display and operating modul

Note!

The FXN672 can be used with all 2-wire devices of the Prosonic M family.

Endress+Hauser 7

Page 8

Prosonic M

-

ENDRESS+HAUSER

RN 221N

ENDRESS+HAUSER

RN 221N

.

20...45 V

DC

FXN 520

FXN 520

1

12

System integration via Fieldgate

Vendor Managed Inventory

By using Fieldgates to interrogate tank or silo levels remotely, suppliers of raw materials can provide

their regular customers with information about the current supplies at any time and, for example,

account for them in their own production planning. For their part, the Fieldgates monitor the

configured level limits and, if required, automatically activate the next supply. The spectrum of options

here ranges from a simple purchasing requisition via e-mail through to fully automatic order

administration by coupling XML data into the planning systems on both sides.

Remote maintenance of measuring equipment

Fieldgates not only transfer the current measured values, they also alert the responsible standby

personnel, if required, via e-mail or SMS. In the event of an alarm or also when performing routine

checks, service technicians can diagnose and configure connected HART devices remotely. All that is

required for this is the corresponding HART operating software (e.g. FieldCare) for the connected

device. Fieldgate passes on the information transparently, so that all options for the respective

operating software are available remotely. Some on-site service operations can be avoided by using

remote diagnosis and remote configuration and all others can at least be better planned and prepared.

The complete measuring system consists of devices and:

1 Fieldgate FXA520

2 Multidrop Connector FXN520

Note!

The number of instruments which can be connected in mutidrop mode can be calculated by the

"FieldNetCalc" program. A description of this program can be found in Technical Information

TI00400F/00/EN (Multidrop Conncector FXN520).

The program is available form your Endress+Hauser sales organisation or in the internet at:

"www.endress.com select your country download search: Fieldnetcalc

8 Endress+Hauser

A0019306

Page 9

Prosonic M

Input

Measured variable The distance D between the sensor membrane and the product surface is measured.

Using the linearization function, the device uses D to calculate:

•level L in any units

• volume V in any units

• Flow Q across measuring weirs or open channels in any units

Measuring range The measuring range is limited by the range of a sensor. The sensor range is, in turn, dependent on the

operating conditions. To estimate the actual range, proceed as follows (see also the calculation

example in the diagram):

1. Determine which of the influences shown in the following table are appropriate for your process.

2. Add the corresponding attenuation values.

3. From the total attenuation, use the diagram to calculate the range.

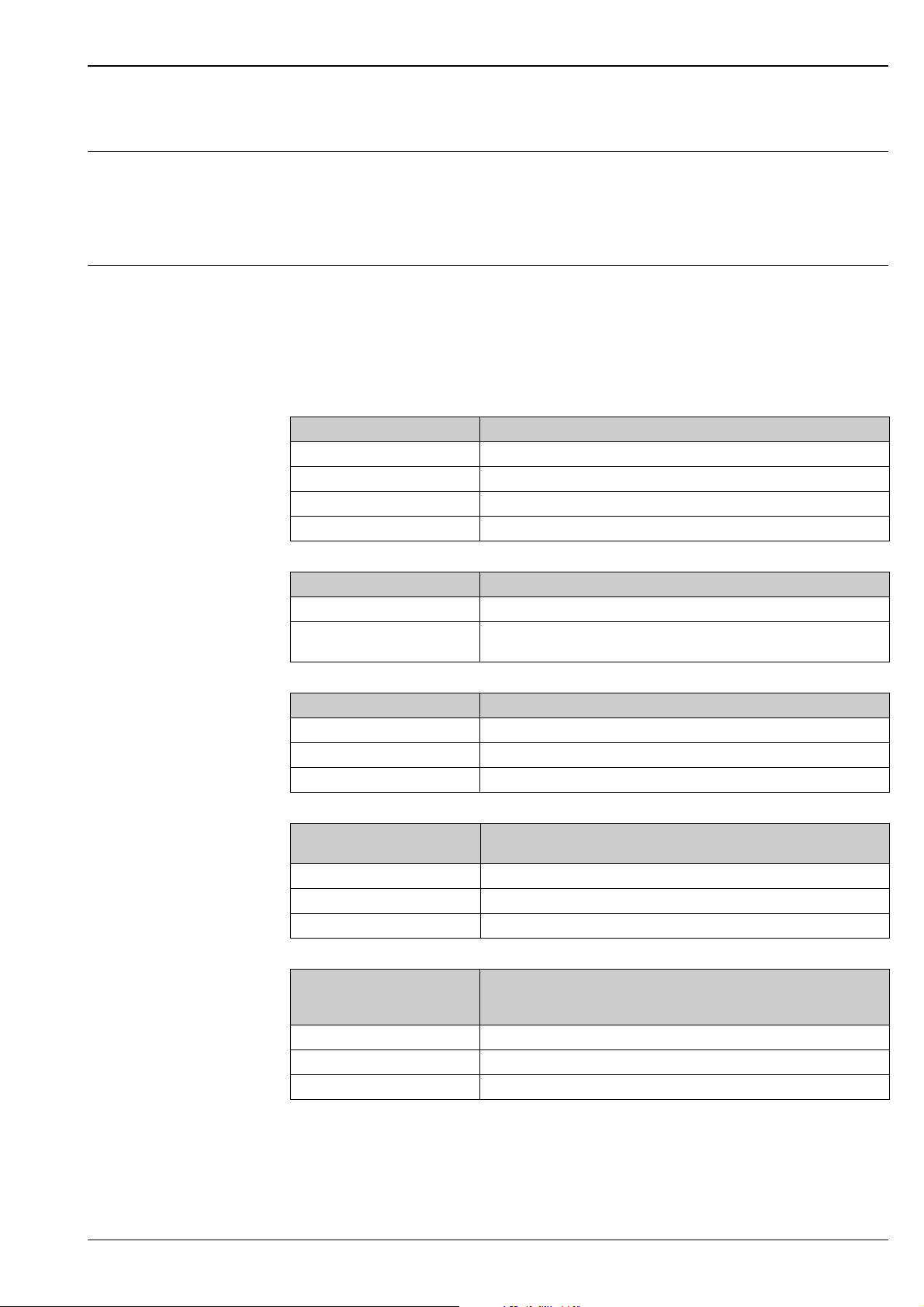

Fluid surface Attenuation

Calm 0 dB

Waves 5 to 10 dB

Strong turbulence (e.g. stirrers) 10 to 20 dB

Foaming Please contact your Endress+Hauser sales representative.

Bulk material surface Attenuation

Hard, rough (e.g. rubble) 40 dB

Soft (e.g. peat, dust-covered

clinker)

Dust Attenuation

No dust formation 0 dB

Little dust formation 5 dB

Heavy dust formation 5 to 20 dB

Filling curtain in detection

range

None 0 dB

Small quantities 5 to 10 dB

Large quantities 10 to 40 dB

Temperature difference

between sensor and product

surface

to 20 °C (68 °F) 0 dB

to 40 °C (104 °F) 5 to 10 dB

to 80 °C (176 °F) 10 to 20 dB

40 to 60 dB

Attenuation

Attenuation

Endress+Hauser 9

Page 10

Prosonic M

10 20 304050 607080

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

FMU44

A [dB]

R [m]

0

FMU43

FMU42

FMU41

FMU40

AAttenuation (dB)

RRange (m)

Example (for FMU43)

For typical solid applications, a certain amount of dust coverage is normally present. Therefore, the

following range results from the table and the diagram:

Operating frequency

• Dust-covered rubble approx. 50 dB

• No dust formation 0 dB

• No filling curtain in

detection range 0 dB

• Temperature diff. < 20°C 0 dB

approx. 50 dB range approx. 7 m (23 ft)

These measuring conditions have been taken into account during the calculation of the maximum

measuring range in solid applications.

Sensor Operating frequency

FMU40 approx. 70 kHz

FMU41 approx. 50 kHz

FMU42 approx. 42 kHz

FMU43 approx. 35 kHz

FMU44 approx. 30 kHz

10 Endress+Hauser

A0019268

Page 11

Prosonic M

Output

Output signal According to the instrument version ordered:

• 4…20 mA with HART protocol

•PROFIBUS PA

• FOUNDATION Fieldbus

Signal on alarm Error information can be accessed via the following interfaces:

• On-site display (error symbol, error code and plain text description)

• Current output, signal on error can be selected (e.g. according to NAMUR recommendation NE43)

• Digital interface

Load HART Minimum load for HART communication: 250

Output damping Freely selectable, 0 to 255 s

Linearization The linearization function of the Prosonic M allows conversion of the measured value into any unit of

length or volume. In open channels or measuring weirs, also a flow linearization is possible (calculation

of the flow from the measured level). The linearization table for calculating the volume in an horizontal

cylindrical tank is preprogrammed. You can also enter any number of other tables containing up to 32

value pairs either manually or semi-automatically (by filling the vessel under controlled conditions).

The supplied FieldCare operating program can automatically calculate the table for any tank, weir or

flume and upload it into the device.

Flow curves for open channels can be calculated and entered into the instrument by the FieldCare as

well ( ä 29, "Operation with FieldCare").

Endress+Hauser 11

Page 12

Prosonic M

1

A

B

2

1

4

AB

3

3

1234 5 612

L- L+ I+ I-

I+ I-

L1/L+ N/L-

4

1

5

Power supply

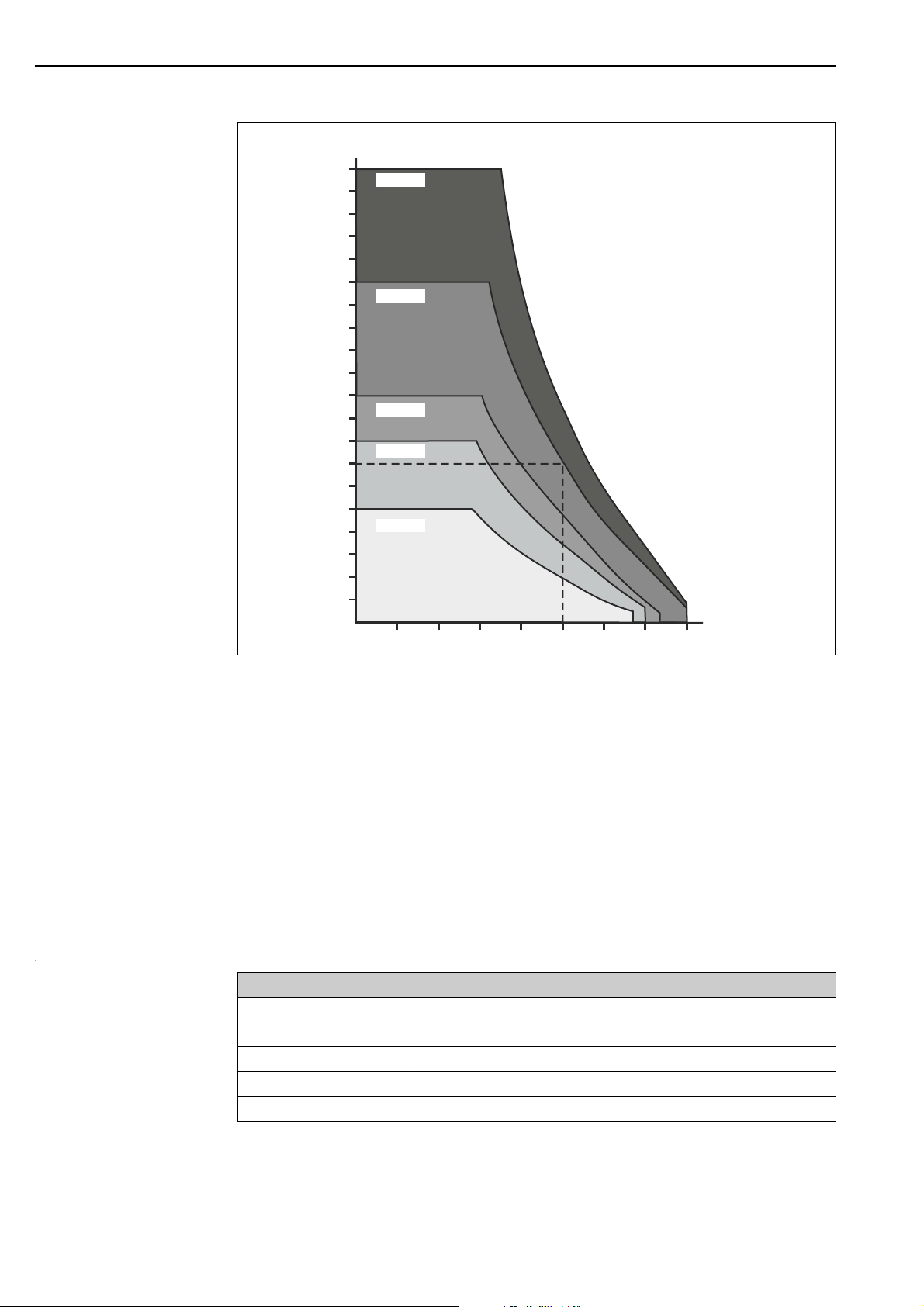

Terminal compartment In the F12 housing, the terminals are located underneath the housing cover. In the T12 housing, they

are under the cover of the separate terminal compartment.

A0019271

A F12 housing

B T12 housing

1 Sealed terminal compartment

Terminal assignment

A0019268

A Loop-powered version 3 Plant ground

B 4-wire version (active) 4 4-20 mA HART

1Power 5Display unit, recorder, PCS

2 Test clamp for testing of the signal current

• Connect the connecting line to the screw terminals (line cross-sections of 0.5 to 2.5mm (20 to

14 AWG)) in the terminal compartment.

• Use 2-wire twisted pair cable with screen for the connection.

• Protective circuitry against reverse polarity, RFI and over-voltage peaks is built into the device (see

also Technical Information TI00241F/00/EN "EMC Test Procedures") ä 21, "Electromagnetic

compatibility (EMC)".

• A standard installation cable is sufficient if only the analogue signal is used. Use a screened cable

when working with a superimposed communication signal (HART).

12 Endress+Hauser

Page 13

Prosonic M

3

4

1

2

+–

3

1

2

3

4

1

2

+–

3

21

3

4

2

1

4

3

PROFIBUS PA

1T-Box

2PROFIBUS PA

3 Plant ground

A0019276

FOUNDATION Fieldbus

A0019275

The digital communication signal is transmitted to the bus via a 2-wire connection. The bus also

provides the auxiliary energy. Use 2-wire twisted pair cable with screen.

Refer to the following operating manuals for information on cable types, and how to set up and ground

the network:

• BA00034S "PROFIBUS DP/PA: "Guidelines for planning and commissioning PROFIBUS DP/PA", PNO

Guideline 2.092 "PROFIBUS PA User and Installation Guideline" and IEC61158-2 (MBP).

• BA00013S "FOUNDATION Fieldbus Overview", FONDATION Fieldbus Guideline and IEC61158-2

(MBP).

Fieldbus plug connectors For the versions with fieldbus plug connector (M12 or 7/8"), the signal line can be connected without

opening the housing.

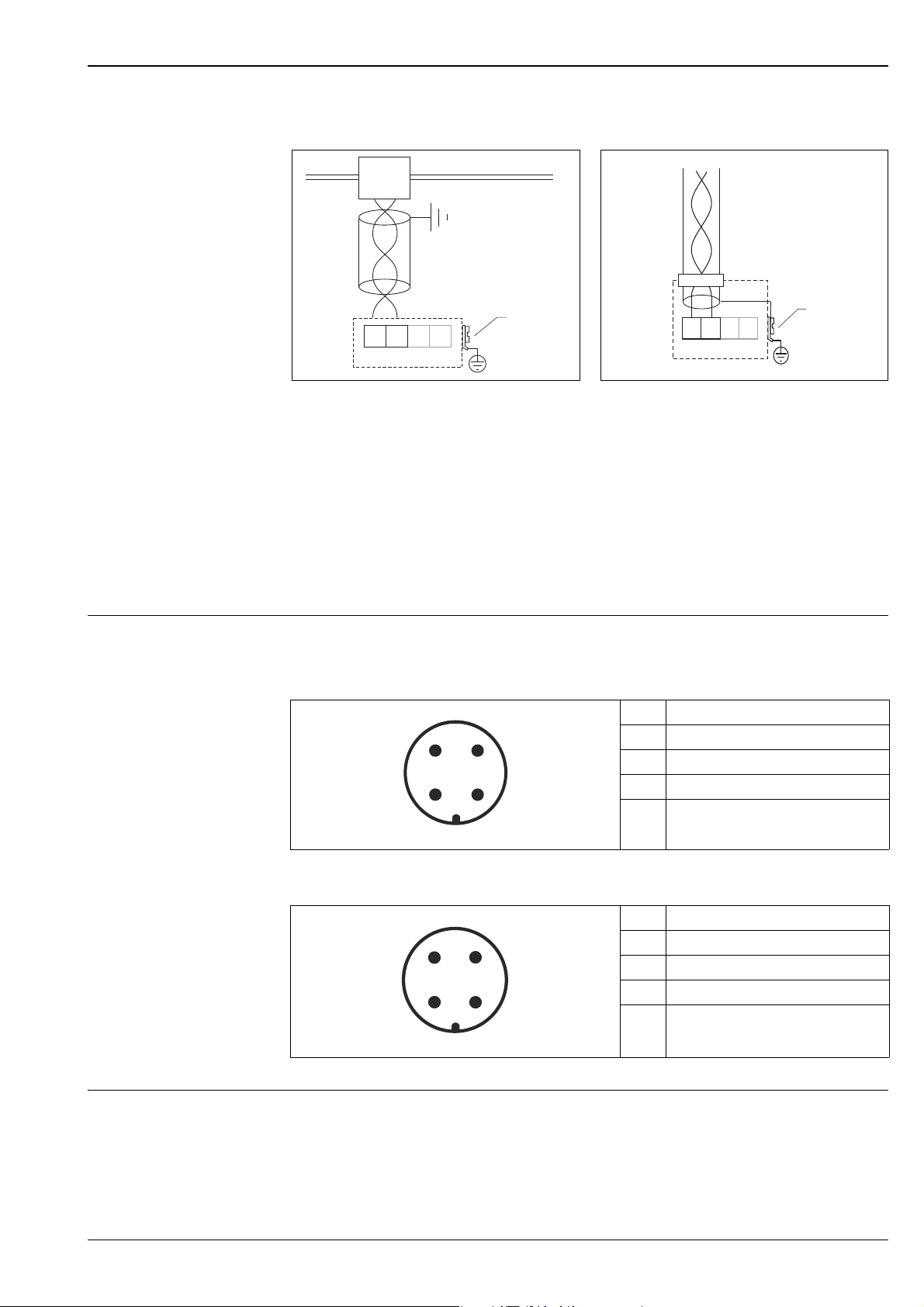

Pin assignment of the M12 plug connector (PROFIBUS PA plug)

Pin Meaning

1Signal +

2not connected

3Signal -

4Ground

A0011175

Pin assignment of the 7/8" plug connector (FOUNDATION Fieldbus plug)

Pin Meaning

1Signal -

2Signal +

3Shield

4Not connected

A0011176

Supply voltage HART, 2-wire

The following values are the voltages across the terminals directly at the instrument:

Endress+Hauser 13

Page 14

Prosonic M

Version

Standard

2-wire HART

Fixed current,

adjustable, e.g. for

solar power

operation

(measured value

via HART)

Fixed current for

HART multidrop

mode

1) Start-up current 11 mA

Ex ia

Ex d

Standard 11 mA 10 V 36 V

Ex ia 11 mA 10 V 30 V

Standard 4 mA

Ex ia 4 mA

Current

consumption

4 mA 14 V 36 V

20 mA 8 V 36 V

4 mA 14 V 30 V

20 mA 8 V 30 V

4 mA 14 V 30 V

20 mA 11 V 30 V

1)

1

Terminal voltage

minimum

14 V 36 V

14 V 30 V

HART, 4-wire, active

Version Voltage Max. load

DC 10.5 to 32 V 600

AC 50/60 Hz 90 to 253 V 600

Terminal voltage

maximum

Terminals Cable cross-section: 0.5 to 2.5 mm2 (20 to 14 AWG)

Cable entry • Cable gland: M20x1.5 (recommended cable diameter 6 to 10 mm (0.24 to 0.39 in))

• Cable entry G ½" or NPT ½"

• PROFIBUS PA M12 plug

• FOUNDATION Fieldbus 7/8" plug

Power consumption

Current consumption (2 wire instruments)

Version Power consumption

2-wire 51 mW to 800 mW

4-wire AC max. 4VA

4-wire DC; FMU40/41 330 mW to 830 mW

4-wire DC; FMU42/43 600 mW to 1 W

Communication Current consumption

HART 3.6 to 22 mA

PROFIBUS PA max. 13 mA

FOUNDATION Fieldbus max. 15 mA

HART ripple 47 to 125 Hz: Vpp = 200 mV (measured at 500 )

Max. noise HART 500 Hz to 10 kHz: Vrms = 2.2 mV (measured at 500 )

14 Endress+Hauser

Page 15

Prosonic M

Galvanic isolation With 4-wire devices, the evaluation electronics and mains voltage are galvanically isolated from each

other.

Performance characteristics

Reaction time The reaction time depends on the parameter settings. The minimum values are:

• 2-wire devices (FMU40/41/42): min. 2 s

• 2-wire diveces (FMU43 - PROFIBUS PA or FOUNDATION Fieldbus): min. 2 s

• 2-wire devices (FMU44): min. 3 s

• 4-wire devices (FMU40/41/42/43/44): 0.5 s

Reference operating conditions

• Temperature = +20 °C (+68 °F)

• Pressure = 1013 mbar abs. (15 psi abs.)

• Humidity = 50 %

• Ideal reflective surface (e.g. calm, smooth fluid surface)

• No interference reflections within signal beam

• Set application parameters:

– Tank shape = dome ceiling

– Medium property = liquid

– Process conditions = standard liquid

Measured value resolution

Sensor Measured value resolution

FMU40 1 mm (0.04 in)

FMU41 1 mm (0.04 in)

FMU42 2 mm (0.08 in)

FMU43 2 mm (0.08 in)

FMU44 2 mm (0.08 in)

Pulse frequency • 2-wire devices (FMU40/41/42): max. 0.5Hz

• 2-wire devices (FMU43 - PROFIBUS PA or FOUNDATION Fieldbus): max. 0.5 Hz

• 2-wire devices (FMU44): max. 0.3 Hz

• 4-wire devices (FMU40/41/42/43/44): max. 2Hz

The exact values are dependent on the type of device and the parameter settings.

1)

Maximum measuring error

Typical measuring error

2)±0.2 % of the maximum span of the sensor

Include linearity, repeatability and hysteresis

Better than:

Sensor Measuring error

FMU40 ±2 mm (0.08 in) or 0.2 % of measuring distance

FMU41 ±2 mm (0.08 in) or 0.2 % of measuring distance

FMU42 ±4 mm (0.16 in) or 0.2 % of measuring distance

FMU43 ±4 mm (0.16 in) or 0.2 % of measuring distance

FMU44 ±4 mm (0.16 in) or 0.2 % of measuring distance

* whichever is greater

1) according to EN 61298-2

2) with reference operating conditions

*

*

*

*

*

Endress+Hauser 15

Page 16

Prosonic M

ENDRESS+HAUSER

Prosonic M

ENDRESS+HAUSER

Prosonic M

AB

C

D

1

1

1

2

3

4

Influence of the vapor pressure

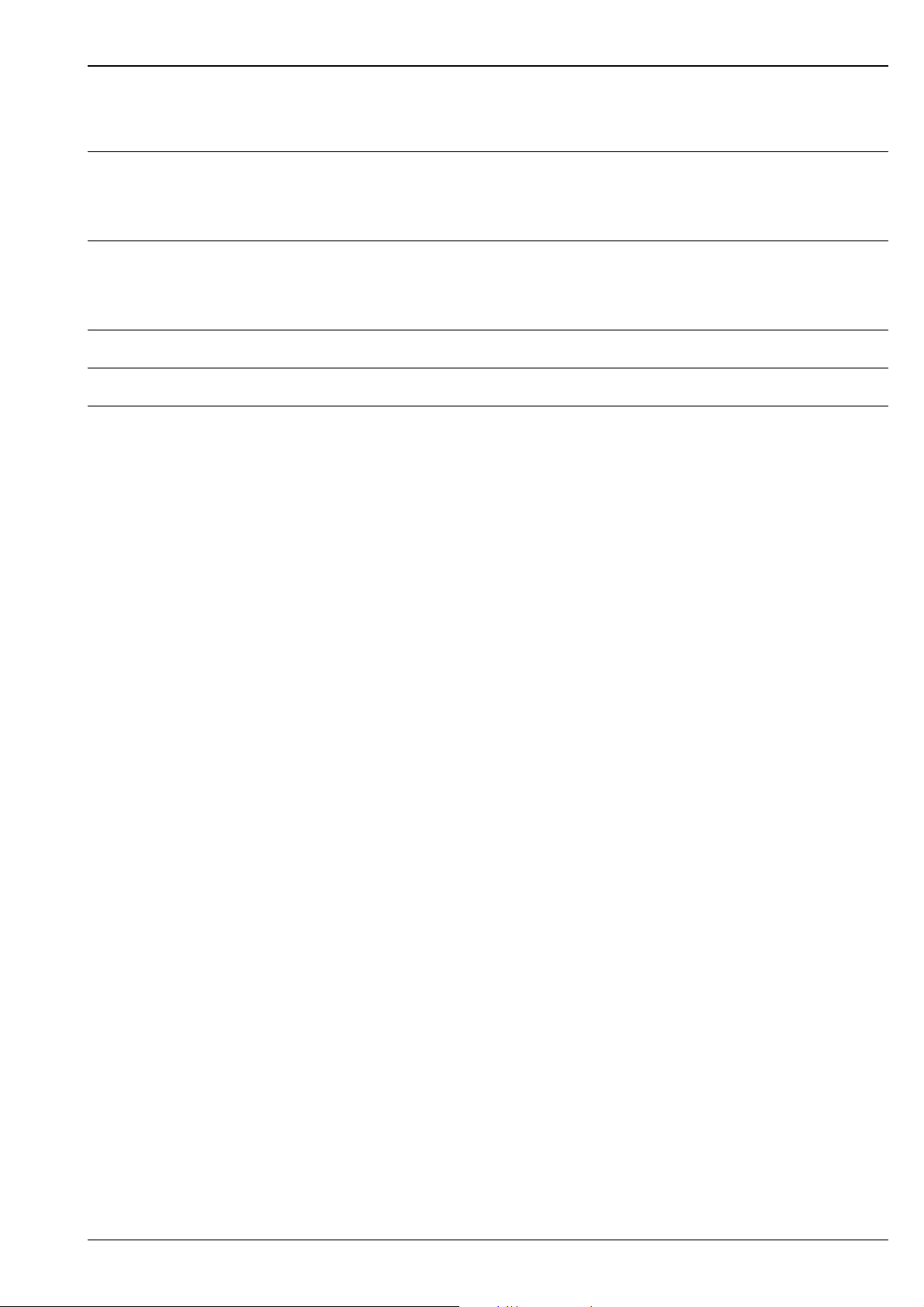

Installation variants FMU40, FMU41

The vapor pressure at 20 °C (68 °F) gives a hint on the accuracy of the ultrasonic level measurement. If

the vapor pressure at 20 °C (68 °F) is below 50 mbar (1 psi), ultrasonic level measurement is possible

with a very high accuracy. This is valid for water, aqueous solutions, water-solid-solutions, dilute acids

(hydrochloric acid, sulfuric acid, ...), dilute bases (caustic soda, ...), oils, greases, slurries, pastes, ...

High vapor pressures or outgassing media (ethanol, acetone, ammonia, ...) can influence the accuracy.

If conditions like these are present, please contact your Endress+Hauser sales representative.

Installation

A Installation with counter nut

1 Counter nut (PC) supplied for G 1½" and G 2" instruments

B Installation with sleeve

1 Sealing (EPDM) supplied

C Installation with installation bracket

D Installation with screw in flange

1 Sealing (EPDM) supplied

2Nozzle

3Sensor

4Screw in flange

For installation bracket or adapter flange ä 43, "Accessories".

16 Endress+Hauser

A0019052

Page 17

Prosonic M

AB

-

.

ENDRESS+HAUSER

ProsonicM

1

3

2

A

B

-

.

234

1/6D

D

1

5

6

L

r

7

Installation variants FMU42, FMU44

Installation variants FMU43

A Installation with universal flange (Ex-hazardous, e.g. Zone 20)

B Installation with mounting bracket (Non-Ex-hazardous, Zone 20)

A0019280

A Installation with universal slip-on flange (option), (Ex-hazardous, e.g. Zone 20)

1Sensor

2Nozzle

3 Slip-on flange

B Installation with mounting bracket (Non-Ex-hazardous, Zone 20)

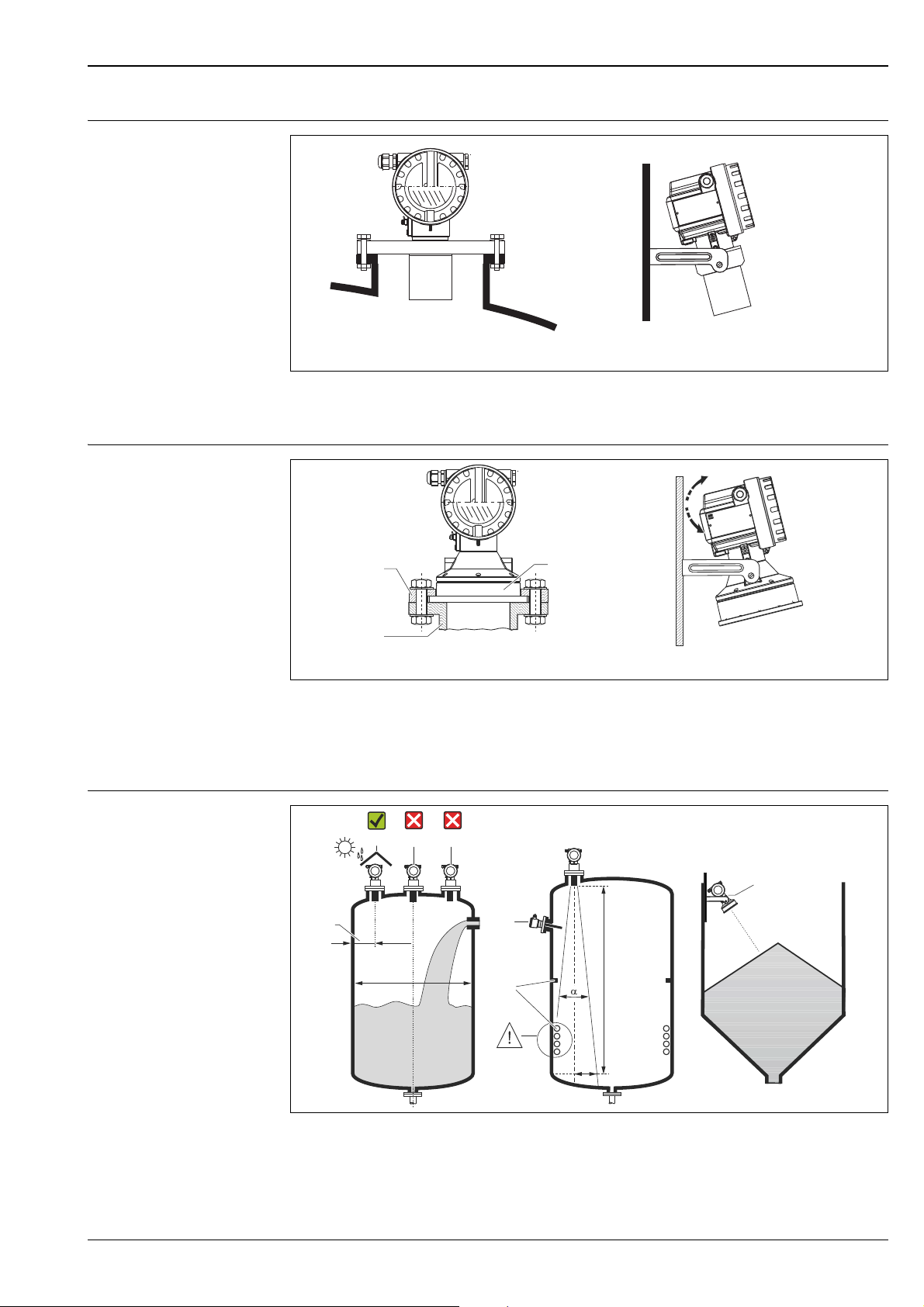

Installation conditions for level measurements

• Do not install the sensor in the middle of the tank (3). We recommend leaving a distance between

• Use a protective cover, in order to protect the device from direct sun or rain (2) ä 43, "Weather

the sensor and the tank wall (1) measuring 1/6 of the tank diameter.

protection cover".

A0019053

A0019278

Endress+Hauser 17

Page 18

Prosonic M

1

• Avoid measurements through the filling curtain (4).

• Make sure that equipment (5) such as limit switches, temperature sensors, etc. are not located

within the emitting angle . In particular, symmetrical equipment (6) such as heating coils, baffles

etc. can influence measurement.

• Align the sensor so that it is vertical to the product surface (7).

• Never install two ultrasonic measuring devices in a tank, as the two signals may affect each other.

• To estimate the detection range, use the 3 dB emitting angle .

Installation in narrow shafts

Sensor L

FMU40 11° 5 (16) 0.48 (1.6)

FMU41 11° 8 (26) 0.77 (2.5)

FMU42 9° 10 (33) 0.79 (2.6)

FMU43 6° 15 (49) 0.79 (2.6)

FMU44 11 ° 20 (66) 1.93 (6.3)

m (ft)

max

r

max

In narrow shafts with strong interference echoes,

we recommend using an ultrasound guide pipe

(e.g. PE or PVC wastewater pipe) with a minimum

diameter of 100 mm (3.94 in).

Make sure that the pipe is not soiled by accumulated dirt. If necessary, clean the pipe at regular

intervals.

1Venting hole

A0019310

Installation conditions for flow measurements

• Install the Prosonic M at the inflow side, as close above the maximum water level H

as possible

max

(take into account the blocking distance BD).

• Position the Prosonic M in the middle of the channel or weir.

• Align the sensor membrane parallel to the water surface.

• Keep to the installation distance of the channel or weir.

• You can enter the "Flow to Level" linearization curve ("Q/h curve") using FieldCare or manually via the

on-site display.

18 Endress+Hauser

Page 19

Prosonic M

1 x b

0

b

0

BD

A

E

B C

V

H

max

=F

(= F)

min. 3 H

H

min. 2 H

a

min. 2 H

BD

E

max.

max.

max.

max.

Example: Khafagi-Venturi flume

A Khafagi-Venturi flume

B Inflow

C Outflow

BD Blocking distance

E Empty calibration

F Full calibration

V Direction of flow

A0019606

Example: Triangular weir

Endress+Hauser 19

BD Blocking distance

E Empty calibration

F Full calibration

A0019312

Page 20

Prosonic M

F

E

BD

SD

L

D

L

D

L

D

AB C

Blocking distance, nozzle installation

Install the Prosonic M at a height so that the blocking distance BD is not undershot, even at maximum

fill level. Use a pipe nozzle if you cannot maintain the blocking distance in any other way. The interior

of the nozzle must be smooth and may not contain any edges or welded joints. In particular, there

sh ould be no burr on t he in side of the tank side nozzle end. Note the specified limits for nozzle diameter

and length. To minimise disturbing factors, we recommend an angled socket edge (ideally 45°).

A0019311

A FMU40, FMU41

B FMU42, FMU44

C FMU43

BD Blocking distance F Full calibration (span)

SD Safety distance D Nozzle diameter

E Empty calibration L Nozzle length

Maximum nozzle length [mm (in)]

Nozzle diameter FMU40 FMU41 FMU42 FMU43 FMU44

DN50/2" 80 (3.15)

DN80/3" 240 (9.45) 240 (9.45) 250 (9.84)

DN100/4" 300 (11.8) 300 (11.8) 300 (11.8) 300 (11.8)

DN150/6" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

DN200/8" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

DN250/10" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

DN300/12" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

Sensor characteristics

Emitting angle 11° 11° 9° 6° 11°

Blocking distance [m (ft)] 0.25 (0.8) 0.35 (1.1) 0.4 (1.3) 0.6 (2.0) 0.5 (1.6)

Max. range [m (ft)]

in liquids

Max. range [m (ft)]

in solids

5 (16.0) 8 (26.0) 10 (33.0) 15 (49.0) 20 (66.0)

2 (6.6) 3.5 (11.0) 5 (16.0) 7 (23.0) 10 (33.0)

Caution!

If the blocking distance is undershot, it may cause device malfunction.

Note!

In order to notice if the level approaches the blocking distance, you can specify a safety distance (SD).

If the level is within this safety distance, the Prosonic M outputs a warning or alarm message.

20 Endress+Hauser

Page 21

Prosonic M

Environment

Ambient temperature – 40 °C to +80 °C (–40 °F to +176 °F)

The functionality of the LC display becomes restricted at Tu<–20 °C (Tu<–4 °F) and Tu>+60 °C

(Tu>140 °F).

If the device is operated outdoors in strong sunlight, you should use a protective cover ( ä 43).

Storage temperature –40 °C to +80 °C (–40 °F to +176 °F)

Resistance to alternating temperature cycles

Climate class DIN EN 60068-2-38 (Test Z/AD) DIN/IEC 68 T2-30Db

Ingress protection • With closed housing, tested according to

Vibration resistance DIN EN 60068-2-64 / IEC 68-2-64: 20…2000 Hz, 1 (m/s

Electromagnetic compatibility (EMC)

To DIN EN 60068-2-14; Nb test: +80°C/–40°C (+176 °F/–40 °F), 1K/min, 100cycles

– IP68, NEMA 6P (24h at 1.83 m (6 ft) under water surface)

– IP66, NEMA 4x

• With open housing: IP20, NEMA 1 (also ingress protection of the display)

Caution!

Degree of protection IP68 NEMA 6P applies for M12 PROFIBUS-PA plugs and for 7/8" FF plug only

when the cable is plugged in.

• Electromagnetic compatibility according to all relevant requirements of the EN 61326- series and

NAMUR recommendation EMC (NE21). For details see declaration of conformity.

• A standard installation cable is sufficient if only the analogue signal is used. Use a screened cable

when working with a superimposed communication signal (HART).

Process

Process temperature –40°C to +80 °C (–40 °F...+176 °F)

A temperature sensor is integrated in the sensor for correction of the temperature-dependent time-offlight.

)2

/Hz; 3 x 100 min

Process pressure • FMU40/41: 0.7 bar to 3bar abs. (10.15 psi...43.5 psi abs.)

• FMU42/43/44: 0.7 bar to 2.5bar abs. (10.15 psi...36.25 psi abs.)

Endress+Hauser 21

Page 22

Mechanical construction

65

(2.6)

78

(3.1)

ø129 (5.1)

~86 (3.4)

78

(3.1)

85

(3.3)

85

(3.3)

65

(2.6)

ø129 (5.1)

162 (6.4)

150 (5.9)

68

(2.7)

~148 (5.8)

~

83 (3.3)

22 (0.9)

CD

ø39 (1.5)

ø50 (2.0)

~

148 (5.8)

~87 (3.4)

22 (0.9)

ENDRESS+HAUSER

Prosonic M

ENDRESS+HAUSER

Prosonic M

32 (1.3)

AB

G 1½"

NPT 1½"

94

(3.7)

60 60

G 2"

NPT 2"

mm (in)

~110 (4.3)

ø70 (2.8)

~85 (3.3)

C

65

(2.6)

78

(3.1)

ø129 (5.1)

86

(3.4)

78

(3.1)

85 (3.3)

65

(2.6)

ø129 (5.1)

162 (6.4)

150 (5.9)

68

(2.7)

94

(3.7)

ENDRESS+HAUSER

Prosonic M

ENDRESS+HAUSER

Prosonic M

32 (1.3)

AB

D

ø98 (3.9)

07 (4.2)

~1

~145 (5.7)

85 (3.3)

mm (in)

Design; dimensions FMU40, FMU41

Prosonic M

A0019317

A F12 housing B T12 housing

C FMU40 D FMU41

FMU42, FMU44 with slip-on flange

A F12 housing B T12 housing

C FMU42 D FMU44

A0019318

22 Endress+Hauser

Page 23

Prosonic M

ENDR

ESS+HA

USER

Prosonic

M

75

(3.0)

119 (4.7)

105 (4.1)

A

ENDRESS+HA

USER

Prosonic

M

B

119 (4.7)

30 (1.2)

98 (3.9)

125 (4.9)

30 (1.2)

1 1

mm (in)

85 (3.3)

65

(2.6)

78

(3.1)

ø129 (5.1)

150 (5.9)

~248 (9.8)

E

N

D

RE

SS+

H

A

U

SE

R

Pro

son

ic

M

ø230 (9.1)

89 (3.5)

A

B

~86

(3.4)

mm (in)

75 (3.0)

158 (6.

2)

1

11 (0.43)

119 (4.68)

2 (0.08)

25 (0.98)

120 (4.7)

~123 (4.8)

40 (1.6) 40 (1.6)

mm (in)

FMU42, FMU44 with mounting bracket

A FMU42 ( T12, F12 housing) B FMU44 (T12, F12 housing)

1M8

FMU43

A0019322

A With slip-on flange (ANSI 4" DN 100) B With mounting bracket (F12 housing)

12xM8

Mounting bracket for FMU42, FMU43 and FMU44

Endress+Hauser 23

A0019337

A0019342

Page 24

Flanges for FMU42 and FMU44

G 2"

ISO228

20 (0.8)

C

E

A

B

D

mm (in)

Prosonic M

Weight

A0019343

suitable for A B C D E number of

boreholes

3" 150 lbs / DN80 PN16 / 10K 80 150 mm

(5.91")

4" 150 lbs / DN100 PN16 / 10K 100 175 mm

6" 150 lbs / DN150 PN16 / 10 K 150 240 mm

8" 150 lbs 298.5 mm

DN200 PN16 / 10 K 200 290 mm

Sensor Weight kg (lbs)

FMU40 approx. 2.5 (5.51)

FMU41 approx. 2.6 (5.73)

FMU42 approx. 3 (6.62)

FMU43 approx. 3.5 (7.72)

FMU44 approx. 4 (8.82)

(6.90")

(9.45")

(11.75")

(11.42")

160 mm

(6.30")

190.5 mm

(7.50")

241.3 mm

(9.50")

298.5 mm

(11.75")

295 mm

(11.61")

200 mm

(7.87")

228.6 mm

(9.00")

285 mm

(11.22")

342.9 mm

(13.50")

340 mm

(13.39")

19 mm

(0.75")

19 mm

(0.75")

23 mm

(0.91")

22. 5 mm

(0.89")

23 mm

(0.91")

45° 8

45° 8

45° 8

45° 8

30° 12

24 Endress+Hauser

Page 25

Prosonic M

Housing design Types of housings

• F12 housing with sealed terminal compartment for standard or Ex ia applications

• T12 housing with separate terminal compartment and explosionproof encapsulation

Material

Aluminium, powder-coated ( ä 26)

Cover

• Aluminium, for version without on-site display

• Inspection glass for version with on-site display. This version cannot be supplied together with the

ATEX II 1/2 D certificate.

Process connection

Sensor Process connection

FMU40 • Thread G 1½“

• Thread NPT 1½“ - 11.5

FMU41 • Thread 2"

•Thread NPT 2" - 11.5

FMU42 • Universal flange DN 80 PN16 / ANSI 3" 150 lbs / JIS 10K 80

• Universal flange DN 100 PN16 / ANSI 4" 150 lbs / JIS 10K 100

•Mounting bracket

FMU43 • Universal flange DN 100 / ANSI 4" / JIS16K100

•Mounting bracket

FMU44 • Universal flange DN 100 PN16 / ANSI 4" 150 lbs / JIS 10K 100

• Universal flange DN 150 PN16 / ANSI 6" 150 lbs / JIS 10K 150

• Universal flange DN200 PN16 / JIS 10K 200

• Flange ANSI 8" 150 lbs

•Mounting bracket

Endress+Hauser 25

Page 26

Prosonic M

AB

ENDRESS+HAUSER

IP 65

O

r

d

e

r

C

o

d

e

:

S

e

r

.

-N

o

.

:

M

e

s

s

b

e

r

e

ic

h

M

e

a

s

u

r

in

g

r

an

g

e

U

1

6

..

.

36

V

D

C

4

..

.2

0

m

A

m

ax

.

2

0

m

Mad

e

in Germany

Ma

ulburg

T

>

7

0

°

C

:

A

t

>

8

5°

C

Madein Germany

Maulburg

ENDRESS+HAUS

ER

IP 65

Order Code:

Ser.-No.:

Messbereich

Measuring r

ange

U 16...36

V DC

4...20

mA

max

. 20 m

Madein Germany

Maulburg

T

>70°C :

A

t >

8

5

°C

987

56

98

56

3

2

1

4

2

1

3

3

7

Material

T12 and F12 housing (powder-coated)

(not in contact with process)

A T12 housing

B F12 housing

Pos. Part Material

1 T12 and F12 housing AlSi10Mg

Cover (Display) AlSi10Mg

O-ring EPDM

2

Window ESG-K-Glass

Sealing of the glass Silicone sealing compound Gomastit 402

Cable gland Polyamid (PA), CuZn nickel-plated

O-Ring EPDM

3

Plug

PBT-GF30 or 1.0718 galvanized

PE or 3.1655

Adapter 316L (1.4435) or AlMgSiPb (anodized)

Cover (Connection compartment) AlSi10Mg

4

O-ring EPDM

Clamp Screw: A4; Clamp: CuZn nickel-plated; Spring washer: A4

5O-ring EPDM

Tag 304 (1.4301)

6

Rope VA

Crimp sleeve Aluminium

Nameplate 316L (1.4404)

7

Groove pin A4 (1.4571)

8Ground terminal

Screw: A2; Springwasher: A4; Clamp: 304 (1.4301)

Holder: 301 (1.4310)

9Screw A2-70

Note!

Seawater-resistant parts please order on request (complete in 316L (1.4404)).

A0019273

26 Endress+Hauser

Page 27

Prosonic M

1

2a

3

2a

3

1

1

6

5

9

7

2b

AB

CC

B

8

2a

4

2b

2a

Material (in contact with process)

A0019054

Pos. Part A

FMU40, FMU41BFMU42, FMU44

1 Sensor PVDF PVDF

2a Sealing EPDM EPDM or FKM EPDM

2b O-ring EPDM - EPDM

3Flange -

4 Counter nut PC - -

5Screws - - V2A

Thread insert for

6

mounting bracket

7 Sensor membrane - - 316 Ti (1.4571)

Mounting bracket (retainer)

8

Screws

Mounting bracket

9

Screws

1) Endress+Hauser supplies DIN/EN flanges made of stainless steel AISI 316L with the material number

1.4404 or 1.4435. With regard to their temperature stability properties, the materials 1.4404 and 1.4435

are grouped under 13E0 in EN 1092-1 Tab. 18. The chemical composition of the two materials can be identical.

--CuZn

-

-

-

-

PP, PVDF or stainless steel

316L (1.4435 or 1.4404)

316 Ti (1.4571)

V4A

316 Ti (1.4571)

V2A

C

FMU43

UP (Unsaturated

polyester resin)

PP or 316 Ti

1)

(1.4571)

316 Ti (1.4571)

V2A

-

-

Note!

The chemical compatibility of the sensors must be checked before installation with compatibility

charts.

Endress+Hauser 27

Page 28

Operability

ENDRESS + HAUSER

E

+

–

1

2

3

4

Prosonic M

Display and operating elements

The LCD module VU331 for display and operation is located beneath the housing cover. The measured

value is legible through the glass in the cover. Open the cover to operate the device.

A0019274

1 LCD liquid crystal display

2Snap fit

3Keys

4 Symbols

Symbol in display

continuous flashing

Meaning Alarm Warning Communication Security Locking

Function of the keys

Key(s) Meaning

Navigate upwards in the selection list

Edit numeric value within a function

Navigate downwards in the selection list

Edit numeric value within a function

Navigate to the left within a function group

Navigate to the right within a function group, confirmation.

Contrast settings of the LCD

Hardware lock / unlock

After a hardware lock, an operation of the instrument via display or

communication is not possible!

F

The hardware can only be unlocked via the display. An unlock parameter must

be entered to do so (unlock parameter: 100).

O

S

and S and

O

O

S

X

F

and

or

and

F

F

28 Endress+Hauser

Page 29

Prosonic M

X

X

X

X

S

S

O

O

FF

F

F

HOME

FG00

F000 F001 F002 F003 F004 ...

FG01

FG02

FG03

FG04

FG05

FG06

FG07

...

ENDRESS + HAUSER

E

+–

Headline Position indicator

Main value

Unit

Symbol

Selection list

Function groups -> Functions

Help text

Envelope

curve

On-site operation Operation with VU331

The LC-Display VU331 allows configuration via 3 keys directly at the instrument. All device functions

can be set through a menu system. The menu consists of function groups and functions. Within a

function, application parameters can be read or adjusted. The user is guided through a complete

configuration procedure. For ease operation can choose between 4 language (PROFIBUS PA) or 7

language (HART, FOUNDATION Fieldbus): (de: german; en: english; es: spanish*; fr: french; it:

italian*; ja: japanese; nl: dutch*).

*) HART and FOUNDATION Fieldbus only

Remote operation Operation with FieldCare

Operation via Field Xpert

Compact, flexible and robust industry handheld terminal for remote parametrization and measured

value inspection via the HART current output or FOUNDATION Fieldbus. For details refer to Operating

Instructions BA00060S/04/EN.

FieldCare is Endress+Hauser's FDT based Plant Asset Management Tool. It can configure all intelligent

field devices in your plant and supports you in managing them. By using status information, it also

provides a simple but effective means of checking their health. Hardware and software requirements

you can find on the internet: www.endress.com select your country search: FieldCare FieldCare

Technical Data.

The FieldCare supports the following functions:

• Configuration of transmitters in online operation

• Signal analysis via envelope curve

• Tank linearization

• Loading and saving of instrument data (Upload/Download)

• Documentation of measuring point

Connection options

• HART with Commubox FXA195 and the USB port on a computer

• PROFIBUS PA via segment coupler and PROFIBUS interface card

• Commubox FXA291 with ToF Adapter FXA291 (USB) via service interface

L00-FMU4xxxx-07-00-00-en-004

Endress+Hauser 29

Page 30

Menu-guided commissioning:

Prosonic M

L00-FMU4xxxx-19-00-00-en-021

Signal analysis via envelope curve:

L00-FMU4xxxx-19-00-00-en-022

30 Endress+Hauser

Page 31

Prosonic M

Operation with NI-FBUS Configurator (only FOUNDATION Fieldbus)

The NI-FBUS Configurator is an easy-to-use graphical environment for creating linkages, loops, and a

schedule based on the fieldbus concepts.

You can use the NI-FBUS Configurator to configure a fieldbus network as follows:

• Set block and device tags

• Set device addresses

• Create and edit function block control strategies (function block applications)

• Configure vendor-defined function and transducer blocks

• Create and edit schedules

• Read and write to function block control strategies (function block applications)

• Invoke Device Description (DD) methods

• Display DD menus

• Download a configuration

• Verify a configuration and compare it to a saved configuration

• Monitor a downloaded configuration

•Replace devices

• Save and print a configuration

Certificates and Approvals

CE mark The measuring system meets the legal requirements of the EC-guidelines. Endress+Hauser confirms

the instrument passing the required tests by attaching the CE-mark.

Ex approval The available certificates are listed in the ordering information. Note the associated safety instructions

(XA) and control or installation drawings (ZD).

External standards and guidelines

EN 60529

Protection class of housing (IP-code)

EN 61326 series

EMC product family standard for electrical equipment for measurement, control and laboratory use

NAMUR

User association for automation technology in process industries

Endress+Hauser 31

Page 32

Ordering information

Product structure FMU40 Versions that mutually exclude one another are not marked.

010 Certificates

A Variant for non-hazardous area

E NEPSI Ex nA IIC T6 Gc

G ATEX II 3G Ex nA IIC T6 Gc

I NEPSI Ex ia IIC T6

J NEPSI Ex d(ia) IIC T6

K INMETRO Ex ia IIC T6 Ga/Gb

L INMETRO Ex d [ia] IIC T6 Ga/Gb

N CSA General Purpose

QNEPSI DIP

S FM IS Cl. I,II,III Div. 1 Gr. A-G / NI Cl. I Div. 2

T FM XP Cl. I,II,III Div. 1 Gr. A-G

U CSA IS Cl. I,II,III Div. 1 Gr. A-G / NI Cl. I Div. 2

V CSA XP Cl. I,II,III Div. 1 Gr. A-G

1 ATEX II 1/2G Ex ia IIC T6 Ga/Gb

2 ATEX II 1/2D, Alu blind cover

4 ATEX II 1/2G Ex d (ia) IIC T6 Ga/Gb

5 ATEX II 1/3D

6 ATEX II 3D Ex ta IIIC T* °C Dc

Y Special certificate

020 Process connection

R G 1½“ threadISO 228

N NPT 1½“ - 11,5 thread

Y Special version

030 Power supply/communication

B 2 wire, 4...20mA-loop/HART

H 4 wire, 10,5...32 VDC / 4-20mA HART

G 4 wire, 90...253 VAC / 4-20mA HART

D 2 wire, PROFIBUS PA

F 2 wire, FOUNDATION Fieldbus

J 2-wire, 4-20mA HART, 5-point linearity protocol

K 2-wire, PROFIBUS PA, 5-point linearity protocol

L 2-wire, FOUNDATION Fieldbus, 5-point linearity protocol

M 4-wire, 90-253VAC; 4-20mA HART, 5-point linearity protocol

N 4-wire, 10.5-32VDC;4-20mA HART, 5-point linearity protocol

P 2-wire, 4-20mA HART, 3-point linearity protocol

Q 2-wire, PROFIBUS PA, 3-point linearity protocol

R 2-wire, FOUNDATION Fieldbus, 3-point linearity protocol

S 4-wire, 90-253 VAC, 4-20mA HART, 3-point linearity protocol

T 4-wire, 10.5-32 VDC, 4-20mA HART, 3-point linearity protocol

Y Special version

040 Display / on-site operation

1 Without LC display

2 With LC display VU331 incl. on-site operation

3 Prepared for remote display FHX 40

9 Special version

050 Housing

A Aluminium F12 housing coated to IP68 NEMA6P

C Aluminium T12 housing coated to IP68 NEMA6P; with separate terminal

compartment

D Aluminium T12 housing coated to IP68 NEMA6P+OVP; with separate terminal

compartment; with overvoltage protection

9Special version

Prosonic M

32 Endress+Hauser

Page 33

Prosonic M

050 Housing

060 Screw union/entry

2 M20x1.5 screw union

3 G 1/2“ entry

4 NPT 1/2“ entry

5 M12 PROFIBUS-PA plug-in connector

6 7/8" FF plug

9 Special version

995 Marking

1Tagging (TAG)

2Bus address

FMU40 - Product designation

Endress+Hauser 33

Page 34

Prosonic M

Product structure FMU41

010 Certificates

A Variant for non-hazardous area

E NEPSI Ex nA IIC T6 Gc

G ATEX II 3G Ex nA IIC T6 Gc

I NEPSI Ex ia IIC T6

J NEPSI Ex d(ia) IIC T6

K INMETRO Ex ia IIC T6 Ga/Gb

L INMETRO Ex d [ia] IIC T6 Ga/Gb

N CSA General Purpose

QNEPSI DIP

S FM IS Cl. I,II,III Div. 1 Gr. A-G / NI Cl.I Div.2, zone 0,1,2

T FM XP Cl. I,II,III Div. 1 Gr. A-G / zone 1,2

U CSA IS Cl. I,II,III Div. 1 Gr. A-G / NI Cl. I Div. 2, zone 0,1,2

V CSA XP Cl. I,II,III Div. 1 Gr. A-G / zone 1,2

1 ATEX II 1/2 G Ex ia IIC T6 Ga/Gb

2 ATEX II 1/2D, Alu blind cover

4 ATEX II 1/2 G Ex d [ia] IIC T6 Ga/Gb

5 ATEX II 1/3D

6 ATEX II 3D Ex ta IIIC T* °C Dc

Y Special certificate

020 Process connection

R G 2“ threadISO 228

N NPT 2“ - 11,5 thread

Y Special version

030 Power supply/communication

B 2 wire, 4...20mA-loop/HART

H 4 wire, 10.5...32VDC / 4-20mA HART

G 4 wire, 90...253VAC / 4-20mA HART

D 2 wire, PROFIBUS PA

F 2 wire, FOUNDATION Fieldbus

J 2-wire, 4-20mA HART, 5-point linearity protocol

K 2-wire, PROFIBUS PA, 5-point linearity protocol

L 2-wire, FOUNDATION Fieldbus, 5-point linearity protocol

M 4-wire, 90-253VAC; 4-20mA HART, 5-point linearity protocol

N 4-wire, 10.5-32VDC;4-20mA HART, 5-point linearity protocol

P 2-wire, 4-20mA HART, 3-point linearity protocol

Q 2-wire, PROFIBUS PA, 3-point linearity protocol

R 2-wire, FOUNDATION Fieldbus, 3-point linearity protocol

S 4-wire, 90-253 VAC, 4-20mA HART, 3-point linearity protocol

T 4-wire, 10.5-32 VDC, 4-20mA HART, 3-point linearity protocol

Y Special version

040 Display / on-site operation

1 Without LC display

2 With LC display VU331 incl. on-site operation

3 Prepared for remote display FHX40

9 Special version

050 Housing

A Aluminium F12 housing coated to IP68 NEMA 6P

C Aluminium T12 housing coated to IP68 NEMA 6P; with separate terminal

compartment

D Aluminium T12 housing coated to IP68 NEMA 6P; with separate terminal

compartment; with overvoltage protection

9Special version

060 Screw union/entry

2 M20x1.5 screw union

3 G 1/2“ entry

4 NPT 1/2“ entry

5 M12 PROFIBUS-PA plug-in connector

6 7/8" FF plug

9Special version

34 Endress+Hauser

Page 35

Prosonic M

995 Marking

1Tagging (TAG)

2Bus address

FMU41 - Product designation

Endress+Hauser 35

Page 36

Prosonic M

Product structure FMU42

010 Certificates

A Variant for non-hazardous area

E NEPSI Ex nA IIC T6 Gc

G ATEX II 3G Ex nA IIC T6 Gc

I NEPSI Ex ia IIC T6

J NEPSI Ex d (ia) IIC T6

K INMETRO Ex ia IIC T6 Ga/Gb

L INMETRO Ex d [ia] IIC T6 Ga/Gb

N CSA General Purpose

QNEPSI DIP

S FM IS Cl. I,II,III Div. 1 Gr. A-G / NI Cl. I Div. 2

T FM XP Cl. I,II,III Div. 1 Gr. A-G

U CSA IS Cl. I,II,III Div. 1 Gr. A-G / NI Cl. I Div. 2

V CSA XP Cl. I,II,III Div. 1 Gr. A-G

1 ATEX II 1/2 G Ex ia IIC T6 Ga/Gb

2 ATEX II 1/2 D, Alu blind cover

4 ATEX II 1/2 G Ex d [ia] IIC T6 Ga/Gb

5 ATEX II 1/3D

6 ATEX II 3D Ex ta IIIC T* °C Dc

Y Special certificate

020 Process connection

MMounting bracket FAU20

P UNI flange 3"/DN80/80, PP, max. 2.5bar abs./ 36psia

suitable for 3" 150lbs / DN80 PN16 / 10K 80

Q UNI flange 3"/DN80/80, PVDF, max. 2.5bar abs./ 36psia

suitable for 3" 150lbs / DN80 PN16 / 10K 80

S UNI flange 3"/DN80/80, 316L, max. 2.5bar abs./ 36psia

suitable for 3" 150lbs / DN80 PN16 / 10K 80

T UNI flange 4"/DN100/100, PP, max. 2.5bar abs./ 36psia

suitable for 4" 150lbs / DN100 PN16 / 10K100

U UNI flange 4"/DN100/100, PVDF, max. 2.5bar abs./ 36psia

suitable for 4" 150lbs / DN100 PN16 / 10K100

V UNI flange 4"/DN100/100, 316L, max. 2.5bar abs./ 36psia

suitable for 4" 150lbs / DN100 PN16 / 10K100

Y Special version

030 Power supply/communication

B 2 wire, 4...20mA-loop/HART

H 4 wire, 10.5...32VDC / 4-20mA HART

G 4 wire, 90...253VAC / 4-20mA HART

D 2 wire, PROFIBUS PA

F 2 wire, FOUNDATION Fieldbus

J 2-wire, 4-20mA HART, 5-point linearity protocol

K 2-wire, PROFIBUS PA, 5-point linearity protocol

L 2-wire, FOUNDATION Fieldbus, 5-point linearity protocol

M 4-wire, 90-253VAC; 4-20mA HART, 5-point linearity protocol

N 4-wire, 10.5-32VDC;4-20mA HART, 5-point linearity protocol

P 2-wire, 4-20mA HART, 3-point linearity protocol

Q 2-wire, PROFIBUS PA, 3-point linearity protocol

R 2-wire, FOUNDATION Fieldbus, 3-point linearity protocol

S 4-wire, 90-253 VAC, 4-20mA HART, 3-point linearity protocol

T 4-wire, 10.5-32 VDC, 4-20mA HART, 3-point linearity protocol

Y Special version

040 Display / on-site operation

1 Without LC display

2 With LC display VU331 incl. on-site operation

3 Prepared for remote display FHX40

9 Special version

36 Endress+Hauser

Page 37

Prosonic M

050 Housing

A Aluminium F12 housing coated to IP68 NEMA 6P

C Aluminium T12 housing coated to IP68 NEMA 6P, with separate terminal

compartment

D Aluminium T 12 housing coated to IP68 NEMA 6P, with separate terminal

compartment; with overvoltage protection

YSpecial version

060 Gland/Entry

2 M20x1.5 gland

3 G 1/2“ entry

4 NPT 1/2“ entry

5 M12 PROFIBUS-PA plug

6 7/8" FF plug

9 Special version

070 Sealing Sensor/Flange

2 VITON flat sealing

3 EPDM flat sealing

9 special version

080 Additional options

A Additional options not selected

995 Marking

1Tagging (TAG)

2Bus address

FMU42 - Product designation

Endress+Hauser 37

Page 38

Prosonic M

Product structure FMU43

010 Certificates

A Variant for non-hazardous area

2 ATEX II 1/2D, Alu blind cover

5 ATEX II 1/3D

6 ATEX II 3D Ex ta IIIC T* °C Dc

M FM DIP Cl.II Div.1 Gr.E-G, NI Cl.I Div.2, Zone 2

N CSA General Purpose

P CSA DIP Cl.II Div.1 Gr.E-G, NI Cl.I Div.2, zone 2

QNEPSI DIP

Y Special version

020 Process connection/material

P Flange DN 100/ANSI 4"/JIS 16K100, PP (universal slip-on flange included)

S Flange DN 100/ANSI 4"/JIS 16K100, SS 316TI (universal slip-on flange included)

K Without slip-on flange/without mounting bracket (customer mounting equipment)

MWith mounting bracket FAU20

Y Special version

030 Power supply/communication

H 4 wire, 10,5...32 VDC / 4-20mA HART

G 4 wire, 90...253 VAC / 4-20mA HART

D 2 wire, PROFIBUS PA

F 2 wire, FOUNDATION Fieldbus

K 2-wire, PROFIBUS PA, 5-point linearity protocol

L 2-wire, FOUNDATION Fieldbus, 5-point linearity protocol

M 4-wire, 90-253VAC; 4-20mA HART, 5-point linearity protocol

N 4-wire, 10.5-32VDC;4-20mA HART, 5-point linearity protocol

Q 2-wire, PROFIBUS PA, 3-point linearity protocol

R 2-wire, FOUNDATION Fieldbus, 3-point linearity protocol

S 4-wire, 90-253 VAC, 4-20mA HART, 3-point linearity protocol

T 4-wire, 10.5-32 VDC, 4-20mA HART, 3-point linearity protocol

Y Special version

040 Display / on-site operation

1 Without LC display

2 4-line display VU331, Envelope curve display on site

3 Prepared for remote display FHX 40

9 Special version

050 Housing

A Aluminium F12 housing coated to IP68 NEMA 6P

9Special version

060 Screw union/entry

2 M20x1.5 screw union

3 G 1/2“ entry

4 NPT 1/2“ entry

5 M12 PROFIBUS-PA plug-in connector

6 7/8" FF plug

9Special version

995 Marking

1 Tagging (TAG)

2Bus address

FMU43 - Product designation

38 Endress+Hauser

Page 39

Prosonic M

Product structure FMU44

010 Approval

A Non-hazardous area

1 ATEX II 1/2G Ex ia IIC T6 Ga/Gb

4 ATEX II 1/2G Ex d (ia) IIC T6 Ga/Gb

G ATEX II 3G Ex nA IIC T6 Gc

2 ATEX II 1/2 D, Alu blind cover

5 ATEX II 1/3 D

6 ATEX II 3D Ex ta IIIC T* °C Dc

S FM IS Cl.I,II,III Div.1 Gr.A-G, NI Cl.I Div.2, Zone 0,1,2

T FM XP Cl.I,II,III Div.1 Gr.A-G, Zone 1,2

NCSA General Purpose

U CSA IS Cl.I,II,III Div.1 Gr.A-G, NI Cl.I Div.2, zone 0,1,2

V CSA XP Cl.I,II,III Div.1 Gr.A-G

K INMETRO Ex ia IIC T6 Ga/Gb

L INMETRO Ex d [ia] IIC T6 Ga/Gb

I NEPSI Ex ia IIC T6

J NEPSI Ex d(ia) IIC T6

E NEPSI Ex nA IIC T6 Gc

QNEPSI DIP

Y Special version, to be specified

020 Process connection

A 8" 150lbs FF, 316L, max 2.5bar abs./36psia

E UNI flange 6"/DN150/150, PP, max 2.5bar abs./ 36psia,

suitable for 6" 150lbs / DN150 PN16 / 10K 150

F UNI flange 6"/DN150/150, PVDF, max 2.5bar abs./36psia,

suitable for 6" 150lbs /DN150 PN16 / 10K 150

G UNI flange 6"/DN150/150, 316L, max 2.5bar abs. 36psia,

suitable for 6" 150lbs / DN150 PN16 / 10K 150

H UNI flange DN200/200, PP, max 2.5bar abs./ 36 psia,

suitable for DN200 PN16 / 10K 200

J UNI flange DN200/200, PVDF, max 2.5bar abs./ 36psia,

suitable for DN200 PN16 / 10K 200

K UNI flange DN200/200, 316L, max 2.5bar abs./ 36psia,

suitable for DN200 PN16 / 10K 200

L 8" 150lbs FF, PP, max 2.5bar abs./ 36psia

MMounting bracket FAU20

N 8" 150lbs FF, PVDF, max 2.5bar abs./ 36psia

T UNI flange 4"/DN100/100, PP, max 2.5bar abs./ 36psia,

suitable for 4" 150lbs / DN100 PN16 / 10K 100

U UNI flange 4"/DN100/100, PVDF, max. 2.5bar abs./ 36 psia,

suitable for 4" 150lbs / DN100 PN16 / 10K 100

V UNI flange 4"/DN100/100, 316L, max 2.5bar abs./ 36psia,

suitable for 4" 150lbs / DN100 PN16 / 10K 100

Y Special version, to be specified

030 Power supply; Output

B 2-wire, 4-20mA HART

D 2-wire, PROFIBUS PA

F 2-wire, FOUNDATION Fieldbus

G 4-wire, 90-253 VAC, 4-20mA HART

H 4-wire, 10.5-32 VDC, 4-20mA HART

J 2-wire, 4-20mA HART, 5-point linearity protocol

K 2-wire, PROFIBUS PA, 5-point linearity protocol

L 2-wire, FOUNDATION Fieldbus, 5-point linearity protocol

M 4-wire, 90-253 VAC; 4-20mA HART, 5-point linearity protocol

N 4-wire, 10.5-32 VDC;4-20mA HART, 5-point linearity protocol

P 2-wire, 4-20mA HART, 3-point linearity protocol

Q 2-wire, PROFIBUS PA, 3-point linearity protocol

R 2-wire, FOUNDATION Fieldbus, 3-point linearity protocol

S 4-wire, 90-253 VAC, 4-20mA HART, 3-point linearity protocol

T 4-wire, 10.5-32 VDC, 4-20mA HART, 3-point linearity protocol

Y Special version, to be specified

Endress+Hauser 39

Page 40

040 Operation

1 w/o display, via communication

2 4-line display VU331, Envelope curve display on site

3 Prepared for FHX40, Remote display (accessory)

9 Special version, to be specified

050 Housing

A F12 Alu, coated IP68 NEMA6P

C T12 Alu, coated IP68 NEMA6P, Separate conn. compartment

D T12 Alu, coated IP68 NEMA6P + OVP, Sep. conn. compartment, OVP = overvol-

tage protection

9 Special version, to be specified

060 Cable entry

2 Gland M20 (Ex d > thread M20)

3Thread G1/2

4Thread NPT 1/2

5Plug M12

6Plug 7/8“

9 Special version, to be specified

070 Process Sealing Sensor/ Flange

2Viton

3EPDM

9 Special version, to be specified

080 Additional option

A Basic version

Y Special version, to be specified

995 Marking

1 Tagging (TAG)

2Bus address

FMU44 - complete product designation

Prosonic M

40 Endress+Hauser

Page 41

Prosonic M

R

A

B

1

3

2

3-point linearity protocol If the "3-point linearity protocol" option has been selected, the three measuring points of the linearity

protocol are defined depending of the selected sensor:

A0023651

Points of the 3-point linearity protocol

A Distance from reference point R to first measuring point

B Distance from reference point R to third measuring point

R Reference point of the measurement

1 First measuring point

2 Second measuring point (centered between first and third measuring point)

3 Third measuring point

Measuring device A B

FMU40 1000 (39) 5000 (197)

FMU41

FMU42

FMU43

FMU44

1000 (39) 6000 (236)

Dimensions mm (in)

Note!

The position of the measuring points may vary by ±1 cm (±0,04 in).

Note!

The linearity is checked under reference conditions.

Endress+Hauser 41

Page 42

Prosonic M

R

A

F

E

S

5-point linearity protocol The following must be taken into account if option "5 point linearity protocol" has been selected:

• The five points of the linearity protocol are evenly distributed across the measuring range (0 % to

100 %). In order to define the measuring range, Empty calibration (E) and Full calibration (F) have

to be specified.

3)

• The following restrictions have to be taken into account when defining E and F:

A0019522

Pos. Measuring range FMU40 FMU41 FMU42 FMU43 FMU44

E Maximum value for the empty calibra-

tion

F Maximum value for the full calibration 4 750

S Minimum span E-A 100

A Minimum distance between reference

point R from sensor and 100 % level

5000

(197)

(187)

(3.94)

250

(9.84)

Note!

The linearity is checked under reference conditions.

Scope of delivery • Instrument according to the version ordered

• Endress+Hauser operating program on the enclosed CD-ROM

• Brief operating instructions according to the communication version

• For certified instrument versions: Safety Instructions, Control- or Installation drawings

• For FMU40 *R**** and FMU41 *R****: counter nut (PC)

• For FMU40/41: sealing ring (EPDM)

• For gland M20x1.5:

– 1 cable gland for 2-wire instruments

– 2 cable glands for 4-wire instruments

The cable glands are mounted on delivery.

8000

(315)

7500

(295)

100

(3.94)

500

(19.7)

10000

(394)

9600 (378) 14400

100 (3.94) 150 (591) 250 (9.84)

400 (15.7) 600 (23.6) 500 (19.7)

15000

(591)

(567)

Dimensions mm (in)

20000

(787)

19500

(768)

3) If the values for the full calibration and empty calibration are missing or outside the specified area, the devices are tested with the maximum value

according to the table.

42 Endress+Hauser

Page 43

Prosonic M

Madein Germany Ma

ulburg

Madein Germany Maulburg

A

mm (in)

240 (9.45)

135 (5.31)

95 (3.74)

70 (2.76)

45°

400 (15.7)

120 (4.72)

120

(4.72)

30 (1.2)

250 (9.84)

G

ø16 (0.6)

3 (0.12)

mm (in)

Accessories

Weather protection cover A Weather protection cover made of stainless steel is recommended for outdoor mounting. The

shipment includes the protective cover and tension clamp.

A0019345

A F12 housing, T12 housing

Part Order No. Material

Protective cover, tension clamp

Screw, nut, disk A2

543199-0001

304 (1.4301)

Installation bracket for FMU40, FMU41

A0019346

Sensor Order No. Material Weight

FMU40, G 1½" 942669-0000

FMU41, G 2" 942669-0001

Suited for NPT 1½" and 2" as well

316 Ti (1.4571) 3.4 kg (7.5 lbs)

Endress+Hauser 43

Page 44

Screw in flange

4

1

3

2

1Screw in flange

2 Nozzle

3Sensor

4 Sealing ring EPDM (supplied)

Screw in flange FAX50

015Material:

BR1 DN50 PN10/16 A, steel flange EN1092-1

BS1 DN80 PN10/16 A, steel flange EN1092-1

BT1 DN100 PN10/16 A, steel flange EN1092-1

JF1 2" 150lbs FF, steel flange ANSI B16.5

JG1 3" 150lbs FF, steel flange ANSI B16.5

JH1 4" 150lbs FF, steel flange ANSI B16.5

JK2 8" 150lbs FF, PP max 3bar abs/44psia flange ANSI B16.5

XIF UNI flange 2"/DN50/50, PVDF max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

XIG UNI flange 2"/DN50/50, PP max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

XIJ UNI flange 2"/DN50/50, 316L max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

XJF UNI flange 3"/DN80/80, PVDF max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

XJG UNI flange 3"/DN80/80, PP max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

XJJ UNI flange 3"/DN80/80, 316L max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

XKF UNI flange 4"/DN100/100, PVDF max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K

100

XKG UNI flange 4"/DN100/100, PP max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K 100

XKJ UNI flange 4"/DN100/100, 316L max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K

100

XLF UNI flange 6"/DN150/150, PVDF max 4bar abs/58psia, suitable for 6" 150lbs/DN150 PN16/10K

150

XLG UNI flange 6"/DN150/150, PP max 4bar abs/58psia, suitable for 6" 150lbs/DN150 PN16/10K 150

XLJ UNI flange 6"/DN150/150, 316L max 4bar abs/58psia, suitable for 6" 150lbs/DN150 PN16/10K

150

XMG UNI flange DN200/200, PP max 4bar abs/58psia, suitable for DN200 PN16/10K 200

XNG UNI flange DN250/250, PP max 4bar abs/58psia, suitable for DN250 PN16/10K 250

YYY Special version

020 Sensor Connection:

A Thread ISO228 G3/4

B Thread ISO228 G1

C Thread ISO228 G1-1/2

D Thread ISO228 G2

EThread ANSI NPT3/4

FThread ANSI NPT1

GThread ANSI NPT1-1/2

HThread ANSI NPT2

Y Special version

Prosonic M

A0019281

015 020

FAX50 -

44 Endress+Hauser

Page 45

Prosonic M

ENDRESS+HAUSER

Prosonic M

ENDRESS+HAUSER

Prosonic M

3

1

2

AB

1

A

D

M8

35 (1.4)

50 (2.0)

20 (0.8)

105 (4.1)

50/62

(2.0/2.4)

22 (0.9)

C

C

6.5 (0.3)

15 (0.6)

100 (3.9)

25 (1.0)

35 (1.4)

100 (3.9)75 (2.9)

B

20 (0.8)

75 (2.9)

mm (in)

Cantilever with mounting frame or wall bracket

A Installation with cantilever and wall bracket

B Installation with cantilever and mounting frame

1 Cantilever

2Mounting frame

3 Wall bracket

Cantilever

A0019523

A B C D Weight for Sensor Material Order Code

585 (23) 250 (9.84) 2 (0.08) 200 (7.87) 1.9 kg

1085

(42.7)

750 (29.5) 3 (0.12) 300 (11.8) 4.4 kg

mm (in)

• The 50 mm (1.97 in) or 62 mm (2.44 in) orifices serve for the mounting of the FMU40 or FMU41

sensor, respectively.

• The 22 mm (0.87 in) orifice may be used for an additional sensor.

Fixing screws are supplied.

Endress+Hauser 45

(4.2 lbs)

(9.7 lbs)

A0019349

FMU40 316Ti (1.4571) 52014132

galv. steel 52014131

FMU41 316Ti (1.4571) 52014136

galv. steel 52014135

FMU40 316Ti (1.4571) 52014134

galv. steel 52014133

FMU41 316Ti (1.4571) 52014138

galv. steel 52014137

Page 46

Mounting Frame

3.2 (0.13)

20 (0.8)

55 (2.17)

100 (3.94)

25(0.98)

700/1400

(27.6 / 55.1)

45 (1.77)

76

(2.99)

100

(3.94)

200 (7.87)

13 (0.5)

ø33.7 (1.3)

130 (5.12)

150 (5.91)

100

(3.94)

60 (2.36)

4 (0.16)

6.5 (0.3)

mm (in)

110 (4.3)

25 (1.0)

5 (0.2)

6.5 (0.3)

150 (5.9)

ø33.7 (1.3)

3.2 (0.1)

110 (4.3)

13 (0.5)

150 (5.9)

180 (7.1)

~213 (8.4)

~ (3.5)88

mm (in)

Prosonic M

Height Material Weight Order Code

700 (27.6) galv. steel

700 (27.6) 316Ti (1.4571) 919791-0001

1400 (55.1) galv. steel

1400 (55.1) 316Ti (1.4571) 919791-0003

mm (in)

3.2 kg (7.06 lbs)

4.9 kg (10,08 lbs)

919791-0000

919791-0002

Wall Bracket

A0019279

919792-0000

Material Weight Order Code

galv. steel

316Ti (1.4571) 919792-0001

1.4 kg (3.09 lbs)

46 Endress+Hauser

A0019350

Page 47

Prosonic M

Made in Germany Maulbu

rg

82 (3.23)

6

.3

106 (4.71)

122 (4.8)

120 (4.72)

mm (in)

max. 80 (3.15)

min. 30 (1.18)

96 (3.78)

88

(3.46)

160 (6.3)

118 (4.65)

180 (7.09)

1

122

(4.8)

80

(3.51)

2

3

AB

4

150 (5.91)

8.5

(0.33)

(0.25)

Commubox FXA195 HART For intrinsically safe communication with FieldCare via the USB interface.

For details refer to TI00404F/00/EN.

Commubox FXA291 The Commubox FXA291 connects Endress+Hauser field instruments via the service interface to the

USB interface of a personal computer or a notebook. For details refer to TI00405C/07/EN.

Note!

For the instrument you need the "ToF Adapter FXA291" as an additional accessory.

ToF Adapter FXA291 The ToF Adapter FXA291 connects the Commubox FXA291 via the USB interface of a personal

computer or a notebook to the instrument. For details refer to KA00271F/00/A2.

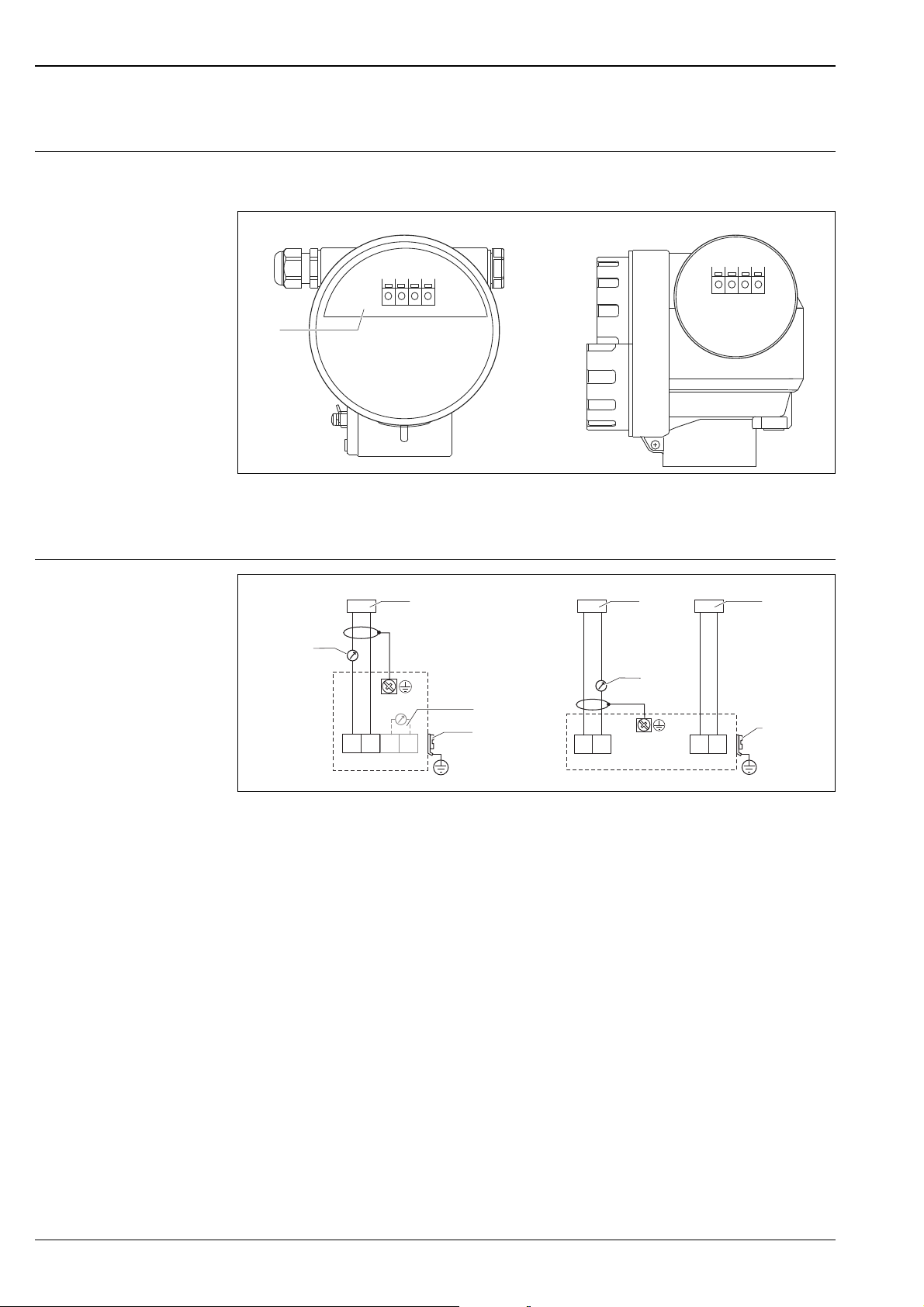

Remote display FHX40

A0019277

A Wall mounting (without mounting bracket)