Page 1

Description of Instrument Functions

Prosonic M

FMU40/41/42/43/44

with HART, PROFIBUS-PA

and FOUNDATION Fieldbus

BA00240F/00/EN/13.12

71164400

Valid as of software version:

V 01.04.00 (amplifier)

V 01.04.00 (communication)

Page 2

Short instructions

E

+

-

+

E

+

-

F

L

D

E

E

E

-

… …

KA 183F/00/a2/02.02

52010993

BD

… …

100%

0%

100 (HART)

2457 (PA,FF)

333 (HART)

33333 (PA,FF)

… …

52010993

… …

Prosonic M - Quick Setup

- dome

ceiling

- horizontal

cyl.

- bypass

…

- unknown

- liquid

- > 4 mm

- < 4 mm

- standard

- calm

surface

- add.

agitator

…

input E

(s. sketch)

input F

(s. sketch)

- ok

- too small

- too big

- unknown

- manual

displayed

(s. sketch)

D and L are

confirm

or specify

range

suggestion

000

measured value

Group

selection

00

basic setup

01

safety settings

0C

system

parameter

0E

Envelope curve

04

linearisation

05

extended calibr.

06

output (HART, FF)

profibus param.(PA)

0A

diagnostics

0A0

present

error

002

tank shape

004

process

cond.

005

empty

calibr.

006

full

calibr.

008

dist./

meas value

051

check

distance

003

medium

property

052

range of

mapping

053

start

mapping

008

dist./

meas value

0E1

plot settings

0E2

recording

curve

0A1

previous

error

0A4

unlock

parameter

0E

temperature

09

display

092

language

BD: blocking distance

0A3

reset

0C0

tag no.

059

blocking

distance

B

displayed

(s. sketch)

D is

Contrast: +or +

Short instructions

Contents of the operating instructions

This operating instrucitons contain all functions off the Prosonic M operating menu. All types of devices (FMU40/41/42/43/44)

and all communication variants are considered.

Information on mounting, wiring, trouble shooting and maintenance can be found in the following documents. These documents can

be found on the CD-ROM "Device Desriptions + Documentation".

• BA00237F/00/EN (HART)

• BA00238F/00/EN (PROFIBUS PA)

• BA00239F/00/EN (FOUNDATION Fieldbus)

2 Endress+Hauser

Page 3

Prosonic M Contents of the operating instructions

1 Notes on use . . . . . . . . . . . . . . . . . . . . 5

1.1 Using the table of contents to locate a function

description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Using the graphic of the function menu to locate a

function description . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Using the index of the function menu to locate a

function description . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Function menu Prosonic M . . . . . . . . 13

3 Function group "basic setup" (00) . . . 17

3.1 Function "measured value" (000) . . . . . . . . . . . . . . 17

3.2 Function "tank shape" (002) . . . . . . . . . . . . . . . . . 17

3.4 Function "process cond." (004) . . . . . . . . . . . . . . . 18

3.6 Function "blocking dist." (059) . . . . . . . . . . . . . . . 20

3.8 Display (008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.10 Function "range of mapping" (052) . . . . . . . . . . . . 23

3.11 Funktion "start mapping" (053) . . . . . . . . . . . . . . . 23

4 Function group "safety settings" (01). 25

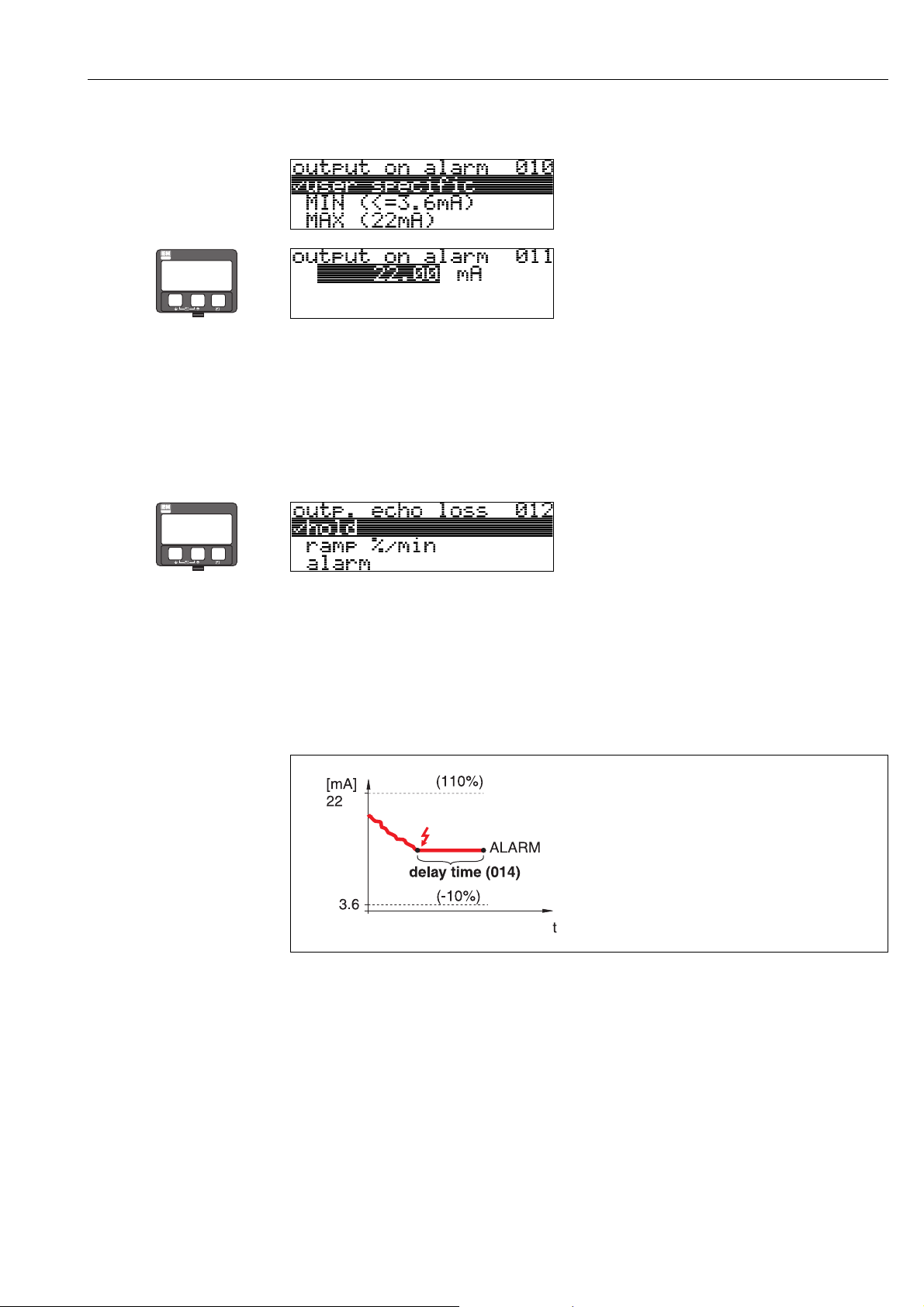

4.1 Function "output on alarm" (010) . . . . . . . . . . . . . 25

4.3 Function "outp. echo loss" (012) . . . . . . . . . . . . . . 27

4.4 Function "ramp %span/min" (013) . . . . . . . . . . . . 28

4.6 Function "safety distance" (015) . . . . . . . . . . . . . . . 29

5 Function group "temperature" (03) . . 33

5.1 Function "measured temp." (030) . . . . . . . . . . . . . 33

5.2 Function "max. temp. limit" (031) . . . . . . . . . . . . . 33

5.3 Function "max. meas. temp." (032) . . . . . . . . . . . . 33

5.5 Function "defect temp. sens." (034) . . . . . . . . . . . . 34

8.2 Function "instrument addr." (060),

PROFIBUS-PA only . . . . . . . . . . . . . . . . . . . . . . . . 49

8.4 Function "ident number" (061), PROFIBUS-PA only 50

8.6 Function "set unit to bus" (062), PROFIBUS-PA only .

51

8.8 Function "out value" (063), PROFIBUS-PA only . . . 52

8.10 Function "out status" (064), PROFIBUS-PA only . . . 53

8.12 Function "simulation value" (066) . . . . . . . . . . . . . 55

8.14 Function "2nd cyclic value" (067),

PROFIBUS-PA only . . . . . . . . . . . . . . . . . . . . . . . . 56

8.15 Function "4mA-value" (068), HART only . . . . . . . . 56

8.17 Function "20mA-value" (069), HART only . . . . . . . 57

8.18 Function "display value" (069), PROFIBUS-PA only 57

9 Function group "Envelope curve" (0E) 59

9.1 Function "plot settings" (0E1) . . . . . . . . . . . . . . . . . 59

9.2 Function "recording curve" (0E2) . . . . . . . . . . . . . . 59

10 Function group "display" (09) . . . . . . . 63

10.1 Function "language" (092) . . . . . . . . . . . . . . . . . . . 63

10.2 Function "back to home" (093) . . . . . . . . . . . . . . . 63

10.4 Function "no.of decimals" (095) . . . . . . . . . . . . . . . 64

10.5 Function "sep. character" (096) . . . . . . . . . . . . . . . 64

10.6 Function "display test" (097) . . . . . . . . . . . . . . . . . 65

11 Function group "diagnostics" (0A) . . . 67

11.2 Function "previous error" (0A1) . . . . . . . . . . . . . . . 68

11.3 Function "clear last error" (0A2) . . . . . . . . . . . . . . . 68

11.6 Function "measured dist." (0A5) . . . . . . . . . . . . . . . 72

11.8 Function "detection window" (0A7)

(from Software 01.04.00) . . . . . . . . . . . . . . . . . . . . 73

6 Function group "linearisation" (04) . . 35

6.1 Function "level/ullage" (040) . . . . . . . . . . . . . . . . . 35

6.5 Function "input level" (044) . . . . . . . . . . . . . . . . . . 41

6.7 Function "max. scale" (046) . . . . . . . . . . . . . . . . . . 42

6.8 Function "diameter vessel" (047) . . . . . . . . . . . . . . 42

7 Function group "extended calibr." (05) .

43

7.1 Function "selection" (050) . . . . . . . . . . . . . . . . . . . 43

7.2 Function "check distance" (051) . . . . . . . . . . . . . . 43

7.3 Function "range of mapping" (052) . . . . . . . . . . . . 44

7.4 Function "start mapping" (053) . . . . . . . . . . . . . . . 44

7.5 Function "pres. map dist." (054) . . . . . . . . . . . . . . . 45

7.7 Function "echo quality" (056) . . . . . . . . . . . . . . . . 46

7.8 Function "offset" (057) . . . . . . . . . . . . . . . . . . . . . 47

7.9 Function "output damping" (058) . . . . . . . . . . . . . . 47

7.10 Function "blocking dist." (059) . . . . . . . . . . . . . . . 47

8 Function group "output" (06),

- "profibus param." (06), PROFIBUS-PA

only . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Function "commun. address" (060), HART only . . . 49

12 Function group "system parameters" (0C)

75

12.1 Function "tag no." (0C0) . . . . . . . . . . . . . . . . . . . . 75

12.2 Function "device tag" (0C0), FOUNDATION

Fieldbus only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.3 Function "Profile Version" (0C1),

PROFIBUS-PA only . . . . . . . . . . . . . . . . . . . . . . . . 75

12.4 Function "protocol+sw-no." (0C2) . . . . . . . . . . . . . 75

12.6 Function "device id" (0C4), FOUNDATION

Fieldbus only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.7 Function "distance unit" (0C5) . . . . . . . . . . . . . . . . 76

12.9 Function "download mode" (0C8) . . . . . . . . . . . . . 77

13 Function group "service" (0D). . . . . . . 79

13.1 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

14 Signal evaluation . . . . . . . . . . . . . . . . . 81

14.1 Envelope curve . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

15 Trouble shooting . . . . . . . . . . . . . . . . . 85

15.1 System error messages . . . . . . . . . . . . . . . . . . . . . . 85

Endress+Hauser 3

Page 4

Contents of the operating instructions Prosonic M

4 Endress+Hauser

Page 5

1 Notes on use

1Notes on use

You have various options for accessing the descriptions of instrument functions or how to enter

parameters.

1.1 Using the table of contents to locate a function description

All the functions are listed in the table of contents sorted by function group (e.g. basic setup,

safety settings, etc.). You can access a more detailed description of a function by using a page reference / link.

The table of contents is on ä 3.

1.2 Using the graphic of the function menu to locate a

function description

This guides you step by step from the highest level, the function groups, to the exact function

description you require.

All the available function groups and instrument functions are listed in the table ( ä 13). Select

your required function group or function. You can access an exact description of the function group

or function by using a page reference.

1.3 Using the index of the function menu to locate a

function description

To simplify navigation within the function menu, each function has a position which is shown in

the display. You can access each function via a page reference in the function menu index ( ä 91)

which lists all the function names alphabetically and numerically.

Endress+Hauser 5

Page 6

1 Notes on use

2

005

1

1.4 General structure of the operating menu

The operating menu is made up of two levels:

• Function groups (00, 01, 03, …, 0C, 0D):

The individual operating Selection of the instrument are split up roughly into different function

groups. The function groups that are available include, e.g.: "basic setup", "safety settings",

"output", "display", etc.

• Functions (001, 002, 003, …, 0D8, 0D9):

Each function group consists of one or more functions. The functions perform the actual operation

or parameterisation of the instrument. Numerical values can be entered here and parameters can

be selected and saved. The available functions of the “basic setup (00)” function group include,

e.g.: "tank shape (002)",

"medium property (003)", "process cond. (004)", "empty calibr. (005)", etc.

If, for example, the application of the instrument is to be changed, carry out the following procedure:

1. Select the “basic setup (00)” function group.

2. Select the "tank shape (002)" function (where the existing tank shape is selected).

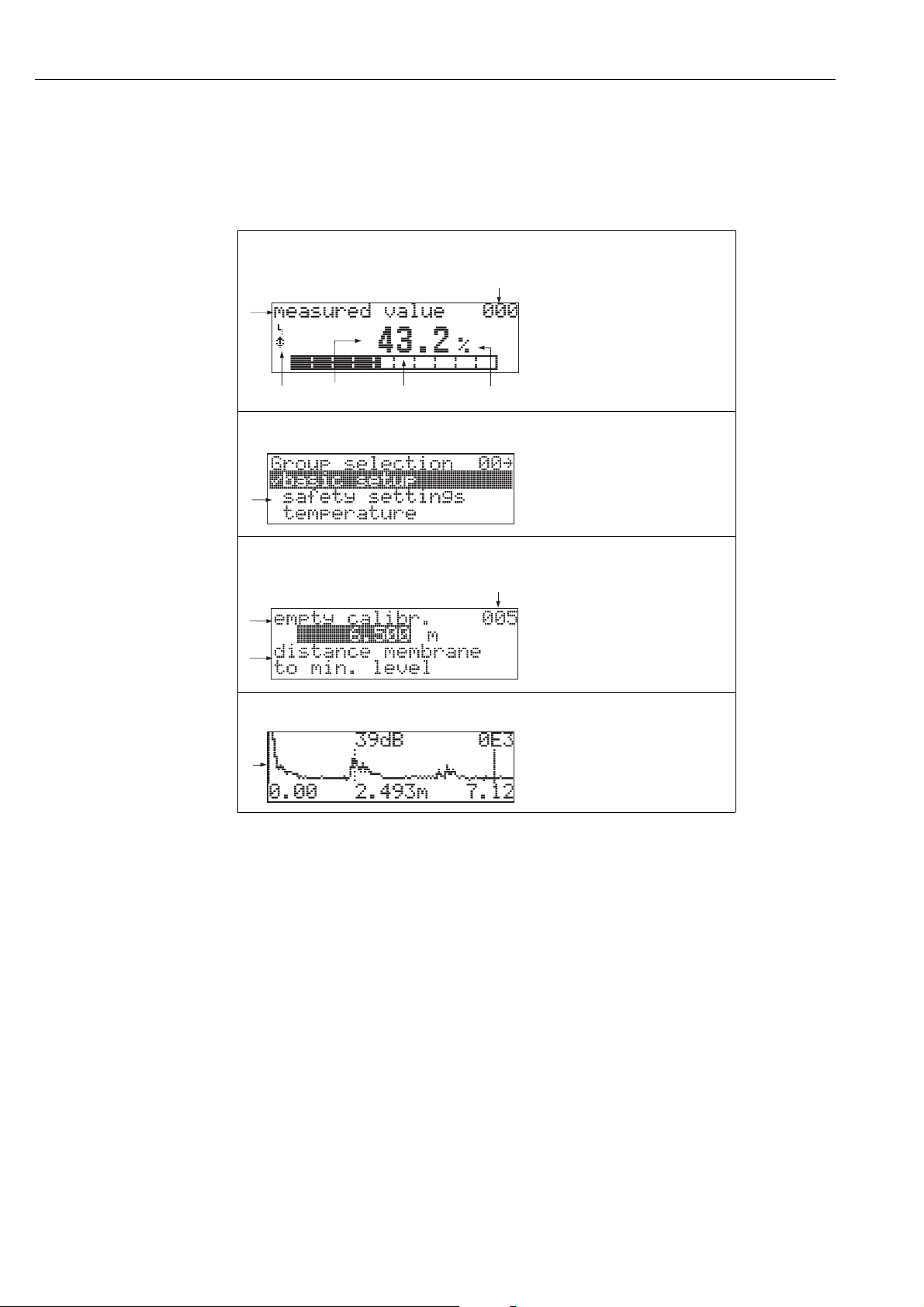

1.4.1 Identifying the functions

For simple orientation within the function menus ( ä 13), for each function a position is shown

on the display.

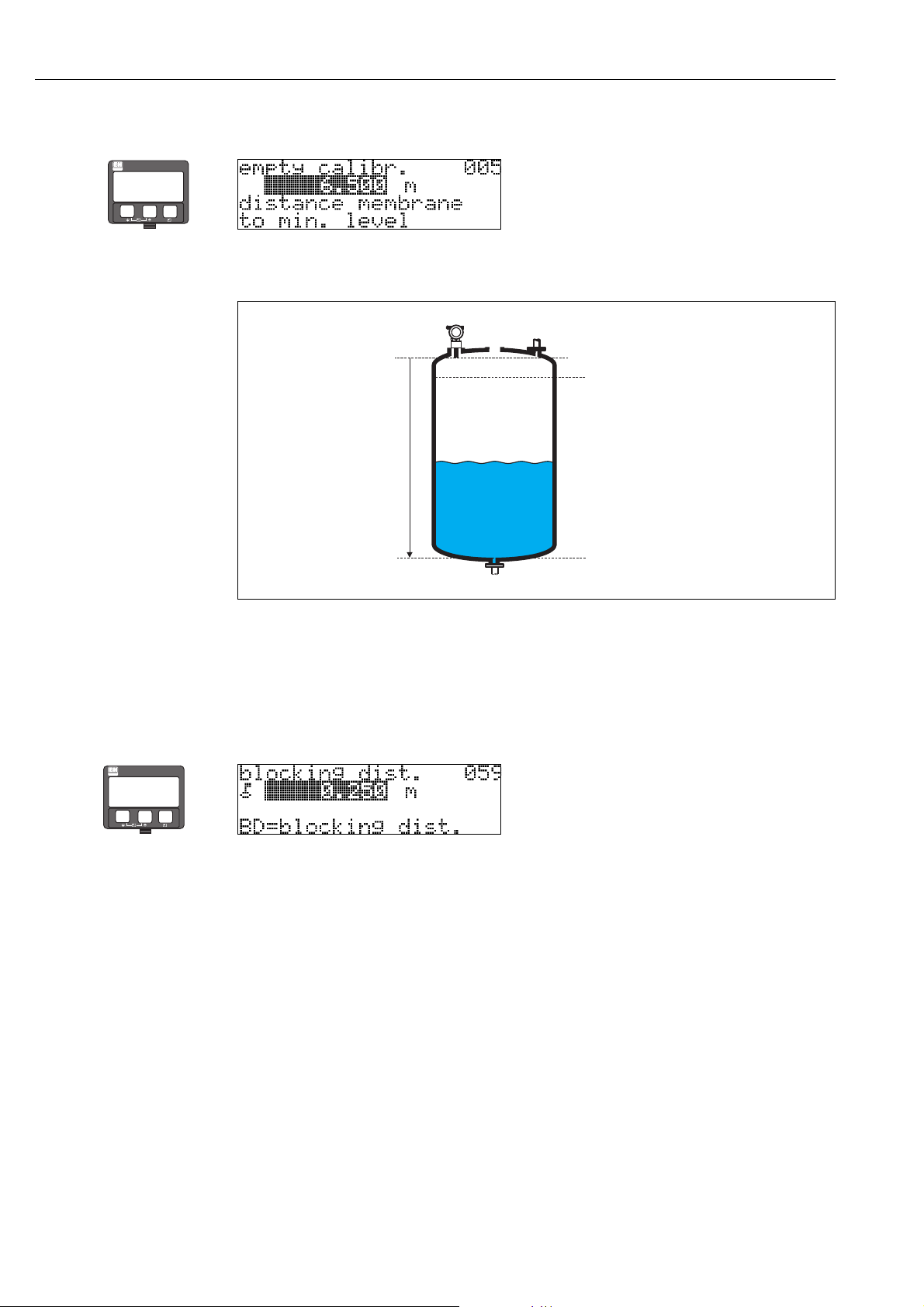

empty calibr. 005

6.500 m

distance membrane

to min. level

1 Function group

2 Function

The first two digits identify the function group:

•basic setup 00

• safety settings 01

• temperature 03

…

The third digit numbers the individual functions within the function group:

•basic setup 00 • tank shape 002

• medium property 003

• process cond. 004

…

Hereafter the position is always given in brackets (e.g. "tank shape" (002)) after the described

function.

6 Endress+Hauser

Page 7

1.5 Display and operating elements

ENDRESS + HAUSER

E

+

–

E

N

D

R

E

S

S

+

H

A

U

S

E

R

M

I

C

R

O

P

I

L

O

T

I

I

ENDR

ESS+HA

U

SER

MI

C

R

O

PIL

O

T I

I

I

P

6

5

I

P 6

5

O

r

d

e

r

C

o

d

e

:

S

e

r

.

N

o

.

:

Ord

e

r

C

od

e:

Ser.-No.:

M

e

s

s

b

e

re

ic

h

M

e

a

s

u

r

in

g

r

a

n

g

e

Mes

s

be

reic

h

Measuring ran

g

e

U

1

6

.

.

.

3

6

V

D

C

4

.

..

2

0

m

A

U

1

6..

.36

V

DC

4.

..20

mA

m

a

x

.

2

0

m

m

a

x

.

2

0 m

Made in Germany MaulburgMade in Germany Maulburg

T>

7

0

°

C

:

A

t

>

8

5

°

C

T>70

°

C :

A

t >8

5

°C

1

2

3

4

1 LCD liquid crystal display

2Snap fit

3Keys

4Symbols

1 Notes on use

L00-FMxxxxxx-07-00-00-yy-001

Endress+Hauser 7

Page 8

1 Notes on use

4

1

6

3

5

2

1

2

1

3

1

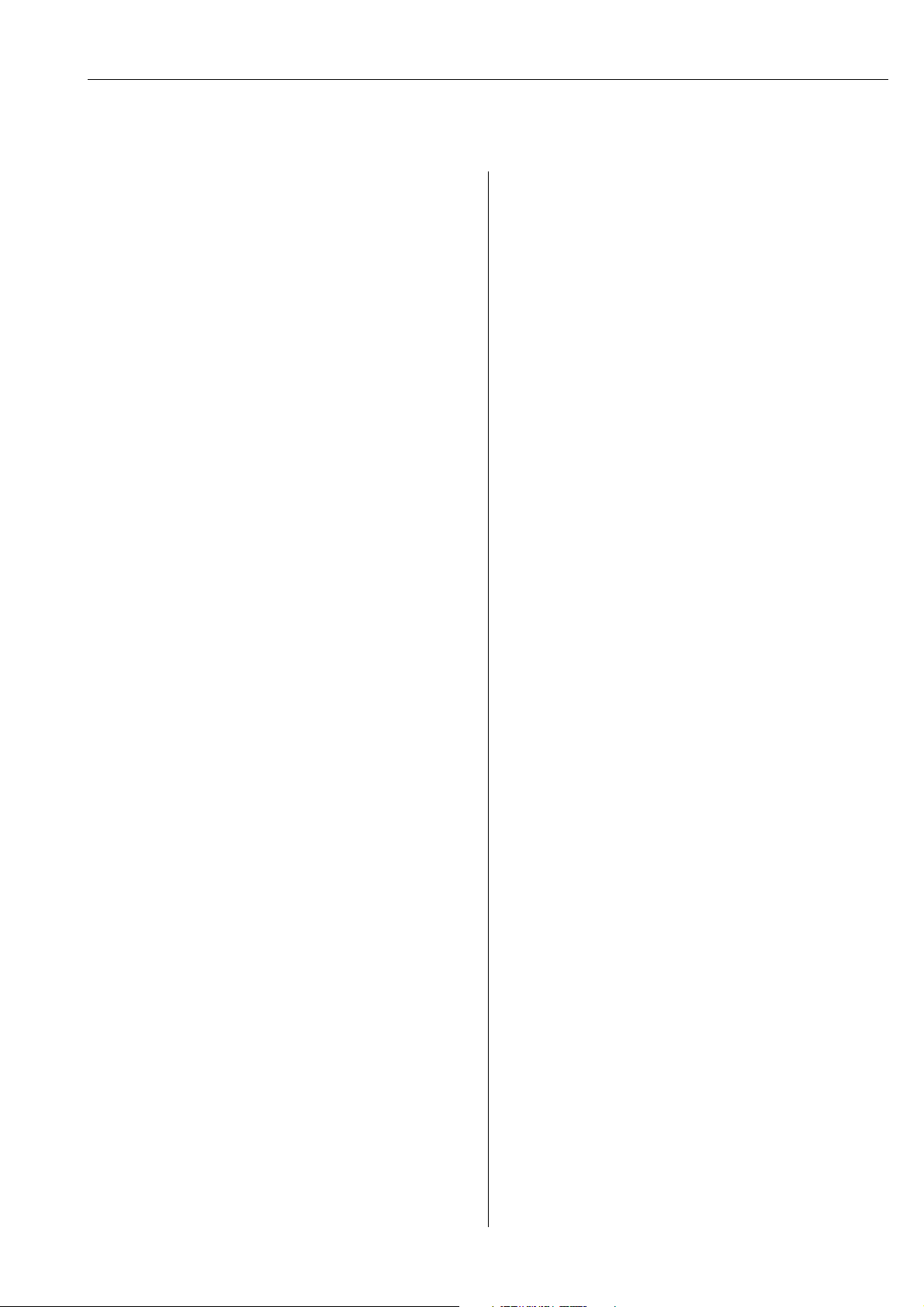

1.5.1 Display

Liquid crystal display (LCD):

Four lines with 20 characters each. Display contrast adjustable through key combination.

measured value display

1. label

2. symbol

3. value

4. bargraph

5. unit

6. position in menu

group selection

1. selection list

Function with free parameter

envelope curve

1. label

2. help texts

3. position in menu

1. envelope curve

8 Endress+Hauser

Page 9

1.5.2 Display symbols

The following table describes the symbols that appear on the liquid crystal display:

Symbols Meaning

ALARM_SYMBOL

This alarm symbol appears when the instrument is in an alarm state. If the symbol flashes, this indicates

a warning.

LOCK_SYMBOL

This lock symbol appears when the instrument is locked,i.e. if no input is possible.

COM_SYMBOL

This communication symbol appears when a data transmission via e.g. HART, PFOFIBUS-PA or FOUNDATION Fieldbus is in progress.

SIMULATION_SWITCH_ENABLE

*

This communication symbol appears when simulation in FF is enabled via the DIP switch.

1 Notes on use

1.5.3 Key assignment

The operating elements are located inside the housing and are accessible for operation by opening

the lid of the housing.

Function of the keys

Key(s) Meaning

O or V

S or W

X or Z

Navigate upwards in the selection list

Edit numeric value within a function

Navigate downwards in the selection list

Edit numeric value within a function

Navigate to the left within a function group

F or M Navigate to the right within a function group, confirmation.

O and F

or

Contrast settings of the LCD

S and F

Hardware lock / unlock

After a hardware lock, an operation of the instrument via display or

O and S and F

communication is not possible!

The hardware can only be unlocked via the display. An unlock parameter must

be entered to do so.

Endress+Hauser 9

Page 10

1 Notes on use

X

X

X

X

S

SS

O

OO

FF

>3 s

F

ENDRESS + HAUSER

E

+–

...

2x

...

...

unknown

liquid

solid<4mm

solid>4mm

Return to

Group Selection

basic setup

safety settings

temperature

linearisation

tank shape

dome ceiling

horizontal cyl

bypass

stilling well

flat ceiling

sphere

no ceiling

medium property

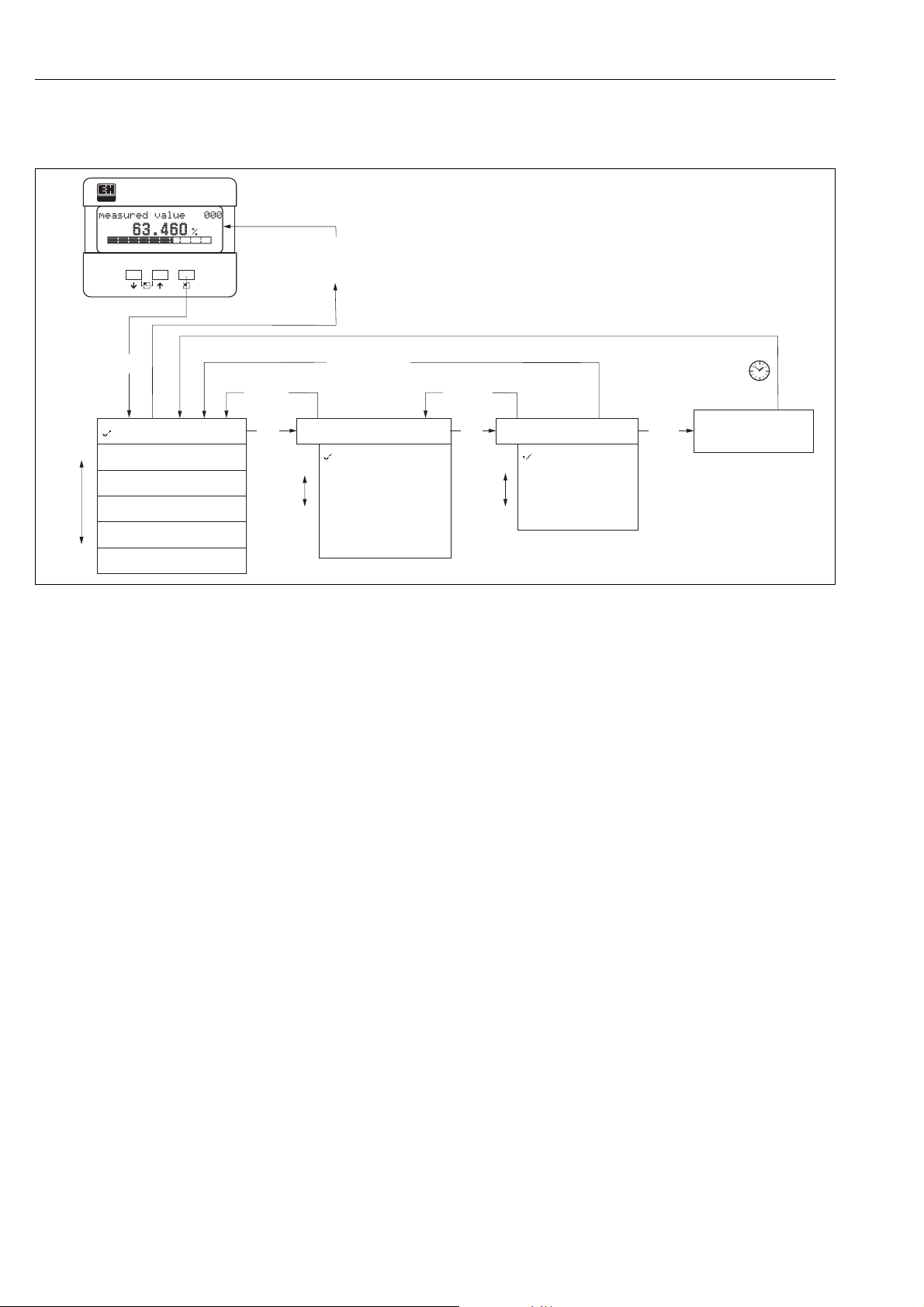

1.5.4 Operation with the VU331

1. Change from Measured Value Display to Group Selection by pressing F.

2. Press S or O to select the required Function Group and confirm by pressing F.

Note!The active selection is marked by a ✓ in front of the menu text.

3. Activate Edit mode with O or S .

Selection menus

a) Select the required Parameter in selected function with S oder O .

b) F confirms selection; ✓appears in front of the selected parameter.

c) F confirms the edited value; system quits edit mode.

d) O and S (= Q) interrupts selection; system quits edit mode.

Typing in numerals and text

a) Press O or S to edit the first character of the numeral / text.

b) F positions the cursor at the next character; continue with a. until you have completed your

input.

c) If a symbol appears at the cursor, press F to accept the value entered; system quits edit

mode.

d) If a symbol appears at the cursor, press F to return to the previous character (e.g. for

correction of entries).

e) O and S (= Q) interrupts selection; system quits edit mode.

4. Press F to select the next function.

5. Press O and S (= Q) once; return to previous function.

Press O and S (= Q) twice; return to Group Selection.

6. Press O and

S (= Q) to return to Measured value display.

10 Endress+Hauser

Page 11

1.6 Commissioning

ENDRESS + HAUSER

E

+

–

1.6.1 Switching on the measuring device

After switching on the supply voltage, the instrument is first initialised.

Then the following appear for approximately five seconds:

• Device type

•Software version

Press E to exit this display.

Select the language

(this message appears the first time the instrument is

switched on)

Select the basic unit

(this message appears the first time the instrument is

switched on)

1 Notes on use

The current measured value is displayed

After F is pressed, you reach the group selection.

This selection enables you to perform the basic setup

Endress+Hauser 11

Page 12

1 Notes on use

12 Endress+Hauser

Page 13

2 Function menu Prosonic M

2 Function menu Prosonic M

Function group Function Description

basic setup 00 measured value 000 Page 17

(see Page 17)

tank shape 002 Page 17

medium property 003 Page 18

process cond. 004 Page 18

empty calibr. 005 Page 20

blocking dist. 059 Page 20

full calibr. 006 Page 21

display 008 Page 21

check distance 051 Page 22

range of mapping 052 Page 23

start mapping 053 Page 23

display 008 Page 24

safety settings 01

(see Page 25)

temperature 03

(see Page 33)

linearisation 04

(see Page 35)

output on alarm 010 Page 25

output on alarm (HART only) 011 Page 27

outp. echo loss 012 Page 27

ramp %span/min 013 Page 28

delay time 014 Page 29

safety distance 015 Page 29

in safety dist. 016 Page 30

ackn. alarm 017 Page 32

measured temp. 030 Page 33

max. temp. limit 031 Page 33

max. meas. temp. 032 Page 33

react high temp. 033 Page 34

defect temp. sens. 034 Page 34

level/ullage 040 Page 35

linearisation 041 Page 36

customer unit 042 Page 40

table no. 043 Page 41

input level 044 Page 41

input volume 045 Page 42

max. scale 046 Page 42

diameter vessel 047 Page 42

extended calibr. 05

(see Page 43)

selection 050 Page 43

check distance 051 Page 43

range of mapping 052 Page 44

start mapping 053 Page 44

pres. map dist. 054 Page 45

cust. tank map 055 Page 46

echo quality 056 Page 46

offset 057 Page 47

output damping 058 Page 47

blocking dist. 059 Page 47

Endress+Hauser 13

Page 14

2 Function menu Prosonic M

Function group Function Description

output 06 commun. address (HART only) 060 Page 49

profibus param. 06

PROFIBUS-PA only

(see Page 49)

instrument addr. (PROFIBUS-PA only) 060 Page 49

no. of preambels (HART only) 061 Page 50

ident number (PROFIBUS-PA only) 061 Page 50

thres. main val. (HART only) 062 Page 51

set unit to bus (PROFIBUS-PA only) 062 Page 51

current output mode (HART only) 063 Page 52

out value (PROFIBUS-PA only) 063 Page 52

fixed cur. value (HART only) 064 Page 53

out status (PROFIBUS-PA only) 064 Page 53

simulation 065 Page 54

simulation value 066 Page 55

output current (HART only) 067 Page 56

2nd cyclic value (PROFIBUS-PA only) 067 Page 56

4 mA value (HART only) 068 Page 56

select v0h0 (PROFIBUS-PA only) 068 Page 57

20 mA value (HART only) Page 57

display value (PROFIBUS-PA only) 069 Page 57

envelope 0E

(see Page 59)

display 09

(see Page 63)

diagnostics 0A

(see Page 67)

plot settings 0E1 Page 59

recording curve 0E2 Page 59

envelope curve display 0E3 Page 60

language 092 Page 63

back to home 093 Page 63

format display 094 Page 64

no.of decimals 095 Page 64

sep. character 096 Page 64

display test 097 Page 65

present error 0A0 Page 68

previous error 0A1 Page 68

clear last error 0A2 Page 68

reset 0A3 Page 69

unlock parameter 0A4 Page 71

measured dist. 0A5 Page 72

measured level 0A6 Page 73

detection window 0A7 Page 73

application par. 0A8 Page 74

14 Endress+Hauser

Page 15

2 Function menu Prosonic M

system parameter 0C tag no. 0C0 Page 75

(see Page 75)

device tag (FOUNDATION Fieldbus only) 0C0 Page 75

Profile Version (PROFIBUS-PA only) 0C1 Page 75

protocol+sw-no. 0C2 Page 75

serial no. 0C4 Page 76

device id (FOUNDATION Fieldbus only) 0C4 Page 76

distance unit 0C5 Page 76

temperature unit 0C6 Page 77

download mode 0C8 Page 77

service D00

service level D00 Page 79

Endress+Hauser 15

Page 16

2 Function menu Prosonic M

16 Endress+Hauser

Page 17

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS+HAUSER

Prosonic M

ABC

DE

F

3 Function group "basic setup" (00)

3.1 Function "measured value" (000)

This function displays the current measured value in the selected unit

(see "customer unit" (042) function). The number of places after decimal point can be selected in

the "no.of decimals" (095) function.

3.2 Function "tank shape" (002)

This function is used to select the tank shape.

Selection

A: dome ceiling

B: horizontal cyl.

C: bypass, stilling well/ultrasonic guide pipe

D: no ceiling, e.g. dumps, open levels, chanels, weirs

E: sphere

F: flat ceiling

Endress+Hauser 17

Page 18

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

3.3 Function "medium property" (003)

This function is used to set the medium properties:

• unknown (e.g. pasty media such as greases, creams, gels etc.)

• liquid

• solid, grain size < 4mm (fine)

• solid, grain size > 4mm (coarse)

3.4 Function "process cond." (004)

This function is used to select the process conditions.

Selection:

standard liquids calm surface turb. surface

For all fluid applications which do not

fit in any of the following groups.

The filters and output damping are set

to average values.

Storage tanks with immersion tube or

bottom filling

The averaging filters and output

damping are set to large values.

-> Stable measured value

-> Accurate measurement

-> Slow reaction time

Storage / accumulation tanks with

uneven surface due to free filling,

mixing nozzles or small bottom stirrers

Special filters for stabilising the input

signal are activated.

-> Stable measured value

-> Medium reaction time

18 Endress+Hauser

Page 19

3 Function group "basic setup" (00)

ENDRESS+HAUSER

Prosonic M

add. agitator fast change standard solid

Moving surfaces (poss. with vortex

formation) due to agitators

Rapid level change, particularly in

small tanks

For all bulk solids applications which

do not fit in any of the following

groups.

Special filters for stabilising the input

signal are set to large values.

-> Stable measured value

-> Medium reaction time

The averaging filters are set to small

values.

-> Rapid reaction time

-> Possibly unstable measured value

The filter and output damping are set

to average values.

solid dusty conveyor belt Test: no filter

Dusty bulk solids Bulk solids with rapid level change All the filters can be switched off for

purposes of service and diagnosis.

The filters are set to detect even relatively weak signals.

The averaging filters are set to small

values.

All filters off

-> Rapid reaction time

-> Possibly unstable measured value

Endress+Hauser 19

Page 20

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

100%

0%

E

ENDRESS + HAUSER

E

+

–

3.5 Function "empty calibr." (005)

This function is used to enter the distance from the sensor membrane (reference point of the measurement) to the minimum level (=zero).

"

E: empty calibration

Caution!

For dish bottoms or conical outlets, the zero point should be no lower than the point at which the

radar beam hits the bottom of the tank.

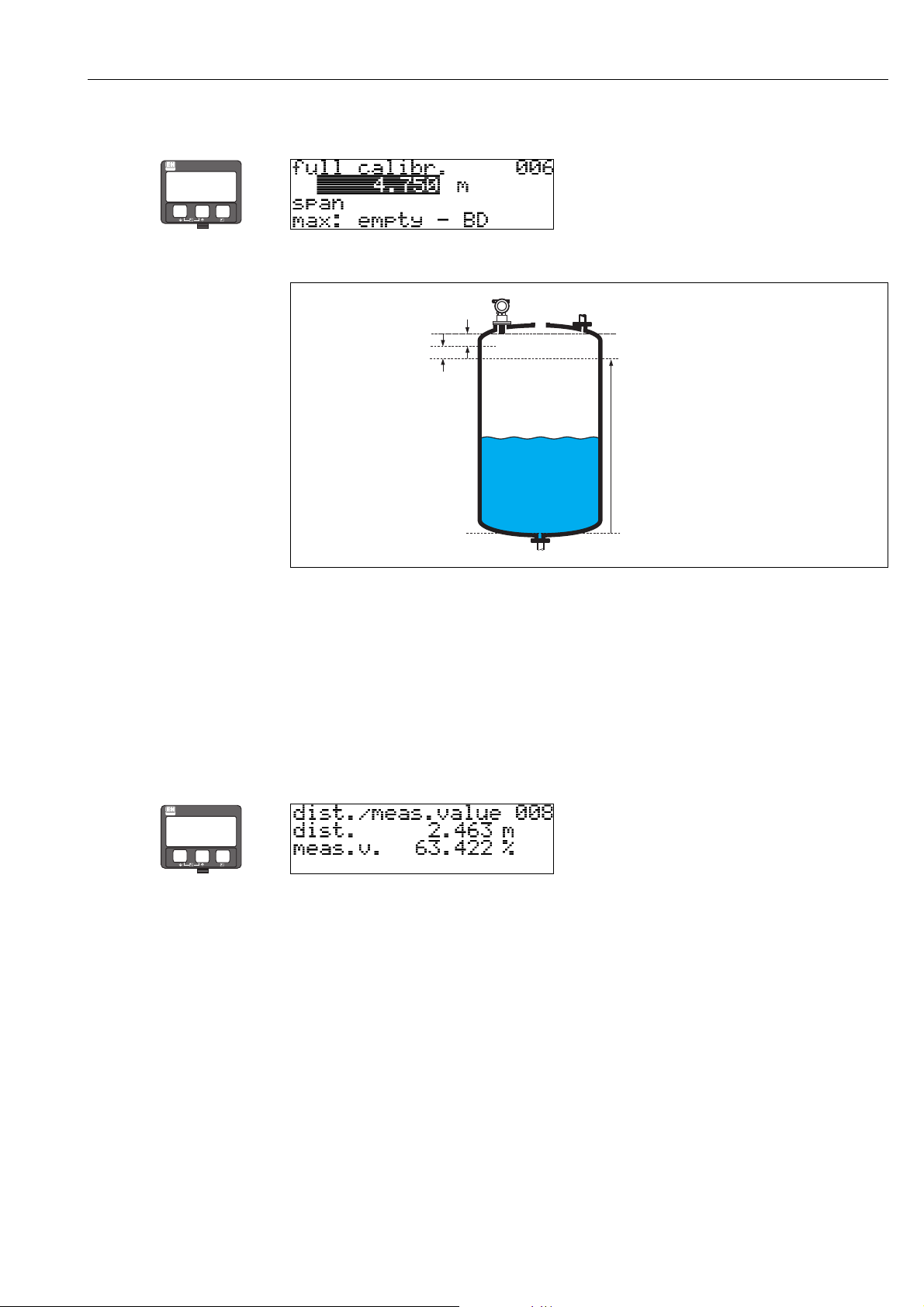

3.6 Function "blocking dist." (059)

In this function the blocking distance is displayed. Level echoes within the blocking distance can

not be detected by the Prosonic M. Make sure that the maximum level will never run into the blocking distance.

20 Endress+Hauser

Page 21

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

100%

0%

F

BD

SD

ENDRESS + HAUSER

E

+

–

3.7 Function "full calibr." (006)

This function is used to enter the distance from the minimum level to the maximum level (=span).

"

F: full calibration (span); BD: blocking distance; SD: safety distance

Caution!

The maximum level may not project into the blocking distance (BD). If the blocking distance is compromised, it may cause device malfunction.

After basic calibration, enter a safety distance (SD) in the "safety distance" (015) function. If the

level is within this safety distance, the Prosonic M signals a warning or an alarm, depending on your

selection in the "in safety distance" (016) function.

3.8 Display (008)

The distance measured from the sensor membrane to the product surface and the level calculated

with the aid of the empty calibration are displayed. Check whether the values correspond to the

actual level or the actual distance. The following cases can occur:

• Distance correct – level correct -> continue with the next function, "check distance" (051)

• Distance correct – level incorrect -> Check "empty calibr." (005)

• Distance incorrect – level incorrect -> continue with the next function, "check distance" (051)

Endress+Hauser 21

Page 22

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

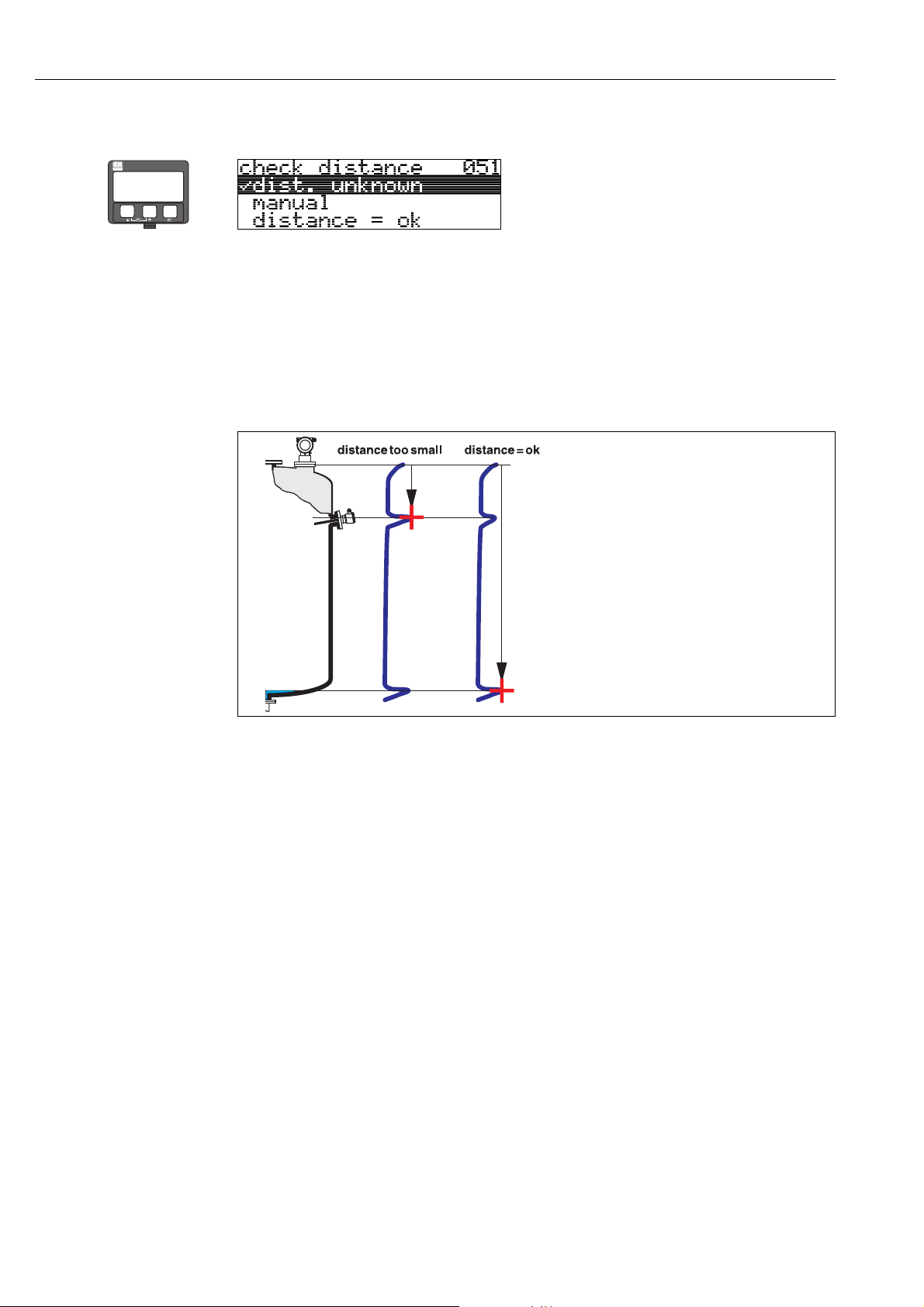

3.9 Function "check distance" (051)

This function triggers the mapping of interference echoes. To do so, the measured distance must be

compared with the actual distance to the product surface. The following options are available for

selection:

Selection:

•distance = ok

• dist. too small

• dist. too big

• dist. unknown

• manual

"

distance = ok

• mapping is carried out up to the currently measured echo

• The range to be suppressed is suggested in the "range of mapping (052)" function

Anyway, it is wise to carry out a mapping even in this case.

dist. too small

• At the moment, an interference is being evaluated

• Therefore, a mapping is carried out including the presently measured echoes

• The range to be suppressed is suggested in the "range of mapping (052)" function

dist. too big

• This error cannot be remedied by interference echo mapping

• Check the application parameters (002), (003), (004) and "empty calibr." (005)

dist. unknown

If the actual distance is not known, no mapping can be carried out.

manual

A mapping is also possible by manual entry of the range to be suppressed. This entry is made in the

"range of mapping (052)" function.

Caution!

The range of mapping must end 0.5 m (1.6 ft) before the echo of the actual level. For an empty tank,

do not enter E, but E – 0.5 m (1.6 ft).

22 Endress+Hauser

Page 23

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

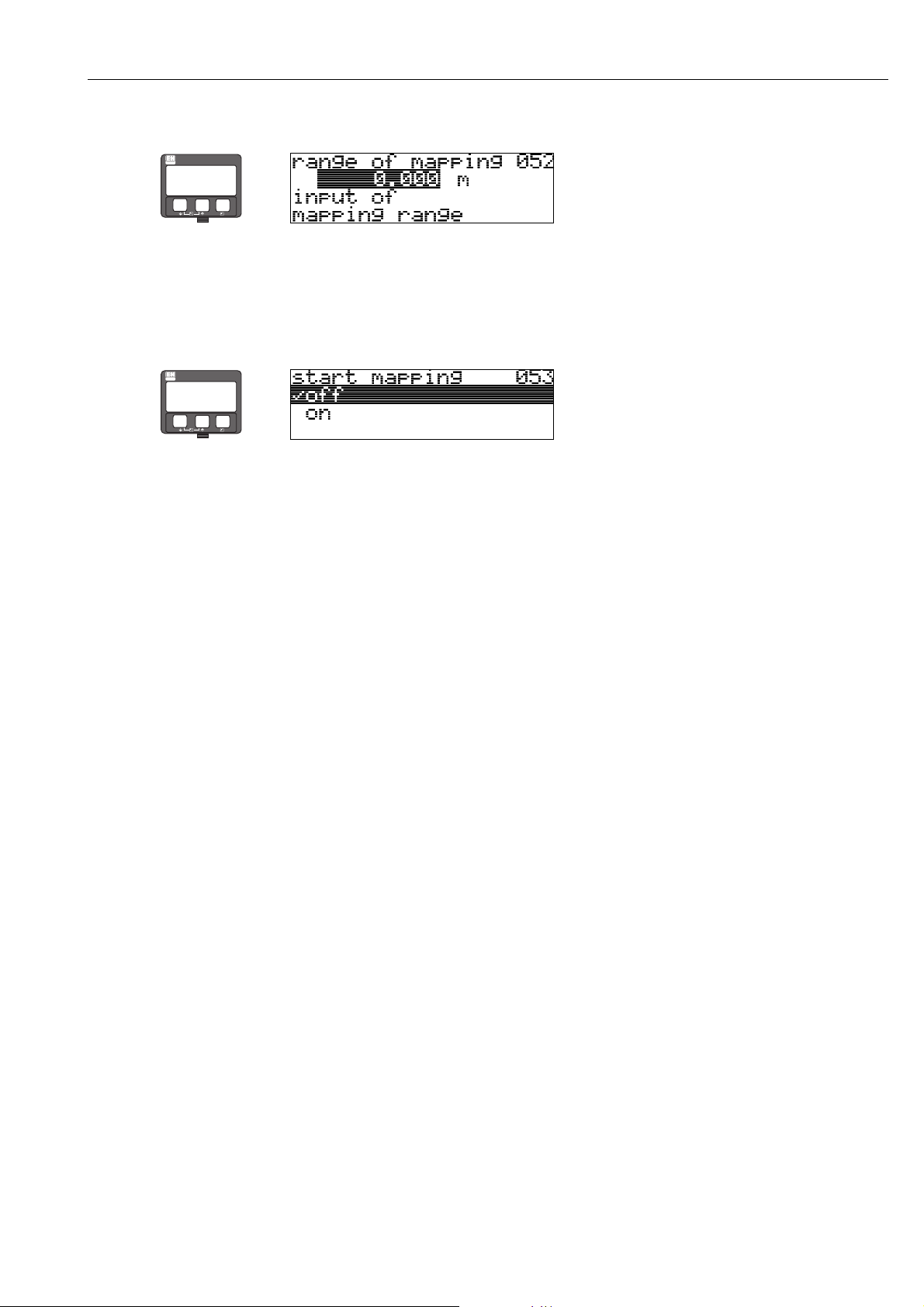

3.10 Function "range of mapping" (052)

This function displays the suggested range of mapping. The reference point is always the sensor

membrane. This value can be edited by the operator.

For manual mapping, the default value is: 0 m.

3.11 Funktion "start mapping" (053)

This function is used to start the interference echo mapping up to the distance given in "range of

mapping" (052).

!

Selection:

• off: no mapping is carried out

• on: mapping is started

Note!

If a mapping already exists, it is overwriten up to the distance specified in

"range of mapping" (052). Beyond this value the existing mapping remains unchanged.

Endress+Hauser 23

Page 24

3 Function group "basic setup" (00)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

3.12 Display (008)

The distance measured from the reference point to the product surface and the level calculated with

the aid of the empty alignment are displayed again. Check whether the values correspond to the

actual level or the actual distance. The following cases can occur:

• Distance correct – level correct -> basic setup completed

• Distance incorrect – level incorrect -> a further interference echo mapping must be carried out

• Distance correct – level incorrect -> check "empty calibr." (005)

"check distance"(051).

!

Note!

After the basic setup, an evaluation of the measurement with the aid of the envelope curve

("display" (09) function group) is recommended.

After 3 s, the following message appears

24 Endress+Hauser

Page 25

4 Function group "safety settings" (01)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

(110%)

(-10%)

3.6

(2.4)

t

[mA]

22

-99999

t

HART PROFIBUS-PA

4 Function group "safety settings" (01)

4.1 Function "output on alarm" (010)

This function is used to select the reaction of the device on an alarm.

Selection:

• MIN (<= 3.6mA)

• MAX (22mA)

•hold

• user specific

MIN (<= 3.6 mA)

If the instrument is in alarm state, the output changes as follows:

• HART:MIN-Alarm 3.6 mA (2.4 mA for four-wire instruments)

• PROFIBUS-PA:MIN-Alarm -99999

Endress+Hauser 25

Page 26

4 Function group "safety settings" (01)

HART PA / FF

(110%)

(-10%)

3.6

t

[mA]

22

-10 %

110 %

t

MAX (22mA)

If the instrument is in alarm state, the output changes as follows:

• HART:MAX-Alarm 22 mA

• PROFIBUS-PA:MAX-Alarm +99999

hold

If the instrument is in alarm state, the last measured value is held.

user specific

If the instrument is in an alarm state, the output is set to the value configured in "output on alarm"

(011) (x mA).

Caution!

"

This selection is available for HART devices only!

26 Endress+Hauser

Page 27

"

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

4 Function group "safety settings" (01)

4.2 Function "output on alarm" (011), HART only

fl

The current (in mA) which will be output in case of an alarm. This function is active when you

selected "user specific" in the "output on alarm" (010) function.

Caution!

This function is available for HART devices only!

4.3 Function "outp. echo loss" (012)

Use this function to set the output response on echo loss.

Selection:

•alarm

•hold

• ramp %/min

alarm

On echo loss, the instrument switches to alarm state after an adjustable "delay time" (014). The

output response depends on the configuration set in "output on alarm" (010).

hold

Endress+Hauser 27

Page 28

4 Function group "safety settings" (01)

ENDRESS + HAUSER

E

+

–

On echo loss, a warning is generated after a definable "delay time" (014). Output is held.

ramp %/min

On echo loss, a warning is generated after a definable "delay time" (014). The output is changed

towards 0% or 100% depending on the slope defined in "ramp %span/min" (013).

4.4 Function "ramp %span/min" (013)

Ramp slope which defines the output value on echo loss. This value is used if "ramp %span/min"

is selected in "outp. echo loss" (012). The slope is given in % of the measuring range per minute.

28 Endress+Hauser

Page 29

4 Function group "safety settings" (01)

ENDRESS + HAUSER

E

+

–

safety distance

(SD)

blocking dist.

(BD)

ENDRESS + HAUSER

E

+

–

4.5 Function "delay time" (014)

Use this function to enter the delay time (Default = 60 s) after which a warning is generated on echo

loss, or after which the instrument switches to alarm state.

4.6 Function "safety distance" (015)

A configurable safety distance is placed before the "blocking dist." (059) ( ä 47). This distance

warns you that any further level increase would make the measurement invalid, because the blocking distance would be compromised.

Enter the size of the safety distance here. The default value is: 0.1 m.

Endress+Hauser 29

Page 30

4 Function group "safety settings" (01)

ENDRESS + HAUSER

E

+

–

4.7 Function "in safety dist." (016)

This function defines the response when the level enters the safety distance .

Selection:

•alarm

• warning

• self holding

alarm

Instrument enters the defined alarm state ("output on alarm" (011)). The alarm message E651 -

"level in safety distance - risk of overspill" is displayed.

If the level drops out of the safety distance, the alarm warning disappears and the instrument starts

to measure again.

warning

Instrument displays a warning E651 -"level in safety distance - risk of overspill", but contin-

ues to measure. If the level leaves the safety distance, the warning disappears.

30 Endress+Hauser

Page 31

4 Function group "safety settings" (01)

self holding

Instrument switches to defined alarm state ("output on alarm" (011)). The alarm message E651 -

"level in safety distance - risk of overspill" is displayed.

If the level leaves the safety distance, the measurement continues only after a reset of the self holding (function: "ackn. alarm" (017)).

Endress+Hauser 31

Page 32

4 Function group "safety settings" (01)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

4.8 Function "ackn. alarm" (017)

This function acknowledges an alarm in case of "self holding".

Selection:

•no

• yes

no

The alarm is not acknowledged.

yes

Acknowledgement takes place.

After 3 s, the following message appears

32 Endress+Hauser

Page 33

5 Function group "temperature" (03)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

5 Function group "temperature" (03)

5.1 Function "measured temp." (030)

In this function the temperature at the sensor is displayed. The temperature unit is determined by

the function "temperature unit" (0C6).

5.2 Function "max. temp. limit" (031)

In this function the maximum permitted temperature of the sensor is displayed. The temperature

unit is determined by the function "temperature unit" (0C6). If this temperature is exceeded, the

sensor may become damaged.

5.3 Function "max. meas. temp." (032)

In this function the maximum temperature, which has ever been measured at the senosr, is displayed. The temperature unit is determined by the function "temperature unit" (0C6). This function is not influenced by a reset of the parameters.

Endress+Hauser 33

Page 34

5 Function group "temperature" (03)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

5.4 Function "react high temp." (033)

In this function you determine, how the Prosonic M will react if the maximum permitted temperature of the sensor is exceeded.

You may choose one of the following options:

Warning

The instrument continues measuring. An error message is displayed.

Alarm

The current output adopts the value defined in the funcion "output on alarm" (010). Additionally

an error message is displayed.

5.5 Function "defect temp. sens." (034)

In this function you determine, how the Prosonic M will react, if the maximum permitted temperature of the sensor is exceeded.

You may choose one of the following options:

Alarm

The current output adopts the value defined in the funcion "output on alarm" (010). Additionally

an error message is displayed.

Warning

The instrument continues measuring. An error message is displayed.

34 Endress+Hauser

Page 35

6 Function group "linearisation" (04)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

6.1 Function "level/ullage" (040)

Selection:

• level CU

• level DU

• ullage CU

• ullage DU

level CU

Level in customer units. The measured value can be linearised.

The "linearisation" (041) default value is set to a linear 0...100%.

6 Function group "linearisation" (04)

!

level DU

Level in the selected "distance unit" (0C5).

ullage CU

Ullage in customer units. The value can be linearised.

The "linearisation" (041) default value is set to a linear 0...100%.

ullage DU

Ullage in the selected "distance unit" (0C5).

Note!

Reference point for the ullage is "full calibr." (=span).

Endress+Hauser 35

Page 36

6 Function group "linearisation" (04)

ENDRESS + HAUSER

E

+

–

100%

20

mA

0%

4

mA

kg, m3,ft3, ... = customer unit (042)

max.scale

(046)

6.2 Function "linearisation" (041)

Linearisation defines the ratio of level to container volume or product weight and allows a measurement in customer units, e.g. metres, hectolitres etc. The measured value in (000) is then displayed

in the selected unit.

This function is used to select the linearisation modes.

Selection:

• linear

• horizontal cyl

• manual

• semi-automatic

•table on

•clear table

linear

The tank is linear e.g. a cylindrical vertical tank. You can measure in customer units by entering a

maximum volume/weight.

You can select the "customer unit" (042). Define the volume value corresponding to the calibra-

tion in "max. scale" (046). This value corresponds to an output of 100% (= 20 mA for HART).

36 Endress+Hauser

Page 37

6 Function group "linearisation" (04)

100%

20

mA

0%

4

mA

kg, m3,ft3, ... = customer unit (042)

max.scale

(046)

diameter vessel (047)

100%

20

mA

0%

4

mA

(2)

(4)

(3)

kg, m3,ft3, ... = customer unit (042)

horizontal cyl

The volume, mass etc. are calculated automatically in cylindrical horizontal tanks by entering the

"diameter vessel" (047), the "customer unit" (042) and the "max. scale" (046). The

"max. scale" (046) corresponds to an output of 100% (= 20 mA for HART).

manual

If the level is not proportional to the volume or weight within the set measuring range, you can enter

a linearisation table in order to measure in customer units. The requirements are as follows:

• The 32 (max.) value pairs for the linearisation curve points are known.

• The level values must be given in ascending order. The curve is monotonously increasing.

• The level heights for the first and last points on the linearisation curve correspond to empty and

full calibration respectively.

• The linearisation takes place in the basic setup unit ("distance unit" (0C5)).

Endress+Hauser 37

Each point (2) in the table is described by a value pair: level (3) and, for example, volume (4). The

last value pair defines the 100% output (= 20 mA for HART).

!

Note!

The manual linearisation mode can also be used for flow measurements. To do this, simply enter

the respective flow level (instead of the volume) into the table. You can find the appropriate flow

values in the Q/h table of your channel or weir.

Page 38

6 Function group "linearisation" (04)

ENDRESS + HAUSER

E

+

–

fl

Select the table point (Point 1).

fl

Enter the level belonging to Point 1.

fl

Enter the corresponding volume.

fl

!

!

Enter a further table point?

fl

Next table point.

fl

Continue until "

Note!

After making entries into the table, activate it with "table on".

The 100% value (=20 mA for HART) is defined by the last point in the table.

Note!

Before confirming 0.00 m as the level or 0.00% as the volume, activate the Edit mode with

Entries can be made into the linearisation table in FieldCare using the table editor.

You can also display the contents graphically.

next point" (045) is answered with

...

no.

O or S.

38 Endress+Hauser

Page 39

6 Function group "linearisation" (04)

semi-automatic

The tank is filled in stages when the linearisation curve is entered semi-automatically. The

Prosonic M automatically detects the level and the corresponding volume/weight has to be entered.

The procedure is similar to manual table entry, where the level value for each table point is given

automatically by the instrument.

!

!

Note!

If the tank is emptied (out litres), pay attention to the following points:

• The number of points must be known in advance.

• The first table number = (32 - number of points).

•Entries in "Tab. no." (043) are made in reverse order (last entry = 1).

table on

An entered linearisation table only becomes effective when activated.

clear table

Before making entries into the linearisation table, any existing tables must be deleted. The linearisation mode automatically switches to linear.

Note!

A linearisation table can be deactivated by selecting "linear" or "horizontal cyl" (or the "level/

ullage" (040) function = "level DU", "ullage DU"). It is not deleted and can be reactivated at any

time by selecting "table on".

Endress+Hauser 39

Page 40

6 Function group "linearisation" (04)

ENDRESS + HAUSER

E

+

–

6.3 Function "customer unit" (042)

You can select the customer unit with this function.

Selection:

•%

• Volume: l, hl, m3,

• Weight: kg, t, lb, ton

• Length: m, ft, mm, inch

• Flow: l/s, l/min, l/h, m3/s, m3/min, m3/h, ft3/s, gal/s, gal/m, gal/hr, mgal/d, igal/s, igal/

Dependence

The units of the following parameters are changed:

• measured value (000)

• input volume (045)

• max. scale (046)

• simulation value (066)

min, igal/h

dm3, cm3, ft3, usgal, i gal

40 Endress+Hauser

Page 41

6.4 Function "table no." (043)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

Position of the value pair in the linearisation table.

6 Function group "linearisation" (04)

Dependence

Updates "input level" (044) , "input volume" (045).

6.5 Function "input level" (044)

You can enter the level for each point of the linearisation curve with this function. When the linearisation curve is entered semi-automatically, Micropilot detects the level automatically.

User input:

Level in "distance unit" (0C5).

Endress+Hauser 41

Page 42

6 Function group "linearisation" (04)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

6.6 Function "input volume" (045)

Specify the volume for each point of the linearisation curve with this function.

User input:

Volume in "customer unit" (042).

6.7 Function "max. scale" (046)

You can enter the end value of the measuring range with this function. This input is necessary if you

selected "linear" or "horizontal cyl" in the "linearisation" (041) function.

6.8 Function "diameter vessel" (047)

Enter the tank diameter with this function. This entry is necessary if you selected "horizontal cyl"

in the "linearisation" (041) function.

42 Endress+Hauser

Page 43

7 Function group "extended calibr." (05)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

7 Function group "extended calibr." (05)

7.1 Function "selection" (050)

Select the function of the extended calibration.

Selection:

• common

leads to the functions "echo quality" (056), "offset" (057), "output damping" (058) and

"blocking distance" (059)

•mapping

leads to the functions for an interference echo suppression (tank map): (051) ... (053)

• extended map

leads to the functions " pres. map. dist." (054) and "cust. tank map" (055)

7.2 Function "check distance" (051)

This function triggers the mapping of interference echoes. To do so, the measured distance must be

compared with the actual distance to the product surface. The following options are available for

selection:

Selection:

•distance = ok

• dist. too small

• dist. too big

• dist. unknown

• manual

Endress+Hauser 43

Page 44

7 Function group "extended calibr." (05)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

distance = ok

• mapping is carried out up to the currently measured echo

• The range to be suppressed is suggested in the "range of mapping (052)" function

Anyway, it is wise to carry out a mapping even in this case.

dist. too small

• At the moment, an interference is being evaluated

• Therefore, a mapping is carried out including the presently measured echoes

• The range to be suppressed is suggested in the "range of mapping (052)" function

dist. too big

• This error cannot be remedied by interference echo mapping

• Check the application parameters (002), (003), (004) and "empty calibr." (005)

dist. unknown

If the actual distance is not known, no mapping can be carried out.

manual

A mapping is also possible by manual entry of the range to be suppressed. This entry is made in the

"range of mapping (052)" function.

"

Caution!

The range of mapping must end 0.5 m (1.6 ft) before the echo of the actual level. For an empty tank,

do not enter E, but E – 0.5 m (1.6 ft).

7.3 Function "range of mapping" (052)

This function displays the suggested range of mapping. The reference point is always the sensor

membrane. This value can be edited by the operator.

For manual mapping, the default value is: 0 m.

7.4 Function "start mapping" (053)

This function is used to start the interference echo mapping up to the distance given in "range of

mapping" (052).

Selection:

• off: no mapping is carried out

• on: mapping is started

Caution!

"

44 Endress+Hauser

If a mapping already exists, it is overwriten up to the distance specified in

"range of mapping" (052). Beyond this value the existing mapping remains unchanged.

Page 45

7.5 Function "pres. map dist." (054)

ENDRESS + HAUSER

E

+

–

Displays the distance up to which a mapping has been recorded.

A value of 0 indicates that no mapping was recorded so far.

7 Function group "extended calibr." (05)

Endress+Hauser 45

Page 46

7 Function group "extended calibr." (05)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

20 mA

100%

4 mA

0%

echo quality (056)

7.6 Function "cust. tank map" (055)

This function displays the evaluation mode using the customer tank map.

Selection:

• inactive

• active

• reset

inactive

No tank mapping has been recorded, or map is switched off. Evaluation is only using FAC

( ä 83).

active

Evaluation is using the customer tank map ( ä 82).

reset

Deletes the complete tank map.

7.7 Function "echo quality" (056)

The echo quality is the benchmark for measurement reliability. It describes the amount of reflected

energy and depends primarily on the following conditions:

• Surface characteristics (waves, foam etc.)

• Distance between sensor and product

Low values increase the probability that the echo is lost through a change in measurement conditions, e.g. turbulent surface, foam, large measuring distance.

46 Endress+Hauser

Page 47

7 Function group "extended calibr." (05)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

7.8 Function "offset" (057)

This function corrects the measured level by a constant value. The entered value is added to the

measured level.

7.9 Function "output damping" (058)

Influences the time an output requires to react to a sudden level jump (63% of steady state). A high

value attenuates, for example, the influences of rapid changes on the measured variable.

User input:

0...255 s

The default value depends on the selected application parameters "tank shape" (002),

"medium property" (003) and "process cond." (004).

7.10 Function "blocking dist." (059)

In this function the blocking distance is displayed. Level echoes within the blocking distance can

not be detected by the Prosonic M. Make sure that the maximum level will never run into the blocking distance.

After 3 s, the following message appears

Endress+Hauser 47

Page 48

7 Function group "extended calibr." (05)

48 Endress+Hauser

Page 49

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8 Function group "output" (06),

- "profibus param." (06), PROFIBUS-PA only

Display at HART and FOUNDATION Fieldbus

instrument

Display at PROFIBUS-PA instrument

8.1 Function "commun. address" (060), HART only

Enter the communication address for the instrument with this function.

• Standard: 0

• Multidrop: 1-15

The output current is constant at 4mA in multidrop mode.

"

"

Caution!

This function is available for HART devices only!

8.2 Function "instrument addr." (060),

PROFIBUS-PA only

The PA bus address is displayed in this field. The address is set either directly on the instrument

using DIP switches (see instrument operating instructions) or using a special SetSlaveAddress command via the bus, e.g. by the FieldCare.

Caution!

This function is available for PROFIBUS-PA devices only!

Endress+Hauser 49

Page 50

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8.3 Function "no. of preambels" (061), HART only

Enter the number of preambles for the HART protocol with this function.

An increase in the value is advisable for "bad" lines with communications problems.

Caution!

"

This user input is available for HART devices only!

8.4 Function "ident number" (061), PROFIBUS-PA only

• manufacturer

• profile

"

manufacturer

Set to152C hex according to manufacturer (PNO registered).

profile

Setting defined as in PA Profile 3.0: 9700 hex - instrument with one AI block.

Caution!

This function is available for PROFIBUS-PA devices only!

50 Endress+Hauser

Page 51

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8.5 Function "thres. main val." (062), HART only

The output of negative level values can be suppressed with this function.

Selection:

• off:minimum output -10% (3.8 mA for HART)

•on:minimum output 0% (4 mA for HART)

"

"

Caution!

This user input is available for HART devices only!

8.6 Function "set unit to bus" (062), PROFIBUS-PA only

•confirm

After confirming this function, the unit of the measured variable is taken over in

the AI block (PV scale -> Out scale).

This function must always be executed after changing the unit.

Caution!

This function is available for PROFIBUS-PA devices only!

Endress+Hauser 51

Page 52

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

[mA]

20

[mA]

20

4

100 [%]0

4

100 [%]0

curr. turn down

fixed current

standard

ENDRESS + HAUSER

E

+

–

8.7 Function "curr. output mode" (063), HART only

In this function you specify the mode of the current output.

You may choose one of the following options:

"

standard

The total measuring range (0 ... 100%) will be mapped to the current intervall

(4 ... 20 mA).

curr. turn down

Only a part of the measuring range will be mapped to the current intervall

(4 ... 20 mA).

Use the functions "4-mA-value" (068) and "20-mA-value" (069) to define the concerning

range.

fixed current

The current is fixed. The measured value is transmitted by the HART signal only. The value of the

current is defined in the "fixed current" (064) function.

Caution!

This function is active for HART devices only.

8.8 Function "out value" (063), PROFIBUS-PA only

This displays the AI block output.

Caution!

"

52 Endress+Hauser

This function is available for PROFIBUS-PA devices only!

Page 53

"

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

8.9 Function "fixed cur. value" (064), HART only

Set the fixed current value with this function. This entry is necessary when you have switched on

the "fixed current" (063) function.

User input:

3,8...20,5 mA

Caution!

This user input is available for HART devices only!

8.10 Function "out status" (064), PROFIBUS-PA only

"

Displays the current output status (for value, see operating instructions of relevant instrument).

Caution!

This function is available for PROFIBUS-PA devices only!

Endress+Hauser 53

Page 54

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

D

A

4...20 mA

0...100%

ENDRESS + HAUSER

E

+

–

sim. level

sim. volume

sim. current (HART only)

8.11 Function "simulation" (065)

If necessary, linearisation, the output signal and the current output can be tested with the simulation

function. You have the following simulation options:

Selection:

• sim. off

• sim. level

• sim. volume

• sim. current (HART only)

sim. off

Simulation is switched off.

sim. level

Enter the level value in "simulation value" (066).

The functions

• measured value (000)

• measured level (0A6)

• output current" (067) - only with HART instruments!

follow the entered values.

sim. volume

Enter the volume value in "simulation value" (066).

The functions

• measured value (000)

• output current" (067) - only with HART instruments!

follow the entered values.

sim. current (HART only)

Enter the current value in "simulation value" (066).

The function

• output current" (067) - only with HART instruments!

follows the entered values.

54 Endress+Hauser

Page 55

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8.12 Function "simulation value" (066)

After selecting the "sim. level" option in the "simu-

lation

" (065) function, the following message

appears in the display: you can enter the level.

After selecting the "sim. volume" option in the

"

simulation" (065) function, the following message

appears in the display: you can enter the volume.

After selecting the "sim. current" option in the

"

simulation" (065) function, the following message

appears in the display: Enter the output current (only for

HART instruments).

Endress+Hauser 55

Page 56

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8.13 Function "output current" (067), HART only

Displays the output current in mA.

Caution!

"

This function is available for HART devices only!

8.14 Function "2nd cyclic value" (067),

PROFIBUS-PA only

"

Selects the second cyclical value.

• height/dist.

•temperature

The Prosonic M always transmits the distance as the second cyclical value.

Caution!

This function is available for PROFIBUS-PA devices only!

8.15 Function "4mA-value" (068), HART only

In this function specify the level (or volume, weight, flow resp.), at which the output current should

be 4 mA. This value will be used if you choose the option "curr. turn down" in the "current output

mode" (063) function.

56 Endress+Hauser

Page 57

"

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

8.16 Function "select v0h0" (068), PROFIBUS-PA only

Selects the value displayed in "measured value" (000).

Selection:

• measured value

• display value

measured value The configured measured value is displayed in the "measured value" (000) function.

display value

The value in "display value" (069) is displayed in the "measured value" (000) function.

Caution!

This function is available for PROFIBUS-PA devices only!

"

8.17 Function "20mA-value" (069), HART only

In this function specify the level (or volume, weight, flow resp.), at which the output current should

be 20 mA. This value will be used if you choose the option "curr. turn down" in the "current out-

put mode" (063) function.

8.18 Function "display value" (069), PROFIBUS-PA only

This field can be set externally, e.g. from a PLC. The value is then displayed as the main measured

variable in the display by selecting the "select v0h0" (068) = "display value" function.

Caution!

This function is available for PROFIBUS-PA devices only!

Endress+Hauser 57

Page 58

8 Function group "output" (06), - "profibus param." (06), PROFIBUS-PA only

58 Endress+Hauser

Page 59

9 Function group "Envelope curve" (0E)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

9 Function group "Envelope curve" (0E)

9.1 Function "plot settings" (0E1)

Here select which information is displayed in the LCD:

• envelope curve

• env.curve+FAC (on FAC see ä 83)

• env.curve+cust.map (i.e. customer tank map is also displayed, see ä 82)

!

9.2 Function "recording curve" (0E2)

This function defines whether the envelope curve is read as a

• single curve

or

• cyclic.

Note!

If the cyclical envelope curve is active in the display, the measured variable is refreshed in a slower

cycle time. It is therefore recommended to exit the envelope curve display after optimising the

measuring point.

Endress+Hauser 59

Page 60

9 Function group "Envelope curve" (0E)

minimum distance

of the plot

maximum distance

of the plot

distance of

evaluated echo

interference echo

evaluated echo

is marked

quality of

evaluated echo

empty calibr.

envelope curve

only

envelope curve and

interference echo

suppression (map)

level echo

map

full calibr.

…

OE3

Move mode:

- m-oved to the left

moved to the right

Horizontal Zoom mode:

- h-orizontal zoom in

horizontal zoom out

Vertical Zoom mode:

- vertical zoom (4 steps)

9.3 Function "envelope curve display" (0E3)

The envelope curve is displayed in this function. You can use it to obtain the following information:

Navigating in the envelope curve display

Using navigation, the envelope curve can be scaled horizontally and vertically and shifted to the left

or the right. The active navigation mode is indicated by a symbol in the top left hand corner of the

display.

60 Endress+Hauser

Page 61

9 Function group "Envelope curve" (0E)

+

-

+

-

+

-

Horizontal Zoom mode

Firstly, go into the envelope curve display. Then press

igation. You are then in Horizontal Zoom mode. Either or is displayed.

You now have the following options:

•

+ increases the horizontal scale.

•

- reduces the horizontal scale.

Move mode

Then press

You now have the following options:

•

+ shifts the curve to the right.

•

- shifts the curve to the left.

E to switch to Move mode. Either or is displayed.

+ or - to switch to the envelope curve nav-

Vertical Zoom mode

E once more to switch to Vertical Zoom mode. is displayed.

Press

You now have the following options:

•

+ increases the vertical scale.

•

- reduces the vertical scale.

The display icon shows the current zoom factor ( to ).

Exiting the navigation

•Press

•Press

E again to run through the different modes of the envelope curve navigation.

+ and - to exit the navigation. The set increases and shifts are retained. Only when you

reactivate the "recording curve" (0E2) function does the Prosonic use the standard display

again.

Endress+Hauser 61

Page 62

9 Function group "Envelope curve" (0E)

62 Endress+Hauser

Page 63

10 Function group "display" (09)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

10.1 Function "language" (092)

Selects the display language.

Selection:

•English

•Deutsch

• Français

•Español

• Italiano

• Nederlands

• Japanese

10 Function group "display" (09)

Dependence

All texts are changed.

10.2 Function "back to home" (093)

If no entry is made using the display during the specified time period, the display returns to the

measured value display.

9999 s means that there is no return.

User input:

3...9999 s

Endress+Hauser 63

Page 64

10 Function group "display" (09)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

10.3 Function "format display" (094)

Selects the display format.

Selection:

•decimal

•1/16''

decimal

The measured value is given in decimal form in the display (e.g. 10.70%).

1/16''

The measured value is given in the display in this format (e.g 5'05-14/16").

This option is only possible for "distance unit" (0C5) -"ft" and "in"!

10.4 Function "no.of decimals" (095)

Selection:

•x

•x.x

•x.xx

•x.xxx

10.5 Function "sep. character" (096)

Selection:

•.

•,

.

The decimal place is separated by a point.

,

The decimal place is separated by a comma.

64 Endress+Hauser

Page 65

10 Function group "display" (09)

ENDRESS + HAUSER

E

+

–

10.6 Function "display test" (097)

All display pixels are switched on. If the whole LCD is dark, it is working correctly.

Endress+Hauser 65

Page 66

10 Function group "display" (09)

66 Endress+Hauser

Page 67

11 Function group "diagnostics" (0A)

ENDRESS + HAUSER

E

+

–

11 Function group "diagnostics" (0A)

In the "diagnostics" function group, you can display and confirm error messages.

Type of error

Errors that occur during commissioning or measuring are displayed immediately on the local display. If two or more system or process errors occur, the error with the highest priority is the one

shown on the display.

The measuring system distinguishes between two types of error:

• A (Alarm):

Instrument goes into a defined state (e.g. MAX)

Indicated by a constant

(For a description of the codes, ä 86)

• W (Warning):

Instrument continue measuring, error message is displayed.

Indicated by a flashing

(For a description of the codes, ä 86)

• E (Alarm / Warning):

Configurable (e.g. loss of echo, level within the safety distance)

Indicated by a constant/flashing

(For a description of the codes, ä 86)

symbol.

symbol.

symbol.

Endress+Hauser 67

Page 68

11 Function group "diagnostics" (0A)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

11.1 Function "present error" (0A0)

The present error is shown using this function.

11.2 Function "previous error" (0A1)

The last error presented is shown with this function.

11.3 Function "clear last error" (0A2)

"

Selection:

•keep

•erase

Caution!

This function can be performed on the display only!

68 Endress+Hauser

Page 69

"

ENDRESS + HAUSER

E

+

–

11 Function group "diagnostics" (0A)

11.4 Function "reset" (0A3)

Caution!

A reset sets the instrument back to the factory settings. This can lead to an impairment of the measurement. Generally, you should perform a basic setup again following a reset.

A reset is only necessary:

• if the instrument no longer functions

• if the instrument must be moved from one measuring point to another

• if the instrument is being de-installed /put into storage/installed

Entry ("reset" (0A3)):

• 333 = customer parameters (HART)

• 33333 = customer parameters (PROFIBUS-PA and FOUNDATION Fieldbus)

333 = reset customer parameters for HART

33333 = reset customer parameters for PROFIBUS-PA and FOUNDATION Fieldbus

This reset is recommended whenever an instrument with an unknown 'history' is to be used in an

application:

• The Micropilot is reset to the default values.

• The customer specific tank map is not deleted.

• A linearisation is switched to "linear" although the table values are retained. The table can be

reactivated in the "linearisation" (04) function group.

!

Note!

5-point linearity protocol

The specified measuring accuracy is a typical value. With the production of the 5-point linearity

protocol the measuring system (sensor and electronic) is adjusted exactly to one another and the

measuring accuracy is optimized for the specified range. To realize this, the parameter "zero

distance" is fine adjusted. After a reset the value for the zero distance has to be re-parameterized in

the service menu according to the data on the associated 5-point linearity protocol. Please contact

the Endress+Hauser service.

List of functions that are affected by a reset:

• tank shape (002)

• empty calibr. (005)

• full calibr. (006)

• output on alarm (010)

• output on alarm (011)

• outp. echo loss (012)

• ramp %span/min (013)

• delay time (014)

• safety distance (015)

• in safety dist. (016)

• level/ullage (040)

• linearisation (041)

• customer unit (042)

• diameter vessel (047)

• range of mapping (052)

• pres. Map dist (054)

• offset (057)

• low output limit (062)

• fixed current (063)

• fixed cur. value (064)

• simulation (065)

• simulation value (066)

• format display (094)

• distance unit (0C5)

• download mode (0C8)

The tank map can also be reset in the "cust. tank map" (055) function of the "extended

calibr." (05) function group.

Endress+Hauser 69

Page 70

11 Function group "diagnostics" (0A)

This reset is recommended whenever an instrument with an unknown 'history' is to be used in an

application or if a faulty mapping was started:

• The tank map is deleted. The mapping must be recommenced.

70 Endress+Hauser

Page 71

11 Function group "diagnostics" (0A)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

11.5 Function "unlock parameter" (0A4)

Set-up can be locked and unlocked with this function.

11.5.1 Locking of the configuration mode

The Micropilot can be protected in two ways against unauthorised changing of instrument data,

numerical values or factory settings:

"unlock parameter" (0A4):

A value <> 100 for HART (e.g. 99) or <> 2457 for PROFIBUS-PA and FOUNDATION Fieldbus (e.g. 2456) must be entered in "unlock parameter" (0A4) in the "diagnostics" (0A) function

group. The lock is shown on the display by the

display or by communication.

Hardware lock:

The instrument is locked by pressing the

The lock is shown on the display by the

via the display by pressing the

unlock the hardware by communication.

All parameters can de displayed even if the instrument is locked.

O and S and F keys at the same time again. It is not possible to

symbol and can be released again either via the

O and S and F keys at the same time.

symbol and can only be unlocked again

O and S and F press simultaneous

The LOCK_SYMBOL appears on the LCD.

Endress+Hauser 71

Page 72

11 Function group "diagnostics" (0A)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

11.5.2 Unlocking of configuration mode

If an attempt is made to change parameters when the instrument is locked, the user is automatically

requested to unlock the instrument:

"unlock parameter" (0A4):

By entering the unlock parameter (on the display or via communication)

the Micropilot is released for operation.

Hardware-Verriegelung:

After pressing the

eter

100 = for HART devices

2457 = for PROFIBUS-PA and FOUNDATION Fieldbus devices

O and S and F keys at the same time, the user is asked to enter the unlock param-

100 = for HART devices

2457 = for PROFIBUS-PA and FOUNDATION Fieldbus devices.

"

O and S and F press simultaneous

fl

Please enter unlock code and confirm with F.

fl

Caution!

Changing certain parameters such as all sensor characteristics, for example, influences numerous

functions of the entire measuring system, particularly measuring accuracy. There is no need to

change these parameters under normal circumstances and consequently, they are protected by a

special code known only to the Endress+Hauser service organization. Please contact

Endress+Hauser if you have any questions.

11.6 Function "measured dist." (0A5)

Display of measured distance in the selected "distance unit" (0C5).

72 Endress+Hauser

Page 73

11.7 Function "measured level" (0A6)

ENDRESS + HAUSER

E

+

–

20 mA

100%

4mA

0%

measured

distance

measured

level

ENDRESS + HAUSER

E

+

–

Display of measured level in the selected "distance unit" (0C5).

11 Function group "diagnostics" (0A)

11.8 Function "detection window" (0A7)

(from Software 01.04.00)

Is used to switch the detection window on and off and to reset an existing detection window.

If this function is switched on, a window is defined surrounding the current level echo (typical

width: 1 to 2.5 m; depending on the application parameters).

The window always moves togehter with a rising a falling echo.

Echos beyond the limits of the window are ignored for a certain time.

Selection:

•off

•on

• reset

After selection of this option, the current window is reset, the level echo is looked for in the

complete measuring range and a new window is defined surrounding the current level echo.

Endress+Hauser 73

Page 74

11 Function group "diagnostics" (0A)

ENDRESS + HAUSER

E

+

–

ENDRESS + HAUSER

E

+

–

11.9 Function "application par." (0A8)

Displays whether or not one of the settings dependent on the "tank shape" (002),

"medium property" (003) and "process cond." (004) application parameters has been changed

or not.

If, for example, the "output damping" (058) is changed, the

"application par."shows"modified".

Display:

• not modified

• modified

After 3 s, the following message appears

74 Endress+Hauser

Page 75