Endress+Hauser FMR540 Operating Manual

BA00326F/00/EN/15.14

M

a

d

e

i

n

G

e

r

m

a

n

y

M

a

u

lb

u

r

g

Made in Germany Maulburg

O

rd

e

r

C

o

d

e

:

S

e

r

.-

N

o

.

:

Order Code:

Ser.-No.:

IP65

M

e

s

s

b

e

r

e

ic

h

M

e

a

s

u

rin

g

ra

n

g

e

U

1

6

.

..

3

6

V

D

C

4

..

.2

0

m

A

m

a

x

.

2

0

m

T>

7

0

°

C

:

A

t >

8

5

°C

SS+HAUSER

OPILOTFMR

M

a

d

e

i

n

G

e

r

m

a

n

y

M

a

u

l

b

u

r

g

Made in Germany Maulburg

O

rd

er C

ode

:

Se

r

.-N

o.:

Order Code:

Ser.-No.:

IP6

5

M

e

ssbereic

h

M

easu

ring ra

nge

U 16

...3

6 V

D

C

4...2

0 m

A

m

ax. 20

m

T>

70°C :

A

t

>

85

°C

S

S

+

H

A

U

S

E

R

O

P

IL

O

T

F

M

R

71263407

Valid as of software version:

V 01.01.xx (amplifier)

V 01.01.xx (communication)

Products Solutions Services

Operating Instructions

Micropilot S FMR540

Level-Radar

Brief operating instructions

E

+

-

+

E

+

-

E

-

……

…

KA255F/00/a2/09.06

52027735

…

F

L

D

E

52027735

Micropilot S FMR540 - Brief operating instructions

- dome

ceiling

- horizontal

cyl.

- bypass

…

- unknown

- DC: <1.9

- DC: 1.9 … 4

- DC: 4 … 10

- DC: >10

- standard

- calm

surface

- add.

agitator

…

input E

(see sketch)

input F

(see sketch)

only for

bypass +

stilling well

- ok

- too small

- too big

- unknown

- manual

displayed

(see sketch)

D and L are

confirm

or specify

range

suggestion

000

measured

value

Group

selection

00

basic

setup

01

safety settings

0C

system parameter

09

display

0E

envelope

curve

04

linearisation

03

dip table

05

extended calibr.

06

output

092

language

0A

diagnostics

0A0

present error

002

tank

shape

002

tank

shape

004

process

cond.

005

empty

calibr.

006

full

calibr.

007

pipe

diameter

008

dist./

meas value

051

check

distance

003

medium

cond.

052

range of

mapping

009

set value

008

dist./

meas value

- envel. curve

- incl. FAC

- incl. cust. map

- single curve

- cyclic

= 100: unlocked

100: locked¹

0E1

plot settings

0E2

recording

curve

0A1

previous error

0A4

unlock parameter

HART

}

Contrast: +or +

flange:

reference point

of measurement

This operating manual explains the installation and initial start-up for the level

transmitter. All functions that are required for a typical measuring task are taken into

account here. In addition, the Micropilot S provides many other functions that are not

included in this operating manual, such as optimising the measuring point and

converting the measured values.

An overview of all device functions can be found on ä 74.

The operating manual BA00341F/00/EN "Description of Instrument Functions"

provides an extensive description of all device functions, which can be found on the

enclosed CD-ROM.

The Operating Instructions can also be found on our homepage: www.endress.com

Endress+Hauser

A0021525-EN

Micropilot S FMR540 4 to 20 mA HART

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . . . . . . 4

1.3 Operational safety and process safety . . . . . . . . . . 4

1.4 Notes on safety conventions and symbols . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

2.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . 10

3.2 Incoming acceptance, transport, storage . . . . . . 10

3.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . 11

3.4 Installation instructions . . . . . . . . . . . . . . . . . . . . 15

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 23

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Connecting the measuring unit . . . . . . . . . . . . . . 26

4.3 Recommended connection . . . . . . . . . . . . . . . . . . 29

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 29

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 29

8 Accessories. . . . . . . . . . . . . . . . . . . . . . . 63

8.1 Weather protection cover . . . . . . . . . . . . . . . . . . . 63

8.2 Sensor alignment tool for alignment device . . . 63

8.3 Commubox FXA195 HART . . . . . . . . . . . . . . . . . . 64

8.4 Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5 ToF Adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . 64

8.6 Field Xpert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9 Trouble-shooting . . . . . . . . . . . . . . . . . 65

9.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . 65

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . 66

9.3 Application errors . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.7 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.8 Contact addresses of Endress+Hauser . . . . . . . . . 71

10 Technical data . . . . . . . . . . . . . . . . . . . . 72

10.1 Additional technical data . . . . . . . . . . . . . . . . . . . . 72

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . 74

11.1 Operating menu HART (display modul) . . . . . . . 74

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . 30

5.2 Display and operating elements . . . . . . . . . . . . . 32

5.3 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 Display and acknowledging error messages . . . 38

5.5 HART communication . . . . . . . . . . . . . . . . . . . . . 39

6 Commissioning. . . . . . . . . . . . . . . . . . . . 42

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2 Switching on the measuring device . . . . . . . . . . 42

6.3 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4 Basic Setup with the device display VU331 . . . . 45

6.5 Basic Setup with the

Endress+Hauser operating program . . . . . . . . . . 57

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . 62

7.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.2 Replacing seals . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.3 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.4 Repairs to Ex-approved devices . . . . . . . . . . . . . . 62

7.5 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Endress+Hauser 3

Safety instructions Micropilot S FMR540 4 to 20 mA HART

CAUTION

!

1 Safety instructions

1.1 Designated use

The Micropilot S is a compact radar level transmitter for the continuous, contactless

measurement of predominantly solids. The device can also be freely mounted outside closed

metal vessels because of its operating frequency in the K-band and a maximum radiated

pulsed energy of 1 mW (average power output 1 μW). Operation is completely harmless to

humans and animals.

1.2 Installation, commissioning and operation

The Micropilot S has been designed to operate safely in accordance with current technical,

safety and EU standards. If installed incorrectly or used for applications for which it is not

intended, however, it is possible that application-related dangers may arise, e.g. product

overflow due to incorrect installation or calibration. For this reason, the device must be

installed, connected, operated and maintained according to the instructions in this manual:

personnel must be authorised and suitably qualified. The manual must have been read and

understood, and the instructions followed. Modifications and repairs to the device are

permissible only when they are expressly approved in the manual.

1.3 Operational safety and process safety

Alternative monitoring measures must be taken to ensure operational safety and process

safety during configuration, testing and maintenance work on the device.

1.3.1 Hazardous areas

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with

the installation instructions and ratings as stated in this supplementary documentation is

mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local regulations.

1.3.2 FCC approval

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. this device must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the part responsible for

compliance could void the user’s authority to operate the equipment.

4 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Safety instructions

DANGER

WARNING

CAUTION

NOTICE

1.4 Notes on safety conventions and symbols

In order to highlight safety-relevant or alternative operating procedures in the manual, the

following conventions have been used, each indicated by a corresponding symbol in the

margin.

1.4.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-EN

A0011190-EN

A0011191-EN

A0011192-EN

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.4.2 Electrical symbols

Symbol Meaning

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0018339

1.4.3 Tool symbols

Symbol Meaning

Allen key

A0011221

Endress+Hauser 5

Safety instructions Micropilot S FMR540 4 to 20 mA HART

1.4.4 Symbols for certain types of information

Symbol Meaning

Allowed

Indicates procedures, processes or actions that are allowed.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to page

Refers to the corresponding page number.

A0015484

, , ,... Series of steps

1.4.5 Symbols in graphics

Symbol Meaning

1, 2, 3, 4, ... Item numbers

, , ,... Series of steps

A, B, C, D, ... Views

1.4.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

A0019159

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

A0019221

6 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Identification

Order Code:

Ser.-No.:

ENDRESS+HAUSER

Made in Germany

D-79689 Maulburg

if modification

see sep. label

X =

MICROPILOT S

0700

Anschlusswerte u. Temp.-Klasse siehe/

Connection values and temp.-classific.

see

T > 60°C

amb

1

2

3

76

9

10

t >85°C

8

Messbereich

Measuring range

max.

Antenne

T max. °C

5

PN max.

4

Dat./Insp.:

12

11

ENDRESS+HAUSER

MICROPILOT S FMR

Hersteller / Producer :

Zert.Messbereich/Cert.Measuring range

Umgeb./Environm.

bis

to

min

max

von

from

Baujahr

Year of constr.

Zertifikat-Nr.

Certification no.

T

m

°C

D00748-C

Tank-Nr.

Tank-no.

Tankreferenzhöhe

Tank reference height

m

1

2

3

4

5

56

7

2 Identification

2.1 Device designation

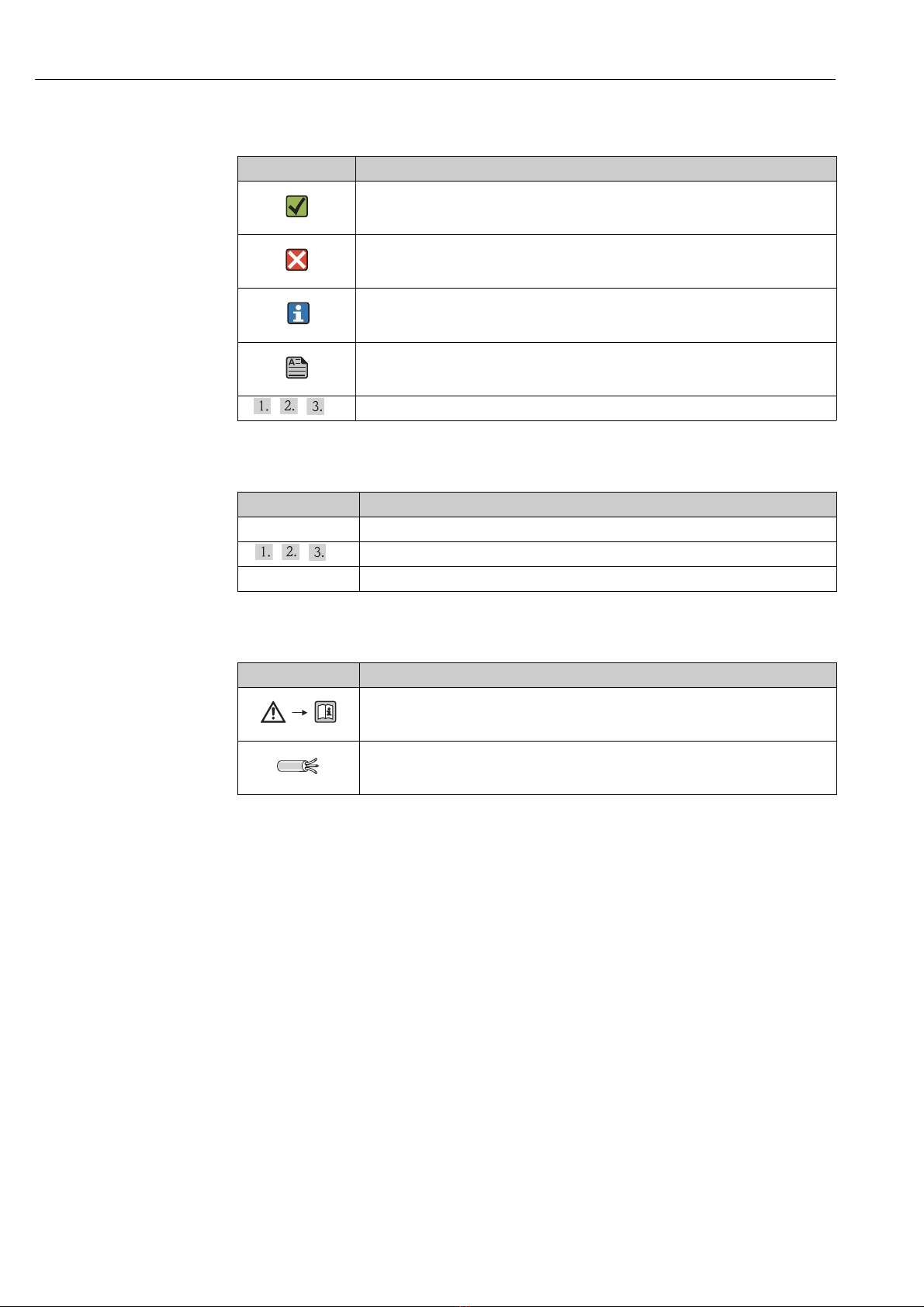

2.1.1 Nameplate

Device nameplate

The following technical data are given on the device nameplate:

1Order code

2 Serial number

3 Degree of protection e.g. IP65, IP67

4 Max. permissible pressure in tank

5 Max. permissible temperature on the antenna

6 Certificate symbol (optional) e.g. Ex

7 Approval number and type of protection

8Max. measuring range

9Power supply

10 Current supply

11 Safety infromation (Connection values and temp.-classific.)

12 Dat.Insp. xx/yy (xx = week of production, yy = year of production)

NMI type plate

Note!

The fields are only filled if in feature "70" "Weight + measures approval" the variant "F" is selected.

1 Certificate number

2Year of construction

3 Tank reference height

4Tank number

5 Certificated measuring range from ... to ...

6 Min. environment temperature

7 Max. environment temperature

A0021526

A0020413

Endress+Hauser 7

Identification Micropilot S FMR540 4 to 20 mA HART

ENDRESS+HAUSER

MICROPILOT S FMR

Hersteller / Producer :

Tank-Nr.

Tank-no.

Baujahr

Year of constr.

Tankreferenzhöhe

Tank reference height

m

D00549-B

Zert.Messbereich/Cert.Measuring range

Umgeb./Environm.

bis

to

min

max

von

from

T

m

°C

1

2

3

4

5

66 7 8

PTB type plate

A0020446

Note!

The fields are only filled if in feature "70" "Weight + measures approval" the variant "G" is selected.

1 Approval number

2 Year and month of type approval

3 Year of construction

4 Tank reference height

5Tank number

6 Certificated measuring range from ... to ...

7 Min. environment temperature

8 Max. environment temperature

8 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Identification

CAUTION

!

2.2 Scope of delivery

It is essential to follow the instructions concerning the unpacking, transport and

storage of measuring devices given in the chapter "Incoming acceptance, transport,

storage", ä 10!

The scope of delivery consists of:

• Assembled device

• Accessories ( ä 63)

•2 seals

• Endress+Hauser operating program on the enclosed CD-ROM

• Brief operating instructions KA01059F/00/EN for quick commissioning

• Brief operating instructions KA00255F/00/A2 (basic setup/troubleshooting), housed in

the device

• Approval documentation: if this is not included in the operating manual

• CD-ROM with further documentation, e.g.

– Operating Instructions

– Description of Instrument Functions

2.3 Certificates and approvals

CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EG directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

2.4 Registered trademarks

KALREZ®, VITON®, TEFLON

Registered trademark of the company, E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

®

Registered trademark of the company, Ladish & Co., Inc., Kenosha, USA

®

HART

Registered trademark of HART Communication Foundation, Austin, USA

®

ToF

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PulseMaster

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PhaseMaster

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

FieldCare

®

Registered trademark of the Endress+Hauser Process Solutions AG, Reinach, Switzerland

®

Endress+Hauser 9

Installation Micropilot S FMR540 4 to 20 mA HART

CAUTION

!

90°

90°

2

1

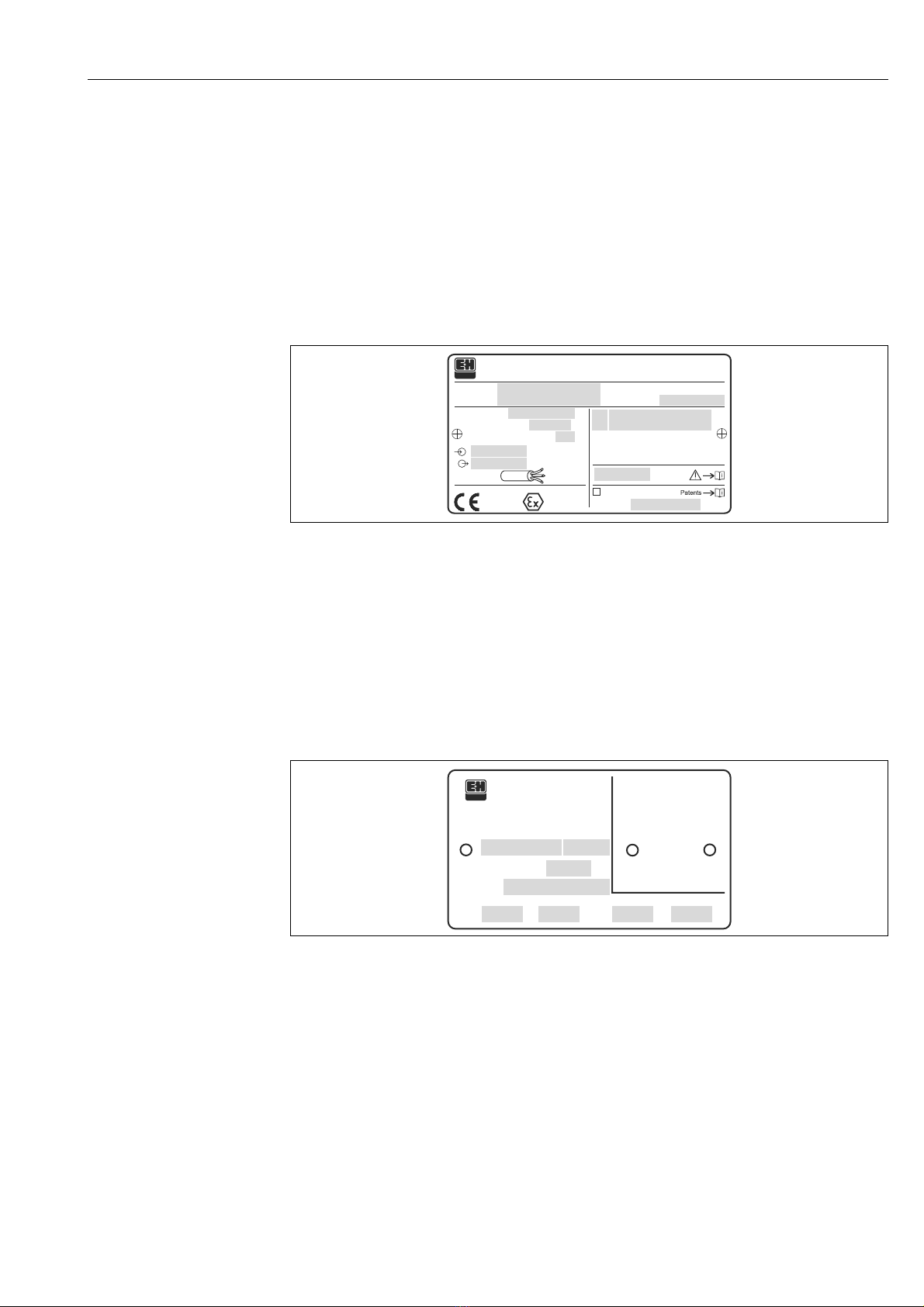

3Installation

3.1 Quick installation guide

A0020810

1Marker at sensor

2 Marker at flange

3.2 Incoming acceptance, transport, storage

3.2.1 Incoming acceptance

Check the packing and contents for any signs of damage. Check the shipment, make sure

nothing is missing and that the scope of supply matches your order.

3.2.2 Transport

Follow the safety instructions and transport conditions for devices of more than

18 kg (39.69 lbs).

3.2.3 Storage

Pack the measuring device so that is protected against impacts for storage and transport.

The original packing material provides the optimum protection for this.

The permissible storage temperature is -40 to +80 °C (-40 to +176 °F).

10 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

1

234

1

3

2

BD

SD

3.3 Installation conditions

3.3.1 Engineering hints

Orientation

• Recommended distance (1) wall - outer

edge of nozzle: ~1/6 of tank diameter

("Beam angle", ä 12).

• Not in the centre (3), interference can

cause signal loss.

• Not above the fill stream (4).

• It is recommended to use a weather

protection cover (2) in order to protect the

transmitter from direct sun or rain.

Assembly and disassembly is simply done

by means of a tension clamp ("Accessories",

ä 63).

A0020541

Tank installations

• Avoid any installations (1), like limit

switches, temperature sensors, etc., inside

the signal beam ("Beam angle", ä 12).

• It is essential that HiHi alarm is below the

blocking distance (BD) and the safety

distance (SD).

• Symmetrical installations (2), e.g. vacuum

rings, heating coils, baffles, etc., can also

interfere with the measurement.

Optimization options

• Antenna size: the bigger the antenna, the

smaller the beam angle, the less

interference echoes.

• Mapping: the measurement can be

optimized by means of electronic

suppression of interference echoes.

• Antenna alignment:

"Optimum mounting position", ä 15.

• Stilling well: a stilling well can always be

used to avoid interference. The FMR532

A0020450

with planar antenna is recommended for

stilling wells with a diameter DN150 (6")

and larger.

• Metallic screens (3) mounted at a slope

spread the radar signals and can,

therefore, reduce interference echoes.

Please contact Endress+Hauser for further

information.

Endress+Hauser 11

Installation Micropilot S FMR540 4 to 20 mA HART

D

W

a

D

W

a

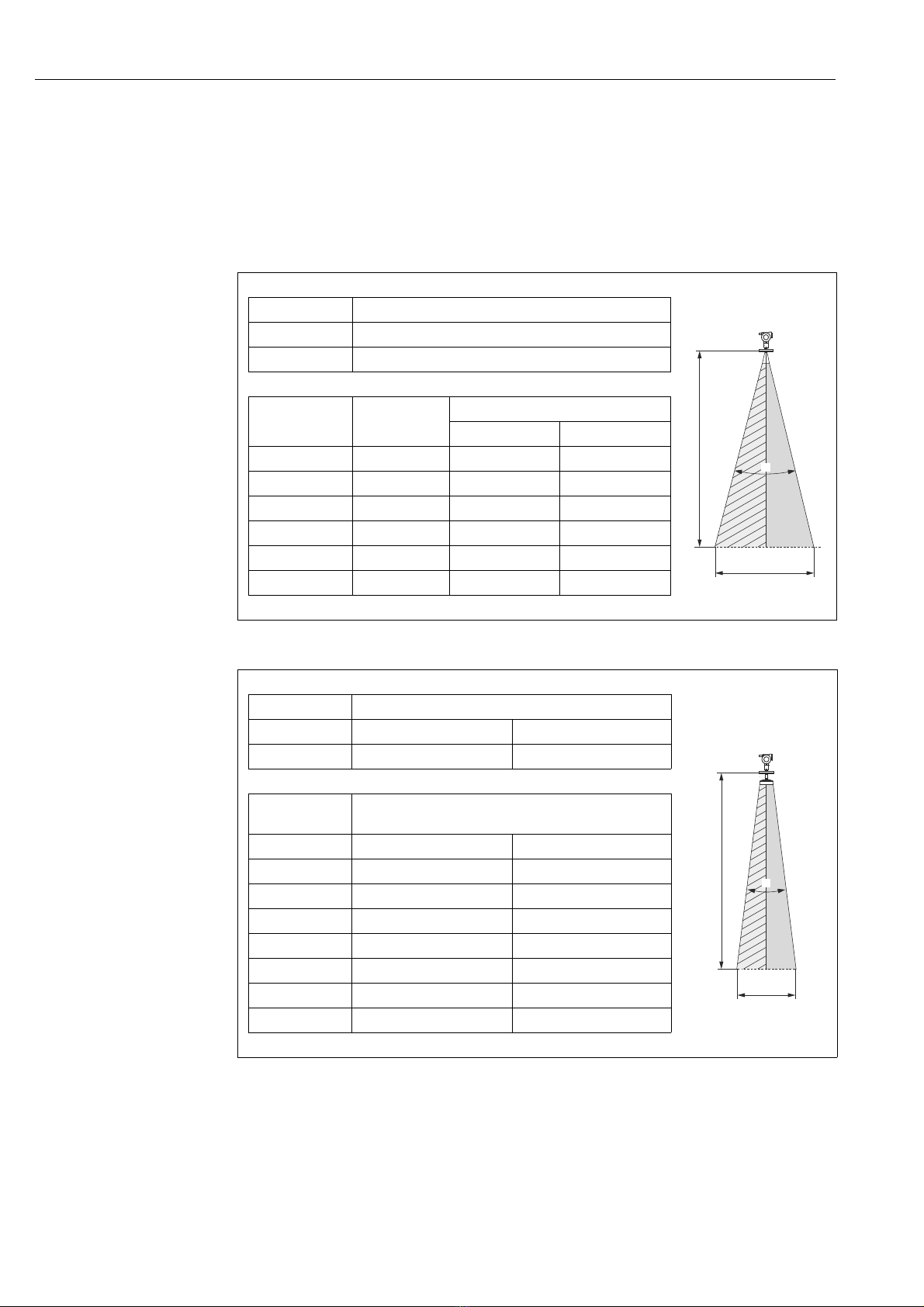

Beam angle

The beam angle is defined as the angle where the energy density of the radar waves

reaches half the value of the maximum energy density (3dB-width). Microwaves are also

emitted outside the signal beam and can be reflected off interfering installations. Beam

diameter W is a function of antenna type (beam angle ) and measuring distance D. The

recommended distance to the tank wall is indicated in the tables below. It is strongly

recommended to avoid any mechanical obstacles within the highlighted area.

Horn antenna

Antenna size 100 mm (4")

Beam angle () 8°

Measuring

distance (D)

5 m (16 ft) 0,70 m (2.3 ft) 0,89 m (2.9 ft) 0,62 m (2 ft)

10 m (33 ft) 1,40 m (2.6 ft) 1,77 m (5.8 ft) 1,23 m (4 ft)

15 m (49 ft) 2,10 m (6.9 ft) 2,65 m (8.7 ft) 1,85 m (6.1 ft)

20 m (66 ft) 2,80 m (9.2 ft) 3,53 m (12 ft) 2,46 m (8.1 ft)

25 m (82 ft) 3,50 m (11 ft) 4,41 m (14 ft) 3,07 m (10 ft)

30 m (98 ft) 4,20 m (14 ft) 5,29 m (17 ft) 3,69 m (12 ft)

Antenna size 200 mm (8") 250 mm (10")

Beam angle () 4.4° 3.3°

Measuring

distance (D)

5m (16ft) 0,35 m (1.1ft) 0,2 m (0.7ft)

10 m (33 ft) 0,70 m (2.3 ft) 0,5 m (1.6 ft)

15 m (49 ft) 1,05 m (3.4 ft) 0,75 m (2.5 ft)

20 m (66 ft) 1,40 m (2.6 ft) 1,05 m (3.4 ft)

25 m (82 ft) 1,75 m (5.7 ft) 1,3 m (4.3 ft)

30 m (98 ft) 2,10 m (6.9 ft) 1,6 m (5.2 ft)

35 m (115 ft) 2,45 m (8 ft) 1,85 m (6.1 ft)

40 m (131 ft) 2,80 m (9.2 ft) 2,10 m (6.9 ft)

Beamwidth

diameter (W)

Recommended distance to wall

Recommended distance to wall

0° tilting 3° tilting

Parabolic antenna

A0020805

A0020806

12 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

100%

0%

B

A

C

Measuring conditions

• Tank diameter and height should be at least dimensioned such that a reflection of the

radar signal on both sides of the tank can be avoided.

• In case of media with a low dielectric constant (media groups A and B), the tank bottom

can be visible through the medium at low levels (low height C). Reduced accuracy has to

be expected in this range. If this is not acceptable, we recommend positioning the zero

point at a distance C (see Fig.) above the tank bottom in these applications.

• In principle it is possible to measure up to the tip of the antenna with FMR540. However,

due to considerations regarding accuracy corrosion and build-up, the end of the measuring

range should not be chosen any closer than A (see A in Fig.).

1)

4" Horn antenna 8" Parabolic antenna 10" Parabolic antenna All antennas

FMR540 (without extension) 870 (34.3) 502 (19.8) 530 (20.9) >0.5 (1.6) >300 (11.8)

FMR540 with Extension 150 mm (5.9 in) 1020 (40.2) 652 (25.7) 680 (26.8) >0.5 (1.6) >300 (11.8)

FMR540 with Extension 250 mm (9.8 in) 1120 (44.1) 752 (29.6) 780 (30.7) >0.5 (1.6) >300 (11.8)

FMR540 with Extension 450 mm (18 in) 1320 (52.0) 952 (37.5) 980 (38.6) >0.5 (1.6) >300 (11.8)

1) All values are based on reference conditions.

A [mm (in)] B [m (ft)] C [mm (in)]

Behaviour if measuring range is exceeded

The behaviour in case of the measuring range being exceeded can be freely set:

The default setting is a current of 22 mA and the generation of a digital warning (E651).

A0020737

Endress+Hauser 13

Installation Micropilot S FMR540 4 to 20 mA HART

Measuring range

The usable measuring range depends on the size of the antenna, the reflectivity of the

medium, the mounting location and eventual interference reflections. To achieve an

optimised signal strength it is recommended to use an antenna with as large as possible

diameter (DN200(8") or DN250 (10") parabolic antenna).

The following tables describe the groups of media as well as the achievable measuring range

as a function of application and media group. If the dielectric constant of a medium is

unknown, it is recommended to assume media group B to ensure a reliable measurement.

Media group DC (r) Examples

A1 1.4 to 1.6 Propane, butane

A2 1.6 to 1.9 Non-conducting liquids, kerosene, jet fuels, gasoline, LPG

B 1.9 to 4

C 4 to 10 E.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, …

D > 10 Conducting liquids, e.g. aqueous solutions, dilute acids and alkalis

Non-conducting liquids, e.g. gasline, diesel fuel, heavy oil, motor oil, asphalt,

bitumen, BTEX, residual fuel

Measuring range depending on sensor type and media group

Media group Horn antenna

A1 DC (r) = 1.4 to 1.6 Please contact your Endress+Hauser sales organization.

A2 DC (

Max. measuring range with

cudstody transfer approval

r) = 1.6 to 1.9 0,6...20 m (2...66 ft) 0,6...40 m (2...131 ft)

B DC (

r) = 1.9 to 4 0,6...20 m (2...66 ft) 0,6...40 m (2...131 ft)

C DC (

r) = 4 to 10 0,6...30 m (2...98 ft) 0,6...40 m (2...131 ft)

D DC (r) > 10 0,6...30 m (2...98 ft) 0,6...40 m (2...131 ft)

without sensor extension

Measuring range

NMi: 23 m (75 ft)

PTB: 23 m (75 ft)

1)

Parabolic antenna

without sensor extension

Measuring range

NMi: 26 m (85 ft)

PTB: 30 m (98 ft)

1)

1) All values are based on reference conditions.

For stilling well applications Micropilot S FMR532 is recommended

(see TI01122F/00/EN).

14 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

90°

90°

2

1

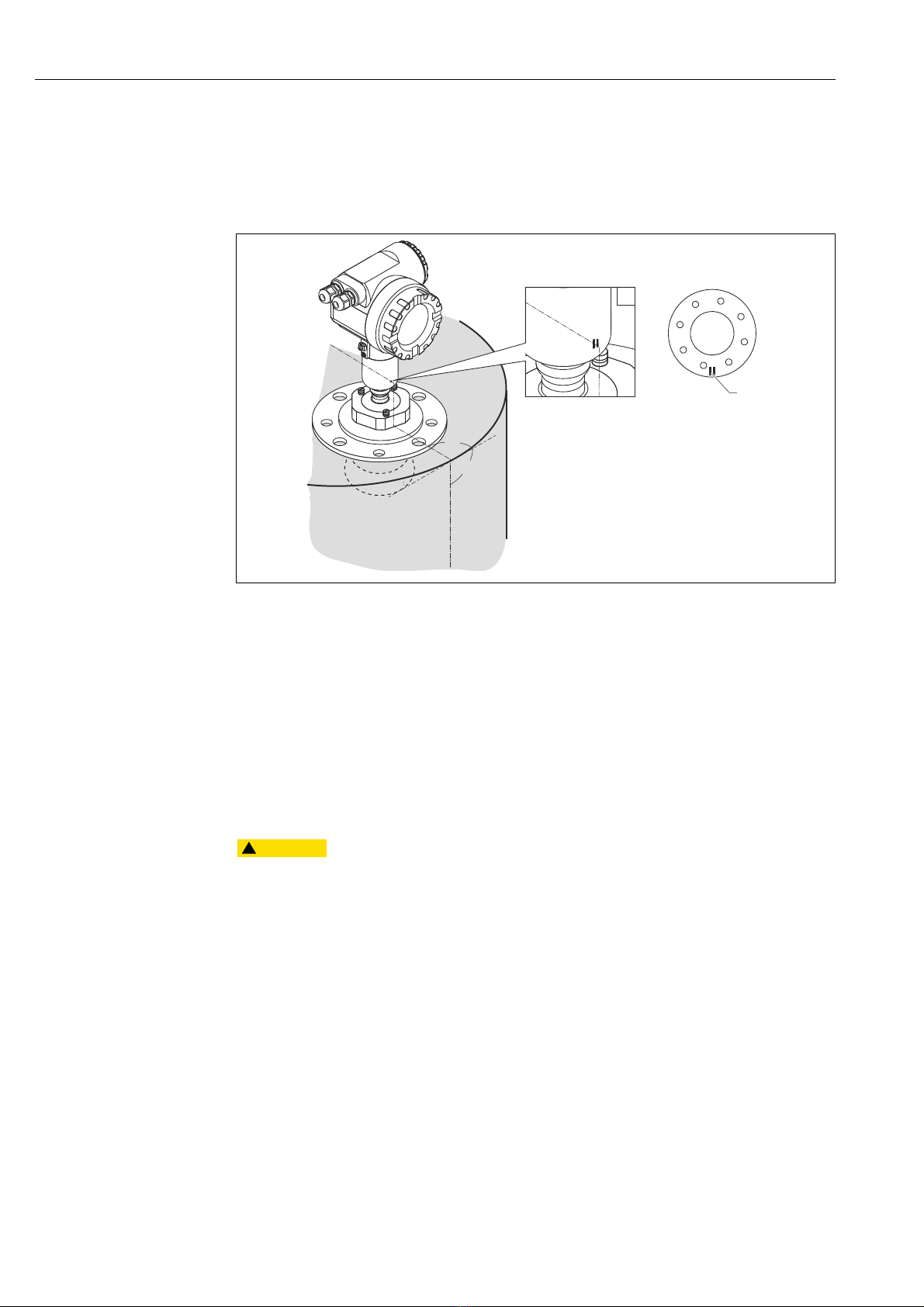

3.4 Installation instructions

3.4.1 Mounting kit

For the mounting , you will require the following tool:

• The tool for flange mounting

• 90 mm wrench for adjustment of the alignment device

(only for devices with alignment device)

• 4 mm (0.1") Allen wrench for turning the housing

3.4.2 Installation in vessel

Optimum mounting position

A0020810

1Marker at sensor

2 Marker at flange

Endress+Hauser 15

Installation Micropilot S FMR540 4 to 20 mA HART

H

øD

Standard installation FMR540 with horn

antenna

• Observe installation instructions, ä 11.

• Marker must be aligned towards tank wall.

The marker is located clearly visible on the

sensor neck or the flange.

• After mounting, the housing can be turned

350° in order to simplify access to the

display and the terminal compartment.

• Adjust vertical sensor alignment in case

the flange is not parallel to the face is

medium surface.

• The horn antenna should protrude from

the nozzle. If necessary, choose version

with antenna extension. Please contact

Endress+Hauser for application with

A0020809

higher nozzle.

• The horn antenna should be installed with

3° inclination towards the tank center.

To avoid interference reflections or for

optimum alignment within the tank, the

FMR540 with optional alignment device

can be swiveled by 15° in all directions. For

more informations please see Operating

Instructions KA00274F/00/A2.

Please contact Endress+Hauser Service

Organization for commissioning.

Antenna size 100 mm (4")

D [mm (in)] 95 (3.74)

H [mm (in)]

(without antenna extension)

< 430 (16.9)

16 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

øD

H

AB

1

a

a

Standard installation FMR540 with parabolic antenna

• Observe installation instructions, ä 11.

• Marker is aligned towards tank wall.

The marker is located clearly visible on the sensor neck or the flange.

• After mounting, the housing can be turned 350° in order to simplify access to the display

and the terminal compartment.

• Ideally the parabolic antenna should protrude from the nozzle (1). Particularly when using

the alignment device, please ensure that the parabolic reflector is protruding from the

nozzle/roof so as not to inhibit alignment.

For application with higher nozzle install parabolic antenna completely in the

nozzle (B), including RF-wave guide.

• The parabolic antenna should be installed vertically.

To avoid interference reflections or for optimum alignment within the vessel, the FMR540

with optional alignment device can be swiveled by 15° in all directions.

For more informations please see Operating Instructiosn KA00274F/00/A2.

Please, contact Endress+Hauser Service organization for commissioning.

A Antenna protrudes from the nozzle

B Antenna mounted in nozzle

1 Mounted perpendicular to the liquid surface

aObserve distance

(without antenna extension)

Antenna size 200 mm (8") 250 mm (10")

D [mm (in)] 173 (6.81) 236 (9.29)

H [mm (in)]

< 200 7.87) < 200 (7.87)

A0020808

Endress+Hauser 17

Installation Micropilot S FMR540 4 to 20 mA HART

±15°

±15°

90 °

90 °

A

FMR540 with alignment device

Micropilot S should be installed vertically towards the Liquid surface for best measuring

performance of ±1 mm (0.04 in). Using the alignment device it is possible to tilt the antenna

axis by up to 15° in all directions. The alignment device is used for the optimum alignment

of the radar beam to the liquid surface. The Sensor should be positioned vertical to the liquid

surface in inclination of 0° for Parabolic Antenna and up to 3° for Horn Antenna.

A0020807

AMedium

To align the antenna as precisely as possible, it is recommended to use the sensor alignment

tool, which is available as an accessory.

For more informations please see instructions in KA00274F/00/A2.

In case of custody Application, the screws must be locked with wires.

18 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

M

a

d

e

in

G

e

r

m

a

n

y

M

a

u

l

b

u

r

g

Made in Germany Maulburg

IP65

M

e

s

s

b

e

re

ic

h

M

e

a

s

u

rin

g

r

a

n

g

e

Messbereich

Measuring range

U

1

6

...3

6

V

D

C

4

...

2

0

m

A

U 16...36 V DC

4...20 mA

m

a

x

. 2

0

m

max. 20 m

T>

70

°

C

:

A

t >

8

5°C

T >70°C :

A

t >85°C

O

rd

e

r

C

o

d

e

:

S

e

r

.

-

N

o

.

:

Order Code:

Ser.-No.:

SS+HAUSER

OPILOTFM

R

SS+HAUSER

OPILOTFMR

1

3

2

±15°

±15°

90 °

90 °

A

Sensor alignment tool for alignment device

A sensor alignment tool (1) is recommended to be

used at the time of installation for FMR540 with

alignment device.

Alignment procedure

This procedure is only applicable to the sensors

purchased with alignment device (3). To carry

out this procedure requires an accessory from

Endress+Hauser, sensor alignment tool (1) for

Micropilot S FMR540.

Before starting this procedure, please observe

Micropilot S FMR540 has been mounted on the

tank in proper position and all flange bolts (2) are

tightened.

Tools: 90 mm open wrench

Accessory Package contains:

Sensor alignment tool (part no. 52026756)

A0021554

Description of procedure "Sensor Alignment using

Sensor alignment tool"

(KA00274F/00/A2 part no. 52027425)

Loosen the nut (3), so that the FMR540 can tilt

smoothly.

Observe the sensor can smoothly tilt its

position. The nut should not be too loose.

Tilt the Micropilot S to approximately vertical

to the medium surface (A) or horizontal plane.

A0020807

Endress+Hauser 19

Installation Micropilot S FMR540 4 to 20 mA HART

90°

90°

M

a

d

e

in

G

e

rm

a

n

y

M

a

u

lb

u

rg

Made in Germany Maulburg

IP65

M

e

s

s

b

er

e

ic

h

M

e

a

s

u

rin

g

ra

n

g

e

Messbereich

Measuring range

U

16

...3

6

V

D

C

4

...2

0

m

A

U 16...36 V DC

4...20 mA

m

a

x

. 2

0

m

max. 20 m

T>

7

0

°

C

:

A

t

>

8

5

°

C

T >70°C :

A

t >85°C

O

rd

er

C

o

d

e

:

S

e

r

.-

N

o

.:

Order Code:

Ser.-No.:

SS+

HAUSE

R

O

PILO

T

FM

R

SS+HAUSER

OPILOTFMR

1

4

5

3°

2°

1°

0°

Endress+Hauser

52026756

Place the Sensor alignment tool (1) for

Micropilot S FMR540. Please, note to avoid any

obstacles between the backside of the

Alignment tool and the nameplate of

Micropilot S FMR540.

A0021550

Micropilot S FMR540 with Horn Antenna:

Tilt the FMR540 targeting the direction of tank

center up to the position where the angle

indicators`s outer circle reaches the circle of 3

deg (4).

Exceeding the 3 degree position may

cause a weaker signal (or loss of signal).

Micropilot S FMR540 with Parabolic

Antenna:

Tilt the FMR540 to the position where the

bubble comes into the center (5) of the

inclination indicator (0 deg).

Gradually tighten the nut of the alignment tool

and make sure to keep the position of 0

degree/3 degree inclination.

After tightening the nut, check if the sensor

A0021415

cannot tilt and change its position. Torque for

the nut: 80 to 85 Nm (59 to 62.69 lbf ft).

If it is required by the local custody transfer

authority, please seal the alignment device at

the sealing screws using the provided wires

and seal metals.

20 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

NOTICE

M

a

d

e

i

n

G

e

r

m

a

n

y

M

a

u

l

b

u

r

g

IP 65

M

essb

ereich

M

eas

urin

g

range

U

16...36 V DC

4...20 mA

m

ax.

20 m

T >70

°C :

A

t

>

8

5

°

C

O

rder Code:

Ser.-No

.:

Order Code:

Ser.-No.:

SS

+HAUSER

OPILOT FM

R

1

4 mm

Sealing for custody transfer applications

The alignment device can be sealed using

the provided slotted capstan screws. The seal

wires must be installed against the open

direction in order to assure that a loosening

of the alignment device is not possible.

It is recommended to seal at least two of the

three sealing points provided.

A0021559

Integrated air purge connection

In some applications, the integrated air

purge connection can prevent clogging of

the antenna.

• Permanent operation:

recommended pressure range of the purge

air: 1.2 to 1.5 bar (18 to 22.5 psi) abs.

•Pulsed operation:

max. pressure of purge air: 6 bar abs.

Moisture or dust can collect and lead to

false measurement results!

‣ Make sure to use dry purge air!

1 Air purge connection G1/4"

(max. torque 3,5 Nm (2.58 lbft ft)

A0020799

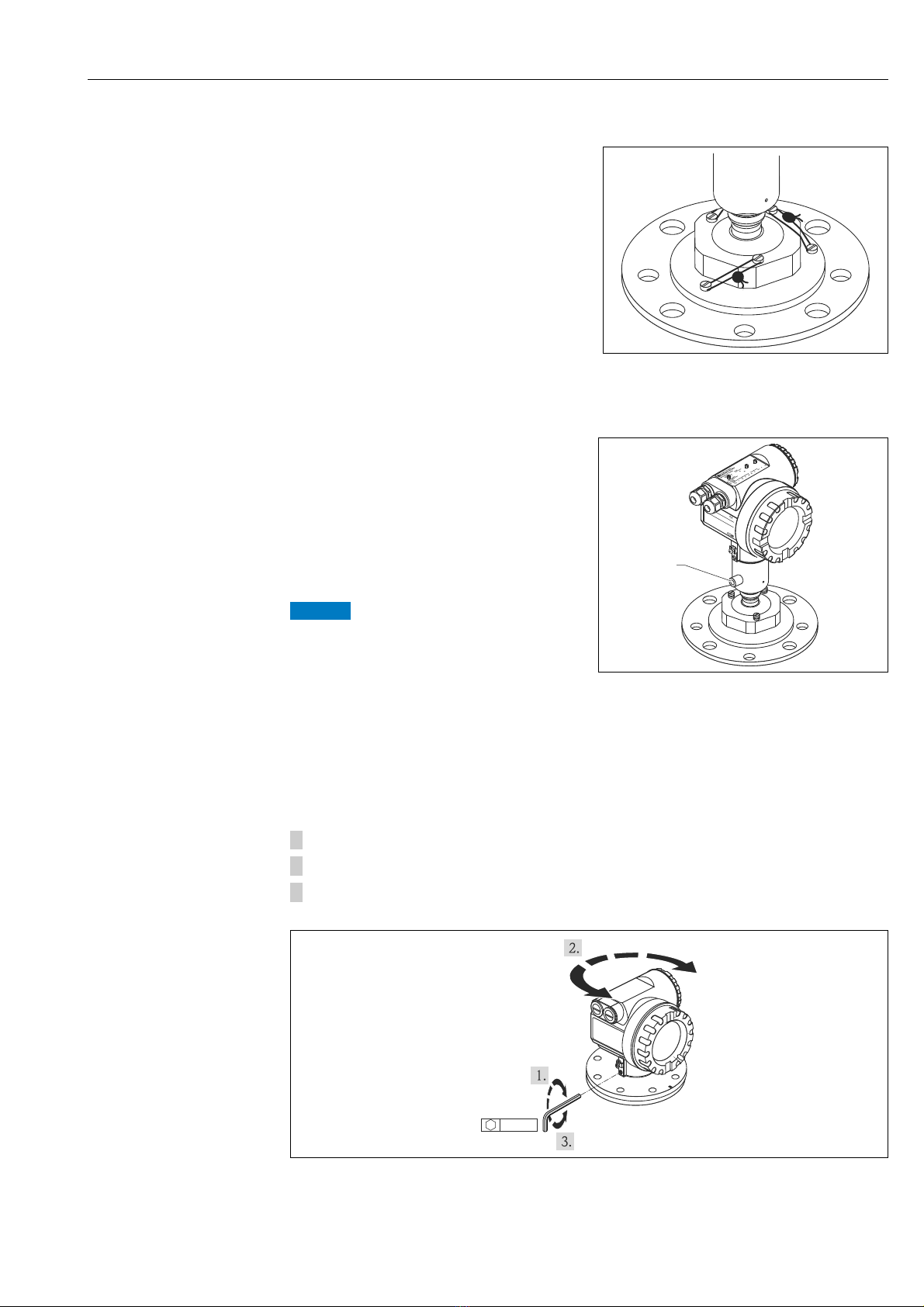

3.4.3 Turn housing

After mounting, the housing can be turned 350° in order to simplify access to the display and

the terminal compartment. Proceed as follows to turn the housing to the required position:

1. Undo the allen screw

2. Turn the housing in the required direction

3. Tighten up the allen screw strongly by hand

A0020470

Endress+Hauser 21

Installation Micropilot S FMR540 4 to 20 mA HART

90°

280 (11.0)

ø23 (0.91)

240 (9.45)

A-A

8 (0.31)

ø80.3 (3.16)

A

A

A

A

ø340 (13.4)

ø405 (15.9)

90°

60°

60°

ø26 (1.02)

ø29 (1.14)

ø358 (14.1)

ø294.5 (11.6)

A

A

BC

D

3.4.4 Endress+Hauser UNI flange

The number of bolts has sometimes been reduced. The bolt-holes have been enlarged for

adaption of dimensions, therefore, the flange needs to be properly aligned to the

counterflange before the bolts are tightened.

Dimensions: mm (in)

Endress+Hauser

UNI Flange

B DN150 PN16; ANSI 6" 150 lbs; JIS 10K 150 040 XVJ

C DN200 PN16; ANSI 8" 150 lbs; JIS 10K 200 040 X3J

D DN250 PN16; ANSI 10" 150lbs; JIS 10K 250 040 X5J

Compatibel with: Feature Option

A0020793

model

22 Endress+Hauser

Micropilot S FMR540 4 to 20 mA HART Installation

8 (0.31)

±15°

56.8 (2.24)

A

A-A

A

90

2

1

3.4.5 Alignment unit with Endress+Hauser UNI flange

A0020791

Dimensions: mm (in)

1Viton-Dichtung

2 Endress+Hauser UNI Flange DN200/DN250

Please, also see sensor alignment tool ä 63.

3.5 Post-installation check

After the measuring device has been installed, perform the following checks:

• Is the measuring device damaged (visual check)?

• Does the measuring device correspond to the measuring point specifications such as

process temperature/pressure, ambient temperature, measuring range, etc.?

• Is the flange marking correctly aligned ( ä 10)?

• Have the flange screws been tightened up with the respective tightening torque?

• Are the measuring point number and labeling correct (visual check)?

• Is the measuring device adequately protected against rain and direct sunlight ( ä 63)?

Endress+Hauser 23

Wiring Micropilot S FMR540 4 to 20 mA HART

CAUTION

!

CAUTION

!

CAUTION

!

1

3

2

6

112233445

5

8

A

B

5

7

4

4 Wiring

4.1 Quick wiring guide

When grounding conductive screens, the corresponding directives EN 60079-14 and

EN 1127-1 must be observed. Recommendation for safe grounding of conductive screens:

Before connection please note the following:

‣ The power supply must be identical to the data on the nameplate.

‣ Switch off power supply before connecting the device.

‣ Connect equipotential bonding to transmitter ground terminal before connecting the

device.

‣ Tighten the locking screw:

It forms the connection between the antenna and the housing ground potential.

‣ When you use the measuring system in hazardous areas, make sure you comply with

national standards and the specifications in the safety instructions (XA’s)

4.1.1 Wiring

Before connection please note the following:

‣ The power supply to be delivered by a transmitter supply unit.

‣ Befor removing housing cover at seperate connection compartment turn off the power

supply!

Insert cable through gland . Use screened,

twisted 2-wire or 4-wire cable.

Only ground screening of the line on

sensor side.

Make connection (see pin assignment).

Tighten cable gland.

Replace and tighten off housing cover.

Switch on power supply.

A Micropilot S situated in a hazardous

area is connected as a single device to a

power supply unit and transmitter

situated outside of the hazardous area.

In this case, it is recommended that the

screen be connected directly to the

Micropilot at the housing’s earth,

whereby the Micropilot S and the power

supply unit are connected to the same

potential equalization line.

24 Endress+Hauser

A Power 24 VDC; from a transmitter supply unit

B Signal 24 VDC; from a transmitter supply unit

1Housing cover

2Cable

3 Cable gland

4 Alternative connection

5 Commubox FXA195, Field Communicator

6Shield ground

7 Test socket; Output current

8 PML (potential matching line)

A0020479

Loading...

Loading...