Endress+Hauser FMR532 Operating Manual

BA00208F/00/EN/14.13

71229223

Valid as of software version

V 01.03.00 (amplifier)

V 01.03.00 (communication)

Products Solutions Services

Operating Instructions

Micropilot S FMR532

Level-Radar

Brief operating instructions

E

E

E

+

-

E

+

-

+

-

……

F

L

D

E

52006294

……

K

++

KA 161F/00/a2/12.01

52006294

- flat

ceiling

- stilling

well

…

- unknown

- <1.9

- 1.9 … 4

- 4 … 10

- >10

- standard

- calm

surface

- add. agitator

…

input E

(see sketch)

input F

(see sketch)

only for

bypass +

stilling well

- ok

- too small

- too big

- unknown

- manual

displayed

(see sketch)

D and L are

confirm

or specify

range

suggestion

000

measured value

Group

selection

00

basic setup

01

safety settings

03

mounting

calibr.

09

display

04

linearisation

05

extended calibr.

06

output

0C

system

parameters

092

language

0A

diagnostics

0A0

present

error

002

tank

shape

004

process

cond.

005

empty

calibr.

006

full

calibr.

007

pipe

diameter

008

dist./

meas value

009

history

reset

051

check

distance

003

medium

property

052

range of

mapping

053

start

mapping

008

dist./

meas value

flange:

referencepoint

of measurement

- envel. curve

- incl. FAC

- incl. cust. map

- single curve

- cyclic

= 100: unlocked

100: locked≠

09A

plot settings

09B

recording

curve

0A1

previous

error

0A4

unlock

parameter

- dip table

- auto correct.

030

tank

gauging

033

dip table

mode

034/035

dip table

555 = Histor y Reset

(333 = reset customer parameters)

0A3

reset

basic setup

dip tab le

offsetfirst point corrects

further points correct linearity

histor y reset (= 555)

Contrast: or

Micropilot S - Quick Setup

This operating manual explains the installation and initial start-up for the level

transmitter. All functions that are required for a typical measuring task are taken into

account here. In addition, the Micropilot S provides many other functions that are not

included in this operating manual, such as optimising the measuring point and

converting the measured values.

An overview of all device functions can be found on ä 82.

The operating manual BA00217F/00/EN "Description of Instrument Functions"

provides an extensive description of all device functions, which can be found on the

enclosed CD-ROM.

The Operating Instructions can also be found on our homepage: www.endress.com

A0021144-EN

Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART

Table of Contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . . . . . . 4

1.3 Operational safety and process safety . . . . . . . . . . 4

1.4 Notes on safety conventions and symbols . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

2.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . 10

3.2 Incoming acceptance, transport, storage . . . . . . 10

3.3 Installation Conditions . . . . . . . . . . . . . . . . . . . . . 11

3.4 Installation instructions . . . . . . . . . . . . . . . . . . . . 14

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 23

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Connecting the measuring unit . . . . . . . . . . . . . . 26

4.3 Recommended connection . . . . . . . . . . . . . . . . . . 29

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 29

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 29

8 Accessories. . . . . . . . . . . . . . . . . . . . . . . 71

8.1 Weather protection cover . . . . . . . . . . . . . . . . . . . 71

8.2 Commubox FXA195 HART . . . . . . . . . . . . . . . . . . 71

8.3 Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . . 71

8.4 ToF Adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . 71

8.5 Field Xpert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.6 Mounting with Sample hatch on stilling well . . . 72

9 Trouble-shooting . . . . . . . . . . . . . . . . . 73

9.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . 73

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . 74

9.3 Application errors . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.7 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.8 Contact addresses of Endress+Hauser . . . . . . . . . 79

10 Technical data . . . . . . . . . . . . . . . . . . . . 80

10.1 Additional technical data . . . . . . . . . . . . . . . . . . . . 80

10.2 Supplementary Documentation . . . . . . . . . . . . . . 80

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . 82

11.1 Operating menu HART (Display modul) . . . . . . . 82

11.2 Integrated in tank gauging system . . . . . . . . . . . . 84

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . 30

5.2 Display and operating elements . . . . . . . . . . . . . 32

5.3 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 Display and acknowledging error messages . . . 38

5.5 HART communication . . . . . . . . . . . . . . . . . . . . . 39

6 Commissioning. . . . . . . . . . . . . . . . . . . . 42

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2 Switching on the measuring device . . . . . . . . . . 42

6.3 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4 Basic Setup with the device display VU331 . . . . 45

6.5 Mounting calibration

with device display VU331 . . . . . . . . . . . . . . . . . 54

6.6 Basic Setup with the

Endress+Hauser operating program . . . . . . . . . . 64

6.7 Mounting calibration with the

Endress+Hauser operating program . . . . . . . . . . 68

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . 70

7.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.2 Replacing seals . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.4 Repairs to Ex-approved devices . . . . . . . . . . . . . . 70

7.5 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Endress+Hauser 3

Safety instructions Micropilot S FMR532 4 to 20 mA HART

CAUTION

!

1 Safety instructions

1.1 Designated use

The Micropilot S is a compact radar level transmitter for the continuous, contactless

measurement of liquids. The device can also be freely mounted outside closed metal vessels

because of its operating frequency of about 6 GHz and a maximum radiated pulsed energy

of 1 mW (average power output 1 μW). Operation is completely harmless to humans and

animals.

1.2 Installation, commissioning and operation

The Micropilot S has been designed to operate safely in accordance with current technical,

safety and EU standards. If installed incorrectly or used for applications for which it is not

intended, however, it is possible that application-related dangers may arise, e.g. product

overflow due to incorrect installation or calibration. For this reason, the device must be

installed, connected, operated and maintained according to the instructions in this manual:

personnel must be authorised and suitably qualified. The manual must have been read and

understood, and the instructions followed. Modifications and repairs to the device are

permissible only when they are expressly approved in the manual.

1.3 Operational safety and process safety

Alternative monitoring measures must be taken to ensure operational safety and process

safety during configuration, testing and maintenance work on the device.

1.3.1 Hazardous areas

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with

the installation instructions and ratings as stated in this supplementary documentation is

mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local regulations.

1.3.2 FCC approval

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. this device must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the part responsible for

compliance could void the user’s authority to operate the equipment.

4 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Safety instructions

1.4 Notes on safety conventions and symbols

In order to highlight safety-relevant or alternative operating procedures in the manual, the

following conventions have been used, each indicated by a corresponding symbol in the

margin.

1.4.1 Safety symbols

Symbol Meaning

DANGER

A0011189-EN

WARNING

A0011190-EN

CAUTION

A0011191-EN

NOTICE

A0011192-EN

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.4.2 Electrical symbols

Symbol Meaning

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0018339

1.4.3 Tool symbols

Symbol Meaning

Allen key

A0011221

Endress+Hauser 5

Safety instructions Micropilot S FMR532 4 to 20 mA HART

1.4.4 Symbols for certain types of information

Symbol Meaning

Allowed

Indicates procedures, processes or actions that are allowed.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to page

Refers to the corresponding page number.

A0015484

, , ,... Series of steps

1.4.5 Symbols in graphics

Symbol Meaning

1, 2, 3, 4, ... Item numbers

, , ,... Series of steps

A, B, C, D, ... Views

1.4.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

A0019159

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

A0019221

6 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Identification

ENDRESS+HAUSER

Ser.-No.:

Order Code:

MICROPILOT S

TA > 70°C:

Dat./Insp.:

D00676-F

x =

0032

0560

Made in Germany

79689 Maulburg

PN max.

Antenne

Anschlusswerte u. Temp.-Klasse siehe/

Connection values and temp.-classic. see

T max. °C

if modification

see sep. label

t >85°C

1

3

54

6

7

8

9

10

11

12

2

Messbereich

Measuring range

max.

ENDRESS+HAUSER

MICROPILOT S FMR

Hersteller / Producer :

Zert.Messbereich/Cert.Measuring range

Umgeb./Environm.

bis

to

min

max

von

from

Baujahr

Year of constr.

Zertifikat-Nr.

Certification no.

T

m

°C

D00748-C

Tank-Nr.

Tank-no.

Tankreferenzhöhe

Tank reference height

m

1

2

3

4

5

56

7

2 Identification

2.1 Device designation

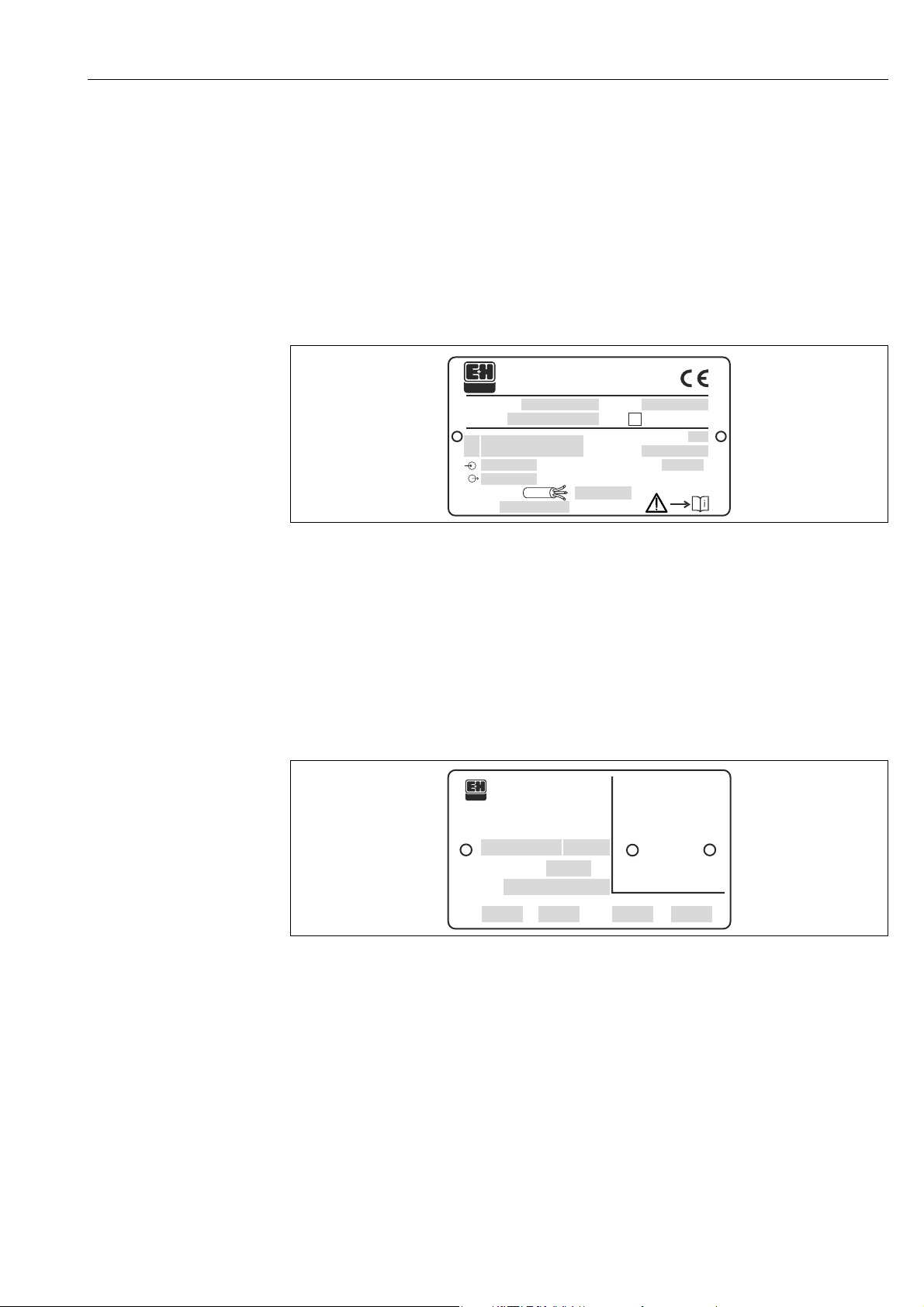

2.1.1 Nameplate

Device nameplate

The following technical data are given on the device nameplate:

1Order code

2 Degree of protection e.g. IP65, IP67

3 Serial number

4 Certificate symbol (optional) e.g. Ex

5 Approval number and type of protection

6Max. measuring range

7 Max. permissible pressure in tank

8 Max. permissible temperature on the antenna

9Power supply

10 Current supply

11 Safety infromation (Connection values and temp.-classific.)

12 Dat.Insp. xx/yy (xx = week of production, yy = year of production)

NMI type plate

Note!

The fields are only filled if in feature "70" "Weight + measures approval" the variant "F" is selected.

1 Certificate number

2Year of construction

3 Tank reference height

4Tank number

5 Certificated measuring range from ... to ...

6 Min. environment temperature

7 Max. environment temperature

A0020445

A0020413

Endress+Hauser 7

Identification Micropilot S FMR532 4 to 20 mA HART

ENDRESS+HAUSER

MICROPILOT S FMR

Hersteller / Producer :

Tank-Nr.

Tank-no.

Baujahr

Year of constr.

Tankreferenzhöhe

Tank reference height

m

D00549-B

Zert.Messbereich/Cert.Measuring range

Umgeb./Environm.

bis

to

min

max

von

from

T

m

°C

1

2

3

4

5

66 7 8

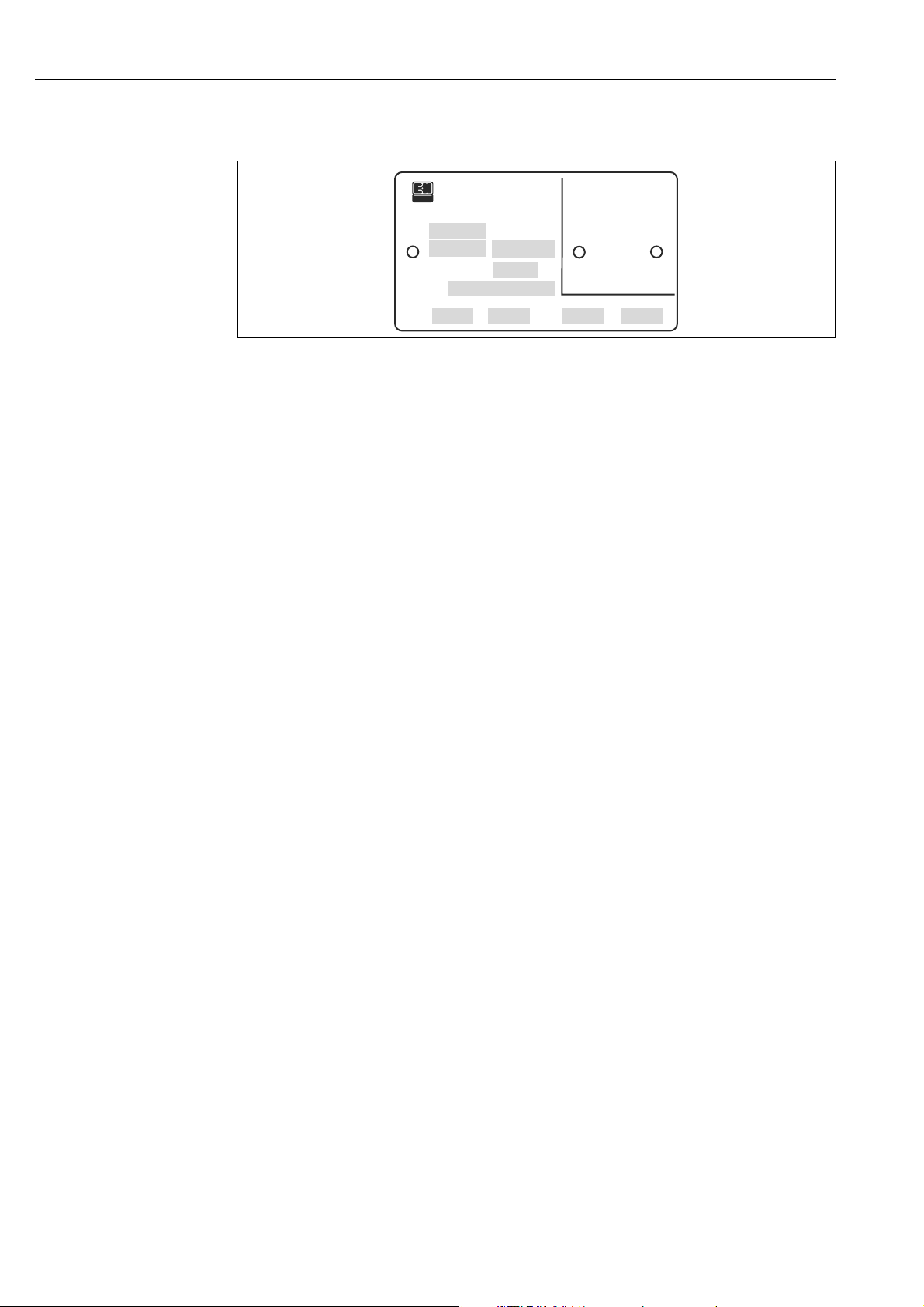

PTB type plate

A0020446

Note!

The fields are only filled if in feature "70" "Weight + measures approval" the variant "G" is selected.

1 Approval number

2 Year and month of type approval

3 Year of construction

4 Tank reference height

5Tank number

6 Certificated measuring range from ... to ...

7 Min. environment temperature

8 Max. environment temperature

8 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Identification

CAUTION

!

2.2 Scope of delivery

It is essential to follow the instructions concerning the unpacking, transport and

storage of measuring devices given in the chapter "Incoming acceptance, transport,

storage", ä 10!

The scope of delivery consists of:

• Assembled device

• Accessories ( ä 71)

•2 seals

• Endress+Hauser operating program on the enclosed CD-ROM

• Brief operating instructions KA01057F/00/EN for quick commissioning

• Brief operating instructions KA00161F/00/A2 (basic setup/troubleshooting), housed in

the device

• Approval documentation: if this is not included in the operating manual

• CD-ROM with further documentation, e.g.

– Operating Instructions

– Description of Instrument Functions

2.3 Certificates and approvals

CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EG directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

2.4 Registered trademarks

KALREZ®, VITON®, TEFLON

Registered trademark of the company, E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

®

Registered trademark of the company, Ladish & Co., Inc., Kenosha, USA

®

HART

Registered trademark of HART Communication Foundation, Austin, USA

®

ToF

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PulseMaster

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PhaseMaster

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

FieldCare

®

Registered trademark of the Endress+Hauser Process Solutions AG, Reinach, Switzerland

®

Endress+Hauser 9

Mounting Micropilot S FMR532 4 to 20 mA HART

CAUTION

!

90°

.

.

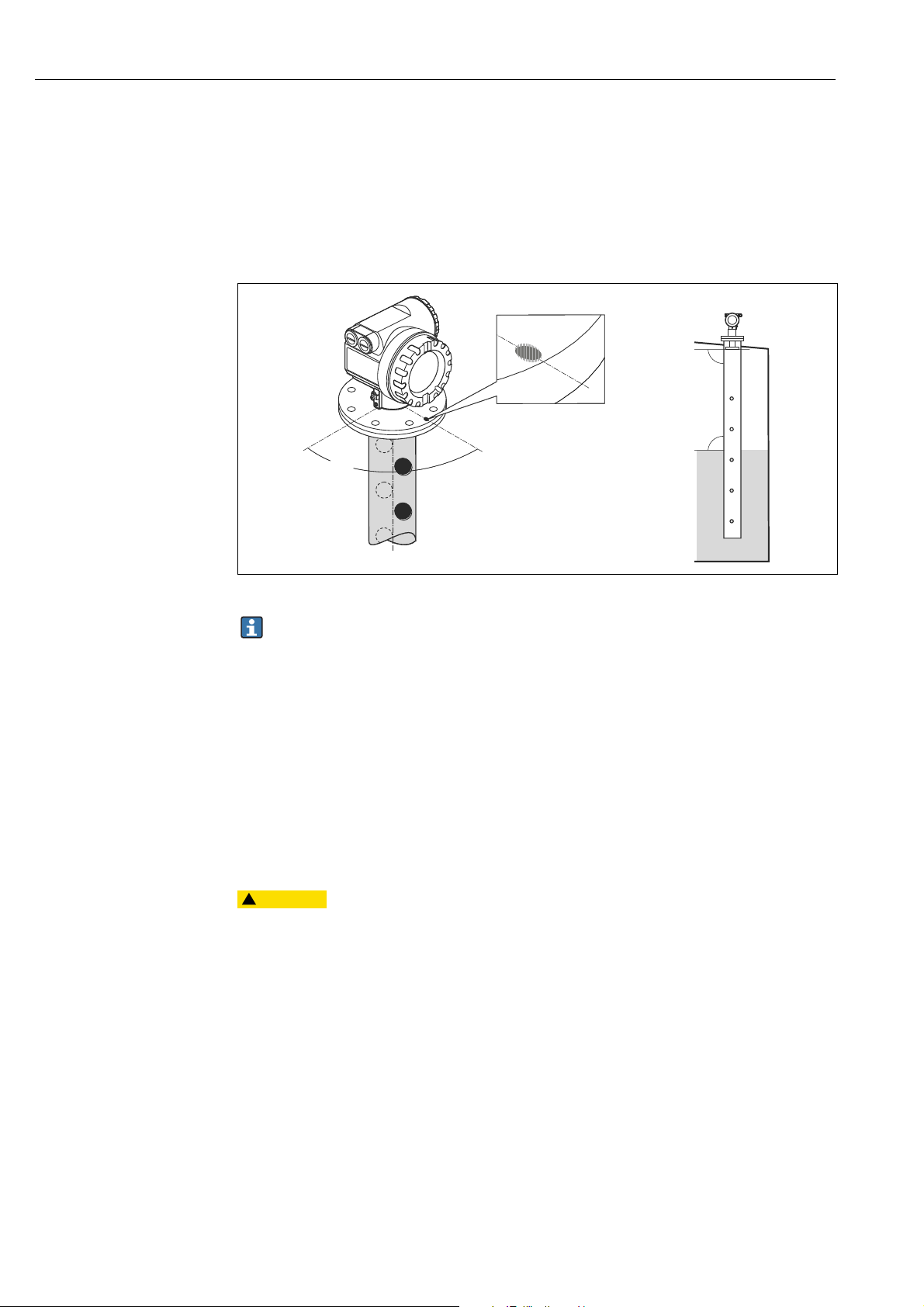

3Mounting

3.1 Quick installation guide

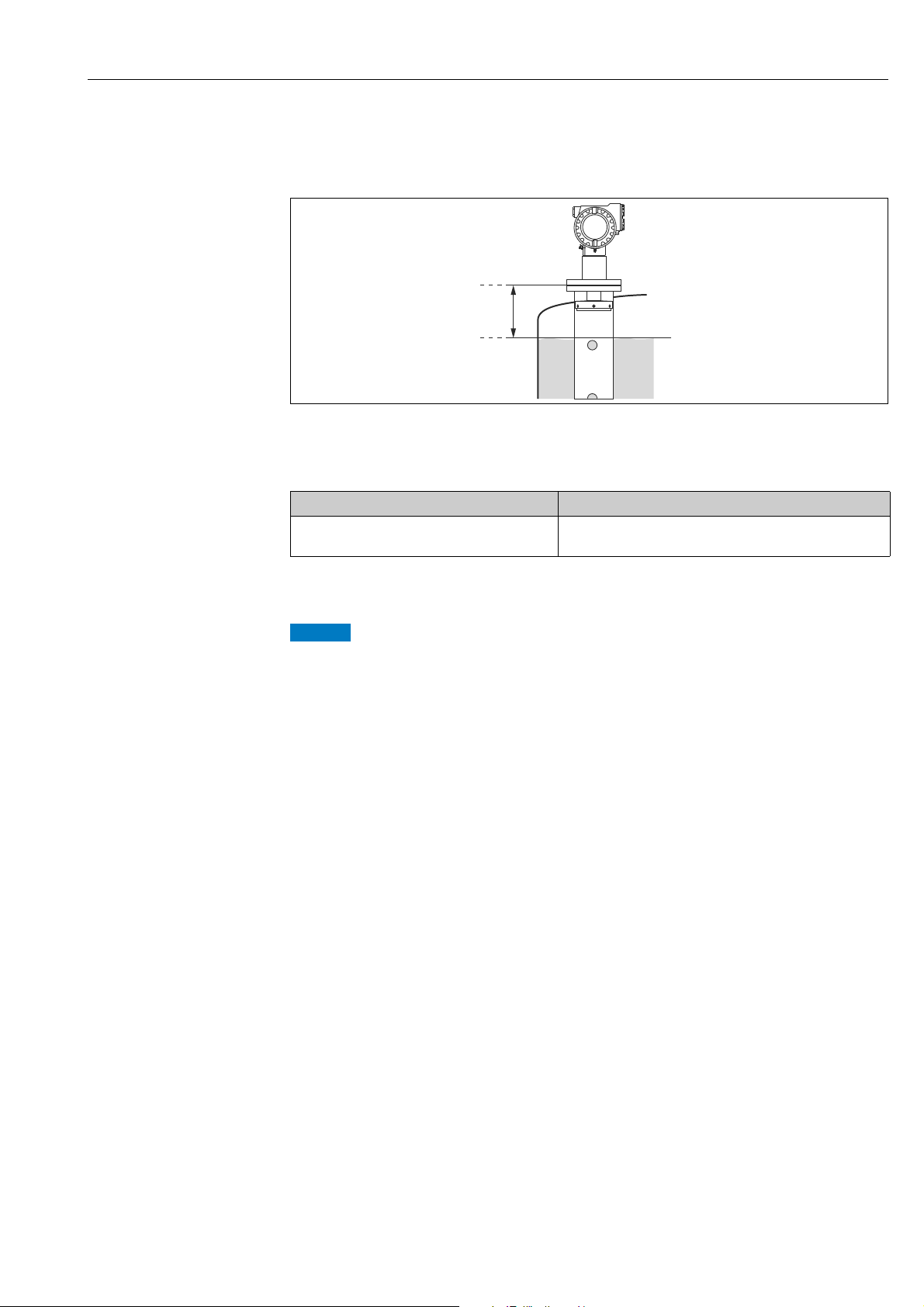

3.1.1 Installation only in stilling well

A0021216

The performance of the planar antenna is not dependent on the alignment or

geometry of standard stilling wells. No special alignment is required. However, make

sure that the planar antenna is installed vertically relative to the stilling well axis.

3.2 Incoming acceptance, transport, storage

3.2.1 Incoming acceptance

Check the packing and contents for any signs of damage. Check the shipment, make sure

nothing is missing and that the scope of supply matches your order.

3.2.2 Transport

Follow the safety instructions and transport conditions for devices of more than

18 kg (39.69 lbs).

3.2.3 Storage

Pack the measuring device so that is protected against impacts for storage and transport.

The original packing material provides the optimum protection for this.

The permissible storage temperature is -40 to +80 °C (-40 to +176 °F).

10 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Mounting

BD

SD

A

100%

0%

B

C

1

3.3 Installation Conditions

3.3.1 Engineering hints

Measuring conditions

• The measuring range begins where the beam hits the tank bottom. Particularly with dish

bottoms or conical outlets the level cannot be detected below this point.

•For overfill prevention, it is possible to define a safety distance (SD) additionally to the

blocking distance (BD).

• Depending on its consistence, foam can either absorb microwaves or reflect them off the

foam surface. Measurement is possible under certain conditions.

• The smallest possible measuring range B depends on the antenna version (see Fig.).

• The zero should be positioned at the end of the tube, as the electromagnetic waves do not

propagate completely outside the tube. It must be taken into account that the accuracy

may be reduced in the area C. In order to guarantee the required accuracy in these cases,

it is recommended to position the zero-point at a distanc C above the tank bottom (see

Fig.).

• In applications with planar antennas, especially for media with low dielectric constants

(media group A and B, ä 12), the end of the measuring range should not be closer than

1 m (3.3 ft) to the flange (cf. A in following figure).

• The safety distance (SD) is set to 0.5 m (1.6 ft) by default, generating an alarm in case the

product level rises inside the safety distance.

A0020735

1Max. level

Reference: flange / BD (cf. picture) Reference: antenna tip (cf. picture)

Blocking distance Safety distance Recommended additional settings

BD [m (ft)] SD [m (ft)] A [mm (in)] B [m (ft)] C [mm (in)]

1 (3.3) 0,5 (1.6) 1000 (39.4) 0,5 (1.6)

150 to 300

(5.91 to 11.8)

Behaviour if measuring range is exceeded

The behaviour in case of the measuring range being exceeded can be freely set:

The default setting is a current of 22 mA and the generation of a digital warning (E681).

Endress+Hauser 11

Mounting Micropilot S FMR532 4 to 20 mA HART

Measuring range

The usable measuring range depends on the size of the antenna, the reflectivity of the

medium, the mounting location, and eventual interference reflections.

The following tables describe the groups of media as well as the achievable measuring range

as a function of application and media group. If the dielectric constant of a medium is

unknown, it is recommended to assume media group B to ensure a reliable measurement.

Media group DC (r) Examples

A 1.4 to 1.9

B 1.9 to 4

C 4 to 10 E.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, …

D > 10 Conducting liquids, e.g. aqueous solutions, dilute acids and alkalis

Non-conducting liquids, e.g. liquefied gas (LPG). For more information please

contact your Endress+Hauser representative.

Non-conducting liquids, e.g. benzene, oil, toluene, white products, black

products, crudes, bitumen/asphalts, …

Measuring range depending on product class

Media group Stilling well/ Bypass

A DC (

max. measuring range with

custody transfer approvals

r) = 1.4 to 1.9

B DC (r) = 1.9 to 4

r) = 4 to 10

C DC (

r) > 10

D DC (

A0020746

Measuring range

FMR532 DN 150

38 m (125 ft)

NMi: 25 m (82 ft)

PTB: 30 m (98 ft)

12 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Mounting

NOTICE

20 mA

100%

BD

A

B

Blocking distance

The blocking distance (= BD) is the minimum distance from the reference point of the

measurement (mounting flange) to the medium surface at maximum level.

A0021842

A Reference point of measurement

B Maximum level

Blocking distance (BD)

from flange 1 m (3.3 ft)

1) 1 mm accuracy under reference conditions

1)

(see chapter "Mechanical construction" in TI01122F/00/EN)

Free space (Storage tank)

Inside the blocking distance a reliable measurement can not be guaranteed.

Endress+Hauser 13

Mounting Micropilot S FMR532 4 to 20 mA HART

BBAA

1111

90°

3.4 Installation instructions

3.4.1 Mounting kit

For the mounting, you will require the following tool:

• The tool for flange mounting

• 4 mm (0.1") Allen wrench for turning the housing

3.4.2 Installation in tank (stilling well)

Optimum mounting position

A0021159

1 Marker at instrument flange

A DN 150, ANSI 6"

B DN 200 to 250, ANSI 8 to 10"

Standard installation

• Observe installation instructions, ä 11.

• After mounting, the housing can be turned 350° in order to simplify access to the display

and the terminal compartment.

• Planar axis vertical to flange.

• Measurements can be performed through an open ball valve without any problems.

14 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Mounting

NOTICE

Recommendations for the stilling well

• Metal (no enamel coating, plastic on request).

• Constant diameter.

• When using a FMR532, an increase of the pipe diameter from DN 150 to DN 200 /

DN 200 to DN 250 / DN 250 to DN 300 is acceptable. A larger step-width for the increase

of the pipe diameter (e.g. DN 150 to DN 300) is possible if the upper part of the pipe has

a suitable length. The length of the stilling well enlargement must be kept. In this case, the

upper end of the pipe must have a minimum length of 0.5 m (1.6 ft) before the diameter

increases (refer to table, ä 16). If the length is less than "L", please contact

Endress+Hauser in order to determine a suitable antenna adapter (separable antenna

horn). Ideally, a sample hatch is used.

• Any rectangular increase of the pipe diameter has to be avoided.

• Weld seam as smooth as possible and on the same axis as the slots.

• For best radar propagation behavior holes it is recommended to have holes instead of slots.

If slots can not be avoided, they should be as thin and short as possible.

• The diameter of the holes (deburred) can be up to 1/7 of the pipe diameter but should not

exceed 30 mm (1.18 in).

• Length and number of the holes do not affect the measurement.

• Maximum gap allowed between the antenna/horn and the inside of the stilling well is

5 mm (0.2 in).

• At any transition (e.g. when using a ball valve or mending pipe segments), no gap may be

created exceeding 1 mm (0.04 in).

• The stilling well must be smooth on the inside. Use extruded or parallel welded steel pipe.

An extension of the pipe is possible with welded flanges or pipe sleeves. Flange and pipe

have to be properly aligned at the inside.

• Do not weld through the pipe wall. The inside of the stilling well must remain smooth. In

case of unintentional welding through the pipe, the weld seam and any unevenness on the

inside need to be carefully removed and smoothed. Otherwise, strong interference echoes

will be generated and material build-up will be promoted.

Selection of antenna size

‣ Select antenna extension as big as possible. For intermediate sizes

(e.g. 180 mm (7.09 in)) select next larger antenna extension and adapt it mechanically.

Maximum gap allowed between the antenna/horn and the inside of the stilling well is

5 mm (0.2 in).

‣ The antenna extension of the FMR532 is mounted with defined pressure.

It is strongly recommended not to dismantle this antenna.

‣ Dimensions of a nozzle for manual gauging must be adapted to the dimensions of the

horn antenna used, compare ä 16.

Endress+Hauser 15

Mounting Micropilot S FMR532 4 to 20 mA HART

100 %

100 %

AB

<1/7

8

5

4

3

2

6

1

1 (0.04)≤

7

≤5 (0.2)

Examples for the construction of stilling wells

Dimensions: mm (in)

A Installation in stilling well

B Installation in stilling well with sample hatch

1 <1/7 pipe diameter

2 Gap <5 mm (0.2 in)

3Weld-neck flange

4 Flange (DIN, ANSI, JIS, JPI)

5 Micropilot S FMR532

6 Endress+Hauser UNI flange

7 Gap <1 mm (0.04 in)

8Sample hatch

A0020747

16 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Mounting

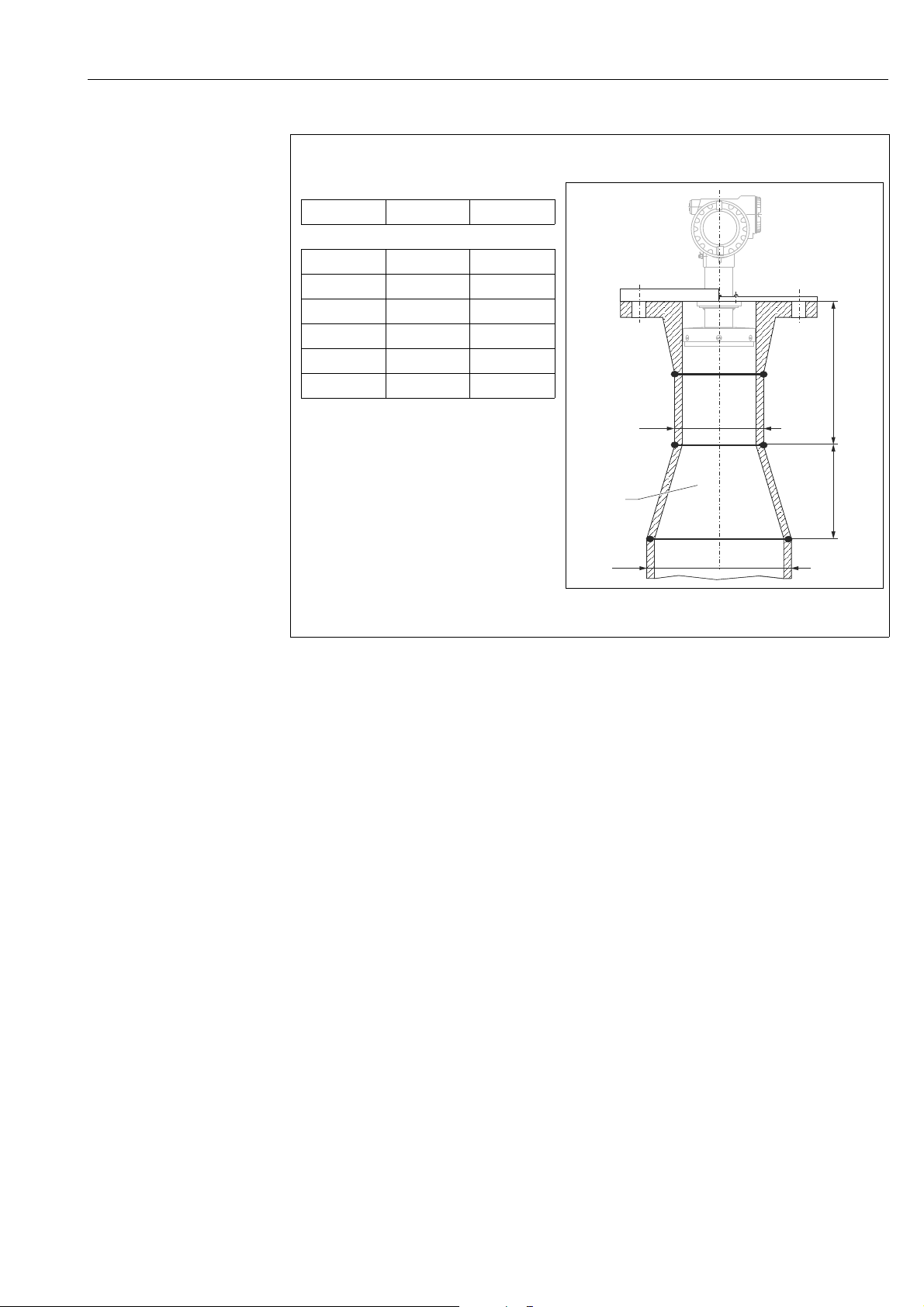

øD1

øD2

L

500 (19.7)

1

For retrofit of mechanical sysstems recommended

increase of diameter:

D1 D2 L

150 (5.91) 200 (7.87) 300 (11.8)

150 (5.91) 250 (9.84) 300 (11.8)

150 (5.91) 300 (11.8) 450 (17.7)

200 (7.87) 250 (9.84) 300 (11.8)

200 (7.87) 300 (11.8) 450 (17.7)

250 (9.84) 300 (11.8) 450 (17.7)

Dimensions: mm (in)

A0020786

Endress+Hauser 17

Mounting Micropilot S FMR532 4 to 20 mA HART

4 mm

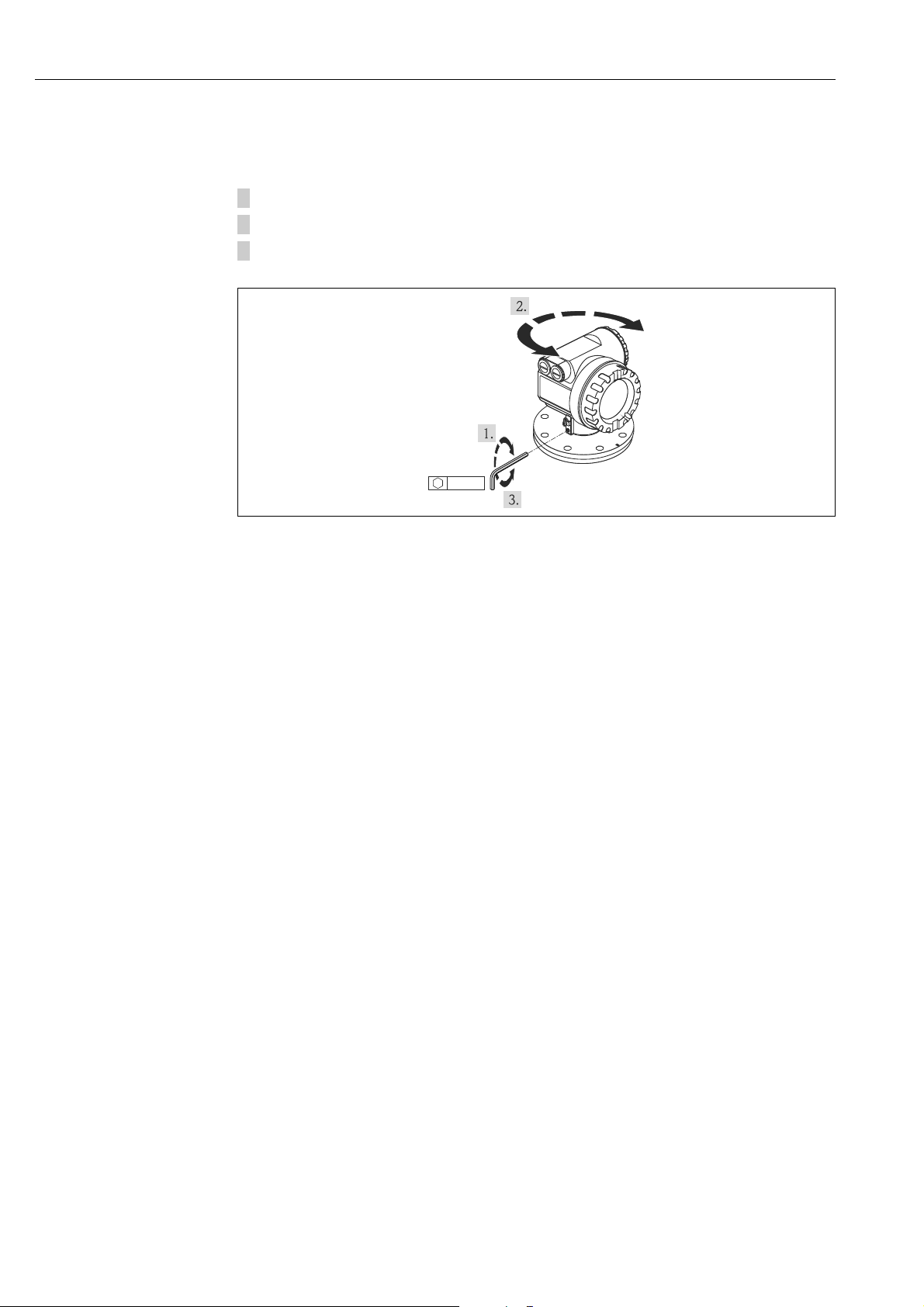

3.4.3 Turn housing

After mounting, the housing can be turned 350° in order to simplify access to the display and

the terminal compartment. Proceed as follows to turn the housing to the required position:

1. Undo the allen screw

2. Turn the housing in the required direction

3. Tighten up the allen screw strongly by hand

A0020470

18 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Mounting

øK

øD

ø23 (0.91)

ø12 (0.47)

øK

60°

90°

15°

øD

ø26 (1.02)

ø78 (3.07)

ø101 (3.98)

øK

øD

ø29 (1.14)

30°

A

A

A-A

1 (0.04)

8 (0.31)

3

1

2

ø63.2 (2.49)

B

D

C

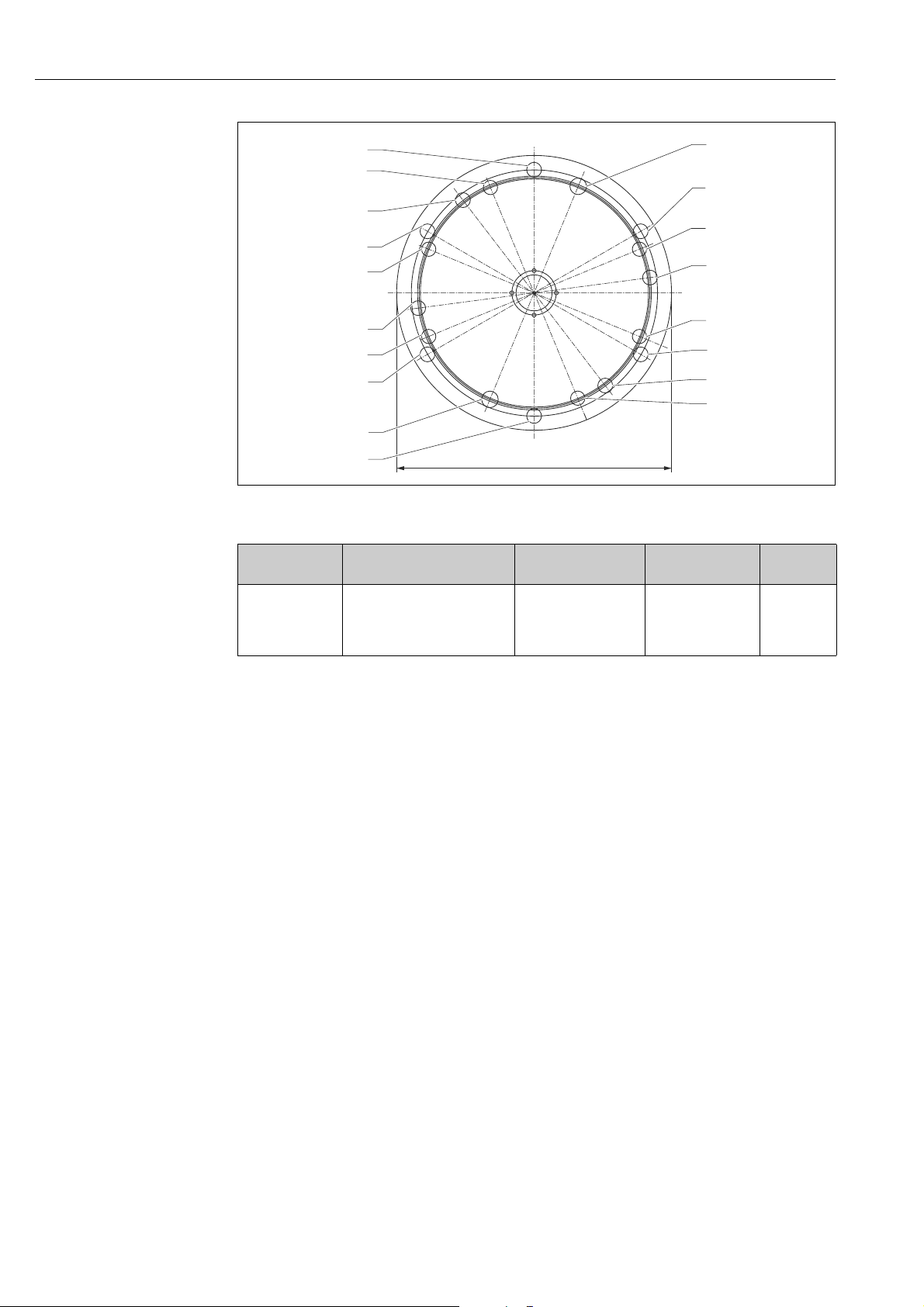

3.4.4 Installation with Endress+Hauser UNI flange

Installation hints

Endress+Hauser UNI flanges are designed for non-pressurized operation respectively

max. 1 bar (14.5 psi) absolute pressure. The number of bolts has sometimes been reduced.

The bolt-holes have been enlarged for adaption of dimensions, therefore, the flange needs

to be properly aligned to the counterflange before the bolts are tightened.

Endress+Hauser UNI flange. Dimensions: mm (in).

1 4 x ø7 mm (0.28 in) moved 90°

2 Sealing surface

3 For small bolts

UNI

Flange

B • DN150 PN16

C • DN200 PN16

D • DN250 PN16

Compatible with øD (mm [in]) øK (mm [in]) Type plate Material

• ANSI 6" 150lbs

• JIS 10K 150

• ANSI 8" 150lbs

• JIS 10K 200

• ANSI 10" 150lbs

• JIS 10K 250

A0021069

280 (11,0) 240 (9,45) 942455-3001

340 (13,4) 294,5 (11,6) 942455-3002

1.4301

405 (15,9) 358 (14,1) 942455-3003

Endress+Hauser 19

Mounting Micropilot S FMR532 4 to 20 mA HART

0°

2 [0°]

4 [22.5°]

2 [60°]

1 [67.5°]

3 [82.5°]

1 [112.5°]

2 [120°]

3 [142.5°]

1 [157.5°]

2 [180°]

4 [202.5°]

2 [240°]

1 [247.5°]

3 [262.5°]

1 [292.5°]

3 [322.5°]

1 [337.5°]

2 [300°]

ø482 (19) ±1.5

A0021069

Endress+Hauser UNI flange. Dimensions: mm (in).

Position Bolt circle diameter øK

1: for JIS

2: for ANSI

3: for DIN

4: for DIN+JIS

[mm (in)]

ø25 (0,98): 400 (15.7)

ø26 (1,02): 431.8 (17)

ø26* (1,02): 410 (16.1)

ø29 (1,14): 404.5 (15.9)

Compatible with Type plate Material

• DN300 PN16

• ANSI 12" 150lbs

•JIS 10K 300

942455-3004 1.4301

20 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Mounting

CAUTION

!

Made in Germany MaulburgMade in Germany Maulburg

ENDRESS+HAUSER

MICROPILOT

II

ENDRESS+HAUSER

MICROPILOTII

IP65IP 65

Order Code:

Ser.-No.:

Order Code:

Ser.-No.:

Messbereich

Measuringrange

Messbereich

Measuringrange

U 16...36 V DC

4...20 mA

U 16...36 V DC

4...20 mA

max.20 mmax. 20 m

T >70°C :

A

t >85°C

T >70°C :

A

t >85°C

ENDRESS+HAUSER

Preparation for the installation of the Endress+Hauser UNi flange

The mounting requires the following tools:

• Philips screw driver size 1

• Flat screw driver for M3/M4

• Hexagon key AF2.5/AF4

• Unplug tool for antenna plug (order nr.: 52007646)

• Eventually a pair of tweezers

A0021218

Order of exchange:

1. Unscrew lid from terminal compartment.

2. Disconnect cable at terminal module. Unscrew mounting screws at terminal module and

disconnect ground cable. Pull out terminal module. A connection to a cable feed-through

is located at the rear side of the module (the feed-through can be unscrewed, if required).

3. Unscrew lid from electronics compartment.

4. If installed, take display out of holder by pushing the hook upwards. Break the calibration

seal to unplug the sealing pin.

If the calibration seal is broken, the national calibration authority should be informed

within 24 hours.

Endress+Hauser 21

Mounting Micropilot S FMR532 4 to 20 mA HART

CAUTION

!

ENDRESS+HAUSER

ENDRESS+HAUSER

1x

5x

Pull front panel off.

Unplug display cable.

Loosen screw in cover and remove cover.

Loosen mounting screws at electronics

housing.

Pull electronics module out of the

housing. Unplug connection cable (right)

to the terminal module from the

electronics. Unplug antenna cable (left)

with unplug tool.

Don’t damage the antenna cable.

Press lower hook at module housing

slightly inwards.

Loosen the set screw in the housing about

1 turn. (Hexagon key AF4)

Unscrew the stop screw in the housing

about 4-5 turns. (Hexagon key AF2.5)

While turning the complete antenna

assembly, pull it out of the housing.

22 Endress+Hauser

A0021252

Micropilot S FMR532 4 to 20 mA HART Mounting

9 (0.35)

ø78 (3.07)

ø62.5 (2.46)

ø99.5 (3.92)

4

3

2

A

1

A Flange hub for the connection to flanges provided by the customer

1 Endress+Hauser UNI flange (max. 1 bar (14.5 psi))

1 Mounting: 4 bolts M6 / 90°; e.g.: DIN912

2 O-Ring 85.3x3.53; included (same material as sensor seal)

3Flange hub

The mounting of the housing and electronic raised last in - first out how disassembly.

3.5 Post-installation check

After the measuring device has been installed, perform the following checks:

• Is the measuring device damaged (visual check)?

• Does the measuring device correspond to the measuring point specifications such as

process temperature/pressure, ambient temperature, measuring range, etc.?

• Is the flange marking correctly aligned ( ä 10)?

• Have the flange screws been tightened up with the respective tightening torque?

• Are the measuring point number and labeling correct (visual check)?

• Is the measuring device adequately protected against rain and direct sunlight ( ä 71)?

A0021253

Endress+Hauser 23

Wiring Micropilot S FMR532 4 to 20 mA HART

CAUTION

!

CAUTION

!

CAUTION

!

1

3

2

6

112233445

5

8

A

B

5

7

4

4 Wiring

4.1 Quick wiring guide

When grounding conductive screens, the corresponding directives EN 60079-14 and

EN 1127-1 must be observed. Recommendation for safe grounding of conductive screens:

Before connection please note the following:

‣ The power supply must be identical to the data on the nameplate.

‣ Switch off power supply before connecting the device.

‣ Connect equipotential bonding to transmitter ground terminal before connecting the

device.

‣ Tighten the locking screw:

It forms the connection between the antenna and the housing ground potential.

‣ When you use the measuring system in hazardous areas, make sure you comply with

national standards and the specifications in the safety instructions (XA’s)

4.1.1 Wiring

Before connection please note the following:

‣ The power supply to be delivered by a transmitter supply unit.

‣ Befor removing housing cover at seperate connection compartment turn off the power

supply!

Insert cable through gland . Use screened,

twisted 2-wire or 4-wire cable.

Only ground screening of the line on

sensor side.

Make connection (see pin assignment).

Tighten cable gland.

Replace and tighten off housing cover.

Switch on power supply.

A Micropilot S situated in a hazardous

area is connected as a single device to a

power supply unit and transmitter

situated outside of the hazardous area.

In this case, it is recommended that the

screen be connected directly to the

Micropilot at the housing’s earth,

whereby the Micropilot S and the power

supply unit are connected to the same

potential equalization line.

24 Endress+Hauser

A Power 24 VDC; from a transmitter supply unit

B Signal 24 VDC; from a transmitter supply unit

1Housing cover

2Cable

3 Cable gland

4 Alternative connection

5 Commubox FXA195, Field Communicator

6Shielding cable

7 Test socket; Output current

8 PML (potential matching line)

A0020479

Micropilot S FMR532 4 to 20 mA HART Wiring

CAUTION

!

CAUTION

!

1

3

2

1234

112233445

5

16

20

24

28

17

21

25

29

18

22

26

30

19

23

27

31

p

- -

- -

-

-

+ +

+ +

+

+

H

12

3

4

H

H

OPT1

D+

S+

D-

S-

OPT2

OPT3

OPT4

6

7

8

9

A

B

5

4

4.1.2 Wiring with Tank Side Monitor NRF590

Before connection please note the following:

‣ Make sure you use the specified cable gland.

‣ Befor removing housing cover at seperate connection compartment turn off the power

supply!

Insert cable through gland . Use screened,

twisted 2-wire or 4-wire cable.

Only ground screening of the line on

sensor side.

Make connection (see pin assignment).

Tighten cable gland.

Replace and tighten off housing cover.

Switch on power supply.

The Micropilot S is - possibly in

combination with other devices connected to a Tank Side Monitor in a

hazardous area. In this case, it is

recommended that you ground the cable

screen centrally at the NRF590 and

connect all devices to the same potential

equalization line (PML). If, for functional

reasons, a capacitive coupling is required

between local earth and screen (multiple

grounding), ceramic condensers with a

dielectric strength of min. 1500 Veff

must be used, whereby the total capacitance of 10 nF must not be exceeded.

Notes on grounding

interconnected intrinsically safe devices

are provided by the FISCO model. If there

is no way to set a ground cable between

NRF590 and Micropilot S it is possible to

ground single side (grounding on side

NRF590). In this case it’s imperative to

ground the shield (on Micropilot S side)

via a ceramic capacitor with a maximum

capacitance of 10 nF and a minimum

insulating voltage of 1500 V.

A Tank Side Monitor NRF590

B Micropilot S

1Housing cover

2Cabel

3Cable gland

4 Intrinsically safe terminal board

5 Only for Micropilot S

6HART Sensor

7 Grounding single sided on Tank Side Monitor NRF590

8Shielding cable

9 PML (potential equalization line)

AA0020479

Endress+Hauser 25

Wiring Micropilot S FMR532 4 to 20 mA HART

1

2

3

4

5

AB

4.2 Connecting the measuring unit

Terminal compartment

The housing features a separate terminal compartment.

A0020471

APower supply

BSignal

Load HART

Minimum load for HART communication: 250

Cable entry

Description Feature Option model

Cable gland M20 060 2

Thread for cable gland G ½" 060 3

Thread for cable gland NPT ½" 060 4

Supply voltage

DC voltage: per table below

Communication Terminal voltage minimum maximum

Power supply

Signal Ex

Standard U (20 mA) = 16 V 36 V

Ex U (20 mA) = 16 V 30 V

U (4 mA) = 11.5 V 30 V

U (20 mA) = 11.5 V 30 V

Power consumption

• Max. 330 mW at 16 V

• Max. 500 mW at 24 V

• Max. 600 mW at 30 V

• Max. 700 mW at 36 V

Current consumption

Max. 21 mA (50 mA inrush current).

26 Endress+Hauser

Micropilot S FMR532 4 to 20 mA HART Wiring

Overvoltage protector

• The level transmitter Micropilot S is equipped with an internal overvoltage protector

(600 Vrms surge arrester) according to EN/IEC 60079-14 or EN/IEC 60060-1 (impulse

current test 8/20 μs, Î = 10 kA, 10 pulses). Additionally, the device is protected by a

galvanic insulation of 500 Vrms between the power supply and the (HART) current ouput.

Connect the metallic housing of the Micropilot S to the tank wall or screen directly with an

electrically conductive lead to ensure reliable potential matching.

• Installation with additional overvoltage protector HAW560Z/HAW562Z

(see XA00081F "Safety instructions for electrical apparatus certified for use in explosionhazardous areas").

– Connect the external overvoltage protector and the Micropilot S transmitter to the local

potential matching system.

– Potentials shall be equalised both inside and outside the explosion hazardous area.

– The cable connecting the overvoltage protector and the Micropilot S transmitter shall

not exceed 1 m (3.3 ft) in length.

– The cable shall be protected e.g. routed in an armoured hose.

Power supply

• For stand alone operation via two Endress+Hauser RN221N.

• Integrated in tank gauging system via Endress+Hauser Tank Side Monitor NRF590

(recommended operation mode).

Highly accurate measurement

For highly accurate measurements the measured variable must be transmitted using HART

protocol to ensure the necessary resolution.

4.2.1 Connection to Tank Side Monitor NRF590

"Wiring with Tank Side Monitor NRF590", ä 25.

Endress+Hauser 27

Loading...

Loading...