Page 1

micropilot

FMR 231

Microwave

Level Measurement

Operating Instructions

ENDRESS+HA

USER

MICROPILOTII

IP65

O

rder

Code:

S

er

.-N

o

.:

M

essbereic

h

M

easuring

range

U16.

..36VD

C

4...20m

A

m

ax.

20m

MadeinGermany Maulburg

T>70°C

:

A

t >

8

5

°C

ENDRESS+HA

USER

MICROPILOTII

IP65

O

rder

C

ode:

Ser

.-N

o

.:

M

essbereic

h

M

easuring

range

U16.

..36VD

C

4...20m

A

m

ax.

20m

MadeinGermany Maulburg

T>70°C

:

A

t >

8

5

°C

BA 171F/00/en/06.01

Software version 2.0

017479-1000

Hauser

+

Endress

The Power of Know How

Page 2

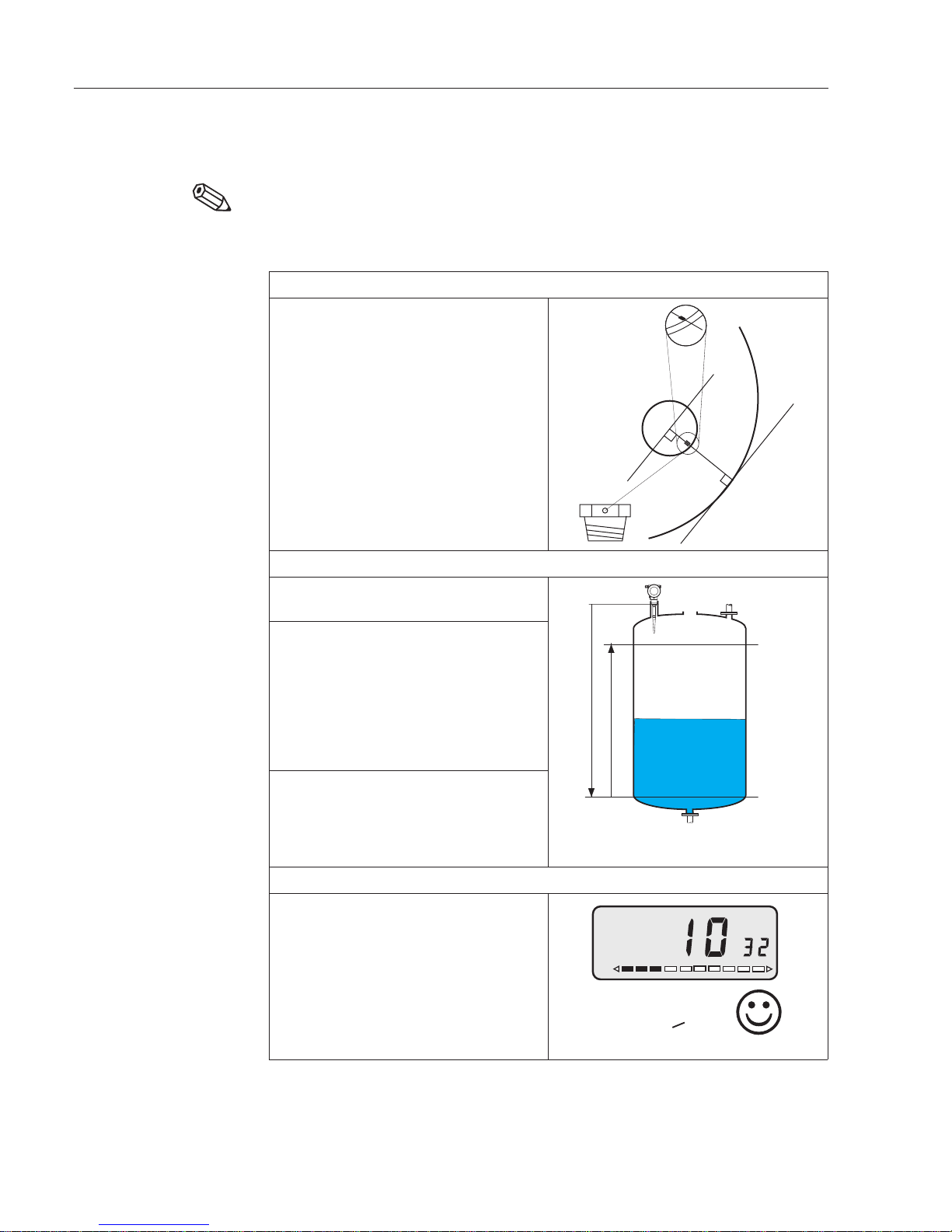

Short Instructions

Note!

• The datum point for the empty distance "E" is always the lower face of the process

connection.

• The full distance "F" can extend up to the tip of antenna.

• For stilling wells see Chapter 6.2

Calibration with VU 330

or remote operation for

buffer and storage tanks

Note!

➀ Check installation

1. Check that the alignment mark points

to the tank wall, see also Chapter 2.1.

➁ Calibration

1. Reset

V9H5 = 333

2. Empty and full calibration

V0H1 = E

V0H2 = F

V0H3 = A (application parameter)

A = 0: Tanks up to 7 m

A = 1: Tanks up to 1.5 m

A = 2: Tanks up to 7 m, ε

r

<10

A = 3: Tanks from 7 m to 20 m

3. False echo suppression

Tank empty (≤E)!

V3H0 = 4

V3H1 = (E – 0,8 m)

For partially full tanks see Chapter 6.1.

➂ Check echo quality

1. Echo qualitity

Observe when filling tank

V3H2 ≥ 10 dB

Measurement in order

V3H2 < 10

Measurement not in order:

Optimise alignment, see Chapter 7.5.

Try different nozzle position,

see Chapter 2.1.

flange

tank wall

alignment

mark points

to tank wall

nozzlemin.

30 cm from

wall

thread

F

E

100%

20mA

0%

4mA

V H

V3H2 >10:

Short Instructions Micropilot FMR 231

Endress+Hauser

Page 3

TableofContents

NotesonSafety........... 3

1 Introduction ............ 5

1.1 Measurement principle...... 6

1.2 Measuringsystem........ 8

2 Installation............. 9

2.1 Mountingina tank........ 9

2.2 Mountinginstillingwells...... 12

2.3 Protectivecover......... 13

3 Connection............. 14

3.1 Wiringexamples......... 15

4 Operation ............. 16

4.1 On-site operation ........ 16

4.2 Remoteoperation........ 18

5 On-sitecalibrationwithoutdisplay

VU330...............21

6 CalibrationwithDisplay/Remote

Operation ............. 23

6.1 Basic calibration for tanks..... 24

6.2 Basic calibration for bypasspipes

and stillingwells: ........ 26

6.3 Linearisation.......... 28

6.4 Analogueoutput......... 31

6.5 Safetyfunctions......... 32

6.6 Locking/unlocking the matrix.... 33

6.7 Measuringpointinformation.... 34

7 Trouble-Shooting ..........35

7.1 Self-monitoring .........35

7.2 Error messages.........36

7.3 Faultanalysis..........37

7.4 Applicationparameter ......39

7.5 Echo quality ..........40

7.6 Falseechosuppression......41

7.7 Windowsuppression.......42

7.8 Plausibility...........42

7.9 Simulation ...........43

7.10Reset.............44

8 Maintenance andRepair .......45

8.1 Maintenance ..........45

8.2 Repairs ............45

8.3 Spare parts...........46

9 Technical Data ...........49

9.1 Dimensions...........52

9.2 Deratingdiagrams........53

9.3 Productstructure FMR231E....54

9.4 Productstructure FMR231A....55

10 OperatingMatrix ..........56

10.1Matrixoperation.........56

10.2HART.............57

Index ...............58

Micropilot FMR231 Table of Contents

Endress+Hauser 1

Page 4

Software History

Software

version

Manual

version

Device/

Software

No.

Software revision Changes in manual

1.0 02.98 2310 Original software operable with

Commuwin II, from software version

1.41

HART handheld from software

version 1.11 with DD version 1.0

2.0 11.98 2320 Improvement of evaluation

algorithms

Introduction of matrix field V8H6,

plausibility

Operable via Commuwin II,

software version 2.0

HART handheld from software

version 1.11 with DD version 1.0

No effect on operation

Plausibility described in Chapter 7.8

No visible effects on operation

Bypass pipe application removed,

Chapters 2 and 6 revised

An up/download of device data between devices with different software versions is not possible without special

software tools.

Micropilot FMR 231 Software History

2 Endress+Hauser

Page 5

Notes on Safety

Approved usageThe Micropilot FMR 231 is a compact level transmitter designed for continuous,

non-contact level measurement of liquids, pastes and slurries.

The operating frequency of 5.8 GHz lies in a frequency band approved for industrial use.

FCC approved devices operate at 6.3 GHz. Its low pulse power of 1 mW (1 µW ERP)

allows safe installation in metallic and non-metallic vessels, with no risk to humans or the

environment.

Installation,

commissioning,

operation

The Micropilot FMR 231 has been designed to operate safely in accordance with current

technical, safety and EU standards. If installed incorrectly or used for applications for

which it is not intended, however, itis possible that application-related dangers mayarise,

e.g. product overflow due to incorrect installation or calibration. For this reason, the

instrument must be installed, connected, operated and maintained according to the

instructions in this manual: personnel must be authorised and suitably qualified. The

manual must have been read and understood, and the instructions followed.

Modifications and repairs to the device are permissible only when they are expressly

approved in the manual.

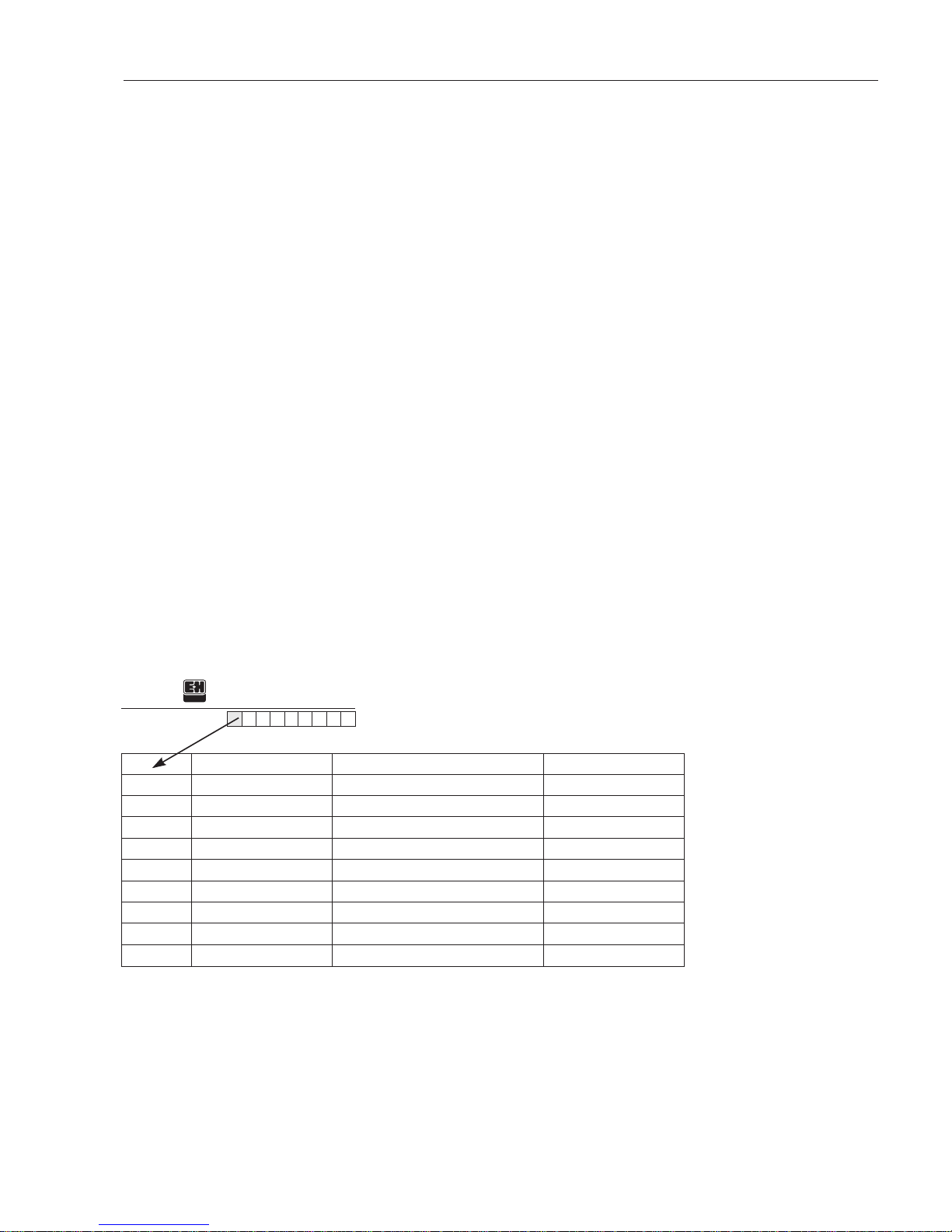

Explosion hazardous

areas

If the device is to be installed in an explosion hazardous area, then the specifications in

the certificate as well as all national and local regulations must be observed. The

instrument can be delivered with the certificates listed in the table below. The certificate

can be identified from the first letter of the order code stamped on the nameplate.

•

Ensure that all personnel are suitably qualified

•

Observe the specifications in the certificate as well as national and local

regulations.

•

Switch off the power before opening the T12 housing in explosion hazardous

areas. The display module is stowed in a separate housing (EEx ia) which can be

opened when the Micropilot is in operation.

FCC approvalThis device complies with part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference and (2) this device

must accept any interference received including interference that may cause undesired

operation. In addition, the device may be used in metal vessels only.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

Code Certificate Protection Housing

A none none F12

1 PTB ATEX II 1/2 G EEx ia IIC T3...T6 F12

2 PTB ATEX II 1/2 G EEx e m [ia] T3...T6 T12

K TIIS Ex ia IIC T3 F12

R none none F12 (FCC approval)

S FM IS Cl. I, Div. 1, Group A-D F12 (FCC approval)

T FM XP Cl. I, Div. 1, Group A-D T12 (FCC approval)

U CSA IS Cl. I, Div. 1, Group A-D F12

V CSA XP Cl. I, Div. 1, Group A-D T12

Table S.1

Certificates for use in explosion

hazardous areas

FCC approved devices operate

at 6.3 GHz and are for USA only

ENDRESS+HAUSER

MICROPILOT FMR 231

Order No.FMR 231-

Micropilot FMR 231 Notes on Safety

Endress+Hauser 3

Page 6

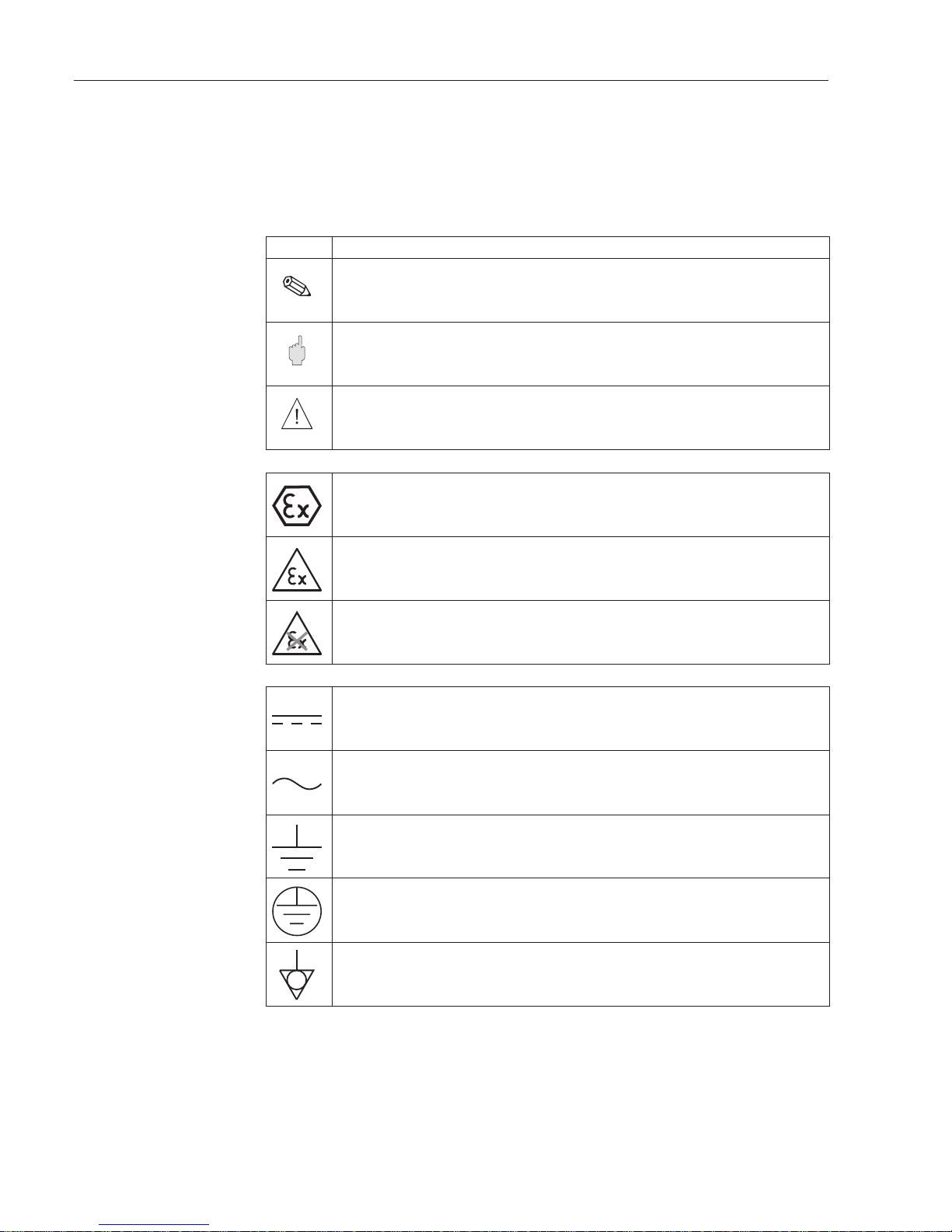

Safety Conventions and Symbols

In order to highlight safety-relevant or alternative operating procedures in the manual,

the following conventions have been used, each indicated by a corresponding icon in

the margin.

Safety conventions

Explosion protection

Electrical symbols

Symbol Meaning

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect

operation or may lead to an instrument response which is not planned

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to

personal injury or incorrect functioning of the instrument

Warning!

A warning highlights actions or procedures which, if not performed correctly, will lead to

personal injury, a safety hazard or destruction of the instrument

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion

hazardous area in accordance with the specifications in the certificate or in a safe area

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas.

Devices located in and wiring entering areas with the designation “explosion hazardous

areas” must conform with the stated type of protection

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas.

Devices located in safe areas stiill require a certificate if their outputs run into explosion

hazardous areas.

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be

applied or supplied

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by

means of an earth grounding system

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to

the equipment

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or

equipotential line according to national or company practice

Note!

Caution!

Warning!

Notes on Safety Micropilot FMR 231

4 Endress+Hauser

Page 7

1 Introduction

ApplicationThe Micropilot FMR 231 is a loop-powered transmitter. It is used to for continuous

non-contact level measurement of liquids, pastes and sludges. It is suitable for use in:

•

storage tanks, buffer tanks and stilling wells

with few internal fittings and where the product surface is generally calm. Changes of

product, temperature gradients, inert gas blankets or vapours do not influence the

measurement.

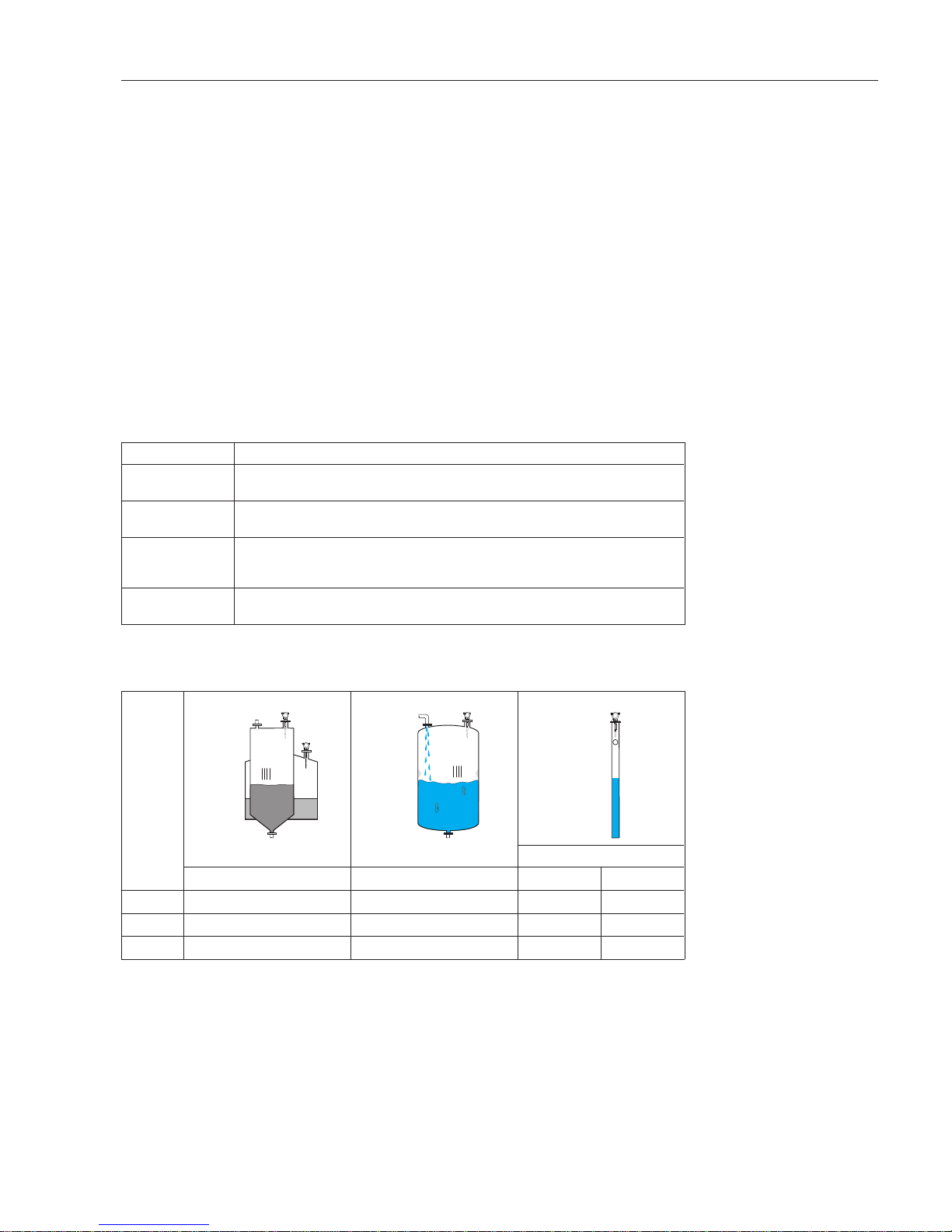

VersionsThe various Micropilot FMR 231 versions result from the combinations between antenna

type, inactive length and the process connection. Table 1.1 summarises them. The

product structure is described in Chapter 9.

BA171Y05

➀

➁

BA171Y06

Fig.1.1

➀

Storage tank

➁

Stilling well or bypass pipe

Application

Standard, for tanks and stilling wells Hygienic, corrosive-resistant, for tanks

and stilling wells

Housing

Housing F12 (standard/EEx ia/Ex IS) or housing T12 (standard/EEx e/Ex XP)

Antenna type

PPS antenna PTFE antenna

Inactive length

100 mm/250 mm

Process connection

Thread 1½ BSPT (R 1½) or 1½ NPT, PVDF

Flange DN50/80/100150/ or ANSI/JIS equivalent

Sanitary coupling: dairy, Tri-clamp or aseptic

Cladding

uncladded cladded or uncladded

Pressure/

flange temperature

0...16 bar

–20°C...+120°C

0...16 bar with cladded flange

0...40 bar uncladded flange

–40°C...+150°C

Wetted parts

PPS, Viton O-ring,

1.4435 flange/thread

Uncladded: PTFE und 1.4435

flange/thread

Cladded: PTFE only

PPS = Polyphenylene sulphide

Table 1.1

Micropilot FMR 231 versions

Micropilot FMR 231 Chapter 1 Introduction

Endress+Hauser 5

Page 8

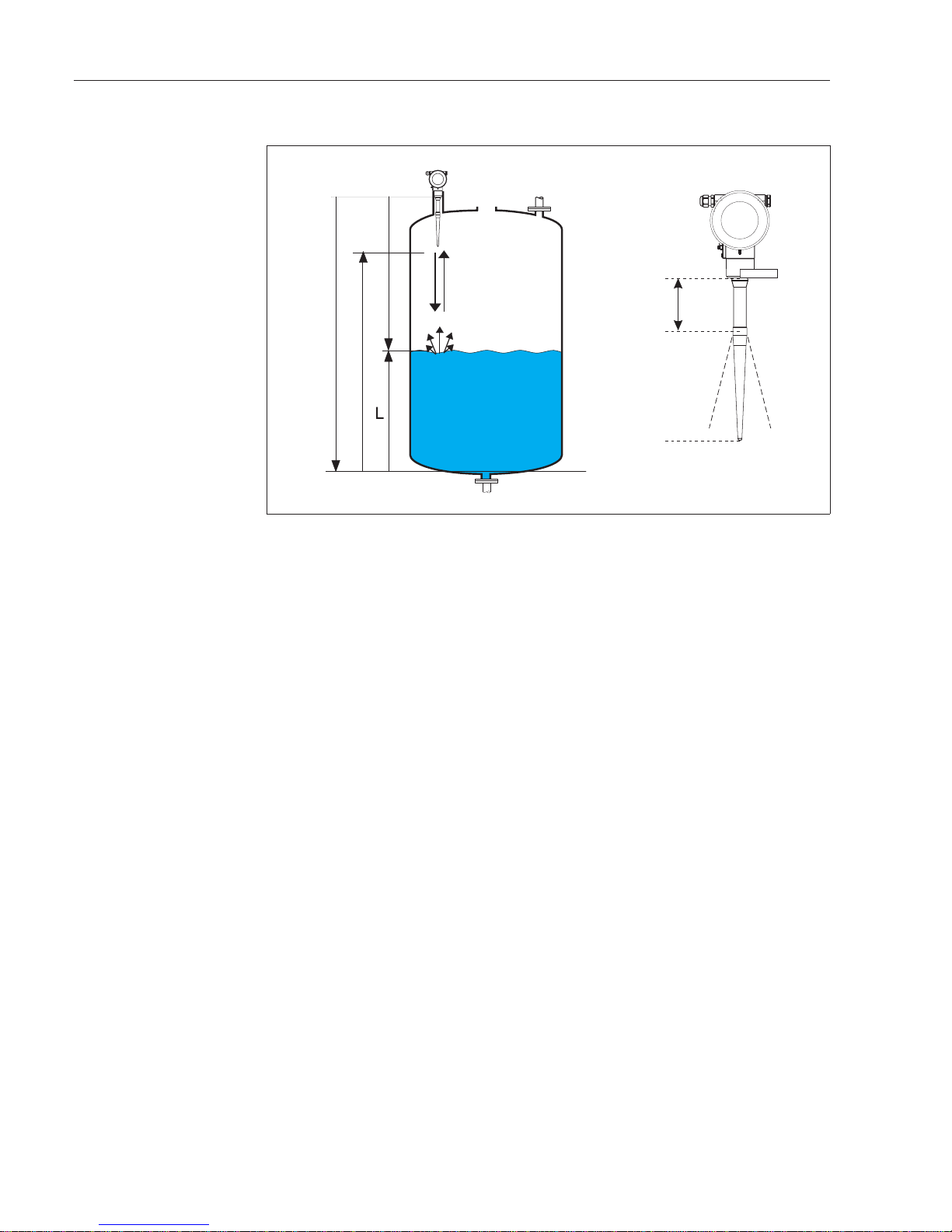

1.1 Measurement principle

Micropilot is a "downward looking" time-of-flight system which measures the distance

from the probe mounting (top of the tank) to the surface of the process medium.

Short microwave pulses are beamed by the antenna towards the product, reflected by

its surface and detected by the same arrangement.

An inactive length at the start of the rod antenna delays the launch of the pulse for a

distance of 100 mm or 250 mm, ensuring that condensation or build-up in the mounting

nozzle does not affect the measurement.

Input The reflected microwaves are detected by the antenna and passed on to the electronics.

Here a microprocessor evaluates the signal and identifies the echo produced by the

reflection of the beam at the product surface. The algorithms used for signal processing

are based on many years of experience in time-of-flight measurement.

The distance D to the product surface isproportional to the time-of-flight of the microwave

pulse t:

D = c • t/2

where c is the speed of propagation

Since the empty distance E is known to the system, it is a simple matter to calculate the

level L:

L = E – D

The datum point for "E" is the bottom face of the process connection.

Micropilot has an echo suppression function which can be activated by the user. This

prevents interference echoes, e.g. caused by fittings within the beam, from being

interpreted as the level echo.

Output Micropilot is calibrated by entering the empty distance E, the full distance F and an

application parameter, which automatically tunes the instrument to the measuring

conditions.

For versions with current output, the points "E" and "F" correspond to 4 mA and 20 mA,

for digital outputs and the display to 0% and 100% level.

F

E

D

BA171Y06

datum point

beam

launched

here

inactive

length

datum point

max.level

Fig.1.2

Microwave measurement

principle

Chapter 1 Introduction Micropilot FMR 231

6 Endress+Hauser

Page 9

A linearisation function, based on a manually or semi-automatically entered table, can

be activated locally at the display unit or via the foreign system interface. This allows

measurement in customer units andprovides a linear outputcurrent for spherical vessels,

horizontal cylinders and tanks with conical outlet.

AccuracyThe accuracy of Micropilot FMR 231 is dependent upon the set measuring range and

material being measured, see Technical Data. Under reference conditions it is capable

of measuring to an accuracy of ±15 mm up to a measuring range of 10 m and ±0.15%

of the range end-value of measuring ranges from 10 m to 20 m..

Measuring rangeThe measuring range depends upon the conditions in the tank and the product to be

measured. Table 1.2 describes the product classes, Table 1.3 the measuring range as

a function of the application and measuring conditions.

In order to ensure the highest accuracy for Class B, we recommend that

•

the empty distance "E" should be 30 cm above the tank bottom.

Class A products can be measured in bypass pipes using the FMR 230V horn antenna,

see operating manual BA 197F.

Product class Examples

A Non-conducting liquids, e.g. propane, buthane etc.

Dielectric constant ε

r.

1.4...1.9

B Non-conducting liquids, e.g. petrochemicals, benzine, oil, toluol, etc.

Dielectric constant ε

r

approx. 1,9...4

C E.g. concentrated acids, organic solvents, analine, esters, alcohols, acetone, etc.

oil/water mixtures

Dielectric constant ε

r

approx. 4...10

D Conducting liquids, watery solutions, dilutte acids and alkalis,

Dielectric constant ε

r

> 10 or electrical conductivity σ>10mS/cm

Table 1.2

Selection of product class

Product

Class

Strorage tank Buffer tank Stilling well or bypass pipe

Measuring range

Measuring range Measuring range

DN 50 DN 80

B

10 m 33 ft 5 m 16 ft 10 m 33 ft 20 m 67 ft

C

15 m 50 ft 8 m 25 ft 10 m 33 ft 20 m 67 ft

D

20 m 67 ft 10 m 33 ft 10 m 33 ft 20 m 67 ft

Table 1.3

Measuring range as a function of

application

Micropilot FMR 231 Chapter 1 Introduction

Endress+Hauser 7

Page 10

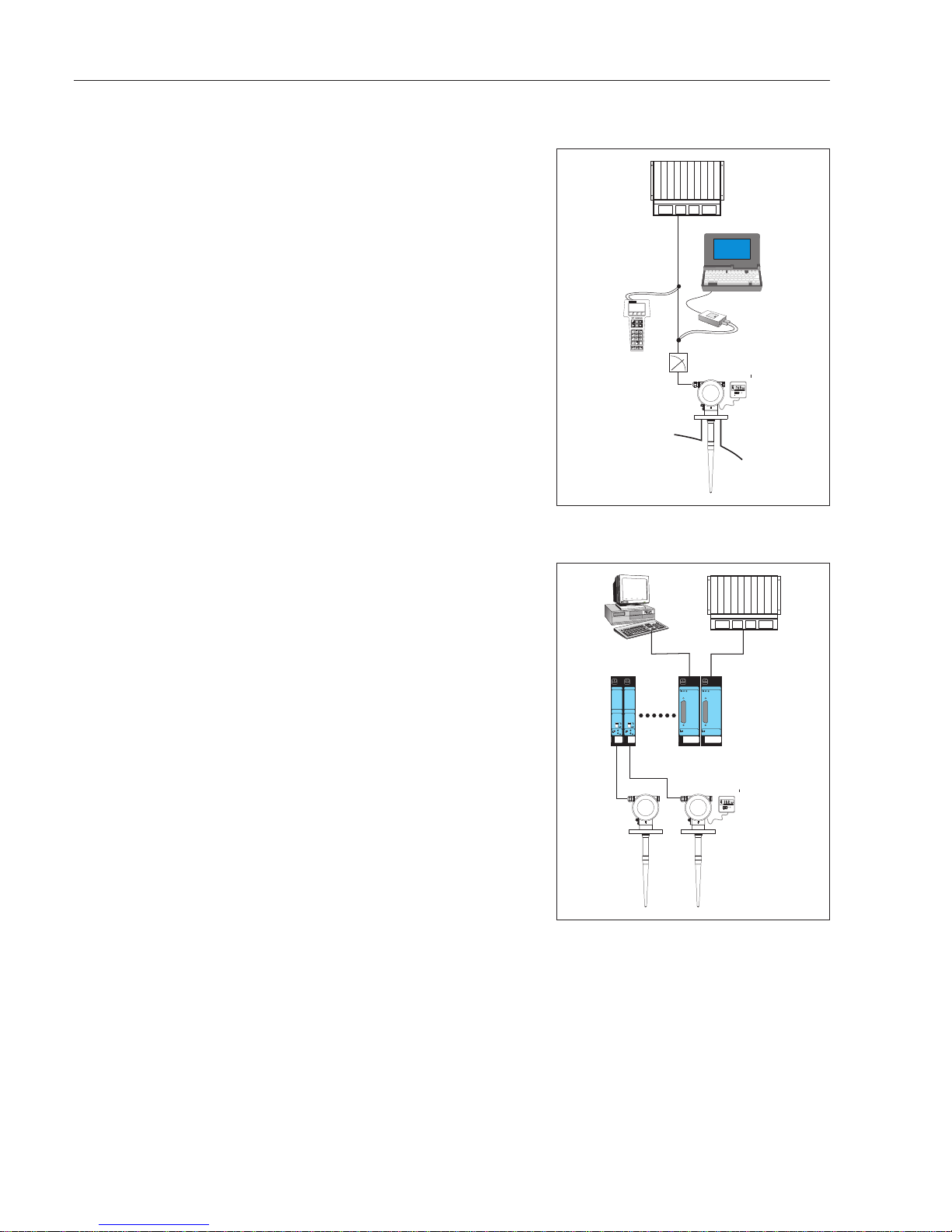

1.2 Measuring system

4...20 mA with HART

Version with passive 4...20 mA current

output and superimposed HART digital

signal.

•

Can be operated either on-site or

remotely with the HART handheld

DXR 275.

•

Alternatively, a personal computer,

Commuwin II and Commubox FXA 191

can be used.

•

Loop-power is provided by a PLC or

power supply unit.

System integration via

Rackbus

Several Micropilot transmitters (or other

devices with HART output) can be linked to

a supervisory bus system with a gateway

ZA.

•

One FXN 672 interface module is

required for each transmitter.

•

Gateways are available for MODBUS,

PROFIBUS, FIP, INTERBUS etc..

•

Both on-site and remote operation are

possible, e.g. with Commuwin II (CW II).

I

O

V

H

+

VH

BA171Y11

DXR

275

4...20 mA

with HART

PLC

loop power

Commubox

with laptop

operating

and display

module

VU 330

FXN 671

mA1

+

FXN 671

mA1

+

V

H

+

VH

ZA672 ZA672

BA171Y11

FXN

672

4...20 mA with HART

PLCPC with

CW II

operating

and display

module

VU 330

busRS 232C

Gateway to

MODBUS, FIP,

PROFIBUS,

INTERBUS etc..

Chapter 1 Introduction Micropilot FMR 231

8 Endress+Hauser

Page 11

2 Installation

2.1 Mounting in a tank

General notes

The microwaves should arrive unhindered

at the product surface.

•

Every object within the beam gives an

echo. The nearer the object, the

stronger the echo.

•

Strong echoes which cannot be

avoided by selecting a different

mounting position interfere with the

measurement and must be suppressed

during calibration.

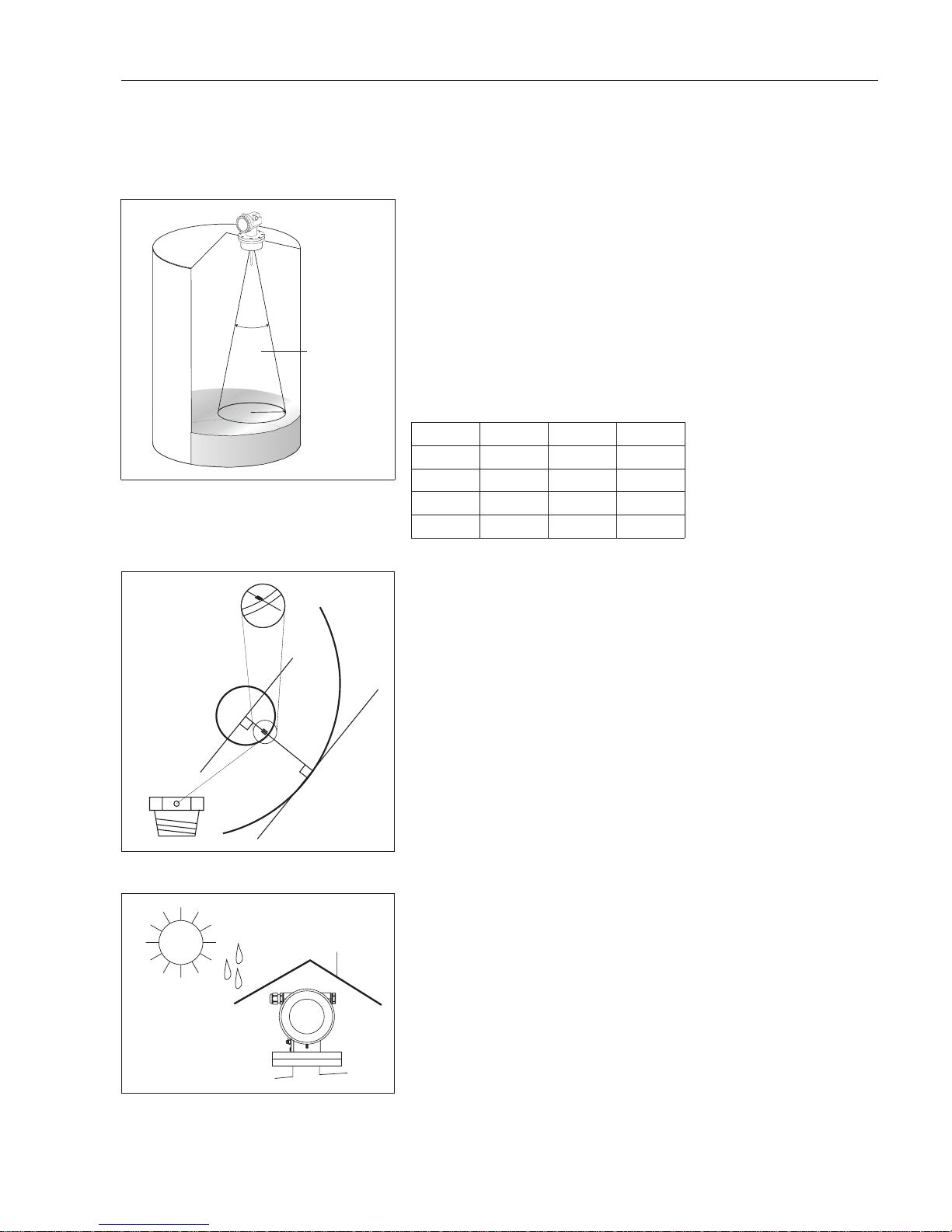

Beam cone

Distance Radius r Distance Radius r

5 m 1 m 16 ft 3ft

10 m 2 m 33 ft 6 ft

15 m 3 m 50 ft 9 ft

20m 4m 67ft 12ft

Alignment

When installed, the alignment mark to be

found on the flange or threadedconnection

of the Micropilot should point towards the

tank wall.

•

Distance from tank wall min. 30 cm

The alignment can be optimised using

V3H2 as described in Chapter 7.5.

Ambient temperature

The ambient temperature of the housing

must be within the following limits, see also

Chapter 9.

•

Housing F12:

standard operation: –40°C...80°C

EEx ia T6 –40°C...50°C*

•

Housing T12:

standard operation: –40°C...80°C

EEx e T6 –40°C...50°C*

*For full details see certificate.

A protective cover is available for outdoor

mounting, Part No. 543199-0001.

BA171Y16

Fittings within

the beam cause

false echoes

23°

r

BA171Y17

tank wall

if possible,

clearance

greater than

30 cm

alignment

mark points to

tank wall

flange

thread

BA171Y21

Use a protective coverwhen

mounting outdoors

Micropilot FMR 231 Chapter 2 Installation

Endress+Hauser 9

Page 12

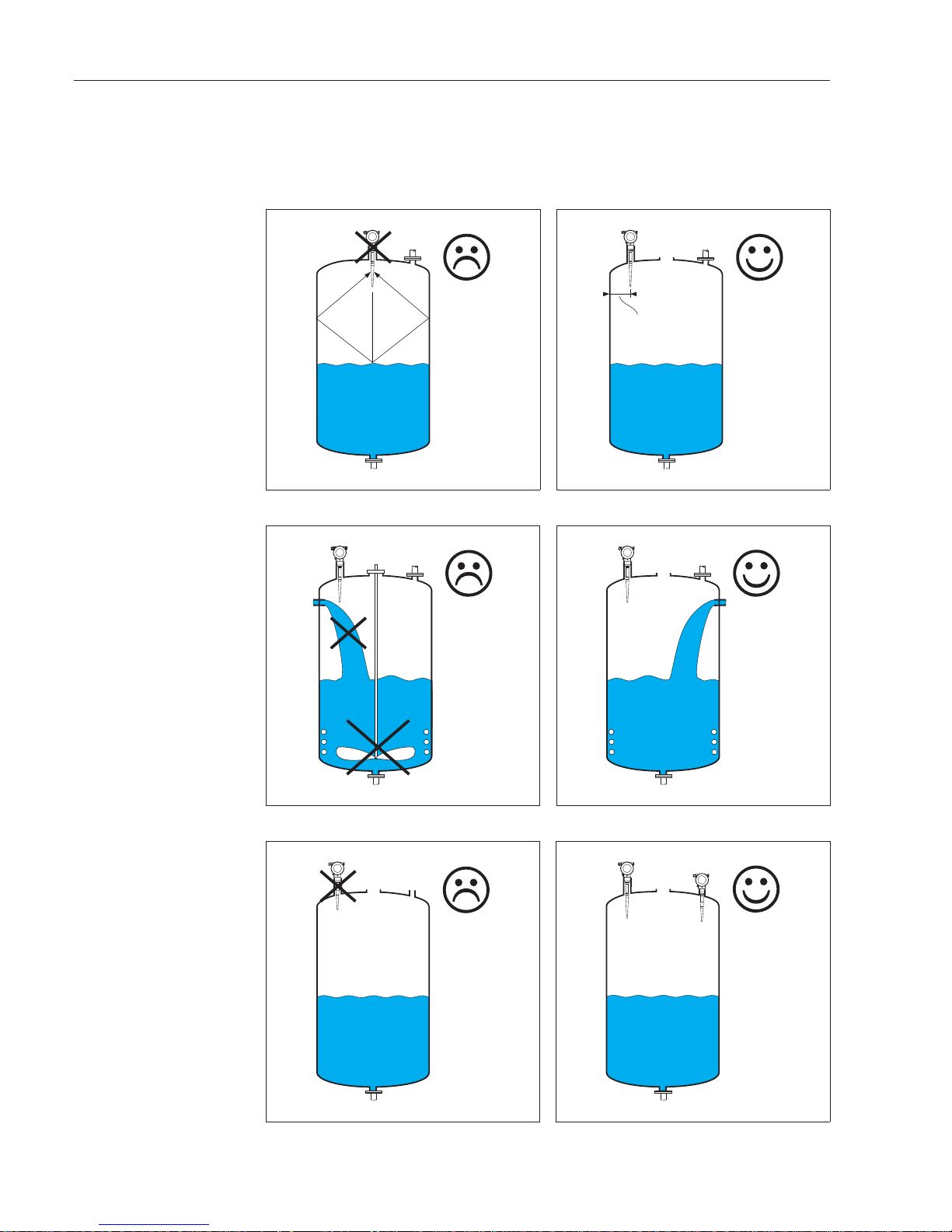

Mounting position

The ideal mounting position is as follows:

•

not in the middle of the tank

•

not above the filling stream

•

no fittings in beam

•

avoid vibration, direct high-pressure

cleaning and lateral loads.

min. 30 cm

BA171Y72

A decentral

position avoids

double echoes

BA171Y71

A central

position

strengthens

double echoes

BA171Y73

A positionaway

from the filling

stream will avoid

interference

echoes

Echos from

fittings are

suppressed

during

calibraatrion

BA171Y74

A positionabove

the fillingstream

will be subject to

interference

echoes

It is not possible

to measure in

tanks with

stirrers

BA171Y76

If the nozzle is too

long, noise will

reduce the signal

quality

BA171Y75

Use either a

longer antenna

or a shorter

nozzle –

see page 11 for

details

Chapter 2 Installation Micropilot FMR 231

10 Endress+Hauser

Page 13

Caution!

•

Applications in hazardous areas: electrostatic charging, e.g. rubbing clean, must be

avoided for standard PTFE and PTFE-clad antennas.

•

Always tighten the locking screw, since this connects the antenna to the ground

potential of the housing.

Nozzle

•

There is no restriction on nozzle

diameter provided that the length is

less than or equal to the inactive length.

•

Max. nozzle length hmax

100 mm for 100 mm inactive length,

250 mm for 250 mm inactive length.

•

The alignment mark on the flange

should point towards the tank wall.

•

After mounting, the housing can be

turned through 350° for convenient

access to the display and connection

compartment. The locking screw must

be loosened before turning.

•

Tighten the locking screw after turning.

Threaded connection

•

The hexagonal nut (AF 60) is used to

screw the transmitter in position.

•

Use e.g. a PTFE tape to seal the

process connection.

•

The alignment point on the threaded

connection should point towards the

tank wall.

•

After mounting, the housing can be

turned through 350° for convenient

access to the display and connection

compartment. The locking screw must

be loosened before turning.

•

Tighten the locking screw after turning.

BA171Y18

ground terminal

locking screw

datum point of

measurement

h

max

100 mm

or

250 mm

beam

launched

here

mark points to

tank wall

max.level

use spring

washers for

cladded

flange

inactivelength

BA171Y19

mark points to

tank wall

max.level

datum point of

measurement

locking screw

ground terminal

sealing tape

h

max

100 mm

or

250 mm

beam

launched

here

inactivelength

Caution!

Micropilot FMR 231 Chapter 2 Installation

Endress+Hauser 11

Page 14

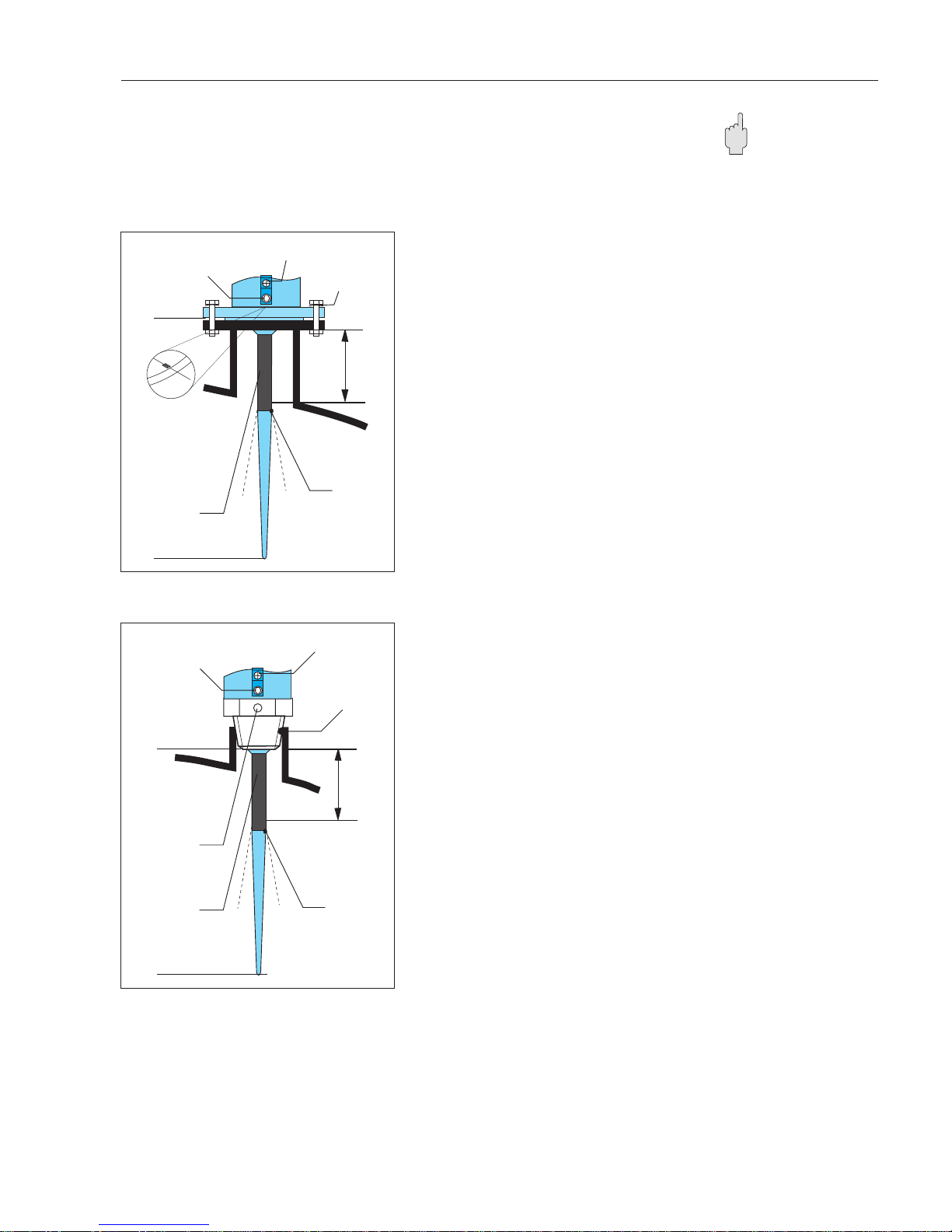

2.2 Mounting in stilling wells

Installation

Mount the antenna perpendicular and in

the centre of the well.

•

Slight unevenness of the well surface or

light build-up do not influence the

measurement

•

Measurements also possible through

open ball valves.

•

The alignment mark to be found on the

flange should point towards the slots.

•

After mounting, the housing can be

turned through 350° for convenient

access to the display and connection

compartment. The locking screw must

be loosened before turning.

•

Tighten the locking screw after turning.

.

Stilling well design

To ensure highest accuracy, the stilling well

should be designed as follows.

•

Metal construction

•

Constant diameter.

•

If possible, welding seam along axis of

slots.

•

Slots offset at 180° (not 90°), deburred

•

Slot width max. 1/10 of pipe diameter.

The length and number of slots has no

effect on the measurement.

Ambient temperature

The ambient temperature of the housing

must be within the following limits, see also

Chapter 9.

•

Housing F12:

standard operation: –40°C...80°C

EEx ia T6 –40°C...50°C*

•

Housing T12:

standard operation: –40°C...80°C

EEx e T6 –40°C...50°C*

*For full details see certificate.

A protective cover is available for outdoor

mounting, Part No. 543199-0001.

BA171Y77

inactive

length

100 mm

or

250 mm

locking screw

datum point for

measurement

alignment mark

pointing towards

the slots

spring

washer

for

cladded

flange

beam

launched

here

ground terminal

max.level

d

BA171Y22

if possible

welded along

axis of slots

slots offset

by 180°

slot width

max.

1

/10of

pipe diameter

BA171Y21

Use a protective cover when

mounting outdoors

Chapter 2 Installation Micropilot FMR 231

12 Endress+Hauser

Page 15

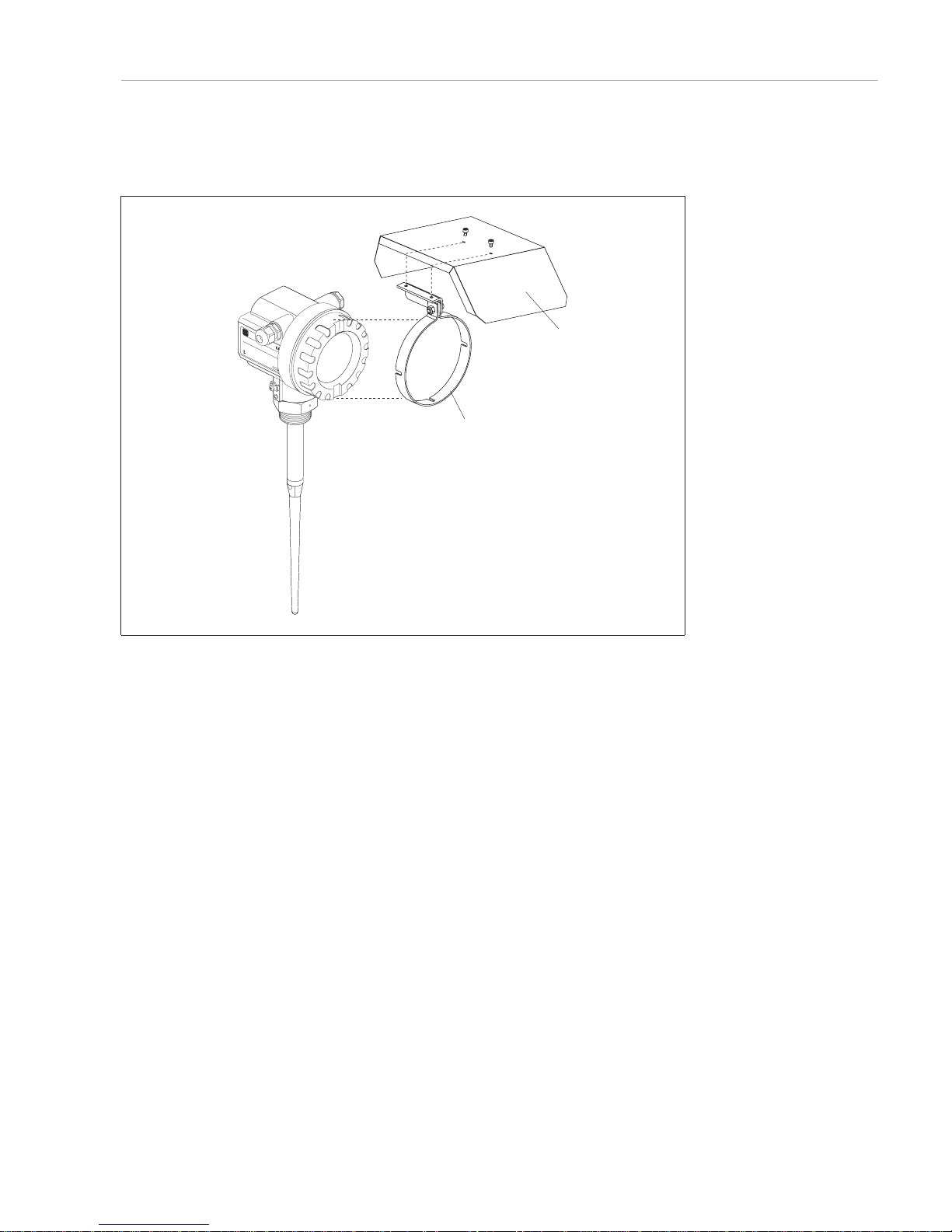

2.3 Protective cover

A protective cover is available for outdoor mounting, Part No. 543199-0001. The scope

of delivery comprises the cover and clamping ring.

ENDRESS+HAUSER

MICRO

P

ILOTII

ENDRESS+HAUSER

MICROPILOTII

IP65

IP65

OrderCode:

Ser.-No.:

OrderCode:

Ser.-No.:

Messber

eich

Measuringrange

Messbereich

Measuringrange

U16...36VDC

4...20mA

U16...36V DC

4...20mA

max.20m

max.20m

MadeinGermany Maulburg

T>70°C:

A

t >85°C

T >70°C:

A

t >85°C

BA171Y78

clamping ring

protectivecover

Micropilot FMR 231 Chapter 2 Installation

Endress+Hauser 13

Page 16

3 Connection

General notes The Micropilot is a loop-powered transmitter with 4...20 mA analogue output and

superimposed HART signal. Note the following before connecting up:

•

The power supply rating must correspond to that on the nameplate.

•

Turn off the power before connecting up.

•

Connect the external ground terminal of the transmitter to the plant grounding

system before connecting up.

•

Always tighten the locking screw, since this connects the antenna to the ground

potential of the housing.

Hazardous areas If the measuring system is to be installed in a hazardous area, local regulations, national

guidelines and the specifications inthe certificate are tobe observed.The specified cable

gland must be used.

For certified transmitters, the explosion protection is realised as follows:

•

Housing F12: EEx ia.

The power supply must be intrinsically safe.

•

Housing T12: EEx e m.

The housing must be integrated into the plant grounding system.

The power must be switched off before the connection compartment is opened.

The electronics and current output are galvanically isolated from the antenna circuit.

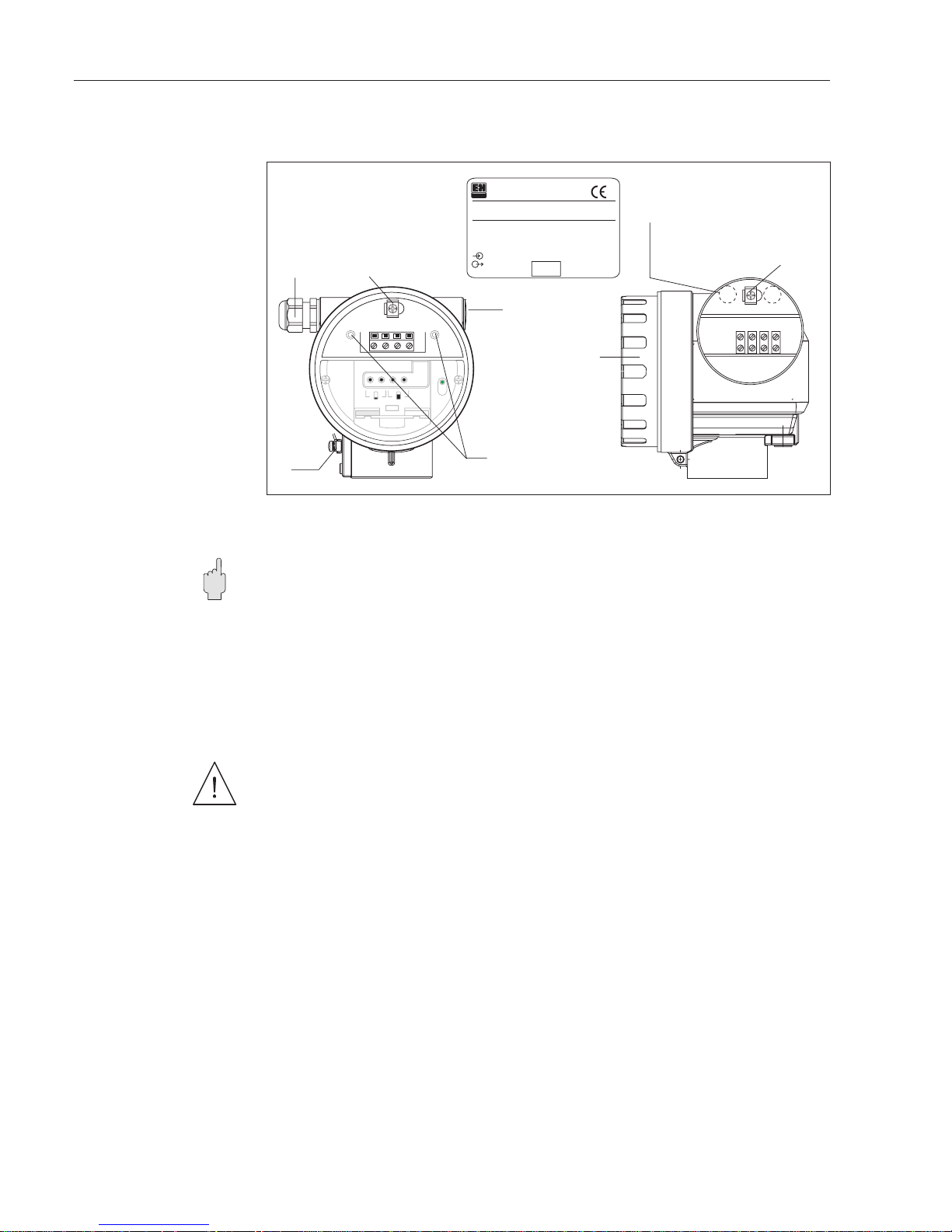

Connection Connect up the Micropilot as follows:

•

Switch off power.

•

Unscrew lid of housing or connection compartment.

•

For F12 housing: If appropriate, remove VU 330.

Remove cover plate to connection compartment.

•

Pull out terminal module with plastic loop.

•

Thread cable through cable gland or conduit

•

Connect up, see wiring examples.

•

Push terminal module back into place.

•

For F12 housing: Screw cover plate to connection compartment

If appropriate, stow away VU 330.

•

Screw on housing or connection compartment lid and screw cable gland or

conduit tight.

•

Switch on power.

Caution!

1

234

–

+

–

+

1

234

ENDRESS+HAUSER

MICROPILOT II

Order Code:FMR231-CEGGJ1A1A

Ser.-No.:PIZ0187

IP 65

EEx ia

Messbereich max.20 m

Measuring range

PN max 15 bar

T max. 150°C

antenna

BZT G133

414J

T < 80°C

A

U 16...30 DC

4...20 mA

Cable gland

Nameplate

external

ground

terminal

Connection compartment

behind cover plate –

loosen screws

BA171Y23

2nd cable entry

Operating elements in

display compartment

ground

terminal

HousingT12Housing F12

2x cable entries

at the rear

Fig.3.1

Micropilot connection

compartments and nameplate

Warning!

Chapter 3 Connection Micropilot FMR 231

14 Endress+Hauser

Page 17

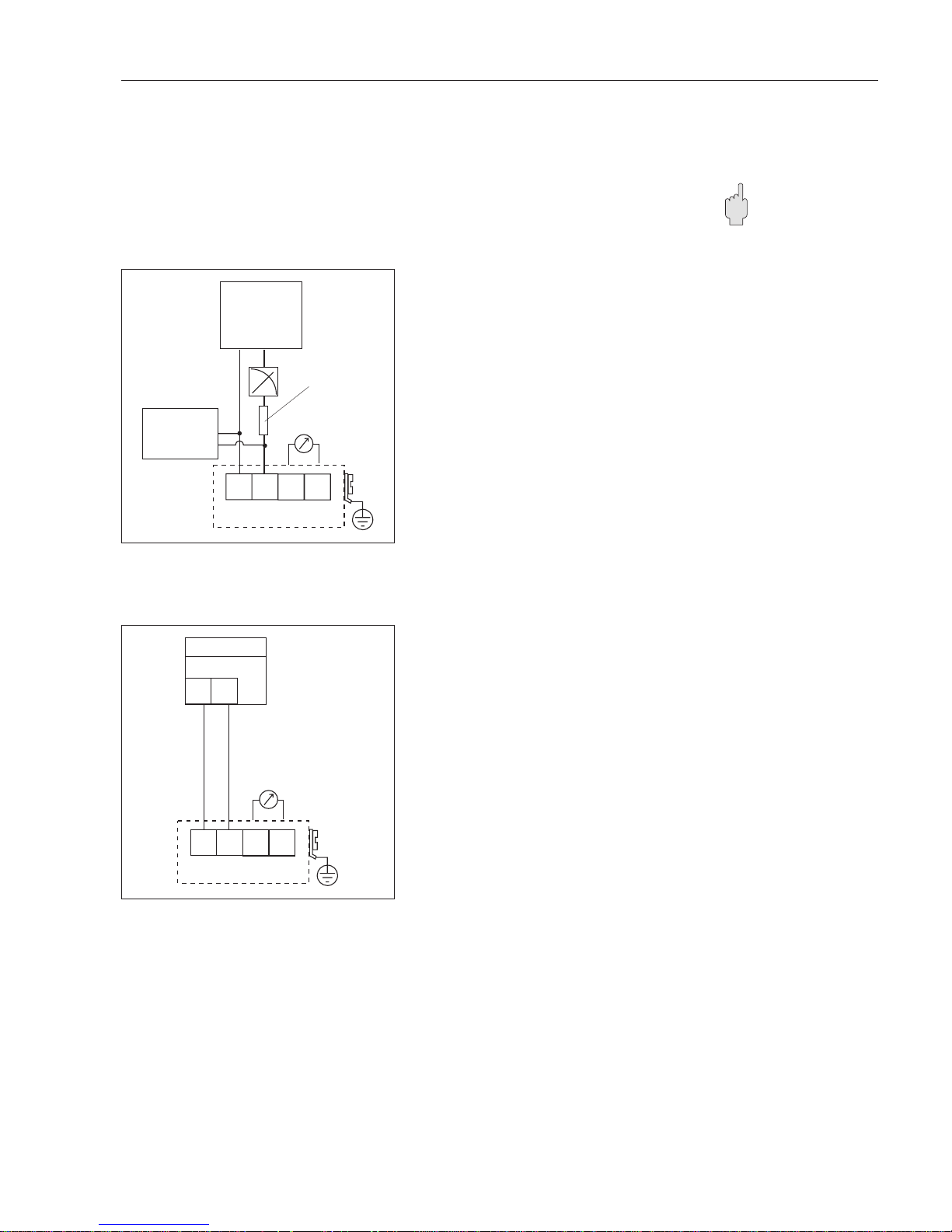

3.1 Wiring examples

The following figures show wiring examples for typical applications: In general:

•

If possible, ground both ends of the signal line screening. If this is not possible,

ground at the sensor side only.

•

In hazardous areas, the signal line may be grounded at the sensor side only.

Observe the instructions in the certificate.

4...20 mA with HART

Use screened, twisted pairs.

•

Min. load for HART 250 Ω

•

Max. load:

Housing F12: 1100 Ω, for EEx ia 820 Ω

Housing T12: 750 Ω, for EEx e 750 Ω.

•

Power

(load dependent, see Chapter 9.2.)

Housing F12

standard 16...36 VDC

EEx ia 16...30 VDC

Housing T12

standard 16...30 VDC

EEx e 16...30 VDC

System integration via

4...20 mA with HART

System Integration via interface FXN 672

and Rackbus gateway ZA 67x.

•

Power: supplied by FXN 672

Screened, twisted pairs are recommended

for the loop-power line.

1234

L- L+

I+ I-

BA171Y24

optional PLC

with active

output

power

plant

ground

DXR 275

or

FXA 191

communication

resistor

test sockets

(via interlock

diode)

Caution!

1

d4

ZA 67x

FXN 672

d2

234

L- L+

I+ I-

BA171Y25

plant

ground

Rackbus

Micropilot FMR 231 Chapter 3 Connection

Endress+Hauser 15

Page 18

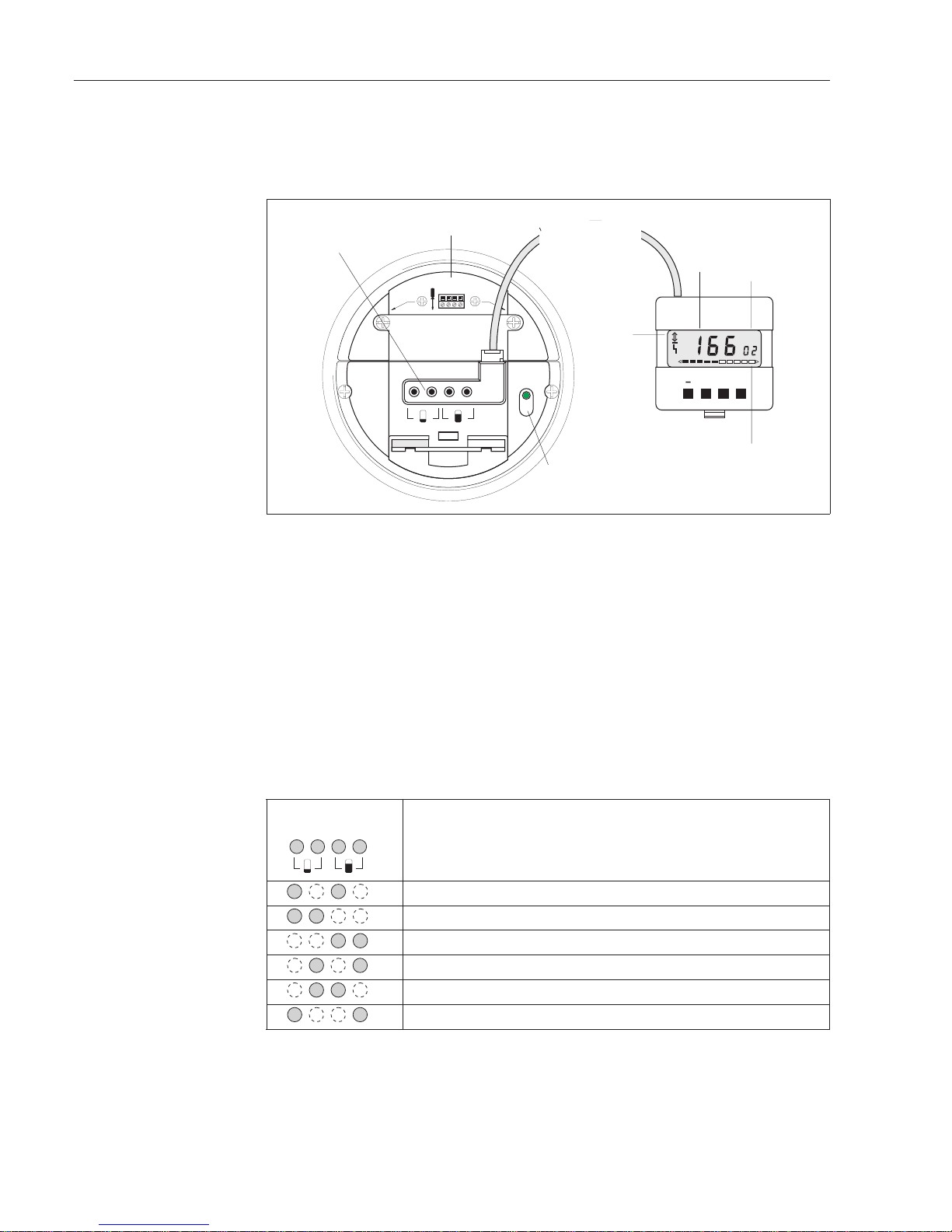

4 Operation

4.1 On-site operation

For the F12 housing, the operating elements are located within the transmitter housing

and can be operated when the cover is open. The T12 housing has a separate display

compartment which also can be opened in hazardous areas. The Micropilot has four

keys and an LED.

•

The LED flashes when an entered value is registered as well as during the

suppression of interference echoes. During operation it remains off.

•

The device keys allow the basic calibration of the Micropilot, but are deactivated

when the operating and display module VU 330 is connected.

Operation without the

VU 330

The function of the device keys when the operating and display module is not connected

is summarised in the table below. The two keys must always be pressed simultaneously.

The keys are used as follows, see Chapter 5:

Terminal

V H

V+ H

–

+

–

+

BA171Y26

bargraph

(current output/edho quality)

indicator

communication

fault

Operating and display module VU 330

matrix position

green LED

device

operating

keys

measured

not presentwith housing

T12

Fig.4.1

Operating elements of

Micropilot FMR 231

Keys Function

Reset to factory settings, see Chapter 7.9

Empty calibration, see Chapter 5

Full calibration, see Chapter 5

False echo suppression, see Chapter 5

Lock parameter entry, see Chapter 5

Unlock parameter entry, see Chapter 5

+

+

__

Chapter 4 Operation Micropilot FMR 231

16 Endress+Hauser

Page 19

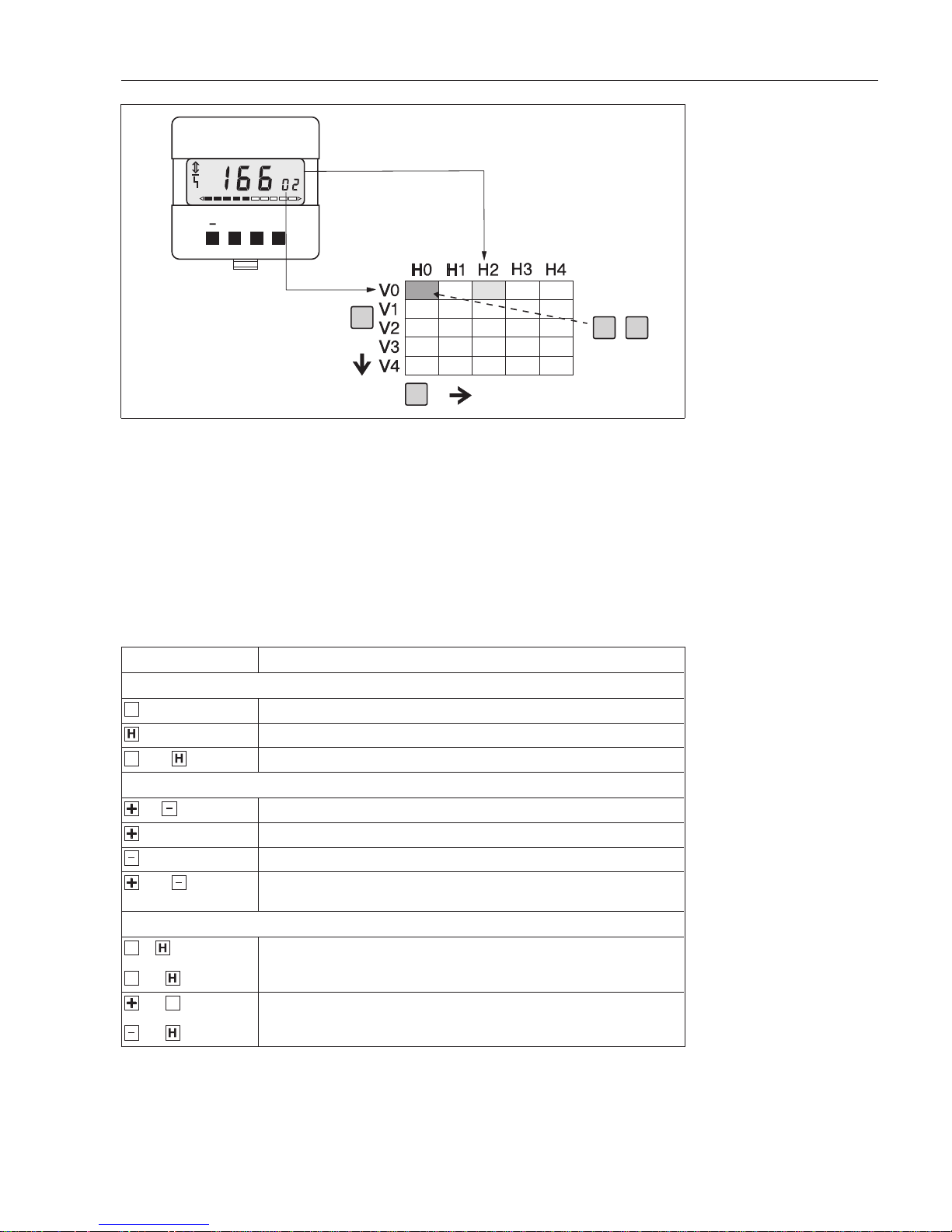

Operation with the

VU 330

If the Micropilot is equipped with an operating and display module VU 330, then it is

operated via a 10 x 10 operating matrix.

•

Each row is allocated to a particular function,

•

Each field sets or displays one parameter.

On-site operation with the operating and display module andcommunication both access

the same matrix. This is to be found in Chapter 10. If the HART handheld DXR 275 is

used, the transmitter is operated by a menu which is derived from this matrix.

The table below summarises the key functions of the operating and display module

VU 330.

V

H

VH

+

VH

V+ H

BA171Y27

Fig.4.2

Matrix operation using the

operating and display module

VU 330

Keys Function

Selection of matrix field

Selection of vertical matrix position

Selection of horizontal matrix position

and When V and H are pressed simultaneously the display springs to V0H0

Parameter entry

or Activates selected matrix position. The selected digit flashes.

Changes the value of the flashing digit by +1

Changes the value of the flashing digit by –1

and Sets the parameter just entered back to its original value, provided it has not

already been registered

Registration of the entry

or or

and

Registration of the entry and quitting of the matrix field

Registration of entry and jump to field V0H0

and or

and

+ and V lock entries,

– and H unlock entries, see Section 6.7

V

V

V

V

V

Micropilot FMR 231 Chapter 4 Operation

Endress+Hauser 17

Page 20

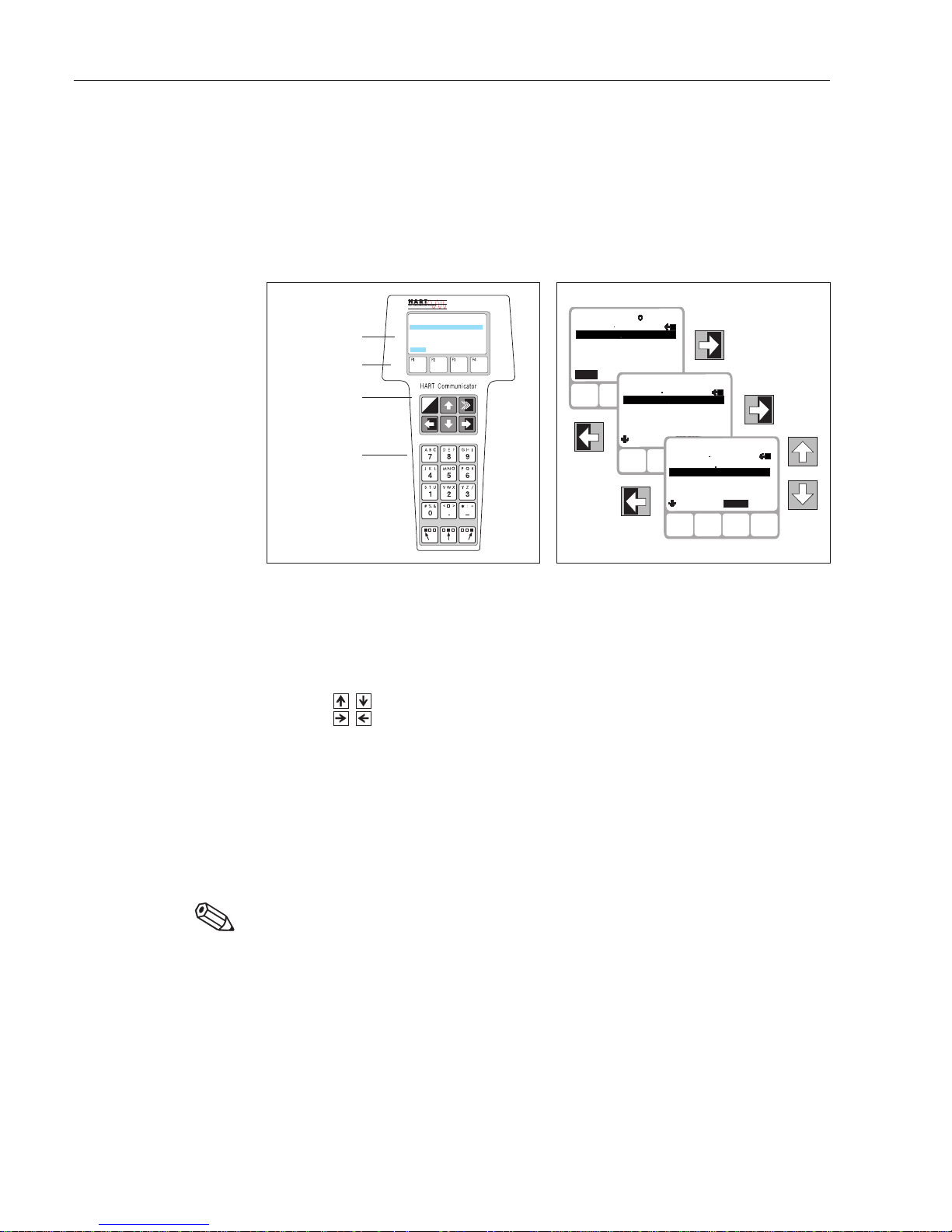

4.2 Remote operation

The Micropilot can be remotely operated via the communication interface 4...20 mA with

HART.

For HART, the operation depends on the measuring system.

•

For computer operation via Commubox FXA 191 or FXN 672 and gateway, the

operating matrix is used, see page 17.

•

For operation via handheld, a menu is used.

HART handheld DXR 275 The operation of the HART handheld DXR 275 is described in the manual supplied with

it.

The Group Select menu calls the matrix. The rows are the menu headers. Parameters

are set in the roll-down menus.

•

Keys , navigate up and down the menu.

•

Keys , change to the previous or to the following menu.

•

Parameters are entered by the corresponding keys.

– SEND registers the entries

•

Keys F1 - F4 call the displayed functions, e.g. HOME.

In the procedures described in this manual, the DXR 275 menu lines appear in the

"significance" column. Chapter 10 contains a listing ofmenu positions with corresponding

matrix fields.

Note!

•

The HART device description Version 2.0 for Micropilot FMR 231 must be loaded in

the DXR 275 before the device can be operated by the handheld. Updates of the

device descriptions can be obtained from Endress+Hauser.

I

O

FMR 231:LIC0001

Online

1 >GroupSelect

2PV 8.7m

HELP

BA171Y28

parameter entry keys

LC display with

menu texts

menu selection

keys

function keys

Fig.4.3

Operating elements and key

functions of the HART handheld

DXR 275

F1 F4F2 F3

FMR231: LIC0001

Online

2 PV 8.7m

HELP

1->Group Select

F1 F4F2 F3

FMR231 : LIC0001

2 Linearisation

3 Ext. Calibration

4 Service

5 Operating mode

Group Select

1->Calibration

HOME

F1 F4F2 F3

FMR231: LIC0001

3 Full Calibration

4 Application Parameter

5 Output Damping

Calibration

1 Measured Value

2->Empty Calibration

HOME

BA171Y29

Note!

Chapter 4 Operation Micropilot FMR 231

18 Endress+Hauser

Page 21

Commuwin IIA full description of the operating program Commuwin II is to be found in operating

instructions BA 124F. All Commuwin II functions are supported. The "envelope curve"

cannot be displayed. The transmitter is configured either via the operating matrix or the

graphic interface.

ConnectionThe table summarises the Commuwin connections,

Note!

•

Micropilot transmitters with HART interface can also be configured on site via the

keys. If the device keys are used to lock the matrix, then parameters cannot be

entered remotely via communication.

•

The Micropilot FMR 231 device description Version 2.0 is required for operation with

Commuwin II, see Operating Instructions BA 124F.

V1

V Calibration0

8.00

EMPTY CALIBRATION

7.50

FULL CALIBRATION

0

LINEARISATION

1

ECHO SUPPRESSION

1

TAB LE NO.

7.2

SUPPRESSION DIST.

0

ENTER LEVEL

27

ECHO QUALITY

67.5%

MEASURED VALUE

V Linearisation2

V Ent.calibration3

V4

V5

V6

V Service7

FMR 231

BA171E31

Fig.4.4

Device menu in Commuwin II

Note!

Interface Hardware Server Live list

HART Commubox 191 set to HART

Computer with RS-232C port

HART Connected device only

FXN 672 interface module

Gateway for MODBUS,

PROFIBUS, INTERBUS, FIP etc.

Computer with RS-232C port or

PROFIBUS card

ZA 673 for

PROFIBUS

ZA 672 for

others

List of all connected Rackbus

devices – select the FXN 672 via

its bus address

Micropilot FMR 231 Chapter 4 Operation

Endress+Hauser 19

Page 22

Graphical support mode The graphical support mode is called via the Device menu. Thus offers an alternative

method of configuring the Micropilot. Various pictures are offered when the Graphics

menu is clicked. These correspond to the procedures described in Chapter 6.

•

Status: software version, measuring point tag, diagnosis code and measured

value are displayed.

•

Commissioning: reset, measuring point tag, etc.

•

Basic calibration for tank: procedure for basic calibration in tanks.

•

Basic calibration for stilling wells: procedure for basic calibration in stilling wells.

•

Basic calibration Step 2: procedure for false echo suppression.

•

Technical units: settings for linear relationships.

•

Safety parameters: configuration of the analogue output for normal and failure

operation.

•

Service: parameters required for service call.

A linearisation can be called from the matrix window.

Off-line operation Commuwin also allows the Micropilot to be configured off-line. After all parameters have

been entered, the file generated can be loaded into the connected Micropilot. This can

now be commissioned by simply running the echo suppression procedure.

Up-/Download This function allows the parameters of an already configured Micropilot FMR 231 to be

loaded and stored in Commuwin II. If several Micropilots (with the same software version)

have to be configured in the same way, the parameters can now be downloaded into the

devices. In this case as well, an echo suppression must be made when the devices are

commissioned.

It is not possible to up and download parameters between Micropilots with different

software versions.

Graphical support - Basic calibration -Step 1-

EMPTY CALIBRATION

2.

3.50

FULL CALIBRATION

3.

3.00

APPLICATION

LOCK MATRIX

4.

1.* Code "333" Code >< "333"

4.* "0": Tank...approx. 7 m

"1": Tank...approx. 1.5 m

"2": Tank...approx. 7 m, DC<10

"3": Tank7 m... 20 m

1.

1

333

3

2

100%

20mA

0%

4mA

BA171E32

Abb.4.5

Graphic support window in

Commuwin II

Chapter 4 Operation Micropilot FMR 231

20 Endress+Hauser

Page 23

5 On-site calibration without display VU 330

Test pathAn on-site calibration without the operating and display module VU 330 requiresa defined

level echo. In order to avoid the danger of acquiring an interference echo from a fitting

as the zero point, it is recommended that the calibration be made outside the tank along

a suitable test path.

•

The length of the test path must correspond to the required empty distance "E".

•

A suitable reflector, e.g. a flat wall, must be available.

•

The Micropilot is pointed at the wall about 1.5 m above the ground.

Calibration and echo

suppression

•

The datum point for the empty distance

"E" and the distance "D" is always the

lower face of the process connection.

# Keys Significance

1 Micropilot ready for operation in test zone

2 Reset

Wait 20 seconds

3 Set empty distance "E".

Wait 2 minutes,

press keys.

4 Set distance "D".

Wait 2 minutes,

press keys.

5 Mount Micropilot on tank

6 Empty tank (at least to "E")

7 Echo suppression.

Wait until green LED stops

flashing.

Result

•

E ≡ 4 mA (= 0%)

•

F ≡ 20 mA (= 100%)

Note!

•

Stilling wells cannot be calibrated using

device keys

+

+

__

D

E

BA171Y02

Step 3

Step 4

D

F

E

100%

20mA

0%

4mA

BA171Y31

Steps 5, 6 and 7

Note!

D

F

E

E

100%

20mA

0%

4mA

Test path free of obstacles and with

reflector,e.g., a wall

stable

seating for

Micropilot

90°

BA171Y34

height above

ground

approx..1.5 m

Fig..5.1

Calibration outside tank using

device keys

Micropilot FMR 231 Chapter 5 On-site calibration without display VU 330

Endress+Hauser 21

Page 24

Correction of measuring

range

•

The device must have been calibrated

and the echoes suppressed before the

measuring range can be corrected.

•

The new empty distance "E" may not

exceed that used for the calibration.

Otherwise a new calibration is

necessary, see page 19.

# Keys Significance

1 If appropriate calibration and echo

suppression, p. 19

2 Bring level in tank to "empty",

Wait 2 minutes

3 Empty calibration (4 mA)

= zero

4 Bring level in tank to "full",

Wait 2 minutes

5 Full calibration (20 mA)

= span

After correction of measuring range:

•

"Empty" level E ≡ 4 mA

•

"Full" level F ≡ 20 mA

Lock keys

In order to avoid accidental or

unauthorised changing of the settings, the

keys can be locked for new entries.

# Keys Significance

1 Lock operation:

2 Unlock operation:

After the keys have been locked:

•

All entries, including those via the

operating matrix, are blocked

(VU 330, DXR 275, Commuwin II).

The contents of the matrix fields can be

read, however.

•

Entries can only be unlocked by using

the appropriate key combination, see

above.

Note!

•

After the keys have been used, screw

on the housing cover.

+

+

__

+

+

__

D

F

E

100%

20mA

0%

4mA

BA171Y36

empty distance "E"

of calibration(old)

–

+

–

+

BA171Y35

Note!

Warning!

Chapter 5 On-site calibration without display VU 330 Micropilot FMR 231

22 Endress+Hauser

Page 25

6 Calibration with Display/Remote Operation

The chapter describes the basic calibration and other functions that can be set via the

operating matrix. The matrix can be accessed via:

•

Operating and display module VU 330

•

HART handheld DXR 275

•

Operating program Commuwin II.

The matrix operation using the operating and display module VU 330 is described. At

the start of every procedure, however, the HART handheld menu is shown, e.g.

➤ Simulation.

The chapter is structured as follows:

Start calibration

tank or

pipe

Chapter 6.1

Basic calibration

and false echo

suppression

Chapter 6.2

Basic calibration

and false echo

suppression

Chapter 6.3

Linearisation

Chapter 6.4

Analogue output

Chapter 6.5

Safety functions

Chapter 6.6

Lock/unlock

tank

stilling well

BA171Y68

Micropilot FMR 231 Chapter 6 Calibration with Display/Remote Operation

Endress+Hauser 23

Page 26

6.1 Basic calibration for tanks

After resetting the Micropilot to the factory settings (only required during commissioning),

enter the following parameters:

•

empty distance E, full distance F and application parameter A.

The datum point for the empty distance "E" is always the lower face of the process

connection. The full distance "F" may extend only as far as the antenna tip. The calibration

units are metres or feet, settable in V8H5 (0 = m, 1 = ft).

The user has a choice of four application parameters, see also Chapter 7.

Calibration

# VH Entry Significance

➤ Simulation

1 V9H5 333

VH

Reset

➤ Basic calibration

2 V0H1 E m/ft

H

Empty distance

3 V0H2 F m/ft

VH

Full distance

4 V0H3 A

VH

Application

parameter

0: up to 4 m

1: up to 1.5 m

2: up to 4 m, εr < 4

3: up to 20 m

5 V0H0

V0H9

Current level in %

or m/ft

False echo suppression

•

With the tank empty, check whether

distance displayed in V0H8

corresponds to the distance to the

product surface "D".

# VH Entry Significance

1 Empty vessel as far as possible

➤ Basic calibration

2 V0H8 ****

VH

Check value

3 Values correspond?

Echo is level echo➝ procedure A

Suppression up to echo

Values do not correspond?

Echo is false echo ➝ Procedure B

Suppression inclusive echo

Code Application Significance

0 Tank up to 74 m high For slow changes in level (factory setting)

1 Tank up to 1.5 m high For small tanks with rapid changes in level

2 Tank up to 7 m high, ε

r

< 10 For Product Class B, see page 7

3 Tank from 7 m to 20 m high For high storage tanks

F

E

100%

20mA

0%

4mA

BA171014

V0H8

D

BA171Y37

false echo

levelecho

Chapter 6 Calibration with Display/Remote Operation Micropilot FMR 231

24 Endress+Hauser

Page 27

Procedure A

Echo is level echo

# VH Entry Significance

➤ Extended calibration

1 V3H0 2

H

2: up to echo

2 V3H1 ****

+

H

Register value

when display

flashes

3 Wait approx. 3 minutes until the fault indicator

disappears.

Procedure B

Echo is false echo

# VH Entry Significance

➤ Extended calibration

1 V3H0 3

H

3: inclusive echo

2 V3H1 ****

+

H

Register value

when display

flashes

3 Wait approx. 3 minutes until the fault indicator

disappears.

➤ Basic calibration

4 V0H8 ****

VH

Check value again

5 Repeat steps 2...4 until V0H8 = D.

Then Procedure A.

Note!

•

The LED and fault indicator flash while the false echo suppression map is being

recorded. Warning E514 appears.

•

There is a further method of recording a false echo suppression map (V3H0 = 4)

which is described in Chapter 7.6

Check echo quality

# VH Entry Significance

➤ Extended calibration

1 V3H2 ****

H

Echo quality

≥ 10: OK

<10: Optimise

alignment

Chapter 7.5.

Change

position.

After calibrationAfter calibration, the Micropilot measures level in %. The analogue output follows the

display in V0H0. The current values 4 mA and 20 mA are automatically assigned to the

levels 0% and 100%.

V0H8

D

BA171Y80

V H

V3H2 >10:

BA171Y70

V0H8

D

BA171Y80

Note!

Micropilot FMR 231 Chapter 6 Calibration with Display/Remote Operation

Endress+Hauser 25

Page 28

6.2 Basic calibration for bypass pipes and stilling wells:

After resetting the Micropilot to the factory settings (only required during commissioning),

enter the following parameters:

•

empty distance E, full distance F, application parameter A, microwave factor MF.

The datum point for the empty distance "E" is always the lower face of the process

connection. The full distance "F" may extend only as far as the antenna tip. The calibration

units are metres or feet, settable in V8H5 (0 = m, 1 = ft).

•

For Product Class B, it is recommended that the empty distance "E" is set 30 cm

above the tank bottom.

.

The microwave factor MF =

√1 – (X/d

2

),

whereby d = internal diameter of the pipe in mm

X = 925 at 5.8 GHz and 784 at 6.3 GHz (FCC approval)

The user has a choice of three application parameters, see also Chapter 7.4.

Calibration

# VH Entry Significance

➤ Simulation

1 V9H5 333

VH

Reset

➤ Basic calibration

2 V0H1 E m/ft

H

Empty distance

3 V0H2 F m/ft

VH

Full distance

4 V0H3 A

VH

Application

parameter

4: up to 7 m

5: up to 1.5 m

6: 7 m to 20 m

➤ Extended calibration

5 V3H3 MF

VH

Microwave factor

6 V0H0

V0H9

Current level in %

or m/ft

Version DN50 PN16 DN80 PN 16/40 DN 100 PN16 DN 150 PN16

MF (5.8 GHz) 0.8298 (d = 54.5) 0.9296 (d = 82.5) 0.9574 (d = 105.3) 0.9811 (d = 157.1)

Version ANSI 2"/150 lbs ANSI 3"/150 lbs ANSI 4"/150 lbs ANSI 6"/150 lbs

MF (5.8 GHz) 0.8151 (d = 52.5) 0.9281 (d = 81.7) 0.9574 (d = 105.3) 0.9811 (d = 157.1)

MF (6.3 GHz) 0.8459 (d = 52.5) 0.9394 (d = 81.7) 0.9640 (d = 105.3) 0.9840 (d = 157.1)

Code Application Significance

4 Stilling well up to 7 m long For slow changes in level

5 Stilling well up to 1.5 m long For short stilling wells with rapid level changes

6 Stilling well from 7 m to 20 m

long

For long stilling wells in high storage tanks

F

E

100%

20mA

0%

4mA

BA171Y03

30 cm from

tank bottom

for product

group B

Chapter 6 Calibration with Display/Remote Operation Micropilot FMR 231

26 Endress+Hauser

Page 29

False echo suppression

•

With the tank empty, check whether

distance displayed in V0H8

corresponds to the distance to the

product surface "D".

# VH Entry Significance

1 Empty vessel as far as possible

➤ Basic calibration

2 V0H8 ****

VH

Check value

3 Values correspond?

Echo is level echo➝ procedure A

Suppression up to echo

Values do not correspond?

Echo is false echo ➝ Procedure B

Suppression inclusive echo

Procedure A

Echo is level echo

# VH Entry Significance

➤ Extended calibration

1 V3H0 2

H

2: up to echo

2 V3H1 ****

+

H

Register value

when display

flashes

3 Wait approx. 3 minutes until the fault indicator

disappears.

Procedure B

Echo is false echo

# VH Entry Significance

➤ Extended calibration

1 V3H0 3

H

3: inclusive echo

2 V3H1 ****

+

H

Register value

when display

flashes

3 Wait approx. 3 minutes until the fault indicator

disappears.

➤ Basic calibration

4 V0H8 ****

VH

Check value again

5 Repeat steps 2...4 until V0H8 = D.

Then Procedure A.

Note!

•

The LED and fault indicator flash while the false echo suppression map is being

recorded. Warning E514 appears.

•

There is a further method of recording a false echo suppression map (V3H0 = 4)

which is described in Chapter 7.6

Check echo quality

# VH Entry Significance

➤ Extended calibration

1 V3H2 ****

H

Echo quality

≥ 10: OK

<10: Optimise

alignment

Chapter 7.5.

Change

position.

After calibrationAfter calibration, the Micropilot measures level in %. The analogue output follows the

display in V0H0. The current values 4 mA and 20 mA are automatically assigned to the

levels 0% and 100%.

D

V0H8

BA171Y39

DD

V0H8

V0H8

BA171Y81

Procedure A

Procedure B

V H

V3H2 >10:

BA171Y70

Note!

Micropilot FMR 231 Chapter 6 Calibration with Display/Remote Operation

Endress+Hauser 27

Page 30

6.3 Linearisation

Linearisation mode A linearisation describes the relationship between level and the tank volume or product

weight and allows a measurement in technical units, e.g. metres, hectolitre, tonnes etc.

Afterwards, the measured value is displayed in the selected units in V0H0 and the

analogue output is proportional to the volume or weight. The table below lists the

linearisation modes.

Warnings During entry of the table, an error message is generated and the device indicates an

alarm. After the curve has been entered, it is checked for plausibility. The following

warnings and alarms can appear.

De-activation A linearisation table can be deactivated by setting V2H0 = 0 (m/ft) or 5 (linear). It is not

deleted and can be re-activated at any time by setting V2H0 = 1.

The setting V2H0 = 4 deletes the entire table. The linearisation mode "linear" (V2H5 = 5)

is automatically selected.

Note!

•

The values in V2H5, V0H5 and V0H6 must be changed as necessary.

Note!

Entry

V2H0

Linearisation mode Significance

0

Level Linear display of level in m or ft.

2

Manual entry Max. 30 pairs of values, level and volume, are entered as the

linearisation curve.

3

Semi-automatic entry In the case of semi-automatic entry, the tank is filled in stages. The

device automatically displays the level, the associated volume is

entered manually.

5

Linear relationship Factory setting. The relationship between the technical units and

level is linear. By entering the max. volume or weight, the measured

value is output in the technical units chosen by the user.

In addition, V2H0 offers the functions:

1

Activate table The entered linearisation table only comes into effect after it has

been activated.

4

Delete table Before a new linearisation table is entered, any previously active

table must be deleted. On deletion the linearisation mode is

automatically set to linear.

Code Type Significance

E602 Warning The linearisation curve does not rise continuously.

The number of the last valid pair automatically appears in V2H1. All

value pairs from this number onwards must be re-entered.

E604 Warning The linearisation curve comprises less than two value pairs.

Enter more points.

E605 Alarm The manual linearisation table is incomplete

Disappears after activation of table.

Chapter 6 Calibration with Display/Remote Operation Micropilot FMR 231

28 Endress+Hauser

Page 31

Linear dependencyFor tanks with a linear dependency between level and volume or weight, technical units

can be set by entering the maximum volume or weight in V2H5 and V0H6.

# VH Entry Significance

➤ Linearisation

1 V2H0 5

H

Linear

2 V2H5 e.g. 500 kg

VH

Max. volume

Volumen/weight at

level F

➤ Basic calibration

3 V0H6 e.g. 500 kg

VH

Value for 20 mA

Volumen/weight at

level F

Result

•

Lower range-value E = e.g. 0 kg (4 mA)

•

Upper range-value F = e.g. 500 kg

(20 mA)

Linearisation tableIf volume or weight is not proportional to level within the set measuring range, then a

linearisation table must be entered before the measured value can be displayed in

technical units. The prerequisites are as follows:

•

The max. 30 value pairs for the linearisation curve are known

•

The level values must be entered in increasing order. The curve constantly

increases (monotonic).

•

The levels for the first and last points correspond to those of the empty and full

calibration (E and F)

•

The level points are entered in the units of calibration.

# VH Entry Significance

1 If no calibration yet see Section 6.1/6.2

➤ Linearisation

2 V2H0 4

H

Delete existing

curve

3 V2H0 2

H

Linearisation mode

"manual"

4 V2H1 e.g. 1

H

1st value pair

5 V2H2 e.g. 0 m/ft

H

Level point 1

6 V2H3 e.g. 0 kg

H

Volume/weight

point 1

7 Repeat steps 4...6 for up to 30 value pairs

8 V2H0 1

H

Activate

linearisation

➤Basic calibration

9 V0H6 e.g. 600 kg

VH

Value for 20 mA

Volumen/weight at

level F

10 V0H0

V0H9

Measured value in

technical units

Level in m/ft

F

E

BA171Y38

100%

0

V2H5

V0H6

level

technical

units

F

E

BA171Y41

F m/ft

0

Vmax

V0H6

levelm/ft

technical

units

Micropilot FMR 231 Chapter 6 Calibration with Display/Remote Operation

Endress+Hauser 29

Page 32

Horizontal cylinder A linearisation curve for a horizontal cylinder can also be entered manually by using the

table below:

•

Starting at the completely full tank (level/volume = 100%, calculate the % volume

for each level point.

Volume at L % level = Total volume x Volumen %

100

Tab.-No

V2H1

LevelV2H2 Volume V2H3

% m/ft % T. unit

10 0

2 10 5.20

3 20 14.24

4 30 25.23

5 40 37.35

6 50 50.00

7 60 61.64

8 70 74.77

9 80 85.76

10 90 94.79

11 100 100

Semi-automatic entry The tank is filled and the level automatically acquired. The associated volume must be

entered by hand.

# VH Entry Significance

1 If no calibration yet see Section 6.1/6.2

2 Fill tank step-by-step

➤ Linearisation

3 V2H0 4

H

Delete existing

curve

4 V2H0 3

H

Linearisation mode

"semi-automatic"

5 V2H1 e.g. 1

H

1st value pair

6 V2H2 ****

H

Current level

7 V2H3 e.g. 0.6 hl

H

Volume for V2H2

8 Repeat steps 2...7 for up to 30 value pairs

9 V2H0 1

VH

Activate table

➤ Basic calibration

10 V0H5 Volume at

"E"

H

Lower range-value

volume/weight

11 V0H6 Volume at

"F"

VH

Upper range-value

volume/weight

12 V0H0

V0H9

Measured value in

technical units

Level in m/ft

Note!

If the tank is emptied step-by-step, the following must be noted:

•

The number of points must determined before starting.

•

The first table no. = (30 – no. of points)

•

The entries in V2H1 must be made in descending order (last entry = 1).

F

E

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

BA171Y43

F

E

BA171Y42

F m/ft

0

Vmax

V0H6

levelm/ft

technical

units

Note!

Chapter 6 Calibration with Display/Remote Operation Micropilot FMR 231

30 Endress+Hauser

Page 33

6.4 Analogue output

The analogue output can be set using the fields listed below. If required, a scaling or

inversion of the output can be set in V0H5 and V0H6.

Settings

Example:

Analogue output

# VH Entry Significance

➤ Operating mode

1 V8H1 e.g. 1

H

Output min. 4 mA

0: off

1: on

➤ Basic calibration

2 V0H4 e.g. 10

H

Output damping

3 V0H5 e.g. 40%

H

Value for 4 mA

4 V0H6 e.g. 70%

H

Value for 20 mA

5 V0H7 e.g. 0

VH

Safety alarm

0 = MIN

1 = MAX

2 = HOLD

BA171Y44

100%

0%

V0H6

level

V0H5

4mA 20mA

Field Parameter Significance

V8H1 Current output min 4 mA

0: off

1: on

Sets behaviour of analogue output. Default = 1.

0: 3.8...20.5 mA continuous output

1: as above, but 4 mA limit in normal operation

The ouput follows the setting in V0H7 if a fault is detected

V0H4 Output damping τ

0...255 s

Influences the time it takes for the analogue output to

react to a sudden change in level (63% of steady-state

value). Default 5 s. Increasing the value damps the effect

of e.g. rapid level changes on the measured value.

V0H5

V0H6

4 mA value

20 mA value

Lower range-value of analogue output

Upper range-value of analogue output

Entry in % or after a linearisation in technical units

V0H7 Safety alarm (Output on alarm)

0: MIN

1: MAX

2: HOLD

In order to signal an alarm, the measured value assumes

the selected value.

MIN = 3.8 mA; MAX = 22 mA

HOLD = holds last current value

V9Hß Current output Displays current value of analogue output

Micropilot FMR 231 Chapter 6 Calibration with Display/Remote Operation

Endress+Hauser 31

Page 34

6.5 Safety functions

The Micropilot offers the user the following safety functions:

Example:

Safety functions

# VH Entry Significance

➤ Operating mode

1 V8H3 e.g. 60

H

Delay time E641

2 V8H5 e.g. 1

H

Within safety

distance =

Alarm

Field Parameter Significance

V3H5 Window suppression Defines a distance measured from the datum point in

which no echoes are measured. It is used for suppressing

strong echoes in the immediate vicinity of the antenna,

see Chapter 7.7.

The default setting extends to the tip of the antenna.

A smaller distance cannot be entered.

V8H3 Delay on lost echo If the echo is lost, alarm E641 is output. V8H3 determines

the time which elapses between the loss of the echo and

the response of the Micropilot. Default = 30 s.

V8H5 In safety distance

0: Warning

1: Alarm

2: Alarm, self-holding

3: Reset 2

A safety zone extends 10 cm in front of the window

suppressiion zone. This is to warn, that if the level

continues to rise, the measurement will become invalid. If

product enters the safety zone, the Micropilot responds

according to the setting in V8H5:

0: Warning E643 is output: the device continues to

measure

1: Alarm E643 is output: measurement is suspended until

the product leaves the safety zone.

2: Alarm E643 is output: measurement is suspended until

the alarm is acknowledged.

3: Acknowledges the alarm in case 2..

V8H6 Plausibility

0: off

1: on

The plausibility check is automatically set after the entry of

the application parameter A:

off: application parameters 0 - 3

on: application parameters 4 - 6

When the plausibility check is activated, the current level

is checked against the previous level, in order to establish

whether the value is plausible .If this is not the case, error

code E643 is output and the Micropilot reacts according

to the setting in V8H5 – see also Chapter 7.8.

Chapter 6 Calibration with Display/Remote Operation Micropilot FMR 231

32 Endress+Hauser

Page 35

6.6 Locking/unlocking the matrix

After all parameters have been entered, the matrix can be locked.

•

On-site with the device keys, see Chapter 5, or

•

via the matrix by entering a three digit code not equal to 333 in V9H9.

(333 is the code for unlocking the matrix)

This protects the measuring point from accidental and unauthorised entries.

# VH Entry Significance

➤ Simulation

Lock

1 V9H9 e.g. 100

VH

Matrix locked

(except V9H9)

Unlock

2 V9H9 333

VH

Matrix unlocked

Note!

•

If the Micropilot is locked by means of the device operating keys, then the entire

matrix including V9H9 is locked. No parameters can be changed, not even via the

communication interface. The contents of the matrix fields can be read, however.

•

The matrix can only be unlocked by using the device operating keys on the

Micropilot.

BA171Y45

Note!

Micropilot FMR 231 Chapter 6 Calibration with Display/Remote Operation

Endress+Hauser 33

Page 36

6.7 Measuring point information

The following information about the measuring point can be read:

Communication level The matrix row "VA communication" can only be accessed via the the HART handheld

DXR 275 or Commuwin II.

Matrix field Display (or entry)

Measured value

V0H0

Principle measured value

V0H8

Distance to product surface

Bargraph shows echo quality: 1 segment = 5 dB

V0H9

Level before linearisation

Bargraph shows echo quality: 1 segment = 5 dB

Sensor data

V0H3

Application parameter

V0H5

Value for 4 mA

V0H6

Value for 20 mA

V2H0

Linearisation mode

V3H0

False echo suppression: 0 = factory set, 1 = customer set

V3H1

Dtance up to which echoes have been suppressed.

V3H2

Echo quality in dB: the higher, the better

V3H3

Microwave factor

V8H1

Currrent output min. 4 mA: 0 = off, 1 = on

V8H2

Unit of calibration: 0 = metre, 1 = feet

V8H3

Delay time on lost echo

V8H5

In safety distance: 0 = warning, 1 = alarm, 2 = alarm, self-holding

Information on measuring point

V9H3

xxyy: communications (xx) and software number (yy)

(xx = 80 = HART, yy = 10 = software version 1.0)

V9H4

HART communication address

Diagnosis

V9H0

Current diagnosis code

V9H1

Last diagnosis code

Matrix field Display (or entry)

VAH0

Measuring point Tag. No.

8 characters (ASCII) can be entered here

VAH3

Units of measured value (for handheld)

Chapter 6 Calibration with Display/Remote Operation Micropilot FMR 231

34 Endress+Hauser

Page 37

7 Trouble-Shooting

When the instructions in the manual have been followed correctly, the system must now

function. Should this not be the case, the Micropilot provides a number of possibilities

for analysing and correcting faults.

7.1 Self-monitoring

The self-monitoring system differentiates between alarms and warnings.

On an alarm

•

The fault indicator appears at the

operating and display module VU 330.

•

The analogue output responds

according to the settings in V0H7,

V8H3 and V8H5, see table below.

•

The bargraph follows the analogue

output.

An error code is displayed at matrix

position V9H0 to help locate the fault. V9H1

indicates the previous error code.

On a warning

•

The fault indicator appears at the

operating and display module VU 330.

•

The Micropilot continues to measure.

An error code is displayed at matrix

position V9H0 to help locate the fault. V9H1

indicates the previous error code.

Analogue output

The analogue output responds according to the setting in V0H7. If the Micropilot has

been configured with the device keys (no VU 330, DXR 275 or Commuwin II), then the

analogue output goes to MAX (= 22 mA) on a fault.

V H

V+ H

BA171Y33

fault indicator

V H

V+ H

BA171Y46

Faultindicator

Analogue output at V0H7 = 0 (MIN) V0H7 = 1 (MAX) V0H7 = 2 (HALTEN)

Current

3.8 mA 22 mA last current held

Micropilot FMR 231 Chapter 7 Trouble-Shooting

Endress+Hauser 35

Page 38

7.2 Error messages

Error messages can be read with communication (DXR 275 or Commuwin II) or the

display module only. The current error code is displayed in V9H0.

•

The last error code is displayed in V9H1.

•

The display in V9H1 can be cleared by pressing the + key and leaving the field.

Table 7 lists the error codes with the corresponding messagepage

Code Message Significance Remedy

E101

E102

Warning Checksum error Check power supply,

switch on and off, reset

E103 Warning FRAM storage fault Disappears after a while

if not: ☎ Call Service

E106 Alarm Download of data to Micropilot Appears during download from

computer. Measurement is

suspended until the download is

complete.

E110 Alarm Checksum error Check power supply,

switch on and off, reset

E111...

E115

Alarm Device fault ☎ Call Service

E116 Alarm Download error Check download file,

Restart download

E121 Alarm Invalid D/A calibration ☎ Call Service

E231 Alarm No sensor signal ☎ Call Service

E232 Alarm Faulty sensor signal ☎ Call Service

E512 Warning Mapping false echos Disappears when procedure

complete

E602 Warning Linearisation error – does not rise

or fall continuously (monotonic)

e.g. identical level values

Reenter faulty value pair, page 25

E604 Warning Linearisation table comprises less

than two pairs

Enter further pairs

E605 Alarm Manual linearisation table

incomplete

Disappears when table activated

E613 Warning Simulation Disappears when simulation

switched off, V9H6 = 0

E620 Warning Current out of range Check calibration and linearisation

E621 Warning Mapping false echos (Service) Disappears when procedure

complete

E641 Alarm Lost echo See Fault Analysis, page 33

E643 Warning

Alarm

Product within safety distance.

Danger of overspill

Response selected in V8H6, see

Safety Functions, page 29

Disappears as soon as level falls

or alarm is acknowledged

(V8H5 = 3)

Table 7.1

Error messages

Chapter 7 Trouble-Shooting Micropilot FMR 231

36 Endress+Hauser

Page 39

7.3 Fault analysis

Table 7.2 lists the most common measuring errors with possible remedies. If the first

measure is successful, the remaining steps are not required.

Fault Analogue output Possible reason Remedy

Measured value incorrect

Distancw D (V0H8)

correct?

➀ Stilling well?

Check microwave factor,

see basic calibration, page 23

➁ False echo, see below

➂ Offset (V3H6) > 0?

Set to zero

Calibration /

Linearisation

correct?

➀ Check E (V0H1) and F (V0H2),

if necessary re-enter application

parameter V0H3, page 35

or. simulation, page 39

4/20 mA settings

correct?

➀ Re-enter V0H5 and V0H6, page 28

➀

☎Call Service!

Measured value remains

constant on emptying

(No warning E641)

Measured value jumps to

higher value when tank almost

empty

Measured value jumps

sporadically with constant

level but waves on surface

False echoes from

fittings/nozzle

➀ False echo suppression

see page 24

➁ Optimise alignment,

see page 36

Build-up on or near

the antenna causing

weak echoes

➀ Activate window suppression,

see page 38

➁ Carefully clean antenna

Signal weakened by waves – false

echo sometimes

stronger

➀ Select application parameter 1/2

(V0H3), page 22, 23

➁ Activate window suppression,

page 38

➂ Increase output damping, page 28

➃ Active false echo suppression,

page 24

➄ Optimise alignment, page 36 or .

check mounting position,

page 9 - 11

if possible, select better position

➅

☎Call Service!

20 mA

F m/ft

E m/ft

D m/ft (V0H8)

4mA t→

expected

happened

no

yes

no

yes

no

yes

20 mA

4mA t→

expected

happened

20 mA

4mA t→

expected

happened

20 mA

4mA t→

happened

expected

yes

no

yes

no

yes

Micropilot FMR 231 Chapter 7 Trouble-Shooting

Endress+Hauser 37

Page 40

Fault Analogue output Possible reason Remedy

Measured value jumps to

lower values despite constant

level

Multiple echoes ➀ If possible, increase first echo factor

page 35

➁ Optimise alignment

page 36

➂ If necessary, remount Micropilot in a

less central position

➃

☎Call Service

Measured value drops to lower

value on approach to 100%

Product in window

suppression zone

➀ Match measuring range to window

suppression zone, page 38

➁ For levels over 100 % change

E and F if necessary, see basic

calibration, page 22, 23

E641 appears when the tank is

filled or emptied

Echo too weak to

be detected

➀ Change application parameter in

V0H3, page 39

➁ Optimise alignment, page 36 or .

check mounting position,

page 9 - 11

if possible, select better position

➂ Foam (measurement impossible)

➃☎Call Service

Analogue output does not

function correctly

Incorrect wiring or

wire broken

➀ Check wiring

No power ➀ Connect power supply

Electronics fault ➀

☎Call Service

order spare part

No smart communication

Incorrect wiring

EMC fault

➀ Check wiring and min./max. load

see Technical Data, page 45

➀ Check screening,

see Connection, page 13

➀

☎Call Service

20 mA

4mA t→

expected

happened

yes

yes

20 mA

4mA t→

expected

happened

20 mA

E641

4mA t→

expected

happened

yes

yes

no

yes

no

yes

no

yes

no

Chapter 7 Trouble-Shooting Micropilot FMR 231

38 Endress+Hauser

Page 41

7.4 Application parameter

Application parameterThe application parameter that is entered during calibration sets the various elements of

the signal evaluation such that the Micropilot is ideally matched to the application.

Parameters are set in both the operating and the service level.

Table 7.3 summarises the parameters available.

HeightThe height is the principle element in determining the type of tank, the speed of level

changes and the conditions at the product surface. It also affects the mounting position,