Endress+Hauser FMR10 Specifications

TI01266F/00/EN/05.17

71356673

Products

Solutions Services

Technical Information

Micropilot FMR10

Free space radar

Level measurement for liquids

Application

• Ingress protection: IP66/68 / NEMA 4X/6P

• Measuring range: up to 8 m (26.25 ft)

• Process temperature: –40 to 60 °C (–40 to 140 °F)

• Process pressure: –1 to 3 bar (–14 to 43 psi)

• Accuracy: up to ± 5 mm (0.2 in)

Your benefits

• Level measurement for liquids in storage tanks, open basins, pump shafts and

canal systems

• Radar measuring device with Bluetooth® wireless technology

• Simple, safe and secure wireless remote access – ideal for installation in areas or

places difficult to reach

• Commissioning, operation and maintenance via free iOS / Android app SmartBlue

– saves time and reduces costs

• Full PVDF body – for a long sensor lifetime

• Hermetically sealed wiring and fully potted electronics – eliminates water ingress

and allows operation under harsh environmental conditions

• Most compact radar due to unique radar chip design – fits in limited space

installations

• Best price-performance-ratio radar

Table of contents

Micropilot FMR10

Important document information ............... 3

Symbols for certain types of information .............. 3

Safety symbols ............................... 3

Electrical symbols ............................. 3

Symbols in graphics ............................ 3

Terms and abbreviations ..................... 5

Registered trademarks ....................... 5

Product life cycle ............................ 6

Engineering ................................. 6

Procurement ................................ 6

Installation ................................. 6

Commissioning ............................... 6

Operation .................................. 6

Maintenance ................................ 6

Retirement .................................. 6

Measuring principle ......................... 7

Input ...................................... 7

Output .................................... 7

Input ..................................... 8

Measured variable ............................. 8

Measuring range .............................. 8

Operating frequency ........................... 8

Transmission power ............................ 8

Output ................................... 9

Output signal ................................ 9

Digital output ................................ 9

Signal on alarm ............................... 9

Linearization ................................ 9

Electrical connection ....................... 10

Cable assignment ............................ 10

Supply voltage .............................. 10

Power consumption ........................... 10

Current consumption .......................... 10

Starting time ............................... 10

Power supply failure .......................... 10

Connection 4 to 20 mA ........................ 11

Cable specification ............................ 11

Overvoltage protection ......................... 11

Performance characteristics .................. 12

Reference operating conditions ................... 12

Maximum measured error ....................... 12

Measured value resolution ...................... 12

Response time .............................. 12

Influence of ambient temperature ................. 13

Environment .............................. 21

Ambient temperature range ..................... 21

Storage temperature .......................... 21

Climate class ............................... 21

Installation height as per IEC 61010-1 Ed.3 ........... 21

Degree of protection .......................... 21

Vibration resistance ........................... 21

Electromagnetic compatibility (EMC) ............... 21

Process .................................. 22

Process temperature, process pressure ............... 22

Dielectric constant ............................ 22

Mechanical construction .................... 23

Dimensions ................................ 23

Weight ................................... 24

Materials .................................. 25

Connecting cable ............................. 25

Operability ............................... 26

Operating concept ............................ 26

Via Bluetooth® wireless technology ................ 26

Certificates and approvals ................... 27

CE mark ................................... 27

RoHS ..................................... 27

EAC conformity .............................. 27

RCM-Tick marking ............................ 27

Ex approval ................................ 27

Pressure equipment with allowable pressure

≤ 200 bar (2 900 psi) .......................... 27

EN 302729-1/2 radio standard ................... 27

FCC / Industry Canada ......................... 28

Japanese Radio Law and Japanese Telecommunications

Business Law Compliance ....................... 29

Other standards and guidelines ................... 29

Ordering information ....................... 30

Accessories ............................... 31

Device-specific accessories ...................... 31

Communication-specific accessories ................ 34

System components ........................... 34

Supplementary documentation ............... 35

Standard documentation ........................ 35

Installation ............................... 14

Installation conditions ......................... 14

2 Endress+Hauser

Micropilot FMR10

A

DANGER

WARNING

CAUTION

NOTICE

1.

Important document information

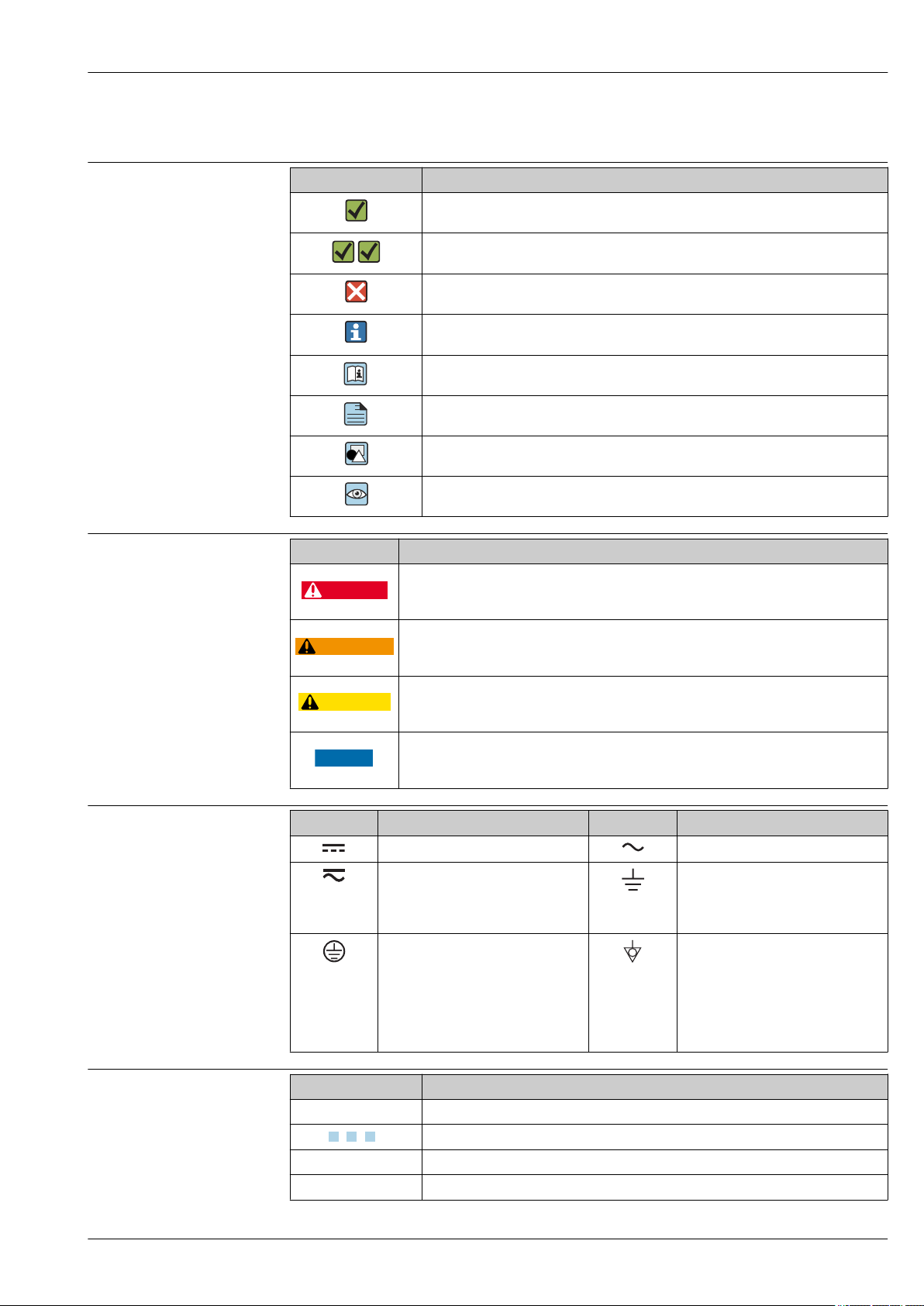

Symbols for certain types of information

Safety symbols

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Electrical symbols

Symbols in graphics

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line

or a star grounding system depending

on national or company codes of

practice.

Endress+Hauser 3

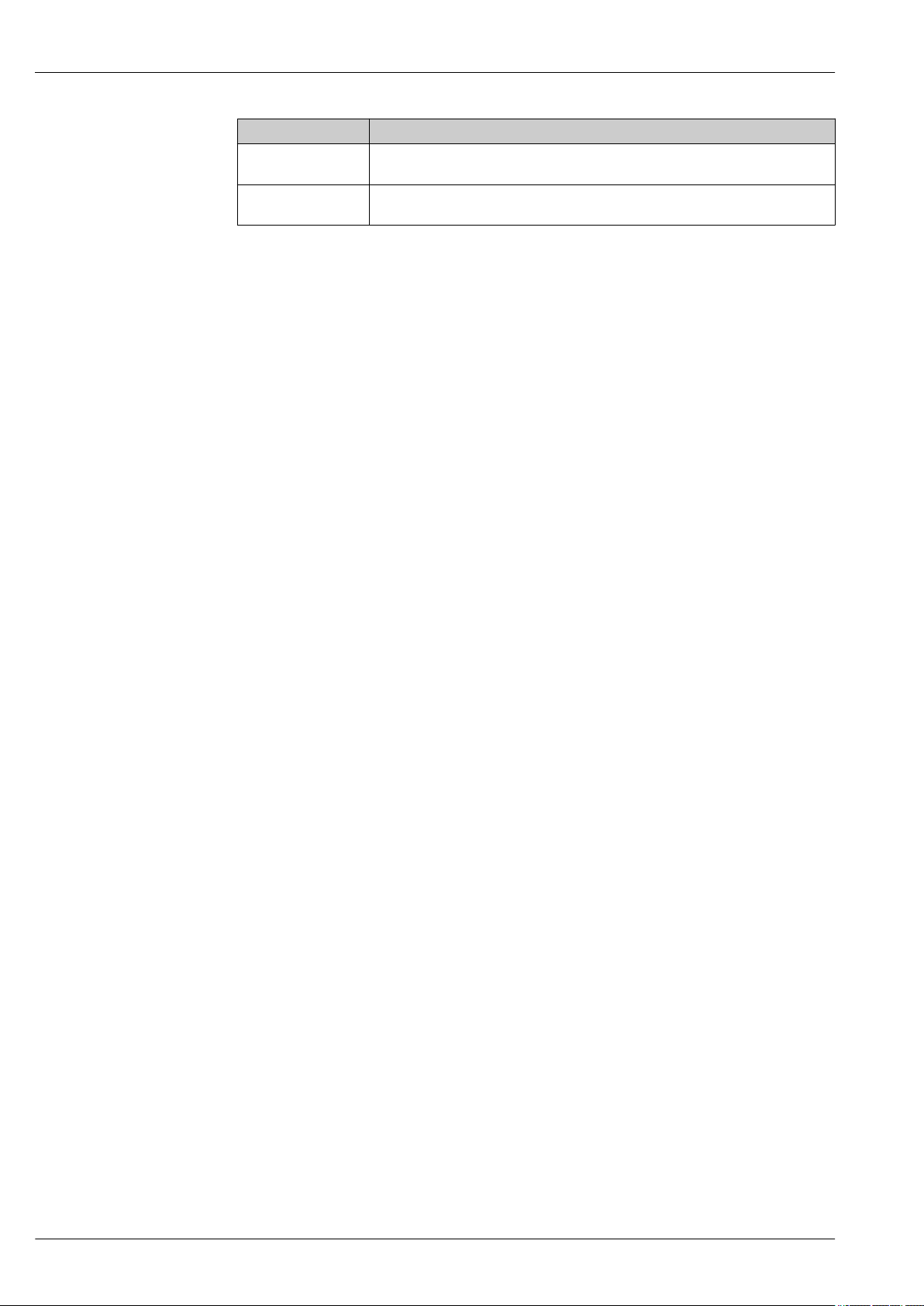

Symbol Meaning

-

.

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

Micropilot FMR10

4 Endress+Hauser

Micropilot FMR10

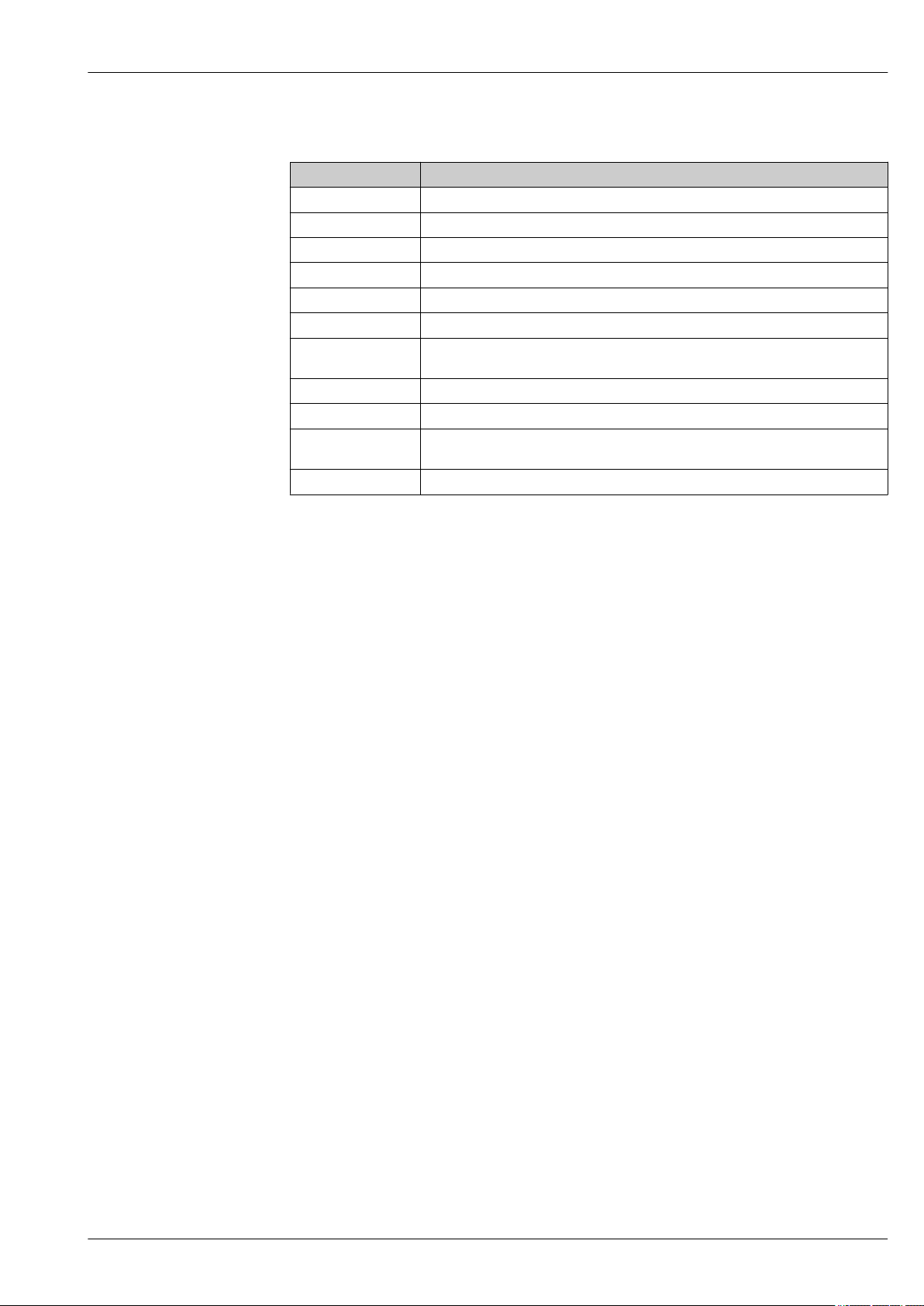

Terms and abbreviations

Term/abbreviation Explanation

BA Document type "Operating Instructions"

KA Document type "Brief Operating Instructions"

TI Document type "Technical Information"

SD Document type "Special Documentation"

XA Document type "Safety Instructions"

PN Nominal pressure

MWP Maximum Working Pressure

The MWP can also be found on the nameplate.

ToF Time of Flight

DC Relative dielectric constant ε

Operating tool The term "operating tool" is used in place of the following operating software:

SmartBlue (app), for operation using an Android or iOS smartphone or tablet.

BD Blocking Distance; no signals are analyzed within the BD.

r

Registered trademarks

Bluetooth®

The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc. and

any use of such marks by Endress+Hauser is under license. Other trademarks and trade names are

those of their respective owners.

Apple®

Apple, the Apple logo, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S.

and other countries. App Store is a service mark of Apple Inc.

Android®

Android, Google Play and the Google Play logo are trademarks of Google Inc.

Endress+Hauser 5

Product life cycle

Micropilot FMR10

Engineering

Procurement

Installation

Commissioning

Operation

Maintenance

• Proven radar measuring technology

• Indication of over-flooding situation

• 2D / 3D drawings

• Spec Sheet Producer

• Applicator Selection tool for the selection of the perfect measurement solution

Device not compatible with transmitters and sensors of ultrasonic measurement technology

(e.g. Prosonic FMU9x, FDU9x)

• Best price-performance-ratio radar

• Easy to order via Global E-direct Portal with 48h delivery time

• Global availability

Rear- and front side thread for flexible installation

• Easy and fast setup via SmartBlue (app)

• No additional tools or adapters required

• Local languages (up to 15)

• Continuous self-monitoring

• Diagnosis information acc. NAMUR NE107 with clear text messages remedy directives

• Signal curve via SmartBlue (app)

• Encrypted single point-to-point data transmission (Fraunhofer-Institut, third party, tested) and

password-protected communication via Bluetooth® wireless technology

• No maintenance required

• Technical experts on-call around the global

Retirement

• Environmentally responsible recycling concepts

• RoHS compliance (Restriction of certain hazardous substances), lead-free soldering of electronic

components

6 Endress+Hauser

Micropilot FMR10

D

Q

R

100%

0%

D

L

F

E

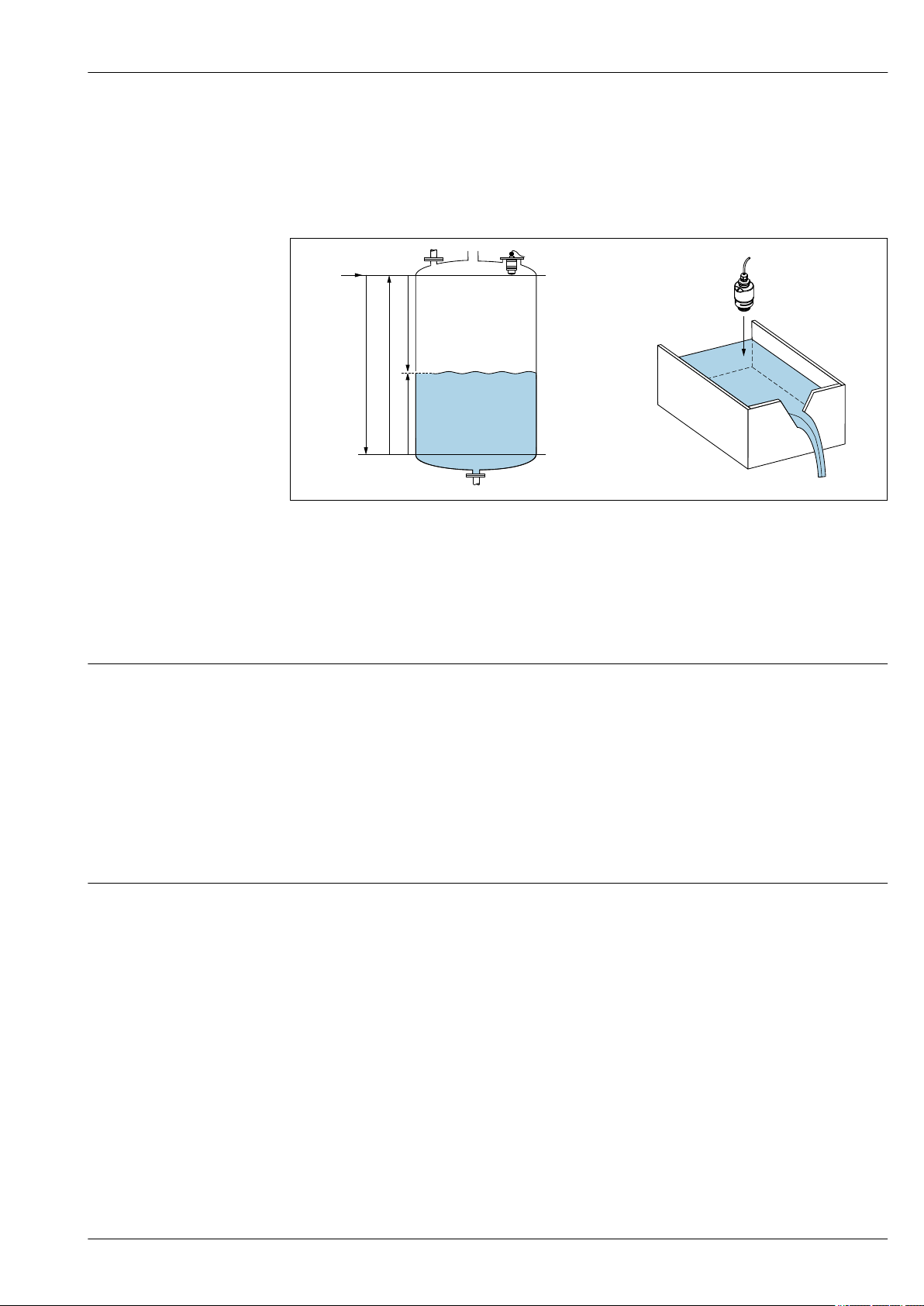

Measuring principle

The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight

method (ToF). It measures the distance from the reference point R to the product surface. Radar

impulses are emitted by an antenna, reflected off the product surface and received again by the radar

system.

A0028409

1 Setup parameters of the Micropilot

E Empty calibration (= zero)

F Full calibration (= span)

D Measured distance

L Level (L = E - D)

Q Flow rate at measuring weirs or channels (calculated from the level using linearization)

R Reference point

Input

The reflected radar impulses are received by the antenna and transmitted into the electronics. A

microprocessor evaluates the signal and identifies the level echo caused by the reflection of the radar

impulse at the product surface. This clear signal detection system benefits from over 30 years'

experience with time-of-flight procedures.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c · t/2,

where c is the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

Output

The Micropilot is adjusted by entering the empty distance E (= zero point) and the full distance F (=

span).

• Current output: 4 to 20 mA

• Digital output (SmartBlue): 0 to 5 m (0 to 16 ft) or 0 to 8 m (0 to 26.25 ft) in combination with

accessory "flooding protection tube"

Endress+Hauser 7

Input

Micropilot FMR10

Measured variable

The measured variable is the distance between the reference point and the product surface.

The level is calculated based on E, the empty distance entered.

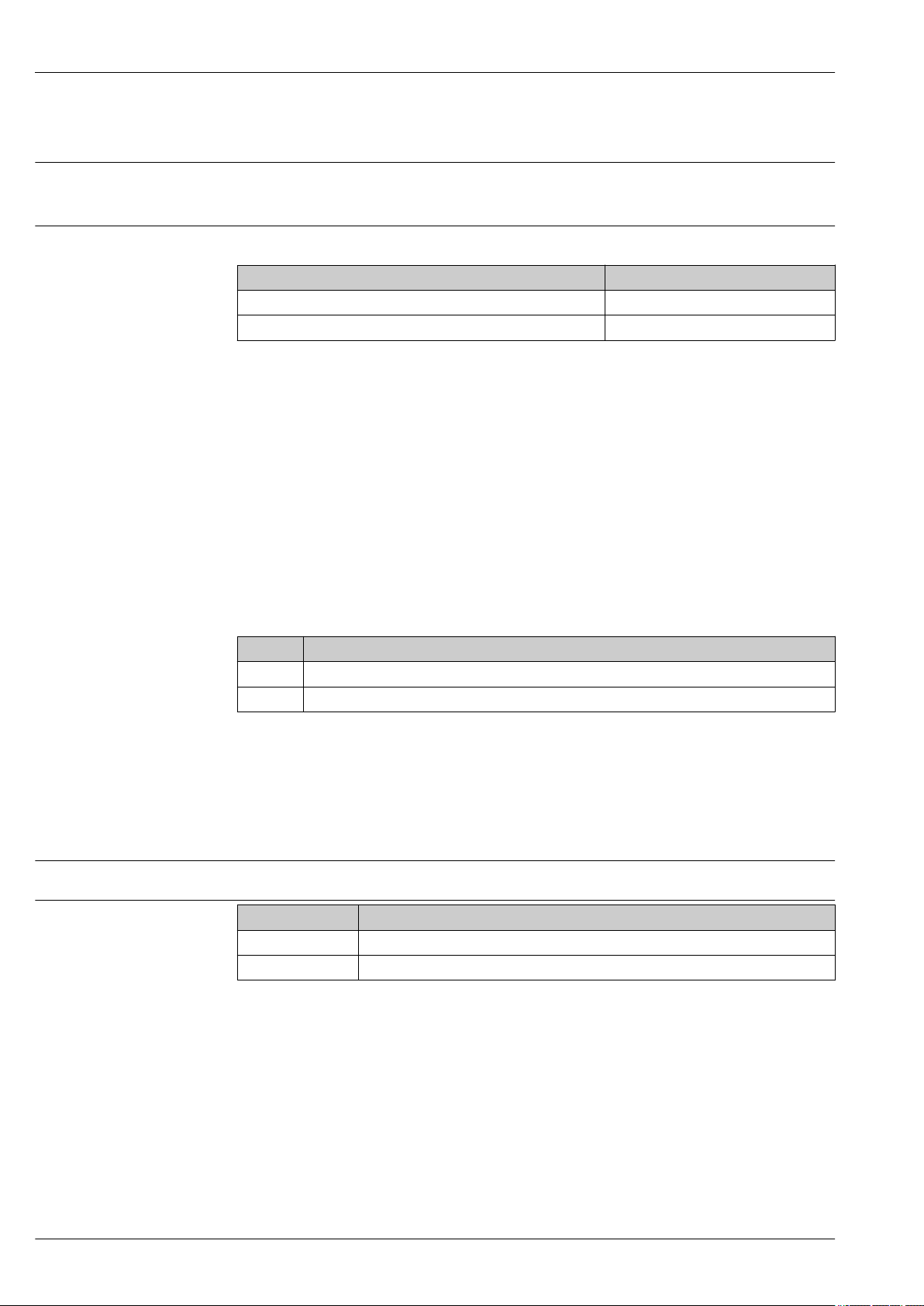

Measuring range Maximum measuring range

Device Maximum measuring range

FMR10 5 m (16 ft)

FMR10 with accessory "flooding protection tube" 8 m (26.25 ft)

Requirements of the installation

• Tank height > 1.5 m (5 ft)

• Open channel minimum width 0.5 m (1.6 ft)

• Calm surfaces

• No agitators

• No buildup

• Relative dielectric constant εr > 4

Usable measuring range

The usable measuring range depends on the antenna size, the medium's reflective properties, the

installation position and any possible interference reflections.

The following table describes the media groups.

Media groups

Operating frequency

Transmission power

ε

r

4 to 10 e.g. concentrated acid, organic solvents, ester, aniline, alcohol, acetone.

> 10 conductive liquids, aqueous solutions, diluted acids and bases

Example

Reduction of the max. possible measuring range by:

• Media with bad reflective properties (= low εr value)

• Formation of buildup, particularly of moist products

• Strong condensation

• Foam generation

• Freezing of sensor

K-band (~ 26 GHz)

Distance Mean power density in the direction of the beam

1 m (3.3 ft) < 12 nW/cm

5 m (16 ft) < 0.4 nW/cm

2

2

8 Endress+Hauser

Micropilot FMR10

Output

Output signal 4 to 20 mA

An 4 to 20 mA interface is used for measured value output and to power to the device.

Digital output Bluetooth® wireless technology

The device has a Bluetooth® wireless technology interface and can be operated and configured via

this interface using the SmartBlue app.

• The range under reference conditions is 25 m (82 ft)

• Incorrect operation by unauthorized persons is prevented by means of encrypted communication

and password encryption.

• The Bluetooth® wireless technology interface can be deactivated.

Signal on alarm

Linearization

Depending on the interface, failure information is displayed as follows:

• Current output

Alarm current: 22.5 mA (as per NAMUR RecommendationNE 43)

• SmartBlue (app)

– Status signal (as per NAMUR Recommendation NE 107)

– Plain text display with remedial action

The linearization function of the device allows the conversion of the measured value into any unit of

length, weight, flow or volume.

When operating via SmartBlue (app), up to 32 value pairs can be entered manually into the

linearization table.

Endress+Hauser 9

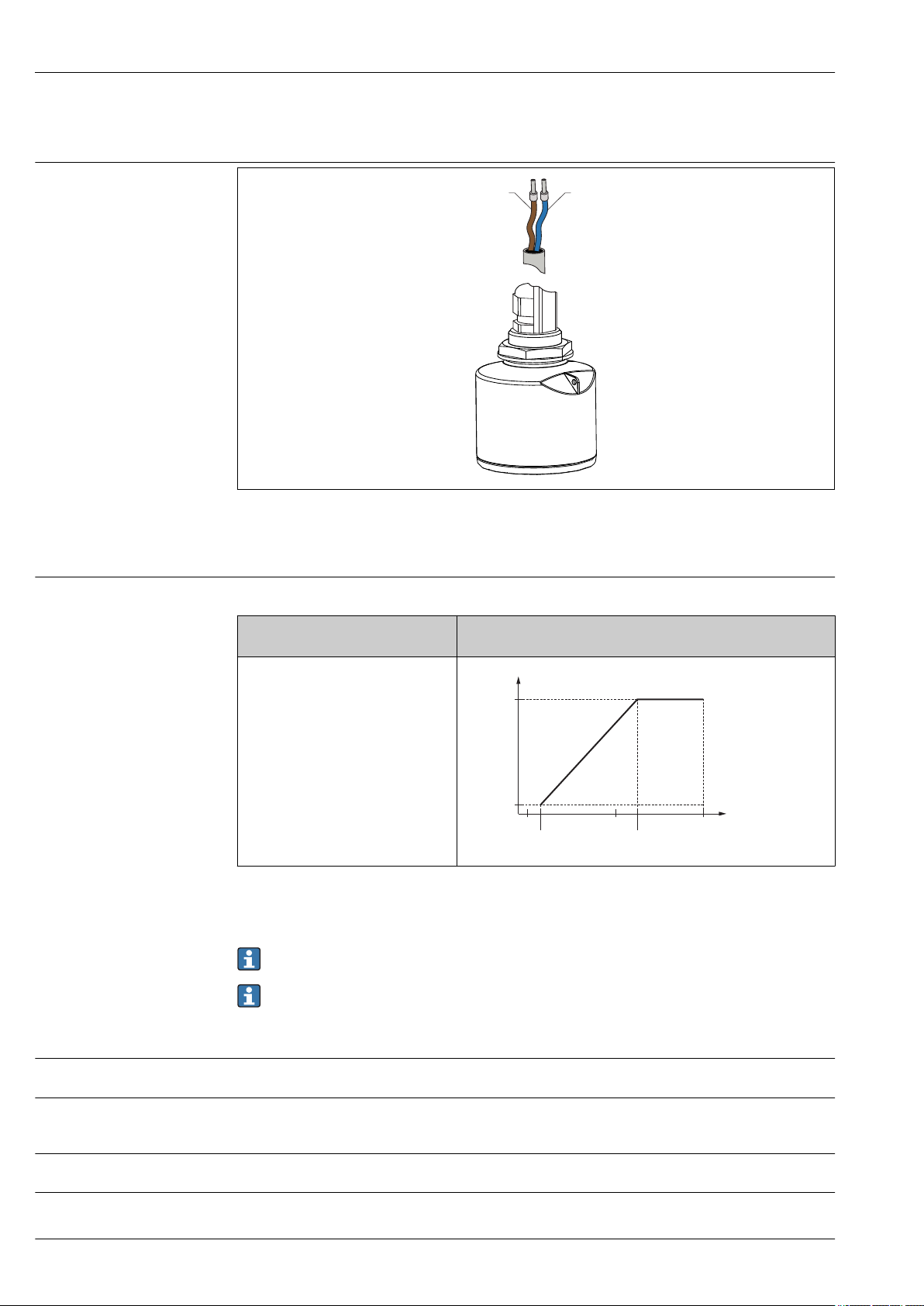

Cable assignment

-

+

1

2

R [ ]W

U0[V]

10

10.5 21.75

20 30

0

500

Micropilot FMR10

Electrical connection

A0028954

2 Cable assignment

1 Plus, brown wire

2 Minus, blue wire

Supply voltage

An external power supply is necessary.

Terminal voltage U at device Maximum load R, depending on supply voltage U0 of power supply

unit

10.5 to 30 VDC 2-wire

A0029226

Potential equalization

No special measures for potential equalization are required.

Various power supply units can be ordered from Endress+Hauser.

Battery operation

The sensor's Bluetooth® wireless technology communication can be disabled to increase the

operating life of the battery.

Power consumption

Current consumption

Starting time

Power supply failure

10 Endress+Hauser

Maximum input power: 675 mW

• maximum input current: <25 mA

• Maximum start-up current: 3.6 mA

First stable measured value after 20 s (with supply voltage = 24 VDC)

The configuration remains stored in the sensor.

Micropilot FMR10

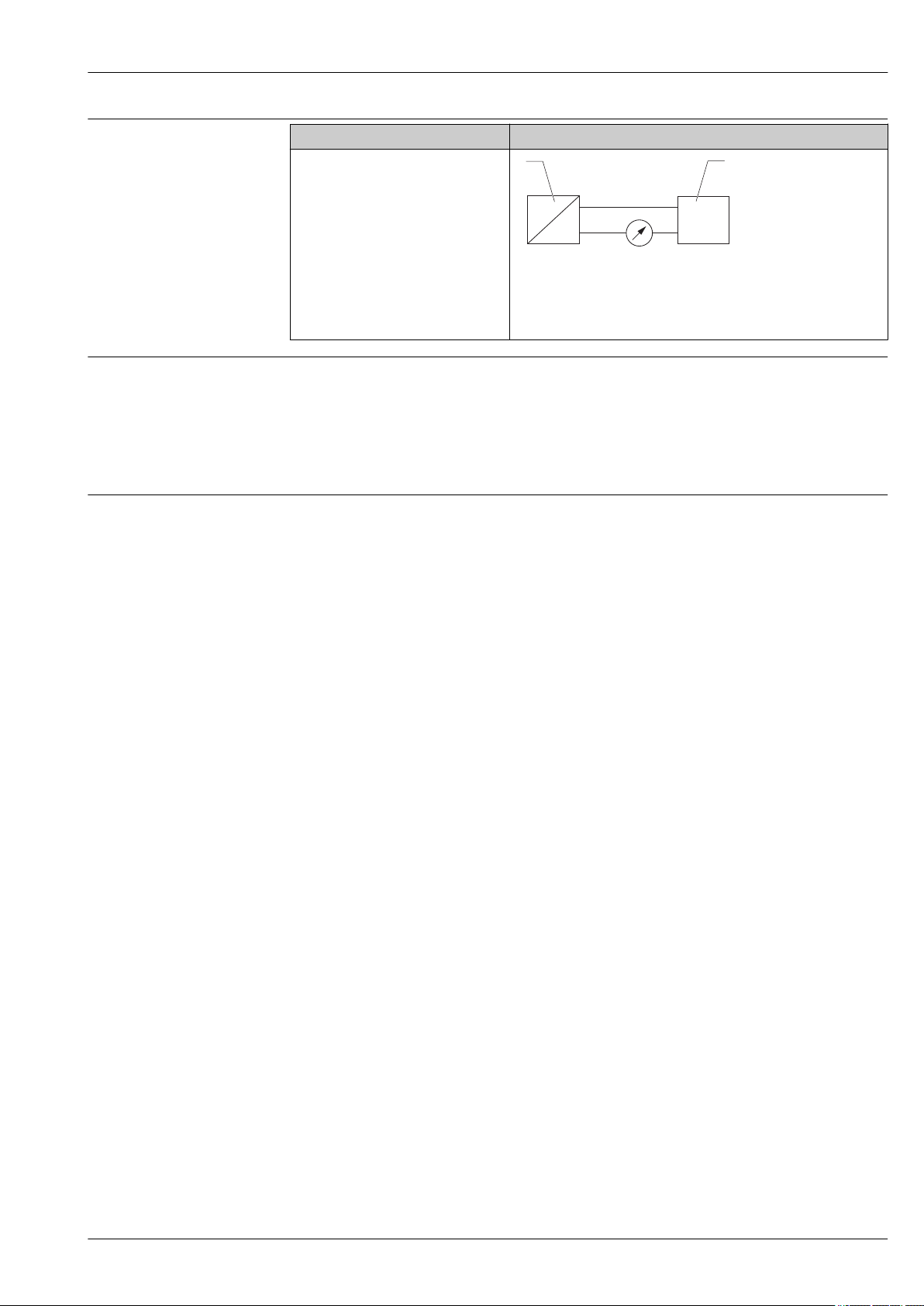

2

Y

+ +

- -

I

1

mA

Connection 4 to 20 mA

Cable specification

Overvoltage protection

Circuit diagram / Description

FMR10 connection with voltage source

and 4 to 20 mA display

A0028907

3 FMR10 block diagram

1 Micropilot FMR10, 4 to 20 mA

2 Power supply

Unshielded cable, 2 × 0.75 mm

2

• UV- and weather-resistant acc. ISO 4892-2

• Flame retardant acc. IEC 60332-1-2

As per IEC/EN 60079-11 section 10.9, the cable is designed for a tensile strength of 30 N (6.74 lbf)

(over a period of 1 h).

The FMR10 is supplied with 10 m (33 ft) cable length as standard.

The device is equipped with integrated overvoltage protection.

Endress+Hauser 11

Loading...

Loading...