Page 1

BA00274P/00/EN/18.16

71336359

valid from Software version:

02.30.zz

Products Solutions Services

Description of Instrument Functions

Cerabar S PMC71, PMP71, PMP75

Deltabar S FMD77 / 78, PMD75

Deltapilot S FMB70

Process pressure / Differential pressure, Flow /

Hydrostatic

Page 2

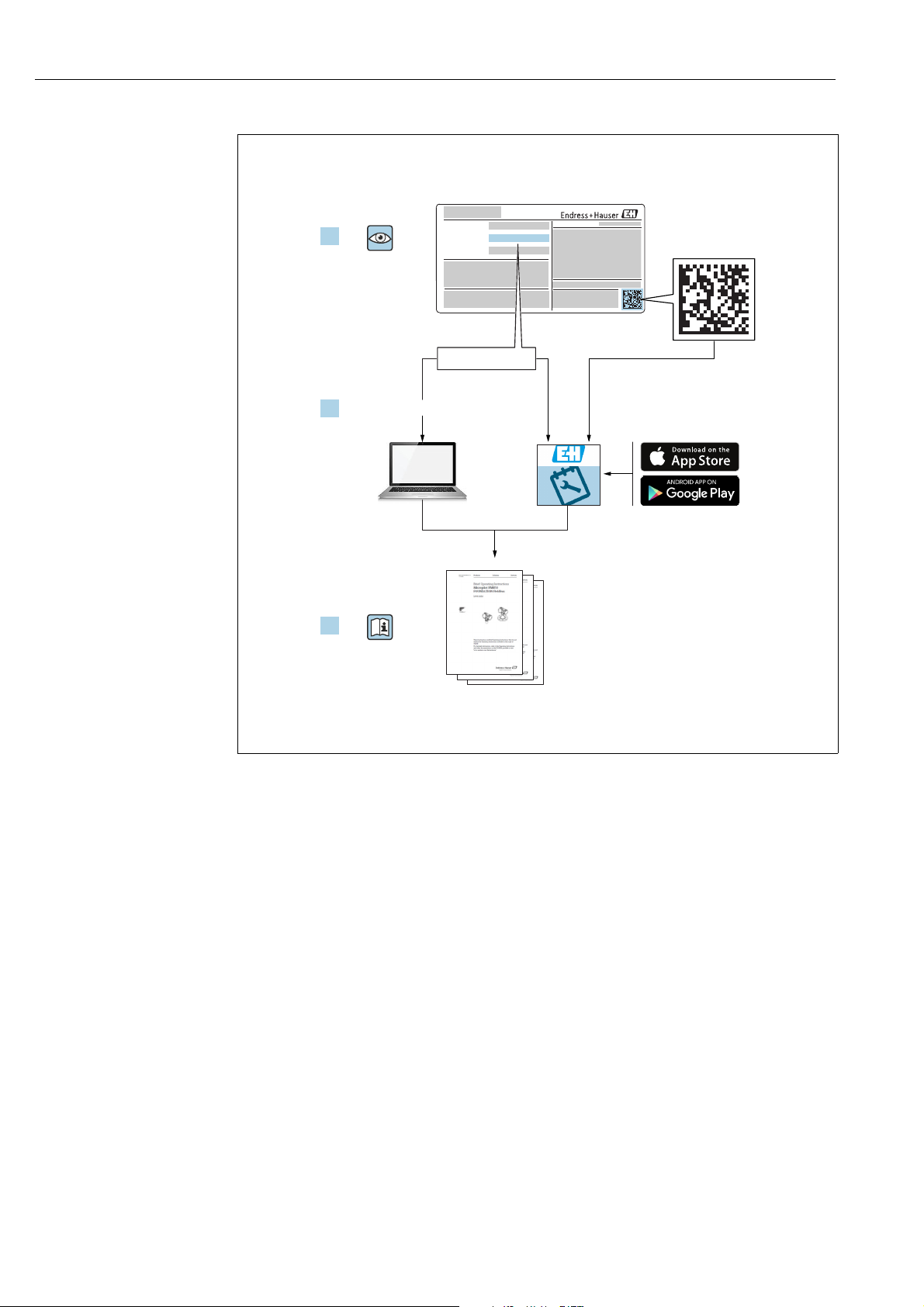

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to these

Instructions.

2 Endress+Hauser

Page 3

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

Table of contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Basic safety instructions . . . . . . . . . . . . . 4

3 Notes on use . . . . . . . . . . . . . . . . . . . . . . . 4

4 Pressure measurement . . . . . . . . . . . . . . 5

4.1 Calibration with reference pressure . . . . . . . . . . . . 5

4.2 Calibration without reference pressure . . . . . . . . . 6

5 Level measurement . . . . . . . . . . . . . . . . . 8

5.1 Overview of level measurement . . . . . . . . . . . . . . 8

5.2 "Level Easy Pressure" level selection . . . . . . . . . . . . 9

5.3 "Level Easy Height" level selection . . . . . . . . . . . . 13

5.4 "Level Standard" level selection,

"Linear" level type . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5 "Level Standard" level selection,

"Pressure Linearized" level type . . . . . . . . . . . . . . 21

5.6 "Level Standard" level selection,

"Height Linearized" level type . . . . . . . . . . . . . . . 26

6 Flow measurement . . . . . . . . . . . . . . . .33

6.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7 On-site display operating menu . . . . .36

8 FieldCare operating menu . . . . . . . . . .43

9 Description of parameters . . . . . . . . . .62

10 Troubleshooting. . . . . . . . . . . . . . . . . .131

10.1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

10.2 Response of outputs to errors . . . . . . . . . . . . . . 140

10.3 Confirming messages . . . . . . . . . . . . . . . . . . . . . 141

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Endress+Hauser 3

Page 4

Document information Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

DANGER

WARNING

CAUTION

NOTICE

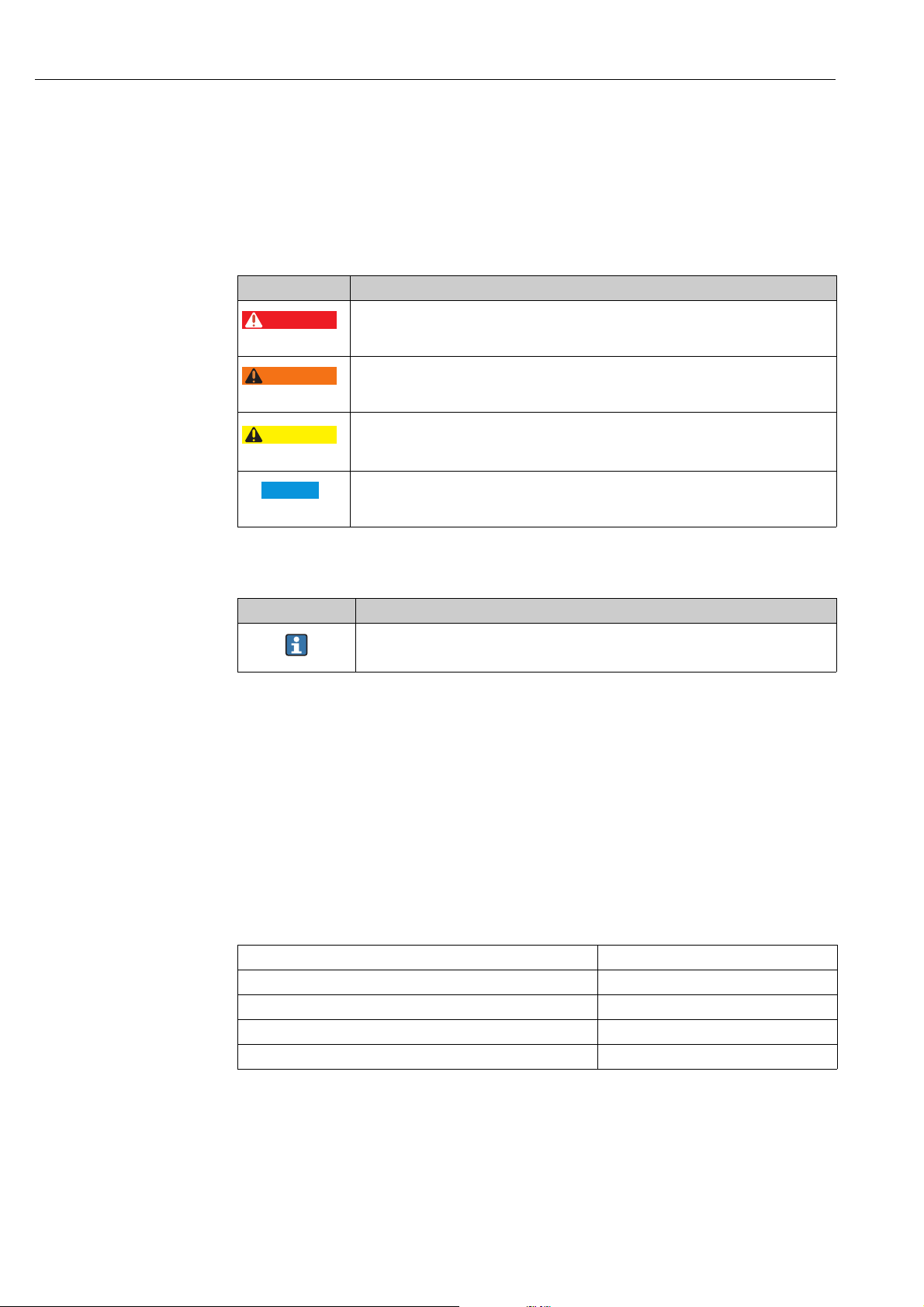

1 Document information

1.1 Symbols used

1.1.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-DE

A0011190-DE

A0011191-DE

A0011192-DE

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

seriousor fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

seriousor fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minoror medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personalinjury.

1.1.2 Symbols for certain types of information

Symbol Meaning

Tip

Indicates additional information.

A0011193

2 Basic safety instructions

Siehe Betriebsanleitung:

Deltabar S BA00270P

Cerabar S BA00271P

Deltapilot S BA00332P

3 Notes on use

Typical examples of configuration see chapter 4 to 6

Operating menu of the on-site display see Chapter 7

FieldCare operating menu see Chapter 8

Parameter description see Chapter 9

Finding parameter description using parameter names (index) see Page 142

4 Endress+Hauser

Page 5

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Pressure measurement

WARNING

!

4 Pressure measurement

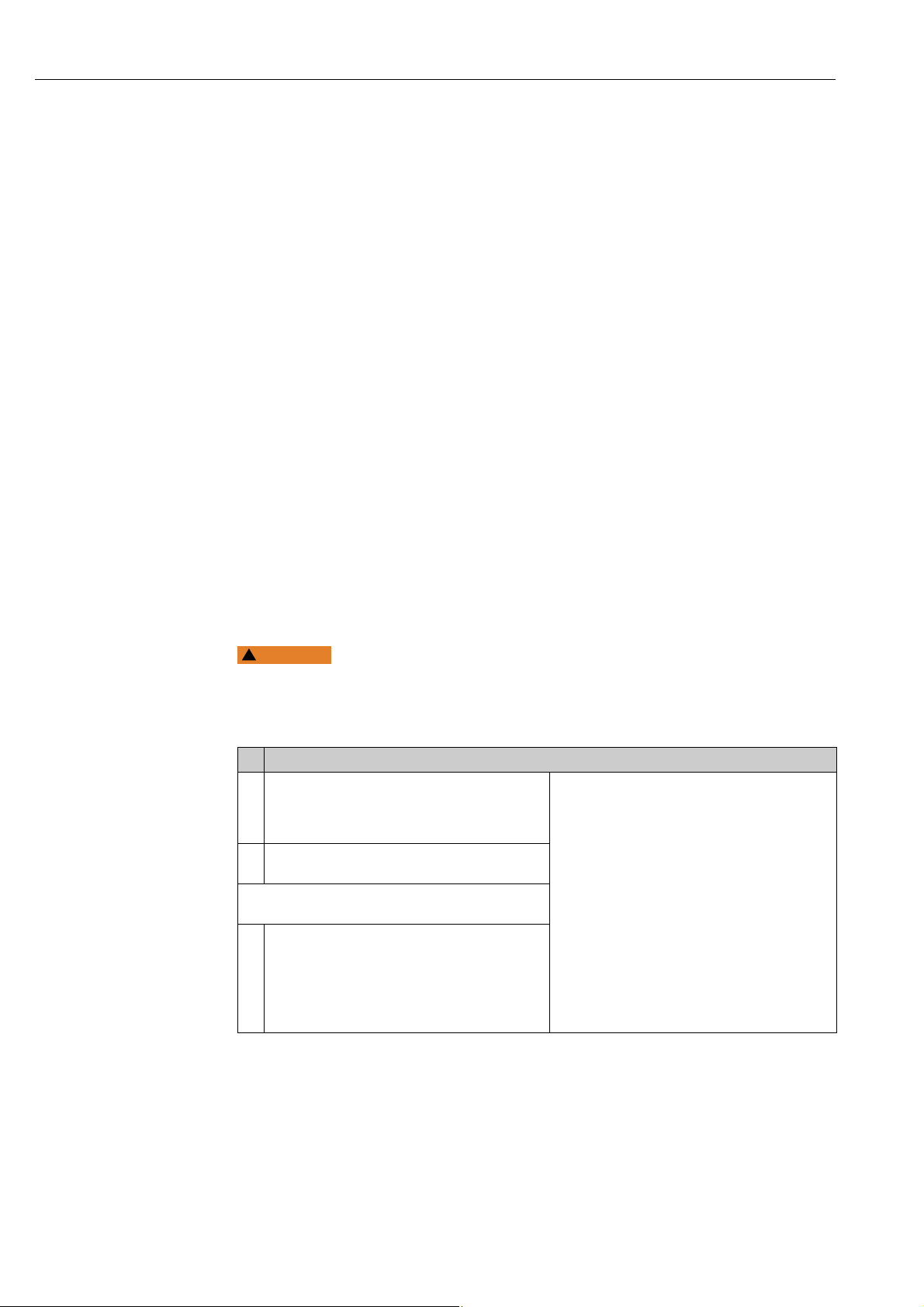

4.1 Calibration with reference pressure

Example:

In this example, a device with a 500 mbar (7.5 psi) sensor is configured for the 0...+300

mbar (4.5 psi)measuring range, i.e. 0 mbar and 300 mbar (4.5 psi) are assigned to the 4 mA

value and 20 mA value respectively.

Prerequisite:

• The pressure values 0 mbar and 300 mbar (4.5 psi) can be specified. The device is already

installed, for example.

• See also Operating Instructions Deltabar S (BA00270P), Section "Differential pressure

measurement", Cerabar S (BA00271P), Section "Pressure measurement" or Deltapilot S

(BA00332P), Section "Pressure measurement".

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 69, Table 7: BASIC SETUP.

• For a description of further relevant parameters, see

– Page 100, Table 15: EXTENDED SETUP

– Page 120, Table 25: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Endress+Hauser 5

Page 6

Pressure measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

+

–

20

4

I

[mA]

0 300

p

[mbar]

➀

➁

Description

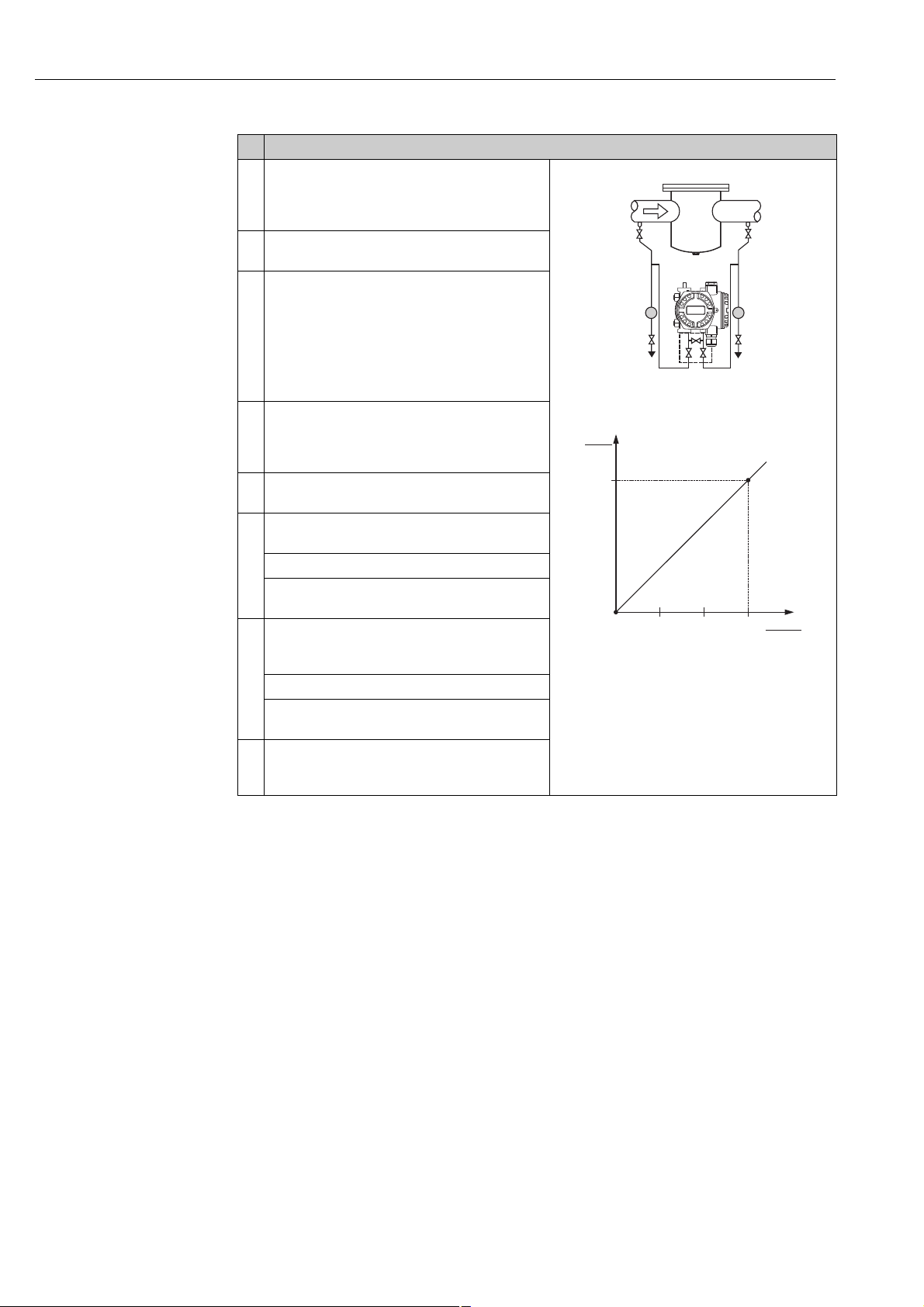

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and

filled with fluid. See Operating Instructions

BA00270P.

2 Carry out position adjustment if necessary. See Page

68, Table 6: POSITION ADJUSTMENT.

3 If necessary, select the "Pressure" measuring mode

via the MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

4On-site display:

Select BASIC SETUP function group.

Menu path: GROUP SELECTION OPERATING

MENU SETTINGS BASIC SETUP

5 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

6 The pressure for the lower range value (4 mA value)

is present at the device, here 0 mbar for example.

Select GET LRV parameter.

Confirm value present. The pressure value present is

assigned to the lower current value (4 mA).

7 The pressure for the upper range value (20 mA

value) is present at the device, here 300 mbar (4.5

psi) for example.

Select GET URV parameter.

Confirm value present. The pressure value present is

assigned to the upper current value (20 mA).

8Result:

The measuring range is set for 0...+300 mbar (4.5

psi).

Fig. 1: Calibration with reference pressure

1 See table, step 6.

2 See table, step 7.

P01-PMD75xxx-19-xx-xx-xx-000

P01-xxxxxxxx-05-xx-xx-xx-010

You can also specify a customer-specific unit. See parameter description for PRESS. ENG.

UNIT (Page 69).

4.2 Calibration without reference pressure

Example:

In this example, a device with a 400 mbar (6 psi) sensor is configured for the 0...+300 mbar

(4.5 psi) measuring range, i.e. 0 mbar and 300 mbar (4.5 psi) are assigned to the 4 mA value

and 20 mA value respectively.

Prerequisite:

• This is a theoretical calibration, i.e. the pressure values for the lower range and upper

6 Endress+Hauser

range value are known.

• See also Operating Instructions Deltabar S (BA00270P), Section "Differential pressure

measurement", Cerabar S (BA00271P), Section "Pressure measurement" or Deltapilot S

(BA00332P), Section "Pressure measurement".

• Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the MEASURED VALUE parameter does not display zero. To

perform a position adjustment see also Page 68, Table 6: Position adjustment.

Page 7

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Pressure measurement

WARNING

!

20

4

I

[mA]

0 300

p

[mbar]

➀

➁

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 69, Table 7: BASIC SETUP.

• For a description of further relevant parameters, see

– Page 100, Table 15: EXTENDED SETUP

– Page 120, Table 27: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

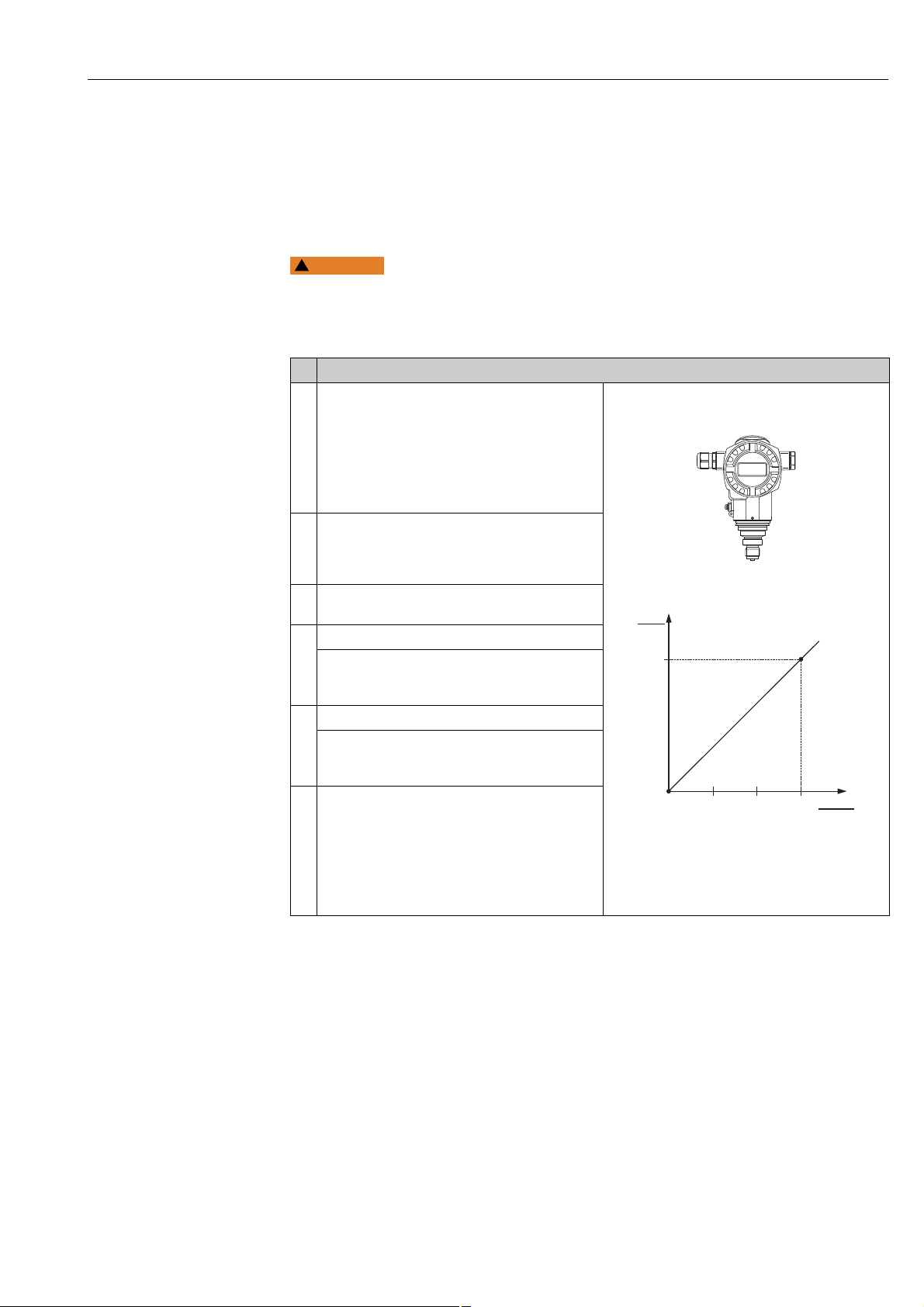

Description

1 If necessary, select the "Pressure" measuring mode

via the MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

2 On-site display:

Select BASIC SETUP function group.

Menu path: GROUP SELECTION OPERATING

MENU SETTINGS BASIC SETUP

3 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

4 Select SET LRV parameter.

Enter value, here 0 mbar, for the SET LRV parameter

and confirm. This pressure value is assigned to the

lower current value (4 mA).

5 Select SET URV parameter.

Enter value, here 300 mbar (4.5 psi), for the SET

URV parameter and confirm. This pressure value is

assigned to the upper current value (20 mA).

6 Result:

The measuring range is set for 0...+300 mbar (4.5

psi).

Fig. 2: Calibration without reference pressure

1 See table, step 4.

2 See table, step 5.

P01-PMP71xxx-19-xx-xx-xx-000

P01-xxxxxxxx-05-xx-xx-xx-010

Endress+Hauser 7

• You can also perform calibration without reference pressure by means of the QUICK SETUP

menu. See Page 64 ff, Table 3: QUICK SETUP menu.

• You can also specify a customer-specific unit. See parameter description for PRESS. ENG.

UNIT (Page 69).

Page 8

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

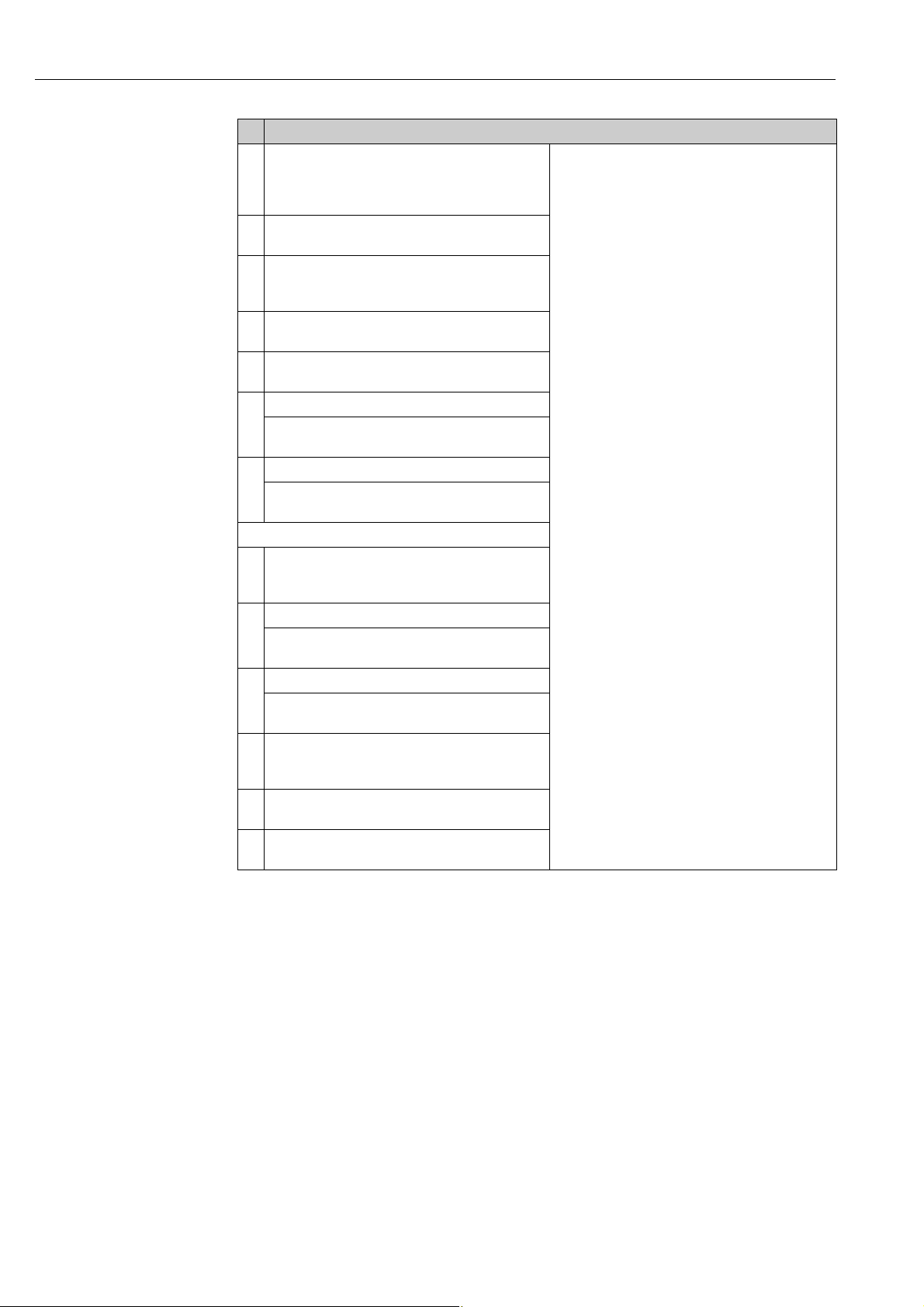

5 Level measurement

5.1 Overview of level measurement

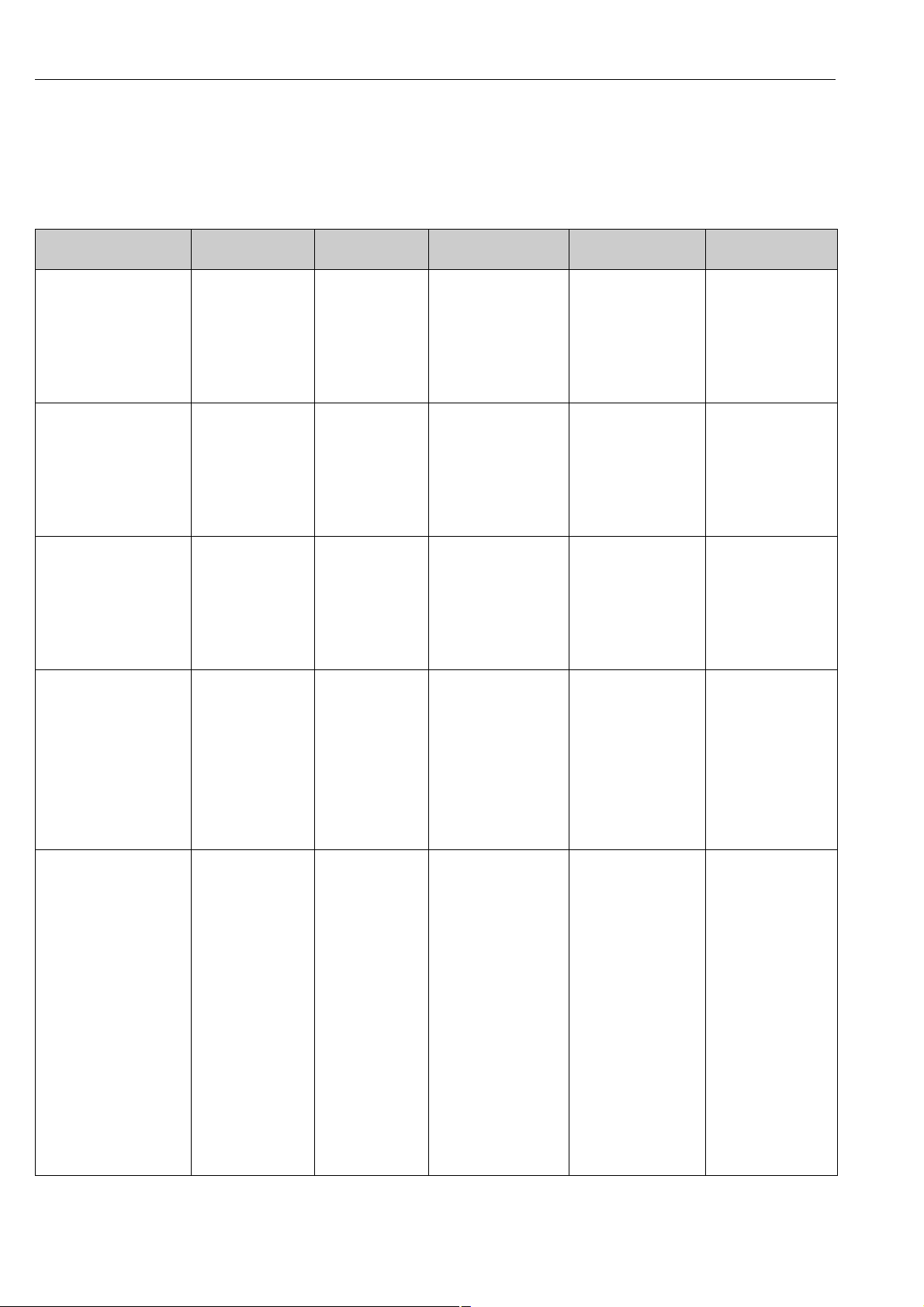

Measuring task LEVEL SELECTION/

The measured variable is in

direct proportion to the

measured pressure.

Calibration is performed by

entering two pressure-level

value pairs.

The measured variable is in

direct proportion to the

measured pressure.

Calibration is performed by

entering the density and

two height-level value

pairs.

The measured variable is in

direct proportion to the

measured pressure.

The measured variable is

not in direct proportion to

the measured pressure as,

for example, with

containers with a conical

outlet. A

linearisation table must be

entered for the calibration.

– Two measured variables

are required or

– The container shape is

given by value pairs, such

as height and volume.

The 1st measured variable

%-height or height must be

in direct proportion to the

measured pressure. The

2nd measured variable

volume, mass or % must

not be in direct proportion

to the measured pressure.

A linearisation table must

be entered for the 2nd

measured variable. The 2nd

measured variable is

assigned to the 1st

measured variable by

means of this table.

LEVEL MODE

LEVEL SELECTION:

Level Easy Pressure

LEVEL SELECTION:

Level Easy Height

LEVEL SELECTION:

Level standard/

LEVEL MODE:

Linear

LEVEL SELECTION:

Level standard/

LEVEL MODE:

Pressure Linearized

LEVEL SELECTION:

Level standard/

LEVEL MODE:

Height Linearized

Measured

variable options

Via OUTPUT UNIT

parameter: %, level,

volume or mass

units.

Via OUTPUT UNIT

parameter: %, level,

volume or mass

units.

Via LIN.

MEASURAND

parameter:

–% (Level)

– Level

–Volume

–Mass

Via LINd

MEASURAND

parameter:

– Pressure + %

– Pressure +

Volume

– Pressure + Mass

Via COMB.

MEASURAND

parameter:

–Height + Volume

–Height + Mass

–Height + %

–%-Height +

Volume

–%-Height + Mass

–%-Height + %

Description Comment Measured value

–Calibration with

reference pressure –

wet calibration, see

Page 9, Section 5.2.1

– Calibration without

reference pressure –

dry calibration, see

Page 11, Section 5.2.2

–Calibration with

reference pressure –

wet calibration, see

Page 13, Section 5.3.1

– Calibration without

reference pressure –

dry calibration, see

Page 15, Section 5.3.2

–Calibration with

reference pressure –

wet calibration, see

Page 17, Section 5.4.1

– Calibration without

reference pressure –

dry calibration, see

Page 19, Section 5.4.2

–Calibration with

reference pressure:

semiautomatic entry

of linearisation table,

see Page 21, Section

5.5.1

– Calibration without

reference pressure:

manual entry of

linearisation table, see

Page 24, Section 5.5.2

–Calibration with

reference pressure:

wet calibration and

semiautomatic entry

of linearisation table,

see Page 26, Section

5.6.1

– Calibration without

reference pressure:

dry calibration and

manual entry of

linearisation table, see

Page 30, Section 5.6.2

– Incorrect entries are

possible

– SIL mode possible

– Customised units are

not possible

– Incorrect entries are

possible

– SIL mode not possible

– Customised units are

not possible

– Incorrect entries are

rejected by the device

– SIL mode not possible

– Customised level,

volume and mass

units are possible

– Incorrect entries are

rejected by the device

– SIL mode not possible

– Customised level,

volume and mass

units are possible

– Incorrect entries are

rejected by the device

– SIL mode not possible

– Customised level,

volume and mass

units are possible

display

The measured value

display and the LEVEL

BEFORE LIN parameter

show the measured

value.

The measured value

display and the LEVEL

BEFORE LIN parameter

show the measured

value.

The measured value

display and the LEVEL

BEFORE LIN parameter

show the measured

value.

The measured value

display and the TANK

CONTENT parameter

show the measured

value.

The measured value

display and the TANK

CONTENT parameter

show the 2nd

measured value

(volume, mass or %).

The LEVEL BEFORE

LIN parameter displays

the 1st measured value

(%-height or height).

8 Endress+Hauser

Page 9

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

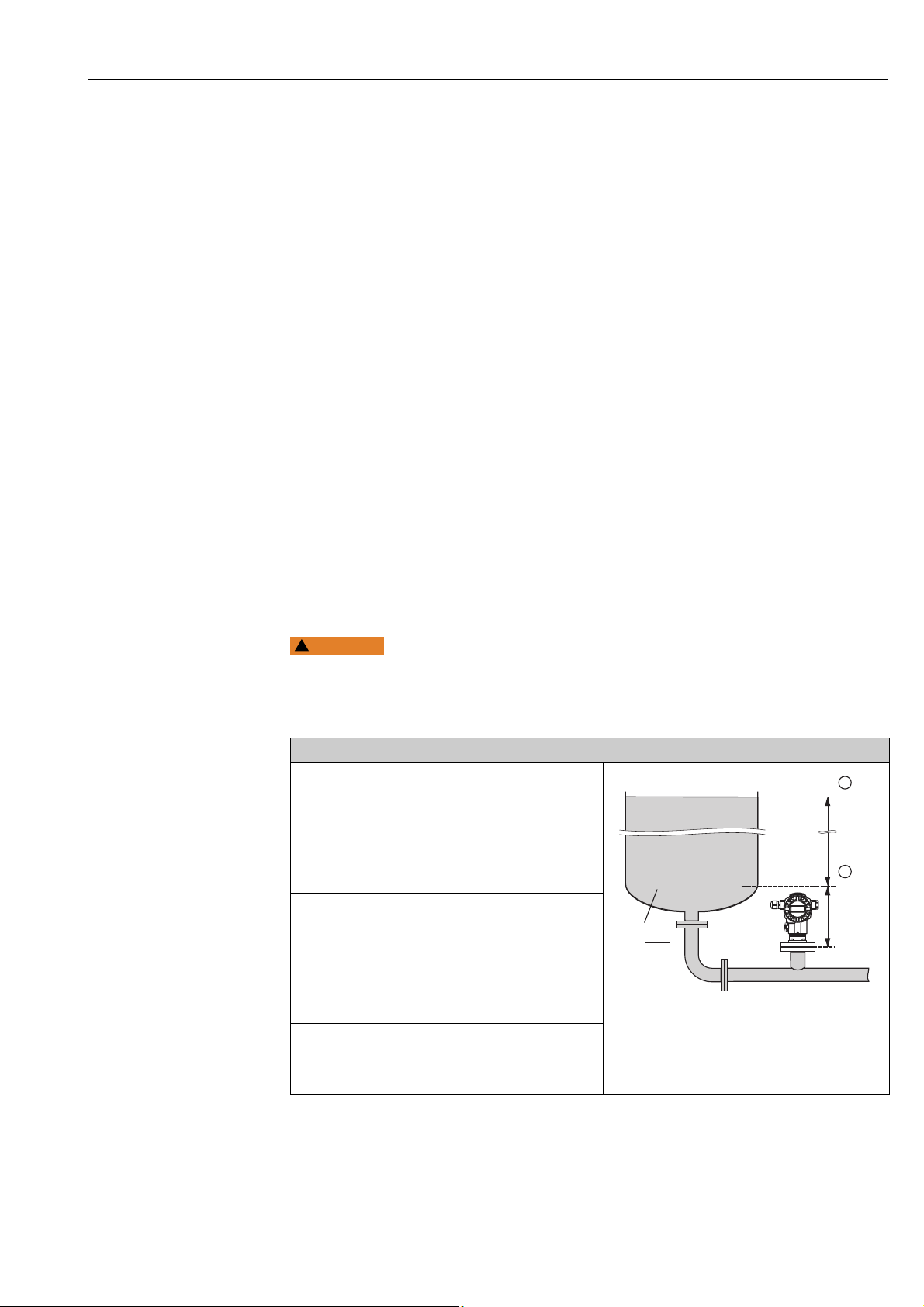

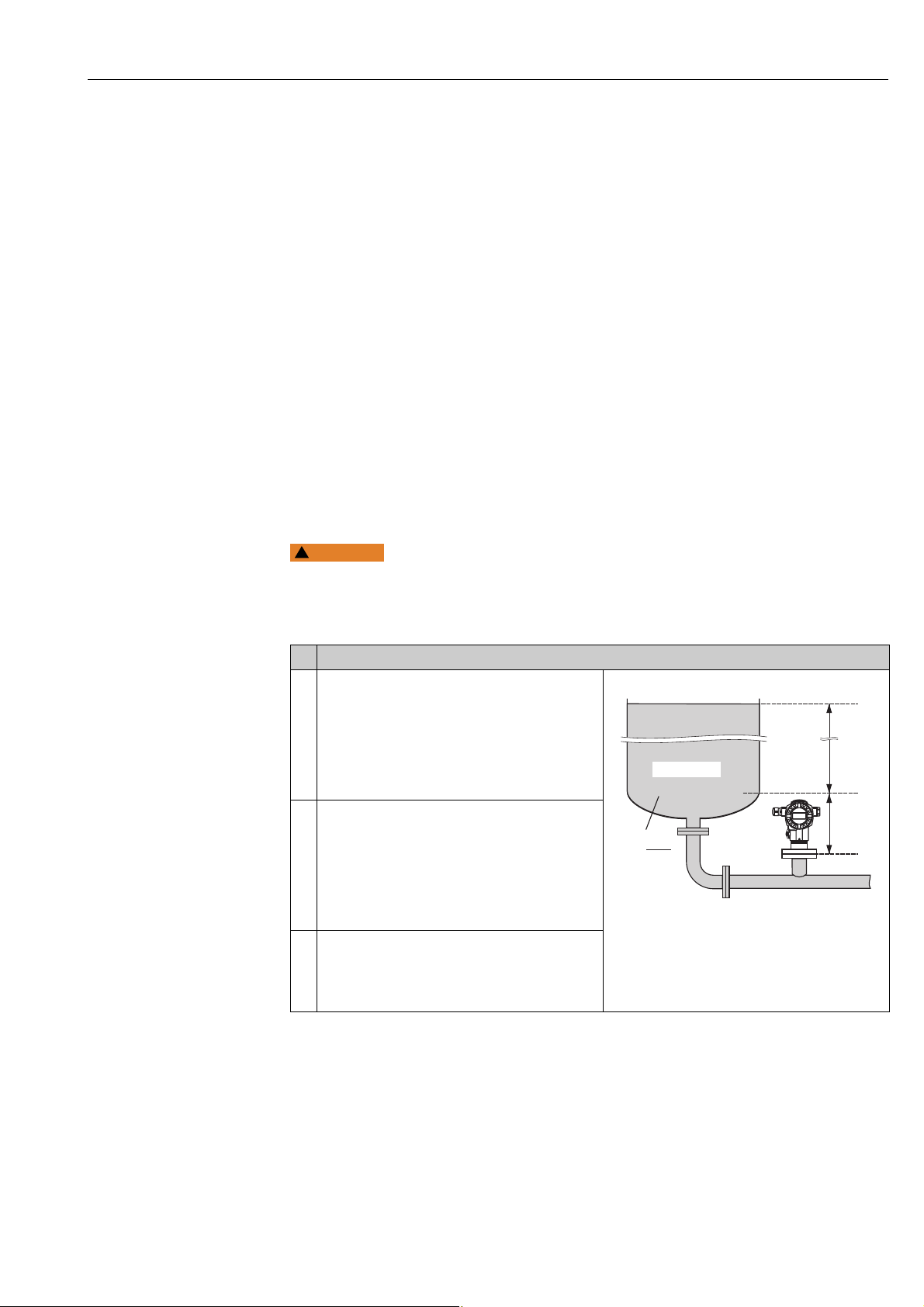

WARNING

!

➀

➁

0 mbar

300 mbar

3 m

0 m

5.2 "Level Easy Pressure" level selection

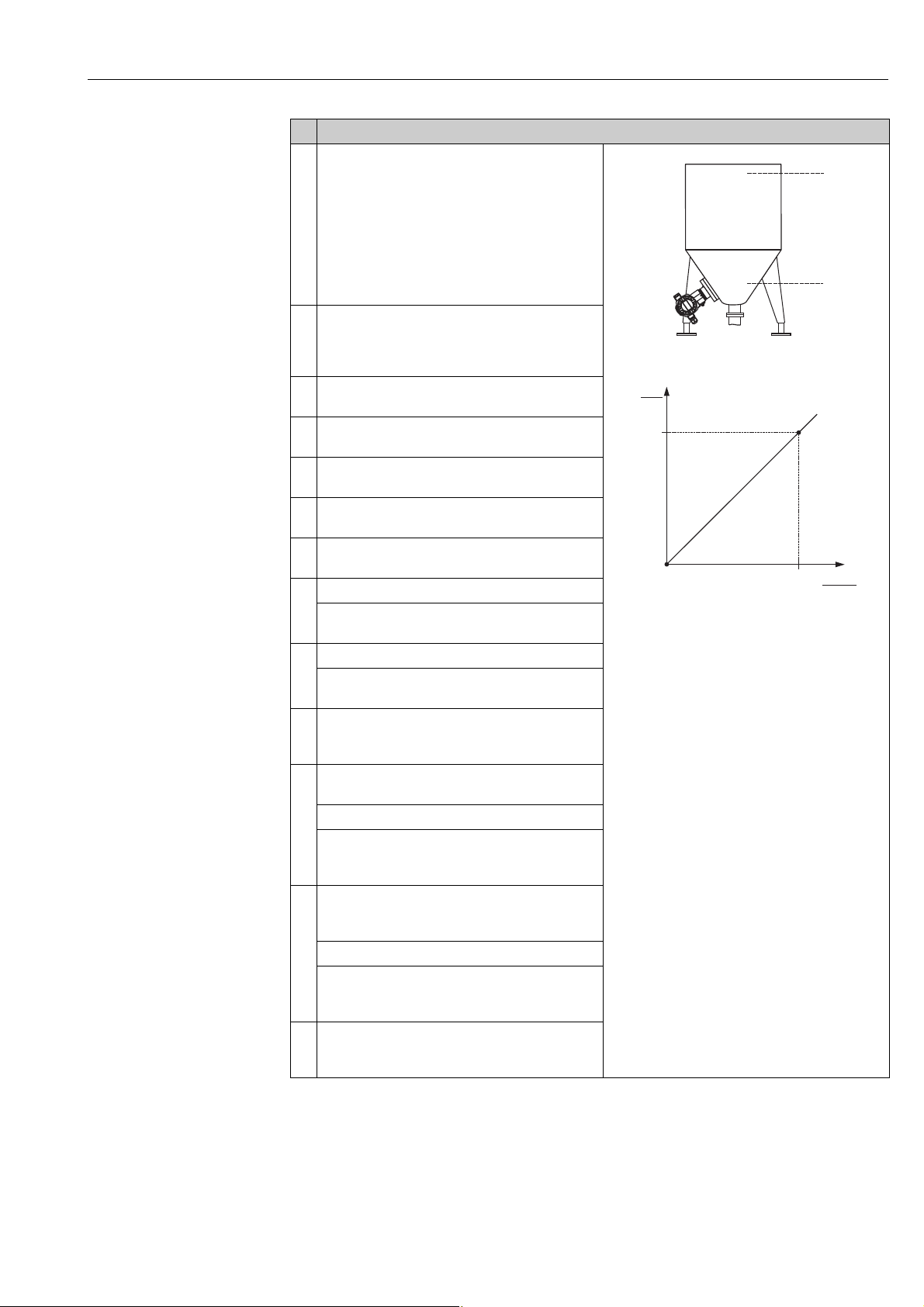

5.2.1 Calibration with reference pressure – wet calibration

Example:

In this example, the level in a tank should be measured in m. The maximum level is 3 m (9.8

ft). The pressure range is set to 0 to 300 mbar (4.5 psi).

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• The tank can be filled or emptied.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• The values entered for EMPTY CALIB./FULL CALIB. and SET LRV/SET URV must have a

minimum interval of 1% for the "Level Easy Pressure" level mode. The value will be rejected

with a warning message if the values are too close together. Further limit values are not

checked; i.e. the values entered must be appropriate for the sensor and the measuring task

so that the measuring device can measure correctly.

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 70, Table 8: LEVEL SELECTION "Level Easy Pressure"

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

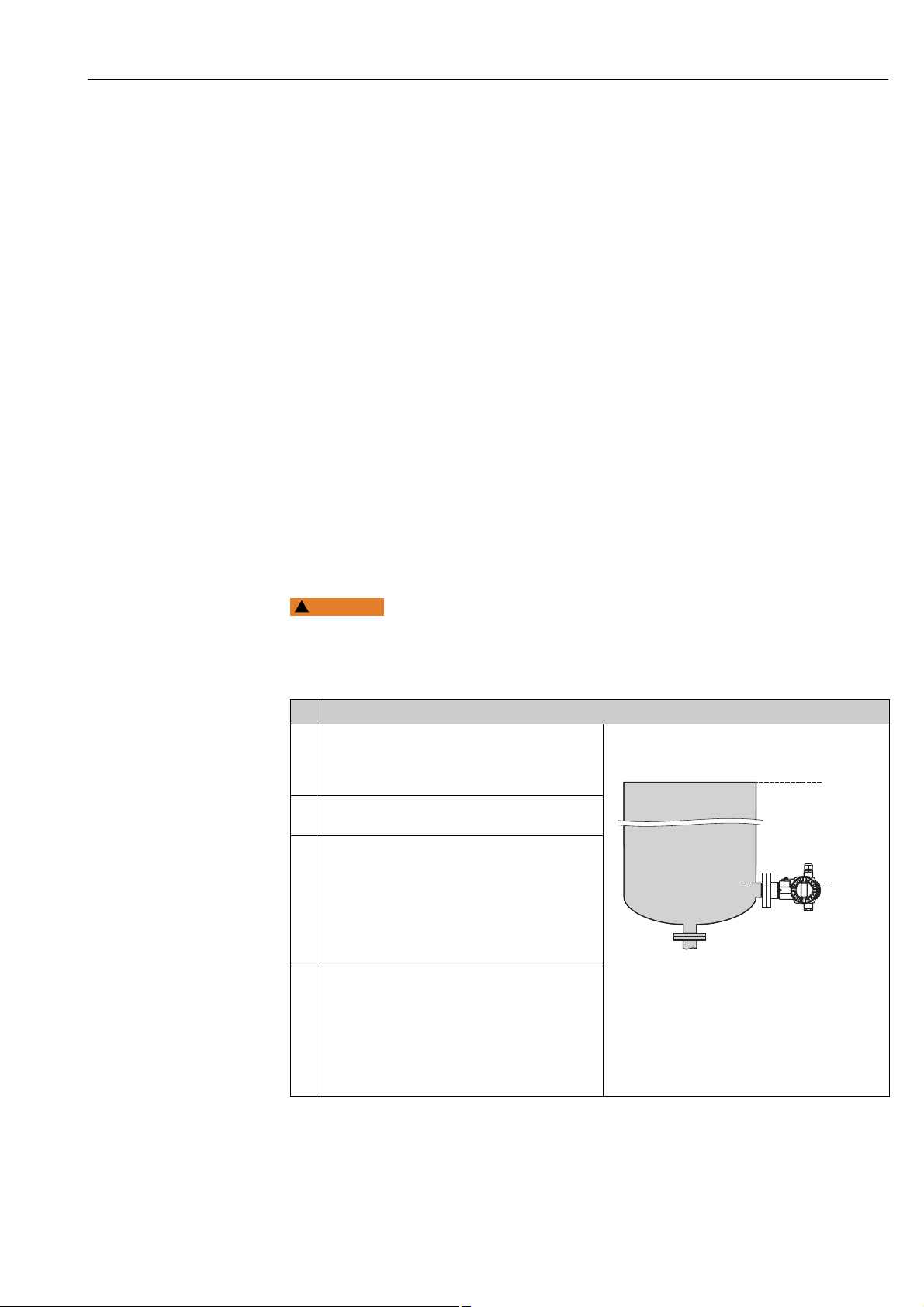

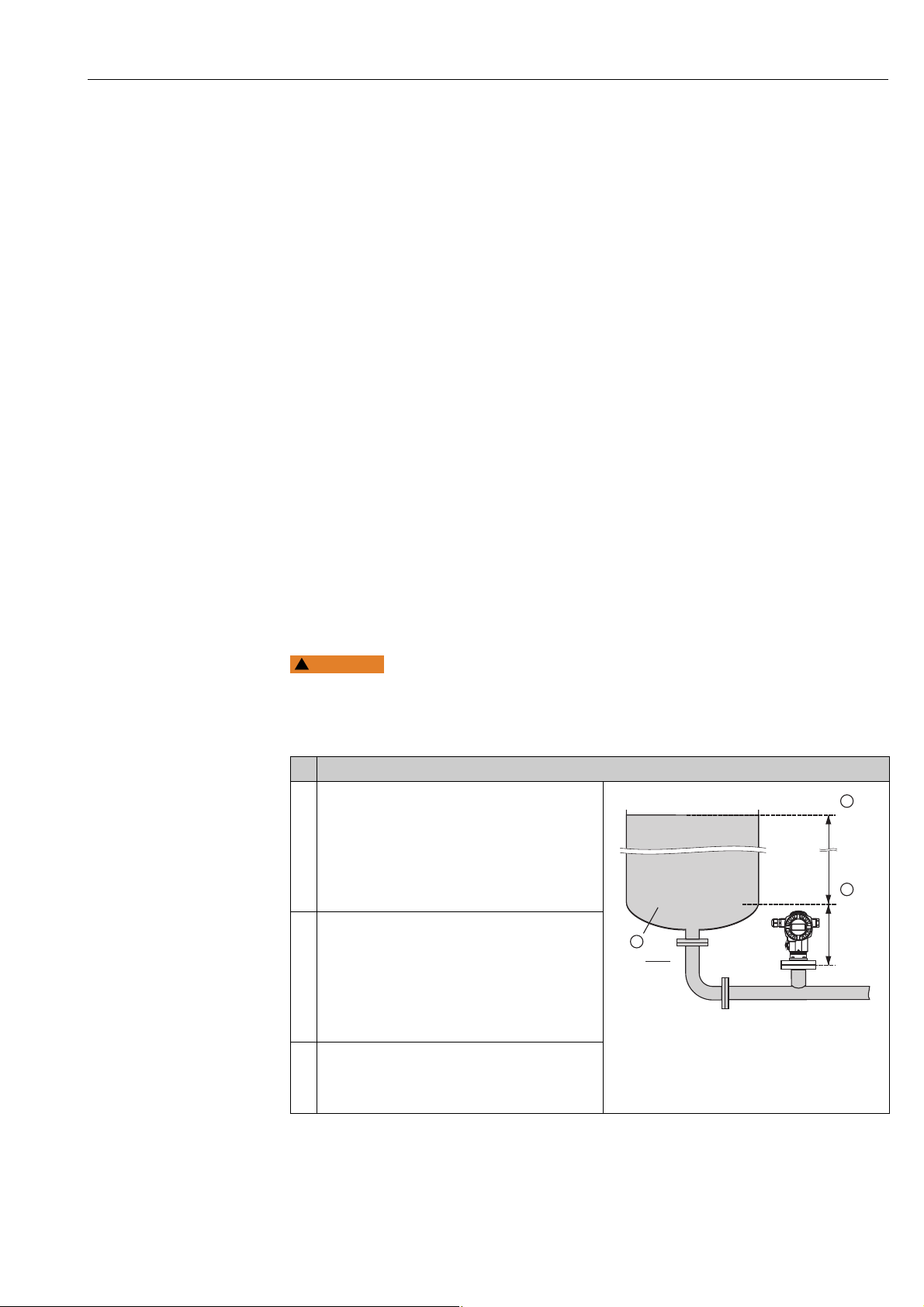

Description

1 Deltabar S: Before you configure the device for your

application, the pressure piping must be cleaned and

filled with medium. See Operating Instructions

BA00270P.

2 Carry out position adjustment if necessary. See Page

68, Table 6: POSITION ADJUSTMENT.

3 If necessary, select the "Level" measuring mode via

the MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

4 If necessary, select "Level Easy Pressure" level mode

using the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

Fig. 3: Calibration with reference pressure –

wet calibration

1 See Table, Step 9.

2 See Table, Step 10.

P01-PMP75xxx-19-xx-xx-xx-008

Endress+Hauser 9

Page 10

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

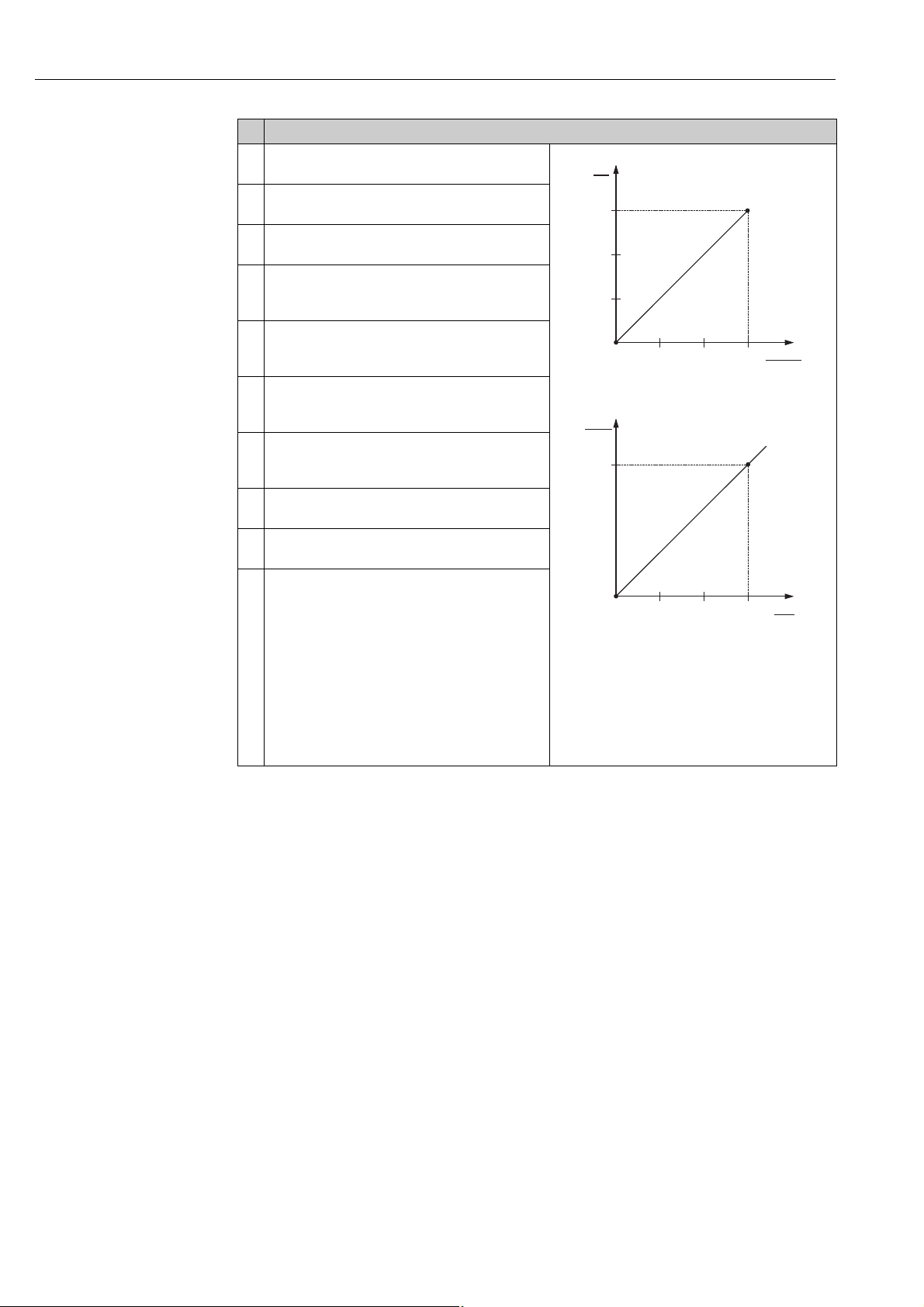

3

0

h

[m]

0 300

p

[mbar]

➀

➁

20

4

I

[mA]

0

3

h

[m]

➂

➃

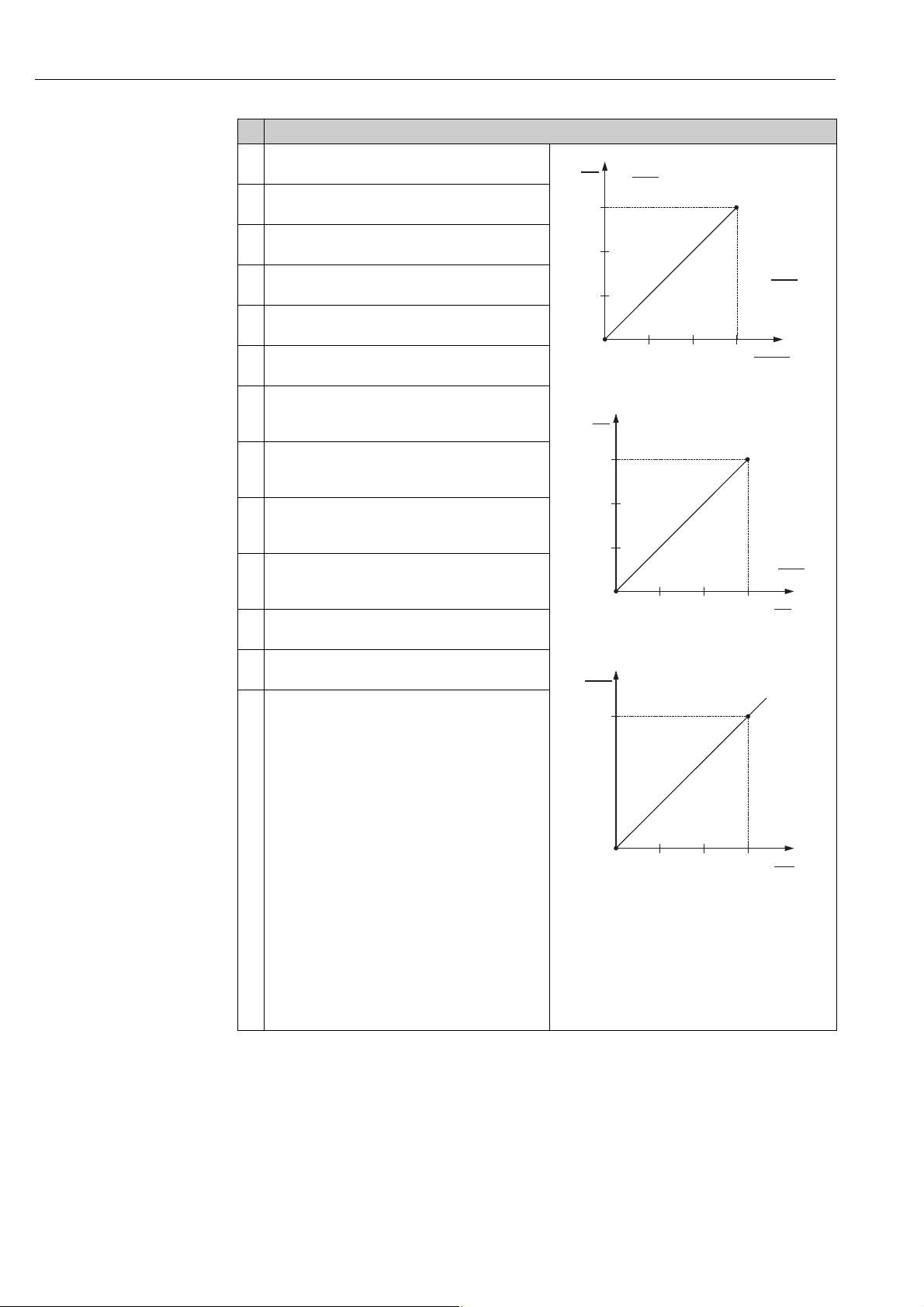

Description

5On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

6 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

7 Select a level unit via the OUTPUT UNIT parameter,

here m for example.

8 Select the "Wet" option by means of the

CALIBRATION MODE parameter.

9 Hydrostatic pressure for the lower calibration point

is present at the device, here 0 mbar for example.

Select EMPTY CALIB. parameter.

Enter the level value, here 0 m for example. Confirm

the value to assign the pressure value present to the

lower level value.

To accept the value displayed you must first switch

to the Edit mode (see the "Editing values" section)

and then press the button to save the value.

10 Hydrostatic pressure for the upper calibration point

is present at the device, here 300 mbar (4.5 psi) for

example.

Select FULL CALIB. parameter.

Enter the level value, here 3 m (9.8 ft) for example.

Confirm the value to assign the pressure value

present to the upper level value.

To accept the value displayed you must first switch

to the Edit mode (see the "Editing values" section)

and then press the button to save the value.

11 Set the value for the lower current value (4 mA) by

means of the SET LRV parameter.

12 Set the value for the upper current value (20 mA) by

means of the SET URV parameter.

13 Result:

The measuring range is set for 0 to 3 m (9.8 ft).

Fig. 4: Calibration with reference pressure –

1 See Table, Step 9.

2 See Table, Step 10.

3 See Table, Step 11.

4 See Table, Step 12.

wet calibration

P01-xxxxxxxx-05-xx-xx-xx-011

P01-xxxxxxxx-05-xx-xx-xx-014

1. You can also perform calibration with reference pressure by means of the QUICK SETUP

menu. See Page 65 ff, Table 4: QUICK SETUP menu.

2. For this level mode, the measured variables %, level, volume and mass are available.

See also parameter description for OUTPUT UNIT, Page 71.

3. For operation using the on-site display, the parameters EMPTY CALIB. (Page 72) and

FULL CALIB. (Page 73) also show the respective pressure present at the device. For

operation using Digital communication, the pressure present at the device is displayed

in the PROCESS VALUES group (menu path: OPERATING MENUPROCESSINFO

PROCESS VALUES).

10 Endress+Hauser

Page 11

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

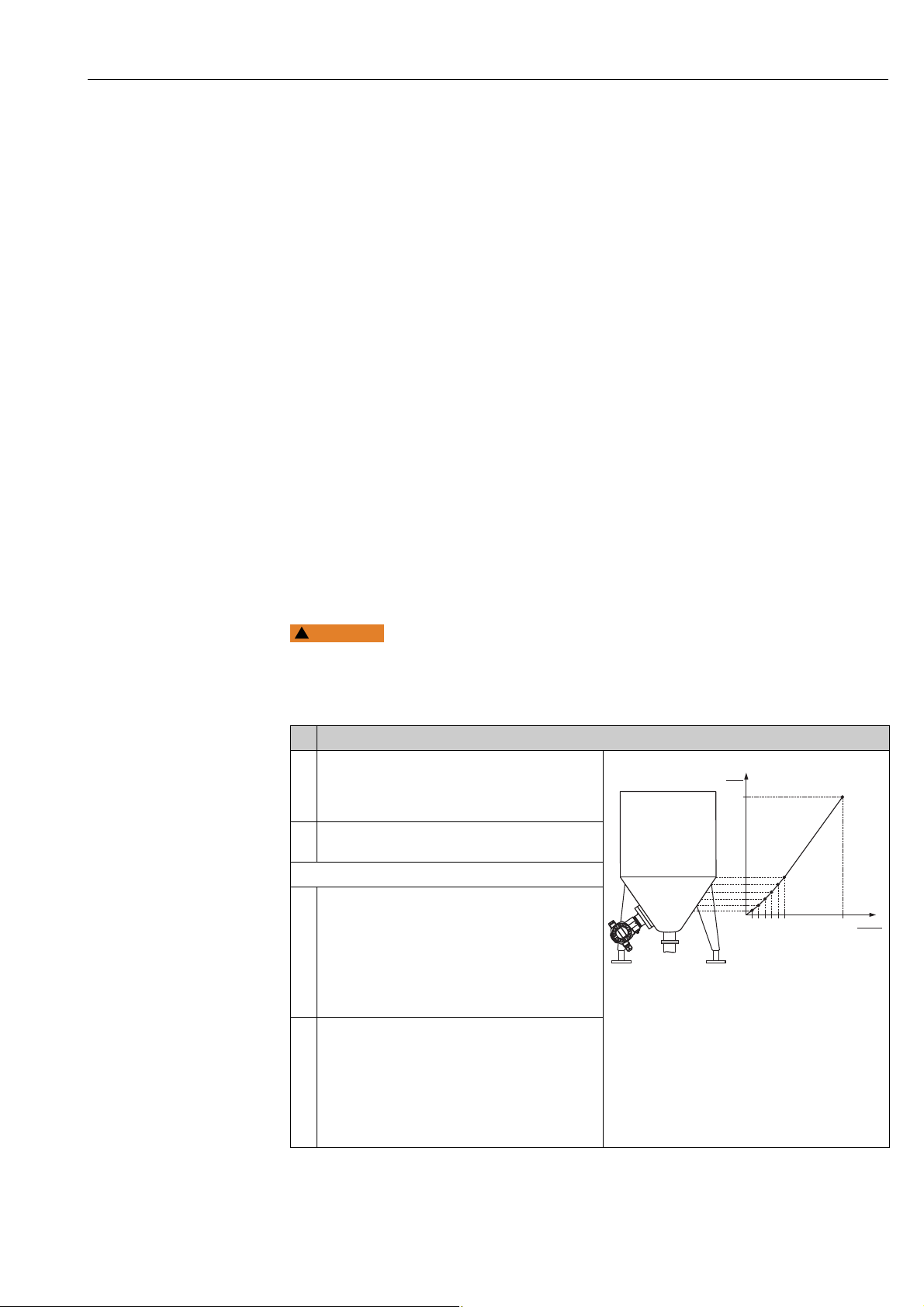

WARNING

!

1000 l

50 mbar

450 mba

0 l

ρ = 1

kg

dm

3

1

2

5.2.2 Calibration without reference pressure – dry calibration

Example:

In this example, the volume in a tank should be measured in litres.The maximum volume of

1000 litres (264 US gal) corresponds to a pressure of 450 mbar (6.75 psi). The minimum

volume of 0 litres corresponds to a pressure of 50 mbar (0.75 psi), as the device is mounted

below the level lower range value. The device is mounted below the level lower range value.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration i.e. the pressure and volume values for the lower and upper

calibration point must be known.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• The values entered for EMPTY CALIB./FULL CALIB. and SET LRV/SET URV must have a

minimum interval of 1% for the "Level Easy Pressure" level mode. The value will be rejected

with a warning message if the values are too close together. Further limit values are not

checked; i.e. the values entered must be appropriate for the sensor and the measuring task

so that the measuring device can measure correctly.

• Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the MEASURED VALUE parameter does not display zero. To

perform a position adjustment see also Page 68, Table 6: Position adjustment.

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 70, Table 8: LEVEL SELECTION "Level Easy Pressure"

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Select the "Level" measuring mode via the

MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

2 If necessary, select "Level Easy Pressure" level mode

using the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

3 On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

Fig. 5: Calibration without reference pressure –

1 See Table, Steps 7 and 8.

2 See Table, Steps 9 and 10.

dry calibration

P01-PMC71xxx-19-xx-xx-xx-000

Endress+Hauser 11

Page 12

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

1000

0

V

[l]

50 450

p

[mbar]

➀

➁

➂

➃

20

4

I

[mA]

0 1000

V

[l]

➄

➅

Description

4 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

5 Select a volume unit via the OUTPUT UNIT

parameter, here l (litres) for example..

6 Select the "Dry" option by means of the

CALIBRATION MODE parameter.

7 Enter the volume value for the lower calibration

point via the EMPTY CALIB. parameter, here 0 l for

example.

8 Enter the pressure value for the lower calibration

point via the EMPTY PRESSURE parameter, here 50

mbar (0.75 psi) for example.

9 Enter the volume value for the upper calibration

point via the FULL CALIB. parameter, here 1000 l

(264 gal) for example.

10 Enter the pressure value for the upper calibration

point via the FULL PRESSURE parameter, here 450

mbar (6.75 psi) for example.

11 Set the value for the lower current value (4 mA) by

means of the SET LRV parameter.

12 Set the value for the upper current value (20 mA) by

means of the SET URV parameter.

13 Result:

The measuring range is set for 0 to 1000 l (264 gal).

P01-xxxxxxxx-05-xx-xx-xx-026

P01-xxxxxxxx-05-xx-xx-xx-028

Fig. 6: Calibration with reference pressure –

1 See Table, Step 7.

2 See Table, Step 8.

3 See Table, Step 9.

4 See Table, Step 10.

5 See Table, Step 11.

6 See Table, Step 12.

wet calibration

For this level mode, the measured variables %, level, volume and mass are available. See

also parameter description for OUTPUT UNIT, Page 71.

12 Endress+Hauser

Page 13

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

WARNING

!

1000 l

0,5 m

4,5 m

0 l

ρ = 1

kg

dm

3

1

3

2

5.3 "Level Easy Height" level selection

5.3.1 Calibration with reference pressure – wet calibration

Example:

In this example, the volume in a tank should be measured in litres. The maximum volume of

1000 litres (264 US gal) corresponds to a level of 4.5 m (15 ft). The minimum volume of 0

litres corresponds to a level of 0.5 m (1.6 ft), as the device is mounted below the level lower

range value. The density of the medium is 1 kg/dm

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• The tank can be filled or emptied.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• The values entered for EMPTY CALIB./FULL CALIB., EMPTY PRESSURE/FULL PRESSURE,

EMPTY HEIGHT/FULL HEIGHT and SET LRV/SET URV must have a minimum interval of

1% for the "Level Easy Height" level mode. The value will be rejected with a warning

message if the values are too close together. Further limit values are not checked; i.e. the

values entered must be appropriate for the sensor and the measuring task so that the

measuring device can measure correctly.

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 73, Table 9: LEVEL SELECTION "Level Easy Height"

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

3

.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Deltabar S: Before you configure the device for your

application, the pressure piping must be cleaned and

filled with medium. See Operating Instructions

BA00270P.

2 Carry out position adjustment if necessary. See Page

68, Table 6: POSITION ADJUSTMENT.

3 Select the "Level" measuring mode via the

MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

4 If necessary, select the "Level Easy Height" level mode

using the LEVEL SELECTION parameter.

Endress+Hauser 13

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

5 On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

Fig. 7: Calibration with reference pressure –

1 See Table, Steps 10 and 11.

2 See Table, Step 12.

3 See Table, Step 13.

wet calibration

P01-PMC71xxx-19-xx-xx-xx-001

Page 14

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

4.5

0.5

h

[m]

49 441

p

[mbar]

h =

p

r · g

r = 1

g

cm

3

➀

1000

0

V

[l]

0.5 4.5

➁

➂

h =

p

ρ · g

h

[m]

20

4

I

[mA]

0 1000

V

[l]

➃

➄

Description

6 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

7 Select a volume unit via the OUTPUT UNIT

parameter, here l (litres) for example..

8 Select a height unit via the HEIGHT UNIT parameter,

here m for example.

9 Select the "Wet" option via the CALIBRATION MODE

parameter.

10 Select a density unit via the DENSITY UNIT

parameter, here kg/dm

11 Enter the density of the fluid using the ADJUST

DENSITY parameter, here kg/dm

12 Enter the volume value for the lower calibration

point via the EMPTY CALIB. parameter, here 0 l for

example. (The currently measured hydrostatic

pressure is displayed as height, here 0.5 m (1.6 ft)

for example.)

To accept the value displayed you must first switch

to the Edit mode (see the "Editing values" section)

and then press the button to save the value.

13 Enter the volume value for the upper calibration

point via the FULL CALIB. parameter, here 1000 l

(264 US gal) for example. (The currently measured

hydrostatic pressure is displayed as height, here 4.5

m (15 ft) for example.)

3

for example.

3

for example.

P01-xxxxxxxx-05-xx-xx-xx-029

To accept the value displayed you must first switch

to the Edit mode (see the "Editing values" section)

and then press the button to save the value.

14 Set the value for the lower current value (4 mA) by

means of the SET LRV parameter.

15 Set the value for the upper current value (20 mA) by

means of the SET URV parameter.

16 Result:

The measuring range is set for 0 to 1000 l (264 US

gal).

Fig. 8: Calibration with reference pressure –

1 See Table, Steps 10 and 11.

2 See Table, Step 12.

3 See Table, Step 13.

4 See Table, Step 14.

5 See Table, Step 15.

wet calibration

P01-xxxxxxxx-05-xx-xx-xx-030

P01-xxxxxxxx-05-xx-xx-xx-031

For this level mode, the measured variables %, level, volume and mass are available. See

also parameter description for OUTPUT UNIT, Page 75.

14 Endress+Hauser

Page 15

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

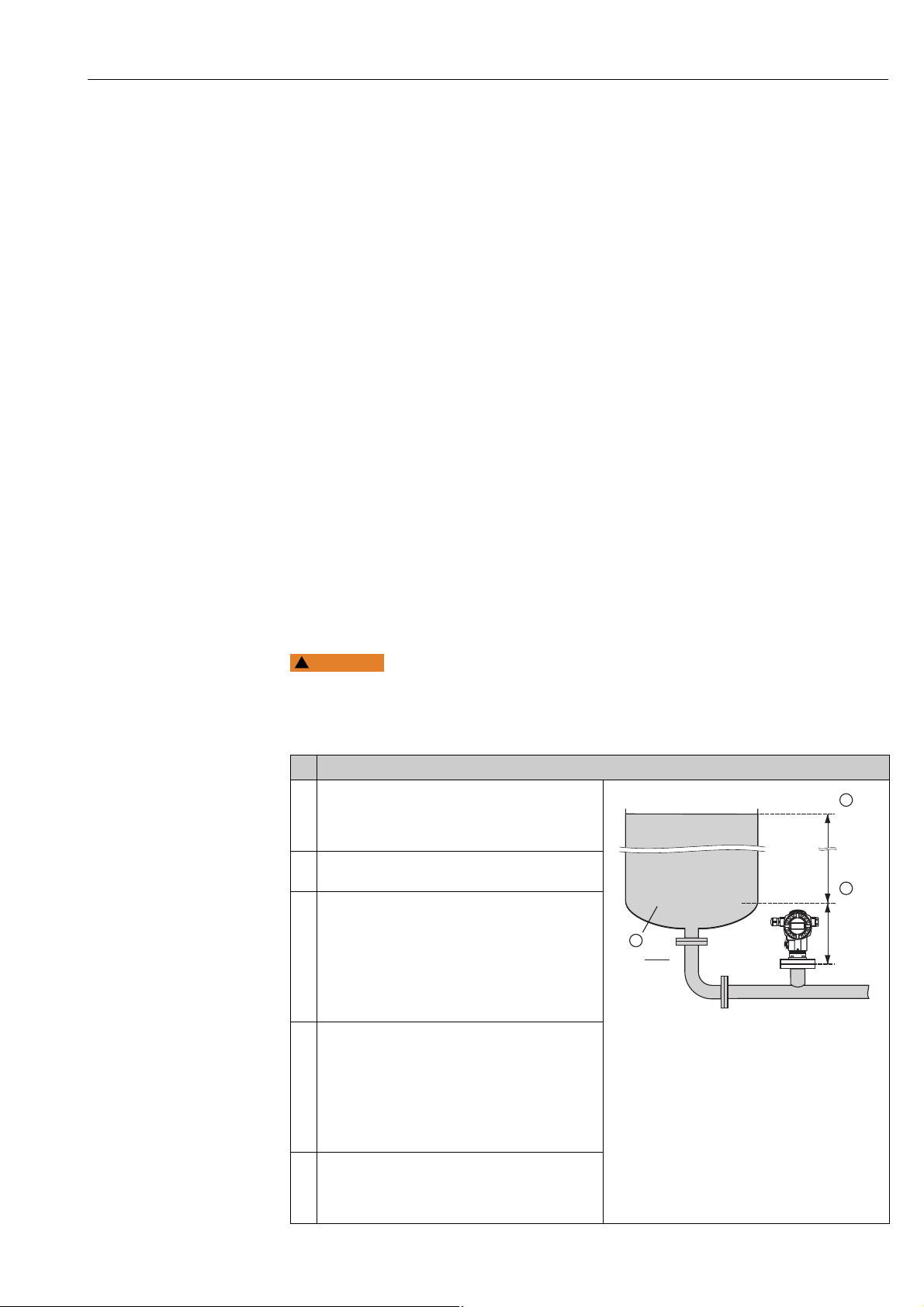

WARNING

!

1000 l

0,5 m

4,5 m

0 l

ρ = 1

kg

dm

3

1

3

2

5.3.2 Calibration without reference pressure – dry calibration

Example:

In this example, the volume in a tank should be measured in litres. The maximum volume is

1000 l (264 US gal), and the maximum height is 4.5 m (15 ft). The minimum volume of 0

litres corresponds to a level of 0.5 m (1.6 ft), as the device is mounted below the level lower

range value. The density of the fluid is 1 kg/dm

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration i.e. the height and volume values for the lower and upper

calibration point must be known.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• The values entered for EMPTY CALIB./FULL CALIB., EMPTY PRESSURE/FULL PRESSURE,

EMPTY HEIGHT/FULL HEIGHT and SET LRV/SET URV must have a minimum interval of

1% for the "Level Easy Height" level mode. The value will be rejected with a warning

message if the values are too close together. Further limit values are not checked; i.e. the

values entered must be appropriate for the sensor and the measuring task so that the

measuring device can measure correctly.

• Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the MEASURED VALUE parameter does not display zero. To

perform a position adjustment see also Page , Table 6: Position adjustment.

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 73, Table 9: LEVEL SELECTION "Level Easy Height"

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

3

.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

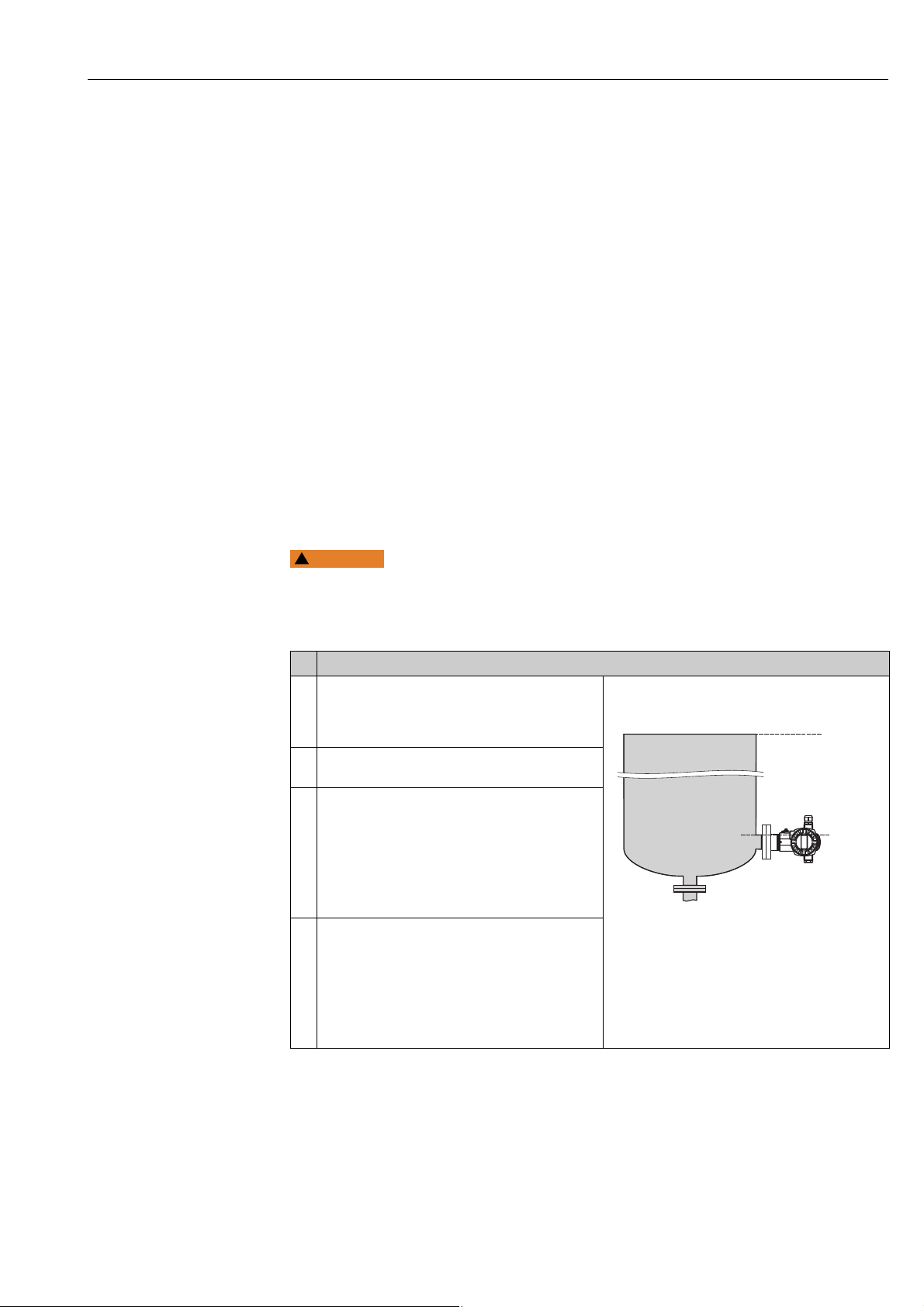

Description

1 Select the "Level" measuring mode via the

MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

2 If necessary, select "Level Easy Height" level mode

using the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

3 On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

Fig. 9: Calibration without reference pressure –

1 See Table, Steps 8 and 9.

2 See Table, Steps 10 and 11.

3 See Table, Steps 12 and 13.

dry calibration

P01-PMC71xxx-19-xx-xx-xx-007

Endress+Hauser 15

Page 16

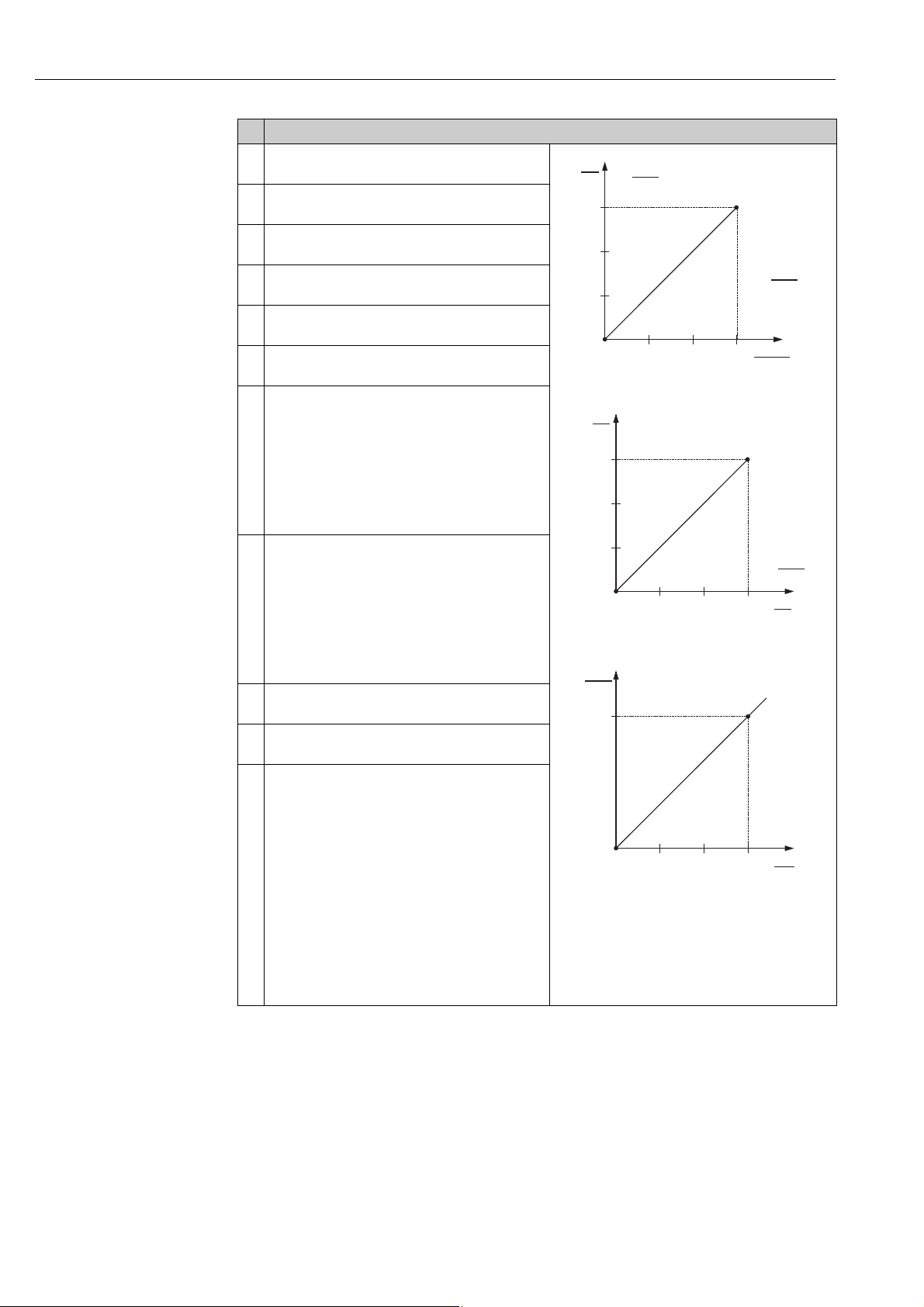

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

4.5

0.5

h

[m]

49 441

p

[mbar]

h =

p

r · g

r = 1

g

cm

3

➀

1000

0

V

[l]

0.5 4.5

➁

➂

h =

p

ρ · g

h

[m]

➃

➄

20

4

I

[mA]

0 1000

V

[l]

➅

➆

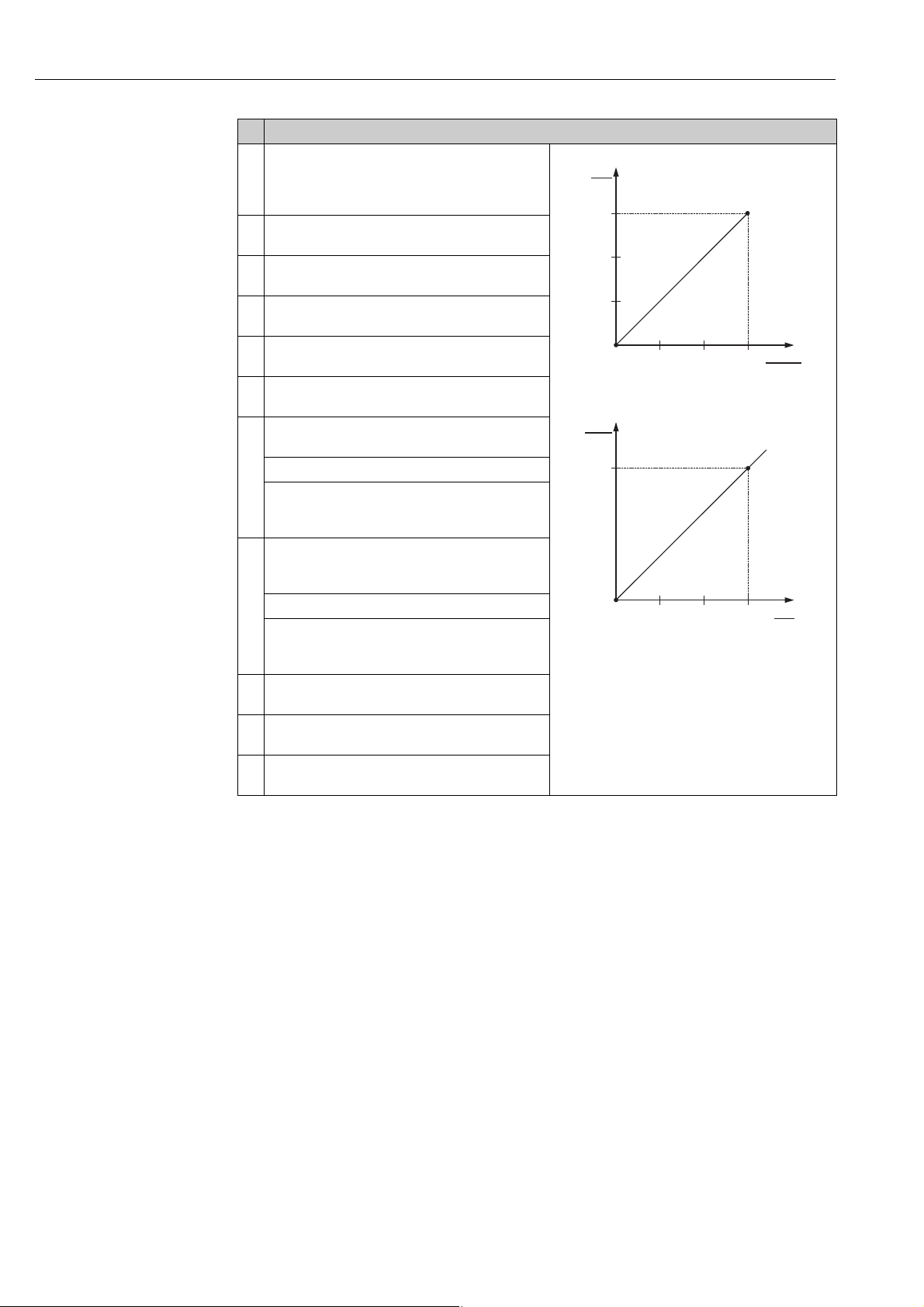

Description

4 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

5 Select a volume unit via the OUTPUT UNIT

parameter, here l (litres) for example.

6 Select a height unit via the HEIGHT UNIT parameter,

here m for example.

7 Select the "Dry" option via the CALIBRATION MODE

parameter.

8 Select a density unit via the DENSITY UNIT

parameter, here kg/dm

9 Enter the density of the fluid using the ADJUST

DENSITY parameter, here kg/dm

10 Enter the volume value for the lower calibration

point via the EMPTY CALIB. parameter, here 0 l for

example.

11 Enter the height value for the lower calibration point

via the EMPTY HEIGHT parameter, here 0.5 m (1.6

ft) for example.

12 Enter the volume value for the upper calibration

point via the FULL CALIB. parameter, here 1000 l

(litres) (264 US gal) for example.

13 Enter the height value for the upper calibration point

via the FULL HEIGHT parameter, here 4.5 m (15 ft)

for example.

14 Set the value for the lower current value (4 mA) by

means of the SET LRV parameter.

15 Set the value for the upper current value (20 mA) by

means of the SET URV parameter.

16 Result:

The measuring range is set for 0 to 1000 l (litres)

(264 US gal).

3

for example.

3

for example.

P01-xxxxxxxx-05-xx-xx-xx-029

P01-xxxxxxxx-05-xx-xx-xx-032

P01-xxxxxxxx-05-xx-xx-xx-033

Fig. 10: Calibration with reference pressure –

1 See Table, Steps 8 and 9.

2 See Table, Step 10.

3 See Table, Step 11.

4 See Table, Step 12.

5 See Table, Step 13.

6 See Table, Step 14.

7 See Table, Step 15.

wet calibration

For this level mode, the measured variables %, level, volume and mass are available. See

also parameter description for OUTPUT UNIT, Page 75.

16 Endress+Hauser

Page 17

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

WARNING

!

➀

➁

0 mbar

300 mbar

3 m

0 m

5.4 "Level Standard" level selection,

"Linear" level type

5.4.1 Calibration with reference pressure – wet calibration

Example:

In this example, the level in a tank should be measured in m. The maximum level is 3 m (9.8

ft). The pressure range is set to 0 to 300 mbar (4.5 psi).

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• The tank can be filled or emptied.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 77, Table 10: BASIC SETUP

– Page 79, Table 11: BASIC SETUP – "Linear" level type.

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and

the device filled with fluid. See Operating

Instructions BA00270P.

2 Carry out position adjustment if necessary. See Page

68, Table 6: POSITION ADJUSTMENT.

3 If necessary, select the "Level" measuring mode via

the MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

4 If necessary, select "Level Standard" level mode using

the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

Fig. 11: Calibration with reference pressure –

1 See table, step 11.

2 See table, step 12.

wet calibration

P01-PMP75xxx-19-xx-xx-xx-008

Endress+Hauser 17

Page 18

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

3

0

h

[m]

0 300

p

[mbar]

➀

➁

20

4

I

[mA]

0

3

h

[m]

➂

➃

Description

5On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

6 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

7 Select the "Linear" option by means of the LEVEL

MODE parameter.

8 Select the "Level" option by means of the LIN.

MEASURAND parameter.

9 Select a level unit via the HEIGHT UNIT parameter,

here m for example.

10 Select the "Wet" option by means of the

CALIBRATION MODE parameter.

11 The pressure for the lower calibration point is

present at the device, here 0 mbar for example.

Select EMPTY CALIB. parameter.

Enter the level value, here 0 m for example. Confirm

the value to assign the pressure value present to the

lower level value.

12 The pressure for the upper calibration point is

present at the device, here 450 mbar (6.75 psi) for

example.

Select FULL CALIB. parameter.

Enter the level value, here 3 m (9.8 ft) for example.

Confirm the value to assign the pressure value

present to the upper level value.

13 Set the value for the lower current value (4 mA) by

means of the SET LRV parameter.

14 Set the value for the upper current value (20 mA) by

means of the SET URV parameter.

15 Result:

The measuring range is set for 0...3 m (9.8 ft).

Fig. 12: Calibration with reference pressure –

1 See table, step 11.

2 See table, step 12.

3 See table, step 13.

4 See table, step 14.

wet calibration

P01-xxxxxxxx-05-xx-xx-xx-034

P01-xxxxxxxx-05-xx-xx-xx-014

1. You can also perform calibration with reference pressure by means of the QUICK SETUP

menu. See Page 65 ff, Table 4: QUICK SETUP menu.

2. You can also specify customer-specific units. See parameter description for PRESS. ENG.

UNIT (Page 77), HEIGHT UNIT ( Page 79), UNIT VOLUME (Page 80) and MASS

UNIT (Page 81).

3. For this level type, the measured variables %, level, volume and mass are available.

See Page 79 ff.

4. The EMPTY PRESSURE (Page 83) and FULL PRESSURE (Page 83) parameters

display the pressure values belonging to the EMPTY CALIB. and FULL CALIB.

parameters.

18 Endress+Hauser

Page 19

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

WARNING

!

4 m

–0.5 m

➂

➃

➁

r = 1

kg

dm

3

V = 5 m

3

➀

5.4.2 Calibration without reference pressure – dry calibration

Example:

In this example, the volume in a tank should be measured in m

3

m

and the maximum height 4 m (13 ft). The density of the fluid is 1 kg/dm3. The device is

3

. The maximum volume is 5

mounted below the level lower range value.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration, i.e. the tank volume, tank height and density of the fluid

are known.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the MEASURED VALUE parameter does not display zero. To

perform a position adjustment see also Page 68, Table 6: Position adjustment.

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 77, Table 10: BASIC SETUP

– Page 79, Table 11: BASIC SETUP – "Linear" level type.

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 26: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Select the "Level" measuring mode via the

MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

2 If necessary, select "Level Standard" level mode using

the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

3 On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

P01-PMP75xxx-19-xx-xx-xx-003

Fig. 13: Calibration without reference pressure –

1 See table, step 9.

2 See table, step 10.

3 See table, step 11.

4 See table, step 12.

dry calibration

Endress+Hauser 19

Page 20

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

20

4

I

[mA]

05

V

[m ]

3

➀

➁

Description

4 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

5 Select the "Linear" option by means of the LEVEL

MODE parameter.

6 Select the "Volume" option by means of the LIN.

MEASURAND parameter.

7 Select a volume unit via the UNIT VOLUME

parameter, here m

8 Select the "Dry" option by means of the

CALIBRATION MODE parameter. See also the

following note, point 3.

9 Enter the value for density via the ADJUST DENSITY

parameter, here 1 kg/dm

10 Enter the tank volume via the TANK VOLUME

parameter, here 5 m

11 Enter the tank height via the TANK HEIGHT

parameter, here 4 m (13 ft) for example.

12 Enter the level offset via the ZERO POSITION

parameter, here –0.5 m (-1,6 ft) for example.

13 Set the value for the lower current value (4 mA) by

means of the SET LRV parameter.

14 Set the value for the upper current value (20 mA) by

means of the SET URV parameter.

15 Result:

The measuring range is set for 0...5 m

3

for example.

3

for example.

3

for example.

P01-xxxx xxxx-19-xx-xx-xx-012

Fig. 14: Current output calibration

5 See table, step 13.

6 See table, step 14.

3

.

1. For this level type, the measured variables %, level, volume and mass are available.

See Page 79 ff.

2. You can also specify customer-specific units. See parameter description for PRESS. ENG.

UNIT (Page 77), HEIGHT UNIT ( Page 79), UNIT VOLUME (Page 80) and MASS

UNIT (Page 81).

3. A level value is assigned to the lower and upper current value by means of the SET LRV

( Page 86) and SET URV (Page 86) parameters respectively. Once you have

selected the "Dry" calibration mode, the error message A711 "LRV or URV out of edit

limits" can appear. The error message goes out as soon as level values which are within

the editing limits are entered for the SET LRV and SET URV parameters.

By means of the ENTER RESET CODE parameter ( Page 124), you can use the code

2710 to automatically set the SET LRV and SET URV parameters to level values which

are within the editing limits.

20 Endress+Hauser

Page 21

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

WARNING

!

3.5

0

0 350

V

[m ]

3

p

[mbar]

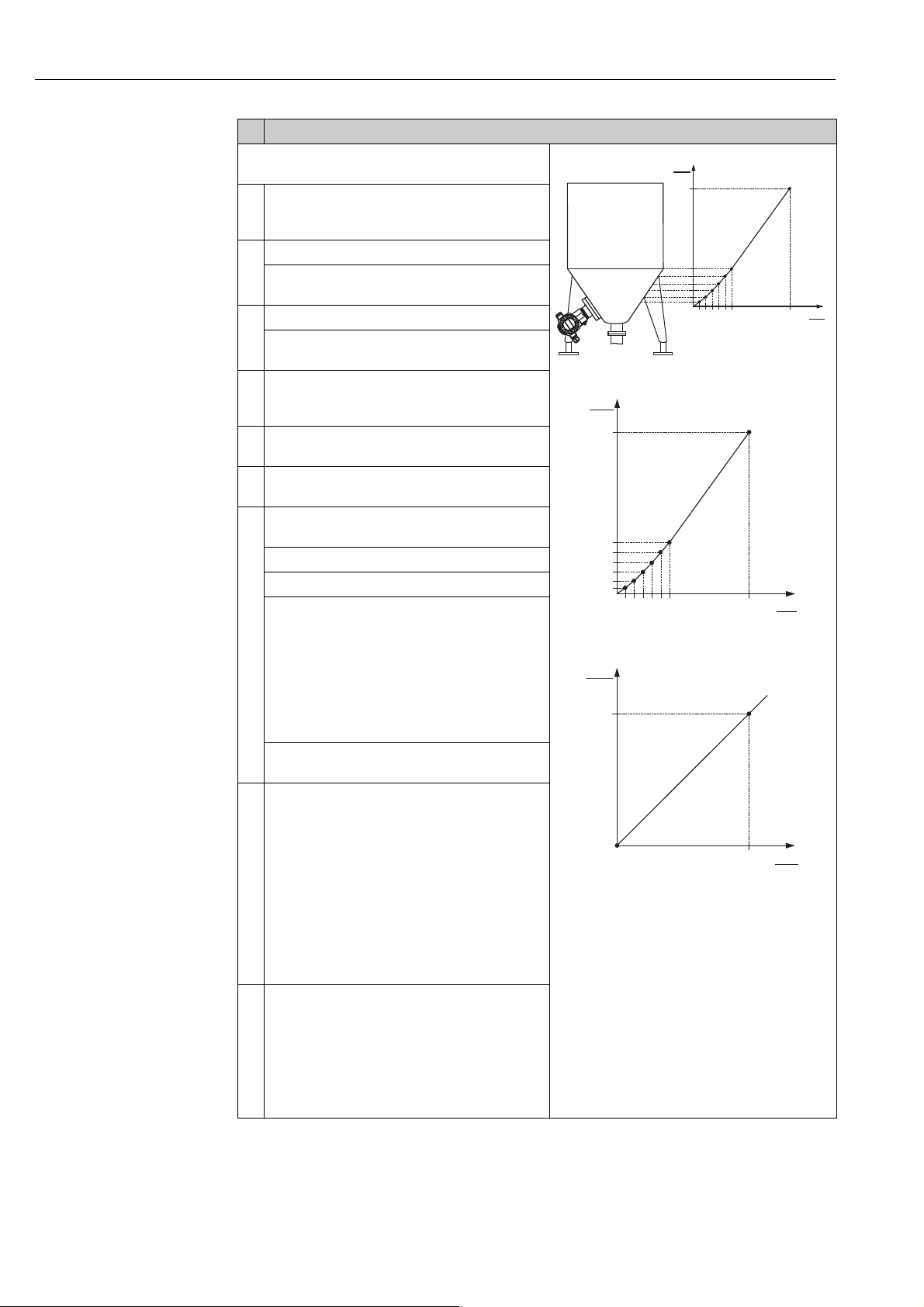

5.5 "Level Standard" level selection, "Pressure Linearized" level type

5.5.1 Semiautomatic entry of the linearisation table

Example:

In this example, the volume in a tank with a conical outlet should be measured in m

3

.

Prerequisite:

• The tank can be filled. The linearisation characteristic must rise continuously.

• A minimum gap of 0.5 % of the distance between two points must be maintained. Spans

for the "Pressure linearized" option: HYDR. PRESS MAX. – HYDR. PRESS MIN.; TANK

CONTENT MAX. – TANK CONTENT MIN. Spans for the "Height linearized" option: LEVEL

MAX – LEVEL MIN; TANK CONTENT MAX. – TANK CONTENT MIN.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P) or

Deltapilot S (BA00332P).

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 77, Table 10: BASIC SETUP

– Page 87, Table 11: BASIC SETUP – "Pressure Linearized" level type

– Page 104, Table 18: LINEARISATION – on-site operation

– Page 107, Table 19: LINEARISATION – Digital communication.

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 26: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and

filled with fluid. See Operating Instructions

BA00270P.

2 Carry out position adjustment if necessary. See Page

68, Table 6: POSITION ADJUSTMENT.

Carry out basic setup:

3 If necessary, select the "Level" measuring mode via

the MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication:

See Page 62

4 If necessary, select "Level Standard" level mode using

the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

See Page 63

P01-PMP75xxx-19-xx-xx-xx-002

Endress+Hauser 21

Page 22

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

Description

5On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

6 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

7 Select the "Pressure Linearized" option by means of

the LEVEL MODE parameter. See also the following

note, point 3.

8 Select the "Volume" option by means of the LINd.

MEASURAND parameter.

9 Select a volume unit via the UNIT VOLUME

parameter, here m

10 Select HYDR. PRESS MIN. parameter.

Enter the minimum hydrostatic pressure to be

expected, here 0 mbar for example.

11 Select HYDR. PRESS MAX

Enter the maximum hydrostatic pressure to be

expected.

Carry out linearisation:

12 Change the function group:

Menu path: (GROUP SELECTION ) OPERATING

MENU SETTINGS LINEARISATION

13 Select TANK CONTENT MIN parameter.

Specify the minimum tank contents to be expected,

here 0 m

3

14 Select TANK CONTENT MAX parameter.

Specify the maximum tank contents to be expected,

here 3.5 m

15 On-site display:

Select the "Editor table" option by means of the

TABLE SELECTION parameter.

16 Select the "Semiautomatic" option by means of the

LIN. EDIT MODE parameter.

17 Select the "New table" option by means of the EDITOR

TABLE parameter.

3

for example.

for example.

3

for example.

.

22 Endress+Hauser

Page 23

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

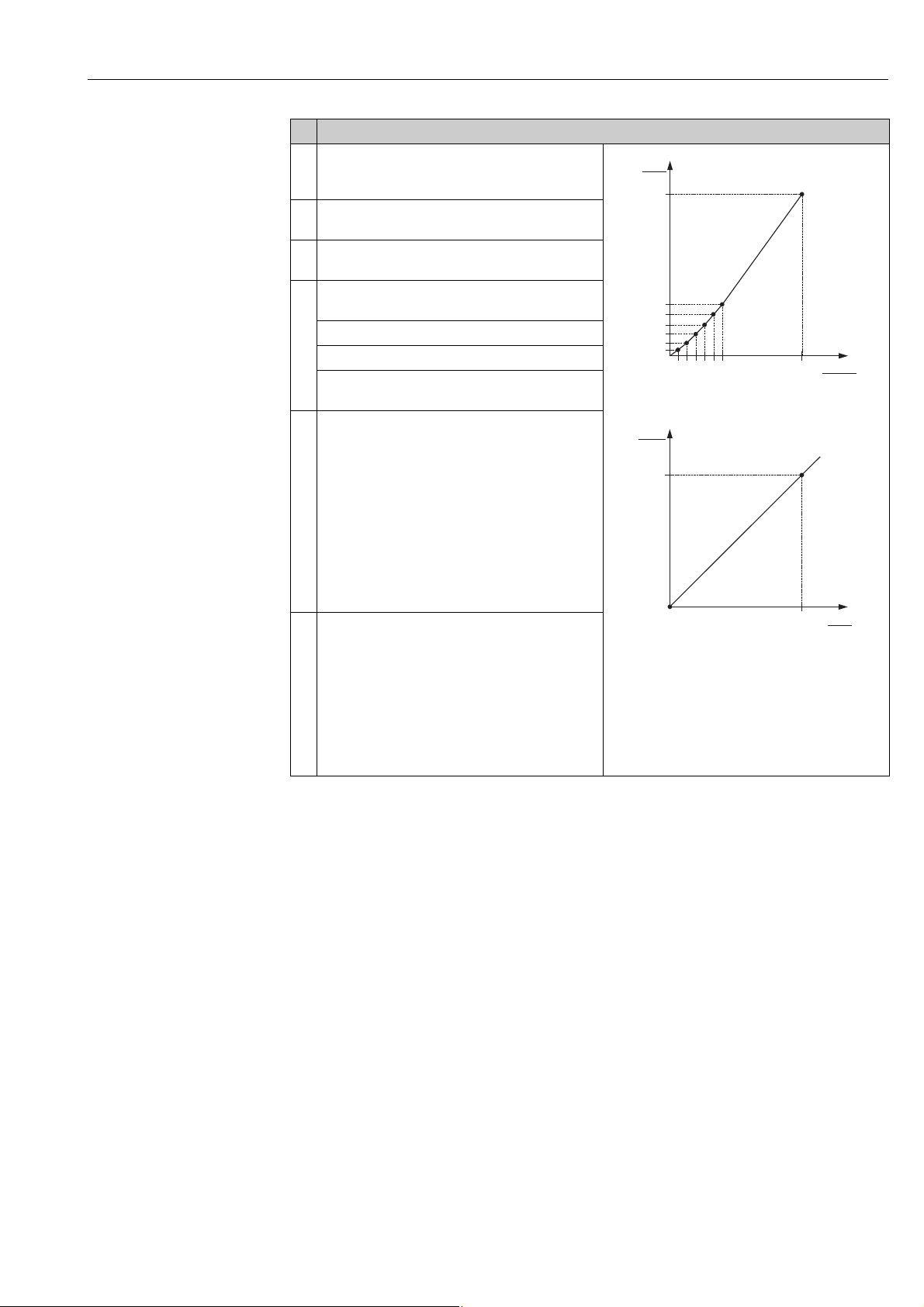

➀

3.5

0

0 350

V

[m ]

3

p

[mbar]

➂

➁

➃

➄

20

4

I

[mA]

0 3.5

V

[m ]

3

➆

➅

Description

18 Enter linearisation table (min. 2 points, max.

32 points).

Fill the tank to the height of the 1st point.

LINE-NUMB: confirm value displayed.

X-VAL.: the hydrostatic pressure present is

displayed.

On-site display, Digital communication:

The X-VAL. displayed is saved by confirming the Yvalue. See following line, Y-VAL.

HART handheld terminal:

Confirm X-VAL. displayed.

Y-VAL.: enter the volume value, here 0 m

example, and confirm the value.

19 On-site display:

If you want to enter another point for the

linearisation table, select the "Next point" option and

enter the point as described in step 18.

If you want to finish entering the values and activate

the linearisation table, select the "Accept input table"

option.

Digital communication:

You can enter further points for the linearisation

table as explained in step 18. Once all the points

have been entered, the table must be activated by

means of the TAB. ACTIVATE parameter.

19 Result:

The linearisation table has been entered.

3

for

P01-xxxxxxxx-05-xx-xx-xx-015

P01-xxxxxxxx-05-xx-xx-xx-016

Fig. 15: Semiautomatic entry of the linearisation table

1 See table, step 10.

2 See table, step 11.

3 See table, step 13.

4 See table, step 14.

5 See table, steps 15 – 19.

6 See the following note, point 4.

7 See the following note, point 4

Endress+Hauser 23

1. For this level type, the measured variables %, volume and mass are available.

See Page 87 ff.

2. You can also specify customer-specific units. See parameter description for PRESS. ENG.

UNIT (Page 77), HEIGHT UNIT ( Page 87), UNIT VOLUME (Page 87) and MASS

UNIT ( Page 88).

3. Once you have selected the "Pressure Linearized" level type, the warning message "W710

Set span too small. Not allowed." can appear. At this stage the linearisation table already

consists of two points as standard. It could be the case that the 2nd value, and thus the

highest X-VAL. of the linearisation table, is smaller than the minimum span permitted

( MINIMUM SPAN, Page 120). The message goes out as soon as the highest X-VAL.

is larger than the minimum span.

4. A level value is assigned to both the lower and upper current value with the SET LRV

( Page 102) and SET URV (Page 102) parameters. If you enter values for TANK

CONTENT MIN (Page 104 or 107) and TANK CONTENT MAX (Page 104 or 107),

the SET LRV and SET URV parameters are also changed. If you want to assign values

other than those for TANK CONTENT MIN and TANK CONTENT MAX to the lower and

upper current values, the desired values must be entered for SET LRV and SET URV.

Page 24

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

WARNING

!

3.5

0

0 350

V

[m ]

3

p

[mbar]

5.5.2 Manual entry of the linearisation table

Example:

In this example, the volume in a tank with a conical outlet should be measured in m

3

.

Prerequisite:

• This is a theoretical calibration, i.e. the points for the linearisation table are known.

• A minimum gap of 0.5 % of the distance between two points must be maintained. Spans

for the "Pressure linearized" option: HYDR. PRESS MAX. – HYDR. PRESS MIN.; TANK

CONTENT MAX. – TANK CONTENT MIN. Spans for the "Height linearized" option: LEVEL

MAX – LEVEL MIN; TANK CONTENT MAX. – TANK CONTENT MIN.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 77, Table 10: BASIC SETUP

– Page 87, Table 12: BASIC SETUP – "Pressure Linearized" level type

– Page 104, Table 18: LINEARISATION – on-site operation

– Page 107, Table 19: LINEARISATION – Digital communication.

• For a description of further relevant parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Perform basic setup as per Section 5.3.1, steps 2 to

11.

Carry out linearisation:

2 Change the function group:

Menu path: (GROUP SELECTION ) OPERATING

MENU SETTINGS LINEARISATION

3 Select TANK CONTENT MIN parameter .

Specify the minimum tank contents to be expected,

here 0 m

4 Select TANK CONTENT MAX parameter .

Specify the maximum tank contents to be expected,

here 3.5 m

3

for example.

3

for example.

P01-PMP75xxx-19-xx-xx-xx-002

24 Endress+Hauser

Page 25

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

➀

3.5

0

0 350

V

[m ]

3

p

[mbar]

➂

➁

➃

➄

20

4

I

[mA]

0 3.5

V

[m ]

3

➆

➅

Description

5 On-site display:

Select the "Editor table" option by means of the

TABLE SELECTION parameter.

6 Select the "Manual" option by means of the LIN. EDIT

MODE parameter.

7 Select the "New table" option by means of the

EDITOR TABLE parameter.

8 Enter linearisation table (min. 2 points, max.

32 points).

LINE-NUMB: confirm value displayed.

X-VAL.: enter the pressure value and confirm.

Y-VAL.: enter the volume value, here 0 m

example, and confirm.

9 On-site display

If you want to enter another point for the

linearisation table, select the "Next point" option and

enter the point as described in step 8.

If you want to finish entering the values and activate

the linearisation table, select the "Accept input table"

option.

Digital communication:

You can enter further points for the linearisation

table as explained in step 8. Once all the points have

been entered, the table must be activated by means

of the TAB. ACTIVATE parameter.

10 Result:

The linearisation table has been entered.

3

for

P01-xxxxxxxx-05-xx-xx-xx-015

P01-xxxxxxxx-05-xx-xx-xx-016

Fig. 16: Manual entry of the linearisation table

1 See Section 5.3.1, table, step 9.

2 See Section 5.3.1, table, step 10.

3 See table, step 3.

4 See table, step 4.

5 See table, steps 5 – 9.

6 See the following note, point 4.

7 See the following note, point 4.

Endress+Hauser 25

1. For this level type, the measured variables %, volume and mass are available.

See Page 87 ff.

2. You can also specify customer-specific units. See parameter description for PRESS. ENG.

UNIT (Page 77), HEIGHT UNIT ( Page 87), UNIT VOLUME (Page 87) and MASS

UNIT ( Page 88).

3. Once you have selected the "Pressure Linearized" level type, the warning message "W710

Set span too small. Not allowed." can appear. At this stage the linearisation table already

consists of two points as standard. It could be the case that the 2nd value, and thus the

highest X-VAL. of the linearisation table, is smaller than the minimum span permitted

( MINIMUM SPAN, Page 120). The message goes out as soon as the highest X-VAL.

is larger than the minimum span.

4. A level value is assigned to both the lower and upper current value with the SET LRV

( Page 102) and SET URV (Page 102) parameters. If you enter values for TANK

CONTENT MIN (Page 104 or 107) and TANK CONTENT MAX (Page 104 or 107),

the SET LRV and SET URV parameters are also changed. If you want to assign values

other than those for TANK CONTENT MIN and TANK CONTENT MAX to the lower and

upper current values, the desired values must be entered for SET LRV and SET URV.

Page 26

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

WARNING

!

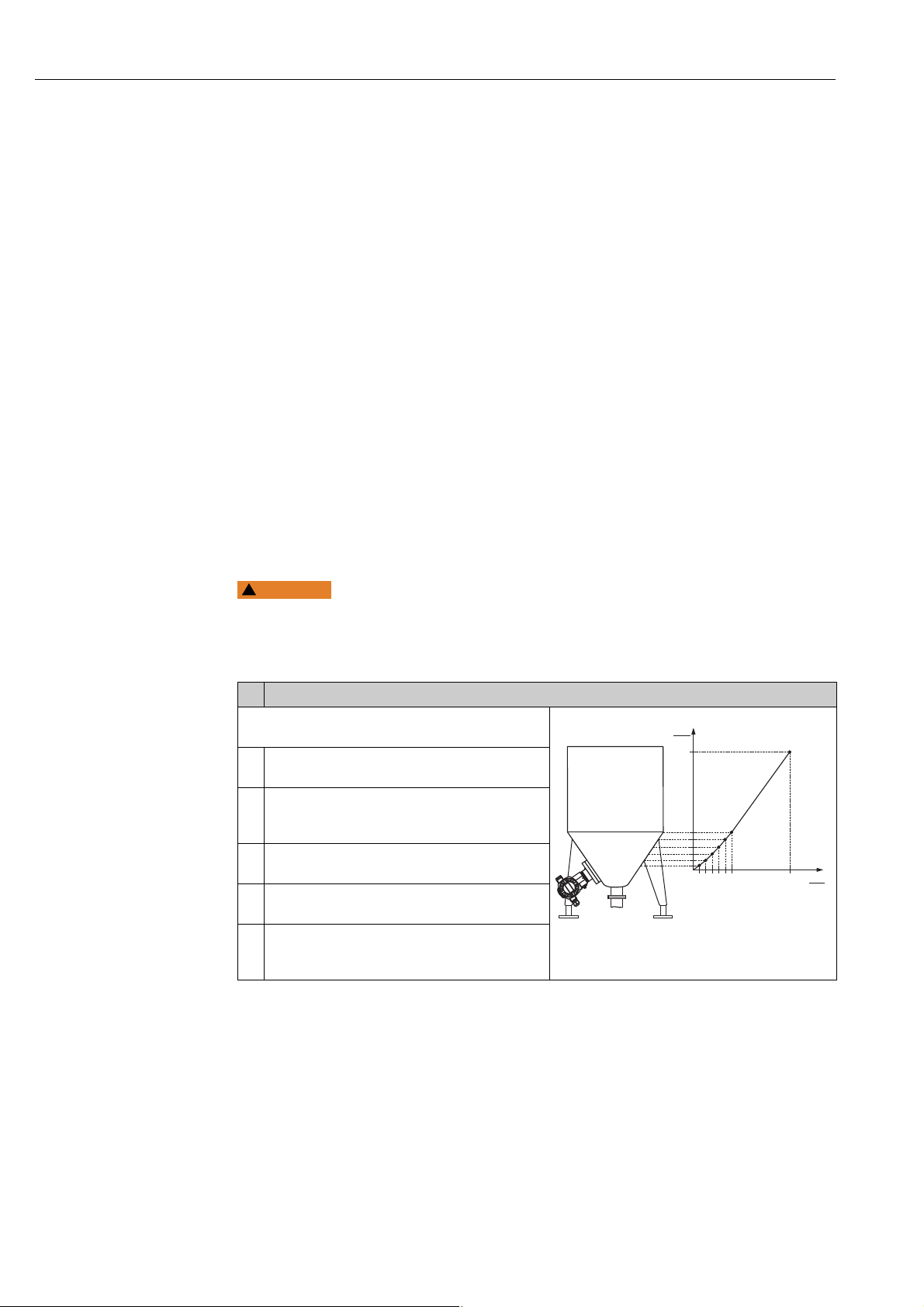

5.6 "Level Standard" level selection, "Height Linearized" level type

5.6.1 Wet calibration and semiautomatic entry of the linearisation

table

Example:

In this example, the height and the volume should be measured at the same time.

Prerequisite:

• The tank can be filled. The linearisation characteristic must rise continuously.

• A minimum gap of 0.5 % of the distance between two points must be maintained. Spans

for the "Pressure linearized" option: HYDR. PRESS MAX. – HYDR. PRESS MIN.; TANK

CONTENT MAX. – TANK CONTENT MIN. Spans for the "Height linearized" option: LEVEL

MAX – LEVEL MIN; TANK CONTENT MAX. – TANK CONTENT MIN.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P) or

Deltapilot S (BA00332P).

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 68, Table 6: POSITION ADJUSTMENT

– Page 77, Table 10: BASIC SETUP

– Page 89, Table 13: BASIC SETUP – "Height Linearized" level type

– Page 104, Table 18: LINEARISATION – on-site operation

– Page 107, Table 19: LINEARISATION – Digital communication.

• For a description of further parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and

filled with fluid. See Operating Instructions

BA00270P.

2 Carry out position adjustment if necessary. See Page

68, Table 6: POSITION ADJUSTMENT.

Perform calibration for the 1st measured

variable:

3 If necessary, select the "Level" measuring mode via

the MEASURING MODE parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE

See Page 62

26 Endress+Hauser

Page 27

➂

➃

➀

➁

p

[mbar]

➂➀

➁➃

3

0

h

[m]

0 300

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

Description

4 If necessary, select "Level Standard" level mode using

the LEVEL SELECTION parameter.

On-site display:

Menu path: GROUP SELECTION MEASURING

MODE "Level" LEVEL SELECTION

Digital communication:

Menu path: OPERATING MENU SETTINGS

BASIC SETUP MEASURING MODE "Level"

LEVEL SELECTION

5 On-site display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

6 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

7 Select the "Height Linearized" option by means of the

LEVEL MODE parameter.

8 Select the "Height + Volume" option by means of the

COMB. MEASURAND parameter.

9 Select the unit for the 1st measured value via the

HEIGHT UNIT parameter, here m for example.

10 Select the unit for the 2nd measured variable via the

UNIT VOLUME parameter, here m3 for example.

11 Select LEVEL MIN parameter.

Enter the minimum level to be expected, here 0 m

for example.

12 Select LEVEL MAX parameter.

Enter the maximum level to be expected, here 3 m

(9.8 ft) for example.

13 Select the "Wet" option via the CALIBRATION MODE

parameter (calibration mode for the 1st measured

variable).

14 The pressure for the lower calibration point is

present at the device, here 0 mbar for example.

Select EMPTY CALIB. parameter.

Enter the level value, here 0 m for example. Confirm

the value to assign the pressure value present to the

lower level value.

15 The pressure for the upper calibration point is

present at the device, here 300 mbar (4.5 psi) for

example.

Select FULL CALIB. parameter.

Enter the level value, here 3 m (9.8 ft) for example.

Confirm the value to assign the pressure value

present to the upper level value.

16 Result:

The calibration for the 1st measured variable is

carried out.

Fig. 17: Calibrating the 1st measured variable

1 See table, step 11.

2 See table, step 12.

3 See table, step 14.

4 See Table, step 15.

P01-PMP75xxx-19-xx-xx-xx-004

P01-xxxxxxxx-05-xx-xx-xx-017

Endress+Hauser 27

Page 28

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

5

0

03

V

[m ]

3

h

[m]

5

0

03

V

[m ]

3

h

[m]

➄

➆

➅

20

4

I

[mA]

05

V

[m ]

3

➈

➇

Description

Perform linearisation (calibration for the 2nd

measured variable)

17 Change the function group.

Menu path: (GROUP SELECTION ) OPERATING

MENU SETTINGS LINEARISATION

18 Select TANK CONTENT MIN parameter.

Specify the minimum tank contents to be expected,

here 0 m

19 Select TANK CONTENT MAX parameter.

Specify the maximum tank contents to be expected,

here 5 m

20 On-site display:

Select the "Editor table" option by means of the

TABLE SELECTION parameter.

21 Select the "Semiautomatic" option by means of the

LIN. EDIT MODE parameter.

22 Select the "New table" option by means of the EDITOR

TABLE parameter.

23 Enter linearisation table (min. 2 points, max.

32 points).

Fill the tank to the height of the 1st point.

LINE-NUMB: confirm value displayed.

X-VAL.: the hydrostatic pressure present is

measured and converted to the corresponding level

and displayed.

On-site display, Digital communication:

The X-VAL. displayed is saved by confirming the

Y-value. See following line, Y-VAL.

HART handheld terminal:

Confirm X-VAL. displayed.

Y-VAL.: enter the volume value, here 0 m

example, and confirm the value.

24 On-site display

If you want to enter another point for the

linearisation table, select the "Next point" option and

enter the point as described in step 23.

If you want to finish entering the values and activate

the linearisation table, select the "Accept input table"

option.

Digital communication:

You can enter further points for the linearisation

table as explained in step 23. Once all the points

have been entered, the table must be activated by

means of the TAB. ACTIVATE parameter.

25 Result:

– The linearisation table has been entered.

– The measured value display and the

– The LEVEL BEFORE LIN parameter displays the

3

for example.

3

for example.

3

for

TANK CONTENT parameter display the 2nd

measured value (here the volume).

1st measured value (here the height). See also the

following note, point 5.

P01-PMP75xxx-19-xx-xx-xx-005

P01-xxxxxxxx-05-xx-xx-xx-018

P01-xxxxxxxx-05-xx-xx-xx-019

Fig. 18: Calibrating the 2nd measured variable

5 See table, step 18.

6 See table, step 19.

7 See table, steps 20 – 24.

8 See the following note, point 4.

9 See the following note, point 4.

28 Endress+Hauser

Page 29

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

1. For this level type, the measured variables "Height + %", "Height + Volume", "Height +

Mass", "%-Height + %", "%-Height + Volume" and "%-Height + Mass" are available. See

Page 87 ff.

2. You can also specify customer-specific units. See parameter description for PRESS. ENG.

UNIT (Page 77), HEIGHT UNIT ( Page 90), UNIT VOLUME (Page 91) and MASS

UNIT ( Page 92).

3. Once you have selected the "Pressure Linearized" level type, the warning message "W710

Set span too small. Not allowed." can appear. At this stage the linearisation table already

consists of two points as standard. It could be the case that the 2nd value, and thus the

highest X-VAL. of the linearisation table, is smaller than the minimum span permitted

( MINIMUM SPAN, Page 120). The message goes out as soon as the highest X-VAL.

is larger than the minimum span.

4. A level value is assigned to both the lower and upper current value with the SET LRV

( Page 102) and SET URV (Page 102) parameters.

You can use the ASSIGN CURRENT parameter (Page 114) to specify whether the

current output should depict the 1st or 2nd measured variable. Depending on the

setting of the ASSIGN CURRENT parameter, enter the following values for SET LRV and

SET URV:

– ASSIGN CURRENT = tank content (factory setting) %-value, volume value or

mass value

– ASSIGNMENT = height level value

The following applies for the setting ASSIGN CURRENT "Tank content":

If you enter values for TANK CONTENT MIN (Page 104 or 107) and TANK CONTENT

MAX ( Page 104 or 107), the SET LRV and SET URV parameters are also changed. If

you want to assign values other than those for TANK CONTENT MIN and TANK

CONTENT MAX to the lower and upper current values, the desired values must be

entered for SET LRV and SET URV.

The following applies for the setting ASSIGN CURRENT "Height":

If you enter values for LEVEL MIN (Page 93) and LEVEL MAX (Page 93), the SET

LRV and SET URV parameters are also changed. If you want to assign values other than

those for LEVEL MIN and LEVEL MAX to the lower and upper current values, the

desired values must be entered for SET LRV and SET URV.

5. You can use the MENU DESCRIPTOR parameter (Page 111) to specify which

measured value should be displayed on the on-site display.

Endress+Hauser 29

Page 30

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

WARNING

!

5

0

03

V

[m ]

3

h

[m]

5.6.2 Dry calibration and manual entry of the linearisation table

Example:

In this example, the height and the volume should be measured at the same time.

Prerequisite:

• This is a theoretical calibration, i.e. the points for the linearisation table are known.

• A minimum gap of 0.5 % of the distance between two points must be maintained. Spans

for the "Pressure linearized" option: HYDR. PRESS MAX. – HYDR. PRESS MIN.; TANK

CONTENT MAX. – TANK CONTENT MIN. Spans for the "Height linearized" option: LEVEL

MAX – LEVEL MIN; TANK CONTENT MAX. – TANK CONTENT MIN.

• See also Operating Instructions for Deltabar S (BA00270P) or Cerabar S (BA00271P),

Section "Level measurement" or Deltapilot S (BA00332P), Section "Level measurement".

• Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the MEASURED VALUE parameter does not display zero. To

perform a position adjustment see also Page 68, Table 6: Position adjustment.

• For a description of the parameters mentioned, see

– Page 62, Table 2: MEASURING MODE

– Page 77, Table 10: BASIC SETUP

– Page 89, Table 12: BASIC SETUP – "Height Linearized" level type

– Page 104, Table 18: LINEARISATION – on-site operation

– Page 107, Table 19: LINEARISATION – Digital communication.

• For a description of further parameters, see

– Page 100, Table 16: EXTENDED SETUP

– Page 121, Table 28: PROCESS VALUES.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Description

Perform calibration for the 1st measured

variable:

1 Perform calibration as per Section 5.4.2, steps 3 to

12.

2 Select the "Dry" option via the CALIBRATION MODE

parameter (calibration mode for the 1st measured

variable).

3 Enter the density of the fluid via the ADJUST

DENSITY parameter, here 1 kg/dm

4 If necessary, enter a level offset via the ZERO

POSITION parameter, here 0 m for example.

5Result:

The calibration for the 1st measured variable is

carried out.

3

for example.

P01-PMP75xxx-19-xx-xx-xx-005

30 Endress+Hauser

Page 31

Cerabar S/Deltabar S/Deltapilot S 4...20mA HART Level measurement

5

0

03

V

[m ]

3

h

[m]

➄

➆

➅

20

4

I

[mA]

05

V

[m ]

3

➈

➇

Description

Perform linearisation (calibration for the 2nd

measured variable)

6 Change the function group.

Menu path: (GROUP SELECTION ) OPERATING

MENU SETTINGS LINEARISATION

7 Select TANK CONTENT MIN parameter.

Specify the minimum tank contents to be expected,

here 0 m

8 Select TANK CONTENT MAX parameter.

Specify the maximum tank contents to be expected,

here 5 m

9 On-site display:

Select the "Editor table" option by means of the

TABLE SELECTION parameter.

10 Select the "Manual" option by means of the LIN. EDIT

MODE parameter.

11 Select the "New table" option by means of the EDITOR

TABLE parameter.

12 Enter linearisation table (min. 2 points, max.

32 points).

LINE-NUMB: confirm value displayed.

X-VAL.: enter the height value and confirm.

Y-VAL.: enter the volume value, here 0 m

example, and confirm.

13 On-site display

If you want to enter another point for the

linearisation table, select the "Next point" option and

enter the point as described in step 12.

If you want to finish entering the values and activate

the linearisation table, select the "Accept input table"

option.

Digital communication:

You can enter further points for the linearisation

table as explained in step 12. Once all the points

have been entered, the table must be activated by

means of the TAB. ACTIVATE parameter.

14 Result:

– The linearisation table has been entered.

– The measured value display and the

– The LEVEL BEFORE LIN parameter displays the

3

for example.

3

for example.

3

for

TANK CONTENT parameter display the 2nd

measured value (here the volume).

1st measured value (here the height). See also the

following note, point 5.

P01-xxxxxxxx-05-xx-xx-xx-018

P01-xxxxxxxx-05-xx-xx-xx-019

Fig. 19: Calibrating the 2nd measured variable

5 See table, step 7.

6 See table, step 8.

7 See table, steps 9 – 13.

8 See the following note, point 4.

9 See the following note, point 4.

Endress+Hauser 31

1. For this level type, the measured variables "Height + %", "Height + Volume", "Height +

Mass", "%-Height + %", "%-Height + Volume" and "%-Height + Mass" are available. See

Page 87 ff.

2. You can also specify customer-specific units. See parameter description for PRESS. ENG.

UNIT (Page 77), HEIGHT UNIT ( Page 90), UNIT VOLUME (Page 91) and MASS

UNIT ( Page 92).

3. Once you have selected the "Pressure Linearized" level type, the warning message "W710

Set span too small. Not allowed." can appear. At this stage the linearisation table already

consists of two points as standard. It could be the case that the 2nd value, and thus the

highest X-VAL. of the linearisation table, is smaller than the minimum span permitted

Page 32

Level measurement Cerabar S/Deltabar S/Deltapilot S 4...20mA HART

( MINIMUM SPAN, Page 120). The message goes out as soon as the highest X-VAL.

is larger than the minimum span.

4. A level value is assigned to both the lower and upper current value with the SET LRV

(Page 102) and SET URV (Page 102) parameters.

You can use the ASSIGN CURRENT parameter (Page 114) to specify whether the

current output should depict the 1st or 2nd measured variable. Depending on the

setting of the ASSIGN CURRENT parameter, enter the following values for SET LRV and

SET URV:

– ASSIGN CURRENT = tank content (factory setting) %- value, volume value or

mass value

– ASSIGNMENT = height level value

The following applies for the setting ASSIGN CURRENT "Tank content":

If you enter values for TANK CONTENT MIN (Page 104 or 107) and TANK CONTENT

MAX ( Page 104 or 107), the SET LRV and SET URV parameters are also changed. If

you want to assign values other than those for TANK CONTENT MIN and TANK

CONTENT MAX to the lower and upper current values, the desired values must be

entered for SET LRV and SET URV.

The following applies for the setting ASSIGN CURRENT "Height":

If you enter values for LEVEL MIN (Page 93) and LEVEL MAX (Page 93), the SET