Page 1

BA00301P/00/EN/19.16

71336231

valid from Software version:

04.00.zz

Products Solutions Services

Operating Instructions

Deltabar S FMD77, FMD78,

PMD75

Differential pressure measurement

Page 2

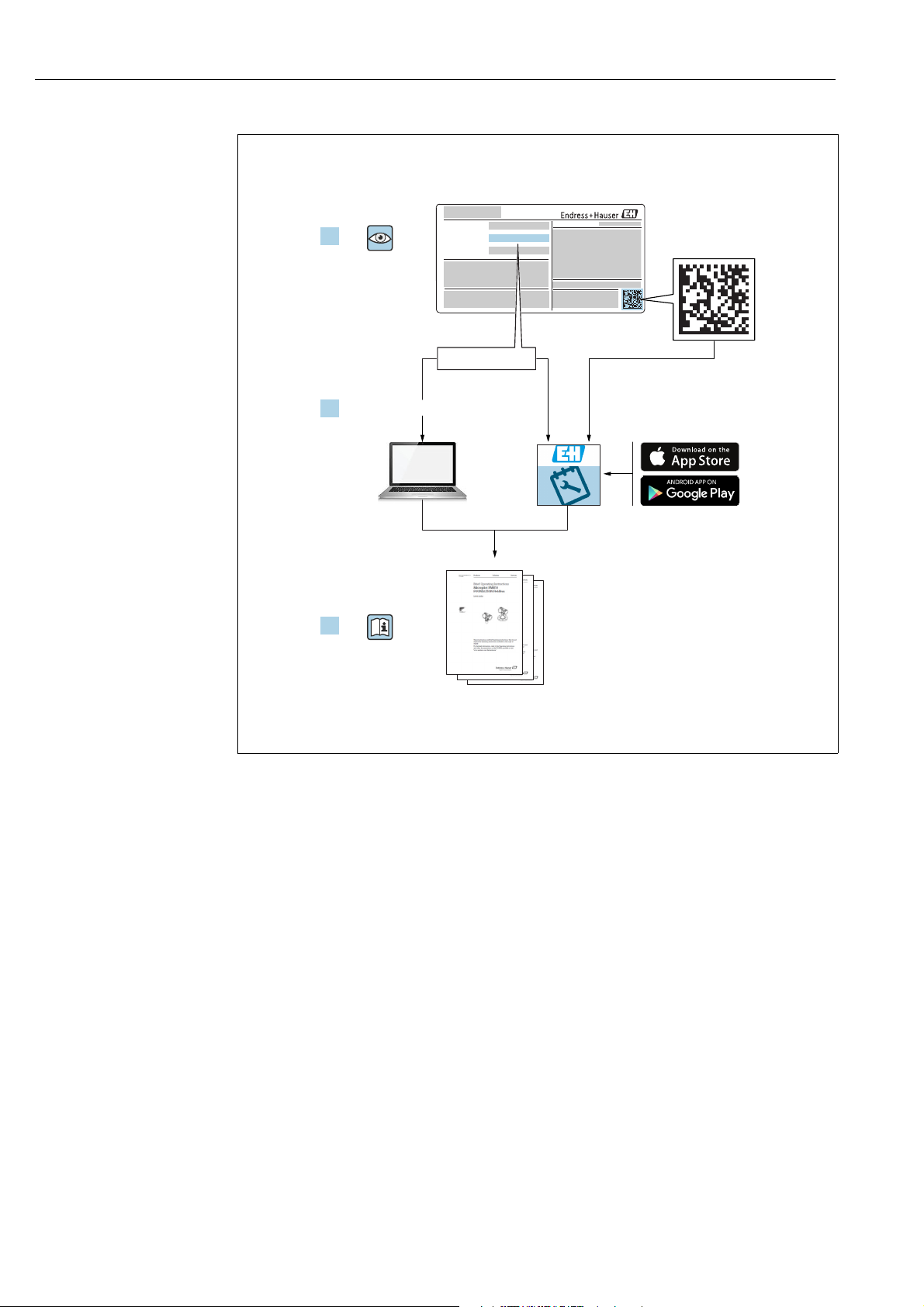

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to these

Instructions.

2 Endress+Hauser

Page 3

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

Table of contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . 6

1.5 Turn down calculation . . . . . . . . . . . . . . . . . . . . . . . 7

2 Basic safety instructions . . . . . . . . . . . . . 8

2.1 Requirements concerning the staff . . . . . . . . . . . . . 8

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Identification . . . . . . . . . . . . . . . . . . . . . 10

3.1 Product identification . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Device designation . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 CE mark, Declaration of Conformity . . . . . . . . . . 12

3.5 Registered trademarks . . . . . . . . . . . . . . . . . . . . . 12

4 Installation . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Incoming acceptance and storage . . . . . . . . . . . . 13

4.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . 13

4.3 Installation instructions . . . . . . . . . . . . . . . . . . . . 14

4.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 30

5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 Connecting the device . . . . . . . . . . . . . . . . . . . . . 31

5.2 Connecting the measuring unit . . . . . . . . . . . . . . 32

5.3 Overvoltage protection (optional) . . . . . . . . . . . . 33

5.4 Post-connection check . . . . . . . . . . . . . . . . . . . . . 33

7.6 Flow measurement . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.7 Level measurement . . . . . . . . . . . . . . . . . . . . . . . . 70

7.8 Differential pressure measurement . . . . . . . . . . . 77

7.9 Scaling the OUT parameter . . . . . . . . . . . . . . . . . . 79

7.10 Configuring event behavior in accordance with

FOUNDATION Fieldbus Specification FF912 Field

Diagnostic Profile . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8 Maintenance . . . . . . . . . . . . . . . . . . . . . 91

8.1 Cleaning instructions . . . . . . . . . . . . . . . . . . . . . . . 91

8.2 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9 Diagnostics and troubleshooting . . . . 92

9.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.2 Diagnostic information on local display . . . . . . . . 93

9.3 Diagnostic event in the operating tool . . . . . . . . . 94

9.4 Diagnostic messages in the DIAGNOSTIC

Transducer Block (TRDDIAG) . . . . . . . . . . . . . . . . 95

9.5 Overview of diagnostic events . . . . . . . . . . . . . . . . 99

9.6 Response of outputs to errors . . . . . . . . . . . . . . 108

9.7 Confirming messages . . . . . . . . . . . . . . . . . . . . . 109

9.8 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.9 Repair of Ex-certified devices . . . . . . . . . . . . . . 110

9.10 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

9.11 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

9.12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

9.13 Software history . . . . . . . . . . . . . . . . . . . . . . . . . 111

10 Technical data . . . . . . . . . . . . . . . . . . . 111

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 34

6.1 Onsite display (optional) . . . . . . . . . . . . . . . . . . . 34

6.2 Operating elements . . . . . . . . . . . . . . . . . . . . . . . 36

6.3 FOUNDATION Fieldbus interface . . . . . . . . . . . . 38

6.4 Local operation – onsite display connected . . . . 51

6.5 HistoROM®/M-DAT (optional) . . . . . . . . . . . . . . 54

6.6 FieldCare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.7 Locking/unlocking operation . . . . . . . . . . . . . . . 57

6.8 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.9 Factory setting (reset) . . . . . . . . . . . . . . . . . . . . . 59

7 Commissioning. . . . . . . . . . . . . . . . . . . . 62

7.1 Configuring messages . . . . . . . . . . . . . . . . . . . . . 62

7.2 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.3 Commissioning via an FF configuration program . .

62

7.4 Selecting the language and measuring mode . . 64

7.5 Position adjustment . . . . . . . . . . . . . . . . . . . . . . . 65

Endress+Hauser 3

Page 4

Document information Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

DANGER

WARNING

CAUTION

NOTICE

)

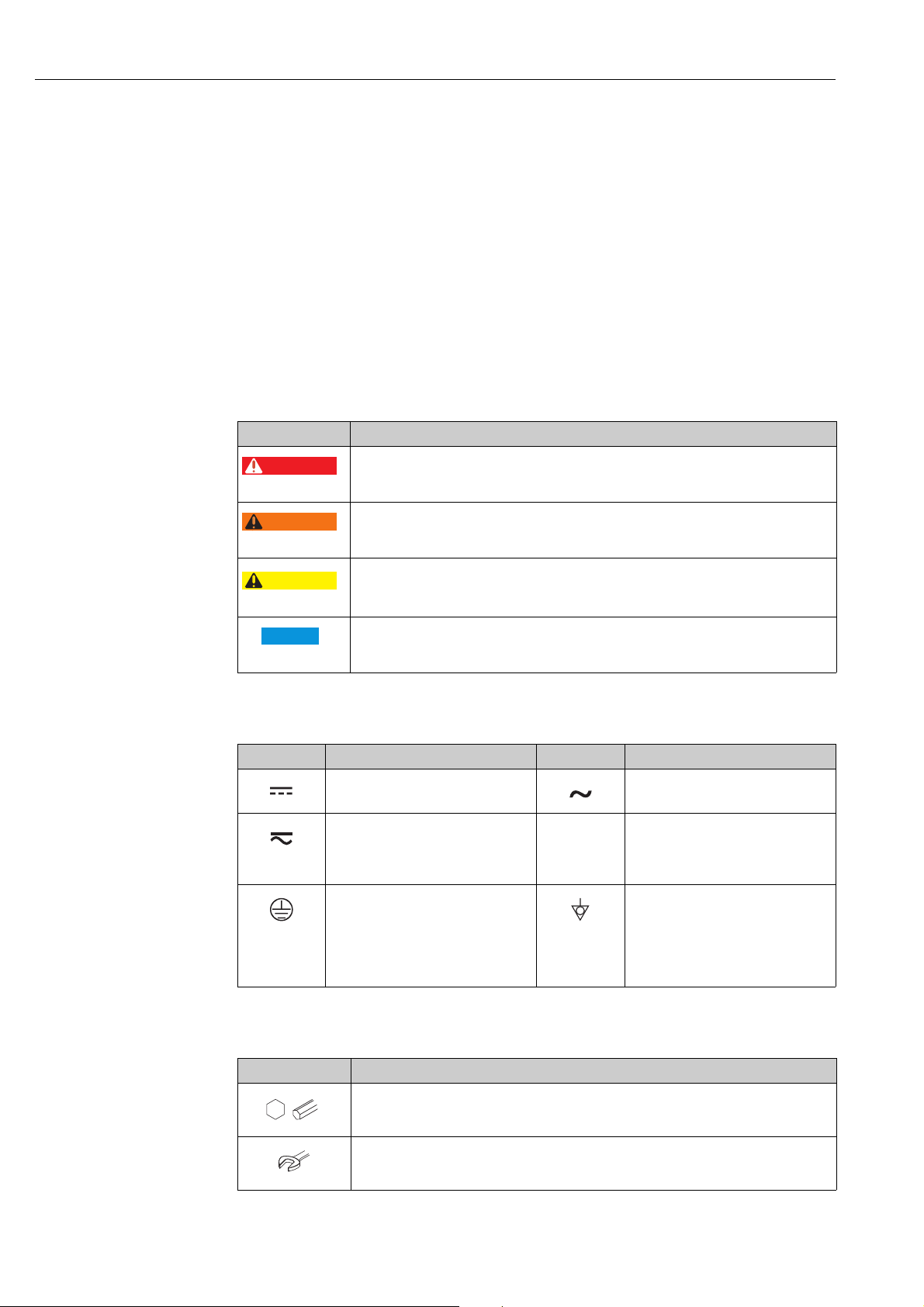

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and storage,

to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-DE

A0011190-DE

A0011191-DE

A0011192-DE

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

seriousor fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

seriousor fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minoror medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personalinjury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

1.2.3 Tool symbols

Symbol Meaning

Allen key

A0011221

Hexagon wrench

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line or

a star grounding system depending on

national or company codes of practice.

A0011222

4 Endress+Hauser

Page 5

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Document information

,…,

1.

2.

3.

,…,

1.

2.

3.

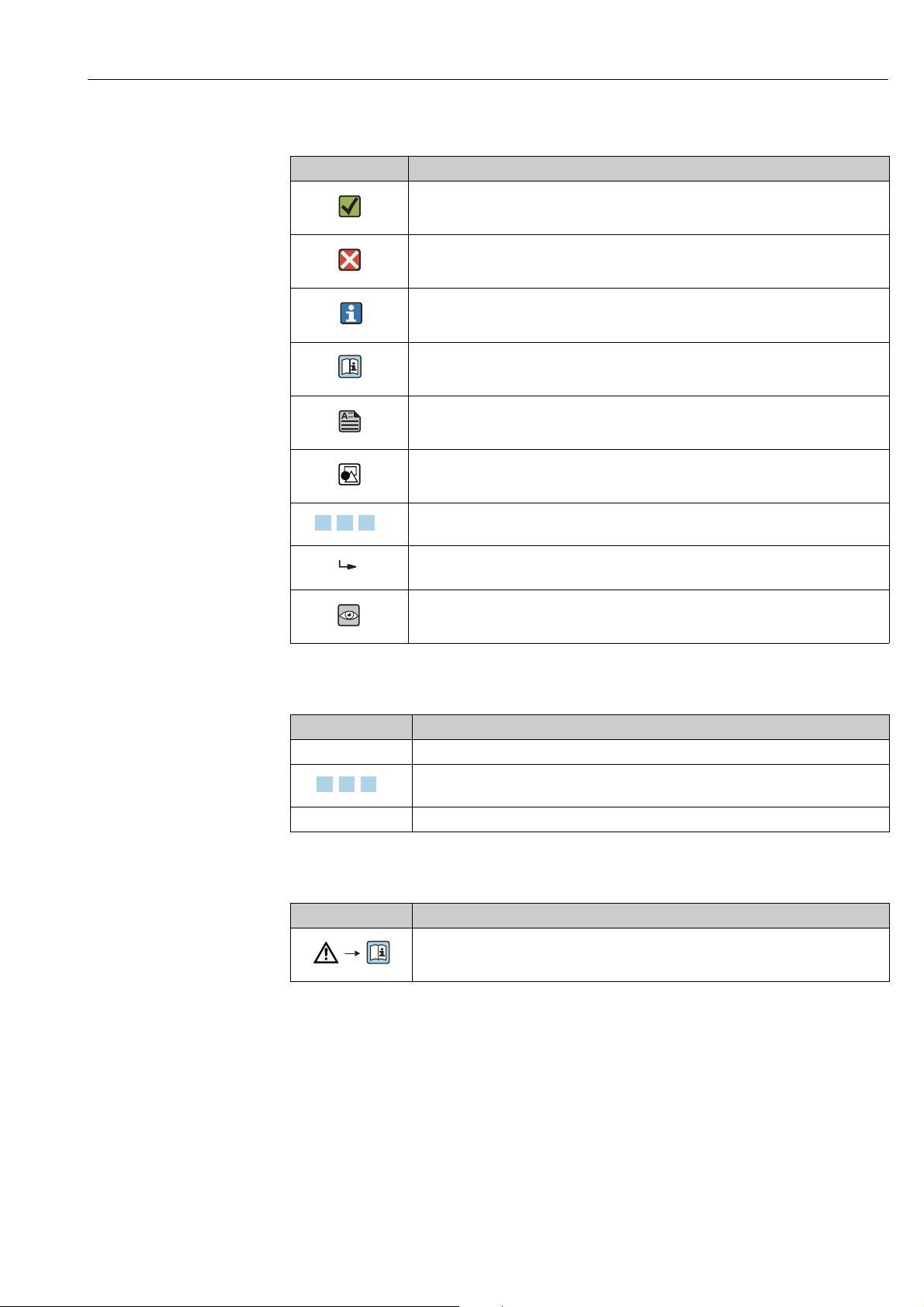

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

A0015482

Reference to page

A0015484

Reference to graphic

A0015487

Series of steps

A0031595

Result of a sequence of actions

A0018343

Visual inspection

A0015502

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3, 4, ... Item numbers

Series of steps

A0031595

A, B, C, D, ... Views

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

A0019159

1.3 Registered trademarks

KALREZ, VITON, TEFLON

Registered trademarks of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

Registered trademark of Ladish & Co., Inc., Kenosha, USA

®

TM

Fieldbus

FOUNDATION

Registered trademark of the FieldComm Group, Austin, USA

GORE-TEX

Registered trademarks of W.L. Gore & Associates, Inc., USA

Endress+Hauser 5

Page 6

Document information Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

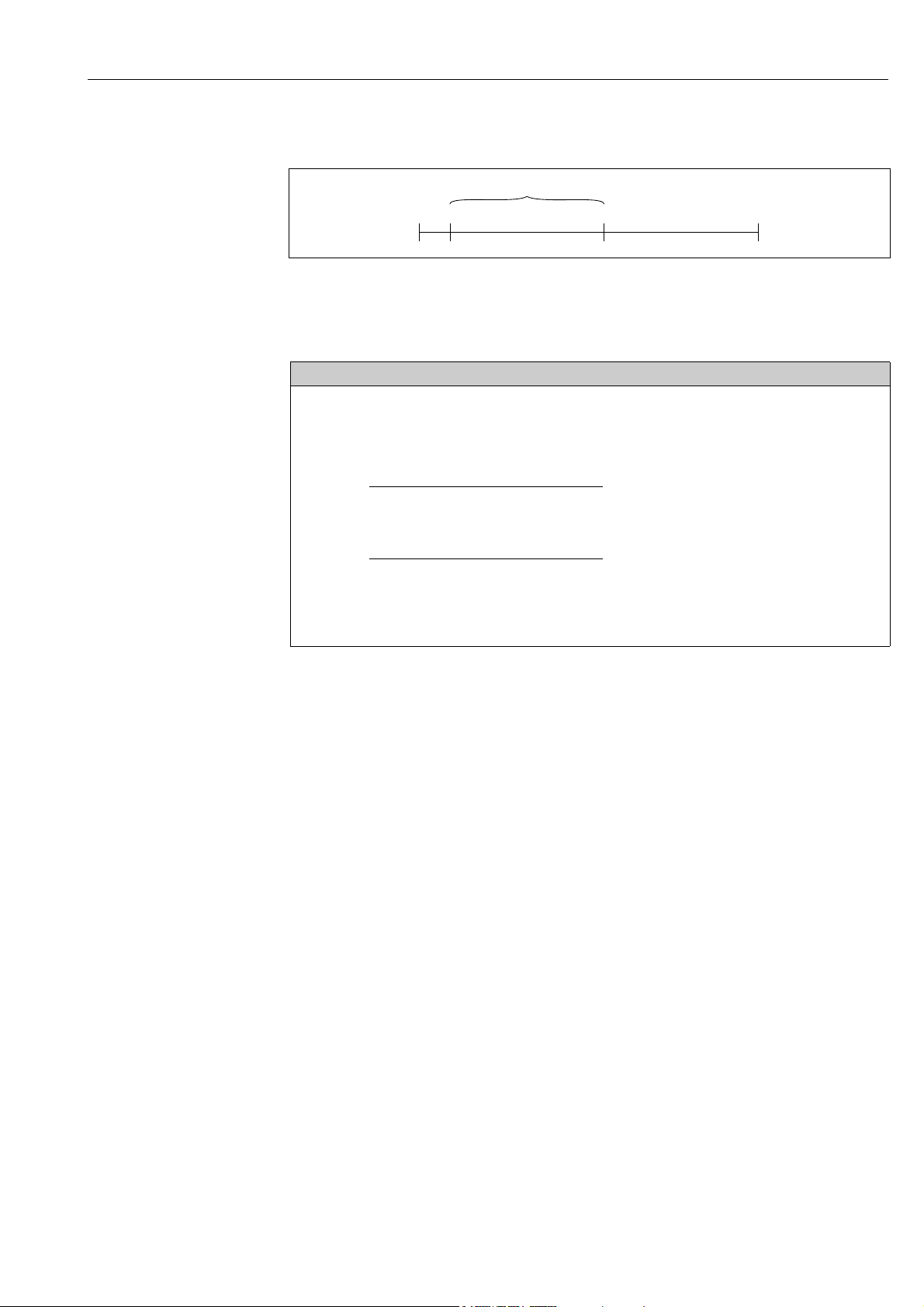

1.4 Terms and abbreviations

A0029505

Position Term/Abbreviation Explanation

1 OPL The OPL (over pressure limit = sensor overload limit) for the sensors

depends on the lowest-rated element, with regard to pressure, of the

selected components, i.e. the process connection must be taken into

consideration in addition to the measuring cell. Also observe pressuretemperature dependency. For the relevant standards and additional notes,

see technical information.

The OPL may be applied for a limited time period.

2 MWP The MWP (maximum working pressure) for the sensors depends on the

lowest-rated element, with regard to pressure, of the selected components,

i.e. the process connection has to be taken into consideration in addition to

the measuring cell. Also observe pressure-temperature dependency. For the

relevant standards and additional notes, see technical information.

The MWP may be applied for an unlimited time.

3Maximum sensor

measuring range

4 Calibrated/Adjusted

measuring span

p - Pressure

- LRL Lower range limit

-URL Upper range limit

- LRV Lower range value

-URV Upper range value

-TD Turn down

Range between LRL and URL

This span is the maximum calibratable/adjustable measuring span.

Range between LRV and URV

Factory setting: 0...URL

Other calibrated spans can be ordered with customised settings.

6 Endress+Hauser

Page 7

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Document information

LRV

URLURV

LRL

1 = 2

3

1.5 Turn down calculation

A0029545

Fig. 1:

1 Calibrated/Adjusted measuring span

2 Zero-based span

3 Upper range limit

Example

• Sensor: 10 bar (150 psi)

• Upper range limit (URL) = 10 bar (150 psi)

Turn down (TD):

TD =

|URV - LRV|

URL

• Calibrated/Adjusted measuring span: 0...5 bar

(0...75 psi)

• Lower range value (LRV) = 0 bar

• Upper range value (URV) = 5 bar (75 psi)

TD =

In this example, the TD is thus 2:1.

This span is based on the zero point.

|5 bar (75 psi) - 0 bar (0 psi)|

10 bar (150 psi)

=2

Endress+Hauser 7

Page 8

Basic safety instructions Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

2 Basic safety instructions

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner-operator

• Following the instructions in these Operating Instructions

2.2 Designated use

The Deltabar S is a differential pressure transmitter for measuring differential pressure, flow

and level.

2.2.1 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability.

2.3 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.4 Operational safety

Risk of injury!

‣ Operate the device in proper technical condition and fail-safe condition only.

‣ The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers:

‣ If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

‣ Carry out repairs on the device only if they are expressly permitted.

‣ Observe federal/national regulations pertaining to repair of an electrical device.

‣ Use original spare parts and accessories from Endress+Hauser only.

8 Endress+Hauser

Page 9

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Basic safety instructions

2.5 Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous

area (e.g. explosion protection, pressure vessel safety):

• Based on the nameplate, check whether the ordered device is permitted for the intended

use in the hazardous area.

• Observe the specifications in the separate supplementary documentation that is an

integral part of these Instructions.

2.6 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the- art safety requirements, has been tested, and left the factory in a condition in

which they are safe to operate. It fulfills general safety requirements and legal requirements.

It also conforms to the EC directives listed in the device-specific EC declaration of conformity.

Endress+Hauser confirms this fact by applying the CE mark.

Endress+Hauser 9

Page 10

Identification Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

Ser. no.:

Order code:

Ext. order code:

2

5

6

3

4

1

3 Identification

3.1 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

For an overview of the technical documentation provided, enter the serial number from the

nameplates in the W@M Device Viewer (www.endress.com/deviceviewer).

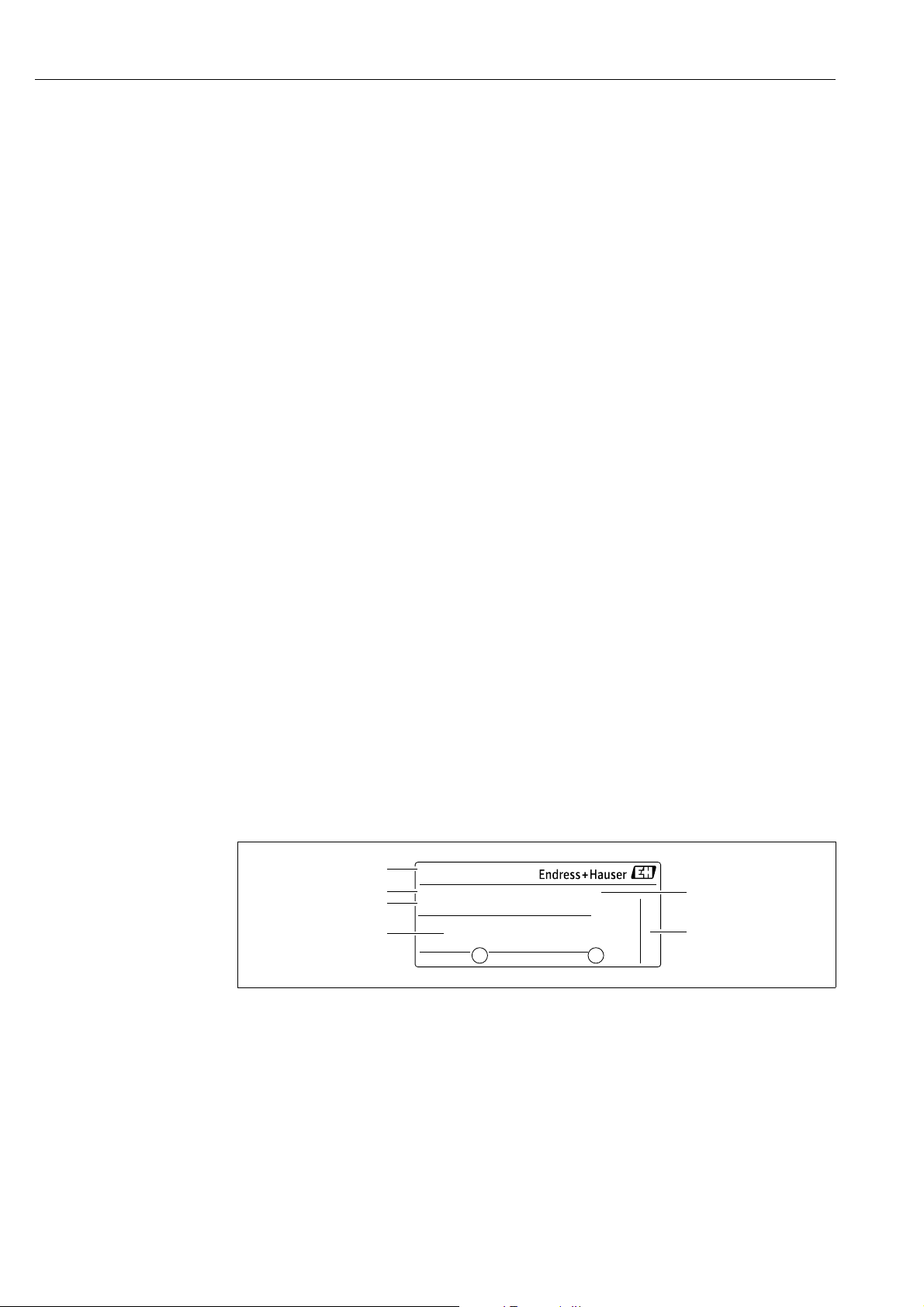

3.2 Device designation

3.2.1 Nameplates

• The MWP (maximum working pressure) is specified on the nameplate. This value refers

to a reference temperature of +20 °C (68°F) and may be applied to the device for an

unlimited time. Observe temperature dependency of the MWP. The pressure values

permitted at higher temperatures can be found in the standards EN 1092-1: 2001 Tab. 18

(With regard to their stability-temperature property, the materials 1.4435 and 1.4404 are

grouped together under 13EO in EN 1092-1 Tab. 18. The chemical composition of the two

materials can be identical.), ASME B 16.5a – 1998 Tab. 2-2.2 F316, ASME B 16.5a –

1998 Tab. 2.3.8 N10276, JIS B 2220.

• For PMD75, the MWP applies for the temperature ranges specified in the Technical

Information TI00382P in the "Ambient temperature range" and "Process temperature

limits" sections.

• The test pressure corresponds to the over pressure limit (OPL) of the device = MWP x 1.5.

• The Pressure Equipment Directive (2014/68/EU) uses the abbreviation "PS".

The abbreviation "PS" corresponds to the MWP (maximum working pressure) of the

measuring device.

Aluminium housing (T14/T15) and stainless steel housing (T14)

Fig. 2: Nameplate

1Device name

2 Order code (for re-orders)

3 Extended order code (complete)

4Technical data

5 Serial number (for identification)

6 Address of manufacturer

10 Endress+Hauser

A0016056

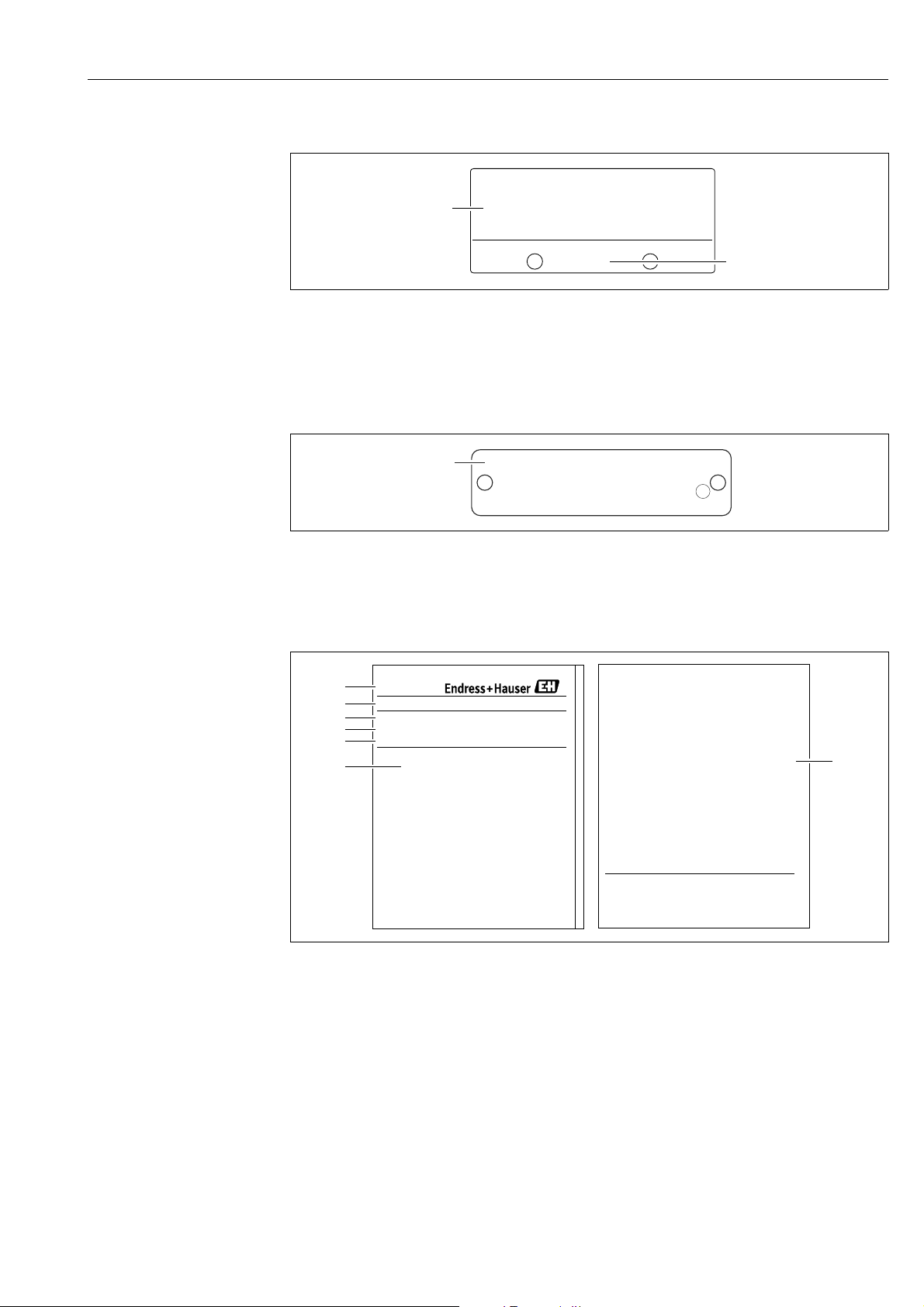

Page 11

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Identification

2

1

1

2

7

3

4

5

6

1

Ser. no.:

Order code:

Ext. ord. cd.:

Devices for use in hazardous areas are fitted with an additional nameplate.

A0021222

Fig. 3: Additional nameplate

1 Approval-specific information

2 Document number for safety instructions or drawing number

Devices suitable for oxygen applications or with PVDF process connection are fitted with an

additional nameplate.

A0022683

Fig. 4: Additional nameplate

1 Application limits

Hygenic stainless steel housing (T17)

A0021552

Fig. 5: Nameplate

1 Device name

2 Address of manufacturer

3 Order code (for re-orders)

4 Extended order code (complete)

5 Serial number (for identification)

6Technical data

7 Approval-specific information and document number for safety instructions or drawing number

3.2.2 Identifying the sensor type

See parameter "Sensor Meas.Type" in Operating Instruction BA00303P.

Endress+Hauser 11

Page 12

Identification Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

3.3 Scope of delivery

The scope of delivery comprises:

• Deltabar S differential pressure transmitter

• For PMD75 with side flanges made of AISI 316L or C22.8: additionally 2 vent valves, AISI

316L

• PMD75 with side flanges made of AISI 316L or C22.8 and side vent: additionally 4 locking

screws, AISI 316L

• For devices with the "HistoROM/M-DAT" option: CD-ROM with Endress+Hauser operating

program

• Optional accessories

Documentation supplied:

• Operating Instructions BA00301P and BA00303P are available via the Internet.

See: www.endress.com Download.

• Brief Operating Instructions KA01024P

• Fold-out brochure KA00252P

• Final inspection report

• Additional Safety Instructions with ATEX, IECEx and NEPSI devices

• Optional: factory calibration form, test certificates

3.4 CE mark, Declaration of Conformity

The devices are designed to meet state-of-the-art safety requirements, have been tested and

left the factory in a condition in which they are safe to operate. The devices comply with the

applicable standards and regulations as listed in the EC Declaration of Conformity and thus

comply with the statutory requirements of the EC Directives. Endress+Hauser confirms the

conformity of the device by affixing to it the CE mark.

3.5 Registered trademarks

KALREZ, VITON, TEFLON

Registered trademarks of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

Registered trademark of Ladish & Co., Inc., Kenosha, USA

FOUNDATION

Registered trademark of the Fieldbus Foundation Austin, Texas, USA

TM

Fieldbus

12 Endress+Hauser

Page 13

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

NOTICE

WARNING

!

1

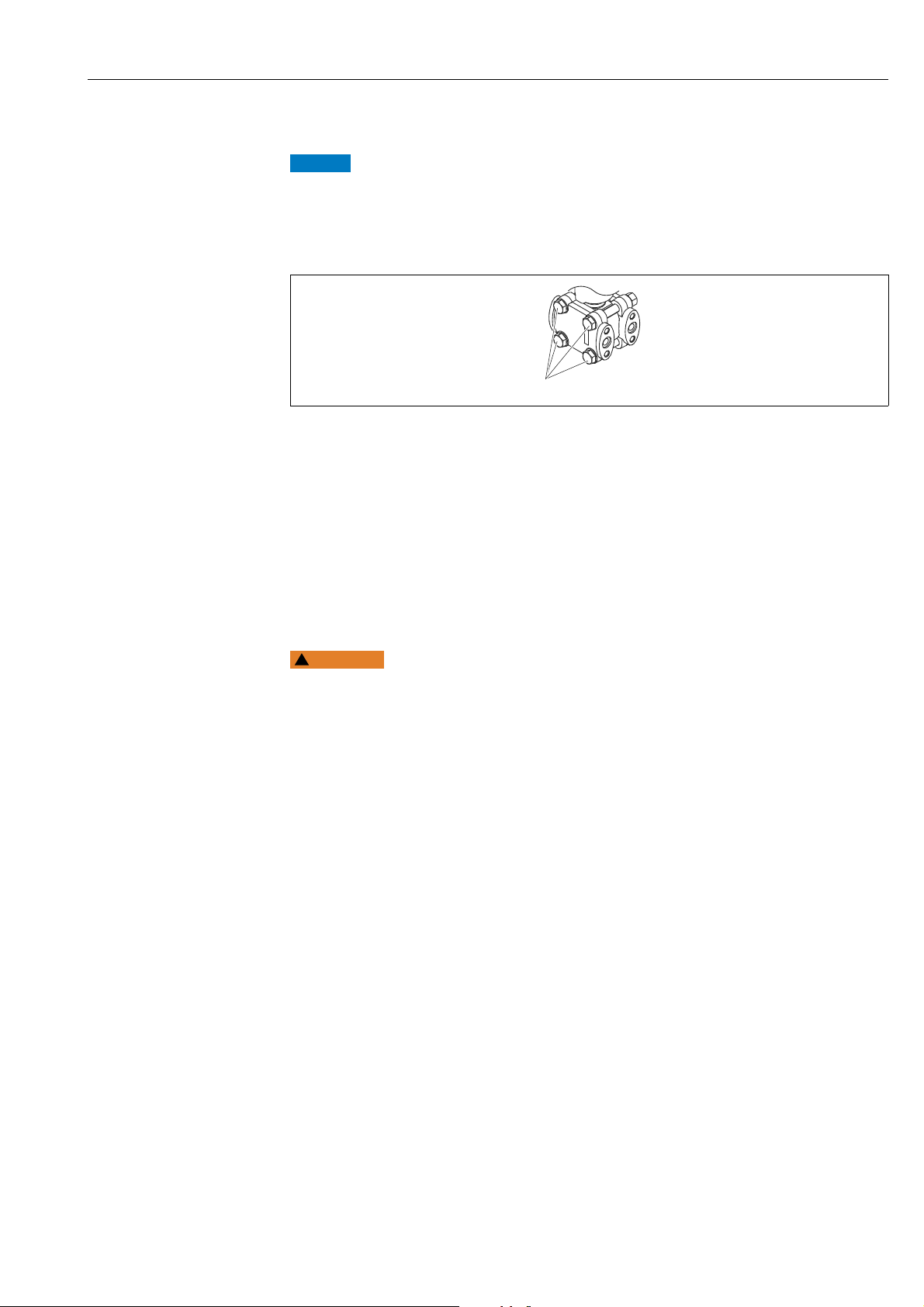

4Installation

Incorrect handling!

Damage of the device!

‣ Disassembly of the screws with item number (1) is not permissible under any

circumstances and will result in loss of warranty.

A0025336

4.1 Incoming acceptance and storage

4.1.1 Incoming acceptance

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches

your order.

4.1.2 Transport

Incorrect transport

Housing and diaphragm may be damaged and and there is a risk of injury!

‣ Transport the measuring device to the measuring point in its original packaging or by the

process connection (with secure transport protection for the diaphragm).

‣ Follow the safety instructions and transport conditions for devices of more than 18 kg

(39.69 lbs).

‣ Do not use capillaries as a carrying aid for the diaphragm seals.

4.1.3 Storage

The device must be stored in a dry, clean area and protected against impact (EN 837-2).

Storage temperature range:

• –40 to +90°C (–40 to +194 °F)

• Onsite display: –40 to +85°C (–40 to +185°F)

• Separate housing: –40 to +60°C (–40 to +140°F)

4.2 Installation conditions

4.2.1 Dimensions

For dimensions, please refer to the Technical Information for Deltabar S TI00382P,

"Mechanical construction" section.

Endress+Hauser 13

Page 14

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

➀

➂

➃

+

–

➁

4.3 Installation instructions

• Due to the orientation of the Deltabar S, there may be a shift in the measured value, i.e.

when the container is empty or partially full, the measured value does not display zero. You

can correct this zero point shift using the "Zero" key on the electronic insert or externally

on the device or via the onsite display. ä 36, Section 6.2.1 "Position of the operating

elements", ä 37, Section 6.2.3 "Function of the operating elements – onsite display

connected" and ä 65, Section 7.5 "Position adjustment"..

• For FMD77 and FMD78, please refer to Section 4.3.4 "Installation instructions for devices

with diaphragm seals (FMD78)", ä 21.

• General recommendations for routing the pressure piping can be found in DIN 19210

"Methods for measurement of fluid flow; differential piping for flow measurement devices"

or the corresponding national or international standards.

• Using a three-way or five-way valve manifold allows for easy commissioning, installation

and maintenance without interrupting the process.

• When routing the pressure piping outdoors, ensure that sufficient antifreeze protection is

used, e.g. by using pipe heat tracing.

• Install the pressure piping with a monotonic gradient of at least 10%.

• To ensure optimal readability of the onsite display, it is possible to rotate the housing up

to 380°. ä 29, Section 4.3.9 "Rotating the housing".

• Endress+Hauser offers a mounting bracket for installing on pipes or walls.

ä 26, Section 4.3.7 "Wall and pipe-mounting (optional)".

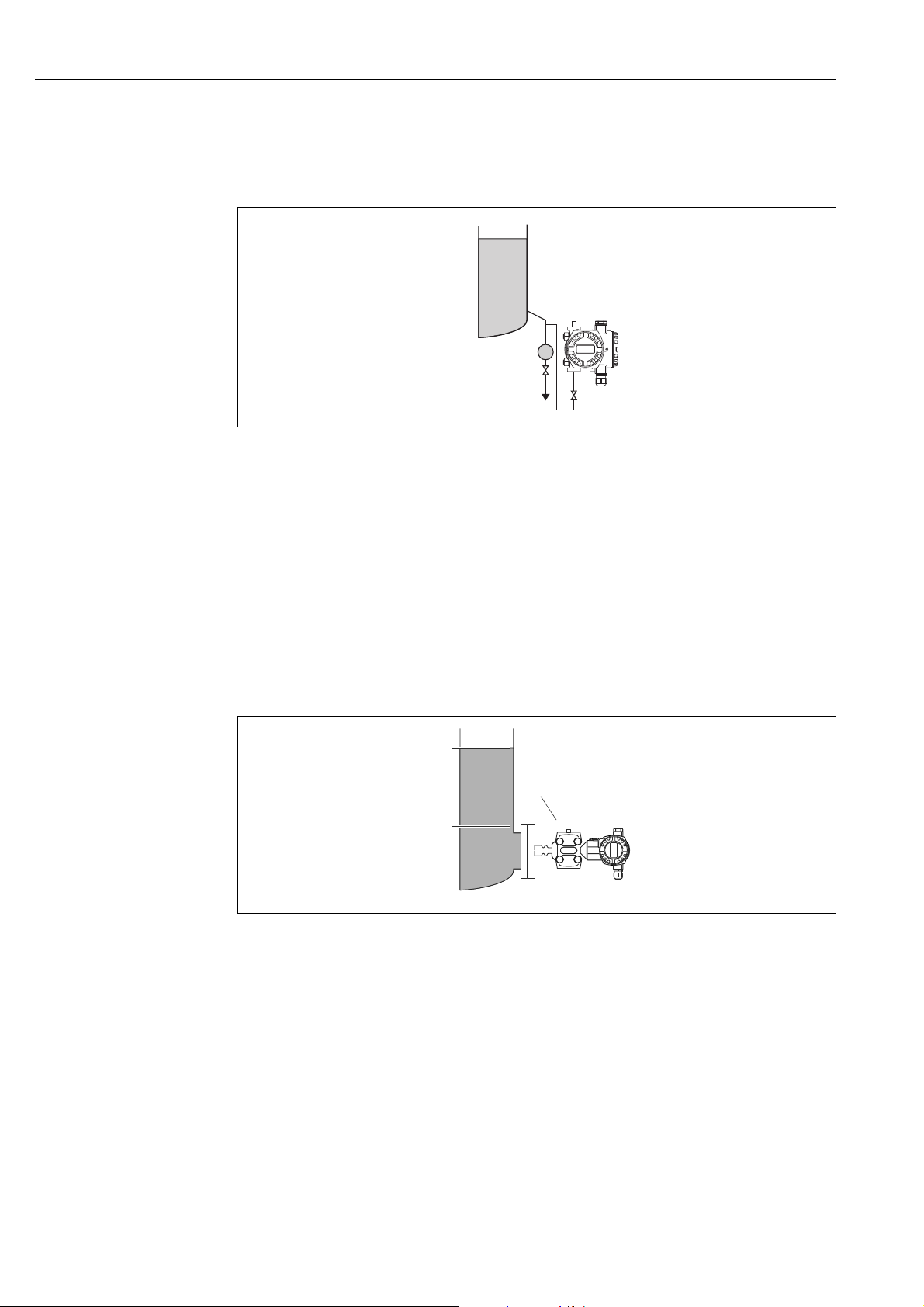

4.3.1 Installation for flow measurement

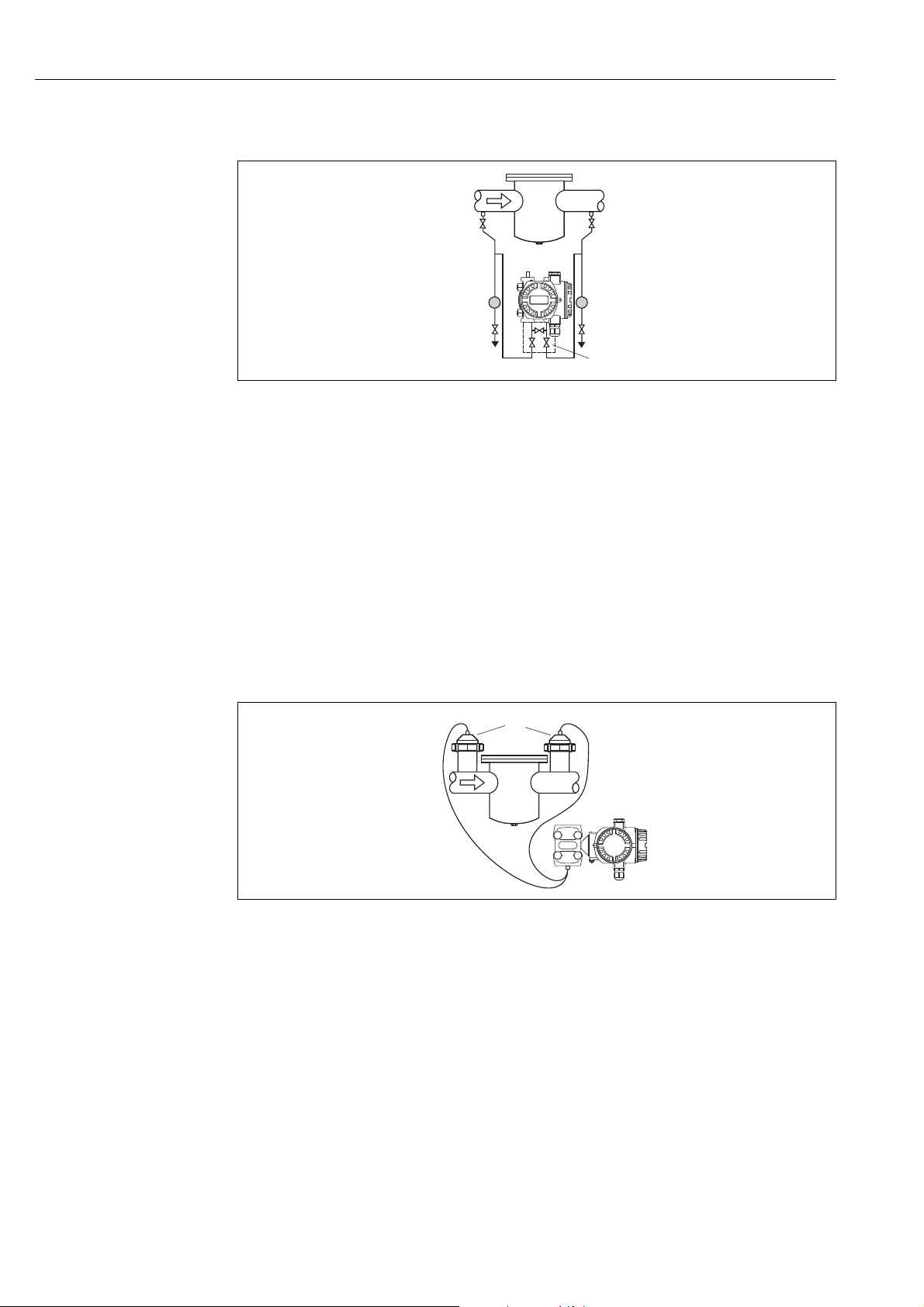

Flow measurement in gases with PMD75

P01-PMD75xxx-11-xx-xx-xx-000

Fig. 6: Measuring arrangement for flow measurement in gases with PMD75

1 Deltabar S, here PMD75

2 Three-way valve manifold

3 Shutoff valves

4 Orifice plate or Pitot tube

• Mount the Deltabar S above the measuring point so that the condensate can run off into

the process piping.

14 Endress+Hauser

Page 15

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

➀

➁

➃

+

–

➂

➅

➄

➆

➂

➅

➄

+

–

➀

➂

➅

➁

➃

➄

➁

➃

➄

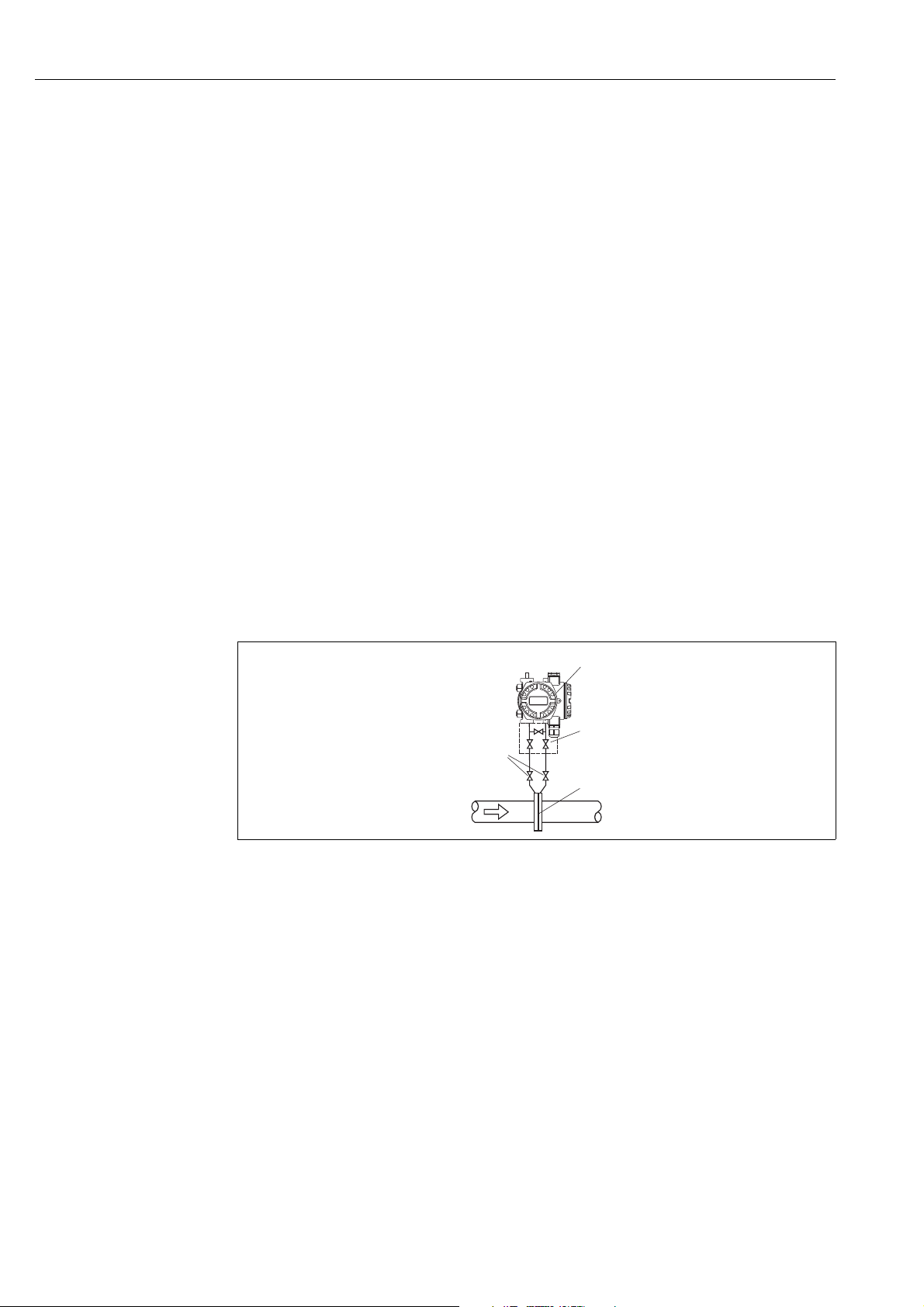

Flow measurement in steam with PMD75

P01-PMD75xxx-11-xx-xx-xx-001

Fig. 7: Measuring arrangement for flow measurement in steam with PMD75

1 Condensate traps

2 Orifice plate or Pitot tube

3Shutoff valves

4 Deltabar S, here PMD75

5Separator

6 Drain valves

7 Three-way valve manifold

• Mount the Deltabar S below the measuring point.

• Mount the condensate traps at the same level as the tapping points and at the same

distance to the Deltabar S.

• Prior to commissioning, fill the pressure piping to the level of the condensate traps.

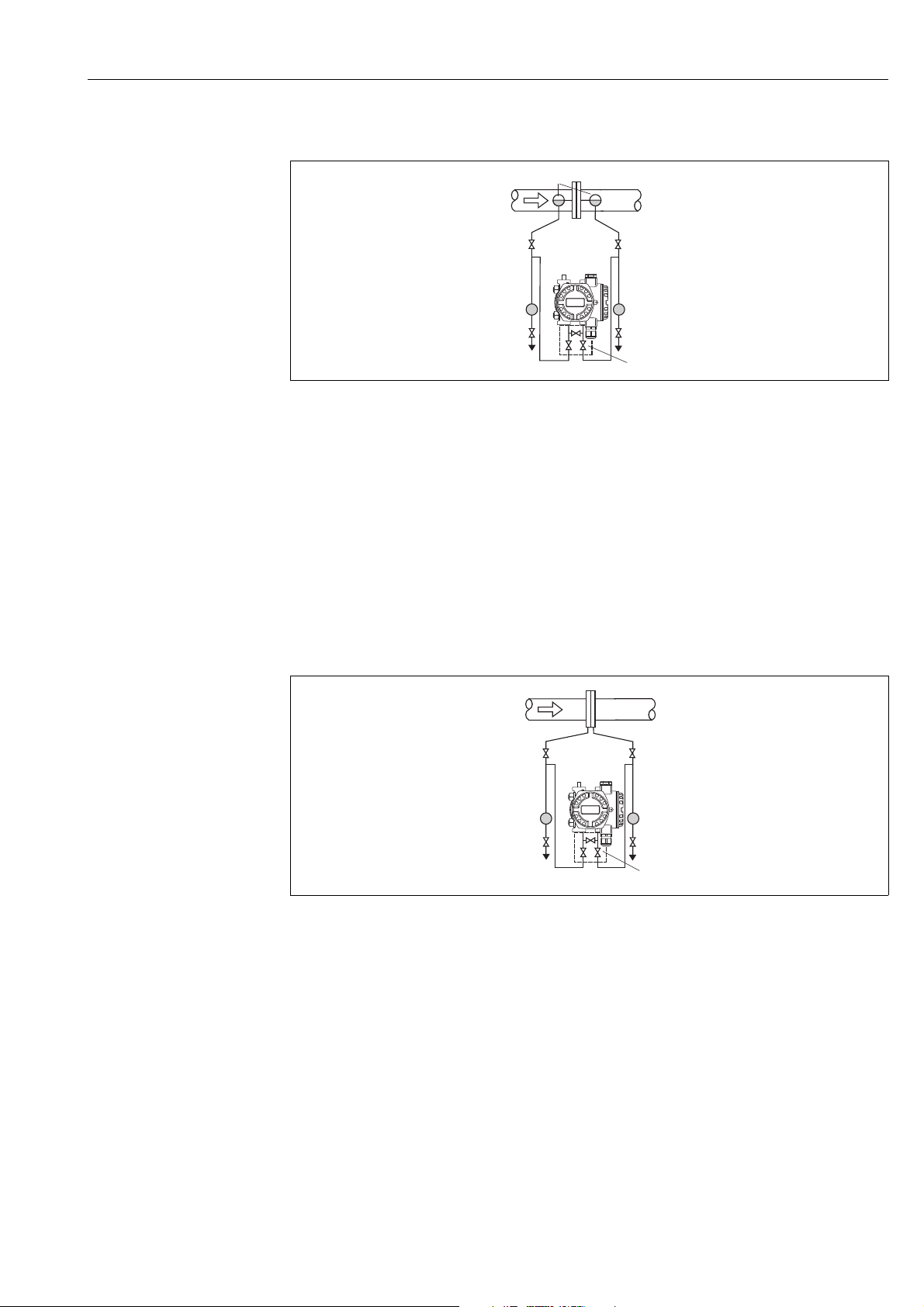

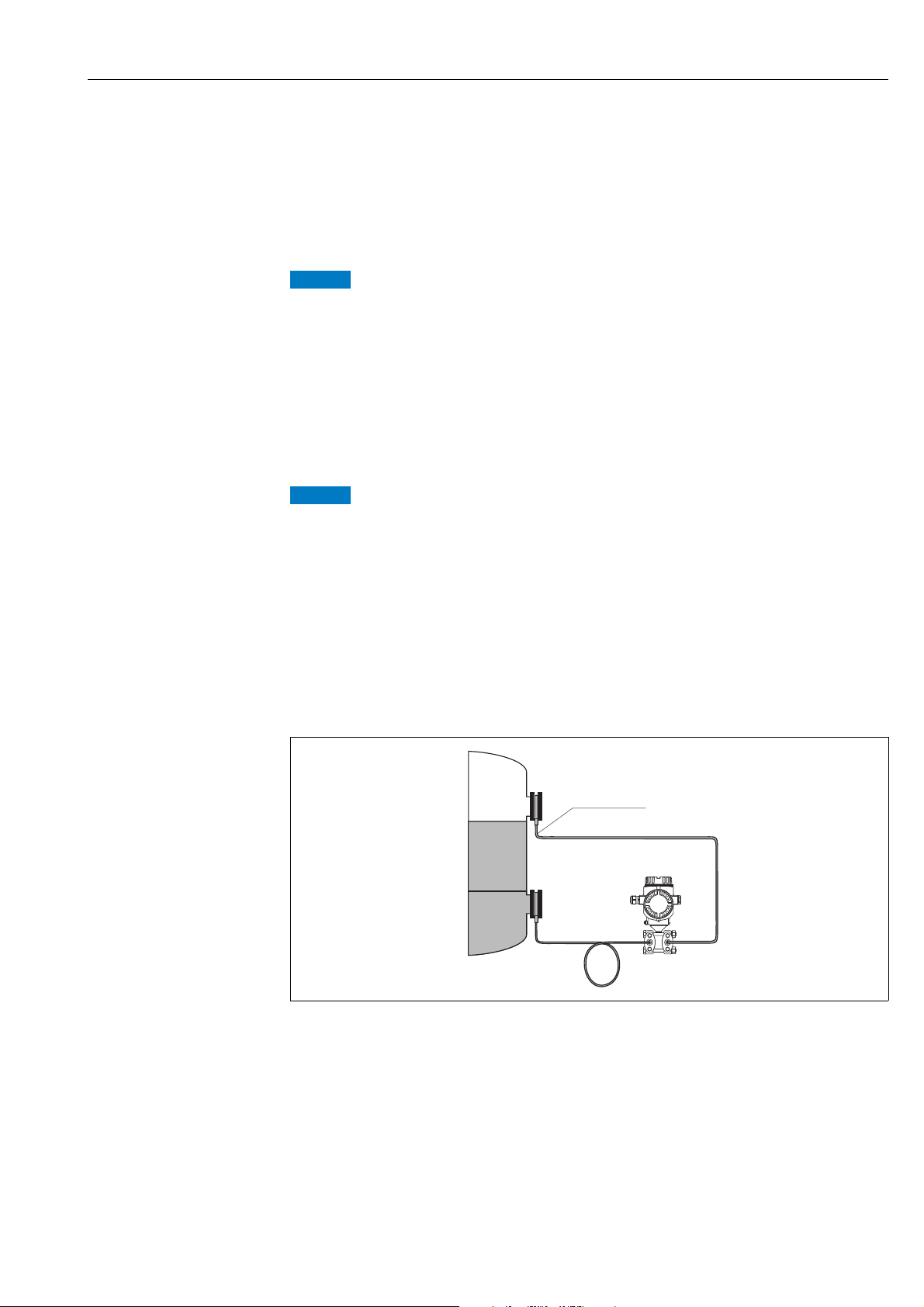

Flow measurement in liquids with PMD75

P01-PMD75xxx-11-xx-xx-xx-002

Fig. 8: Measuring arrangement for flow measurement in liquids with PMD75

1 Orifice plate or Pitot tube

2Shutoff valves

3 Deltabar S, here PMD75

4Separator

5 Drain valves

6 Three-way valve manifold

• Mount the Deltabar S below the measuring point so that the pressure piping is always

filled with liquid and gas bubbles can run back into the process piping.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Endress+Hauser 15

Page 16

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

+

➃

➂

➀

➁

➄

p

atm

min.

p

atm

+

–

min.

max.

1

2

p

atm

p

atm

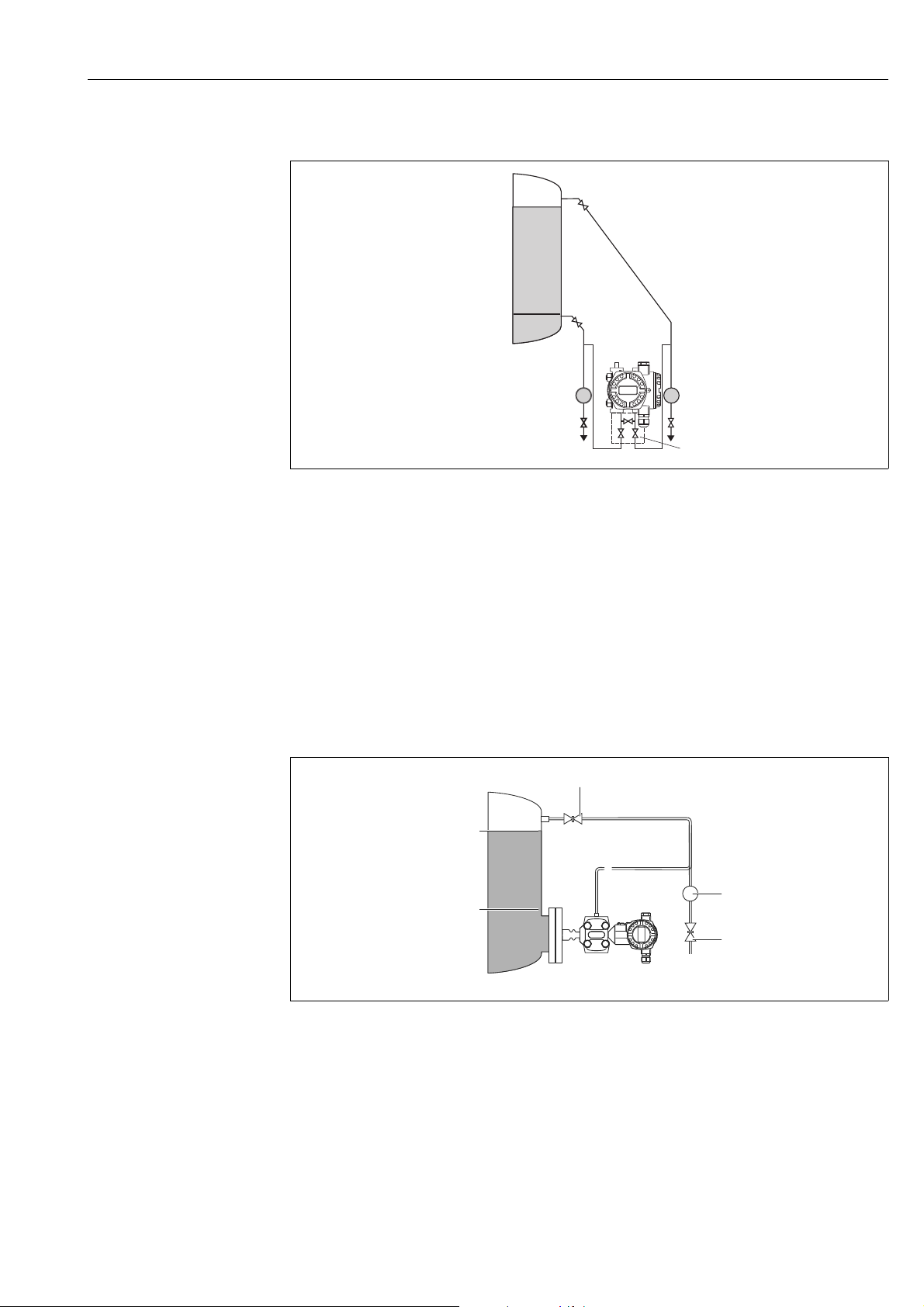

4.3.2 Installation for level measurement

Level measurement in an open container with PMD75

P01-PMD75xxx-11-xx-xx-xx-003

Fig. 9: Measuring arrangement for level measurement in an open container with PMD75

1 The negative side is open to atmospheric pressure

2 Deltabar S, here PMD75

3 Shutoff valve

4Separator

5 Drain valve

• Mount the Deltabar S below the lower measuring connection so that the pressure piping

is always filled with liquid.

• The negative side is open to atmospheric pressure.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Level measurement in an open container with FMD77

A0024164

Fig. 10: Measuring arrangement for level measurement in an open container with FMD77

1 Deltabar S, here FMD77

2 The negative side is open to atmospheric pressure

• Mount the Deltabar S directly on the container. ä 23, Section 4.3.5 "Seal for flange

mounting".

• The negative side is open to atmospheric pressure.

16 Endress+Hauser

Page 17

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

+

–

➀

➂

➃

➄

➁

➀

➂

➃

min.

max.

+

–

min.

max.

1

2

3

4

Level measurement in a closed container with PMD75

P01-PMD75xxx-11-xx-xx-xx-004

Fig. 11: Measuring arrangement for level measurement in a closed container with PMD75

1Shutoff valves

2 Deltabar S, PMD75

3Separator

4 Drain valves

5 Three-way valve manifold

• Mount the Deltabar S below the lower measuring connection so that the pressure piping

is always filled with liquid.

• Always connect the impulse piping of negative side above the maximum level.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Level measurement in a closed container with FMD77

A0024163

Fig. 12: Measuring arrangement for level measurement in a closed container with FMD77

Endress+Hauser 17

1 Shutoff valve

2Separator

3 Drain valve

4 Deltabar S, here FMD77

• Mount the Deltabar S directly on the container. ä 23, Section 4.3.5 "Seal for flange

mounting".

• Always connect the impulse piping of negative side above the maximum level.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Page 18

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

+

–

➀

min.

max.

+

–

➂

➀

➁

➃

➄

➅

➃

➄

min.

max.

➁

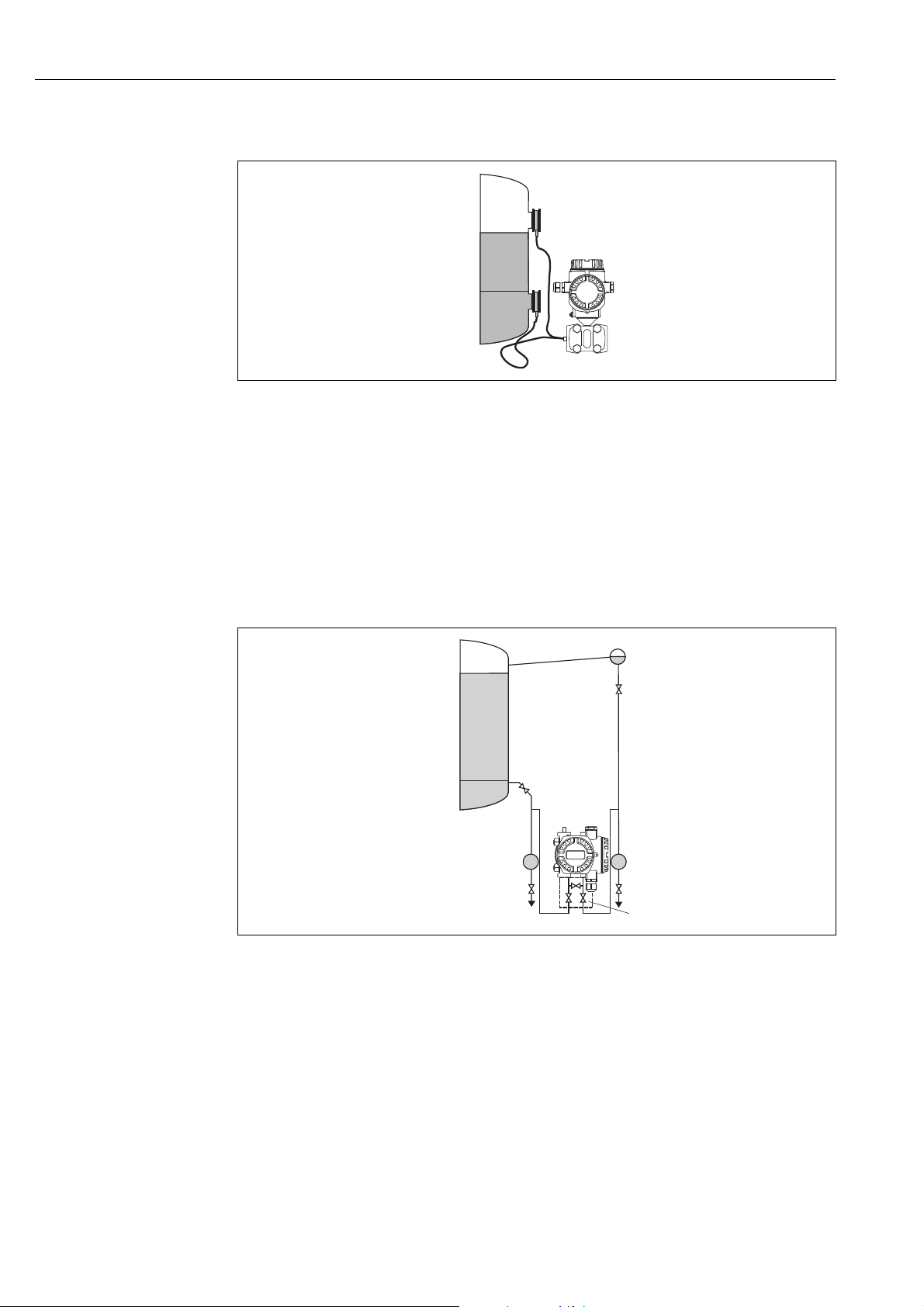

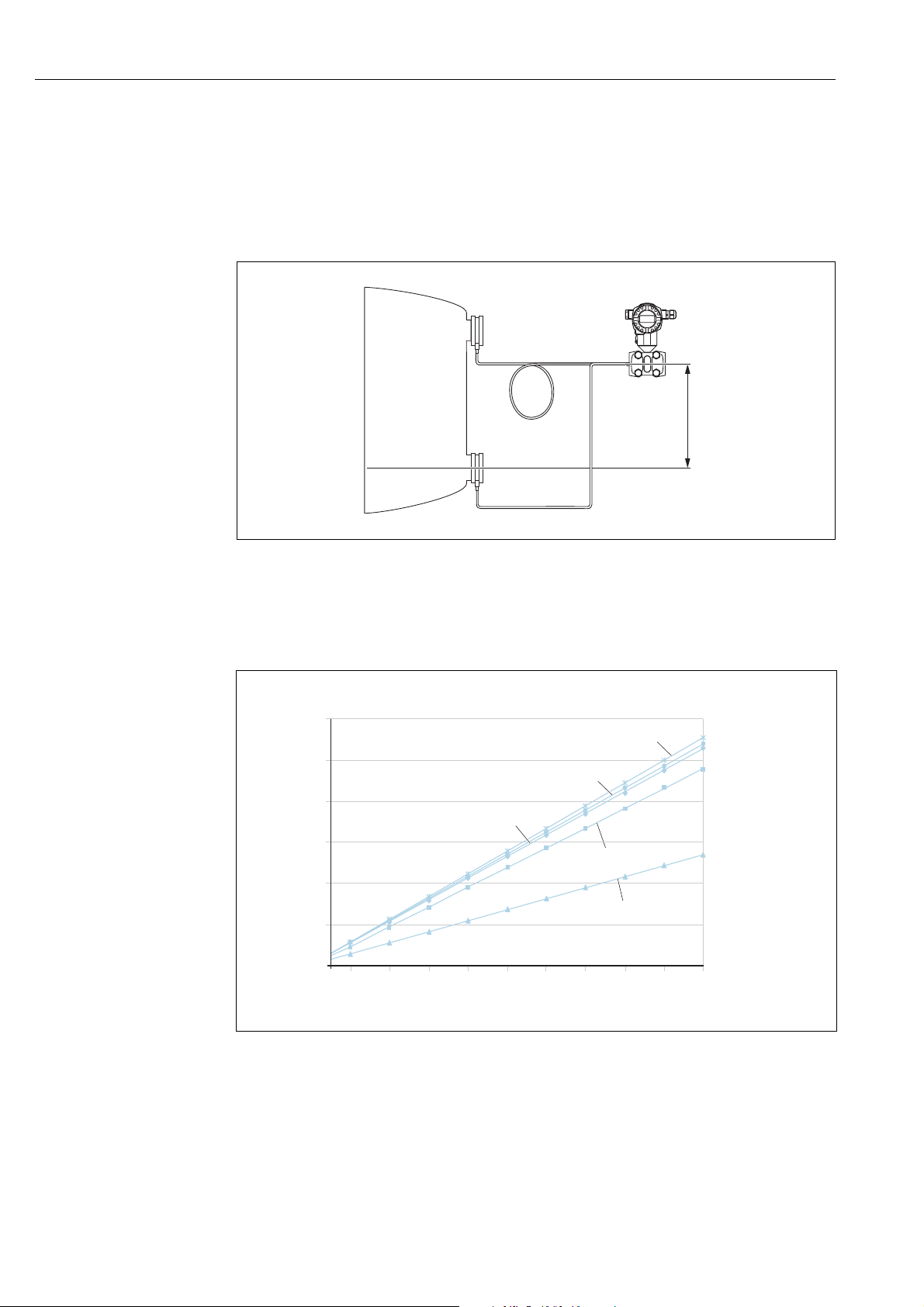

Level measurement in a closed container with FMD78

P01-FMD78xxx-11-xx-xx-xx-000

Fig. 13: Measuring arrangement for level measurement in a closed container with FMD78

1 Deltabar S, here FMD78

• Mount the Deltabar S below the lower diaphragm seal. ä 21, Section 4.3.4 "Installation

instructions for devices with diaphragm seals (FMD78)".

• The ambient temperature should be the same for both capillaries.

Level measurement is only ensured between the upper edge of the lower diaphragm seal and

the lower edge of the upper diaphragm seal.

Level measurement in a closed container with superimposed steam with PMD75

P01-PMD75xxx-11-xx-xx-xx-005

Fig. 14: Measuring arrangement for level measurement in a container with superimposed steam with PMD75

1 Condensate trap

2 Shutoff valves

3 Deltabar S, here PMD75

4Separator

5 Drain valves

6 Three-way valve manifold

• Mount the Deltabar S below the lower measuring connection so that the pressure piping

is always filled with liquid.

• Always connect the impulse piping of negative side above the maximum level.

• A condensate trap ensures constant pressure on the negative side.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

18 Endress+Hauser

Page 19

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

+

–

min.

max.

3

4

2

1

5

+

➂

➀

➁

➂

➃

Level measurement in a closed container with superimposed steam with FMD77

A0024162

Fig. 15: Measuring arrangement for level measurement in a container with superimposed steam with FMD77

1 Condensate trap

2 Shutoff valve

3Separator

4 Drain valve

5 Deltabar S, here FMD77

• Mount the Deltabar S directly on the container. ä 23, Section 4.3.5 "Seal for flange

mounting".

• Always connect the impulse piping of negative side above the maximum level.

• A condensate trap ensures constant pressure on the negative side.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

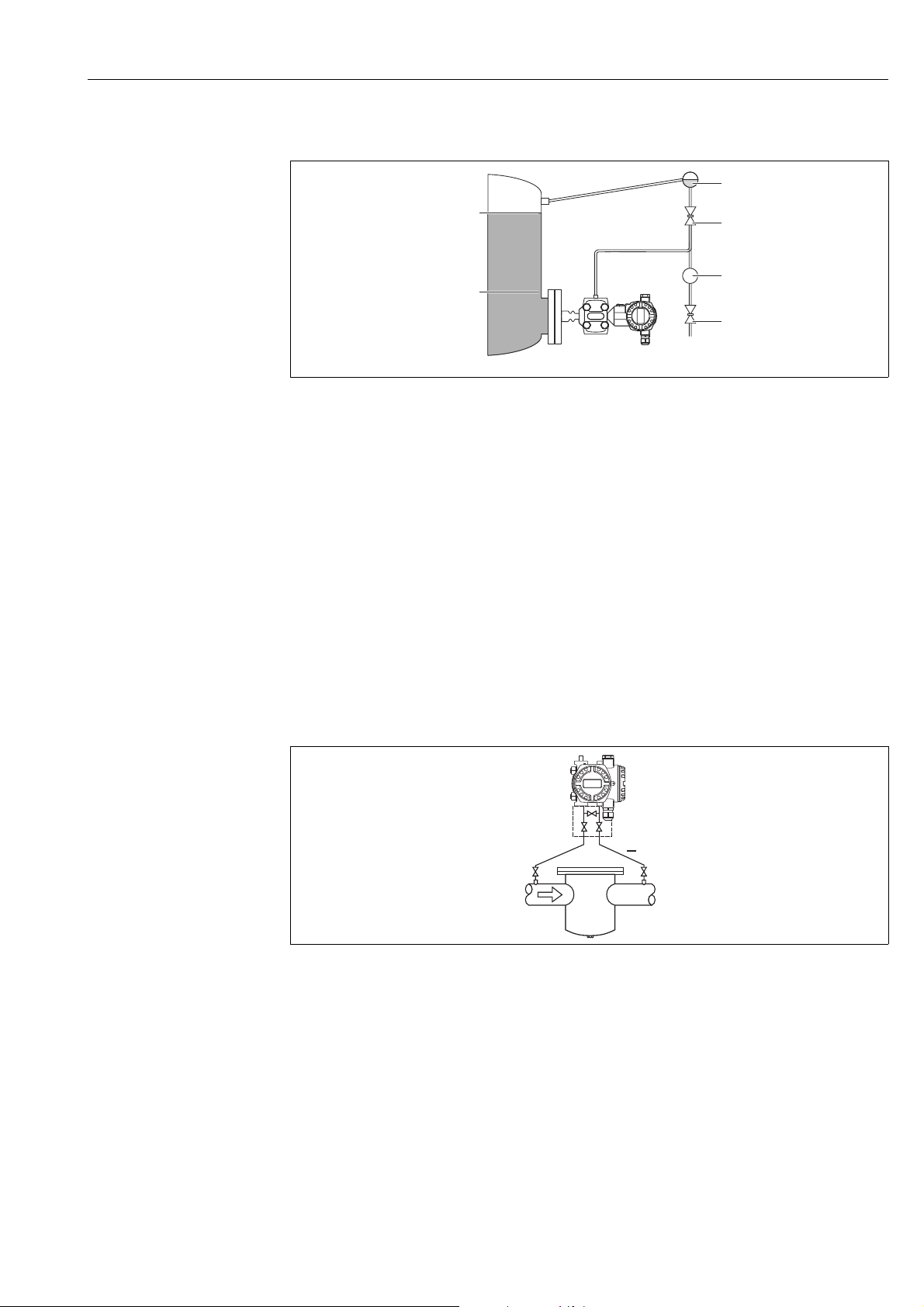

4.3.3 Installation for differential pressure measurement

Differential pressure measurement in gases and steam with PMD75

P01-PMD75xxx-11-xx-xx-xx-006

Fig. 16: Measuring arrangement for differential pressure measurement in gases and steam with PMD75

1 Deltabar S, here PMD75

2 Three-way valve manifold

3Shutoff valves

4 e.g. filter

• Mount the Deltabar S above the measuring point so that the condensate can run off into

the process piping.

Endress+Hauser 19

Page 20

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

+

–

➂

➅

➁➁

➄

➃

➄

➃

➀

+

–

➂

➁

➃

➀

➁

Differential pressure measurement in liquids with PMD75

P01-PMD75xxx-11-xx-xx-xx-007

Fig. 17: Measuring arrangement for differential pressure measurement in liquids with PMD75

1 e.g. filter

2 Shutoff valves

3 Deltabar S, here PMD75

4Separator

5 Drain valves

6 Three-way valve manifold

• Mount the Deltabar S below the measuring point so that the pressure piping is always

filled with liquid and gas bubbles can run back into the process piping.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Differential pressure measurement in gases, steam and liquids with FMD78

P01-FMD78xxx-11-xx-xx-xx-000

Fig. 18: Measuring arrangement for differential pressure measurement in gases, steam and liquids with FMD78

1Diaphragm seal

2 Capillary

3 e.g. filter

4 Deltabar S, here FMD78

• Mount the diaphragm seal with capillaries at the top or on the side on the piping.

• For vacuum applications: mount the Deltabar S below the measuring point. ä 22,

Section 4.3.4, "Vacuum application (FMD78)".

• The ambient temperature should be the same for both capillaries.

20 Endress+Hauser

Page 21

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

NOTICE

NOTICE

+ –

+

–

≥ 100 mm

4.3.4 Installation instructions for devices with diaphragm seals

(FMD78)

• Please note that the hydrostatic pressure of the liquid columns in the capillaries can cause

zero point shift. The zero point shift can be corrected.

• Do not clean or touch the process isolating diaphragm of the diaphragm seal with hard or

pointed objects.

• Do not remove process isolating diaphragm protection until shortly before installation.

Improper handling!

Damage to the device!

‣ A diaphragm seal and the pressure transmitter together form a closed, oil-filled

calibrated system. The fill fluid hole is sealed and may not be opened.

‣ When using a mounting bracket, sufficient strain relief must be ensured for the

capillaries in order to prevent the capillary bending down (bending radius 100

(3.94 in)).

‣ Please observe the application limits of the diaphragm seal filling oil as detailed in the

Technical Information for Deltabar S TI00382P, "Planning instructions for diaphragm

seal systems" section.

In order to obtain more precise measurement results and to avoid a defect in the device,

mount the capillaries as follows:

‣ Vibration-free (in order to avoid additional pressure fluctuations)

‣ Not in the vicinity of heating or cooling lines

‣ Insulate if the ambient temperature is below or above the reference temperature

‣ With a bending radius of 100 mm (3.94 in).

‣ Do not use the capillaries as a carrying aid for the diaphragm seals!

‣ The ambient temperature and length of both capillaries should be the same when using

two-sided diaphragm seal systems.

‣ Two diaphragm seals which are the same (e.g. with regard to diameter, material, etc.)

should always be used for the negative and positive side (standard delivery).

P01-FMD78xxx-11-xx-xx-xx-005

Fig. 19: Mounting Deltabar S, FMD78 with diaphragm seals and capillaries, recommended mounting for vacuum applications:

Endress+Hauser 21

mount pressure transmitter below the lowest diaphragm seal!

Page 22

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

+

–

H1

1

2

3

4

5

A

B

0.0

2.0

4.0

6.0

8.0

10.0

12.0

50 100 300 400 500 600 700 800 900 1000200

[mbar ]

abs

[m]

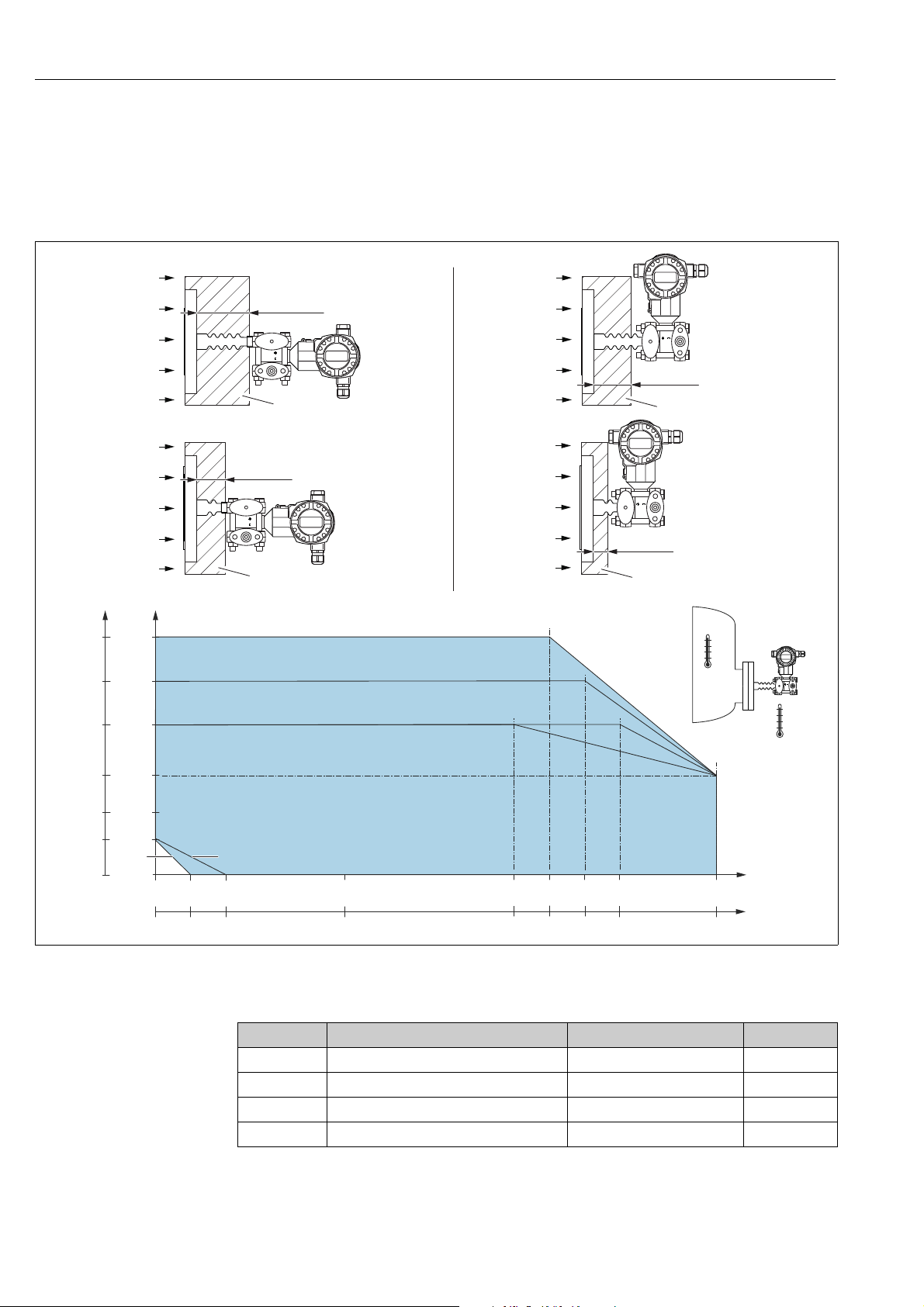

Vacuum application (FMD78)

For applications under vacuum, Endress+Hauser recommends mounting the pressure

transmitter below the diaphragm seal. This prevents vacuum loading of the diaphragm seal

caused by the presence of fill fluid in the capillary.

When the pressure transmitter is mounted above the diaphragm seal, the maximum height

difference H1 in accordance with the illustrations below must not be exceeded.

Fig. 20: Installation above the lower diaphragm seal

The maximum height difference depends on the density of the filling oil and the smallest

ever pressure that is permitted to occur at the diaphragm seal (empty vessel), see illustration

below:

Fig. 21: Diagram of maximum installation height above the lower diaphragm seal for vacuum applications depending on the

A Height difference H1

B Pressure at diaphragm seal

1 Low temperature oil

2 Vegetable oil

3 Silicone oil

4 High-temperature oil

5Inert oil

pressure at the diaphragm seal on the positive side

A0023986-en

A0023983

22 Endress+Hauser

Page 23

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

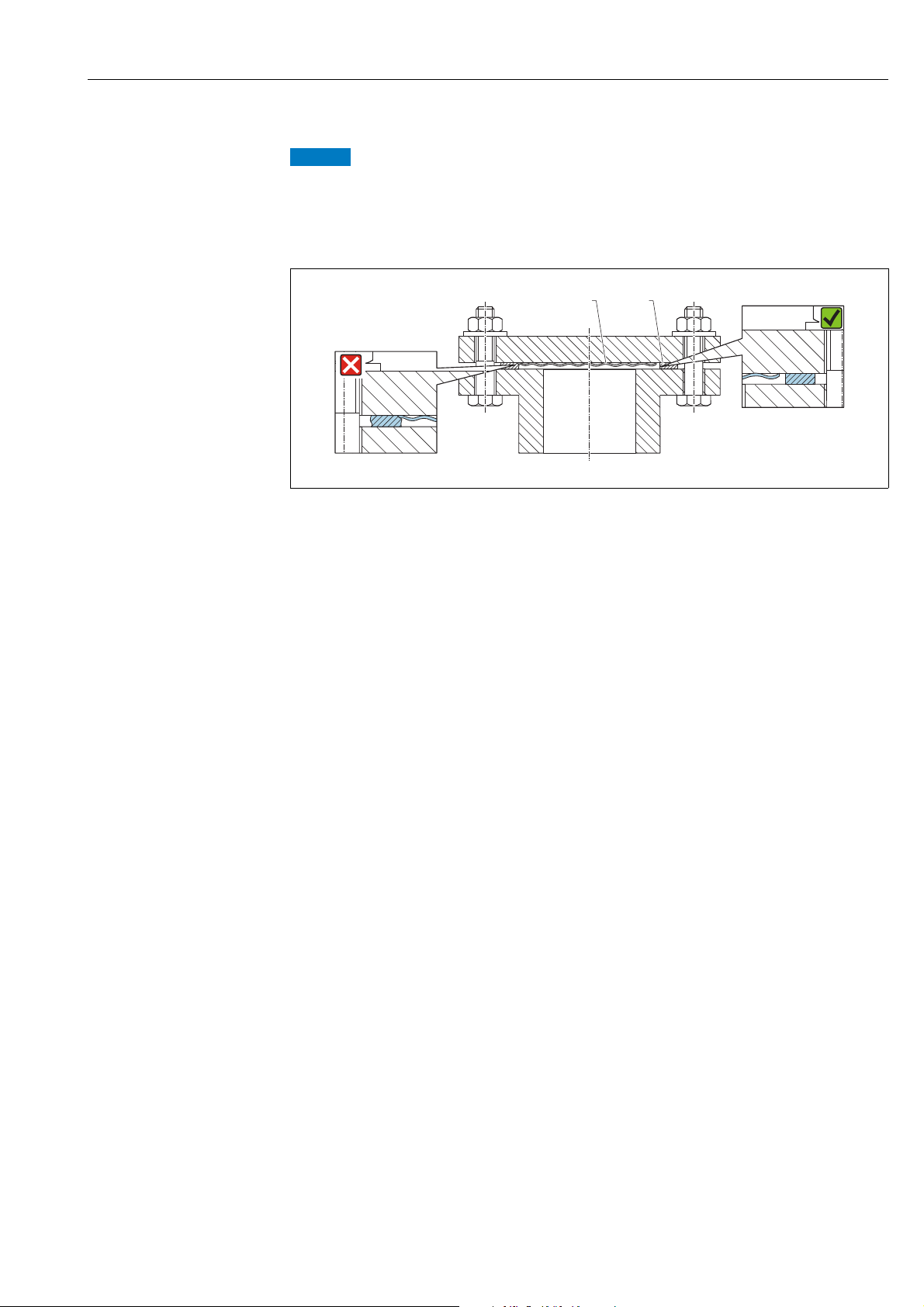

NOTICE

12

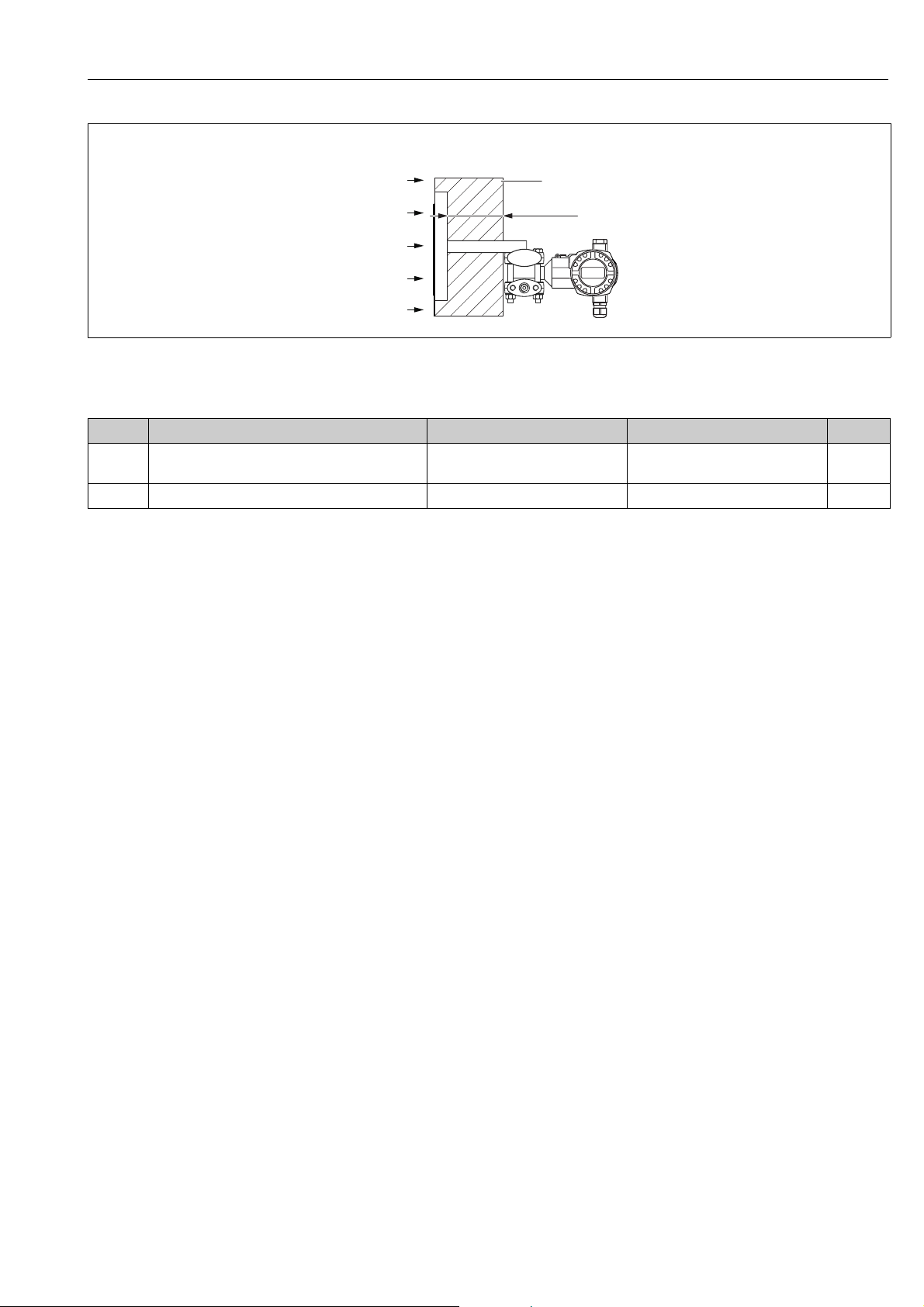

4.3.5 Seal for flange mounting

Distorted measurement results.

The seal is not allowed to press on the process isolating diaphragm as this could affect the

measurement result.

‣ Ensure that the seal is not touching the process isolating diaphragm.

A0017743

Fig. 22:

1 Process isolating diaphragm

2Seal

Endress+Hauser 23

Page 24

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

30 (1.18)

T

a

T

P

53 (2.09)

A

C

B

D

100 (3.94)

77 (3.03)

A, B

T

a

T

P

T

1

1

1

1

p

T

a

+32

60

55

+85

50

45

140

131

+185122

113

200

85

−70

300

392

185

+32

−40

−94

572

+400+752

T

a

[°C]

[°F]

[°C][°F]

T

p

A

B

D

−−−40 35 30

−−−40 31 22

0

0

−40

C

C, D

4.3.6 Heat insulation – FMD77

The FMD77 must only be insulated up to a certain height. The maximum permitted

insulation height applies to an insulation material with a heat conductivity 0.04 W/

(m x K) and to the maximum permitted ambient and process temperature. The data were

determined under the most critical application "quiescent air".

A0025889

1)

Fig. 23: Maximum insulation height

1 Insulation material

Without insulation, the ambient temperature decreases by 5 K.

Position Design Temperature isolator Option

A Transmitter horizontally long MA

B Transmitter vertical long MB

C Transmitter horizontally short MC

D Transmitter vertical short MD

1) Product Configurator, order code for "Process connection"

24 Endress+Hauser

Page 25

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

T

U

T

P

E

+

–

100 (3.94)

1

A0023984

Fig. 24: Maximum insulation height

1 Insulation material

Position Design Ambient temperature T

E U-bracket, Transmitter horizontally

70 °C (158 °F) max. 350 °C (662 °F) , depending on

(for devices which require a CRN approval)

U

Process temperature T

P

the diaphragm seal filling oil used

Option

2)

F Compact version, Transmitter vertical - - 5, 6, 7, 8

1) Product Configurator, order code for "Process connection"

2) In combination with CSA approval.

1)

Endress+Hauser 25

Page 26

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

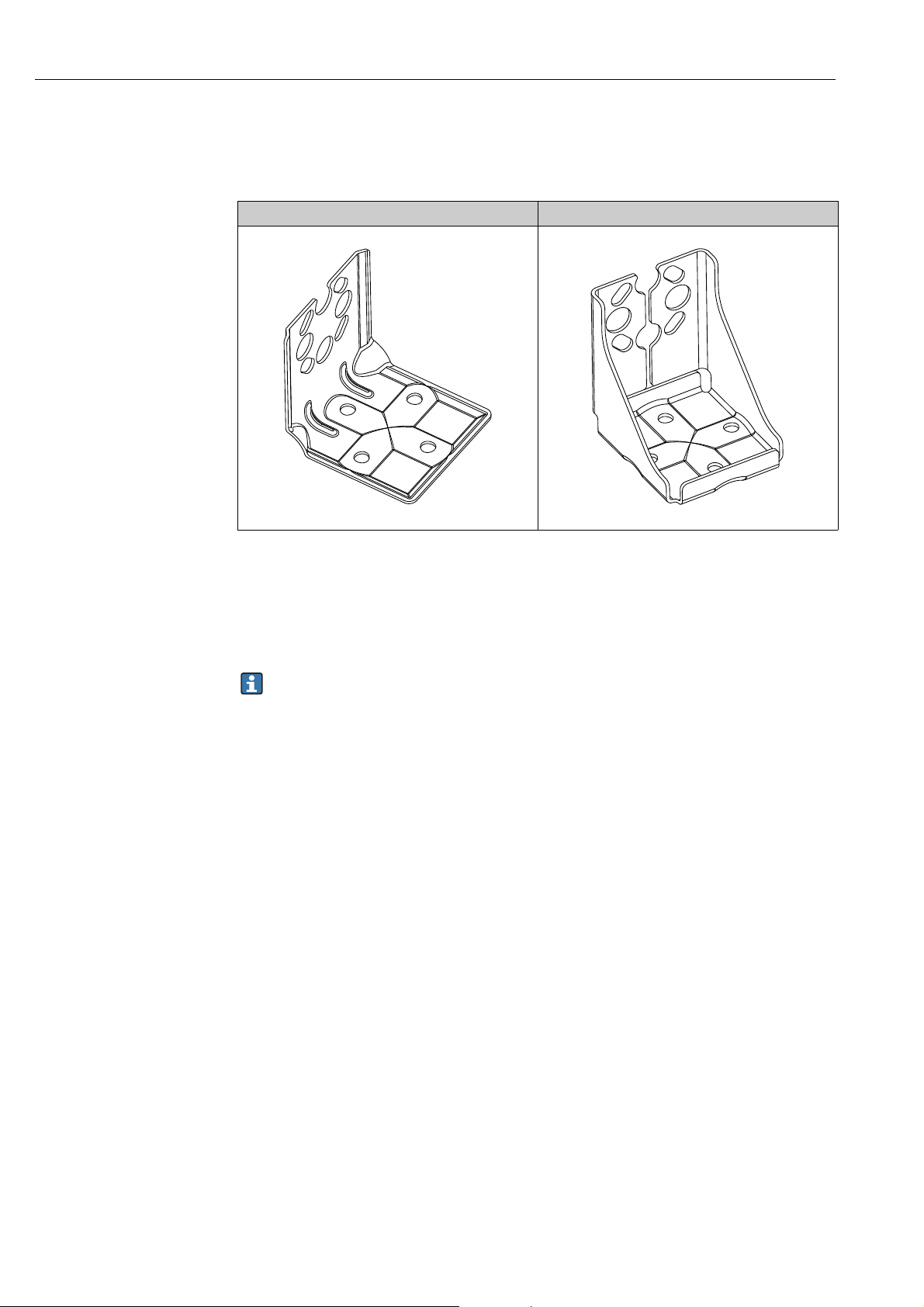

4.3.7 Wall and pipe-mounting (optional)

Endress+Hauser offers the following mounting brackets for installing the device on pipes or

walls:

Standard design Heavy duty design

A0031326 A0031327

The standard mounting bracket version is not suitable for use in an application subject to

vibrations.

The vibration resistance of the reinforced version of the mounting bracket has been tested

according to IEC 61298-3, see the "Vibration resistance" section in the technical

documentation TI00382P.

When using a valve block, the block's dimensions must be taken into account.

Bracket for wall and pipe mounting including retaining bracket for pipe mounting and two

nuts.

material of the screws used to secure the device depend on the order code.

Technical data (e.g. dimensions or order numbers for screws) see accessory document

SD01553P/00/EN.

Please note the following when mounting:

• To prevent the mounting screws from scoring, lubricate them with a multi-purpose grease

prior to mounting.

• In the case of pipe mounting, the nuts on the bracket must be tightened uniformly with a

torque of at least 30 Nm (22.13 lbf ft).

• For installation purposes, only use the screws with item number (2) (see the following

diagram).

26 Endress+Hauser

Page 27

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

NOTICE

1

2

1

2

Incorrect handling!

Damage of the device!

‣ Disassembly of the screws with item number (1) is not permissible under any

circumstances and will result in loss of warranty.

A0025335

Endress+Hauser 27

Page 28

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

r ³ 120 mm

1

2

4

5

6

7

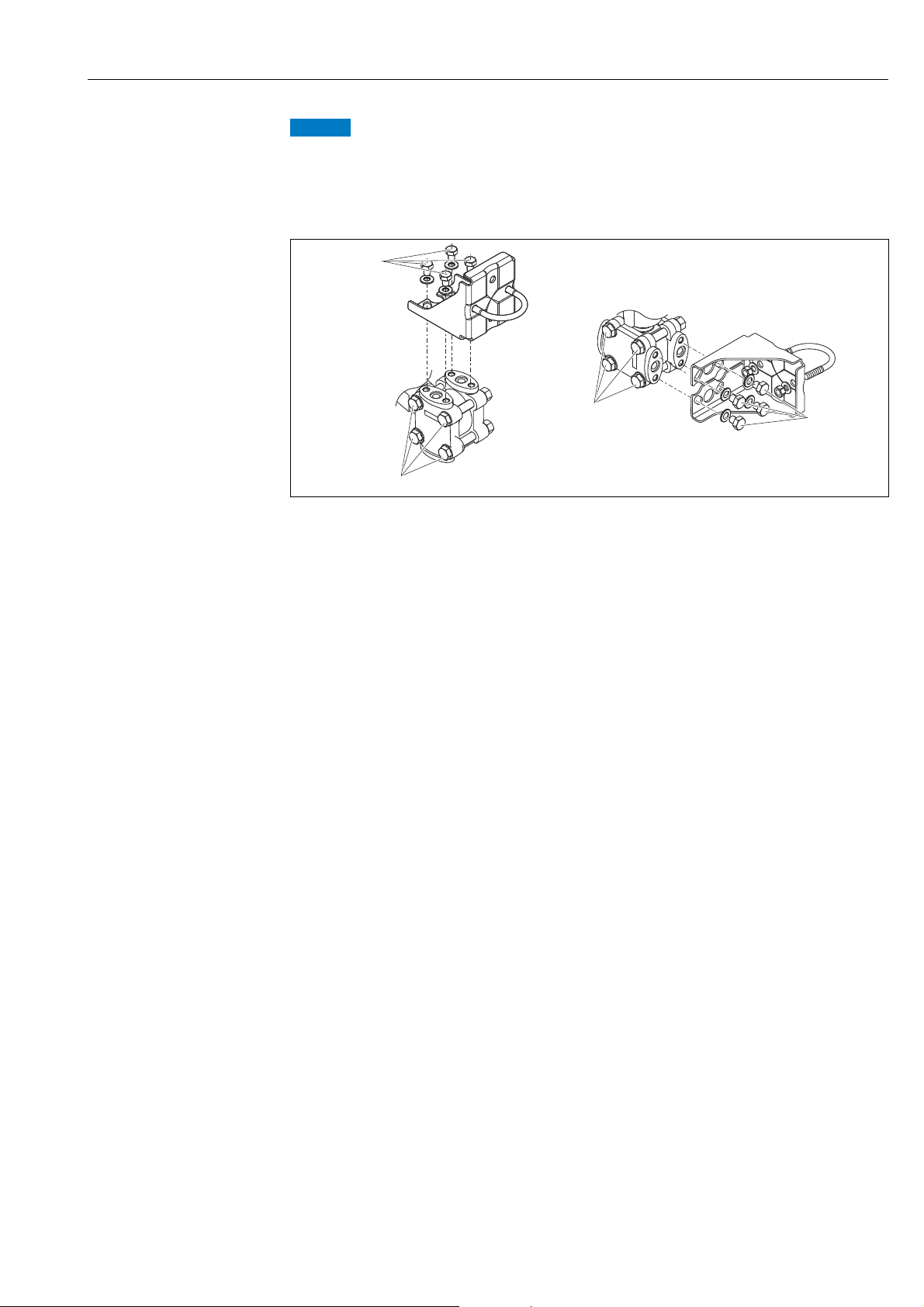

4.3.8 Assembling and mounting the "separate housing" version

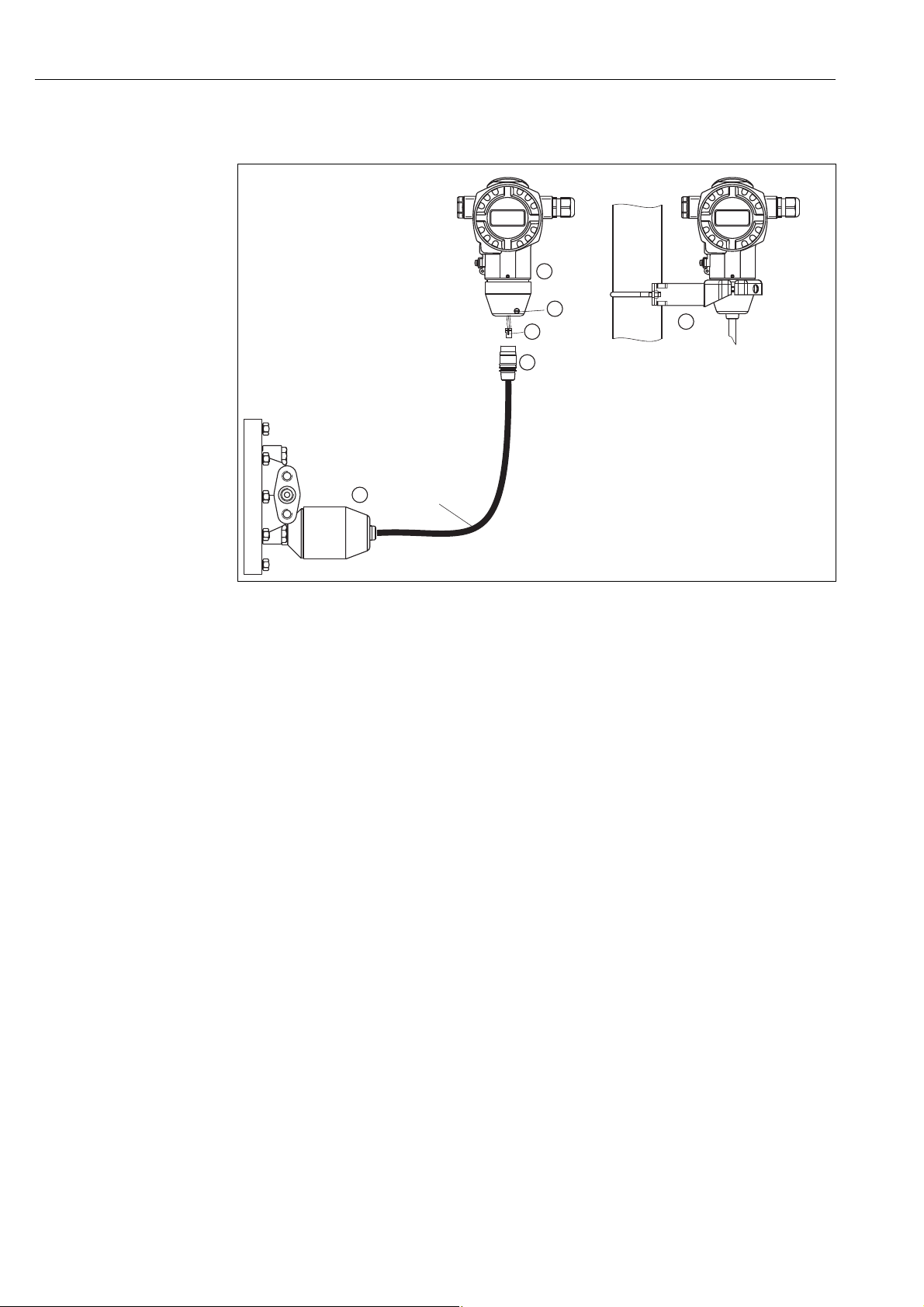

P01-xMD7xxxx-11-xx-xx-xx-011

Fig. 25: "Separate housing" version

1 In the "separate housing" version, the sensor is supplied with the process connection and cable ready-fitted.

2 Cable with connection jack

4Plug

5Locking screw

6 Housing fitted with housing adapter, included

7 Mounting bracket suitable for wall and pipe mounting, included

Assembly and mounting

1. Insert the 10-pin connector (item 4) into the corresponding connection jack of the cable

(item 2).

2. Plug the cable into the housing adapter (item 6).

3. Tighten the locking screw (item 6).

4. Mount the housing on a wall or pipe using the mounting bracket (item 7).

When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of

at least 5 Nm (3.69 lbs ft).

Mount the cable with a bending radius (r) 120 mm (4.72 in).

28 Endress+Hauser

Page 29

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Installation

NOTICE

NOTICE

T14

T15

T17

2 3

+

–

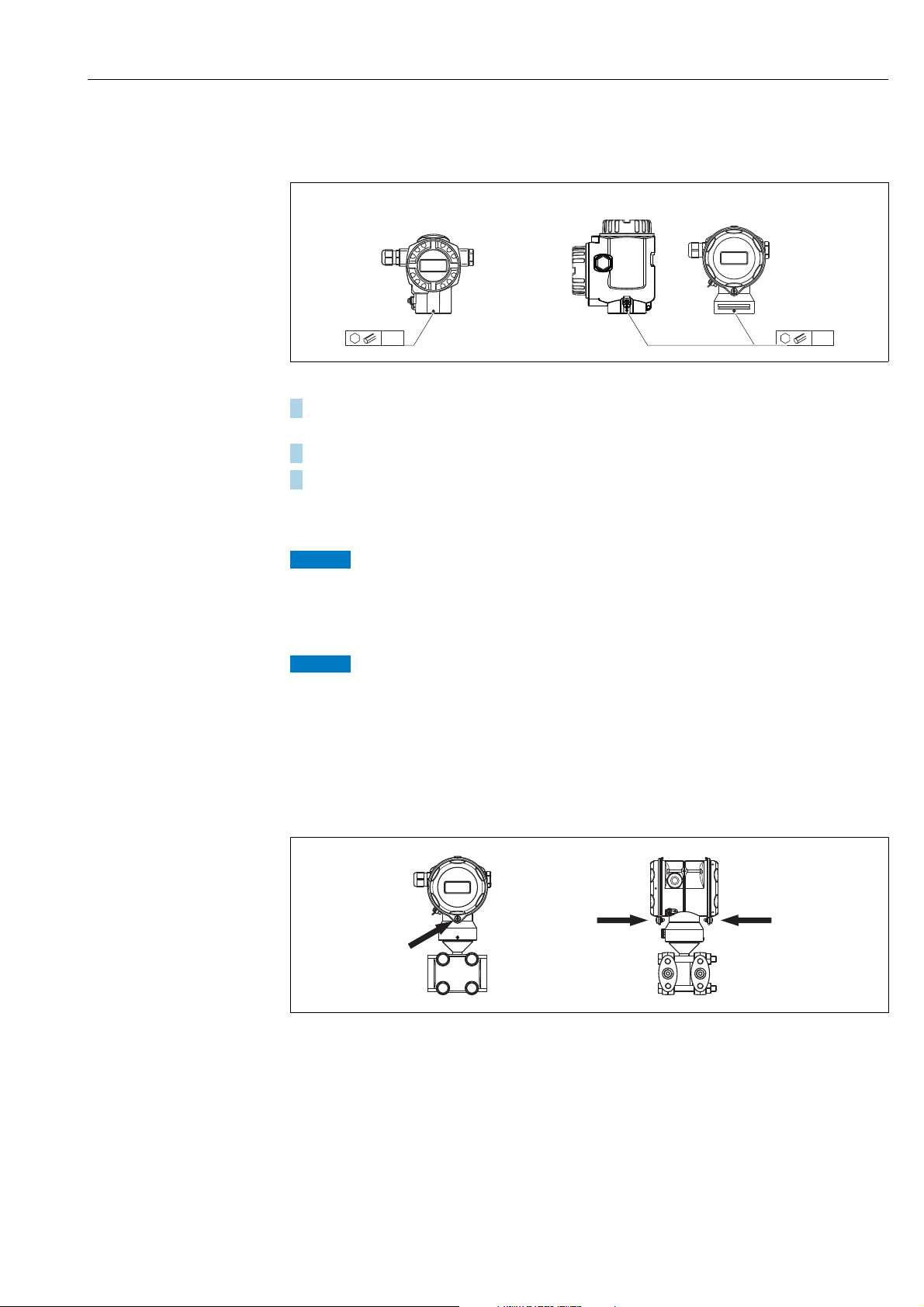

4.3.9 Rotating the housing

The housing can be rotated up to 380° by loosening the Allen screw.

A0019996

1. T14 housing: Loosen setscrew with a 2 mm (0.08 in) Allen key.

T15 andT17 housing: Loosen setscrew with a 3 mm (0.12 in) Allen key.

2. Rotate housing (max. up to 380 °).

3. Retighten setscrew with 1 Nm (0,74 lbf ft.

4.3.10 Closing the housing cover

Devices with EPDM cover seal - transmitter leakiness!

Mineral-based, animal-based or vegetable-based lubricants cause the EPDM cover seal to

swell and the transmitter to become leaky.

‣ The thread is coated at the factory and therefore does not require any lubrication.

The housing cover can no longer be closed.

Damaged thread!

‣ When closing the housing cover, please ensure that the thread of the cover and housing

are free from dirt, e.g. sand.If you feel any resistance when closing the cover, check the

thread on both again to ensure that they are free from dirt.

Closing the covers on the hygienic stainless steel housing (T17)

Fig. 26: Closing the covers

The covers for the terminal and electronics compartment are hooked into the housing and

closed with a screw. These screws should be tightened handtight (2 Nm (1.48 lbf ft)) to the

stop to ensure that the covers sit tightly.

Endress+Hauser 29

P01-PMD75xxx-17-xx-xx-xx-000

Page 30

Installation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

4.4 Post-installation check

After installing the device, carry out the following checks:

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

• Are all locking screws and vent valves firmly tightened?

30 Endress+Hauser

Page 31

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Wiring

WARNING

!

WARNING

!

➀

➁

➂

➃

➄

FF FF

FF FF

5 Wiring

5.1 Connecting the device

Risk of electric shock!

If the operating voltage is > 35 VDC: Dangerous contact voltage at terminals.

‣ In a wet environment, do not open the cover if voltage is present.

Limitation of electrical safety due to incorrect connection!

• Risk of electric shock and/or explosion in hazardous areas! In a wet environment, do not

open the cover if voltage is present.

• When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or

Installation or Control Drawings.

• Devices with integrated overvoltage protection must be grounded.

• Protective circuits against reverse polarity, HF influences and overvoltage peaks are

installed.

• The supply voltage must match the power supply on the nameplate. ( ä 10,

Section 3.2.1 "Nameplates".)

• Switch off the supply voltage before connecting the device.

• Remove the housing cover of the terminal compartment.

• Guide the cable through the gland. For cable specifications, ä 32, Section 5.2.4.

• Connect the device in accordance with the following diagram.

• Screw down the housing cover.

• Switch on the supply voltage.

P01-xMx7xxxx-04-xx-xx-xx-009

Fig. 27: Electrical connection of FOUNDATION Fieldbus

1Housing

2 Internal ground terminal

3 External ground terminal

4 Supply voltage, for version in non-hazardous area = 9 to 32 V DC

5 Devices with integrated overvoltage protection are labeled OVP (overvoltage protection) here.

Please refer also to Section 5.2.1 "Supply voltage",

ä

32.

Endress+Hauser 31

Page 32

Wiring Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

WARNING

!

4

2

31

5.1.1 Connecting devices with 7/8" plug

PIN assignment for 7/8" connector PIN Meaning

PIN Meaning

1Signal –

2Signal +

3Shield

4Not assigned

A0011176

5.2 Connecting the measuring unit

For further information on the network structure and grounding and for further bus system

components such as bus cables, see the relevant documentation, e.g. Operating Instructions

BA00013S "FOUNDATION Fieldbus Overview" and the FOUNDATION Fieldbus Guideline.

5.2.1 Supply voltage

• Version for non-hazardous area: 9 to 32 V DC

Supply voltage might be connected!

Risk of electric shock and/or explosion!

‣ When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or

Installation or Control Drawings.

‣ All explosion protection data are given in separate documentation which is available

upon request. The Ex documentation is supplied as standard with all devices approved for

use in explosion hazardous areas.

5.2.2 Current consumption

15.5 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause 21.

5.2.3 Terminals

• Supply voltage and internal ground terminal: 0.5 to 2.5 mm2 (20 to 14 AWG)

• External ground terminal: 0.5 to 4 mm

5.2.4 Cable specification

• Use a twisted, shielded two-wire cable, preferably cable type A.

• Outer cable diameter: 5 to 9 mm (0.2 to 0.35 in)

2

(20 to 12 AWG)

For further information on the cable specifications, see Operating Instructions BA00013S

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2

(MBP).

32 Endress+Hauser

Page 33

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Wiring

NOTICE

5.2.5 Grounding and shielding

Deltabar S must be grounded, for example by means of the external ground terminal.

Different grounding and shielding installation methods are available for FOUNDATION

Fieldbus networks such as:

• Isolated installation (see also IEC 61158-2)

• Installation with multiple grounding

• Capacitive installation

5.3 Overvoltage protection (optional)

Device could be destroyed!

Devices with integrated overvoltage protection must be earthed.

Devices showing version "M" in feature 100 "Additional options 1" or feature 110 "Additional

options 2" in the order code are equipped with overvoltage protection (see also Technical

Information TI00382P "Ordering information").

• Overvoltage protection:

– Nominal functioning DC voltage: 600 V

– Nominal discharge current: 10 kA

• Surge current check î = 20 kA as per DIN EN 60079-14: 8/20 s satisfied

• Arrester AC current check I = 10 A satisfied

5.4 Post-connection check

Perform the following checks after completing electrical installation of the device:

• Does the supply voltage match the specifications on the nameplate?

• Is the device connected as per Section 5.1?

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

As soon as voltage is applied to the device, the green LED on the electronic insert lights up

for a few seconds or the connected onsite display lights up.

Endress+Hauser 33

Page 34

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

6Operation

Feature 20 "Output; operation" in the order code provides you with information on the

operating options available to you.

Versions in the order code Operation

P FOUNDATION Fieldbus; external operation, LCD Via onsite display and 1 key on the exterior of

the device

Q FOUNDATION Fieldbus; internal operation, LCD Via onsite display and 1 key on the inside of the

device

R FOUNDATION Fieldbus; internal operation Without onsite display, 1 key on the inside of

6.1 Onsite display (optional)

A 4-line liquid crystal display (LCD) is used for display and operation. The onsite display

shows measured values, fault messages and notice messages. The display of the device can

be turned in 90° steps. Depending on the orientation of the device, this makes it easy to

operate the device and read the measured value.

Functions:

• 8-digit measured value display including sign and decimal point, unit display

• Bar graph as graphic display of the current pressure measured value in relation to the set

pressure range in the Pressure Transducer Block. The pressure range is set by means of the

SCALE_IN parameter.

• Easy and complete menu guidance by dividing the parameters into several levels and

groups

•Menu guidance

The onsite display is available in English. Needless to say, the device can also be operated

in 6 languages (de, en, fr, es, jp, ch) via the DTM or EDD. The FieldCare program is an E+H

DTM operating tool and can be acquired from endress.com.

• Each parameter has a 3-digit ID to aid navigation

• Option of configuring the display according to individual requirements and preferences,

such as alternating display, contrast setting, display of other measured values such as

sensor temperature

• Comprehensive diagnostic functions (fault and warning message, maximum indicator,

etc.)

• Rapid and safe commissioning using Quick Setup menus

the device

34 Endress+Hauser

Page 35

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Operation

E

+

–

Bargraph

Operating keys

Symbol

Bargraph

ValueFunction name

Unit

Header line

Information

line

Main line

Parameter

Identification

number

Editing modes

Selection

options

Value that

can be edited

Current measured

value

Measured value display

P01-xxxxxxxx-07-xx-xx-en-011

The following table illustrates the symbols that can appear on the onsite display. Four

symbols can occur at one time.

Symbol Meaning

Alarm symbol

– Symbol flashing: warning, device continues measuring.

– Symbol permanently lit: error, device does not continue measuring.

Note: The alarm symbol may overlie the tendency symbol.

Lock symbol

The operation of the device is locked. Unlock device, ä 57, Section 6.7 "Locking/

unlocking operation".

Communication symbol

Data transfer via communication

Square root symbol

Active measuring mode "Flow measurement"

Simulation symbol

Simulation mode is activated. DIP switch 2 for simulation is set to "On".

See also Section 6.2.1 "Position of the operating elements" and ä 59,

Section 6.8 "Simulation".

Tendency symbol (increasing)

The primary value of the Pressure Transducer Block is increasing.

Tendency symbol (decreasing)

The primary value of the Pressure Transducer Block is decreasing.

Tendency symbol (constant)

The primary value of the Pressure Transducer Block has remained constant over the

past few minutes.

Endress+Hauser 35

Page 36

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

➀

0%

Zero

HW

21

PC

1

2

➀➁

➃

on

off

➂

➄

➅

Sim

.

Sensor

on

off

Simulation

0%

Zero

Display

Histo

ROM

0%

Zero

1

2

on

off

Sim.

6.2 Operating elements

6.2.1 Position of the operating elements

On the aluminum housing (T14/T15), the operating key is located either under the

protective flap on the exterior of the device or inside on the electronic insert. In the case of

the hygienic stainless steel housing (T17), the operating key is always inside on the

electronic insert. In addition, there are three operating keys on the optional onsite display.

P01-xMD7xxxx-19-xx-xx-xx-074

Fig. 28: Operating key external, under the protective flap

1 Operating key for position adjustment (zero point

correction) and total reset

Fig. 29: Operating keys, internal

1 Green LED to indicate value is accepted

2 Operating key for position adjustment (zero point

3 Slot for optional display

4 Slot for optional HistoROM

5 DIP switch for locking/unlocking parameters relevant to

6 DIP switch for simulation mode

6.2.2 Function of operating elements

Key(s) Meaning

– Position adjustment (zero point correction): press key for at least 3 seconds. The

LED on the electronic insert lights up briefly if the pressure applied has been

accepted for position adjustment.

See also the following section "Performing position adjustment on site".

P02-xxxxxxxx-19-xx-xx-xx-107

P01-xxxxxxxx-19-xx-xx-xx-134

– Total reset: press key for at least 12 seconds. The LED on the electronic insert

lights up briefly if a reset is being carried out.

– DIP switch 1: for locking/unlocking parameters relevant to the measured value.

Factory setting: off (unlocked)

ä 57, Section 6.7 "Locking/unlocking operation".

– DIP switch 2: for simulation mode

Factory setting: off (simulation mode off)

ä 59, Section 6.8 "Simulation"

correction) and total reset

the measured value

®

/M-DAT

P01-xxxxxxxx-19-xx-xx-xx-106

Performing position adjustment on site

36 Endress+Hauser

• Operation must be unlocked. ä 57, Section 6.7 "Locking/unlocking operation".

• The device is configured for the Pressure measuring mode as standard.

– Operation via FF configuration program: In the Pressure Transducer Block, change the

measuring mode by means of the PRIMARY_VALUE_TYPE and LINEARIZATION

parameters.

– Operation via digital communication: change the measuring mode by means of the

MEASURING MODE parameter.

– You can change the measuring mode by means of the MEASURING MODE parameter.

ä 64, Section 7.4 "Selecting the language and measuring mode".

Page 37

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Operation

1

2

on

off

Sim.

• The pressure applied must be within the nominal pressure limits of the sensor. See

information on the nameplate.

Perform position adjustment:

1. Pressure is present at device.

2. Press key for at least 3 seconds.

3. If the LED on the electronic insert lights up briefly, the pressure applied has been

accepted for position adjustment.

If the LED does not light up, the pressure applied was not accepted. Observe the input

limits. For error messages, ä 93, Section 9.2 "Diagnostic information on local

display".

6.2.3 Function of the operating elements – onsite display connected

Key(s) Meaning

– Navigate upwards in the picklist

– Edit numerical values or characters within a function

– Navigate downwards in the picklist

– Edit numerical values or characters within a function

–Confirm entry

–Go to next item

Contrast setting of onsite display: increase

O

O

S

F

and

F

and

S

O

F

and

S

P01-xxxxxxxx-19-xx-xx-xx-134

Contrast setting of onsite display: reduce

ESC functions:

– Exit the editing mode without saving the altered value

– You are in the menu within a function group: the first time you press the keys

simultaneously, you go back one parameter in the function group. Every

subsequent time you press the keys simultaneously, you go up one level in the

menu.

– You are in the menu on a selection level: every time you press the keys

simultaneously, you go up one level in the menu.

Note: For the terms function group, level, selection level, ä 51, Section 6.4.1

– DIP switch 1: for locking/unlocking parameters relevant to the measured value.

Factory setting: off (unlocked)

– DIP switch 2: for the simulation mode Factory setting: off (simulation mode off)

Endress+Hauser 37

Page 38

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

FF-H1

FF-H1

BT

BT

PS

PS

BT

SB

BT

FF-HSE

Industrial Network

LD

6.3 FOUNDATION Fieldbus interface

6.3.1 System architecture

The following diagram shows two typical examples of a FOUNDATION Fieldbus network

with the associated components.

P01-xxxxxxxx-02-xx-xx-xx-001

Fig. 30: FOUNDATION Fieldbus system architecture with associated components

FF-HSE: High Speed Ethernet, FF-H1: FOUNDATION Fieldbus-H1, LD: Linking Device FF-HSE/FF-H1, PS: Bus Power Supply, SB: Safety

Barrier, BT: Bus Terminator

The system can be connected in the following ways:

– A linking device makes the connection to higher-order fieldbus levels (e.g. High Speed Ethernet (HSE)) possible.

– An FF-H1 connecting card is needed for direct connection to a process control system.

Further information on FOUNDATION Fieldbus can be found in Operating Instructions

BA00013S "FOUNDATION Fieldbus Overview, Installation and Commissioning Guidelines",

the FOUNDATION Fieldbus Specification or on the Internet at "http://www. fieldbus.org".

38 Endress+Hauser

Page 39

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Operation

6.3.2 Number of devices

• Endress+Hauser Deltabar S devices meet the requirements specified by the FISCO model.

• Due to the low current consumption, the following can be operated at one bus segment

when installation is performed

according to FISCO:

Up to HW version 1.10:

– Up to 7 Deltabar S devices for Ex ia, CSA and FM IS applications

– Up to 25 Deltabar S devices in all other applications, e.g. in non-hazardous areas, Ex nA

etc.

As of HW version 02.00:

– Up to 6 Deltabar S devices for Ex ia, CSA and FM IS applications

– Up to 24 Deltabar S devices in all other applications, e.g. in non-hazardous areas, Ex nA

etc.

The maximum number of measuring devices at one bus segment is defined by their current

consumption, the performance of the bus coupler, and the required bus length.

As of hardware version 1.10, you will find a label in the device on the electronic insert.

6.3.3 Operation

You can obtain special configuration and operating programs from various manufacturers

for the configuration, such as the FieldCare operating program from Endress+Hauser

ä 57, Section 6.6 "FieldCare". These configuration programs make it possible to configure

FF functions and all the device-specific parameters. The predefined function blocks allow

uniform access to all the network and device data.

6.3.4 Network configuration

You require the following to configure a device and integrate it into an FF network:

• An FF configuration program

• The Cff file (Common File Format: *.cff, *.fhx)

• The device description (Device Description: *.sym, *.ffo, *.sy5, *.ff5)

Pre-defined standard DDs, which can be obtained from FOUNDATION Fieldbus, are available

for the basic functions of measuring devices. You require the device-specific DD to be able to

access all the functions.

The files for Deltabar S can be acquired as follows:

• Internet Endress+Hauser: http://www.de.endresss.com Search for FOUNDATION

Fieldbus

• Internet FOUNDATION Fieldbus: http://www.fieldbus.org

• On CD-ROM from Endress+Hauser, order number: 56003896

The device is integrated into the FF network as follows:

• Start the FF configuration program.

• Download the Cff and device description files (ffo, *.sym, *.cff or *.fhx files) to the system.

• Configure the interface, see Note.

• Configure the device for the measuring task and for the FF system.

• For more in-depth information on integrating the device into the FF system, see the

description for the configuration software used.

• When integrating the field devices into the FF system, make sure you are using the right

files. You can read out the required version by means of the DEV_REV and DD_REV

parameters in the Resource Block.

Endress+Hauser 39

Page 40

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

–

–

RS_XXXXXXXXXXX (RB2)

EH_DeltabarS-XXXXXXXXXXXXXXXX

➀➁

TRD1_(PCD)XXXXXXXXXXX

SERVICE_(SERVICE)XXXXXXXXXXX

DIAGNOSTIC_(DIAGNOSTIC)XXXXXXXXXXX

DISPLAY_ (DISP)XXXXXXXXXXX

AI1_ (AI)XXXXXXXXXXX

AI2_ (AI)XXXXXXXXXXX

DO_(DO)XXXXXXXXXXX

PID_(PID)XXXXXXXXXXX

ARTH_ (ARB)XXXXXXXXXXX

CHAR_ (SCB)XXXXXXXXXXX

ISEL_ (ISB)XXXXXXXXXXX

INTG_ (ITB)XXXXXXXXXXX

AALM_ (AALB)XXXXXXXXXXX

DI_ (DI)XXXXXXXXXXX

DP_FLOW_(DPFLOW)XXXXXXXXXXX

AI3_ (AI)XXXXXXXXXXX

6.3.5 Device identification and addressing

FOUNDATION Fieldbus identifies the device using its ID code and automatically assigns it a

suitable field address. The identity code cannot be changed.

The device appears in the network display once you have started the FF configuration

program and integrated the device into the network. The blocks available are displayed

under the device name.

If the device description has not yet been loaded, the blocks report "Unknown" or "(UNK)".

Deltabar S reports as follows:

P01-xMx7xxxx-05-xx-xx-xx-005

Fig. 31: Typical Deltabar S display in a configuration program after the connection has been established

1Device name

2 Serial number

6.3.6 Deltabar S block model

With FOUNDATION Fieldbus, all the device parameters are categorized according to their

functional properties and task and are generally assigned to three different blocks.

A FOUNDATION Fieldbus device has the following block types:

• A Resource Block (device block):

This block contains all the device-specific features of the device.

• One or more Transducer Blocks

A Transducer Block contains all the measuring and device-specific parameters of the

device. The measuring principles, such as pressure or totalizers, are mapped in the

40 Endress+Hauser

Transducer Blocks.

• One or more function blocks:

Function blocks contain the automation functions of the device. A distinction is made

between different function blocks such as the Analog Input Block or Proportional Integral

Differential Block (PID). Each of these function blocks is used to execute different

application functions.

The function blocks can be connected by means of an FF configuration program, depending

on the automation task. The device thus takes on simple control functions, thereby relieving

the workload on the higher-order process control system.

Deltabar S has the following blocks:

• Resource Block (device block)

Page 41

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Operation

•5 Transducer Blocks

– Pressure Transducer Block (TRD)

This Block supplies the output variables PRIMARY_VALUE and SECONDARY_VALUE. It

contains all the parameters to configure the measuring device for the measuring task

such as measuring mode selection, linearization function and unit selection.

– Service Transducer Block

This Block supplies the output variables COUNTER P_PMAX, PRESSURE_1_ MAX_

RESETABLE and PRESSURE_1_AFTER_DAMPING. It also includes all the counters for

measuring range overshoot/undershoot for pressure and temperature, minimum and

maximum measured values for pressure and temperature and the HistoROM function.

– DP Flow Block

This Block supplies the output variable TOTALIZER_1_VALUE/TOTALIZER 1. It

contains all the parameters that are needed to configure this totalizer.

– Display Transducer Block

This Block does not return any output variables. It contains all the parameters for

configuring the onsite display such as DISPLAY_CONTRAST.

– Diagnostic Transducer Block

This Block does not return any output variables. It contains

– the simulation function for the Pressure Transducer Block

– parameters to configure the alarm response

– parameters to set the user limits for pressure and temperature.

• 9 function blocks

– 3 Analog Input Blocks (AI)

– Discrete Output Block (DO)

– Discrete Input Block (DI)

– PID Block (PID)

– Arithmetic Block (ARB)

– Signal Characterizer Block (SCB)

– Input Selector Block (ISB)

– Analog Alarm Block (AALB)

– Integrator Block (IT)

In addition to the pre-instantiated blocks already mentioned, the following blocks can also

be instantiated:

• 3 Analog Input Blocks (AI)

• 1 Discrete Output Block (DO)

•1 PID Block (PID)

• 1 Arithmetic Block (ARB)

• 1 Signal Characterizer Block (SCB)

• 1 Input Selector Block (ISB)

• 1 Analog Alarm Block (AALB)

• Integrator Block (IT)

A total of 20 blocks can be instantiated in Deltabar S altogether, including the blocks already

instantiated. For instantiating blocks, see the appropriate Operating Instructions of the

configuration program used.

Endress+Hauser Guideline BA00062S.

The guideline provides an overview of the standard function blocks that are described in

FOUNDATION Fieldbus Specifications FF 890 - 894.

It is designed to help operators use the blocks implemented in the Endress+Hauser field

devices.

Endress+Hauser 41

Page 42

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

CAUTION

!

Pressure

Tra nsducer Block

Analog Input Block 1

CHANNEL = 1

L_TYPE = Direct

Analog Input Block 2

CHANNEL = 2

L_TYPE = Direct

Analog Input Block 3

CHANNEL = 6

L_TYPE = Direct

DP Flow

Tra nsducer Block

Display

Tra nsducer Block

Diagnostic

Tra nsducer Block

Service

Tra nsducer Block

Primary value

Sensor Temperature

Resource Block

Integrator

Block

Discrete Input

Block

PID Block

Analog Alarm

Block

Input Selector

Block

Signal

Characterizer

Block

Discrete Output

Block

Arithmetic Block

Measured variable

Sensor

Signal evaluation

Display

with scaling

TOTAL IZER 1

Block configuration when device is delivered

The block model shown below illustrates the block configuration when the device is

delivered.

Fig. 32: Block configuration when device is delivered

The Pressure Transducer Block supplies the Primary Value and the sensor temperature

(secondary value). In the DP Flow Transducer Block, the flow is totalized in the "Flow"

measuring mode and output by means of the TOTALIZER_1_VALUE/TOTALIZER 1

parameter. The Primary Value, Secondary Value and TOTALIZER_1_VALUE are each

transferred to one Analog Input Block by means of the CHANNEL parameter (see also the

following section).

The Discrete Output, PID, Arithmetic, Signal Characterizer, Input Selector and Analog Alarm

Block are not connected in the as-delivered state.

Note Dependencies when setting parameters!

‣ Please note that the links between the blocks are deleted and the FF parameters are reset

P01-xMD7xxxx-02-xx-xx-en-004

to the default values following a reset by means of the RESTART parameter in the

Resource Block, "Default" option.

42 Endress+Hauser

Page 43

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Operation

6.3.7 Assignment of Transducer Blocks (CHANNEL)

Settings for the Analog Input Block

Process variable Transducer Block Parameter name CHANNEL parameter in

the Analog Input Block

Primary Value, a pressure, level

or flow value depending on the

measuring mode

Secondary Value

(sensor temperature)

Totalizer ("Flow" measuring

3)

mode)

Pressure after damping Service Transducer Block PRESSURE_1_AFTER_D

Maximum measured pressure PRESSURE_1_MAX_RE

Overshoot counter for

maximum set user limit for

pressure

1)

2)

Pressure Transducer

Block

DP Flow Block TOTALIZER_1_VALUE/

PRIMARY_VALUE 1

MEASURED_TEMPERA

TURE/TEMP. SENSOR

TOTALIZER 1

AMPING/PRESSURE

STABLE/MAX. MEAS.

PRESS.

COUNTER: P > Pmax 5

2

6

3

4

1) Factory setting for Analog Input Block 1

2) Factory setting for Analog Input Block 2

3) Factory setting for Analog Input Block 3

Settings for the Discrete Output Block

Process variable Transducer Block Parameter name CHANNEL parameter in

the Discrete Output

Block

Totalizer ("Flow" measuring

mode)

Overshoot counter for

maximum set user limit for

1)

pressure

1) Factory setting

DP Flow Block TOTALIZER_1_VALUE/

TOTALIZER 1

Service Transducer Block COUNTER: P > Pmax 1

2

Endress+Hauser 43

Page 44

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

Discrete Input Block settings

Alarm conditions Transducer Block Parameter name Parameter CHANNEL,

Discrete Input Block

General device error

Configuration error 2

Sensor overpressure 3

Sensor underpressure 4

Sensor overtemperature 5

Sensor undertemperature 6

Process isolating diaphragm broken 7

Electronic overtemperature 8

Electronic undertemperature 9

Temperature transmitter override 10

Pressure transmitter override 11

Pmin PROCESS underrun 12

Pmax PROCESS overrun 13

Tmin PROCESS underrun 14

Tmax PROCESS overrun 15

Diagnostic

Transducer Block

DIAGNOSTIC_CODE

1

44 Endress+Hauser

Page 45

Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus Operation

6.3.8 Index tables of Endress+Hauser parameters

The following tables list the manufacturer-specific device parameters for the Resource Block,

the Transducer Blocks and the Analog Input Blocks. For the FF parameters, see either the

FF Specification or Operating Instructions BA00303P "Description of Device Functions,

Cerabar S/ Deltabar S/Deltapilot S". These parameters are not displayed in the block view in

FieldCare (exception: Analog Input Blocks).

General explanatory remarks

Data type

• DS: data structure, contains data types such as Unsigned8, Octet String etc.

• Bit enumerated

• Float: IEEE 754 format

• Visible String: ASCII coded

• Unsigned:

– Unsigned8: value range = 0 to 255

– Unsigned16: value range = 0 to 65535

Storage Class

• D: dynamic parameter

• N: nonvolatile parameter

•S: static parameter

If this is a write parameter, the MODE_BLK column indicates the block mode in which the

parameter can be written. Some parameters can only be written in the OOS block mode.

The "Reset codes" column indicates which reset codes reset the parameter.

Resource Block

Parameter name,

option "Symbolic name"

ENP_VERSION ENP version 44 Visible String 16 S x

DEVICE_TAG Device tag 45 Visible String 32 S x x

SERIAL_NUMBER Serial number 46 Visible String 16 S x x

ORDER_CODE Order code 47 Visible String 32 S x x

FIRMWARE_VERSION Firmware version 48 Visible String 16 S x

SW_LOCK Insert PIN no. 49 Unsigned16 2 S x x AUTO, OOS 7864, 333

STATUS_LOCKING Status locking 50 Unsigned16 2 D x

HARDWARE_REVISION Hardware rev. 74 Visible String 16 S x

FF_COMM_VERSION FF comm. version 75 Visible String 16 S x

BLOCK_ERR_DESC_1 Block Error desc. 76 Bit enumerated 4 D x

DEVICE_DIALOG Device dialog 77 Unsigned8 1 D x

ELECTRONIC_SERIAL_NUMBER Electr. serial no. 78 Visible String 16 S x

PROCESS_CONNECTION_TYPE Proc. conn. type 79 Unsigned16 2 S x x AUTO, OOS 7864, 333

MAT_PROC_CONN_POS Mat. proc. conn. + 80 Unsigned16 2 S x x AUTO, OOS 7864, 333

MAT_PROC_CONN_NEG Mat. proc. conn. - 81 Unsigned16 2 S x x AUTO, OOS 7864, 333

SEAL_TYPE Seal type 82 Unsigned16 2 S x x AUTO, OOS 7864, 333

SCI_OCTET_STRING SCI_OCTET_STR 83 Visible String 40 S x x AUTO, OOS

MS_RESOURCE_DIRECTORY RESOURCE DIRECTORY 84 Unsigned16 20x2 S x

Parameter name,

option "Label"

Index Data type Size

(Byte

)

Storage

Class

Read WriteMODE_BLK Reset

codes

1)

AUTO, OOS

)

AUTO, OOS

)

AUTO, OOS

1) Can be written with service code

Endress+Hauser 45

Page 46

Operation Deltabar S FMD77, FMD78, PMD75 with FOUNDATION Fieldbus

Pressure Transducer Block

Parameter name,

option "Symbolic name"

MEASURED_TEMPERATURE Temperature 32 DS-65 5 D x

MEASURED_TEMPERATURE_UNIT Temp. eng. unit 33 Unsigned16 2 S x x OOS

DEVICE_DIALOG Device dialog 34 Unsigned8 1 D x

SW_LOCK Insert PIN no. 35 Unsigned16 2 S x x AUTO, OOS,

STATUS_LOCKING Status locking 36 Unsigned16 2 D x

LINEARIZATION Linearization 37 Unsigned8 2 S x x OOS 7864, 333

SCALE_IN Scale In 38 DS-68 11 S x x OOS 7864, 333

SCALE_OUT Scale Out 39 DS-68 11 S x x OOS 7864, 333

DAMPING_VALUE Damping value 40 Float 4 S x x OOS 7864, 333

ZERO_POSITION_ADJUST Pos. zero adjust 41 Unsigned8 1 D x x OOS

POSITION_INPUT_VALUE Pos. input value 42 Float 4 S x x OOS 7864, 333,

CALIBRATION_OFFSET Calib. offset 43 Float 4 S x x OOS 7864, 333,