Endress+Hauser FMD71 Specifications

TI01033P/00/EN/06.17

71376031

Products Solutions Services

Technical Information

Deltabar FMD71, FMD72

Level measurement with electronic differential

pressure

Electronic differential pressure transmitter with

ceramic and metal sensors

Application

The Deltabar FMD71/FMD72 is used to measure the differential pressure or level,

volume or mass of liquids in pressurized or vacuum vessels

Your benefits

The electronic differential pressure system eliminates traditional mechanical

issues resulting in greater process availability and reliability

• Safety risks are minimized with the electronic differential pressure system

architecture and design

• Lowest total cost of ownership due to reduced installation time, maintenance,

downtime and spare requirements, downtime and spare requirements.

• Multivariable level measurement: HART-based differential pressure, head pressure

and sensor temperatures from one system

• Continuous health indication of the entire system via HART-based diagnostic

• High reproducibility and long-term stability

• Overload-resistant and function-monitored

Table of contents

Deltabar FMD71, FMD72

Document information ....................... 4

Document function ............................ 4

Symbols used ................................ 4

Documentation ............................... 5

Terms and abbreviations ........................ 7

Turn down calculation .......................... 8

Registered trademarks .......................... 8

Function and system design ................... 9

Measuring principle - electronic differential pressure

measurement ................................ 9

Measuring system ............................ 10

Device selection .............................. 10

Product design .............................. 11

System integration ........................... 11

Input .................................... 12

Measured variable ............................ 12

FMD71: measuring range of individual sensors ......... 12

FMD72: measuring range of individual sensors ......... 13

Output .................................. 14

Output Signal ............................... 14

Signal range 4 to 20 mA ........................ 14

Signal on alarm 4 to 20 mA ...................... 14

Maximum load .............................. 14

Dead time, Time constant ....................... 15

Dynamic behavior, current output .................. 15

Dynamic behavior, HART ....................... 15

Damping .................................. 15

alarm current setting .......................... 15

Firmware version ............................ 15

Protocol-specific data .......................... 16

Power supply ............................. 17

Terminals ................................. 17

Terminal assignment .......................... 17

Supply voltage .............................. 17

Cable entries ............................... 18

Cable specification for transmitter connection .......... 18

Residual ripple .............................. 18

Influence of power supply ....................... 18

Overvoltage protection ......................... 18

Performance characteristics of ceramic process

isolating diaphragm ........................ 19

Reference operating conditions ................... 19

Influence of the installation position depending on sensor . 19

Resolution ................................. 19

Vibration effects ............................. 19

Application limits ............................ 19

Reference accuracy ........................... 20

Thermal change in the zero output and the output span ... 20

Total performance ............................ 21

Long-term stability ........................... 21

Total error ................................. 22

Warm-up period ............................. 22

Performance characteristics of metallic process

isolating diaphragm ........................ 23

Reference operating conditions ................... 23

Influence of the installation position depending on sensor . 23

Resolution ................................. 23

Vibration effects ............................. 23

Application limits ............................ 23

Reference accuracy ........................... 24

Thermal change of the zero output and the output span ... 24

Total performance ........................... 25

Long-term stability ........................... 25

Total error ................................. 25

Warm-up period ............................. 25

Installation ............................... 26

Mounting location ............................ 26

Orientation ................................ 26

General installation instructions ................... 26

Thermal insulation - FMD71 high-temperature version ... 26

Installing the sensor modules .................... 27

Mounting sensor modules with PVDF installation

coupling .................................. 27

Installing the transmitter ....................... 27

Sensor and transmitter cable ..................... 28

Environment .............................. 29

Ambient temperature range ..................... 29

Storage temperature range ...................... 29

Climate class ............................... 29

Degree of protection .......................... 29

Vibration resistance ........................... 29

Electromagnetic compatibility .................... 29

Process .................................. 30

Process temperature range for devices with ceramic

process isolating diaphragm FMD71 ................ 30

Process temperature range for devices with metallic

process isolating diaphragm FMD72 ................ 31

Pressure specifications ......................... 31

Mechanical construction .................... 32

Device height ............................... 32

T14 transmitter housing (optional display on the side) .... 33

T17 transmitter housing (optional display on the side) .... 33

Sensor housing .............................. 34

Selecting the electrical connection ................. 34

FMD71 process connections, internal process isolating

diaphragm ................................. 35

FMD71 process connections, internal process isolating

diaphragm ................................. 36

FMD71 process connections, internal process isolating

diaphragm ................................. 37

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 38

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 39

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 40

2 Endress+Hauser

Deltabar FMD71, FMD72

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 41

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 44

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 45

FMD71 process connections, flush-mounted process

isolating diaphragm ........................... 46

FMD72 process connections, internal process isolating

diaphragm ................................. 47

FMD72 process connections, internal process isolating

diaphragm ................................. 48

FMD72 process connections, flush-mounted process

isolating diaphragm ........................... 49

FMD72 process connections, flush-mounted process

isolating diaphragm ........................... 50

FMD72 process connections, flush-mounted process

isolating diaphragm ........................... 51

FMD72 process connections, flush-mounted process

isolating diaphragm ........................... 52

FMD72 process connections, flush-mounted process

isolating diaphragm ........................... 53

Wall and pipe mounting with mounting bracket ........ 56

Materials in contact with process .................. 57

Materials not in contact with process ............... 58

Operability ............................... 62

Operation concept ............................ 62

Local operation .............................. 62

Operating languages .......................... 64

Certificates and approvals ................... 65

CE approval ................................ 65

RoHS ..................................... 65

RCM-Tick marking ............................ 65

Ex approvals ................................ 65

Suitability for hygienic processes .................. 65

Pressure Equipment Directive 2014/68/EU (PED) ....... 65

Manufacturer declaration ....................... 66

Other standards and guidelines ................... 66

CRN approvals .............................. 67

Classification of process sealing between electrical

systems and (flammable or combustible) process fluids in

accordance with ANSI/ISA 12.27.01 ................ 67

Calibration unit .............................. 67

Calibration ................................. 67

Inspection certificates .......................... 68

Ordering information ....................... 69

Scope of delivery ............................. 69

Measuring point (TAG) ......................... 69

Supplementary documentation ............... 70

Field of Activities ............................ 70

Technical Information ......................... 70

Operating Instructions ......................... 70

Brief Operating Instructions ..................... 70

Safety Instructions (XA) ........................ 70

Registered trademarks ...................... 71

HARTâ ................................... 71

Endress+Hauser 3

Document information

DANGER

WARNING

CAUTION

NOTICE

A

Deltabar FMD71, FMD72

Document function

The document contains all the technical data on the device and provides an overview of the

accessories and other products that can be ordered for the device.

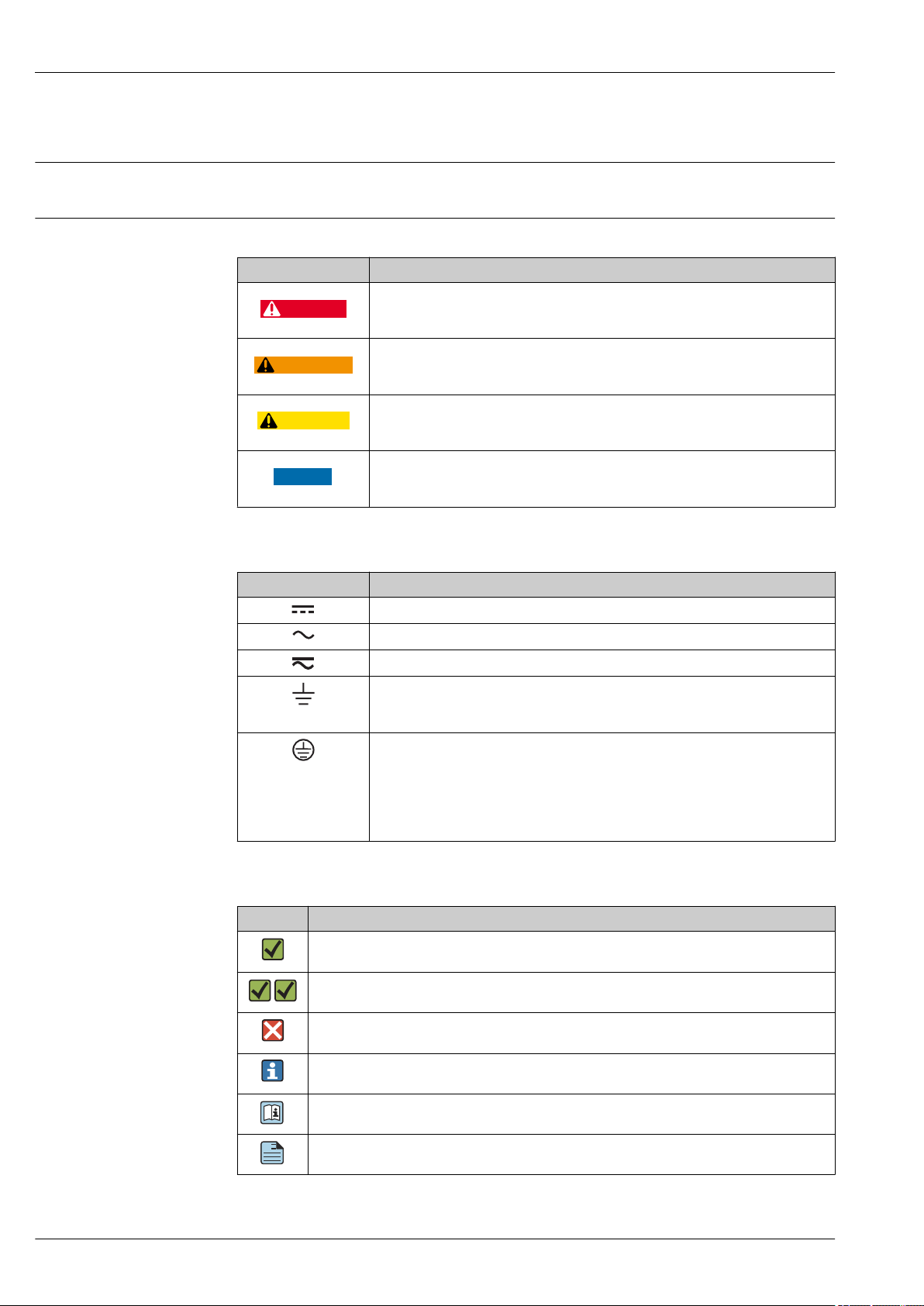

Symbols used Safety symbols

Symbol Meaning

Electrical symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

4 Endress+Hauser

Deltabar FMD71, FMD72

,…,

1.

2.

3.

Symbol Meaning

Reference to graphic

Visual inspection

Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Documentation

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com → Download

Brief Operating Instructions (KA): getting the 1st measured value quickly

KA01105P:

The Brief Operating Instructions contain all the essential information from incoming acceptance to

initial commissioning.

Operating Instructions (BA): your comprehensive reference

BA01044P:

These Operating Instructions contain all the information that is required in various phases of the life

cycle of the device: from product identification, incoming acceptance and storage, to mounting,

connection, operation and commissioning through to troubleshooting, maintenance and disposal.

Description of Device Parameters (GP): reference for your parameters

GP01013P:

The document provides a detailed explanation of each individual parameter in the operating menu.

The description is aimed at those who work with the device over the entire life cycle and perform

specific configurations.

Safety Instructions (XA)

Safety Instructions (XA) are supplied with the device depending on the approval. These instructions

are an integral part of the Operating Instructions.

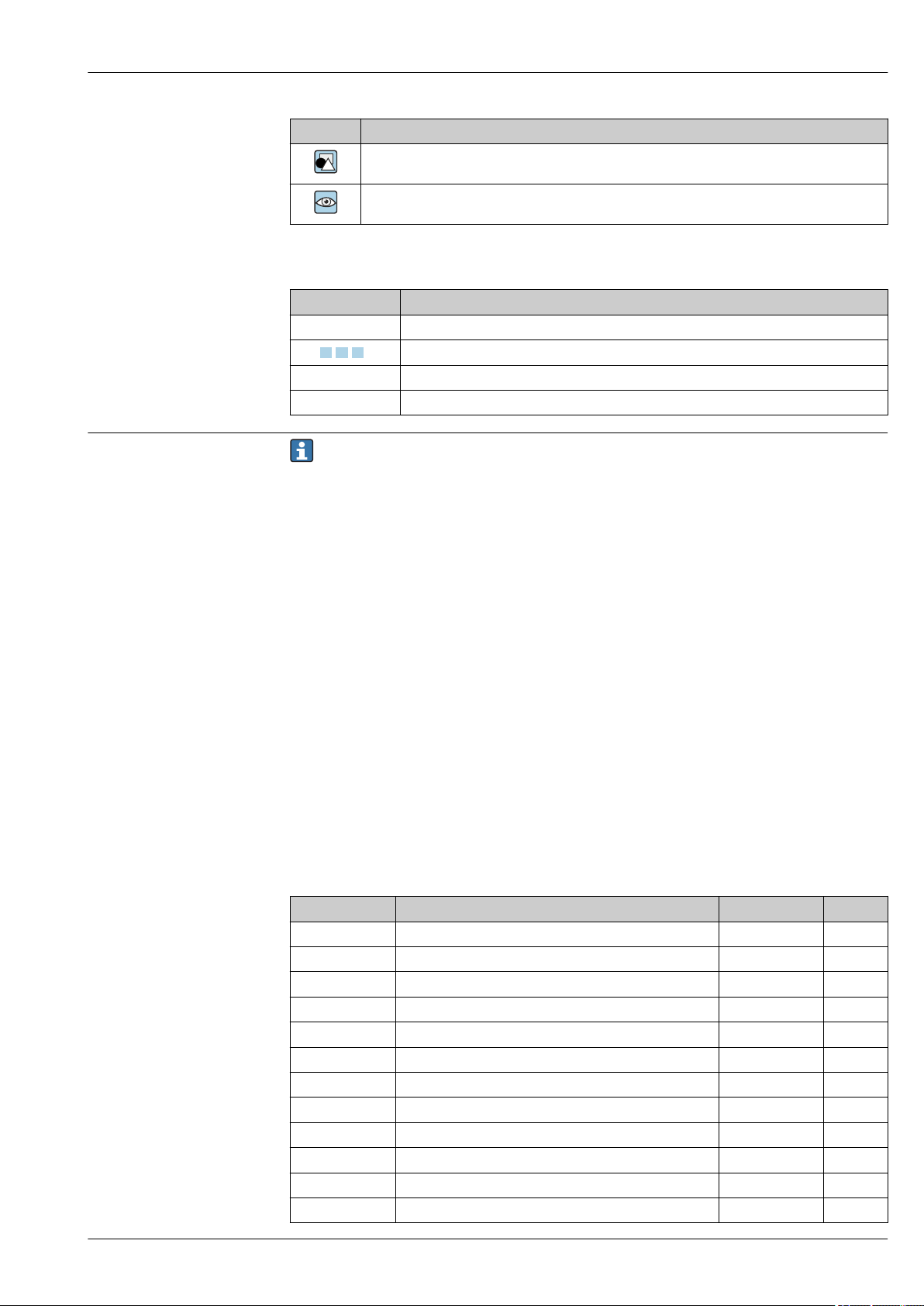

Device Directive Documentation Option

FMD71, FMD72 ATEX II 1/2G Ex ia IIC T6 Ga/Gb XA00619P BA

FMD71, FMD72 ATEX II 1/2G Ex d [ia] IIC T6 Ga/Gb XA00620P BC

FMD71, FMD72 ATEX II 3G Ex nA IIC T6 GC XA00621P BD

FMD71, FMD72 IEC Ex ia IIC T6 Ga/Gb XA00622P IA

FMD71, FMD72 IEC Ex d [ia] IIC T6 Ga/Gb XA00623P IB

FMD71, FMD72 CSA General Purpose - CD

FMD71, FMD72 NEPSI Ex ia IIC T4/T6 Ga/Gb XA01352P NA

FMD71, FMD72 NEPSI Ex d [ia] IIC T4/T6 Ga/Gb XA01353P NB

FMD71, FMD72 INMETRO Ex ia IIC T6...T4 Ga/Gb XA01378P MA

FMD71, FMD72 INMETRO Ex d [ia] IIC T6...T4 Ga/Gb XA01379P MC

FMD71, FMD72 EAC Ga/Gb Ex ia IIC T6...T4 XA01594P GA

FMD71, FMD72 EAC Ga/Gb Ex d [ia] IIC T6...T4 X XA01595P GB

1)

Endress+Hauser 5

Deltabar FMD71, FMD72

Device Directive Documentation Option

FMD71 FM C/US IS Cl.I Div.1 Gr.A-D, AEx ia, Zone 0,1,2 XA00628P FA

FMD71 FM C/US XP AIS Cl.I Div.1 Gr.A-D, Exd [ia] Zone 0,1,2 XA00629P FB

FMD71 CSA C/US XP Cl.I Div.1 Gr.A-D, Ex d [ia], Zone 0,1,2 XA00631P CB

FMD71 FM C/US NI Cl.I Div.2 Gr.A-D, Zone 2 XA00668P FD

FMD71 CSA C/US NI, Cl.I Div. 2, Gr.A-D Cl.I, Zone 2, IIC XA00670P CC

FMD71 CSA C/US IS Cl.I Div.1 Gr.A-D, Ex ia Zone 0,1,2 XA00630P CA

FMD72 CSA C/US IS Cl.I Div.1 Gr.A-D, Ex ia Zone 0,1,2 XA00626P CA

FMD72 CSA C/US XP Cl.I Div.1 Gr.A-D, Ex d [ia], Zone 0,1,2 XA00627P CB

FMD72 CSA C/US NI, Cl.I Div.2 Gr.A-D, Zone 2 XA00671P CC

FMD72 FM C/US IS Cl.I Div.1 Gr.A-D, AEx ia, Zone 0,1,2 XA00624P FA

FMD72 FM C/US XP AIS Cl.I Div.1 Gr.A-D, Exd [ia] Zone 0,1,2 XA00625P FB

FMD72 FM C/US NI Cl.I Div.2 Gr.A-D, Zone 2 XA00669P FD

1) Product Configurator order code for "Approval"

The nameplate provides information on the Safety Instructions (XA) that are relevant for the

device.

1)

6 Endress+Hauser

Deltabar FMD71, FMD72

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

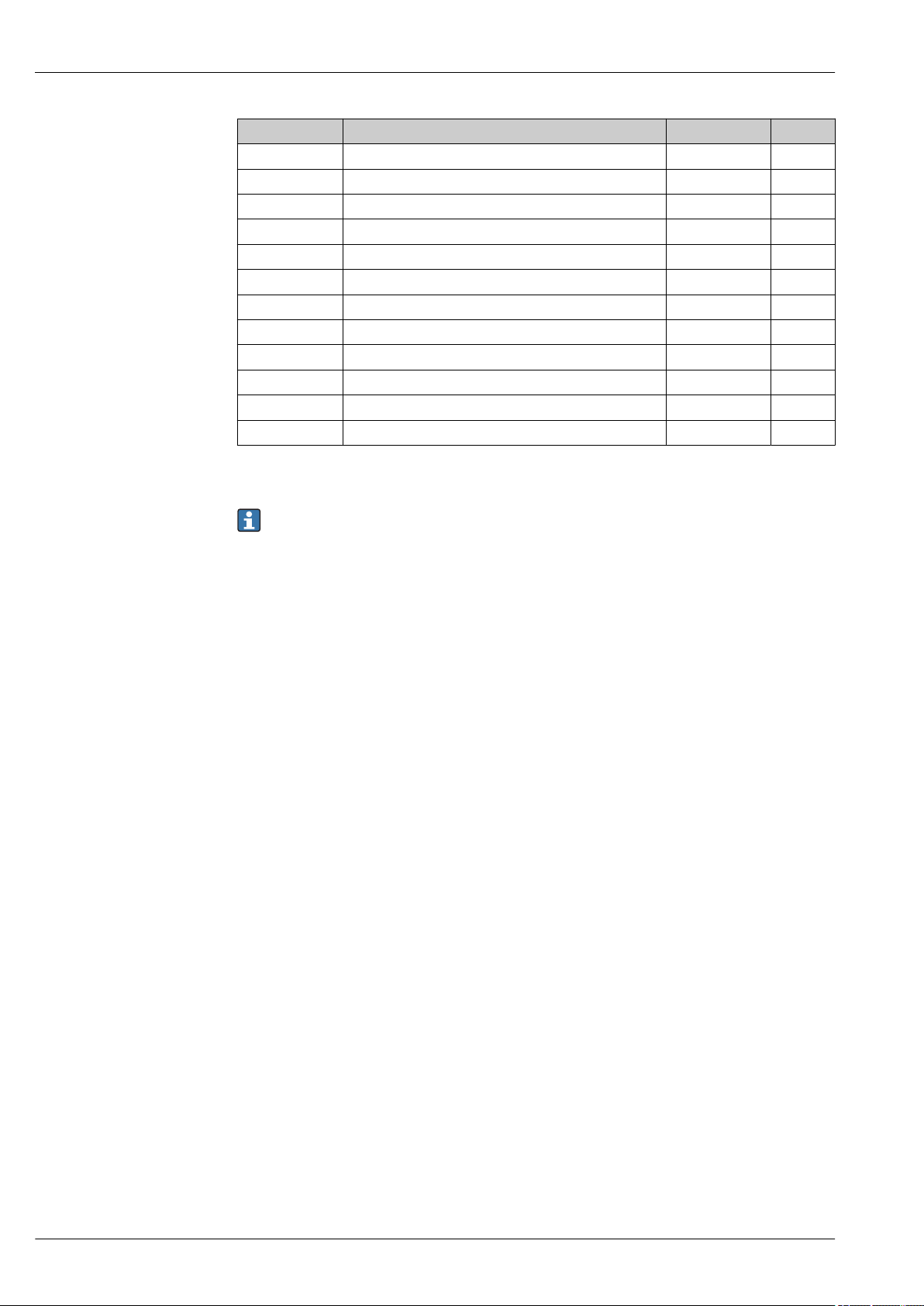

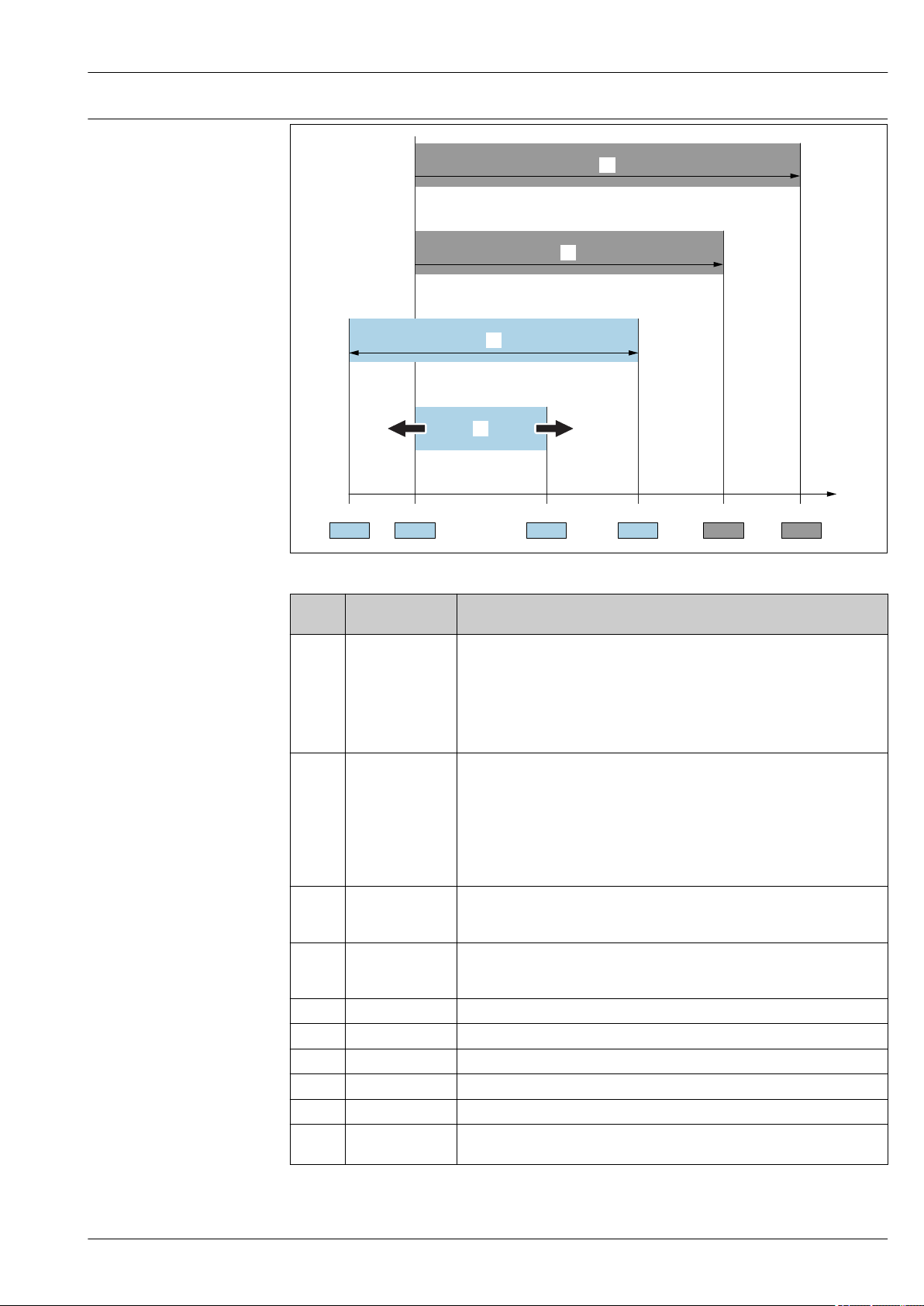

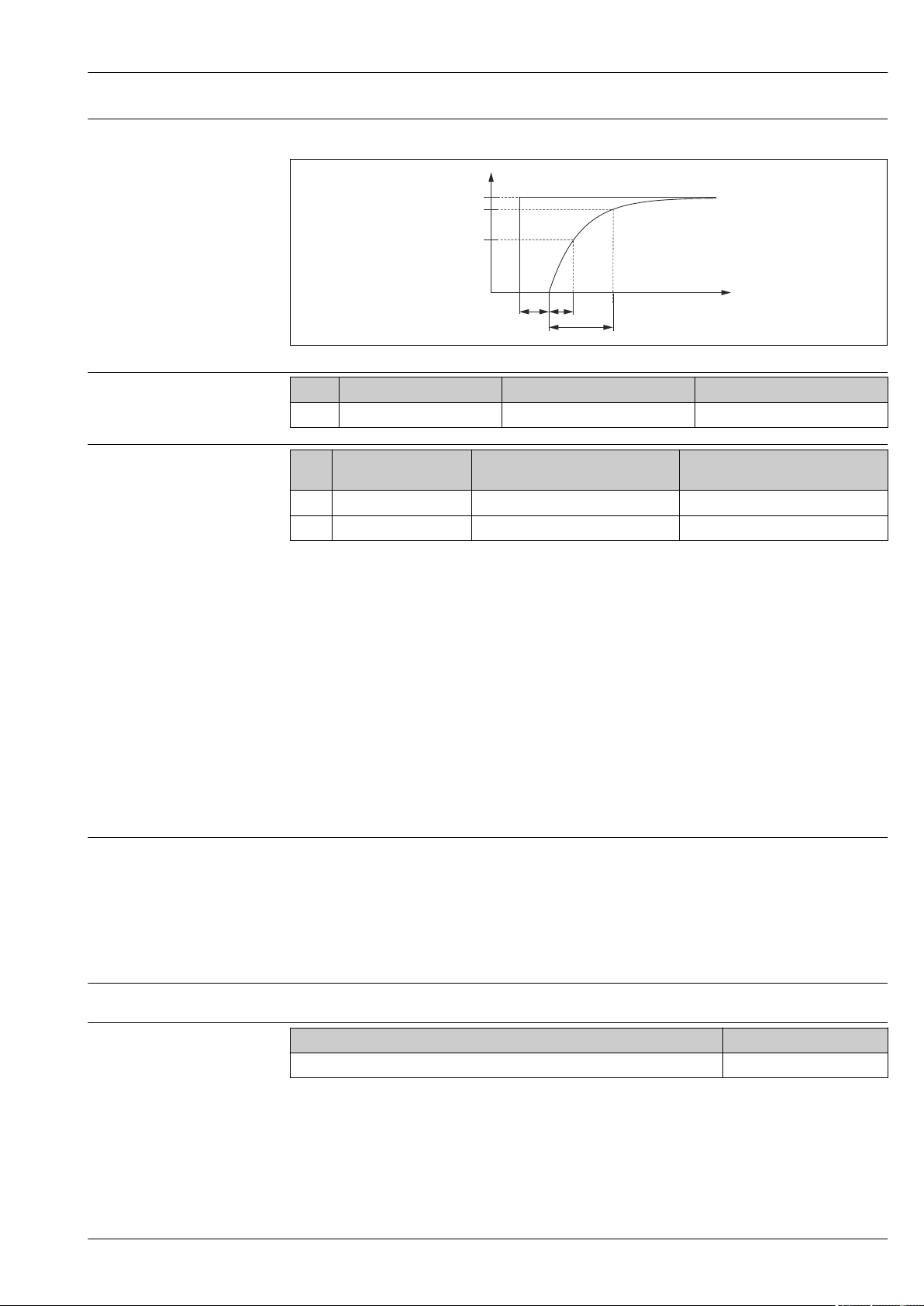

Terms and abbreviations

A0029505

Position Term/

abbreviation

1 OPL The OPL (over pressure limit = sensor overload limit) for the measuring device

2 MWP The MWP (maximum working pressure) for the sensors depends on the lowest-

3 Maximum sensor

measuring range

4 Calibrated/

adjusted span

p - Pressure

- LRL Lower range limit

- URL Upper range limit

- LRV Lower range value

- URV Upper range value

- TD (Turn down) Turn down

Explanation

depends on the lowest-rated element, with regard to pressure, of the selected

components, i.e. the process connection has to be taken into consideration in

addition to the measuring cell. Also observe pressure-temperature dependency.

For the relevant standards and additional notes, see the "Pressure specifications"

section → 31.

The OPL may only be applied for a limited period of time.

rated element, with regard to pressure, of the selected components, i.e. the

process connection has to be taken into consideration in addition to the

measuring cell. Also observe pressure-temperature dependency. For the

relevant standards and additional notes, see the "Pressure specifications" section

→ 31.

The MWP may be applied at the device for an unlimited period.

The MWP can also be found on the nameplate.

Span between LRL and URL

This sensor measuring range is equivalent to the maximum calibratable/

adjustable span.

Span between LRV and URV

Factory setting: 0 to URL

Other calibrated spans can be ordered as customized spans.

Example - see the following section.

Endress+Hauser 7

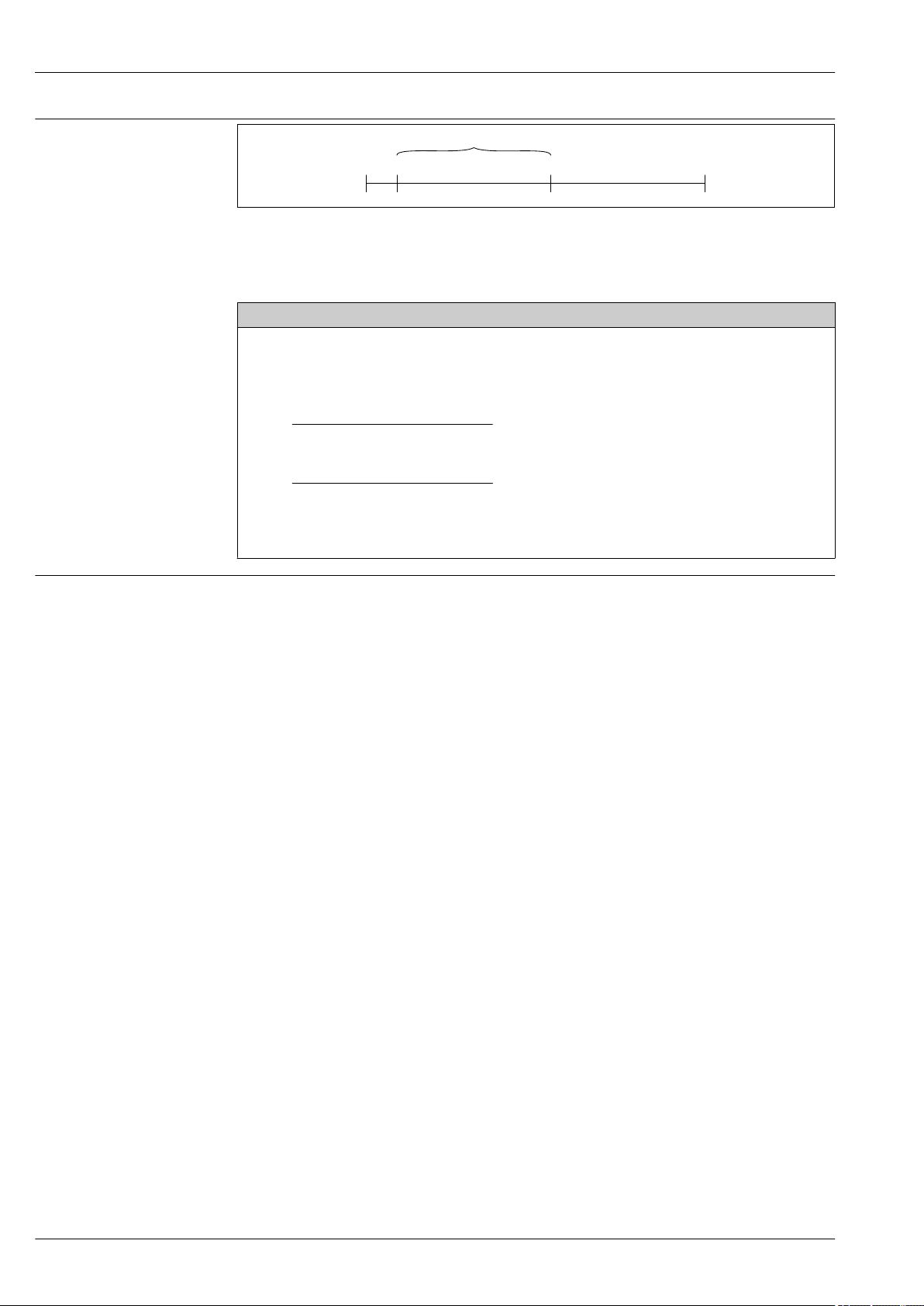

Turn down calculation

LRV

URLURV

LRL

1 = 2

3

1 Calibrated/adjusted span

2 Zero point-based span

3 URL sensor

Example

• Sensor:10 bar (150 psi)

• Upper range value (URL) = 10 bar (150 psi)

Turn down (TD):

Deltabar FMD71, FMD72

A0029545

• Calibrated/adjusted span: 0 to 5 bar (0 to 75 psi)

• Lower range value (LRV) = 0 bar (0 psi)

• Upper range value (URV) = 5 bar (75 psi)

TD =

TD =

In this example, the TD is 2:1.

This span is based on the zero point.

Registered trademarks HART®

Registered trademark of the FieldComm Group, Austin, USA

URL

|URV - LRV|

10 bar (150 psi)

= 2

|5 bar (75 psi) - 0 bar (0 psi)|

8 Endress+Hauser

Deltabar FMD71, FMD72

1

2

3

4

p

p

1

3

4

2

Function and system design

Measuring principle electronic differential

pressure measurement

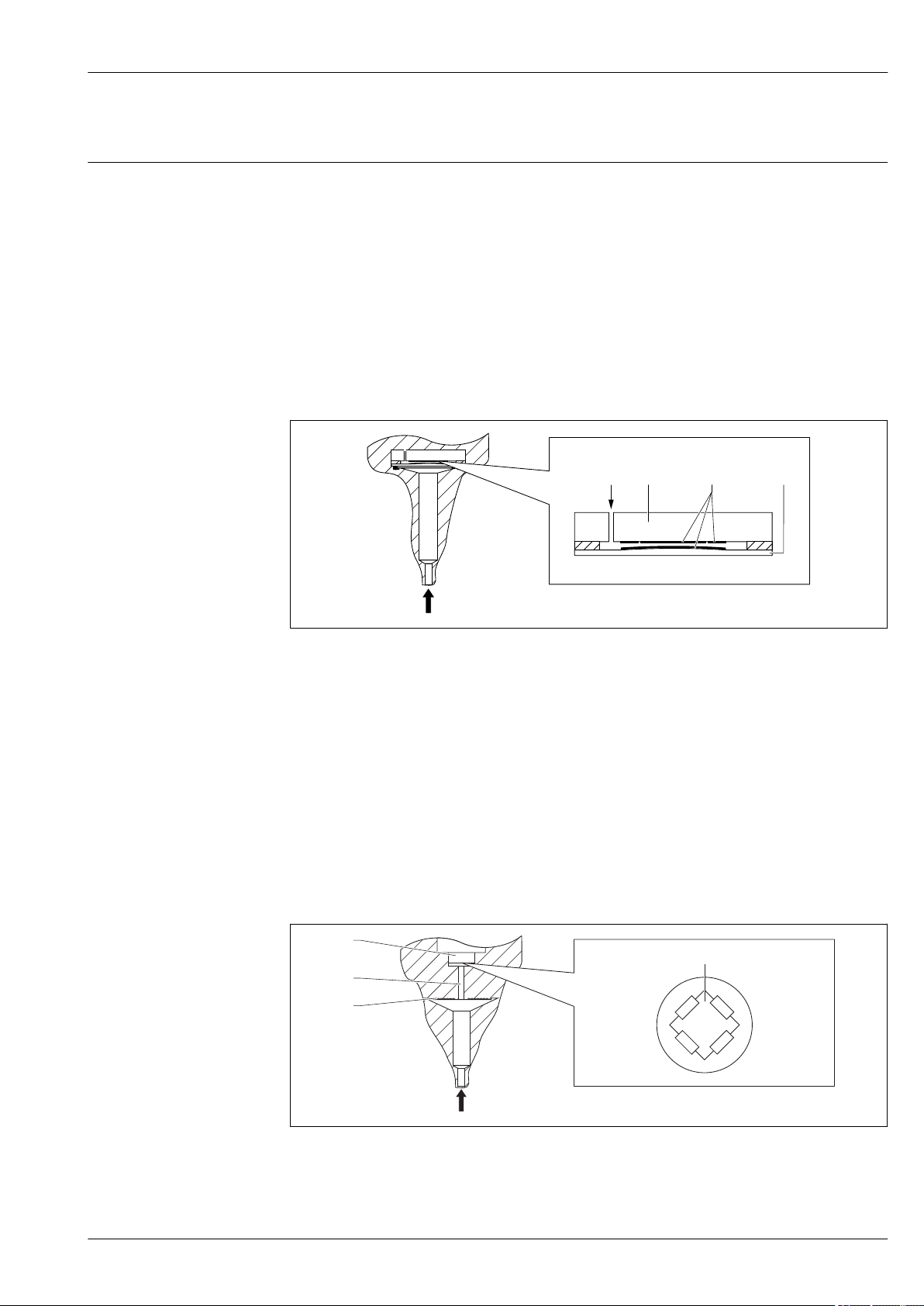

FMD71 - Devices with ceramic process isolating diaphragm (Ceraphire®)

The ceramic sensor is an oil-free sensor, i.e. the process pressure acts directly on the robust ceramic

process isolating diaphragm and causes it to deflect. A pressure-dependent change in capacitance is

measured at the electrodes of the ceramic substrate and the process isolating diaphragm. The

measuring range is determined by the thickness of the ceramic process isolating diaphragm.

Advantages:

• Guaranteed overload resistance up to 40 times the nominal pressure

• The ultrapure 99.9% ceramic (Ceraphire®, see also "www.endress.com/ceraphire") ensures:

– Extremely high chemical durability

– Less relaxation

– High mechanical durability

• Can be used in absolute vacuums up to 150 °C (302 °F)

• Small measuring ranges

A0020465

1 Air pressure (relative pressure sensors)

2 Ceramic substrate

3 Electrodes

4 Ceramic process isolating diaphragm

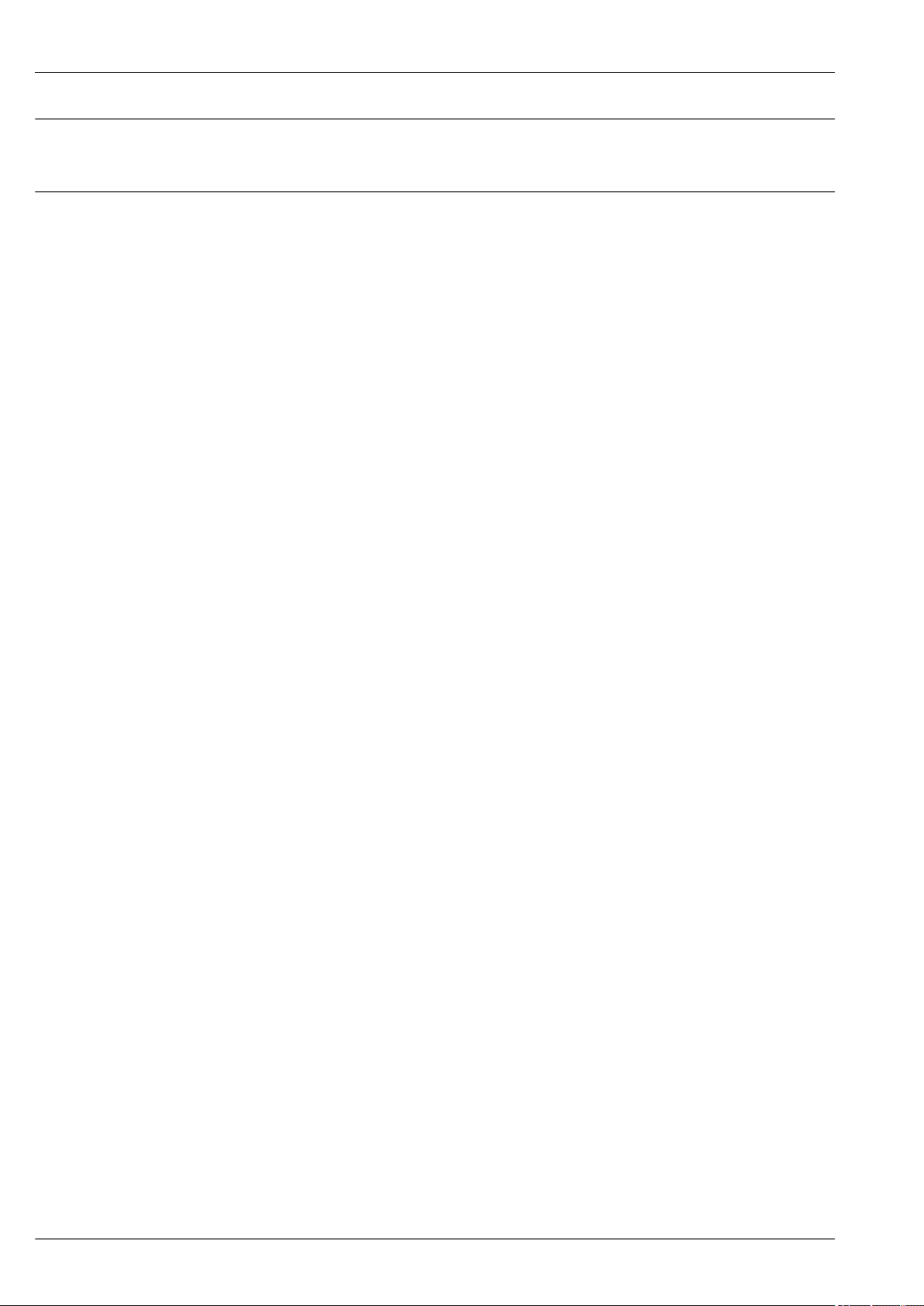

FMD72 - Devices with metal process isolating diaphragm

The process pressure deflects the metal process isolating diaphragm of the sensor and a fill fluid

transfers the pressure to a Wheatstone bridge (semiconductor technology). The pressure-dependent

change in the bridge output voltage is measured and evaluated.

Advantages:

• Can be used for process pressures up to 40 bar (600 psi)

• Fully welded process isolating diaphragm

• Small, flush-mounted process connections

• Significantly reduced thermal effect e.g. compared to diaphragm seal systems with capillaries

1 Silicon measuring element, substrate

2 Wheatstone bridge

3 Channel with fill fluid

4 Metal process isolating diaphragm

A0016448

Endress+Hauser 9

Deltabar FMD71, FMD72

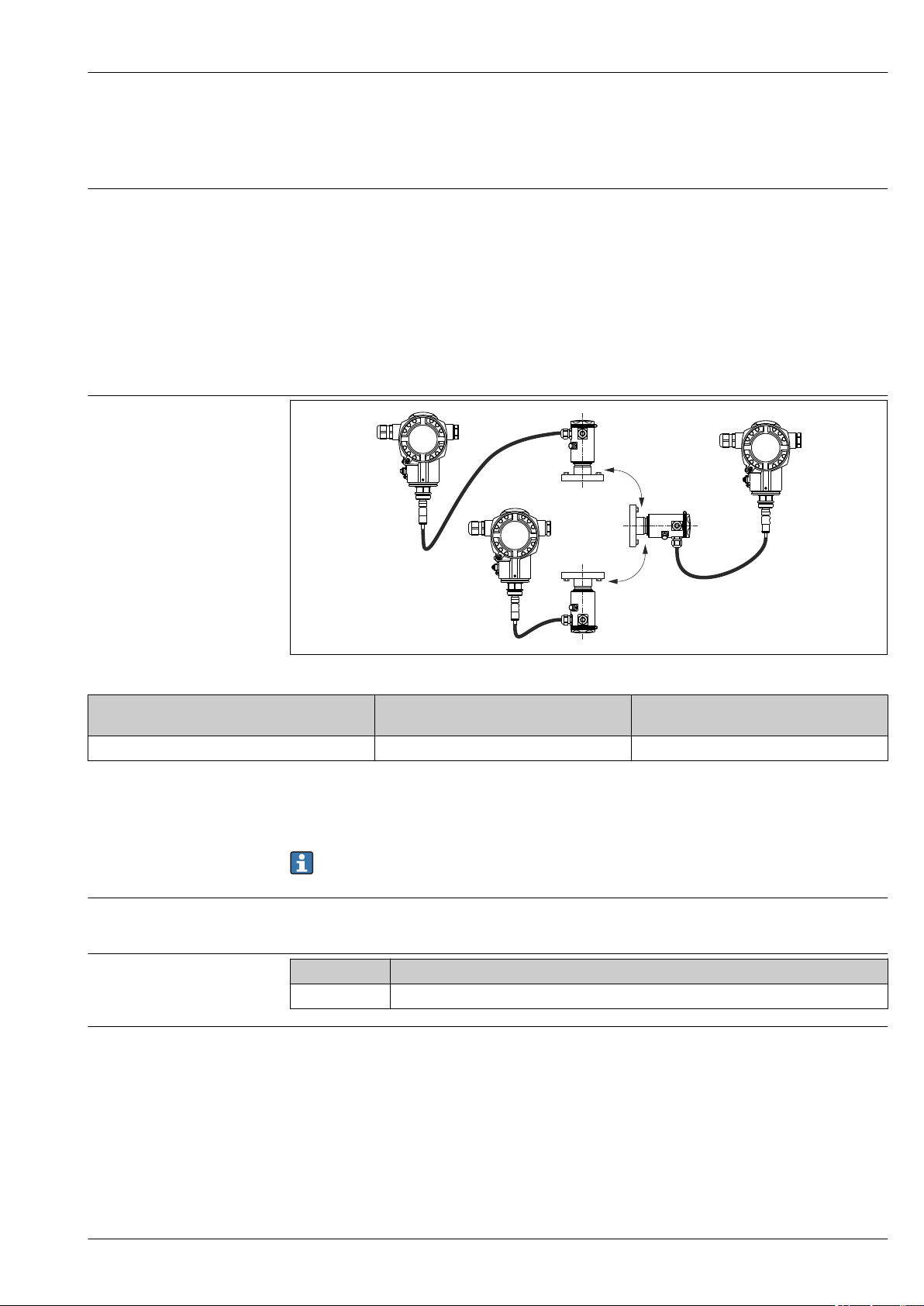

Measuring system

Device selection Field of application

The FMD71/FMD72 consists of 2 sensor modules and one transmitter. One sensor module measures

the hydrostatic pressure (high pressure) and the other one the head pressure (low pressure). The

level (electronic differential pressure) is calculated in the transmitter using these two digital values.

• Level

• Differential pressure

Process connections

• Thread

• EN and ASME flanges

• Flush-mounted hygienic connections

Measuring ranges (differential pressure)

FMD71:

from –100 to +100 mbar (–1.5 to +1.5 psi)

to –1 to +40 bar (–15 to +600 psi)

FMD72:

from –400 to +400 mbar (–6 to +6 psi)

to –1 to +40 bar (–15 to +600 psi)

MWP (depends on the lowest-rated element, with regard to pressure, of the selected

components)

FMD71:

to 60 bar (900 psi)

FMD72:

to 160 bar (2 400 psi)

Process temperature limits

FMD71:

• Thread / Flanges:

–25 to +125 °C (–13 to +257 °F)/150 °C (302 °F)

• Hygienic process connections:

–25 to +130 °C (–13 to +266 °F) , 150 °C (302 °F) for max. 1 hour

FMD72:

• Process connections with internal process isolating diaphragm:

–40 to +125 °C (–40 to +257 °F)

• Process connections with flush-mounted process isolating diaphragm:

–40 to +100 °C (–40 to +212 °F)

• Hygienic process connections with flush-mounted process isolating diaphragm:

–40 to +130 °C (–40 to +266 °F) , 150 °C (302 °F) for max. 1 hour

• Higher process temperature limits available on request (up to +250 °C (480 °F))

Ambient temperature range

–40 to +80 °C (–40 to +176 °F)

Reference accuracy of the individual sensors

• Up to ±0.075% of the set span

• PLATINUM version: up to ±0.05 % of the set span

Supply voltage

• Version for non-hazardous areas: 12 (13) to 45 V DC

• Ex ia: 12 (13) to 30 V DC

Output

4 to 20 mA with superimposed HART protocol

10 Endress+Hauser

Deltabar FMD71, FMD72

LP 1

HP

p1

p2

P = p2

LP

P = p1 + p2

HP

Options

• NACE-compliant materials

• Software pre-configurations

Product design

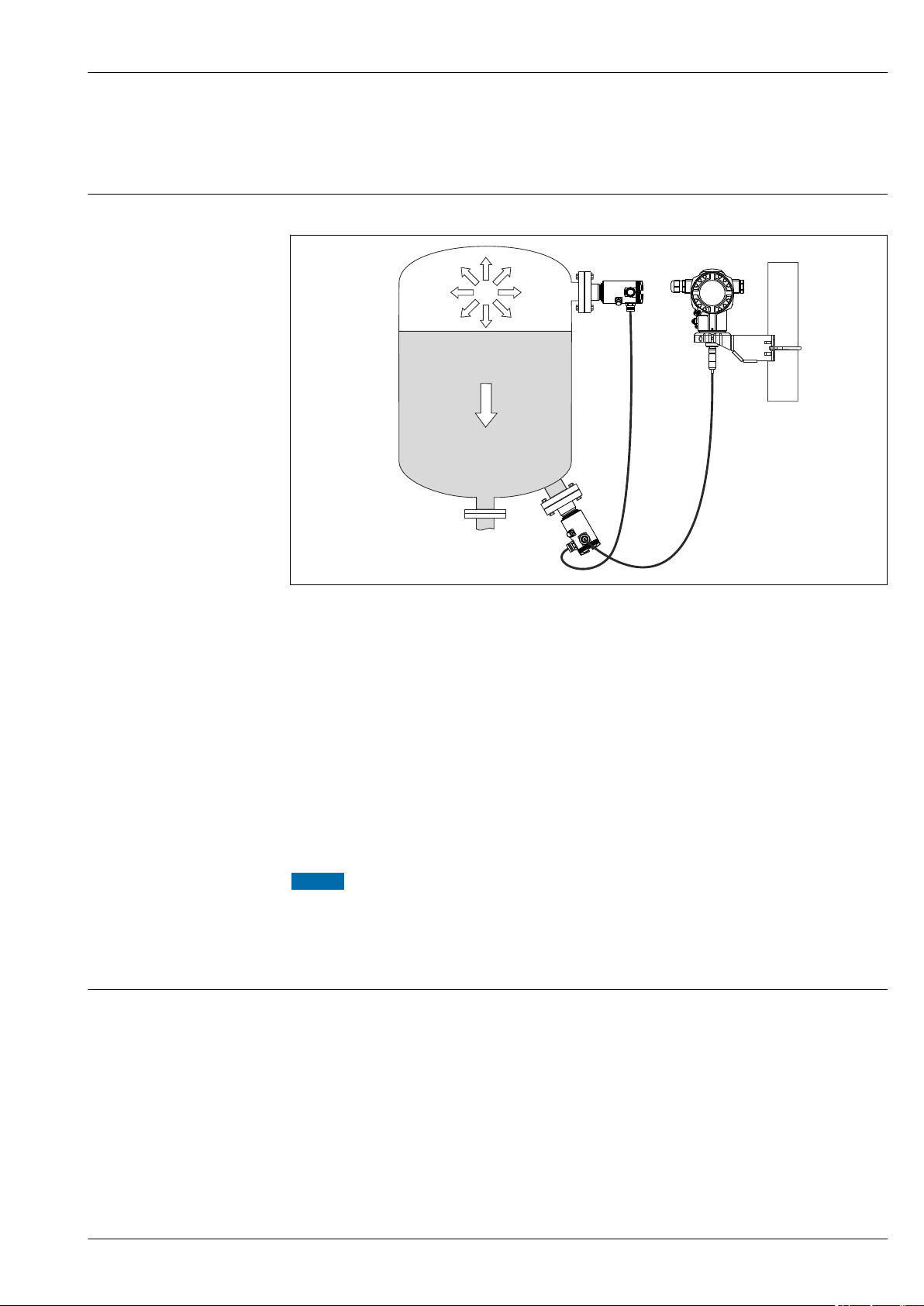

Level measurement (level, volume and mass) with Deltabar:

A0016449

LP Sensor module LP (low pressure)

HP Sensor module HP (high pressure)

p2 Head pressure

p1 Hydrostatic pressure

1 Transmitter

System integration

The FMD71/FMD72 is best suited to level measurement in vessels with pressure overlay or in

vacuum vessels and tanks, high distillation columns and other vessels with changing ambient

temperatures.

The sensor module HP is mounted on the lower measuring connection and the sensor module LP is

mounted above the maximum level. The transmitter can be mounted on pipes or walls with the

mounting bracket.

The sensor signal is transmitted digitally. In addition, sensor temperatures and the individual process

pressures present at the respective sensor modules can be individually evaluated and transmitted.

NOTICE

Incorrect sizing/order of sensor modules

In a closed system, please note that the sensor module is affected by the superimposed head

‣

pressure (p2) in addition to the hydrostatic pressure (p1). This must be taken into account when

sizing the sensor module on the high-pressure side (HP).

The device can be given a tag name (max. 8 alphanumeric characters).

Measuring point (TAG), see additional specifications.: Product Configurator order code for

"Identification", option "Z1"

Endress+Hauser 11

Input

Measured variable Measured process variables

• Pressure HP and Pressure LP

• Sensor temperature HP and sensor temperature LP

• Transmitter temperature

Calculated process variables

• Differential pressure

• Level (level, volume or mass)

Deltabar FMD71, FMD72

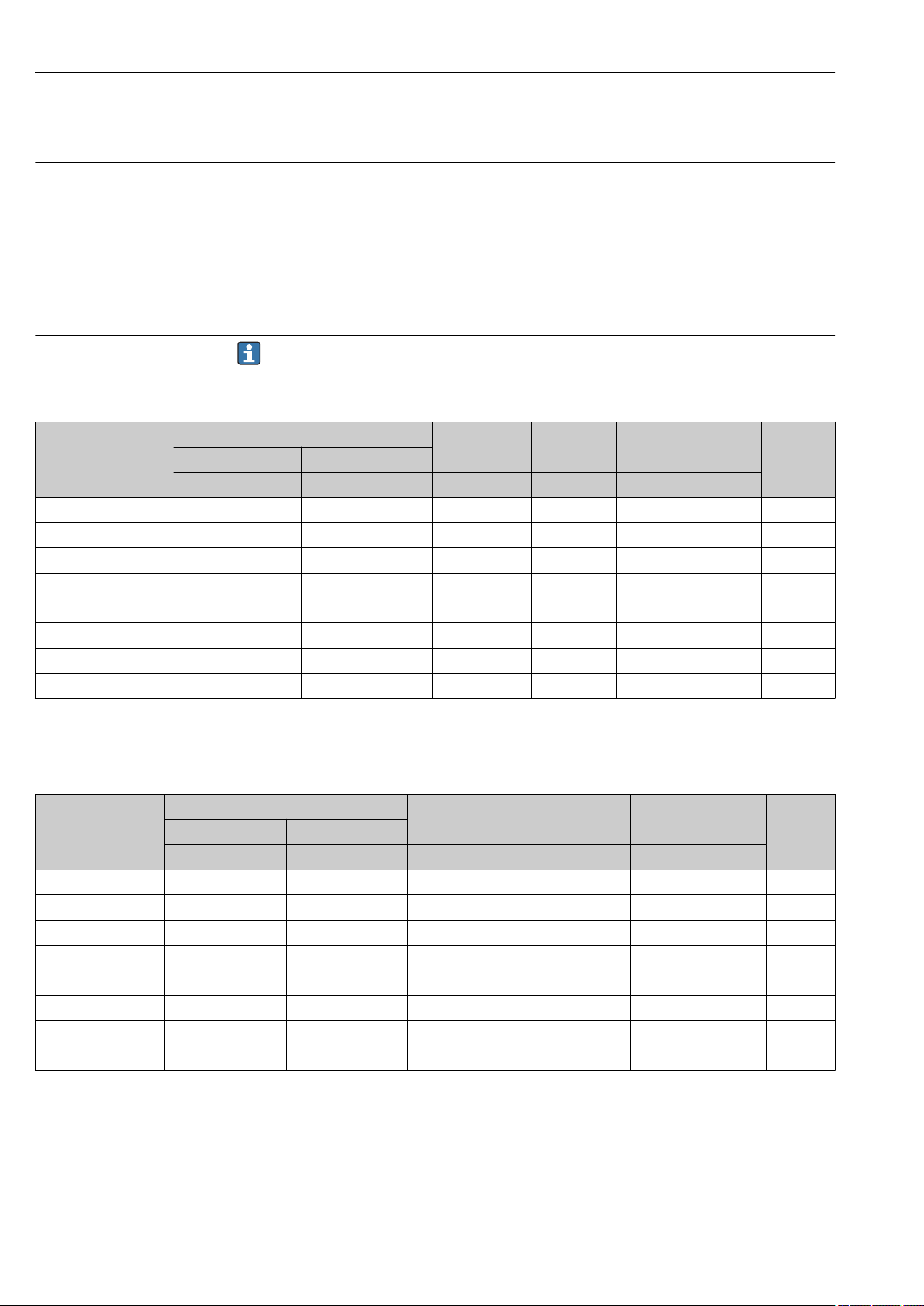

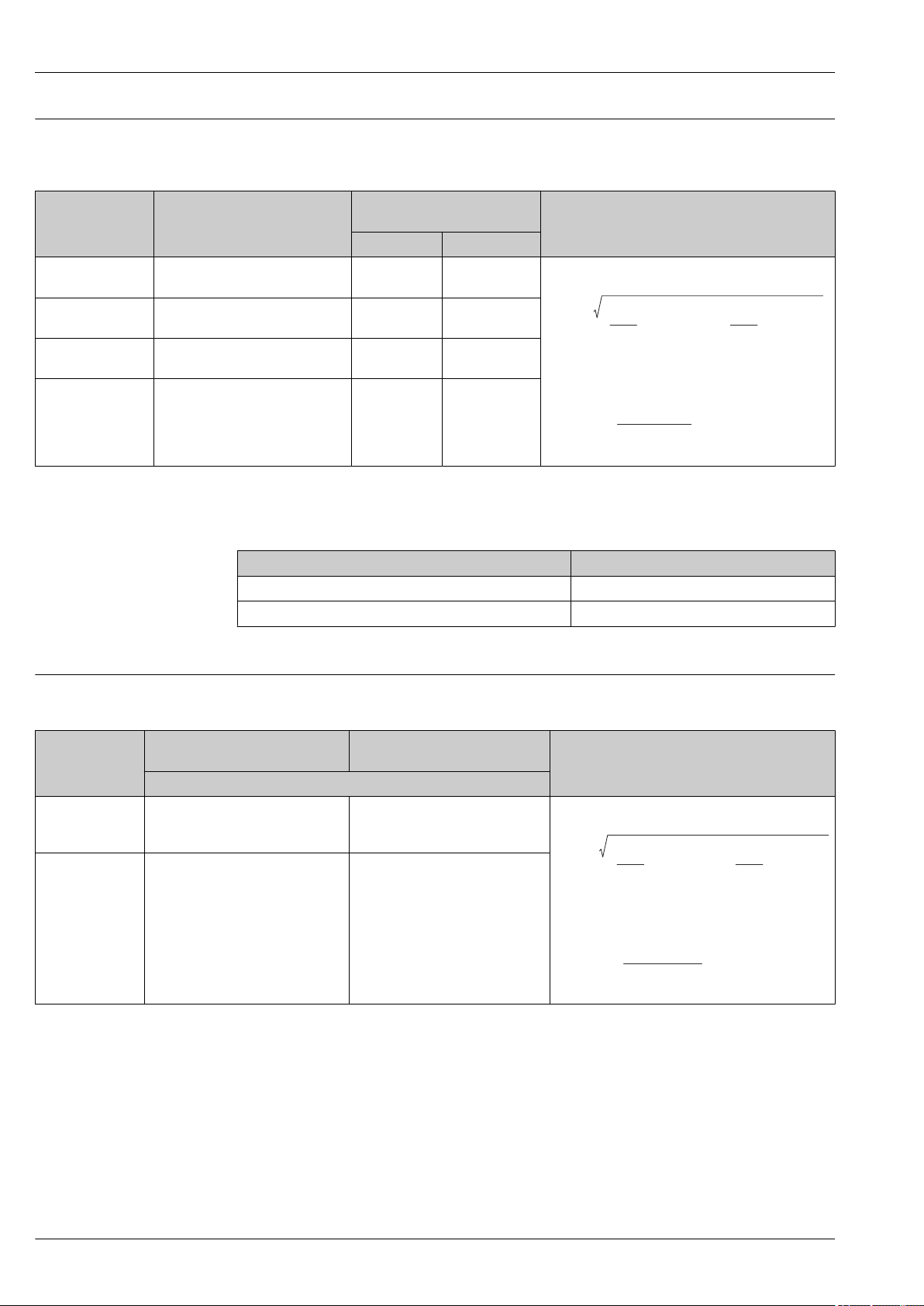

FMD71: measuring range of

The maximum span of the differential pressure corresponds to the URL of the HP sensor.

individual sensors

Gauge pressure

Sensor Maximum sensor measuring range MWP OPL Vacuum resistance Option

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar

abs

(psi

abs

)]

100 mbar (1.5 psi) –0.1 (–1.5) +0.1 (+1.5) 2.7 (40.5) 4 (60) 0.7 (10.5) 1C

250 mbar (4 psi) –0.25 (–4) +0.25 (+4) 3.3 (49.5) 5 (75) 0.5 (7.5) 1E

400 mbar (6 psi) –0.4 (–6) +0.4 (+6) 5.3 (79.5) 8 (120) 0 1F

1 bar (15 psi) –1 (–15) +1 (+15) 6.7 (100.5) 10 (150) 0 1H

2 bar (30 psi) –1 (–15) +2 (+30) 12 (180) 18 (270) 0 1K

4 bar (60 psi) –1 (–15) +4 (+60) 16.7 (250.5) 25 (375) 0 1M

10 bar (150 psi) –1 (–15) +10 (+150) 26.7 (400.5) 40 (600) 0 1P

40 bar (600 psi) –1 (–15) +40 (+600) 40 (600) 60 (900) 0 1S

1) Product Configurator order code for "Sensor range"

Absolute pressure

1)

Sensor Maximum sensor measuring range MWP OPL Vacuum resistance Option

lower (LRL) upper (URL)

[bar

(psi

abs

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

abs

)]

100 mbar (1.5 psi) 0 +0.1 (+1.5) 2.7 (40.5) 4 (60) 0 2C

250 mbar (4 psi) 0 +0.25 (+4) 3.3 (49.5) 5 (75) 0 2E

400 mbar (6 psi) 0 +0.4 (+6) 5.3 (79.5) 8 (120) 0 2F

1 bar (15 psi) 0 +1 (+15) 6.7 (100.5) 10 (150) 0 2H

2 bar (30 psi) 0 +2 (+30) 12 (180) 18 (270) 0 2K

4 bar (60 psi) 0 +4 (+60) 16.7 (250.5) 25 (375) 0 2M

10 bar (150 psi) 0 +10 (+150) 26.7 (400.5) 40 (600) 0 2P

40 bar (600 psi) 0 +40 (+600) 40 (600) 60 (900) 0 2S

1) Product Configurator order code for "Sensor range"

1)

12 Endress+Hauser

Deltabar FMD71, FMD72

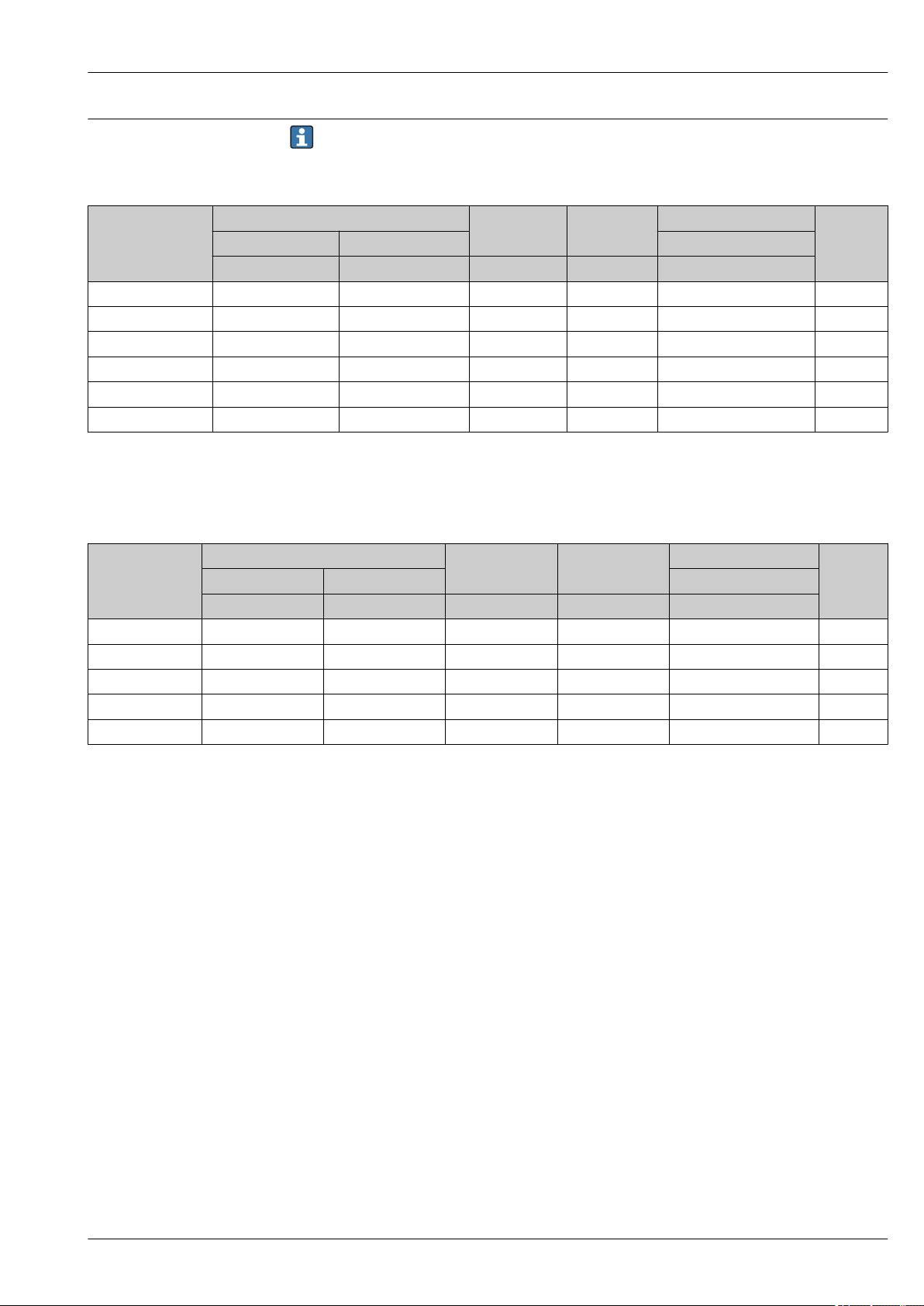

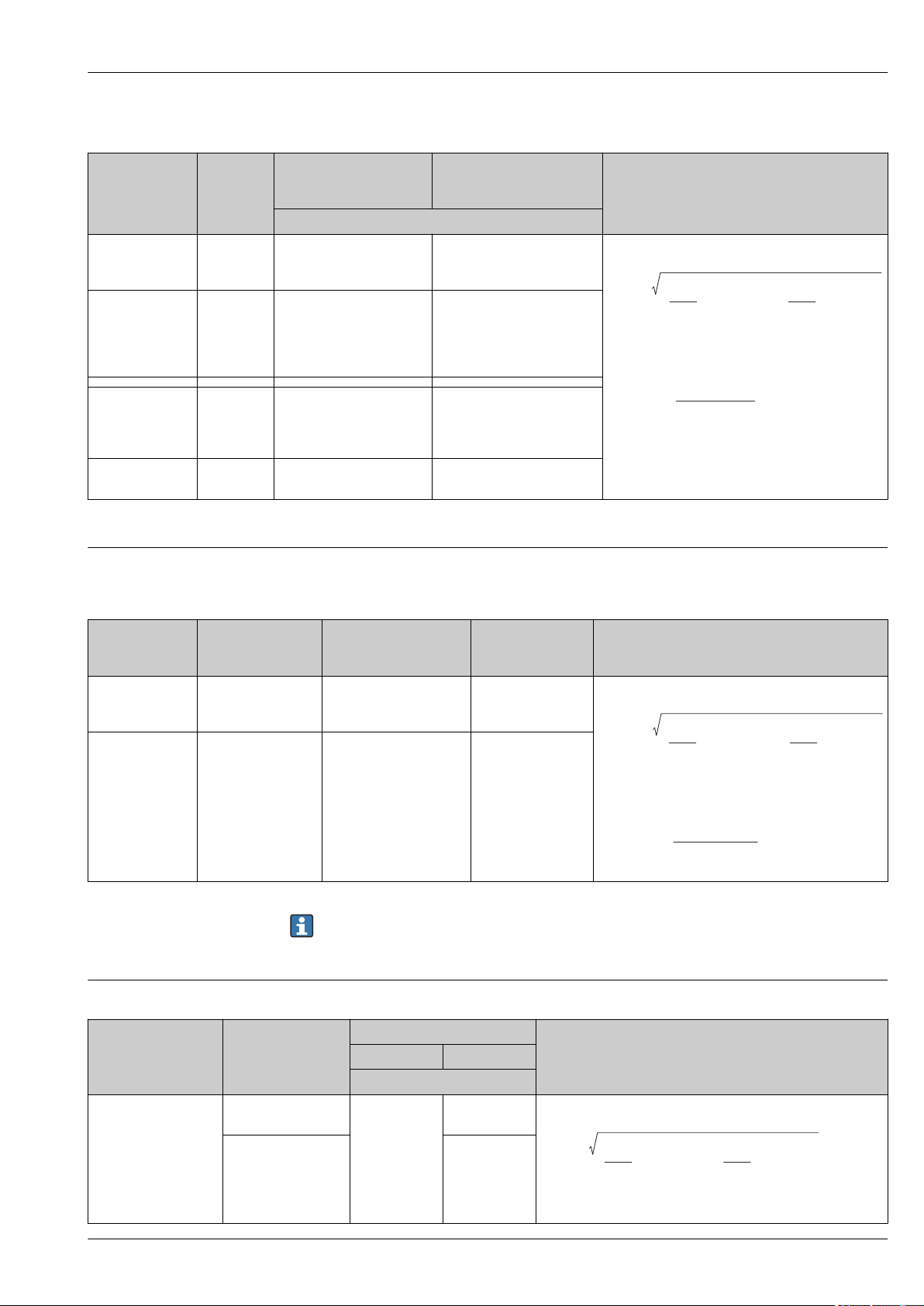

FMD72: measuring range of

The maximum span of the differential pressure corresponds to the URL of the HP sensor.

individual sensors

Gauge pressure

abs

1)

Option

)]

Sensor Maximum sensor measuring range MWP OPL Vacuum resistance

lower (LRL) upper (URL) silicone oil

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar

abs

(psi

400 mbar (6 psi) –0.4 (–6) +0.4 (+6) 4 (60) 6 (90) 0.01 (0.15) 1F

1 bar (15 psi) –1 (–15) +1 (+15) 6.7 (100) 10 (150) 0.01 (0.15) 1H

2 bar (30 psi) –1 (–15) +2 (+30) 13.3 (200) 20 (300) 0.01 (0.15) 1K

4 bar (60 psi) –1 (–15) +4 (+60) 18.7 (280.5) 28 (420) 0.01 (0.15) 1M

10 bar (150 psi) –1 (–15) +10 (+150) 26.7 (400.5) 40 (600) 0.01 (0.15) 1P

40 bar (600 psi) –1 (–15) +40 (+600) 100 (1500) 160 (2400) 0.01 (0.15) 1S

1) The vacuum resistance applies for the measuring cell under reference operating conditions. (see "Reference operating conditions" section)

2) Product Configurator order code for "Sensor range"

Absolute pressure

abs

1)

Option

)]

Sensor Maximum sensor measuring range MWP OPL Vacuum resistance

lower (LRL) upper (URL) silicone oil

[bar

(psi

abs

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

)] [bar

abs

abs

(psi

1 bar (15 psi) 0 +1 (+15) 6.7 (100) 10 (150) 0.01 (0.15) 2H

2 bar (30 psi) 0 +2 (+30) 13.3 (200) 20 (300) 0.01 (0.15) 2K

4 bar (60 psi) 0 +4 (+60) 18.7 (280.5) 28 (420) 0.01 (0.15) 2M

10 bar (150 psi) 0 +10 (+150) 26.7 (400.5) 40 (600) 0.01 (0.15) 2P

40 bar (600 psi) 0 +40 (+600) 100 (1500) 160 (2400) 0.01 (0.15) 2S

2)

2)

1) The vacuum resistance applies for the measuring cell under reference operating conditions. (see "Reference operating conditions" section)

2) Product Configurator order code for "Sensor range"

Endress+Hauser 13

Output

on on

off off

damp.

damp.

Display Display

Sensor Sensor

HART HART

R R

FIELD COMMUNICATION PROTOCOL FIELD COMMUNICATION PROTOCOL

SW /min

SW /min

E

+

–

E

+

–

U – 12 V

U – 13 V

R

L

max

23 mA

23 mA

£

30

20

12

U

[V]

40 45

1217

1435

783

348

[ ]W

[ ]W

R

L

max

R

L

max

30

20

13

40 45

1174

1391

739

304

Test

Test

£

3

A B

1

3

2

1

2

R

L

max

U

[V]

Deltabar FMD71, FMD72

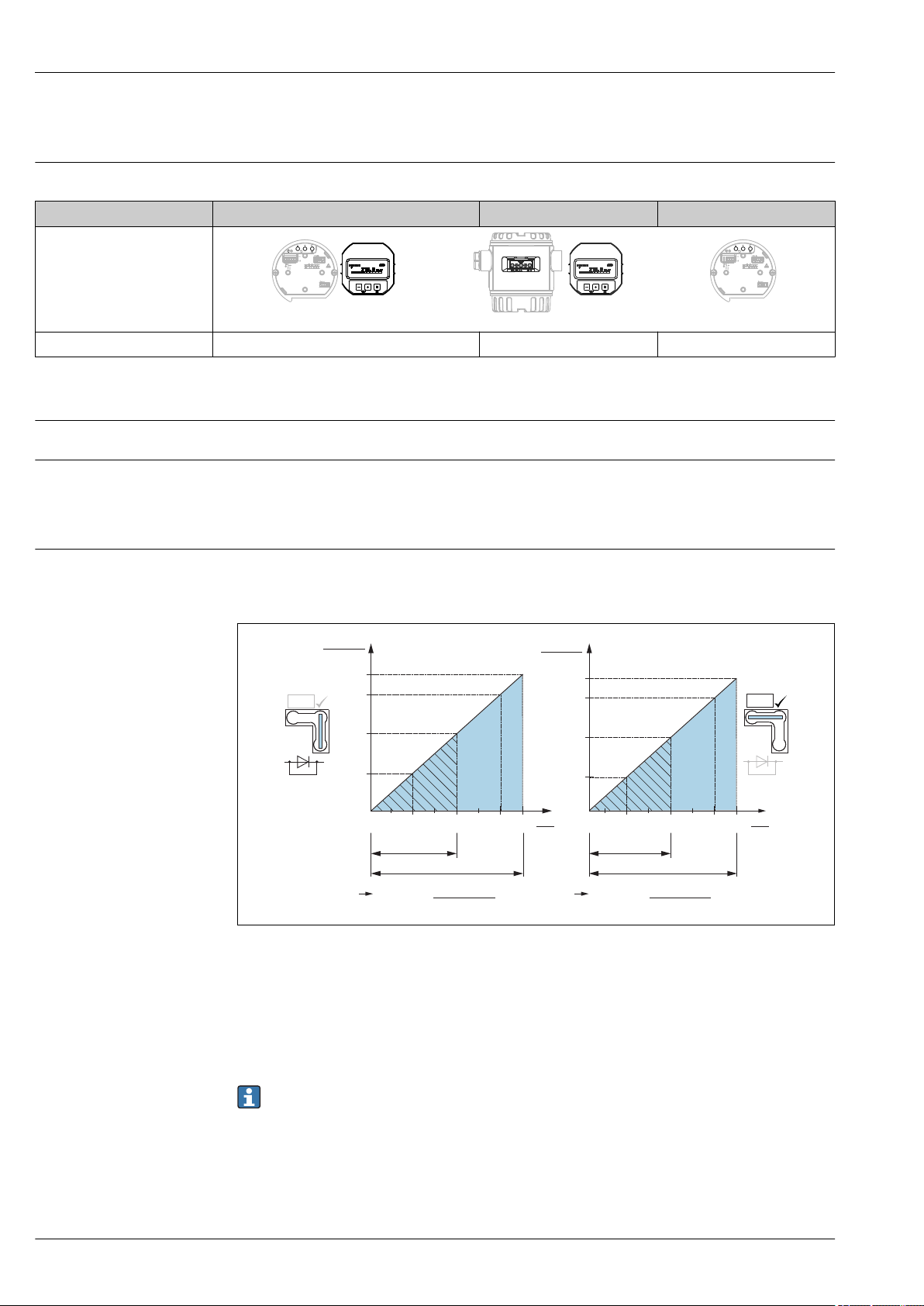

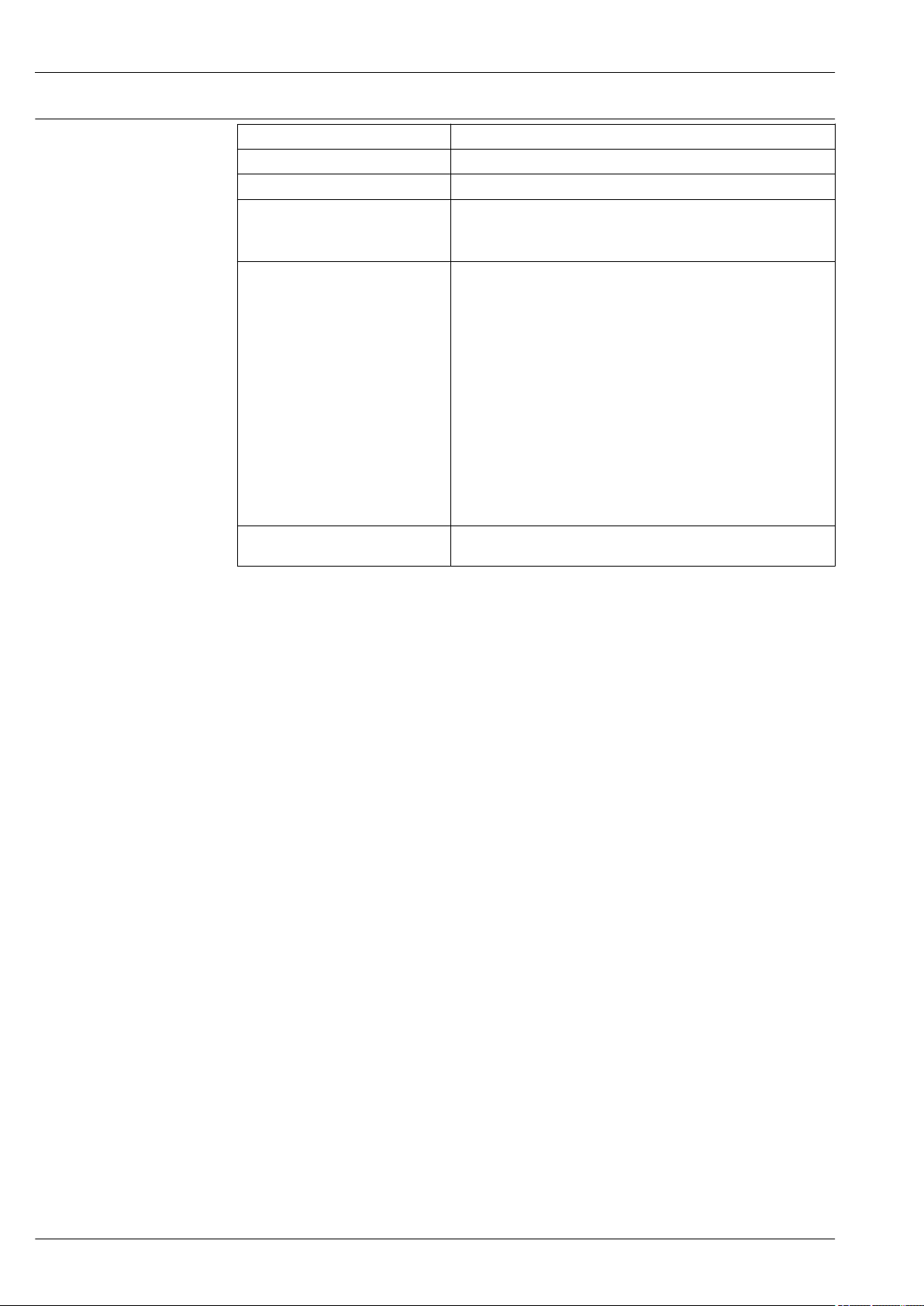

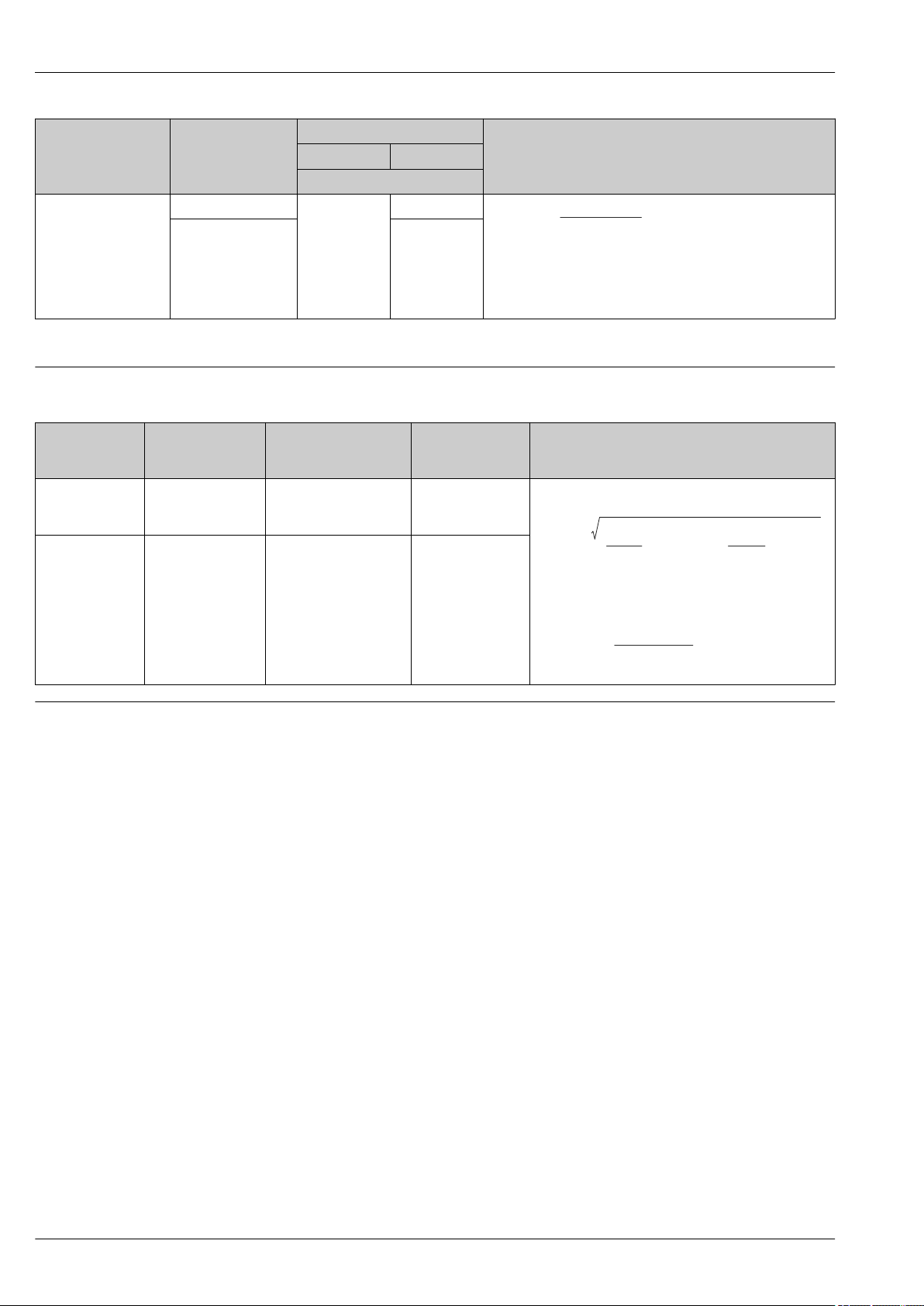

Output Signal

Software operation Internal + LCD External

Order code option

2)

4 to 20 mA with superimposed digital communication protocol HART 6.0, 2-wire

1)

+ LCD Internal

4 5 8

1) In the case of the T17 transmitter housing, the operating keys are always arranged internally on the electronic insert.

2) Product Configurator order code for "Display, operation:"

Signal range 4 to 20 mA

Signal on alarm 4 to 20 mA

3.8 mA to 20.5 mA

As per NAMUR NE43

• Max. alarm: (factory setting: 22 mA) can be set from 21 to 23 mA

• Hold measured value: last measured value is held

• Min. alarm: 3.6 mA

Maximum load

In order to guarantee sufficient terminal voltage in two-wire devices, a maximum load resistance R

(including line resistance) must not be exceeded depending on the supply voltage U0 of the supply

unit. In the following load diagrams, observe the position of the jumper and the explosion protection:

A0021280

A Jumper for 4 to 20 mA test signal set to "Non-test" position

B Jumper for 4 to 20 mA test signal set to "Test" position

1 Power supply for II 1/2 G Ex ia, FM IS, CSA IS

2 Power supply for devices for the non-hazardous area, 2 G Ex d, 3 G Ex nA, FM XP, FM NI, CSA XP, CSA dust

ignition-proof

3 R

U Supply voltage

maximum load resistance

Lmax

When operating via a handheld terminal or via a PC with an operating program, a minimum

communication resistance of 250 Ω must be taken into account.

14 Endress+Hauser

A0017533

Deltabar FMD71, FMD72

I

63 %

100 %

t

t1t

2

90 %

t

3

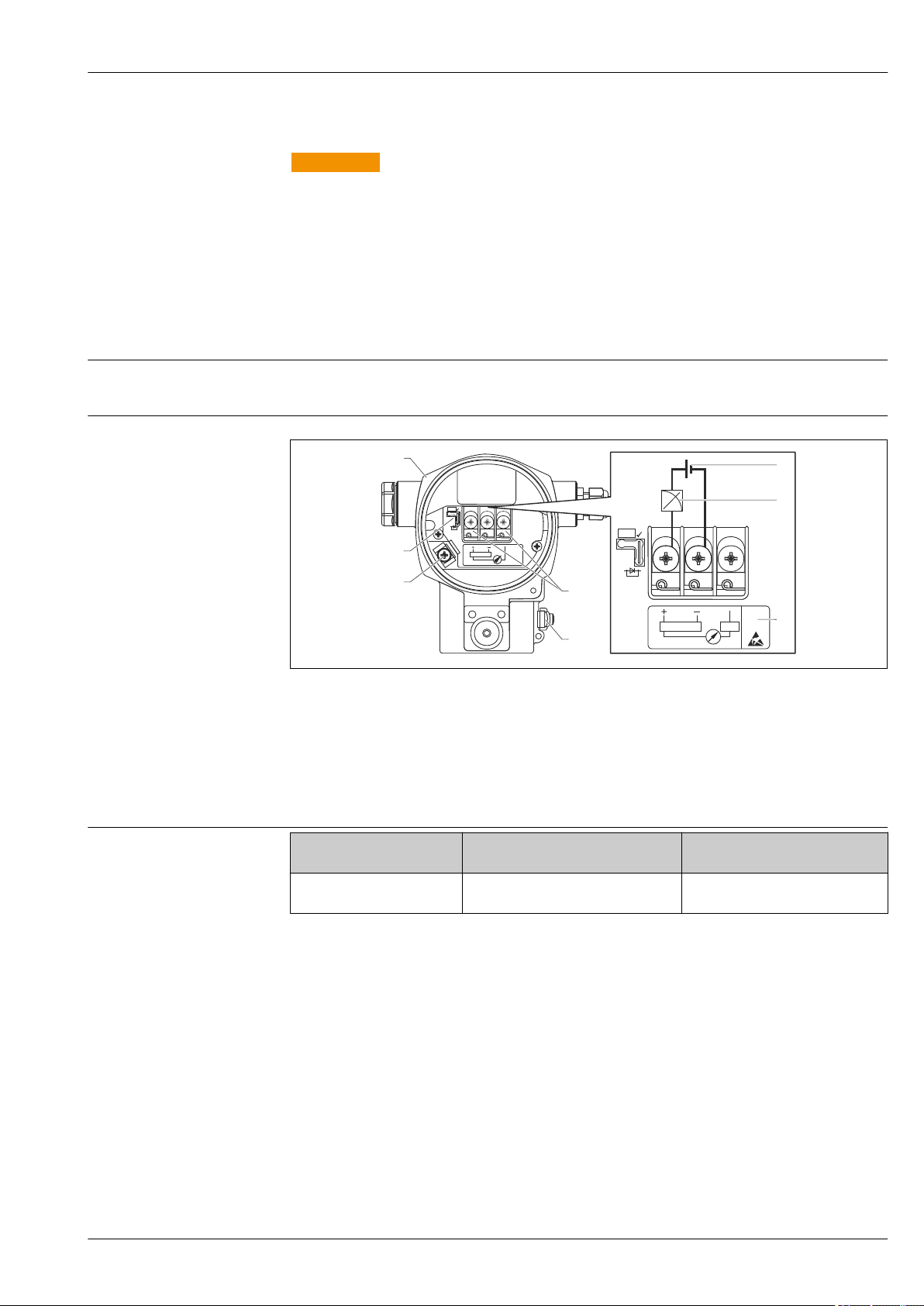

Dead time, Time constant

Dynamic behavior, current output

Dynamic behavior, HART

Presentation of the dead time and the time constant:

A0019786

Dead time (t1) [ms] Time constant (T63), t

max. 120 120 280

Dead time (t1) [ms] Dead time (t1) [ms] +

Time constant T63 (= t2) [ms]

min. 280 400 560

max. 1100 1220 1380

2

Time constant (T90), t

Dead time (t1) [ms] +

Time constant T90 (= t3) [ms]

3

Reading cycle

• Acyclic: max. 3/s, typical 1/s (depends on command # and number of preambles)

• Cyclic (Burst): max. 3/s, typical 2/s

The Deltabar FMD71/FMD72 offers BURST MODE functionality for cyclical value transmission via

the HART communication protocol.

Damping

alarm current setting

Firmware version

Cycle time (update time)

Cyclic (burst): min. 300 ms

Response time

• Acyclic: min. 330 ms, typically 590 ms (depending on command # and number of preambles)

• Cyclic (burst): min. 160 ms, typically 350 ms (depending on command # and number of

preambles)

A damping affects all outputs (output signal, display):

• Via onsite display, handheld terminal or PC with operating program, continuous from 0 to 999 s

• Via DIP switch on the electronic insert, switch position "on" = set value and "off"

• Factory setting: 2 s

Damping can be switched on or off using a switch on the electronic insert. If the switch is on, the

time constant can be set via a parameter in the menu and if the switch is off, the output signal is not

damped (time constant = 0.0).

Adjusted min. alarm current: Product configurator order code for "Service", option "IA"

Description Option

01.00.zz, HART, DevRev01 78

1) Product Configurator, order code for "Firmware version"

1)

Endress+Hauser 15

Deltabar FMD71, FMD72

Protocol-specific data

Manufacturer ID 17 (0x11)

Device type ID 39 (0x27)

HART specification 6.0

Device description files (DTM, DD) Information and files can be found:

• www.endress.com

• www.fieldcommgroup.org

HART device variables Measured values for PV (primary variable)

• Differential pressure

• Level linear (before lin.)

• Level after linearization table

Measured values for SV, TV, QV (second, third and fourth variable)

• Measured differential pressure

• Corrected pressure

• Measured pressure HP

• Sensor pressure HP

• Sensor temperature HP

• Measured pressure LP

• Sensor pressure LP

• Sensor temperature LP

• Level before linearization

• Tank content

• Electronic temperature

Supported functions • Burst mode

• Additional transmitter status

16 Endress+Hauser

Deltabar FMD71, FMD72

4... 20mA

Test

Test

Test

4... 20mA Test

1

8

6

7

2

3

4

5

Power supply

WARNING

L

Electrical safety is compromised by an incorrect connection!

In accordance with IEC/EN61010 a separate circuit breaker must be provided for the device .

‣

When using the measuring device in hazardous areas, installation must comply with the

‣

corresponding national standards and regulations and the Safety Instructions or Installation or

Control Drawings.

All explosion protection data are given in separate documentation which is available upon

‣

request. The Ex documentation is supplied as standard with all devices approved for use in

explosion hazardous areas.

Devices with integrated overvoltage protection must be grounded.

‣

Protective circuits against reverse polarity, HF influences and overvoltage peaks are integrated.

‣

Terminals

Terminal assignment

• Supply voltage and internal ground terminal: 0.5 to 2.5 mm2 (20 to 14 AWG)

• External ground terminal: 0.5 to 4 mm2 (20 to 12 AWG)

A0019989

1 Housing

2 Supply voltage

3 4 to 20 mA

4 Devices with integrated overvoltage protection are labeled "OVP" (overvoltage protection) here.

5 External ground terminal

6 4 to 20 mA test signal between positive and test terminal

7 Internal ground terminal, minimum supply voltage = 12 V DC, jumper is set as illustrated in the diagram.

8 Jumper for 4 to 20 mA test signal

Supply voltage

Electronic version Jumper for 4 to 20 mA test signal in

"Test" position (delivery status)

4 to 20 mA HART, version for

non-hazardous areas

13 to 45 V DC 12 to 45 V DC

Jumper for 4 to 20 mA test signal

in "Non-test" position

Measuring a 4 to 20 mA test signal

A 4 to 20 mA test signal may be measured via the positive and test terminal without interrupting

the measurement. The minimum supply voltage of the device can be reduced by simply changing the

position of the jumper. As a result, operation is also possible with a lower supply voltage. To keep the

measured error below 0.1 %, the current measuring device should exhibit an internal resistance of

<0.7Ω. Observe the position of the jumper in accordance with the following table.

Endress+Hauser 17

Deltabar FMD71, FMD72

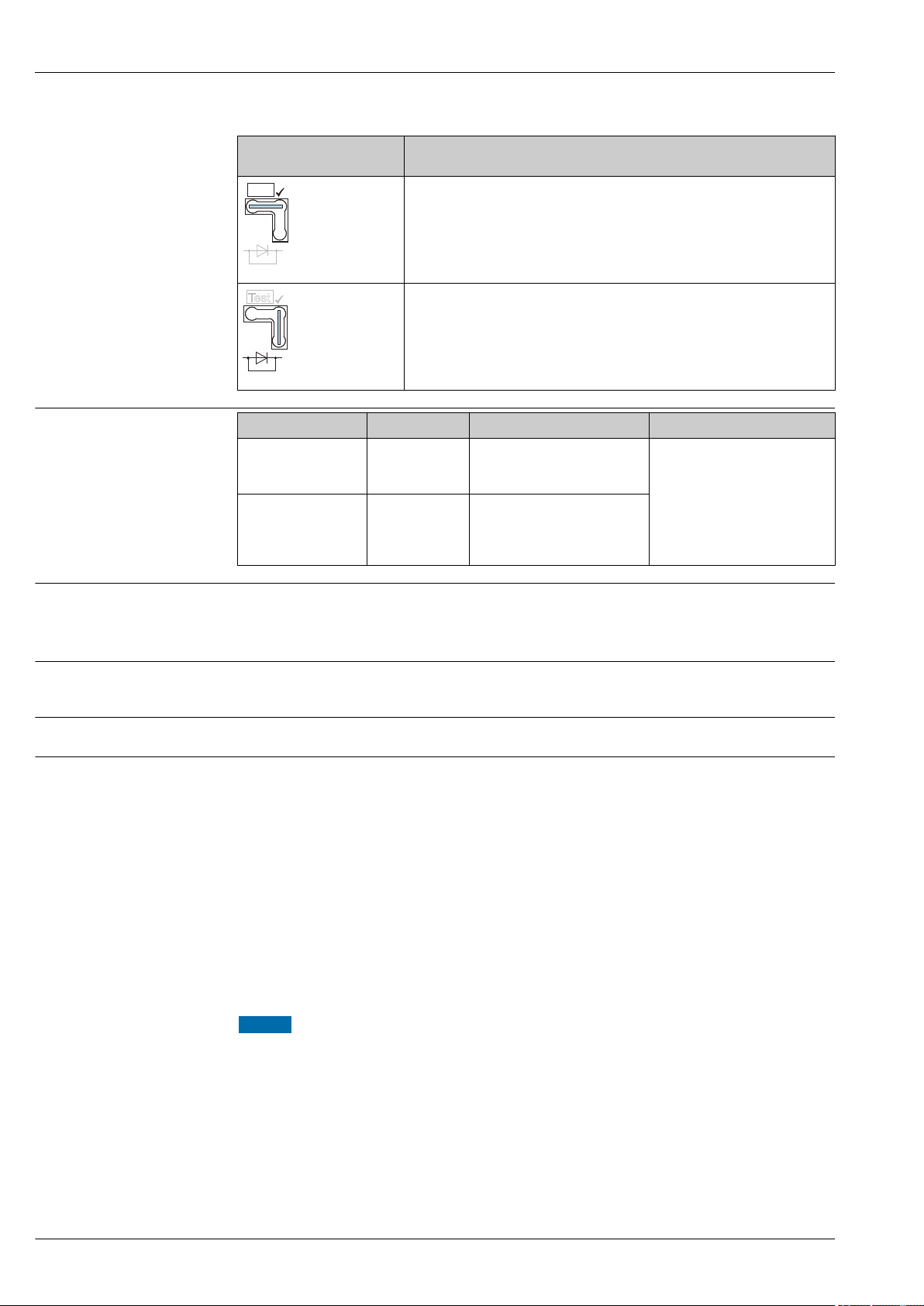

Test

Test

Cable entries

Cable specification for transmitter connection

Jumper position for test

signal

Explosion protection Cable gland Permitted cable diameter Permitted wire cross-sections

• Standard

• Ex ia

• Ex ic

• Ex tD

• Ex nA

• FM approval

• CSA approval

Description

• Measurement of 4 to 20 mA test signal via the positive and test terminal:

possible. (Thus, the output current can be measured without interruption via

the diode.)

• Delivery status

• Minimum supply voltage: 13 V DC

A0019992

• Measurement of 4 to 20 mA test signal via positive and test terminal: not

possible.

• Minimum supply voltage: 12 V DC

A0019993

Plastic M20x1.5 5 to 10 mm (0.2 to 0.39 in) 0.5 to 2.5 mm2 (20 to 14 AWG)

Metal M20 x 1.5 7 to 10.5 mm (0.28 to 0.41 in)

• Endress+Hauser recommends using twisted, shielded two-wire cables.

• Terminals for core cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• The cable outer diameter depends on the cable entry used.

Residual ripple

Without influence on 4 to 20 mA signal up to ±5 % residual ripple within the permitted voltage

range [according to HART hardware specification HCF_SPEC-54 (DIN IEC 60381-1)]

Influence of power supply

≤0.0006 % of URL/1 V

Overvoltage protection Standard version

The standard version of the pressure instruments does not contain any special elements to protect

against overvoltage ("wire to ground"). Nevertheless the requirements of the applicable EMC

standard EN 61000-4-5 (testing voltage 1kV EMC wire/ground) are met.

Optional overvoltage protection

Devices showing version "NA" in feature 610 "Accessory Mounted" in the order code are equipped

with overvoltage protection.

• Overvoltage protection:

– Nominal functioning DC voltage: 600 V

– Nominal discharge current: 10 kA

• Surge current check î = 20 kA satisfied as per DIN EN 60079-14: 8/20 μs

• Arrester AC current check I = 10 A satisfied

NOTICE

Device could be destroyed!

Devices with integrated overvoltage protection must be grounded.

‣

18 Endress+Hauser

Deltabar FMD71, FMD72

90°

90°

C

A

B

Performance characteristics of ceramic process isolating diaphragm

Reference operating conditions

Influence of the installation position depending on sensor

• As per IEC 60770

• Ambient temperature TA = constant, in the range of:+21 to +33 °C (+70 to +91 °F)

•

Humidity j= constant, in the range of: 5 to 80 % RH

• Ambient pressure pA = constant, in the range of:860 to 1 060 mbar (12.47 to 15.37 psi)

• Position of measuring cell = constant, in range: horizontal ±1° (see also "Influence of the

installation position" section → 19)

• Input of Lo Trim Sensor and Hi Trim Sensor for lower range value and upper range value

• Zero based span

• Material of process isolating diaphragm: Al2O3 (aluminum-oxide ceramic, Ceraphire®)

• Supply voltage: 24 V DC ±3 V DC

• Load with HART: 250 Ω

Process isolating diaphragm axis is horizontal (A) Process isolating diaphragm pointing

upwards (B)

Calibration position, no measuring error < +0.2 mbar (+0.003 psi) < –0.2 mbar (–0.003 psi)

This effect can be corrected using the function to adjust the position (position adjustment) for the

differential pressure. Additional position adjustments for individual pressure signals are not

available.

A position-dependent zero shift can be corrected on the device.

Resolution

Vibration effects

Application limits

• Current output: 1 μA

• Display: can be set (factory setting: presentation of the maximum accuracy of the transmitter)

Test standard Vibration effects

IEC 61298-3 ≤ Reference accuracy up to 10 to 60 Hz: ±0.35 mm (±0.01 in); 60 to 500 Hz: 2 g

A high ratio between the level and head pressure or between the differential pressure and static

pressure can result in large measured errors. A maximum ratio of 1:10 is recommended. For

calculation purposes, please use the free "Applicator" calculation tool, which is available online at

"www.endress.com/applicator" or on CD-ROM.

Process isolating diaphragm pointing

downwards (C)

A0016465

Endress+Hauser 19

Deltabar FMD71, FMD72

A

Diff

HP HP

2

(A URL )

+=

.

LP LP

2

(A URL )

.

100 100

A [%]

P

100

.

Diff

Diff

=

A

Diff

T

Diff

HP HP

2

(T URL )

+=

.

LP LP

2

(T URL )

.

100 100

T [%]

P

100

.

Diff

Diff

=

T

Diff

Reference accuracy

The reference accuracy contains the non-linearity [DIN EN 61298-2 3.11] including the pressure

hysteresis [DIN EN 61298-23.13] and non-repeatability [DIN EN 61298-2 3.11] in accordance with

the limit point method as per [DIN EN 60770].

Measuring cell Sensor Reference accuracy (A)

[%URL for every sensor]

Standard Platinum

100 mbar (1.5 psi) Gauge pressure A =

250 mbar (3.75 psi) Gauge pressure A =

400 mbar (6 psi) Gauge pressure A =

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

1) For hygienic process connections

Gauge pressure/ Absolute pressure A =

A =

A =

A =

A =

±0.075

±0.15

±0.075

±0.15

±0.075

±0.15

±0.075

±0.15

- Calculation (mbar, bar or psi):

1)

-

1)

-

1)

A = ±0.05

1)

Ordering Information

Description Option

Platinum D

Standard G

±0.075

Calculated reference accuracy (A

of the differential pressure

Percentage calculation of URL dP:

1)

1)

Diff

)

A0016468

A0016469

1) Product Configurator order code for "Reference accuracy"

Thermal change in the zero output and the output span Standard version

Measuring cell –10 °C (+14 °F)to ≤

+60 °C (+140 °F)

% of the set span for every sensor

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

T

= ±0.176 T

total

T

= ±0.092 T

total

–20 to –10 °C (–4 to +14 °F)

> +60 to +125 °C (+140 to +257 °F)

= ±0.276 Calculation (mbar, bar or psi):

total

= ±0.250

total

Calculated thermal change (T

of the differential pressure

Percentage calculation of URL dP:

Diff

)

A0016474

A0016475

20 Endress+Hauser

Deltabar FMD71, FMD72

T

Diff

HP HP

2

(T URL )

+=

.

LP LP

2

(T URL )

.

100 100

T [%]

P

100

.

Diff

Diff

=

T

Diff

TP

Diff

HP HP

2

(TP URL )

+=

.

LP LP

2

(TP URL )

.

100 100

TP [%]

P

100

.

Diff

Diff

=

TP

Diff

L

Diff

HP HP

2

(L

100 100

URL )

+=

.

LP LP

2

(L URL )

.

High temperature version and hygienic version

Measuring cell Sensor –10 °C (+14 °F)to ≤

+60 °C (+140 °F)

% of the set span for every sensor

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi) Absolute

1) For hygienic process connections

Total performance

Gauge

pressure

Gauge

pressure

Absolute

pressure

pressure

T

= ±0.176

T

T

T

T

T

T

T

total

Total

total

total

total

total

total

total

= ±0.352

= ±0.092

= ±0.184

= ±0.092

= ±0.184

= ±0.092

= ±0.184

1)

1)

1)

1)

The "Total performance" specification comprises the non-linearity including hysteresis, nonreproducibility as well as the thermal change in the zero point. All specifications apply to the

temperature range –10 to +60 °C (+14 to +140 °F).

>

+60 to +150 °C

(140 to +302 °F)

T = ±0.75

T = ±1.25

T = ±0.5

T = ±0.75

T = ±0.75

T = ±1.25

T = ±0.5

T = ±0.75

1)

1)

1)

1)

Calculated thermal change (T

of the differential pressure

Calculation (mbar, bar or psi):

Percentage calculation of URL dP:

Diff

)

A0016474

A0016475

Measuring cell % of URL for every

sensor - standard

version

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

TP = ±0.2 TP = ±0.46 TP = ±0.575 Calculation (mbar, bar or psi):

TP = ±0.15 TP = ±0.46 TP = ±0.5

% of URL for every

sensor - hightemperature version

% of URL for every

sensor - hygienic

version

Calculated total performance (TP

of the differential pressure

Percentage calculation of URL dP:

The "Applicator Sizing Electronic dp" selection tool, available free of charge on the Endress

+Hauser web site (www.endress.com/applicator), enables detailed calculations for your

respective applications.

Long-term stability

Measuring ranges Sensor Standard version Calculated long-term stability (L

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

Gauge pressure L = ±0.1

Absolute pressure L = ±0.3

'

1 year 10 years

% of URL for every sensor

L = ±0.2

L = ±0.25

1)

L = ±0.45

L = ±0.55

of the differential pressure

Calculation (mbar, bar or psi):

1)

1)

Diff

)

Diff

A0016470

A0016471

)

A0016463

Percentage calculation of URL dP/year:

Endress+Hauser 21

Deltabar FMD71, FMD72

L [%]

P

100

.

Diff

Diff

=

L

Diff

TE

Diff

HP HP

2

(TE URL )

+=

.

LP LP

2

(TE URL )

.

100 100

TE [%]

P

100

.

Diff

Diff

=

TE

Diff

Measuring ranges Sensor Standard version Calculated long-term stability (L

of the differential pressure

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

1) For hygienic process connections

Gauge pressure L = ±0.05

Absolute pressure L = ±0.3

Total error

1 year 10 years

% of URL for every sensor

L = ±0.2

L = ±0.1

1)

The total error comprises the total performance and long-term stability. All specifications apply to

the temperature range –10 to +60 °C (+14 to +140 °F).

Measuring cell % of URL for every

sensor - standard

version

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

TE = ±0.25 TE = ±0.51 TE = ±0.925 Calculation (mbar, bar or psi):

TE = ±0.2 TE = ±0.51 TE = ±0.7

% of URL for every

sensor - hightemperature version

% of URL for every

sensor - hygienic

version

Calculated total error (TE

of the differential pressure

Percentage calculation of URL dP:

Diff

Diff

)

A0016464

)

A0016472

Warm-up period

A0016473

4 to 20 mA HART: < 10 s

22 Endress+Hauser

Loading...

Loading...