Page 1

BA00332P/00/EN/19.16

71336242

valid from Software version:

02.30.zz

Products Solutions Services

Operating Instructions

Deltapilot S FMB70

Hydrostatic level measurement

Page 2

Deltapilot S FMB70 with 4...20 mA HART

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

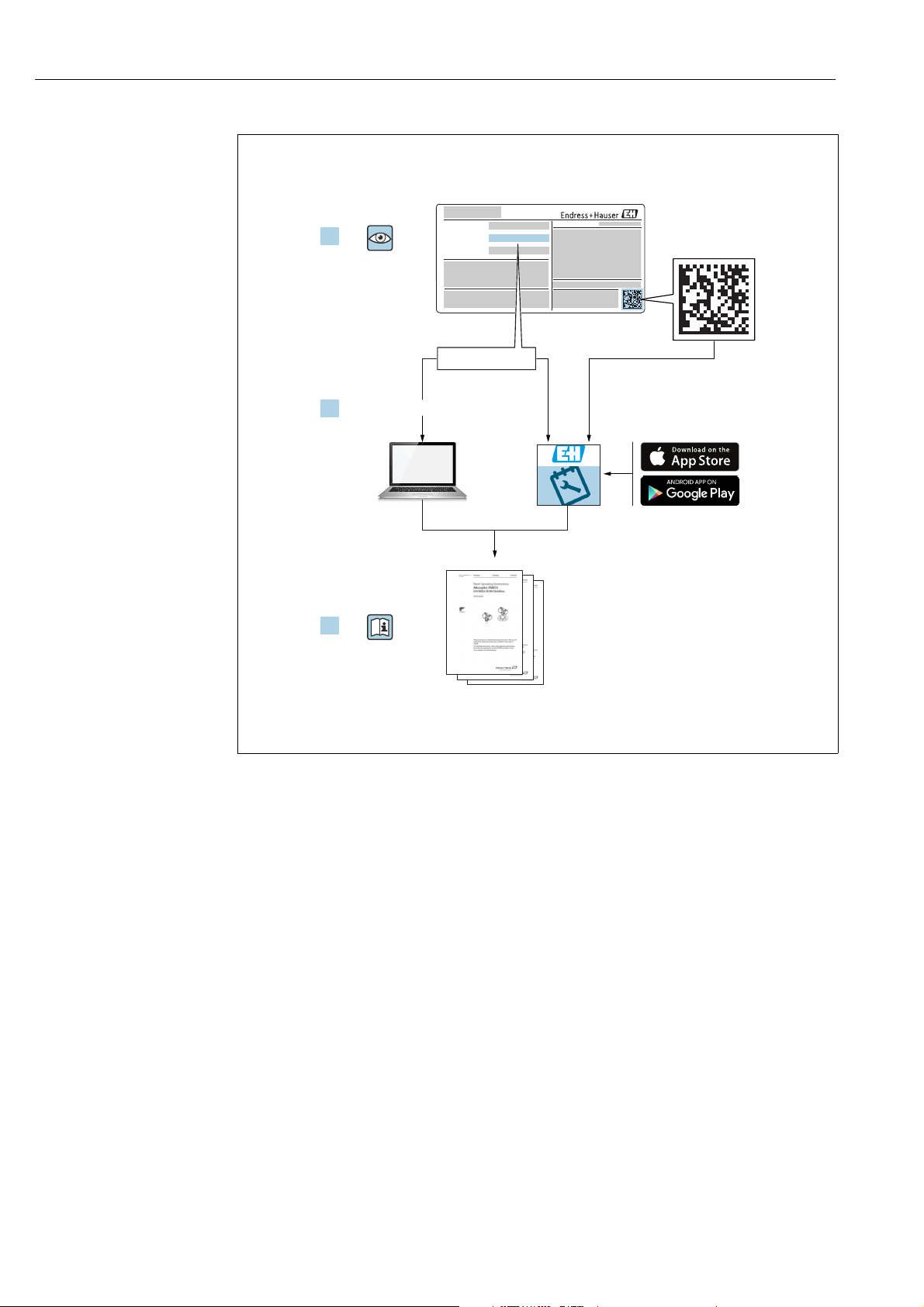

1.

3.

2.

A0023555

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to these

Instructions.

2 Endress+Hauser

Page 3

Deltapilot S FMB70 with 4...20 mA HART

Table of contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . 6

1.5 Turn down calculation . . . . . . . . . . . . . . . . . . . . . . . 7

2 Basic safety instructions . . . . . . . . . . . . . 8

2.1 Requirements concerning the staff . . . . . . . . . . . . . 8

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Functional Safety SIL3 (optional) . . . . . . . . . . . . . . 9

3 Identification . . . . . . . . . . . . . . . . . . . . . 10

3.1 Product identification . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Device designation . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 CE mark, declaration of conformity . . . . . . . . . . 12

4 Installation . . . . . . . . . . . . . . . . . . . . . . . 13

7.3 Selecting language and measuring mode . . . . . . 39

7.4 Position adjustment . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5 Level measurement . . . . . . . . . . . . . . . . . . . . . . . . 42

7.6 Pressure measurement . . . . . . . . . . . . . . . . . . . . . 46

8 Maintenance . . . . . . . . . . . . . . . . . . . . . 47

8.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9 Trouble-shooting . . . . . . . . . . . . . . . . . 48

9.1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2 Response of outputs to errors . . . . . . . . . . . . . . . . 56

9.3 Confirming messages . . . . . . . . . . . . . . . . . . . . . . . 58

9.4 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.5 Repair of Ex-certified devices . . . . . . . . . . . . . . . . 59

9.6 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.7 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.9 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10 Technical data . . . . . . . . . . . . . . . . . . . . 60

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.1 Incoming acceptance and storage . . . . . . . . . . . . 13

4.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . 13

4.3 General installation instructions . . . . . . . . . . . . . 13

4.4 Installation instructions . . . . . . . . . . . . . . . . . . . . 14

4.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 19

5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Connecting the device . . . . . . . . . . . . . . . . . . . . . 20

5.2 Connecting the measuring unit . . . . . . . . . . . . . . 22

5.3 Potential matching . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 Overvoltage protection (optional) . . . . . . . . . . . . 24

5.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 24

6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 On-site display (optional) . . . . . . . . . . . . . . . . . . 25

6.2 Operating elements . . . . . . . . . . . . . . . . . . . . . . . 26

6.3 On-site operation –

on-site display not connected . . . . . . . . . . . . . . . 28

6.4 On-site operation –

on-site display connected . . . . . . . . . . . . . . . . . . . 31

6.5 HistoROM®/M-DAT (optional) . . . . . . . . . . . . . . 33

6.6 Operation via SFX100 . . . . . . . . . . . . . . . . . . . . . . 36

6.7 Endress+Hauser operating program . . . . . . . . . . 36

6.8 Locking/unlocking operation . . . . . . . . . . . . . . . 36

6.9 Factory setting (reset) . . . . . . . . . . . . . . . . . . . . . 37

7 Commissioning. . . . . . . . . . . . . . . . . . . . 39

7.1 Configuring messages . . . . . . . . . . . . . . . . . . . . . 39

7.2 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Endress+Hauser 3

Page 4

Document information Deltapilot S FMB70 with 4...20 mA HART

DANGER

WARNING

CAUTION

NOTICE

)

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and storage,

to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

1.2 Symbols used

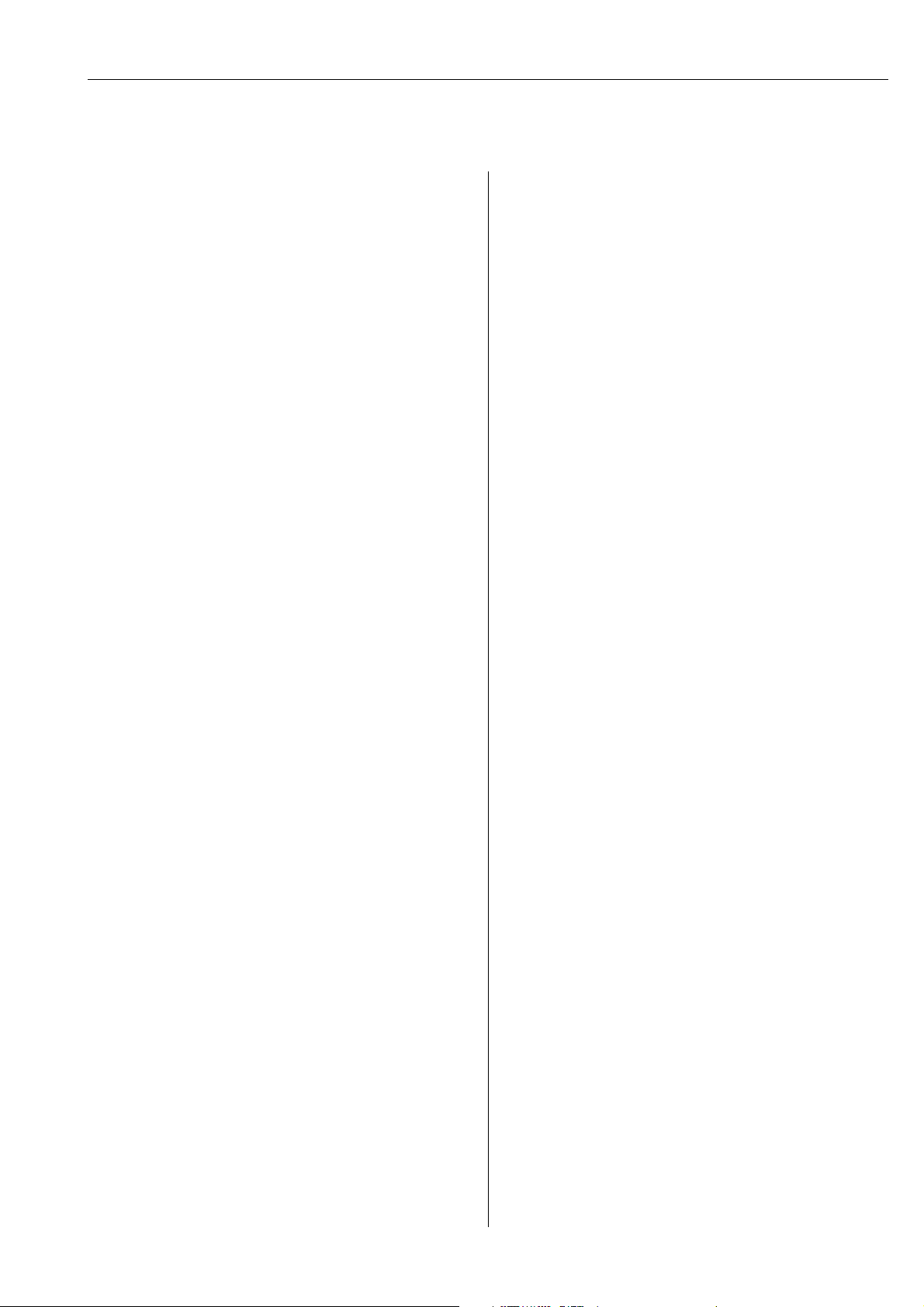

1.2.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-DE

A0011190-DE

A0011191-DE

A0011192-DE

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

seriousor fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

seriousor fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minoror medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personalinjury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

1.2.3 Tool symbols

Symbol Meaning

Allen key

A0011221

Hexagon wrench

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line or

a star grounding system depending on

national or company codes of practice.

A0011222

4 Endress+Hauser

Page 5

Deltapilot S FMB70 with 4...20 mA HART Document information

A

,…,

1.

2.

3.

,…,

1.

2.

3.

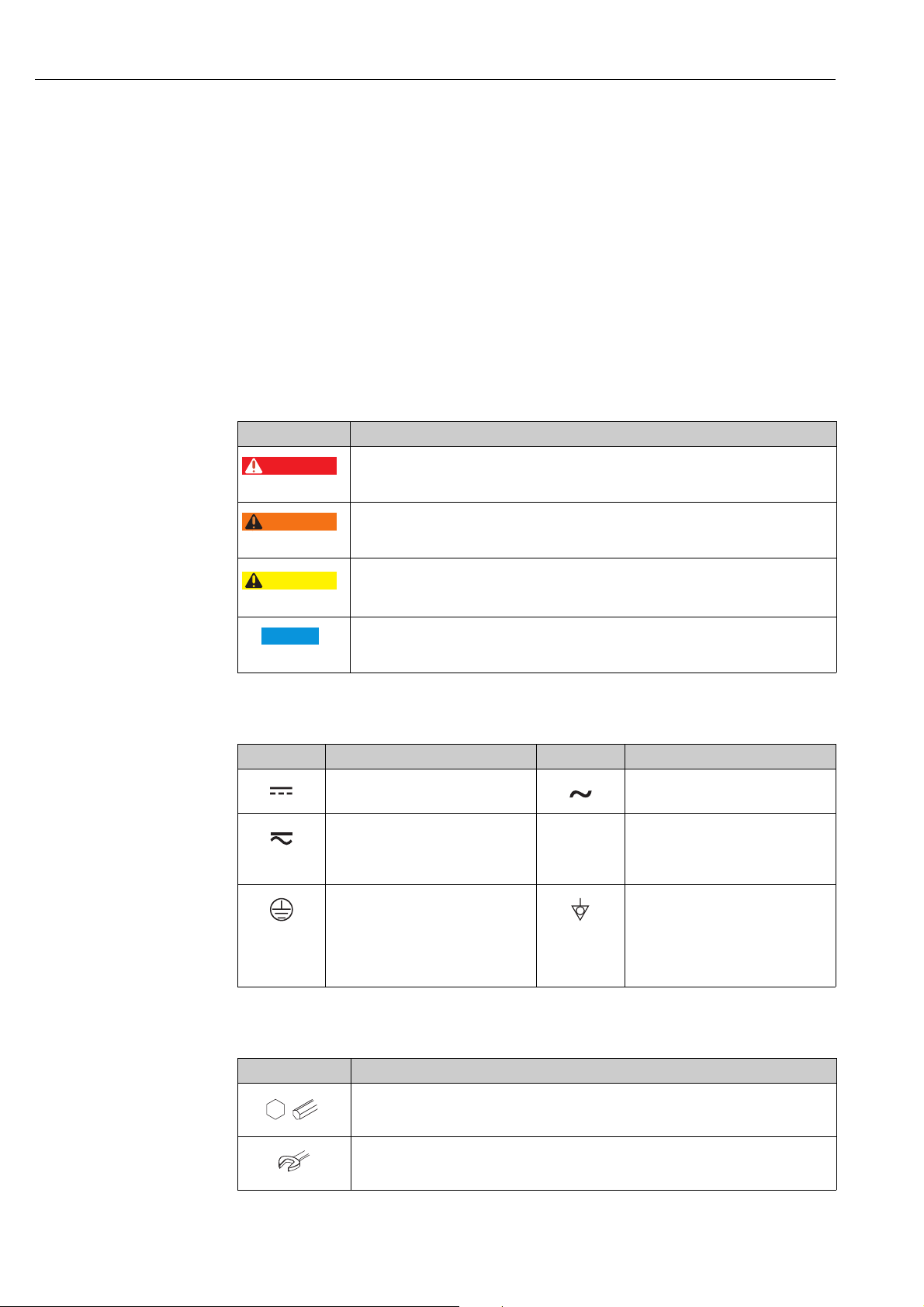

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

A0028658

Reference to page

A0028659

Reference to graphic

A0028660

Series of steps

A0031595

Result of a sequence of actions

A0018343

Visual inspection

A0028673

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3, 4, ... Item numbers

Series of steps

A0031595

A, B, C, D, ... Views

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

A0019159

1.3 Registered trademarks

KALREZ, VITON, TEFLON

Registered trademarks of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

Registered trademark of Ladish & Co., Inc., Kenosha, USA

HART

Registered trademark of the HART Communication Foundation, Austin, USA.

GORE-TEX

Registered trademarks of W.L. Gore & Associates, Inc., USA

®

Endress+Hauser 5

Page 6

Document information Deltapilot S FMB70 with 4...20 mA HART

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

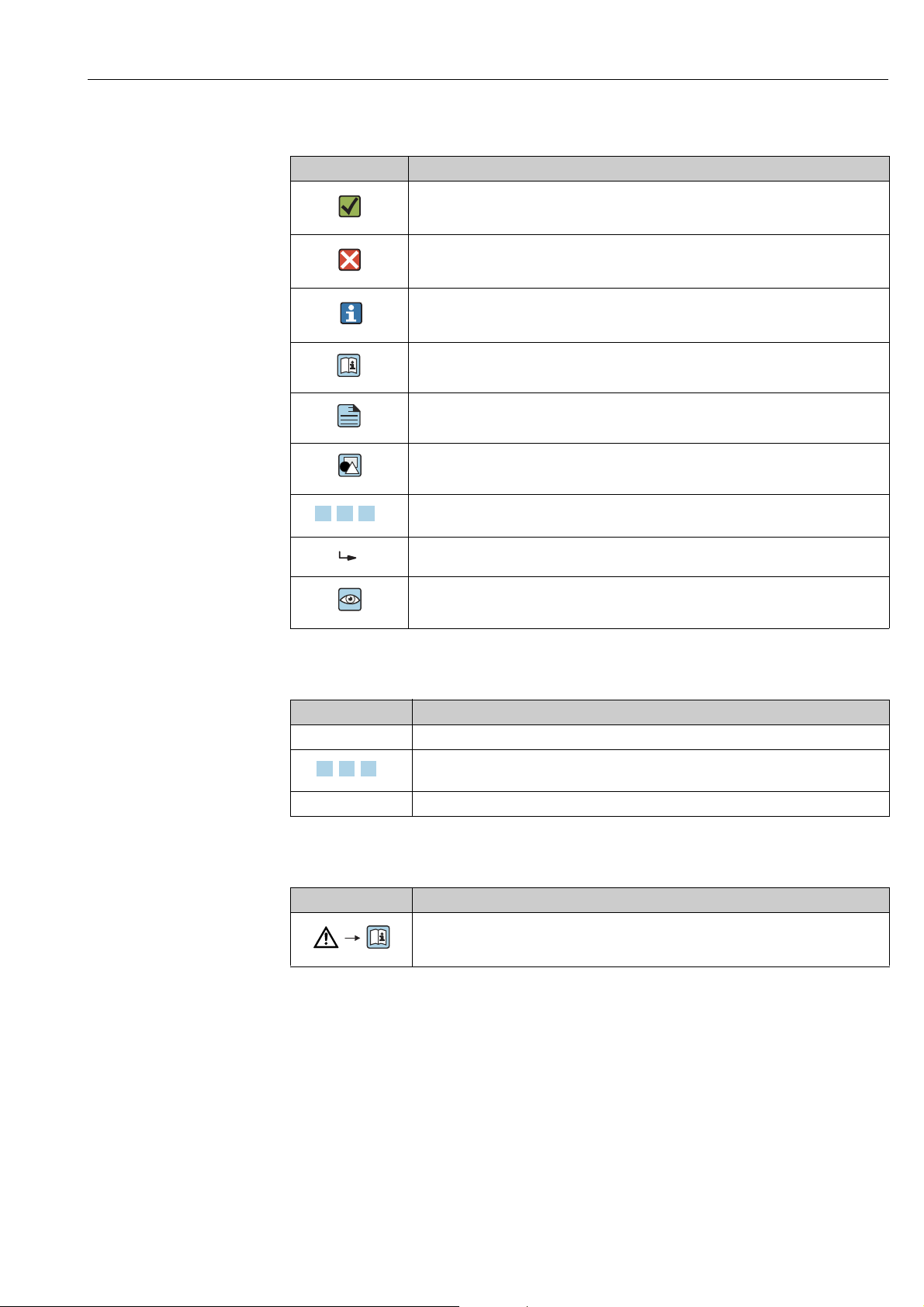

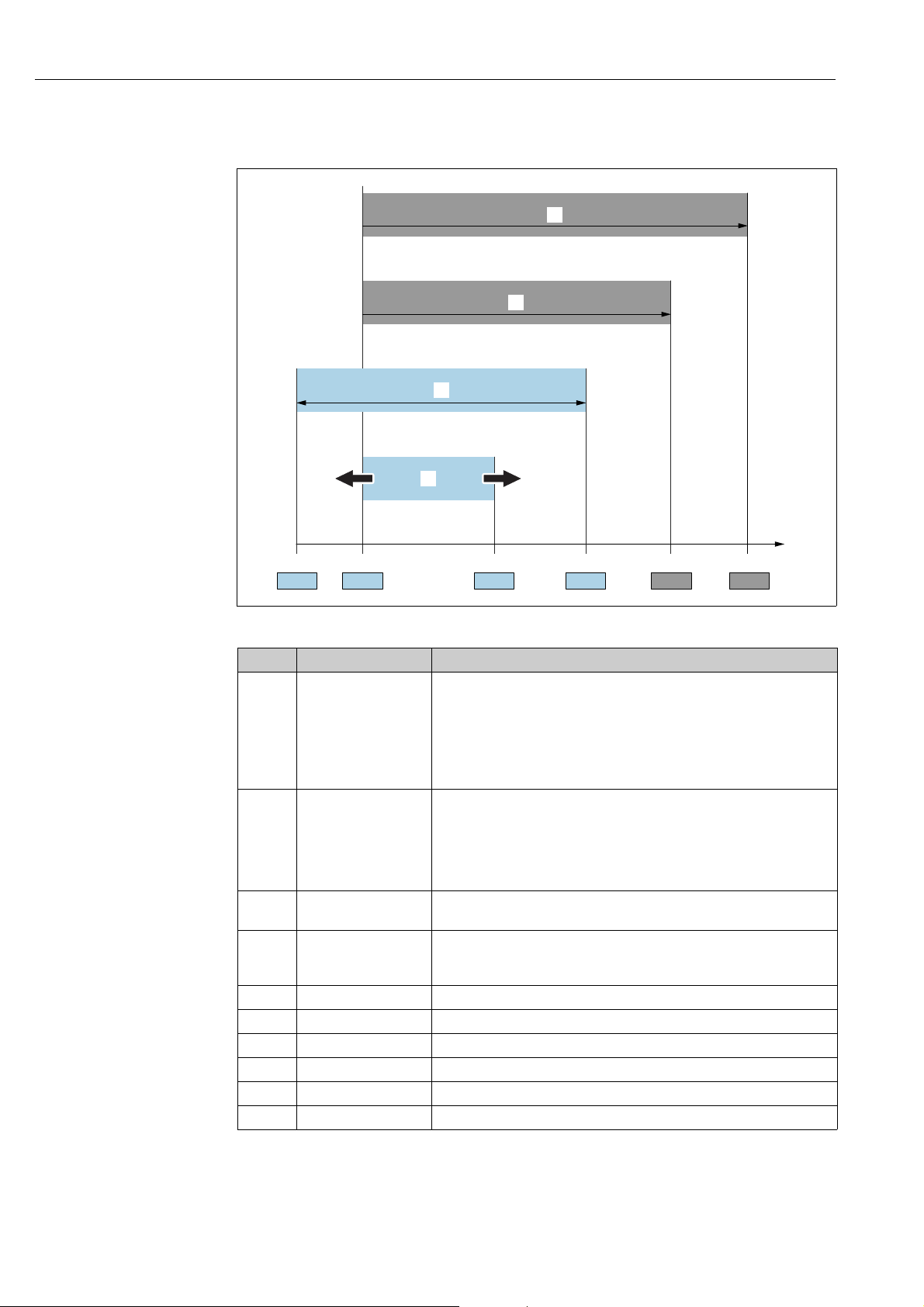

1.4 Terms and abbreviations

A0029505

Position Term/Abbreviation Explanation

1 OPL The OPL (over pressure limit = sensor overload limit) for the sensors

depends on the lowest-rated element, with regard to pressure, of the

selected components, i.e. the process connection must be taken into

consideration in addition to the measuring cell. Also observe pressuretemperature dependency. For the relevant standards and additional notes,

see technical information.

The OPL may be applied for a limited time period.

2 MWP The MWP (maximum working pressure) for the sensors depends on the

lowest-rated element, with regard to pressure, of the selected components,

i.e. the process connection has to be taken into consideration in addition to

the measuring cell. Also observe pressure-temperature dependency. For the

relevant standards and additional notes, see technical information.

The MWP may be applied for an unlimited time.

3Maximum sensor

measuring range

4 Calibrated/Adjusted

measuring span

p - Pressure

- LRL Lower range limit

-URL Upper range limit

- LRV Lower range value

-URV Upper range value

-TD Turn down

Range between LRL and URL

This span is the maximum calibratable/adjustable measuring span.

Range between LRV and URV

Factory setting: 0...URL

Other calibrated spans can be ordered with customised settings.

6 Endress+Hauser

Page 7

Deltapilot S FMB70 with 4...20 mA HART Document information

LRV

URLURV

LRL

1 = 2

3

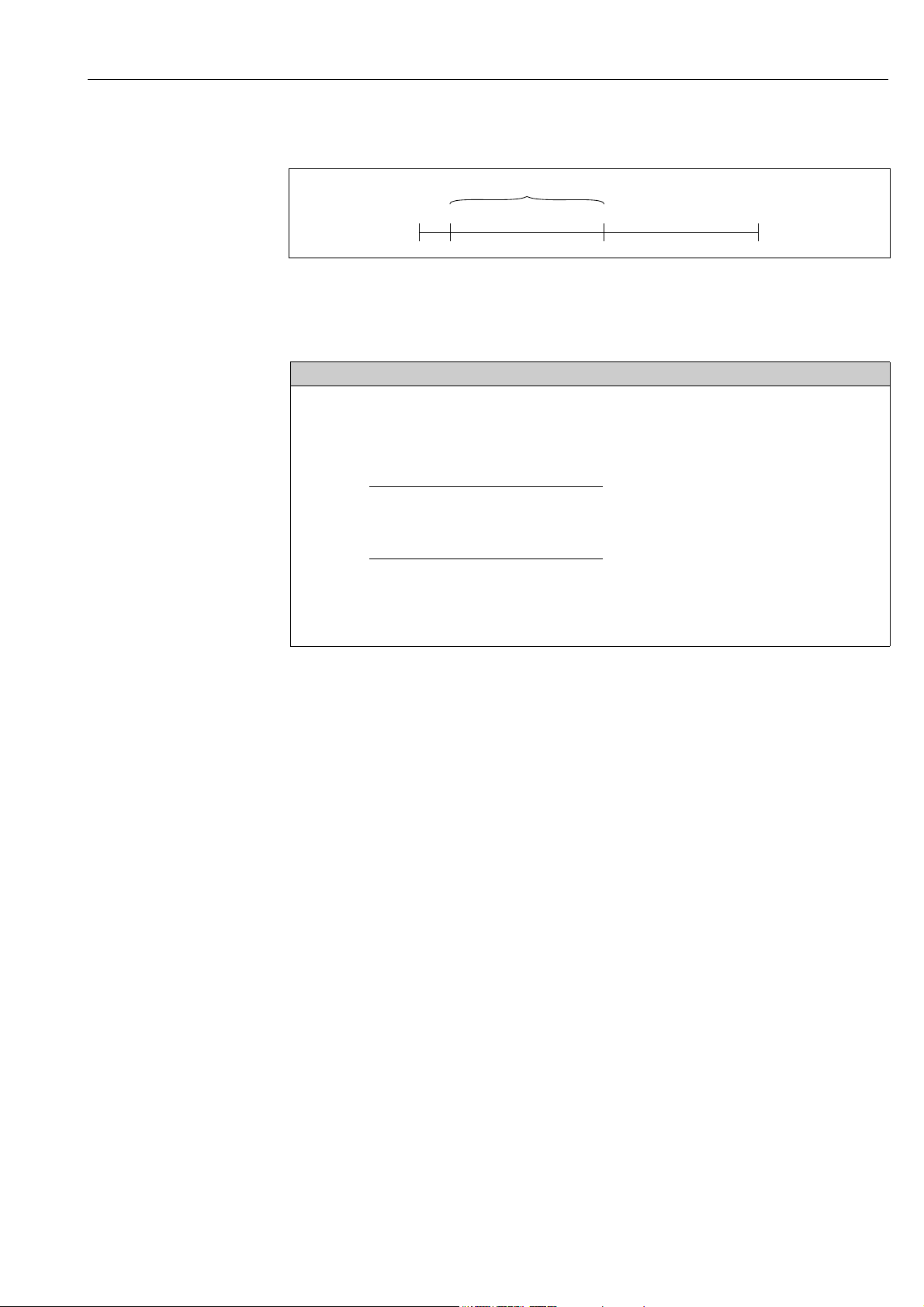

1.5 Turn down calculation

A0029545

Fig. 1:

1 Calibrated/Adjusted measuring span

2 Zero-based span

3 Upper range limit

Example

• Sensor: 10 bar (150 psi)

• Upper range limit (URL) = 10 bar (150 psi)

Turn down (TD):

TD =

|URV - LRV|

URL

• Calibrated/Adjusted measuring span: 0...5 bar

(0...75 psi)

• Lower range value (LRV) = 0 bar

• Upper range value (URV) = 5 bar (75 psi)

TD =

In this example, the TD is thus 2:1.

This span is based on the zero point.

|5 bar (75 psi) - 0 bar (0 psi)|

10 bar (150 psi)

=2

Endress+Hauser 7

Page 8

Basic safety instructions Deltapilot S FMB70 with 4...20 mA HART

2 Basic safety instructions

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner-operator

• Following the instructions in these Operating Instructions

2.2 Designated use

The Deltapilot S is a hydrostatic pressure transmitter for measuring level and pressure.

2.2.1 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability.

2.3 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.4 Operational safety

Risk of injury!

‣ Operate the device in proper technical condition and fail-safe condition only.

‣ The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers:

‣ If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

‣ Carry out repairs on the device only if they are expressly permitted.

‣ Observe federal/national regulations pertaining to repair of an electrical device.

‣ Use original spare parts and accessories from Endress+Hauser only.

8 Endress+Hauser

Page 9

Deltapilot S FMB70 with 4...20 mA HART Basic safety instructions

2.5 Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous

area (e.g. explosion protection, pressure vessel safety):

• Based on the nameplate, check whether the ordered device is permitted for the intended

use in the hazardous area.

• Observe the specifications in the separate supplementary documentation that is an

integral part of these Instructions.

2.6 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the- art safety requirements, has been tested, and left the factory in a condition in

which they are safe to operate. It fulfills general safety requirements and legal requirements.

It also conforms to the EC directives listed in the device-specific EC declaration of conformity.

Endress+Hauser confirms this fact by applying the CE mark.

2.7 Functional Safety SIL3 (optional)

If using devices for applications with safety integrity, the Functional Safety Manual must be

observed thoroughly.

Endress+Hauser 9

Page 10

Identification Deltapilot S FMB70 with 4...20 mA HART

Ser. no.:

Order code:

Ext. order code:

2

5

6

3

4

1

3 Identification

3.1 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer) : All information about the measuring device is

displayed.

For an overview of the technical documentation provided, enter the serial number from the

nameplates in the W@M Device Viewer (www.endress.com/deviceviewer).

3.1.1 Manufacturer address

Endress+Hauser GmbH+Co. KG

Hauptstraße 1

79689 Maulburg, Germany

Address of the manufacturing plant: See nameplate.

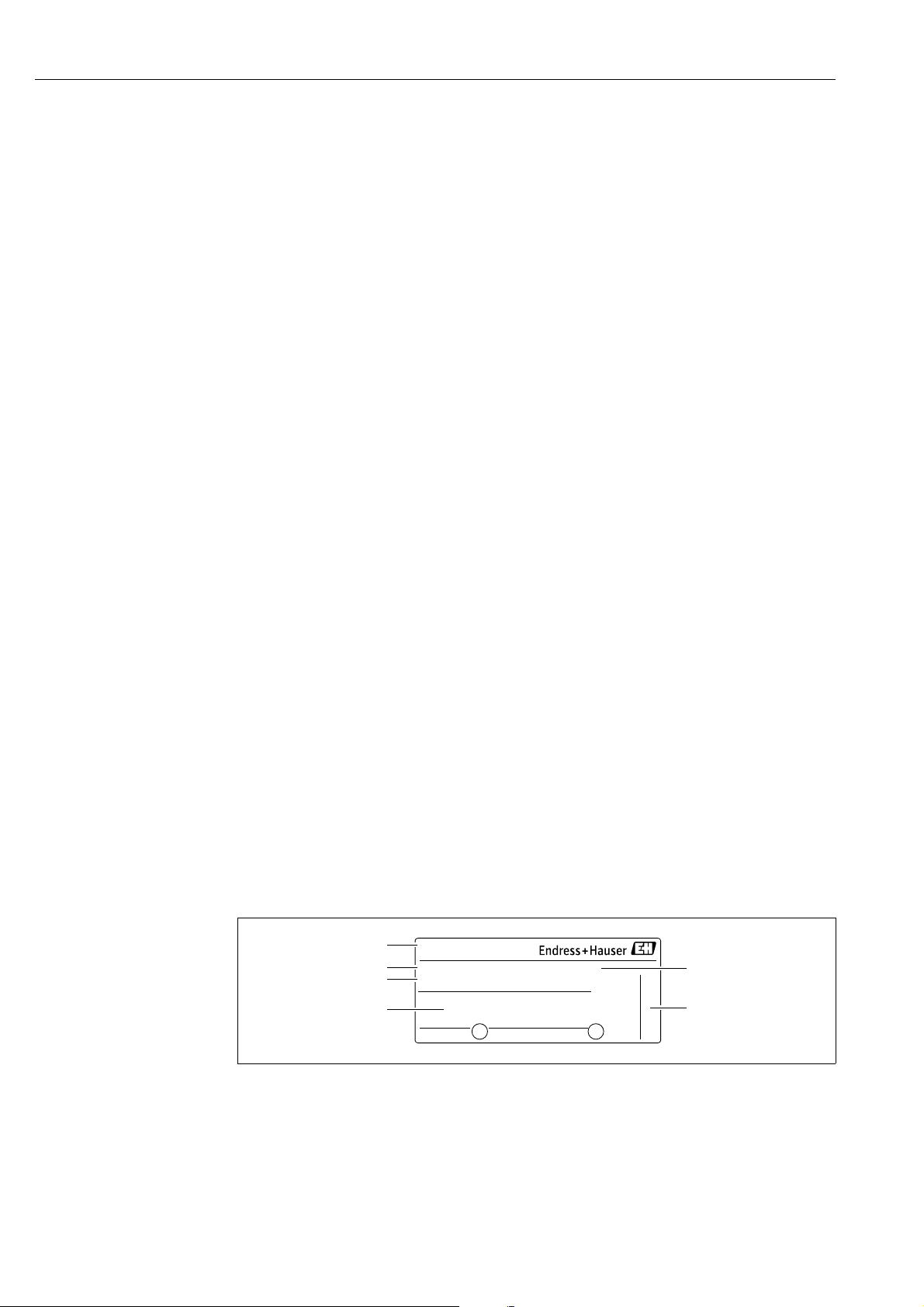

3.2 Device designation

3.2.1 Nameplate

• The MWP (maximum working pressure) is specified on the nameplate. This value refers

to a reference temperature of +20 °C (68°F) and may be applied to the device for an

unlimited time. Observe temperature dependency of the MWP. The pressure values

permitted at higher temperatures can be found in the standards EN 1092-1: 2001 Tab. 18

(With regard to their stability-temperature property, the materials 1.4435 and 1.4404 are

grouped together under 13EO in EN 1092-1 Tab. 18. The chemical composition of the two

materials can be identical.), ASME B 16.5a – 1998 Tab. 2-2.2 F316, ASME B 16.5a –

1998 Tab. 2.3.8 N10276, JIS B 2220.

• The test pressure corresponds to the over pressure limit (OPL) of the device = MWP x 1.5.

• The Pressure Equipment Directive (2014/68/EU) uses the abbreviation "PS".

The abbreviation "PS" corresponds to the MWP (maximum working pressure) of the

measuring device.

Aluminum housing (T14/T15)

Fig. 2: Nameplate

1Device name

2 Order code (for re-orders)

3 Extended order code (complete)

4Technical data

5 Serial number (for identification)

6 Address of manufacturer

10 Endress+Hauser

A0016056

Page 11

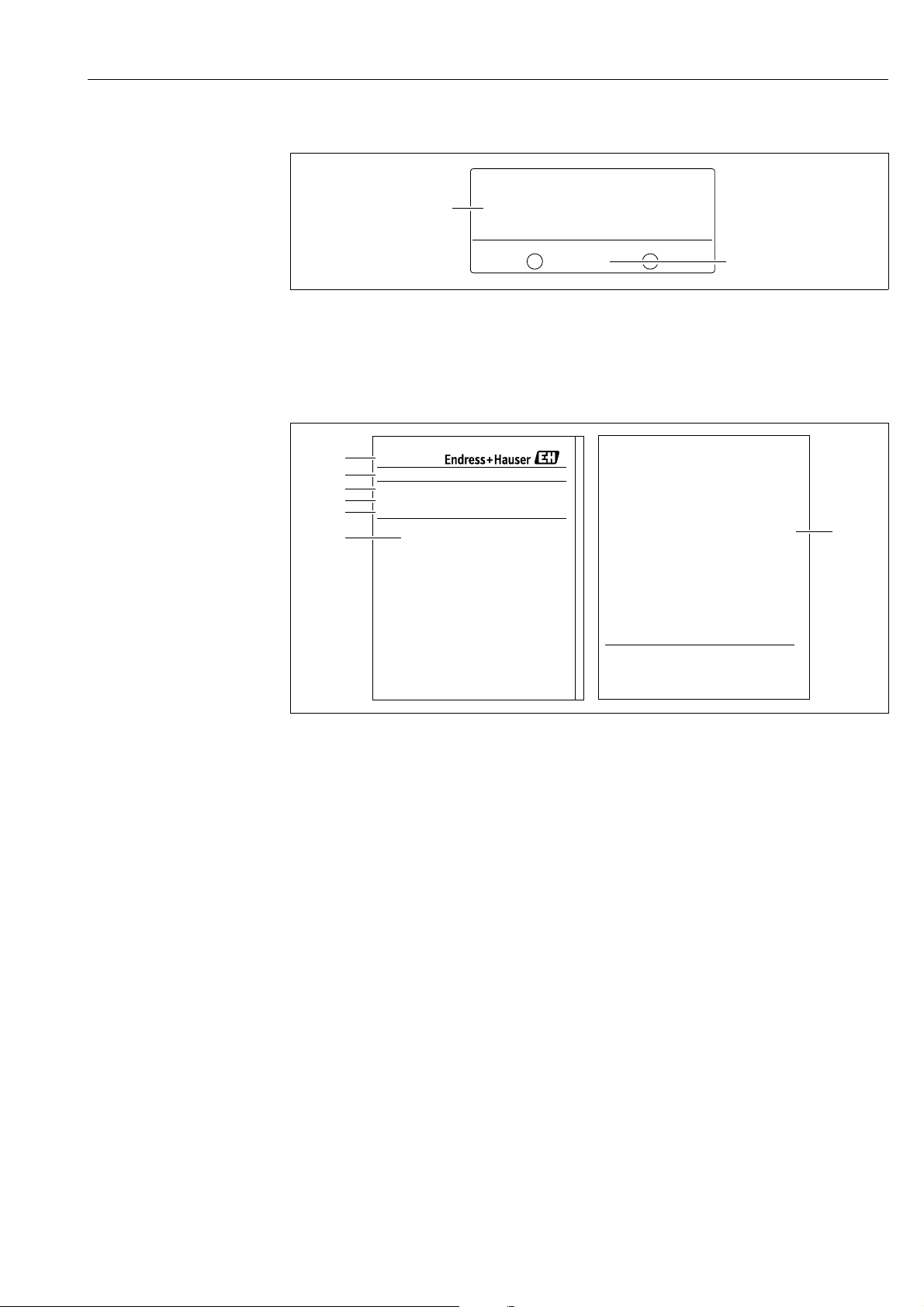

Deltapilot S FMB70 with 4...20 mA HART Identification

2

1

2

7

3

4

5

6

1

Ser. no.:

Order code:

Ext. ord. cd.:

Devices for use in hazardous areas are fitted with an additional nameplate.

A0021222

Fig. 3: Additional nameplate

1 Approval-specific information

2 Document number for safety instructions or drawing number

Hygenic stainless steel housing (T17)

A0021552

Fig. 4: Nameplate

1 Device name

2 Address of manufacturer

3 Order code (for re-orders)

4 Extended order code (complete)

5 Serial number (for identification)

6Technical data

7 Approval-specific information and document number for safety instructions or drawing number

3.2.2 Identifying the sensor type

See parameter "Sensor Meas.Type" in Operating Instruction BA00274P.

Endress+Hauser 11

Page 12

Identification Deltapilot S FMB70 with 4...20 mA HART

3.3 Scope of delivery

The scope of delivery comprises:

• Deltapilot S hydrostatic pressure transmitter

• For devices with the "HistoROM/M-DAT" option:

CD-ROMs with Endress+Hauser operating program

• Optional accessories

Documentation supplied:

• The Operating Instructions BA00332P and BA00274P are available via the Internet.

See: www.endress.com Download.

• Brief Operating Instructions KA01020P

• Leporello KA00218P

• Final inspection report

• Also Safety Instructions with devices for use in hazardous areas

• Optional: factory calibration form, test certificates

3.4 CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device complies with the

applicable standards and regulations as listed in the EC declaration of conformity and thus

complies with the statutory requirements of the EC Directives. Endress+Hauser confirms the

successful testing of the device by affixing to it the CE mark.

12 Endress+Hauser

Page 13

Deltapilot S FMB70 with 4...20 mA HART Installation

WARNING

!

4Installation

4.1 Incoming acceptance and storage

4.1.1 Incoming acceptance

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches

your order.

4.1.2 Transport

Incorrect transportation

Housing and diaphragm may become damaged, and there is a risk of injury!

‣ Transport the measuring device to the measuring point in its original packaging or by the

process connection (with secure transport protection for the diaphragm).

‣ Follow the safety instructions and transport conditions for devices weighing more than

18 kg (39.6 lbs).

4.1.3 Storage

The device must be stored in a dry, clean area and protected against damage from impact

(EN 837-2).

Storage temperature range:

• –40 to +90°C (–40 to +194°F)

• On-site display: –40 to +85°C (–40 to +185°F)

• Separate housing: –40 to +60°C (–40 to +140°F)

4.2 Installation conditions

4.2.1 Dimensions

For dimensions, please refer to the Technical Information for Deltapilot S TI00416P,

"Mechanical construction" section.

4.3 General installation instructions

• Devices with a G 1 1/2 thread:

When screwing the device into the tank, the flat seal has to be positioned on the sealing

surface

of the process connection. To avoid additional strain on the process isolating diaphragm,

the thread should never be sealed with hemp or similar materials.

• Devices with NPT threads:

– Wrap Teflon tape around the thread to seal it.

– Tighten the device at the hexagonal bolt only. Do not turn at the housing.

– Do not overtighten the thread when screwing. Max. torque: 20 to 30 Nm (14.75 to

22.13 lbf ft)

Endress+Hauser 13

Page 14

Installation Deltapilot S FMB70 with 4...20 mA HART

NOTICE

1

1

1

FIELDTERMINALS

FIELDTERMINALS

FIELDTERMINALSFIELDTERMINALS

F

IE

L

D

T

E

R

M

IN

A

L

S

FIELDTERMINALS

F

IE

L

D

T

E

R

M

IN

A

L

S

FIELDTERMINALS

F

IE

L

D

T

E

R

M

IN

A

L

S

FIELDTERMINALS

4.4 Installation instructions

• Due to the orientation of the Deltapilot S, there may be a shift in the measured value, i.e.

when the container is empty, the measured value does not display zero. You may correct

this zero point shift either directly on the device using the -key or by remote operation.

ä 27, "Function of the operating elements – on-site display not connected" or ä 40,

"Position adjustment"..

• To ensure optimal readability of the on-site display, it is possible to rotate the housing up

to 380°. ä 18, Section 4.4.5 "Rotating the housing".

• The on-site display can be rotated in 90° stages.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls. ä 16,

Section 4.4.3 "Wall and pipe mounting (optional)".

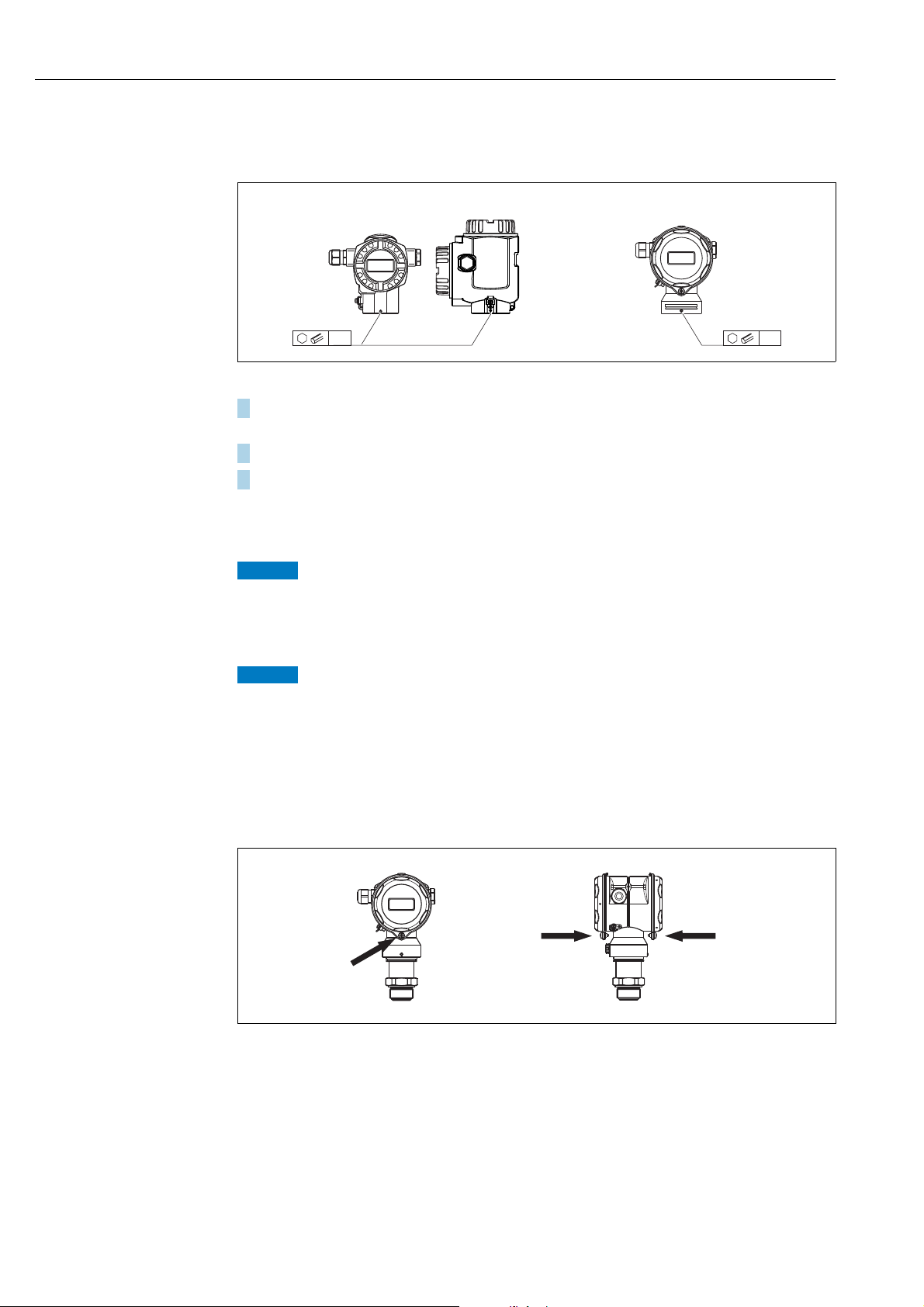

4.4.1 Installation instructions

Damage to the device!

If a heated Deltapilot S is cooled during the cleaning process (e.g. by cold water), a vacuum

develops for a short time, whereby moisture can penetrate the sensor through the pressure

compensation (1).

‣ If this is the case, mount the sensor with the pressure compensation (1) pointing

downwards.

®

• Keep the pressure compensation and GORE-TEX

filter (1) free from contaminations.

• Do not clean or touch process isolating diaphragm with hard or pointed objects.

• The device must be installed as follows in order to comply with the cleanability

requirements of the ASME-BPE (Part SD Cleanability):

14 Endress+Hauser

Page 15

Deltapilot S FMB70 with 4...20 mA HART Installation

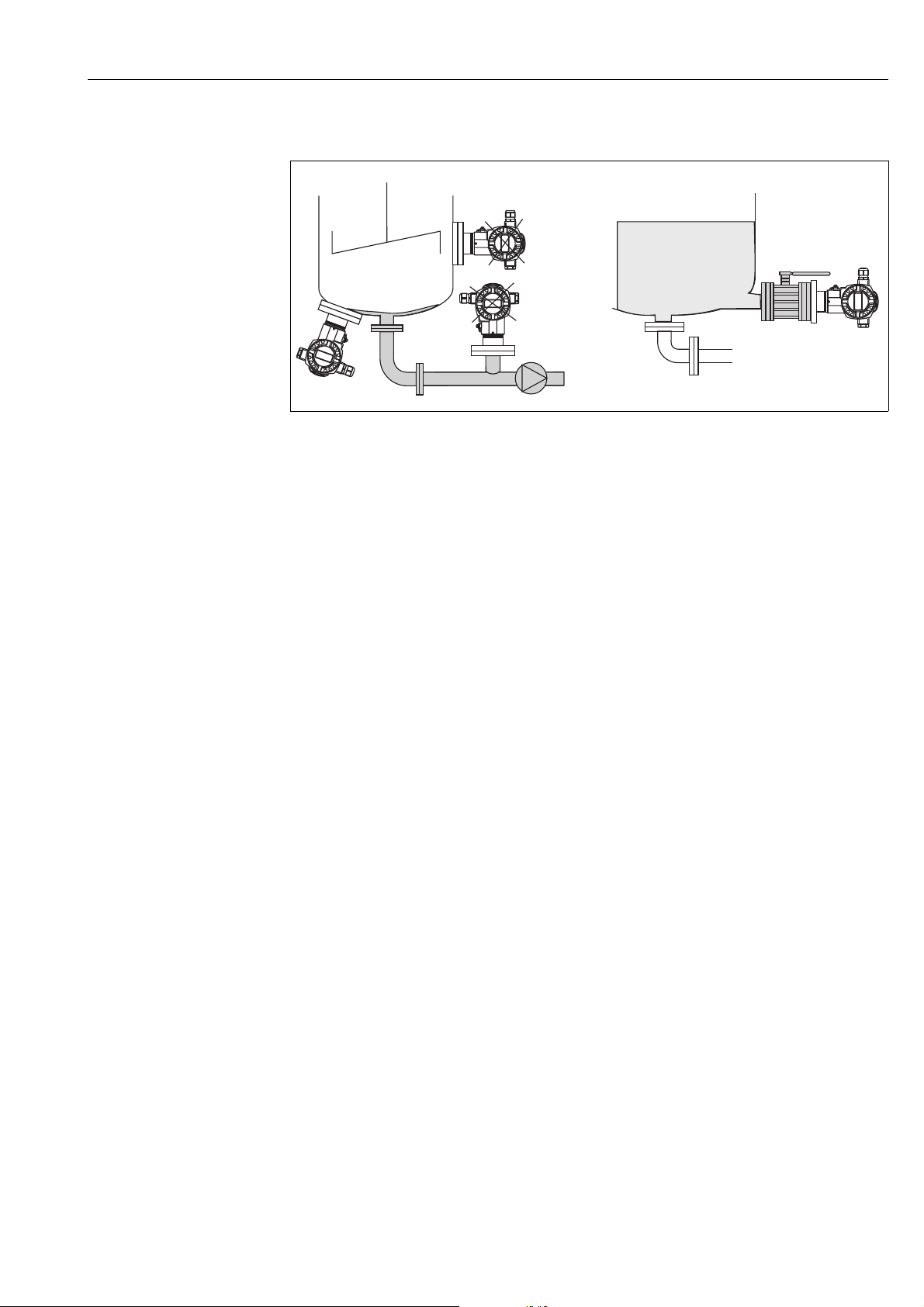

Level measurement

P01-PMP75xxx-11-xx-xx-xx-000

Fig. 5: Measuring arrangement for level

• Always install the device below the lowest measuring point.

• Do not install the device at the following positions:

– in the filling curtain

– in the tank outflow

– in the suction area of a pump

– or at a point in the tank that can be affected by pressure pulses from the agitator

• The calibration and functional test can be carried out more easily if you mount the device

downstream of a shutoff device.

• Deltapilot S must be included in the insulation for media that can harden when cold.

Pressure measurement in gases

• Mount Deltapilot S with shutoff device above the tapping point so that any condensate can

flow into the process.

Pressure measurement in steams

• Mount Deltapilot S with siphon above the tapping point.

• Fill the siphon with liquid before commissioning.

The siphon reduces the temperature to almost the ambient temperature.

Pressure measurement in liquids

• Mount Deltapilot S with the shutoff device below or at the same level as the tapping point.

Endress+Hauser 15

Page 16

Installation Deltapilot S FMB70 with 4...20 mA HART

NOTICE

12

122 (4.8)

52 (2.05)

86 (3.39)

70 (2.76)

140 (5.51)

158 (6.22)

175 (6.89)

ø6 (0.24)

ø42...60 (1.65...2.36)

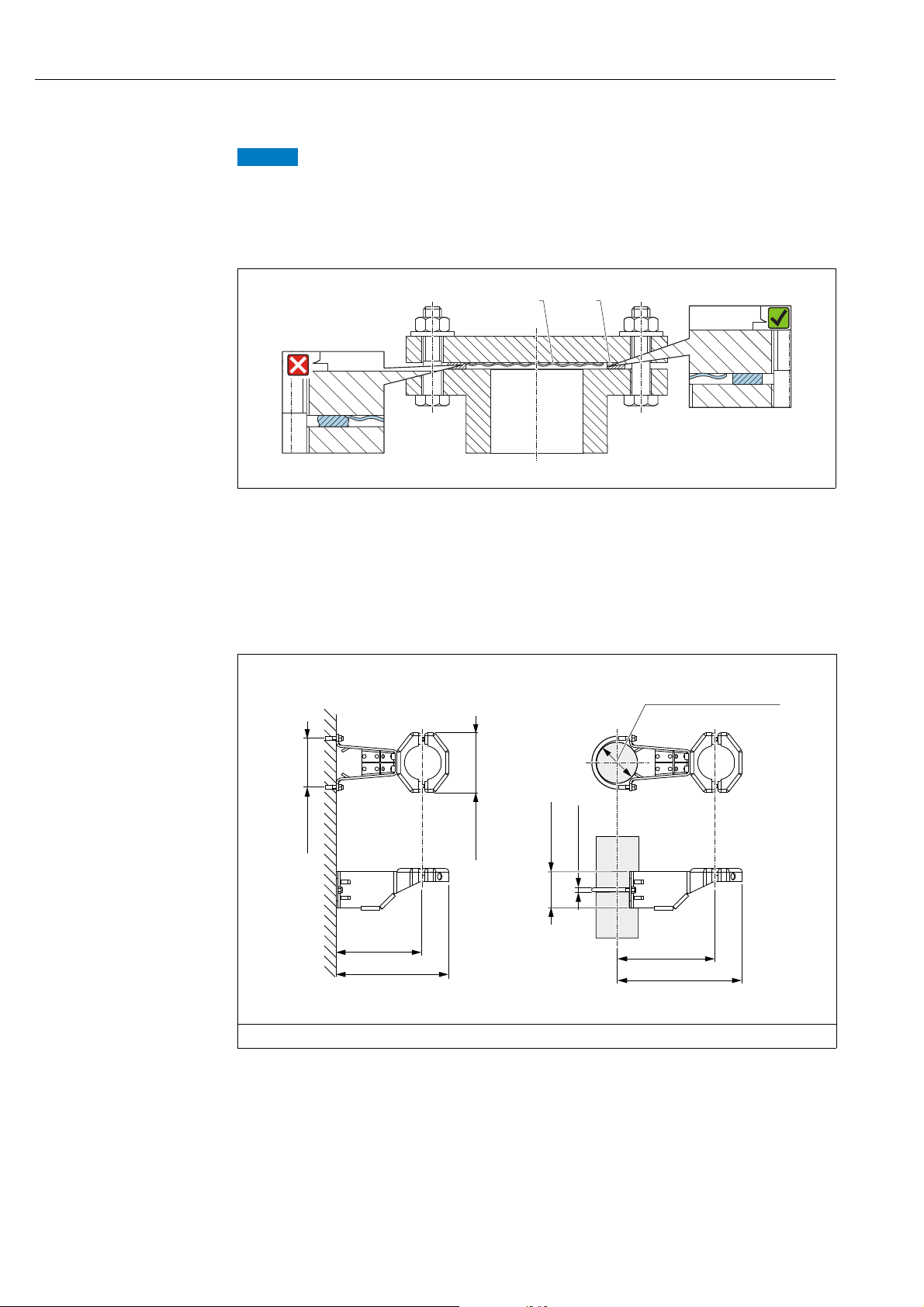

4.4.2 Seal for flange mounting

Corrupted measurement results.

The seal is not allowed to press against the process isolating diaphragm as this could affect

the measurement result.

‣ Ensure that the seal is not touching the process isolating diaphragm.

A0017743

Fig. 6:

1 Process isolating diaphragm

2Seal

4.4.3 Wall and pipe mounting (optional)

Endress+Hauser offers a mounting bracket for installation on pipes or walls (for pipe

diameters from 1 ¼" to 2").

Engineering unit mm (in)

A0028493

Please note the following when mounting:

• Devices with capillary tubes: mount capillaries with a bending radius 100 mm (3.94 in).

• When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at

least 5 Nm (3.69 lbs ft).

16 Endress+Hauser

Page 17

Deltapilot S FMB70 with 4...20 mA HART Installation

r ³ 120 mm

1

2

3

5

6

8

7

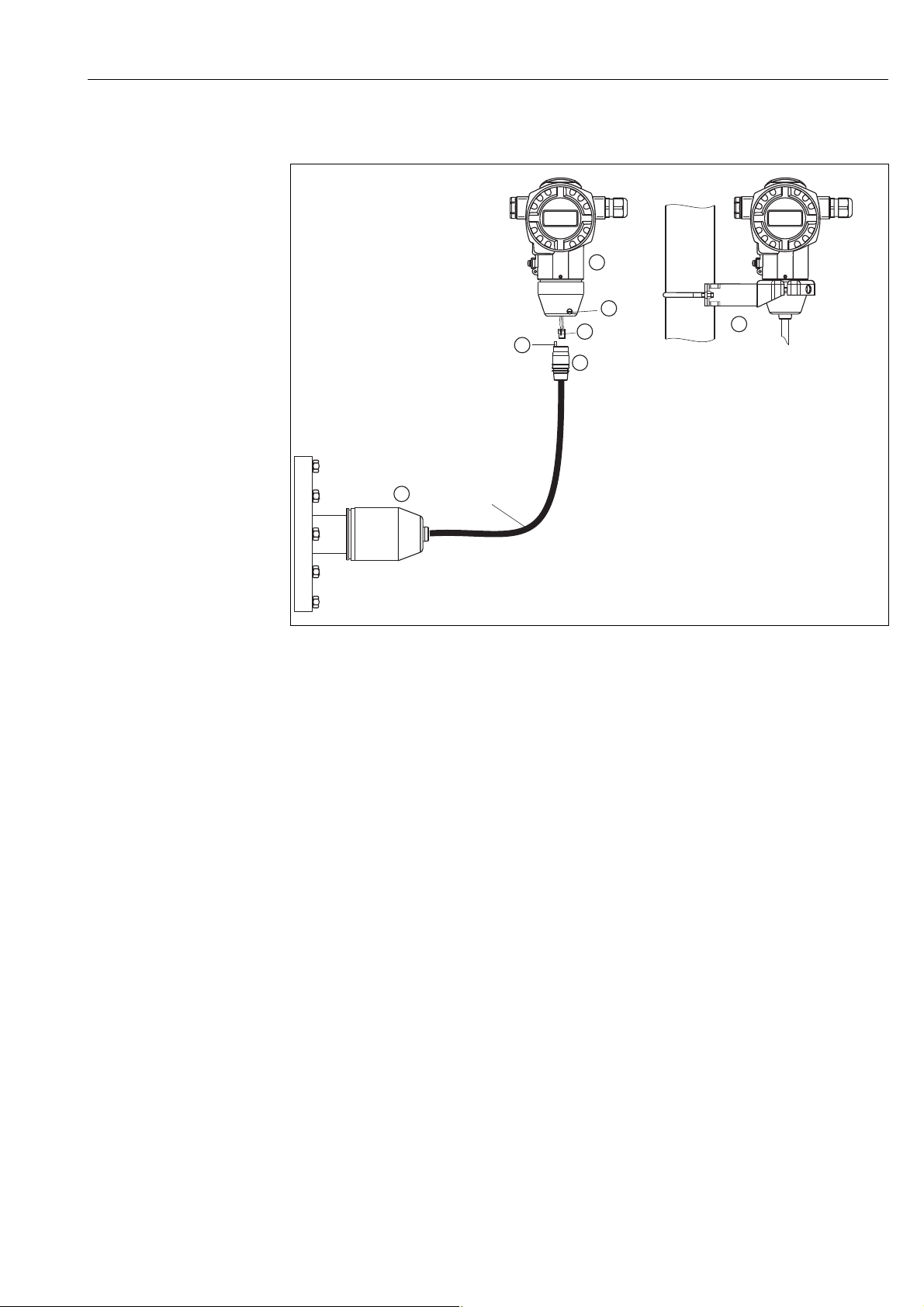

4.4.4 Assembling and mounting the "separate housing" version

P01-FMB70xxx-11-xx-xx-xx-003

Fig. 7: "Separate housing" version

1 In the "separate housing" version, the sensor is supplied with process connection and cable fitted.

2 Cable with connection jack

3 Pressure compensation

5Plug

6Locking screw

7 Housing fitted with housing adapter, included

8 Mounting bracket suitable for wall and pipe mounting, included

Assembly and mounting

1. Connect plug (item 5) into the corresponding connection jack of the cable (item 2).

2. Plug the cable into the housing adapter (item 7).

3. Tighten the locking screw (item 5).

4. Mount the housing on a wall or pipe using the mounting bracket (item 8). When

mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at least

5 Nm (3.69 lbs ft).

Mount the cable with a bending radius (r) 120 mm (4.72 in).

Endress+Hauser 17

Page 18

Installation Deltapilot S FMB70 with 4...20 mA HART

NOTICE

NOTICE

T14

T15

T17

32

4.4.5 Rotating the housing

The housing can be rotated up to 380° by loosening the Allen screw.

A0019996

1. T14 and T15 housing: Loosen setscrew with a 2 mm (0.08 in) Allen key.

T17 housing: Loosen setscrew with a 3 mm (0.12 in) Allen key.

2. Rotate housing (max. up to 380 °).

3. Retighten setscrew with 1 Nm (0,74 lbf ft.

4.4.6 Closing the housing cover

Devices with EPDM cover seal - transmitter leakiness!

Mineral-based, animal-based or vegetable-based lubricants cause the EPDM cover seal to

swell and the transmitter to become leaky.

‣ The thread is coated at the factory and therefore does not require any lubrication.

The housing cover can no longer be closed.

Damaged thread!

‣ When closing the housing cover, please ensure that the thread of the cover and housing

are free from dirt, e.g. sand.If you feel any resistance when closing the cover, check the

thread on both again to ensure that they are free from dirt.

Close cover on a hygenic stainless steel housing (T17)

P01-FMB70xxx-17-xx-xx-xx-001

Fig. 8: Close cover

The covers for the terminal and electronics compartment are hooked into the casing and

closed with a screw. These screws should be finger-tightened (2 Nm (1.48 lbf ft)) to the stop

to ensure that the covers sit tightly.

18 Endress+Hauser

Page 19

Deltapilot S FMB70 with 4...20 mA HART Installation

4.4.7 Mounting of the profile seal for universal process mounting

adapter

For details on mounting, see KA00096F/00/A3.

4.5 Post-installation check

After installing the device, carry out the following checks:

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

Endress+Hauser 19

Page 20

Wiring Deltapilot S FMB70 with 4...20 mA HART

WARNING

!

WARNING

!

4…20 mA

➅

10.5 V DC

➆

11.5 V DC

4... 20mA

Test

Test

➀

➁

➂

➃

➄

Test

➇

4... 20mATest

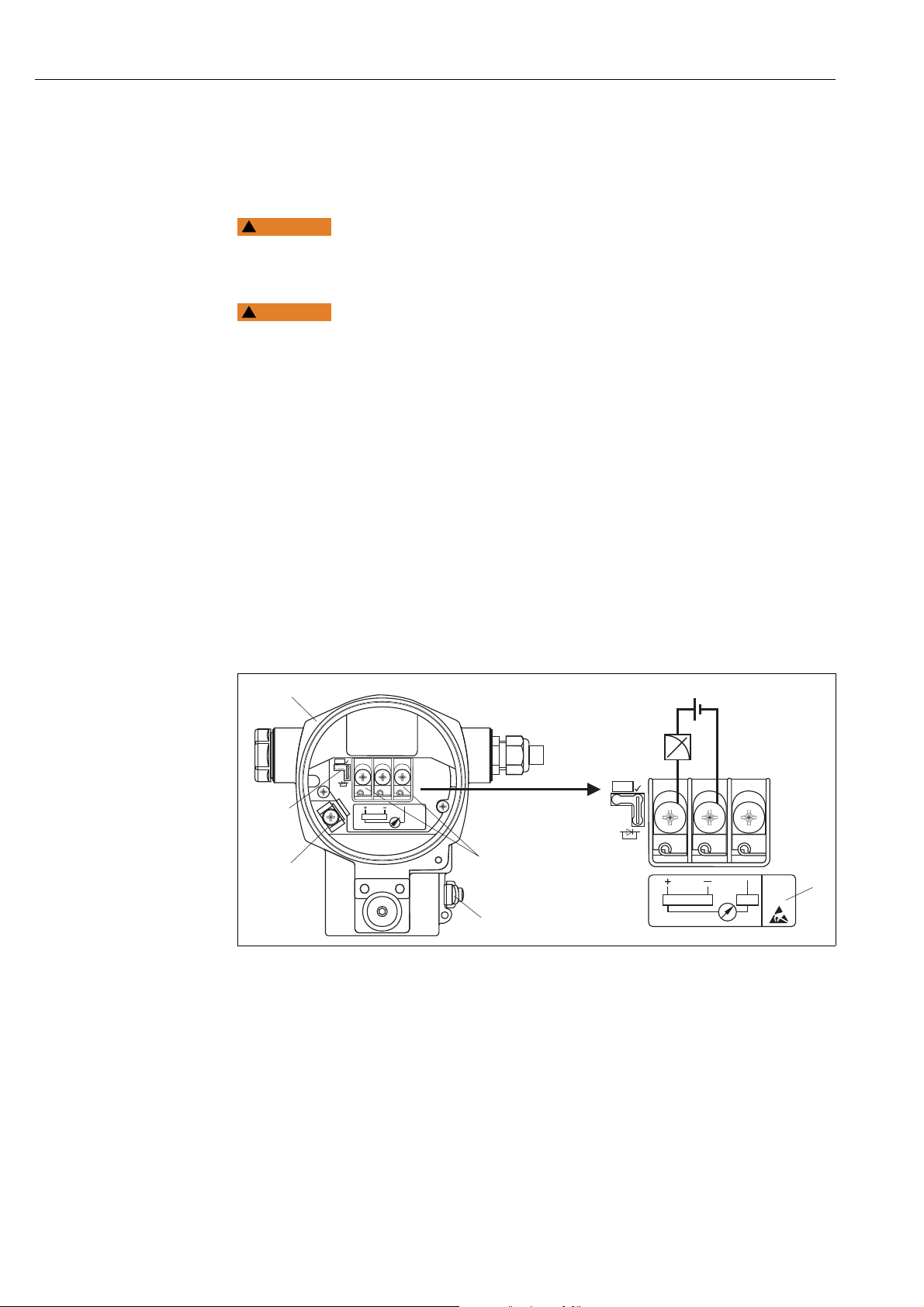

5 Wiring

5.1 Connecting the device

Risk of electric shock!

If the operating voltage is > 35 VDC: Dangerous contact voltage at terminals.

‣ In a wet environment, do not open the cover if voltage is present.

Limitation of electrical safety due to incorrect connection!

• Risk of electric shock and/or explosion in hazardous areas! In a wet environment, do not

open the cover if voltage is present.

• When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or

Installation or Control Drawings.

• Devices with integrated overvoltage protection must be earthed.

• Protective circuits against reverse polarity, HF influences and overvoltage peaks are

installed.

• The supply voltage must match the supply voltage on the nameplate. ( ä 10,

Section 3.2.1 "Nameplate")

• Switch off the supply voltage before connecting the device.

• Remove housing cover of the terminal compartment.

• Guide cable through the gland. Preferably use twisted, screened two-wire cable.

• Connect device in accordance with the following diagram.

• Screw down housing cover.

• Switch on supply voltage.

P01-xMx7xxxx-04-xx-xx-xx-001

Fig. 9: Electrical connection 4 to 20 mA HART

1Housing

2 Jumper for 4 to 20 mA test signal.

3 Internal earth terminal

4 External earth terminal

5 4 to 20 mA test signal between plus and test terminal

6 Minimum supply voltage = 10.5 V DC, jumper is inserted in accordance with the illustration.

7 Minimum supply voltage = 11.5 V DC, jumper is inserted in "Test" position.

8 Devices with integrated overvoltage protection are labelled OVP (overvoltage protection) here.

20 Endress+Hauser

Observe also Section 5.2.1 "Supply voltage",

ä

22, Section 5.2.1 "Taking 4 to 20 mA test signal" part.

ä

22.

Page 21

Deltapilot S FMB70 with 4...20 mA HART Wiring

Han7D

–

+

+–

–

+

1

5

4

6

7

8

2

3

AB

2

1

34

–

+

+

PE

–

rd

bk

gnye

4...20 mA

5.1.1 Connecting devices with Harting plug Han7D

A0019990

Fig. 10:

A Electrical connection for devices with Harting plug Han7D

B View of the plug connector at the device

5.1.2 Connecting devices with an M12 connector

PIN assignment for M12 connector PIN Meaning

1Signal +

2Not assigned

3Signal –

4Earth

A0011175

5.1.3 Connecting the cable version

Fig. 11: rd = red, bk = black, gnye = green-yellow

P01-PMx4xxxx-04-xx-xx-xx-010

Endress+Hauser 21

Page 22

Wiring Deltapilot S FMB70 with 4...20 mA HART

WARNING

!

Test

TestTest

5.2 Connecting the measuring unit

5.2.1 Supply voltage

Supply voltage might be connected!

Risk of electric shock and/or explosion!

‣ When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or

Installation or Control Drawings.

‣ All explosion protection data are given in separate documentation which is available

upon request. The Ex documentation is supplied as standard with all devices approved for

use in explosion hazardous areas.

Electronic version Jumper for 4 to 20 mA test signal

4 to 20 mA HART, for nonhazardous areas

in "Test" position (Delivery status)

11.5 to 45 V DC 10.5 to 45 V DC

Jumper for 4 to 20 mA test signal

in "Non-Test" position

Taking 4 to 20 mA test signal

A 4 to 20 mA signal may be measured via the positive and test terminal without interrupting

the measurement. The minimum supply voltage of the device can be reduced by simply

changing the position of the jumper. As a result, operation is also possible with lower voltage

sources. To keep the measured error below 0.1%, the current measuring device should

display an internal resistance of < 0.7 . Observe the position of the jumper in accordance

with the following table.

Jumper position for test signal Description

– Taking 4 to 20 mA test signal via plus and test terminal:

possible. (Thus, the output current can be measured without

interruption via the diode.)

–Delivery status

– minimum supply voltage: 11.5 V DC

– Taking 4 to 20 mA test signal via plus and test terminal:

not possible.

– minimum supply voltage: 10.5 V DC

5.2.2 Terminals

• Supply voltage and internal ground terminal: 0.5 to 2.5 mm2 (20 to 14 AWG)

• External ground terminal: 0.5 to 4 mm

2

(20 to 12 AWG)

5.2.3 Cable specification

• Endress+Hauser recommends using twisted, screened two-wire cables.

• Cable external diameter: 5 to 9 mm (0.2 to 0.35 in)

22 Endress+Hauser

Page 23

Deltapilot S FMB70 with 4...20 mA HART Wiring

U – 10.5 V

R

L

max

23 mA

≤

30

20

10.5

U

[V]

40 45

1282

1500

847

413

[]Ω

R

L

max

30

20

11.5

U

[V]

40 45

1239

1456

804

369

[]Ω

R

L

max

TestTest

➀

➁

U – 11.5 V

R

L

max

23 mA

≤

➂

➃

➂

➃

5.2.4 Load

P01-xMD7xxxx-05-xx-xx-xx-005

Fig. 12: Load diagram, observe the position of the jumper and the explosion protection. (

1 Jumper for the 4 to 20 mA test signal inserted in "Non-Test" position

2 Jumper for the 4 to 20 mA test signal inserted in "Test" position

3 Supply voltage 10.5 (11.5) to 30 V DC for Ex ia, 1/2 D, 1 GD, 1/2 GD, FM IS and CSA IS, IEC Ex ia, NEPSI Ex ia

4 Supply voltage10.5 (11.5) to 45 V DC for devices for non-hazardous areas, 1/3 D, Ex nA, FM DIP, FM NI

R

Lmax

U Supply voltage

mA test signal" part.)

Maximum load resistance

ä

22, Section 5.2.1 "Taking 4 to 20

When operating via a handheld terminal or via PC with an operating program, a minimum

communication resistance of 250 must exist within the loop.

5.2.5 Screening/potential matching

• You achieve optimum screening against disturbances if the screening is connected on both

sides (in the cabinet and on the device). If you have to reckon with potential equalisation

currents in the plant, only earth screening on one side, preferably at the transmitter

(possibility of hydrogen diffusion).

• When using in hazardous areas, you must observe the applicable regulations.

Separate Ex documentation with additional technical data and instructions is included

with all Ex systems as standard.

5.2.6 Connecting Field Xpert SFX100

Compact, flexible and robust industry handheld terminal for remote parametrization and

measured value inspection via the HART current output (4-20mA).

For details refer to Operating Instructions BA00060S/04/EN.

5.2.7 Connecting Commubox FXA195

The Commubox FXA195 connects intrinsically safe transmitters with the HART protocol to

a computer's USB port. This allows remote operation of the transmitter using

Endress+Hauser's FieldCare operating program. Power is supplied to the Commubox

through the USB port. The Commubox is also suitable for connection to intrinsically safe

circuits. See Technical Information TI00404F for further information.

Endress+Hauser 23

Page 24

Wiring Deltapilot S FMB70 with 4...20 mA HART

NOTICE

5.2.8 Connecting Commubox FXA291/ToF Adapter FXA291 for

operation via FieldCare

Connecting Commubox FXA291

The Commubox FXA291 connects Endress+Hauser field instruments with CDI interface (=

Endress+Hauser Common Data Interface) to the USB interface of a personal computer or a

notebook. For details refer to TI00405C/07/en.

For the following Endress+Hauser instruments you need the "ToF Adapter FXA291" as an

additional accessory:

• Cerabar S PMC71, PMP7x

• Deltabar S PMD7x, FMD7x

• Deltapilot S FMB70

Connecting ToF Adapter FXA291

The ToF Adapter FXA291 connects the Commubox FXA291 via the USB interface of a

personal computer or a notebook to the following Endress+Hauser instruments:

• Cerabar S PMC71, PMP7x

• Deltabar S PMD7x, FMD7x

• Deltapilot S FMB70

For details refer to KA00271F/00/a2.

5.3 Potential matching

Ex applications: Connect all devices to the local potential matching.

Observe the applicable regulations.

5.4 Overvoltage protection (optional)

Device could be destroyed!

Devices with integrated overvoltage protection must be earthed.

Devices showing version "M" in feature 100 "Additional options 1" or feature 110 "Additional

options 2" in the order code are equipped with overvoltage protection (see also Technical

Information TI00416P "Ordering information".

• Overvoltage protection:

– Nominal functioning DC voltage: 600 V

– Nominal discharge current: 10 kA

• Surge current check î = 20 kA as per DIN EN 60079-14: 8/20 s satisfied

• Arrester AC current check I = 10 A satisfied

5.5 Post-connection check

Perform the following checks after completing electrical installation of the device:

• Does the supply voltage match the specifications on the nameplate?

• Is the device connected as per Section 5.1?

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

As soon as voltage is applied to the device, the green LED on the electronic insert lights up

for a few seconds or the connected on-site display lights up.

24 Endress+Hauser

Page 25

Deltapilot S FMB70 with 4...20 mA HART Operation

E

+

–

Bargraph

Operating keys

Symbol

Bargraph

ValueFunction name

Measured value display

Unit

Header line

Information

line

Main line

Parameter

Identification

number

Editing modes

Selection

options

Value that

can be ed

ited

Current measured value

6Operation

Feature 20 "Output; operation" in the order code provides you with information on the

operating options available to you.

6.1 On-site display (optional)

A 4-line liquid crystal display (LCD) is used for display and operation. The on-site display

shows measured values, dialog texts, fault messages and notice messages.

The display of the device can be turned in 90° steps.

Depending on the installation position of the device, this makes it easy to operate the device

and read the measured values.

Functions:

• 8-digit measured value display including sign and decimal point, bargraph for current

display

• simple and complete menu guidance thanks to separation of the parameters into several

levels and groups

• each parameter is given a 3-digit ID number for easy navigation

• option for configuring the display according to individual requirements and desires, such

as language, alternating display, contrast setting, display of other measured values such

as sensor temperature

• comprehensive diagnostic functions (fault and warning message, peak-hold indicators,

etc.)

• rapid and safe commissioning with the Quick Setup menus

Endress+Hauser 25

P01-xMx7xxxx-07-xx-xx-xx-001

Page 26

Operation Deltapilot S FMB70 with 4...20 mA HART

➀

➂

➀

➁

➃

21

PC

t

on

off

➅

➄

The following table illustrates the symbols that can appear on the on-site display. Four

symbols can occur at one time.

Symbol Meaning

Alarm symbol

– Symbol flashing: warning, device continues measuring.

– Symbol permanently lit: error, device does not continue measuring.

Note: The alarm symbol may overlie the tendency symbol.

Lock symbol

The operation of the device is locked. Unlock device, ä 36.

Communication symbol

Data transfer via communication

Note: The alarm symbol may overlie the communication symbol.

Tendency symbol (increasing)

The measured value is increasing.

Tendency symbol (decreasing)

The measured value is decreasing.

Tendency symbol (constant)

The measured value has remained constant over the past few minutes.

6.2 Operating elements

6.2.1 Position of operating elements

With regard to aluminium housings (T14/T15), the operating keys are located either

outside the device under the protection cap or inside on the electronic insert. In hygenic

stainless steel housings (T17), the operating keys are always located inside on the electronic

insert.

Fig. 13: Operating keys, external

1 Operating keys on the exterior of the device under the

protective flap

P01-PMx7xxxx-19-xx-xx-xx-009

P01-xxxxxxxx-19-xx-xx-xx-104

Fig. 14: Operating keys, internal

1 Operating keys

2 Slot for optional display

3 Slot for optional HistoROM

4 DIP-switch for locking/unlocking measured-value-

relevant parameters

5 DIP-switch for damping on/off

6 Green LED to indicate value being accepted

®

/M-DAT

26 Endress+Hauser

Page 27

Deltapilot S FMB70 with 4...20 mA HART Operation

1

2

τ

on

off

6.2.2 Function of the operating elements –

on-site display not connected

Press and hold the key or the key combination for at least 3 seconds to execute the

corresponding function. Press the key combination for at least 6 seconds for a reset.

Operating key(s) Meaning

Adopt lower range value. A reference pressure is present at the device.

ä 28, Section 6.3.1 "Level measuring mode" or ä 30, Section 6.3.2 "Level

measuring mode".

Adopt upper range value. A reference pressure is present at the device.

ä 28, Section 6.3.1 "Level measuring mode" or ä 30, Section 6.3.2 "Level

measuring mode".

Position adjustment

Reset all parameters. The reset via operating keys corresponds to the software reset

and and

code 7864.

Copy the configuration data from the optional HistoROM

and

and

P01-xxxxxxxx-19-xx-xx-xx-057

device.

Copy the configuration data from the device to the optional HistoROM

module.

– DIP-switch 1: for locking/unlocking measured-value-relevant parameters

Factory setting: off (unlocked)

– DIP-switch 2: damping on/off,

Factory setting: on (damping on)

6.2.3 Function of the operating elements –

on-site display connected

Operating key(s) Meaning

– Navigate upwards in the picklist

– Edit the numerical values and characters within a function

– Navigate downwards in the picklist

– Edit the numerical values and characters within a function

–Confirm entry

–Jump to the next item

Contrast setting of on-site display: darker

O

O

S

F

and

F

®

/M-DAT module to the

®

/M-DAT

Contrast setting of on-site display: brighter

and

S

O

Endress+Hauser 27

and

F

S

ESC functions:

– Exit edit mode without saving the changed value.

– You are in a menu within a function group. The first time you press the keys

simultaneously, you go back a parameter within the function group. Each time you

press the keys simultaneously after that, you go up a level in the menu.

– You are in a menu at a selection level. Each time you press the keys

simultaneously, you go up a level in the menu.

Note: The terms function group, level and selection level are explained in ä 31,

Section 6.4.1.

Page 28

Operation Deltapilot S FMB70 with 4...20 mA HART

WARNING

!

6.3 On-site operation – on-site display not connected

To operate the device with a HistoROM®/M-DAT module ä 33, Section 6.5 "HistoROM®/

M-DAT (optional)".

6.3.1 Level measuring mode

If no on-site display is connected, the following functions are possible by means of the three

keys on the electronic insert or on the exterior of the device:

• Position adjustment (zero point correction)

• Assign the lower and upper pressure value to the lower and upper level value

• Device reset, ä 27, Section 6.2.2 "Function of the operating elements – on-site display

not connected", Table.

•The "-" and - keys only have a function in the following cases:

– LEVEL SELECTION "Level Easy Pressure", CALIBRATION MODE "Wet"

– LEVEL SELECTION "Level Standard", LEVEL MODE "Linear",

CALIBRATION MODE "Wet"

The keys have no function in other settings.

• The device is configured for the Level measuring mode as standard. You can switch

measuring modes by means of the MEASURING MODE parameter. ä 39, Section 7.3

"Selecting language and measuring mode".

The following parameters are set to the following values in the factory:

– LEVEL SELECTION: Level Easy Pressure

–CALIBRATION MODE: Wet

– OUTPUT UNIT or LIN. MEASURAND: %

– EMPTY CALIB.: 0.0

– FULL CALIB.: 100.0.

– SET LRV: 0.0 (corresponds to 4 mA value)

– SET URV: 100.0 (corresponds to 20 mA value)

These parameters can only be modified by means of the on-site display or remote

operation such as the FieldCare.

• The operation must be unlocked. ä 36, Section 6.8 "Locking/unlocking operation".

• The pressure applied must be within the nominal pressure limits of the sensor. See

information on the nameplate.

• ä 42, Section 7.5 "Section 7.5". For parameter description see Operating Instructions

BA00274P.

• LEVEL SELECTION, CALIBRATION MODE, LEVEL MODE, EMPTY CALIB., FULL CALIB,

SET LRV and SET URV are parameter names used for on-site display or remote operation

such as FieldCare, for instance.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

28 Endress+Hauser

Page 29

Deltapilot S FMB70 with 4...20 mA HART Operation

Carry out position adjustment.

Pressure is present at device. Desired pressure for lower

1)

Setting lower pressure value. Setting upper pressure value.

Desired pressure for upper

pressure value (EMPTY

PRESSURE

2)

) is present at device.

pressure value (FULL PRESSURE

is present at device.

Press -key for 3 s. Press -key for 3 s. Press -key for 3 s.

Does the LED on the electronic

insert light up briefly?

Does the LED on the electronic

insert light up briefly?

Does the LED on the electronic

insert light up briefly?

Yes No Yes No Yes No

Applied

pressure for

position

adjustment has

been accepted.

Applied

pressure for

position

adjustment has

not been

accepted.

Observe the

input limits.

The pressure

present was

saved as the

lower pressure

value (EMPTY

PRESSURE

2

)

and assigned to

the lower level

value (EMPTY

2

CALIB.

).

The pressure

present was not

saved as the

lower pressure

value. Observe

the input limits.

The pressure

present was

saved as the

upper pressure

value (FULL

PRESSURE

2

)

and assigned to

the upper level

value (FULL

2

CALIB.

).

The pressure

present was not

saved as the

upper pressure

value. Observe

the input limits.

1) Observe "Warning" on ä 39, Section 7 "Commissioning".

2) Parameter name used for the on-site display or remote operation such as the FieldCare.

1

)

Endress+Hauser 29

Page 30

Operation Deltapilot S FMB70 with 4...20 mA HART

WARNING

!

6.3.2 Pressure measuring mode

If no on-site display is connected, the following functions are possible by means of the three

keys on the electronic insert or on the exterior of the device:

• Position adjustment (zero point correction)

• Setting lower range value and upper range value

• Device reset, ä 27, Section 6.2.2 "Function of the operating elements – on-site display

not connected", Table.

• The operation must be unlocked. ä 36, Section 6.8 "Locking/unlocking operation".

• The device is configured for the Level measuring mode as standard. You can switch

measuring modes by means of the MEASURING MODE parameter. ä 39, Section 7.3

"Selecting language and measuring mode".

• The pressure applied must be within the nominal pressure limits of the sensor. See

information on the nameplate.

Changing the measuring mode can affect the adjustment data!

This situation can result in product overflow.

‣ Check calibration data when the measuring mode is changed.

Carry out position adjustment.

Pressure is present at device. Desired pressure for lower range

Press -key for 3 s. Press -key for 3 s. Press -key for 3 s.

Does the LED on the electronic

insert light up briefly?

YesNo YesNo YesNo

Applied

pressure for

position

adjustment has

been accepted.

1) Observe "Warning" on ä 39, Section 7 "Commissioning".

Applied

pressure for

position

adjustment has

not been

accepted.

Observe the

input limits.

1)

Setting lower range value. Setting upper range value.

value is present at device.

Does the LED on the electronic

insert light up briefly?

Applied

pressure for

lower range

value has been

accepted.

Applied

pressure for

lower range

value has not

been accepted.

Observe the

input limits.

Desired pressure for upper range

value is present at device.

Does the LED on the electronic

insert light up briefly?

Applied

pressure for

upper range

value has been

accepted.

Applied

pressure for

upper range

value has not

been accepted.

Observe the

input limits.

30 Endress+Hauser

Page 31

Deltapilot S FMB70 with 4...20 mA HART Operation

6.4 On-site operation – on-site display connected

If the on-site display is connected, the three operating keys are used to navigate through the

operating menu and parameter input, ä 27, Section 6.2.3 "Function of the operating

elements – on-site display connected".

6.4.1 General structure of the operating menu

The menu is split into four levels. The three upper levels are used to navigate while you use

the bottom level to enter numerical values, select options and save settings.

The entire operating menu is shown in the operating instructions BA00274P "Cerabar S/

Deltabar S/Deltapilot S, Description of Instrument Functions".

The structure of the OPERATING MENU depends on the measuring mode selected, e.g. if the

"Pressure" measuring mode is selected, only the functions necessary for this mode are

displayed.

6.4.2 Selecting an option

Example: select "English" as the language of the menu.

On-site display Operation

German is selected as the language. A in front of the

menu text indicates the active option.

P01-xxxxxxxx-19-xx-xx-xx-017

Select English with or .

P01-xxxxxxxx-19-xx-xx-xx-033

1. Confirm your choice with . A in front of the

menu text indicates the active option. (English is

now selected as the menu language.)

2. Jump to the next item with .

P01-xxxxxxxx-19-xx-xx-xx-034

Endress+Hauser 31

Page 32

Operation Deltapilot S FMB70 with 4...20 mA HART

6.4.3 Editing a value

Example: adjusting DAMPING VALUE function from 2.0 s to 30.0 s. ä 27, Section 6.2.3

"Function of the operating elements – on-site display connected".

On-site display Operation

The on-site display shows the parameter to be

changed. The value highlighted in black can be

changed. The "s" unit is fixed and cannot be changed.

P01-xxxxxxxx-19-xx-xx-xx-023

1. Press or to get to the editing mode.

2. The first digit is highlighted in black.

P01-xxxxxxxx-19-xx-xx-xx-027

1. Use to change "2" to "3".

2. Confirm "3" with . The cursor jumps to the next

position (highlighted in black).

P01-xxxxxxxx-19-xx-xx-xx-028

P01-xxxxxxxx-19-xx-xx-xx-029

P01-xxxxxxxx-19-xx-xx-xx-030

P01-xxxxxxxx-19-xx-xx-xx-031

P01-xxxxxxxx-19-xx-xx-xx-032

The decimal point is highlighted in black, i.e. you can

now edit it.

1. Keep pressing or until "0" is displayed.

2. Confirm "0" with .

The cursor jumps to the next position. is

displayed and is highlighted in black. See next

graphic.

Use to save the new value and exit the editing mode.

See next graphic.

The new value for the damping is now 30.0 s.

– Jump to the next parameter with .

– You can get back to the editing mode with or

.

32 Endress+Hauser

Page 33

Deltapilot S FMB70 with 4...20 mA HART Operation

NOTICE

6.4.4 Taking pressure applied at device as value

Example: configuring upper range value – assign 20 mA to the pressure value 400 mbar.

On-site display Operation

The bottom line on the on-site display displays the

pressure present, here 400 mbar.

P01-xxxxxxxx-19-xx-xx-xx-035

Use or to switch to the "Confirm" option. The

active selection is highlighted in black.

P01-xxxxxxxx-19-xx-xx-xx-036

Use to assign the value (400 mbar) to the GET URV

parameter. The device confirms the calibration and

jumps back to the parameter, here GET URV (see next

graphic).

P01-xxxxxxxx-19-xx-xx-xx-037

Switch to the next parameter with .

P01-xxxxxxxx-19-xx-xx-xx-035

6.5 HistoROM®/M-DAT (optional)

Device could be destroyed!

Detach HistoROM

deenergised state only.

HistoROM

®

fulfils the following functions:

• Back-up copy of configuration data

• Copying configuration data of a transmitter into another transmitter

• Cyclic recording of pressure and sensor-temperature measured values

• Recording diverse events, such as alarms, configuration changes, counters for measuring

range undershooting and exceeding for pressure and temperature, exceeding and

undershooting the user limits for pressure and temperature, etc.

•The HistoROM

• The HistoROM data and the data in the device are analysed once a HistoROM

attached to the electronic insert and power is reestablished to the device. During the

analysis, the messages "W702, HistoROM data not consistent" and "W706, Configuration

in HistoROM and device not identical" can occur. For measures, ä 48, Section 9.1

"Messages".

®

/M-DAT from the electronic insert or attach it to the insert in a

/M-DAT is a memory module, which is attached to the electronic insert and

®

/M-DAT module may be retrofitted at any time (Order No.: 52027785).

®

/M-DAT is

Endress+Hauser 33

Page 34

Operation Deltapilot S FMB70 with 4...20 mA HART

HW-Version:

SW-Version:

250002271-

–

HART

R

FIELD COMMUNICATION PROTOCOL

1

2

➀

➁

21

PC

t

on

off

6.5.1 Copying configuration data

P01-xxxxxxxx-19-xx-xx-xx-099

Abb. 15:

1Optional HistoROM

2 To copy configuration data from the HistoROM

Electronic insert with optional HistoROM®/M-DAT memory module

®

/M-DAT

operation must be unlocked (DIP-switch 1, Position "off", parameter INSERT PIN NO. = 100). Observe

"Locking/unlocking operation".

®

/M-DAT module to a device or from a device to a HistoROM®/M-DAT, the

ä

36, Section 6.8

On-site operation – on-site display not connected

Copying configuration data from a device to a HistoROM

®

/M-DAT module:

The operation must be unlocked.

1. Disconnect device from supply voltage.

2. Attach the HistoROM

®

/M-DAT module to the electronic insert.

3. Reestablish supply voltage to the device.

4. Press and "-"-keys (for at least 3 seconds) until the LED on the electronic insert lights

up.

5. Wait approx. 20 seconds. Configuration data are loaded from the device to the

HistoROM

6. Before removing the HistoROM

®

/M-DAT. The device is not restarted.

®

/M-DAT again from the electronic insert, disconnect

the device from supply voltage.

Copying configuration data from a HistoROM

®

/M-DAT to a device:

The operation must be unlocked.

1. Disconnect device from supply voltage.

2. Attach the HistoROM

another device are stored in the HistoROM

®

/M-DAT module to the electronic insert. Configuration data from

®

/M-DAT.

3. Reestablish supply voltage to the device.

4. Press und -keys (for at least 3 seconds) until the LED on the electronic insert lights

up.

5. Wait approx. 20 seconds. All parameters except DEVICE SERIAL No, DEVICE DESIGN.,

CUST. TAG NUMBER, LONG TAG NUMBER, DESCRIPTION, BUS ADDRESS, CURRENT

MODE and the parameters in the POSITION ADJUSTMENT and PROCESS CONNECTION

group are loaded into the device by HistoROM®/M-DAT. The device is restarted.

6. Before removing the HistoROM

®

/M-DAT again from the electronic insert, disconnect

the device from supply voltage.

34 Endress+Hauser

Page 35

Deltapilot S FMB70 with 4...20 mA HART Operation

On-site operation via on-site display (optional) or remote operation

Copying configuration data from a device to a HistoROM

®

/M-DAT:

The operation must be unlocked.

1. Disconnect device from supply voltage.

2. Attach the HistoROM

®

/M-DAT module to the electronic insert.

3. Reestablish supply voltage to the device.

4. Using the HistoROM CONTROL parameter select the option "Device HistoROM" as the

data transfer direction (Menu path: GROUPSELECTION OPERATING MENU

OPERATION).

The DOWNLOAD SELECT. parameter setting has no influence on an upload from the

device into HistoROM.

5. Wait approx. 20 seconds. Configuration data are loaded from the device to the

HistoROM

6. Before removing the HistoROM

®

/M-DAT. The device is not restarted.

®

/M-DAT again from the electronic insert, disconnect

the device from supply voltage.

Copying configuration data from a HistoROM

®

/M-DAT to a device:

The operation must be unlocked.

1. Disconnect device from supply voltage.

2. Attach the HistoROM

another device are stored in the HistoROM

®

/M-DAT module to the electronic insert. Configuration data from

®

/M-DAT.

3. Reestablish supply voltage to the device.

4. Use the DOWNLOAD SELECT parameter to select which parameters are to be

overwritten (Menu path: (GROUPS SELECTION )OPERATING MENU

OPERATION).

The following parameters are overwritten according to the selection:

– Configuration copy (factory setting):

all parameters except DEVICE SERIAL No., DEVICE DESIGN, CUST. TAG NUMBER,

LONG TAG NUMBER, DESCRIPTION, BUS ADDRESS, CURRENT MODE and the

parameters in the POSITION ADJUSTMENT, PROCESS CONNECTION, CURR. TRIM

(SERVICE /SYSTEM 2), SENSOR TRIM and SENSOR DATA group.

– Device replacement:

all parameters except DEVICE SERIAL No., DEVICE DESIGN and the parameters in the

POSITION ADJUSTMENT, PROCESS CONNECTION, CURR. TRIM (SERVICE/SYSTEM

2), SENSOR TRIM and SENSOR DATA group.

– Electronics replace:

all parameters except the parameters in the CURR. TRIM (SERVICE/SYSTEM 2) and

SENSOR DATA group.

Factory setting: Configuration copy

5. Using the HistoROM CONTROL parameter select the option "HistoROM Device" as the

data transfer direction.

(Menu path: GROUP SELECTION OPERATING MENU OPERATION)

6. Wait approx. 20 seconds. Configuration data are loaded from the device to the

HistoROM

7. Before removing the HistoROM

®

/M-DAT. The device is restarted.

®

/M-DAT again from the electronic insert, disconnect

the device from supply voltage.

Endress+Hauser 35

Page 36

Operation Deltapilot S FMB70 with 4...20 mA HART

6.6 Operation via SFX100

Compact, flexible and robust industry handheld terminal for remote parametrization and

measured value inspection via the HART current output (4-20mA).

For details refer to Operating Instructions BA00060S/04/EN.

6.7 Endress+Hauser operating program

FieldCare is an Endress+Hauser asset management tool based on FDT technology. With

FieldCare, you can configure all Endress+Hauser devices as well as devices from other

manufacturers that support the FDT standard. Hardware and software requirements you can

find on the internet: www.endress.com select your country Search: FieldCare

FieldCare Technical Data.

FieldCare supports the following functions:

• Configuration of transmitters in online operation

• Loading and saving device data (upload/download)

•HistoROM

• Documentation of the measuring point

Connection options:

• HART via Commubox FXA195 and USB interface of a computer

• HART via Fieldgate FXA520

®

/M-DAT analysis

• ä 23, Section 5.2.7, "Connecting Commubox FXA195".

• In the "Level Standard" measuring mode, the configuration data that were loaded with FDT

upload cannot be written again (FDT download). These data are only used to document the

measuring point.

• ä 24, Section 5.2.8, "Connecting Commubox FXA291/ToF Adapter FXA291 for

operation via FieldCare".

• Further information on the FieldCare can be found on the Internet (http://

www.endress.com, Download Search for: FieldCare).

6.8 Locking/unlocking operation

Once you have entered all the parameters, you can lock your entries against unauthorised

and undesired access.

You have the following possibilities for locking/unlocking the operation:

• Via a DIP-switch on the electronic insert, locally on the display.

• Via the on-site display (optional)

• Via digital communication.

The -symbol on the on-site display indicates that operation is locked. Parameters which

refer to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST can still be

altered.

If operation is locked by means of the DIP-switch, you can only unlock operation again by

means of the DIP-switch. If operation is locked by means of the on-site display or remote

operation e.g. FieldCare, you can only unlock operation again by means of the on-site display

or remote operation.

36 Endress+Hauser

Page 37

Deltapilot S FMB70 with 4...20 mA HART Operation

➀

➁➂

off

on

21

off

on

21

Damping [

]t

Damping [

]t

E

+

–

HW-Version:

SW-Version:

250002271-

–

HART

R

FIELD COMMUNICATION PROTOCOL

1

2

21

PC

The table provides an overview of the locking functions:

Locking via View/read

parameter

Modify/write via

On-site

display

1)

Remote

operation

Unlocking via

DIP-switch On-site

display

Remote

operation

DIP-switch Yes No No Yes No No

On-site display Yes No No No Yes Yes

Remote operation Yes No No No Yes Yes

1) Parameters which refer to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST can still be

altered.

6.8.1 Locking/unlocking operation locally via DIP-switch

Fig. 16: DIP-switch position "Hardware locking" on the electronic insert

1 If necessary, remove on-site display (optional)

2DIP-switch is at "on": operation is locked.

3 DIP-switch is at "off": operation is unlocked (operation possible)

6.8.2 Locking/unlocking operation via on-site display or remote

operation

Description

Locking operation 1. Select INSERT PIN NO. parameter,

Menu path: OPERATING MENU OPERATION INSERT PIN NO.

2. To lock operation, enter a number for this parameter between 0 to 9999 that is

100.

Unlocking operation 1. Select INSERT PIN NO. parameter.

2. To unlock operation, enter "100" for the parameter.

6.9 Factory setting (reset)

By entering a certain code, you can completely, or partially, reset the entries for the

parameters to the factory settings. (For factory settings refer to the Operating

Instructions BA00274P "Cerabar S/Deltabar S/Deltapilot S, Description of device functions".)

Enter the code by means of the ENTER RESET CODE parameter (Menu path: (GROUP

SELECTION ) OPERATING MENU OPERATING).

There are various reset codes for the device. The following table illustrates which parameters

Endress+Hauser 37

are reset by the particular reset codes. Operation must be unlocked to reset parameters

( ä 37, Section 6.9).

Any customer-specific configuration carried out by the factory is not affected by a reset

(customer-specific configuration remains). If, after a reset, you wish the parameters to be

reset to the factory settings, please contact Endress+Hauser Service.

P01-xxxxxxxx-19-xx-xx-xx-133

Page 38

Operation Deltapilot S FMB70 with 4...20 mA HART

Reset code Description and effect

1846 Display reset

62 PowerUp reset (warm start)

2710 Measuring mode level reset

333 User reset

7864 Total reset

8888 HistoROM reset

– This reset resets all parameters which have to do with how the display appears

(DISPLAY group).

– Any simulation which may be running is ended.

– The device is restarted.

– This reset resets all the parameters in the RAM. Data are read back anew from the

EEPROM (processor is initialised again).

– Any simulation which may be running is ended.

– The device is restarted.

– Depending on the settings for the LEVEL MODE, LIN MEASURAND,

LINdMEASURAND or COMB. MEASURAND parameters, the parameters needed

for this measuring task will be reset.

– Any simulation which may be running is ended.

– The device is restarted.

Example LEVEL MODE = linear and LIN. MEASURAND = Height

•HEIGHT UNIT = m

•CALIBRATION MODE = wet

•EMPTY CALIB. = 0

• FULL CALIB. = Sensor end value converted to mH

mbar (6 psi) sensor

– Affects the following parameters:

–Function group POSITION ADJUSTMENT

– Function group BASIC SETUP, except for the customer-specific units

– Function group EXTENDED SETUP

–Group OUTPUT

–Function group HART DATA: CURRENT MODE, BUS ADDRESS and PREAMBLE

NUMBER

– Any simulation which may be running is ended.

– The device is restarted.

– Affects the following parameters:

–Function group POSITION ADJUSTMENT

– Function group BASIC SETUP

– Function group EXTENDED SETUP

– Function group LINEARISATION (an existing linearisation table is erased)

–Group OUTPUT

–Function group PEAK HOLD INDICATOR

–Function group HART DATA

– All configurable messages ("Error" type) are set to factory setting.

See also ä 48, Section 9.1 "Messages" and ä 56, Section 9.2 "Response of

outputs to errors".

–Function group USER LIMITS

–Function group SYSTEM 2

– Any simulation which may be running is ended.

– The device is restarted.

The measured value memory and event memory are cleared. During the reset, the

HistoROM must be attached to the electronic insert.

O, e.g. 4.079 mH2O for a 400

2

38 Endress+Hauser

Page 39

Deltapilot S FMB70 with 4...20 mA HART Commissioning

WARNING

!

NOTICE

7 Commissioning

The device is configured for the level measuring mode as standard. The measuring range and

the unit in which the measured value is transmitted correspond to the specifications on the

nameplate.

Exceeding the maximum allowable working pressure!

Risk of injury due to bursting of parts! Warning messages are generated if pressure is too

high.

‣ If a pressure greater than the maximum permitted pressure is present at the device, the

messages "E115 Sensor overpressure" and "E727 Sensor pressure error - overrange" are

output in succession! Use the device only within the sensor range limits

Shortfall of the allowable working pressure!

Output of messages if pressure is too low.

‣ If a pressure smaller than the minimum permitted pressure is present at the device, the

messages "E120 Sensor low pressure" and "E727 Sensor pressure error - overrange" are

output in succession! Use the device only within the sensor range limits

7.1 Configuring messages

• Messages E727, E115 and E120 are "Error"-type messages and can be configured as a

"Warning" or an "Alarm". These messages are configured as "Warning" messages at the

factory. This setting prevents the current output from assuming the set alarm current

value for applications (e.g. cascade measurement) where the user is consciously aware of

the fact that the sensor range can be exceeded

• We recommend setting messages E727, E115 and E120 to "Alarm" in the following

instances:

– The sensor range does not have to be exceeded for the measuring application.

– Position adjustment has to be carried out that has to correct a large measured error as a

result of the orientation of the device (e.g. devices with a diaphragm seal).

7.2 Function check

Carry out a post-installation and a post-connection check as per the checklist before

commissioning the device.

• "Post-installation check" checklist see Section 4.5

• "Post-connection check" checklist see Section 5.5

7.3 Selecting language and measuring mode

7.3.1 On-site operation

The LANGUAGE and MEASURING MODE parameters are located on the top menu level.

The following measuring modes are available:

• Pressure

•Level

Endress+Hauser 39

Page 40

Commissioning Deltapilot S FMB70 with 4...20 mA HART

7.3.2 Digital communication

The following measuring modes are available:

• Pressure

•Level

The LANGUAGE parameter is arranged in the DISPLAY group (OPERATING MENU

DISPLAY).

• Use the LANGUAGE parameter to select the menu language for the on-site display.

• Select the menu language for ToF Tool via the "Options" menu "Options" "Display"

"Language".

• Select the menu language for FieldCare by means of the "Language Button" in the

configuration window. Select the menu language for the FieldCare frame via the "Extra"

menu "Options" "Display" "Language".

7.4 Position adjustment

Due to the orientation of the device, there may be a shift in the measured value, i.e. when

the container is empty, the measured value parameter does not display zero. There are three

options to choose from when performing position adjustment.

(Menu path: (GROUP SELECTION ) OPERATING MENU SETTINGS POSITION

ADJUSTMENT)

Parameter name Description

POS. ZERO ADJUST (685)

Entry

POS. INPUT VALUE (563)

Entry

Position adjustment – the pressure difference between zero (set point) and the

measured pressure need not be known.

Example:

– MEASURED VALUE = 2.2 mbar (0.032 psi)

– Correct the MEASURED VALUE via the POS. ZERO ADJUST parameter with the

"Confirm" option. This means that you are assigning the value 0.0 to the pressure

present.

– MEASURED VALUE (after pos. zero adjust) = 0.0 mbar

– The current value is also corrected.

The CALIB. OFFSET parameter displays the resulting pressure difference (offset) by

which the MEASURED VALUE was corrected.

Factory setting:

0.0

Position adjustment – the pressure difference between zero (set point) and the

measured pressure need not be known. To correct the pressure difference, you

need a reference measurement value (e. g. from a reference device).

Example:

– MEASURED VALUE = 0.5 mbar (0.0073 psi)

– For the POS. INPUT VALUE parameter, specify the desired set point for the

MEASURED VALUE, e.g. 2.0 mbar (0.029 psi).

(MEASURED VALUE

– MEASURED VALUE (after entry for POS. INPUT VALUE) = 2.0 mbar (0.029 psi)

– The CALIB. OFFSET parameter displays the resulting pressure difference (offset)

by which the MEASURED VALUE was corrected.

CALIB. OFFSET = MEASURED VALUE

here: CALIB. OFFSET = 0.5 mbar (0.0073 psi) – 2.0 mbar (0.029 psi) = – 1.5

mbar (0.022 psi))

– The current value is also corrected.

Factory setting:

0.0

= POS. INPUT VALUE)

new

old

– POS. INPUT VALUE,

40 Endress+Hauser

Page 41

Deltapilot S FMB70 with 4...20 mA HART Commissioning

Parameter name Description

CALIB. OFFSET (319)

Entry

Position adjustment – the pressure difference between zero (set point) and the

measured pressure is known.

Example:

– MEASURED VALUE = 2.2 mbar (0.032 psi)

– Via the CALIB. OFFSET parameter, enter the value by which the MEASURED

VALUE should be corrected. To correct the MEASURED VALUE to 0.0 mbar, you

must enter the value 2.2 here.

(MEASURED VALUE

– MEASURED VALUE (after entry for calib. offset) = 0.0 mbar

= MEASURED VALUE

new

– CALIB. OFFSET)

old

– The current value is also corrected.

Factory setting:

0.0

Endress+Hauser 41

Page 42

Commissioning Deltapilot S FMB70 with 4...20 mA HART

WARNING

!

7.5 Level measurement

7.5.1 Information on level measurement

• The Pressure and Level operating modes each have a quick setup menu which guides you

through the most important basic functions. See ä 44 for the "Level" quick setup menu.

• Furthermore, the three level modes "Level Easy Pressure", "Level Easy Height" and "Level

Standard" are available to you for level measurement. You can select from the "Linear",

"Pressure linearized" and "Height linearized" level types for the "Level Standard" level mode.

The table in the "Overview of level measurement" section below provides an overview of the

various measuring tasks.

– In the "Level Easy Pressure" and "Level Easy Height" level modes, the values entered are

not tested as extensively as in the "Level Standard" level mode. The values entered for

EMPTY CALIB./FULL CALIB., EMPTY PRESSURE/FULL PRESSURE, EMPTY HEIGHT/

FULL HEIGHT and SET LRV/SET URV must have a minimum interval of 1% for the "Level

Easy Pressure" and "Level Easy Height" level modes. The value will be rejected with a

warning message if the values are too close together. Further limit values are not