Page 1

Products Solutions Services

BA00235R/09/EN/16.14

71252244

SW Version

01.00

Operating Instructions

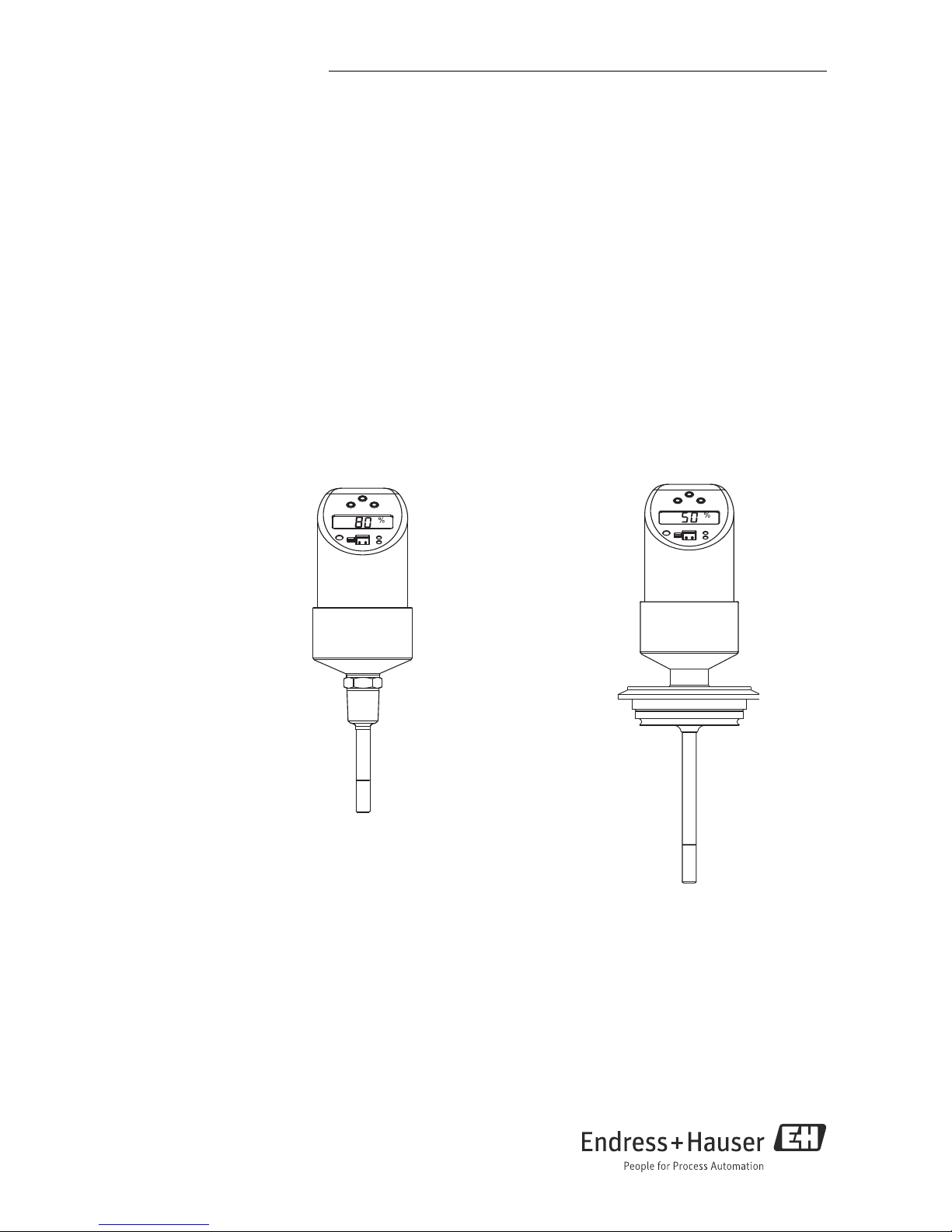

Flowphant T

DTT31, DTT35

Flow Switch

AUTHORIZED DISTRIBUTOR:

InstrumentsAndControl.com

Houston, Texas USA

sales@InstrumentsAndControl.com

832-615-3588

Page 2

Brief overview

For quick and easy commissioning:

Safety instructions → Page 4

Æ

Installation → Page 7

Æ

Wiring → Page 13

Æ

Operation → Page 14

Display and operating elements

Onsite operation

Operation with PC and configuration software

Æ

Troubleshooting → Page 32

Page 3

Endress+Hauser

DTT31, DTT35

Table of contents

1 Safety instructions . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and

operation . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . 4

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Notes on safety conventions and icons . . 5

2 Device identification . . . . . . . . . 6

2.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Certificates and approvals . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . . 7

3.1 Incoming acceptance, storage . . . . . . . . . 7

3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Process connection . . . . . . . . . . . . . . . . . . 8

3.4 Installation instructions . . . . . . . . . . . . . 10

4 Wiring . . . . . . . . . . . . . . . . . . . . 12

4.1 DC voltage version with M12x1

connector . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 DC voltage version with valve connector 13

5 Operation. . . . . . . . . . . . . . . . . . 13

5.1 Onsite operation . . . . . . . . . . . . . . . . . . . 13

5.2 Operation with PC and configuration

software . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Maintenance. . . . . . . . . . . . . . . 26

7 Accessories . . . . . . . . . . . . . . . . 27

7.1 Welding bosses and coupling . . . . . . . . 27

7.2 Electrical connection . . . . . . . . . . . . . . . . 28

7.3 Configuration kit . . . . . . . . . . . . . . . . . . . 29

7.4 Configuration software . . . . . . . . . . . . . . 30

8 Troubleshooting. . . . . . . . . . . . 31

8.1 Error messages and warning messages 31

8.2 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.4 Change status (release) . . . . . . . . . . . . . 33

8.5 Software history . . . . . . . . . . . . . . . . . . . . 33

9 Technical data. . . . . . . . . . . . . . 34

9.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . 34

9.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.3 Operating conditions . . . . . . . . . .. . . . . . . . 35

Page 4

Safety instructions DTT31, DTT35

4 Endress+Hauser

1 Safety instructions

1.1 Designated use

The Flowphant T is a flow switch for monitoring mass flow rates in industrial processes. The

device is designed to meet state-of-the-art safety requirements and conforms to applicable

standards and EC regulations. It can, however, be a source of danger if used incorrectly or for

anything other than the designated use.

1.2 Installation, commissioning and operation

Installation, electrical connection, commissioning, operation and maintenance of the measuring

system must be carried out by trained, qualified specialists authorized to perform such work by

the facility's owner-operator. The specialist must have read and understood these Operating

Instructions and must follow the instructions they contain. The device may only be modified and

repair work carried out if this is explicitly permitted in the Operating Instructions. Damaged

devices which could be a source of danger may not be commissioned and must be labeled and

identified as defective.

1.3 Operational safety

• Functional safety

The Flowphant T flow switch has been developed in accordance with the IEC 61508 and

IEC 61511-1 (FDIS) standards. The device version with a PNP switch output and additional

analog output is equipped with features for detecting and preventing errors within the

electronics and software.

•Ex-area

The Flowphant T is not approved for use in Ex-areas.

1.4 Return

The following procedures must be carried out before a device is returned to Endress+Hauser:

• Always enclose a fully completed “Declaration of Contamination” form with the device. Only

then can Endress+Hauser transport and examine a returned device. A copy of the

“Declaration of Contamination” can be found on the second last page of these Operating

Instructions.

• Remove all fluid residues. This is particularly important if the fluid is hazardous to health, e.g.

flammable, toxic, caustic, carcinogenic, etc.

WARNING

!

Do not return a device if you are not absolutely certain that all traces of hazardous

substances have been removed, e.g. substances which have penetrated crevices or diffused

through plastic.

Page 5

DTT31, DTT35 Safety instructions

Endress+Hauser 5

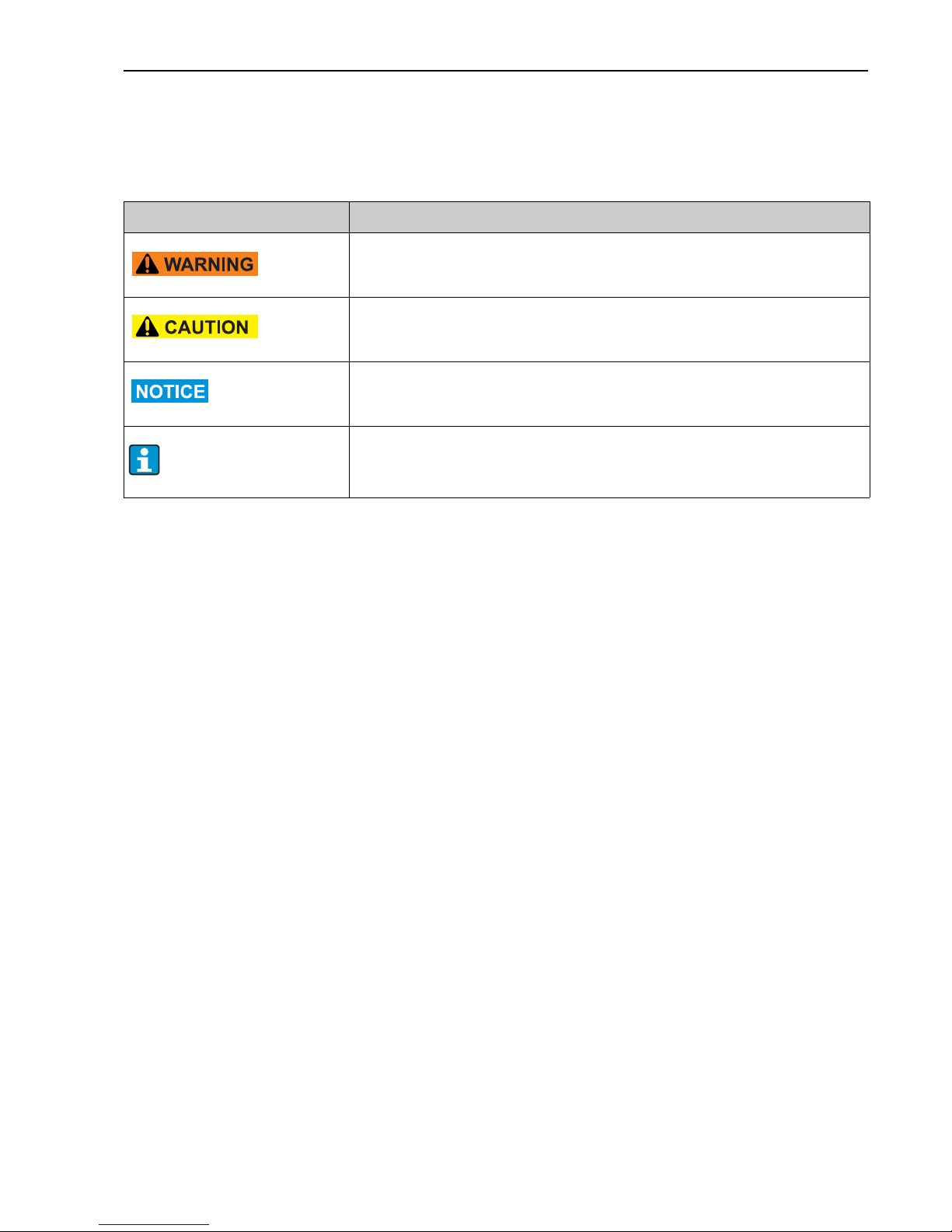

1.5 Notes on safety conventions and icons

Always refer to the safety instructions in these Operating Instructions labeled with the following

symbols:

Symbol Meaning

A0011190-EN

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

A0011191-EN

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

A0011192-EN

NOTICE

This symbol contains information on procedures and other facts which do not

result in personal injury.

A0011193

Indicates additional information, Tip

Page 6

Device identification DTT31, DTT35

6 Endress+Hauser

2 Device identification

2.1 Nameplate

To identify your device, compare the complete order code and the version information on the

delivery papers with the data on the nameplate.

A0006981

Fig. 1: Nameplate for device identification (as example)

2.2 Certificates and approvals

CE mark, declaration of conformity

On leaving the factory, the device was in perfect condition from the point of view of safety. It

complies with the standards EN 61010 -1 "Protection Measures for Electrical Equipment for

Measurement, Control, Regulation and Laboratory Procedures" and with the EMC requirements

of IEC/EN 61326. The device meets the legal requirements of the EU Directives. The

manufacturer confirms a positive completion of all tests by fitting the unit with a CE mark.

Hygiene standard

The DTT35 flow switch meets the requirements of Sanitary Standard no. 74-06.

Endress+Hauser confirms this by applying the 3–A symbol (not valid for process connection

conical metal-metal).

16YV

MEASURING EQUIPMENT

m

n

o

p

q

r

s

t

u

v

Flowphant T

Made in Germany D-87484 Nesselwang

Order Code: DTT3x-xxxxxxxx

Ser.No.: xxxxxxxxxxxxxx

TAG No.: Xxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxx

Rel.: X.XX.XX

Flow (0.03 … 3m/s; -20 °C...+85 °C)

-40°C < Ta < 85°C

Output < 250 mA

Current consump.100mA

18 - 30V DC

PNP

1

4

3

2

L+

L-

12

IP6X

m Order code r Connection diagram

n Serial number s Measuring range

o TAG number t Ambient temperature range

p Release number (change status) u Degree of protection

q Connection values v Approvals

The release number indicates the change status of the device. A change in the last two

figures does not have any affect on the compatibility, → Chap. 8.4.

Page 7

DTT31, DTT35 Installation

Endress+Hauser 7

UL listed for Canada and USA

The device was examined by Underwriters Laboratories Inc. (UL) in accordance with the

standards UL 61010B-1 and CSA C22.2 No. 1010.1-92 and listed under the number E225237

UL.

3 Installation

3.1 Incoming acceptance, storage

• Incoming acceptance:

Check the packaging and the device for damage. Check that the goods delivered are complete

and nothing is missing.

•Storage:

Storage temperature -40 °C to +85 °C (-40 °F to 185 °F).

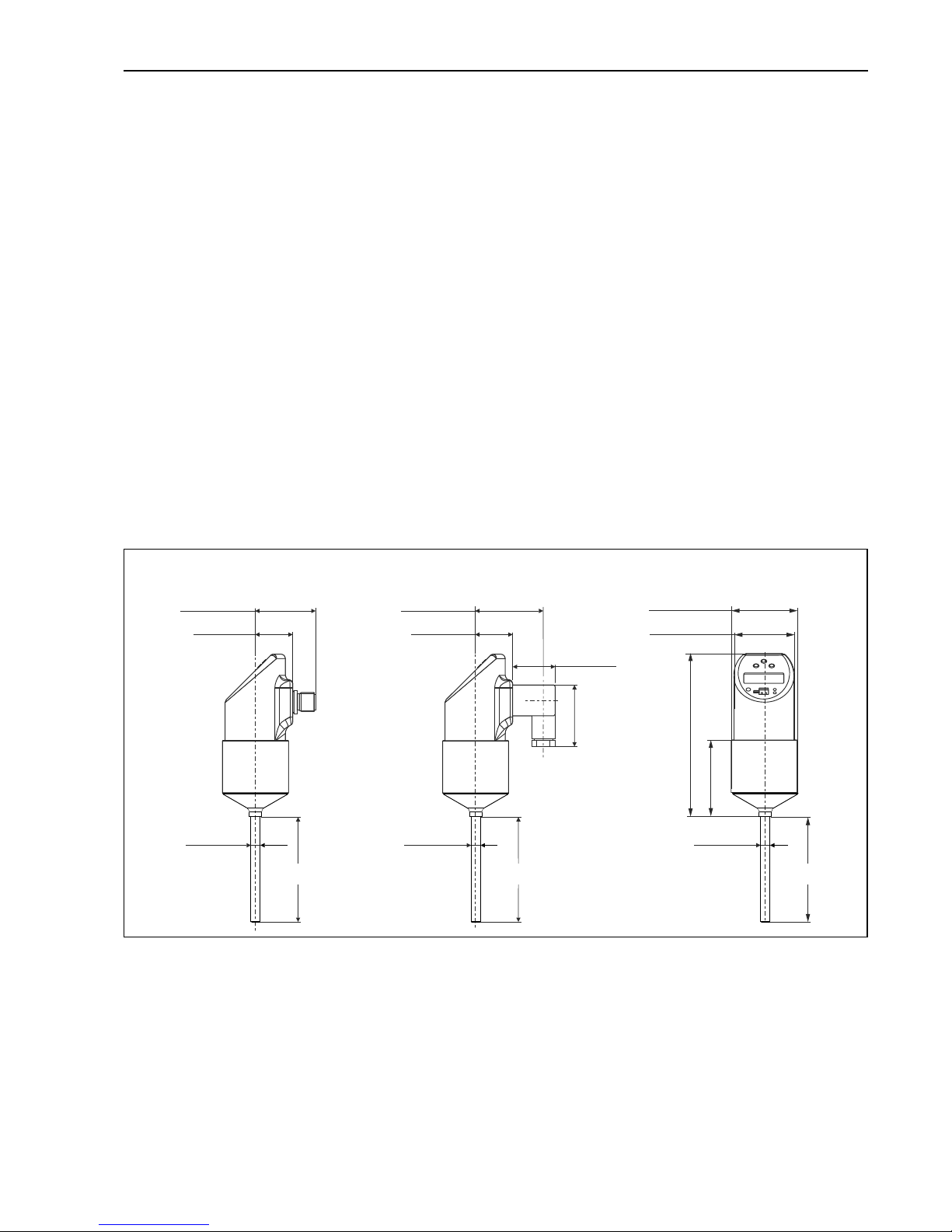

3.2 Dimensions

A0005279

Fig. 2: Dimensions in mm (in)

Version L with 30 and 100 mm (1.18 and 3.94 in) for DTT31

Version L with 30, 50 and 100 mm (1.18, 1.97 and 3.94 in) for DTT35

M12x1 connector as per IEC 60947-5-2

M16x1.5 or NPT ½" valve connector as per DIN 43650A/ISO 4400

42.3 (1.66)

97.1 (3.82)

42.1 (1.66)

38.7 (1.52)

38.7 (1.52)

36 (1.42)

24 (0.95)

24 (0.95)

52 (2.05)

38.5 (1.52)

M16x1.5 / NPT ½”

M12x1

LL L

6 (0.24)

6 (0.24)

6 (0.24)

Page 8

Installation DTT31, DTT35

8 Endress+Hauser

3.3 Process connection

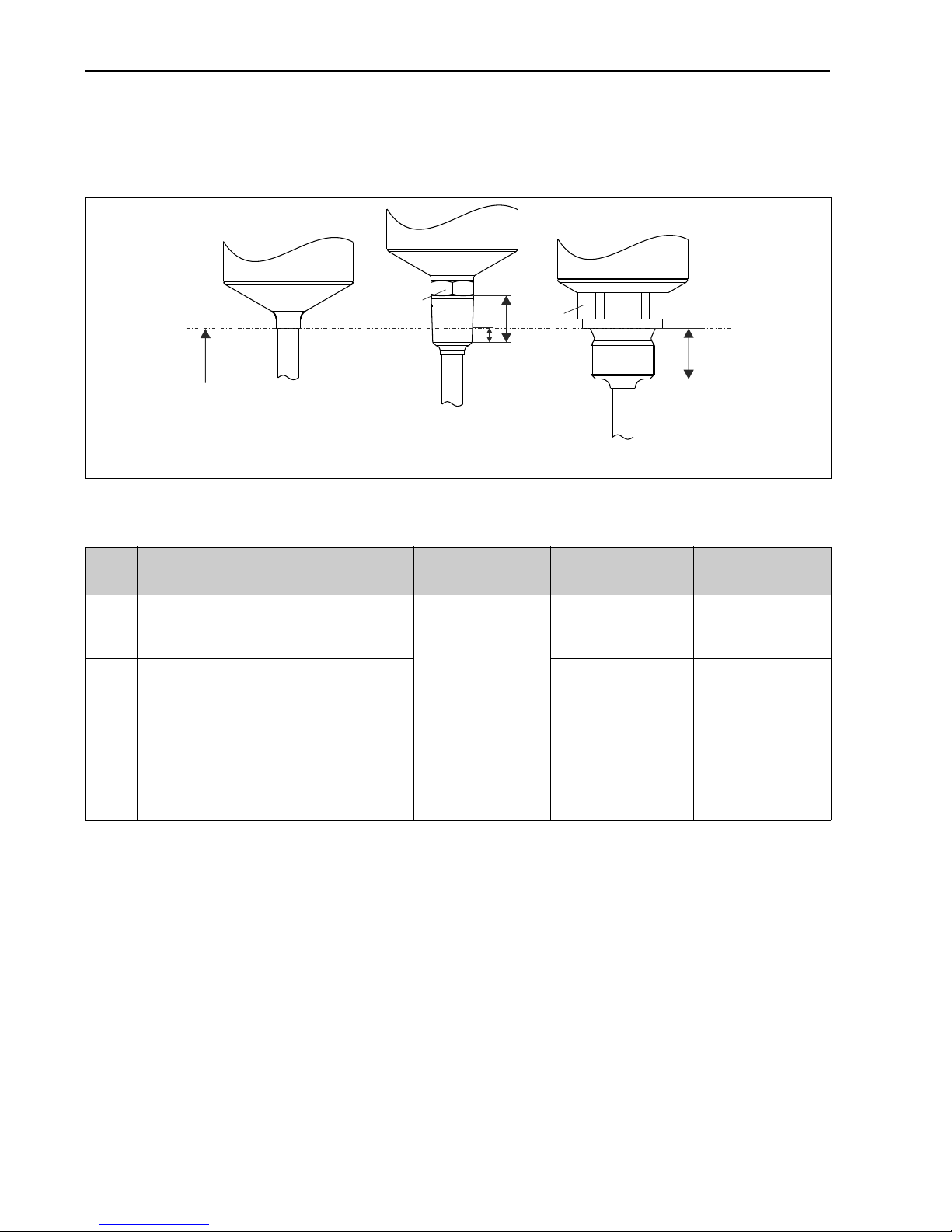

3.3.1 DTT31 design, dimensions of the process connections

A0007101

Fig. 3: Process connection versions of DTT31

m

AB

C

n

L

L1

L2

L1 = L2

Item

no.

Version Insertion length L Thread length L

1

Thread length L

2

A Without process connection. For suitable

welding boss and coupling see chapter

’accessories’.

30 or 100 mm

(1.18 or 3.94 in)

--

B Thread process connection:

• ANSI NPT ¼" (m = AF15)

• ANSI NPT ½" (m = AF22)

• 14.3 mm (0.56 in)

• 19 mm (0.75 in)

• 5.8 mm (0.23 in)

• 8.1 mm (0.32 in)

C Thread process connection cylindrical as

per ISO 228:

•G¼" (n = AF19)

•G½" (n = AF27)

• 12 mm (0.47 in)

• 14 mm (0.55 in)

-

Page 9

DTT31, DTT35 Installation

Endress+Hauser 9

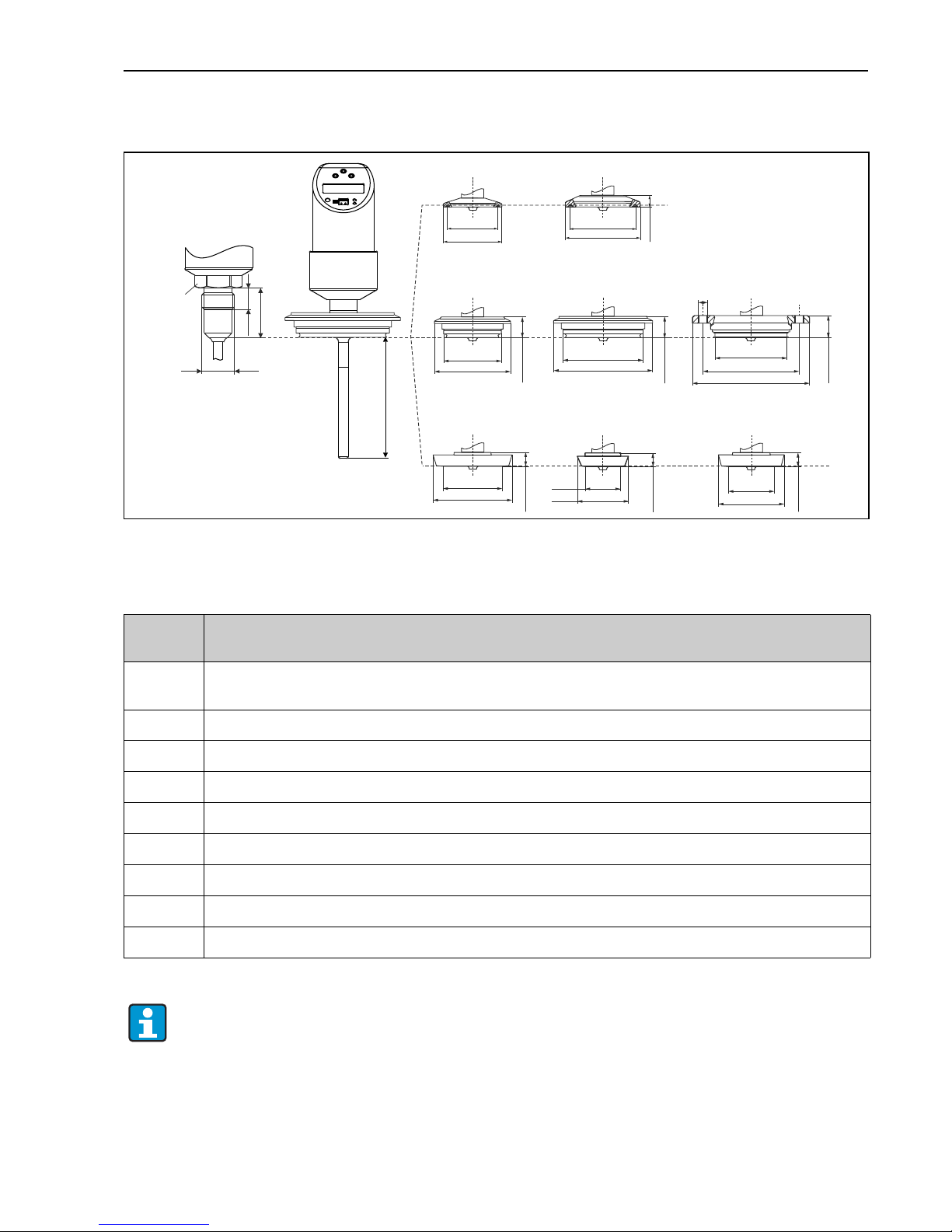

3.3.2 DTT35 design, dimensions of the process connections

A0011776

Fig. 4: Hygienic process connections. All dimensions in mm (in)

L = Insertion length L

DB

DL

56.5 (2.22)

64 (2.52)

LL

18 (0.71)

HL

B

19 (0.75)

PL

13 (0.51)

PH

13 (0.51)

(APV-Inline)

(CLAMP 1”) (CLAMP 2”)

(Varivent N)

LB

18 (0.71)

(Varivent F)

(DIN 11851)

(DIN 11851)

L

13 (0.51)

PG

(DIN 11851)

10 (0.39)

MB

L1

SW/

AF 22

37 (1.46)

G½”

43.5 (1.71)

50.5 (1.99)

84 (3.31)

68 (2.68)

61.5 (2.42)

82 (3.23)

100 (3.94)

66 (2.6)

50 (1.97)

51 (2.01)

68 (2.68)

27 (1.06)

44 (1.73)

39 (1.54)

56 (2.21)

Item no. Process connection versions DTT35

Insertion length L = 30, 50 or 100 mm (1.18, 1.97 or 3.94 in)

MB Conical metal-metal for hygienic processes, G½" thread, thread length L1 = 14 mm (0.55 in).

Suitable welding boss available as accessory.

DB Clamp 1"...1½" (ISO 2852) or DN 25...DN 40 (DIN 32676)

DL Clamp 2" (ISO 2852) or DN 50 (DIN 32676)

LB Varivent F DN25-32, PN 40

LL Varivent N DN40-162, PN 40

HL APV-Inline, DN50, PN40, 316L, B = bores 6 x Ø8.6 (0.34 in) + 2 x thread M8

PL DIN 11851, DN50, PN40 (including coupling nut)

PG DIN 11851, DN25, PN40 (including coupling nut)

PH DIN 11851, DN40, PN40 (including coupling nut)

The maximum process pressure for the conical metal-metal process connection

(→ Fig. 4, item MB) is 16 bar!

Page 10

Installation DTT31, DTT35

10 Endress+Hauser

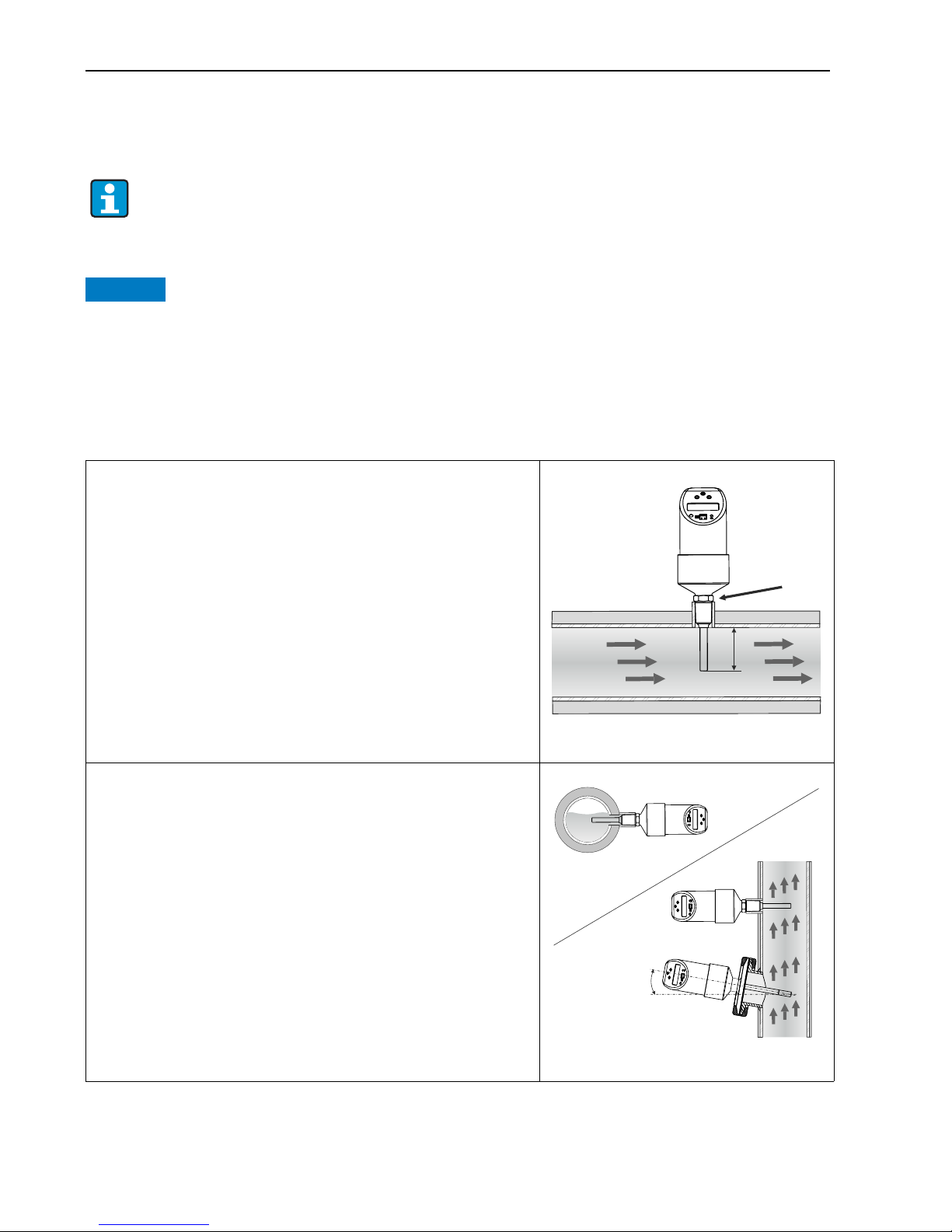

3.4 Installation instructions

3.4.1 Installation conditions

NOTICE

Do not turn the device into the process connection thread at the housing. Always install the

device at the spanner flats (Fig. 5, item 1). Use a suitable open-ended wrench for this task (see

Table → Chap. 3.3.1).

• The onsite display can be rotated electronically 180°, → Chap. 5.1 "Onsite operation".

• The upper housing section can be rotated mechanically up to 310°.

The sensor requires a fully developed flow profile for correct monitoring.

For this reason, steadying sections (5x DN) must be provided in the pipe after a pump,

pipe bend, internal fittings and cross-sectional changes.

• The sensor tip should be completely surrounded by medium.

• Position the sensor tip in the area of maximum fluid velocity (pipe

center).

• Minimum sensor immersion length: L

i

≥10 mm.

A0006976

Fig. 5: Installation conditions

Orientation

• For horizontal pipes: lateral installation.

Installation from above (see Fig. 5) only if the pipe is completely

filled with medium during operation.

• For vertical pipes: installation in the ascending pipeline.

• Installation of DTT35 by min. 3° inclination, because of self draining.

A0006977

Fig. 6: Correct orientation

80

%

L

i

v

m

1

80

%

80

%

80

%

3°=

Page 11

DTT31, DTT35 Installation

Endress+Hauser 11

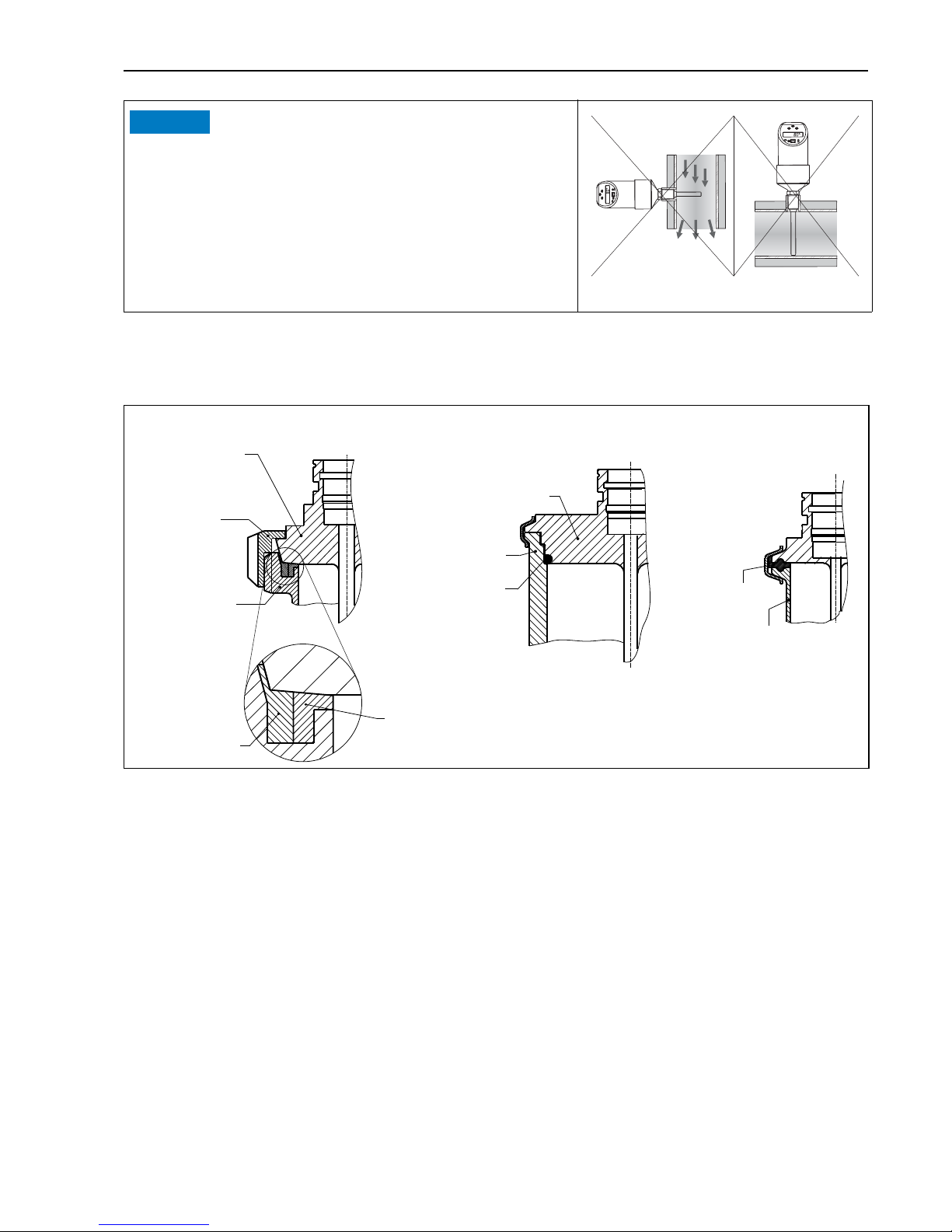

3.4.2 Mounting instructions for installation in hygienic processes

A0011673-EN

Fig. 8: Installation in hygienic processes

A Milk pipe connection as per DIN 11851 (connection PL, PG, PH), only in linkage with EHEDG certified and self

centering ring

B Varivent and APV-Inline (connection LB, LL, HL)

C Clamp as per ISO 2852 (connection DB, DL)

NOTICE

Do not install in down pipes open towards the end.

The sensor tip should never touch the pipe wall.

A0006978

Fig. 7: Incorrect installation!

ABC

Sensor with

milk pipe

connection

Sensor with

Varivent connection

Shaped

gasket

Companion

connection

O-Ring

Groove

slip-on nut

Centering ring

Sealing

Companion

connection

Companion

connection

Page 12

Installation DTT31, DTT35

12 Endress+Hauser

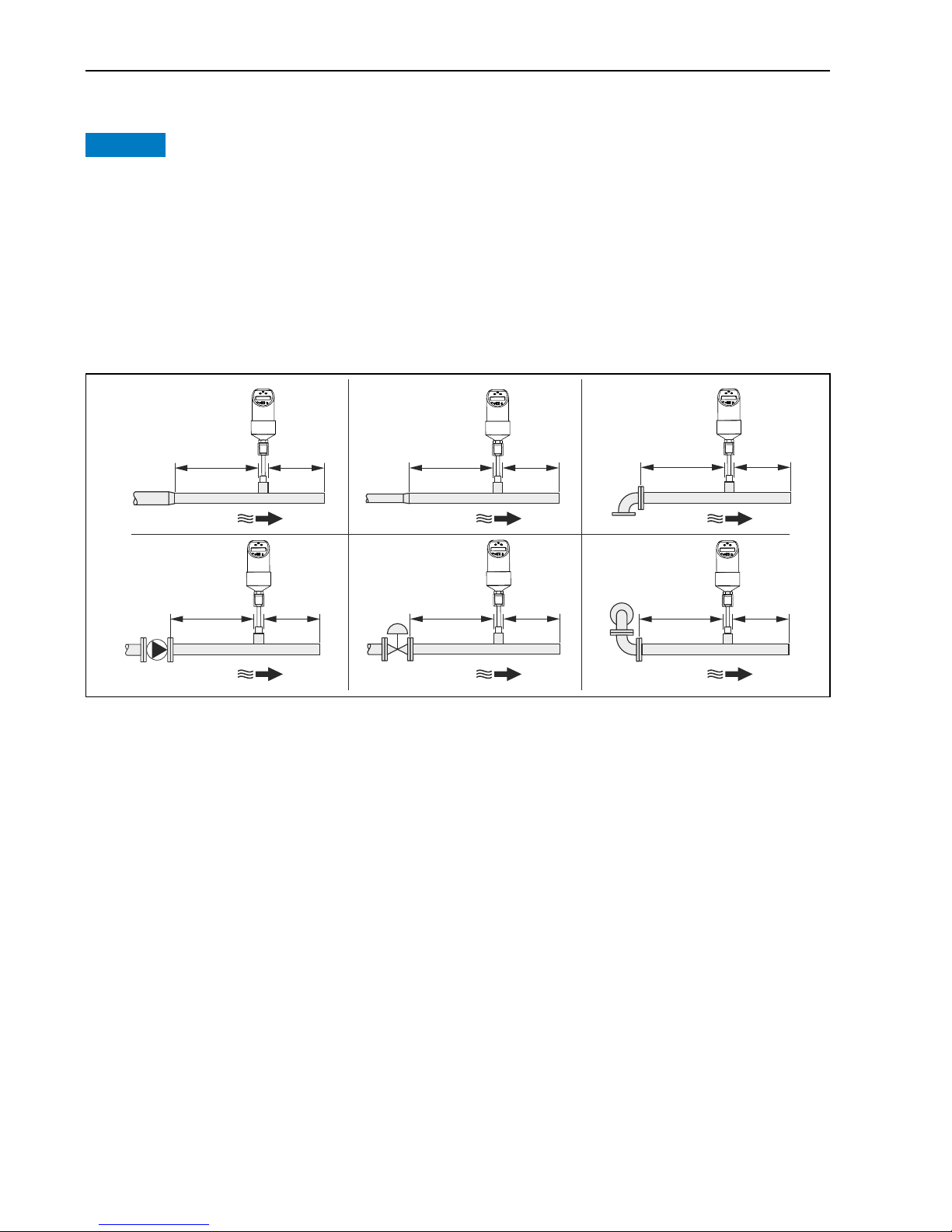

3.4.3 Inlet and outlet run

NOTICE

The thermal measuring principle is sensitive to disturbed flow conditions.

‣ As a general rule, install the measuring device as far away as possible from any flow

disturbances. For further information → ISO 14511.

‣ If possible, install the sensor upstream from fittings such as valves, T-pieces, elbows, etc.

‣ To attain the specified level of accuracy of the measuring device, the inlet and outlet runs

mentioned below must be maintained at the very minimum.

‣ If there are several flow disturbances present, the longest specified inlet run must be

maintained.

A0023225

Fig. 9: Inlet and outlet run

1Reduction

2Expansion

3 90° elbow or T-section

4Pump

5 Control valve

6 2x 90° elbow 2- or 3-dimensional

5 × DN

3 × DN

3 × DN

15 × DN

5 × DN

3 × DN

3 × DN

3 × DN

5 × DN

3 × DN

10 × DN

5 × DN

1

4

2

6

3

5

Page 13

DTT31, DTT35 Wiring

Endress+Hauser 13

4 Wiring

4.1 DC voltage version with M12x1 connector

A0006818

Flowphant T with M12x1 connector

A1: 1x PNP switch output

A2: 2x PNP switch outputs R1 and m (R2)

A2’: 2x PNP switch output R1 and m (diagnosis/NC contact for "DESINA" setting)

A3: 1x PNP switch output and 1x analog output (4 to 20 mA)

CAUTION

!

To avoid any damage to the analog input of a PLC, do not connect the active PNP switch output

of the device to the 4 to 20 mA input of a PLC.

DESINA (→ Chap. 5.1.6, basic settings):

R2 = diagnosis/NC contact (more information on DESINA can be found at www.desina.de).

NOTICE

Once connected to the power supply, the sensor tip of the device heats up! The temperature can

reach up to approx. 90 °C (194 °F).

DTT35: Electrical cables must comply with 3-A standard.

They must be smooth, corrosion resistant and cleanable.

4...20 mA

L–

L–

L–

L+

L+

L+

2

2

2

1

1

1

3

3

3

4

4

4

R1

m

R2

R1

A1

A2

A2’

A3

Page 14

Operation DTT31, DTT35

14 Endress+Hauser

4.2 DC voltage version with valve connector

P01-PTx3xxxx-04-xx-xx-xx-0 03

Fig. 10: Flowphant T with M16x1.5 valve connector or NPT ½"

B: 1x PNP switch output

5Operation

5.1 Onsite operation

The Flowphant T is operated by means of three keys. The digital display and the light emitting

diodes (LED) support navigation in the operating menu.

A0020825-EN

Fig. 11: Position of operating elements and possibilities for display

Operating keys

E

Communication jack

for personal computer

LED for status

Green = ok

Red = error/fault

LED red/green blinking = warning

Digital display

Illumination white (= ok)

Illumination red (= error/fault)

Yellow LEDs for switching states

LED on = switch closed

LED off = switch open

Page 15

DTT31, DTT35 Operation

Endress+Hauser 15

5.1.1 Navigating in the operating menu

T09-TTR31xxx-19-xx-xx-xx-0 02

Fig. 12: Navigating in the operating menu

A Function group selection

B Function selection

w

Enter the operating menu

–Press the E key for longer than 3 s

x

Select the "Function group" with the + or − key

y

Select the "Function" with the E key

z

Enter or change parameters with the + or − key

–Then return to "Function" with the E key Note: If software locking is enabled, it must be disabled before making

entries or changes

{

Return to the "Function group" by pressing the E key several times

–until the appropriate function group is reached again

|

Jump to the measuring position (Home position)

–Press the E key for longer than 3 s

}

Query to save data (select "YES" or "NO" with the + or − key)

–Confirm with the E key

Changes to the parameter settings only become effective if you choose s 'YES' when

asked to save data.

Page 16

Operation DTT31, DTT35

16 Endress+Hauser

5.1.2 Navigating the Calibration function group (CAL)

Variable limits for HIF (Learn High Flow) or LOWF (Learn Low Flow) can be configured using

the 'Learn' function.

• HIF configuration (Learn High Flow): Enter a random flow rate between 70% and 100% of the

maximum value in the process. The measuring device uses this value to automatically

calculate the corresponding 100% value.

• LOWF configuration (Learn Low Flow): Enter a random flow rate between 0% and 20% of the

maximum value in the process. The measuring device uses this value to automatically

calculate the corresponding 0% value.

A0010787

Fig. 13: Navigating the 'Learn' function using the Calibration (CAL) function group as an example

B Select function

w

Select the HIF (Learn High Flow) or LOWF (Learn Low Flow) function with the E key

C Select settings

x

Select the "RUN" function with the + key, 'Learn' function is initialized

y

Select the flow rate with the + key, press for longer than 2 s:

– If the HIF is configured (Learn High Flow), the upper flow rate (70% - 100%) is selected. Enter the current relative

flow rate in increments of 1% with the + or - key (factory setting 80%).

– If the LOWF is configured (Learn Low Flow), the lower flow rate (0% - 20%) is selected. Enter the current relative

flow rate in increments of 1% with the + or - key (factory setting 0%).

z

Select the "WAIT" function with the E key

{

Accept ('Learn') the current measured value after approx. 10 s - "OK" appears on the display

|

Or: The message "W432" appears on the display after 60 s

–A sufficiently stable flow rate was not detected during the learning process. The system takes an average of the 10

values last measured during the learning process.

}

Return to the CAL function group (Home position) with the E key

The device is still operative if message W432 appears. There can be large measuring

uncertainties however. Recommendation: Repeat 'Learn' process (points 1 to 4) until

"OK" appears on the display.

Page 17

DTT31, DTT35 Operation

Endress+Hauser 17

5.1.3 Navigating the 'Learn' switch point (SPL)

A0005785

Fig. 14: Navigating the 'Learn' switch point

B Select function

w

SPL ('Learn' switch point), optional SPL2 ('Learn' switch point 2) with the E key

C Select settings

x

Select the "RUN" function with the + key, 'Learn' function is initialized

y

Select the "WAIT" function with the + key, press for longer than 2 s

z

Accept ('Learn') the current measured value after approx. 10 s - "OK" appears on the display

{

Or: The message "W432" or "NOK" appears on the display after 60 s

–W432: A sufficiently stable flow rate was not detected during the learning process. The system takes an average of

the 10 values last measured during the learning process.

–NOK: The switch point determined is under 5% of the measuring range and cannot be accepted as the switch point

must be a min. of 5% greater than the switch-back point (RSP).

|

Return to the OUT function group (Home position) with the E key

The device is still operative if message "W432" or "NOK" appears.

However, large deviations at the switch point may result. Recommendation:

Repeat 'Learn' process (points 1 to 4) until "OK" appears on the display.

Page 18

Operation DTT31, DTT35

18 Endress+Hauser

5.1.4 Structure of the operating menu for 2 switch outputs

A0005784

Fig. 15: Operating menu: A function groups, B functions, C settings

Page 19

DTT31, DTT35 Operation

Endress+Hauser 19

5.1.5 Structure of the operating menu for 1 x analog output (4 to 20 mA) and

1 x switch output.

A0006819

Fig. 16: Operating menu: A function groups, B functions, C settings

Page 20

Operation DTT31, DTT35

20 Endress+Hauser

5.1.6 Basic settings

5.1.7 Calibration

Function

group

Function Settings Description

BASE

Basic

settings

DISP Display PV

PVRO

TMP

TMPR

OFF

OFFR

PV: displays the current measured value

PVRO: displays the current measured value rotated

180°

TMP: displays the current medium temperature

TMPR: displays the current medium temperature

rotated 180°

OFF: display off

OFFR: display off, rotated 180°

Factory setting: current measured value (PV)

UNIT Technical

unit

×C

×F

Display medium temperature unit °C or °F

Factory setting: °C

Only visible if the current medium

temperature TMP is selected in the DISP

mode.

TAU Damping 0.0 Measured value damping with regard to display

value and output: 0 (no damping) or 9 to 40 s (in

increments of 1 second)

Factory setting: 0 s

DESI DESINA

Only for 2 x

PNP switch

outputs

NO

YES

Behavior as per DESINA: PIN assignment of the M12

connector is in accordance with the guidelines of

DESINA

(DESINA = DistributEd and Standardized

INstAllation technology for machine tools and

manufacturing systems)

Factory setting: NO

Function

group

Function Settings Description

CAL

Calibration

HIF Learn High

Flow

RUN

WAIT

RUN, WAIT: setting for the maximum flow rate

occurring. 100% value (→ Page 16)

LOWF Learn Low

Flow

RUN

WAIT

RUN, WAIT: setting for the minimum flow rate

occurring. 0% value (→ Page 16)

Page 21

DTT31, DTT35 Operation

Endress+Hauser 21

5.1.8 Settings for output - 2 x switch output

Functions of the switch point

• Hysteresis function

The hysteresis function enables

two-point control via a hysteresis.

Depending on the mass flow, the

hysteresis can be set via the switch

point SP and the switch-back point

RSP.

A0005280

Fig. 17: m Hysteresis function, n NO contact, o NC contact

SP switch point; RSP switch-back point

• NO contact or NC contact

This switch function is freely

selectable.

• Delay times for switch point SP and

switch-back point can be set in

increments of 1 s. By this means

undesirable temperature peaks of

short duration or of high frequency

can be filtered out.

Function

group

Function Settings Description

OUT

Output 1

OUT2

Output 2,

optional

MODE Switching

mode

FLOW

TEMP

Output switching mode for channel 2

FLOW: flow rate or TEMP: temperature

Factory setting: FLOW

UNIT Technical

unit

×C

×F

Temperature unit selection °C or °F

Function only visible if the switching mode

MODE is set to temperature TEMP in the

2nd output.

Factory setting: °C

Page 22

Operation DTT31, DTT35

22 Endress+Hauser

OUT/

OUT2

continued

FUNC

FNC2

Switching

characteris

tics

HYNC

HYNO

HYNC: hysteresis/NC contact

HYNO: hysteresis/NO contact

(→ Fig. 17)

Factory setting: HYNO

SP

SP2

Switch

point value

0.0 • Enter value 5 to 100% in increments of 1%.

Factory setting: 50%

Or optionally for SP2:

• Enter value -15 to 85 °C (-5 to 185 °F) in

increments of

1 °C (1 °F) if the switching mode MODE is set to

temperature TEMP.

Factory setting: 55 °C

SPL

SP2L

Switch

point

’Learn’

RUN

WAIT

RUN, WAIT: take the current flow rate as the switch

point SP or SP2. See ’Navigating the Learn function’

(→ Fig. 13).

RSP

RSP2

Switchback

point value

0.0 • Enter value 0 to 95% in increments of 1%.

Factory setting: 40%

The value has to be at least 5% smaller

than the switch point (SP or SP2).

Or optionally for RSP2:

• Enter value -20 to 80 °C (-4 to 176 °F) in

increments of

1 °C (1 °F) if the switching mode MODE is set to

temperature TEMP.

Factory setting: 50 °C

Value has to be at least 5 °C (9 °F) smaller

than switch point 2 (SP2).

TSP

TSP2

Switch

point delay

0.0 Can be set anywhere between 0 and 99 s in

increments of 1 second.

Factory setting: 0 s

TRSP

TRSP2

Switchback

point delay

0.0 Can be set anywhere between 0 and 99 s in

increments of 1 second.

Factory setting: 0 s

Function

group

Function Settings Description

Page 23

DTT31, DTT35 Operation

Endress+Hauser 23

5.1.9 Settings for output - 1 x analog output (4 to 20 mA) and 1 x switch output

Function

group

Function Settings Description

4-20

Output 1

MODE Measurement

mode for

analog output

FLOW

TEMP

Output FLOW: flow rate or TEMP: temperature

For TEMP setting (temperature), the

measuring range is specified at -20 °C to

+85 °C (-4 °F to 185 °F).

Factory setting: FLOW

FCUR Error current MIN

MAX

HOLD

Current value in event of error:

MIN = ≤ 3.5 mA

MAX = ≥ 21.7 mA

HOLD = last current value

Factory setting: MAX

OUT

Output 2

MODE Switching

mode

FLOW

TEMP

Output switching mode FLOW: flow rate or TEMP:

temperature

Factory setting: temperature (TEMP)

UNIT Technical unit ×C

×F

Temperature unit selection °C or °F

Function only visible if the switching mode

MODE is set to temperature TEMP in the

2nd output.

Factory setting: °C

FUNC Switching

characteristics

HYNC

HYNO

HYNC: hysteresis/NC contact

HYNO: hysteresis/NO contact

(→ Fig. 17)

Factory setting: HYNO

SP Switch point

value

0.0 • Enter value 5 to 100% in increments of 1%.

Factory setting: 50%

or:

• Enter value -15 to 85 °C (-5 to 185 °F) in

increments of

1 °C (1 °F) if the switching mode MODE is set to

temperature TEMP.

Factory setting: 55 °C

SPL Switch point

’Learn’

RUN

WAIT

RUN, WAIT: take the current flow rate as the

switch point SP. See ’Navigating the Learn function’

(→ Page 16).

Page 24

Operation DTT31, DTT35

24 Endress+Hauser

OUT

continued

RSP Switchback

point value

0.0 • Enter value 0 to 95% in increments of 1%.

Factory setting: 40%

The value has to be at least 5% smaller

than the switch point SP.

or:

• Enter value -20 to 80 °C (-4 to 176 °F) in

increments of 1 °C (1 °F) if the switching mode

MODE is set to temperature TEMP.

Factory setting: 50 °C

Value has to be at least 5 °C (9 °F)

smaller than switch point SP2.

TSP Switch point

delay

0.0 Can be set anywhere between 0 and 99 s in

increments of 1 second.

Factory setting: 0 s

TRSP Switchback

point delay

0.0 Can be set anywhere between 0 and 99 s in

increments of 1 second.

Factory setting: 0 s

Function

group

Function Settings Description

Page 25

DTT31, DTT35 Operation

Endress+Hauser 25

5.1.10 Setting for service functions

Function

group

Function Settings Description

SERV

Service

functions

LOCK Locking

code

0 Enter the device locking code.

CODE Change

locking

code

0 User-defined code 1 to 9999;

0 = no locking;

Only visible if the locking code is valid.

PRES Reset NO

YES

Reset all entries to factory settings.

REV'

C

Static

revision

counter

0 Configuration counter, incremented each time the

configuration is changed.

STAT Device

status

LST'D Last error 0 Display of last error to occur.

Switch output

version

SIM

SIM2

Simulation

for 2 x

switch

output

OFF

OPEN

CLOS

OFF: no simulation

OPEN: switch output open

CLOS: switch output closed

Analog output

version (4 to 20

mA)

SIM

SIMA

Simulation

for 1 x

analog

output

(SIMA)

and 1 x

switch

output

(SIM)

OFF

OPEN

CLOS

3.5

4

8

...

OFF: no simulation

OPEN: switch output open

CLOS: switch output closed

3.5, 4, 8...:

Simulation values for analog output in mA

(3.5/4.0/8.0/12.0/16.0/20.0/21.7)

Page 26

Operation DTT31, DTT35

26 Endress+Hauser

5.2 Operation with PC and configuration software

A0008072

Fig. 18: Operation, visualization and maintenance with PC and configuration software.

Item 1: PC with ReadWin 2000 or Fieldcare configuration software

Item 2: Configuration kit TXU10-AA or FXA291 with USB port

Item 3: Flow switch

5.2.1 Additional operating options

In addition to the operating options listed in the previous "Onsite operation" section, the

ReadWin 2000 or FieldCare configuration software provides further information on the

Flowphant T:

Function group Function (display) Description

SERV (Service) Switching processes 1

Switching processes 2, optional

Number of changes in switching status for

switch output 1; optionally switch output 2

INFO

(device

information)

TAG 1

TAG 2

Tagging, 18-digit

Order code Order code

Device serial number -

Sensor serial number -

Electronics serial number -

Device revision Display of entire revision

Hardware revision -

Software revision -

Page 27

DTT31, DTT35 Maintenance

Endress+Hauser 27

5.2.2 Hints for the configuration with ReadWin 2000

Comprehensive information on the ReadWin 2000 configuration software may be found in the

Operating Instructions BA137R/09/en.

5.2.3 Hints for the configuration with FieldCare

FieldCare is an universal configuration software based on FDT/DTM technology.

NOTICE

To configure the Flowphant T DTT31/35 with FieldCare the “PCP (ReadWin) Communication

DTM” and the Flowphant Device-DTM are required.

The device supports only offline configuration and up-/download of parameters. The online

configuration is not supported.

Detailed information concerning FieldCare may be found in the operation manual (BA027S/c4)

or see: www.endress.com.

6 Maintenance

Any buildup on the sensor can have a negative effect on the accuracy. For this reason, check the

sensor for buildup at regular intervals.

CAUTION

!

Make sure the process is unpressurized before you remove the device! Do not twist the device

out of the process connection thread at the housing. Always use a suitable open-ended wrench

for disassembly work (see also → Fig. 5) (→ Chap. 3.3.1).

Page 28

Accessories DTT31, DTT35

28 Endress+Hauser

7 Accessories

All dimensions in the drawings are given in mm (in).

7.1 Welding bosses and coupling

7.1.1 Welding boss with sealing taper

7.1.2 Collar welding boss

7.1.3 Welding boss with sealing taper (metal - metal)

Collar welding boss moveable with sealing

taper and pressure screw;

material of parts in contact with the process:

316L, PEEK,

Max. process pressure 10 bar (145 psi)

Order number: 51004751

A0020709-EN

Material of parts in contact with process:

316L

Order no. 51004752

A0020710

Welding boss

Seal, metal-metal,

Material of parts in contact with process:

316L

Max. process pressure 16 bar (232 psi)

Order no. 60021387

A0006621

G½”

25 (0.98)

36 (1.42)

30 (1.18)

6 (0.24)

AF24

25 (0.98)

30 (1.18)

G½”

6 (0.24)

30 (1.18)

16 (0.63)

34 (1.34)

15 (0.6)

G½”

Page 29

DTT31, DTT35 Accessories

Endress+Hauser 29

7.1.4 Coupling

7.2 Electrical connection

7.2.1 Coupling; connecting cable

Moveable coupling, G½" process connection,

material coupling and parts in contact with

process: 316L

Order no. 51004753

A0020174-EN

Coupling M12x1; straight

Connection to M12x1 housing connector

Order number: 52006263

P01-PMP13xxx-00-xx-00-x x-003

Coupling M12x1 for own assembly of the

connecting cable; elbowed

Connection to M12x1 housing connector

Degree of protection (connected):

IP67, PG7

Order number: 51006327

A0020722

G½”

45 (1.77 )

15 (0.59)

6 (0.24)

+1

+0.04

AF14

AF27

20

(0.79)

41

(1.61)

35 (1.38)

14.8

(0.58)

Page 30

Accessories DTT31, DTT35

30 Endress+Hauser

7.3 Configuration kit

PVC cable, 4 x 0.34 mm2 (22 AWG) with

M12x1 coupling (assembled), elbowed,

screw plug, length 5 m (16.4 ft),

degree of protection: IP67

order number: 51005148

Core colors:

•1 = BN brown

•2 = WH white

•3 = BU blue

•4 = BK black

A0020723

PVC cable, 4 x 0.34 mm2 (22 AWG) with

M12x1 coupling, with LED, elbowed, 316L

screw plug, length 5 m (16.4 ft), especially

for hygiene applications,

degree of protection (connected): IP69K

order number: 52018763

Display:

− gn: device operational

− ye1: switch status 1

− ye2: switch status 2

Not suitable for 4 to 20 mA analog

output!

T09-TTR31xxx-00-00-xx-x x-001

• Configuration kit for PC-programmable

transmitters - ReadWin 2000 setup

program and interface cable (4 pin plug)

for PCs with USB port,

Order code: TXU10-AA

• Configuration kit "Commubox FXA291"

with interface cable for PCs with USB

port. Intrinsically safe CDI interface

(Endress+Hauser Common Data

Interface) for transmitters with 4-pole

post connector. Suitable device

configuration tool is e.g. FieldCare.

Order code: FXA291

A0008067

1

2 (WH) nc

2

1 (BN) +

4

3 (BU) -

3

4 (BK) nc

ye 1

ye 2 gn

Page 31

DTT31, DTT35 Accessories

Endress+Hauser 31

7.4 Configuration software

The ReadWin 2000 and FieldCare 'Device Setup' configuration programs can be downloaded free

of charge from the Internet at the following address:

• www.endress.com/readwin

• www.products.endress.com/fieldcare

FieldCare 'Device Setup' can also be ordered from an Endress+Hauser sales office.

Page 32

Troubleshooting DTT31, DTT35

32 Endress+Hauser

8 Troubleshooting

8.1 Error messages and warning messages

If an error occurs in the device, the color of the status LED changes from green to red and the

illumination of the digital display changes from white to red. A status LED flashing red and

green signals a warning. The display shows:

• E-code for errors

In the event of an error message, the measured value is uncertain.

• W-code for warnings

In the event of a warning, the measured value is reliable.

Code Explanation Remedy

E011 Device configuration faulty Reset device (→ Chap. 5.1.10)

E012 Error in measurement or medium temperature outside

measurable range

Check medium temperature, return device

to Endress+Hauser where necessary

E013 Sensor heating defective Return device to Endress+Hauser

E019 Power supply outside specification Check operating voltage

E015

Memory error Return device to Endress+HauserE020

E021

E022 Power is only supplied to the device via the

communication interface (measurement is deactivated)

Check operating voltage

E042 Output current can no longer be generated (only for 4

to 20 mA output, e.g. load at analog output too high or

open analog output)

Check load; switch off analog output

Page 33

DTT31, DTT35 Troubleshooting

Endress+Hauser 33

8.2 Repair

A repair is not planned.

8.3 Disposal

Please pay particular attention to the local disposal regulations of your country. When

disposing, ensure that the materials of the device components are separated and processed

accordingly.

Code Explanation Remedy

W107 Simulation active

W200 Fluid temperature outside specification

(> 85 °C)

Check fluid temperature and, where

necessary, adapt it to the specification

W202 Measured flow rate outside the range between set Low

and High Flow

(< -10% or > 110%)

Set High and Low Flow again, reset device

to factory setting where necessary (PRES

function)

W209 Device starts

W210 Configuration changed (warning code displayed for

approx. 15 s)

W240 Flow velocity too high (> 3 m/s in water), the device is

operated outside its specified measuring range. The

measurement is uncertain.

Reduce flow velocity of the medium

W250 Number of max. switch cycles exceeded

W260 Values for High Flow (HIF) and Low Flow (LOWF) too

close

Set High and Low Flow again (greater

distance apart), reset device to factory

setting where necessary (PRES function)

W270 Short-circuit and overload at output 1 Check output wiring

W280 Short-circuit and overload at output 2 Check output wiring

W432 Values for High Flow (HIF) or Low Flow (LOWF) could

not be determined with certainty (→ Page 16). The

device can be operated however.

Set High and Low Flow again (keep flow

velocity constant!)

Page 34

Troubleshooting DTT31, DTT35

34 Endress+Hauser

8.4 Change status (release)

The release number on the nameplate and in the Operating Instructions indicates the change

status of the device: XX.YY.ZZ (example 01.02.01).

8.5 Software history

XX Change in the main version.

Compatibility no longer provided. Device and Operating Instructions change.

YY Change in functionality and operation.

Compatibility provided. Operating Instructions change.

ZZ Troubleshooting and internal modifications.

Operating Instructions do not change.

Date Software version Software modifications Documentation

02.2006 01.00.00 Original

firmware

BA218r/09/en/02.06

(71022232)

12.2006 01.00.03 Analog output version

(4 to 20 mA) available

BA235r/09/en/12.06

(71036991)

12.2006 01.00.03 - BA235r/09/en/10.07

(71036991)

11.2008 01.00.04 Calibration function: Variable

configuration for HIF (70 to

100%) and LOWF (0 to 20%);

Warning message W200

BA235r/09/en/11.08

(71036991)

11.2008 01.00.04 - BA235r/09/en/06.09

(71098494)

11.2008 01.00.04 - BA235r/09/en/13.10

(71098494)

07.2013 01.00.08 - BA00235R/09/EN/14.13

(71226085)

01.2014 01.00.08 - BA00235R/09/EN/15.14

(71243850)

04.2014 01.00.08 - BA00235R/09/EN/16.14

(71252244)

Page 35

DTT31, DTT35 Technical data

Endress+Hauser 35

9Technical data

9.1 Power supply

Supply voltage

• DC voltage version 18 to 30 V DC

Current consumption

• < 100 mA (open-circuit operation) at 24 V DC, max. 150 mA (open-circuit operation); with

reverse polarity protection

Power supply failure

• Behavior in case of over voltage (> 30 V)

The device works continuously up to 34 V DC without any damage. No damage is caused to

the device in case of a short-term over voltage up to 1 kV (as per EN 61000-4-5). If the supply

voltage is exceeded, the properties specified are no longer guaranteed.

• Behavior in case of under voltage

If the supply voltage drops below the minimum value, the device switches off (status as if not

supplied with power = switch open).

9.2 Output

Switching capacity

• Switch status ON: I

a

≤ 250 mA

• Switch status OFF: Ia ≤ 1 mA

• Switching cycles: > 10,000,000

• Voltage drop PNP: ≤ 2 V

• Overload protection

Automatic load testing of switching current; output is switched off in event of over current,

the switching current is tested again every 0.5 s; max. capacitance load: 14 μF for max. supply

voltage (without resistive load); periodical protective disconnection in event of over current

(f = 2 Hz) and 'Warning' display.

Analog output: Signal on alarm as per NAMUR NE43

• Under ranging:

Linear drop to 3.8 mA

• Over ranging:

Linear rise to 20.5 mA

• Sensor breakage; sensor short-circuit:

≤ 3.6 mA or ≥ 21.0 mA (output 21.7 mA is guaranteed for setting ≥ 21.0 mA)

• Switch outputs: with safe status (switch open)

Page 36

Technical data DTT31, DTT35

36 Endress+Hauser

9.3 Operating conditions

• Orientation, → Chap. 3.4.1

• Top housing section can be rotated 310°

9.3.1 Operating conditions: Environment

• Ambient temperature range

–40 to +85 °C (-40 to 185 °F)

•Storage temperature

–40 to +85 °C (-40 to 185 °F)

•Climate class

4K4H as per DIN EN 60721-3-4

• Degree of protection

IP65 (optional IP66, depending on used connector)

• Shock resistance

50 g as per DIN IEC 68-2-27 (11 ms)

• Vibration resistance

20 g as per DIN IEC 68-2-6 (10-2000Hz)

4 g as per guidelines of German Lloyd GL

• Electromagnetic compatibility

Interference emission as per IEC 61326, class B equipment

Interference immunity as per IEC 61326, Appendix A (industry) and

NAMUR Recommendation NE21

EMC influence: ≤ 0.5%

9.3.2 Operating conditions: Process

• Process flow limits

Liquids: 0.03 to 3.0 m/s (0.1 to 9.84 ft/s)

• Process temperature limits

-20 to 85 °C (-4 to 185 °F)

The sensor can be exposed up to 130 °C (266 °F) without damage; monitoring switches off

automatically at T ≥ 85 °C (185 °F) and starts again at T ≤ 85 °C (185 °F).

• Process pressure limits

Maximum permitted process pressure p

max.

≤ 10 MPa = 100 bar (1450 psi)

NOTICE

The maximum process pressure for the conical metal-metal process connection (MB option)

for the DTT35 is 1.6 MPa = 16 bar (232 psi)!

Page 37

DTT31, DTT35 Technical data

Endress+Hauser 37

Page 38

Technical data DTT31, DTT35

38 Endress+Hauser

Page 39

DTT31, DTT35 Technical data

Endress+Hauser 39

Page 40

www.addresses.endress.com

Loading...

Loading...