Page 1

BA 179C/07/en/02.98

Nr.50088966

FlowFit P CPA 240

Flow Assembly for

pH/Redox Sensors

Operating Instructions

Hauser+Endress

Nothing beats know-how

Quality made by

Endress+Hauser

ISO 9001

AUTHORIZED DISTRIBUTOR:

InstrumentsAndControl.com

Houston, Texas USA

sales@InstrumentsAndControl.com

281-609-7170

Page 2

Table of Contents

1 General Information . . . . . . . . . . . . . . . .................................... 2

1.1 Symbols used ............................................................. 2

1.2 Unpacking ................................................................ 2

1.3 Intended use .............................................................. 2

1.4 Safety notes ............................................................... 2

2 Description of the Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Versions .................................................................. 3

2.2 Order code................................................................ 3

2.3 Dimensions ............................................................... 4

2.4 Measuring system .......................................................... 8

3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Installation of the assembly ................................................... 9

3.2 Installation of electrodes and measuring cables .................................. 10

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Cleaning ................................................................. 11

4.2 Calibration ............................................................... 12

5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Chemoclean spray cleaning system ........................................... 13

5.2 Sonoclean ultrasonic cleaning system ......................................... 14

5.3 Electrolyte reservoir CPY 7 .................................................. 15

6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Index............................................................... 17

xa240e00.chp

FlowFit P CPA 240 Table of Contents

Endress+Hauser 1

Page 3

1 General Information

1.1 Symbols used

Warning:

This symbol alerts to hazards which

may cause serious injuries as well as

damage if ignored.

Caution:

This symbol alerts to possible malfunctions due to operator error.

Note:

This symbol indicates important

items of information.

1.2 Unpacking

Inspect for any damaged packaging or

damaged contents. Inform the post office or

freight carrier of any damage. Damaged

goods must be stored until the matter has

been settled.

Check that the delivery is complete and

agrees with the shipping documents. Check

product type and version on the

nameplate against your order.

The delivery includes:

• FlowFit P CPA 240 assembly

• Operating Instructions BA 179C/07/en.

If you have any questions, consult your

supplier or Endress + Hauser sales office

(see back page of this operating instructions

for addresses).

1.3 Intended use

The FlowFit P CPA 240 is intended for the fitting of pH, redox or temperature sensors in pipes. The assembly version is designed for

universal use in drinking water, feedwater and

waste water environments and in chemical industry.

1.4 Safety notes

Warning:

• The notes and warnings in these

operating instructions must be

strictly adhered to!

• Faults on the assembly may only

be remedied by authorised and

properly trained personnel.

• If faults cannot be remedied, the

assembly must be removed from

service and secured to prevent

accidental start-up.

1 General Information FlowFit P CPA 240

2 Endress+Hauser

Page 4

2 Description of the Assembly

2.1 Versions

The FlowFit P CPA 240 flow assembly is

available in two material versions (stainless

steel and PVDF). For use according to specific

customer

requirements, assemblies for installing in

pipes with horizontal flow are available with

various process connections. In addition an

assembly is available with an inlet at the

bottom and a horizontal outlet.

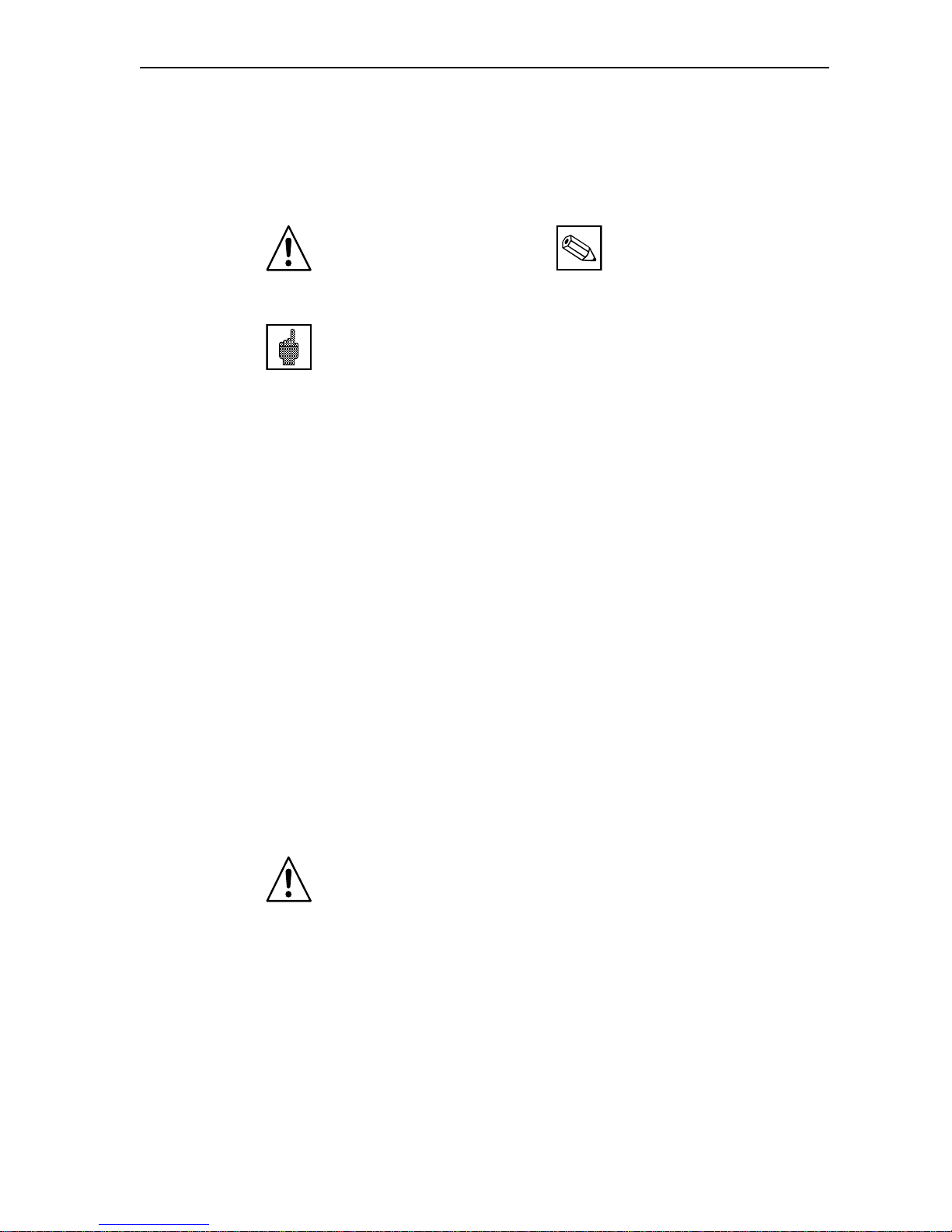

2.2 Order code

You can identify variants by means of the

order code on the nameplate.

Fig. 2.1 Nameplate of CPA 240

Flow assemblyFlowFit P CPA 240

Assembly / PAL materials

21 PVDF / PAL: Hastelloy C4

22 PVDF / PAL: tantalum

30 Stainless steel 1.4404

99 Special version

Flow vessel

A Horizontal flow

B With inlet bottom side

Y Special version

Process coupling

A Weld on connection for pipe DN 25

B Flange DN 25 PN 16

C Flange ANSI 1" 150 lbs

D Flange JIS 10K 25A

E Thread (F)NPT ½ “

Y Special version

Sealing material

1 EPDM

2 Viton

3 Chemraz

4 Fluoraz

9 Special version

Features

10 Basic version

20 Assembly desiliconised

30 Material certificate acc. to EN 10204-3.1B

99 Special version

complete order code

CPA 240-

xa240e02.chp

FlowFit P CPA 240 2 Description of the Assembly

Endress+Hauser 3

Page 5

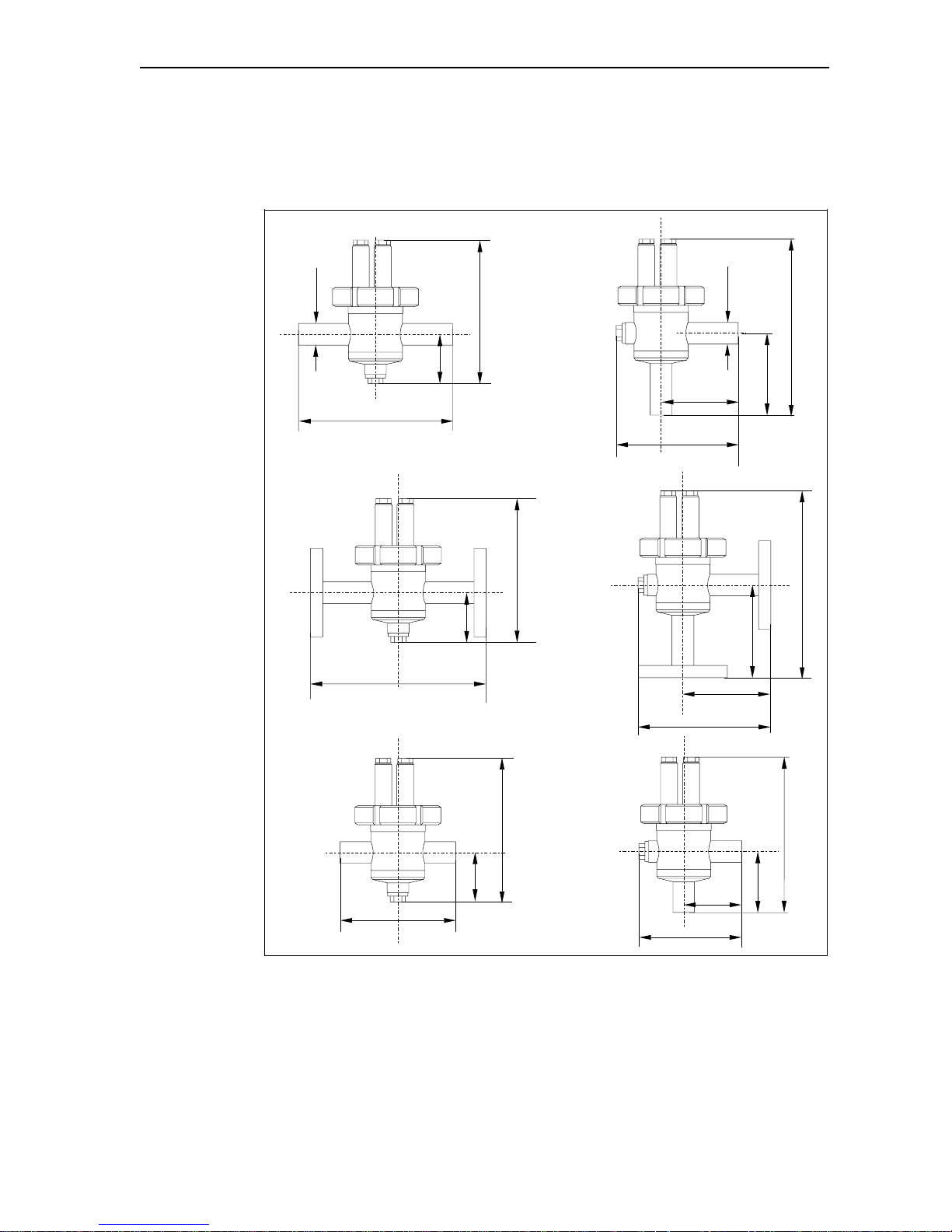

2.3 Dimensions

2.3.1 Versions

250

68

190

(with cover 334)

125

252

(with cover 396)

150

68

140

75

80

202

(with cover 346)

Version:

AA

226

68

190

(with cover 334)

Version:

BA

240

(with cover 384)

118

113

178

Version:

AB, AC, AD

Version:

BB, BC, BD

130

190

Version:

AE

190

(with cover 334)

Version:

BE

240ES-03.CDR

∅ 28 x1,5

∅ 28 x1,5

Fig. 2.2

Versions of stainless steel

assemblies

The protection cover

supplied with the

assembly is not shown.

2 Description of the Assembly FlowFit P CPA 240

4 Endress+Hauser

Page 6

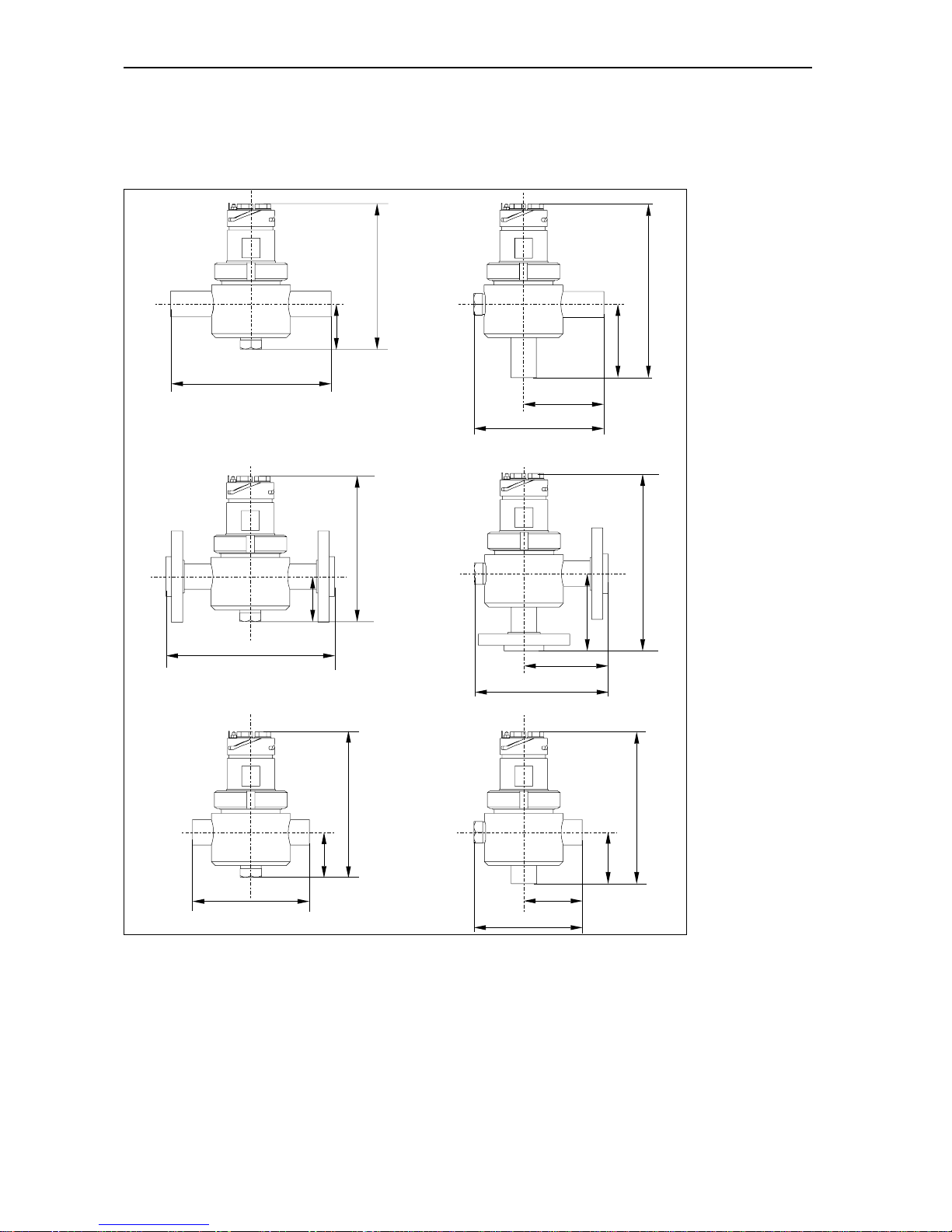

238

52

179

119

111,5

236,5

(with cover 381)

52

177

(with cover 321)

125

117,5

242,5

(with cover 387)

52

177

(with cover 321)

135

75

67,5

192,5

(with cover 337)

240PVDF3.CDR

Version:

BA

Version:

AB, AC, AD

Version:

BB, BC, BD

Version:

AE

250

185

Version:

BE

150

Version:

AA

Fig. 2.3

Versions of stainless

steel assemblies

The protection cover

supplied with the

assembly is not shown.

177

(with cover 321)

xa240e02.chp

FlowFit P CPA 240 2 Description of the Assembly

Endress+Hauser 5

Page 7

2.3.2 Sectional diagrams

b

d

2

a

∅ k

D

Fig. 2.5

Flange dimensions of

stainless steel assembly

Flange

DN 25 ANSI 1“ JIS

PN 16 150 lbs 10K 25A

D 115 108 125

∅ k

85 79 90

d

2

14 16 19

b 141414

a ———

Screws M 12 M 12 M 16

240ES-02.CDR

4

A

∅ 28

NPT ½“

1

2

Section A - A

A

Fig. 2.4

Construction of stainless

steel assembly

(2 different versions):

- left with ½" NPT

- right with DN 25 flange

1 Electrode holder

2 Union nut

3 Potential matching pin

4 Drain screw

5 Shock protection bolt

(1.4401)

horizontal flow

SCHNITT1.CDR

inlet at bottom

Fig. 2.6

Sectional drawing of

stainless steel version

3

5

FLANSCH.CDR

2 Description of the Assembly FlowFit P CPA 240

6 Endress+Hauser

Page 8

Fig. 2.7

Loose flange dimensions

of PVDF assembly

A

4

240PVDF1.CDR

∅ 32

2

1

3

NPT ½“

Section A - A

A

Fig. 2.8

Construction of PVDF

assembly (2 different

versions):

- left with ½" NPT

- right with DN 25 flange

1 Electrode holder

2 Union nut

3 Potential matching pin

4 Drain screw

SCHNITT2.CDR

inlet at bottom

horizontalflow

Fig. 2.9

Sectional drawing of

PVDF version

b

d

2

a

∅ k

D

FLANSCH.CDR

∅ 50

xa240e02.chp

Flange

DN 25 ANSI 1 “ JIS

PN 16 150 lbs 10K 25A

D 115 115 125

∅ k

85 79 90

d

2

14 16 19

b 141414

a 424242

Screws M 12 M 12 M 16

FlowFit P CPA 240 2 Description of the Assembly

Endress+Hauser 7

Page 9

2.4 Measuring system

A complete measuring system comprises:

• the FlowFit P CPA 240 flow assembly

• maximum 3 electrodes from the CPS range

of length 120 mm and diameter 12 mm

• pH/redox transmitter (e.g. MyPro CPM 431

or Mycom CPM 152)

• measuring cable CPK 1, CPK 2 or CPK 7

(terminated).

Optional:

• Pt 100 temperature sensor

• VBA junction box and measuring cable

PMK or CYK 71 (not terminated) for cable

extension.

PARAM

MEAS CAL

DIAG

Measuring cable (e.g. CYK 71))

Junction box VBA

(accessory)

CPA 240

assembly

Instrument (e.g. Mycom CPM 152)

MESSEINR.CDR

Protection

cover

Electrode holder

with 3 mounting

positions

Drain screw

Potential

matching cable

Electrode cable

(e.g. CPK 7)

Fig. 2.10

Complete measuring

system

Power supply

(e.g. 230 V AC / 50 Hz)

Output

(e.g. 0 or 4 ... 20 mA)

2 Description of the Assembly FlowFit P CPA 240

8 Endress+Hauser

Page 10

3 Installation

3.1 Installation of the assembly

The flow assembly should only be installed in

pipes at locations where the pipe cannot run

dry. Installation in the by-pass is preferable to

installation in the process pipe as the by-pass

pipe can be blocked off without interrupting

the process. This permits measurement,

sampling and maintenance of the electrode

without interrupting the process.

The drain screw fitted to the flow assembly

base permits the connection of outlet or

sampling pipes.

Warning:

• Depressurise the pipe before

installing or removing the

assembly.

• The medium pressure in the pipe

must not exceed the maximum

permissible flow assembly or

electrode pressure.

p

1

p

2

p1> p

2

DN 25

Drain /

sampling

pipe

Process pipe

By-pass pipe

DN 25

Fig. 3.1

Pipe by-pass

The pressure build-up

necessary to produce

flow through the

sampling by-pass is

produced by a plate

orifice in the process

pipe.

By-pass pipe

DN 25

p

2>p1

p

2

p

1

Process pipe

Drain /

sampling

pipe

DN 10

Fig. 3.2

Pump by-pass

The pressure build-up

necessary to produce

flow through the

sampling by-pass is

produced by a booster

pump in the process

pipe.

Sampling pipe

DN 25

p

Process pipe

Sampling

Drain

∅ d

Fig. 3.3

Sampling pipe

Stub pipe branching off

from the process pipe

without raising pressure.

MONTAGE2.CDR

MONTAGE3.CDR

MONTAGE4.CDR

xa240e03.chp

FlowFit P CPA 240 3 Installation

Endress+Hauser 9

Page 11

3.2 Installation of electrodes and measuring cables

Note:

• Close off unused electrode

positions with dummy plugs.

• 2 electrodes with KCI fluid and

hose connection cannot be

installed.

• Before screwing in the electrodes

inspect seat and cleanliness of the

O-ring seal.

• Inspect all the O-rings on the flow

assembly for damage at regular

intervals.

• Required mounting clearance

above protection cover: 120 mm

PARAM

MEAS CAL

DIAG

Insert electrode holder into flow

vessel

Screw in electrode until hand

tight

Connect electrode cable to junction box or to instrument

Secure with union nutRemove dummy plugs

Tighten another ¼ turn with

socket spanner

1/4

Screw electrode plug onto

electrode head

Attach PM

plug to

PM pin

Attach on protection cover

MONTAGE1.CDR

3 Installation FlowFit P CPA 240

10 Endress+Hauser

Page 12

4 Maintenance

Electrode soiling may impair measurement to

such an extent that the electrode ceases to

function, e.g. due to:

• coatings on the pH-sensitive glass

membrane → poor response time and low

sensitivity or slope.

• soiling or blockage of the membrane →

poor response time and unstable

measured values.

To ensure reliable measurement clean the

electrodes regularly. The frequency and

intensity of cleaning depend on the medium

to be measured.

4.1 Cleaning

Clean the electrodes:

• before every calibration

• regularly during operation,

if necessary.

Cleaning can be carried out manually or with

an automatic cleaning system such as

Chemoclean or Sonoclean.

Caution:

• Do not use abrasive cleaning

agents on the electrodes. This

could lead to irreparable

malfunctions of the measuring

surfaces.

• After cleaning, thoroughly rinse

the whole system with water

(if possible, distilled or deionised). Any residue of cleaning

agents may severely impair

measurement.

• The measuring system must be

re-calibrated after each cleaning.

Manual cleaning

All parts coming in contact with the medium,

such as electrodes or flow assembly, must be

cleaned regularly. When an outlet or sampling

pipe is installed, rinse the drain on the base of

the flow assembly.

• Light soiling can be removed

with suitable cleaning agents.

• More severe soiling can be removed by

brushing carefully with a soft brush and a

suitable cleaning agent.

• Stubborn dirt may be dissolved by soaking

the appropriate parts in the cleaning fluid.

Automatic cleaning

Cyclic automatic cleaning in an installed

condition may be carried out by the

Chemoclean automatic spray cleaning

system. The complete system includes the

CYR 10 injector box and the CYR 20

programmer (see Chapter 5, Accessories).

Various diluted chemicals or pressurised

water may be used as cleaning agents

depending on the type of soiling.

Use the Sonoclean automatic ultrasonic

cleaning system (see Chapter 5, Accessories)

for automatic cleaning without cleaning

agents.

Selection of cleaning agents

The cleaning agent chosen is dependent on

the type of soiling. The most frequent type of

soiling and the appropriate cleaning agents

are listed in the following table:

Type of soiling Cleaning agent

Grease, lubricants, oils

Detergents or

water-soluble organic

solvents (e.g. alcohol)

Lime deposits or metal

hydroxides

3% HCl

Sulphate deposits from

precipitation reactions

Mixture of 3% HCI with

a 1% Titripex (EDTA)

Protein deposits (food

industry)

Mixture of 3% HCI with

saturated Pepsin

xa240e04.chp

FlowFit P CPA 240 4 Maintenance

Endress+Hauser 11

Page 13

4.2 Calibration

Careful, regular calibration is essential for

reliable, accurate measurement. The

calibration intervals depend on the particular

application and the required measuring

accuracy.

The calibration intervals must be individually

determined in practice for each application.

To begin with it is advisable to calibrate more

often, e.g. once a week to get to know the

operating behaviour.

Calibration steps:

• Depressurise the assembly (vent using the

drain plug or drain valve, if necessary).

• Remove electrode holder by taking off

protective cover and unscrewing union nut.

• Clean electrodes and assembly (see

Chapter 4.1). Automatic cleaning: clean

before removing electrode holder.

• Check electrodes for mechanical damage.

• Fill calibration vessel with buffer solution.

• Calibrate measuring system according to

instructions for measuring instrument.

• Rinse electrode with water.

• Refit electrode holder in assembly.

Caution:

• Do not allow electrodes to stand in

distilled water.

• Do not allow electrodes to stand

dry.

4 Maintenance FlowFit P CPA 240

12 Endress+Hauser

Page 14

5 Accessories

The following accessories can be ordered

separately:

• Chemoclean spray cleaning system

comprising:

– CYR 10 injector

(see Technical Information

TI 046C/07/en, Order No. 50014223)

– CYR 20 programmer

(see Technical Information

TI 046C/07/en, Order No. 50014223)

• Sonoclean ultrasonic cleaning system

• KCI reservoir CPY 7 with CPY 4

electrolyte solution (see Operating

Instructions BA 128C/07/d-e,

Order No. 50069155)

• CPY 2 calibration solution

• Calibrating vessel.

The following spare parts can be reordered:

• O-ring sets

Assembly PVDF

Stainless

steel

Sealing

material

EPDM 50089408 50089412

Viton 50089409 50089413

Chemraz 50089410 50089414

Fluoraz 50089411 50089415

5.1 Chemoclean spray cleaning system

The Chemoclean spray cleaning system is

used for automatic electrode cleaning. The

best cleaning results can be obtained by

using the correct cleaning agent. This

ensures the correct functioning of the sensor.

The Chemoclean cleaning system for the

CPA 240 flow assembly comprises:

• Chemoclean spray head

(shipment due in 07/98)

• cleaning injector CYR 10

• cleaning control system (e.g. CYR 20

programmer or CPM 152 transmitter)

Further information about the Chemoclean

spray cleaning system was not available at the time

of publishing (date of publication: 07/98)

xa240e05.chp

FlowFit P CPA 240 5 Accessories

Endress+Hauser 13

Page 15

5.2 Sonoclean ultrasonic cleaning system

The Sonoclean ultrasonic cleaning system is

used to clean electrodes without the use of

cleaning agents.

Dirt particles adhering to the electrodes are

loosened by pressure fluctuations produced

by ultrasound.

Further information about the Sonoclean

ultrasonic cleaning system was not available

at the time of publishing.

5 Accessories FlowFit P CPA 240

14 Endress+Hauser

Page 16

5.3 Electrolyte reservoir CPY 7

The CPY 7 electrolyte reservoir is used to

supply fluid-filled electrodes. When a

reference electrode is installed, the reservoir

vessel can be used as an electrolyte bridge.

The reservoir is filled with KCI electrolyte

solution CPY 4.

For more information, see Operating

Instructions CPY 7 (BA128C/07/d-e).

220

Fig. 5.1

Electrolyte reservoir CPY7

(wall-mounted version)

Valve

Dummy plug;

reference electrode

position

Dummy plug;

manometer position

Filling mark

Securing nut for

electrolyte vessel

Hose coupling

∅ 20

∅ 87

∅ 72

25

60

70

PA140-01.CDR

xa240e05.chp

FlowFit P CPA 240 5 Accessories

Endress+Hauser 15

Page 17

6 Technical Data

Note:

The operating limits of the system

are determined by the operating

limits of the individual components

used (assembly,sensors, cables,

accessories, etc.).

200-15

2

4

6

8

10

40 60 80 100 120 140 160

Stainless steel1.4404

PVDF

Temperature in °C

PT-DIAGR.CDR

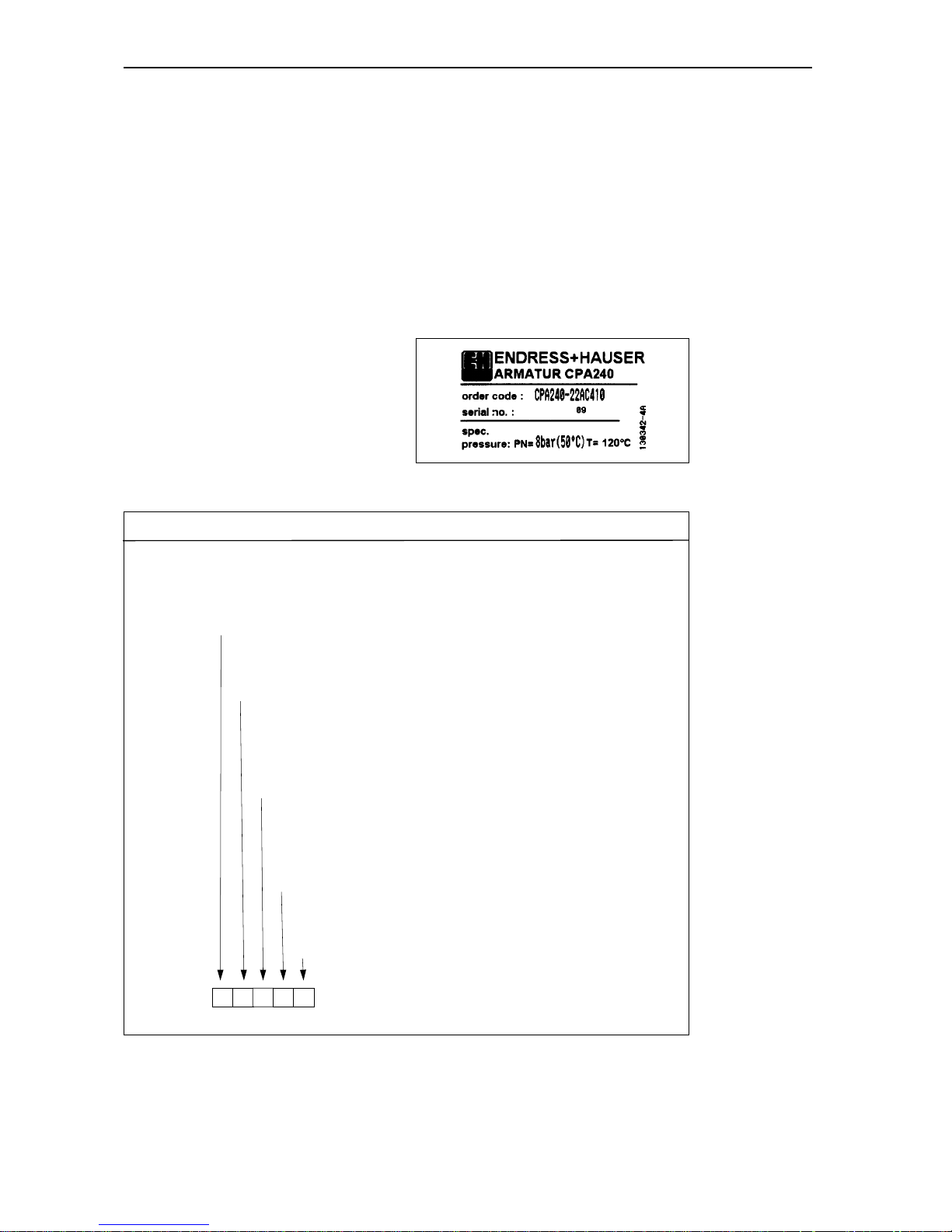

Fig. 6.1

Pressure / temperature

diagram

General data

Manufacturer Endress+Hauser Conducta GmbH+Co.

Designation FlowFit P CPA 240 flow assembly

Number of mounting positions in sensor holder 3 x Pg 13.5

Thread on sampling connection G 1/2"

Process connection

A Weld on connection for DN 25 (Ø 28 x 1.5)

B Flange DN 25 PN 16

C Flange ANSI 1" 150 lbs.

D Flange JIS 10K 25A

E Thread (F)NPT ½ “

Weight

PVDF approx. 2 kg

Stainless steel 1.4404 approx. 3 - 4.5 kg

Materials in contact with medium

Flow assembly PVFD / stainless steel 1.4404

O-rings EPDM / Viton / Chemraz / Fluoraz

Potential matching pin C4 Hastelloy / tantalum

Dummy plugs PEEK

Shock protection bolts PVFD / stainless steel 1.4404

Materials not in contact with medium

Protective cover PES

Union nut stainless steel 1.44301

Operating data

Operating pressure

PVDF version max. 8 bar (at 50°C)

Stainless steel 1.4404 version max. 10 bar

Operating temperature

PVDF version 0 ... +120°C

Stainless steel 1.4404 version -15 ... +150°C (EPDM 140°C)

Subject to modifications

Permissible pressure in bar

6 Technical Data FlowFit P CPA 240

16 Endress+Hauser

Page 18

7 Index

A

Accessories .............. 13-15

Automatic cleaning . . . . . . . . . . . . 11

B

By-Pass . . . . . . . . . . . . . . . . . . 9

C

Calibration . . . . . . . . . . . . . . . . . 12

Calibration intervals . . . . . . . . . . . . 12

Chemoclean . . . . . . . . . . . . . . 11, 13

Cleaning . . . . . . . . . . . . . . . . . . 11

Cleaning agents . . . . . . . . . . . . . . 11

D

Damaged goods . . . . . . . . . . . . . . 2

Delivery . . . . . . . . . . . . . . . . . . 2

Description of the assembly . . . . . . . 3-8

Dimensions . . . . . . . . . . . . . . . . 4

Drain screw . . . . . . . . . . . . . . . 6-9

Dummy plug . . . . . . . . . . . . . . . . 10

E

Electrode holder . . . . . . . . . . . . . . 6

Electrodes . . . . . . . . . . . . . . . . . 8

Electrolyte reservoir . . . . . . . . . . . . 15

Electrolyte solution . . . . . . . . . . . . . 15

F

Flange .................. 6-7

Flow assembly . . . . . . . . . . . . . . . 9

G

General information . . . . . . . . . . . . 2

I

Installation . . . . . . . . . . . . . . . . 9-10

Installation of electrodes . . . . . . . . . . 10

Installation of measuring cables . . . . . . 10

Installation of the assembly . . . . . . . . 9

Intendeduse................ 2

J

Junctionbox................ 8

M

Maintenance . . . . . . . . . . . . . 11-12

Manual cleaning . . . . . . . . . . . . . 11

Materials . . . . . . . . . . . . . . . . . . 16

Measuring cable . . . . . . . . . . . . . . 8

Measuring system . . . . . . . . . . . . . . 8

Medium pressure . . . . . . . . . . . . . . 9

N

Nameplate . . . . . . . . . . . . . . . . . . 3

O

O-ring sets . . . . . . . . . . . . . . . . 13

Operating pressure . . . . . . . . . . . . 16

Operating temperature . . . . . . . . . . 16

Order code . . . . . . . . . . . . . . . . . 3

Outlet pipe . . . . . . . . . . . . . . . 9, 11

P

Potential matching cable . . . . . . . . . . 8

Potential matching pin . . . . . . . . . . 6-7

Pressure . . . . . . . . . . . . . . . . . . . 9

Process . . . . . . . . . . . . . . . . . . . 9

Process connection . . . . . . . . . . . . 16

Protection cover . . . . . . . . . . . . . 8, 10

S

Safetynotes.................2

Sampling pipe . . . . . . . . . . . . . . . . 9

Sectional drawing . . . . . . . . . . . . . 6-7

Shock protection bolt . . . . . . . . . . . . 6

Soiling . . . . . . . . . . . . . . . . . . . 11

Sonoclean............... 11,14

Spare parts . . . . . . . . . . . . . . . . 13

Spray cleaning system . . . . . . . . 11, 13

Symbols . . . . . . . . . . . . . . . . . . . 2

T

Technical data . . . . . . . . . . . . . . 16

Temperature sensor . . . . . . . . . . . . . 8

Transmitter . . . . . . . . . . . . . . . . . 8

U

Ultrasonic cleaning system . . . . . . 11, 14

Unpacking . . . . . . . . . . . . . . . . . . 2

Use .....................2

V

Versions . . . . . . . . . . . . . . . . . . 3-4

W

Weight . . . . . . . . . . . . . . . . . . . 16

xa240e07.chp

CPA 240 7 Index

Endress+Hauser 17

Page 19

Europe

Austria

❑ Endress+Hauser Ges.m.b.H.

Wien

Tel.(01) 88056-0, Fax (01) 8 8056-35

Belarus

Belorgsintez

Minsk

Tel.(0172)2631 66, Fax (01 72) 26 3111

Belgium / Luxembourg

❑ Endress+Hauser S.A./N.V.

Brussels

Tel.(02) 24806 00, Fax (02) 24805 53

Bulgaria

INTERTECH-AUTOMATION

Sofia

Tel.(02) 652809, Fax (02) 65 2809

Croatia

❑ Endress+Hauser GmbH+Co.

Zagreb

Tel.(01) 66014 18, Fax (01) 66014 18

Cyprus

I+G Electrical ServicesCo.Ltd.

Nicosia

Tel.(02) 484788, Fax (02) 48 4690

Czech Republic

❑ Endress+Hauser GmbH+Co.

Praha

Tel.(026)678 4200, Fax (026) 67841 79

Denmark

❑ Endress+Hauser A/S

Søborg

Tel.(31) 673122, Fax (31) 67 3045

Estonia

Elvi-Aqua

Tart u

Tel.(7) 422726, Fax (7) 42 2727

Finland

❑ Endress+Hauser Oy

Espoo

Tel.(90) 85961 55, Fax (90) 85960 55

France

❑ Endress+Hauser

Huningue

Tel.89696768, Fax 89694802

Germany

❑ Endress+Hauser Meßtechnik GmbH+Co.

Weil am Rhein

Tel.(07621) 9 75-01, Fax (0 7621) 975-555

Great Britain

❑ Endress+Hauser Ltd.

Manchester

Tel.(0161)286 5000, Fax (0161) 9981841

Greece

I & G Building Services Automation S.A.

Athens

Tel.(01) 92415 00, Fax (01) 92217 14

Hungary

Mile Ipari-Elektro

Budapest

Tel.(01) 26155 35, Fax (01) 26155 35

Iceland

VatnshreinsunHF

Reykjavik

Tel.(05) 889616, Fax (05) 88 9613

Ireland

Flomeaco Company Ltd.

Kildare

Tel.(045)8686 15, Fax (0 45) 86 8182

Italy

❑ Endress+Hauser Italia S.p.A.

Cernusco s/N Milano

Tel.(02) 921064 21, Fax (02) 921071 53

Jugoslavia

Meris d.o.o.

Beograd

Tel.(11) 44429 66, Fax (11) 430043

Latvia

Raita Ltd.

Riga

Tel.(02) 254795, Fax (02) 7 258933

Lithuania

Agava Ltd.

Kaunas

Tel.(07) 202410, Fax (07) 20 7414

Netherland

❑ Endress+Hauser B.V.

Naarden

Tel.(035)695 8611, Fax (035) 69588 25

Norway

❑ Endress+Hauser A/S

Tranby

Tel.(032)8510 85, Fax (0 32) 851112

Poland

❑ Endress+Hauser Polska Sp. z o.o.

Warszawy

Tel.(022)720 1090, Fax (022) 72010 85

Portugal

Tecnisis - Tecnica de Sistemas Industriais

Linda-a-Velha

Tel.(01)4172637, Fax(01)4185278

Romania

Romconseng SRL

Bucharest

Tel.(01)4101634, Fax(01)4101634

Russia

❑ Endress+Hauser Moscow Office

Moscow

Tel., Fax: see Endress+Hauser GmbH+Co.

Instruments International

Slovak Republic

Transcom Techniks.r.o.

Bratislava

Tel.(7) 52131 61, Fax (7) 52131 81

Slovenia

❑ Endress+Hauser D.O.O.

Ljubljana

Tel.(061)159 2217, Fax (061) 15922 98

Spain

❑ Endress+Hauser S.A.

Barcelona

Tel.(93)4803366, Fax(93)4733839

Sweden

❑ Endress+Hauser AB

Sollentuna

Tel.(08)6261600, Fax(08)6269477

Switzerland

❑ Endress+Hauser AG

Reinach/BL 1

Tel.(061)715 6222, Fax (061) 71116 50

Turkey

Intek Endüstriyel Ölcü ve Kontrol Sistemleri

Istanbul

Tel.(0212) 27513 55, Fax (02 12) 2 662775

Ukraine

Industria Ukraïna

Kiev

Tel.(44)2685213, Fax(44)2685213

Africa

Egypt

Anasia

Heliopolis/Cairo

Tel.(02)4179007, Fax(02)4179008

Morocco

Oussama S.A.

Casablanca

Tel.(02) 241338, Fax (02) 40 2657

Nigeria

J F Technical Invest.Nig.Ltd.

Lagos

Tel.(1) 622345 46, Fax (1) 622345 48

South Africa

❑ Endress+Hauser Pty.Ltd.

Sandton

Tel.(011)444 1386, Fax (011) 44419 77

Tunisia

Controle, Maintenance et Regulation

Tunis

Tel.(01) 793077, Fax (01) 78 8595

America

Argentina

❑ Endress+Hauser Argentina S.A.

Buenos Aires

Tel.(01)5238008, Fax(01)5220546

Bolivia

Tritec S.R.L.

Cochabamba

Tel.(042)569 93, Fax (0 42) 5 0981

Brazil

❑ Samson Endress+Hauser Ltda.

Sao Paulo

Tel.(011) 53634 55, Fax (0 11) 5363067

Canada

❑ Endress+Hauser Ltd.

Burlington, Ontario

Tel.(905) 68192 92, Fax (9 05) 6819444

Chile

DIN Instrumentos Ltda.

Santiago

Tel.(02) 20501 00, Fax (02) 22581 39

Colombia

Colsein Ltd.

Bogota D.C.

Tel.(01) 23676 59, Fax (01) 61078 68

Costa Rica

EURO-TEC S.A.

San Jose

Tel.2961542, Fax 2961542

Ecuador

Insetec Cia. Ltda.

Quito

Tel.(02) 251242, Fax (02) 46 1833

Guatemala

ACISA Automatizacion Y Control IndustrialS.A.

Ciudad de Guatemala, C.A.

Tel.(02) 345985, Fax (02) 32 7431

Mexico

❑ Endress+Hauser I.I.

Mexico City

Tel.(5) 56896 58, Fax (5) 56841 83

Paraguay

Incoel S.R.L.

Asuncion

Tel.(021)213989,Fax (021)26583

Uruguay

Circular S.A.

Montevideo

Tel.(02) 925785, Fax (02) 92 9151

USA

❑ Endress+Hauser Inc.

Greenwood, Indiana

Tel.(317) 535-7138, Fax(317)535-1489

Venezuela

H.Z.Instrumentos C.A.

Caracas

Tel.(02) 97988 13, Fax (02) 97996 08

Asia

China

❑ Endress+Hauser Shanghai

Instrumentation Co.Ltd.

Shanghai

Tel.(021)64646700, Fax(021)64747860

❑ Endress+Hauser Beijing Office

Beijing

Tel.(010) 683440 58, Fax: (010)68344068

Hong Kong

❑ Endress+Hauser (H.K.) Ltd.

Hong Kong

Tel.25283120, Fax 286541 71

India

❑ Endress+Hauser India Branch Office

Mumbai

Tel.(022) 60455 78, Fax (0 22) 6040211

Indonesia

PT Grama Bazita

Jakarta

Tel.(21) 79750 83, Fax (21) 79750 89

Japan

❑ Sakura Endress Co., Ltd.

Tokyo

Tel.(0422) 540611, Fax (0422)550275

Malaysia

❑ Endress+Hauser (M) Sdn.Bhd.

PetalingJaya,Selangor Darul Ehsan

Tel.(03) 73348 48, Fax (03) 73388 00

Pakistan

Speedy Automation

Karachi

Tel.(021) 77229 53, Fax (0 21) 7736884

Papua-Neuguinea

SBS Electrical Pty Limited

Port Moresby

Tel.53251188, Fax 532595 56

Philippines

Brenton Industries Inc.

Makati Metro Manila

Tel.(2) 84306 61-5, Fax (2) 81757 39

Singapore

❑ Endress+Hauser (S.E.A.) Pte., Ltd.

Singapore

Tel.4688222, Fax 46668 48

South Korea

❑ Endress+Hauser (Korea) Co., Ltd.

Seoul

Tel.(02) 65872 00, Fax (02) 6592838

Taiwan

Kingjarl Corporation

Taipei R.O.C.

Tel.(02) 71839 38, Fax (02) 7134190

Thailand

❑ Endress+Hauser Ltd.

Bangkok

Tel.(2) 99678 11-20, Fax (2) 99678 10

Vietnam

Tan Viet Bao Co.Ltd.

Ho Chi Minh City

Tel.(08) 83352 25, Fax (08) 8335227

Iran

Telephone TechnicalServices Co.Ltd.

Tehran

Tel.(021)874 6750, Fax(021) 87372 95

Israel

Instrumetrics Industrial ControlLtd.

Tel-Aviv

Tel.(03) 64802 05, Fax (03) 6471992

Jordan

A.P. Parpas Engineering S.A.

Amman

Tel.(06) 55392 83, Fax (06) 5539205

Kingdom of Saudi Arabia

Anasia

Jeddah

Tel.(02) 67100 14, Fax (02) 6725929

Kuwait

Kuwait Maritime & Mercantile Co.K.S.C.

Safat

Tel.2434752, Fax 24414 86

Lebanon

Nabil Ibrahim

Jbeil

Tel.(3) 254051, Fax (9) 94 4080

Sultanate of Oman

Mustafa& Jawad Sience & Industry Co.

L.L.C.

Ruwi

Tel.602009, Fax 60 7066

United Arab Emirates

Descon TradingEST.

Dubai

Tel.(04) 359522, Fax (04) 35 9617

Yemen

Yemen Company for Ghee and Soap Industry

Taiz

Tel.(04) 230664, Fax (04) 21 2338

Australia + New Zealand

Australia

GEC Alsthom LTD.

Sydney

Tel.(02) 964507 77, Fax (02) 974370 35

New Zealand

EMC Industrial Instrumentation

Auckland

Tel.(09) 44492 29, Fax (09) 4441145

All other countries

❑ Endress+Hauser GmbH+Co.

Instruments International

D-Weil am Rhein

Germany

Tel.(076 21) 9 75-02, Fax (0 7621)975345

BA 179C/07/en/02.98

Printed in Germany / CV5

❑ Companies of the Endress+Hauser Group

Hauser+Endress

Nothing beats know-how

50088966

Loading...

Loading...