Page 1

Products Solutions Services

BA01281C/07/EN/01.13

71238090

Operating Instructions

Flowfit CUA252

Flow assembly for CUS52D turbidity sensor

Page 2

Endress+Hauser

Document information

Warnings

The structure, signal words and safety colors of the signs comply with the specifications of

ANSI Z535.6 ("Product safety information in product manuals, instructions and other

collateral materials").

Symbols

Safety message structure Meaning

DANGER

!

Causes (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the situation will result in a fatal or serious

injury.

WARNING

!

Causes (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the situation can result in a fatal or serious

injury.

CAUTION

!

Causes (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more

serious injuries.

NOTICE

Cause/situation

Consequences if safety

message is not heeded

‣ Action/note

This symbol alerts you to situations that can result in

damage to property and equipment.

Additional information, tips

Permitted or recommended

Forbidden or not recommended

Page 3

Flowfit CUA252

Endress+Hauser 3

Table of contents

1 Basic safety instructions . . . . . . . . . . . . . 4

1.1 Requirements for personnel . . . . . . . . . . . . . . . . . . 4

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Occupational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . 10

3.4 Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 13

4 Commissioning . . . . . . . . . . . . . . . . . . . . 14

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Cleaning the assembly . . . . . . . . . . . . . . . . . . . . . 15

5.2 Cleaning the sensor . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Cleaning agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Checking and replacing the seals . . . . . . . . . . . . 16

6 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Spare parts kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Accessories . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Connection accessories . . . . . . . . . . . . . . . . . . . . . 18

7.2 Bubble trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Wall mounting kit . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 Technical data . . . . . . . . . . . . . . . . . . . . 20

8.1 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.3 Mechanical construction . . . . . . . . . . . . . . . . . . . 21

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 4

Basic safety instructions Flowfit CUA252

4 Endress+Hauser

1 Basic safety instructions

1.1 Requirements for personnel

‣ Installation, commissioning, operation and maintenance of the measuring system must

only be carried out by specially trained technical personnel.

‣ The technical personnel must be authorized for the specified activities by the system

operator.

‣ Electrical connection must only be carried out by a certified electrician.

‣ Technical personnel must have read and understood these Operating Instructions and

must adhere to them.

‣ Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the enclosed Operating Instructions may only be carried out

directly at the manufacturer’s or by the service organization.

1.2 Designated use

The CUA252 flow assembly is designed for the installation of the CUS52D turbidity sensor.

Its main areas of application are:

• Final turbidity measurement in the outlet of waterworks

• Turbidity measurement in the inlet of waterworks

• Turbidity measurement at all stages of the process

• Turbidity measurement for filter monitoring and filter backwashing

• Turbidity measurement in drinking water networks

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is therefore not permitted.

The manufacturer is not liable for damage resulting from improper or non-designated use.

1.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Explosion protection guidelines (only devices approved for use in explosion hazardous

areas)

• Installation instructions

• Local prevailing standards and regulations

Electromagnetic compatibility

This device has been tested for electromagnetic compatibility in accordance with the

applicable European standards for industrial applications.

The electromagnetic compatibility indicated only applies to a device that has been connected

in accordance with the instructions in these Operating Instructions.

1.4 Operational safety

‣ Before commissioning the entire measuring point, make sure all the connections are

correct. Ensure that electrical cables and hose connections are not damaged.

‣ Do not operate damaged products, and secure them against unintentional

commissioning. Label and identify the damaged product as defective.

‣ If faults cannot be rectified, you must take the products out of service and secure them

against unintentional commissioning.

Page 5

Flowfit CUA252 Basic safety instructions

Endress+Hauser 5

1.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested and

left the factory in a condition in which it is safe to operate.

Relevant regulations and European standards have been observed.

Page 6

Incoming acceptance and product identification Flowfit CUA252

6 Endress+Hauser

2 Incoming acceptance and product

identification

2.1 Incoming acceptance

• Make sure the packaging is undamaged!

• Notify the supplier of any damage to the packaging. Keep the damaged packaging until the

matter has been settled.

• Make sure the contents are not damaged!

• Notify the supplier of any damage to the delivery contents. Keep the damaged products

until the matter has been settled.

• Check the delivery to make sure nothing is missing. Compare it against the shipping

documents and your order.

• Pack the product for storage and transportation in such a way that it is reliably protected

against impact and moisture. The original packaging offers the best protection.

Furthermore, the permitted ambient conditions must also be observed (see "Technical

data").

• If you have any questions, contact your supplier or your local sales center.

2.2 Product identification

2.2.1 Nameplate

You can find the following information on the nameplate:

• Manufacturer details

•Order code

• Extended order code

• Serial number

• Operating conditions

• Safety information symbols

Compare the order code on the nameplate with your order.

2.2.2 Identifying the product

The order code and serial number of your device can be found in the following locations:

• On the nameplate

• In the shipping documents

To discover what product version you have, enter the order code on the nameplate into

the search screen at the following address:

www.products.endress.com/order-ident

2.3 Scope of delivery

The scope of delivery comprises:

• 1 Flowfit CUA252 flow assembly in the version ordered

• 1 Set of Operating Instructions BA01281C/07/EN

If you have any questions, contact your supplier or your local sales center.

2.4 Certificates and approvals

Declaration of Conformity

The product meets the requirements of the harmonized European standards.

As such, it complies with the legal specifications of the EC directives.

The manufacturer confirms successful testing of the product by affixing to it the 4 mark.

Page 7

Flowfit CUA252 Installation

Endress+Hauser 7

3Installation

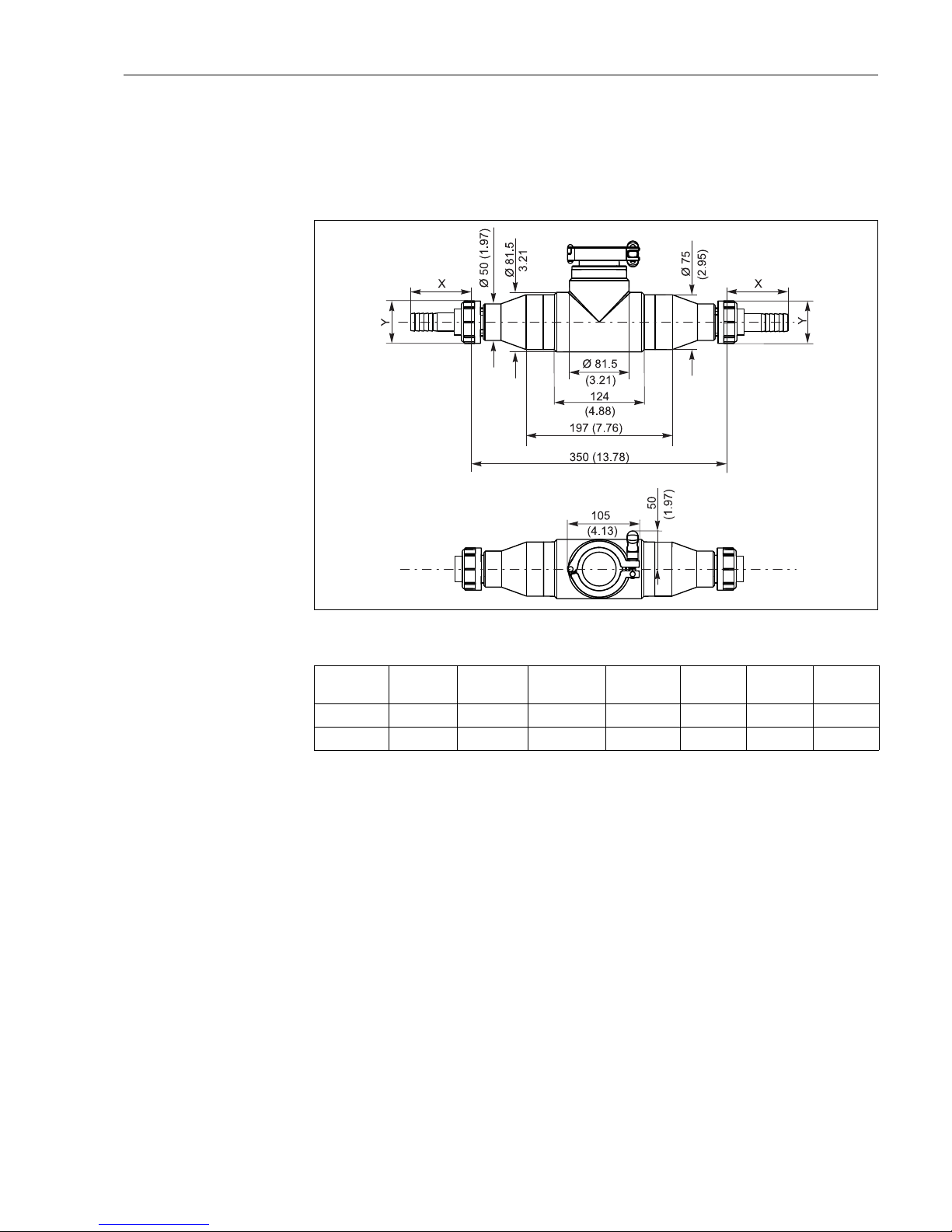

3.1 Dimensions

a0022255

Fig. 1: Dimensions in mm (inch)

Connections NPT ¾" Rp ¾ Glue-in port

D25

ANSI 2" Hose

D25

Hose

D12

G1¼

X mm(inch) 70 (2.76) 64 (2.52) 22 (0.87) 71 (2.80) 74 (2.91) 74 (2.91) 0

Y mm(inch) Ø 58(2.28) Ø 58(2.28) Ø 58(2.28) Ø 152 (5.98) Ø 58(2.28) Ø 58(2.28) Ø 58(2.28)

Page 8

Installation Flowfit CUA252

8 Endress+Hauser

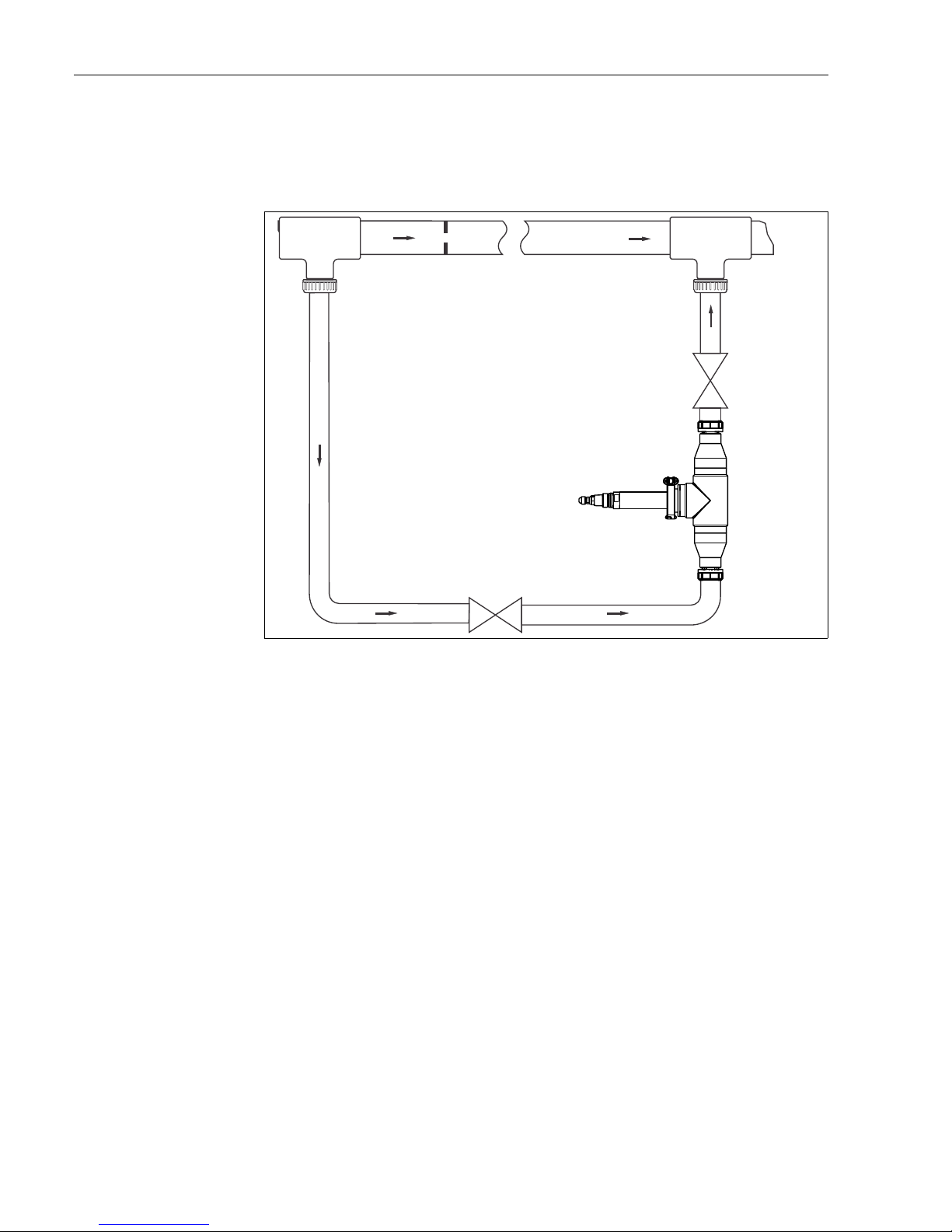

3.2 Installation conditions

To ensure that medium flows through the assembly in a bypass configuration, the pressure

p1 must be greater than the pressure p2. This is achieved by installing an orifice plate in the

main pipe.

a0022258

Fig. 2: Connection example involving a bypass and an orifice plate in the main pipe (supply from below)

p1

p2

p1 > p2

Page 9

Flowfit CUA252 Installation

Endress+Hauser 9

No measures to increase pressure are required for branch pipes that branch off from the

main pipe.

a0022259

Fig. 3: Connection example involving an open outlet

The inlet and outlet connection of the flow assembly are always identical, the system is

symmetrical.

Install the flow assembly vertically.

The supply must be connected at the bottom (upward flow in the pipe).

Avoid buckles and loops in the hose system.

Pay attention to the installation instructions (flow direction) for the sensor.

Many fluids tend to develop gas bubbles in a depressurized state.

Operating the flow assembly under pressure (adjustable valve after the flow assembly)

prevents this behavior in many cases.

Page 10

Installation Flowfit CUA252

10 Endress+Hauser

3.3 Installation instructions

3.3.1 Measuring system

A complete measuring system consists of:

• Flowfit CUA252 flow assembly

• Turbimax CUS52D sensor

• Transmitter, e.g. Liquiline CM442

•Measuring cable

a0022262

Fig. 4: Measuring system (example)

1 Process pipe

2 Liquiline CM442 transmitter

3Measuring cable

4 Return line with shutoff valve

5 CUA252 flow assembly with CUS52D sensor

6 Supply line with shutoff valve

Page 11

Flowfit CUA252 Installation

Endress+Hauser 11

3.3.2 Installation with wall holder unit

a0022264

Fig. 5: Wall holder unit

1 Hanger bolt STST 10x60 (included in the delivery for the wall mounting kit)

Please comply with the following instructions when installing the flow assembly:

• Mount the flow assembly either

–in a bypass

In the bypass pipe, install a shutoff valve upstream and downstream of the flow

assembly. This makes it possible to clean the sensor or perform other maintenance tasks

without affecting the process.

– or in a branch pipe with an open outlet.

Install a shutoff valve upstream of the flow assembly.

• Mount the assembly in a vertical, upright position.

• Establish the medium connection using commercially available connection fittings.

Page 12

Installation Flowfit CUA252

12 Endress+Hauser

3.3.3 Installation with bubble trap

a0022693

Fig. 6: Connection example with bubble trap

1 Supply from below

2 Shutoff valve

3Bubble trap

4 Bubble trap venting (included in the delivery)

5 Shutoff valve (throttle to increase pressure)

6Outlet

7 Transition to D 12 with connection for vent line (included in the delivery)

8 CUA252 flow assembly

9 CUS52D turbidity sensor

10 Transition to D 12

The lost water resulting from the bubble trap is not suitable for feedback into the

process.

For the hose system, use PVC hoses with an internal diameter of 12 mm (3/8").

Secure the hose system with worm drive hose clips (not included in the delivery).

The inlet and outlet connection of the flow assembly are always identical, the system is

symmetrical.

Install the flow assembly vertically.

The supply must be connected at the bottom (upward flow in the pipe).

Insert a orifice plate into the upper process connection ( å 6, item 7) of the flow

assembly to get the desired volume flow rate (included in the delivery):

• 1 mm for volume flow rate < 60 l/h (15.8 gal/hr)

• 3 mm for volume flow rate 60 to 100 l/h (15.8 to 26.4 gal/hr)

• 5 mm for volume flow rate > 100 l/h (26.4 gal/hr)

Avoid buckles and loops in the hose system.

Page 13

Flowfit CUA252 Installation

Endress+Hauser 13

Pay attention to the installation instructions (flow direction) for the sensor.

Observe the maximum pressure and maximum temperature when operating the bubble

trap.

3.4 Sensor installation

Install the sensor so that the optical windows of the sensor ( å 8, item 1) are aligned

against the flow direction (item 2). The installation marking (item 3) helps you ensure the

correct sensor orientation.

3.5 Post-installation check

‣ After installation, check all the connections to ensure they are secure and leak-tight.

‣ Is the orientation correct?

‣ Make sure that the hoses can only be removed by force.

‣ Check all hoses for damage.

a0022864

Fig. 7: Sensor installation

10 CUA252 flow assembly

11 Clamp seal

12 Locking clamp

13 CUS52D turbidity sensor

a0022863

Fig. 8: Sensor orientation

1Optical windows

2 Flow direction

3 Installation marking

Page 14

Commissioning Flowfit CUA252

14 Endress+Hauser

4 Commissioning

Prior to initial commissioning, make sure that:

• All the seals are seated correctly (on the assembly and the process connection)

• The sensor is correctly installed and connected

WARNING

!

Medium incorrectly connected to the assembly

Danger of medium leaking

‣ Before applying pressure to an assembly, make sure the medium is connected correctly!

Otherwise do not introduce the assembly into the process!

Page 15

Flowfit CUA252 Maintenance

Endress+Hauser 15

5Maintenance

You must perform maintenance tasks at regular intervals.

We recommend setting the maintenance times in advance in an operations journal or

calendar.

The maintenance cycle primarily depends on the following:

• The facility

• The installation conditions

• The medium being measured

CAUTION

!

Risk of injury if medium escapes

‣ Prior to performing any maintenance task, make sure that the process pipe is

unpressurized, empty and rinsed.

5.1 Cleaning the assembly

• Use suitable cleaning solutions (see "Cleaning agents" section) to remove light dirt and

fouling.

• Heavy dirt can be removed with a soft brush and a suitable cleaning agent.

• To remove stubborn dirt, soak the parts in a cleaning solution. Then clean the parts with a

brush.

Six months is a typical cleaning interval for drinking water, for example.

5.2 Cleaning the sensor

Cleaning with the ultrasonic cleaning system

If the (optional) CYR52 ultrasonic cleaning system is installed, you can clean the sensor

surfaces during operation.

Enter the following parameters to prevent the ultrasonic transducer from overheating:

Cleaning without the ultrasonic cleaning system

If the assembly is not fitted with an ultrasonic cleaning system, you must remove the sensor

in order to clean it.

You must rinse the sensor thoroughly with water after cleaning it.

Cleaning time: max. 5 seconds

Cleaning interval: min. 5 minutes

Type of fouling Cleaning measure

Lime deposits Immerse the sensor in 1%-5 % hydrochloric acid (for a few minutes).

Dirt particles on the optical windows Use a cleaning cloth to clean the optical windows.

Page 16

Maintenance Flowfit CUA252

16 Endress+Hauser

5.3 Cleaning agent

The choice of cleaning agent depends on the degree and type of fouling. The most common

types of dirt and fouling and the suitable cleaning agents are listed in the following table.

CAUTION

!

Solvents can pose a health hazard

‣ Never use acetone or any organic solvents containing halogens. Such solvents can

damage plastic parts and some are suspected of causing cancer (e.g. chloroform).

5.4 Checking and replacing the seals

Check the seals at regular intervals and replace the seals where necessary.

a0022895

Fig. 9: Position of the seals

1Clamp seal

2O-rings

The seals are available as a spare parts kit (see the "Spare parts kits" section).

Type of fouling Cleaning agent

Greases and oils Agents containing surfactants (alkaline agents) or water-soluble

organic solvents (halogen-free, e.g. ethanol)

Limescale deposits, metal hydroxide

buildup, lyophobic biological buildup

Approx. 3% hydrochloric acid

Sulfide deposits Mixture of 3% hydrochloric acid and thiocarbamide (commercially

available)

Protein buildup Mixture of 3% hydrochloric acid and pepsin (commercially available)

Fibers, suspended substances Pressurized water, possibly surface-active agent

Light biological buildup Pressurized water

1

22

Page 17

Flowfit CUA252 Repair

Endress+Hauser 17

6Repair

6.1 Spare parts kits

Detailed information on the spare parts kits is available in the "Spare Part Finding Tool",

which can be accessed on the Web at:

www.products.endress.com/spareparts_consumables

6.2 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product has been ordered or delivered. According to legal regulations Endress+Hauser, as an

ISO-certified company, is required to follow certain procedures when handling returned

products that are in contact with the medium.

To ensure swift, safe and professional device returns:

Visit our website to obtain information about the return procedure and basic conditions:

www.services.endress.com/return-material

6.3 Disposal

Comply with local regulations when disposing of the product.

Order number Description

71241882 Clamp seal, DN 50, FDA, 2 pcs

71241892 O-ring, EPDM, 2 set

Page 18

Accessories Flowfit CUA252

18 Endress+Hauser

7 Accessories

7.1 Connection accessories

7.2 Bubble trap

Bubble trap

• For sensor CUS52D

• Process pressure: up to 3 bar (43.5 psi)

• Process temperature: 0 to 50 °C (32 to 122 °F)

• Adapter to D 12 with connection for vent line (top connection on CUA252), is included in

the delivery.

• Orifice plates for the following volume flow rates:

– < 60 l/h (15.8 gal/hr)

– 60 to 100 l/h (15.8 to 26.4 gal/hr)

– > 100 l/h (26.4 gal/hr)

• The vent line is fitted with a PVC hose, hose check valve and a Luer lock adapter.

• Order number, suitable for assembly CUA252: 71242170

• Order number, suitable for assembly S of CUS31: 71247364

a0022631

Fig. 10: Bubble trap, dimensions in mm (inch)

1 Medium inlet (without hose system)

2 Air bubble exit (hose system is included in the delivery)

3 Medium exit (without hose system)

Description Order number

Dummy cover for clamp connection; 1 pc 71242180

Adapter, internal thread, RP ¾", material: PE; 1 pc 71242172

Adapter, internal thread, NPT ¾", material: PE; 1 pc 71242173

Adapter, welded connection, D 25, material: PE; 1 pc 71242174

Adapter, hose connection nipple, D 25, material: PE; 1 pc 71242175

Adapter, hose connection nipple, D 12, material: PE; 1 pc 71242176

Adapter, flange ANSI 2", 1 pc 71242177

254 (10.0)

12 (3/8")

12 (3/8")

12

3

Page 19

Flowfit CUA252 Accessories

Endress+Hauser 19

7.3 Wall mounting kit

Wall mounting kit for CUA252

• Order number: 71242171

a0022264

Fig. 11: Wall mounting kit

1 Hanger bolt STST 10x60 mm (included in the delivery)

Page 20

Technical data Flowfit CUA252

20 Endress+Hauser

8Technical data

8.1 Environment

Ambient temperature

range

0 to 55 °C (32 to 131 °F)

Storage temperature 0 to 60 °C (32 to 140 °F), in the original packaging

8.2 Process

Process temperature 0 to 60 °C (32 to 140 °F)

Process pressure 0 to 6 bar (0 to 87 psi)

Pressure-temperature

chart

a0022626

Fig. 12: Pressure-temperature chart

Flow velocity Max. 2 m/s (6.6 ft/s) for low-viscosity media in pipe DN 50

Flow Recommended flow: 60 l/h (15.84 gal/hr)

Range: 10 to 100 l/h (2.64 to 26.4 gal/hr)

When operating with lost sample (lost water)

Pressure loss < 0.05 bar (0.7 psi) for flow up to 100 l/h (26.4 gal/hr)

p [bar]

T[°C]

10 4030

4

20

T[°F]

p [psi]

58

0

32

0

0

6

87

50 60

50

68 86

104

122

140

Page 21

Flowfit CUA252 Technical data

Endress+Hauser 21

8.3 Mechanical construction

Dimensions See "Installation conditions"

Weight 1.17 kg (2.58 lbs) without process connection

Materials

Process connections

a0022263

Fig. 13: Process connections

B1 External thread G1¼ (standard)

B2 Internal thread Rp ¾"

B3 Internal thread NPT ¾"

C1 Glue-in port D 25 PVC

D1 Hose D 25 PVC

D2 Hose D 12 PVC

E2 Flange ANSI 2"

Assembly housing: PE

Seals: EPDM

Flange: PP-GF

Dummy cover: Stainless steel 1.4404 (AISI 316 L)

Bubble trap: Polycarbonate

Process connections: PE

Bubble trap process connection: PVC

Page 22

Flowfit CUA252

22 Endress+Hauser

Index

A

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . 20

B

Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bubble trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12, 18

C

Cleaning agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connection accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

D

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Designated use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

E

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . 4

I

Incoming acceptance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Minimum flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

N

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

O

Occupational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

P

Post-installation check . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Process pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Process temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

R

Replacing seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Requirements for personnel. . . . . . . . . . . . . . . . . . . . . . . . . 4

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

S

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Spare parts kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Storage temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

T

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

U

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

W

Wall holder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Page 23

Flowfit CUA252

Endress+Hauser 23

Page 24

www.addresses.endress.com

71238090

Loading...

Loading...