Page 1

BA00432C/07/EN/13.13

71207066

Products Solutions Services

Operating Instructions

Flexdip CYA112

Wastewater assembly

Page 2

About this document

DANGER

!

WARNING

!

CAUTION

!

NOTICE

Safety messages

The structure, signal words and safety colors of the signs comply with the specifications of

ANSI Z535.6 ("Product safety information in product manuals, instructions and other

collateral materials").

Safety message structure Meaning

This symbol alerts you to a dangerous situation.

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

Failure to avoid the situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or

medium injury.

Cause/situation

Consequences if safety

message is not heeded

‣ Action/note

Symbols

Additional information, tips

Permitted or recommended

Forbidden or not recommended

This symbol alerts you to situations that can result in

damage to property and equipment.

Endress+Hauser

Page 3

Flexdip CYA112

Table of contents

1 Basic safety instructions . . . . . . . . . . . . . 4

1.1 Requirements for the personnel . . . . . . . . . . . . . . . 4

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Post-installation check . . . . . . . . . . . . . . . . . . . . . 15

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Immersion pipe support . . . . . . . . . . . . . . . . . . . . 16

4.2 Maintaining the clamping systems and threads 16

4.3 Cleaning the quick fastener . . . . . . . . . . . . . . . . . 16

5 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Accessories . . . . . . . . . . . . . . . . . . . . . . . 18

7 Technical Data . . . . . . . . . . . . . . . . . . . .28

7.1 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 Process conditions . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.3 Mechanical construction . . . . . . . . . . . . . . . . . . . 28

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Endress+Hauser 3

Page 4

Basic safety instructions Flexdip CYA112

1 Basic safety instructions

1.1 Requirements for the personnel

‣ Installation, commissioning, operation and maintenance of the measuring system must

only be carried out by trained technical personnel.

‣ The technical personnel must be authorized by the plant operator to carry out the

specified activities.

‣ The electrical connection may only be performed by an electrical technician.

‣ The technical personnel must have read and understood these Operating Instructions

and must follow the instructions they contain.

‣ Measuring point faults may only be rectified by authorized and specially trained

personnel.

Repairs not described in the enclosed Operating Instructions may only be carried out

directly at the manufacturer's or by the service organization.

1.2 Designated use

CYA112 is designed as a modular assembly system for sensors in open basins, channels and

tanks.

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation instructions

• Local prevailing standards and regulations.

1.4 Operational safety

‣ Before commissioning the entire measuring point, make sure all the connections are

correct. Ensure that electrical cables and hose connections are not damaged.

‣ Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Mark the damaged product as defective.

‣ If faults cannot be rectified, the products must be taken out of service and secured against

unintentional commissioning.

1.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested and

left the factory in a condition in which it is safe to operate. Relevant regulations and

European standards have been observed.

4 Endress+Hauser

Page 5

Flexdip CYA112 Incoming acceptance and product identification

2 Incoming acceptance and product

identification

2.1 Incoming acceptance

‣ Make sure the packaging is undamaged!

‣ Inform the supplier about any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

‣ Make sure the contents are undamaged!

‣ Inform the supplier about damage to the contents. Keep the damaged products until the

matter has been settled.

‣ Check that the order is complete and agrees with your shipping documents.

‣ The packaging material used to store or to transport the product must provide shock

protection and humidity protection. The original packaging offers the best protection.

Also, keep to the approved ambient conditions (see "Technical data").

‣ If you have any questions, please contact your supplier or your local sales center.

2.2 Scope of delivery

The scope of delivery comprises:

• Ordered assembly version

• Operating Instructions, English.

If you have any questions, please contact your supplier or your local sales center.

2.3 Product identification

2.3.1 Nameplate

The nameplate contains the following information:

• Manufacturer data

•Order code

• Extended order code

• Serial number

• Operating conditions

•Safety icons

Compare the order code on the nameplate with your order.

2.3.2 Identifying the product

The order code and serial number of your device can be found in the following locations:

•On the nameplate

• In the delivery papers

To find out the version of your device, enter the order code indicated on the nameplate

in the search screen at the following address:

www.products.endress.com/order-ident

Endress+Hauser 5

Page 6

Incoming acceptance and product identification Flexdip CYA112

2.4 Certificates and approvals

Explosion protection

The stainless steel version of the CYA112 assembly (CYA112-*A21*2**) is suitable for use

in hazardous zones 1 and 2.

The ATEX directive 94/9/EC does not apply because the assembly has no potential ignition

source. Accordingly, it is not designated according to ATEX. Potential equalization must be

implemented as described in the chapter "Installation conditions".

If sensors have accessible metallic surfaces, these surfaces have to be connected to the

potential match according to the corresponding operating instructions.

6 Endress+Hauser

Page 7

Flexdip CYA112 Installation

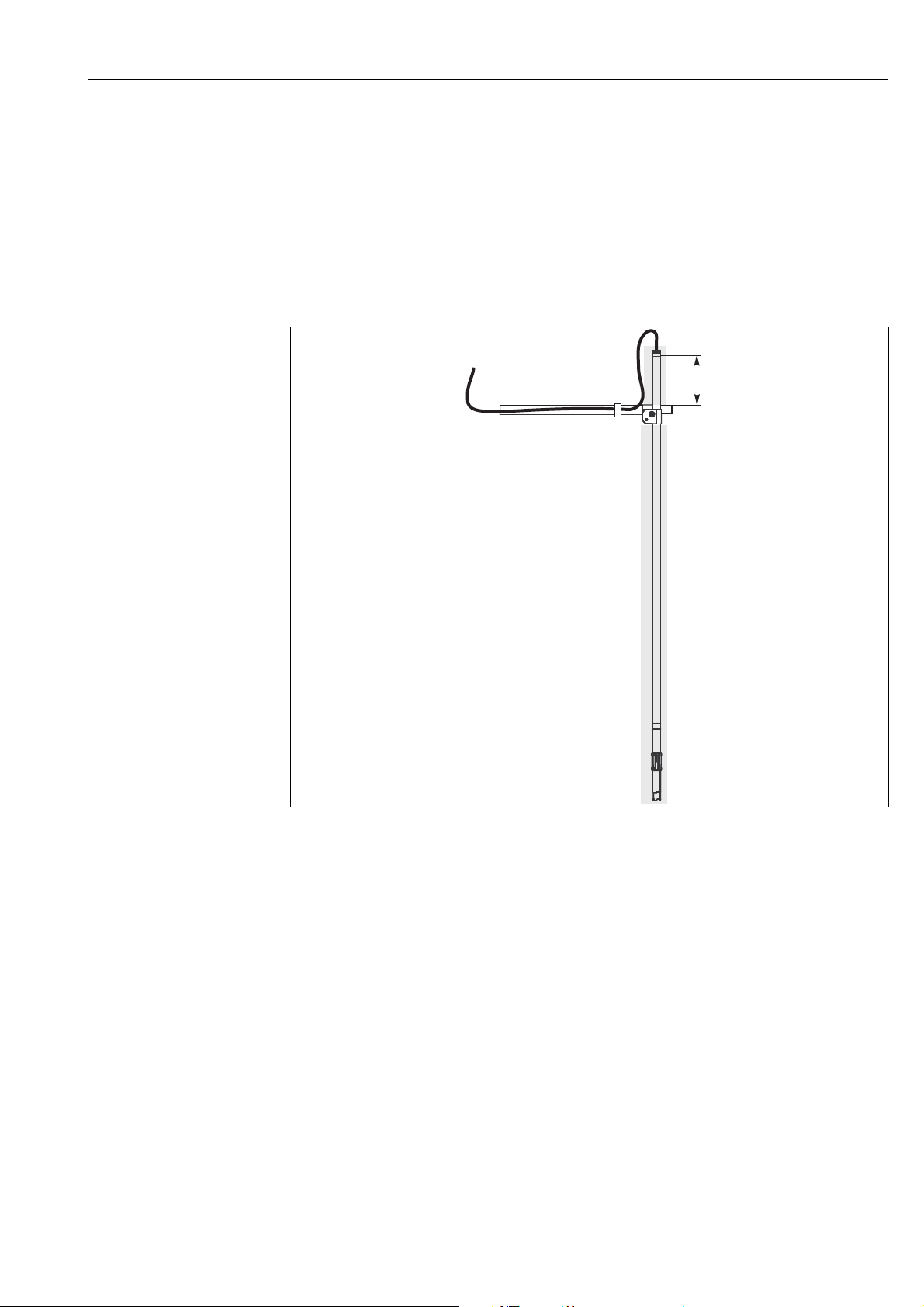

min. 100

(3.94)

mm (inch)

3Installation

3.1 Installation conditions

Install the assembly on a place with enough free space around it so the sensor cannot get

damaged.

When installing the assembly in a fixed position, make sure that it can be easily accessed and

maintained. The immersion pipe has to protrude the holding point by at least 100 mm

(3.94")

Fig. 1: Holding point (illustration without splash protection cap)

The grounding has to be done on-site. All conductive parts have to be connected to each

other.

For use in hazardous areas:

• The immersion pipe side of the assembly has to be conductively connected to the

corresponding holder or fixing.

• When the assembly is fixed via chain or mounting bracket a separate conductor for

potential match is needed beside the measuring cable.

• If sensors have accessible metallic surfaces, these surfaces have to be connected to the

potential match according to the corresponding operating instructions.

a0011037

Endress+Hauser 7

Page 8

Installation Flexdip CYA112

3.2 Installation instructions

3.2.1 Mounting the stainless steel parts

You have to screw the pipes together finger-tight (without any gaps). The threads are

lubricated and provided with an O-ring.

3.2.2 Gluing the PVC parts

PVC assemblies up to 1200 mm (47.2") in size are delivered as ready-to-install units

and do not have to be glued.

Where required, cleaning cloths and glues form part of the scope of supply.

Glue the PVC parts as follows:

1. Clean the surfaces to be glued (exterior pipe end, sleeve or internal angle piece) with the

cleaning cloth.

2. Allow the cleaned surfaces to dry for approx. 5 minutes.

3. Apply an even film of glue to the surfaces to be glued (sleeve first, then the pipe).

4. Join the parts within one minute (push together until the stop).

5. Remove the excess glue.

6. Allow the glued parts to harden for at least 5 minutes.

8 Endress+Hauser

Page 9

Flexdip CYA112 Installation

1

2

3

4

3.2.3 Mounting the sensor

Preparatory steps:

1. Screw or glue the connecting bracket onto the immersion tube.

2. Where necessary, screw the sensor adapter onto the connection bracket.

Mount the sensor as follows:

1. Guide the sensor cable through the immersion tube.

2. Where necessary, connect the sensor cable to the sensor.

3. Screw the sensor into the adapter or into the connection bracket. To prevent the sensor

cable from twisting, rotate the assembly and not the sensor.

1

Splash protection cap

2

Sensor cable

3

Rubber plug

4

Immersion tube

a0011111

Fig. 2: Cable run

4. Shorten the tip of the rubber plug so that it suits the cable diameter.

5. Fit the rubber plug onto the sensor cable and press it onto the immersion tube.

6. Route the sensor cable downwards in a loop (do not bend) and fit on the splash

protection cap. The splash protection cap is fixed by the lip of the rubber plug.

Endress+Hauser 9

Page 10

Installation Flexdip CYA112

1

2

3

4

3.2.4 Fixed installation of the assembly on a transverse pipe

Prerequisite: The sensor is already mounted.

The cross clamp is mounted in such a way that one closed side points to the center of

the basin while the other closed side points upwards.

Mount the immersion tube as follows:

Immersion tube

1

Cross clamp, closed side to basin center

2

Cross clamp, closed side at top

Transverse pipe

3

4

a0011292

Fig. 3: Mounting the cross clamp

a0014991

Fig. 4: Adjustment of the clamps

1. Adjust the clamps on the cross clamp ( å 4).

2. Slide the cross clamp over the immersion tube. Make sure that the closed side of the

cross clamp is at the top ( å 3).

3. Mount the multifunctional clamp ring (funnel-shaped side facing upwards) on the

immersion tube above the cross clamp. The multifunctional clamp ring acts as an antislip lock.

4. Attach the cross clamp, along with the immersion tube, to the transverse pipe. Make

sure that the closed side of the cross clamp faces the basin ( å 3).

5. Align the assembly and the holder.

6. Tighten the clamp screws finger-tight (finger-tight corresponds to 13 Nm (9.6 lbf ft)).

10 Endress+Hauser

Page 11

Flexdip CYA112 Installation

1

2

3

4

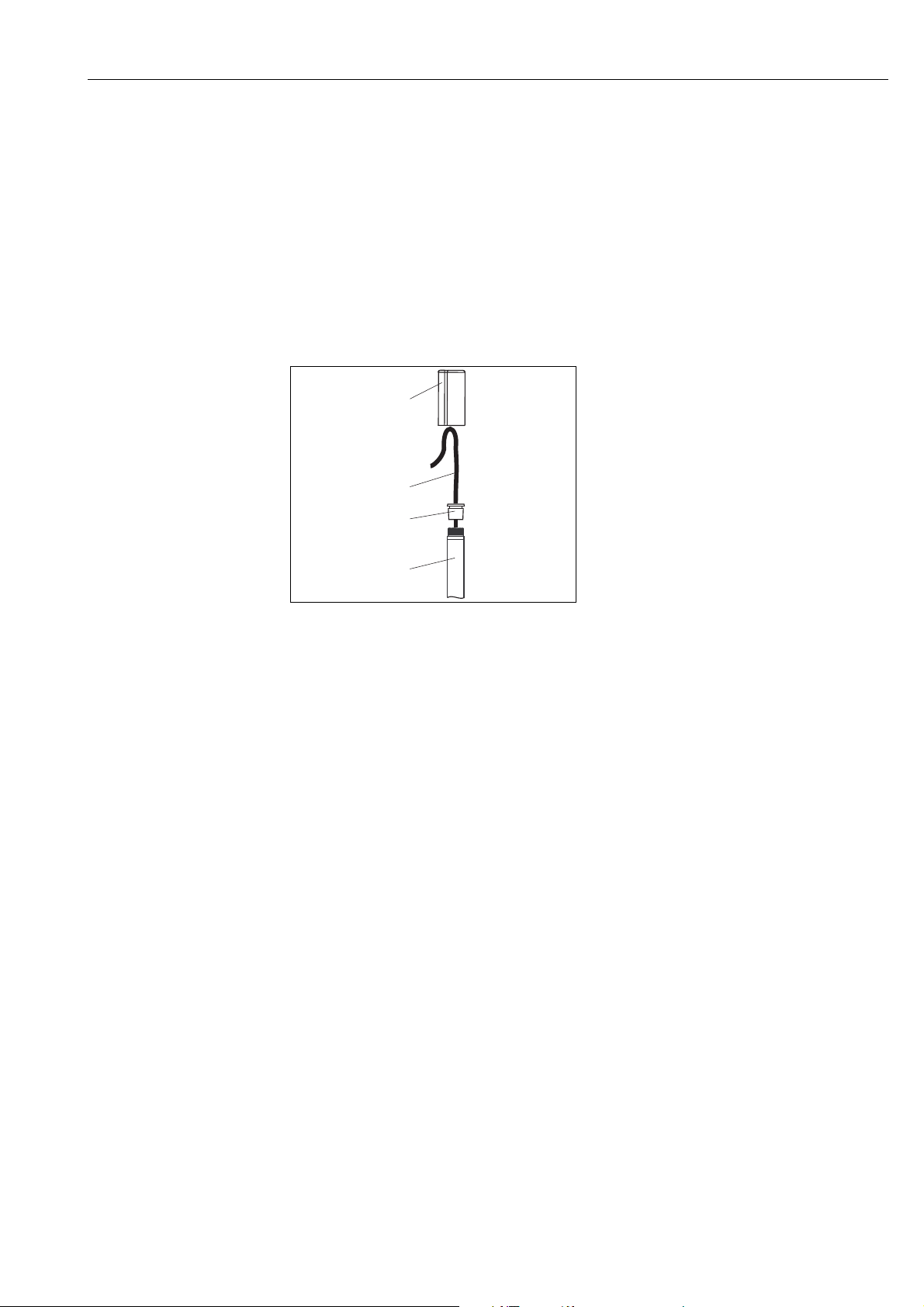

3.2.5 Installation of the assembly on a chain retainer

Prerequisite:

• The immersion tube is fitted with a sensor.

• The transverse pipe is fitted with a chain.

Fig. 5: Mounting the chain retainer

1 Mount the multifunctional clamp ring

2 Loop the bracket into the chain

3 Attach the bracket to the multifunctional clamp ring

4 Fit the splash protection cap

x 60 to 80 mm (2.35 to 3.15 ")

1. Insert the weights into the immersion tube (only PVC immersion tubes).

2. Screw the multifunctional clamp ring onto the immersion tube (funnel-shaped side

facing downwards).

3. Guide the bracket into the lowest link in the chain.

4. Attach the bracket to the multifunctional clamp ring.

1

Splash protection cap

2

Sensor cable

3

Rubber plug

4

Immersion tube

a0011420

a0011111

Fig. 6: Cable run

5. Fit the rubber plug onto the sensor cable and press it onto the immersion tube.

6. Route the sensor cable downwards in a loop (do not bend) and fit on the splash

protection cap.

7. Secure the chain on the holder with the triangular carabiner and determine so the

maximum immersion depth of the assembly.

Endress+Hauser 11

Page 12

Installation Flexdip CYA112

3.2.6 Installation of the assembly with a float

a0011422

Fig. 7: Float mounting

1 Immersion tube with adhesive fitting and sensor adapter (finished ex works)

2Float body

3 Second immersion tube with 45° adhesive fitting

Preparatory steps

1. Slide the float body (item 2) onto the immersion tube (item 1).

2. Glue the second immersion tube (item 3) and the adhesive fitting (item 3) onto the

immersion tube (item 1) (see chapter "Gluing the PVC parts").

3. Adjust the clamps on the cross clamp.

4. Slide the cross clamp over the immersion tube. Make sure that the closed side of the

cross clamp is at the top.

5. Mount the multifunctional clamp ring (funnel-shaped side facing upwards) on the

immersion tube above the cross clamp. The multifunctional clamp ring acts as an antislip lock.

12 Endress+Hauser

Page 13

Flexdip CYA112 Installation

1

2

3

4

Installing the sensor and mounting the assembly

1. Guide the sensor cable through the immersion tube.

2. Where necessary, connect the sensor cable to the sensor.

3. Screw the sensor into the adapter. To prevent the sensor cable from twisting, rotate the

assembly and not the sensor.

1

Splash protection cap

2

Sensor cable

3

Rubber plug

4

Immersion tube

a0011111

Fig. 8: Cable run

4. Shorten the tip of the rubber plug so that it suits the cable diameter.

5. Fit the rubber plug onto the sensor cable and press it onto the immersion tube.

6. Mount the float assembly on the pendulum holder.

7. Align the assembly and the holder.

8. Tighten the clamp screws finger-tight (finger-tight corresponds to 13Nm (9.6 lbf ft)).

9. Route the sensor cable downwards in a loop (do not bend) and fit on the splash

protection cap. The splash protection cap is fixed by the lip of the rubber plug.

Endress+Hauser 13

Page 14

Installation Flexdip CYA112

1

2

3

4

3.2.7 Installation of the quick fastener

a0016947

Fig. 9: Quick fastener

1 Bore - makes it easier to screw the adapter tight

2Adapter

3 Thread adapter nut

4O-rings

Install the quick fastener as follows:

1. Provide both O-rings (item 4) with a thin film of lubricant.

2. Screw the adapter (item 2) into the immersion tube connection bracket.

3. Insert a screwdriver or a similar tool through the bores (item 1, serves as lever) to secure

the adapter.

4. Slide the thread adapter nut (item 3) over the adapter until the thread adapter nut

engages with a click.

5. Guide the sensor cable through the quick fastener and the immersion tube. The

Memosens coupling is secured in the quick fastener and cannot slip.

6. Connect the cable to the sensor.

7. The quick fastener allows to install the sensor without twisting the measuring cable.

Screw the sensor into the quick fastener until the stop. In doing so, turn the thread

adapter nut. Do not turn the sensor.

8. Align the sensor if necessary.

14 Endress+Hauser

Page 15

Flexdip CYA112 Installation

2

2

3

4

1

3

3.2.8 Dismount the quick fastener

Fig. 10: Dismounting the quick fastener

1 quick fastener - thread adapter nut

a0016950

Fig. 11: Dismounting the quick fastener

2 Connection clips

a0016951

Dismount the quick fastener as follows:

1. Move the thread adapter nut in the direction of the arrow to the stop position

( å 10). This pushes the connection clips towards the center ( å 11).

2. Stick the mounting tool onto the connection clips ( å 12) and push the mounting

tool very hard in the direction of the arrow.

3. The connection clips are unlocked. Pull off the thread adapter nut and the mounting

tool( å 13).

4. Unscrew the adapter from the immersion pipe.

a0016952

Fig. 12: Dismounting the quick fastener

3 Mounting tool

a0016953

Fig. 13: Dismounting the quick fastener

1 Quick fastener - thread adapter nut

3 Mounting tool

4 Quick fastener - adapter

3.3 Post-installation check

• After mounting, check whether all the screws are tightened correctly.

• If mounting using a pendulum holder, ensure the assembly has sufficient clearance.

Endress+Hauser 15

Page 16

Maintenance Flexdip CYA112

WARNING

!

4 Maintenance

There is a risk of infection when working with wastewater

‣ Wear protective gloves, goggles and protective clothing.

4.1 Immersion pipe support

a0011372

Fig. 14: Immersion tube tray for assembly service position

1 Immersion tube tray

The immersion tube tray makes it easier to perform maintenance tasks with rail mounting

involving a pendulum holder and cross clamp.

4.2 Maintaining the clamping systems and threads

Lubricate the clamping systems and threads at regular intervals.

Proceed as follows to do so:

1. Clean the clamps and threads with soapy water.

2. Dry the clamps and threads.

3. Provide the cleaned parts with a thin film of lubricant (e.g. Syntheso Glep1).

4.3 Cleaning the quick fastener

Preparatory steps:

1. Remove the sensor and cable.

2. Insert the removal tool (see "Accessories" section) into the thread adapter nut so that the

thread adapter nut is disengaged and can be removed.

Clean the quick fastener with soapy water.

16 Endress+Hauser

Page 17

Flexdip CYA112 Repair

5Repair

5.1 Return

The device must be returned if repairs or a factory calibration are required, or if the wrong

device has been ordered or delivered. According to legal regulations, Endress+Hauser, as an

ISO-certified company, is required to follow certain procedures when handling returned

products that are in contact with medium.

To ensure swift, safe and professional device returns, please read the return procedures and

conditions on the internet site:

www.services.endress.com/return-material

5.2 Disposal

Please dispose of the device in accordance with the local regulations.

Endress+Hauser 17

Page 18

Accessories Flexdip CYA112

6 Accessories

Multifunctional clamp ring

• Chain retainer in conjunction with the triangle carabiner

• Working height adjustment of the main pipe (version main pipe with transverse pipe)

• The multifunctional clamp ring acts as an anti-slip lock on transverse pipes, main pipes

and assemblies.

• Material: POM - GF

• Order No. 71092049

a0016879

Fig. 15: Multifunctional clamp ring

18 Endress+Hauser

Page 19

Flexdip CYA112 Accessories

Immersion pipe support

• Immersion pipe support for comfortable maintenance

• Material: stainless steel 1.4404 (AISI 316L)

• Order No. 71092054

a0016880

Fig. 16: Immersion pipe support

Endress+Hauser 19

Page 20

Accessories Flexdip CYA112

Wall mounting set

• 2 pipe clamps D 40; material: PE

• 1 worm-drive hose clip for height adjustment

• Order No.: 71132469

Fig. 17: Pipe clamp

Triangle carabiner

• Used to fix the chain (together with multifunctional clamp ring)

• Material: stainless steel

• Order No. 71092052

Fig. 18: Triangle carabiner

a0016767

a0016873

Hook-and-loop cable ties (set of 4 pieces)

• To fix the cables

• Material: PE / PA (polyethylene / polyamide)

• Order No. 71092051

20 Endress+Hauser

Page 21

Flexdip CYA112 Accessories

90 (3.54)

128 (5.04)

44.5 (1.75)

G 1

mm (inch)

Mounting tool

• Tool to remove the quick fastener

• Material: stainless steel

• Order No. 71093438

a0016305

Fig. 19: Mounting tool

Quick fastener

• For the quick and easy installation and exchange of sensors

• Material: POM - GF

• Order No. 71093377

a0016286

Fig. 20: Quick fastener

Endress+Hauser 21

Page 22

Accessories Flexdip CYA112

Sensor adapter NPT ¾"

• Sensor adapter G1 to NPT ¾"

• Material: POM - GF

• Order No. 71093382

Fig. 21: Sensor adapter G1 to NPT¾"

Sensor adapter G¾

• Sensor adapter G1 to G¾

• Material: POM - GF

• Order No. 71093383

a0016285

a0016284

Fig. 22: Sensor adapter G1 to G¾

22 Endress+Hauser

Page 23

Flexdip CYA112 Accessories

Sensor adapter Pg 13.5

• Sensor adapter G1 to Pg 13.5

• Material: POM - GF

• Order No. 71093384

Fig. 23: Sensor adapter G1 to Pg 13.5

Immersion pipe

• Connection thread: M36

• Material: stainless steel

Fig. 24: Immersion pipe

• length x = 600 mm (23.6"): Order No. 71073767

• length x = 1200 mm (47.3"): Order No. 71073706

a0011169

a0011042

Endress+Hauser 23

Page 24

Accessories Flexdip CYA112

Immersion-pipe connection straight

• M36 to G1

• Material: stainless steel

• Order No. 71073768

a0016270

Fig. 25: Immersion-pipe connection straight

Immersion-pipe connection 45°

• M36 to G1

• Material: stainless steel

• Order No. 71073769

Fig. 26: Immersion-pipe connection 45°

a0016271

24 Endress+Hauser

Page 25

Flexdip CYA112 Accessories

Immersion-pipe connection 90°

• M36 to G1

• Material: stainless steel

• Order No. 71073770

Fig. 27: Immersion-pipe connection 90°

Protective cap

• Connection thread: M36

• Cable gland Pg 13.5

• Material: stainless steel

• Order No. 71115553

a0016273

a0016283

Fig. 28: Protective cap

Endress+Hauser 25

Page 26

Accessories Flexdip CYA112

271 (10.67)

Ø 99 (3.9)

44

(1.73)

129 (5.08)

Ø 74.3

(2.93)

Ø 41 (1.61)

1

2

3

mm (inch)

PVC protector for flexible mounting of CUS71D

• The PVC protector protects the ultrasonic sensor from getting damaged by the surface

skimmer.

• Order number: 71178584

Fig. 29: PVC protector for CUS71D

1 Assembly CYA112

2PVC-protector

3 Ultrasonic sensor CUS71D

a0016892

26 Endress+Hauser

Page 27

Flexdip CYA112 Accessories

CYA112 spray cleaning for installation on immersion pipe

• Versions in 600 mm and 1200 mm

• For assembly CYA112 version: 600 to 2400 mm, straight

• Material:

– Pipe: PVC-U

– Spacers: PA

– Worm drive hose clips: stainless steel 1.4401 (AISI 316)

• Order No. for 600 mm - version: 71158245

• Ordet No. for 1200 mm - version: 71158246

Fig. 30: Spray cleaning for CYA112

A Version: 1200 mm

B Version: 600 mm

Fig. 31: Example of an installed spray cleaning

a0017182

a0017805

Endress+Hauser 27

Page 28

Technical Data Flexdip CYA112

7Technical Data

7.1 Environment

Air temperature -20 to +60 °C (-4 to 140 °F)

7.2 Process conditions

Process temperature

range

Process pressure range unpressurized

0 to 60 °C (32 to 140 °F)

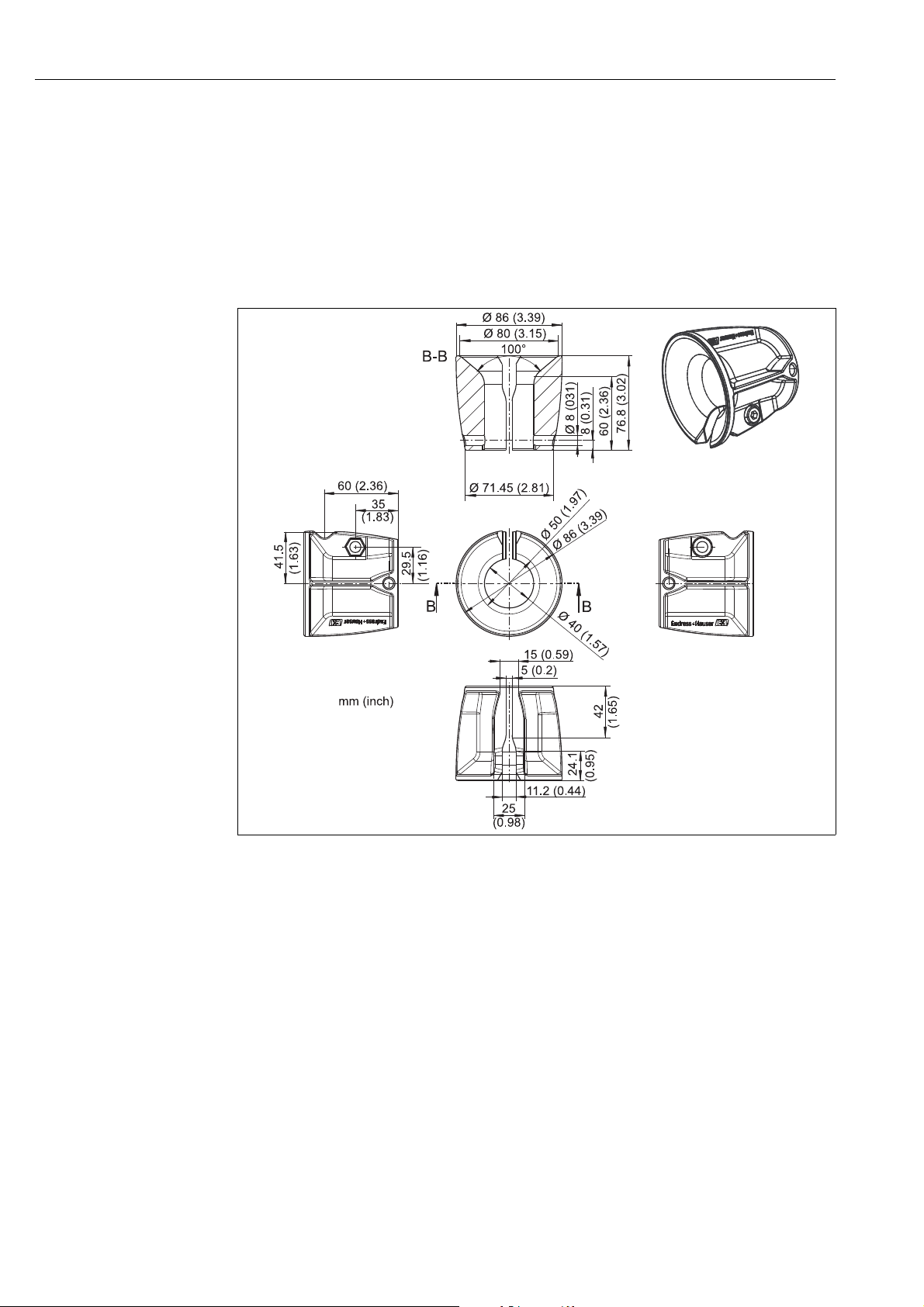

7.3 Mechanical construction

Dimensions

Weight

Materials

Immersion pipe (PVC): Ø 40 mm (1.57"), length: 600, 1200, 1800 and 2400 mm

Immersion pipe (stainless steel): Ø 40 mm (1.57"), length: 600, 1200, 1800, 2400 and

Immersion pipe (stainless steel)

(length 1 / 2 / 3 / 4 / 5):

Immersion pipe (PVC)

(length 1 / 2 / 3 / 4): 0.3 / 0.6 / 0.95 / 1.3 kg (0.7 / 1.4 / 2.1 / 2.8 lbs)

Multifunctional clamp ring: 0.15 kg (0.33 lbs)

Weights for immersion pipe

(PVC): 0.32 kg (0.71 lbs)

Immersion pipe: stainless steel 1.4404 (AISI 316 L)

Connection angle: stainless steel 1.4404 (AISI 316 L)

Welded threads stainless steel 1.4571 (AISI 316 Ti)

Sensor adaption: POM - GF

Quick fastener: POM - GF

Multifunctional clamp ring: POM - GF

Cap: PE

Chain bracket: stainless steel 1.4571 (AISI 316 Ti) or 1.4404 (AISI

O-rings: EPDM

Floater, yellow: PVC (up to middle of 2012)

Floater, black: EPP (from middle of 2012 on)

(23.6", 47.2", 70.9" and 94.5")

3600 mm (23.6", 47.2", 70.9", 94.5" and 142")

0.6 / 1.2 / 1.8 / 2.4 / 3.5 kg (1.3 / 2.6 / 4.0 / 5.3 /

10.8 lbs)

316 L)

28 Endress+Hauser

Page 29

Flexdip CYA112 Technical Data

Endress+Hauser 29

Page 30

Flexdip CYA112

Index

A

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

C

Checking

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

D

Designated use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dismount the quick fastener . . . . . . . . . . . . . . . . . . . . . . 15

F

Fixed installation on transverse pipe . . . . . . . . . . . . . . . 10

Float

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

G

Gluing the PVC parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

I

Immersion pipe support . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Incoming acceptance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Assembly on chain retainer . . . . . . . . . . . . . . . . . . . . 11

Fixed installation on transverse pipe . . . . . . . . . . . . 10

Float. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PVC parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Quick fastener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stainless steel pipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

S

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stainless steel pipes

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

T

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

U

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

W

Workplace safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

M

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

N

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

O

Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

P

Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Q

Quick fastener

Dismount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

R

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Requirements for the personnel . . . . . . . . . . . . . . . . . . . . . 4

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

30 Endress+Hauser

Page 31

Flexdip CYA112

Endress+Hauser 31

Page 32

www.addresses.endress.com

71207066

Loading...

Loading...