Page 1

Operating Instructions

Fieldgate FXA720

Ethernet/PROFIBUS DP gateway with Web server

8

BA030S/04/en/07.07

Product Version 2. 0 0. xx

56004856

Page 2

Page 3

Fieldgate FXA720

Table of Contents

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Software Compatibility . . . . . . . . . . . . . . . . . . . . . . 3

Registered Trademarks . . . . . . . . . . . . . . . . . . . . . . . 3

1 Safety

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Installation, commissioning and operation . . . . . . . . 3

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Technical improvement . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Declaration of conformity . . . . . . . . . . . . . . . . . . . . 4

1.6 Writing conventions . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Drawing conventions . . . . . . . . . . . . . . . . . . . . . . . 6

2 Identification

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Licensing agreement . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Function and System Design

3.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.1 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.2 Display elements (LEDs) . . . . . . . . . . . . . . . 9

3.3 System architecture . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 System requirements . . . . . . . . . . . . . . . . . . . . . . . 12

4 Hardware Installation

4.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . 14

4.2.2 Communication ports . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . .

13

6 Configuring the Web Server

6.1 Logging on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3

7

8

6.2.1 Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.2 Navigation bar . . . . . . . . . . . . . . . . . . . . . . 31

6.2.3 Information & Configuration pages . . . . . . . 32

6.3 Fieldgate location page . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Security setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5 Network setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5.1 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5.2 E-mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5.3 Time server . . . . . . . . . . . . . . . . . . . . . . . . 37

6.6 PROFIBUS setup . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.6.1 Communication settings . . . . . . . . . . . . . . 38

6.6.2 Scan settings . . . . . . . . . . . . . . . . . . . . . . . 40

6.6.3 Live list . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.7 Overview of selected devices . . . . . . . . . . . . . . . . . 41

6.7.1 Device detail parameters . . . . . . . . . . . . . . 42

6.7.2 E-mail on alarm . . . . . . . . . . . . . . . . . . . . . 42

6.7.3 Expert mode for Slot/Index configuration . 43

. . . . . . . . .

7 Viewing Information (User Mode)

7.1 Logging on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Live list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Overview of selected devices . . . . . . . . . . . . . . . . . 46

7.4 Fieldgate information . . . . . . . . . . . . . . . . . . . . . . . 47

7.5 XML export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.6 Other view functions . . . . . . . . . . . . . . . . . . . . . . . 49

7.6.1 Refresh function . . . . . . . . . . . . . . . . . . . . 49

7.6.2 Endress+Hauser function . . . . . . . . . . . . . . 49

8 Firmware Update

. . . . . . . . . . . . . . . . . . .

. . .

29

44

50

5 Getting Started

5.1 Preparing for installation . . . . . . . . . . . . . . . . . . . . 16

5.1.1 Checking the system requirements . . . . . . 16

5.1.2 Installing the documentation . . . . . . . . . . . 17

5.1.3 Adobe Acrobat Reader . . . . . . . . . . . . . . . . 17

5.2 Establishing communication . . . . . . . . . . . . . . . . . 18

5.2.1 Making initial contact . . . . . . . . . . . . . . . . 18

5.2.2 Changing the Fieldgate address . . . . . . . . . 20

5.3 Installing FXA720 PROFIBUS Driver . . . . . . . . . . . 21

5.3.1 Installing the driver . . . . . . . . . . . . . . . . . . 21

5.3.2 Configuring the driver . . . . . . . . . . . . . . . . 23

5.3.3 Setting PROFIBUS DP bus parameters

in FieldCare . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.4 Setting PROFIBUS DP bus parameters

in P View . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 Modifying, repairing or removing the application . . 28

5.4.1 Fieldgate FXA720 PROFIBUS Driver . . . . . 28

5.4.2 Fieldgate FXA720 documentation . . . . . . . 28

Endress+Hauser 1

. . . . . . . . . . . . . . . . . . . . . .

16

9 Trouble-Shooting

9.1 Problems and remedies . . . . . . . . . . . . . . . . . . . . . 51

9.2 FAQ - Frequently Asked Questions . . . . . . . . . . . . . 51

9.3 Troubleshooting on no connection . . . . . . . . . . . . . 52

10 Accessories

10.1 E+H power supply units . . . . . . . . . . . . . . . . . . . . 53

11 Technical Data

12 Appendix

12.1 Changing the Internet address (Windows 2000) . . . 55

12.2 XML data elements . . . . . . . . . . . . . . . . . . . . . . . . 57

12.3 PROFIBUS bus parameter ranges . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

51

53

54

55

Page 4

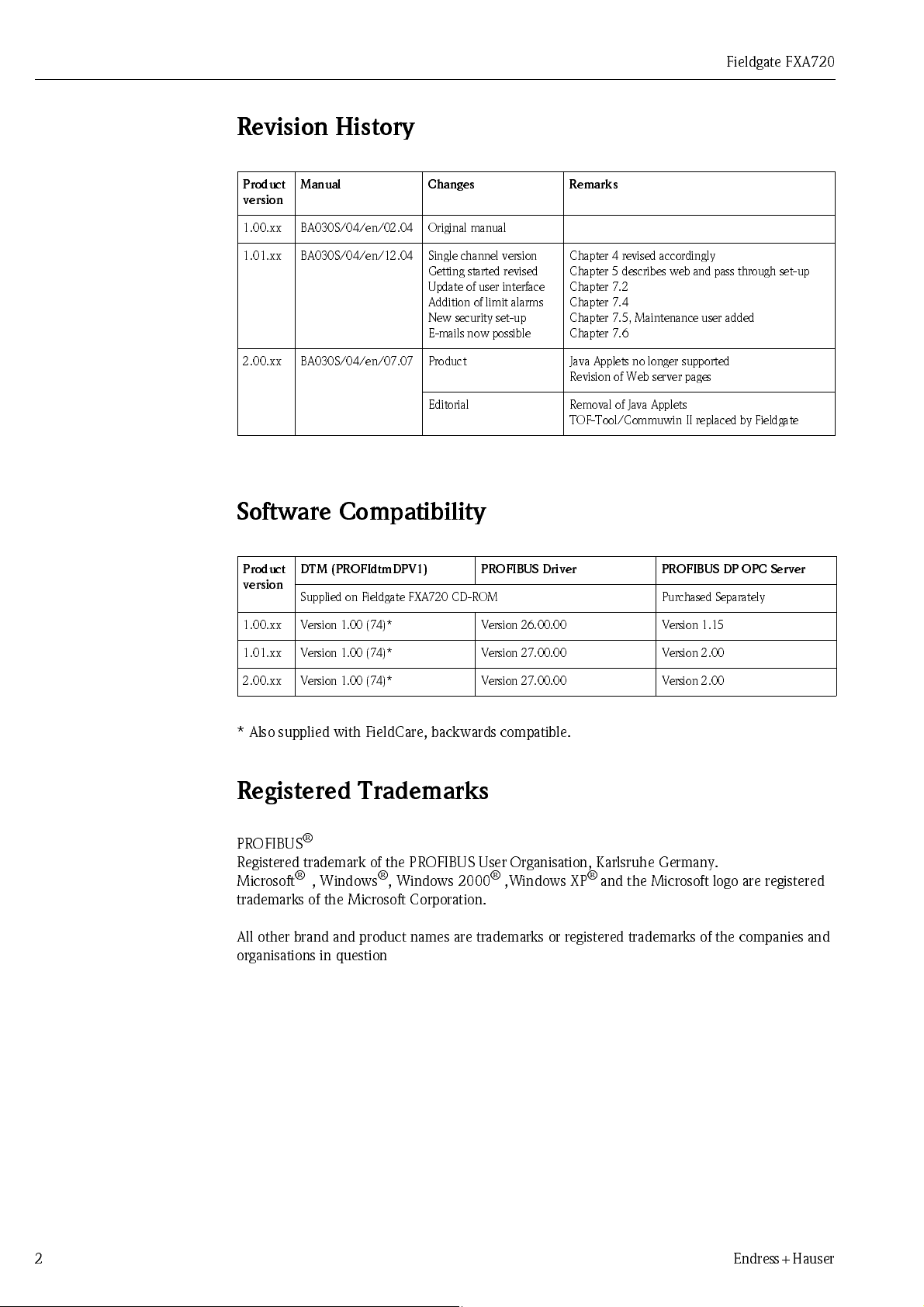

Revision Hi story

Fieldgate FXA720

Product

version

1.00.xx BA030S/04/en/02.04 Original manual

1.01.xx BA030S/04/en/12.04 Single channel version

2.00.xx BA030S/04/en/07.07 Product Java Applets no longer supported

Manual Changes Remarks

Chapter 4 revised accordingly

Getting started revised

Update of user interface

Addition of limit alarms

New security set-up

E-mails now possible

Editorial Removal of Java Applets

Chapter 5 describes web and pass through set-up

Chapter 7.2

Chapter 7.4

Chapter 7.5, Maintenance user added

Chapter 7.6

Revision of Web server pages

TOF-Tool/Commuwin II replaced by Fieldgate

Software Compatibil ity

Product

version

1.00 . xx V ers i o n 1 .0 0 ( 74)* Versio n 26. 0 0.00 V e r sio n 1.15

DTM (PROFIdtmDPV1) PROFIBUS Driver PROFIBUS DP OPC Server

Supplied on Fieldgate FXA720 CD-ROM Purchased Separately

1.01 . xx V ers i o n 1 .0 0 ( 74)* Versio n 27. 0 0.00 V e r sio n 2. 00

2.00. xx V ers i o n 1 .0 0 ( 74)* Versio n 27. 0 0.00 V e r sio n 2. 00

* Also supplied with FieldCare, backwards compatible.

Registered Trademarks

PROFIBUS

Registered trademark of the PROFIBUS User Organisation, Karlsruhe Germany.

Microsoft

trademarks of the Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of the companies and

organisations in question

®

®

, Windows®, Windows 2000® ,Windows XP® and the Microsoft logo are registered

2 Endress+Hauser

Page 5

Fieldgate FXA720 1 Safety

1 Safety

1.1 Designated use

Fieldgate FXA720 is a PROFIBUS/Ethernet Gateway with integrated web server that can be used:

• as a PROFIBUS DP/Ethernet gateway within a PROFIBUS monitoring and control system

• as a remote data acquisition module for PROFIBUS devices connected to its PROFIBUS DP

channels.

More information on these applications is to be found in the manual, or visit the Fieldgate web page

at www.products.endress.com/fieldgate.

1.2 Installation, commissioning and operation

Fieldgate FXA720 must be installed, connected, operated and maintained according to the

instructions in this manual: personnel must be authorised and suitably qualified.

Warning

• You require a unique IP address to set up Fieldgate. The use of IP addresses is strictly

controlled. Usually your system administrator will be authorised to allocate unique addresses

for your Fieldgates. Assigning an unauthorised address to a Fieldgate may result in conflicts

within your system and the failure of the associated devices!

Repair

1.3 Operational safety

The uni t m us t no t b e use d i n e x p l o si o n haz ar d ous areas. T he p e r mi s si b l e am b i en t co nd i t i o ns gi v e n

in the technical data must be complied with.

Do not open the housing of the Fieldgate FXA720. It does not contain any parts that need to be

maintained or repaired by the user. In the event of a fault or defect, return the unit to the vendor.

Opening the unit will void the warranty!

1.4 Technical improvement

Endr ess+ Haus er r ese rv es th e r ight to mak e te chni cal i mp ro vem ents to its har dwar e an d so ft war e at

any time and without prior notification. Where such improvements have no effect on the operation

of the equipment, they are not documented. If the improvements effect operation, a new version of

the operating instructions is normally issued, see Revision History.

Endress+Hauser 3

Page 6

1Safety Fieldgate FXA720

1.5 Declaration of conformity

CE Notice

North America

Fieldgate FXA720 complies with the requirements of the EC Directives 89/336/EEC

"Electromagnetic Compatibility" (EMC directive).

• Emission: EN 50022:1998 Class A (ITE Product Standard)

EN 50011:1998 Group 1 Class A (ISM Product Standard)

• Immunity: EN 61000-4-5:1999 Generic Immunity Standard

EN 61000-4-3: 1996 RF Electromagnetic Fields

A Declaration of Conformity in compliance with the above standards has been made and can be

inspected at Endress+Hauser Process Solutions AG on request.

Fieldgate FXA720 conforms with the following North American Electromagnetic Compatibility

standards:

• UL 508: Industrial Control Equipment

• CSA C22.2 # 14.795: Industrial Control Equipment

Note!

• For compliance with the legal EMC requirements, the other components (AC adapter, PROFIBUS

stations, etc.) must also meet these requirements.

• To meet t he EM C co nd iti on s, the de vice must be i nst all ed and conne cted i n acco rd ance w ith the

Installation Instructions.

Warning!

• This is a Class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equi p m en t ge ne r at es, us es, and can r adiat e radi o f reque ncy e ne rgy and , i f not i ns ta l l ed and use d i n

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

4 Endress+Hauser

Page 7

Fieldgate FXA720 1 Safety

1.6 Writing conventions

The following writing conventions and symbols have been used to provide the user with a better

overview of the contents of this manual and to highlight important information:

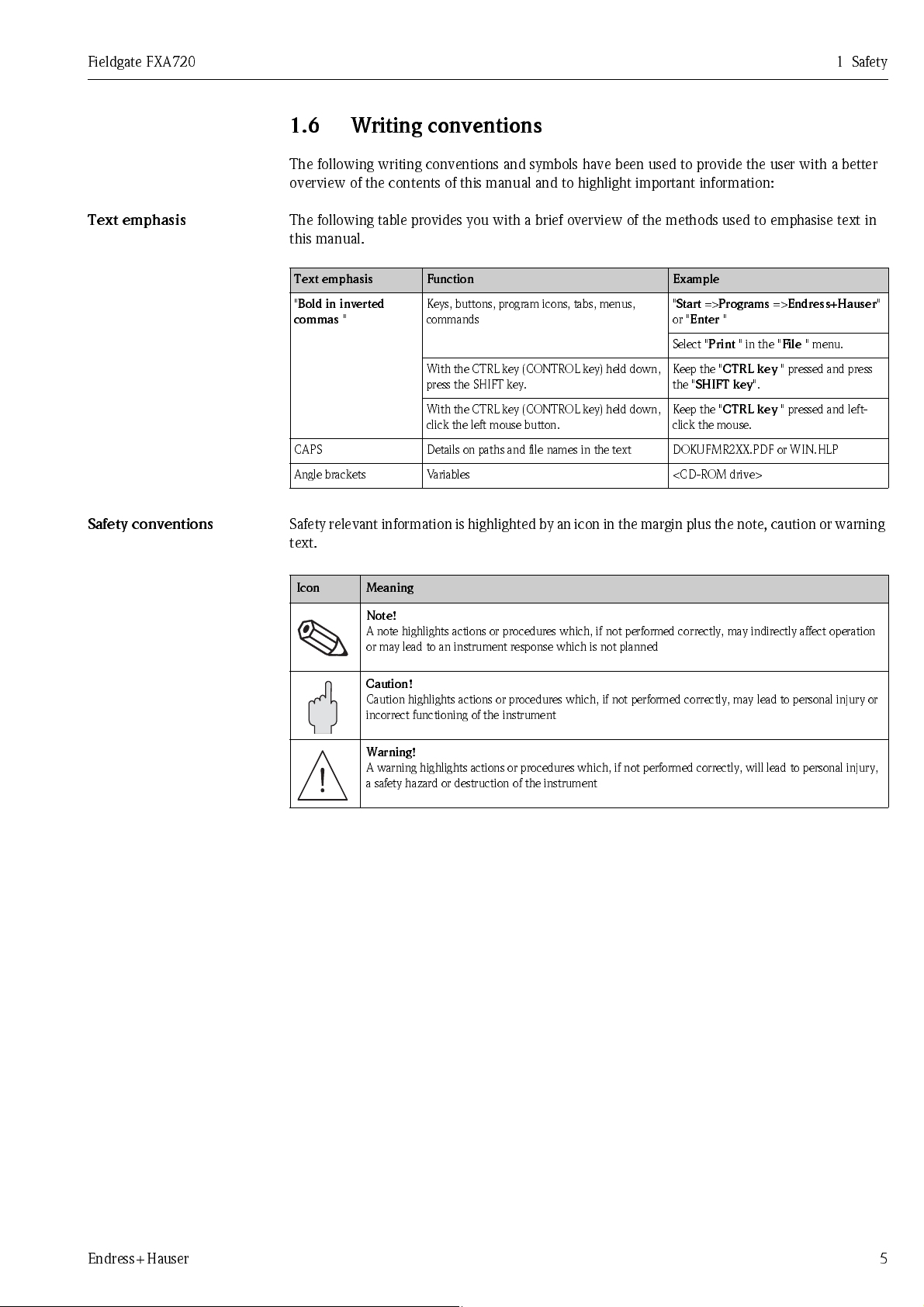

Text emphasis

Safety conventions

The following table provides you with a brief overview of the methods used to emphasise text in

this manual.

Text emphasis Function Example

"

Bold in inverted

commas

CAPS Details on paths and file names in the text DOKUFMR2XX.PDF or WIN.HLP

Angle brackets Variables <CD-ROM drive>

"

Keys, buttons, program icons, tabs, menus,

commands

With the CTRL key (CONTROL key) held down,

press the SHIFT key.

With the CTRL key (CONTROL key) held down,

click the left mouse button.

"

Start

=>

Programs

or "

Enter

"

Select "

Print

" in the "

Keep the "

the "

Keep the "

click the mouse.

CTRL key

SHIFT key

CTRL key

=>

Endress+Hauser

File

" menu.

" pressed and press

".

" pressed and left-

Safety relevant information is highlighted by an icon in the margin plus the note, caution or warning

text .

.

Icon Meaning

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect operation

or may lead to an instrument response which is not planned

"

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal injury or

incorrect functioning of the instrument

Warning!

A warning highlights actions or procedures which, if not performed correctly, will lead to personal injury,

a safety hazard or destruction of the instrument

Endress+Hauser 5

Page 8

1Safety Fieldgate FXA720

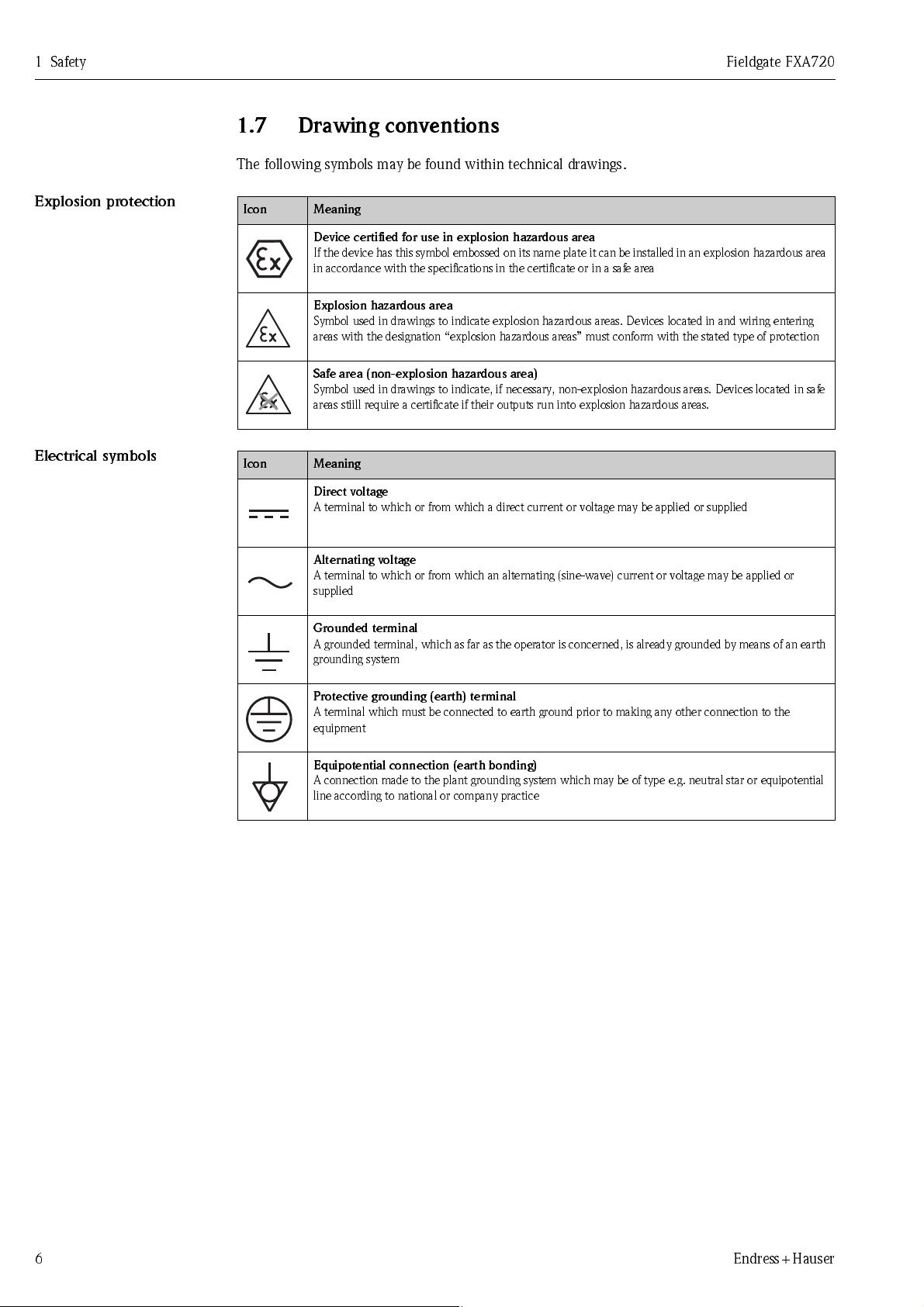

1.7 Drawing conventions

The following symbols may be found within technical drawings.

Explos i on prot ect ion

Elect ric al s ymbol s

.

Icon Meaning

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion hazardous area

in accordance with the specifications in the certificate or in a safe area

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in and wiring entering

areas with the designation “explosion hazardous areas” must conform with the stated type of protection

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas. Devices located in safe

areas stiill require a certificate if their outputs run into explosion hazardous areas.

.

Icon Meaning

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be applied or

supplied

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by means of an earth

grounding system

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to the

equipment

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or equipotential

line according to national or company practice

6 Endress+Hauser

Page 9

Fieldgate FXA720 2 Identification

2 Identification

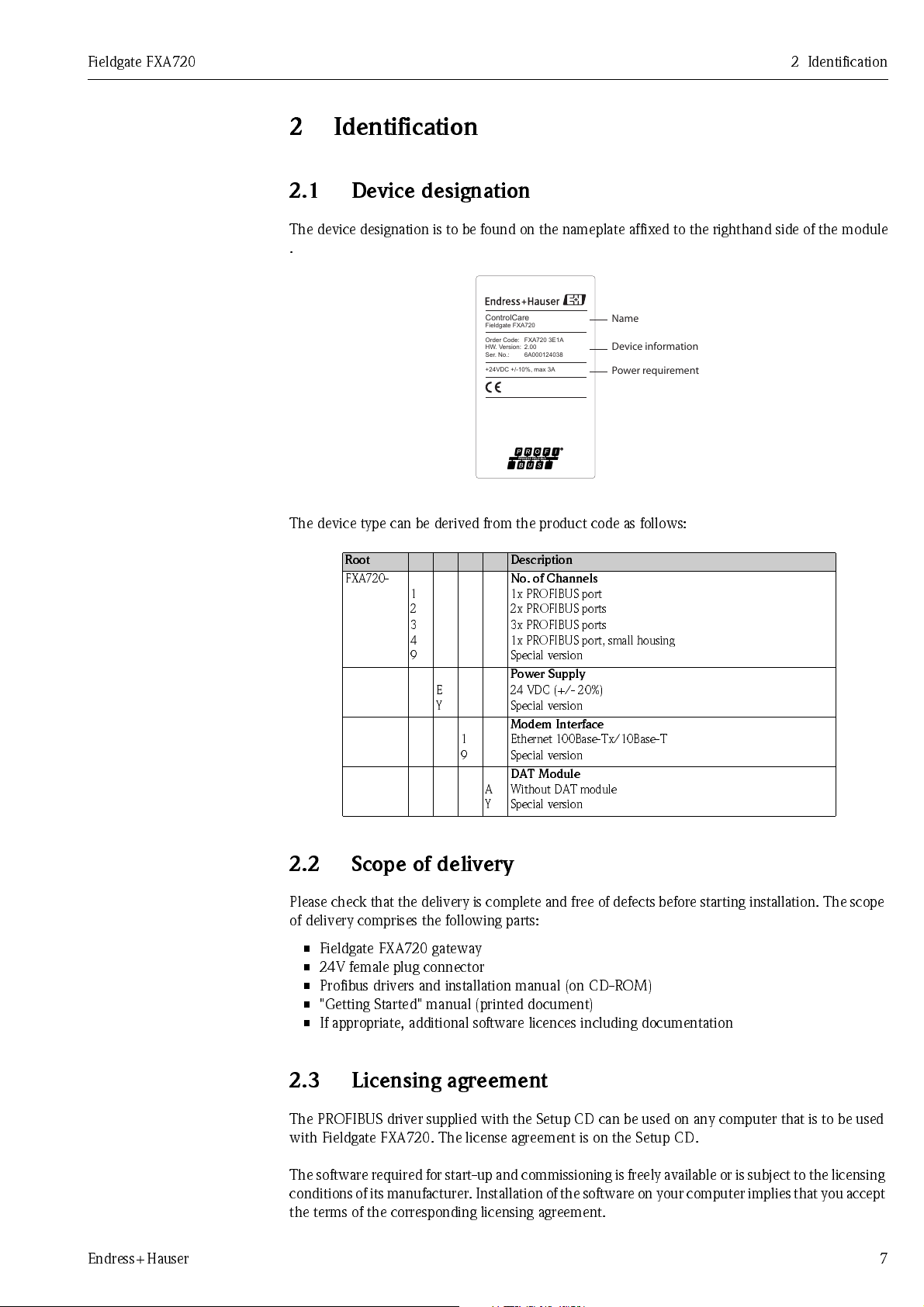

2.1 Device designation

The device designation is to be found on the nameplate affixed to the righthand side of the module

.

ControlCare

Fieldgate FXA720

FXA720 3E1A

Order Code:

2.00

HW. Version:

6A000124038

Ser. No.:

+24VDC +/-10%, max 3A

Name

Device information

Power requirement

The device type can be derived from the product code as follows:

Root Description

FXA720-

1

2

3

4

9

E

Y

1

9

No. of Channels

1x PROFIBUS port

2x PROFIBUS ports

3x PROFIBUS ports

1x PROFIBUS port, small housing

Special version

Power Supply

24 VDC (+/- 20%)

Special version

Modem Interface

Ethernet 100Base-Tx/10Base-T

Special version

DAT Module

A

Without DAT module

Y

Special version

2.2 Scope of delivery

Please check that the delivery is complete and free of defects before starting installation. The scope

of delivery comprises the following parts:

• Fieldgate FXA720 gateway

• 24V female plug connector

• Profibus drivers and installation manual (on CD-ROM)

• "Getting Started" manual (printed document)

• If appropriate, additional software licences including documentation

2.3 Licensing agreement

The PROFIBUS driver supplied with the Setup CD can be used on any computer that is to be used

with Fieldgate FXA720. The license agreement is on the Setup CD.

The software required for start-up and commissioning is freely available or is subject to the licensing

condi tio ns of its m anufact urer . Ins talla tion of t he sof tware on you r com puter imp lies that you acce pt

the terms of the corresponding licensing agreement.

Endress+Hauser 7

Page 10

3 Function and System Design Fieldgate FXA720

3 Function and Sys tem De si gn

3.1 Function

Fieldgate FXA720 connects host systems to PROFIBUS DP networks via Ethernet. It can be

equipped with up to three RS-485 ports, each giving access to up to 125 PROFIBUS DP devices.

Fieldgate is designed for Windows and web-based applications such as configuration, monitoring,

and visualisation. Process data can be monitored with the integrated Web server.

Fieldgate can also be integrated into system applications via OPC, DTM or XML, eg.:

• OPC for exchanging data with applications such as SCADA/HMI OPC clients,

e.g. P View SPV200

• DTM for exchanging data with FDT frame applications, e.g. FieldCare

• XML for exchanging data with Microsoft Office applications or simple visualisation applications

such as Field Viewer SPV10

8 Endress+Hauser

Page 11

Fieldgate FXA720 3 Function and System Design

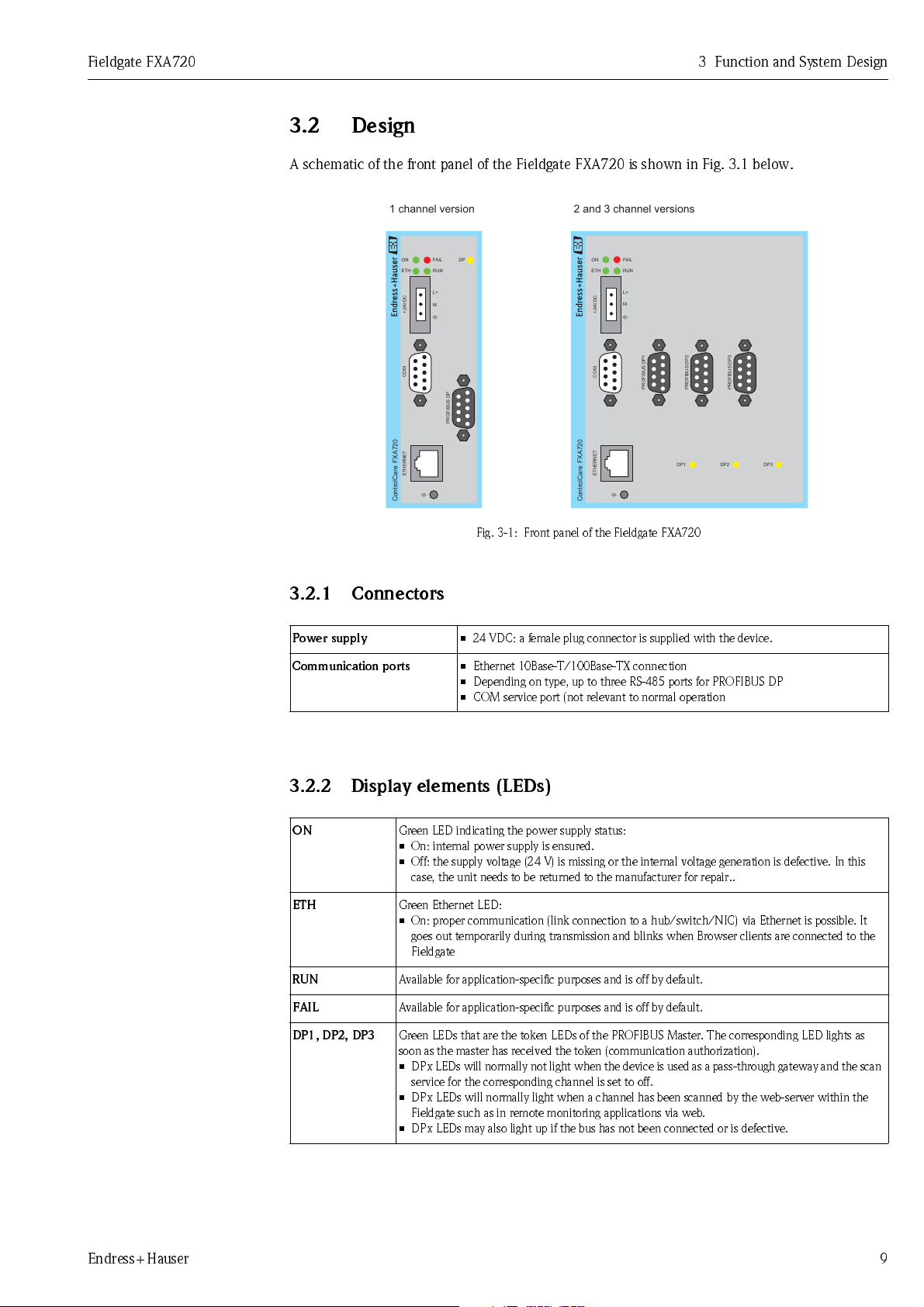

3.2 Design

A schematic of the front panel of the Fieldgate FXA720 is shown in Fig. 3.1 below.

1 channel version 2 and 3 channel versions

FAIL

ON

ETH

+24VDC

FAIL

DP

RUN

L+

M

ON

ETH

+24VDC

RUN

L+

M

COM

PROFIBUS DP

FXA720ControlCare

ETHERNET

Fig. 3-1: Front panel of the Fieldgate FXA720

3.2.1 Connectors

Power supply

Communication ports

• 24 VDC: a female plug connector is supplied with the device.

• Ethernet 10Base-T/100Base-TX connection

• Depending on type, up to three RS-485 ports for PROFIBUS DP

• COM service port (not relevant to normal operation

3.2.2 Display elements (LEDs)

COM

FXA720ControlCare

ETHERNET

PROFIBUS DP1

DP1

PROFIBUS DP2

PROFIBUS DP3

DP2 DP3

ON

Green LED indicating the power supply status:

• On: internal power supply is ensured.

• Off: the supply voltage (24 V) is missing or the internal voltage generation is defective. In this

case, the unit needs to be returned to the manufacturer for repair..

ETH

Green Ethernet LED:

• On: proper communication (link connection to a hub/switch/NIC) via Ethernet is possible. It

goes out temporarily during transmission and blinks when Browser clients are connected to the

Fieldgate

RUN

FAIL

DP1, DP2, DP3

Available for application-specific purposes and is off by default.

Available for application-specific purposes and is off by default.

Green LEDs that are the token LEDs of the PROFIBUS Master. The corresponding LED lights as

soon as the master has received the token (communication authorization).

• DPx LE Ds will normally not lig ht when the device is used as a pass-through gateway and the scan

service for the corresponding channel is set to off.

• DPx LEDs will normally light when a channel has been scanned by the web-server within the

Fieldgate such as in remote monitoring applications via web.

• DPx LEDs may also light up if the bus has not been connected or is defective.

Endress+Hauser 9

Page 12

3 Function and System Design Fieldgate FXA720

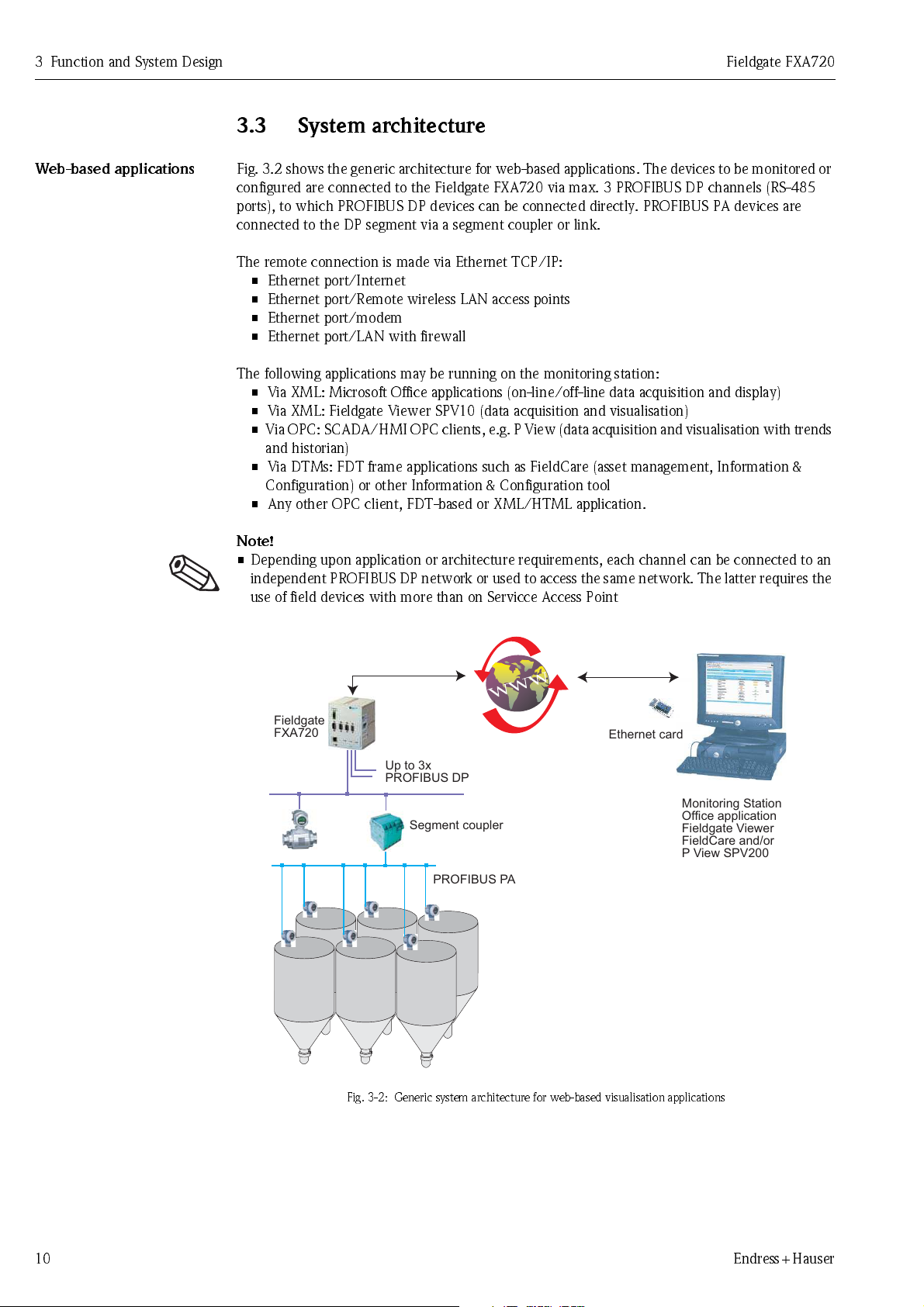

3.3 System architecture

Web-base d appl icat io ns

Fig. 3.2 shows the generic architecture for web-based applications. The devices to be monitored or

configured are connected to the Fieldgate FXA720 via max. 3 PROFIBUS DP channels (RS-485

ports), to which PROFIBUS DP devices can be connected directly. PROFIBUS PA devices are

connected to the DP segment via a segment coupler or link.

The remote connection is made via Ethernet TCP/IP:

• Ethernet port/Internet

• Ethernet port/Remote wireless LAN access points

• Ethernet port/modem

• Ethernet port/LAN with firewall

The following applications may be running on the monitoring station:

• Via XML: Microsoft Office applications (on-line/off-line data acquisition and display)

• Via XML: Fieldgate Viewer SPV10 (data acquisition and visualisation)

• Via OPC: SCADA/HMI OPC clients, e.g. P View (data acquisition and visualisation with trends

and historian)

• Via DTMs: FDT frame applications such as FieldCare (asset management, Information &

Configuration) or other Information & Configuration tool

• Any other OPC client, FDT-based or XML/HTML application.

Note!

• Dependi ng up o n ap p l i cat i o n o r ar ch i te ct ur e r eq u i rements , each chan nel can be co nnected to an

independent PROFIBUS DP network or used to access the same network. The latter requires the

use of field devices with more than on Servicce Access Point

Fieldgate

FXA720

Ethernet card

Up to 3x

PROFIBUS DP

Monitoring Station

Segment coupler

PROFIBUS PA

Fig. 3-2: Generic system architecture for web-based visualisation applications

Office application

Fieldgate Viewer

FieldCare and/or

P View SPV200

10 Endress+Hauser

Page 13

Fieldgate FXA720 3 Function and System Design

Fieldgate

FXA720

PROFIBUS DP

Segment

coupler

Segment

coupler

PROFIBUS PAPROFIBUS PA

ETHERNET

HMI

e.g. P View

Asset Management

e.g. FieldCare

Enterprise

e.g. Office

Controller

e.g.

ControlCare

SFC173

Network applications

When used as a Ethernet/PROFIBUS gateway, Fieldgate FXA720 will normally provide the

connection between host applications running on Ethernet and PROFIBUS devices connected to a

PROFIBUS DP or PROFIBUS PA network. Fig. 3.3 shows a typical example.

Examples of applications running on Ethernet are:

• Via OPC: SCADA/HMI OPC clients, e.g. P View

• Via DTM: Asset management tools based on FDT frames, e.g. FieldCare

• Via XML: Microsoft Office and e-Commerce applications

• Any other OPC client, FDT-based or XML/HTML application.

Fig. 3-3: Typical example of a PROFIBUS DP control network with Fieldgate used in pass-through mode

Endress+Hauser 11

Page 14

3 Function and System Design Fieldgate FXA720

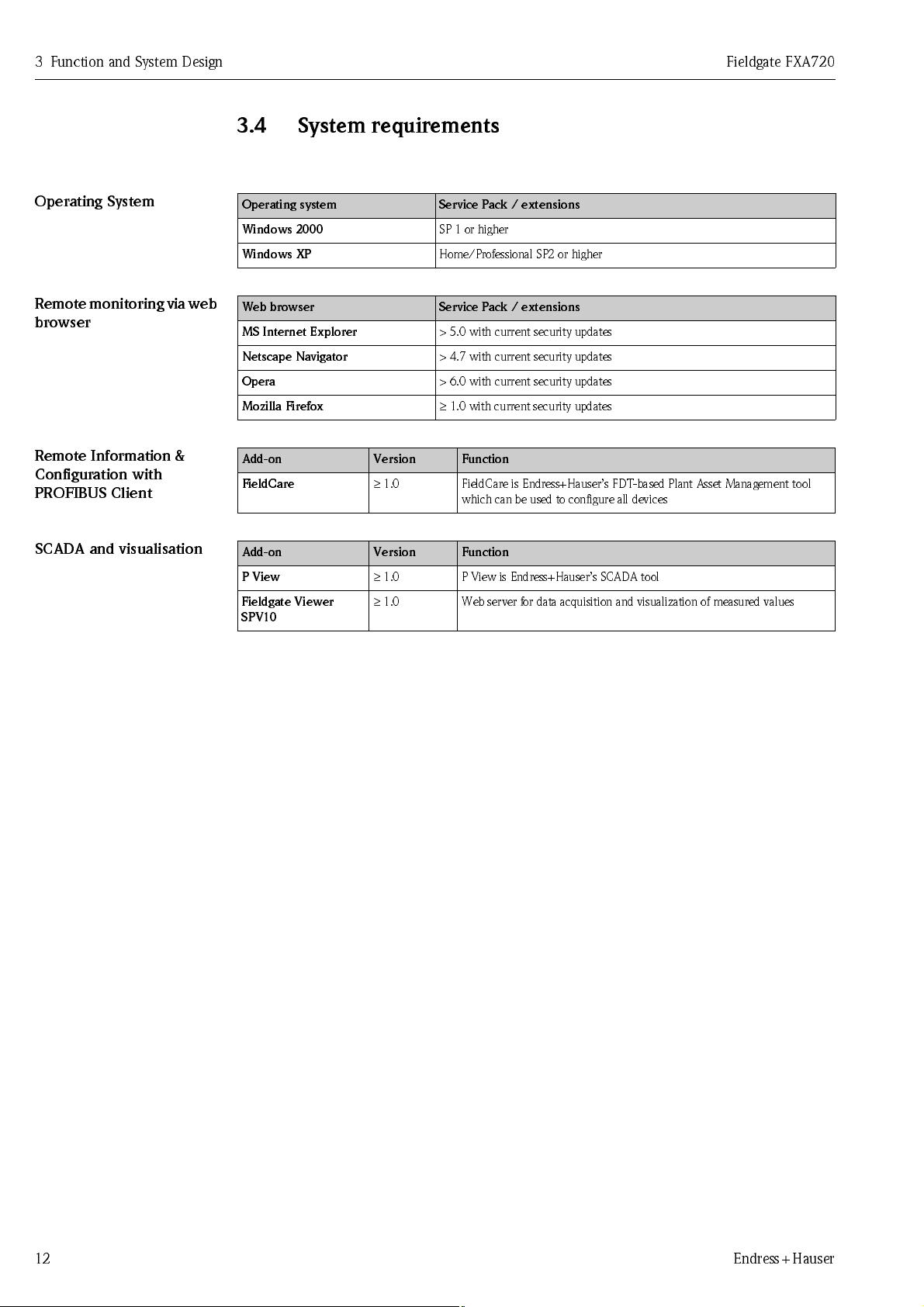

3.4 System requirements

Operating Syste m

Remot e monit oring via w eb

browser

Remote Information &

Configuration with

PROFIBUS Clie nt

SCADA and vis uali s atio n

Operating system Service Pack / extensions

Windows 2000

Windows XP

Web browser Service Pack / extensions

MS Internet Explorer

Netscape Navigator

Opera

Mozilla Firefox

Add-on Version Function

FieldCare

Add-on Version Function

P View

Fieldgate Viewer

SPV10

≥

1.0 FieldCare is Endress+Hauser’s FDT-based Plant Asset Management tool

≥

1.0 P View is Endress+Hauser’s SCADA tool

≥

1.0 Web server for data acquisition and visualization of measured values

SP 1 or higher

Home/Professional SP2 or higher

> 5.0 with current security updates

> 4.7 with current security updates

> 6.0 with current security updates

≥

1.0 with current security updates

which can be used to configure all devices

12 Endress+Hauser

Page 15

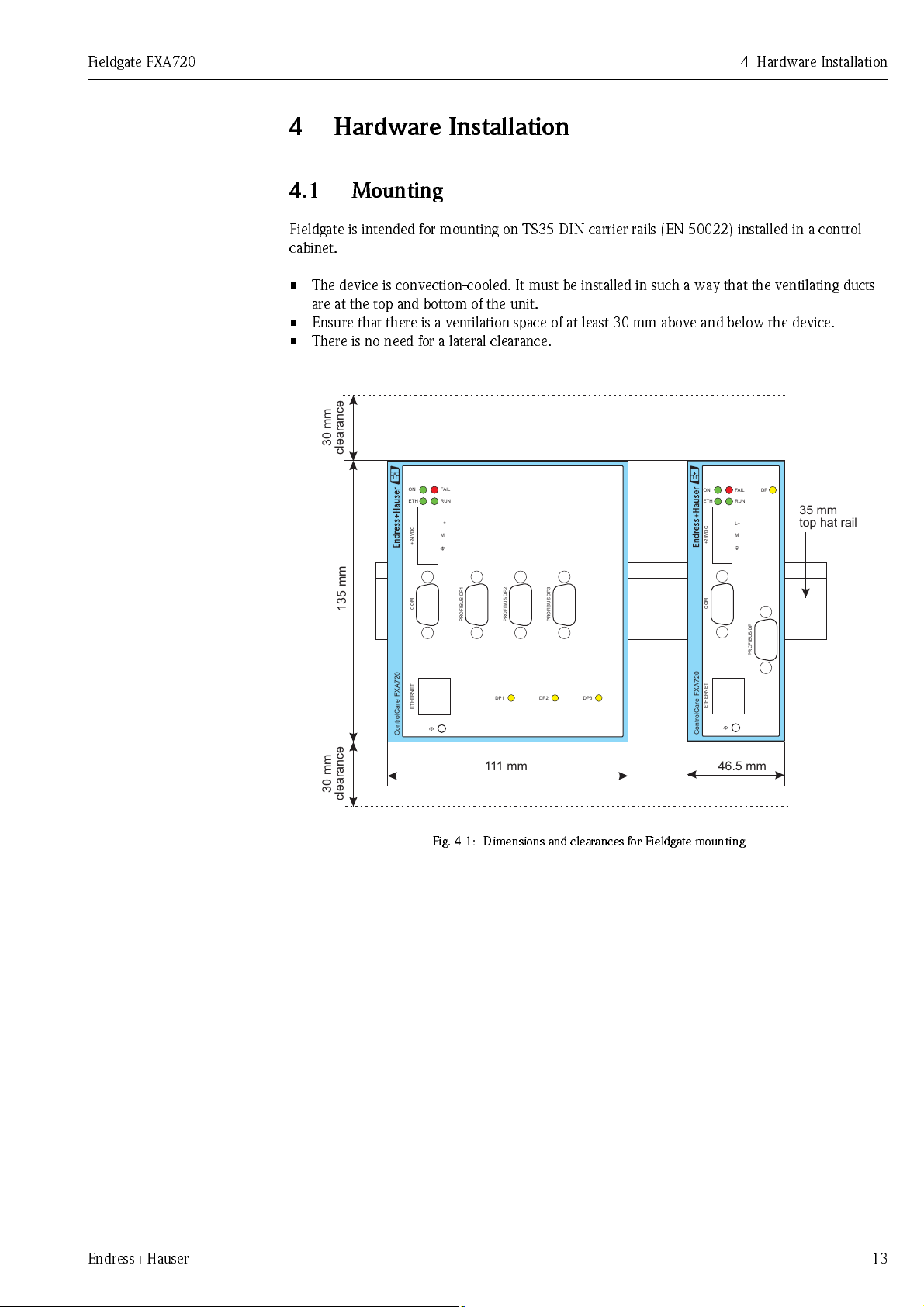

Fieldgate FXA720 4 Hardware Installation

111 m m

35 mm

top hat rail

135 mm

30 mm

clearance

30 mm

clearance

FAIL

ON

ETH

RUN

+24VDC

COM

PROFIBUS DP1

ETHERNET

DP1

PROFIBUS DP2

PROFIBUS DP3

DP2 DP3

L+

M

FXA720ControlCare

COM

ETHERNET

PROFIBUS DP

FAIL

ON

ETH

RUN

DP

+24VDC

L+

M

FXA720ControlCare

46.5 mm

4 Hardware Ins tall ation

4.1 Mounting

Fieldgate is intended for mounting on TS35 DIN carrier rails (EN 50022) installed in a control

cabinet.

• The device is convection-cooled. It must be installed in such a way that the ventilating ducts

are at the top and bottom of the unit.

• Ensure that there is a ventilation space of at least 30 mm above and below the device.

• There is no need for a lateral clearance.

Fig. 4-1: Dimensions and clearances for Fieldgate mounting

Endress+Hauser 13

Page 16

4 Hardware In stall at i o n Fieldgate FXA720

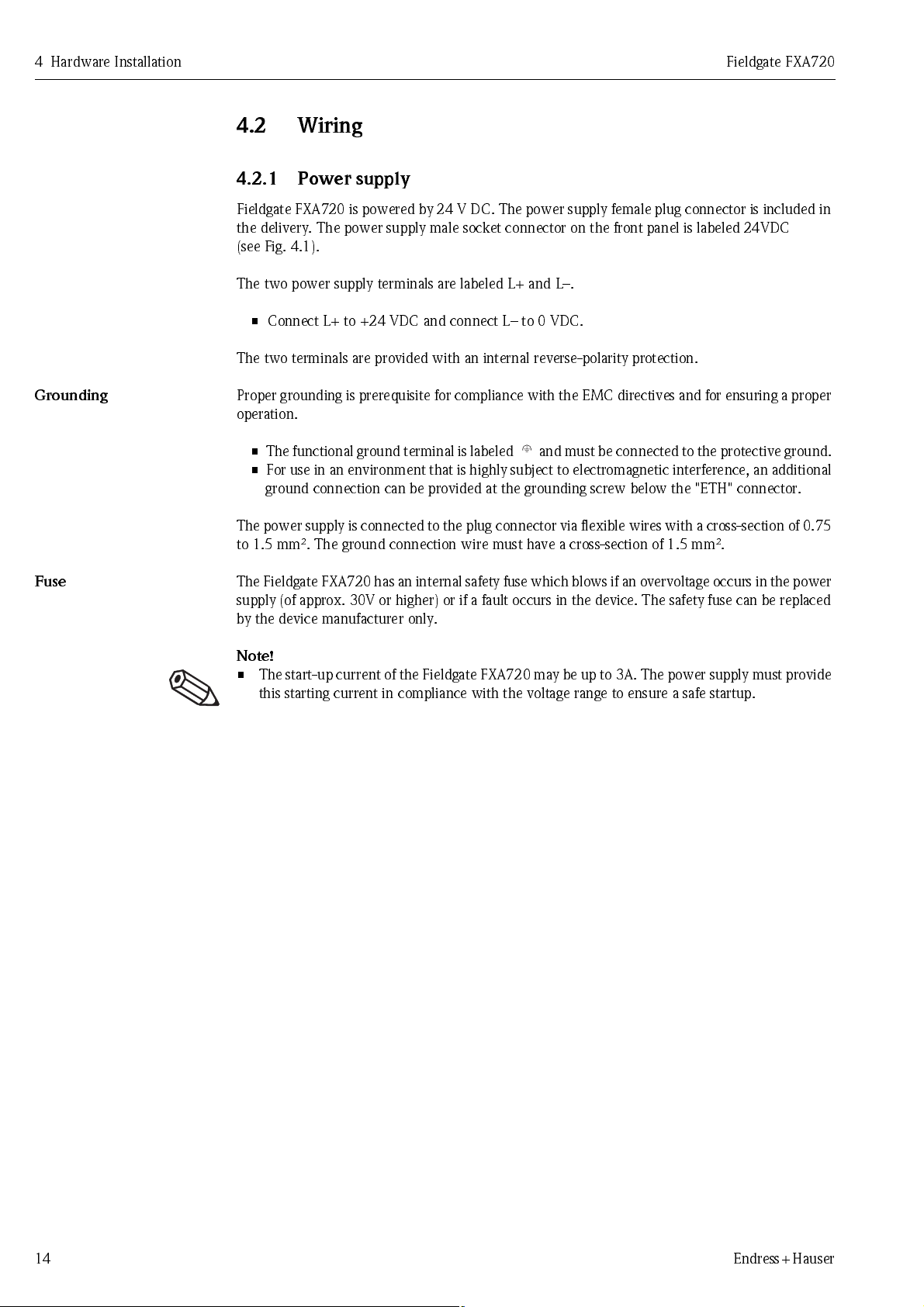

4.2 Wiring

4.2.1 Power supply

Fieldgate FXA720 is powered by 24 V DC. The power supply female plug connector is included in

the delivery. The power supply male socket connector on the front panel is labeled 24VDC

(see Fig. 4.1).

The two power supply terminals are labeled L+ and L–.

• Connect L+ to +24 VDC and connect L– to 0 VDC.

The two terminals are provided with an internal reverse-polarity protection.

Grounding

Fuse

Proper grounding is prerequisite for compliance with the EMC directives and for ensuring a proper

operation.

• The functional ground terminal is labeled and must be connected to the protective ground.

• F o r us e i n a n e nv i r o nm en t th at i s hi gh l y sub j e ct to el e ct r o ma gn et i c i n te r f e r en ce, an ad d i t i o na l

ground connection can be provided at the grounding screw below the "ETH" connector.

The p ower sup pl y is co nnect ed to the plu g conn ecto r v ia f lex ib le wir es wit h a cro ss -se cti on o f 0. 75

to 1.5 mm². The ground connection wire must have a cross-section of 1.5 mm².

The Fi eld gate FX A720 has an i nter nal safe ty fuse which bl ows if an over volt age occur s in the power

supply (of approx. 30V or higher) or if a fault occurs in the device. The safety fuse can be replaced

by the device manufacturer only.

Note!

• The start-up current of the Fieldgate FXA720 may be up to 3A. The power supply must provide

this starting current in compliance with the voltage range to ensure a safe startup.

14 Endress+Hauser

Page 17

Fieldgate FXA720 4 Hardware Installation

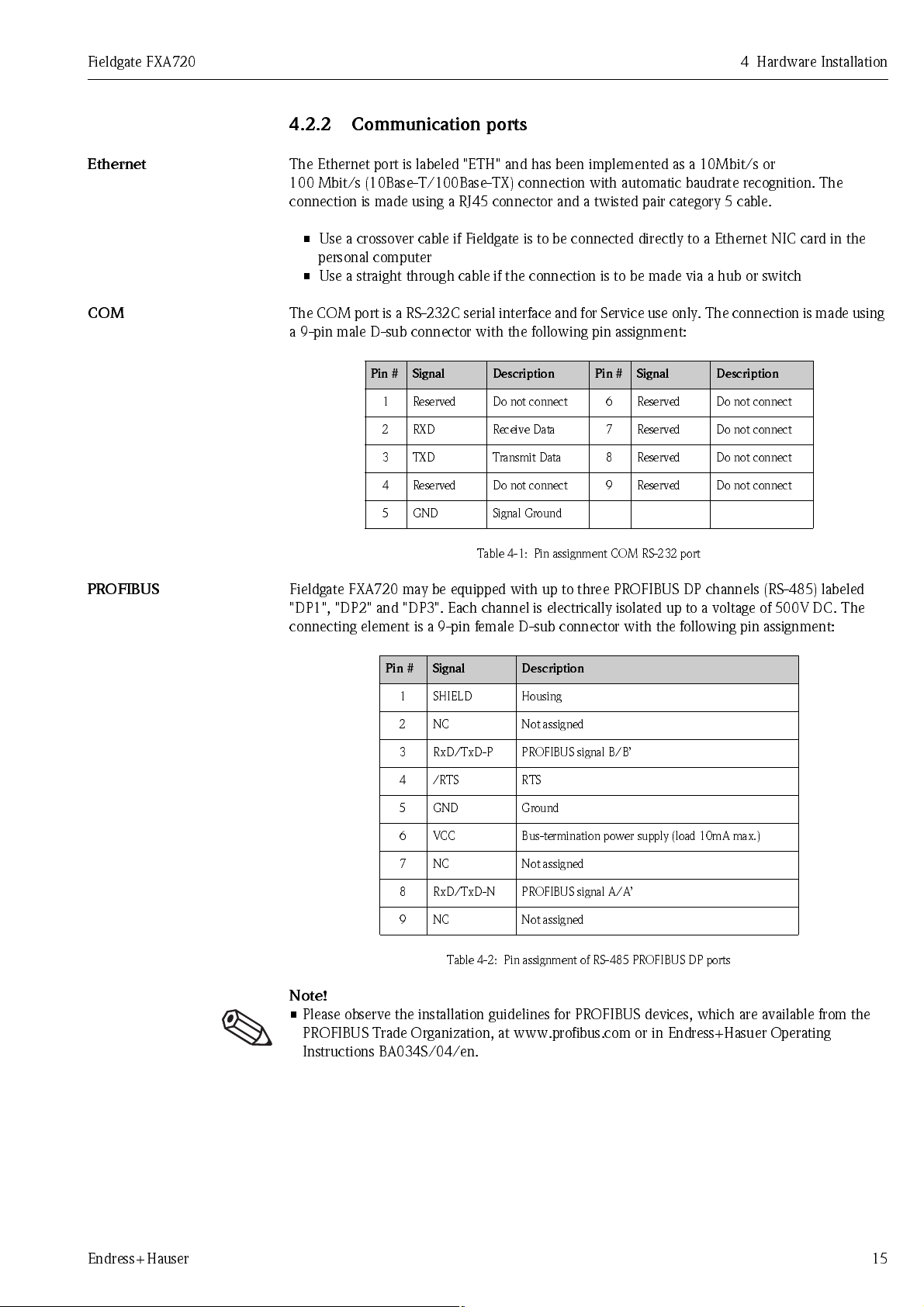

4.2.2 Communication ports

Ethernet

COM

PROFIBUS

The Ethernet port is labeled "ETH" and has been implemented as a 10Mbit/s or

100 Mbit/s (10Base-T/100Base-TX) connection with automatic baudrate recognition. The

connection is made using a RJ45 connector and a twisted pair category 5 cable.

• Use a crossover cable if Fieldgate is to be connected directly to a Ethernet NIC card in the

personal computer

• Use a straight through cable if the connection is to be made via a hub or switch

The COM port is a RS-232C serial interface and for Service use only. The connection is made using

a 9-pin male D-sub connector with the following pin assignment:

Pin # Signal Description Pin # Signal Description

1 Reserved Do not connect 6 Reserved Do not connect

2 RXD Receive Data 7 Reserved Do not connect

3 TXD Transmit Data 8 Reserved Do not connect

4 Reserved Do not connect 9 Reserved Do not connect

5 GND Signal Ground

Table 4-1: Pin assignment COM RS-232 port

Fieldgate FXA720 may be equipped with up to three PROFIBUS DP channels (RS-485) labeled

"DP1", "DP2" and "DP3". Each channel is electrically isolated up to a voltage of 500V DC. The

connecting element is a 9-pin female D-sub connector with the following pin assignment:

Pin # Signal Description

1SHIELD Housing

2 NC Not assigned

3 RxD/TxD-P PROFIBUS signal B/B’

4/RTS RTS

5 GND Ground

6 VCC Bus-termination power supply (load 10mA max.)

7 NC Not assigned

8 RxD/TxD-N PROFIBUS signal A/A’

9 NC Not assigned

Table 4-2: Pin assignment of RS-485 PROFIBUS DP ports

Note!

• Please observe the installation guidelines for PROFIBUS devices, which are available from the

PROFIBUS Trade Organization, at www.profibus.com or in Endress+Hasuer Operating

Instr u ct i o ns BA 03 4 S /04/en.

Endress+Hauser 15

Page 18

5 Getting Started Fieldgate FXA720

5 Getting Started

Before you start the installation:

• Check that you have administrator rights for your computer.

• Check that you have a unique IP address for each Fieldgate to be installed together with

subnet, gateway (LAN/router/firewall) and, if appropriate, broadcast IP addresses.

If a previous version is installed on your computer, we recommend that you deinstall it before

installing the new version.

Warning!

• The use of IP addresses is strictly controlled. Usually your system administrator will be

authorised to allocate unique addresses for your Fieldgates. Assigning an unauthorised address

to a Fieldgate may result in conflicts within your system and the failure of the associated

devices!

5.1 Preparing for installation

Procedure

5.1.1 Checking the system requirements

1. Place the Fieldgate CD-ROM in your CD-ROM drive, the Setup menu appears.

2. First check that your computer fulfils the minimum requirements as described below, see also

Section 3.4.

3. N ow car ef ull y re ad th e

them up.

"Release Notes"

before starting the installation - a double-click opens

16 Endress+Hauser

Page 19

Fieldgate FXA720 5 Getting Started

5.1.2 Installing the documentation

Procedure

1. Now install the documentation: Click on the

2. Click on

"Install Doc ume ntati on"

to install the FieldCare FXA720 manual:

"Compone nt Instal lat io n"

option:

3. The installation wizard appears: Proceed with the installation by clicking the

4. To open, select

English => Manuals"

"Start => Programs => Endre ss +H aus er => Fieldgate => FXA 720 =>

and select the document you require.

"Next"

button.

5.1.3 Adobe Acrobat Reader

You require Adobe Acrobat Reader to read the PDF file. The current Reader version is supplied on

the CD-ROM.

1. To install, select the

Acrobat Reader"

2. The installation wizard appears: Proceed with the installation by clicking the

"Compo nent Inst all ati on"

.

option. Then, double-click on

"Next"

"Adobe

button.

Endress+Hauser 17

Page 20

5 Getting Started Fieldgate FXA720

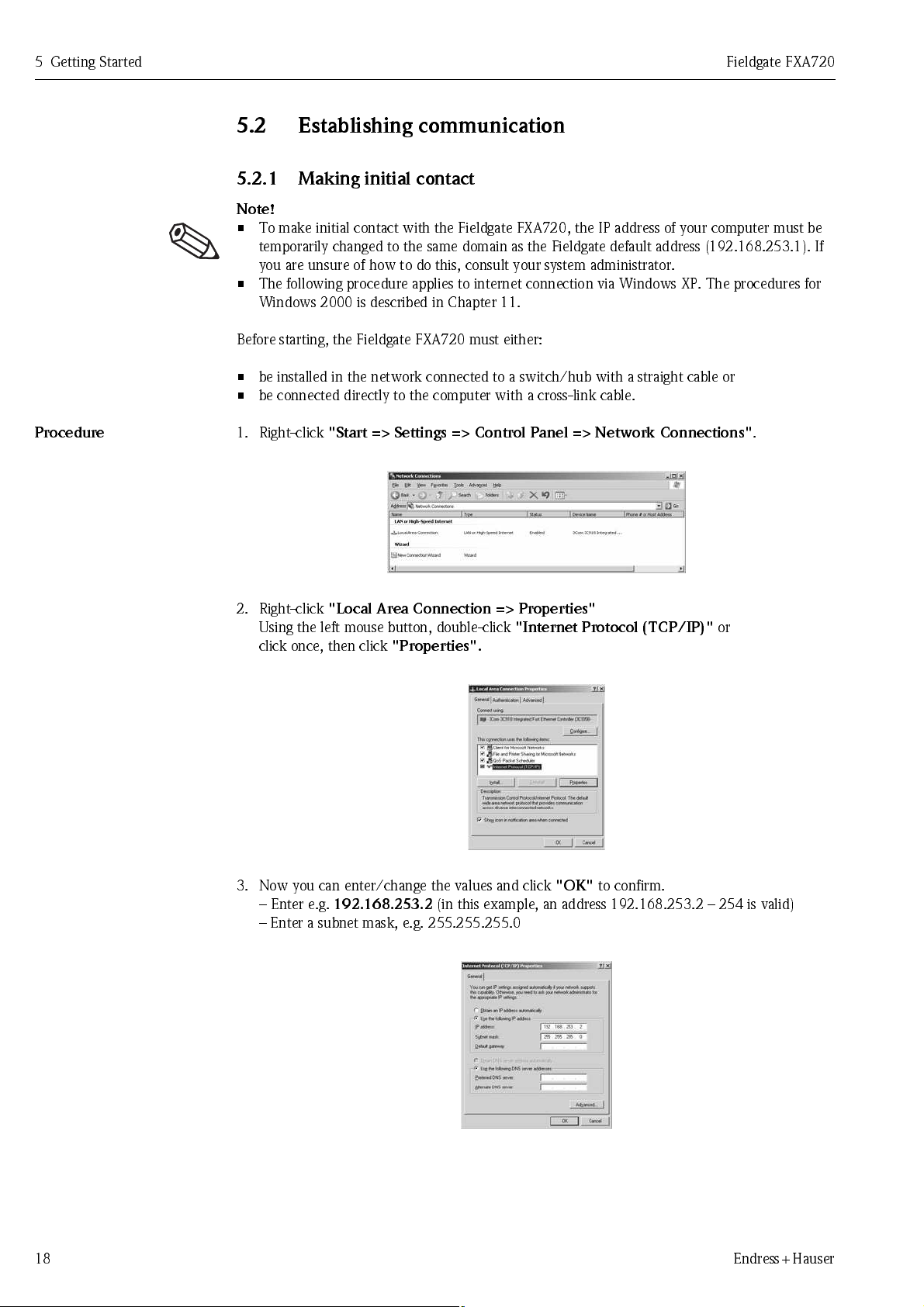

5.2 Establishing communication

5.2.1 Making initial contact

Note!

• To make initial contact with the Fieldgate FXA720, the IP address of your computer must be

temporarily changed to the same domain as the Fieldgate default address (192.168.253.1). If

you are unsure of how to do this, consult your system administrator.

• The following procedure applies to internet connection via Windows XP. The procedures for

Windows 2000 is described in Chapter 11.

Before starting, the Fieldgate FXA720 must either:

• be installed in the network connected to a switch/hub with a straight cable or

• be connected directly to the computer with a cross-link cable.

Procedure

1. Right-click

2. Right-click

Using the left mouse button, double-click

click once, then click

"Start => Settings => Control Panel => Network Connections"

"Local Ar ea Co nnec tio n => Properti es"

"Properties".

"Internet Protocol (TCP/IP)"

.

or

3. Now you can enter/change the values and click

– Enter e.g.

– Enter a subnet mask, e.g. 255.255.255.0

18 Endress+Hauser

192.168.253.2

(in this example, an address 192.168.253.2 – 254 is valid)

"OK"

to confirm.

Page 21

Fieldgate FXA720 5 Getting Started

4. Start the web browser, e.g. Internet Explorer.

Now enter the default address of the Fieldgate

browser and press the

"Enter"

key of your computer.

"192.168.253.1"

in the address field of your

5. The br o wse r mak es conn ect i o n wi th the F i el d g at e, a User

– Enter the password:

– Press

– If no connection can be made, consult Chapter 12.3.

6. After the password has been entered, the Fieldgate Web Server opens

(you will not necessarily see devices at this point):

"Login"

"superb"

to display the entry page of the Fieldgate.

Login

window appears.

Endress+Hauser 19

Page 22

5 Getting Started Fieldgate FXA720

5.2.2 Changing the Fieldgate address

Procedure

1. Press "

2. The live list is displayed (you may not necessarily see devices at this stage)

3. Now press "

Switch to Specialist Mode

– Enter the user name "

– Press "

– All active addresses on the bus are displayed

– Masters are normally listed with N.A. entries

– In the

– Enter the

– If appropriate, enter a

Login

"

Information & Co nfigu rati on

Ethernet

in this example 192.168.253.50:

Subnet mask

admin"

screen enter the

, in this example 255.255.255.0

Gateway

"

and password "

" followed by "

IP address

address (router/firewall connecting LAN to WAN/WWW)

super

"

Network Setup

given to you by the system administrator,

"

– Press

4. Contact with the Fieldgate may break down at this stage.

In all cases, close the browser.

5. Reset the IP address in your computer back to the original value, see Section 5.2.1.

6. You can now make contact with Fieldgate FXA720 through the network browser by entering

the new address.

7. Now set up the Fieldgate web server as described in Chapter 6.

20 Endress+Hauser

"Send"

to download the parameters to the Fieldgate.

Page 23

Fieldgate FXA720 5 Getting Started

5.3 Installing FXA720 PROFIBUS Driver

The FXA720 PROFIBUS Driver must be installed only if Fieldgate FXA720 is to be used in pass-

through mode to allow a host application, e.g. P View, to access a PROFIBUS DP network.

Warning!

• Do not install this driver if a Fieldgate PROFIBUS driver has already been installed with the

Host application, e.g. in connection with FieldCare. Overwriting the original will cause the

application to malfunction. You will be warned during installation, if a driver already exists.

5.3.1 Installing the driver

Procedure

1. Place the Fieldgate CD-ROM in your CD-ROM drive, the Setup menu appears.

2. Click on

3. Click on

"Component Installation"

"FXA 720 PRO FIBUS Drive r"

to start the software installation process.

to install the Fieldgate tool.

4. The Setup program immediately starts the installation process.

Endress+Hauser 21

Page 24

5 Getting Started Fieldgate FXA720

5. Read the license agreement and check "

– "Print"

– "C a n c el "

6. Now enter your customer information

Press

causes the license to be printed out

breaks off the installation procedure

"Next"

to proceed.

I accept ...

" then press "

Next".

7. Press

8. Press

"Install"

"Finish"

to start the installation.

to close the wizard.

22 Endress+Hauser

Page 25

Fieldgate FXA720 5 Getting Started

5.3.2 Configuring the driver

Procedure

1. Open the Control Panel via

Double-click on the

Note!

If you are using Fieldgate FXA720 with FieldCare, the select the

2. Select the

3. Now select the

PROFIBUS DP

"Fieldgate FXA720"

START => Settings => Control Panel .

"Fieldgate FXA720"

line, to display the general release information

icon to open the driver.

line and press

"Add"

"PROFIGate"

.

driver

4. A symbolic node name for each PROFIBUS DP channel (Default value: "Node 0") can now be

entered. Click

Endress+Hauser 23

"Next"

to proceed with the configuration.

Page 26

5 Getting Started Fieldgate FXA720

5. Enter the current

with the node specified in Step 4).

6. Click "

Finish

Caution:

Timeout settings should be changed by PROFIBUS specialists only

Fieldgate IP

" to accept the default timeout settings and end the configuration.

address and select the

Bus connector

(the channel to be used

7. If the Fieldgate is found in the network and is working properly, then the Node line will be

marked with a green check mark. In addition, Fieldgate information is displayed.

– The node configuration can be modified from this screen by clicking the

"Edit"

button. To save the configuration please click

8. For single channel Fieldgates, press

configuration window, otherwise continue with Step 9.

"OK"

to store the configuration and close the

"Apply".

24 Endress+Hauser

Page 27

Fieldgate FXA720 5 Getting Started

For two and three channel

versio ns

9. Now configure the other channels of your Fieldgate by pressing the

– Follow the sequence from Step 3 to Step 5 inclusive.

– Enter the same IP address: Fieldgate requires only one IP address for operation.

– Select

10.Click "

Caution:

"Bus 2" or "Bus 3"

Finish

" to accept the default timeout settings and end the configuration.

Timeout settings should be changed by PROFIBUS specialists only

as appropriate.

"Add".

button.

11.On completion, the new node will be added to the network tree:

– Press

Note: the screenshot shows the two channel version.

12.When all channels have been configured, press

configuration window.

"Apply"

to store the configuration

"OK"

to store the configuration and close the

Endress+Hauser 25

Page 28

5 Getting Started Fieldgate FXA720

5.3.3 Setting PROFIBUS DP bus parameters in FieldCare

Note!

• FieldCare uses the PROFIGate driver for Fieldgate FXA720. This should be configured before

the PROFIBUS DP parameters are set (The procedure is identical to that in Section 5.3.2)

When Fieldgate FXA720 is used together with FieldCare, the PROFIBUS DP baudrate is set in the

Fieldgate FXA720 CommDTM (PROFIdtmDPV1).

Procedure

1. Create your project as described in the extended Getting Started manual supplied on the

FieldCare CD-ROM.

2. Add the Communication device PROFIdtmDPV1 - this is the Fieldgate FXA720 CommDTM.

Right-click on the node (in our example it has been re-named Fieldgate FXA720) and select

"Configuration"

. The CommDTM for Fieldgate FXA720 appears

3. The board names are automatically taken from the node names set in the

– Select the node you want to use

– Enter a station address

– Set the bus parameters for communication on the PROFIBUS DP network

– Press

– Repeat the procedure for any other nodes where FieldCare is to have access

– Press

"Apply"

"Close"

to confirm the changes

return to the main program.

PROFIGate

driver.

26 Endress+Hauser

Page 29

Fieldgate FXA720 5 Getting Started

5.3.4 Setting PROFIBUS DP bus parameters in P View

Note!

• If you are using P View and FieldCare together, the PROFIGate driver should be used for the

Fieldgate, see Section 5.3.2.

When Fieldgate FXA720 is used together with ControlCare P View, the PROFIBUS DP baudrate is

set in the PROFIBUS OPC server.

Procedure

1. Start the OPC server from the Control Panel and set it up as decribed in the P View manual.

Click on the Fieldgate node (Master) to open the configuration window.

2. In the

3. In the

"Basic"

– Station name

– Station address

– Baudrate

– Master Class 2

– If necessary check "Read All Slaves" and press "Quickstart" to scan the bus

"Details"

– Bus parameters

folder, set

folder, set

4. Press "OK" to store the parameters.

Endress+Hauser 27

Page 30

5 Getting Started Fieldgate FXA720

5.4 Modifying, repairing or removing the application

5.4.1 Fieldgate FXA720 PROFIBUS Driver

If you have already installed the Fieldgate application, you can modify, repair or remove it by starting

the Fieldgate Maintenance program.

Procedure

1. Start the Fieldgate FXA720 Maintenance program by clicking on

Control Panel => Add or Rem ove Program s => Fie l dgate FX A720"

2. To install or remove individual components to remove select

– Now select or deselect

– Press

3. To repeat the installation procedure and install the Fieldgate application again, select "

– Now select the components you desire and press

– Press

4. To remove the Fieldgate application entirely, select

– Press "

"Finish"

"Finish"

OK"

to confirm

"PROFIBUS Driver"

to complete the installation.

to complete the installation.

and press

"Next"

"Remove"

"Start => Settings =>

"Modify"

"Next"

to install.

.

then

to proceed.

"Next".

Repair"

.

Procedure

5.4.2 Fieldgate FXA720 documentation

If you have already installed the Fieldgate application, you can modify, repair or remove it by starting

the Fieldgate Maintenance program.

1 Start the Fieldgate FXA720 Maintenance program by clicking on

Control Panel => Add or Rem ove Program s => Fie l dgate FX A720"

2 To install or remove individual components to remove select

– Now select or deselect

– Press

"Finish"

"Manuals"

to complete the installation.

and press

"Next"

to proceed.

"Start => Settings =>

"Modify"

then

"Next".

28 Endress+Hauser

Page 31

Fieldgate FXA720 6 Configuring the Web Server

6 Configuring the Web Se rver

Note!

• For security reasons, Fieldgate will automatically logout of the Specialist mode if it registers no

activity in the User Interface for a period of two minutes.

• You cannot change device parameters with the Fieldgate Web Server. This requires the help of

a configuration tool, e.g. FieldCare, that uses Fieldgate as a pass-through interface

6.1 Logging on

Once the IP address has been entered in your web browser and the connection made, you are

prompted to enter a user role and the password.

Note!

• All Fieldgate FXA720 passwords are case sensitive

User roles and default

passwords

Logging off

Fig. 6-1: User login dialogue

Table 7.1 lists the user roles with passwords that are currently available in the Fieldgate. Security

Setup, Chapter 6.5, provides more information on setting up passwords etc.

Role User name Defau lt

Administrator admin super Can access Fieldgate in both User and and Specialist mode:

Maintenance maint great Can access Fieldgate in both User and and Specialist mode:

Executive exec superb Can access Fieldgate in User Mode only

In specialist mode, click on the

password

"Logout"

Rights

• Can configure network settings

• Can set all passwords and user IDs

• Can change visualisation page settings

• Can set events, alarms, e-mail and time parameters

• Can configure PROFIBUS settings

• Can set special page options

• Can reset Fieldgate to factory settings

• Can configure PROFIBUS settings

• Can reset Fieldgate to factory settings

• Can view any page with the exception of the factory, communication

and special settings, but has no rights to change parameters

Table 6-1: Fieldgate user roles and rights

link then close the internet browser. In user mode, close

the internet browser.

Endress+Hauser 29

Page 32

6 Configuring the Web Server Fieldgate FXA720

6.2 User interface

Once logged on, depending upon the devices connected, a display such the following might appear

in the web browser. If you are connecting up for the first time, it is also possible that only the

Navigation bar appears because the Fieldgate needs to be set up to enable communication with the

PROFIBUS devices in the network, see Chapter 6.6.

Fig. 6-2: Fieldgate home page

Approx. 1 second update time is required for every measured value in the overview. For a large

network, this means that the first build up of the overview may take some time.

The user interface consists of the following elements:

• Menu bar (belongs to the web browser installed)

• Navigation bar

• Information & Configuration pages

6.2.1 Menu bar

Example of how the menu bar is displayed in MS Internet Explorer

The IP address of the Fieldgate is entered in the address field of the Internet web browser.

Note!

• The menu bar contains the standard functions of the installed web browser. More detailed

information on the individual menus is provided in the documentation on the web browser.

• It is possible that additional or modified menu bars appear when Fieldgate is operating with

plug-ins from other applications.

30 Endress+Hauser

Page 33

Fieldgate FXA720 6 Configuring the Web Server

6.2.2 Navigation bar

In User mode:

The navigation bar offers the following functions in

Fig. 6-3: Navigation bar in User mode

Function Description

Refresh Updates the current display with fresh information from

Endress+Hauser Calls the Endress+Hauser Fieldgate Web site

Overview of Selected

Devices

Switch to Specialist Mode Switches the navigation to specialist mode:

Information & Configuration Displays information on Fieldbus location and hardware

Time and Date Current time and date in selected format

Live List Displays all devices connected to the Fieldgate according to

XML Export Exports all information about Fieldgate and the devices

the Fieldgate

Displays the values you have selected for monitoring and

visualisation

the user is asked to log on with name and password

chan ne l

connected to it in XML format

"User"

or

"Specialist"

mode.

In Specialist mode:

Table 6-2: Functions available in User mode

Fig. 6-4: Navigation bar in Specialist Mode

Function Description

Refresh Updates the current display with fresh information from

the Fieldgate

Logout Changes to User Mode

Endress+Hauser Calls the Endress+Hauser Fieldgate Web site

Live List Displays all devices connected to the Fieldgate and allows

them to be configured and selected for display.

Switch to User Mode Switches the navigation to user mode

Information & Configuration Allows the Fieldgate location to be entered and displays the

hardware configuration. Reveals the following Setup

menus:

• Security Setup – Password administration

• Network Setup – IP address, etc

• PROFIBUS Setup – Communication parameters

• Service Setup – Firmware download

• Java Applets Setup – Selection of device parameters in

Java Applets SPV 60 application

Time and Date Current time and date in selected format

Overview of Selected

Devices

XML Export Exports all information about Fieldgate and the devices

Displays the values you have selected for monitoring and

allows the list to be modified

connected to it in XML format

Table 6-3: Functions available in Specialist Mode

Endress+Hauser 31

Page 34

6 Configuring the Web Server Fieldgate FXA720

6.2.3 Information & Configuration pages

Depending upon whether User or Specialist Mode is selected, clicking on Information &

Configuration reveals the Fieldgate information or configuration pages. A change from one view to

another is made by clicking on:

Switch to Specialist Mode/Switch to User Mode

as appropriate and when prompted, by entering the corresponding password, see Chapter 6.1.

Field gate Infor mati on

Field gate Co nfi gurati on

The Fieldgate Information page (User Mode) provides a read-only view of the Fieldgate Location

and Hardware Information:

Fig. 6-5: Fieldgate Information page

The user information on the Fieldgate Location page can be edited in Specialist mode.

Additional pages allow the configuration of users and well as the setup of Ethernet and PROFIBUS

networks.

Fig. 6-6: Fieldgate Configuration page

32 Endress+Hauser

Page 35

Fieldgate FXA720 6 Configuring the Web Server

6.3 Fieldgate location page

The Fieldgate location function provides you with the option of entering additional information on

the location and characteristics of the Fieldgate. These data are entered in the Specialist Mode but

have no effect on the functionality of the Fieldgate.

Fieldgate Location

parameters

1 If not already selected, press

2 Press

"Informatio n & Confi gurati on" ,

"Switch to Specialist Mode"

the Fieldgate location screens appear:

and log in as administrator.

3 Enter the parameters required – their significance is described in the following sections.

4 Press

Parameter Description

Fieldgate Tag

Identification

"Send"

to download the parameters to the Fieldgate.

Enter the name of the Fieldgate (e.g. FXA720-...) which is also displayed on the overview page, in

the header of your browser, in the XML file and the header of the e-mail (in preparation).

Note!

Please note the characters which are permitted and not permitted for defining the Fieldgate

identification (= name of the Fieldgate).

Permitted charac te rs are:

– Letters "a " ... "z " and "A " ... "Z " (without taking case into account)

– Numbers "0 " ... "9 "

– Special characters such as ". " (= period) and "– " (= minus), not however as the first character

– All other characters are

and spaces.

not

permitted. These include German umlauts, symbols such as "&"

Fieldgate Location

Installation date

Remarks

You can enter additional information on the location of the Fieldgate here. These data have no

effect on the functionality and solely serve to provide additional information.

Enter the date of installation or maintenance of the network, etc.

You can enter remarks and additional information here, e.g. on the Fieldgate or network

maintenance, service etc.. These data have no effect on the functionality and serve solely to

provide additional information. When using text e-mails, these remarks are entered in the e-mail

(e.g. "We hereby order…").

Table 6-4: Significance of Fieldgate Location parameters

Endress+Hauser 33

Page 36

6 Configuring the Web Server Fieldgate FXA720

Procedure

6.4

Access rights to the Fieldgate are managed with the

Security setup

"Security Setup"

function. As the

administrator, you can create and manage users here.

Caution!

• To avoid unauthorised access to the Fieldgate setup parameters, the administrator and

maintenance passwords should always be changed from the default settings!

• If you have updated from Version 1.00.21 to Version 1.01.00, see also Chapter 8, you will

need to set up a maintenance password.

1 If not alr ea d y sel e ct ed, pre ss

2 Press

"Information & Configuration",

"Switch to Special is t M ode "

then

"Securit y Setup"

and log in as administrator.

.

The Security Setup screen appears:

Security parameters

3 Enter the parameters you require in the screen – their significance is described in the table

below:

– Administrator rights allow access to all Fieldgate setup parameters.

– Maintenance rights allow access to all Fieldgate setup parameters except security

– Executive rights allow access for viewing parameters only.

A full description of roles and rights is to be found in Table 6-1 in Section 6.1.

4 Press

Parameter Description

User Name

New Password

Retype New

Password

"Send"

to download the security parameters to the Fieldgate.

Fixed by default: admin, exec or maint respectively

Enter your new password here.

Enter your new password again to confirm the change.

Table 6-5: Significance of Security Setup parameters

34 Endress+Hauser

Page 37

Fieldgate FXA720 6 Configuring the Web Server

6.5 Network setup

The

"Network Setup"

network related parameters as well as addresses for e-mails and SMS messages (in preparation).

function contains the parameters for setting up Ethernet, SMTP and other

Procedure

1 If not already selected, press

2 Press

"Informatio n & Confi gurati on" ,

"Switch to Specialist Mode"

then

"Network Setup"

and log in as administrator.

.

The Network Setup screens appear:

6.5.1 Ethernet

1 The Ethernet screen allows you to configure the Ethernet connections of the Fieldgate.

2 Enter your settings and confirm with "

Caution

• Each IP address may only occur once in a network! You can get an IP address from your

Internet provider or your system administrator.

• If you change the IP address in this screen:

– Close the connection (it may break off automatically)

– Use the new address in your browser to call up the Fieldgate.

– If appropriate, enter the new IP address in the PROFIBUS driver of any host application,

see Chapter 5.3.

Send

".

Network parame te rs

Parameter Description

Fieldgate

Hostname

IP Address

Subnet Mask

Gateway

Enter a host name for the Fieldgate. This is a symbolic name (string) that can be more easily

memorized than an IP address.

Enter the IP address of the Fieldgate here (factory setting is 192.168.253.1). You can get this

address from your system administrator.

Enter the IP address of the netmask.

If appropriate, enter the address of the gateway connecting the LAN to the worldwide web via

firewall/router

Table 6-6: Ethernet network parameters

Endress+Hauser 35

Page 38

6 Configuring the Web Server Fieldgate FXA720

6.5.2 E-mail

Procedure

E-mail param et ers

1 Scroll down to reveal the e-mail settings page.

– Enter your settings and confirm with "

Send

".

2 After the parameters downloaded to the Fieldgate a test e-mail is sent to the address defined

– Depending on the STMP server, this may take several hours to arrive

Parameter Description

SMTP Gateway

SMTP User Name

If appropriate, enter the IP address of your e-mail server here.

If authentication is required for the specified SMTP Gateway, enter the user name here

– Leave blank if no authentication is requested or no SMTP Gateway is used

SMTP Password

Sender Address

Alarms E-Mail

Address

Alarm on PV

Limits

Events E-Mail

Address

Login as

Administrator

Device

Connection/

Disconnection

Fieldgate Res tart

If authentication is required for the specified SMTP Gateway, enter the password here

– Leave blank if no authentication is requested or no SMTP Gateway is used

Enter the sender address of the Fieldgate here, e.g. fieldgate@company.co.uk. This address

appears in the sender field. Depending on the mail server used, this field can have any name or

must correspond to a valid account. Ask your system administrator.

– With some providers, the e-mail address of the account holder must be specified as the sender

address. No mails will be accepted from other sender addresses.

Enter the recipient of the alarm mails here, e.g. name@company.co.uk.

– Alarm notifications are sent in accordance with the settings made in the "E-Mail on Alarm"

column of the device details page, see Chapter 6.4.

– If the Fieldgate is restarted when alarm violations are present, e-mails will be resent, although

the an alarm notification has already been sent.

Tick this box if you want an alarm e-mail to be sent when the range limits you specified in the

device "Description" are exceeded, see Chapter 6.4

Enter the recipient of the event mails here, e.g. name@company.co.uk.

– Event notifications are sent in accordance with the settings of the parameters below

Tick this box if an event notification is to be sent everytime someone attempts to log on as

administrator

Tick this box if an event notification is to be sent everytime a sensor is connected to or

disconnected from the network attached to the Fieldgate Web Server

– The measured value last determined is sent a separate event notification.

– Two other event notifications are sent as soon as contact is re-established, one to confirm the

connection and the other with the current measured value.

Tick this box if an event notification is to be sent everytime the Fieldgate is restarted

Table 6-7: E-mail parameters

36 Endress+Hauser

Page 39

Fieldgate FXA720 6 Configuring the Web Server

6.5.3 Time server

With the aid of a time server, the Fieldgate automatically synchronises its time with the time of the

configured server, if present in the LAN. An Internet connection or a time server in the local

network is required for this. If you have any questions, please contact your system administrator.

Procedure

Time se rve r param ete rs

1 Scroll down to reveal the time server settings page.

– Enter your settings and and confirm with "

Send

".

2 A manual time setting must come effective within about 10 seconds

– If this is not the case, stop PROFIBUS scanning (Section 6.3.2) and re-enter the time.

Parameter Description

Time Server

Protocol

Enter the IP address of the time server here. You can find information on public NTP servers

under:

– "http://www.eecis.udel.edu/~mills/ntp/servers.htm" or

– "http://www.google.de/search?q=public+ntp+servers"

Set the protocol used by the time server here:

– SNTP: (Standard port: 123)

– MAN: Manual time setting.... timing is restarted with settings entered in "Set time"

The time server operator can tell you the protocol the server uses.

Periodic Fetch

Time Zone

Date/Time format

Set Time (Manual)

Enter the time interval after which the internal clock is to be resynchronised with the time server

If appropriate, enter an offset from UTC time here

Select the date and time format to be used in the Web pages from the drop-down menu

If no time server is available in the LAN (Protocol = MAN), set the time manually here.

– Format: dd.mm.yyyy hh:mi:ss

– If the Fieldgate is switched off, the manually set time is lost.

Table 6-8: Time server parameters

Endress+Hauser 37

Page 40

6 Configuring the Web Server Fieldgate FXA720

Procedure

6.6

The

Fieldgate channels used by the web server.

Note!

• Where Fieldgate FXA720 is used in pass-through mode, the bus settings are made in the

PROFIBUS setup

"PROFIBUS Setup"

PROFIBUS OPC server (ControlCare P View) or the CommDTM PROFIdtmDPV1 (FieldCare).

function allows the user to set up communication and scanning on the

6.6.1 Communication settings

1 If not alr ea d y sel e ct ed, pre ss

main te nan ce en gi ne er.

2 Press

"Information & Configuration"

The following screen appears (the number of channels depends on the Fieldgate):

"Switch to Special is t M ode "

then

"PROFIBUS Setup"

and log in as administrator or

3 Set up each channel by entering or ticking the parameters, see Table 6-9.

– The settings depend on the coupler or link in use, see the associated documentation.

– Press

"Send"

to download the parameters to the Fieldgate.

38 Endress+Hauser

Page 41

Fieldgate FXA720 6 Configuring the Web Server

Communication

parameters

Parameter Description

Master Class

Channel ID

Station Address

Highest Station

Address

Bus Settings

Baudrate

Communication Settings

Slot Time

Min. Station Delay

Response Time

Fieldgate master class = Type 2

Channel identification (user parameter, not required by PROFIBUS application)

Fieldgate PROFIBUS DP address (Master Class 2), 0 – 126, default values are 3, 4 and 5.

If two or more channels are connected to the same network, enter different addresses.

Determines the address range to be scanned for token passing.

• Enter highest PROFIBUS master address to be found on the network connected to the channel.

• If two channels or more channels are connected to the same network, then all connected

masters must be considered.

Can be set sepa rately for each channel - the other com munication par ameters change to the

factory def aults for the selected baudrat e if the "Set factor y default" box is checked

For more information on individual settings see Appendix 12.3

All the PROFIBUS DP devices, including couplers and links, connected to a particular

channel must have the same comm uni cat ion sett ings

Monitoring time – 'Wait for receipt' – of the senders (Requestor) of telegram for the

acknowledgement of the recipient (Responder). After expiration, a retry occurs in accordance

with the value of 'Max. telegram retries'.

Shortest time period that must elapse before a remote recipient (Responder) may send an

acknowledgement of a received query telegram.

The shortest time period between receipt of the last Bit of a tele gram to the sending of the f irst Bit

of a following telegram.

.

Max. Station Delay

Response Time

Quiet Time

Setup Time

Token Rotation

Time

Gap Update fact or

Max Retries Limit

Repeat Channel 1

settings..

Use Default

Communication

Settings for

Selected Baud rate

Longest time period that must elapse before a Sender (Requestor) may send a further query

telegram.

Greatest time period between receipt of the last Bit of a telegram to the sending of the first Bit of

a following telegram.

The Sender (Requestor, Master) must wait at least for this time period after the sending of an

unacknowledged telegram (e.g. Broadcast only) before a new telegram is sent.

Time delay that occurs for modulators (Modulator-trip time) and Repeaters (Repeater-switch

time) for the change over from sending to receiving.

Minimum period "reaction time" between the receipt of an acknowledgement to the sending of a

new query telegram (Reaction) by the Sender (Requestor).

Pre-set nominal Token cycling time within which the Sender authorization (Token) will cycle

around the ring. How much time the Master still has available for sending data telegrams to the

Slaves is dependent on the difference between the nominal and the actual token cycling time.

Factor for determining after how many Token cycles an added participant is accepted into the

Token ring. After expiry of the time period G*TTR, the Station searches to see whether a further

participant wishes to be accepted into the logical ring.

Number of times the Fieldgate will try to establish communication with a device before it flags it

as faulty

A tick causes the channel 1 settings to be loaded into the other channels

A tick causes the factory default settings for the selected baudrate to be loaded

If the box is not ticked, the values entered in the appropriate fields are used

Table 6-9: PROFIBUS communication parameters

Endress+Hauser 39

Page 42

6 Configuring the Web Server Fieldgate FXA720

Procedure

Scan parameters

6.6.2

Scan settings

1 Now set the scan parameters. For a description see Table 6-10 below:

2 Press

Parameter Description

Scan Cycle Time

Scan for New

Devices

Automatic Live

List Update every

"Send"

to download the parameters to the Fieldgate.

Interval at which the devices on the channel are to be scanned.

• Select a scan time from the drop-down menu for all channels that are being used by the

Internet browser (Web server)

• Check that the setting is "off" (default) for all channels where an OPC client or configuration

tool is using Fieldgate as a pass-through interface.

Tick this box to cause the Fieldgate to scan for new devices when "

Interval at which aa new live list is read

• Select a scan time from the drop-down menu for all channels that are being used by the

Internet browser (Web server

Send

" is pressed.

Procedure

Table 6-10: Scan setup parameters

6.6.3 Live list

1 Select

2 Fieldgate scans each channel used by the web server and displays a list of all the devices found

Note!

• Fieldgate cannot reproduce the live lists of channels that are being used in pass-through mode

(Scan Cycle Time = off). No devices are shown for these channels.

"Live List"

in the navigation bar.

in the network attached to it

– All active addresses are listed.

– Fieldgate and other masters on the bus can be distinguished by the N.A. entries

40 Endress +Hauser

Page 43

Fieldgate FXA720 6 Configuring the Web Server

6.7 Overview of selected devices

In Specialist Mode, the

parameters that are to be displayed in the device overview and to set alarms and e-mail responses.

1 If not already selected, press

maintenance engineer.

2 By default, the

3 Click on the

– Setup each device function block according to the descriptions in Table 6-6.

– After the parameters have been set up for each device, press

"Live List"

"Live List"

Device Tag

function allows the user to select the devices and device

"Switch to Specialist Mode"

automatically appears:

(in column Address/Device Tag) to reveal the details of the device.

and log in as administrator or

"Send"

to do wnl o ad th em .

4 Now click the

Overview page.

5 Return to the

channel.

Device T ag

"Live List"

(in header, top left) to view the selection you have made in the

and repeat the procedure for every device function block and every

Endress+Hauser 41

Page 44

6 Configuring the Web Server Fieldgate FXA720

6.7.1 Device detail parameters

Parameter Description

Show in Overview

Point Name

Current Value and

Status

Limit Status

Limit

Checking this box causes the parameters in the associated line to be shown in the overview of

devices

Read only parameter from device showing Block name and Measuring Tag (if configured)

– These parameters are read from the device and cannot be changed from the web server

Read only parameter showing the current measured value and status of the measuring point

– OK: device is operating correctly

– UNCERTAIN: device is operating, but the status of the output value is uncertain, e.g. because

a limit value within the device has been violated

– BAD: the device has detected a fault, e.g. sensor failure

(based on PA Profile 3.0, Chapter 3.11.4)

Read only value showing whether the associated value is within the alarm limits set in the web

server for this parameter:

– OK: within alarm limits

– HH: High high alarm, the measured value is above the high high limit

– H: High alarm, the measured value is above the high limit but below the high high limit

– L: Low alarm, the measured value is below the low limit but above the low low limit

– LL: Low low alarm, the measured value is below the low low limit

– EDIT!: The limits set in the Web server and the range in the parameter description are not

consistant.

Note: The limit status applies to the limit values set in the web server. It has nothing to do with

any limits set within the device itself

Allows four limits to be set in the web server on the parameter concerned:

– HH: High high limit, an alarm is set when measured value moves above the high high limit

– H: High limit, an alarm is set when the measured value moves above the high limit

– L: Low alarm, an alarm is set when the measured value moves below the low limit

– LL: Low low alarm, an alarm is set when the measured value moves below the low low limit

The status is flagged in the Limit Status column. If no value is entered, the limit is disabled.

Note: These limits are applied by the Fieldgate to the value it reads from the connected device.

These limits have nothing to do with those that can be set within the device itself

Hysteresis

E-mail on alarm

Description

Allows a hysteresis band in percent of set range to be set below HH and H limits and above L and

LL limits. When a measured value violates a limit, an alarm is im mediately set. When it returns to

within limits, the alarm is reset only when the value leaves the hysteresis band.

Allows the response to an alarm event to be set. Check the options as appropriate:

– SET: when checked will cause an e-mail to be sent on violation of a limit

– RST: when checked will cause an e-mail to be sent when the value returns to normal

The e-mail set up is described in Section 6.6.2, the alarm status table in Table 6-7.

Allows two lines of text and the set range of the device to be entered. This text is displayed in the

device overview

Table 6-11: Device detail parameters for overview

6.7.2 E-mail on alarm

Table 6-12 blelow shows the alarm status settings for the function "E-mail on alarm"

to LL to L to OK to H to HH

from LL

from L

from OK

fromH

from HH

– RST RST SET S ET

SET – RS T SET S ET

SET S ET – SET S ET

SET S ET RST – SET

SET SET RS T R ST –

Table 6-12: Alarm status table for e-mail messaging

42 Endress +Hauser

Page 45

Fieldgate FXA720 6 Configuring the Web Server

6.7.3 Expert mode for Slot/Index configuration

Note

• This function should be used only by PROFIBUS experts possessing the necessary knowledge

about profile versions, slot/index tables and PROFIBUS data types. Concrete information on

these topics can be found in the operating instructions of the field devices concerned

In Specialist Mode, a click on the "Device Details" switches over to the configuration page for slot/

index entries.

Depending upon requirement, this page allows the value, status and, if necessary, the engineering

units of parameters other than those offered by default to be read from the function block and

displayed in the Web browser.

Endress+Hauser 43

Page 46

7 Viewing Information (User Mode) Fieldgate FXA720

7 Viewing Informati on (Us er Mode)

The information provided by the the devices and Fieldgate is viewed in User Mode.

7.1 Logging on

Procedure

1. Enter the Fieldgate IP address your web browser: after connection has been made,

you will be asked to log on

2. Enter your password in the "Password" field (default password = superb)

3. The Fieldgate home page is now shown with the "

Overvie w of Sel e cte d Devi ce s

":

44 Endress+Hauser

Page 47

Fieldgate FXA720 7 Viewing Information (User Mode)

7.2 Live list

The live list provides information on all devices connected to the Fieldgate sorted according to

channel.

Note!

• The Live List identifies all active participants on the bus.

• The scan functions for PROFIBUS Profile 3.0 devices, since these can be uniquely identified.

• Dependi ng u p on th e d e vi c e, Pr o fil e 2. 0 o r ear l ier ma y wo r k co r r e ct l y, bu t no g uar a nt ee can b e

given .

Procedure

Live list parameters

1 Press

"Live List"

– All active addresses are listed.

– Fieldgate and other masters on the bus can be distinguished by the N.A. entries

– The significance of the parameters is described in the table below.

1 By clicking the mouse over the

"Address"

link you can change from the Live List to the

Overview.

2 By clicking the mouse over the

"Device Tag"

link you can change from the Live List to the

Device Details.

Parameter Description

Show in Overview

Address/

Device Tag

Devices checked in this column will appear in the Overview

PROFIBUS address and tag number or name of the device

These also link to the Overview and Device Detail pages respectively

Device Type

Status

Manufacturer

Serial #

SW Rev #

HW Rev #

Profile

Name or model type designation of the device

Profibus device status: OK, UNC (Uncertain), BAD

Name of the manufacturer of the device

Device serial number

Revision number of the device firmware

Revision number of the device hardware

PROFIBUS Profile version, e.g. Profile 2, Profile 3 etc.

Table 7-1: Parameters in Live List view page

Endress+Hauser 45

Page 48

7 Viewing Information (User Mode) Fieldgate FXA720

7.3 Overview of selected devices

The

"Overvie w of Sel ec ted Devi ce s"

parameters he has selected. This is the standard view when connection is made to the Fieldgate.

function allows the user to view the devices and

Parameters

1 Press

"Overview".

The significance of the parameters is in described in the table below.

Parameter Description

Address/

Device Tag

Device Type

Manufacturer

Device Status

Point Name

PROFIBUS address and tag number or name of the device

The Device Tag also toggles between the Overview and Device Detail pages

Name or model type designation of the device

Name of the manufacturer of the device

Device status, general status

The name of the parameter that is being monitored at the assocation address

Current value

Limit

Description

The current value of the parameter with parameter status and time stamp

The status of the limit values set in the Fieldgate for the parameter with time when last status

change occured:

– OK: within alarm limits

– HH: High high alarm, the measured value is above the high high limit

– H: High alarm, the measured value is above the high limit but below the high high limit

– L: Low alarm, the measured value is below the low limit but above the low low limit

– LL: Low low alarm, the measured value is below the low low limit