Page 1

TI00396F/00/EN/16.15

FDU92

FDU93

FDU95

FDU91

FDU90

FDU91F

71308097

Products Solutions Services

Technical Information

Prosonic S

FDU90/91/91F/92/93/95

Ultrasonic measurement

Time-of-Flight

Ultrasonic sensors for level and flow measurement for connection to FMU9x

Field of application

• Continuous, non-contact level measurement of fluids and

bulk material in silos, on belts, stockpiles and in crushers

• Flow measurement in open channels and at weirs

• Maximum measuring range

– FDU90: 3 m (9.8 ft) in fluids

1.2 m (3.9 ft) in bulk materials

– FDU91/FDU91F: 10 m (33 ft) in fluids

5 m (16 ft) in bulk materials

– FDU92: 20 m (66 ft) in fluids

10 m (33 ft) in bulk materials

– FDU93: 25 m (82 ft) in fluids

15 m (49 ft) in bulk materials

– FDU95: 45 m (148 ft) in bulk materials

• International explosion protection certificates

Benefits

• Integrated temperature sensor for Time-of-Flight correction.

Accurate measurements are possible, even if temperature

changes are present

• Hermetically welded PVDF sensors FDU91/92 for highest

chemical resistance

• Suited for rough ambient conditions thanks to separate

installation from the transmitter (up to 300 m (984 ft))

• Reduced build-up formation because of the self-cleaning

effect

• Weather resistant and flood-proof (IP68)

• Dust-Ex and Gas-Ex certificates available

Page 2

Table of Contents

Prosonic S FDU90/91/91F/92/93/95

Safety symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Function and system design . . . . . . . . . . . . . . . . . . . . . .3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Time-of-flight correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Blocking distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Signal transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sensor heater (for FDU91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connection hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Extension cables for the sensors . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shortening the sensor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation options (Examples) . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation conditions for level measurements . . . . . . . . . . . . 11

Installation conditions for flow measurements . . . . . . . . . . . . 12

Flush mounting with slip-on flange FAU80 . . . . . . . . . . . . . . 13

Nozzle installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ultrasound guide pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Certificates and Approvals. . . . . . . . . . . . . . . . . . . . . . 21

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

External standards and directives . . . . . . . . . . . . . . . . . . . . . . . 21

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Extension cable for sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Protective cover for FDU90 and FDU91 . . . . . . . . . . . . . . . . . . 23

Screw in flange FAX50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Flooding protection tube for FDU90 . . . . . . . . . . . . . . . . . . . . . 25

Cantilever with mounting frame or wall bracket . . . . . . . . . . . 26

Mounting bracket for ceiling mounting . . . . . . . . . . . . . . . . . . 28

Alignment unit FAU40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power supply RNB130 for the FDU90/FDU91 sensor heater 30

IP66 protective housing for the power supply RNB130 . . . . . 30

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operating instructions (for transmitter FMU90) . . . . . . . . . . 30

Description of Instrument Functions (for transmitter FMU90) .

31

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Explosion hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Process temperature, Process pressure . . . . . . . . . . . . . . . . . . . 16

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 17

Counter nut G 1" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions FDU90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions FDU91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions FDU91F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions FDU92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions FDU93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions FDU95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 Endress+Hauser

Page 3

Prosonic S FDU90/91/91F/92/93/95

DANGER

WARNING

CAUTION

NOTICE

100%

0%

D

L

F

E

BD

V

Q

D

1

2

2

1

Safety symbols

Symbol Meaning

A0011189-DE

A0011190-DE

A0011191-DE

A0011192-DE

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result

in personal injury.

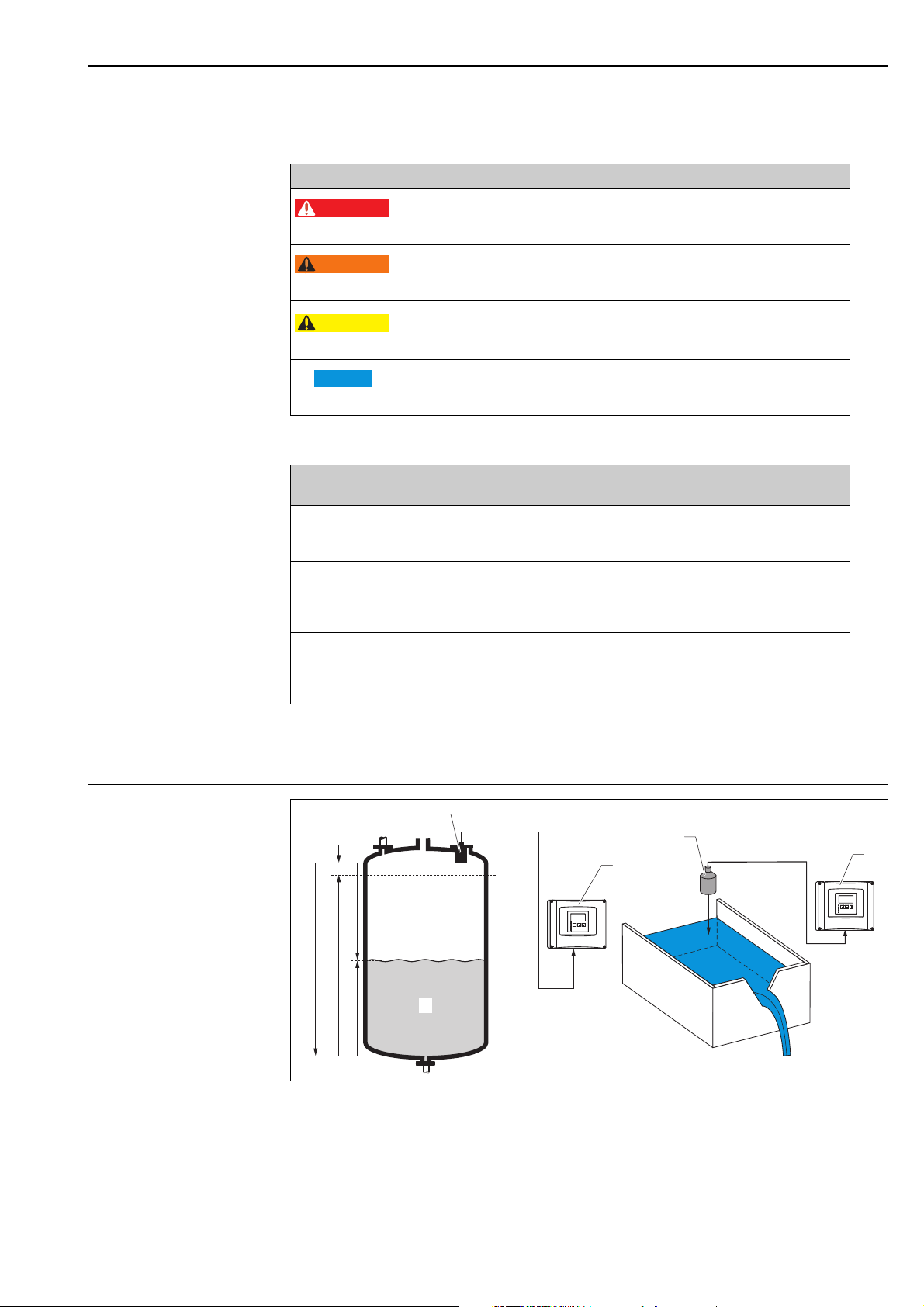

Measuring principle

Explosion

protection

0

-

.

Meaning

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an

explosion hazardous area

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in

and wiring entering areas with the designation “explosion hazardous areas” must

conform with the stated type of protection.

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas.

Devices located in safe areas still require a certificate if their outputs run into

explosion hazardous areas

Function and system design

1FDU9x

2Prosonic S FMU90

BD: blocking distance, D: distance from sensor membrane to fluid surface, E: empty distance F: span (full distance),

L: level, V: volume (or mass), Q: flow

Endress+Hauser 3

L00-FMU90xxx-15-00-08-xx-900

Page 4

Prosonic S FDU90/91/91F/92/93/95

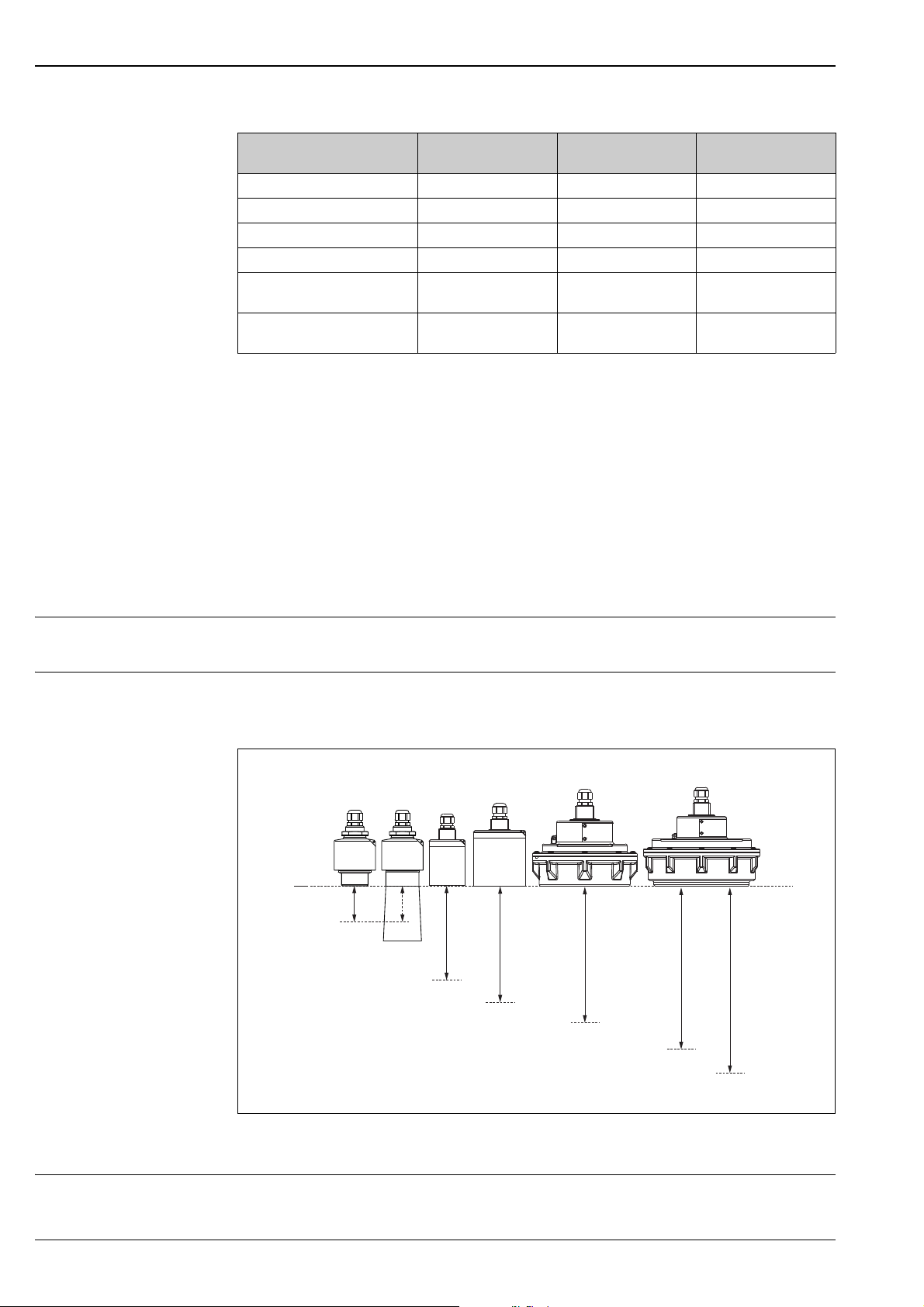

FDU91

FDU92

FDU90

0.07

(0.23)

0.3 (1.0)

0.4 (1.3)

FDU93

0.6 (2.0)

AB

FDU95

FDU95-#2###: 0.9 (3.0)

FDU95-#1###: 0.7 (2.3)

C

m (ft)

Sensor BD Maximum range

fluids

FDU90 0.07 (0.2) 3 (9.8) 1.2 (3.9)

FDU91 (F) 0.3 (1.0) 10 (33) 5 (16)

FDU92 0.4 (1.3) 20 (66) 10 (33)

FDU93 0.6 (2.0) 25 (82) 15 (49)

FDU95 (low temperature

version)

FDU95 (high temperature

version)

m (ft)

0.7 (2.3) − 45 (148)

0.9 − 45 (148)

Maximum range

bulk materials

Time-of-flight method

The sensor transmits ultrasonic pulses in the direction of the product surface. There, they are reflected

back and received by the sensor. The transmitter Prosonic S measures the time t between pulse

transmission and reception. From t (and the velocity of sound c) it calculates the distance D from the

reference point (see the figure → ä 4) to the product surface:

D = c · t/2

From D results the desired measuring value:

• Level L

•Volume V

• Flow Q across measuring weirs or open channels

Time-of-flight correction In order to compensate for temperature dependent time-of-flight changes, a temperature sensor

(NTC) is integrated in the ultrasonic sensors.

Blocking distance The level L may not extend into the blocking distance BD. Level echoes within the blocking distance

can not be evaluated due to the transient characteristics of the sensor and thus a reliable measurement

is not possible. The blocking distance BD is dependent on the type of sensor:

A: Without flooding protection tube, B: With flooding protection tube, C: Reference point of the sensor

L00-FDU9xxxx-05-00-00-xx-002

Transmitter The sensors can be connected to the transmitter FMU90 and FMU95. The transmitter recognizes the

type of sensor automatically.

4 Endress+Hauser

Page 5

Prosonic S FDU90/91/91F/92/93/95

0 20 40 60 80 100

45

25

20

10

0

FDU95

FDU96

FDU93

FDU92

A[dB]

R [m]

FDU90

3

FDU91 F

50

( )

Input

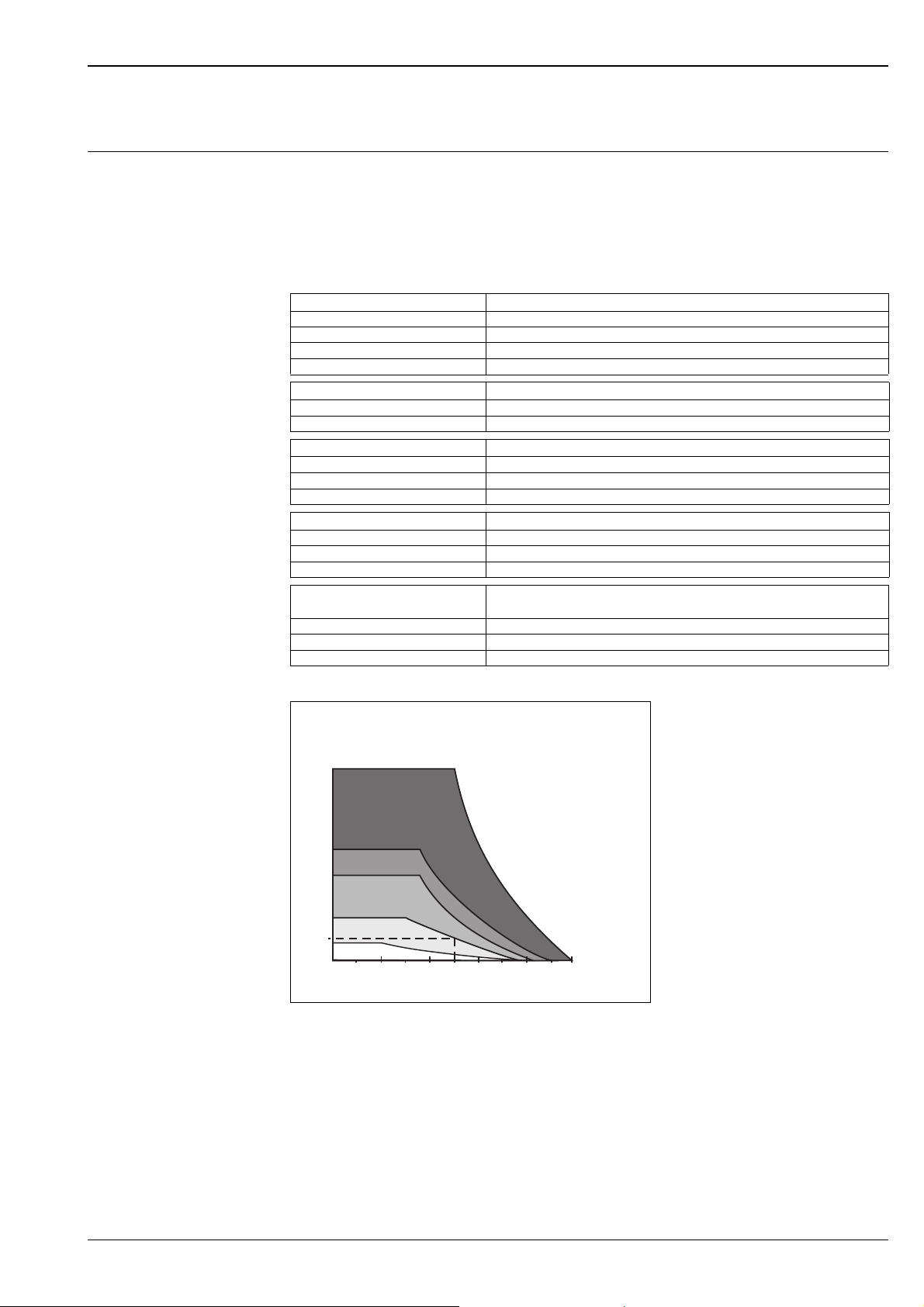

Measuring range The effective range of the sensors is dependent on the operating conditions. To estimate the range,

proceed as follows (see also the example):

1. Determine which of the influences shown in the following table are appropriate for your process.

2. Add the corresponding attenuation values.

3. From the total attenuation, use the diagram to calculate the range.

Fluid surface Attenuation

calm 0 dB

waves 5 to 10 dB

strong turbulence (e.g. stirrers) 10 to 20 dB

foaming Please contact your Endress+Hauser sales representative.

Bulk material surface Attenuation

hard, rough (e.g. rubble) 40 dB

soft (e.g. peat, dust-covered clinker) 40 to 60 dB

Dust Attenuation

no dust formation 0 dB

little dust formation 5 dB

heavy dust formation 5 to 20 dB

Filling curtain in detection range Attenuation

none 0 dB

small quantities 5 dB

large quantities 5 to 20 dB

Temperature difference between

sensor and product surface

to 20 °C (68 °F) 0 dB

to 40 °C (104 °F) 5 to 10 dB

to 80 °C (176 °F) 10 to 20 dB

Attenuation

Example for FDU91(F)

• Silo with rubble: ~ 40 dB

• Small quantities of

filling curtain: ~ 5 dB

•Little dust: ~ 5dB

Attenuation total: ~ 50 dB

Range approx. 5 m (16 ft)

L00-FDU9xxxx-05-00-00-xx-100

A: Attenuation (dB)

R: Range (m)

These measuring conditions have been taken into account during the calculation of the maximum

measuring range in solid applications.

Endress+Hauser 5

Page 6

Prosonic S FDU90/91/91F/92/93/95

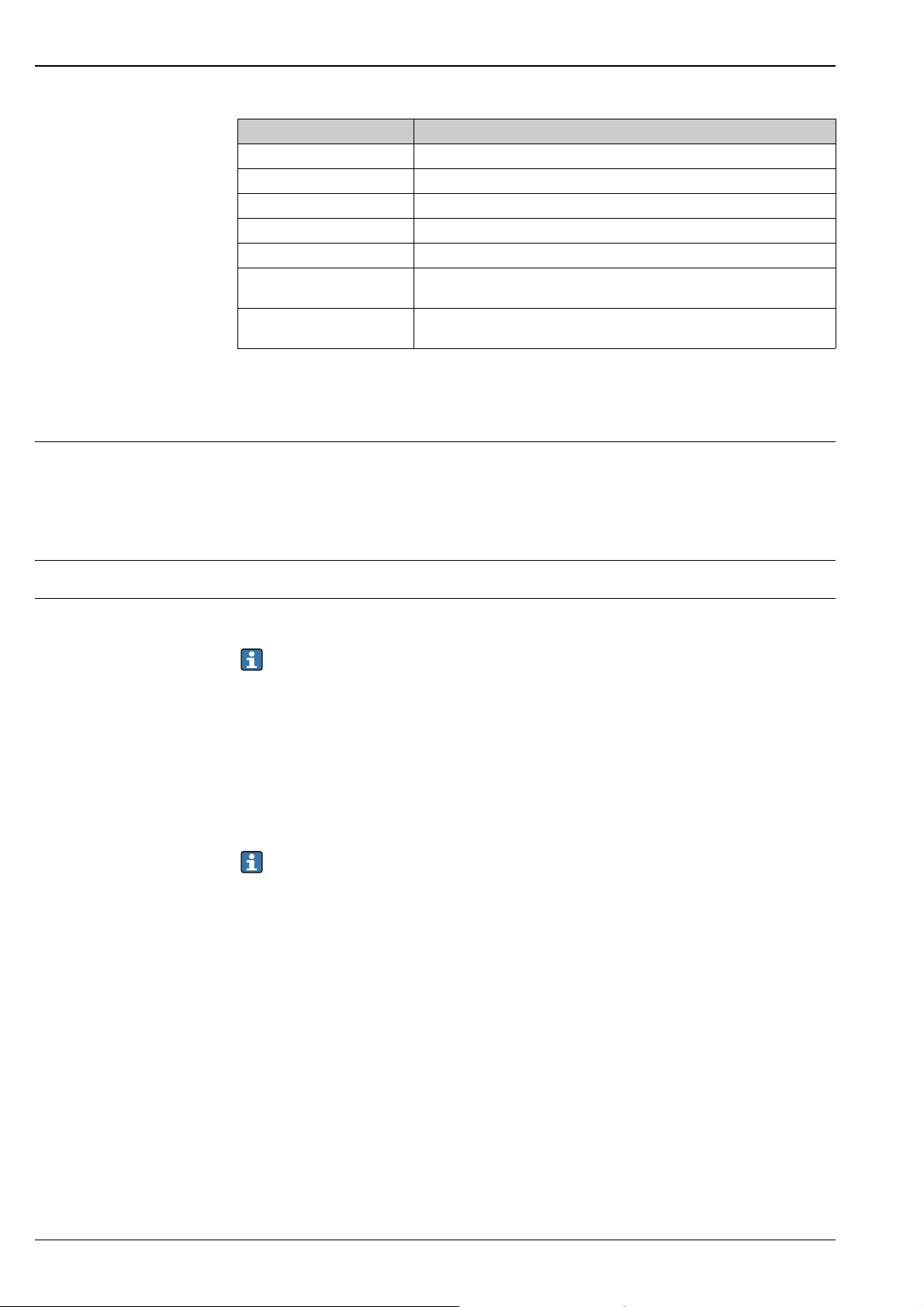

Operating frequency

Sensor Operating frequency

FDU90 90 kHz

FDU91 43 kHz

FDU91F 42 kHz

FDU92 30 kHz

FDU93 27 kHz

FDU95 - *1***

(low temperature version)

FDU95 - *2***

(high temperature version)

Output

Signal transmission analogue voltages

Power supply

17 kHz

18 kHz

Power supply supplied by the transmitter FMU90

Sensor heater (for FDU91) The FDU90 and FDU91 sensors are optionally available in a version with sensor heater.

The sensor heater needs an external power supply.

The power for the heater can be supplied by the power supply RNB130 from Endress+Hauser

(→ ä 30).

The power supply for the sensor heater is connected to the brown (BN) and blue (BU) strand of the

sensor cable.

Technical data

• 24 VDC ±10 %; residual ripple < 100 mV

• 250 mA per sensor

• If the sensor heater is applied, the integrated temperature sensor can not be used. Instead,

an external temperature sensor (Pt100 or FMT131 from Endress+Hauser) must be used.

• The transmitter FMU90 is available in a version with an input for the external temperature

sensor. For details refer to Technical Information TI00397F.

6 Endress+Hauser

Page 7

Prosonic S FDU90/91/91F/92/93/95

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU90/91/92

BK

YE

RD

1

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU91F/93/95

BK

YE

RD

GNYE

2

3

FMU90

2

3

FMU90

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU90/91

BK

YE

RD

FMU90

BN BU

24 VDC

+

-

A

B

C

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU91F/93/95

BK

YE

RD

GNYE

FMU90

D

300 m

(984 ft)

≤

≤30 m

(98 ft)

1

300 m

(984 ft)

≤

≤30 m

(98 ft)

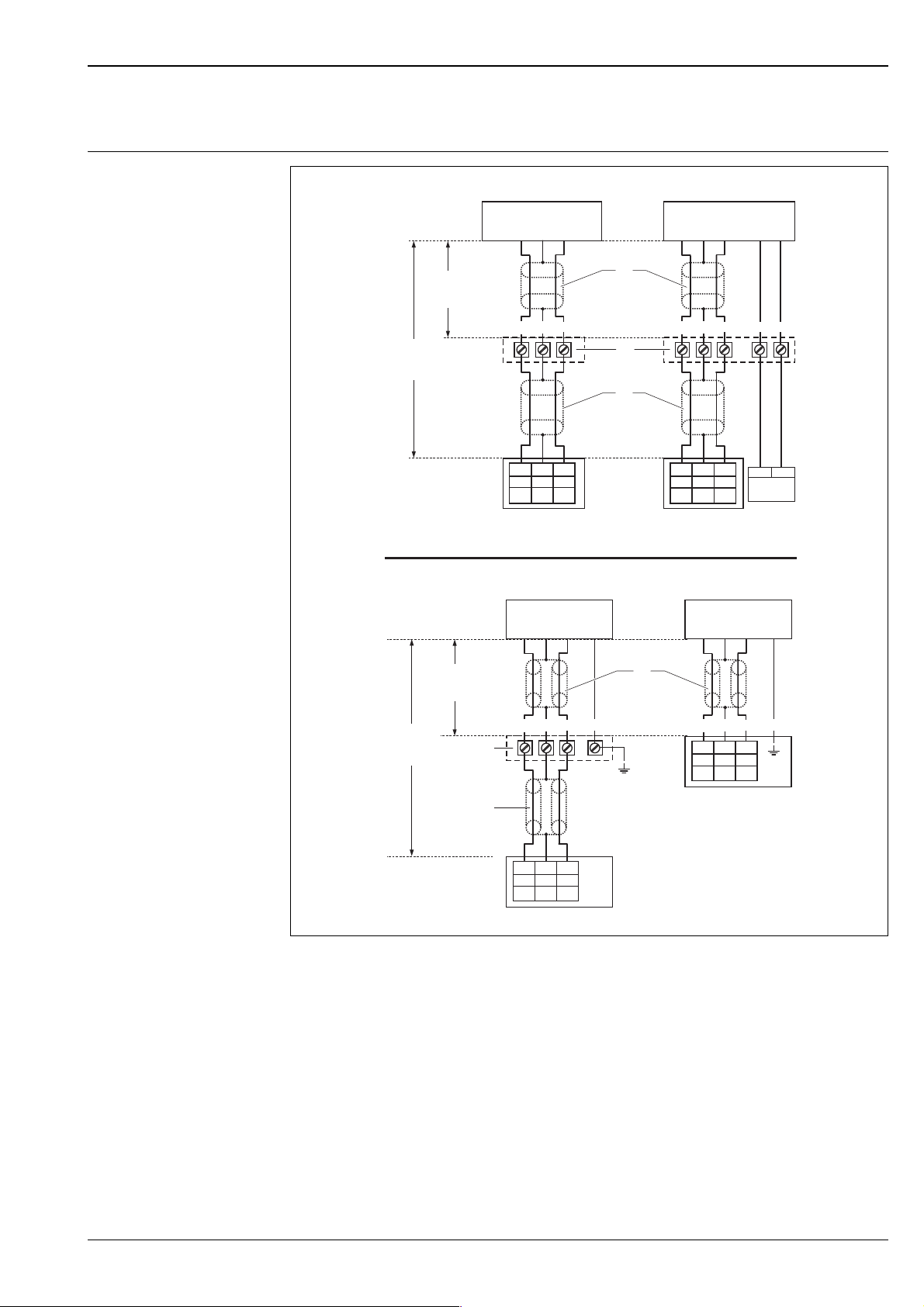

Electrical connection

Connection diagram

A Without sensor heater

B With sensor heater

C Grounding at the terminal box

D Grounding at the transmitter FMU90

1 Shield of the sensor cable

2Terminal box

3 Shield of the extension cable

Colours of the strands: YE = yellow; BK = black; RD = red; BU = blue; BN = brown; GNYE = green-yellow

L00-FDU9xxxx-04-00-00-xx-002

Endress+Hauser 7

Page 8

Prosonic S FDU90/91/91F/92/93/95

WARNING

!

WARNING

!

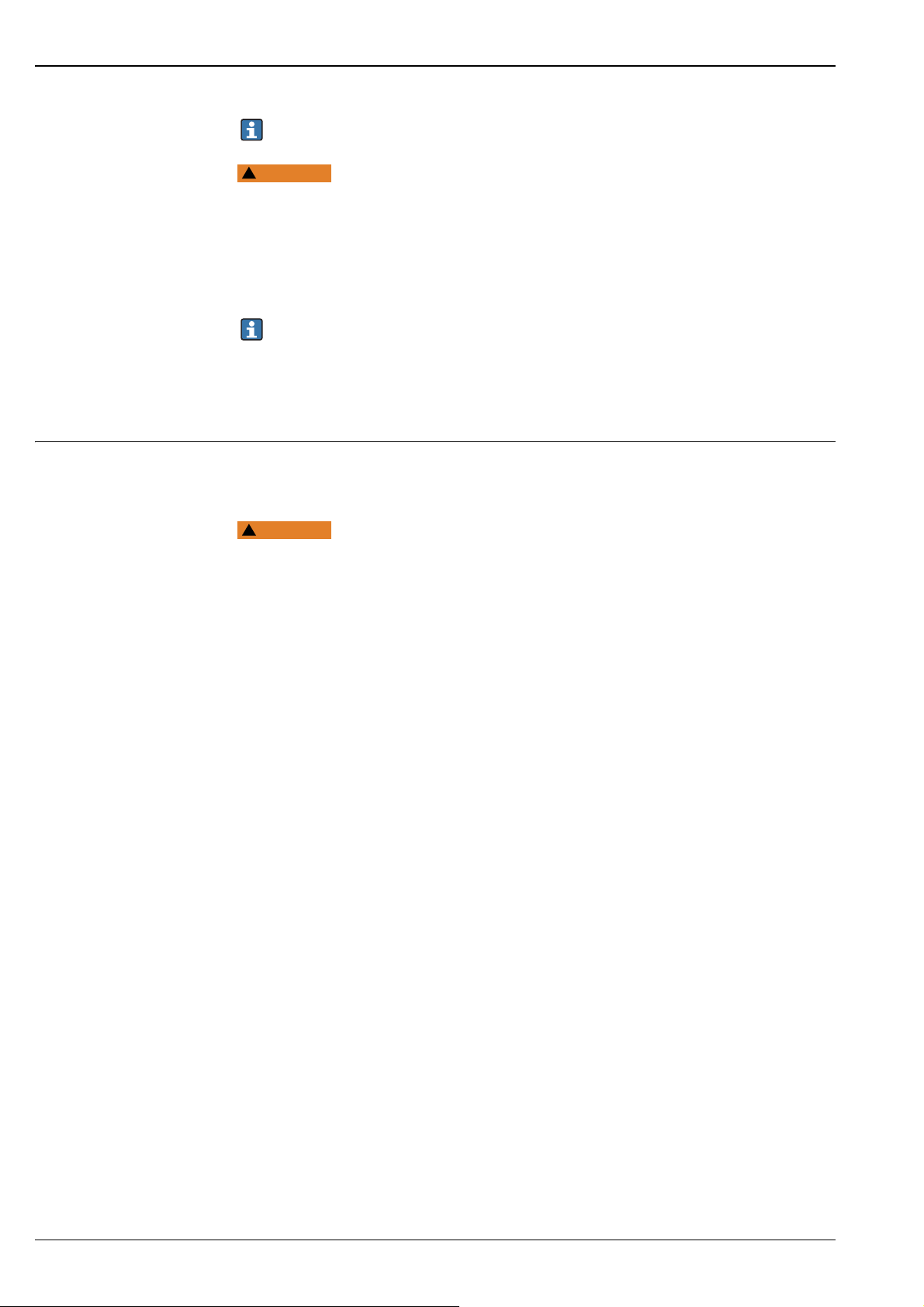

Connection hints

Extension cables for the sensors

In order to avoid interference, do not route the sensor cables parallel to high-voltage or

electric power lines and not close to frequency converters.

Limitation of electrical safety.

‣ The protective conductor (GNYE) of the sensors FDU91F/93/95 must be connected to the local

potential equalization after a maximum distance of 30 m (98 ft).

The protective conductor (GNYE) of the sensors can be connected at this locations:

•Terminal box

• Transmitter FMU90

•Cabinet

The cable shield serves as a return cable and must be connected to the transmitter without

any electrical break. With the preassembled cables, the shield ends in a black strand (BK).

With the extension cable, the shield must be twisted together and connected to the "BK"

terminal. The cable shield must not be connected to the local potential equalization.

For easier mounting it is advisable to use the sensors FDU90/91/92 with a maximum cable length of

30 m (98 ft) as well. For longer distances an extension cable with a terminal box should be used.

For distances up to 30 m (98 ft) the sensor can be directly connected by the sensor cable. For longer

distances, it is recommended to use an extension cable. The extension cable is connected via a terminal

box. The total length (sensor cable + extension cable) may be up to 300 m (984 ft).

Explosion hazard!

In explosion hazardous areas, sparks can cause explosions. This may lead to serious or fatal injury.

Additionally, the device and installation may be seriously damaged.

‣ If the terminal box is installed in explosion hazardous areas, all applicable national guidelines must

be observed.

‣ Pay attention to the measures and notes in Chapter Certificates and Approvals → ä 21.

Suitable extension cables can be obtained from Endress+Hauser (→ ä 23 "Accessories")

Alternatively, cables with the following properties can be used:

• Number of cores according to the connection diagram (→ ä 7 "Connection diagram")

• Braided wire shield for the yellow (YE) and red (RD) core (no foil shield)

• Length: up to 300 m (984 ft), sensor cable + extension cable

• Cross section: 0.75 mm

2

to 2.5 mm2 (18 to 14 AWG)

•Up to 8Ω per core

• Max. 60 nF (between core and shield)

• For FDU91F/93/95: The protective conductor (GNYE) must not be within the shield.

8 Endress+Hauser

Page 9

Prosonic S FDU90/91/91F/92/93/95

FDU90/91/92

FDU91F/93/95

RDBK

YE

RDBKYE

24 VDC

BN (+)

BU (-)

GNYE

BN

BU

RD

YE

GNYE

RD

YE

A

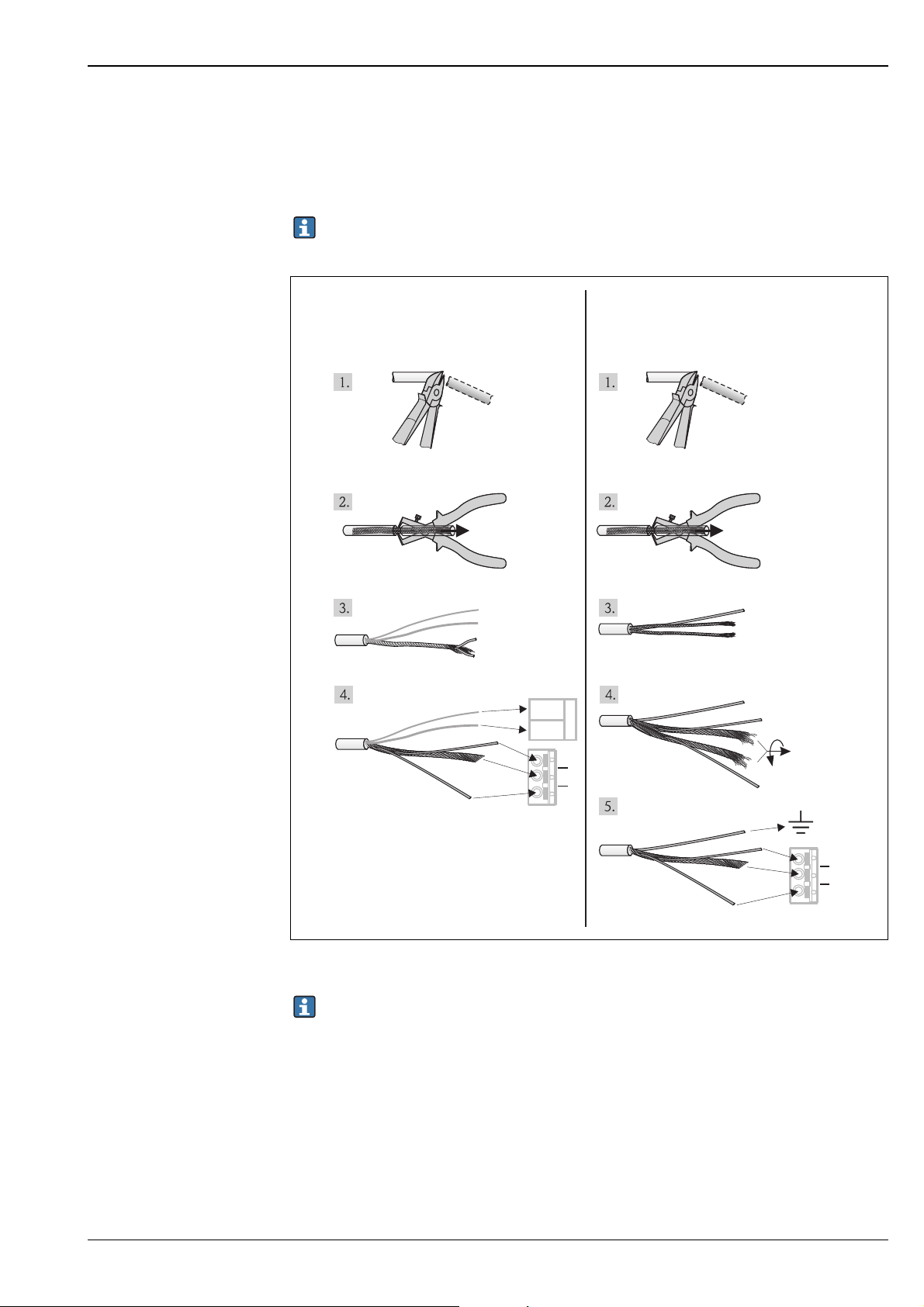

B

Shortening the sensor cable If required, the sensor cable can be shortened. Please note:

• Do not damage the cores when removing the insulation.

• The cable is shielded by a metallic braiding. This shielding serves as a return cable and corresponds

to the black (BK) strand of the unshortened cable. After shortening the cable, loosen the metallic

braiding, twist it together securely and connect it to the "BK" terminal.

The protective conductor (GNYE), which is present in some of the sensor cables, may not be

electrically connected to the cable shield.

L00-FMU90xxx-04-00-00-xx-015

Colours of the strands: YE = yellow; BK = black; RD = red; BU = blue; BN = brown; GNYE = green-yellow

The blue (BU) and brown (BN) strands is only present for sensors with heater.

Endress+Hauser 9

Page 10

WARNING

!

NOTICE

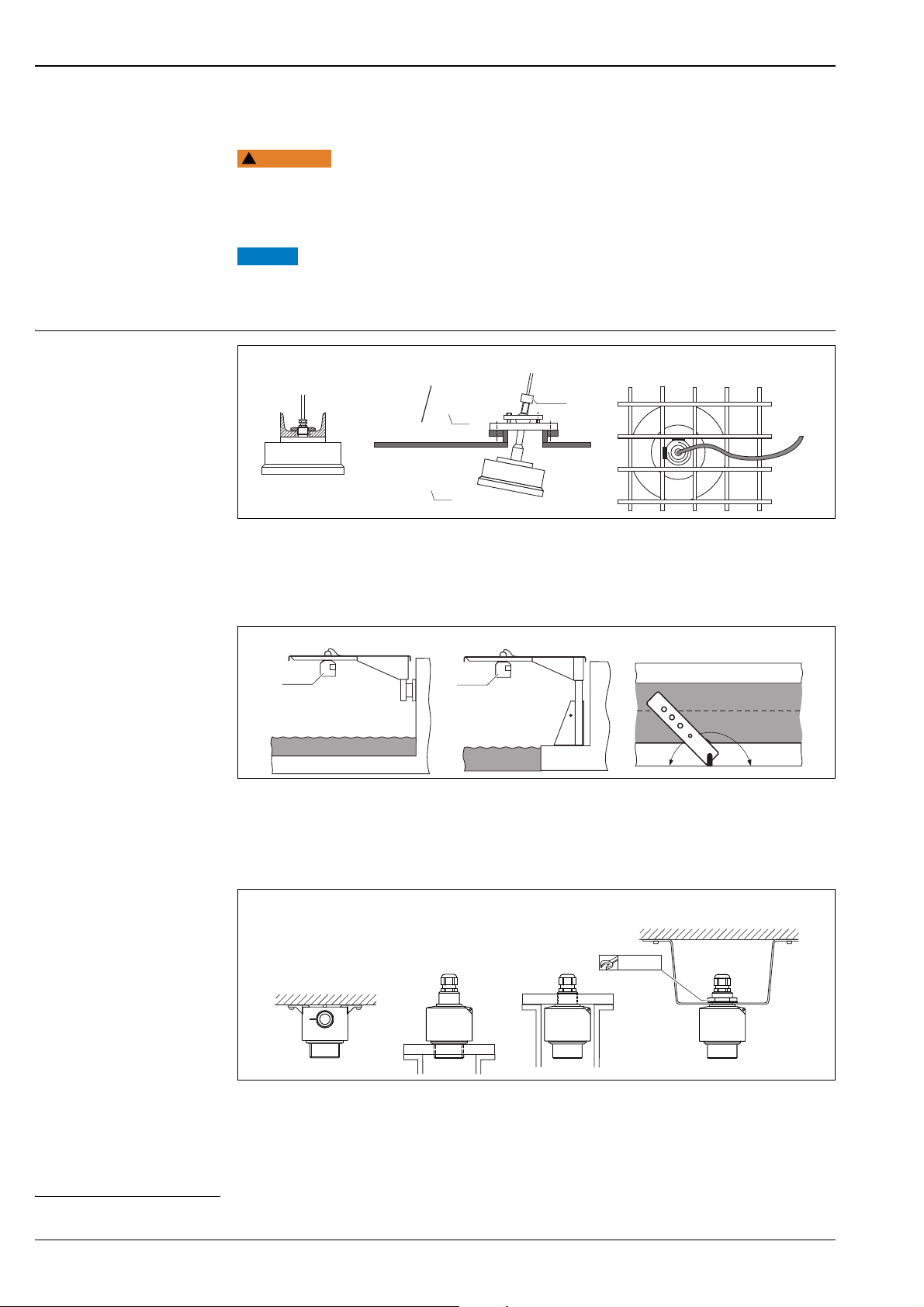

Installation options

ABC

-

-

.

3

2

1

A

B

C

1

1

ABC D

41 mm

(Examples)

Prosonic S FDU90/91/91F/92/93/95

Installation

Hazard of accidents!

If sensors are not fastened properly, they can fall down and cause serious injury and property damage.

‣ Only install sensors in areas that are stable and sufficiently able to take the load.

‣ Fasten sensors only with fastening material that is proper and suited for the environment.

Risk of sensor damage.

‣ Do not use the sensor cable for suspension.

‣ Protect sensor membrane from damage during installation.

L00-FDU9xxxx-17-00-00-xx-001

1FAU40

2Zone 20

3Zone 21

A: at girder or angle bracket, B: with alignment unit FAU40, in ATEX Zone 20 the alignment unit can be used for zone separation,

C: with a 1" sleeve welded to a grating

L00-FDU9xxxx-17-00-00-xx-007

1FDU9x

A: Installation with cantilever and wall bracket, B: Installation with cantilever and mounting frame, C: The cantilever can be turned

in order to position the sensor over the centre of the flume.

Cantilever, wall bracket and mounting frame are available as accessories (

→ ä

23).

L00-FDU90xxxx-17-00-00-xx-001

A: FDU90: Ceiling mounting

B: FDU90: Mounted at front thread (G 1½" or NPT 1½" )

C: FDU9x: Mounted at rear thread (G 1" or NPT 1")

D: FDU90, FDU91, FDU92: Mounting with G 1" counter nut

1)

1) The counter nut with gasket is supplied for the sensors FDU90, FDU91 and FDU92 with a metric thread G 1" at the process connection.

10 Endress+Hauser

Page 11

Prosonic S FDU90/91/91F/92/93/95

WARNING

!

1

4

5

1/6D

r

a

L

BD

6

BD

23

D

BD

Installation conditions for level measurements

L00-FDU9xxxx-17-00-00-xx-003

• If possible, install the sensor so that its lower edge projects into the vessel.

• Make sure, that the maximum level does not reach into the blocking distance (BD, see table).

• Do not install the sensor in the middle of the tank (2). We recommend leaving a distance (1)

between the sensor and the tank wall measuring 1/6 of the tank diameter.

• Avoid measurements through the filling curtain (3).

• Make sure that equipment (4) such as limit switches, temperature sensors, baffles etc. are not

located within the emitting angle α. Emitting angles of the individual sensors are given in the table

below. In particular, symmetrical equipment (5) such as heating coils etc. can influence the

measurement.

• Align the sensor vertically to the product surface (6). An alignment unit (FAU40) is available as an

accessory (→ ä 23).

• If the two-channel version of the transmitter FMU90 or the multi-channel version of the transmitter

FMU90 is used, both sensors can be mounted in one vessel.

• To estimate the detection range, use the 3 dB emitting angle α:

Sensor α (typically) L (max) r (max)

FDU90 12° 3 (9.8) 0.31 (1.0)

FDU91 9° 10 (33) 0.79 (2.6)

FDU91F 12° 10 (33) 1.05 (3.4)

FDU92 11° 20 (66) 1.92 (6.3)

FDU93 4° 25 (82) 0.87 (2.9)

FDU95 5° 45 (148) 1.96 (6.4)

m (ft)

Explosion hazard!

In explosion hazardous areas, sparks can cause explosions. This may lead to serious or fatal injury.

Additionally, the device and installation may be seriously damaged.

‣ Pay attention to the measures and notes in Chapter Certificates and Approvals (see → ä 21).

Endress+Hauser 11

Page 12

Prosonic S FDU90/91/91F/92/93/95

1xb

0

b

0

BD

A

E

BC

V

H

max

=F

FDU91

max

min. 3 H

BD

H

max

E

(= F)

Installation conditions for flow measurements

• Install the sensor at the inflow side (B), above the maximum water level H

(=F) plus the

max

blocking distance BD.

• Position the sensor in the middle of the channel or weir.

• Align the sensor vertically to the water surface.

• Comply to the installation distance of the channel or weir.

2)

• Use a protective cover, in order to protect the sensor from direct sun or rain. A protective cover is

available for the sensors FDU90 and FDU91 (→ ä 23).

Example: Khafagi-Venturi flume

L00-FDU9xxxx-17-00-00-xx-004

A: Khafagi-Venturi flume, B: inflow, C: outflow, BD: blocking distance, E: empty calibration, F: full calibration, V: direction of flow

Example: V-notch weir

L00-FDU9xxxx-17-00-00-xx-005

BD: blocking distance, E: empty calibration, F: full calibration

2) The installation distances of important flumes and weirs are specified in the Operating Instructions BA00289F (FMU90 with HART) and

BA00293F (FMU90 with PROFIBUS).

12 Endress+Hauser

Page 13

Prosonic S FDU90/91/91F/92/93/95

0.5

A

A

D

k

ø97.5

d

2

b

ø81

75.7

d

2

k

ø76

D

ø81

ø130

b

15

75.7

1

2

Flush mounting with slip-on flange FAU80

The FDU91F sensor can be flush mounted using a FAU80 slip-on flange. Flanges in polypropylene (PPFR) should only be used with pressures up to 1.5 bar

Order code Material

FAU80 - CAP PP-FR

FAU80 - CAJ 316L (1.4435)

FAU80 - AAP PP-FR

FAU80 - AAJ 316L (1.4435)

FAU80 - KAP PP-FR

FAU80 - KAJ 316L (1.4435)

b

[mm (in)]

20 (0.79) 200 (7.87) 18 (0.71) 160 (6.3) 8

23.9

(0.94)

18 (0.71) 185 (7.28) 19 (0.75) 150 (5.9) 8

øD

[mm (in)]

190.5

(7.5)

(22 psi abs), flanges in 316L also above.

abs

L00-FDU9xxxx-17-00-00-xx-009

ød2

[mm (in)]k [mm (in)]

19.1

(0.75)

152.4

(6.0)

No. d2 Standard

DN80 PN16 A

(DIN EN 1092-1

(DIN2527 B))

ANSI 3" 150 lbs FF

4

(ANSI B 16.5)

JIS 10K 80A FF

(JIS B 2220)

L00-FDU9xxxx-17-00-00-xx-010

The adapter flange and the screws are included in the delivery.

Position Part Material

1Screws V2A

2 Washer PP-FR or 316/316L (1.4435)

Order code Material b [mm] øD [mm] ød2 [mm] k [mm] No. d2 Standard

FAU80 - CHP PP-FR

FAU80 - CHJ 316L (1.4435)

FAU80 AHP

FAU80 - AHJ 316L (1.4435)

FAU80 - KHP PP-FR

FAU80 - KHJ 316L (1.4435)

PP-FR

20 (0.79) 220 (8.66) 18 (0.71) 180 (7.09) 8

23.9

(0.94)

18 (0.71) 210 (8.27) 19 (0.75) 175 (6.89) 8

228.6

(9.0)

19.1

(0.75)

190.5

(7.5)

4

DN100 PN16 A

(DIN EN 1092-1

(DIN2527 B))

ANSI 4" 150 lbs FF

(ANSI B 16.5)

JIS 10K 100A FF

(JIS B 2220)

Endress+Hauser 13

Page 14

Prosonic S FDU90/91/91F/92/93/95

L

D

FDU9x

D

FDU91F

45°

L

L

D

L

D

FDU90

FDU90

45°

45°

45°

•The process seal is not included in the delivery.

• Endress+Hauser supplies DIN/EN flanges made of stainless steel AISI 316L with the

material number 1.4404 or 1.4435. With regard to their temperature stability properties, the

materials 1.4404 and 1.4435 are grouped under 13E0 in EN 1092-1 Tab. 18. The chemical

composition of the two materials can be identical.

•For 3A-applications: The internal diameter of the nozzle should be selected according to the

valid allowable limits for 3A applications. Usually, the internal diameter of the nozzle should

be larger than or equal to the internal diameter of the sensor.

Nozzle installation Install the sensor at a height so that the blocking distance BD is not undershot, even at maximum fill

level. Use a pipe nozzle if you cannot maintain the blocking distance in any other way. The interior of

the nozzle must be smooth and may not contain any edges or welded joints. In particular, there should

be no burr on the inside of the tank side nozzle end. Note the specified limits for nozzle diameter and

length. To minimise disturbing factors, we recommend an angled socket edge (ideally 45°).

L00-FDU9xxxx-17-00-00-xx-006

Maximum nozzle length [mm (in)]

Nozzle diameter FDU90

DN50/2" − 50 (1.97) −−−−−

DN80/3" 340 (13.4) 250 (9.84) 340 (13.4) 250 (9.84)

DN100/4" 390 (15.4) 300 (11.8) 390 (15.4) 300 (11.8)

DN150/6" 400 (15.7) 300 (11.8) 400 (15.7) 300(11.8)

DN200/8" 400 (15.7) 300 (11.8) 400 (15.7) 300(11.8)

DN250/10" 400 (15.7) 300 (11.8) 400 (15.7) 300(11.8)

DN300/12" 400 (15.7) 300 (11.8) 400 (15.7) 300(11.8)

Sensor characteristics

Emission angle α 12° 12° 9° 12° 11° 4° 5°

Blocking distance

[m (ft)]

Max. measuring

range [m (ft))

in liquids

Max. measuring

range [m]

in solids

1)

0.07 (0.2) 0.07 (0.2) 0.3 (1) 0.3 (1) 0.4 (1.3) 0.6 (2) 0.7 (2.3)

3 (9.8) 3 (9.8) 10 (33) 10 (33) 20 (66) 25 (82) −

1.2 (3.9) 1.2 (3.9) 5 (16) 5 (16) 10 (33) 15 (49) 45 (148)

FDU90

2)

FDU91 FDU91F FDU92 FDU93 FDU95

3)

−−−

3

−−−

3

400 (15.7) −−

3

400 (15.7) 520 (20.5) −

3

400 (15.7) 520 (20.5) 630 (24.8)

3

400 (15.7) 520 (20.5) 630 (24.8)

1) mounted at the rear side thread

2) mounted at the front side thread (flush mounting)

14 Endress+Hauser

3) Valid for flush mounting; for mounting with G/NPT 1" and DN100 or higher see FDU91.

Page 15

Prosonic S FDU90/91/91F/92/93/95

1

Ultrasound guide pipe In narrow shafts with strong interference echoes,

we recommend using an ultrasound guide pipe

(e.g. PE or PVC wastewater pipe) with a minimum

diameter of DN80 for FDU90, DN100 for FDU91,

DN200 for FDU92.

Make sure that the pipe is not soiled by

accumulated dirt. If necessary, clean the pipe at

regular intervals

L00-FDU9xxxx-17-00-00-xx-008

1Venting hole

Endress+Hauser 15

Page 16

Prosonic S FDU90/91/91F/92/93/95

Environment

Ingress protection Tested according to IP68/NEMA6P (24 h at 6 ft under water surface)

2)2

Vibration resistance DIN EN 600068-2-64; 20 to 2000 Hz; 1 (m/s

Storage temperature Identical to process temperature, see below

Thermal shock resistance According to DIN EN 60068-2-14; examination to min/max process temperature; 0.5 K/min; 1000 h

/Hz; 3x100 min.

Electromagnetic compatibility

Electromagnetic compatibility according to all relevant requirements of the EN 61326- series and

NAMUR recommendation EMC (NE21). For details see declaration of conformity.

With respect to interference emission the devices meet the requirements of class A and are only

provided for use in an "industrial environment"!

Explosion hazardous area Pay attention to the measures and notes in Chapter Certificates and Approvals → ä 21.

Process

Process temperature, Process pressure

Sensor Process temperature Process pressure (abs.)

FDU90 −40 to +80 °C (−40 to +176 °F)

FDU91 −40 to +80 °C (−40 to +176 °F)

FDU91F

FDU92

FDU93

FDU95 - *1***

(low temperature version)

FDU95 - *2***

(high temperature

version)

-40 to +105 °C (-40 to +221 °F)

(30 min/135 °C (275 °F))

for Ex instruments: -40 to +80 °C (-40 to +176 °F)

−40 to +95 °C (−40 to+203 °F)

for Ex instruments: -40 to +80 °C (-40 to +176 °F)

−40 to +95 °C (−40 to +203 °F)

for Ex instruments: -40 to +80 °C (-40 to +176 °F)

−40 to +80 °C (−40 to +176 °F)

−40 to +150 °C (−40 to +302 °F)

for Dust-Ex versions: −40 to +130 °C

1

1)

2)

0.7 to 4 bar (10.15 to 58 psi)

0.7 to 4 bar (10.15 to 58 psi)

0.7 to 4 bar (10.15 to 58 psi)

0.7 to 4 bar (10.15 to 58 psi)

0.7 to 3 bar (10.15 to

43.5 psi)

0.7 to 1.5 bar (10.15 to

22 psi)

0.7 to 1.5 bar (10.15 to

22 psi)

1) In order to avoid ice build-up, the sensors FDU90 and FDU91 are available in a version with integrated

sensor heater (→ ä 6). If this heater is used, an external temperature sensor has to be applied for time-offlight correction. The transmitter FMU90 is available in a version with an input for the external

temperature sensor. For details refer to Technical Information TI00397F.

2) Only valid for Tri-clamp and flush mounting

16 Endress+Hauser

Page 17

Prosonic S FDU90/91/91F/92/93/95

8 (0.31)

G 1"

1

2 (0.08)

41 mm

2 (0.08)

mm (in)

~109 (4.29)

~28 (1.1)

26 (1.02)

~137 (5.39)

a

ø75 (2.95)

85 (3.35)

58 (2.28)

8 (0.31)

R2.5 (0.1)

89 (3.5)

121 (4.76)

a

86 (3.39)

~28 (1.1)

26 (1.02)

b

FDU90-*G***

FDU90-*N***

FDU90-*W***

AB

A

B

ø75 (2.95)

mm (in)

110 (4.33)

20 (0.79)

ø72 (2.83)

G 1"

NPT 1"

28 (1.1)

26 (1.02)

AB

mm (in)

Mechanical construction

Counter nut G 1"

Dimensions FDU90

• Is supplied for the sensor FDU90, FDU91 and

FDU92 with a metric G 1" thread.

• Material: PA6.6

• Gasket (EPDM) is supplied

Note!

The counter nut is not for NPT thread.

L00-FDU9xxxx-06-00-00-xx-004

1Gasket

L00-FDU90xxxx-06-00-00-xx-004

A: Cable gland for approval versions FDU90-C/D/E/G/H/J/R/U/V/1

B: Conduit connection NPT ½" for approval versions FDU90-Q/S

The conduit connection is partly potted (half-filled)

a: G 1-1½" or NPT 1-1½" (see product structure: 020 "Process connection"

b: G 1" or NPT 1" (see product structure: 020 "Process connection"

→ ä

21)

→ ä

21)

Dimensions FDU91

A: Cable gland for approval versions FDU91-C/D/E/G/H/J/R/U/V/1

B: Conduit connection NPT 1/2" for approval versions FDU91-Q/S

The conduit connection is partly potted (half-filled).

Endress+Hauser 17

L00-FDU91xxx-06-00-00-xx-001

Page 18

Dimensions FDU91F

ø97.5 (3.84)

ø76 (2.99)

~124 (4.88)

ø80 (3.15)

~28

(1.1)

~152 (5.98)

~56 (2.2)

ø

ø106 (FDU91F-#T##)

119 (FDU91F-#S##)

~124 (4.88)

25

(1.0)

3 (0.12)

G 1"

NPT 1"

FDU91F - #F##

FDU91F - #G##

FDU91F - #N##

FDU91F - #S##

FDU91F - #T##

26

(1.0)

AB

AB

AB

ø80 (3.15)

ø80 (3.15)

ø97.5 (3.84)

ø76 (2.99)

26

(1.0)

26

(1.0)

~28

(1.1)

ø76 (2.99)

mm (in)

125 (4.92)

20 (0.79)

ø98 (3.86)

A

B

28

(1.1)

26

(1.02)

G 1"

NPT 1"

mm (in)

145 (5.71)

ø187 (7.36)

A

B

G 1"

NPT 1"

26

(1.0)

28

(1.1)

25 (1.0)

mm (in)

A: Cable gland for approval versions FDU91F-C/D/E/G/H/J/R/U/V

B: Conduit connection NPT 1/2" for approval versions FDU91F-Q/S

The conduit connection is partly potted (half-filled).

Prosonic S FDU90/91/91F/92/93/95

L00-FDU91Fxx-06-00-00-xx-001

Dimensions FDU92

Dimensions FDU93

A: Cable gland for approval versions FDU92-C/D/E/G/H/J/R/U/V/1

B: Conduit connection NPT 1/2" for approval versions FDU92-Q/S

The conduit connection is partly potted (half-filled).

L00-FDU92xxx-06-00-00-xx-001

18 Endress+Hauser

A: Cable gland for approval version FDU93-C/D/E/G/H/J/R/U/W/1

B: Conduit connection NPT 1/2" for approval versions FDU93-P/T

The conduit connection is partly potted (half-filled).

L00-FDU93xxx-06-00-00-xx-001

Page 19

Prosonic S FDU90/91/91F/92/93/95

170 (6.69)

ø235 (9.25)

A

B

G 1"

NPT 1"

28

(1.1)

25 (1.0)

26

(1.0)

mm (in)

NOTICE

FDU91

FDU92

FDU90

FDU91F

1

1

1

2

4

3

5

5

4

4

3

3

5

2

2

5

6

6

3

2

4

5

1

6

Dimensions FDU95

A: Cable gland for approval versions FDU95-C/D/E/H/J/R/U/W/1

B: Conduit connection NPT 1/2" for approval versions FDU95-P/T

The conduit connection is partly potted (half-filled).

L00-FDU95xxx-06-00-00-xx-001

Weight

Sensor Weight (including 5 m (16 ft) cable)

FDU90 • approx. 0.9 kg (1.98 lbs) without flooding protection tube

• approx. 1.0 kg (2.21 lbs) with flooding protection tube

FDU91 approx. 1.1 kg (2.43 lbs)

FDU91F approx. 1.6 kg (3.53 lbs)

FDU92 approx. 2 kg (4.41 lbs)

FDU93 approx. 2.9 kg (6.39 lbs)

FDU95 approx. 4.5 kg (9.92 lbs)

Materials

Risk of sensor damage caused by chemical substances.

‣ Prior to application, check the chemical compatibility of the sensors with compatibility charts.

L00-FDU9xxxx-16-00-00-xx-001

Endress+Hauser 19

Page 20

Prosonic S FDU90/91/91F/92/93/95

FDU93

FDU95

7

7

4

5

3

32

2

1

1

6

6

8

8

5

5

5

4

Pos. Part FDU90 FDU91 FDU91F FDU92

1Sensor housing PVDF

2 Counter nut PA6.6 − PA6.6

3 Cable gland PA

4 Adpater CuZn nickel-plated

5O-ring

6Sealing

EPDM

316L

(1.4404/1.4435)

PVDF

Pos. Part FDU93 FDU95

1 Sensor UP (Unsaturated polyester resin)

2 Cable gland CuZn nickel-plated

3 Adpater CuZn nickel-plated

4O-ring VMQ

5 Sealing VMQ

6Screws V2A

7 Nameplate 304 (1.4301)

8 Membrane ALU with PFA coated

Connecting cable 5 to 300 m (16 to 984 ft)

For cable length > 30 m (> 98 ft), an extension cable is recommended.

In this case, the total length (sensor cable + extension cable) must not exceed 300 m (984 ft).

L00-FDU9xxxx-16-00-00-xx-002

FDU95 - *1***

(low temperature version): 316L

(1.4404) and PE coated

FDU95 - *2***

(high temperature version): 316L

(1.4404)

Cable Material

for FDU90/91/91F/92/93 PVC

20 Endress+Hauser

for FDU95 VMQ

Page 21

Prosonic S FDU90/91/91F/92/93/95

Certificates and Approvals

CE mark The measuring system meets the legal requirements of the EC-guidelines. Endress+Hauser confirms

the instrument passing the required tests by attaching the CE-mark.

Ex approval The available certificates are listed in the ordering information. Note the associated safety instructions

(XA) and control or installation drawings (ZD).

Warning!

• Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with the

installation instructions and ratings as stated in this supplementary documentation is mandatory.

– Ensure that all personnel are suitably qualified.

– Observe the specifications in the certificate as well as national and local standards and regulations.

• The transmitter may only be installed in suitable areas.

• Sensors with a certificate for hazardous areas may be connected to a transmitter without a

certificate.

• For FM approvals: Unauthorized substitution of components may impair the suitability for Division 1

or Division 2.

• Do not disconnect equipment unless the area is known to be non-hazardous.

Note!

The sensor must be installed and used in a way that eliminates any danger. Possible installation

positions: in tanks, vessels, silos, over stockpiles, open channels, weirs or other bins.

External standards and directives

EN 60529

Protection class of housing (IP code)

EN 61326 series

EMC product family standard for electrical equipment for measurement, control and laboratory use

NAMUR

User association for automation technology in process industries

Ordering information

Ordering information Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser web site: www.endress.com → Choose your

country → Products → Select measuring technology, soware or components → Select product

(picklists: measurement method, product family etc.) → Device support (right-hand column):

Configure the selected product → The Product Configurator for the selected product is opened.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Endress+Hauser 21

Page 22

Prosonic S FDU90/91/91F/92/93/95

R

A

F

mm (in)

E

S

5-point linearity protocol The following must be taken into account if option "5 point linearity protocol" has been selected:

• The five points of the linearity protocol are evenly distributed across the measuring range (0% to

100%). In order to define the measuring range, Empty calibration (E) and Full calibration (F) have

to be specified.

3)

• The following restrictions have to be taken into account when defining E and F:

A0019526

Pos. Measuring range FDU90 FDU91/

E Maximum value for the empty calibration 3000

F Maximum value for the full calibration 2900

S Minimum span (E-F) 100

A Minimum distance between reference point

R from sensor and 100 % level

• The linearity is checked under reference conditions.

• The 5-point linearity protocol is always carried out for the complete measuring system

(consisting of the sensor FDU9x and transmitter FMU9x) and it is valid for this combination.

It must be defined, at which sensor channel the sensor is to be tested. There are up to 2

channels for FMU90 and up to 5 or 10 channels for FMU95.

• The selected values of Empty calibration and Full calibration are only used to record the

linearity protocol and are reset to default values thereafter.

For details see the Technical Information TI00397F or TI00398F.

Scope of delivery • Instrument according to the version ordered

• This Technical Information (TI00396F/00/EN, serves as installation and operating instruction)

• For certified instrument versions: Safety Instructions (XA) and/or Control Drawings (ZD)

• For FDU90/91 with sensor heater: terminal module, to be mounted in the field housing of the

transmitter FMU90

• For FDU90/91/92 with G 1" process connection: counter nut (PA6.6) + seal (EPDM)

• For FDU93/95 with Ex-certificate: process seal (VMQ)

(118)

(114)

(3.94)

160

(6.30)

FDU91F

10000

(394)

9700

(382)

100

(3.94)

300

(11.8)

FDU92 FDU93 FDU95

20000

(787)

19600

(772)

200

(7.87)

400

(15.7)

20000

(787)

19400

(764)

250

(9.84)

600

(23.6)

20000

(787)

18000

(709)

450

(17.7)

2000

(78.7)

mm (in)

3) If the values for the full calibration and empty calibration are missing or outside the specified area, the devices are tested with the maximum value

according to the table.

22 Endress+Hauser

Page 23

Prosonic S FDU90/91/91F/92/93/95

FDU91

FDU90

90 (3.54)

ø98 (3.86)

90 (3.54)

ø98 (3.86)

mm (in)

Accessories

Extension cable for sensors

Protective cover for FDU90 and FDU91

for Sensor Material Cable type Order code

•FDU90

•FDU91

•FDU92

• FDU91F

•FDU93

•FDU95

• FDU95 Silicone (−40 to +150 °C)

• FDU90/FDU91

with heater

PVC LiYCY 2x(0.75) 71027742

PVC (−40 to +105 °C)

(−40 to +221 °F)

(−40 to +302 °F)

PVC LiYY 2x(0.75)D+2x0.75 71027746

LiYY 2x(0.75)D+1x0.75 71027743

Li2G2G 2x(0.75)D+1x0.75 71027745

Total length (sensor cable + extension cable)*: up to 300 m (984 ft)

* The sensor cable and the extension cable are of the same type.

•Material: PVDF

• Order code: 52025686

L00-FDU9xxxx-06-00-00-xx-003

Endress+Hauser 23

Page 24

Screw in flange FAX50

4

1

3

2

Prosonic S FDU90/91/91F/92/93/95

L00-FMU30xxx-00-00-00-xx-001

1Screw in flange

2 Nozzle

3Sensor

4 Sealing ring EPDM (supplied)

Product structure FAX50

015Material:

BR1 DN50 PN10/16 A, steel flange EN1092-1

BS1 DN80 PN10/16 A, steel flange EN1092-1

BT1 DN100 PN10/16 A, steel flange EN1092-1

JF1 2" 150lbs FF, steel flange ANSI B16.5

JG1 3" 150lbs FF, steel flange ANSI B16.5

JH1 4" 150lbs FF, steel flange ANSI B16.5

JK2 8" 150lbs FF, PP max 3bar abs/44psia flange ANSI B16.5

XIF UNI flange 2"/DN50/50, PVDF max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

XIG UNI flange 2"/DN50/50, PP max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

XIJ UNI flange 2"/DN50/50, 316L max 4bar abs/58psia suitable for 2" 150lbs/DN50 PN16/10K 50

XJF UNI flange 3"/DN80/80, max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

XJG UNI flange 3"/DN80/80, PP max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

XJJ UNI flange 3"/DN80/80, 316L max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

XKF UNI flange 4"/DN100/100, PVDF max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K

100

XKG UNI flange 4"/DN100/100, PP max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K 100

XKJ UNI flange 4"/DN100/100, 316L max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K

100

XLF UNI flange 6"/DN150/150, PVDF max 4bar abs/58psia, suitable for 6" 150lbs/DN150 PN16/10K

150

XLG UNI flange 6"/DN150/150, PP max 4bar abs/58psia, suitable for 6" 150lbs/DN150 PN16/10K 150

XLJ UNI flange 6"/DN150/150, 316L max 4bar abs/58psia, suitable for 6" 150lbs/DN150 PN16/10K

150

XMG UNI flange DN200/200, PP max 4bar abs/58psia, suitable for DN200 PN16/10K 200

XNG UNI flange DN250/250, PP max 4bar abs/58psia, suitable for DN250 PN16/10K 250

YYY Special version

020 Sensor Connection:

A Thread ISO228 G3/4

B Thread ISO228 G1

C Thread ISO228 G1-1/2

D Thread ISO228 G2

EThread ANSI NPT3/4

FThread ANSI NPT1

GThread ANSI NPT1-1/2

HThread ANSI NPT2

Y Special version

015 020

FAX50 -

24 Endress+Hauser

Page 25

Prosonic S FDU90/91/91F/92/93/95

BD

SD

–

+

E

ø69

(2.72)

125 (4.92)

G 1-1/2"

mm (in)

Flooding protection tube for FDU90

BD: Blocking distance, SD: Safety distance

L00-FDU90xxx-15-00-00-xx-001

Usage

The flooding protection tube prevents the level to rise into the blocking distance of the FDU90 sensor

even if the sensor is flooded.

The user can set a safety distance SD in the transmitter FMU90/FMU95 and define that a warning

signal is generated as soon as the level rises into the safety distance.

Mounting hints

In order to ensure tightness, the supplied gasket has to be applied and the flooding protection tube

must be screwed hand tight up to limit stop. When re-equipping the flooding protection tube, repeat

the basic setup including the mapping

Note!

• The flooding protection tube has a G 1-1/2" thread.

• If it is ordered together with the FDU90 sensor in the product structure, the sensor always has a G 11/2" thread at its front side, irrespective of the selection in feature 020, "Process connection".

• If the flooding protection tube is ordered as an accessory, it can only be used for sensors with a G 11/2" thread at the front side.

Material Weight Order code

PP 0.12 kg (0.26 lbs) 71091216

Gasket EPDM

Endress+Hauser 25

Page 26

Cantilever with mounting

3

1

2

AB

1

A

D

M8

35 (1.4)

50

(2.0)

20

(0.8)

105 (4.1)

35

(1.4)

22

(0.9)

C

C

6.5

(0.3)

15

(0.6)

100 (3.9)

25

(1.0)

35 (1.4)

100 (3.9)75 (2.9)

B

20 (0.8)

75 (2.9)

frame or wall bracket

Prosonic S FDU90/91/91F/92/93/95

A Installation with cantilever and wall bracket

B Installation with cantilever and mounting frame

1 Cantilever

2Mounting frame

3 Wall bracket

Cantilever

The cantilever is used to mount the sensors FDU90, FDU91 and FDU92 above open channels for

example.

A0019589

A B C D Material Weight Order code

585 (23) 250 (9.84) 2 (0.08) 200 (7.87)

1085 (42.7) 750 (29.5) 3 (0.12) 300 (11.8)

mm (in)

galvanised steel 2.1 kg (4.63 lbs) 919790-0000

316Ti (1.4571) 2.0 kg (4.41 lbs) 919790-0001

galvanised steel 4.5 kg (9.92 lbs) 919790-0002

316Ti (1.4571) 4.3 kg (9.48 lbs) 919790-0003

• The 35 mm (1.38 in) orifices are for the sensors FDU9x.

• The 22 mm (0.87 in) orifice may be used for an external temperature sensor (e.g. FMT131).

Fixing screws are supplied.

26 Endress+Hauser

A0019592

Page 27

Prosonic S FDU90/91/91F/92/93/95

3.2 (0.13)

20 (0.8)

55 (2.17)

100 (3.94)

25 (0.98)

700/1400

(27.6 / 55.1)

45 (1.77)

76

(2.99)

100

(3.94)

200 (7.87)

13 (0.5)

ø33.7 (1.3)

130 (5.12)

150 (5.91)

100

(3.94)

60 (2.36)

4 (0.16)

6.5 (0.3)

110 (4.3)

25 (1.0)

5 (0.2)

6.5 (0.3)

150 (5.9)

ø33.7 (1.3)

3.2 (0.1)

110 (4.3)

13 (0.5)

150 (5.9)

180 (7.1)

~213 (8.4)

~ (3.5)88

Mounting Frame

Height Material Weight Order Code

700 (27.6) Steel, galvanized

700 (27.6) 316Ti (1.4571) 919791-0001

1400 (55.1) Steel, galvanized

1400 (55.1) 316Ti (1.4571) 919791-0003

mm (in)

3.2kg (7.06lbs)

4.9 kg (10,08 lbs)

Wall Bracket

A0019279

919791-0000

919791-0002

Material Weight Order Code

Steel, galvanized

316Ti (1.4571) 919792-0001

Endress+Hauser 27

1.4kg (3.09lbs)

919792-0000

A0019350

Page 28

Mounting bracket for ceiling

185 (7.28)

5 (0.2)

15 (0.59)

15 (0.59)

50

(1.97)

10 (0.39)

95 (3.74)

ø35

(1.38)

12 (0.47)

10 (0.39)

ø5.6 (0.22)

155 (6.1)

1.5 (0.06)

75 (2.95)

100 (3.94)

110 (4.33)

2±

105 (4.13)

10 (0.39)

mm (in)

mounting

Prosonic S FDU90/91/91F/92/93/95

Suited for sensors: Material Order No.

FDU90, FDU91, FDU91F, FDU92 316L (1.4404) 71093130

L00-FDU9xxxx-00-00-00-xx-001

28 Endress+Hauser

Page 29

Prosonic S FDU90/91/91F/92/93/95

500 (19.7)

70 (2.76)

<360

(14.2)

NPT

¾-14"

10

(0.39)

NPT

1-11½"

G 1"A

1

2

4

5

19 (0.75)

101 (3.98)

125 (4.92)

ø155 (6.1)

27

(1.06)

8

6

30

(1.18)

21

(0.8)

7

3

13

4

mm (in)

15°

<

Alignment unit FAU40 For measurements in solids, usage of the alignment unit FAU40 is recommended. It is designed for

simple mounting and alignment of a FDU sensor on the product surface and can be used for zone

separation in explosion hazardous areas.

L00-FAU40xxx-06-00-00-xx-001

1 Cable gland M20x1.5 (present if selected in the product structure)

2Sealant here

3 Two Allen screws for height adjustment [8 Nm ±2 (5.900 lbf ft)]

4Ground pin

5O-ring

6 Seal supplied with the sensor, must be used for applications in ATEX zone 20

7 Screw for lateral movement [18 Nm ±2 (13.276 lbf ft)]

8 Mounting grooves (present in the UNI flange)

The alignment unit can be rotated up to 15°.

For further information see Technical Information T00179F.

Product structure

010 Process connection (Flange)

1 Welding flange, 304/1.4301

2 UNI flange 2"/DN50/50, 304, max. 1.5 bar abs./22psia

020 Sensor connection

FAU40 - product designation

suitable for 2" 150lbs / DN50 PN16 / 10K 50

S Thread G1, cable gland M20, 304/1.4301

G Thread G1, cable gland M20, galvanized steel

N Thread NPT1, cable entry3/4, galvanized steel

Endress+Hauser 29

Page 30

Prosonic S FDU90/91/91F/92/93/95

Power supply RNB130 for the FDU90/FDU91 sensor heater

IP66 protective housing for the power supply RNB130

Technical data

• Primary switched-mode power supply

• Input: 100 - 240 V AC

• Output: 24 V DC connection, max. 30 V in the event of a fault

• Connection to monophased a.c. networks or to two phase conductors of three-phase supply

networks

(TN, TT or IT networks as per VDE 0100 T 300/IEC 364-3) with 100 - 240 V AC nominal voltage

For further information see Technical Information TI00120R.

Product structure

010 Approvals

A Non-hazardous area

020 Connection

1Screw strip

3 Screw connection, power terminal block

030 Version

AStandard

RNB130 - complete product designation

Order code: 51002468

For additional information refer to Technical Information TI00080R.

Documentation

Technical Information TI00397F

Technical Information for the transmitter Prosonic S FMU90

TI00179F

Technical Information for the alignment unit FAU40

Operating instructions (for transmitter FMU90)

Depending on the instrument version, the following operating instructions are supplied with the

Prosonic S FMU90:

Operating instructions Output Application Instrument version

BA00288F

BA00289F

BA00292F

BA00293F

HART

PROFIBUS DP

• level measurement

• alternating pump control

• screen and rake control

• flow measurement

• backwater and dirt detection

• totalizers and counters

• level measurement

• alternating pump control

• screen and rake control

• flow measurement

• backwater and dirt detection

• totalizers and counters

FMU90 - *******1****

FMU90 - *******2****

FMU90 - *2*****1****

FMU90 - *4*****1****

FMU90 - *2*****2****

FMU90 - *4*****2****

FMU90 - *******3****

FMU90 - *2*****3****

FMU90 - *4*****3****

These operating instructions describe installation and commissioning of the respective version of the

Prosonic S. It contains those functions from the operating menu, which are required for a standard

measuring task. Additional functions are described in this document: Description of Instrument

Functions for Prosonic S FMU90, document number BA00290F.

30 Endress+Hauser

Page 31

Prosonic S FDU90/91/91F/92/93/95

Description of Instrument Functions (for transmitter FMU90)

BA00290F

The document BA00290F contains a detailed description of all functions of the Prosonic S and is valid

for all instrument versions.

You will find this document in the Download Area of the Endress+Hauser Internet site:

www.endress.com→ Download

Safety Instructions The following Safety Instructions are supplied with certified versions of the sensors. If the sensors are

used in hazardous areas, comply with all the specifications in these Safety Instructions.

Sensor version Certificate Safety Instructions

ATEX

• FDU90 - J...

• FDU91 - J...

• FDU91F - J...

• FDU92 - J...

• FDU90 - E...

• FDU91 - E...

• FDU91F - E...

• FDU92 - E...

• FDU93 - J...

• FDU95 - J...

• FDU93 - E...

• FDU95 - E...

IEC Ex

• FDU90 - C...

• FDU91 - C...

• FDU91F - C...

• FDU92 - C...

• FDU93 - D...

• FDU95 - D...

• FDU90 - D...

• FDU91 - D...

• FDU91F - D...

• FDU92 - D...

• FDU93 - C...

• FDU95 - C...

• II 2 G Ex ma IIC T5 Gb (FDU90)

• II 2 G Ex ma IIC T6 Gb (FDU91/91F/92)

• II 2 G Ex ma IIC T5 Gb (FDU90)

• II 2 G Ex ma IIC T6 Gb (FDU91/91F/92/93/95)

• II 1/2 D Ex ta/tb IIIC Txx°C Da/Db IP68

• II 2 D Ex tb IIIC Txx°C Db IP68

• II 1/2 D Ex ta/tb IIIC Txx°C Da/Db IP68

• II 2 D Ex tb IIIC Txx°C Db IP68

• IEC Ex ma IIC T5 Gb (FDU90)

• IEC Ex ma IIC T6 Gb (FDU91/91F/92/93/95)

• IEC Ex ta/tb IIIC Txx°C Da/Db IP68

• IEC Ex tbIIIC Txx°C DbIP68

• IEC Ex ma IIC T5 Gb (FDU90)

• IEC Ex ma IIC T6 Gb (FDU91, FDU91F, FDU92)

• IEC Ex ta/tb IIIC Txx°C Da/Db IP68

• IEC Ex tbIIIC Txx°C Db IP68

XA00321F

XA00322F

XA00323F

XA00481F

XA00482F

XA00483F

Endress+Hauser 31

Page 32

www.addresses.endress.com

71308097

Loading...

Loading...