Page 1

Operating Instructions

Multi Channel Recorder RSG30

Ecograph T

BA194R/09/en/13.10

No.: 51009564

Software

ETU00xA, V2.02.xx

Page 2

Brief overview

E

For quick and easy commissioning:

1. Consider the safety instructions Page 5

2. Install the unit Page 8

3. Wire up the unit Page 11

4. Install the provided PC software Page 22

5. Connect the unit with the PC Page 22

6. Set up the unit (via provided PC software) Page 27

7. Transmit the set up files to the unit Page 27

Brief Operating Instructions

Your new unit has the Operating Instructions built-in. The unit's simple control system enables you

to commission for many applications, practically without any paper. Your unit displays instructions

at the push of a button directly on screen. This description is nevertheless delivered with the unit it is a supplement to the Operating Instructions built into the unit. Anything that is not described

directly at the unit by plain text or menus is explained here.

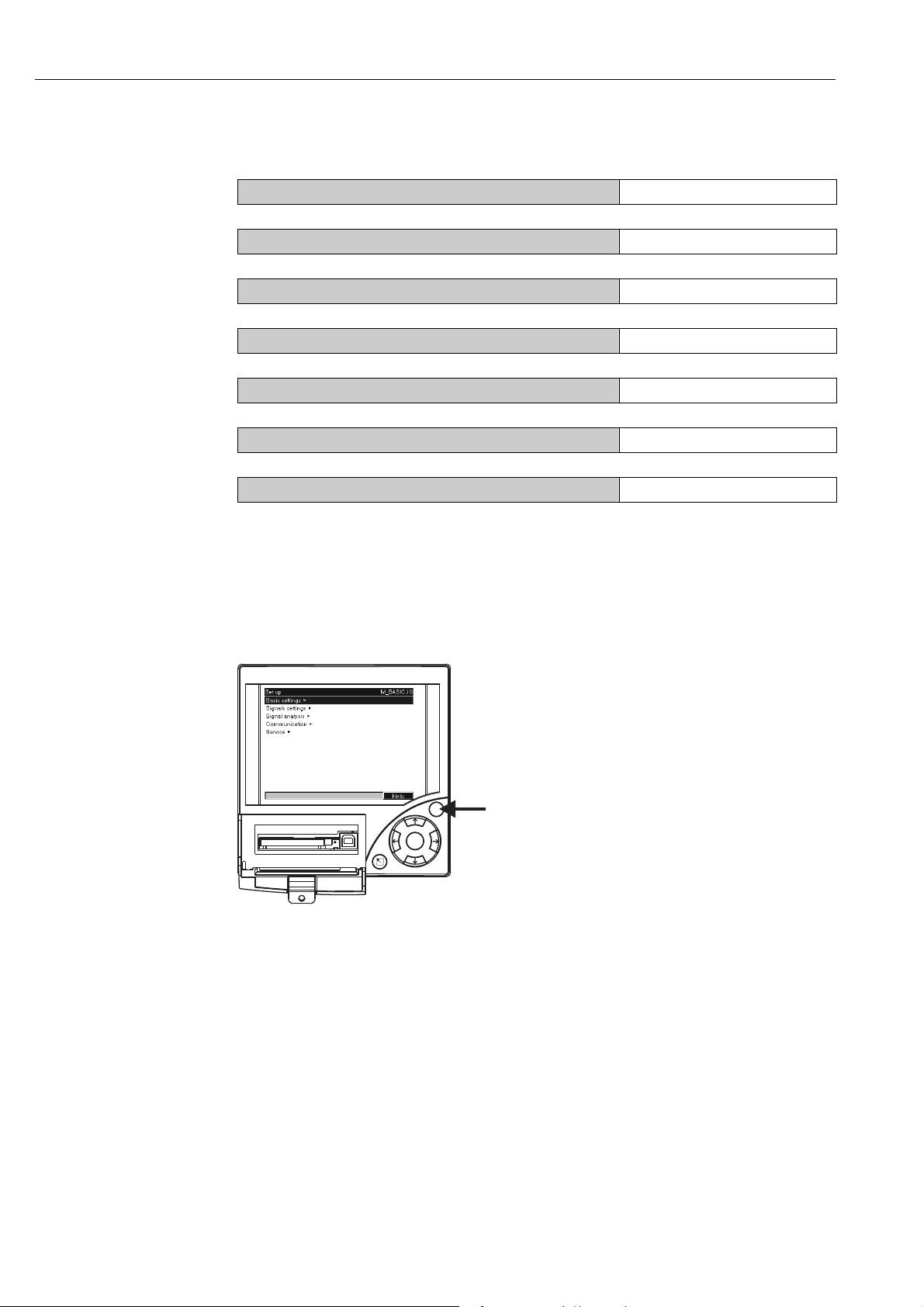

Fig. 1: Variable softkey (e.g. calling up internal Help function in the Setup menu)

Index

A very extensive index can be found at the end of these Operating Instructions. It acts as a

complement to the table of contents and helps you find special terms and functions.

2

Page 3

3

Page 4

Table of contents

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Notes on safety conventions and icons . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 7

3 Installation . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Incoming acceptance, transport, storage . . . . . . . . . 8

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Mechanical locking . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 10

4 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Post-connection check . . . . . . . . . . . . . . . . . . . . . 18

9 Troubleshooting. . . . . . . . . . . . . . . . . . 66

9.1 Diagnostic/unit information . . . . . . . . . . . . . . . . . 66

9.2 Troubleshooting instructions . . . . . . . . . . . . . . . . . 67

9.3 System error messages . . . . . . . . . . . . . . . . . . . . . 68

9.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.7 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10 Technical data . . . . . . . . . . . . . . . . . . . 72

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.3 Power supply/terminal diagram . . . . . . . . . . . . . . 75

10.4 Performance characteristics . . . . . . . . . . . . . . . . . . 76

10.5 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 76

10.6 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.7 Mechanical construction . . . . . . . . . . . . . . . . . . . . 78

10.8 Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.9 Certificates and approvals . . . . . . . . . . . . . . . . . . . 81

10.10 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.11 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5 Operation . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Quick operating guide . . . . . . . . . . . . . . . . . . . . . 19

5.2 Display and operating elements . . . . . . . . . . . . . . . 20

5.3 Entering text and numbers . . . . . . . . . . . . . . . . . . 21

5.4 Overview of the symbols used . . . . . . . . . . . . . . . 21

5.5 Confirming error messages . . . . . . . . . . . . . . . . . . 22

5.6 Communication; PC software installation . . . . . . . 22

6 Commissioning. . . . . . . . . . . . . . . . . . 26

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Switching on the unit . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Unit Set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 The set up window (at main menu) . . . . . . . . . . . 30

6.5 The main menu . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.6 Saving measured values . . . . . . . . . . . . . . . . . . . . 61

6.7 Important functions of the provided PC software . 62

7 Maintenance. . . . . . . . . . . . . . . . . . . . 64

7.1 Software update via the provided PC software . . . . 64

7.2 Instruction for releasing a software option e.g.

"Integration + Analysis + Maths" . . . . . . . . . . . . . 64

8 Accessories. . . . . . . . . . . . . . . . . . . . . 65

8.1 Accessory parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4

Page 5

Safety instructions

1 Safety instructions

1.1 Designated use

This unit is designed for the electronic acquisition, display, recording, analysis, remote transmission

and archiving of analog and digital input signals in non-hazardous areas.

• The unit is designed for installation in a panel or a cabinet and may only be operated in an installed

state.

• The manufacturer does not accept liability for damage caused by improper or non-designated use.

The unit can cause danger if used improperly or other than intended.

1.2 Installation, commissioning and operation

• The unit may only be installed, connected, commissioned and serviced by qualified and

authorized expert staff (e.g. electrical technicians) strictly adhering to the instructions contained

in this manual, the applicable norms, legal regulations and certificates (depending on the

application).

• These experts must have read and understood this manual and follow the instructions it contains.

• The unit may only be modified or repaired if expressly permitted in the Operating Instructions.

• Damaged units which could pose a source of danger may not be put into operation and must be

marked as defective.

• Primarily observe local regulations regarding opening and repairing electrical units.

#

1.3 Operational safety

• The unit is safely built and tested according to state-of-the-art technology and has left the factory

in perfect condition as regards technical safety. The applicable regulations and European standards

have been taken into account.

• Please observe the technical data on the nameplate! The nameplate is on the left-hand side of the

housing.

Desk top version

Warning!

• The mains plug must only be inserted into a socket with grounding contact.

• The protective effect must not be removed by an extension lead without ground wire.

• Relay outputs: U(max) = 30 V eff (AC) / 60 V (DC)

Repairs

Repairs that are not described in these Operating Instructions must only be carried out directly by

the manufacturer or by the service department.

Electromagnetic compatibility

The measuring system meets the general safety requirements of IEC 61010 and the EMC

requirements of IEC 61326.

Technical improvement

The manufacturer reserves the right to adapt technical data to the most up-to-date technical

developments without any special announcement. Ask your supplier for information about activities

and possible extensions to these Operating Instructions.

1.4 Return

The following measures must be taken before you return a measuring unit, e.g. for repair or

calibration:

• The unit must be packed in protective packaging. The original packaging offers the best

protection.

5

Page 6

Safety instructions

#

"

!

1.5 Notes on safety conventions and icons

Always refer to the safety instructions in these Operating Instructions labeled with the following

symbols:

Warning!

This symbol draws attention to activities or procedures that can lead to injuries to persons, safety

risks or the destruction of the unit if not carried out properly.

Caution!

This symbol draws attention to activities or procedures that can lead to defective operation or to

destruction of the unit if not carried out properly.

Note!

This symbol draws attention to activities or procedures that have an indirect effect on operation, or

can trigger an unforeseen unit reaction if not carried out properly.

ESD - Electrostatic discharge

Protect the terminals against electrostatic discharge. Failure to comply with this instruction can

result in the destruction of parts of the electronics.

6

Page 7

Identification

2 Identification

2.1 Device designation

2.1.1 Nameplate

Compare the nameplate on the left-hand side of the unit with the delivery note and with the

following diagram:

Fig. 2: 1. Order code

2. Serial number

3. Software version

4. Fields for indicating the installed software updates

5. Supply voltage, power frequency, power consumption

6. Ambient temperature range

7. Unit approvals

2.2 Scope of delivery

• Unit (with terminals, as per your order)

• 4 fastening clips

• USB cable

• Optional CompactFlash CF card (CF card is enclosed separately.)

• PC operating and configuration software on CD-ROM

• Delivery note

• Multilanguage Brief Operating Instructions as hard copy

• Operating Instructions on CD-ROM

• locking plate

Anything missing? Then please inform your supplier.

2.3 Certificates and approvals

An overview of all certificates and approvals can be found in the Technical Data, Section 10.

7

Page 8

Installation

3 Installation

3.1 Incoming acceptance, transport, storage

3.1.1 Incoming acceptance

After receiving the goods, check the following points:

• Is the packaging or the contents damaged?

• Is the delivery complete? Compare the goods delivered with what you ordered.

3.1.2 Transport and storage

Observe the following points:

• The unit must be packed in shockproof packaging for storage (and transport). The original

packaging offers the best protection for this.

• The permitted storage temperature is -20 to +60 °C (-4 to 140 °F)

3.2 Installation conditions

Working temperature range:

0 to 50 °C (32 to 122 °F), max. 75% rel. humidity without condensation.

Caution!

"

• To avoid heat accumulation, please always ensure that the unit is sufficiently cooled.

• Maintain distance from strong magnetic fields (see Section 10 "Technical data", interference

immunity )

• Environment at front in accordance with unit ingress protection IP 54

3.3 Installation instructions

3.3.1 Mounting tool

To install the control panel, all you need is a screwdriver.

8

Page 9

3.3.2 Panel mounting, installation dimensions

Y

X

137.9 mm

5.43”

21 mm

0.83”

150 mm

5.9”

36.1 mm

1.42”

138 mm

5.43 “

+1

+0.04

138 mm

5.43 “

+1

+0.04

86.5 mm

3.4”

144 mm

5.67”

144 mm

5.67”

Installation

!

Fig. 3: Panel mounting and installation dimensions

• Installation depth: approx. 171 mm (6.73 inch) (incl. terminals and fastening clips)

• Panel cutout: 138

+1

x 138+1 mm (5.43

+0.04

x 5.43

+0.04

inch)

• Panel thickness: 2 to 40 mm (0.08 to 1.57 inch)

• Maximum point of view range: From the display center 50° to the left and right, 20° upward, 30°

downward.

• Securing to DIN 43 834

1. Push the unit through the panel cutout from the front. To avoid heat accumulation, we

recommend keeping a distance of > 15 mm (> 0.59 in) from the walls and other units.

2. Hold the unit level and then hang jack screws in the openings (2 x top, 2 x bottom).

3. Tighten the screws on the jack screws equally with a screwdriver, such that a secure seal to

the control panel is guaranteed.

Note!

A distance of min. 15 mm (0.59 in) between the units has to be observed if aligning the units in the

Y-direction (vertically above one another).

The units can be arranged horizontally beside one another in the X direction without any spacing

between the units.

9

Page 10

Installation

3.4 Mechanical locking

The CompactFlash card can be secured against unauthorized removal using the locking plate

supplied. For this purpose, insert the locking plate into the slit below the handle of the cover plate

(see Fig. 4). Now you can lead-seal or seal the cover plate with a suitable lock.

Fig. 4: Inserting the locking plate

3.5 Post-installation check

After installing the control panel, please check the following points:

• Is the unit fixed firmly in the center of the control panel cutout?

• Does the seal run all around the housing collar?

10

Page 11

4 Wiring

4.1 Quick wiring guide

Wiring

#

"

!

Warning!

Please note that the entire electrical connection may only take place when the unit is de-energized.

Caution!

• The ground connection must be made before all other connections. Any interruption in the

ground can cause danger.

• Before commissioning, compare the supply voltage with the information specified on the

nameplate (left-hand side of the housing).

• The mixed connection of safety extra-low voltage and dangerous contact voltage to the relay is

not permitted.

• Provide a suitable switch or circuit breaker when installing in a building. This switch must be

installed near to the unit (easily accessible) and be labeled as a separator.

• An overcurrent protective unit (nominal current 10 A) is required for the power cable.

Note!

Please also refer to the terminal diagram on the rear of the unit.

4.1.1 Channel color table

When wiring the analog channels, please ensure that the color display on the display for the

individual channels is specified as follows:

3-channel version

Analog 1: Blue Analog 2: Red

Analog 3: Green Digital 1: Cyan

Digital 2: Red Digital 3: Green

6-channel version

Analog 1: Magenta Analog 2: Red

Analog 3: Black Analog 4: Green

Analog 5: Blue Analog 6: Brown

Digital 1: Cyan Digital 3: Red

Digital 2: Green

11

Page 12

Wiring

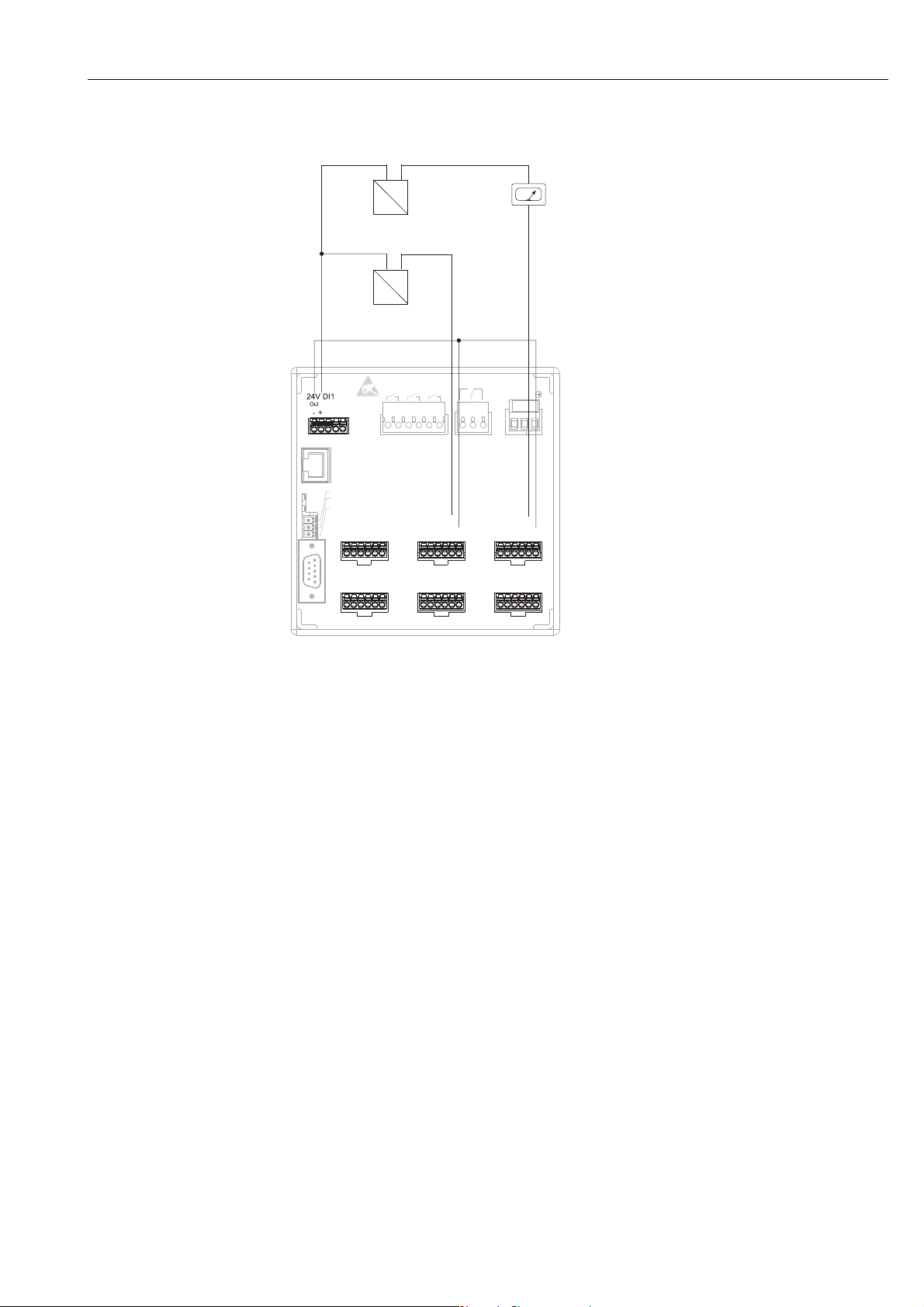

4.1.2 Wiring diagram

12

Fig. 5: Circuit diagram

Page 13

4.1.3 Auxiliary voltage output for 2-wire sensors

5

6

9

1

DI3

93

92

91

GND

RxD/TxD +

RxD/TxD -

Ethernet

RS232

Rel2

41

42

31

32

21

22

111312

L+N-PE

Rel4 Rel3

Rel1

RS485

CH 4 CH 5 CH 6

611

612

613

614

615

616

411

412

413

414

415

416

CH 1

CH 2

CH 3

111

112

113

114

115

116

211

212

213

214

215

216

311

312

313

314

315

316

511

512

513

514

515

516

_

+

-

Y

+

-

Y

+

+

_

Out: max. 250 mA

On connecting channels 1-4 see

terminal connections CH 5-6

Sensor 1

e.g. TR10 from E+H

Sensor 2

External display

(optional) e.g.

RIA261 from E+H

Wiring

Fig. 6: Using the auxiliary voltage output as power supply for 2-wire sensors (at current measurement range)

13

Page 14

Wiring

5

6

9

1

GND

RxD/TxD +

RxD/TxD -

Ethernet

RS232

Rel2

41

42

31

32

21

22

111312

L+N-PE

Rel4 Rel3

Rel1

RS485

CH 4 CH 5 CH 6

611

612

613

614

615

616

411

412

413

414

415

416

CH 1

CH 2

CH 3

111

112

113

114

115

116

211

212

213

214

215

216

311

312

313

314

315

316

511

512

513

514

515

516

DI3

93

92

91

_

+

-

Y

+

+

_

+

-

Y

Out: max.250 mA

On connecting channels 1-4 see

terminal connections CH 5-6

Sensor 1 e.g. TR13 from E+H

Sensor 2

Ext. display

(optional)

e.g. RIA261 from E+H

4.1.4 Auxiliary voltage output for 4-wire sensors

"

!

Fig. 7: Using the auxiliary voltage output as power supply for 4-wire sensors (at current measurement range)

4.2 Terminal assignment

Caution!

If high-energy transients occur when using long signal cables, we recommend connecting a suitable

overvoltage protection (e.g. E+H HAW560/562).

Use shielded signal lines for serial interfaces!

4.2.1 Cable specification, spring terminals

All connections on the rear of the unit are designed as screw or spring terminal blocks with reverse

polarity protection. This makes the connection very quick and easy. The spring terminals are

unlocked with a slotted screwdriver (size 0).

Please note the following when connecting:

• Digital I/O wire cross-section, RS485 and analog inputs: max. 1.5 mm

terminals)

2

• Power wire cross-section: max. 2.5 mm

• Relay wire cross-section: max. 2.5 mm

(13 AWG) (screw terminals)

2

(13 AWG) (spring terminals)

• Stripping length: 10 mm (0.39 in)

Note!

No ferrules have to be used when connecting flexible wires to spring terminals.

2

(14 AWG) (spring

14

Page 15

Wiring

L+N-PE

CH x

x11

x12

x13

x14

x15

x16

4.2.2 Supply voltage

Power supply type Terminal

100-230 VAC L+ N- GND

Phase L Zero conductor N Ground

24 V AC/DC L+ N- GND

Phase L or + Zero conductor N or - Ground

4.2.3 Analog inputs

The first digit (x) of the three-digit terminal number corresponds to the associated channel (1.. to

6..: channels 1 to 6):

Type Terminal

x11 x12 x13 x14 x15 x16

Current (+) (-)

Voltage > 1 V (+) (-)

Voltage 1 V (+) (-)

Resistance

thermometer

RTD (2-wire)

Resistance

thermometer

RTD (3-wire)

Resistance

thermometer

RTD (4-wire)

Thermocouples

TC

(A) (B)

(A) b (sense) (B)

(A) a (sense) b (sense) (B)

(+) (-)

15

Page 16

Wiring

DI3

93

92

91

41

42

31

32

21

22

111312

Rel4 Rel3

Rel2

Rel1

4.2.4 Digital I/O

Type Terminal

(-) (+) 91 92 93

Digital input Digital input 1 Digital input 2 Digital input 3

Auxiliary voltage

output, not stabilized,

max. 250 mA

Ground Approx. + 24 V

4.2.5 Relay

Type Terminal

41 42 31 32 21 22 11 13 12

Alarm

relay 1

Relay 2 Switching

Relay 3 Switching

contact

Normally

open

contact

2)

(NO)

contact

Normally

open

contact

2)

(NO)

Normally

open

contact

2)

(NO)

Changeover

contact

Normally

closed

contact

1)

(NC)

Relay 4 Switching

contact

1) NC = normally closed (breaker)

2) NO = normally open (maker)

16

!

Normally

open

contact

2)

(NO)

Note!

The opening and closing function (= activation or deactivation of the relay coil) in case of a limit

value can be defined in the setup "Setup - Relay"

Page 17

Wiring

4.2.6 "Ethernet" option

Ethernet connection

An IEEE 802.3 compatible connector on a shielded RJ45 plug on the rear side of the unit is available

as a network connection. Through this connection, the unit can be connected with a hub or switch

to units in an office environment. For safe spacing distances, the office equipment standard EN

60950 must be observed. The pin assignment corresponds to a standard MDI interface (AT&T258),

so that a shielded 1:1 cable with a maximum length of 100 meters (328 ft) can be used here. The

Ethernet interface is designed as 10BASE-T. Direct connection to a PC is possible with a crossover

cable. Half duplex and full-duplex data communication is supported.

!

Fig. 8: RJ45 socket (assignment AT&T256)

LED description

Beneath the Ethernet connection (see rear of unit) there are two light emitting diodes which

indicate the status of the Ethernet interface.

• Yellow LED: link signal; is on when the unit is connected to a network. If this LED is not

illuminated then communication is impossible.

• Green LED: Tx/Rx; when the unit is receiving or sending data it flashes irregularly, otherwise is

continuously on.

4.2.7 USB connection

USB connection

A compatible USB connection (V1.1, lowspeed 1.5 Mbit/s) is available on a shielded USB-B socket

at the front of the unit. The unit can be connected to a laptop via this connection. The pin

assignment corresponds to a standard USB interface, so that a shielded standard cable with a

maximum length of 3 meters (9.8 ft) can be used here.

Note!

USB2.0 is compatible to USB1.1, i.e. communication is possible.

17

Page 18

Wiring

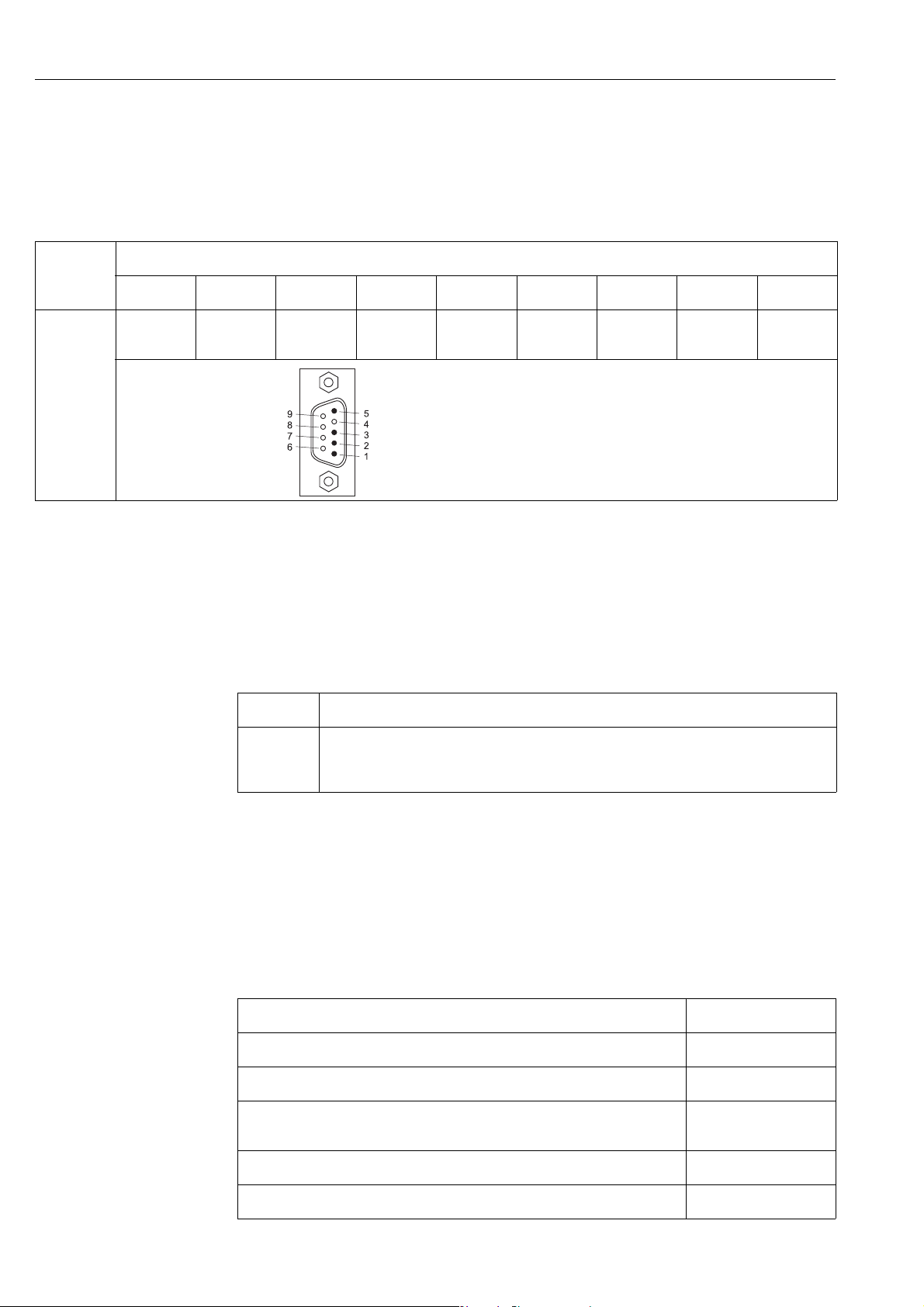

4.2.8 Option "RS232/RS485 interface"

RS232 connection

A compatible RS232 connection is available on a shielded SUB-D9 socket at the rear of the unit.

This can be used to transmit data or programs or as a modem connection. The pin assignment

corresponds to a standard RS232 interface, so that a shielded 1:1 cable can be used here.

Pin of the SUB-D9 socket

123456789

RS232

assignmen

t

Shield TxD (data

output)

Fig. 9: RS232 assignment

RS485 connection

A compatible RS485 connection is available on the rear of the unit. This can be used to transmit

data or programs or as a modem connection. Use a shielded cable.

Caution!

"

Only one interface can be used at any one time (RS232 or RS485).

Terminal RS485 assignment:

GND

RxD/TxD +

RxD/TxD -

RxD (data

input)

GND

RxD/TxD +

RxD/TxD -

GND

Caution!

"

Unoccupied connections should be left empty. The RS232/RS485 interfaces

cannot be used simultaneously. Choose the interface to be used under “Extras

- Serial Interface”.

18

4.3 Degree of protection

At the front, the unit meets all the requirements of ingress protection IP54.

4.4 Post-connection check

After completing the unit's electrical connections, carry out the following checks:

Unit status and specifications Notes

Is the unit or cable damaged (visual inspection)? -

Electrical connection Notes

Does the supply voltage match the information on the nameplate? Compare nameplate on

the unit

Are the mounted cables relieved of tension? -

Are all the terminals firmly seated at the contacts? -

Page 19

Operation

E

5Operation

5.1 Quick operating guide

Your new unit has the Operating Instructions built-in. The unit's simple control system enables you

to commission for many applications, practically without any operating instructions. Your unit

displays instructions at the push of a button directly on screen. This description is a supplement to

the Operating Instructions built into the unit. Anything that is not described directly in plain text or

menus is explained here. We reserve the right to make alterations that contribute to technical

progress.

Fig. 10: Variable softkey (e.g. calling up internal Help function in the Setup menu)

19

Page 20

Operation

5.2 Display and operating elements

Fig. 11: Unit display / control units

Operating element (Item No.) Operating function

(Display mode = Signal display)

(Setup menu = Operation in the Setup menu)

1

Z

UT

V

W

F

1a Function indicator of the softkey

2 Slot for CF card

2a Key to eject the CF card

2b LED at CF slot

2c USB socket

At display mode: Quick return to current time

At Setup menu: ESC key to abort the input and/or quick return to the preceding display.

At display mode: Changes between the various display modes (e.g. bargraph,...)

At Setup menu: Moves the cursor to left or right

At display mode: Rewinds recording (history display - "remove paper")

At Setup menu: Moves the cursor bar upwards, changes parameter / signs

At display mode: Forwards recording to current time ("wind on paper")

At Setup menu: Moves the cursor bar downwards, changes parameter / signs

At display mode: Displays main menu

At Setup menu: ENTER key = Selection of the marked function, start the parameter change

Variable softkey (e.g. calling up internal Help function in the Setup menu)

Caution!

"

Do not actuate if LED (2b) is lit! Risk of data loss!

LED lights up if the unit is reading or writing to the CF card.

20

Page 21

Operating element (Item No.) Operating function

(Display mode = Signal display)

(Setup menu = Operation in the Setup menu)

3 At display mode: Window for measured value display

Displays the current measured values depending on the signal display selected.

Note!

!

If a measuring point has limit value status, the corresponding channel identifier is displayed in red (quick detection of limit

values). When you are operating the unit, measured value acquisition continues to run without interruption.

4 At display mode: Displays the current date/time

At Setup menu: Displays the operating item

5 At display mode: Indicates what portion of the CF card is already written to (in %)

6 At display mode: Functions of the LED displays on the display (as per NAMUR NE44:)

At Setup menu: Displays the operating code

• Green LED lights up: power supply OK, unit working without faults

• Red LED flashes: need for maintenance if unit-external problem occurs (e.g. cable open circuit etc.) or a message /

note to be acknowledged is pending, calibration in progress.

5.3 Entering text and numbers

A virtual keyboard is available for entering text and numbers. This is opened automatically if

needed. Here, use the arrow keys to select the letters you need and confirm with the "E" key.

Operation

Fig. 12: Virtual keyboard

5.4 Overview of the symbols used

Symbol Explanation

Intermediate statistics

Daily analysis

Monthly analysis

Annual analysis

21

Page 22

Operation

Symbol Explanation

Total analysis

Measured value

5.5 Confirming error messages

Error messages on the display are acknowledged by pressing the "E" key.

5.6 Communication; PC software installation

!

!

!

!

Note!

The current PC operating software (CD-ROM supplied) must be installed to be able to establish

communication between the unit and the PC (minimum V1.23.0.0).

5.6.1 Installing the provided PC software

Note!

The "Arial Unicode MS™" font must be installed on your PC to operate the provided PC software.

Otherwise certain characters might be displayed incorrectly or not at all. Check this on your PC

under "Control Panel - Fonts". If this font is not installed, please refer to your Microsoft Office

Microsoft Windows

Note!

The provided PC software is only supported by Windows

rights are required!

1. Install the supplied PC software on your computer. The program's Operating Instructions can

be printed out after installation, if required.

2. After the successful installation you can call up the program under "Start - Programs".

®

manual.

®

2000 and Windows® XP. Administrator

®

or

5.6.2 Communication via USB / USB driver installation

Once the provided PC operating software has been installed successfully, the unit can be connected

to the PC with a USB cable. The operating system automatically recognizes the new USB unit.

Note!

Proceed as follows to then install the USB driver (depends on operating system):

1. The Windows prompt "Should a connection be established with Windows Update to look for

software?" appears. Click "No, not this time" and then "Next".

22

!

2. The "What do you want the wizard to do?" window appears. Select "Install the software

automatically (Recommended)" and then click "Next".

You can now start the provided PC software to establish communication with the unit.

Note!

In the provided PC software, the USB interface is addressed like a COM port (serial interface). In

the Windows device manager, you can determine the COM port via which the unit can be

addressed. The unit is displayed in the device manager under "Connections (COM and LPT)" as

"ETU00xA (Com x)". The provided PC software supports the COM-ports 1 to 20 (from version

V1.21.2.0), if necessary reduce the allocation accordingly in the Windows equipment manager.

Page 23

!

2

3

5

2

3

4

5

6

7

8

2

3

5

2

3

4

5

6

7

20

Unit SUB-D 9-pin

modem SUB-D 9-pin

Unit SUB-D 9-pin

modem SUB-D 25-pin

"

Operation

5.6.3 Communication via serial interfaces RS232 / RS485

The RS232 serial interface can be accessed from the rear (9-pin Sub-D socket).

Note!

It is not possible to use the RS232 and RS485 interface simultaneously. The desired interface type

must be selected in the setup under "Communication - Serial Interface".

Alternatively to the RS232 interface, the RS485 interface can be accessed from the rear of the unit.

Caution!

When using an RS232/RS485 converter, ensure that it supports automatic changeover between

"sending" and "receiving" (e.g. W+T type 86000).

5.6.4 Communication via modem

In principle, any modem with a complete AT command set can be used for data transfer between

your unit with RS232 interface and the supplied PC software.

!

!

Note!

An industrial modem with a watch dog is recommended (e.g. WESTERMO).

Modem at unit

The modem, which is later connected to the unit, must be initialized once with the provided PC

software (Extras - Preparing modem for unit). The modem is, therefore, connected to the PC with

its original cable (1:1 modem calble - normally enclosed with every modem).

Initialization must be carried out with the same data format (baudrate, data bits, parity) with which

the measuring unit works.

After successful initialization, the modem is connected to the unit with a special modem cable.

Only three cables (TxD, RxD, GND), and 2 bridges on modem side are required.

Cable assignment:

Note!

The modem's original cable cannot be used for this because the unit and the modem have the same

pin assignments at the interface plug.

Fig. 13: Modem cable assignment

Modem at PC

The modem, which works from the PC, does not have to be initialized. Connection to the PC is

made with the original modem cable (normally included with the modem).

The first connection to the receiver is made as follows:

• In the provided PC software, select "Display/change unit setup - Add new device"

• Select unit, set interface parameters manually (COM, baudrate, number of data bits, parity)

• Activate modem operation - set up modem

23

Page 24

Operation

!

• Enter receiver's telephone number.

• OK

• Now enter the telephone number under which the unit connected by modem can be reached and

start the connection with "OK".

Fig. 14: Modem connection at unit and PC

5.6.5 Communication via Ethernet (TCP/IP)

In principle, all units equipped with an internal Ethernet interface can be integrated into a PC

network (TCP/IP Ethernet).

The unit(s) can be accessed by any of the PCs in the network using the provided PC software. There

is no need to install driver software ("COM redirection") on the PC because the provided PC

software has direct access to the Ethernet.

The system parameters "IP address", "Subnetmask" and "Gateway" are input directly at the unit.

Changes to the system parameters are not activated until the SETUP menu is closed and the settings

accepted. Only then will the unit work with the new settings.

Note!

It is not possible for several clients (PC) to communicate with a server (unit) at the same time. If a

second client (PC) tries to establish a connection, he receives an error message.

Ethernet commissioning

Before a connection can be established via the PC network, the system parameters in the unit must

be set via "Setup - Communication - Ethernet".

!

!

Note!

You can obtain the system parameters from your relevant network administrator.

The following system parameters must be set:

1. IP address

2. Subnetmask

3. Gateway

Note!

This menu does not appear unless the unit is equipped with an internal Ethernet interface.

24

Page 25

Operation

5.6.6 Communication in the network via the provided PC software

After the unit has been configured and connected to the PC network, a connection to one of the

PCs in the network can be established.

The following steps are required for this:

1. Install the supplied PC software on the PC via which communication is to take place.

(see Section 5.6.1)

2. A new unit now has to be registered in the database. After the unit description has been input,

select how the unit settings are to be transferred. In this case, select Ethernet (TCP/IP).

Fig. 15: Registering a new unit in the PC database

Now enter the IP address. The port address is 8000.

The unit address set at the unit and the release code must also be set correctly here.

Fig. 16: Entering the IP address of the new unit

Confirm the entry with "Continue" and start the transfer with OK.

The connection is now established and the unit is saved in the unit database.

25

Page 26

Commissioning

6 Commissioning

6.1 Function check

Make sure that all post-connection checks have been carried out before you put your unit into

operation:

• See Section 3.5 'Post-installation check'

• Checklist in Section 4.4 'Post-connection check'

6.2 Switching on the unit

Once the operating voltage is applied, the display lights up and the unit is ready for operation.

• When you first commission the unit, program the set up in accordance with the description in the

Operating Instructions.

• If you are commissioning a unit that is already configured, measuring is immediately started in

accordance with the settings. The values of the display group currently configured appear on the

display.

6.2.1 Setting the operating language

The default setting for the operating language is English (GB). A different operating language can be

configured in the set up (see Section 6.4.1).

-> Set up ->Basic settings -> Language

F

Fig. 17: Change the operating language

6.3 Unit Set up

6.3.1 General

Access to the set up is released when the unit leaves the factory and can be locked in various ways,

e.g. entering a 4-digit release code ( Chap. 6.4.1 "Basic settings").

When locked, basic settings can be checked but not changed.

26

You can also put your unit into service and/or configure it via PC. The following are available for

this:

1. CompactFlash card slot for reading in parameters saved on CompactFlash card.

2. Rear RS232/RS485/Ethernet system interface

3. Front-panel USB system port

Advantages of configuration via PC

• The unit data is saved in a database and can be accessed again at any time.

• Text entries can be carried out more quickly and efficiently by keyboard.

Page 27

Commissioning

• Measured values can also be read out, archived and displayed on the PC with the same program.

!

!

Note!

The interfaces cannot be used at the same time for configuration. Select the interface used under

"Set up - Communication".

Note!

To delete the temporary set up files you should delete the CompactFlash CF card and the internal

memory after the commissioning (unit set up).

Delete CF:

Delete internal memory:

memory

Main menu -> CompactFlash (CF) functions -> Delete CF

F

Main menu -> Diagnostic/unit information -> Delete internal

F

6.3.2 Set up via interface and provided PC software

Fig. 18: Example: Set up via the provided PC software

Procedure for set up via interface and the provided PC software:

Start

Install the provided PC software on the PC or laptop (see chapter 5.5)

Connect the unit interface (RS232 / RS485, USB or Ethernet) to the PC

Check selected communication settings in the unit (see Section 6.4.4 communication)

Create the new unit in the provided PC software and make interface settings

Once the PC software has identified the unit, the current unit settings are displayed. Now all the parameters can be

Save the settings in the unit database and send to the unit

configured (see the next chapter)

End

27

Page 28

Commissioning

Procedure set up via interface and the provided PC software:

!

!

Note!

In order to be able to use this function, the unit must already be registered in the PC database, and/

or register in the PC database at first.

1. Connect the unit interface (RS232 / RS485, USB or Ethernet) to the PC.

2. Start the provided PC software and add new unit in the PC database:

- Select "Unit -> Display/change unit set-up/add new unit"

- Select "Unit -> Add new unit" in the new window.

- Assign general informations for the new unit. Select the interface for the unit set up. Select

"Continue". Select the appropriate interface parameters (must agree with the attitudes to

communication on the unit). Select "Continue". A summary of the data to the new unit is

indicated. With "OK" a connection to the unit is made and the new unit will be registered in

the PC data base.

3. Adjust the unit settings and select "Finished -> Transmit set-up to unit". The new set up

parameters are automatically transferred to the unit.

4. Finally, the unit settings should be saved in the unit database. Select "Finished -> Store set-up

into unit database".

6.3.3 Set up via CompactFlash card

Save the unit settings on the PC onto the CompactFlash card using the provided PC software. This

set up file can be adopted into the unit if released under "Main menu -> CompactFlash (CF)

functions -> Load set-up from CF".

Note!

In order to be able to use this function, the unit must already be registered in the PC database, and/

or register in the PC database at first. In addition a CompactFlash card slot must be present at the

PC.

Procedure set up via CompactFlash card:

1. Copy set up to CompactFlash card:

- Insert a formatted CompactFlash card into the unit.

- In the main menu, select "CompactFlash (CF) functions -> Copy set-up to CF".

- In the main menu, select "CompactFlash (CF) functions -> Safely remove CF".

- Remove the CompactFlash card from the unit and insert it into the CompactFlash card slot

in the PC.

2. Start the provided PC software and add new unit in the PC database:

- Select "Unit -> Display/change unit set-up/add new unit"

- Select "Unit -> Add new unit" in the new window.

- Assign general informations for the new unit. Select "Parameter file from a data source (e.g.

diskette, ATA flash card)". Select "Continue". Select the appropriate parameter file (*.rpd) from

the CompactFlash card. Select "Continue". A summary of the data to the new unit is indicated.

With "OK" the new unit will be registered in the PC data base.

3. Adjust set up in the provided PC software and save in the associated database:

- Adjust the unit settings.

- Select "Finished -> Store set-up into unit data base". The new set up parameters are saved in

the PC database. Transfer the new set up file to the CompactFlash card in your PC: select

"Finished -> Create set-up data carrier (diskette/ATA flash card)" and select the suitable

CompactFlash card slot.

- Remove the CompactFlash card from the slot in the PC and insert it into the unit.

4. Read the new set up into one (or more) unit(s):

- In the main menu, select "CompactFlash (CF) functions -> Load set-up from CF". Repeat this

procedure, to set up further units with this parametrization.

28

Page 29

"

"

!

Commissioning

Caution!

If the set up CompactFlash card is not removed, the measurement data will begin to be saved after

approx. 5 minutes. The set up data is still kept. Please change the CompactFlash card if the

measurement data is not meant to be saved onto this card.

Caution!

Correct and safe functioning is only guaranteed with genuine CompactFlash cards of the

manufacturer (see "Accessories", Section 8).

6.3.4 Set up direct at the unit (via unit keyboard)

•Press F. The main menu appears.

•With

• Confirm with

• Use the softkey to call up the Help on the entry selected.

Key function in set up

Cancel entries or return to previous screen.

Z

UT

VW

: Enter key = selects the highlighted function, starts parameter change.

F

Note!

• Every parameter is modified via a dialog box.

• The altered settings only take effect once you return to normal operation by pressing

times (confirm you accept changes with

data.

Procedure for unit configuration/set up:

or W select the desired chapter

V

F

Moves cursor left or right.

Moves bar up or down, changes parameter/sign.

). Until this time, the unit still works with the previous

F

several

Z

Start

Basic settings (language, date/time, save cycle, CompactFlash, etc.)

Signal settings for the analog inputs (signal type, input range, etc.)

Signal settings for the digital inputs (function, designation, etc.)

Signal settings of the set points and alarm relays (if necessary)

Signal settings for the relays (operating mode, description, etc.)

Communication settings (USB/RS232/RS485/Ethernet)

End

29

Page 30

Commissioning

6.4 The set up window (at main menu)

Fig. 19: The main menu

Fig. 20: The set up window

The individual parameters are summarized in the set up menu in the following sections:

Basic settings

see Section 6.4.1

Signal settings

see Section 6.4.2

Signal analysis

see Section 6.4.3

Communication

see Section 6.4.4

Service

see Section 6.4.5

Settings that are not channel specific, this means date, time etc.

Settings of the connected analog inputs (incl. set point settings), relays and the digital

input.

Set up, in order to obtain signal analysis for presettable time ranges/cycles as well as a

manual reset of the signal analysis. Function only visible if a digital input has been

activated as a counter!

Set up only required if you are using the USB, RS232, RS485 or Ethernet interface of the

unit (PC operation, serial data read-out, modem operation, etc.).

Settings such as calibration etc.

Caution!

"

Changes must only be made by skilled personnel. The unit will operate incorrectly if

incorrect settings are made!

Input principle:

1. Begin changing parameters each time with

2. Use

3. If the parameter is set correctly, press

or W to scroll through the values, symbols and picklists.

V

F

.

F

.

30

Page 31

Commissioning

!

Note!

• Any settings that are displayed in gray cannot be selected/cannot be changed (only notes, or

option not available/not activated).

• With the factory setting "0000" (delivery status), configuration is possible at any time. It can be

protected against unauthorized manipulation by entering a 4-digit release code. This has to be

entered when the settings are later changed, if the unit settings are to be changed by keyboard.

Tip: Make a note of your release code. Store it somewhere where unauthorized persons do not

have access to it.

• The altered settings only take effect once you return to normal operation by pressing

times and confirming with

. Until this time, the unit still works with the previous data.

F

several

Z

6.4.1 Set up - Basic settings

Settings that are not channel specific, this means date, time etc.

Procedure for basic settings:

Start

Assign unit identifier

Select the operating language from the list

Select decimal separator (comma or point)

Select temperature unit (°C, °F, K)

Select the save cycle for saving measured values

Select alarm cycle (= measured value save cycle in event of alarm limit violation)

Set the release code. Factory setting: "0000", i.e. unit setting is possible any time without code.

Make date/time settings (e.g. select region for summer time changeover).

Make settings for external memory (CompactFlash)

Set rear illumination. The "screen saver" increases the operating life of the rear illumination.

End

31

Page 32

Commissioning

Fig. 21: Set up, Basic settings

"Basic settings"

menu items

Unit identifier Individual unit identifier (max. 22 characters).

Note!

!

Is also saved on the CompactFlash card.

Language Select unit operating language. Factory setting: English (GB)

Decimal separator Select in which form the decimal separator character is to be displayed. Picklist: comma, point

Temp. units Selection of temperature units. All directly connected thermocouples or resistance thermometers (RTD) are displayed in the preset

engineering units. Picklist: °C, °F, K

Save cycle Selects the cycle for normal operation (= no set point alarm) in which data is stored and displayed

Alarm cycle Selects the cycle for alarm condition (e.g. alarm set point violation) in which data is stored and displayed.

Release code Using this code set up access can be protected from unauthorized persons. In order to change any parameter the correct code must

Picklist: off, 1s to 1h, (1min)

Note!

!

Depending upon adjusted save cycle the available recording length changes. Tables to the typical recording length you will find in

the technical data, chapter 10.8.3.

Picklist: off, 1s to 1h, (1min)

be entered. Factory setting: "0", i.e. changes are possible any time.

Tip: Make a note of the code and store in a safe place.

Note!

!

This release code must be also entered in the provided PC software.

Configurable parameters

(Factory settings bold marked)

Set point code The unit is protected by a release code. If a set point code has been set up then the user can change the alarm set points after entering

this code or the unit release code (all other operating positions cannot be changed).

Factory default: "0" means that alarm set points can only be changed by entering the release code.

Note!

!

Alarm set point code and release code should not be identical!

32

Page 33

Commissioning

"Basic settings"

menu items

Submenu:

Date/time set-up

Configurable parameters

(Factory settings bold marked)

Here you can find various date and time settings.

Fig. 22: Set up, Basic settings, "Date/time set-up" submenu

Date format Select in which format the date is to be set and displayed. (DD.MM.YYY)

Time format Select in which format the time is to be set and displayed. Picklist: 12 hours AM/PM or

24 hours

Actual date Set up the actual date for the unit.

Actual time Set up the actual time for the unit.

NT/ST changeover Function for summer time/normal time changeover.

NT/ST region

only at "NT/ST changeover automatic"

Date NT -> ST

only at "NT/ST changeover manual"

Time NT -> ST

only at "NT/ST changeover manual"

Date ST -> NT

only at "NT/ST changeover manual"

Time ST -> NT

only at "NT/ST changeover manual"

“Automatic”: changes as per the local regional regulations

“Manual”: changeover times can be set in the following addresses

“Off”: no changeover times required

Selects the regional settings for summer/normal time changeover. Picklist: Europe,

USA

Day, when in the spring a change from normal to summer time occurs.

Time when the time is moved forward by 1 hour on the day of the changeover from

normal time to summer time. (Format: hh:mm)

Day, when in the autumn a change from summer to normal time occurs.

Time when the time is moved back by 1 hour on the day of the changeover from

summer time to normal time. (Format: hh:mm)

33

Page 34

Commissioning

E

"Basic settings"

menu items

Submenu:

Display

Configurable parameters

(Factory settings bold marked)

Various general settings for the measured value display, e.g. grid etc.

Fig. 23: Set up, Basic settings, "Display" submenu

Channel ident. "Standard, 10 digit"

"With add. channel info.": enables entry of additional 13-character information text per

channel. This means that the channel identifier can be supplemented with, for example

individual tag numbers (e.g.: power station tag systems).

Note!

!

In normal operation, the additional information can be listed along with the 10-digit

channel identifier at "Main Menu -> Signal display -> Measurement point identifier".

Group identifier Group identifier which is used by the provided PC software. A 10-digit text can be

Grid divisions Indicates the number of lines ("amplitude grid") that should be displayed on the screen

Soft-key Please select the function for the softkey in the measured value display mode. Factory

entered here. Factory setting: Group 1

in the display mode "Curve". Example: display of 0 ... 100%: select 10 divisions, display

0 ... 14pH: select 14 divisions. Picklist: 1 to 20 (10)

Fig. 24: Grid divisions setting: example on left, 10 divisions, example on right, 14

setting: Event list

!

In the set up mode the softkey is always occupied with the integrated Help function!

divisions

Note!

34

Abb. 25: Variable "Soft-key"

Page 35

Commissioning

"Basic settings"

menu items

Submenu:

External memory

(CompactFlash CF)

Configurable parameters

(Factory settings bold marked)

Settings for the external data carrier (CompactFlash CF), amongst other things which data is to be stored in which format on the

external data carrier.

Fig. 26: Set up, Basic settings, "Ext. memory" submenu (CompactFlash CF)

Save as "Protected format": all data is stored in a manipulation protected encrypted format.

This data can only be visualized by using our software package.

"Open format (*.csv)": data is stored in a CSV format, this can be opened by a number

of different programs (e.g. MS Excel). (Attention: no manipulation security). MS Excel

limits the open format on max. 65535 lines.

Memory build-up "Stack memory": no more data can be stored once the data carrier is full.

"Ring memory (FIFO)": once the data carrier is full the oldest data is deleted so that new

data can be stored (first in first out (FIFO). Option only possible for "Protected format".

Separator for CSV

only at "Open format (*.csv)"

Operating time

only at "Open format (*.csv)"

Date/time

only at "Open format (*.csv)"

Warning at

only at "Stack memory"

Switches output

only at "Stack memory"

Specify which separator is used by your application (e.g. in Excel = semicolon). Picklist:

comma, semicolon

Specify the format for which operating times should be saved/displayed. (0000:00:00)

Specify whether the date and the time should be saved in a joint column or in two

separate columns when saving the data in CSV format.

Gives warning before the data carrier is x% full. A warning is indicated on the unit and

this is also stored in the event list. A relay can also be switched on. (90%)

When the warning "Data carrier full" is displayed a relay can also be switched on.

Picklist: not used, relay 1 to 4 (Cl. xd-xd)

35

Page 36

Commissioning

"Basic settings"

menu items

Submenu:

Screen saver

Configurable parameters

(Factory settings bold marked)

Note!

!

To increase the life span of the LCDs the rear illumination can be switched off (= screen saver).

If the unit is in an alarm condition (e.g. open circuit or alarm point violation), the screen saver is not switched on or is automatically

switched off. In this way, alarms can be read even if the screen saver is activated.

Fig. 27: Set up, Basic settings, "Screen saver" submenu

Screen saver “Switched off”: LCD is always switched on

“Switch on for x min.”: display goes dark after x minutes. All other functions remain in

operation. Press an operating key: Illumination is switched back on. (x = 10, 30, 60

min.)

“Switched daily”: enter time span. With this setting, the display turns dark 1 minute

after the last key was pressed.

ON daily from

only at "Switched daily"

OFF daily from

only at "Switched daily"

Set time (hh:mm) from which the rear illumination is to be switched off (e.g. shift end

time). (20:00)

Set time (hh:mm) from which the rear illumination is to be switched on (e.g. shift start

time). (07:00)

36

Page 37

Commissioning

6.4.2 Setup - Signal Settings

Setup of the analog and digital inputs, mathematics function, set points, relays and display.

Procedure for the signal settings of the analog inputs:

Start

Set signal for analog input (current, voltage, resistance therm., thermocouple)

Set range for analog input (e.g. 0-20 mA for current)

Enter channel identifier

Select plot type

Enter unit/dimension

Enter number of digits after decimal point

Enter measuring range and zoom range

Enter damping/filter (if necessary)

Enter offset for start and end of measuring range

Set fault mode (e.g. in event of cable open circuit)

Do set points have to be defined? Yes

->

No

Select channel display for curve display, bar graph and digital display

End

See Signal Settings -> Set Points

(see Page 46)

37

Page 38

Commissioning

Fig. 28: Setup, Signal Settings

"Signal Settings"

menu items

Submenu: Analog

Inputs, Analog Input x

Configurable parameters

(factory settings are highlighted in bold)

Setup of the connected analog measurement point

View or change settings for the selected channel.

Fig. 29: Setup, Signal Settings,

Analog Inputs submenu, Analog Input x

Signal Select the type of signal connected (current, voltage, etc.). The channel is switched off

if no signal type is selected (factory default).

Picklist: Switched Off, Current, Voltage, Resistance Therm., Thermocouple or

Mathematics.

38

Setting the mathematics functions:

Channels can be calculated with one another. The mathematics function can be selected

here instead of an analog signal. Here, the user can specify whether an analog signal is

attached or whether a calculation should be performed. Mathematics channels are

treated like "real" analog inputs, e.g. set points, totalizing. If mathematics is selected, an

analog signal can no longer be recorded there. If the device is a 3-channel device, analog

input 4 - 6 can be used as a mathematics channel.

Note!

!

Analog input 1 cannot be selected as a mathematics channel.

Range Select the input range or which resistance thermometer/thermocouple is connected.

Connection

Only for "Resistance thermometer"

Channel Ident. Identifier for the measurement point connected to this input (e.g. "Pressure",

The respective terminal layout can be found in the operating manual or on the rear of

the unit.

Specify whether RTDs are connected as 2-, 3- or 4-wire systems. Factory setting: 3-

wire

"Temperature", "Heater", ...). 10-character entry. Factory setting: Analog x

Page 39

Commissioning

"Signal Settings"

menu items

Configurable parameters

(factory settings are highlighted in bold)

Additional Info.

Note!

!

Only available if switched on in the basic

settings.

Plot Type The analog inputs are scanned in a 100ms cycle. Depending on the save cycle, the

Engineering Unit Input of the engineering (physical) unit for the measuring point connected to this input

Decimal Point Number of places after decimal point for the display. Picklist: 0 to 5 number of places

Formula

Only for "Mathematics"

Additional information on channel identifier, e.g. the respective measurement point tag

number (example: tag numbers in power stations). In normal operation, the additional

information can be listed along with the 10-digit channel identifier at "Main Menu ->

Signal display -> Measurement point identifier". 13-character entry.

selected data are determined from the scanned values and saved (e.g. with a save cycle

of 1 min., the average of 600 values (10x60) is calculated and saved).

"Instantaneous Value": the value pending for the save cycle is saved.

"Average": the average value during the save cycle is calculated and saved.

"Minimum Value": the minimum value is calculated and saved.

"Maximum Value": the maximum value is calculated and saved.

"Envelope Curve": both minimum and maximum values are saved (requires higher

memory capacity)

(e.g. %, bar, °C, m/h, etc.). 6–digit entry.

Note!

!

Note: cannot be changed for resistance thermometers and thermocouples!

after the decimal point

f = (y1*a) ? (y2*b) +c: linking two channels;

f = g(y1...y2) * b + c: calculates the average or sum total of two or more channels.

Mathematics channels are treated like "real" analog inputs, (set points etc.).

Function 'g'

Only for "Mathematics"

Signal 'y1'

Only for "Mathematics"

Factor 'a'

Only for "Mathematics"

Math Operator '?'

Only for "Mathematics"

Signal 'y2'

Only for "Mathematics"

Factor 'b'

Only for "Mathematics"

Constant 'c'

Only for "Mathematics"

Range Start Transmitters convert the physical measurement into a standard signal. Example: 0-14

"Sum" or "Average" of channels 'y1' to 'y2'.

Picklist: Not Used, Sum, Average

'y1' signal that should be linked to another signal.

Picklist: Analog Input x

Note!

!

Other mathematics channels can be used for the calculation if their channel number is

smaller than the number of the mathematics channel that is computed.

Factor 'a' by which the value of the 'y1' signal is multiplied.

Factory setting: 1.0

Mathematical operator for combining the channels. To deactivate the second part of the

formula (y2*b), select "Not Used" for the operator.

Picklist: Not Used, - (Subtraction), + (Addition), * (Multiplication), / (Division)

Second signal, "y2", which is to be linked with the first one, "y1".

Picklist: Analog Input x

Factor 'b' by which the 'y2' signal or the function g(y1...y2) is multiplied.

Factory setting: 1.0

'c' constant is added to the result of linking the two signals y1 and y2. Factory setting:

0.0

Entry in the (technical or physical) unit of the mathematics channel.

pH from the sensor is converted to 4-20 mA. Enter the starting point of the

measurement range. A "0" for 0-14 pH.

Note!

!

Note: cannot be changed for resistance thermometers and thermocouples!

39

Page 40

Commissioning

"Signal Settings"

menu items

Configurable parameters

(factory settings are highlighted in bold)

Meas. Range End The same as "Range Start". Enter the end value for the measurement range, e.g. "14" for

a 0-14 pH transmitter.

Note!

!

Note: cannot be changed for resistance thermometers and thermocouples!

Zoom Start If the total transmitter range is not being used then the lower value of the required range

Zoom End As in "Zoom Start". Enter the upper value of the required range here. Example:

Damping/ Filter The more unwanted interference there is on the measurement signal the higher the

Comparison Point

Only for "Thermocouples"

Comparison Temp.

Only for "Comparison Point - External"

Submenu: Meas. Value Correct.

(Offset)

can be entered here (higher resolution). Example: transmitter 0-14 pH, required range:

5-9 pH. Set "5" here. The zoom has no influence on the storage.

transmitter 0-14 pH, required range: 5-9 pH. Enter "9" here.

value that should be entered here. Result: fast changes will be damped/suppressed.

Only used when directly connecting thermocouples.

"Internal": compensation of the voltage errors by measuring the terminal temperature.

"External": compensation of error voltage by using thermostated comparison points.

Settings for the external comparison temperature (only when connecting thermocouples

directly).

Correction value, this can be entered before further evaluation takes place (e.g. in order

to smooth out measurement chain tolerances).

Follow these instructions:

1. Measure the current value at the lower measurement range.

2. Measure the current value at the upper measurement range.

3. Enter the respective target and actual values in the submenu for the lower and

upper correction values.

Lower Correction Value:

Correction value for the lower measurement range. Example of measuring range 0°C to

100°C:

Target Value: enter the target value here (e.g.: 0°C).

Actual Value: enter the value actually measured here (e.g. 0.5°C).

Upper Correction Value:

Correction value for the upper measurement range. Example of measuring range 0°C to

100°C:

Target Value: enter the target value here (e.g.: 100°C).

Actual Value: enter the value actually measured here (e.g. 100.5°C).

40

Page 41

Commissioning

"Signal Settings"

menu items

Configurable parameters

(factory settings are highlighted in bold)

Submenu: Totalization (option) Settings only required if this analog measuring point is to be totalized for calculating the

volume for example. For analysis periods, see "Signal analysis".

Totalization: using the totalization function, the volume in m3 can be calculated from

an analog signal (e.g. flow in m

Totalization Base: select the corresponding time base. Example: ml/s -> time base

seconds (s); m

Total. Eng. Unit: here, enter the unit for the volume determined by totalization (e.g.

3

").

"m

Scroll Display: select the counter which should be displayed alternately with the

instantaneous value. Factory setting: No, Only Instant Value

Low flow cut off: specify how the device should perform low flow cut off:

Area Around Zero Point: all values in the zero point range that are smaller than the

(absolute) "Low flow cut off" are not totalized (e.g. Low flow cut off = 0.1m/h: all values

<= -0.1m/h and >= 0.1m/h are totalized; all other values are discarded).

Absolute Value: all values that are smaller than the configured "Low flow cut off" are not

totalized (e.g. Low flow cut off = 0.1m/h: all values < 0.1 m/h are not totalized).

Low flow cut off: specify the threshold value for the low flow cut off here. Factory

setting: 0 %

3

/h -> time base hours (h).

3

/h). Picklist: no, yes

Calc. Factor: factor for calculating the totalized value (e.g. the transmitter returns l/s

-> totalization base = second -> desired unit is m

setting: 1

Submenu: Fault Mode Settings that lay down how this channel is to react under fault conditions (e.g. cable

open circuit, over range).

Fault Switches: switches the selected relay under fault conditions. The terminal

numbers are shown in brackets. Picklist: Not Used, Relay x (Term. xx-xx)

Save Event: stores an event in the event memory when a fault condition occurs.

Picklist: No, Yes

Cable Open Circ.: The cable open circuit detection function can be switched on and

off here.

In the case of thermocouples: When thermocouples are switched in parallel, enabled

cable open circuit detection causes false alarms. Picklist: no, yes

In the 1 to 5 V range: Values < 0.8 V or > 5.2 V are assessed as cable open circuits.

There is no underrange/overrange. Picklist: no, yes

NAMUR NE43: Switch monitoring of the 4 to 20 mA range as per NAMUR

Recommendation NE43 on and off. The following error ranges apply when NE43 is

switched on:

3.8 mA: underrange (display shows: vvvvvv)

20.5 mA: overrange (display shows: ^^^^^^)

3.6 mA or 21.0 mA: open circuit (display shows: – – – –)

Picklist: On, Off

-> enter 0.001 as the factor). Factory

On Error: Specify the value the unit should continue to use (for calculations) if the

measured value is not valid (e.g. cable open circuit).

Picklist: Last Valid Value, Range Start, Meas. Range End, Value is Invalid, Free

Configuration

Error Value: only if "Free Configuration" is selected for the error.

The unit continues calculating with this value if a fault occurs. Factory setting: 0 %

(See the following table)

Copy Settings Copies settings from actual channel to selected channel. Picklist: No, in Analog Input x

41

Page 42

Commissioning

Fault mode

Failsafe mode if an

input signal/variable is invalid

(e.g. cable open circuit, invalid result of mathematics calculation; e.g. dividing by zero).

Set failsafe

"Invalid" channel Dependent channels

mode

Value is Invalid • "– – – – –" or "******" are

displayed

• Channel name is highlighted in red

• Status "F" is displayed

• Limit value monitoring is suspended

• Totalization is suspended

• A relay is switched if set.

• Analysis: if the error is pending during the entire analysis

period, the value in the analysis is invalid. If there was at least

1 valid value, the result of the analysis is valid.

All other settings • "– – – – –" or "******" are

displayed

• Channel name is highlighted in red

• Status "F" is displayed

• Value is totalized

• A relay is switched if set.

• Analysis: if the error is pending during the entire analysis

period, the value in the analysis is invalid. If there was at least

1 valid value, the result of the analysis is valid.

• "– – – – –" or "******" are

displayed

• Channel name is highlighted in red

• Status "F" is displayed

• Limit value monitoring/totalization:

depends on the set failsafe mode of this channel

• A relay is switched if set.

• Analysis: if the error is pending during the entire analysis

period, the value in the analysis is invalid. If there was at least

1 valid value, the result of the analysis is valid.

• Calculated value is displayed

• Channel name is highlighted in red

• Status "F" is displayed

The channel is treated as "valid", i.e.:

• Value is totalized

• Limit value monitoring remains active

• If the result of the calculation for this channel is invalid, the set

failsafe mode for this channel applies

• Analyses: the channel is analyzed as normal

42

Page 43

Commissioning

Setup - Signal Settings, submenu: Digital Inputs

Procedure for the signal settings of the digital inputs:

1. Start

2. Select the function of the digital channel

3. Control input 3. On/off event 3. Pulse counter 3. Operational time 3. Event + operation

time

4. Enter channel

identifier

4. Enter channel

identifier

4. Enter channel

identifier

4. Enter channel

identifier

4. Enter channel

identifier

5. Select action 5. Enter event text

for status change

from L->H

5. Enter unit/

dimension

5. Where necessary,

enter current

counter reading to

continue a total/

yearly counter

5. Enter event text

for status change

from L->H

6. End 6. Enter event text

for status change

from H->L

6. Select the number

of decimal places

6. Select display for

counter type (e.g.

daily counter)

6. Enter event text

for status change

from H->L

7. End 7. Enter pulse factor 7. End 7. Where necessary,

enter current

counter reading to

continue a total/

yearly counter

8. Where necessary,

enter current

counter reading to

continue a total/

yearly counter

8. Select display for

counter type (e.g.

daily counter)

9. Select display for

counter type (e.g.

daily counter)

9. End

10. End

43

Page 44

Commissioning

"Signal Settings"

menu items

Submenu:

Digital Inputs

Configurable parameters

(factory settings are highlighted in bold)

Setting up only required if the digital inputs (e.g. events) are to be used.

View or change the settings for the selected digital channel.

Fig. 30: Setup, Signal Settings,

"Digital Input 1" submenu

Function Select the required function. Digital inputs are High active; this means the described

effect is achieved by a high input.

Low = -3 to +5 V, High = +12 to +30 V

Note!

!

Depending on the selected function, the unit's user interface adapts itself, so that each

time only parameters that are required for safe unit functioning have to be checked/set.

The following functions are available:

"Switched Off": digital input is not active.

"Control Input": various control functions can be activated using the digital input.

"On/Off Event": switch conditions of connected units (e.g. pump on/off) are displayed

and stored.

"Pulse Counter": pulses are added up and stored as numeric counter values.

"Operational Time": running times of external units are recorded e.g. for maintenance

purposes.

Example: if the d ai ly r unni ng ti me of a pump is to b e save d, ac ti vat e "Op er ati onal T im e"

here and "Daily Analysis" under "Signal Analysis".

"Event+Operation Time":

both the on/off events and the operating time of an external unit are recorded and

stored.

Channel Ident. Measurement point name (e.g. "Pump") or description of the function of this input (e.g.

"Fault message"). 10-character entry.

Factory setting: digital 1

Additional Info.

Note!

!

Only available if switched on in the basic

settings.

Action

Only for "Control Input"

Additional information on channel identifier, e.g. the respective measurement point tag

number (example: tag numbers in power stations). In normal operation, the additional

information can be listed along with the 10-digit channel identifier at "Main Menu ->

Signal display -> Measurement point identifier". 13-character entry.

Set up the function of the control input.

"Start Recording": data are displayed/stored only if the input is active.

"Screensaver On": display is switched off so long as the input is active.

"Ext. Inter. Analysis": starts and ends the external intermediate analysis (the analysis

progresses as long as the input is active).

"Set Up Lock": setup cannot be changed as long as the input is active.

"Time Synchronization": rounds off the current time to a full minute, rounding off to the

higher minute if >= 30s and to the lower minute if <30s.

44

Page 45

Commissioning

"Signal Settings"

menu items

Configurable parameters

(factory settings are highlighted in bold)

Engineering Unit Technical unit of the count input, e.g. liters, m, etc. Only active for the functions "Pulse

Counter", "Operational Time" and "Event+Operation Time". This value can only be

changed for the "Pulse Counter" function. 6-character entry.

Decimal Point Number of places after decimal point for the display. Picklist: 0 to 5

number of places after the decimal point. Only active for "Impulse Counter" function.

Factory setting: one (XXXX.X)

1 impulse = Pulse factor = factor which, when multiplied by the input pulse, results in the required

physical value. Example: 1 pulse equals 5 m –> enter "5". Only active for "Pulse

Counter" function. Factory setting: 1.0

Description 'H' Description of the status if the digital input is activated. This text is both shown in the

display and saved to memory. Only active for "On/Off Event" and "Event+Operation

Time" functions. Factory setting: on

Description 'L' Description of the status if the digital input is not activated. This text is both shown in

the display and saved to memory. Only active for "On/Off Event" and "Event+Operation

Time" functions. Factory setting: off

Message Window "Do Not Display": no message is output when the digital input switches.

"Display+Acknowledge": a message window is displayed that has to be acknowledged

by pressing a key.

Only active for "On/Off Event" and "Event+Operation Time" functions.

Save Event Determines whether the condition change from low to high or high to low is stored in

the event list. Note: increased memory capacity needed.

Only active for "On/Off Event" and "Event+Operation Time" functions.

Picklist: Yes, No

Event Text L->H Description of condition change from low to high. Event text is stored (e.g. start filling).

22-character entry. Only active for "Event+Operation Time" and "On/Off Event"

functions.

Event Text H->L Description of condition change from high to low. Event text is stored (e.g. stop filling).