Page 1

BA01146R/09/EN/05.16

71344137

Valid as of version

ENU000A, V2.01.xx

Products Solutions Services

Operating Instructions

Ecograph T, RSG35

Universal Data Manager

Page 2

Page 3

Ecograph T, RSG35 Table of contents

Table of contents

1 Document information .............. 6

1.1 Document function ..................... 6

1.2 Symbols used .......................... 6

1.2.1 Safety symbols .................. 6

1.2.2 Electrical symbols ................ 6

1.2.3 Symbols for certain types of

information .................... 7

1.2.4 Symbols in graphics ............... 7

1.3 Terminology .......................... 7

1.4 Registered trademarks ................... 7

2 Basic safety instructions ............ 8

2.1 Requirements concerning the staff .......... 8

2.2 Designated use ........................ 8

2.3 Workplace safety ....................... 8

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 9

2.6 Safety information for table version (option) ... 9

2.7 IT security ............................ 9

3 Product description ................. 9

3.1 Product design ......................... 9

4 Incoming acceptance and product

identification ..................... 10

4.1 Incoming acceptance ................... 10

4.2 Scope of delivery ...................... 10

4.3 Product identification ................... 10

4.3.1 Nameplate .................... 10

4.4 Storage and transport .................. 11

5 Installation ....................... 11

5.1 Mounting requirements ................. 11

5.1.1 Installation dimensions ........... 11

5.2 Mounting the measuring device ........... 11

5.3 Post-mounting check ................... 12

6 Electrical connection .............. 13

6.1 Connection conditions .................. 13

6.2 Connection instructions ................. 13

6.2.1 Cable specification ............... 13

6.3 Connecting the measuring device .......... 14

6.3.1 Terminal assignment on the rear of

the device ..................... 14

6.3.2 Supply voltage .................. 15

6.3.3 Relays ........................ 15

6.3.4 Digital inputs; auxiliary voltage

output ........................ 15

6.3.5 Analog inputs .................. 16

6.3.6 Connection example: Auxiliary

voltage output as transmitter power

supply for 2-wire sensors .......... 17

6.3.7 Connection example: Auxiliary

voltage output as transmitter power

supply for 4-wire sensors .......... 18

6.3.8 Option: RS232/RS485 interface (rear

of device) ..................... 18

6.3.9 Ethernet connection (rear of

device) ....................... 19

6.3.10 Option: Ethernet Modbus TCP slave .. 20

6.3.11 Option: Modbus RTU slave ......... 20

6.3.12 Connections at front of device ...... 20

6.4 Post-connection check .................. 22

7 Operation options ................. 23

7.1 Overview of operation options ............ 23

7.2 Structure and function of the operating

menu .............................. 23

7.2.1 Operating menu for operators and

maintenance personnel ........... 23

7.2.2 Operating menu for experts ........ 24

7.2.3 Submenus and users ............. 24

7.3 Measured value display and operating

elements ............................ 26

7.4 Display representation of symbols used in

operation ........................... 27

7.4.1 Symbols in operating menus ....... 28

7.4.2 Symbols in the event logbook ....... 28

7.5 Entering text and numbers (virtual

keyboard) ........................... 28

7.6 Channel color assignment ............... 29

7.7 Access to the operating menu via the local

display ............................. 29

7.8 Device access via operating tools .......... 29

7.8.1 Field Data Manager (FDM) analysis

software (SQL database support) .... 29

7.8.2 Web server .................... 30

7.8.3 OPC server (optional) ............ 30

7.8.4 FieldCare/DeviceCare configuration

software (included in the delivery) ... 30

8 System integration ................ 31

8.1 Integrating the measuring device in the

system ............................. 31

8.1.1 General notes .................. 31

8.1.2 Ethernet ...................... 31

8.1.3 Modbus RTU/TCP slave ........... 31

9 Commissioning .................... 32

9.1 Function check ....................... 32

9.2 Switching on the measuring device ......... 32

9.3 Setting the operating language ............ 32

Endress+Hauser 3

Page 4

Table of contents Ecograph T, RSG35

9.4 Configuring the measuring device (Setup

menu) .............................. 32

9.4.1 Step-by-step: to the first measured

value ........................ 33

9.4.2 Step-by-step: set or delete the limit

values ........................ 33

9.4.3 Setup directly at the device ........ 33

9.4.4 Setup via SD card or USB stick ...... 34

9.4.5 Setup via Web server ............. 34

9.4.6 Setup via FieldCare/DeviceCare

configuration software (included in

the delivery) ................... 35

9.5 Advanced settings (Expert menu) .......... 36

9.6 Configuration management .............. 36

9.7 Simulation ........................... 37

9.8 Protecting settings from unauthorized

access .............................. 37

10 Operation ......................... 38

10.1 Displaying and modifying current Ethernet

settings ............................. 38

10.2 Reading the device locking status .......... 38

10.3 Reading measured values ................ 39

10.4 Reading measured values via the Web

server .............................. 39

10.4.1 Access to the Web server via HTTP

(HTML) ...................... 40

10.4.2 Access to the Web server via XML ... 40

10.4.3 Remote control via the Web server ... 41

10.5 Data analysis and visualization with the Field

Data Manager software (FDM) provided ..... 41

10.5.1 Structure/layout of a CSV file ....... 42

10.5.2 Importing UTF-8-encoded CSV files

into spreadsheets ............... 43

10.6 Change group ........................ 43

10.7 Block keyboard/navigator ............... 43

10.8 Log on/log out ........................ 43

10.9 SD card/USB stick ..................... 43

10.9.1 Function of SD card or USB stick .... 43

10.9.2 Functions relating to the SD card or

USB stick ..................... 44

10.9.3 Notes on e-mail encryption ........ 45

10.9.4 Notes on WebDAV encryption ...... 45

10.9.5 SSL certificates ................. 46

10.10 Showing measured values history .......... 47

10.10.1 Historical data: changing a group .... 47

10.10.2 Historical data: Scroll speed ........ 47

10.10.3 Historical data: Time scaling ....... 47

10.10.4 Historical data: Time range

displayed ..................... 47

10.10.5 Historical data: Screenshot ......... 47

10.10.6 Historical data: Change the display

mode ........................ 47

10.11 Signal analysis ........................ 48

10.12 Search in trace ........................ 48

10.13 Changing the display mode .............. 48

10.14 Adjusting the brightness of the display ...... 48

10.15 Limit values .......................... 49

10.16 WebDAV Client ....................... 49

10.16.1 Access to the WebDAV server via

HTTP (HTML) .................. 49

11 Diagnostics and troubleshooting ... 50

11.1 General troubleshooting ................. 50

11.2 Troubleshooting ...................... 50

11.2.1 Device error/alarm relay .......... 50

11.3 Diagnostic information on the local display ... 51

11.4 Pending, current diagnostic messages ....... 54

11.5 Diagnosis list ......................... 54

11.6 Event logbook ........................ 55

11.7 Device information .................... 55

11.8 Diagnostics of measured values ........... 55

11.9 Diagnostics of outputs .................. 55

11.10 Simulation ........................... 55

11.10.1 E-mail test .................... 55

11.10.2 Test WebDAV Client ............. 56

11.10.3 Test time synchronization/SNTP .... 56

11.10.4 Relay test ..................... 56

11.11 Initialize modem ...................... 56

11.12 Resetting the measuring device ........... 56

11.13 Firmware history ...................... 57

12 Maintenance ...................... 57

12.1 Updating the device software ("firmware") .... 57

12.2 Instructions for enabling a software option ... 57

12.3 Cleaning ............................ 57

13 Repairs ........................... 58

13.1 General notes ........................ 58

13.2 Spare parts .......................... 58

13.3 Return .............................. 60

13.4 Disposal ............................ 60

14 Accessories ....................... 61

14.1 Device-specific accessories ............... 61

15 Technical data .................... 63

15.1 Function and system design .............. 63

15.2 Input ............................... 64

15.3 Output ............................. 67

15.4 Power supply ........................ 69

15.5 Performance characteristics .............. 71

15.6 Installation .......................... 71

15.7 Environment ......................... 73

15.8 Mechanical construction ................ 73

15.9 Display and operating elements ........... 74

15.10 Certificates and approvals ............... 77

15.11 Ordering information ................... 77

16 Appendix ......................... 78

16.1 Operating items in the "Expert" menu ....... 78

16.1.1 "System" submenu ............... 78

16.1.2 "Inputs" submenu ................ 97

4 Endress+Hauser

Page 5

Ecograph T, RSG35 Table of contents

16.1.3 "Outputs" submenu .............. 119

16.1.4 "Communication" submenu ........ 120

16.1.5 "Application" submenu ........... 134

16.1.6 "Diagnostics" submenu ........... 165

Index ................................. 170

Endress+Hauser 5

Page 6

Document information Ecograph T, RSG35

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

Integrated Operating Instructions

At the push of a button, the device displays operating instructions directly on the screen.

This manual complements the operating instructions in the device and explains what is

not directly described in the operating instructions.

1.2 Symbols used

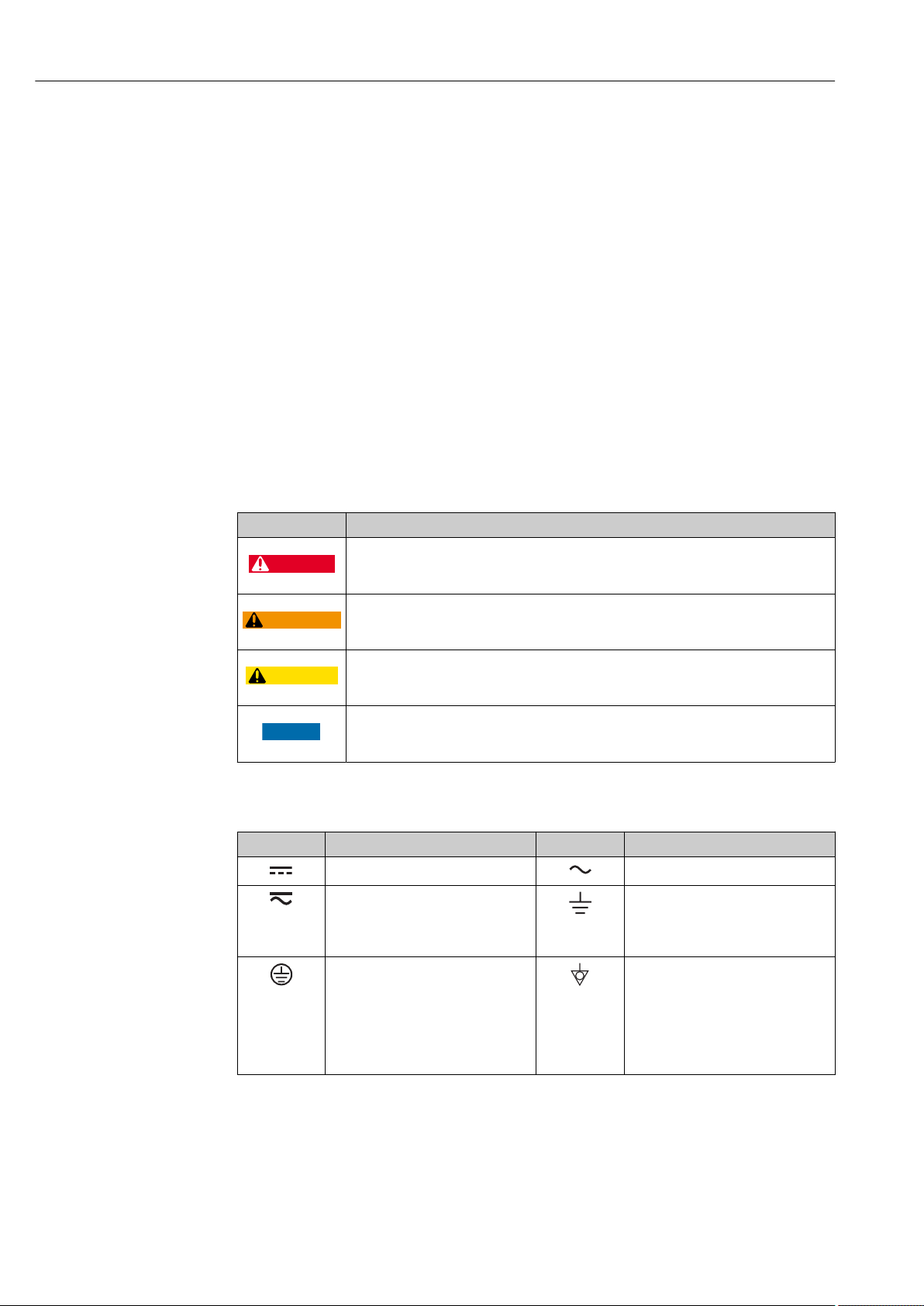

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line

or a star grounding system depending

on national or company codes of

practice.

6 Endress+Hauser

Page 7

Ecograph T, RSG35 Document information

,…,

,…,

-

.

1.2.3 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.4 Symbols in graphics

Symbol Meaning

1, 2, 3,... Item numbers

Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Flow direction

A0013441

Hazardous area

Indicates a hazardous area.

A0011187

Safe area (non-hazardous area)

Indicates a non-hazardous area.

A0011188

1.3 Terminology

To improve clarity, abbreviations or synonyms are used in these instructions for the

following terms:

• Endress+Hauser:

Term used in these instructions: "Manufacturer" or "Supplier"

• Ecograph T RSG35:

Term used in these instructions: "Device" or "Measuring device"

1.4 Registered trademarks

Modbus

Registered trademark of SCHNEIDER AUTOMATION, INC.

Endress+Hauser 7

®

Page 8

Basic safety instructions Ecograph T, RSG35

Internet Explorer®, Excel

Registered trademarks of the Microsoft Corporation

Mozilla Firefox

Registered trademark of the Mozilla Foundation

®

Opera

Registered trademark of Opera Software ASA.

Google Chrome

Registered trademark of Google INC.

®

TM

TM

2 Basic safety instructions

Reliable and safe operation of the device is guaranteed only if the user reads these

Operating Instructions and complies with the safety instructions they contain.

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists: must have a relevant qualification for this specific

‣

function and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

This device is designed for the electronic acquisition, display, recording, analysis, remote

transmission and archiving of analog and digital input signals in non-hazardous areas.

• The manufacturer accepts no liability for damages resulting from incorrect use or use

other than that designated. It is not permitted to convert or modify the device in any

way.

• The device is designed for installation in a panel and must only be operated in an

installed state.

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

8 Endress+Hauser

Page 9

Ecograph T, RSG35 Product description

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with the manufacturer.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from the manufacturer only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection, pressure vessel safety):

Based on the nameplate, check whether the ordered device is permitted for the

‣

intended use in the hazardous area.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. The manufacturer

confirms this by affixing the CE mark to the device.

2.6 Safety information for table version (option)

• The mains plug should only be inserted into a socket with a ground contact.

• The protective effect may not be suspended by an extension cable without a protective

ground.

• Relay outputs: U (max) = 30 V

(AC)/60 V (DC).

eff

2.7 IT security

The manufacturer only provides a warranty if the device is installed and used as described

in the Operating Instructions. The device is equipped with security mechanisms to protect

it against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

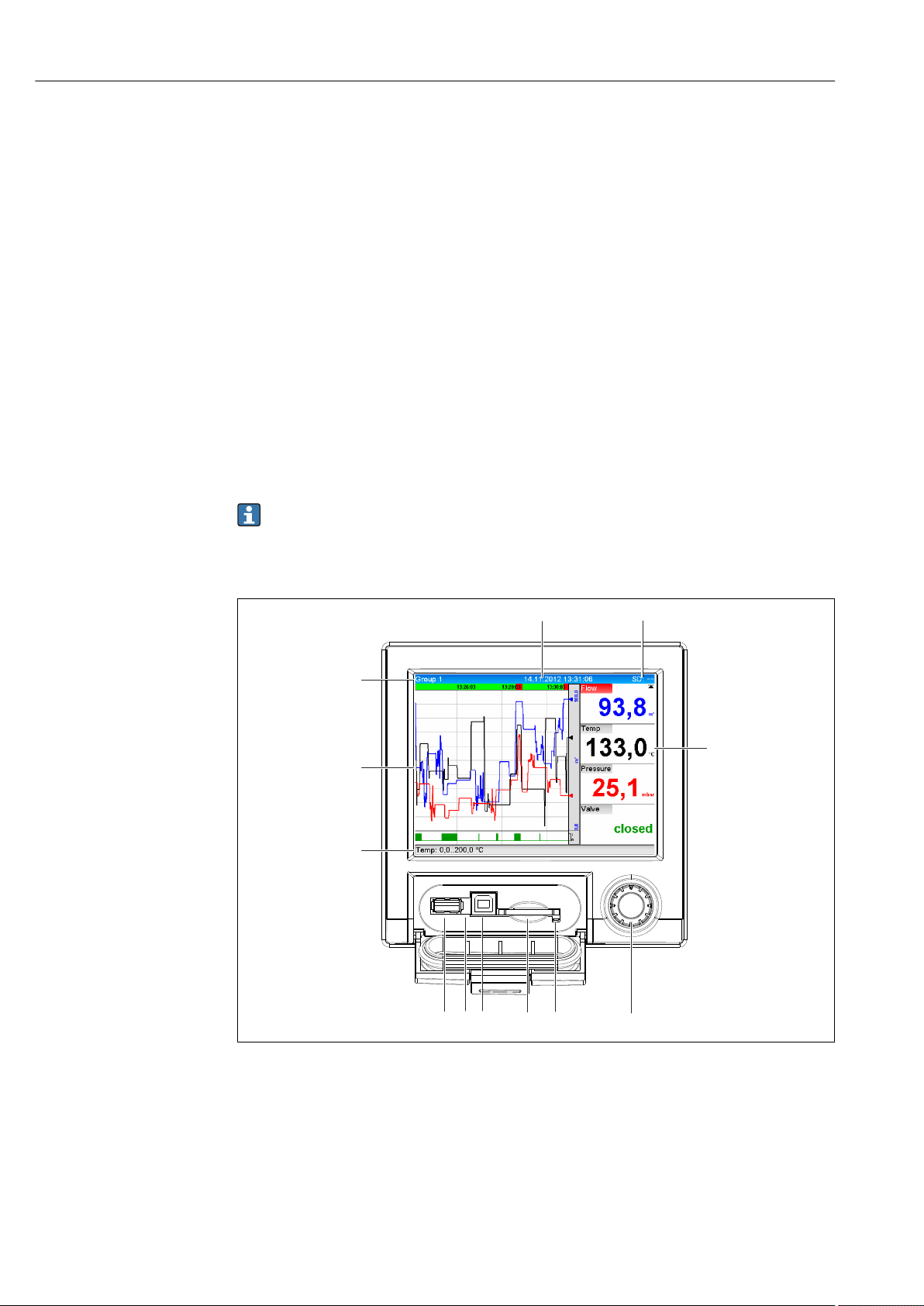

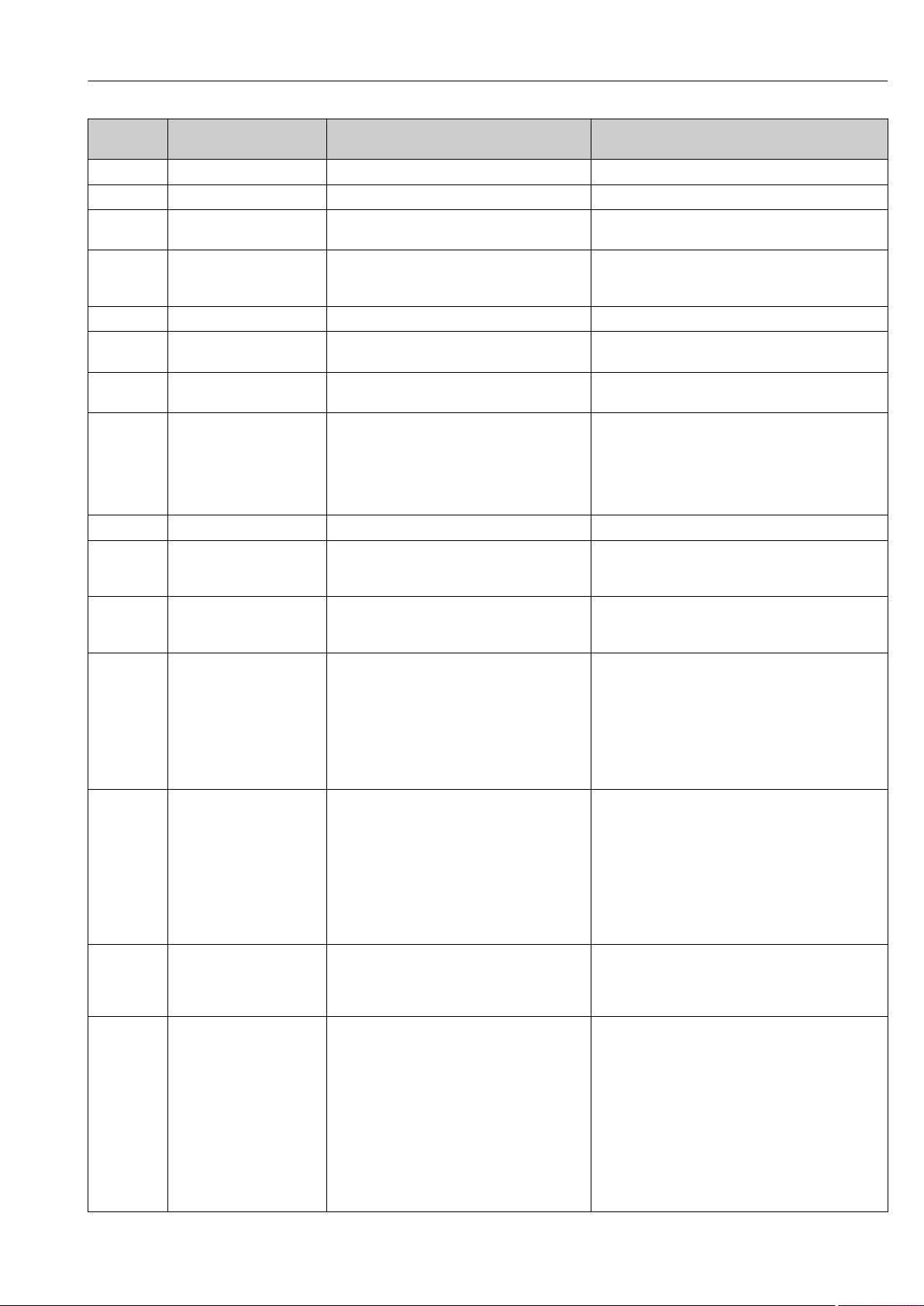

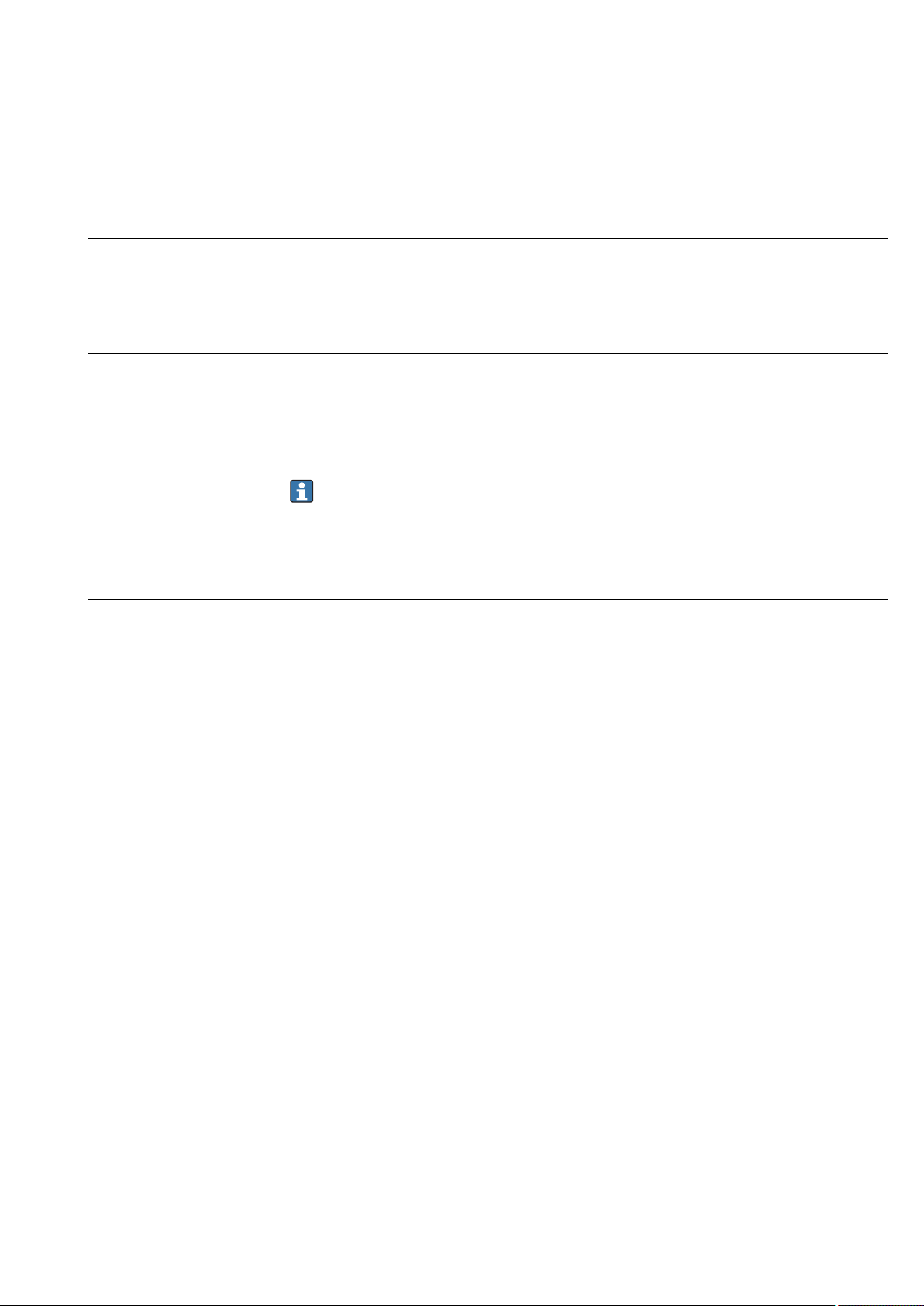

3 Product description

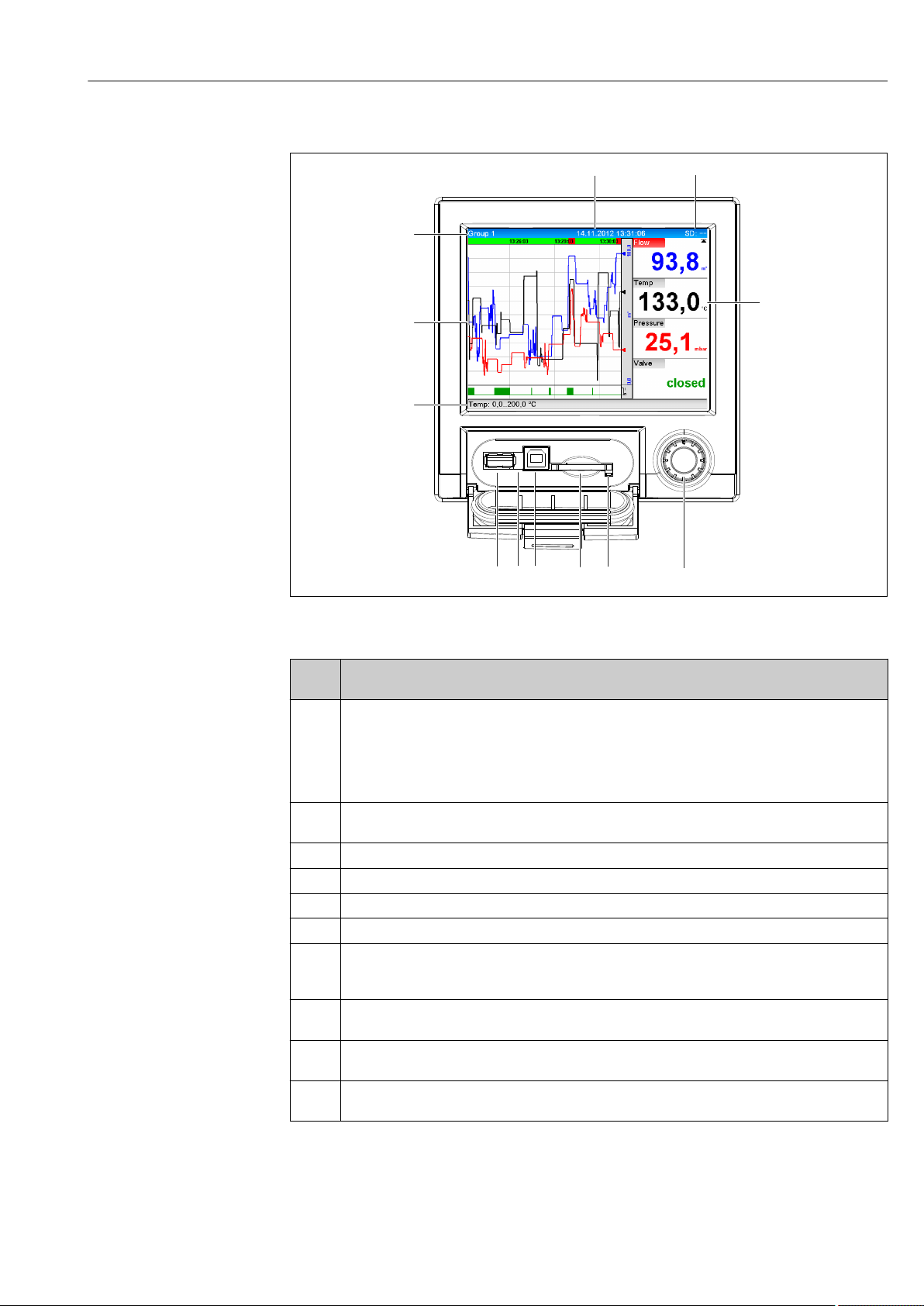

3.1 Product design

This device is best suited for the electronic acquisition, display, recording, analysis, remote

transmission and archiving of analog and digital input signals.

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Ecograph T, RSG35

1

2

3

4

5

6

7

35 VA

The device is intended for installation in a panel or cabinet. There is also the option of

operating it in a table-mounted or field-mounted housing.

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

On receipt of the goods, check the following points:

• Is the packaging or the content damaged?

• Is the delivery complete? Compare the scope of delivery against the information on your

order form.

4.2 Scope of delivery

The scope of delivery of the device comprises:

• Device (with terminals, as per order)

• 2 fastening clips

• USB cable

• Optional: Industrial grade SD card (card is located in the SD slot behind the flap on the

front of the housing)

• "Field Data Manager (FDM)" analysis software on DVD (Essential, Demo or Professional

version, depending on order)

• "FieldCare Device Setup / DeviceCare" configuration software on DVD

• Delivery note

• Multilanguage Brief Operating Instructions, hard copy

4.3 Product identification

4.3.1 Nameplate

Compare the nameplate with the following diagram:

1 Device nameplate (example)

1 Device tag

2 Order code, serial number, extended order code

3 Power supply, mains frequency

4 Maximum power consumption

10 Endress+Hauser

5 Temperature range

6 Software version; MAC address

7 Device approvals

A0019299

Page 11

Ecograph T, RSG35 Installation

4.4 Storage and transport

Compliance with the permitted environmental and storage conditions is mandatory. For

precise specifications, see the "Technical data" section→ 63 of the Operating

Instructions.

Please note the following:

• Pack the device so that is protected against impact for storage and transport. The

original packaging provides optimum protection.

• The permitted storage temperature is –20 to +60 °C (–4 to +140 °F).

5 Installation

5.1 Mounting requirements

NOTICE

Overheating due to buildup of heat in the device

To avoid heat buildup, please always ensure that the device is sufficiently cooled.

‣

The device is designed for use in a panel in non-hazardous areas.

• Ambient temperature range–10 to +50 °C (14 to 122 °F)

• Climate class as per IEC 60654-1: Class B2

• Degree of protection: IP65, NEMA 4 at front / IP20 housing at rear

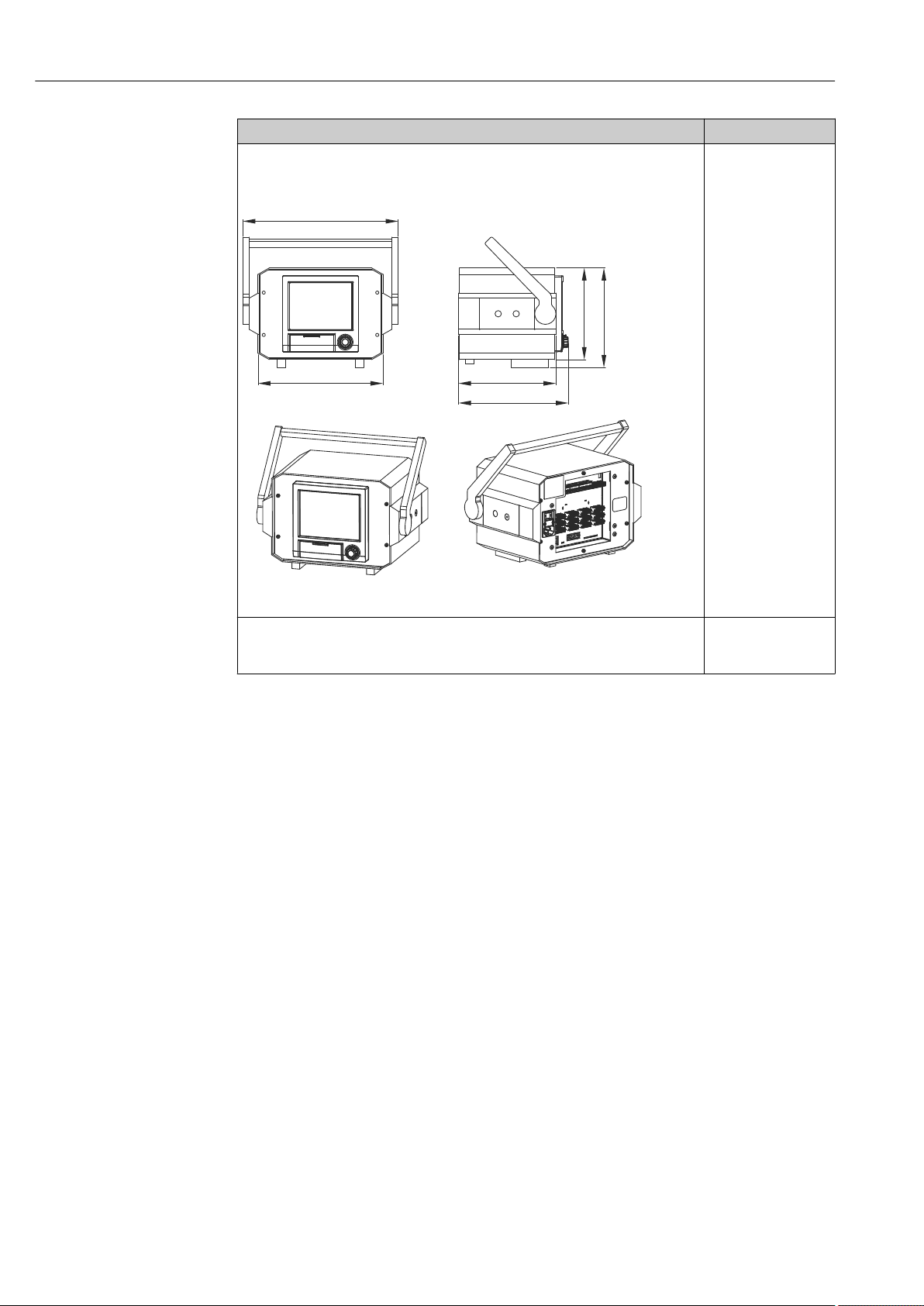

5.1.1 Installation dimensions

Please observe the installation depth of approx. 158 mm (6.22 in) for the device incl.

terminals and fastening clips.

• Panel cutout: 138 to 139 mm (5.43 to 5.47 in) x 138 to 139 mm (5.43 to 5.47 in)

• Panel strength: 2 to 40 mm (0.08 to 1.58 in)

• Angle of vision: from the midpoint axis of the display, 75° to the left and right, 65° above

and below.

• A minimum distance of 15 mm (0.59 in) mm (inch) between the devices must be

observed if aligning the devices in the Y-direction (vertically above one another). A

minimum distance of 10 mm (0.39 in) mm (inch) between the devices must be observed

if aligning the devices in the X-direction (horizontally beside one another).

• Securing to DIN 43 834

5.2 Mounting the measuring device

Mounting tool: For installation in the panel, all you need is a screwdriver.

Endress+Hauser 11

Page 12

Installation Ecograph T, RSG35

144 (5.67)

144 (5.67)

141 (5.55)

17 (0.67)

34

(1.34)

X

Y

A0019301

2 Panel mounting and dimensions in mm (Inch)

1. Push the device through the panel cutout from the front. To avoid heat buildup,

maintain a distance of > 15 mm (>0.59 in) from walls and other devices.

2. Hold the device level and hang the fastening clips in the openings (1 x left, 1 x right).

3. Evenly tighten the screws on the fasting clip using a screwdriver to guarantee a

secure seal to the control panel (torque 100 Ncm).

5.3 Post-mounting check

• Is the sealing ring undamaged?

• Does the seal run all around the housing collar?

• Are the threaded rods properly tightened?

• Is the device fixed firmly in the center of the control panel cutout?

12 Endress+Hauser

Page 13

Ecograph T, RSG35 Electrical connection

6 Electrical connection

6.1 Connection conditions

WARNING

L

Danger! Electric voltage!

The entire connection of the device must take place while the device is de-energized.

‣

The mixed connection of safety extra-low voltage and dangerous contact voltage to the

‣

relay is not permitted.

Apart from the relays and the supply voltage, only energy-limited circuits according to

‣

IEC/EN 61010-1 may be connected.

Danger if protective ground is disconnected

The ground connection must be made before all other connections.

‣

NOTICE

Cable heat load

Use suitable cables for temperatures of 5 °C (9 °F) above ambient temperature.

‣

Incorrect supply voltage can damage the device or cause malfunctions

Before commissioning the device, make sure that the supply voltage matches the

‣

voltage specifications on the nameplate.

Check emergency shutdown for device

Provide suitable switch or circuit breaker in building installation. This switch must be

‣

provided close to the device (within easy reach) and marked as a circuit breaker.

Protect the device from overload

Provide overload protection (nominal current = 10 A) for power cable.

‣

Incorrect wiring may result in the device being destroyed

Note terminal designation on the rear of the device.

‣

Energy-rich transients in the case of long signal lines

Install suitable overvoltage protection (e.g. E+H HAW562) upstream.

‣

6.2 Connection instructions

6.2.1 Cable specification

Cable specification, spring terminals

All connections on the rear of the device are designed as pluggable screw or spring

terminal blocks with reverse polarity protection. This makes the connection very quick and

easy. The spring terminals are unlocked with a slotted screwdriver (size 0).

Please note the following when connecting:

• Wire cross-section, auxiliary voltage output, digital I/O and analog I/O: max. 1.5 mm

(14 AWG) (spring terminals)

• Wire cross-section, mains: max. 2.5 mm2 (13 AWG) (screw terminals)

• Wire cross-section, relays: max. 2.5 mm2 (13 AWG) (spring terminals)

• Stripping length: 10 mm (0.39 in)

No ferrules must be used when connecting flexible wires to spring terminals.

Shielding and grounding

Optimum electromagnetic compatibility (EMC) can only be guaranteed if the system

components and, in particular, the lines - both sensor lines and communication lines - are

2

Endress+Hauser 13

Page 14

Electrical connection Ecograph T, RSG35

5

6

9

1

Frequency

shielded and the shield forms as complete a cover as possible. A shielded line must be used

for sensor lines that are longer than 30 m. A shield coverage of 90% is ideal. In addition,

make sure not to cross sensor lines and communication lines when routing them. Connect

the shield as often as possible to the reference ground to ensure optimum EMC protection

for the different communication protocols and the connected sensors.

To comply with requirements, three different types of shielding are possible:

• Shielding at both ends

• Shielding at one end on the supply side with capacitance termination at the device

• Shielding at one end on the supply side

Experience shows that the best results with regard to EMC are achieved in most cases in

installations with one-sided shielding on the supply side (without capacitance termination

at the device). Appropriate internal device wiring measures must be taken to allow

unrestricted operation when EMC interference is present. These measures have been

taken into account for this device. Operation in the event of disturbance variables as per

NAMUR NE21 is thus guaranteed.

Where applicable, national installation regulations and guidelines must be observed

during the installation! Where there are large differences in potential between the

individual grounding points, only one point of the shielding is connected directly with the

reference ground.

If the shielding of the cable is grounded at more than one point in systems without

potential matching, mains frequency equalizing currents can occur. These can damage

the signal cable or significantly impact signal transmission. In such cases the shielding

of the signal cable is to be grounded on one side only, i.e. it may not be connected to

the ground terminal of the housing. The shield that is not connected should be

insulated!

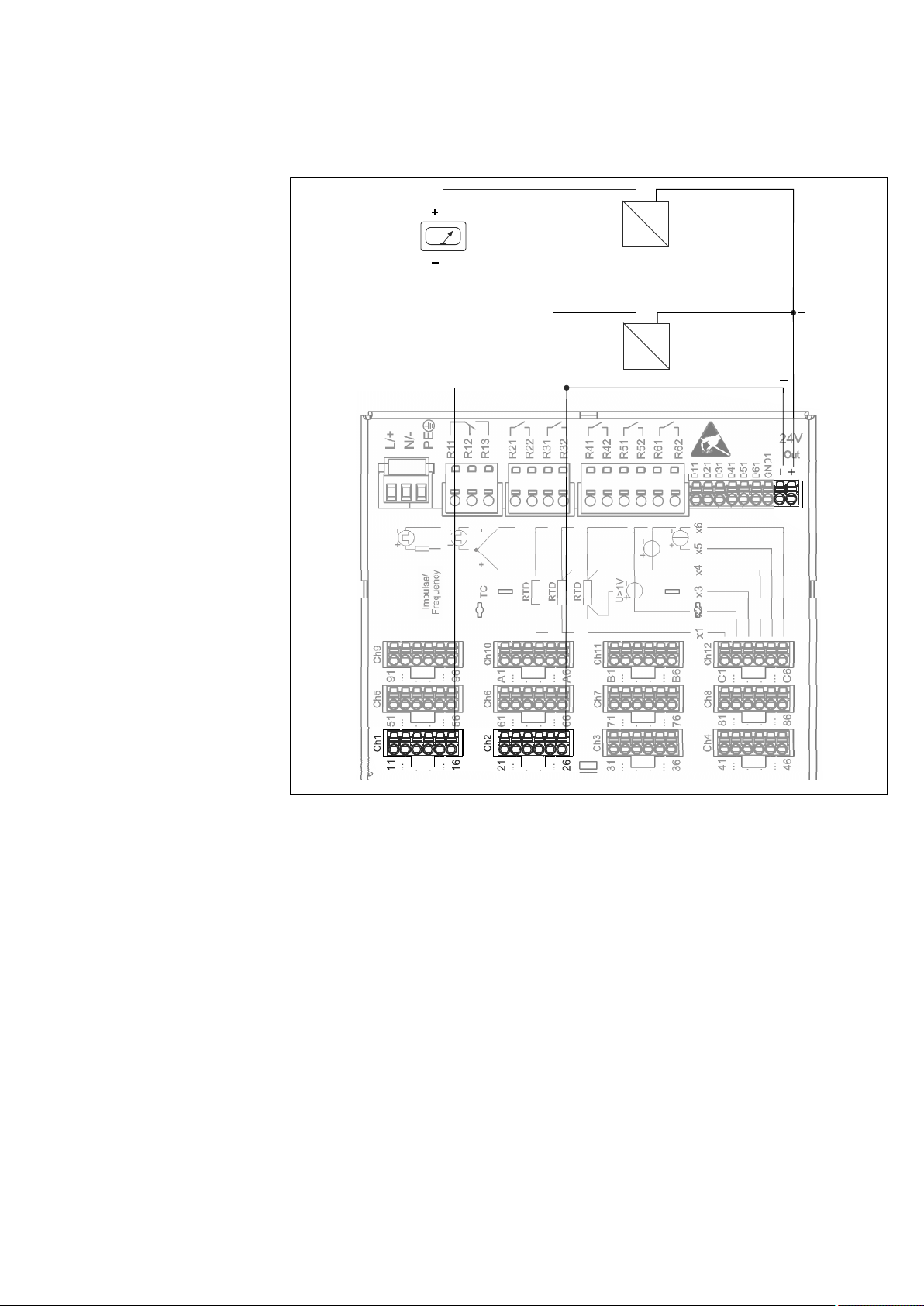

6.3 Connecting the measuring device

6.3.1 Terminal assignment on the rear of the device

A0019304

3 Terminals on the rear of the device

14 Endress+Hauser

Page 15

Ecograph T, RSG35 Electrical connection

6.3.2 Supply voltage

Power unit type Terminal

A0019103

100-230 VAC L+ N- PE

Phase L Zero conductor N Ground

24 V AC/DC L+ N- PE

Phase L or + Zero conductor N or - Ground

6.3.3 Relays

Type Terminal (max. 250 V, 3 A)

Alarm relay 1 R11 R12 R13

Changeover

contact

Normally

closed contact

1)

(NC)

Normally open

contact (NO)

2)

Relay 2 to 6 Rx1 Rx2

Switching contact Normally open

1) NC = normally closed (breaker)

2) NO = normally open (maker)

6.3.4 Digital inputs; auxiliary voltage output

Type Terminal

Digital input

1 to 6

Auxiliary

voltage

output, not

stabilized,

max. 250

mA

D11 to D61 GND1

Digital input 1 to 6

(+)

Ground (-) for digital

inputs 1 to 6

24V Out - 24V Out +

- Ground + 24V (±15%)

contact (NO

2)

A0019103

)

A0019103

Endress+Hauser 15

Page 16

Electrical connection Ecograph T, RSG35

Chx

x1

x2

x3

x4

x5

x6

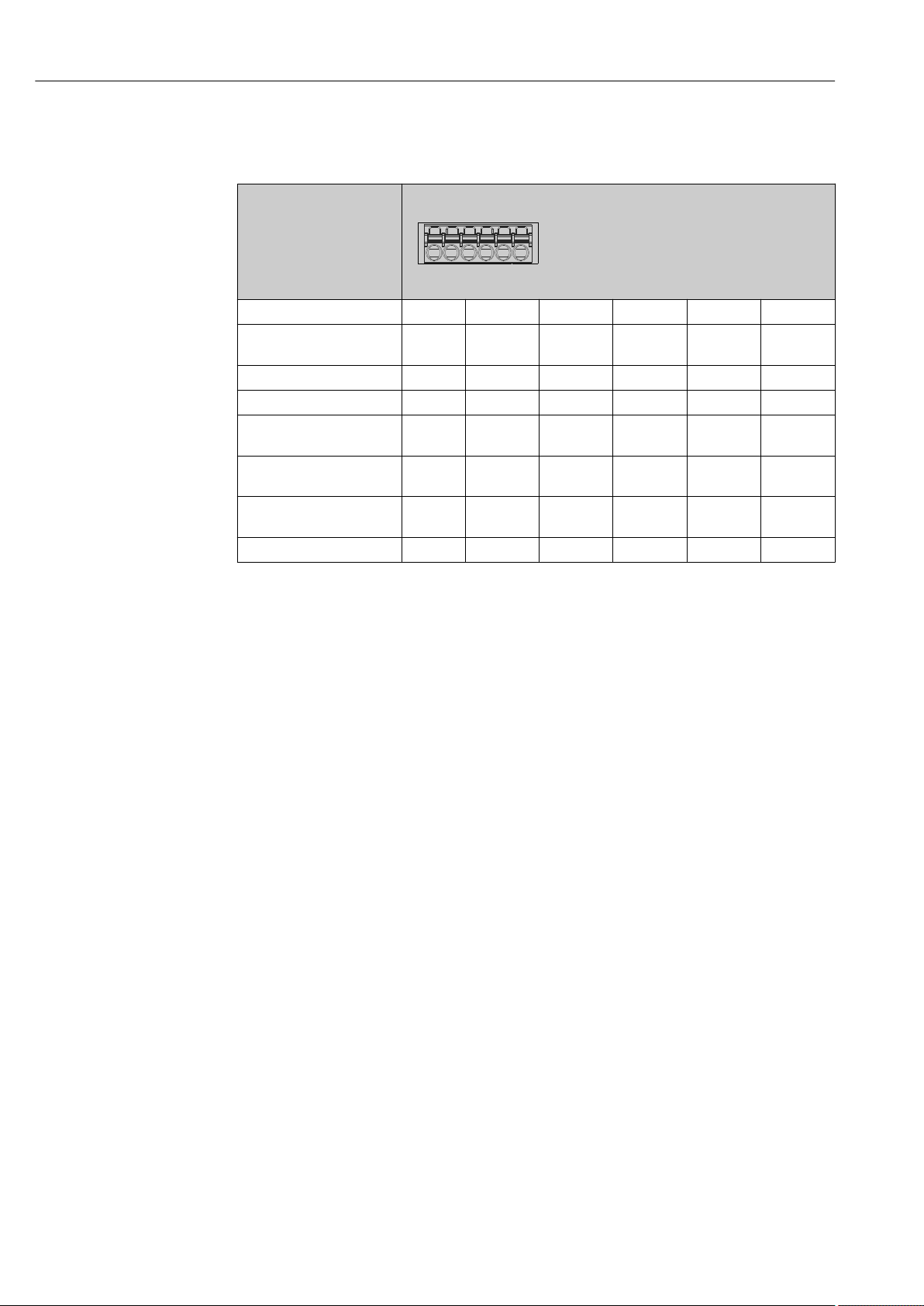

6.3.5 Analog inputs

The first digit (x) of the two-digit terminal number corresponds to the associated channel:

Type Terminal

A0019303

x1 x2 x3 x4 x5 x6

Current/pulse/frequency

1)

input

Voltage > 1V (+) (-)

Voltage ≤1V (+) (-)

Resistance thermometer

RTD (2-wire)

Resistance thermometer

RTD (3-wire)

Resistance thermometer

RTD (4-wire)

Thermocouples TC (+) (-)

(A) (B)

(A) b (sense) (B)

(A) a (sense) b (sense) (B)

(+) (-)

1) If a universal input is used as a frequency or pulse input and the voltage is >2.5 V, a series resistor must be

used in series connection with the voltage source. Example: 1.2 kΩ series resistor at 24 V

16 Endress+Hauser

Page 17

Ecograph T, RSG35 Electrical connection

Frequency

Out: max. 250 mA

_

+

+

-

Y

+

_

+

-

Y

I

I

1

2

3

6.3.6 Connection example: Auxiliary voltage output as transmitter power supply for 2-wire sensors

4 Connecting auxiliary voltage output when using as a transmitter power supply for 2-wire sensors in the

current measuring range. (When connecting channel CH3-12, see pin assignment CH1-2.)

1 Sensor 1 (e.g. Cerabar from Endress+Hauser)

2 Sensor 2

3 External indicator (optional) (e.g. RIA16 from Endress+Hauser)

A0020259

Endress+Hauser 17

Page 18

Electrical connection Ecograph T, RSG35

Frequency

_

+

+

_

Out: max. 250 mA

+

-

Y

+

-

I

24V

+

-

Y

+

-

I

24V

1

2

3

6.3.7 Connection example: Auxiliary voltage output as transmitter power supply for 4-wire sensors

5 Connecting auxiliary voltage output when using as a transmitter power supply for 4-wire sensors in the

1 Sensor 1 (e.g. temperature switch TTR31 from Endress+Hauser)

2 Sensor 2

3 External indicator (optional) (e.g. RIA16 from Endress+Hauser)

6.3.8 Option: RS232/RS485 interface (rear of device)

current measuring range. (When connecting channel CH3-12, see pin assignment CH1-2.)

A0020260

Use shielded signal lines for serial interfaces!

A combined RS232/RS485 connection is available on a shielded SUB D9 socket at the rear

of the device. This can be used for data transfer and to connect a modem. For

communication via modem, we recommend an industrial modem with a watchdog

function.

18 Endress+Hauser

Page 19

Ecograph T, RSG35 Electrical connection

Further units

Termination

resistor

(typical 120 )Ω

To PC: Cable with

9 pol. Sub-D plug

RxD - 3 GND - 5

TxD - 2

To PC: Cable with

25 pol. Sub-D

plug

To modem: Cable with

9 pol. Sub-D socket

To modem: Cable with

25 pol. Sub-D socket

A0019305-EN

Type Pin of the SUB-D9 socket

1 2 3 4 5 6 7 8 9

RS232

assignment

RS485

assignment

TxD (data

output)

RxD (data

input)

GND

GND RxD/TxD – RxD/TxD +

Unoccupied connections should be left empty.

Maximum cable length:

RS232: 2 m (6.6 ft)

RS485: 1000 m (3280 ft)

Only one interface can be used at any one time (RS232 or RS485).

6.3.9 Ethernet connection (rear of device)

The Ethernet interface can be used to integrate the device via a hub or switch into a PC

network (TCP/ IP Ethernet). A standard patch cable (e.g. CAT5E) can be used for the

connection. Using DHCP, the device can be fully integrated into an existing network

without the need for additional configuration. The device can be accessed from every PC in

the network.

• Standard: 10/100 Base T/TX (IEEE 802.3)

• Socket: RJ-45

• Max. cable length: 100 m

• Galvanic isolation; testing voltage: 500 V

Endress+Hauser 19

Page 20

Electrical connection Ecograph T, RSG35

6 4

3

2

1

5

7

8

9

10

11

12

Meaning of the LEDs

Beneath the Ethernet connection (see rear of device) there are two light emitting diodes

which indicate the status of the Ethernet interface.

• Yellow LED: link signal; is lit when the device is connected to a network. If this LED is not

illuminated then communication is impossible.

• Green LED: Tx/Rx; flashes irregularly if the device is transmitting or receiving data.

6.3.10 Option: Ethernet Modbus TCP slave

The Modbus TCP interface is used to connect to higher-ranking SCADA systems (Modbus

master) to transmit all measured values and process values. Up to 12 analog inputs and 6

digital inputs can be transmitted via Modbus and stored in the device. Form a physical

point of view, the Modbus TCP interface is identical to the Ethernet interface.

6.3.11 Option: Modbus RTU slave

The Modbus RTU (RS485) interface is galvanically isolated (testing voltage: 500 V) and is

used to connect to higher-ranking systems to transmit all measured values and process

values. Up to 12 analog inputs and 6 digital inputs can be transmitted via Modbus and

stored in the device. Connection is via the combined RS232/RS485 interface.

Modbus TCP and Modbus RTU cannot be used at the same time.

6.3.12 Connections at front of device

6 Front of device with open flap

1 Navigator

2 LED at SD slot. Orange LED lights up or flashes when the device writes to or reads from the SD card.

3 Slot for SD card

4 USB B socket "Function" e.g. to connect to PC or laptop

5 Green LED lit: power supply present

6 USB A socket "Host" e.g. for USB memory stick or external keyboard

7-12 For a description of the displays, see the "Operability" section

20 Endress+Hauser

A0019501

Page 21

Ecograph T, RSG35 Electrical connection

USB connection type A (host)

A USB 2.0 port is available on a shielded USB A socket at the front of the device. A USB

stick, for example, can be connected to this interface as a storage medium. An external

keyboard or USB hub may also be connected.

USB connection type B (function)

A USB 2.0 port is available on a shielded USB B socket at the front of the device. This can

be used to connect the device for communication with a laptop, for example.

USB-2.0 is compatible with USB-1.1 or USB-3.0, i.e. communication is possible.

Information on USB devices

The USB devices are detected by the "plug-and-play" function. If several devices of the same

type are connected, only the USB device that was connected first is available. Settings for

the USB devices are made in the setup. A maximum of 8 external USB devices (incl. USB

hub) can be connected if they do not exceed the maximum load of 500 mA. If overloaded,

the corresponding USB devices are automatically disabled.

Requirements with regard to an external USB hub

The USB devices are detected by the "plug-and-play" function. If several devices of the same

type are connected, only the USB device that was connected first is available. Settings for

the USB devices are made in the setup. A maximum of 8 external USB devices (incl. USB

hub) can be connected if they do not exceed the maximum load of 500 mA. If overloaded,

the corresponding USB devices are automatically disabled.

Requirements with regard to the USB stick

There is no guarantee that all manufacturers' USB sticks will function faultlessly. That is

why an industrial grade SD card is recommended to ensure the reliable recording of data.

→ 61

The USB stick must be formatted to FAT or FAT32. NTFS format is not readable. The

system supports only USB sticks with max. 32 GB.

The USB stick must not be connected to the device via a USB hub. Interference from

other USB devices may result in data loss.

Requirements with regard to an external USB keyboard

The system only supports keyboards which can be addressed using generic drivers (HID

keyboard - Human Interface Device). Special keys are not supported (e.g. Windows keys).

Users can only enter characters that are available in the entry character set of the device.

All unsupported characters are rejected. It is not possible to connect a wireless keyboard.

The following keyboard layouts are supported: DE, CH, FR, USA, USA International, UK, IT.

See setting under "Setup -> Advanced setup -> System -> Keyboard layout".

Requirements for the SD card

Industrial grade SD-HC cards with max. 32 GB are supported.

Use only the industrial grade SD cards described in the "Accessories" section of the

Operating Instructions. These have been tested by the manufacturer and guaranteed

to function faultlessly in the device. → 61

The SD card must be formatted to FAT or FAT32. NTFS format is not readable.

Endress+Hauser 21

Page 22

Electrical connection Ecograph T, RSG35

6.4 Post-connection check

Device condition and specifications Notes

Are cables or the device damaged? Visual inspection

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate? -

Are all terminals firmly engaged in their correct slot? -

Are the mounted cables strain-relieved? -

Are the power supply and signal cables correctly connected? See connection diagram and

rear of device.

22 Endress+Hauser

Page 23

Ecograph T, RSG35 Operation options

System

Communication

Operation

Setup

Advanced setup

Diagnostics

Measured Values

Operator

Maintenance

Diagnostics list

Outputs

Output

Event logbook

Device information

Simulation

Change group

SD card/USB stick

History

Change date/time

Date/time setup

Change display mode

Adjust brightness

Security

External memory

Messages

Screen saver

Device options,...

Inputs

Universal inputs

Digital inputs

Relaiy 1 - 6

Ethernet

Serial interface

Modbus Slave

Application

Maths

Signal analysis

Limits

Signal groups

E-mail

Initialize modem

Signal analysis

WebDAV Client

Lock operation

Search in trace

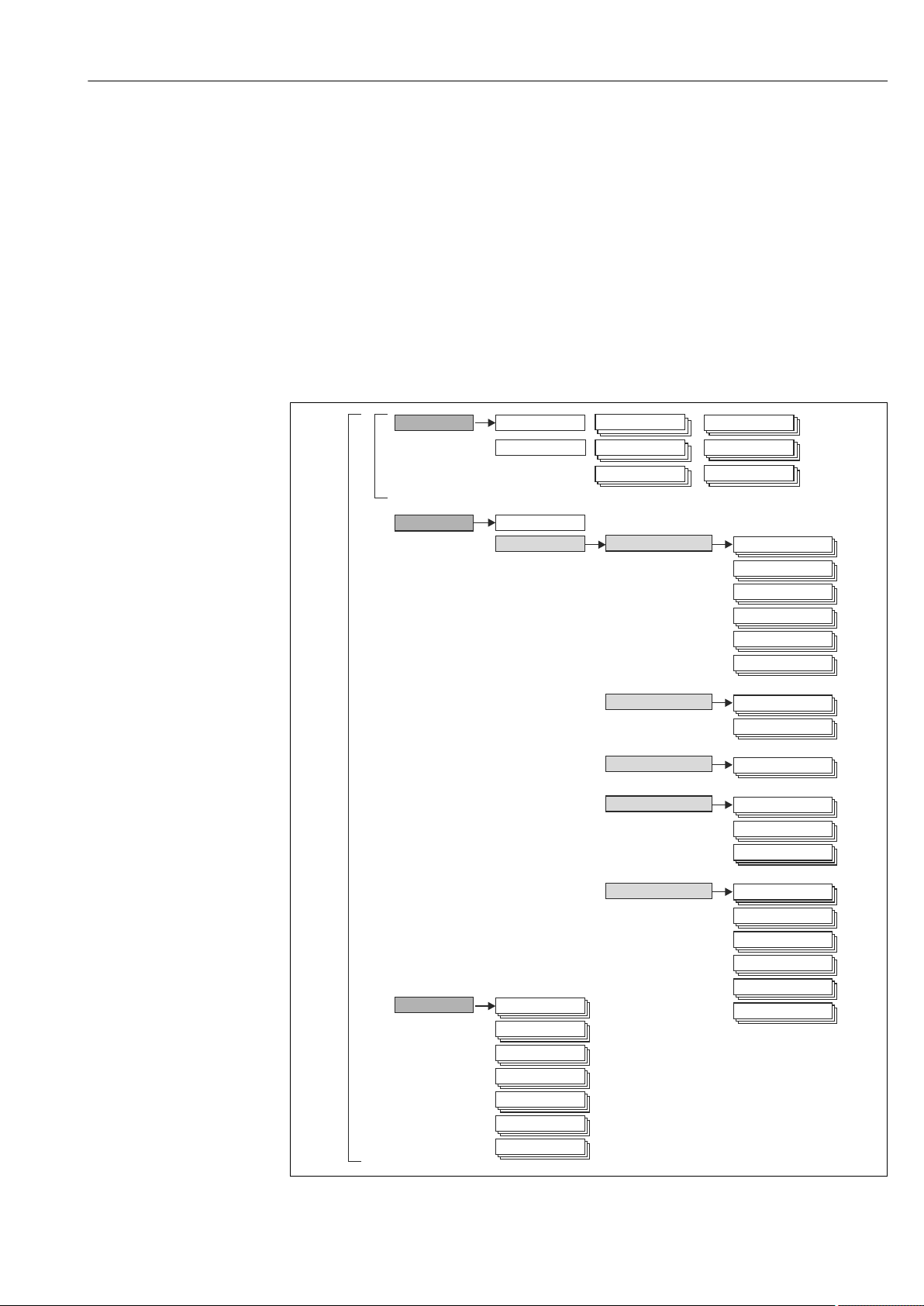

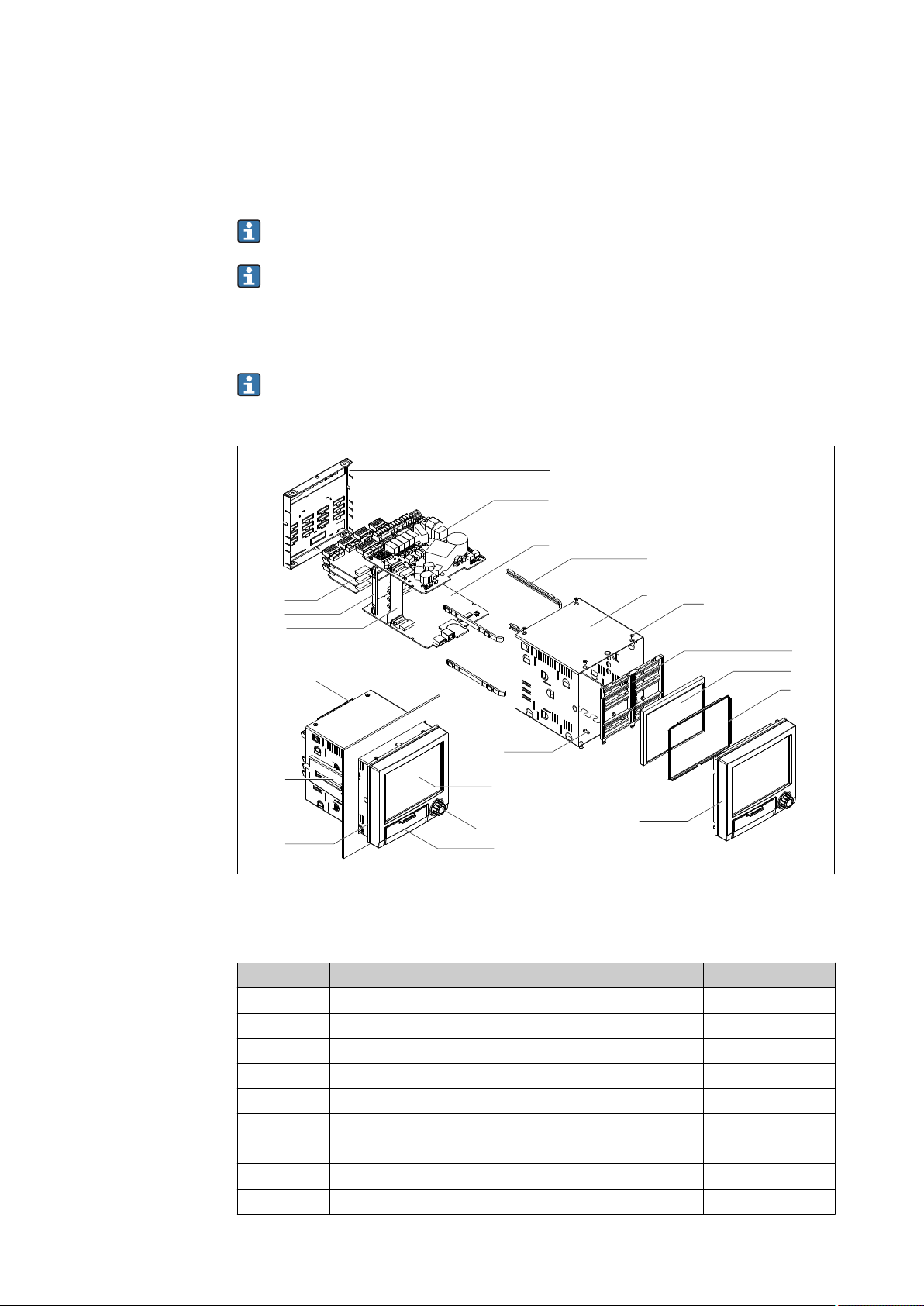

7 Operation options

7.1 Overview of operation options

The device can be operated directly onsite with the Navigator and USB keyboard/mouse or

via interfaces (serial, USB, Ethernet) and operating tools (Web server, FieldCare/

DeviceCare configuration software).

7.2 Structure and function of the operating menu

7.2.1 Operating menu for operators and maintenance personnel

Endress+Hauser 23

A0019594-EN

Page 24

Operation options Ecograph T, RSG35

Expert

Diagnostics

Expert

Outputs

Enter Access code

System

Diagnosis list

(see before)

+Clear memory

+Expert functions

Inputs

Communication

Application

Event logbook

Device information

Simulation

(see before)

(see before)

(see before)

Direct Access

+Expert functions

+Expert functions

+Expert functions

+Expert functions

(see before)

7.2.2 Operating menu for experts

7.2.3 Submenus and users

Certain parts of the menu are assigned to certain user roles. Each user role corresponds to

typical tasks within the lifecycle of the device.

User role Typical tasks Menu Content/meaning

Operator Tasks during operation:

• Configuration of the display.

• Reading measured values.

Maintenance Commissioning:

• Configuration of the measurement.

• Configuration of data processing.

"Operation" Contains all the parameters that are required in

ongoing operation: configuration of the measured value

display (displayed values, display format, etc.).

"Setup" Contains all parameters for commissioning:

• Change date/time

• "Advanced setup" submenu

Contains additional submenus and parameters:

– System: Basic settings required for operating the

device.

– Inputs: Settings for analog and digital inputs.

– Outputs: Setup required only if outputs (e.g.

relays) are to be used.

– Communication: Settings required if you are

using the USB, RS232, RS485 or Ethernet

interface of the device (PC operation, serial data

export, modem operation, etc.).

– Application: Define different application-specific

settings (e.g. group settings, limit values, etc.).

Once values have been set for these parameters, the

measurement should generally be completely

configured.

A0019596-EN

24 Endress+Hauser

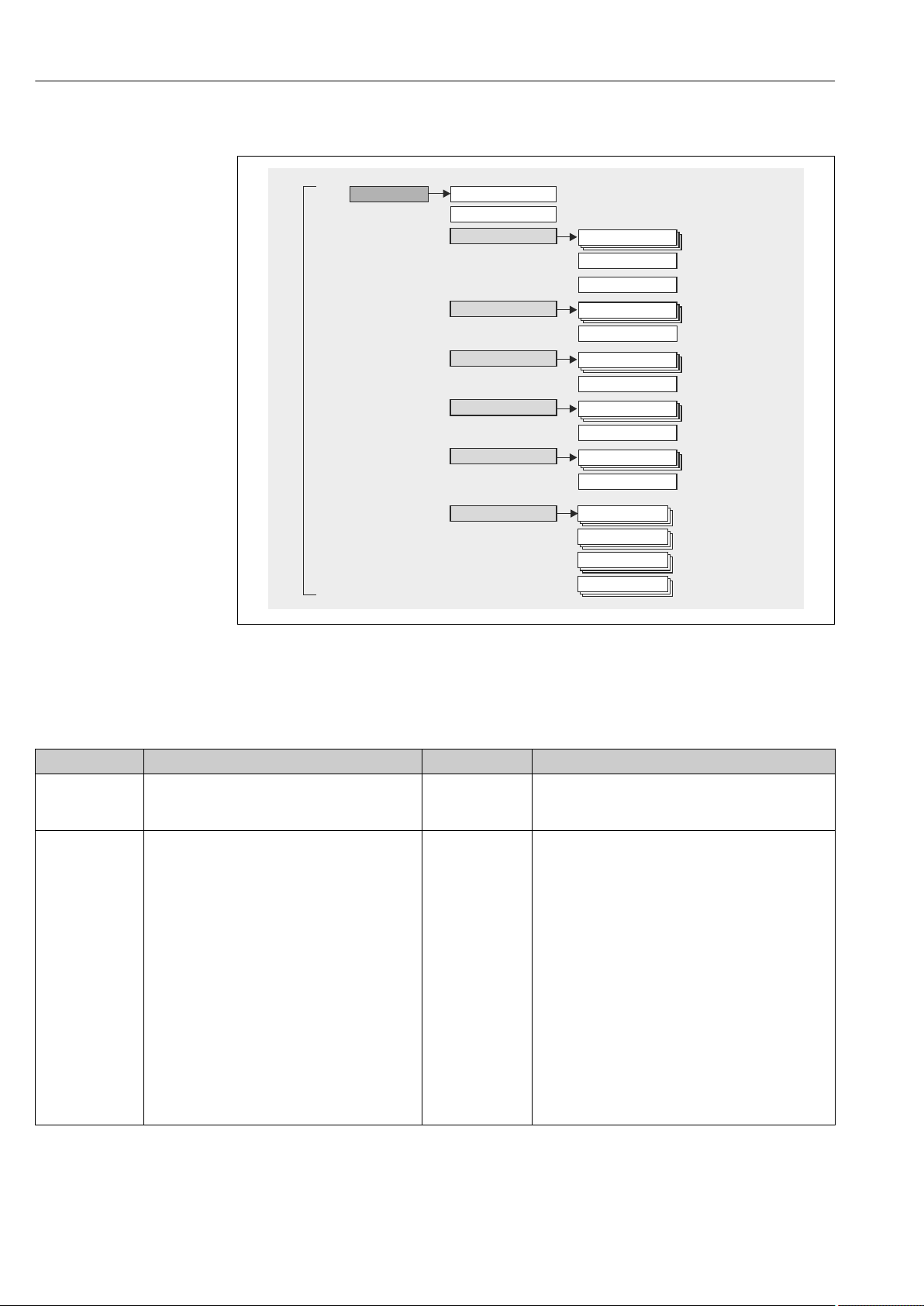

Page 25

Ecograph T, RSG35 Operation options

User role Typical tasks Menu Content/meaning

Fault elimination:

• Diagnosing and eliminating process errors.

• Interpretation of device error messages and

correcting associated errors.

Expert Tasks that require detailed knowledge of the

function of the device:

• Commissioning measurements under difficult

conditions.

• Optimal adaptation of the measurement to

difficult conditions.

• Detailed configuration of the communication

interface.

• Error diagnostics in difficult cases.

"Diagnostics" Contains all parameters for detecting and analyzing

errors:

• Diagnosis list

All diagnosis messages are listed in chronological

order.

• Event logbook

Events such as limit value violations and power

failures are listed in chronological order.

• Device information

Displays important device information (e.g. serial

number, firmware version, device options for

hardware and software, memory information, etc.).

• Measured values

Display of current measured values of device.

• Outputs

Displays the current status of the outputs e.g. switch

status of relay outputs.

• Simulation

Various functions/signals can be simulated for test

purposes here.

Note: In Simulation mode, normal recording of the

measured values is interrupted and the intervention

is logged in the event log.

• Initialize modem

Initializes the modem connected to the serial

interface (for automatic call answering).

"Expert" Contains all parameters of the device (including those

that are already in one of the other menus). The expert

menu is protected by a code. Factory setting: 0000. This

menu is structured according to the function blocks of

the device:

• "System" submenu

Contains all higher-order device parameters that do

not concern the measurement or measured value

communication.

• "Inputs" submenu

Contains all parameters for configuring the analog

and digital inputs.

• "Output" submenu

Contains all parameters for configuring the outputs

(e.g. relays).

• "Communication" submenu

Contains all parameters for configuring the

communication interfaces.

• "Application" submenu

Contains all parameters for configuring applicationspecific settings (e.g. group settings, limit values

etc.).

• "Diagnostics" submenu

Contains all parameters needed to detect and

analyze operational errors.

Endress+Hauser 25

Page 26

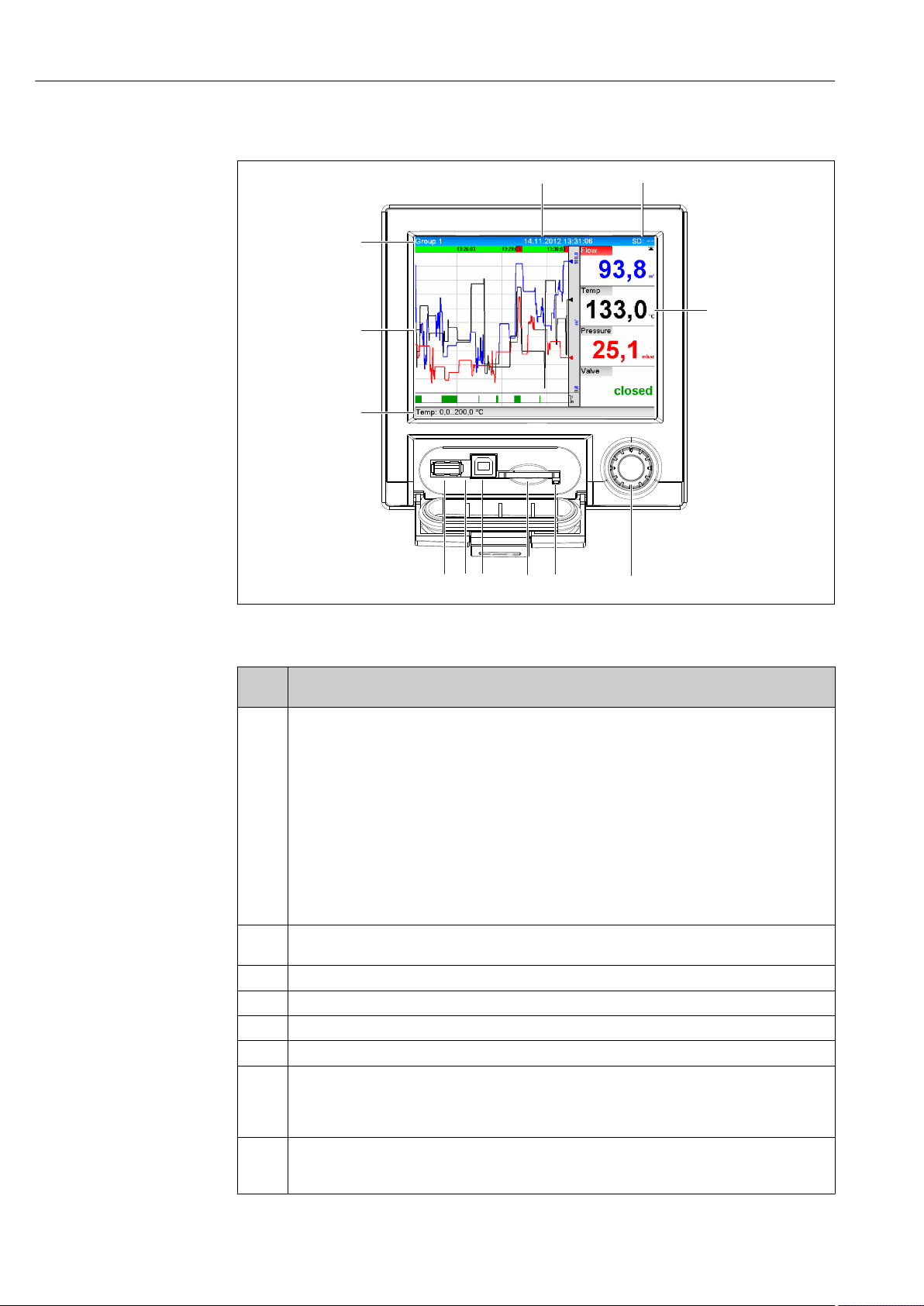

Operation options Ecograph T, RSG35

6 4

3

2

1

5

7

8

9

10

11

12

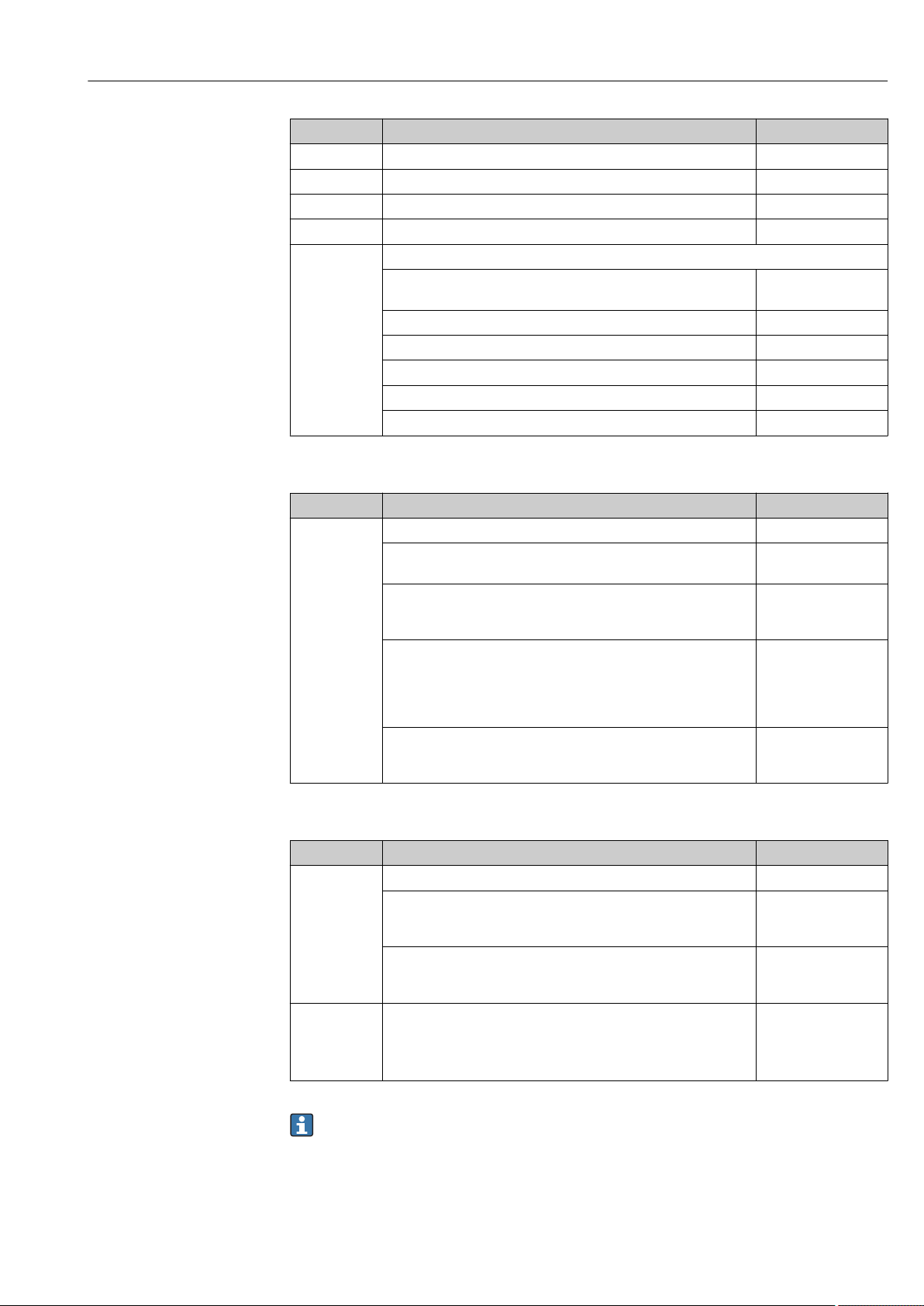

7.3 Measured value display and operating elements

A0020602-EN

7 Front of device with open flap

Item

No.

1 "Navigator": jog/shuttle dial for operating with additional press/hold function.

2 LED at SD slot. Orange LED lit when the device writes to the SD card or reads it.

3 Slot for SD card

4 USB B socket "Function" e.g. to connect to PC or laptop

5 Green LED lit: power supply present

6 USB A socket "Host" e.g. for USB memory stick or external keyboard

7 In display mode: alternating status display (e.g. set zoom range) of the analog or digital inputs in the

8 In display mode: window for measured value display (e.g. curve display).

Operating function (display mode = display of measured values)

(Setup mode = operating in the Setup menu)

'

In display mode: turn the dial to switch between the various signal groups. Press the dial to display the

main menu.

'

In setup mode or in a selection menu: turn the dial anticlockwise to move the bar or the cursor

upwards or counterclockwise, changes the parameter. Turning clockwise moves the bar or cursor

down or clockwise, changes parameter.

Press briefly (<2 sec.) = Select highlighted function, parameter change starts (ENTER key).

Access online help: Press and hold Navigator (>3 sec.) to show information on the selected

function.

To quit the menu immediately, press and hold "Back" (>3 sec.) in the Navigator. The devices

switches to display mode.

Do not remove the SD card if the LED is lit! Risk of data loss!

appropriate color of the channel.

'

In setup mode: different information can be displayed here depending on the display type.

'

In setup mode: display of operating menu

26 Endress+Hauser

Page 27

Ecograph T, RSG35 Operation options

Item

No.

9 In display mode: current group name, type of evaluation

10 In display mode: displays current date/time

11 In display mode: alternating display indicating the percentage space on the SD card or USB stick that

12 In display mode: display of current measured values and the status in the event of an error/alarm

Operating function (display mode = display of measured values)

(Setup mode = operating in the Setup menu)

'

In setup mode: name of the current operating item (dialog title)

In setup mode: --

has already been used.

Status symbols are also displayed in alternation with the memory information (see the following

table).

'

In setup mode: the current "direct access" operating code is displayed

condition. In the case of counters, the type of counter is displayed as a symbol (see the following

table).

If a measuring point has limit value status, the corresponding channel identifier is highlighted

in red (quick detection of limit value violations). During a limit value violation and device

operation, the acquisition of measured values continues uninterrupted.

7.4 Display representation of symbols used in operation

Item

No.

8,12 Symbols for counters:

8, 12 Channel-related symbols:

11 Symbol for status signals:

Function Description

å1

åD

åM

åY

å

Interim analysis/ external analysis

Daily analysis

Monthly analysis

Annual analysis

Totalizer

Violation of lower limit value

Violation of upper limit value or limit value on counter

Violation of upper and lower limit values at the same time

"Out of specification"

e.g. input signal too high/low

Error message "Failure detected"

An operating error has occurred. The measured value is no longer valid (e.g.

a channel not displayed in the current group is defective).

"Maintenance required"

Maintenance is required. The measured value is still valid.

Error, measured value not displayed.

Possible causes: Sensor / input error, line break, invalid value, input signal

too high/low

"Device locked"

Setup is locked via a control input. Disable setup lock via a control input.

"Out of specification"

The device is being operated outside its technical specifications (e.g. during

startup or cleaning).

"Function check"

The device is in Service mode.

Endress+Hauser 27

Page 28

Operation options Ecograph T, RSG35

Item

No.

7 "Historical data"

Function Description

"Maintenance required"

Maintenance is required. The measured value is still valid.

Error message "Failure detected"

An operating error has occurred. The measured value is no longer valid (e.g.

a channel not displayed in the current group is defective).

"External communication"

The device is communicating externally (e.g. via Modbus).

SIM "Simulation"

Simulation is active.

Historical data are currently shown on screen.

7.4.1 Symbols in operating menus

Symbol for setup

Symbol for diagnostics

Symbol for expert setup

Back

Use the "Back" function, which can be found at the bottom of each menu/submenu, to move up

a level in the menu structure.

To quit the menu immediately, press and hold "Back" (>3 sec.) in the Navigator. The

devices switches to display mode.

7.4.2 Symbols in the event logbook

Setup changes

Power on

Power off

Limit value on

Limit value off

1 Digital on (on/off message)

0 Digital off (on/off message)

Service

Texts saved / comments added

Acknowledging message

Back

Continue searching

7.5 Entering text and numbers (virtual keyboard)

A virtual keyboard is available for entering text and numbers. This is opened automatically

if needed. Here, turn the navigator to select the corresponding character and press the

navigator to accept it.

The following characters are available for entering free text:

28 Endress+Hauser

Page 29

Ecograph T, RSG35 Operation options

0-9 a-z A-Z = + - * / \ 2 3 ¼ ½ ¾ ( ) [ ] < > { } I ? ! ` " ' ^ % ° . , : _ µ & # $ € @ § £ ¥ ~

← Jump one position to the left.

If this symbol is selected, the cursor jumps one position to the left.

→ Jump one position to the right.

If this symbol is selected, the cursor jumps one position to the right.

←x Delete backwards.

If this symbol is selected, the character to the left of the cursor position is deleted.

x→ Delete forwards.

If this symbol is selected, the character to the right of the cursor position is deleted.

Delete all.

if this symbol is selected, the entire entry is deleted.

Reject entry.

If this symbol is selected, the entry is rejected and you quit editing mode. The previously set text

remains.

Accept entry.

If this symbol is selected, the entry is applied at the position specified by the user, and you quit

editing mode.

7.6 Channel color assignment

Channel color assignment is performed in the main menu under "Setup -> Advanced

setup -> Application -> Signal groups -> Group x". 8 predefined colors are available per

group and can be assigned to the desired channels.

7.7 Access to the operating menu via the local display

Using the "Navigator" (jog/shuttle dial with additional press function), all settings can be

made directly onsite at the device.

7.8 Device access via operating tools

7.8.1 Field Data Manager (FDM) analysis software (SQL database support)

The PC analysis software offers external, centralized data management with visualization

for recorded data. The analysis software enables the complete archiving of all measuring

point data e.g. measured values, diagnostic events and protocols. The analysis software

stores data in an SQL database. The database can be operated locally or in a network

(client / server). Access is via RS232/RS485, USB or Ethernet interface (network).

Function scope:

• Export of saved data (measured values, analyses, event log)

• Visualization and processing of saved data (measured values, analyses, event log)

• Safe archiving of exported data in a SQL database

The following versions of the software are available:

• Essential version (free, with limited functionalities)

• Professional version (see accessories → 61)

• Demo version (time-limited Professional version)

An "Essential" version of the analysis software is supplied with the device.

For details, see the Operating Instructions on the analysis software DVD provided.

Endress+Hauser 29

Page 30

Operation options Ecograph T, RSG35

7.8.2 Web server

A web server is integrated into the device. This makes the current measured values of the

device available in real time. Access is via an Ethernet interface from a PC in the network

via the standard browser. The installation of additional software is not required.

The Web server offers the following range of functions:

• Display of current and historical data and measured value curves via a standard Web

browser → 38

• Easy configuration without additional installed software → 32

• Remote access to device and diagnostic information

7.8.3 OPC server (optional)

The OPC server makes it possible to access data on the device. These data are made

available to OPC clients in real time. The OPC server meets the requirements of the OPC

specifications regarding the supply of data to an OPC client. Access is via RS232/RS485,

USB or Ethernet interface (network). Communication takes place using automatic device

detection; the operator does not need to make any additional settings. The OPC server

enables the flexible and powerful exchange of data and is easy and convenient to use.

The following momentary values can be provided:

• Analog channels

• Digital channels

• Mathematics

• Totalizer

For details, see Operating Instructions BA00223R/09/xx

7.8.4 FieldCare/DeviceCare configuration software (included in the

delivery)

Function scope

The configuration software is an FDT/DTM-based system asset management tool. It can

configure all smart field devices in a system and helps you manage them. By using the

status information, it is also a simple but effective way of checking their status and

condition. Access is via USB or Ethernet interface (network).

Typical functions:

• Device configuration

• Loading and saving device data (upload/download)

• Documentation of the measuring point

For details, see the Operating Instructions on the configuration software DVD

provided

Overview of device description files (DTM)

Information and files are available free of charge at:

See online at: www.de.endress.com/fieldcare

30 Endress+Hauser

Page 31

Ecograph T, RSG35 System integration

8 System integration

8.1 Integrating the measuring device in the system

8.1.1 General notes

The device has (optional) fieldbus interfaces for exporting process values. Measured values

and statuses can also be transmitted to the device via fieldbus. Note: Counters cannot be

transferred.

Alarms or errors in the context of data transmission are displayed depending on the bus

system (e.g. status byte).

The process values are transferred in the same devices that are used for display at the

device.

8.1.2 Ethernet

Setup → Advanced setup → Communication → Ethernet

The IP address can be entered manually (fixed IP address) or assigned automatically using

DHCP.

The port for data communication is preset to 8000. The port can be changed in the Expert

→ Communication → Ethernet menu.

The following functions are implemented:

• Data communication with PC software (analysis software, configuration software, OPC

server)

• Web server

The following connections are possible at the same time:

• 1x Port 8000 (configuration software, OPC server or analysis software)

• 1x Port 8002 (OPC server only)

• 4x Modbus slave TCP

• 5x Web server

Ports can be changed!

As soon as the maximum number of connections has been reached, new connection

attempts are blocked until an existing connection has been terminated.

8.1.3 Modbus RTU/TCP slave

The device can be connected to a Modbus system via RS485 or Ethernet interface. The

general settings for the Ethernet connection are made in the Setup → Advanced setup →

Communication → Ethernet menu. Configuration for Modbus communication is done in

the Setup → Advanced setup → Communication → Modbus slave menu. Up to 12 analog

inputs and 6 digital inputs can be transmitted via Modbus and stored in the device.

Menu position RTU (RS485) Ethernet

Device address: 1 to 247 IP address manual or automatic

Baud rate: 9600/19200/38400/57600/115200 -

Parity: Even/Odd/None -

Stop bits: 1/2 -

Port: - 502

Endress+Hauser 31

Page 32

Commissioning Ecograph T, RSG35

Transfer of values

The actual Modbus TCP protocol is located between layer 5 to 6 in the ISO/OSI model.

To transfer a value, 3 registers of 2 bytes each (2-byte status + 4-byte float) or 5 registers

of 2 bytes each (2-byte status + 8-byte double) are used.

More detailed information about Modbus is provided in the supplementary

documentation.

9 Commissioning

9.1 Function check

Make sure that all post-connection checks have been carried out before putting your device

into operation:

• "Post-installation check" checklist .→ 12

• "Post-connection check" checklist .→ 22

9.2 Switching on the measuring device

Once the operating voltage is applied, the display lights up and the device is ready for

operation.

If you are commissioning the device for the first time, program the setup as described in

the following sections of the Operating Instructions.

If you are commissioning a device that is already configured or preset, the device starts

measuring immediately as defined in the settings. The values of the channels currently

activated are shown on the display.

Remove the protective film from the display as this would otherwise affect the

readability of the display.

9.3 Setting the operating language

Factory setting: English or ordered local language.

Calling the main menu, configuring the operating language:

1. Press the navigator

2. The main menu appears on the display with the "Sprache/Language" option

3. Change the default language setting: press the navigator, turn it to select the

preferred language and press the navigator again to accept the setting

4. Use "Back" or "ESC" to quit the main menu

The operating language has been changed.

Use the "Back" function, which can be found at the bottom of each menu/submenu,

to move up a level in the menu structure.

To quit the menu immediately and return to the measured value display, press and

hold "Back" (>3 sec.). The changes made are accepted and saved.

9.4 Configuring the measuring device (Setup menu)

Access to the setup is enabled when the device leaves the factory and can be locked in

various ways e.g. by entering a 4-digit access code or via role-based password protection.

32 Endress+Hauser

Page 33

Ecograph T, RSG35 Commissioning

When locked, basic settings can be checked but not changed. You can also use a PC to

commission or configure your device.

Device configuration options:

• Setup directly at the device

• Setup via SD card or USB stick by transferring the parameters stored on it

• Setup via Web server using Ethernet

• Setup via FieldCare/DeviceCare configuration software using USB interface or Ethernet

9.4.1 Step-by-step: to the first measured value

Procedure and necessary settings:

1. Check the date/time in the main menu under "Setup" and set it if necessary

2. Make settings for the interfaces and communication in the main menu under "Setup

-> Advanced setup -> Communication"

3. Create universal or digital inputs in the main menu under "Setup -> Advanced setup

-> Inputs -> Universal inputs/Digital inputs": Add input: select "Universal input

x" or "Digital input x" with which the input signal should be detected. Then select the

newly created input and configure it

4. Activate relays or analog outputs (optional) in the main menu under "Setup ->

Advanced setup -> Outputs"

5. Assign activated inputs to a group in the main menu under "Setup -> Advanced

setup -> Application -> Signal groups -> Group x"

6. Use "Back" or "ESC" to quit the main menu. The changes made are accepted and saved

The device is in the measured value display mode and displays the measured values.

9.4.2 Step-by-step: set or delete the limit values

Procedure for setting limit values:

1. Open the limit values in the main menu under "Setup -> Advanced setup ->

Application -> Limits"

2. Add a limit value: select "Yes"

3. Select and configure "Limit value x"

4. Use "Back" or "ESC" to quit the main menu. The changes made are accepted and saved

The device is in the measured value display mode and displays the measured values.

Procedure for deleting limit values:

1. Open the limit values in the main menu under "Setup -> Advanced setup ->

Application -> Limits"

2. Delete a limit value: select "Yes"

3. Select the limit value to be deleted from the list

4. Use "Back" or "ESC" to quit the main menu. The changes made are accepted and saved

The device is in the measured value display mode and displays the measured values.

9.4.3 Setup directly at the device

You can access the main menu by pressing the Navigator during operation. Turn the

Navigator to navigate through the available menus. When the desired menu is displayed,

press the Navigator to open the menu.

Endress+Hauser 33

Page 34

Commissioning Ecograph T, RSG35

In the "Setup" menu and in the "Advanced setup" submenu, you will find the most

important settings for the device:

Parameters Possible settings Description

Change date/time UTC time zone

dd.mm.yyyy hh:mm:ss

Advanced setup Advanced settings for the device e.g. system settings,

System Basic settings that are needed to operate the device,

Inputs Settings for analog and digital inputs

Outputs Settings only required if outputs (e.g. relays or

Communicati

on

Application Configure various application-specific settings (e.g.

Change the date and time

inputs, outputs, communication, application etc.

(e.g. date/ time, security, memory management,

messages, etc.)

analog outputs) are to be used

Settings required if the USB, RS232/RS485 or

Ethernet interface of the device is to be used (PC

operation, serial data export, modem operation, etc.)

The different interfaces (USB, RS232/RS485,

Ethernet) can be operated in parallel. However,

simultaneous use of the RS232 and RS485

interface is not possible.

group settings, limit values, etc.)

A detailed overview of all the operating parameters is provided in the appendix at the

end of the Operating Instructions. → 78

9.4.4 Setup via SD card or USB stick

An existing device configuration ("Setup data" *.DEH) from another Ecograph T RSG35 or

from FieldCare/DeviceCare can be uploaded directly to the device.

Import new setup directly at the device: The function used to load the setup data can be

found in the main menu under "Operation -> SD card (or USB stick) -> Load setup" ->

Select directory -> Next".

9.4.5 Setup via Web server

To configure the device via the Web server, connect the device via Ethernet to your PC.

Please observe the information and communication settings for Ethernet and the Web

server under .→ 31

To configure the device via a Web server, you must have Administrator or Service

access. ID and password administration is performed in the main menu under "Setup

-> Advanced setup -> Communication -> Ethernet -> Configuration Web server ->

Authentication".

Default value for ID: admin; Password: admin

Note: The password should be changed during commissioning!

Establishing a connection and setup

Procedure for setting up a connection:

1. Connect the device to the PC via Ethernet

2. Start the browser at the PC; open the Web server for the device by entering the IP

address: http://<ip-address> Note: Leading zeros in IP addresses must not be entered

(e.g. enter 192.168.1.11 instead of 192.168.001.011)

34 Endress+Hauser

Page 35

Ecograph T, RSG35 Commissioning

3. Enter ID and password, and confirm each by clicking "OK"

4. The Web server shows the instantaneous value display of the device. Click "Menu ->

Setup -> Advanced setup" in the Web server function bar

5. Starting configuration

Continue with device configuration in accordance with the Operating Instructions for the

device. The complete Setup menu i.e. all of the parameters listed in the Operating

Instructions, can also be found on the Web server. After configuration, accept the setup

with "Save settings".

Procedure to establish a direct connection via Ethernet (point-to-point connection):

→ 38

NOTICE

Undefined switching of outputs and relays

During configuration using a Web server, the device may assume undefined statuses!

‣

This may result in the undefined switching of outputs and relays.

An existing device configuration ("Setup data" *.DEH) from another Ecograph T RSG35

or from FieldCare/DeviceCare can be uploaded directly to the device via the Web

server.

Procedure for uploading a new setup via the Web server:

1. Make the connection to the device with the Web server → 34

2. Click "Data management -> Import device settings" in the Web server function bar

3. Select the setup file and press "OK" to confirm

4. The file is transferred, checked and accepted

5. Once the device settings have been accepted, information to this effect is displayed in

the Web server

9.4.6 Setup via FieldCare/DeviceCare configuration software (included in the delivery)

To configure the device using the configuration software, connect the device to your PC via

USB or Ethernet.

Establishing a connection and setup

For details, see the Operating Instructions on the configuration software DVD

provided.

Continue with device configuration in accordance with the Operating Instructions for the

device.

The complete Setup menu, i.e. all the parameters listed in the Operating Instructions, can

also be found in the configuration software.

NOTICE

Undefined switching of outputs and relays

During configuration using the configuration software, the device may assume

‣

undefined statuses! This may result in the undefined switching of outputs and relays.

Endress+Hauser 35

Page 36

Commissioning Ecograph T, RSG35

9.5 Advanced settings (Expert menu)

You can access the main menu by pressing the Navigator during operation. Turn the

Navigator to navigate to the "Expert" menu. Press the Navigator to open the menu.

The Expert menu is protected by the code "0000". If an access code is set up under

"Setup -> Advanced setup -> System -> Security -> Protected by -> Access code",

this must be entered here.

The "Expert" menu contains all of the device settings:

Parameters Possible settings Description

Direct access 000000-000 Direct access to parameters (fast access)

System Basic settings that are needed to operate the device,

(e.g. date/ time, security, memory management,

messages, etc.)

Inputs Settings for analog and digital inputs

Outputs Settings only required if outputs (e.g. relays or

analog outputs) are to be used

Communication Settings required if the USB, RS232/RS485 or

Ethernet interface of the device is to be used (PC

operation, serial data export, modem operation, etc.)

The different interfaces (USB, RS232/RS485,

Ethernet) can be operated in parallel. However,

simultaneous use of the RS232 and RS485

interface is not possible.

Application Configure various application-specific settings (e.g.

group settings, limit values, etc.)

Diagnosis Device information and service functions for a swift

device check

A detailed overview of all the operating parameters is provided in the appendix at the

end of the Operating Instructions. → 78

9.6 Configuration management

You can save the setup data ("Configuration") to an SD card or a USB stick, to a PC

drive via the Web server, or store them in a database using the configuration

software. This allows additional devices to be configured very easily using the same

settings.

Save setup: The function used to save the setup files can be found in the main menu under

"Operation -> SD card (or USB stick) -> Save setup".

CAUTION

L

If the SD card or USB stick are removed directly:

Risk of data loss on SD card or USB stick.

To remove the SD card or the USB stick, always select "Operation -> SD card (or USB

‣

stick) -> Remove safely" in the main menu!

Procedure for saving a setup via the Web server:

1. Make the connection to the device with the Web server → 34

2. Click "Data management -> Save device settings" in the Web server function bar

3. Select the setup file

4. Transfer the file

5. Verify and accept

36 Endress+Hauser

Page 37

Ecograph T, RSG35 Commissioning

6. Once the device settings have been accepted, information to this effect is displayed in

the Web server

The function for saving the setup data must be enabled at the device for the Web

server under "Setup -> Advanced setup -> Communication-> Ethernet -> Web

server settings; Setup -> Yes".

9.7 Simulation

Various functions/signals can be simulated for test purposes here.

NOTICE

Selecting simulation: Simulation of the relays and the WebDAV client can be found in

the main menu under "Diagnostics -> Simulation". The simulation of the measured

values can be found in the main menu under "Expert -> Diagnostics -> Simulation".

Only the simulated values are recorded during simulation. The simulation is recorded in

the event logbook.

Do not start simulation if measured value recording must not be interrupted!

‣

9.8 Protecting settings from unauthorized access

After configuration, the setup should be protected against unauthorized access. The

following options are available:

• Protection per control input

• Protection via release code

• Protection via user roles

In order to change any parameter, the correct code must first be entered or the device must

be unlocked using the control input.

Setup lock via control input: The settings for the control input can be found in the main

menu under "Setup -> Advanced setup -> Inputs -> Digital inputs -> Digital input X ->

Function: Control input; Action: Lock setup".

It is preferable to lock the setup using a control input.

Setting up an access code: The settings for the access code can be found in the main

menu under "Setup -> Advanced setup -> System -> Security -> Protected by -> Access

code". Factory setting: "open access", i.e. modifications can always be made.

Make a note of the code and store in a safe place.

Setting up user roles: The settings for the user roles (operator, admin and service) are

provided in the main menu under "Setup -> Advanced setup -> System -> Security ->

Protected by -> User roles" . Factory setting: "open access", i.e. modifications can always

be made.

The passwords should be changed during commissioning.

Make a note of the code and store in a safe place.

Endress+Hauser 37

Page 38

Operation Ecograph T, RSG35

10 Operation

The "Operation" menu is geared towards the tasks and activities of the operator. It contains

all the parameters that are needed in ongoing operation. Historical values and analyses,

for example, can be displayed in the "Operation" menu and display settings can be made.

Any settings made for the onsite display have no effect on the measurement section or the

configured device parameters.

The unit's simple control system and the integrated help function enables you to perform

operation for many applications without the need for hard copy operating instructions.

10.1 Displaying and modifying current Ethernet settings

To establish communication with the device via Ethernet, the following settings must be

known or modified where necessary:

Display IP/MAC address (only if DHCP is enabled): The device's IP or MAC address can be

found in the main menu under "Diagnostics -> Device information -> Ethernet".

Display/change Ethernet settings: The device's Ethernet settings can be found in the

main menu under "Setup -> Advanced setup -> Communication -> Ethernet".

Procedure to establish a direct connection via Ethernet (point-to-point connection):

1. Configure the PC (depends on operating system): e.g. IP address: 192.168.1.1; subnet

mask: 255.255.255.0; gateway: 192.168.1.1

2. Disable DHCP on the device

3. Make communication settings on the device: e.g. IP address: 192.168.1.2; subnet

mask: 255.255.255.0; gateway: 192.168.1.1

A crossover cable is not required.

10.2 Reading the device locking status

If setup is locked via a control input, a padlock symbol appears on the top right of the

screen. The setup must first be unlocked via the control input before device parameters can

be edited.

Setup lock via control input: The settings for the control input can be found in the main

menu under "Setup -> Advanced setup -> Inputs -> Digital inputs -> Digital input X ->

Function: Control input; Action: Lock setup".

If setup is locked via the access code, all the operating parameters can be displayed, and

can also be edited as soon as the access code is entered.

38 Endress+Hauser

Page 39

Ecograph T, RSG35 Operation

6 4

3

2

1

5

7

8

9

10

11

12

10.3 Reading measured values

A0020602-EN

8 Front of device with open flap

1 Navigator: press briefly to open the main menu and confirm messages (=Enter); press for longer to open the

online help

2 Orange LED for read/write access to the SD card

3 Slot for SD card

4 USB-B socket "Function"

5 Green LED lit: power supply present

6 USB-A socket "Host"

7 Status bar

8 Area for measured value display (e.g. curve display)

9 Header: group name, analysis type

10 Header: current date/time

11 Header: alternating display indicating the percentage space on the SD card or USB stick that has already been

used. Status symbols are also displayed in alternation with the memory information

12 Display of current measured values and the status in the event of an error/alarm condition. In the case of

counters, the type of counter is displayed as a symbol

An overview of all the symbols and icons is provided in the operating options section.

→ 27

If a measuring point has limit value status, the corresponding channel identifier is