Page 1

EU Valve

D102004X012

Fisherr EU and EW Valves

NPS 16 through 24 x 20

The Fisher NPS 16 through 24 × 20 CL150 through

CL600 EUT-2, EWT-2, EUD, EWD, EUT, and EWT control

valves (figures 3 and 4) are used for either throttling or

on-off control of a wide variety of liquids and gasses.

CL900 NPS 16 and 20 x 16 valves are available upon

request. Please contact your Emerson Process

Management sales office for more details. These

valves have single ports, balanced valve plugs, and

cage guiding.

EUT-2andEWT-2valveswithahangingcage(figure3)

are available for demanding applications in oil and

natural gas to 232_C(450_F). The hanging cage, with

the seat ring threaded into the cage, gives these valves

easy-maintenance trim--no trim parts are threaded

into the valve body. The seal between the plug and

cage and the seal between the seat ring and valve body

are spring-loaded PTFE seals.

Product Bulletin

51.1:EU

September 2014

EUD and EWD valves (figure 4) have a bolted-in seat

ring. These valves have metal-to-metal seating and use

two graphite piston rings between the valve plug and

cage. They are used primarily for high temperature

(over 232_C[450_F]) service. The Bore Seal is used to

obtain Class V shutoff above 316_C (600_F).

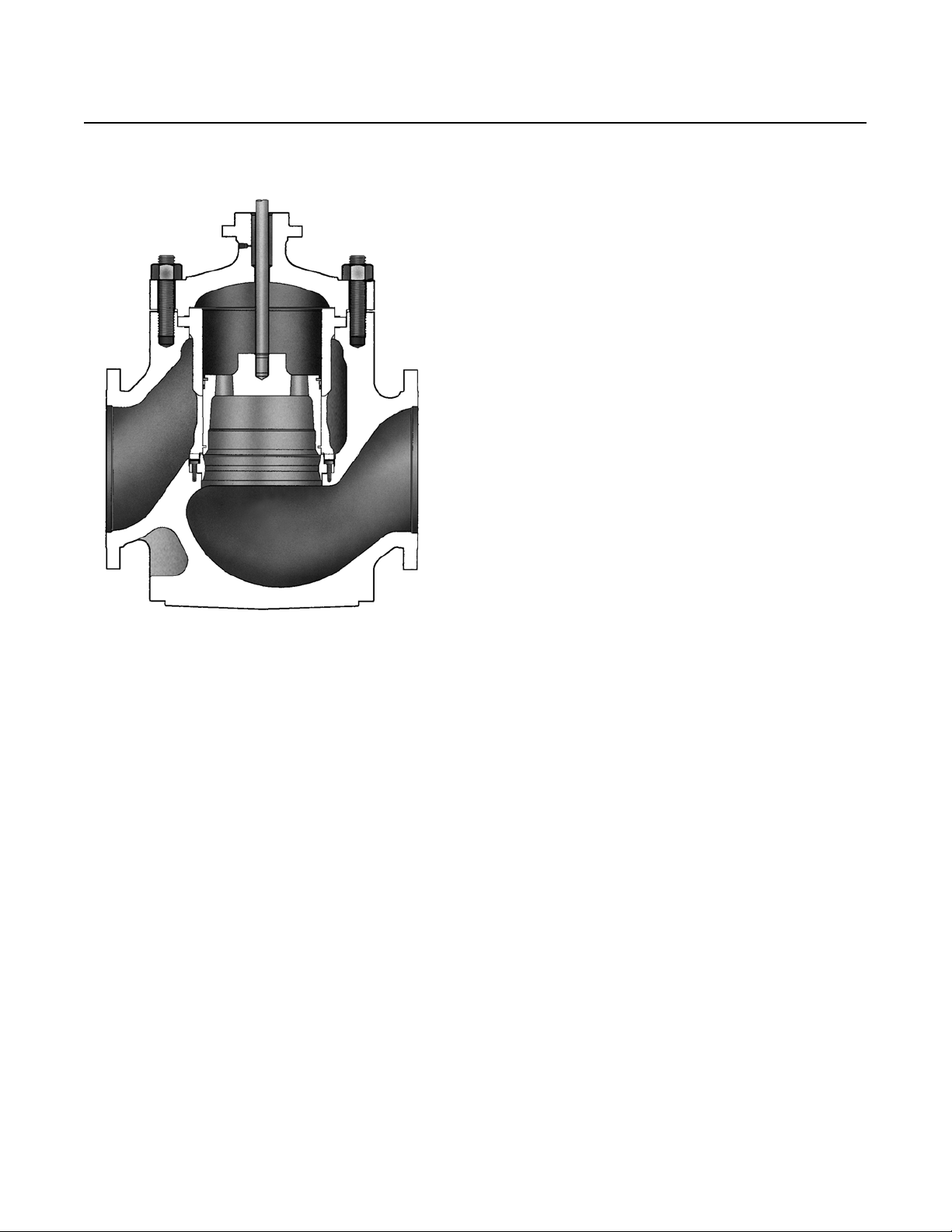

EUT and EWT valves (figure 1) have a bolted-in seat

ring. These valves have metal-to-metal seating and use

PEEK anti-extrusion rings to obtain temperatures up to

316_C(600_F).

Thesevalvessharethefollowingcharacteristics:

multiple trim material choices, trim part

interchangeability, and different cage styles to provide

particular flow characteristics to handle specific

applications.

W9156-2

To help reduce aerodynamic noise in gas service,

Whisper Trimt III (figure 5) and WhisperFlot cages

are available. To eliminate liquid cavitation damage,

Cavitrolt III cages are available. For cavitating liquids

with particulate, DST (dirty service trim) is available.

www.Fisher.com

Page 2

Product Bulletin

51.1:EU

September 2014

Specifications

EU Valve

D102004X012

Valve Sizes

EUT-2, EUD, and EUT:

EWT-2, EWD, and EWT:

J 24 x 16, and J 24 x 20 valves (size designations

J NPS 16 and J 20

J NPS 20 x 16,

are end connection size x nominal trim size)

Construction Materials

Valve Body and Bonnet:

J LCC steel, or J CF8M (316 stainless steel). For

other materials, consult your Emerson Process

Management sales office

Trim and Other Parts: Seetables1,2,and3.

End Connection Styles

Flanged: CL150, 300, and 600 raised-face or ring-type

joint flanges per ASME B16.5

Buttwelding: All ASME B16.25 schedules through

schedule 120 that are compatible with the ASME

B16.34 valve body rating

For other end connections, contact your Emerson

Process Management sales office for details.

Maximum Inlet Pressure

(1)

Flanged: Consistent with CL150, 300, and 600

Flow Characteristics

Standard Cages:

Whisper Trim III and Cavitrol III Cages: Linear

WhisperFlo Cages: Linear

For other characteristics, contact your Emerson

Process Management sales office for details.

Flow Direction

Standard and Cavitrol III Cages: Down

Whisper Trim III Cages: Up

WhisperFlo Cages: Up

pressure-temperature ratings per ASME B16.34

Buttwelding: Consistent with CL600 per

ASME B16.34

Material Temperature and Pressure Drop

Capabilities

(1)

Flow Coefficients

See Fisher Catalog 12

Port Diameters

See tables 6 and 7

See table 1 and figures 6 and 7.

Valve Plug Travel

Shutoff Classifications per ANSI/FCI 70-2andIEC

60534-4

EUT and EWT with Metal Seats

102 through 432 mm (4 to 17 inches).

Contact your Emerson Process Management sales

office for further details if needed

Standard: Class V

EUT-2andEWT-2withMetalSeats

Standard (for all trims except 2

-

Stage Cavitrol Trim):

Class IV

Standard (for 2

Optional (for all trims except 2

-

Stage Cavitrol Trim): Class V

-

Stage Cavitrol Trim):

Class V

EUT-2andEWT-2 with Soft Metal Seats

Class V

EUDandEWDwithMetalSeats

Standard: Class III

Optional: Class IV and V

1. The pressure/temperaturelimits in this bulletin andany applicable standardor code limitation for valve should not be exceeded.

Yoke Boss and Stem Diameters

J 127 mm (5-inch) or J 127 mm (5H-inch) diameter

yoke boss, each with 31.8 mm

(1.25 inch) diameter valve stem

Typical Bonnet Style

Standard Plain (style 1 extension)

Approximate Weights

Seefigure8

J WCC steel, J WC9 steel,

J Linear or J equal percentage

2

Page 3

EU Valve

D102004X012

Figure 1. Fisher EUT / EWT Valve with PEEK Anti-Extrusi on Rings

Product Bulletin

51.1:EU

September 2014

W9518-1

Features

Stable Control at High Pressure Drops-- Rugged

cage guiding stabilizes the valve plug at all points in

itstravelrange.Thisguidingreducesvibration,

mechanical noise, and the need for hydraulic

snubbers.

Economy-- Streamlined flow passages provide

greater capacities per initial investment than most

globe valves of the same size. Balanced valve plug

design can allow use of smaller actuators for high

pressure drops.

Cost-Effective Operation-- Increased wear

resistance of the standard hardened stainless steel

trim means long-lasting service.

Easy Maintenance-- The valve can stay in the

pipeline during removal of trim parts for inspection

or maintenance.

3

Page 4

Product Bulletin

51.1:EU

September 2014

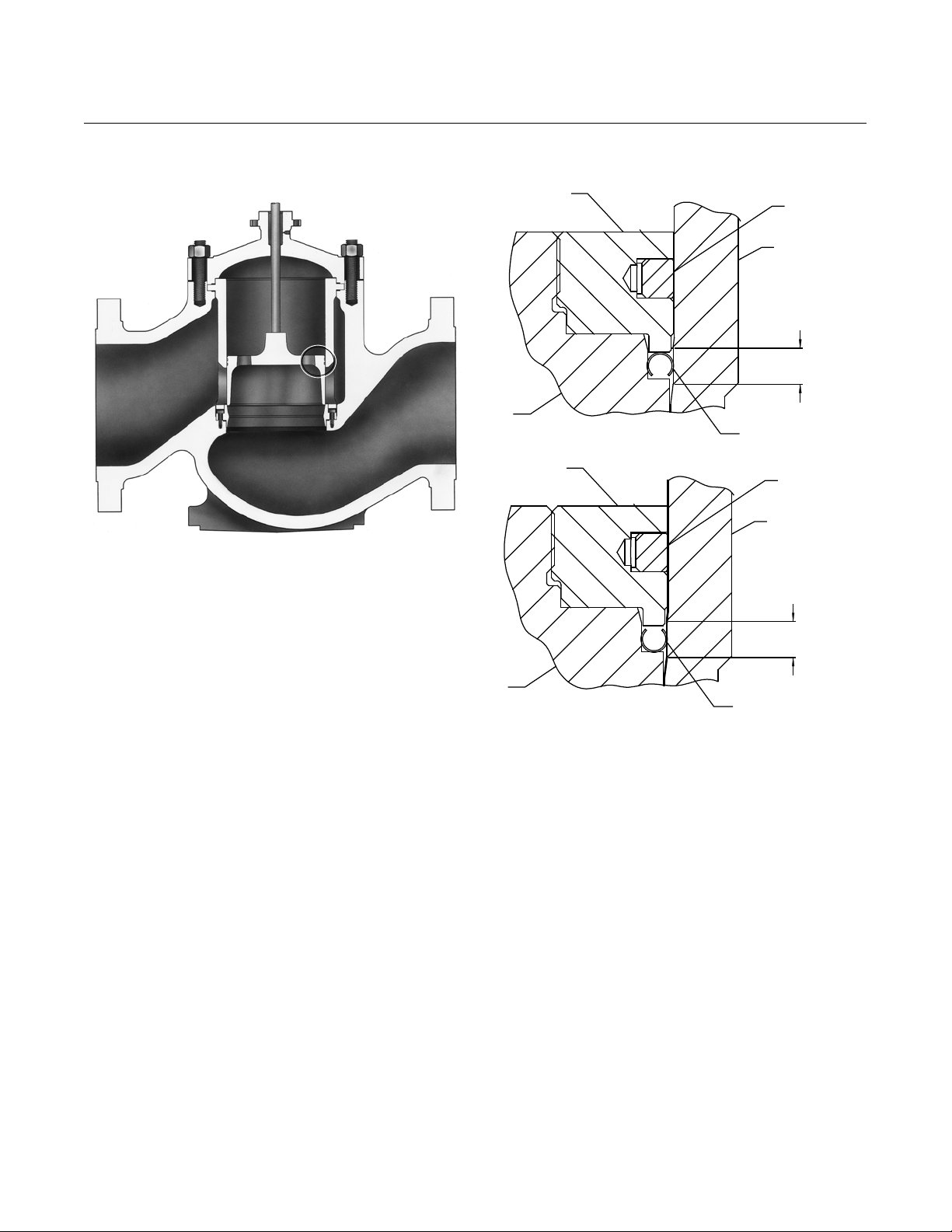

Figure 2. Typical Fisher EUD with Bore Seal

A

RETAINER

EU Valve

D102004X012

PISTON RING

CAGE

SEATING AREA

W6022-2

Bore Seal Description

TheBoreSeal(figure2)isavailablefortheEUDand

EWD only and is required for Class V shutoff

applications where the service temperature exceeds

316_C(600_F). For service temperatures below 316_C

(600_F), the EWT and EUT should be used when Class

V shutoff is required. See table 4 for availability and

temperature limits and figure 2.

TheBoreSealemploysametalCshaped seal ring that

PLUG

RETAINER

PLUG

FLOW DOWN

FLOW UP

VIEW A

BORE SEAL

PISTON RING

CAGE

SEATING AREA

BORE SEAL

is secured to the outside diameter of the valve plug.

When the valve plug comes into contact with the seat

ringtoclosethevalve,theBoreSealiscompressed

against the cage wall, thereby blocking a secondary

leakage path that exists between the plug and cage

wall. When the valve plugis not in contact with the

seat ring (i.e. valve open), theBoreSealisnotengaged

and the piston rings that are also secured to the

outsidediameteroftheplugassumetheroleof

blocking this secondary leakage path.

4

Page 5

EU Valve

D102004X012

Figure 3. Typical Fisher EUT-2 or EWT-2 Valve

TAPPED BONNET

(OPTIONAL)

BONNET GASKET

CAGE GASKET

HANGING CAGE DESIGN

SEAT RING

THREADED

TO CAGE

Product Bulletin

51.1:EU

September 2014

W6088-2

COMPLETE VALVE

SEAT RING

THREADED TO

CAGE

SEAL RING

W6089-1A

SEAT RING SEAL DETAIL

5

Page 6

Product Bulletin

51.1:EU

September 2014

Figure 4. Typical Fisher EUD or EWD Valve

EU Valve

D102004X012

W6022-2

Figure 5. Fisher EWT-2 Valve with Whisper Trim III D3 Cage, Baffle, and Lower Metal Piston Ring

BAFFLE

CAGE

W6202-2

6

Page 7

EU Valve

D102004X012

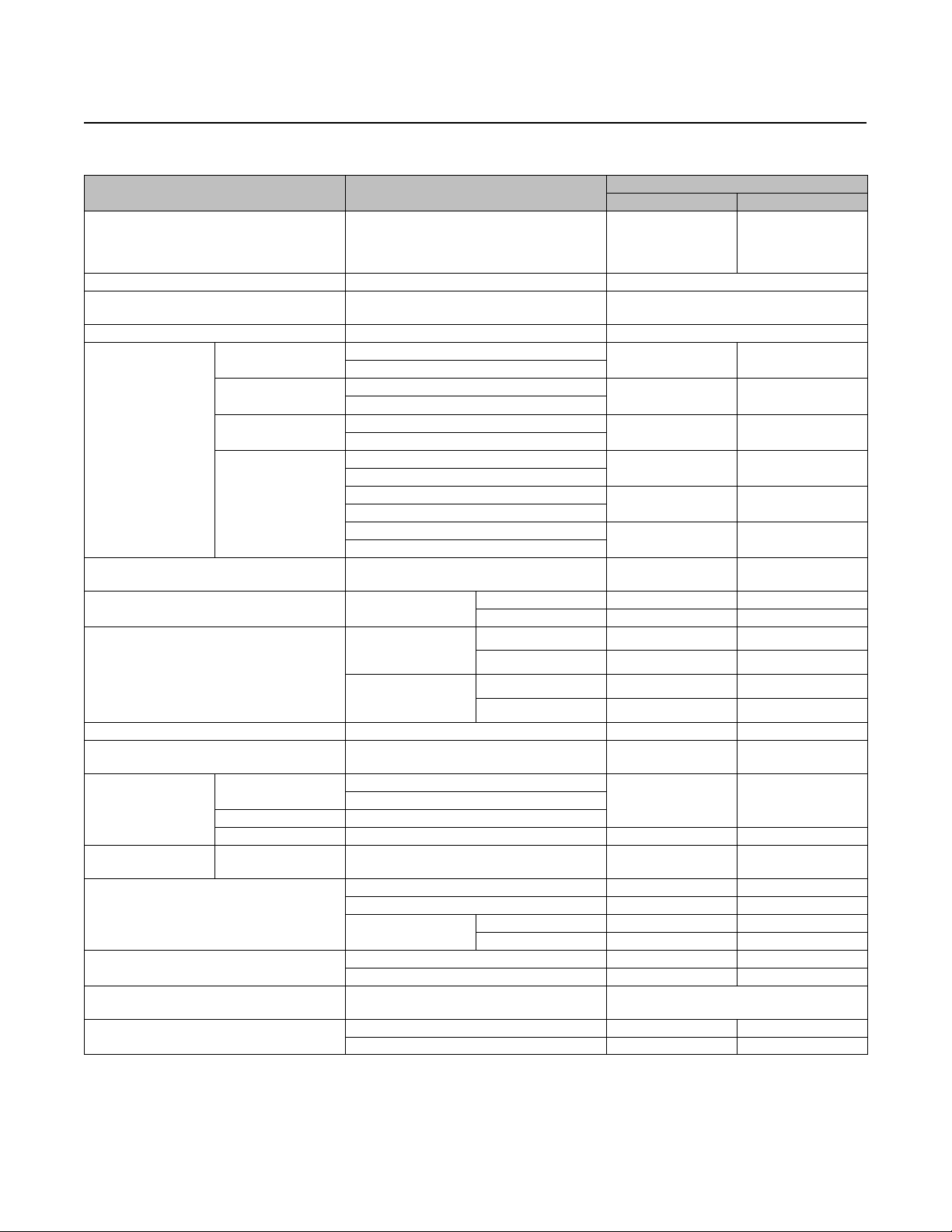

Table 1. Construction Materials

PART MATERIAL

Valve Body and Bonnet

Cage, Seat Ring, and ValvePlug See tables 2 and 3 See figures 6 and 7

Soft Metal Seat (with trim 233 in EUT-2andEWT-2

Valve-to-Bonnet

Bolting

Bonnet, Seat Ring, and Cage Gaskets N06600/Graphite

EUD and EWD Piston Ring or Lower Graphite

Piston Ring (254 mm[10 inch] port only)

EUT-2andEWT-2SeatRingSealRing

EUT and EWT valves

with PEEK

anti-extrusion rings

For applications using a

lower metal piston ring

Packing (Temperatures shown are in-body

temperatures with plain bonnet.)

Packing Flange, Studs, and Nuts

Packing Follower, Spring (PTFE V-Ring Packing), or

valves only)

Valve Stem S20910 SST Not a Limiting Factor

WCC Valve

LCC Valve

WC9 Valve

CF8M Valve

Seat Ring Cap Screws

Graphite (Fisher

Designation FMS

Graphite (Fisher

Designation FMS

EUD and EWD Bore Seal N07718 -198 to593 -325 to1100

andPlugSealRing

Backup ring

Retaining ring 18-8

Seal ring PTFE/graphite with N10276 spring 232 to316 450 to 600

Lower metal piston ring Iron / N07750 -73 to427 -100 to800

Ribbon/Filament

Lantern Ring

Packing Box Ring

Product Bulletin

51.1:EU

September 2014

TEMPERATURE

_C _F

WCC Steel

WC9 Steel

CF8M (316 Stainless Steel)

17F27)

17F39)

N10276/Glass and Moly-Filled PTFE -73 to232 -100 to450

Graphite

S31600 (316Stainless Steel) -198 to593 -325 to1100

LCC

CF8M See figures 6 and 7

SA-193-B7 Studs

SA-194-2H Nuts

SA-193-B7 Studs

SA-194-2H Nuts

SA-193-B7 Studs

SA-194-2H Nuts

S20910 CrCtStuds

S20910 Nuts

B8M Class 2 studs

8M nuts

SA-193-B7 Studs

SA-194-2H Nuts

S17400

N07718

Oxidizing -198 to 427 -325 to 800

Non-Oxidizing -198 to593 -325 to1100

Oxidizing -198 to 427 -325 to 800

Non-Oxidizing -198 to482 -325 to900

Oxidizing -198 to 538 -325 to 1000

Non-Oxidizing -198 to593 -325 to1100

S41000

S31600

PTFE V-Ring -46 to 232 -50 to 450

PTFE Composition -46 to232 -50 to 450

Oxidizing -198 to 354 -325 to 700

Non-Oxidizing -198 to538 -325 to1000

Steel -29 to427 -20 to 800

S31600 Not a Limiting Factor

S17400 -101 to 427 -150 to800

S31600 -198 to 593 -325 to1100

-29 to427

-29 to593

-198 to593

-46 to343

-29 to427 -20 to 800

-46 to343 -50 to 650

-29 to427 -20 to 800

-198 to538 -325 to1000

-198 to427 -325 to800

-29 to427 -20 to 800

-29 to354

-198 to593

Not aLimiting Factor Not a Limiting Factor

-20 to 800

-20 to1100

-325 to1000

-50 to 650

-20 to 700

-325 to1100

7

Page 8

Product Bulletin

51.1:EU

September 2014

EU Valve

D102004X012

Table 2. Typical Combinations of Metal Trim Materials for All Valves Except Those with WhisperFlo Trim

Valve Design Trim Designation Valve Plug Seat Ring Cage

(2)

231

EUT-2, EWT-2

EUD, EWD

EUT, EWT

1. For WhisperFlo trims, see table 3.

2. Cavitrol IIIcage is standardwith trim 231

3. NACE MR0175approved trim materials.

(3)

232

226 CA6NM CB7CU-1 H1075 CB7CU-1 H1075 S17400 H1100

227A

(3)

229

229H

231 CA6NM HT CB7CU-1 H1075 CB7CU-1 H1075 S17400 H1100

(3)

232

(3)

CA6NM HT CB7CU-1 H1075 CB7CU-1 H1075 ---

CF8M with CoCr-A

on Seatand Guide

WC9 Steel with

CoCr-AonSeatand

Guide

CF8M with CoCr-A

on Seatand Guide

CF8M with CoCr-A

on Seatand Guide

CF8M with CoCr-A

on Seatand Guide

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M ENC ---

WC9 Nitrided N07718

CF8M ENC N07718

CF8M

Chrome-Coated

CF8M ENC N07718

Seat Ring Cap

Screws

N07718

Table 3. WhisperFlo Metal Trim Materials and Valve Body/Trim Temperature Capabilities

Valve Design Trim Designation Valve Plug Seat Ring Cage

952 CA6NM HT

EUT-2, EWT-2

953

950 CA6NM HT

EUD, EWD

951

952 CA6NM HT

EUT, EWT

953

1. NACE MR0175approved trim materials.

CF8M with CoCr-A

on seat

(1)

(1)

(1)

CF8M with CoCr-A

on Seatand Guide

CF8M with CoCr-A

on Seatand Guide

CF8M with CoCr-A

on Seatand Guide

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

CF8M with CoCr-A

on seat

410 SST/

ENC/Ultimet

316L SST/

ENC/Ultimet

410 SST/

ENC/Ultimet

316L SST/

ENC/Ultimet

410 SST/

ENC/Ultimet

316L SST/

ENC/Ultimet

Seat Ring Cap

Screws

---

---

N07718

N07718

N07718

N07718

(1)

Temperature

Seefigure6

Seefigure7

Seefigure7

Temperature

Seefigure6

Seefigure7

Seefigure7

Table 4. Bore Seal Availability and Temperature Capabilities (EUD/EWD only)

Valve Design Valve Size, NPS Trim Designation Temperature ANSI/FCI/IEC Shutoff Class

226

EUD and EWD 16, 20x16,24x16, 20, 24x20

8

227A

950

Seefigure7 V

Page 9

Product Bulletin

EU Valve

D102004X012

Figure 6. Temperature and Pressure Drops for Typical Trim Used in Fisher EUT-2 and EWT-2 Valves

FLUID TEMPERATURE, _C FLUID TEMPERATURE, _C

September 2014

51.1:EU

FLUID TEMPERATURE, _F

FOR STANDARD METAL SEATING WITH CL600

MC140-1/AR1

A6890

Notes:

1

higher capabilities.

WCC/LCC STEEL BODY

Do not exceed the maximum pressure and temperature for the class rating of the body materialused, even though thetrims shown may have

FLUID TEMPERATURE, _F

FOR STANDARD METAL SEATING WITH CL600

CF8M (316 STAINLESS STEEL) BODY

9

Page 10

Product Bulletin

51.1:EU

September 2014

Figure 7. Temperature and Pressure Drops for Typical Trim Used in Fisher EUD, EWD, EUT, and EWT Valves

FLUID TEMPERATURE, _C

952, 953

231, 232

3

FLUID TEMPERATURE, _C

D102004X012

EU Valve

FLUID TEMPERATURE, _F

FOR STANDARD METAL SEATING WITH CL600

WCC STEEL BODY

MC140-2/AR1

A6891

FOR STANDARD METAL SEATING WITH CL600

FLUID TEMPERATURE, _F

WC9 CHROME MOLY STEEL BODY

FLUID TEMPERATURE, _C

229

229H

226

229

229H

226

229H

951

229H

229H

FLUID TEMPERATURE, _F

FOR STANDARD METALSEATING WITH CL600

CF8M (316 STAINLESS STEEL) BODY

Notes:

1

2

3

Do not exceed the maximum pressure andtemperature forthe classrating ofthe bodymaterial used,even thoughthe trimsshown mayhave highercapabilities.

482_C (900_F)limit -- WCC steel valve plug

371_C (700_F)limit --S17400 seat ring bolting

316_C (600_F)limit --EUT andEWT valves with 231,232, 952, and 953 trims

10

Page 11

Product Bulletin

EU Valve

D102004X012

Table 5. Dimensions and Approximate Weights

END

CONNECTION

Size,

NPS

16

20 × 16

20

24 × 16

24 × 20

1. RF--raised face; RTJ--ring-type joint; BW--buttwelding.

2. For longertravels, the neck of the valve (the portion of the valve body that supports the bonnet) is longer to accommodate the travel. The longer neck increases the Ddimension.

Type

APPROXIMATE

WEIGHT

(LONG-NECK

(2)

VALVE

(1)

Kg Lb mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch

RF

2540 5600

RTJ 1026 40.38 1073 42.25 1111 43.75

BW 2270 5000 --- --- --- --- 1108 43.62

RF

3540 7800

RTJ 1276 50.25 1327 52.25 1378 54.25

BW 3130 6900 --- --- --- --- 1372 54.00

RF

5220 11500

RTJ --- --- --- --- --- ---

BW 4810 10600 --- --- --- --- 1372 54.00

RF

5220 11500

RTJ 1565 61.62 1623 63.88 1686 66.38

BW 4630 10200 --- --- --- --- 1676 66.00

RF

7710 17000

RTJ 1565 61.62 1623 63.88 1686 66.38

BW 7120 15700 --- --- --- --- 1676 66.00

CL150 CL300 CL600

1016 40.00 1057 41.62 1108 43.62

1267 49.88 1308 51.50 1372 54.00

1267 49.88 1308 51.50 1372 54.00

1556 61.25 1600 63.00 1676 66.00

1556 61.25 1600 63.00 1676 66.00

A

DIMENSION

Standard Plain Bonnet (Style 1 Extension)

G

437 17.19 663 26.12 127 5.00 816 32.12 226 8.88

487 19.19 706 27.81 226 8.88 859 33.81 276 10.88

514 20.25 917 36.12 276 10.88 1121 44.12 378 14.88

526 20.69 816 32.12 226 8.88 1121 44.12 378 14.88

565 22.25 917 36.12 276 10.88 1121 44.12 378 14.88

Short-Neck Valve

D Max. Travel D Max. Travel

(2)

September 2014

Long-Neck Valve

51.1:EU

(2)

Figure 8. Dimensions and Approximate Weights (also see table 5)

A6068

31.8

(1.25)

STEM

DIAMETER

A

2

25

(1.00)

A

MATCH LINE FOR 585C ACTUATORS

AND 657,667, SIZE 100 ACTUATORS

MATCH LINE

FOR ALL OTHER

ACTUATORS

D

G

mm

(INCH)

11

Page 12

Product Bulletin

51.1:EU

September 2014

Table 6. Port Diameters for Fisher EUT-2andEWT-2 CL 150 through CL600 Valves

Valve Size, NPS TRIM

Cast cages

16

20 × 16

24 × 16

20

24 × 20

1. Linear or equal percentage.

Drilled cages

Drilled cages

Drilled cages

Drilled cages

Whisper Trim III A, B, and C 412.8 16.25

Cast cages

Cast cages

(1)

, WhisperFlo, and Cav III 374.7 14.75

Whisper Trim III D 355.6 14.00

(1)

, WhisperFlo, and Cav III 374.7 14.75

(1)

and Whisper TrimIII A,B, and C 412.8 16.25

Whisper Trim III D 355.6 14.00

(1)

, WhisperFlo, and Cav III 374.7 14.75

(1)

and Whisper TrimIII A,B, and C 412.8 16.25

Whisper Trim III D 355.6 14.00

WhisperFlo and Cav III 463.6 18.25

(1)

and Whisper TrimIII A,B, and C 501.7 19.75

Whisper Trim III D 431.8 17.00

WhisperFlo and Cav III 463.6 18.25

(1)

and Whisper TrimIII A,B, and C 501.7 19.75

Whisper Trim III D 431.8 17.00

mm Inches

EU Valve

D102004X012

PORT DIAMETER

Table 7. Port Diameters for Fisher EUD, EWD, EUT and EWT CL 150 through CL600 Valves

Valve Size, NPS TRIM

Linear; Equal Percentage; Whisper Trim III A, B,

16

20 × 16

24 × 16

20

24 × 20

and C; WhisperFlo; and Cav III

Whisper Trim III D 355.6 14.00

Linear; Equal Percentage; Whisper Trim III A, B,

and C; WhisperFlo; and Cav III

Whisper Trim III D 355.6 14.00

Linear; Equal Percentage; Whisper Trim III A, B,

and C; WhisperFlo; and Cav III

Whisper Trim III D 355.6 14.00

Linear; Equal Percentage; Whisper Trim III A, B,

and C; WhisperFlo; and Cav III

Whisper Trim III D 431.8 17.00

Linear; Equal Percentage; Whisper Trim III A, B,

and C; WhisperFlo; and Cav III

Whisper Trim III D 431.8 17.00

mm Inches

374.7 14.75

374.7 14.75

374.7 14.75

463.6 18.25

463.6 18.25

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser andend user.

Fisher, Whisper Trim,WhisperFlo, andCavitrol are marks owned by one of the companies inthe EmersonProcess Management business unitof Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties orguarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. We reserve the right to modify or improve the designs or specificationsof such

products at any time without notice.

Emerson ProcessManagement

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

PORT DIAMETER

E 1992, 2014 Fisher ControlsInternational LLC. All rightsreserved.

12

Loading...

Loading...