Page 1

Product Bulletin

DLC3010 Digital Level Controller

D102727X012

11.2:DLC3010

Fisherr FIELDVUEt DLC3010 Digital Level

Controller

The FIELDVUE DLC3010 digital level controller is used

with level sensors to measure liquid level, the level of

the interface between two liquids, or liquid specific

gravity (density). Changes in level or specific gravity

exert a buoyant force on a displacer, which rotates a

torque tube shaft. The digital level controller converts

this rotational motion to an electronic signal.

The DLC3010 is a communicating,

microprocessor-based instrument that can be

configured to sense the level, interface level, or

density of liquids. In addition to the normal function of

providing a 4 to 20 milliampere current signal, the

DLC3010, using HART

gives easy access to information critical to process

operation. You can obtain information about the

process, instrument, or sensor using the 475 or 375

Field Communicator. The DLC3010 can be used in

analog or HART digital signaling mode with the

Emerson Process Management DeltaVt system.

The connection for HART communication may be

made at any point in the field wiring that meets the

HART impedance requirements. Configuration,

calibration, diagnostics, parameter review, signal

monitoring and alert monitoring are all available

R

communications protocol,

W7977-1

through the HART protocol. Information from the field

can be integrated into control systems or be received

on a single loop basis.

The DLC3010 digital level controller is designed to

directly replace standard pneumatic and electronic

level transmitters. It mounts on a wide variety of Fisher

249 caged and cageless level sensors.

August 2014

www.Fisher.com

Page 2

Product Bulletin

11.2:DLC3010

August 2014

DLC3010 Digital Level Controller Specifications

DLC3010 Digital Level Controller

D102727X012

Available Configurations

DLC3010 Digital Level Controller:

Mounts on caged and cageless 249 sensors. See

tables 4 and 5 and sensor description.

Function: Transmitter

Communications Protocol: HART

Input Signal

Level, Interface, or Density: Rotary motion of torque

tube shaft proportional to changes in liquid level,

interface level, or density that change the buoyancy

of a displacer.

Process Temperature: Interface for 2- or 3-wire

100 ohm platinum RTD for sensing process

temperature, or optional user-entered target

temperature to permit compensating for changes in

specific gravity

Output Signal

Analog: 4 to 20 milliamperes DC (

J direct

action—increasing level, interface, or density

increases output; or

J reverse action—increasing

level, interface, or density decreases output)

High saturation: 20.5 mA

Low saturation: 3.8 mA

High alarm: 22.5 mA

Low Alarm: 3.7 mA

Only one of the above high/low alarm definitions is

available in a given configuration. NAMUR NE 43

compliant when high alarm level is selected.

Digital: HART 1200 Baud FSK (frequency shift keyed)

HART impedance requirements must be met to

enable communication. Total shunt impedance

across the master device connections (excluding the

master and transmitter impedance) must be between

230 and 1100 ohms. The transmitter HART receive

impedance is defined as:

Rx: 42K ohms and

Cx: 14 nF

In point-to-point configuration, analog and digital

signalling are available. The instrument may be

queried digitally for information, or placed in Burst

mode to regularly transmit unsolicited process

information digitally. In multi-drop mode, the output

current is fixed at 4 mA, and only digital

communication is available.

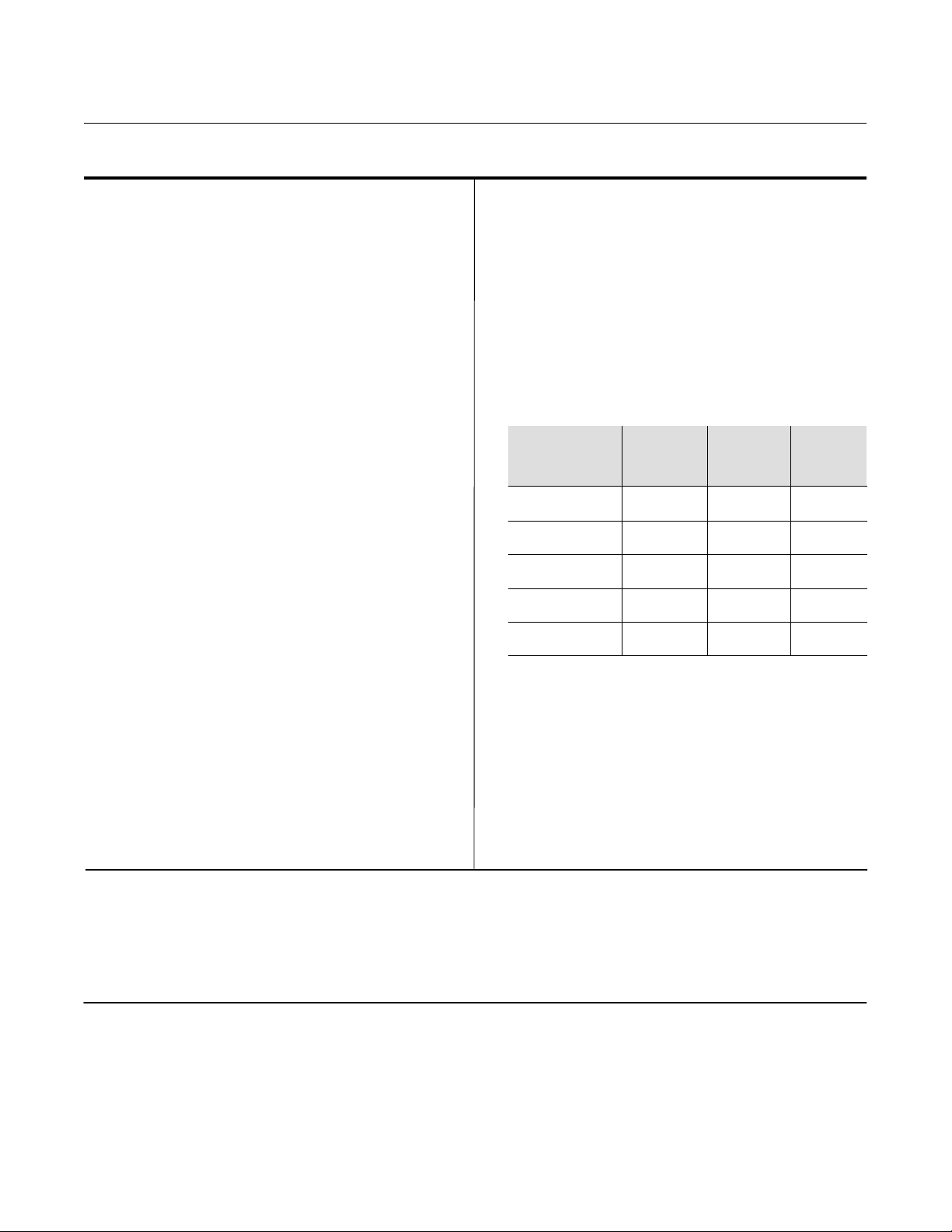

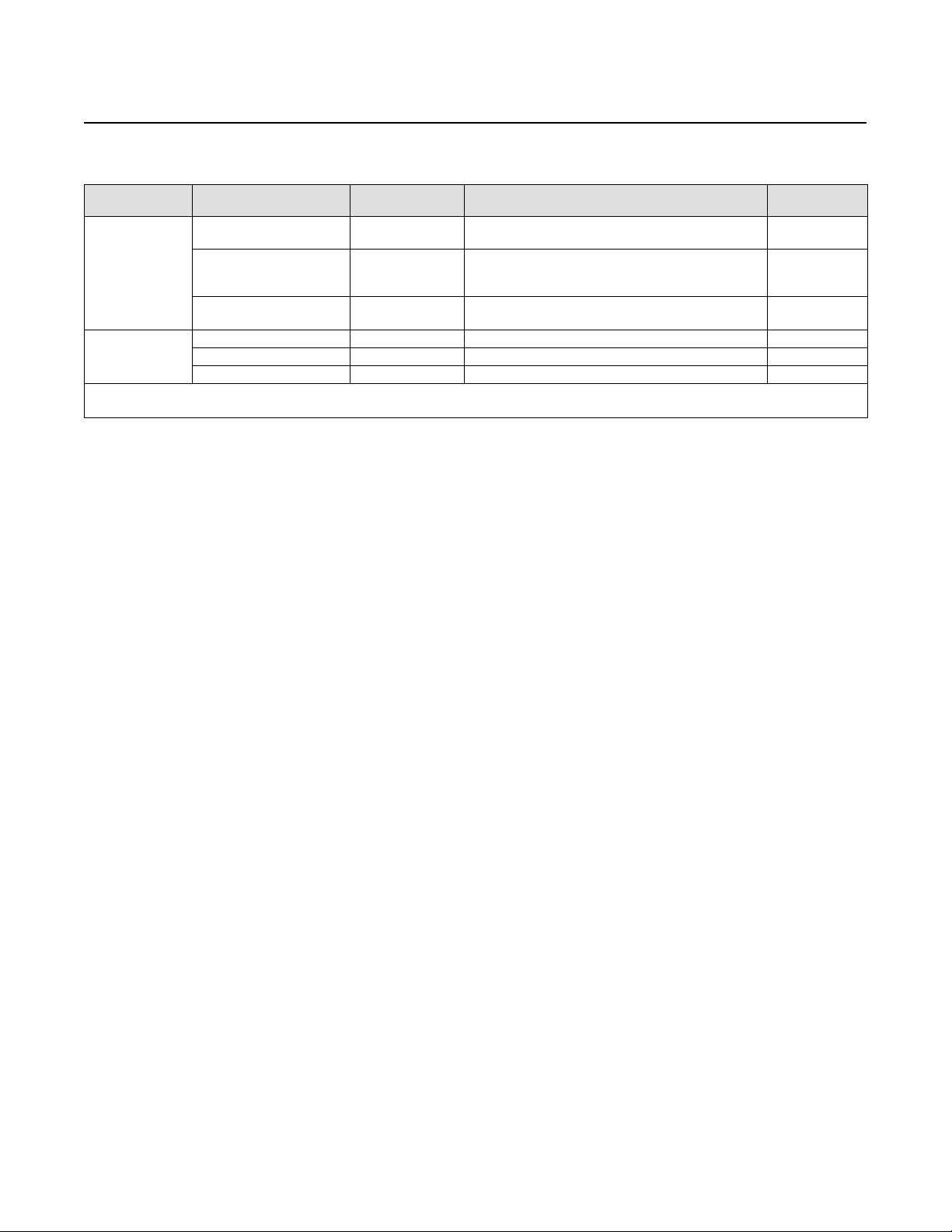

Performance

(1)

w/ 3-Inch

249W, Using

a 14-inch

Displacer

$0.8% of

output span

- - - - - -

$0.5% of

output span

- - - - - -

<1.0% of

output span

w/ All Other

249 Sensors

$0.5% of

output span

$0.3% of

output span

<1.0% of

output span

Performance

Criteria

Independent

Linearity

Hysteresis

Repeatability

Dead Band

Hysteresis plus

Deadband

NOTE: At full design span, reference conditions.

1. To lever assembly rotation inputs.

DLC3010

Digital Level

Controller

$0.25% of

output span

<0.2% of

output span

$0.1% of full

scale output

<0.05% of

input span

- - -

Note: At effective proportional band (PB)<100%,

linearity, dead band, repeatability, power supply

effect, and ambient temperature influence are

potentially derated by the factor (100%/PB)

Operating Influences

Power Supply Effect: Output changes <±0.2% of full

scale when supply varies between minimum and

maximum voltage specifications.

Table of Contents

DLC3010 Specifications 2........................

Features 7.....................................

Principle of Operation 9.........................

249 Level Sensor Specifications 10................

249 Level Sensors 10............................

2

-continued-

Installation 12.................................

Ordering Information 12.........................

Construction 13...............................

Heat Insulator 13..............................

DLC3010 Digital Level Controller 13..........

Page 3

DLC3010 Digital Level Controller

D102727X012

DLC3010 Digital Level Controller Specifications (continued)

Product Bulletin

11.2:DLC3010

August 2014

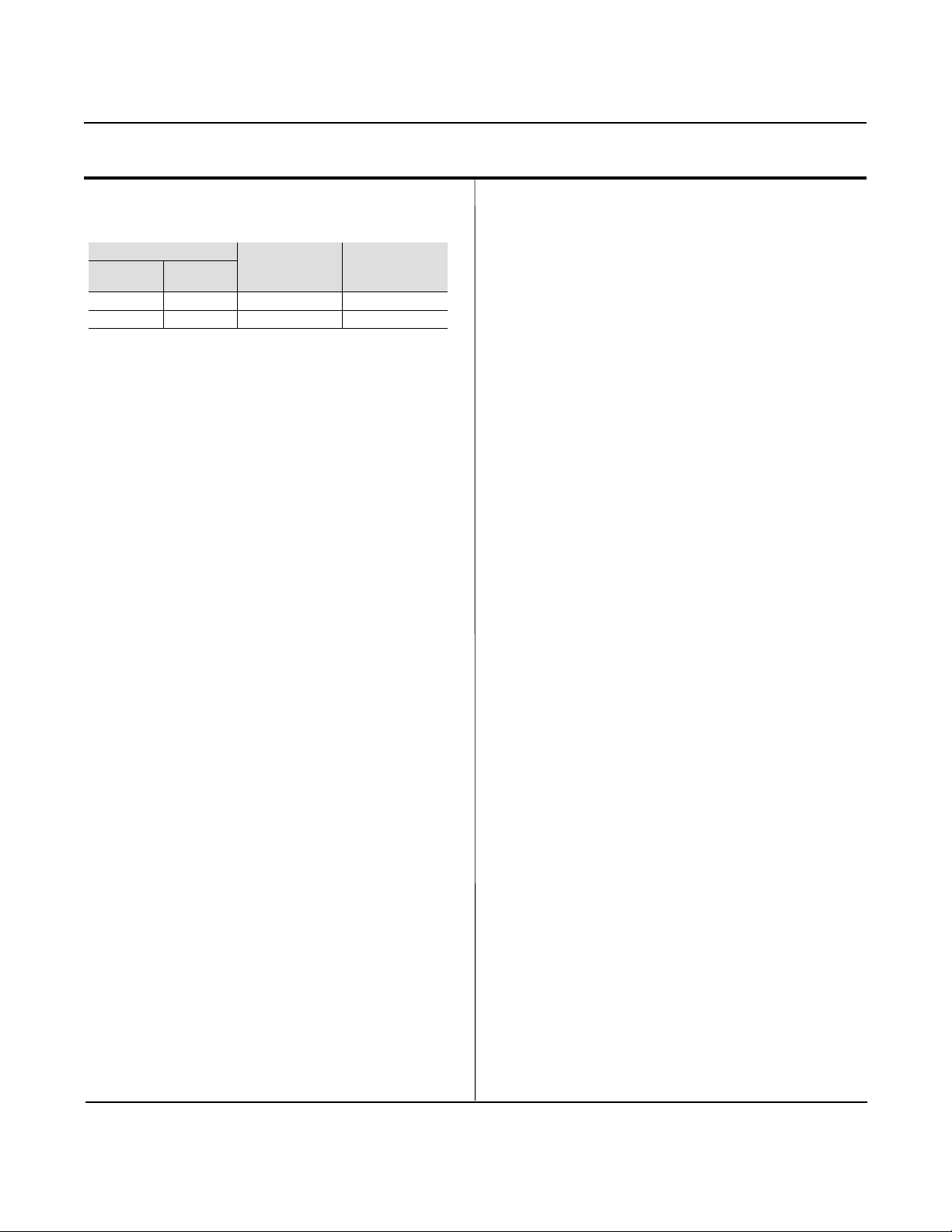

Transient Voltage Protection: The loop terminals are

protected by a transient voltage suppressor. The

specifications are as follows:

Pulse Waveform

Rise Time

(ms)

10 1000 93.6 16

8 20 121 83

Note: μs = microsecond

Decay to

50% (ms)

Max V

CL

(Clamping

Voltage) (V)

Max I

PP

(Pulse Peak

@ Current) (A)

Ambient Temperature: The combined temperature

effect on zero and span without the 249 sensor is less

than 0.03% of full scale per degree Kelvin over the

operating range -40 to 80_C (-40 to 176_F)

Process Temperature: The torque rate is affected by

the process temperature (see figure 1). The process

density may also be affected by the process

temperature.

Process Density: The sensitivity to error in knowledge

of process density is proportional to the differential

density of the calibration. If the differential specific

gravity is 0.2, an error of 0.02 specific gravity units in

knowledge of a process fluid density represents 10%

of span.

Electromagnetic Compatibility

Meets EN 61326‐1 and EN 61326‐2‐3

Immunity—Industrial locations per Table 2 of

EN 61326‐1 and Table AA.2 of EN 61326‐2‐3.

Performance is shown in table 1 below.

Emissions—Class A

ISM equipment rating: Group 1, Class A

signal reasonableness monitor

User-configurable alarms: Hi-Hi and Lo-Lo Limit

process alarms

HART-readable only:

RTD signal reasonableness monitor: When RTD

installed

Processor free-time monitor.

Writes-remaining in Non Volatile Memory monitor.

User-configurable alarms: Hi and Lo limit process

alarms, Hi and Lo limit temperature alarms, Hi and Lo

limit electronics temperature alarms

Diagnostics

Output loop current diagnostic.

LCD meter diagnostic.

Spot specific gravity measurement in level mode: used

to update specific gravity parameter to improve

process measurement

Digital signal-tracing capability: by review of

“troubleshooting variables”, and

Basic trending capability for PV, TV and SV.

LCD Meter Indications

LCD meter indicates analog output on a percent scale

bar graph. The meter also can be configured to

display:

Process variable in engineering units only.

Percent range only.

Percent range alternating with process variable or

Process variable, alternating with process temperature

(and degrees of pilot shaft rotation).

Supply Requirements (See figure 3)

12 to 30 volts DC; instrument has reverse polarity

protection.

A minimum compliance voltage of 17.75 is required

to guarantee HART communication.

Compensation

Transducer compensation: for ambient temperature.

Density parameter compensation: for process

temperature (requires user-supplied tables).

Manual compensation: for torque tube rate at target

process temperature is possible.

Digital Monitors

Linked to jumper-selected Hi (factory default) or Lo

analog alarm signal:

Torque tube position transducer: Drive monitor and

Electrical Classification

Hazardous Area:

CSA— Intrinsically Safe, Explosion‐proof, Division 2,

Dust Ignition‐proof

FM— Intrinsically Safe, Explosion‐proof,

Non‐incendive, Dust Ignition‐proof

ATEX— Intrinsically Safe, Type n, Flameproof

IECEx— Intrinsically Safe, Type n, Flameproof

Refer to tables 8, 9, 10, and 11 for additional approval

information.

Electrical Housing:

CSA— Type 4X

FM— NEMA 4X

ATEX— IP66

IECEx— IP66

-continued-

3

Page 4

Product Bulletin

11.2:DLC3010

August 2014

DLC3010 Digital Level Controller Specifications (continued)

DLC3010 Digital Level Controller

D102727X012

Other Classifications/Certifications

FSETAN—Russian - Federal Service of Technological,

Ecological and Nuclear Inspectorate

GOST‐R—Russian GOST‐R

INMETRO— National Institute of Metrology,

Standardization, and Industrial Quality (Brazil)

NEPSI— National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

PESO CCOE— Petroleum and Explosives Safety

Organisation - Chief Controller of Explosives (India)

TIIS— Technology Institution of Industrial Safety

(Japan)

Contact your Emerson Process Management sales

office for classification/certification specific

information

Minimum Differential Specific Gravity

With a nominal 4.4 degrees torque tube shaft

rotation for a 0 to 100 percent change in liquid level

(specific gravity=1), the digital level controller can be

adjusted to provide full output for an input range of

5% of nominal input span. This equates to a minimum

differential specific gravity of 0.05 with standard

volume displacers.

See 249 sensor specifications for standard displacer

volumes and standard wall torque tubes. Standard

volume for 249C and 249CP is ∼980 cm

most others have standard volume of ∼1640 cm

3

(60 in3),

3

(100 in3).

Operating at 5% proportional band will degrade

accuracy by a factor of 20. Using a thin wall torque

tube, or doubling the displacer volume will each

roughly double the effective proportional band.

When proportional band of the system drops below

50%, changing displacer or torque tube should be

considered if high accuracy is a requirement.

Mounting Positions

Digital level controller can be mounted right- or

left-of-displacer, as shown in figure 8.

Instrument orientation is normally with the coupling

access door at the bottom, to provide proper

drainage of lever chamber and terminal

compartment, and to limit gravitational effect on the

lever assembly. If alternate drainage is provided by

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

user, and a small performance loss is acceptable, the

instrument could be mounted in 90 degree rotational

increments around the pilot shaft axis. The LCD meter

may be rotated in 90 degree increments to

accommodate this.

Construction Materials

Case and Cover: Low-copper aluminum alloy

Internal: Plated steel, aluminum, and stainless steel;

encapsulated printed wiring boards; Neodymium Iron

Boron Magnets

Electrical Connections

Two 1/2-14 NPT internal conduit connections; one on

bottom and one on back of terminal box. M20

adapters available.

Options

J Heat insulator. See description under Ordering

Information.

and Foxboro/Eckhardt displacers available.

J Mountings for Masoneilan, Yamatake

J Level

Signature Series Test (Performance Validation

Report) available (EMA only) for instruments

factory-mounted on 249 sensor.

J Factory

Calibration: available for instruments

factory-mounted on 249 sensor, when application,

process temperature and density(s) are supplied.

J Device is compatible with user-specified remote

indicator.

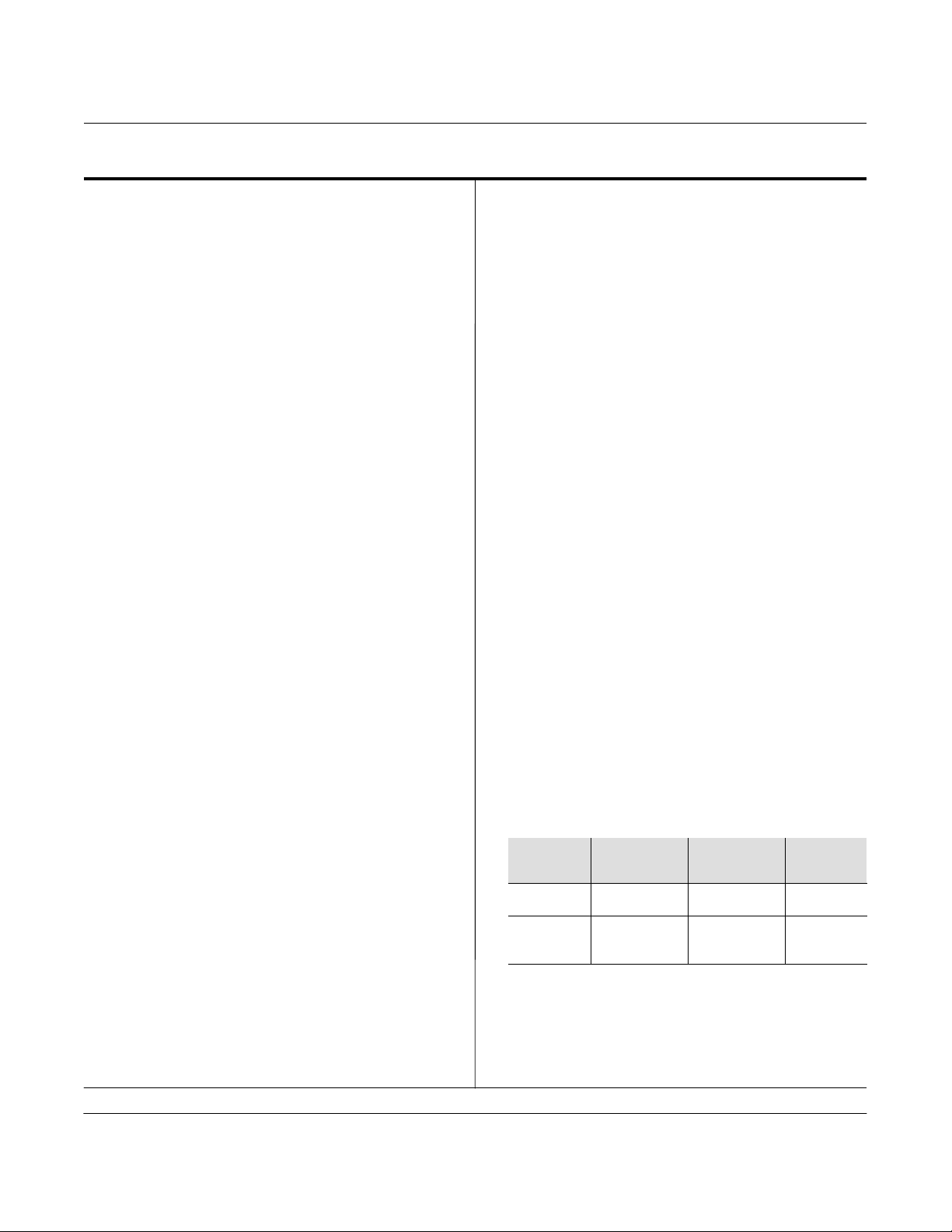

Operating Limits

Process Temperature: See table 3 and figure 2.

Ambient Temperature and Humidity: See below

Conditions

Ambient

Temperature

Ambient

Relative

Humidity

1. LCD meter may not be readable below -20_C (-4_F)

2. Contact your Emerson Process Management sales office or application engineer if

temperatures exceeding these limits are required.

Normal

(1)(2)

Limits

-40 to 80_C

(-40 to 176_F)

0 to 95%,

(non-condensing)

Transport and

Storage

(1)

Limits

-40 to 85_C

(-40 to 185_F)

0 to 95%,

(non-condensing)

Nominal

Reference

25_C

(77_F)

40%

Weight

Less than 2.7 Kg (6 lbs)

(1)

4

Page 5

DLC3010 Digital Level Controller

D102727X012

Table 1. EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level

Electrostatic discharge (ESD) IEC 61000‐4‐2

Enclosure

I/O signal/control

Note: RTD wiring must be shorter than 3 meters (9.8 feet)

1. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering. Specification limit = +/- 1% of span.

2. HART communication was considered as “not relevant to the process” and is used primarily for configuration, calibration, and diagnostic purposes.

Radiated EM field IEC 61000‐4‐3

Rated power frequency

magnetic field

Burst IEC 61000‐4‐4 1 kV A

Surge IEC 61000‐4‐5 1 kV (line to ground only, each) B

Conducted RF IEC 61000‐4‐6 150 kHz to 80 MHz at 3 Vrms A

IEC 61000‐4‐8 60 A/m at 50 Hz A

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

Product Bulletin

11.2:DLC3010

August 2014

Performance

(1)(2)

Criteria

A

A

5

Page 6

Product Bulletin

11.2:DLC3010

August 2014

Figure 1. Theoretical Reversible Temperature Effect on Common Torque Tube Materials

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

1.00

DLC3010 Digital Level Controller

D102727X012

0.98

0.96

0.94

0.92

0.90

Gnorm

0.88

0.86

0.84

0.82

0.80

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420

1

TEMPERATURE (_C)

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

1.00

0.98

0.96

1

N05500

N06600

N10276

S31600

0.94

0.92

0.90

Gnorm

0.88

0.86

0.84

0.82

0.80

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

TEMPERATURE (_F)

Note:

1 Due to the permanent drift that occurs near and above 260_C (500_F), N05500 is not recommended

for temperatures above 232_C (450_F).

6

N05500

N06600

N10276

S31600

Page 7

DLC3010 Digital Level Controller

D102727X012

Product Bulletin

11.2:DLC3010

August 2014

Features

n Simplified Setup and Calibration—For quick analog

transmitter replacement (4-20mA out only), the

instrument may be configured with default sensor

data, zero Level Offset, differential process SG, and

zero/span procedure only. For full compensation

and diagnostic capabilities, complete sensor data

entry and calibration is recommended.

Using Guided Setup, digital level controller start-up

is straightforward and fast. Level and temperature

alarms, specific gravity tables, calibration trim and

trending are readily configurable. The DLC3010 also

supports re-ranging without a fluid reference.

n Responsive to Small Process Changes—Accurate,

high-gain analog-to-digital conversion enables

measurement of small changes in the process

variable. This allows the DLC3010 to be used in

difficult liquid level, interface, or density

applications. In addition, an adjustable input filter

and output damping help to attenuate

displacer-induced ripple in the output signal due to

liquid turbulence.

n Reduced Temperature Effects—An internal

temperature sensor enables consistent

performance of the digital level controller despite

ambient temperature changes. With a temperature

input signal, either via HART protocol or an RTD

connected to the instrument, the digital level

controller can also automatically compensate for

specific gravity changes due to temperature. A

user-supplied table of up to ten linear segments

may be entered to implement this feature. (A

sample water/steam table is provided in the

DLC3010 instruction manual (D102748X012). The

measured torque tube rate may be manually

pre-compensated for a target process temperature

using the data available in the DLC3010 Device

Description (DD).

n Additional Compensation—The instrument

measurement algorithm corrects for the small

motion of the displacer as buoyancy changes,

allowing it to calculate the true cage or vessel level.

This provides additional accuracy on the shorter

displacers.

n Rugged Construction—Mechanical safeguards

designed into the digital level controller help it to

withstand physical abuse often incurred during

installation or in transport, without compromising

performance. The fully encapsulated printed wiring

boards resist the effects of vibration, temperature,

and corrosive atmospheres. The lever assembly is

pinned at the neutral position when the coupling

access door is open, providing shipping stabilization

for a separate transmitter purchase. Locking set

screws are provided for covers and the access door

handle.

n Easy Maintenance—Field wiring connections are in a

compartment separated from the electronics. This

protects the electronics from any moisture brought

into the housing by the field wiring. This also eases

installation and maintenance. The digital level

controller does not have to be removed to facilitate

troubleshooting or service. Modular construction

(figure 4) allows servicing in the field. However, if it

is necessary to remove the digital level controller for

in-shop maintenance and calibration, field wiring

does not need to be disconnected.

n Alarm Jumper—The DLC3010 digital level controller

includes self-diagnostics that detect an error (e.g.

electronics failure) that would render the process

variable measurement inaccurate. The instrument

can also be configured to indicate a process variable

high or low alarm. When a process variable alarm or

an error is detected the analog output signal is

driven either above or below the normal 4 to 20 mA

range, depending on the user-selectable position of

the alarm jumper. The unit ships from the factory

with the jumper in the high position.

7

Page 8

Product Bulletin

11.2:DLC3010

August 2014

DLC3010 Digital Level Controller

D102727X012

Figure 2. Guidelines for Use of Optional Heat

Insulator Assembly

AMBIENT TEMPERATURE (_C)

0

PROCESS TEMPERATURE (_F)

800

400

-325

-40 -30

0

1

TOO

COLD

-10

10 20-20

HEAT INSULATOR

REQUIRED

NO HEAT

INSULATOR NECESSARY

HEAT

INSULATOR REQUIRED

020406080 100 120 140 160

-20-40

AMBIENT TEMPERATURE (_F)

30 40 50 60

TOO

HOT

70

176

80

425

400

300

200

100

0

-100

-200

PROCESS TEMPERATURE (_C)

STANDARD TRANSMITTER

Notes:

1 For process temperature below -29_ (C-20_F) and above 204_C (400_F)

sensor materials must be appropriate for the process (refer to bulletin

34.2:2500).

2. If ambient dew point is above process temperature, ice formation might

cause instrument malfunction and reduce insulator effectiveness.

39A4070-B

A5494-1

Figure 4. FIELDVUE DLC3010 Digital Level Controller Assembly

Figure 3. Power Supply Requirements and Load

Resistance

Maximum Load = 43.5 X (Supply Voltage - 12.0)

783

Load (Ohms)

250

0

10 20 2515

E0284

12 30

SUPPLY VOLTAGE (VDC)

Operating

Region

E1472

ADAPTER RING

LEVER ASSEMBLY

TRANSDUCER ASSEMBLY

ELECTRONICS

MODULE

TERMINAL BOX

TERMINAL BOX

COVER

LCD METER

ASSEMBLY

COVER

8

Page 9

DLC3010 Digital Level Controller

D102727X012

Product Bulletin

11.2:DLC3010

August 2014

Principle of Operation

The DLC3010 digital level controller is a loop-powered

instrument that measure changes in liquid level, level

of an interface between two liquids, or density of a

liquid. A level, density, or interface level change in the

measured fluid causes a change in the displacer

buoyancy (figure 5). This change is transferred to the

torque tube assembly. As the measured fluid changes,

the torque tube assembly rotates.

The rotary motion of the torque tube is transferred to

the digital level controller lever assembly (figure 5).

The rotary motion moves a magnet attached to the

lever assembly, changing the magnetic field that is

sensed by the Hall-effect sensor. The sensor converts

the magnetic field signal to a varying electronic signal,

which is processed digitally to provide linearity

corrections, sensitivity adjustment, and temperature

compensation.

The signal is interpreted as a buoyancy change by

reference to the stored torque rate, coupling point,

and moment arm data. The buoyancy change in turn is

interpreted as a level, interface, or density change by

reference to stored displacer volume, specific gravity,

and displacer length data. In level or interface modes,

the correction for displacer motion is then added, as

well as user-supplied offset to change the PV reference

from the bottom of the displacer or correct for a

coupling point error.

The resultant primary variable (PV) is then compared

to PV alarm thresholds (if enabled) and used to set

status bits and/or trigger the analog alarm current. If

the alarm is not triggered, the PV is used to generate

4-20 mA analog and 0-100% range digital signals by

reference to the stored upper and lower range values.

The resultant analog command is limited at the

saturation values to allow discrimination between

saturated and alarm signals.

Figure 5. Cutaway View of Fisher 249 Displacer Sensor with FIELDVUE DLC3010 Digital Level Controller

W1389-1

TORQUE TUBE

E1471

DISPLACER

9

Page 10

Product Bulletin

11.2:DLC3010

August 2014

249 Level Sensors Specifications

DLC3010 Digital Level Controller

D102727X012

Input Signal

Liquid Level or Liquid-to-Liquid Interface Level:From 0

to 100 percent of displacer length

Liquid Density: From 0 to 100 percent of

displacement force change obtained with given

displacer volume—standard volumes are

(60 inches3) for 249C and 249CP sensors or

J 1640 cm

3

(100 inches3) for most other sensors;

J 980 cm

other volumes available depending upon sensor

construction

Sensor Displacer Lengths

See tables 4 and 5 footnotes

Sensor Working Pressures

Consistent with applicable ASME

pressure/temperature ratings for the specific sensor

constructions shown in tables 4 and 5

Caged Sensor Connection Styles

Cages can be furnished in a variety of end connection

styles to facilitate mounting on vessels; the

equalizing connection styles are numbered and are

shown in figure 7.

Mounting Positions

Most level sensors with cage displacers have a

3

rotatable head. The head may be rotated through

360 degrees to any of eight different positions, as

shown in figure 8.

Construction Materials

See tables 2, 4, and 5

Operative Ambient Temperature

See table 3.

For ambient temperature ranges, guidelines, and use

of optional heat insulator, see figure 2.

Options

J Heat insulator, see description under Ordering

Information

232_C (420 psig at 450_F), and

J Gauge glass for pressures to 29 bar at

J Reflex gauges for

high temperature and pressure applications

249 Level Sensors

249 level sensors used with the DLC3010 digital level

controller are available in both caged and cageless

configurations. Figure 6 shows a DLC3010 mounted on

a caged 249 sensor. Caged sensors provide more

stable operation than do cageless sensors for vessels

with internal obstructions or considerable internal

turbulence. Cageless sensors are generally used on

specific gravity and interface control applications

requiring large displacers that are more easily

accommodated by flange connections up to 8 inches.

The availability of many different displacer stem

lengths permits lowering the displacer down to the

most advantageous depth in the vessel.

Figure 6. FIELDVUE DLC3010 Digital Level Controller

and Fisher 249B Level Sensor

W7926

10

Page 11

DLC3010 Digital Level Controller

D102727X012

Product Bulletin

11.2:DLC3010

August 2014

Table 2. Displacer and Torque Tube Materials

Part Standard Material Other Materials

316 Stainless Steel,

Displacer 304 Stainless Steel

Displacer Stem,

Driver Bearing,

Displacer Rod and

316 Stainless Steel

Driver

Torque Tube N05500

1. N05500 is not recommended for spring applications above 232_C (450_F).

Contact your Emerson Process Management sales office or application engineer if

temperatures exceeding this limit are required.

(1)

Table 4. Caged Displacer Sensors

TORQUE TUBE

ORIENTATION

249

SENSOR

(3)

N10276, N04400,

Plastic, and

Special Alloys

N10276, N04400,

other Austenitic

Stainless Steels, and

Special Alloys

316 Stainless Steel,

N06600, N10276

(1)

STANDARD CAGE, HEAD,

AND TORQUE TUBE ARM

MATERIAL

Cast Iron

Screwed 1-1/2 or 2

Flanged 2

Table 3. Allowable Process Temperatures for

Common Fisher 249 Sensor Pressure Boundary

Materials

MATERIAL

Cast Iron -29_C (-20_F) 232_C (450_F)

Steel -29_C (-20_F) 427_C (800_F)

Stainless Steel -198_C (-325_F) 427_C (800_F)

N04400 -198_C (-325_F) 427_C (800_F)

Graphite Laminate/SST

Gaskets

N04400/PTFE Gaskets -73_C (-100_F) 204_C (400_F)

EQUALIZING CONNECTION

Style Size (NPS)

PROCESS TEMPERATURE

Min. Max.

-198_C (-325_F) 427_C (800_F)

Screwed or optional socket weld 1-1/2 or 2 CL600

Torque tube arm

rotatable with

respect to

equalizing

connections

249B, 249BF

249C

249K Steel

(4)

Steel

Raised face or optional ring type joint

flanged

Screwed 1-1/2 or 2 CL600

(3)

316 Stainless Steel

Raised face flanged

Raised face or optional ring type joint

flanged

249L Steel Ring type joint flanged 2

1. Standard displacer lengths for all styles (except 249) are 14, 32, 48, 60, 72, 84, 96, 108 and 120 inches. The 249 uses a displacer with a length of either 14 or 32 inches.

2. DIN flange connections available in EMA (Europe, Middle East and Africa).

3. Not available in EMA.

4. 249BF available in EMA only. Also available in DIN size DN40 with PN10 to PN100 flanges and size DN50 with PN10 to PN63 flanges.

5. Top connection is 1-inch ring-type joint flanged for connection styles F1 and F2.

1-1/2 CL150, 300, or 600

2 CL150, 300, or 600

1-1/2 CL150, 300, or 600

2 CL150, 300, or 600

1-1/2 or 2 CL900 or 1500

(5)

PRESSURE RATING

CL125 or 250

CL2500

(2)

Table 5. Cageless Displacer Sensors

Mounting Sensor

(1)

Standard Head

(6)

Body

, and Torque Tube

(2)

Arm Material

(4)

Mounts on

249BP

249CP 316 Stainless Steel NPS 3 raised face CL150, 300, or 600

Steel

top of vessel

(5)

249P

Mounts on

side of vessel

249VS

Mounts on top of

vessel or on

customer supplied

249W

cage

1. Standard displacer lengths are 14, 32, 48, 60, 72, 84, 96, 108, and 120 inches.

2. Not used with side-mounted sensors.

3. DIN flange connections available in EMA (Europe, Middle East and Africa).

4. Not available in EMA.

5. 249P available in EMA only.

6. Wafer Body only applicable to 249W.

Steel or Stainless Steel

Cast Iron, Cast Steel or

CF8M (316 Stainless Steel)

WCC (steel) or CF8M

LCC (steel) or CF8M For NPS 4 raised face CL150, 300, or 600

, Wafer

Flange Connection Pressure Rating

NPS 4 raised face or optional ring type joint CL150, 300, or 600

NPS 6 or 8 raised face CL150 or 300

NPS 4 raised face or optional ring type joint

NPS 6 or 8 raised face

For NPS 4 raised face or flat face

CL900 or 1500

(EN PN 10 to DIN PN 250)

CL150, 300, 600, 900, 1500, or

2500

CL125, 150, 250, 300, 900, or

1500 (EN PN 10 to DIN PN 160

For NPS 4 butt weld end, XXS CL2500

For NPS 3 raised face CL150, 300, or 600

(3)

11

Page 12

Product Bulletin

11.2:DLC3010

August 2014

Figure 7. Style Number of Equalizing Connections

DLC3010 Digital Level Controller

D102727X012

TOP AND BOTTOM CONNECTIONS,

SCREWED (S-1) OR FLANGED (F-1)

28B5536-1

B1820-2

STYLE 1

STYLE 2

TOP AND LOWER SIDE CONNECTIONS,

SCREWED (S-2) OR FLANGED (F-2)

Installation

A 249 sensor may be shipped with the DLC3010 digital

level controller installed or they may be shipped

separately.

When shipping a skid mounted system, where the

displacer cannot be restrained, it is recommended that

the transmitter be uncoupled and the lever assembly

locked to prevent damage. The transmitter must be

re-coupled at commissioning, and a zero-trim will be

required.

Dimensions for the DLC3010 and 249 sensor product

construction are shown in figure 9 and tables 6 and 7.

Dimensions of other combinations are available upon

request.

UPPER AND LOWER SIDE CONNECTIONS,

STYLE 3

SCREWED (S-3) OR FLANGED (F-3)

STYLE 4

UPPER SIDE AND BOTTOM CONNECTIONS,

SCREWED (S-4) OR FLANGED (F-4)

Ordering Information

When ordering, specify:

n Process temperature and pressure and ambient air

temperature

n Application

n Liquid level service (specific gravity)

n Interface level service (specific gravity of both

liquids and minimum differential gap or span

required)

n Density service (minimum and maximum specific

gravity required)

12

Page 13

Product Bulletin

DLC3010 Digital Level Controller

D102727X012

Figure 8. Typical Mounting Positions for FIELDVUE DLC3010 Digital Level Controller on Fisher 249 Sensors

11.2:DLC3010

August 2014

SENSOR

CAGED

CAGELESS

LEFT-OF-DISPLACER

7

1

5

1

3

6

4

8

2

3

1

7

RIGHT-OF-DISPLACER

1

5

2

8

4

6

1 Not available for NPS 2 CL300 and 600 249C.

Construction

Refer to the specifications tables. Review the

descriptions below each specification and in the

referenced tables and figures; specify the desired

choice whenever there is a selection to be made.

Heat Insulator

DLC3010 Digital Level Controller

If the DLC3010 and the 249 sensor are ordered as an

assembly, and a heat insulator is required for the

application, order the heat insulator as a 249 sensor

option. If the DLC3010 is ordered separately, the heat

insulator is available as a kit. Order part number

28B5741X012 for the heat insulator kit.

13

Page 14

Product Bulletin

11.2:DLC3010

August 2014

Figure 9. Dimensions for FIELDVUE DLC3010 Digital Level Controller Mounted on a Fisher 249B Sensor

(also see tables 6 and 7)

1-1/2 11-1/2 NPT

103

(4.06)

DLC3010 Digital Level Controller

D102727X012

421

(16.56)

G

F

W

M

106

(4.19)

A

A

S-3 AND F-3 UPPER AND

MATCH

LINE (B)

202.4

(7.97)

3/4-14 NPT

244

(9.62)

203

(8.00)

TOP VIEW

503.4

(19.83)

1/2-14 NPT

CONDUIT

CONN

102.1

(4.02)

125.7

(4.95)

102.6

(4.04)

73.7

(2.90)

DETAILED FRONT VIEW OF

DLC3010 DIGITAL LEVEL CONTROLLER

LOWER SIDE CONNECTIONS

25.F83

19A3071

19A8853-D

17B0219-A

18B5524-1

B1822-5

Table 6. Dimension A for FIELDVUE DLC3010 Digital Level Controller Mounted on a Fisher 249B Sensor

148

148

DIN

A

5.81

5.81

(1)

154

155

6.06

6.12

153

153

154

157

6.06

6.19

SIZE

(NPS)

1-1/22121

SIZE

DN40

DN50

1. Dimension A for 249BF with din flanges.

Screwed NPT CL150 RF CL150 RTJ CL300 RF CL300 RTJ CL600 RF CL600 RTJ

mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches

121

4.75

4.75

PN10/PN16 PN25/PN40 PN63 PN100

mm mm mm mm

143

145

145

145

5.69

5.69

152

151

6.00

5.94

145

147

1/2-14 NPT

CONDUIT CONN

mm

(INCH)

159

159

153

- - -

6.25

6.25

Table 7. Dimensions F, G, M, and W for FIELDVUE DLC3010 Digital Level Controller Mounted on a Fisher 249B Sensor

DISPLACER LENGTH F G M W

mm Inches mm Inches mm Inches mm Inches mm Inches

356 14 356 14.00 197 7.75 284 11.19 394 15.50

813 32 813 32.00 425 16.75 513 20.19 851 33.50

14

Page 15

Product Bulletin

DLC3010 Digital Level Controller

D102727X012

Table 8. Hazardous Area Classifications for Canada—CSA

Certification Body Certification Obtained Entity Rating Temperature Code

Intrinsically Safe

Class I,II,III Division 1 GP A,B,C,D,E,F,G

per drawing 28B5744 T6

CSA

Explosion-proof

Class I, Division 1 GP B,C,D T6

Class I Division 2 GP A,B,C,D T6

Class II Division 1, 2 GP E,F,G T6

Class III

Table 9. Hazardous Area Classifications for United States—FM

Certification Body Certification Obtained Entity Rating Temperature Code

Intrinsically Safe

Class I,II,III Division 1 GP A,B,C,D,E,F,G

per drawing 28B5745 T5

FM

Explosion-proof

Class I, Division 1 GP A,B,C,D

Class I Division 2 GP A,B,C,D

Class II Division 1 GP E,F,G

Class II Division 2 GP F,G

Vmax = 30 VDC

Imax = 226 mA

Ci = 5.5 nF

Li = 0.4 mH

- - - T6 (Tamb ≤ 80_C)

- - - T6 (Tamb ≤ 80°C)

Vmax = 30 VDC

Imax = 226 mA

Pi = 1.4 W

Ci = 5.5 nF

Li = 0.4 mH

- - - T5 (Tamb ≤ 80_C)

- - - T5 (Tamb ≤ 80°C)

11.2:DLC3010

August 2014

T6 (Tamb ≤ 80°C)

T5 (Tamb ≤ 80°C)

Table 10. Hazardous Area Classifications—ATEX

Certificate Certification Obtained Entity Rating Temperature Code

Intrinsically Safe

II 1 G D

Gas

Ex ia IIC T5 Ga

Dust

Ex ia IIIC T83_C Da IP66

Flameproof

II 2 G D

ATEX

Gas

Ex d IIC T5 Gb

Dust

Ex tb IIIC T83_C Db IP66

Type n

II 3 G D

Gas

Ex nA IIC T5 Gc

Dust

Ex t IIIC T83_C Dc IP66

Ui = 30 VDC

Ii = 226 mA

Pi = 1.4 W

Ci = 5.5 nF

Li = 0.4 mH

T5 (Tamb ≤ 80_C)

- - - T5 (Tamb ≤ 80_C)

- - - T5 (Tamb ≤ 80_C)

15

Page 16

Product Bulletin

11.2:DLC3010

August 2014

Table 11. Hazardous Area Classifications—IECEx

Certificate Certification Obtained Entity Rating Temperature Code

Intrinsically Safe

Gas

Ex ia IIC T5 Ga

Dust

Ex ia IIIC T83_C Da IP66

Flameproof

Gas

IECEx

Exd IIC T6 Gb

Dust

Ex t IIIC T83_C Db IP66

Type n

Gas

Ex nA IIC T5 Gc

Dust

Ex t IIIC T83_C Dc IP66

DLC3010 Digital Level Controller

Ui = 30 VDC

Ii = 226 mA

Pi = 1.4 W

Ci = 5.5 nF

Li = 0.4 mH

- - - T5 (Tamb ≤ 80°C)

- - - T5 (Tamb ≤ 80°C)

T5 (Tamb ≤ 80°C)

D102727X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, FIELDVUE, and DeltaV are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. HART is a mark owned by the HART

Communication Foundation. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2000, 2014 Fisher Controls International LLC. All rights reserved.

16

Loading...

Loading...