Page 1

Instruction Manual

D100386X012

Fisherr D and DA Valves

DandDAValves

June 2014

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 2...............................

Educational Services 2.........................

Ceramic Trim 3................................

Installation 3..................................

Maintenance 5.................................

Packing Lubrication 5..........................

Packing Maintenance 6.........................

Replacing Packing 6...........................

Trim Maintenance 8...........................

Disassembly 8.............................

Lapping Metal Seats 8......................

Assembly 9...............................

Parts Ordering 9................................

Parts Kits 10...................................

Parts List 10...................................

Figure 1. Fisher D Valve with 657 Actuator

W0232

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for Fisher D and DA valves. Refer to

separate manuals for instructions covering the actuator, positioner, and accessories.

Do not install, operate, or maintain a D or DA valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Unless otherwise noted, all NACE references are to NACE MR0175-2002.

Description

The D globe-style (figure 1) and DA angle-style (figure 5) valves are single-port, metal-seated valves for high-pressure

applications.

www.Fisher.com

Page 2

DandDAValves

June 2014

Table 1. Specifications

Instruction Manual

D100386X012

Maximum Inlet Pressures and Temperatures

(1)

If the valve nameplate shows an ASME

pressure-temperature class, maximum inlet pressure

and temperature is consistent with applicable ASME

class per ASME B16.34.

If the nameplate does not show an ASME class, it will

show a maximum cold working pressure at 38_C

(100_F) (for example, 3600, 6000, 9000, or 10,000

psi)

Maximum Allowable Pressure Drops

(1)

Flow up: Capable of full rated pressure drops

Flow down: See table 2 for pressure drop limits for

ceramic trim

Shutoff Classification Per ANSI/FCI 70-2

and IEC 60534-4

Standard: Class IV

Optional: Class V

1. Do not exceed thepressure or temperature limitsin this manual and any applicable standard limitations.

Maximum Service Temperature

232_C(450_F)

Flow Characteristic

Equal Percentage

Flow Direction

DValve:Flow up through the seat ring and out past

the valve plug

DA Valve: Flow in either direction

Approximate Weight

DValve:34 kg (75 lbs)

DA Valve: 46 kg (100 lbs)

Specifications

Specifications for these valves are in table 1. Some of the specifications for a given valve appear on a nameplate, which

is attached to the valve actuator or wired to the valve assembly if the valve was purchased without an actuator.

Educational Services

For information on available courses for Fisher D and DA valves, as well as a variety of other products, contact:

Emerson Process Management

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

http://www.emersonprocess.com/education

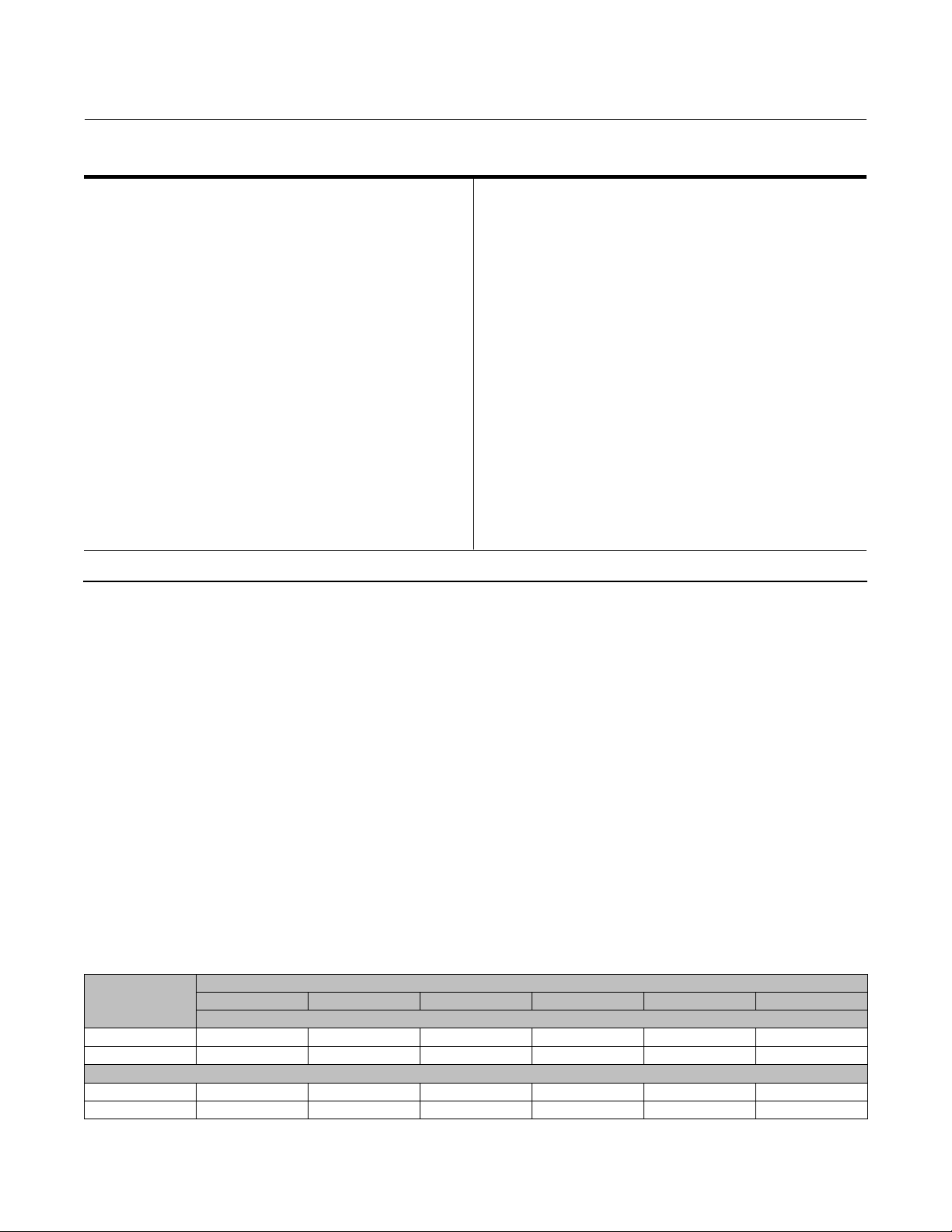

Table 2. Flow Down Pressure Drop Limits - Ceramic Trim Only

VALVE SIZE

NPS

1 414 414 414 193 --- ---

2 689 689 689 462 262 165

1 6000 6000 6000 2800 --- ---

2 10,000 10,000 10,000 6700 3800 2400

6.4 (0.25) 9.5 (0.375) 12.7 (0.5) 19.1 (0.75) 25.4 (1) 31.8 (1.25)

SEAT RING DIAMETER, mm (INCHES)

Pressure Drop, bar

Pressure Drop, psi

2

Page 3

Instruction Manual

D100386X012

DandDAValves

June 2014

Ceramic Trim

Some types of ceramic trim, including the VTC (very tough ceramic) variety, can create a spark under certain

circumstances. When the edge of a ceramic part is struck against a second ceramic part with enough force, a spark can

be created.

WARNING

Avoid personal injury and property damage from ignition of process fluid caused by sparks from ceramic trim.

Do not use ceramic trim where the process fluid is unstable or if it is an explosive mixture (such as ether and air).

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

To avoid personal injury or property damage resulting from the sudden release of process pressure or bursting of parts, do

not install the valve assembly where service conditions could exceed the limits given in this manual or on the appropriate

nameplates. Use pressure-relieving devices as required by government or accepted industry codes and good engineering

practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING a t the beginning of the Maintenance section in this

instruction manual.

CAUTION

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Some body/trim material combinations are limited in their pressure drop

and temperature ranges. Do not apply any other conditions to the valve without first contacting your Emerson Process

Management sales office.

1. Before installing the valve, inspect it to be certain that the valve body cavity is free of foreign material. Clean out all

pipelines to remove scale, welding slag, and other foreign materials.

2. Install the valve so that flow through the valve is in the direction shown by the arrow cast on the valve body. The

control valve assembly may be installed in any position unless limited by seismic considerations. However, the

normal method is with the actuator vertical above the valve. With some valves, the actuator may need support

when it is not vertical. For more information, consult your Emerson Process Management sales office.

3. Use accepted piping and welding practices when installing the valve in the line. For flanged valve bodies, use

suitable gaskets between the body flanges and pipeline flanges.

3

Page 4

DandDAValves

June 2014

Instruction Manual

D100386X012

CAUTION

Depending on valve body materials used, post-weld heat treating might be needed. If so, damage to internal elastomeric

and plastic parts, as well as internal metal parts is possible. Shrink-fit pieces and threaded connections may also loosen. In

general, if post-weld heat treating is needed, remove all trim parts. Contact your Emerson Process Management sales office

for additional information.

For screwed end connections, apply pipe compound to pipeline threads.

4. To allow continuous operation during inspection or maintenance, install a three-valve bypass around the control

valve assembly.

5. If you received the actuator and valve body shipped separately, refer to the appropriate actuator instruction manual

for the actuator mounting procedure.

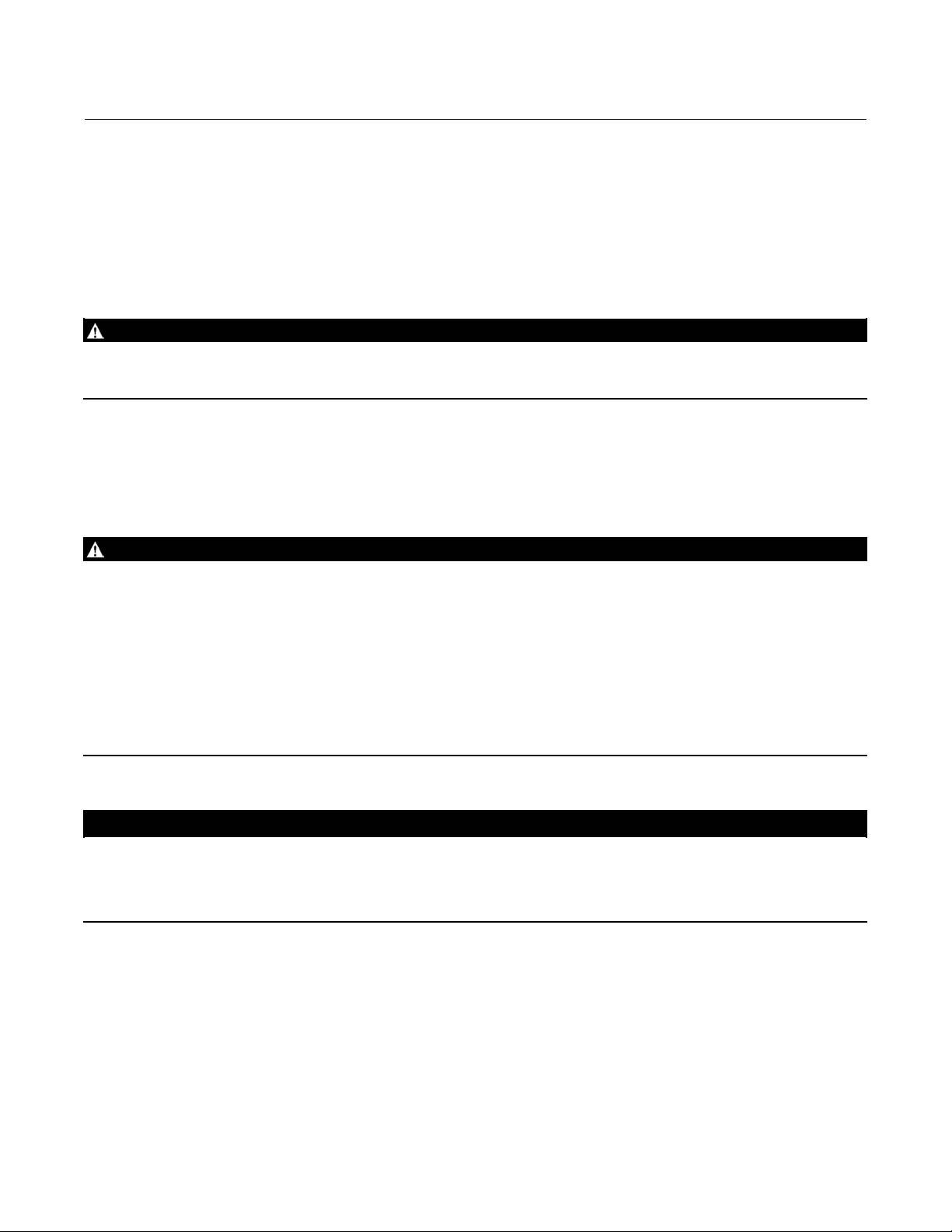

Figure 2. Lubricator and Lubricator/Isolating Valve (optional)

LUBRICATOR

10A9421-A

AJ5428-D

A0832-2

LUBRICATOR/ISOLATING VALVE

WARNING

Personal injury could result from packing leakage. Valve packing was tightened before shipment; however the packing

might require some readjustment to meet specific service conditions.

4

Page 5

Instruction Manual

D100386X012

DandDAValves

June 2014

Maintenance

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Table 3. Bolting Torque for Packing Box Nuts (Key 15)

VALVE

RATING

3600 psi or to CL1500

6000 psi or CL2500

9000 psi

10,000 psi

STEM

DIAMETER

mm Inches NSm LbfSin NSm LbfSin

9.5

12.7

19.1

9.5

2.7

19.1

12.7

19.1

12.7

19.1

3/8

1/2

3/4

3/8

1/2

3/4

1/2

3/4

1/2

3/4

MINIMUM

RECOMMENDED TORQUE

4

7

16

5

9

20

6

20

6

20

36

66

144

42

78

180

54

180

54

180

MAXIMUM

RECOMMENDED TORQUE

5

11

24

7

12

30

8

30

8

30

48

96

216

60

108

264

72

264

72

264

Valve body parts are subject to normal wear and must be inspected and replaced as necessary. Inspection and

maintenance frequency depends on the severity of service conditions. This section includes instructions for packing

lubrication, packing maintenance, trim maintenance, and lapping seating surfaces. All maintenance operations can be

performed with the valve in the line.

Note

Whenever a gasket seal is disturbed by removing or shifting gasketed parts, install a new gasket upon reassembly. This is necessary

to ensure a good gasket seal because the used gasket might not seal properly.

Packing Lubrication

Thevalvemighthaveanoptionallubricatororlubricator/isolatingvalve(figure2)inthetappedbonnet.Usethe

lubricator or lubricator/isolating valve for PTFE/composition or o ther packings that need lubrication. Use a silicon-base

5

Page 6

DandDAValves

June 2014

lubricant. Do not lubricate packing used in oxygen service. To operate the lubricator, turn the cap screw clockwise to

force the lubricant into the packing box. The lubricator/isolating valve operates the same way except open the

isolating valve before turning the cap screw. Close the isolating valve after lubrication is completed.

Instruction Manual

D100386X012

Packing Maintenance

Refer to figures 3, 4, and 5 for key number locations. For spring-loaded single PTFE V-ring packing, the packing spring

(key 9) maintains a sealing force on the packing. If you find leakage around the packing follower (key 10), check to be

sure the packing follower is touching the bonnet (key 5). If the packing follower is not touching the bonnet, tighten

the packing flange nuts (key 15) until the packing follower touches the bonnet. If you cannot stop leakage in this way,

proceed to the Replacing Packing procedure.

If there is unwanted packing leakage with other than spring-loaded packing, first try to limit the leakage and seal the

stem. To limit the leakage, tighten the packing flange nuts (key 15) to at least the minimum recommended torque in

table 3. However, do not exceed the maximum recommended torque in table 3, or excessive friction might result. If

the packing (key 8) is relatively new and tight on the stem, and tightening the packing flange nuts does not stop the

leakage, a worn or nicked valve stem might prevent a seal. If the leakage comes from the outside diameter of the

packing, nicks or scratches around the packing box wall might cause the leakage. While replacing the packing per the

numbered steps below, inspect the valve stem and packing box wall for nicks and scratches.

Replacing Packing

Except where indicated, refer to figures3,4,and5forkeynumberlocations.

WARNING

Refer to the WARNING at the beginning of the Maintenance section in this instruction manual.

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, also shut-off all pressure lines to the power

actuator and any leak-off piping from the bonnet. Release all pressure from the actuator and relieve spring

precompression. Use lock-out procedures to be sure that the above measures stay in effect while you work on the

equipment.

Disconnect the stem connector, and then remove the actuator from the valve body by unscrewing the actuator yoke

locknut (key 14).

2. Loosen the packing flange nuts (key 15) so the packing is not tight on the valve stem. Remove any travel indicator

parts and stem locknuts from the valve stem threads.

3. Unscrew the bonnet (key 5) from the valve body (key 1). Carefully lift off the bonnet and valve plug/stem assembly

(key 4) as a unit. Set the bonnet on a protective surface to prevent damage to the bonnet threads and gasket

surface.

4. Removethevalveplug/stemassemblyfromthebonnet.Ifyouplantore-usethevalveplug,tapeorotherwise

protect the valve plug seating surface and the stem threads to prevent damage.

5. Remove the bonnet gasket (key 7). Cover the opening in the valve body to protect the gasket surface and prevent

foreign material from getting into the body cavity.

6. Remove the packing flange nuts, packing flange, upper wiper, and follower (keys 15, 12, 21, and 10). Carefully push

out all the remaining packing box parts from the bonnet using a rounded rod or other tool that will not scratch the

packing box wall or bottom guide bushing. Clean the packing box and the metal packing box parts.

7. Inspect the valve stem threads and packing box surfaces for any sharp edges that might cut the packing. Scratches

or burrs could cause packing box leakage or damage to the new packing. If you cannot improve the surface

condition by light sanding, replace the damaged parts.

6

Page 7

Instruction Manual

D100386X012

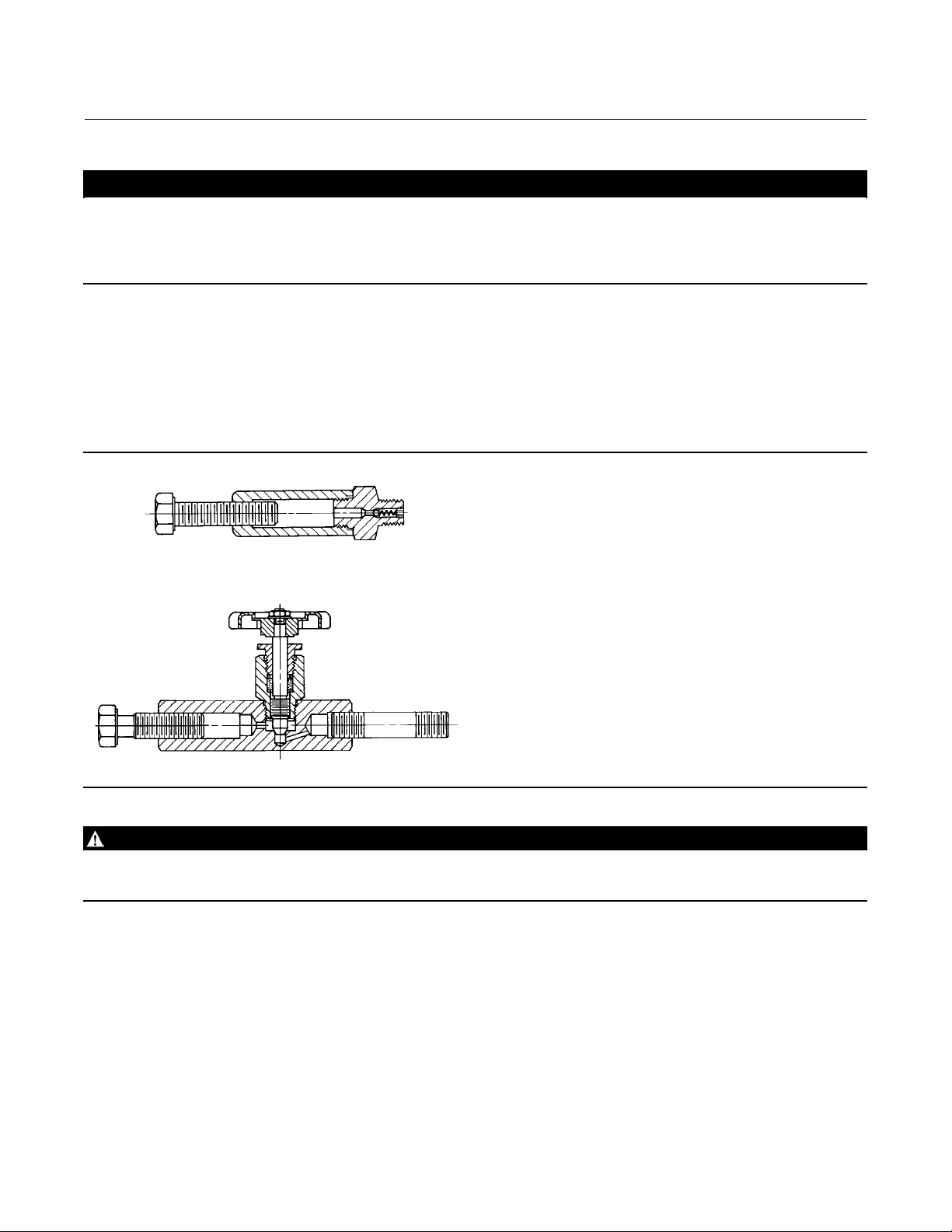

Figure 3. Packing Arrangements

DandDAValves

June 2014

C0755-1

9.5mm(3/8INCH)STEM

9.5 mm

(3/8 INCH)

STEM

12.7 mm (1/2 INCH) STEM

12.7 mm

(1/2 INCH)

STEM

19.1 mm

(3/4 INCH)

STEM

8. Install a new bonnet gasket (key 7), making sure the gasket seating surfaces are clean and smooth. Carefully install

the valve plug/stem assembly into the valve body. Then slide the bonnet over the stem and thread it tightly into the

valve body, per the torque values in table 4.

9. Install new packing and the metal packing box parts according to the correct arrangement in figure 3. Place a

smooth-edged pipe over the valve stem, and gently tap each soft packing part into the packing box.

Table 4. Torque for Body-to-Bonnet Joint

VALVE SIZE

NPS 1 1060 780

NPS 2 - Up to 6000 psi valve rating 2030 1500

NPS 2 - 9000

1. 9000 psi valve rating is available for DA only.

(1)

and 10,000 psi valve rating 2710 2000

NSm

RECOMMENDED TORQUE

LbfSft

7

Page 8

DandDAValves

June 2014

Instruction Manual

D100386X012

Table 5. Torque for Seat Ring (Key 2)

VALVE SIZE, NPS

1 407 300

2 698 515

NSm LbfSft

RECOMMENDED TORQUE

10. Slide the packing follower, upper wiper, and packing flange (keys 10, 21, and 12) into position. Lubricate the

packingflangestuds(key13)andthefacesofthepackingflange nuts (key 15). Install the packing flange nuts.

11. For spring-loaded PTFE V-ring packing, tighten the packing flange nuts (key 15) until the packing follower (key 10)

contacts the bonnet. For other packing arrangements, tighten the packing flange nuts (key 15) alternately in small

equal increments. Continue until one of the nuts reaches the minimum recommended torque shown in table 3.

Then tighten the remaining packing flange nut until the packing flange is level and at a 90-degree angle to the valve

stem.

12. Mount the actuator on the bonnet (key 5) and connect the actuator and valve plug stem according to the

procedure in the appropriate actuator instruction manual.Checkforleakagearoundthe packing follower when you

put the control valve assembly into service. Retighten the packing flange nuts as required.

Trim Maintenance

Refer to figure 4 and 5 for key number locations.

Disassembly

1. Remove the actuator and the bonnet as described in steps 1 through 3 of the Replacing Packing procedure.

CAUTION

Use care to avoid damaging the gasket sealing surfaces.

The stem surface finish of the valve plug/stem assembly (key 4) is critical for making a good packing seal. The seating

surfaces of the seat ring (key 2) and the plug of the valve plug/stem assembly (key 4) are critical for tight shutoff. Protect

these parts from damage if you plan to re-use them in the valve.

2. If you wish, remove the valve plug/stem assembly (key 4)andthepackingpartsfromthebonnet.Ifyouplanto

re-usethevalveplug,tapeorotherwiseprotectthevalveplugseatingsurfaceandthestemthreadstoprevent

damage. Remove the packing parts as described in the Packing Maintenance procedure.

3. Use a socket wrench to remove the seat ring (key 2).

4. Remove the seat ring (key 2) and seat ring gasket (key 3) from the valve body.

5. Inspect parts for wear or damage that would prevent proper operation of the valve body. Clean the gasket surfaces.

6. Replace trim parts as necessary or use the Lapping Metal Seats procedure.

Lapping Metal Seats

A certain amount of leakage should be expected with metal-to-metal seating in any valve body. If the leakage

becomes excessive, however, the condition of the seating surfaces of the valve plug and seat ring (keys 4 and 2, figures

4 and 5) can be improved by lapping. (Deep nicks should be machined out rather than ground out.) Use a good quality

lapping compound of a mixture of 280 to 600-grit. Apply the compound to the bottom of the valve plug.

Partially assemble the valve so the seat ring and valve plug are in place and the bonnet (with bushing installed) is

screwed hand-tight into the body. Make a simple handle from a piece of strap iron locked to the valve plug stem with

8

Page 9

Instruction Manual

D100386X012

nuts. Rotate the handle alternately in each direction with light downward pressure to lap the seats. If you think there is

not enough lubrication (for example, if you hear a squeaking noise or feel vibration), stop the procedure, and apply

more lapping compound before continuing. After lapping, remove the bonnet and valve plug/stem assembly as a unit,

and clean the seating surfaces. Completely assemble as described in the Assembly portion of the Trim Maintenance

procedure.

Testthevalveforshutoff.Repeatthelappingprocedureifleakageisstillexcessive.

DandDAValves

June 2014

Assembly

1. Thoroughly clean the seat ring and bonnet threads in the valve body (key 1). Also clean the valve body seat ring

gasket surfaces.

2. Apply anti-seize lubricant to the threads of the seat ring (key 2), bonnet (key 5), and their mating threads in the

body.

3. Put the seat ring gasket (key 3) into the body.

4. Screw the seat ring into the body. Use a socket wrench to tighten the seat ring to the torque values shown in table

4. Remove all excess lubricant after tightening.

5. Clean the bonnet gasket seating surfaces, and install a new bonnet gasket (key 7).

6. If you had not removed the valve plug/stem assembly and packing from the bonnet, then install the bonnet (key 5)

and valve plug/stem assembly (key 4) as a unit, into the valve body. Keeping the valve plug/stem assembly in an

“up” position, thread the bonnet tightly into the valve body, per torque values in table 4.

7. If you had previously chosen to remove the valve plug/stem assembly and packing from the bonnet, then remove

any protective tape or covering from the valve plug/stem assembly (key 4) and carefully install it into the valve

body. Slide the bonnet (key 5) over the stem and thread it tightly into the valve body. Install new packing and the

metal packing box parts according to the correct arrangement in figure 3. Place a smooth-edged pipe over the valve

stem, and gently tap each soft packing part into the packing box.

8. Slide the packing follower, upper wiper, and packing flange (keys 10, 21, and 12) into position. Lubricate the

packing flange studs (key 13) and the washer surfaces of the packing flange nuts (key 15). Install the packing flange

nuts.

9. For spring-loaded PTFE V-ring packing, tighten the packing flange nuts (key 15) until the packing follower (key 10)

contacts the bonnet. For other packing arrangements, tighten the packing flange nuts (key 15) alternately in small

equal increments. Continue until one of the nuts reaches the minimum recommended torque shown in table 3.

Then tighten the remaining packing flange nut until the packing flange is level and at a 90-degree angle to the valve

stem.

10. Mount the actuator on the bonnet (key 5) and connect the actuator and valve plug stem according to the

procedure in the appropriate actuator instruction manual. Check for leakage around the packing follower (key 10)

when you put the control valve assembly into service. Retighten the packing flange nuts as required.

Parts Ordering

Each body-bonnet assembly is assigned a serial number, which is on the body or nameplate. The serial number also

appears on the actuator nameplate if you bought a valve and actuator assembly. Refer to this serial number when

contacting your Emerson Process Management sales office for technical advice. When ordering replacement parts,

mention the serial number. Also specify key number, part description, material, and part number from the following

lists of Parts Kits and part numbers.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

9

Page 10

DandDAValves

June 2014

Instruction Manual

D100386X012

Parts Kits

Key Description Part Number

- - - Packing Box Parts for Double PTFE V-Ring

Packing (Includes keys 3, 7, 8, 11, 18, 19, and 21)

9.5 mm (3/8 Inch) Stem RDX0000CN12

12.7 mm (1/2 Inch) Stem RDX0000CN22

- - - Trim Package (S31600)

[Includes Equal Percentage S31600 (316 SST) W/R30006 (alloy6)

tip valveplug/stem (key4), S316000 w/alloy 6 seat ring (key 2),

stainless steel gaskets (keys 3 & 7), and single PTFE packing parts

(keys 8, 9, 11, 17, 18, and 21) or double PTFE packing p arts (keys

8, 11, 18, 19, and 21)]

Double PTFE V-Ring Packing

NPS1Valvew/9.5mm(3/8Inch)StemDia.

6.4 mm (0.25 Inch) port dia. RDXCNTRM112

9.5 mm (0.375 Inch) port dia. RDXCNTRM122

12.7 mm (0.5 Inch) port dia. RDXCNTRM132

19.1 mm (0.75 Inch) port dia. RDXCNTRM142

NPS2Valvew/12.7mm(1/2Inch)StemDia.

6.4 mm (0.25 Inch) port dia. RDXCNTRM212

9.5 mm (0.375 Inch) port dia. RDXCNTRM222

12.7 mm (0.5 Inch) port dia. RDXCNTRM232

19.1 mm (0.75 Inch) port dia. RDXCNTRM242

25.4 mm (1-Inch) port dia. RDXCNTRM252

31.8 mm (1.25 Inch) port dia. RDXCNTRM262

- - - Trim Package (Ceramic)

Includes seat ring and valve plug/stemassy (keys 2 and 4)

NPS1Valvew/9.5mm(3/8Inch)StemDia.

6.4 mm (0.25 Inch) port dia. RDXVTC00012

9.5 mm (0.375 Inch) port dia. RDXVTC00022

12.7 mm (0.5 Inch) port dia. RDXVTC00032

19.1 mm (0.75 Inch) port dia. RDXVTC00042

NPS2Valvew/12.7mm(1/2Inch)StemDia.

6.4 mm (0.25 Inch) port dia. RDXVTC00052

9.5 mm (0.375 Inch) port dia. RDXVTC00062

12.7 mm (0.5 Inch) port dia. RDXVTC00072

19.1 mm (0.75 Inch) port dia. RDXVTC00082

25.4 mm (1-Inch) port dia. RDXVTC00092

31.8 mm (1.25 Inch) port dia. RDXVTC00102

Parts List

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

Note

Abbreviations used in this parts list are: SST (stainless steel), RTJ

(ring-type joint), RF (raised face), SCH(schedule), BWE (buttwelding

end), dia. (diameter), in. (inches), mm (millimeters), psi (pounds per

square inch), and zn pl (zinc plated).

Sizes shown in inches are valve sizes unless otherwise stated.

Select parts titled 3600 PSI if your valve has a CL1500 or lower rating and

select parts titled 6000 PSI if your valve has a CL2500 rating.

Key Description Part Number

001 ValveBody

If you need a valve body as a replacement part, order by valve

size, serial number, and desired material.

002* Seat Ring

CF8M or S31600 (316 SST) w/COCR-A seat

NPS 1 valve

6.4 mm (0.25 inch) port dia. 2B5097X0012

9.5 mm (0.375 inch) port dia. 2B5098X0012

12.7 mm (0.5 inch) port dia. 2B5099X0012

19.1 mm (0.75 inch) port dia. 2B5100X0012

NPS 2 valve

6.4 mm (0.25 inch) port dia. 2B5106X0012

9.5 mm (0.375 inch) port dia. 2B5107X0012

12.7 mm (0.5 inch) port dia. 2B5108X0012

19.1 mm (0.75 inch) port dia. 2B5109X0012

25.4 mm (1-inch) port dia. 2B5110X0012

31.8 mm (1.25 inch) port dia. 2K1801X0012

316 SST w/tungsten carbide insert

NPS 1 valve

6.4 mm (0.25 inch) port dia. 1J6886000A2

9.5 mm (0.375 inch) port dia. 1J6887000A2

12.7 mm (0.5 inch) port dia. 1J6888000A2

19.1 mm (0.75 inch) port dia. 1J6889000A2

NPS 2 valve

6.4 mm (0.25 inch) port dia. 1J6899000A2

9.5 mm (0.375 inch) port dia. 1J8154000A2

12.7 mm (0.5 inch) port dia. 1J8156000A2

25.4 mm (1-inch) port dia. 1J8160000A2

Ceramic

NPS 1 valve

6.4 mm (0.25 inch) port dia. 22B8996X012

9.5 mm (0.375 inch) port dia. 22B8997X012

12.7 mm (0.5 inch) port dia. 22B8998X012

19.1 mm (0.75 inch) port dia. 22B8999X012

NPS 2 valve

6.4 mm (0.25 inch) port dia. 22B9000X012

9.5 mm (0.375 inch) port dia. 22B9001X012

12.7 mm (0.5 inch) port dia. 22B9002X012

19.1 mm (0.75 inch) port dia. 22B9003X012

25.4 mm (1-inch) port dia. 22B9004X012

31.8 mm (1.25 inch) port dia. 22B9005X012

10

*Recommended spare parts

Page 11

Instruction Manual

D100386X012

DandDAValves

June 2014

Key Description Part Number

003* Gasket

S31600 (316 SST)

For NPS 1 valves and NACE MR0175-2002

For NPS 2 valves and NACE MR0175-2002

004* Micro-Flute valve plug/stem assembly

NACE MR0175-2002

(1)

S31600, COCR-Aseat - S20910

(1)

(1)

1B198636042

1B198836042

NPS 1 valve, 9.5 mm (3/8 in.)stem

1flute

6.4 mm (0.25 inch) port dia. 2N7147X0032

3flutes

6.4 mm (0.25 inch) port dia. 2F3280X0022

9.5 mm (0.375 inch) port dia. 2N7389X0022

12.7 mm (0.5 inch) port dia. 2N7338X0022

19.1 mm (0.75 inch) port dia. 2N7393X0022

004* Equal percentage valve plug/stem assembly

S31600 (316 SST) w/S20910 (22-13-5) & Alloy 6 for

NACE MR0175-2002

(1)

NPS 1 valve, 9.5 mm (3/8 in.)stem

6.4 mm (0.25 inch) port dia. 2F1388X0042

9.5 mm (0.375 inch) port dia. 2F1389X0032

12.7 mm (0.5 inch) port dia. 2F1390X0032

19.1 mm (0.75 inch) port dia. 2F1391X0032

NPS 2 valve, 12.7 mm (1/2 in.)stem

6.4 mm (0.25 inch) port dia. 2F1427X0022

9.5 mm (0.375 inch) port dia. 2F1428X0022

12.7 mm (0.5 inch) port dia. 2F1429X0022

19.1 mm (0.75 inch) port dia. 2F1430X0022

25.4 mm (1-inch) port dia. 2F1431X0022

31.8 mm (1.25 inch) port dia. 2L5331X0032

S31600 (316 SST) w/tungstencarbide tip for NACE

MR0175-2002

(1)

NPS 1 valve, 9.5 mm (3/8 in.)stem

6.4 mm (0.25 inch) port dia. 2J6894X0022

9.5 mm (0.375 inch) port dia. 2J6895X0022

12.7 mm (0.5 inch) port dia. 2J6896X0022

19.1 mm (0.75 inch) port dia. 2J6897X0022

NPS 2 valve, 12.7 mm (1/2 in.)stem

6.4 mm (0.25 inch) port dia. 2J8189X0022

9.5 mm (0.375 inch) port dia. 2J8191X0022

12.7 mm (0.5 inch) port dia. 2J8193X0022

19.1 mm (0.75 inch) port dia. 2J8195X0022

25.4 mm (1-inch) port dia. 2J8197X0052

31.8 mm (1.25 inch) port dia. 2V2234X0022

Ceramic

NPS 1 valve, 9.5 mm (3/8 in)stem

6.4 mm (0.25 inch) port dia. 22B8956X012

9.5 mm (0.375 inch) port dia. 22B8957X012

12.7 mm (0.5 inch) port dia. 22B8958X012

19.1 mm (0.75 inch) port dia. 22B8959X012

NPS 1 valve, 12.7 mm (1/2 inch) stem

6.4 mm (0.25 inch) port dia. 22B8960X012

9.5 mm (0.375 inch) port dia. 22B8961X012

12.7 mm (0.5 inch) port dia. 22B8962X012

19.1 mm (0.75 inch) port dia. 22B8963X012

NPS 1 valve, 19.1 mm (3/4 in)stem

6.4 mm (0.25 inch) port dia. 22B8964X012

9.5 mm (0.375 inch) port dia. 22B8965X012

Key Description Part Number

12.7 mm (0.5 inch) port dia. 22B8966X012

19.1 mm (0.75 inch) port dia. 22B8967X012

NPS 2 valve, 12.7 mm (1/2 in) stem

6.4 mm (0.25 inch) port dia. 22B8968X012

9.5 mm (0.375 inch) port dia. 22B8969X012

12.7 mm (0.5 inch) port dia. 22B8970X012

19.1 mm (0.75 inch) port dia. 22B8971X012

25.4 mm (1-inch) port dia. 22B8972X012

31.8 mm (1.25 inch) port dia. 22B8973X012

NPS 2 valve, 19.1 mm (3/4 inch) stem

6.4 mm (0.25 inch) port dia. 22B8974X012

9.5 mm (0.375 inch) port dia. 22B8975X012

12.7 mm (0.5 inch) port dia. 22B8976X012

19.1 mm (0.75 inch) port dia. 22B8977X012

25.4 mm (1-inch) port dia. 22B8978X012

31.8 mm (1.25 inch) port dia. 22B8979X012

005 Bonnet/Bushing Assy

If you need a bonnet as a replacement part, order by valve size

and stem diameter, serial number, and desired material.

007* Gasket

S31600 (316 SST)

For NPS 1 valves and NACE MR0175-2002

For NPS 2 valves and NACE MR0175-2002

(1)

(1)

1B198236042

1B198436042

008* Packing Ring

Double PTFE/Composition packing

9.5 mm (3/8 in.) stem (7 req'd) 1F3370X0012

12.7 mm (1/2 in.) stem (10 req'd) 1E319001042

19.1 mm (3/4 in.) stem (8 req'd) 1E319101042

Double PTFE V-Ring

9.5 mm (3/8 in.) stem (6 req'd) 1C752601012

12.7 mm (1/2 in.) stem (6 req'd) 1C752701012

19.1 mm (3/4 in.) stem (6 req'd) 1C752801012

010 Packing Follower

011* Packing Adaptor, male

Double PTFE V-Ring packing

9.5 mm (3/8 in.) stem (2 req'd) 1F124801012

12.7 mm (1/2 in.) stem (2 req'd) 1F124701012

19.1 mm (3/4 in.) stem (2 req'd) 1F124601012

012 Packing Flange

013 Packing Box Stud

014 Yoke Locknut, steel

015 Hex Nut

016 Pipe Plug

016 Stem Lubricator/Isolating Valve

016 Pipe Nipple, for lubricator/isolating valve

016 Stem Lubricator

018* Packing Adaptor, female

Double PTFE V-Ring

9.5 mm (3/8 in.) stem (2 req'd) 1F124401012

12.7 mm (1/2 in.) stem (2 req'd) 1F124301022

19.1 mm (3/4 in.) stem (2 req'd) 1F124201012

019 Lantern Ring

021* Upper Wiper,felt

9.5 mm (3/8 in.) stem 1J872606332

12.7 mm (1/2 in.) stem 1J872706332

19.1 mm (3/4 in.) stem 1J872806332

025 Seal & Wire (not shown), lead

Required only if actuator is not furnished

--- Tag,warning(notshown)

*Recommended spare parts

1. These materials are listed in NACE standardMR0175-2002 as being acceptable for

direct exposure to sour environmentwhen used under conditions stated in that

standard.

11

Page 12

DandDAValves

June 2014

Instruction Manual

D100386X012

Figure 4. Fisher D Globe-Style Valve

Figure 5. Fisher DA Angle-Style Valve

NOTE:

PIPE PLUG (KEY 16) INCLUDED

NOTE:

PIPE PLUG (KEY 16) INCLUDED ONLY IF BONNET IS DRILLED AND TAPPED

FOR PACKING LUBRICATORAND LUBRICATOR IS NOT INSTALLED.

BF2007-F

A5862-1

ONLY IF BONNET IS DRILLED AND

TAPPED FOR PACKING LUBRICA

TOR AND LUBRICATORIS NOT

INSTALLED.

BF2035-D

A5861-1

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remainssolely with the purchaser and end user.

Fisher is a mark owned by one of the companies in theEmerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our t erms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

E 1991, 2014 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...