Page 1

DandDAValves

D100039X012

Fisherr D and DA Control Valves

Fisher D and DA single-port, high-pressure valves are

widely used in oil and gas production industries. These

valves are especially useful for either throttling or

on/off control of liquids or gases which are gritty,

sticky, or which have a tendency to build up on internal

valve parts. The DA valve is also useful in angle piping

or other applications where a self-draining valve is

desired.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

Features

Heavy-Duty Construction–Massive guiding (figure

1) positively aligns the valve plug in the seat ring for

high pressure drop applications. The screwed-in

seat ring completely encloses the seat ring gasket.

Product Bulletin

51.2:D

March 2014

Easy Maintenance–Screwed bonnet/body joint

allows repair or maintenance with a minimum of

tools.

Severe Service Capability–Valve is available with

VTC (ceramic) trim for service in very erosive

applications. The valve plug is also available with a

tungsten carbide tip and the seat ring can be fitted

with a full-bore tungsten carbide insert for erosive

service.

Meets Variety of Specifications–Valve body and end

connection constructions are available for API as

well as ASME standards.

W7859-1

Fisher D Valve with 657 Actuator

NACE Trim Standard–NACE trim and bolting

materials are standard for all applications. These

materials comply with the requirements of NACE

MR0175-2002.

www.Fisher.com

Page 2

Product Bulletin

51.2:D

March 2014

Specifications

DandDAValves

D100039X012

Available Configurations

D: Globe valve with screwed-on bonnet, unbalanced

post-guided valve plug, screwed-in seat ring, metal

seat construction, and push-down-to-close valve plug

action

DA: Same as D valve except in angle configuration

(figure 1)

Valve Sizes and End Connections

(1)

See table 1

Maximum Inlet Pressures and Temperatures

(1)(2)

See table 2

Maximum Allowable Pressure Drops

(2)

Flow up: Capable of full rated pressure drops

Flow down: See table 3 for pressure drop limits for

ceramic trim

Shutoff Classification per ANSI/FCI 70-2

and IEC 60534-4

Standard: Class IV leakage

Optional: Class V

Flow Characteristic

Equal percentage

Flow Direction (see figure 1)

D: Flow up (through seat ring and past valve plug)

DA:

J Flow up (through seat ring and past valve plug)

or

J flow down (past valve plug and through seat

ring)

Flow Coefficients and Noise Level Prediction

See table 5 or Fisher Catalog 12

Port, Yoke Boss, Stem Diameters, and Rated Travels

See table 6

Approximate Weights

Material Temperature Capabilities

-46 to 232_C(-50to450_F)

NPS 1: 34 kg (75 pounds)

NPS 2: 45 kg (100 pounds)

Construction Materials

Body, Bonnet, and Trim: See table 4

Options

Packing:

Standard:

for pressure service

Optional: Double PTFE/Composition

Standard Gaskets: S31600 (316 SST)

1. EN (or other) ratings and end connections can usually besupplied; consult your Emerson Process Management sales office.

2. The pressure/temperaturelimits in this bulletin and in any applicable standard limitations shouldnot be exceeded.

J Single or J double PTFE V-ring packing

J Lubricator/isolating valve J VTC (ceramic) Trim

with equal percentage characteristic (not available

with Micro-Flute trim)

available with Micro-Flute trim)

Contents

Features 1.....................................

Specifications 2................................

Tables

Valve Sizes, Port Diameters, and End Connections 3.

Rated Inlet Pressures and Temperatures 3.........

Flow Down Pressure Drop Limits-

Ceramic Trim Only 3........................

Materials for Standard Trim Constructions 3.......

Flow Coefficient

(C

at Maximum Valve Plug Travel) 4...........

v

Port, Yoke Boss, Stem Diameters,

and Rated Travel Specifications 4..............

Installation 5..................................

Ordering Information 5..........................

Dimensions 6..................................

J Tungsten Carbide trim (not

2

Page 3

DandDAValves

D100039X012

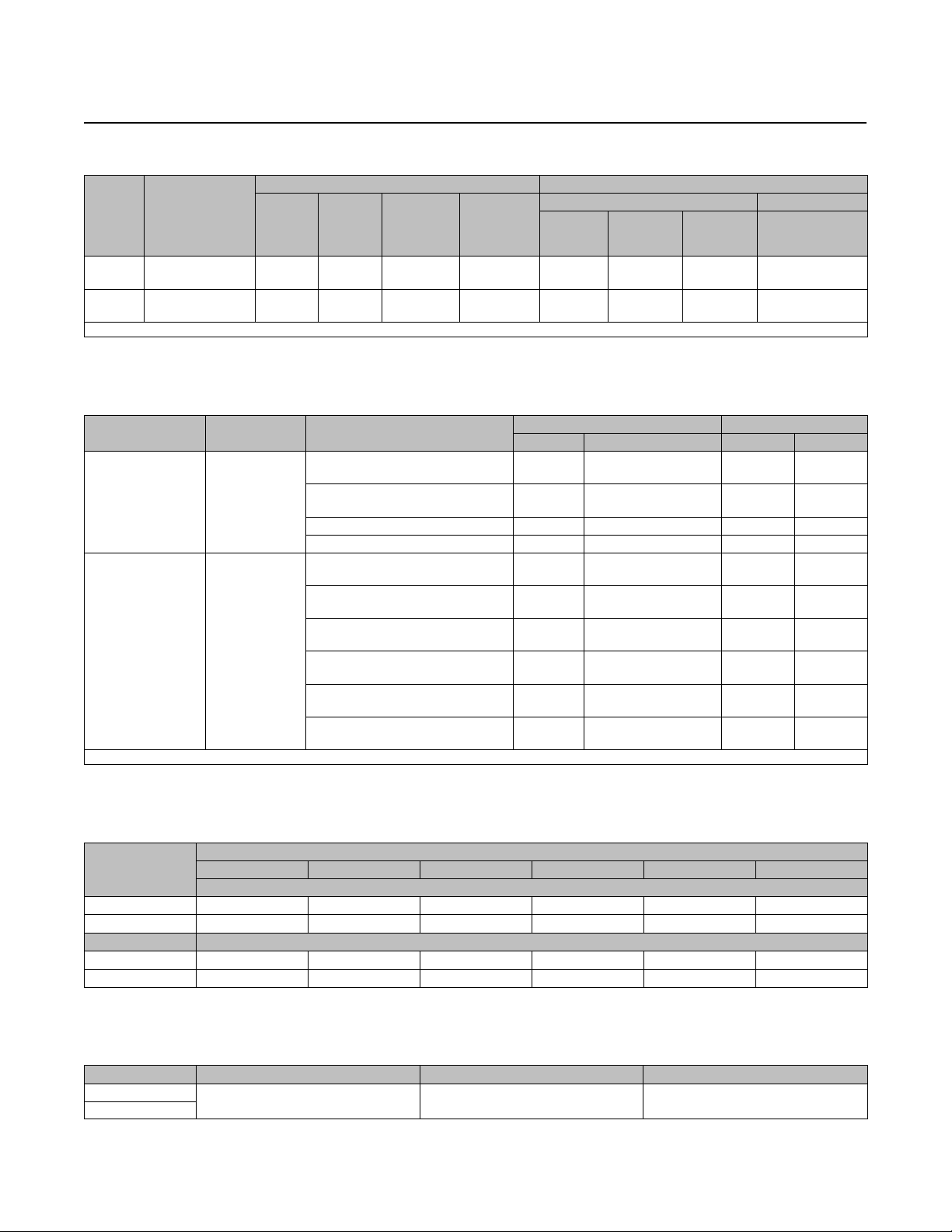

Table 1. Valve Sizes, Port Diameters, and End Connections

SCREWED VALVE BODIES FLANGED VALVE BODIES

VALVE

SIZE,

NPS

1. `X' indicatesavailable construction.

PORT DIA METER

(INCHES)

0.25, 0.375,0.5,

1

2

0.75

0.25, 0.375,0.5,

0.75, 1, 1.25

3600 psi 6000 psi

(1)

X

X X X X X X X X

X --- --- X X X ---

9000 psi

(WCC Steel

DA Only)

10,000 psi

(Except WCC

Steel DA)

CL150

through

CL600

Product Bulletin

ASME API

CL900 and

CL1500

CL2500

51.2:D

March 2014

10,000 lb.

Spec A and C

Table 2. Rated Inlet Pressures and Temperatures

VALVE SIZE,

NPS

1or2 Screwed

1or2 Flanged

1. LCC steel body per ASME B16.34 exceptC5 steel for all API bodies.

TYPE

PRESSURE RATING OR COLD

WORKING PRESSURE LIMIT

CL900 and 1500

CL2500

9000 621 9000 38 100

10,000 689 10,000 38 100

CL150

CL300

CL600

CL900 and 1500

CL2500

API 10,000

Table 3. Flow Down Pressure Drop Limits - Ceramic Trim Only

VALVE SIZE,

NPS

1 414 414 414 193 --- ---

2 689 689 689 462 262 165

1 6000 6000 6000 2800 --- ---

2 10,000 10,000 10,000 6700 3800 2400

6.4 (0.25) 9.5 (0.375) 12.7 (0.5) 19.1 (0.75) 25.4 (1) 31.8 (1.25)

SEAT RINGDIAMETER, mm (INCHES)

bar psi _C _F

259

236

431

394

20.0

12.8

51.7

47.2

103.4

94.5

259

236

431

394

689

689

Pressure Drop, bar

Pressure Drop, psi

PRESSURE

Spec A 10,000

Spec C 10,000

(1)

3750

3425

6250

5710

290

185

750

685

1500

1370

3750

3425

6250

5710

TEMPERATURE

38

232

38

232

38

232

38

232

38

232

38

232

38

232

121

121

100

450

100

450

100

450

100

450

100

450

100

450

100

450

250

250

Table 4. Materials for Standard Trim Constructions

VALVE MATERIAL BONNETMATERIAL PLUG AND SEAT RING VALVE STEM

LCC

WCC

LF2

S31600 (316stainless steel)

hard faced with CoCr-A (Alloy 6)

S20910

3

Page 4

Product Bulletin

51.2:D

March 2014

Table 5. Flow Coefficient (Cvat Maximum Valve Plug Travel)

VALVE SIZE,

NPS

1

2

PORT DIAMETER,

mm (INCHES)

6.4 (0.25)

9.5 (0.375)

12.7 (0.5)

19.1 (0.75)

6.4 (0.25)

9.5 (0.375)

12.7 (0.5)

19.1 (0.75)

25.4 (1)

31.8 (1.25)

Table 6. Port, Yoke Boss, Stem Diameters, and Rated Travel Specifications in mm (Inches)

VALVE

SIZE,

NPS

1

2

PORT

DIAMETER

6.4 (0.25)

9.5 (0.375)

12.7 (0.5)

19.1 (0.75)

6.4 (0.25)

9.5 (0.375)

12.7 (0.5)

19.1 (0.75)

25.4 (1)

31.8 (1.25)

Yoke Boss

Diameter

54 (2-1/8) 9.5 (3/8) 19.1 (0.75)

71 (2-13/16) 12.7 (1/2) 19.1 (0.75) 90 (3-9/16) 19.1 (3/4) 19.1 (0.75)

STANDARD OPTIONAL

Diameter

EQUAL PERCENTAGE D EQUAL PERCENTAGE DA

Flow Up Flow Down

1.66

4.03

6.51

12.3

1.66

4.03

6.82

14.1

23.7

34.5

Stem

Rated

Travel

Yoke Boss

Diameter

71 (2-13/16) 12.7 (1/2) 19.1 (0.75)

90 (3-9/16) 19.1 (3/4) 19.1 (0.75)

DandDAValves

D100039X012

3.21

7.06

11.2

16.8

3.21

7.06

12.1

21.2

31.8

44.9

Stem

Diameter

Rated

Travel

Figure 1. Typical Constructions

W0540-2

W0938-2

4

Page 5

DandDAValves

D100039X012

Product Bulletin

51.2:D

March 2014

Installation

Valve orientation of the D and DA does not affect

operation, but to facilitate changing trim parts, the

valvestemshouldbeverticalwiththeactuatorabove

the valve. Proper flow direction is indicated by the

arrow on the valve.

Dimensions are shown in figures 2 and 3.

Ordering Information

When ordering, specify:

Application

1. Type of application

a. Throttling or on-off

b. Reducing or relief

2. Controlled fluid (include chemical analysis of fluid, if

possible)

6. Pressure drops

a. Range of flowing pressure drops

b. Maximum at shutoff

7. Flow rates

a. Minimum controlled flow

b. Normal flow

c. Maximum flow

8. Maximum permissible noise level, if critical

9. Shutoff classification required

10. Linesizeandschedule

Valve

Refer to the specifications. Review the description for

each specification. Indicate the desired choice

whenever there is a selection (

indicate the valve body design being ordered as

identified in the available configuration specification.

J)tobemade.Always

3. Specific gravity of controlled fluid

4. Fluid temperature

5. Range of flowing inlet pressure

Actuator and Accessories

Refer to separate bulletins covering actuators and

accessories for ordering information.

5

Page 6

Product Bulletin

51.2:D

March 2014

Table 7. Fisher D Dimensions

A

Ring-Type

Joint

ASME

A

G

Raised

Face

Ring-Type

Joint

Inches

mm

G

9.5

(3/8)

FLANGED

VALVE

SIZE,

NPS

1 206 46 219 232 46 232 232 46 173 192 179

2 267 70 267 --- 70 286 289 70 --- 217 213

1 8.12 1.81 8.62 9.12 1.81 9.12 9.12 1.81 6.81 7.56 7.06

2 10.50 2.75 10.50 --- 2.75 11.25 11.38 2.75 --- 8.56 8.38

CL150 CL300 CL600

A-Raised

Face

G

Raised

Face

Table 8. Fisher D Dimensions

FLANGED

VALVE

SIZE,

NPS

1 254 254 46 308 308 54 --- --- --- 173 192 179

2 308 311 70 391 394 83 364 360 83 --- 217 213

1 10.00 10.00 1.81 12.12 12.12 2.12 --- --- --- 6.81

2 12.12 12.25 2.75 15.38 15.50 3.25 14.34 14.19 3.25 --- 8.56 8.38

1. Not applicablefor 10,000 lb.API.

CL900 and 1500 CL2500 10,000 lb.

A

Raised

Face

Ring-Type

Joint

ASME API

A

G

Raised

Face

Ring-Type

Joint

G

mm

Inches

A

Spec A Spec C

G

DandDAValves

D100039X012

D--All Ratings

Stem Size

12.7

(1/2)

D--All Ratings

Stem Size

9.5

(3/8)

(1)

12.7

(1/2)

7.56

(1)

19.1

(3/4)

19.1

(3/4)

7.06

(1)

Table 9. Fisher D Dimensions

SCREWED

VALVE SIZE,

NPS

(1)

1

2 229 70 267 83 --- 216 211

(1)

1

2 9.00 2.75 10.50 3.25 --- 8.50 8.31

1. For 3600 psi and 6000 psi only.

3600 psi

A G A G 9.5 (3/8) 12.7 (1/2) 19.1 (3/4)

168 46 197 54 172 192 178

6.62 1.81 7.75 2.12 6.75 7.50 7.00

6000 psi and

9000 psi

Figure 2. Fisher D Dimensions (also see tables 7, 8, and 9)

MATCH LINE

FOR ACTUATOR

D

G

A

AJ1318-E

A1888-1

2

A

D--All Ratings

Stem Size

mm

Inches

6

Page 7

Product Bulletin

DandDAValves

D100039X012

Table 10. Fisher DA Dimensions

AandG

Joint

ASME

Raised

Face

Ring-Type

Joint

9.5

(3/8)

mm

Inches

FLANGED

VALVE

SIZE,

NPS

1 109 116 116 116 135 154 141

2 155 164 165 167 --- 164 159

1 4.31 4.56 4.56 4.56 5.31 6.06 5.56

2 6.12 6.44 6.50 6.56 -- - 6.44 6.25

CL300 CL600 Stem Size

Raised

Face

Ring-Type

Table 11. Fisher DA Dimensions

Raised

Face

AandG

Ring-Type

Joint

Spec A Spec C

mm

Inches

FLANGED

VALVE

SIZE,

NPS

1 127 127 154 154 --- --- 135 154 141

2 178 179 195 197 182 180 --- 164 159

1 5.00 5.00 6.06 6.06 --- --- 5.31 6.06 5.56

2 7.00 7.06 7.69 7.75 7.1 7 7.09 --- 6.44 6.25

CL900 and 1500 CL2500 10,000 lb. Stem Size

Raised

Face

Ring-Type

ASME API

Joint

D--All Ratings

12.7

(1/2)

9.5

(3/8)

D--All Ratings

12.7

(1/2)

51.2:D

March 2014

19.1

(3/4)

19.1

(3/4)

Table 12. Fisher DA Dimensions

SCREWED

VALVE

SIZE,

NPS

(1)

1

2 102 124 114 130 --- 162 157

(1)

1

2 4.00 4.88 4.50 5.12 --- 6.38 6.19

1. For 3600 psi and 6000 psi only.

3600 psi

A G A G 9.5 (3/8) 12.7 (1/2) 19.1 (3/4)

76 89 89 102 133 152 140

3.00 3.50 3.50 4.00 5.25 6.00 5.50

6000 psi and

9000 psi

Figure 3. Fisher DA Dimensions (also see tables 10, 11, and 12)

MATCH LINE

FOR ACTUATOR

D

G

D--All Ratings

Stem Size

mm

Inches

AJ1318-E

A1887-1

A

7

Page 8

Product Bulletin

51.2:D

March 2014

DandDAValves

D100039X012

Neither Emerson, Emerson Process Management,nor any of their affiliated entitiesassumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any productremains solelywith the purchaser and end user.

Fisher is a mark owned by one of thecompanies inthe Emerson Process Managementbusiness unitof EmersonElectric Co.Emerson ProcessManagement,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request.We reserve the right to modify orimprove thedesigns orspecifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1991, 2014 Fisher ControlsInternational LLC. All rights reserved.

8

Loading...

Loading...