Page 1

Instruction Manual

D104030X012

May 2019

Type CT88 Backpressure Regulator

Table of Contents

Introduction .................................................................. 1

Specifications .............................................................. 2

Principle of Operation .................................................. 2

Installation ................................................................... 3

Overpressure Protection.............................................. 4

Startup ......................................................................... 4

Adjustment...................................................................5

Shutdown.....................................................................5

Maintenance ................................................................ 5

Parts Ordering ............................................................. 8

Parts List......................................................................9

Type CT88

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher™ backpressure regulators must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations

and Emerson Process Management

Regulator Technologies, Inc.

(Emerson) instructions.

If a leak develops or if the outlet

continually vents liquid, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition. Only a qualied

person must install or service the unit.

Installation, operation and maintenance

procedures performed by unqualied

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personal injury.

Figure 1. Type CT88

Use qualied personnel when installing,

operating and maintaining the Type CT88

backpressure regulator.

Introduction

Scope of the Manual

This Instruction Manual provides instructions

for the installation, adjustment, maintenance

and parts ordering information of Type CT88

backpressure regulator.

Product Description

The Type CT88 backpressure regulator (Figure 1) is

used to maintain backpressure on Lease Automatic

Custody Transfer (LACT) skids. It is designed to allow

accurate measurement by the positive displacement

pump or coriolis meter and protect other upstream

LACT skid equipment. The high ow capability,

as compared with other backpressure regulators,

maximizes transfer efciency.

Page 2

Type CT88

Specications

The Specications section lists the specications for the Type CT88 backpressure regulators. Factory specication is

stamped on the nameplate fastened on the backpressure regulator at the factory.

Body Sizes

NPS 2, 3 and 4 / DN 50, 80 and 100

End Connection

CL150 RF

Maximum Working Pressure

(1)(4)

Based on CL150 RF Flange Pressure Rating,

See Table 1

Backpressure Control Ranges

(1)(2)

NPS 2 / DN 50: 10 to 145 psi / 0.7 to 10 bar

NPS 3 and 4 / DN 80 and 100: 15 to 145 psi /

1.0 to 10 bar

Wide-Open Flow Coefcients C

v

NPS 2 / DN 50–Cv: 59

NPS 3 / DN 80–Cv: 148

Shutoff Classication

ANSI Class VI

Temperature Capabilities

Fluorocarbon (FKM)

Construction Materials

Body: Carbon steel (WCB)

Diaphragm and Seals: Fluorocarbon (FKM)

Trim Parts: 316 Stainless steel

Control Line Connection Size

1/4 NPT

Approximate Weights

NPS 2 / DN 50: 89 lbs / 40 kg

NPS 3 / DN 80: 131 lbs / 60 kg

NPS 4 / DN 100: 184 lbs / 84 kg

NPS 4 / DN 100–Cv: 240

Flow Characteristic

Quick Open

1. The pressure/temperature limits in this Instruction Manual and any applicable standard limitation should not be exceeded.

2. For lower set pressures, contact the factory.

3. It may be assumed that the material temperature is the same as the working uid temperature.

4. Maximum inlet pressure depends on working temperature (Refer to ASME B16.42 or Table 1).

5. Fluorocarbon (FKM) is limited to 200°F / 93°C for hot water.

6. Increased working temperature may reduce the maximum inlet pressure range (Refer to ASME B16.42 or Table 1).

(1)(3)

(5)

: 20 to 248°F / -7 to 120°C

(6)

Table 1. Pressure-Temperature Ratings for CL150 Carbon steel (WCB)

TEMPERATURE

20 to 100 290

-7 to 38

1. For intermediate temperatures, linear interpolation is permitted.

(1)

°F psi

200 260

248 245

°C bar

50

100

120

Principle of Operation

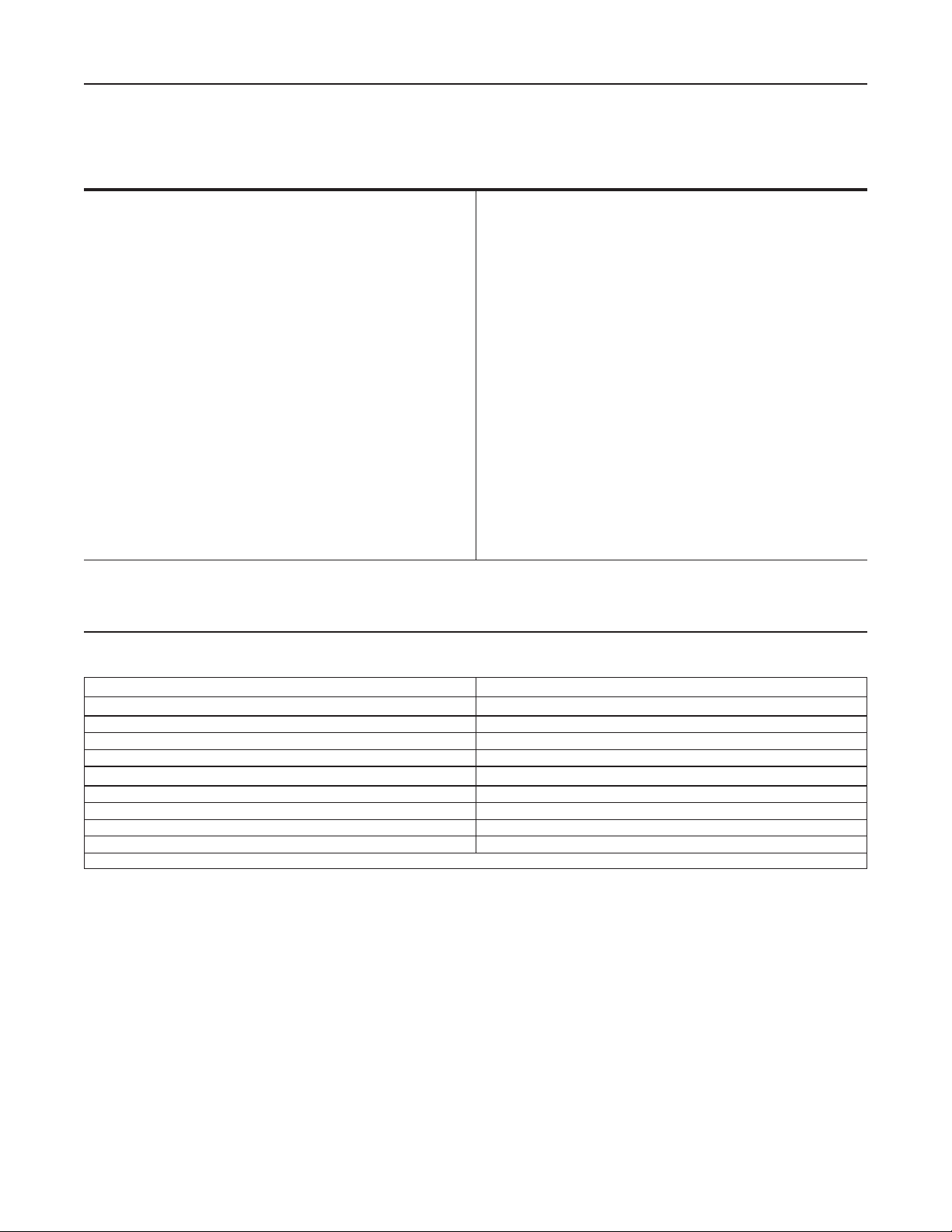

See Figure 2. Type CT88 direct-operated

backpressure regulator responds to changes in inlet

pressure. Inlet pressure is registered on the underside

of the diaphragm through an external sensing line that

is connected to the lower diaphragm casing.

As long as the inlet pressure remains below setpoint,

control spring keeps the disk against the seat ring

providing tight shutoff with no ow through the

backpressure regulator.

MAXIMUM WORKING PRESSURE

20.0

17.0

17.9

16.9

When inlet pressure rises above the set pressure,

pressure on the diaphragm overcomes the control

spring force. This causes the diaphragm to move

upward, lifting valve stem together with the valve plug

away from seat ring. The ow path through the valve

opens and excess pressure is vented. When upstream

pressure drops below setpoint, the valve closes.

2

Page 3

VENT

Type CT88

ADJUSTING SCREW

VENT

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Type CT88 Backpressure Regulator Operational Schematic

Installation

WARNING

!

Personal injury or system damage may

result if this backpressure regulator

is installed, without appropriate

overpressure protection, where service

conditions could exceed the limits given

in the Specications section and/or

backpressure regulator nameplate. Refer

to Overpressure Protection section for

recommendations on how to prevent

service conditions from exceeding

those limits.

Additionally, physical damage to the

backpressure regulator may result in

personal injury or property damage due

to escaping of accumulated uid. To

avoid such injury and damage, install the

backpressure regulator in a safe location.

All vents should be kept open to permit

free ow of gas to the atmosphere.

Protect openings against entrance of

rain, snow, insects or any other foreign

material that may plug the vent.

SPRING CASE

SEAT RING

CONTROL SPRING

DIAPHRAGM

VALVE SPRING

BODY

SENSING LINE

Do not install the Type CT88

backpressure regulator in hazardous

or ammable service indoors or in

an enclosure where accumulation of

vented uid may occur. In hazardous

or ammable uid applications, vented

uid may accumulate and cause

personal injury, death, or property

damage due to re, explosion and/or

chemical contamination.

Note

To avoid premature wear of internal

parts, it is recommended that the

actuator be oriented vertically as shown

in Figures 1 and 2.

General Installation Instructions

• Vertical installation with the actuator installed

directly above the main valve is recommended for

optimal performance, as shown in Figures 1 and 2.

• The use of the bleed plug is recommended for

installations of the actuator mounted above the

main valve.

3

Page 4

Type CT88

• The unit will operate in horizontal installations with

the actuator on the side, however, this could result

in premature wear of the parts.

• Make sure that ow will be in the same direction as

indicated by the ow arrow on the body.

Note

For proper backpressure regulator

control and operation, make sure that the

ow arrow matches the ow direction.

CAUTION

To protect against precipitation,

make sure that the actuator is

oriented upward.

Some installations, such as areas with heavy

snowfall, may require a hood or enclosure to protect

the backpressure regulator from snow load and vent

freeze over.

1. Before installing the backpressure regulator:

• Check for damage which might have occurred

during shipment.

• Check and remove any dirt or foreign

material which may have accumulated in the

backpressure regulator body.

• Blow out any debris, dirt or copper sulfate in the

tubing and pipeline.

2. Body installed horizontally with the actuator spring

case pointing upward is recommended.

3. Use gaskets between pipeline and regulator

anges when installing a regulator with anged

end connections. Use approved piping procedures

when installing the regulator.

Overpressure Protection

WARNING

!

Personal injury, equipment damage or

leakage due to escaping accumulated

liquid or bursting of pressure-containing

parts may result if this backpressure

regulator is:

- Overpressurized;

- Used with incompatible process uid;

- Installed where service conditions

could exceed the limits given in the

Specications section and on the

appropriate nameplate; or

- Where conditions exceed any

ratings of adjacent piping or

piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions

from exceeding those limits.

Overpressuring any portion of this equipment may

result in equipment damage, leaks in the backpressure

regulator or personal injury due to bursting of

pressure-containing parts. The system should be

inspected after any overpressure condition.

The backpressure control range and maximum inlet

pressure can be found in the Specications section.

Startup

WARNING

!

To avoid possible personal injury,

equipment damage or leakage due

to escaping uid, make certain the

backpressure regulator is installed as

instructed in the Installation section.

Escaping process uid from an open

bleed plug may result in backpressure

regulator damage, personal injury and

property damage. To avoid such injury

and damage, make certain the bleed

plug is properly closed after venting air.

Always open bleed plugs slowly. These

plugs contain no packing, so some uid

weepage will occur when the plugs

are opened. Operating personnel must

protect themselves from exposure to

system uids.

CAUTION

Pressure gauges must always be

used to monitor upstream pressure

during startup.

4

Page 5

1. Open the system shutoff valve.

2. Slowly open the outlet block valve.

3. Open the inlet block valve slightly and keep in this

position until pressure is maintained at the desired

setpoint and stabilized.

4. Slowly unscrew the bleed plug to exhaust air that

might have been trapped in the actuator. Screw

and tighten the plug. Exercise caution at all times.

5. If resetting setpoint, then set the regulator

to the desired set pressure according to the

Adjustment procedure.

Adjustment

WARNING

!

Personal injury, equipment damage or

leakage due to escaping uid may result

if adjusting screw and jam nut are not

installed properly.

Always use a pressure gauge to monitor pressure

when making adjustments.

The backpressure regulator spring can be backed

off to 0 psig / 0 bar. Recommended maximum inlet

pressures and temperatures are shown in Table 1.

1. Loosen the jam nut.

2. To increase the setting, turn the adjusting

screw clockwise. Turn the adjusting screw

counterclockwise to decrease the setting.

3. Tighten the jam nut to maintain the desired setting.

Shutdown

WARNING

!

Escaping process uid from an open

bleed plug may result in backpressure

regulator damage, personal injury and

property damage. To avoid such injury

and property damage, make certain

the bleed plug is properly closed after

bleeding process uid.

Type CT88

BLEED PLUG

Figure 3. Diaphragm Case

1. Close the inlet block valve (see Figure 2).

2. Close the outlet block valve.

3. Turn the adjusting screw counterclockwise until all

spring force from the backpressure regulator has

been removed.

4. Slowly open the outlet block valve to release

upstream pressure.

5. Slowly open bleed plug and make sure all pressure

has been relieved from the control line.

Maintenance

WARNING

!

Personal injury, equipment damage

or leakage due to escaping uid may

result if seals are not properly lubricated

or maintained. Due to normal part

wear or damage that may occur from

external sources, this backpressure

regulator should be inspected and

maintained periodically. The frequency

of inspection, maintenance and

replacement of parts depends upon

the severity of service conditions or

the requirements of local, state and

federal regulations.

Backpressure regulators that have been

disassembled for repair must be tested

for proper operation before being returned

to service. Only parts manufactured by

Emerson should be used for repairing

Fisher™ backpressure regulators. Restart

liquid utilization equipment according to

normal startup procedures.

5

Page 6

Type CT88

Note

To protect against reduced performance,

ensure vents are not plugged when

conducting routine maintenance.

• Before maintenance, close the inlet and outlet block

valves and exhaust the pressure in the valve body

and piping as described in the Shutdown section.

• When removing or replacing parts such as the

orice or diaphragm, be careful not to damage it.

• Ensure movable parts can move freely

after reassembly.

• Recommission according to the Installation and

Startup procedures.

• Ensure all connections are tight and check for leaks.

Regular Maintenance

1. Make sure that there is no leakage on the

backpressure regulator and tubing connections.

2. Observe the gauges to make sure that the

pressure being controlled is stable and at the

correct set point.

3. Ensure the pipeline system is clean and free of

foreign materials.

Periodic Maintenance

1. Check Type CT88 backpressure regulator reseat

pressure. Slowly increase the inlet pressure until

the outlet pressure starts to rise, then slowly

decrease the inlet pressure until the outlet

pressure stabilizes. Ensure that the downstream

pressure does not increase.

2. Clean wear parts like the Disk, Diaphragm and

Seat Ring. Make sure to check and replace

deformed and worn out seals when necessary.

3. Check wear parts for damage and replace when

necessary, replace O-rings after disassembly.

Maintenance Instructions for Actuator

Replacement Parts (keys 15, 21, 22, 23,

56 and 68)

Refer to Figure 4 for the Type CT88 Actuator

Assembly, Figure 5 for the NPS 2 / DN 50 body

assembly drawing and Figure 6 for the NPS 3 and 4 /

DN 80 and 100 body assembly drawing.

Actuator Disassembly

1. Isolate the Backpressure Regulator, relieve all

pressure in body and actuator and relieve spring

force by following the procedure described in the

Shutdown section.

2. Loosen and remove sense line from diaphragm

lower casing (key 54).

3. Loosen and remove 8 bolts (key 58), 8 nuts

(key 57) and 8 washers (key 8) around the

actuator ange.

4. Lift the upper casing (key 59) directly upward over

the main spring (key 48). Set aside spring and

upper spring seat (key 50).

5. Loosen and remove 2 hex nuts (keys 60 and 34)

from stem (key 14)

6. Remove lower spring seat (key 37), diaphragm

plate (key 55) diaphragm (key 56), diaphragm

head (key 36) and O-ring (key 68) upward and

over stem (key 14)

pin (key 66) from diaphragm head (key 36).

7. Loosen and remove 4 screws (key 16) and

4 spring washers (key 17).

8. Carefully remove diaphragm lower casing (key 54)

upward and over stem (key 14).

9. Remove bushing (key 20), 2 stem guides (key 21),

O-rings (keys 22 and 23) upward over the stem

(key 14).

10. Remove O-ring (key 15).

(1)

.

(1)

. Do not damage or remove

Actuator Assembly

1. Lightly lubricate O-ring (key 15) and place it into

the body.

2. Carefully place the diaphragm lower casing on

the body, make sure the thread holes on both

of casing and body are aligned. The position of

sense line pipe hole should be aligned with the

sense line pipe hole of the body.

3. Place spring washers (key 17) on screw (key 16),

apply lubricant to the thread of bolts.

4. Bolt body and casing together and tighten screws

(key 16) securely using a multi-pass, criss-cross

pattern. Torque values listed in Table 4.

5. Lightly lubricate O-ring (key 68) and mount it into

the groove of diaphragm head (key 36); Insert the

stem (key 14) through center of the diaphragm

head, and press until it makes contact with

1. Refer to Figures 5 and 6.

6

Page 7

Type CT88

diaphragm lower casing (key 54), make sure the

ribs of the diaphragm head are aligned in between

the screws (key 16) and washers (key 17).

6. Lay the diaphragm (key 56) on the surface

of diaphragm head (key 36); make sure all

diaphragm holes are aligned with the pin (key 66)

and the bolt holes of diaphragm lower casing

(key 54) for the remainder of the assembly steps.

Note

Exercise care to ensure that the

diaphragm (key 56) is not pinched, twisted

or wrinkled while compressing between

the upper and lower diaphragm casings

(keys 59 and 54), diaphragm head and

diaphragm plate (keys 5 and 36).

7. Place the diaphragm plate (key 55) and lower

spring seat (key 37) on the diaphragm in turn and

tighten using two nuts (keys 34 and 60). Thin nut

(key 34) is below the nut (key 60). Make sure the

pin (key 66) is inserted into the hole of diaphragm

plate (key 55). Tighten securely, torque values

listed in Table 4.

Note

Hold the wrench at on top of stem

(key 14) while tightening the nuts

(keys 34 and 60). Make sure the

diaphragm does not move or become

pinched, twisted or wrinkled.

8. Insert upper spring seat (key 50) into the spring

(key 48) and apply lubricant into the hole of the

spring seat that contacts the adjusting screw

(key 53) and to both ends of the spring.

9. Place the spring (key 48) and upper spring seat

(key 50) onto the lower spring seat (key 37).

Note

Make sure the position of stem and

lower spring seat are at the center of

the spring.

10. Place the upper diaphragm casing (key 59) (along

with other attached components) over the spring

(key 48) and upper spring seat (key 50). Align

the bolt holes of the upper diaphragm casing and

lower diaphragm casing.

11. Apply lubricant to the thread of 8 bolts (key 58)

and insert the bolts down through the upper

diaphragm casing (key 59) then through the lower

diaphragm casing (key 54).

12. Place 8 washers (key 8) and 8 nuts (key 57)

onto the 8 bolts (key 58) from below the lower

diaphragm casing (key 54). Tighten the nuts

and bolts using a multi-pass, criss-cross pattern.

Torque values listed in Table 4.

Maintenance Instructions for Body

Replacement Parts (keys 2, 3, 7, 9, 10

and 11)

Refer to Figure 5 for maintenance instructions

for NPS 2 / DN 50 body. Refer to Figure 6 for

maintenance instructions for a NPS 3 and 4 / DN 80

and 100 body.

Body Disassembly

1. Isolate the Backpressure Regulator, relieve all

pressure in body and actuator and relieve spring

force by following the procedure described in the

Shutdown section.

2. Loosen and remove 8 bolts (key 13) and 8

washers (key 8 for NPS 2 / DN 50 and key 26 for

the NPS 3 and 4 / DN 80 and 100 body).

3. Carefully, remove the bonnet (key 12) (along with

all other attached components) upward and out of

the body (key 1).

Note

Some components may stick together

and seem to be connected. Be careful

not to allow these components to drop

or separate unexpectedly e.g. sleeve

(key 6), O-rings (keys 7, 10 and 11) and

sliding ring (key 9).

4. Slide apart sliding ring (key 6) from piston (key 4)

to access 2 sliding rings (key 9) and O-rings

(keys 7 and 10).

5. Remove cage (key 18), seat ring (key 3) and

O-ring (key 2).

6. Replace worn or damaged parts during assembly

by following the procedure described in the Body

Assembly section.

Body Assembly

1. Clean the surface and interior of the body (key 1)

by using penetrating oil, water removal spray,

and/or air gun. Lightly lubricate O-ring (key 2)

and place it on the corner of body/seat ring

(key 3) intersection.

7

Page 8

Type CT88

Table 2. Troubleshooting

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

Backpressure regulator is undersized or oversized Review sizing

Backpressure regulator is not working

Application flow rate exceeds product's advertised capacity Review sizing

Backpressure regulator inlet pressure increases

Debris caught in between disk and seat ring Remove debris

Damaged, deformed or worn out diaphragm Replace diaphragm

Backpressure regulator lock-up

pressure decreases

Debris caught in between disk and seat ring Clean or replace disk

Backpressure regulator inlet pressure fluctuates Actual flow rate much lower than normal

Damaged diaphragm Replace diaphragm

Restrictor or control line is blocked Check restrictor and control line, clean debris

O-ring in disk assembly damaged Replace O-ring

Deformed or worn out disk or seat ring Replace disk or seat ring

Damaged disk assembly O-ring Replace O-ring

Review sizing or check upstream equipment when

upstream pressure fluctuates

Table 3. Spare Parts Kits

BODY SIZE

NPS DN

2 50 RCT88X00F22

3 80 RCT88X00F32

4 100 RCT88X00F42

1. Includes diaphragm, O-rings, stem guide, ring sliding, seat, etc.

2. Place the seat ring (key 3) onto the step inside the

body carefully, make sure the O-ring (key 2) does

not move.

3. Place the cage (key 18) into the groove of the

seat ring (key 3).

4. Lightly lubricate O-ring (key 7) and 2 sliding rings

(key 9), and install the O-ring and sliding rings into

the grooves of the sleeve (key 6) in turn.

5. Lightly lubricate O-ring (key 10) and place it into

the groove at the top of the sleeve (key 6).

6. Insert the trim assembly (key 4 and other attached

components) through the sleeve/sliding ring/

O-ring assembly (keys 6, 7 and 9) from top of the

sleeve, make sure the O-ring (key 7) is not moved

or damaged.

7. Lightly lubricate O-ring (key 11) and place into

the corner of the body/bonnet interface (keys 1

and 12).

8. Insert trim assembly (key 4 and other attached

components) and sleeve/sliding/O-ring assembly

(keys 6, 7 and 9) into body (key 1), press until

piston (key 4) contacts seat ring (key 3) and

sleeve (key 6) contacts cage (key 18).

(1)

SPARE PART NUMBER

9. Carefully align the bonnet (key 12) on to body

(key 1) into the correct orientation.

Note

The sense line hole in the lower diaphragm

casing (key 54) should align with the sense

line hole in the body (key 1).

10. Press bonnet (key 12) down until it contacts the

body (key 1).

11. Apply the lubricant to thread of bolts (key 13), then

bolt together the bonnet and body using washers

(key 8 for NPS 2 / DN 50 and key 26 for the NPS 3

and 4 / DN 80 and 100 body). Tighten bolts using

a multi-pass, criss-cross pattern by using a torque

wrench. Torque values are listed in Table 4.

Parts Ordering

When corresponding with your local Sales Ofce

about this regulator, include the type number and all

other pertinent information stamped on the nameplate.

Specify the part name when ordering new parts

from the following parts list. Separate repair part kits

containing all recommended elastomer spare parts

are available.

8

Page 9

PART NAME

Screw (key 16), 4 required 18.5 to 22.1 25 to 30

Bolts (key 42); Nuts (key 40) 20.7 to 23.6 28 to 32

NPS 2 / DN 50 44.3 to 55.3 60 to 75

Bolts (key 13), 8 required

Hex Nut (key 34) 11.8 to 14 16 to 19

Hex Nut (key 60) 15.5 to 17.7 21 to 24

Bolts (key 45) 18.5 to 22.1 25 to 30

Bolts (key 58), 8 required; Nuts (key 57) 45 to 54.5 61 to 74

Locknut (key 29) 15.5 to 17.7 21 to 24

NPS 3 / DN 80 39.9 to 54.5 54 to 74

NPS 4 / DN 100 69.4 to 94.4 94 to 128

Parts List

Key Description

Type CT88 Spare Part Kits

(Repair Parts kit includes Diaphragm,

O-rings, Stem Guide, Ring Sliding, Seat, etc.) See Table 3

1 Body, Ductile Iron

2 O-ring, Fluorocarbon (FKM)

3 Seat Ring, Stainless steel/Fluorocarbon (FKM)

4 Piston, Stainless steel

5 Valve Spring, Stainless steel

6 Sleeve, Stainless steel

7 O-ring, Fluorocarbon (FKM)

8 Plate Washer, Steel

NPS 2 / DN 50 (16 required) and NPS 3 and 4 /

DN 80 and 100 (8 required)

9 Ring Sliding, 2 required, PTFE/ Molybdenum disulde

10 O-ring, Fluorocarbon (FKM)

11 O-ring, Fluorocarbon (FKM)

12 Bonnet, Carbon steel

13 Bolt, 8 required, Steel

14 Stem, Stainless steel

15 O-ring, Fluorocarbon (FKM)

16 Screw, 4 required, Stainless steel

17 Spring Washer, 4 required, Stainless steel

18 Cage, Stainless steel

19 Plate, Stainless steel

NPS 3 / DN 80

NPS 4 / DN 100

20 Bushing, Stainless steel

21 Stem Guide, 2 required, PTFE

22 O-ring, Fluorocarbon (FKM)

23 O-ring, Fluorocarbon (FKM)

Type CT88

Table 4. Torque Specications

TORQUE FOR ALL BODY SIZES

Ft-Lb N•m

Key Description

24 Plate Washer, 2 required, Steel

26 Plate Washer, 8 required, Steel

NPS 3 / DN 80

NPS 4 / DN 100

29 Locknut, Stainless steel

30 Nameplate

31 Rivet, 6 required

34 Hex Nut, Steel

36 Diaphragm Head, Stainless steel

37 Lower Spring Seat, Lower, Stainless steel

44 Spring Case, Stainless steel

48 Spring, Yellow, Chromium Silicon, 30 to 145 psi / 2 to 10 bar

50 Upper Spring Seat, Carbon steel

51 Spring Cap, Carbon steel

52 Nut, Steel

53 Screw Adjusting, Steel

54 Lower Diaphragm Casing, Lower, Carbon steel

55 Diaphragm Plate, Stainless steel

56 Diaphragm, Fluorocarbon (FKM)

57 Nut, 8 required, Steel

58 Bolt, 8 required, Steel

59 Upper Diaphragm Casing, WCB or Carbon steel

60 Hex Nut, Steel

61 Flow Arrow

65 Drain Valve Manual, Brass

66 Pin, Steel

68 O-ring, Fluorocarbon (FKM)

69 Connector, Steel

67 Restrictor, Stainless steel

9

Page 10

Type CT88

53

52

51

50

30

66

48

44

60

34

37

58

59

8

57

36

68

56

55

17

16

D

54

DETAIL D

65

BLEED PLUG DETAIL

Figure 4. Type CT88 Actuator Assembly

10

Page 11

DETAIL H

Type CT88

31

30

16

17

15

14

61

24

29

13

8

12

11

10

9

4

7

6

21

23

20

3

H

5

18

K

2

1

22

DETAIL K

Figure 5. Type CT88 Body Assembly for NPS 2 / DN 50

11

Page 12

Type CT88

31

DETAIL E

30

16

24

29

15

14

23

22

20

21

17

13

61

12

C

11

10

E

26

DETAIL C

9

7

18

6

5

4 19 3 2

1

Figure 6. Type CT88 Body Assembly for NPS 3 and 4 / DN 80 and 100

Webadmin.Regulators@emerson.com

Fisher.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D104030X012 © 2014, 2019 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 05/19.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for information purposes

only, and while effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available on request. We reserve the right to modify or improve the

designs or specications of our products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...