Emerson Fisher Control-Disk, Fisher GX, Fisher C1, Fisher 2052, Fisher FIELDVUEDVC6200 Brochure

...Page 1

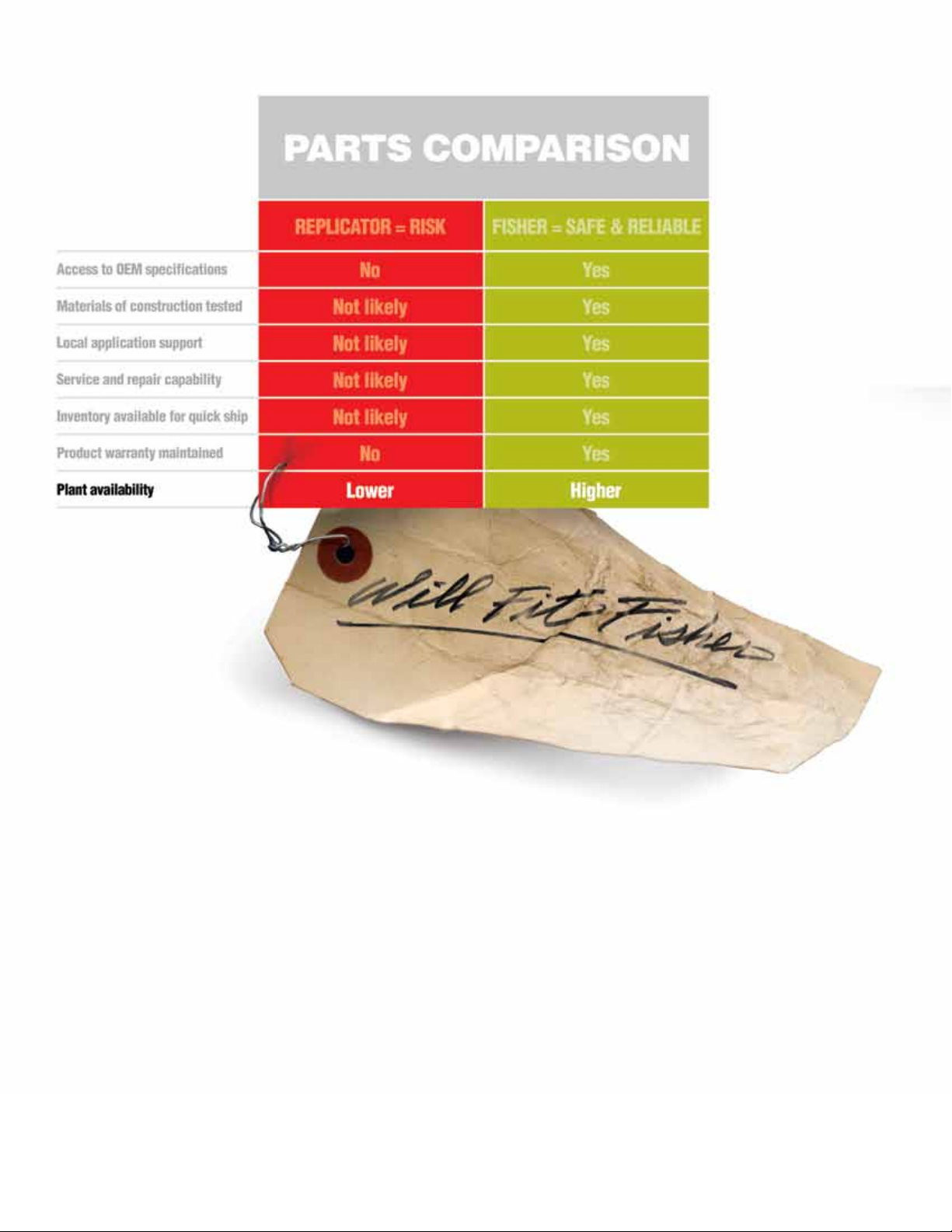

Safe and Reliable or Costly Mistake?

Your plant availability depends on it.

Page 2

Beware of replicator parts.

You can find replicator parts for Fisher® control valves,

actuators, and instruments from a variety of sources. Sure,

some replicator parts look like they can do the job and fit

into Fisher equipment. But if you buy replicator parts, what

are you really getting? Parts that are not ideal for your

Fisher equipment.

Why you should care.

While replicator parts may initially cost less, you will pay

more in the long run.

Replicator parts typically do not last as long as genuine

Fisher parts, so you have to replace them more often. This

results in higher costs for additional parts and may cause

unplanned downtime impacting your profitability.

Sometimes replicator parts are even produced from

wrong or substandard materials. The proper materials of

construction—heat treatments, thermal history, NACE

processing requirements, proprietary coatings, chemical

formulation for non-metallic and composite components—

are critical. Using a replicator part made of wrong materials

for process fluids may threaten worker safety, cause

environmental concerns, damage operating equipment, or

cause a plant shutdown.

Replicator parts are not made to the specifications of

your Fisher equipment, and it is unlikely that the parts are

tested in actual Fisher equipment to verify performance.

Poorly performing replicator parts could lead to process

inefficiencies. Plus the use of unauthorized replacement

parts is not covered by our warranty.

In addition, replicator parts are not made using the

material quality controls, manufacturing techniques,

tooling, or inspection that are used for genuine Fisher parts.

Page 3

Field reports.

Reports from our field offices confirm that using replicator

parts is simply a bad idea.

n A natural gas power plant rebuilt several Fisher valves

using replicator seat rings, plugs, and cages. Within days,

the valves began to fail. Emerson’s Instrument & Valve

Services evaluated the replicator trim and determined that

incorrect materials had been used, heat treating was not

performed, tolerances were not met, and several essential

design features were not incorporated.

n A power utility plant faced problems with valve trim

failure on Fisher valves that had been rebuilt by another

firm. Emerson’s Instrument & Valve Services inspected the

valves in the field and discovered that the pin was 45° out

of alignment. Service vibration caused the groove pin to

work loose allowing the plug to separate from the stem.

n The operators of a co-generation plant replaced trim in

a Fisher valve that had been in service for four years. To

save initial costs they had a local machine shop manufacture

replacement trim. Within two months the replacement

valve trim failed in high pressure service causing expensive

downtime. The machine shop trim did not meet critical

original design specifications.

n A test of genuine Fisher and replicator valve gaskets

revealed that the Fisher gaskets were superior in meeting

compression requirements, thickness, density, and other

critical aspects that affect stack height and ability to seal.

In fact, the replicator spiral wound gasket broke during

testing at 44% of the Fisher compression requirement.

n A nuclear plant experienced leaks at the bonnet-to-body

joint of several Fisher valves. Emerson service technicians

found that original gaskets had been replaced with those

from a local vendor. The problem was resolved when the

valves were rebuilt with genuine Fisher gaskets.

Page 4

Specially formulated Fisher

O-rings for spring-and-diaphragm

and piston actuators have a solid

lubricant dispersed throughout

their cross section. As these

O-rings wear, new lubricant is

exposed, which maintains static

and dynamic friction coefficients

for consistent, smooth operation.

The standard Fisher easy-e

plug, and seat ring are constructed

of hardened stainless steel. Trim

parts are engineered, precision

manufactured, and tested to provide

reliable operation for years to come.

™

cage,

Genuine Fisher parts. No others can match their long-term performance.

Commonly replicated parts.

Commonly replicated soft parts include actuator

diaphragms, O-rings, packing rings, and seals. The plastics

and elastomers in these parts are extremely sensitive to

formulation and molding techniques.

Imagine what could happen if you installed an O-ring in

your valve without the proper chemical formulation.

The O-ring could fracture during flexure at low

temperature. Or it could be incompatible with the flowing

medium, ultimately losing its ability to seal.

For metal parts, precise dimensions and surface finishing

are critical. Vary design tolerances of trim sets, seat rings,

plug tips, shafts, bearings, and discs by the slightest bit,

and performance may suffer significantly.

Long-term advantage.

Genuine Fisher parts comply with international codes,

standards, and approvals including ASME, ANSI, ASTM,

ISA, CSA, FM, CENELEC, ATEX, CE, TÜV, and FCI. Experience

shows their built-in quality results in longer product life

and less downtime. Better control valves mean a better

process yielding better profits. And with greater safety.

The right part - right now.

Genuine Fisher parts are readily available from an Emerson

sales office wherever you are located.

Distribution centers in Asia, Europe, and North America

maintain a significant inventory of genuine Fisher parts.

The FisherFAST™ program uses that inventory to

Page 5

Genuine Fisher packing systems

are engineered and tested to

operate in Fisher control valves at

various pressures and temperatures.

A given packing design has certain

characteristics concerning seal

performance, service life, and

friction. Emerson offers seven

Fisher packing selections to help

you choose the right solution for

your application.

The molded design and formulation

for Fisher actuator diaphragms is

tested to exceed 1,000,000 cycles

in our research and test labs. This

formulation also results in lowtemperature flexibility (-60°F,

-51°C) that may not be matched by

replicator parts.

provide you the best spare and replacement part

deliveries. Options for delivery include same day, next day,

seven day, or emergency service.

Also available are convenient spare parts kits that contain

the parts typically needed for routine maintenance. They

simplify parts inventory management with the use of a

single kit number versus individual part numbers.

Local support.

Emerson parts consultants are ready to assist you

with your spare parts needs. They have access to the

original specification for your control valve, actuator,

or instrument (drawings, material specifications, heat

treatment information, and any non-destructive testing

requirements) even if the device is several decades old.

Call now.

The next time you need parts for your Fisher equipment,

contact the Emerson sales office in your area. Highly skilled

and experienced applications personnel are ready to help

you take advantage of the many benefits of genuine Fisher

parts.

Page 6

Look for this mark

on the packaging of

genuine Fisher parts.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.EmersonProcess.com/Fisher

© 2012 Fisher Controls International LLC. All rights reserved.

Fisher, easy-e, and FisherFAST are marks owned by one of the companies in the Emerson Process Management

business unit of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are

trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has

been made to ensure their accuracy they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify

or improve the designs or specifications of such products at any time without notice. Neither Emerson,

Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection,

use, or maintenance of any product. Responsibility for proper selection, use, and maintenance of any

product remains solely with the purchaser and end user.

D351448X012 / MY111 (H:) / May12

Loading...

Loading...