Page 1

Instruction Manual

D103374X012

Baumann™ 89000 Sanitary Control Valve

89000 Valve

March 2014

Contents

Introduction 2...................................

Scope of Manual 2.............................

Safety Precautions 2...........................

Maintenance 3.................................

Installation 4..................................

Air Piping 4...................................

Valve Body Disassembly 5......................

Replacing O-Ring Seals 6.......................

Valve Body Reassembly 6.......................

Parts Ordering 6................................

Dimensions 8..................................

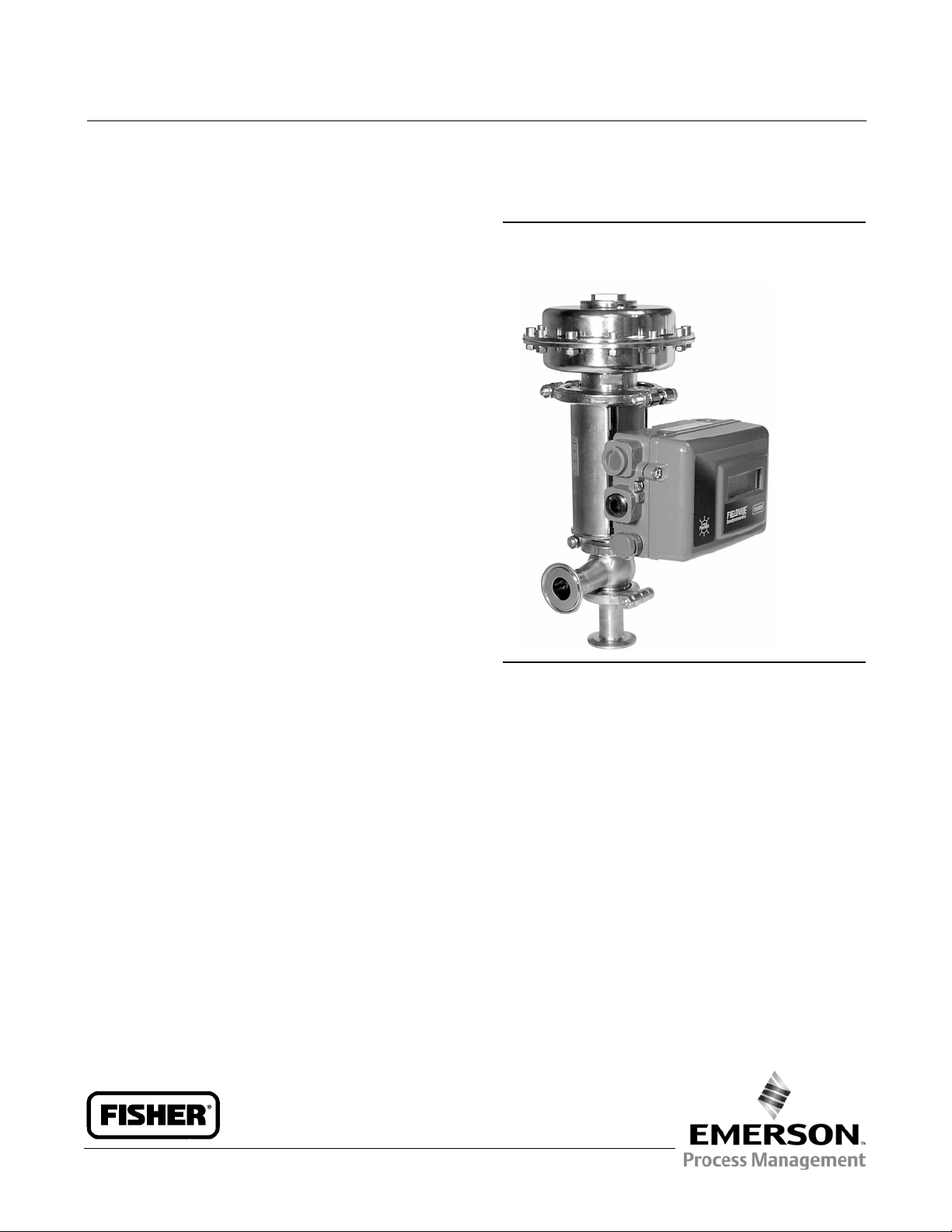

Figure 1. Baumann 89000 NPS 1/2 Sanitary Control

Valve Shown with FIELDVUE™ DVC2000 Digital Valve

Controller

W9850

Introduction

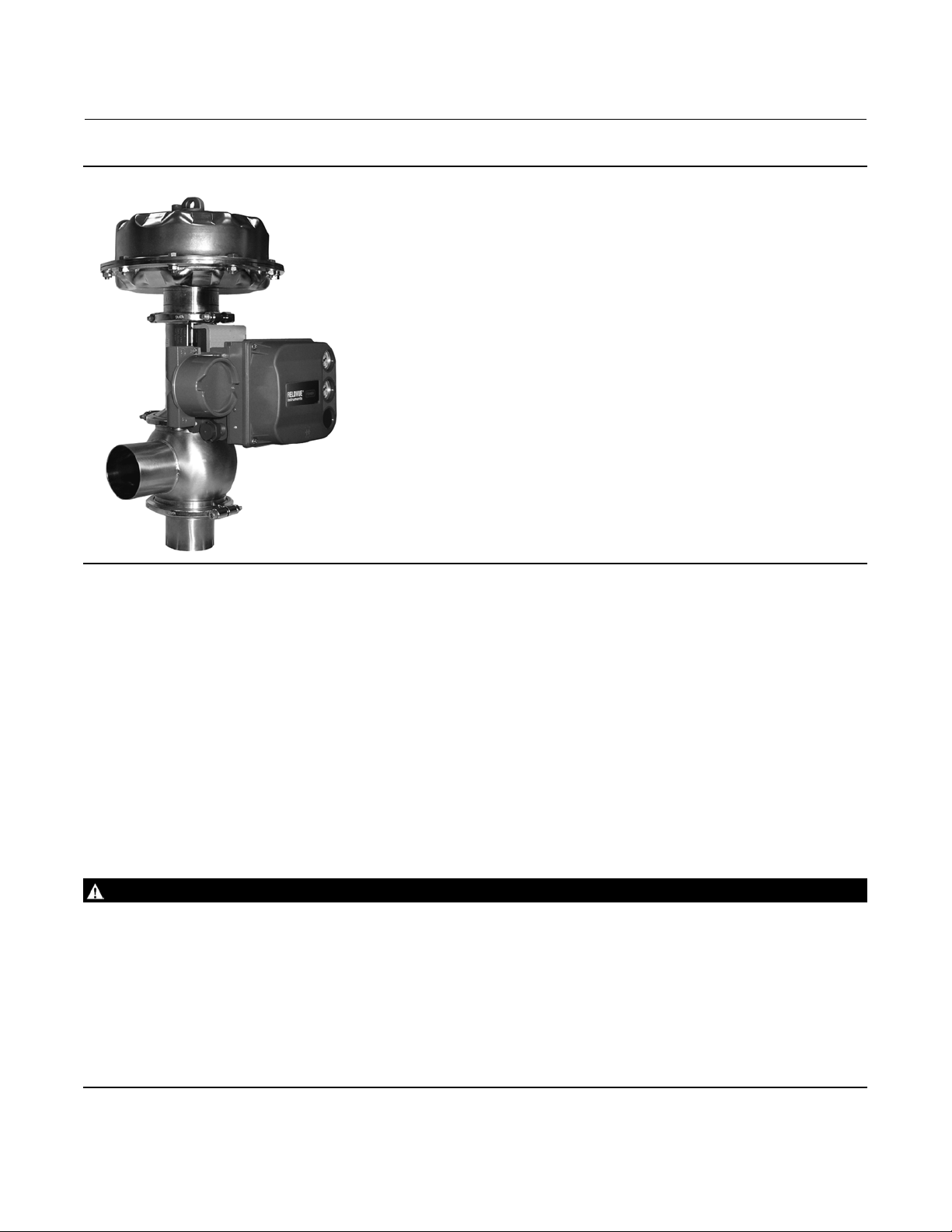

The Baumann 89000 sanitary control valve (figures 1 and 2) provides control solutions for sanitary and aseptic process

systems. These valves meet FDA and USP CLVI standards. They are designed to drain freely from inlet to outlet. In

sanitary and aseptic valve applications, the surface finish of all wetted parts is of the utmost importance and needs to

be free of pits and cracks. The Baumann 89000 series valv es meet all of these requirements.

The 89000 control valve covers a wide range of applications in many industries including food and beverage,

biotechnology, pharmaceutical, and others where cleanliness and sterility are required. The valves are designed for

easy maintenance and all parts in contact with the media are made of corrosion resistant S31603 stainless steel.

www.Fisher.com

Page 2

89000 Valve

March 2014

Instruction Manual

D103374X012

Figure 2. Baumann 89000 NPS 3 Sanitary Control Valve Shown with FIELDVUE DVC6200 Digital Valve Controller

W9851-2

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for the Baumann 89000 series

sanitary control valve.

Do not install, operate, or maintain Baumann 89000 control valves without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and

warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office

before proceeding.

Safety Precautions

WARNING

Always wear protective gloves, clothing and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or property damage caused by sudden release of pressure or bursting of pressure retaining parts may result

if service conditions exceed those for which the product was intended. To avoid injury or damage, provide a relief valve for

over pressure protection as required by government or accepted industry codes and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

2

Page 3

Instruction Manual

D103374X012

89000 Valve

March 2014

CAUTION

This valve is intended for a specific range of pressures, temperatures and other application specifications. Applying

different pressures and temperatures to the valve could result in parts damage, malfunction of the control valve or loss of

control of the process. Do not expose this product to service conditions or variables other than those for which the product

was intended. If you are not sure what these conditions are you should contact your Emerson Process Management sales

office for more complete specifications. Provide the product serial numbers (shown on the nameplate) and all other

pertinent information.

WARNING

If you move or work on an actuator installed on a valve with loading pressure applied, keep your hands and tools away

from the stem travel path to avoid personal injury. Be especially careful when removing the stem connector to release all

loading on the actuator stem whether it be from air pressure on the diaphragm or compression in the actuator springs.

Likewise take similar care when adjusting or removing any optional travel stop. Refer to the relevant actuator Maintenance

Instructions.

If hoisting the valve, take care to prevent people from being injured in case the hoist or rigging slips. Be sure to use

adequate sized hoists and chains or slings to handle the valve.

Maintenance

WARNING

Avoid personal injury and property damage from sudden release of process pressure or bursting of parts. Before

performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Depending on the actuator construction, it will be necessary to manage the pneumatic actuator spring

pre-compression. It is essential to refer to the relevant actuator instructions in this manual to perform safe removal of

the actuator from the valve.

D Use lock-out procedures to be sure the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Note

Whenever a gasket seal is disturbed by removing or shifting gasketed parts, install a new gasket during reassembly. This provides a

good gasket seal because the used gasket may not seal properly.

3

Page 4

89000 Valve

March 2014

Instruction Manual

D103374X012

Installation

1. Before installing the valve in the pipeline, thoroughly clean the line of all dirt, welding chips, scale, oil or grease, and

other foreign material.

2. Install the valve so the controlled fluid will flow through the valve body in the direction indicated. If you are not sure,

reference bulletin 51.2:89SV, D103346X012 or contact your Emerson Process Management sales office.

3. Athree-valvebypassmustbeusedtopermitremovalofthecontrolvalvefromthelinewithoutshuttingdownthe

system.

WARNING

To avoid personal injury or property damage, do not attempt to do any work on a valve while the system is in operation,

the valve must be isolated 100% from the active system and the isolated line voided of pressure and/or hazardous fluids.

Air Piping

1. For an air-to-extend actuator (air-to-close action), connect the actuating air pressure line to the 1/4 NPT opening in

the upper diaphragm case. For an air-to-retract actuator (air-to-open action) connect the actuating air pressure line

to the 1/4 NPT in the lower diaphragm case.

2. Use 6.4 mm (1/4 inch) O.D. tubing on type 20 and 9.6 mm (3/8 inch) on types 50, 50H, and 112 or equivalent for all

air lines. If the air line exceeds 8 m (25 ft) in length, 9.5 mm (3/8 inch) tubing is preferred. Air lines must not leak. Air

pressure not to exceed 6.9 bar (100 psig).

CAUTION

When assembling or disassembling the valve, do not turn the valve stem while the plug is touching the valve seat. This will

damage the valve's seating surfaces.

When adjusting the valve stem, do not grip the stem directly with pliers or a wrench. This will damage the surface of the

stem, and cause damage to the O-ring seals in the valve. Instead, use a spanner or Allen wrench through the recessed holes

on the stem (key 12). This will allow you to turn the stem.

Do not place valve in a vise. This can distort the shape of the valve.

CAUTION

Prior to performing maintenance on the valve, isolate the valve, vent the process pressure, and shut off supply and signal

air lines to the actuator.

4

Page 5

Instruction Manual

D103374X012

89000 Valve

March 2014

Disassembly

Actuator Remov al

Access to the internal components of the valve body can be accomplished with the actuator removed.

Air-to-Close Actuators

1. Disconnect the air supply to the actuator (key 2) and remove the air tubing.

2. Loosen the upper body clamp (key 5) and then remove the plug and stem (key 12) by holding the actuator stem still

while unthreading the plug and stem (key 12) counterclockwise.

3. Remove the stem locknut (key 8) and the upper body clamp (key 5) by sliding the yoke (key 4) and actuator

assembly off from the plug and stem (key 12).

4. Carefully remove the actuator from the valve.

Air-to-Open Actuators

1. Using flexible tubing, apply sufficient air pressure to the actuator (key 2) to lift the plug and stem (key 12) off the

valve seat/lower pipe connection (key 13).

2. Loosen the upper body clamp (key 5) and then remove the plug and stem (key 12) by holding the actuator stem still

while unthreading the plug and stem (key 12) counterclockwise.

3. Remove the stem locknut (key 8) and the upper body clamp (key 5).

4. Carefully remove the actuator from the valve.

Valve Body Disassembly

89000A, Angle Valve Body

1. After removal of the actuator (key 2), the bonnet (key 10) should be visible. Slide the bonnet (key 10) out of the

valve body assembly and off of the plug and stem (key 12). Be sure not to tear the O-ring seals.

2. Remove the plug and stem (key 12) from the valve body (key 1a).

3. Unthread the lower body clamp bolts and remove the bolts from the lower body clamp (key 7). Take the lower body

clamp off of the valve body (key 1a) and the valve seat/lower pipe connection (key 13) from the valve body.

4. Carefully slide the valve seat/lower pipe connection (key 13) from the valve body (key 1a), being sure not to tear the

O-ring seal.

5. Inspect all O-rings and sealing surface for signs of wear and scratches. Replace O-rings if needed.

89000I, Inline Valve Body

1. After removal of the actuator (key 2), the bonnet (key 10) should be visible. Slide the bonnet (key 10) out of the

upper valve body (key 1b) and off of the plug and stem (key 12).

2. Remove the plug and stem (key 12) from the upper valve body (key 1b).

3. Unthread the middle valve body clamp bolts and remove the bolts from the middle body clamp (key 6). Take the

middle body clamp (key 6) off and slide the lower body (key 1c) away from the upper body (key 1b). Be sure not to

tear the O-ring seal.

4. Once the lower body (key 1c) has been removed, the valve seat (key 16) should be visible. Carefully slide the valve

seat (key 16) from the upper valve body (key 1b), being sure not to tear the O-ring seal.

5. Carefully slide the lower valve body wall from the lower valve body (key 1c), being sure not to tear the O-ring seal.

5

Page 6

89000 Valve

March 2014

6. Inspect all O-rings and sealing surfaces for signs of wear and scratches. Replace the O-rings if needed.

Instruction Manual

D103374X012

Replacing O-Ring Seals

Remove the old O-rings by hand or with an appropriate tool. Be sure not to scratch the sealing surfaces of the valve

components. Replace the O-rings with care, being sure not to overstretch, tear, or twist the O-rings.

Valve Body Reassembly

Reverse the previous Valve Body Disassembly procedure. Be sure to take care and not damage the O-rings when

pressing the valve body components back into place.

Parts Ordering

When corresponding with your Emerson Process Management sales office about this equipment, always mention the

valve serial number. When ordering replacement parts, also specify the key number, part name, and desired material

using the following parts tables.

WARNING

Use only genuine Fisherr replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

6

Page 7

Instruction Manual

D103374X012

89000 Valve

March 2014

Figure 3. Baumann 89000A Angle Valve Assembly

E1337

Table 1. Materials of Construction

Key Number Description

1a Angle Valve Body

1b Upper Inline Valve Body

1c Lower Inline Valve Body

2 Diaphragm Actuator

3 Actuator Clamp

4 Yoke

5 Upper Body Clamp

6 Middle Body Clamp

7 Lower Body Clamp

8 Stem Locknut

9 O-Ring

10 Bonnet

11 Bearing

12 Valve Plug with Seat

13 Angle Valve Seat/Lower Pipe Connection (1pc)

14 O-Ring

15 O-Ring

16 Inline Valve Seat

Figure 4. Baumann 89000I Inline Valve Assembly

E1338

7

Page 8

89000 Valve

Instruction Manual

March 2014

Figure 5. Dimensions for Baumann 89000A Angle Valve with FIELDVUE DVC6200 Digital Valve Controller

C

B

D103374X012

A

GE59923-A

ED

Table 2. Baumann 89000A Angle Valve Dimensions

VALVE SIZE

DN NPS Capacity mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch

15 1/2 0.29 62.7 2.5 50 1.97 344 13.5 331 13 165 6.5 261 10.3 65.40 2.57 52.70 2.07

15 1/2 1.2 62.7 2.5 50 1.97 344 13.5 331 13 165 6.5 261 10.3 63.90 2.52 51.20 2.01

20 3/4 1.9 62.7 2.5 50 1.97 344 13.5 331 13 165 6.5 261 10.3 66.35 2.61 53.65 2.11

20 3/4 4.7 62.7 2.5 50 1.97 344 13.5 331 13 165 6.5 261 10.3 62.70 2.47 50.00 1.97

25 1 10 62.7 2.5 50 1.97 344 13.5 331 13 270 10.6 261 10.3 61.75 2.43 49.05 1.93

40 1-1/2 21 10 2.7 4 90 3.54 445 17.5 432 17 270 10.6 261 10.3 104.10 4.1 91.40 3.60

50 2 33 112.7 4.4 100 3.94 45 9 18.1 446 17.6 270 10.6 261 10.3 112.70 4.44 100.00 3.94

--- 3 79 142.7 5.6 130 5.12 531 20.9 519 20.4 270 10.6 261 10.3 148.15 5.83 135.45 5.33

80 --- 99 142.7 5.6 130 5.12 53 1 20.9 519 20.4 270 10.6 261 10.3 142.70 5.62 130.00 5.12

100 4 209 155.9 6.1 140 5.50 552 21.7 536 21.1 270 10.6 261 10.3 155.90 6.14 150.00 5.91

150 6 442 Contact your Emerson Process Management sales office for NPS 6 availability.

Tri-Clamp A Weld End A Tri-Clamp B Weld End B C D Tr-Clamp E Weld End E

DIMENSIONS

8

Page 9

Instruction Manual

D103374X012

Figure 6. Dimensions for Baumann 89000I Inline Valve with FIELDVUE DVC2000 Digital Valve Controller

D

F

E

89000 Valve

March 2014

C

B

E1342

A

A

Table 3. Baumann 89000I Inline Valve Dimensions

VALVE SIZE

DN NPS mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch

15 1/2 62.7 2.5 50 1.97 34.5 1.36 50 1.97 165 6.5 366 14.4 127 5

20 3/4 62.7 2.5 50 1.97 34.5 1.36 50 1.97 165 6.5 366 14.4 127 5

25 1 102.7 4 90 3.54 48 1.89 74 2.91 165 6.5 464 18.3 153 6

40 1-1/2 102.7 4 90 3.54 48 1.89 74 2.91 270 10.6 464 18.3 153 6

50 2 112.7 4.4 100 3.94 56 2.20 85 3.35 270 10.6 488 19.2 153 6

80 3 147.7 5.6 130 5.12 78 3.07 116 4.57 270 10.6 581 22.9 153 6

100 4 1553.9 6.1 140 5.50 86 3.39 136 5.35 270 10.6 617 24.3 153 6

150 6 Contact your Emerson Process Management sales office for NPS 6 availability.

Tri-Clamp A Weld End A B C D E F

DIMENSIONS

9

Page 10

89000 Valve

March 2014

Figure 7. Baumann 89000 Valve Body Spare Parts

Instruction Manual

D103374X012

4

1a

1b

1c

2

Table 4. Baumann 89000 Valve Body Spare Parts

DN NPS Valve Body Type Capacity (Cv) Valve Seat & Plug

Angle

15 1/2

Inline

Angle

20 3/4

Inline

25 1

40 1-1/2

50 2

--- 3

80 ---

100 4

150 6 Inline 442 GE56034X012 GE56035X012

1. Includes key numbers 1a, 1b, and 1c.

2. Includes key numbers 2, 3, 4, and 6 (also includeskey number 5 for a ngle body).

Angle 10 GE56144X012 89T001

Inline 10 GE56518X012 89T007

Angle 21 GE53538X012 89T002

Inline 21 GE56519X012 89T008

Angle 33 GE52287X012 89T003

Inline 33 GE56520X012 89T009

Angle 79 GE52860X012 89T005

Inline 79 GE56521X012 89T011

Angle 99 GE56522X012 89T004

Inline 99 GE56523X012 89T010

Angle 209 GE53537X012 89T006

Inline 209 GE56524X012 89T012

5

6

5

3

3

1

1b

1

2

(1)

0.29 GE56512X012

1.2 GE56142X012

0.29 GE56513X012

1.2 GE56514X012

1.9 GE56143X012

4.7 GE56515X012

1.9 GE56516X012

4.7 GE56517X012

4

6

4

2

ORing Kit

89T001

89T007

89T001

89T007

(2)

10

Page 11

Instruction Manual

D103374X012

89000 Valve

March 2014

11

Page 12

89000 Valve

March 2014

Instruction Manual

D103374X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection,use, and maintenance of any product remains solely with the purchaser and end user.

Baumann, Fisher, and FIELDVUE are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions,which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

E 2009, 2014 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...