Page 1

87000 Valve

D103345X012

Baumann™ 87000 Flexsleev Sanitary

Control Valve

The Baumann 87000 control valve is excellent for

throttling high purity liquid or gaseous media

commonly found in the food and beverage,

pharmaceutical, film, and biotechnology industries.

The valve is suitable for repeated steam sterilization

cycles with 2.4 bar (35 psi) maximum steam pressures.

Assembly of valve body sections using only two bolts

allows for ease of cleaning and inspection. A lower

telltale port is provided. The valve will drain either

horizontally or vertically with the actuator in the

horizontal position. In contrast to diaphragm valves,

the operation is not affected by vacuum.

Features

Unique flow pattern allows for self-draining in both

vertical and horizontal pipelines

W9823

Baumann 87000 Valve Shown in Recommended

Mounting Position for Self-Draining

Product Bulletin

52.1:87FS

November 2011

Streamlined low shear flow contours make it ideal

for sensitive biomedia

Electropolished, wetted interior finishes to ≤ 30 R

microinch (≤ 20 Ramicroinch optional)

Flow area between tubing O.D. and valve body

seating is suitable for fine particulate media

Full and reduced port orifices available to optimize

sizing

Foolproof bolting method assists with ease of valve

body disassembly and reassembly

Epoxy powder-coated actuator with stainless steel

yoke and fasteners for maximum corrosion

resistance

Fisherr FIELDVUE™ digital valve controller available

for remote calibration and diagnostics in facilities

utilizing the PlantWeb™architecture

a

W9824

Baumann 87000 Valve with

FIELDVUE DVC2000 Digital Valve Controller

www.Fisher.com

Page 2

Product Bulletin

52.1:87FS

November 2011

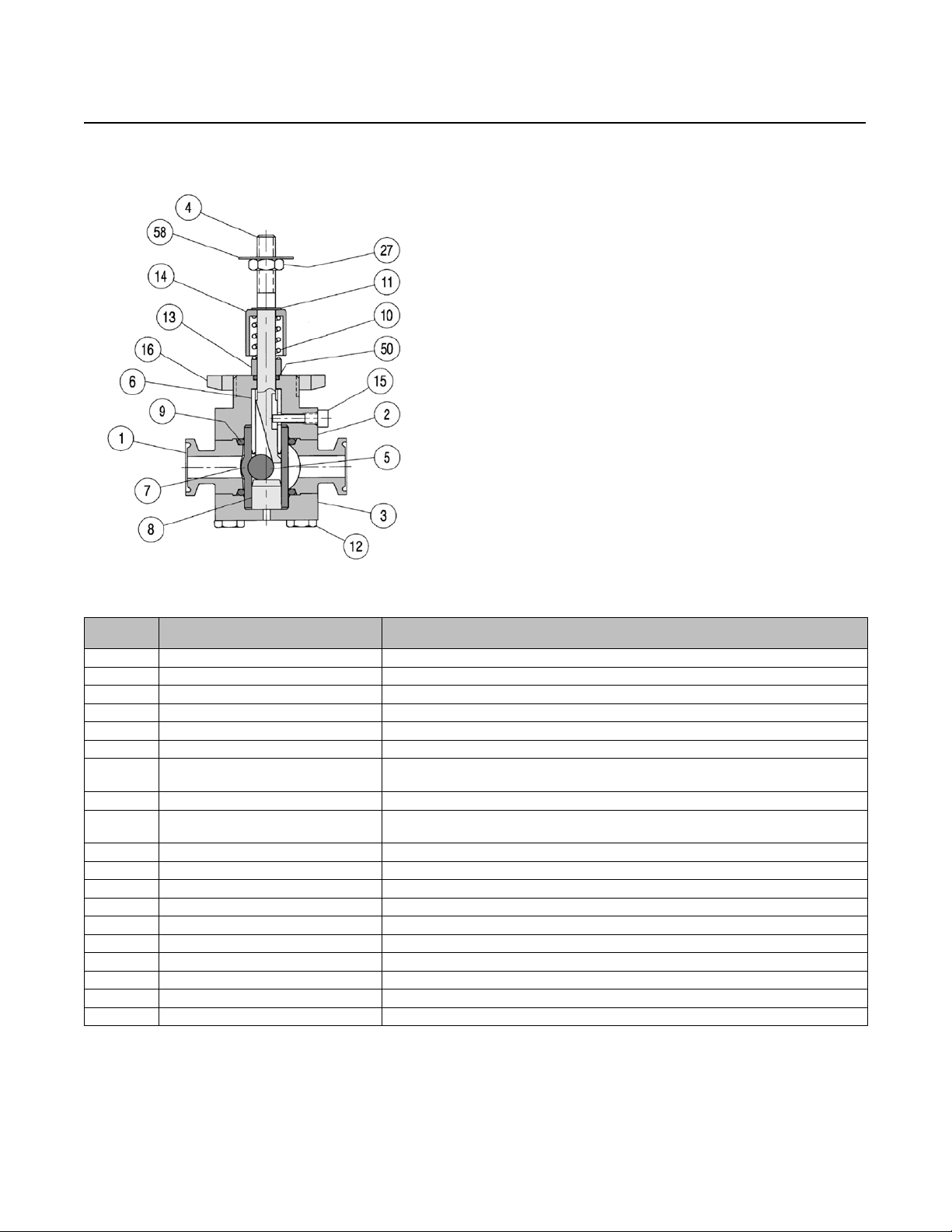

Figure 1. Baumann 87000 Flexsleev Valve Assembly

87000 Valve

D103345X012

E1295

Table 1. Materials of Construction

Key

Number

1 Valve Body ASTM SA479 (S31600/S31603)

2 Bonnet, Upper ASTM SA479 (S31600/S31603)

3 Bonnet, Lower ASTM SA479 (S31600/S31603)

4 Shaft S21800 SST

5 Ceramic Ball Grade 25 Ceramic

6 Sleeve Bushing S30300 Stainless Steel

7 Sleeve

8 Anvil S21800

9 O-Ring

10 Spring Stem Passivated Stainless Steel

11 Retaining Ring S15700

12 Hex Head Cap Screw 18-8 Stainless Steel

13 Spring Seat PA Nylon 6/6

14 Protecting Cap S30300 Stainless Steel

15 Alignment Pin 18-8 Stainless Steel

16 Drive Nut, (Yoke) S31600 SST(ASTM A194 Grade 8M)

27 Jam Nut (locknut) B8 Stainless Steel

50 O-Ring Fluorocarbon (FKM)

58 Travel Indicator ASTM A240 S30400

Description Material

Silicone, fluorocarbon (FKM), EPDM,

Perfluoroelastomer (FFKM)

Silicone, fluorocarbon (FKM), EPDM,

Perfluoroelastomer (FFKM)

2

Page 3

87000 Valve

D103345X012

Product Bulletin

52.1:87FS

November 2011

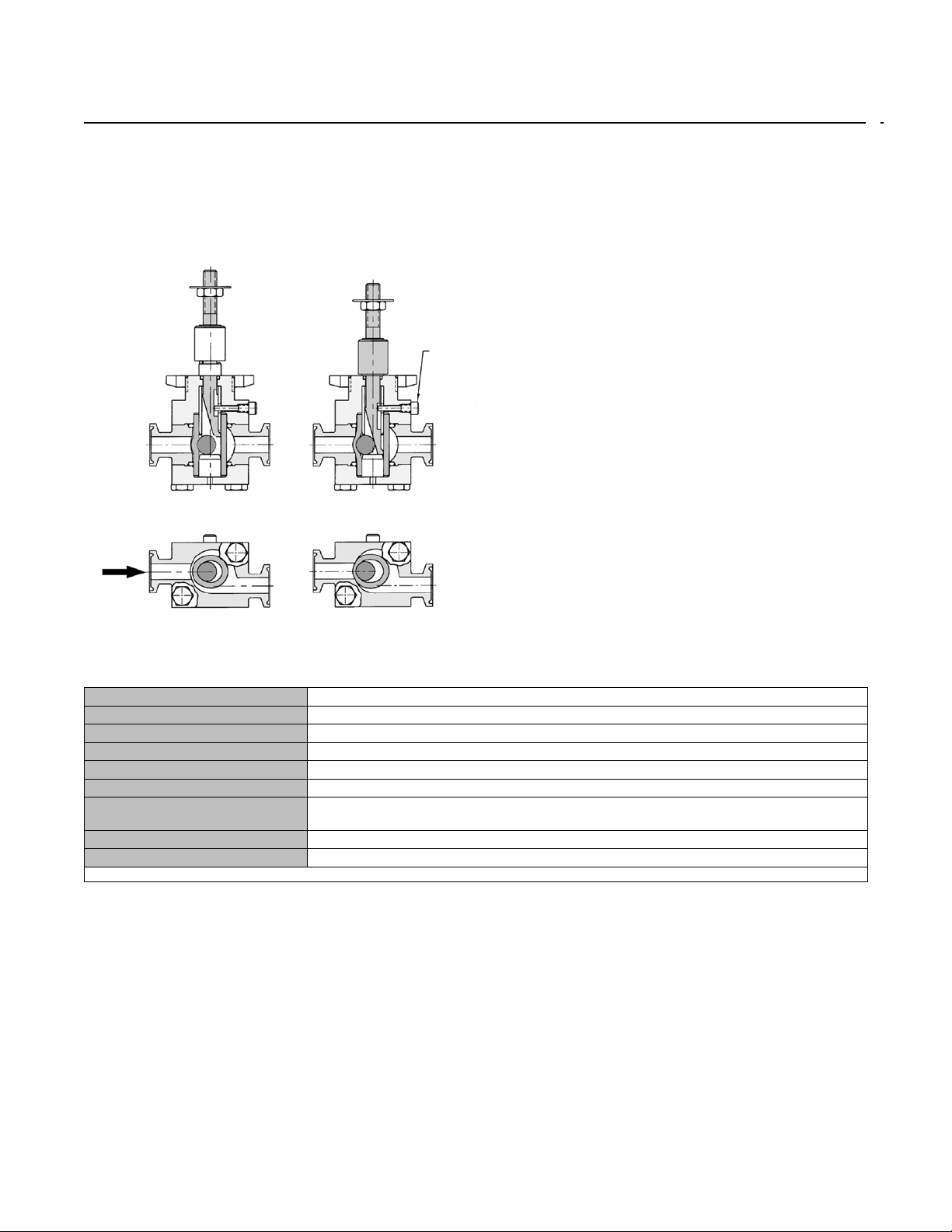

Mode of Operation

As shown in figure 2, a flexible sleeve is inserted

through the length of the valve and sealed between

Figure 2. Mode of Operation

FLOW

the valve body and bonnet by O-rings. The

actuator-motivated valve stem has a tapered groove

that pushes a ceramic ball against the inside of the

sleeve and, thereby, the sleeve against a valve seat.

SHOWN 90DEGREES

OUT OF POSITION FOR

CLARITY

E1296

OPEN

CLOSED

Table 2. Technical Specifications

Valve Body Rating 18.9 bar CWP (275 psi CWP)

Nominal Size 17.7 mm (NPS 1/2)

Connections 17.7 mm (0.5 inch), Tri-Clover / Tri-Clamp (Welded EndsOptional)

Seat Leakage Class VI

Bonnet Bolted

Characteristic Modified Linear

Internal Valve Body Finish (Wetted

Maximum Operating Temperature Refer to table 3

1. Consult your Emerson Process Management sales office for applicable materials.

Interior)

Available Certificates

(1)

< 30 Ra Microinch / 0.76 Ra Micron (standard)

< 20 Ra Microinch / 0.51 Ra Micron (optional - or as required)

USP CL VI, 21CFR 177

(1)

3

Page 4

Product Bulletin

52.1:87FS

November 2011

Table 3. Sleeve Material Temperature Chart

SLEEVE MATERIAL

Silicone -62 to 232_C (-80 to 450_F)

Silicone (steam) -17 to 135_C(0 to 275_F)

Fluorocarbon (general service) -17 to 204_C (-0 to 400_F)

Fluorocarbon (water or steam service) -17 to 37_C (-0 to 100_F)

EPDM -40 to 148_C (-40 to 300_F)

Perfluoroelastomer

1. Medical grade in compliance with FDA 21CFR177.

2. Please consultyour Emerson Process Management sales office before ordering perfluoroelastomer.

3. Sleeve material temperature limitations may reduce allowable shutoff pressures.

Table 4. Actuator Specifications

Nominal Size 103 cm2/16in

Air Failure Open or Closed (Field Reversible)

Bench Spring Range 0.3- 0.9 bar (4-13 psi), fail open / 0.3-1.0 bar (4-15 psi) fail closed

Travel 7.93 mm / 0.3125 inch

Ambient Temperature Range -29 to 71_C (-20 to 160_F)

Maximum Air Pressure 2.4 barg / 35 psig

Diaphragm Material Neoprene, Polyester

Spring Cases

Weight 2.1 kg (4.6 lbs)

(1)

(2)

Type 16 Multi-Spring Diaphragm (Single Acting)

Yoke CF8M stainless steel

TEMPERATURE RANGE

-17 to 248_C (-0 to 480_F)

(3)

Steel, Powder Epoxy-Coated Appliance Whiteper

FDA 21 CFR 175.300 with Stainless Steel Fasteners

SEAT

LEAKAGE

VI To Open 150 10.35

FLOW

DIRECTION

2

87000 Valve

D103345X012

MAXIMUM SHUTOFF

PRESSURE

psi bar

4

Page 5

87000 Valve

D103345X012

Table 5. Flow Coefficients (ASME/ISA/IEC) and ISA Sizing Factors

PLUG

TRAVEL

mm

(INCH)

7.9

(0.3125)

ORIFICE

DIAMETER

mm

(INCH)

3.18

(0.125)

9.40

(0.370)

CvAT VALVE OPENING - PERCENT OF PLUG TRAVEL

5 10 20 30 40 50 60 70 80 90 100

0.002

5

0.003

0

0.012

0.005

0.020 0.12 0.24 0.40 0.532 0.69 0.85 1.0 1.15 1.25 0.87 0.40 0.63 0.66

0.033 0.065 0.125 0.18 0.19 0.215 0.22 0.25 0.87 0.56 0.63 0.66

5

Product Bulletin

52.1:87FS

November 2011

F

F

L

X

d

T

K

C

Table 6. Weights

VALVE ACTUATOR POSITIONER

Size Travel Weight Baumann 16 FIELDVUE DVC2000 FIELDVUE DVC6010

DN NPS mm Inch kg lb kg lb kg lb kg lb

15 1/2 7.9 0.3125 3.6 8 4.5 10 1.5 3.3 3.5 7.7

1. Not available with Fisher 3660/3661 positioner.

(1)

Figure 3. Dimensions

87000 WITH BAUMANN 16 ACTUATOR AND FIELDVUE DVC2000 SHOWN IN

RECOMMENDED MOUNTING POSITION FOR SELF-DRAINING (TOP VIEW SHOWN AT RIGHT)

166

(6.52)

E1299

127 (5.0)

mm

(inch)

5

Page 6

Product Bulletin

52.1:87FS

November 2011

Figure 4. Dimensions

87000 Valve

D103345X012

87000 WITH BAUMANN 16 ACTUATOR SHOWN IN RECOMMENDED

MOUNTING POSITION FOR SELF-DRAINING

FLOW

38

(1.5)

21

(0.83)

21

(0.83)

70

(2.75)

SELF-DRAIN

ANGLE

2 DEGREES

FLOW

9

(0.34)

26

(1.03)

146

(5.8)

159

(46.25)

27

(1.05)

mm

(inch)

9

(0.34)

RECOMMENDED MOUNTING FOR SELF-DRAINING (ACTUATOR SHOULD BE MOUNTED HORIZONTALLY)

E1297

NOTE: ACTUATOR REQUIRES 115mm (4.5 INCHES) VERTICAL CLEARANCE.

6

Page 7

87000 Valve

D103345X012

Figure 5. Dimensions

Product Bulletin

52.1:87FS

November 2011

87000 WITH BAUMANN 16 ACTUATOR AND FIELDVUE DVC6000 SHOWN IN

RECOMMENDED MOUNTING POSITION FOR SELF-DRAINING

(TOP VIEW SHOWN AT RIGHT)

205

(48.06)

6

(40.25)

26

(1.03)

146

(5.8)

250

(9.8)

159

(46.25)

211

(8.3)

R228

(R9.0)

E1298

RECOMMENDED MOUNTING FOR SELF-DRAINING (ACTUATOR SHOULD BE MOUNTED HORIZONTALLY)

NOTE: ACTUATOR REQUIRES 115mm (4.5 INCHES) VERTICAL CLEARANCE.

mm

(inch)

7

Page 8

Product Bulletin

52.1:87FS

November 2011

Table 7. Model Numbering System

16 87

MAX C

ACTUATOR 87000

16 00 0.25 0.22 1 Tri-Clamp S Silicone

01 1.25 1.08 3 Special E EPDM

1. Consult your Emerson Process Management sales office.

v

C

v

K

v

END CONNECTIONS SLEEVE MATERIAL

V Fluorocarbon

K Perfluoroelastomer

87000 Valve

D103345X012

(1)

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Baumann, Fisher, FIELDVUE, and PlantWeb are marks owned by one of the companies in the Emerson Process Management business division of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson ElectricCo. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding theproducts or services described herein or their use or applicability. All sales are

governed by our terms and conditions, whichare availableupon request. We reserve the right to modify orimprove thedesigns or specifications of such

products at any time without notice.

Emerson ProcessManagement

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, KentME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

EFisher Controls International LLC 2009, 2011; All Rights Reserved

8

Loading...

Loading...