Page 1

84000 Valve

D103343X012

Baumannt 84000 Sanitary

Control Valves

The Baumann 84000 sanitary control valves are

designed to satisfy the stringent demands of the

pharmaceutical and biotechnology industries. These

valves are in compliance with 3A Sanitary Standards

Inc. requirements. Incorporating reliable class III

diaphragm technology, the 84000 valves can handle

temperatures up to 160_C(320_F). The uniquely

shaped diaphragm, unlike plug style sanitary valves,

results in low shear forces in the flow stream,

minimizing possible damage to delicate bio-media or

altering the consistency of end product.

W9838

84000 Inline Sanitary Valve with Baumann 32 Actuator

Product Bulletin

52.1:84000

November 2012

Features

Electropolished internal surfaces

USP 24 Class VI PTFE, EPDM backed diaphragm

Designed for Clean-in-Place (CIP) and

Sanitize-in-Place (SIP) service

Self-draining in preferred mounting mode

Compact size, see figures 9 to 10 and tables 14 to

15

FDA approved epoxy powder-coated actuator with

stainless steel fasteners for maximum corrosion

resistance

Stainless steel spring case and yoke available

Multi-spring field-reversible actuators with reduced

deadband permits direct operation from remote

signal devices

Fisherr FIELDVUEt digital valve controller available

for remote calibration and diagnostics in facilities

utilizing the PlantWebt architecture

W9839

84000 Angle Sanitary Valve with Baumann 32 Actuator

and FIELDVUE DVC2000 Digital Valve Controller

W9840

84000 Angle Sanitary Valve with Baumann 54 Actuator

and FIELDVUE DVC6000 Digital Valve Controller

www.Fisher.com

Page 2

Product Bulletin

52.1:84000

November 2012

84000 Valve

D103343X012

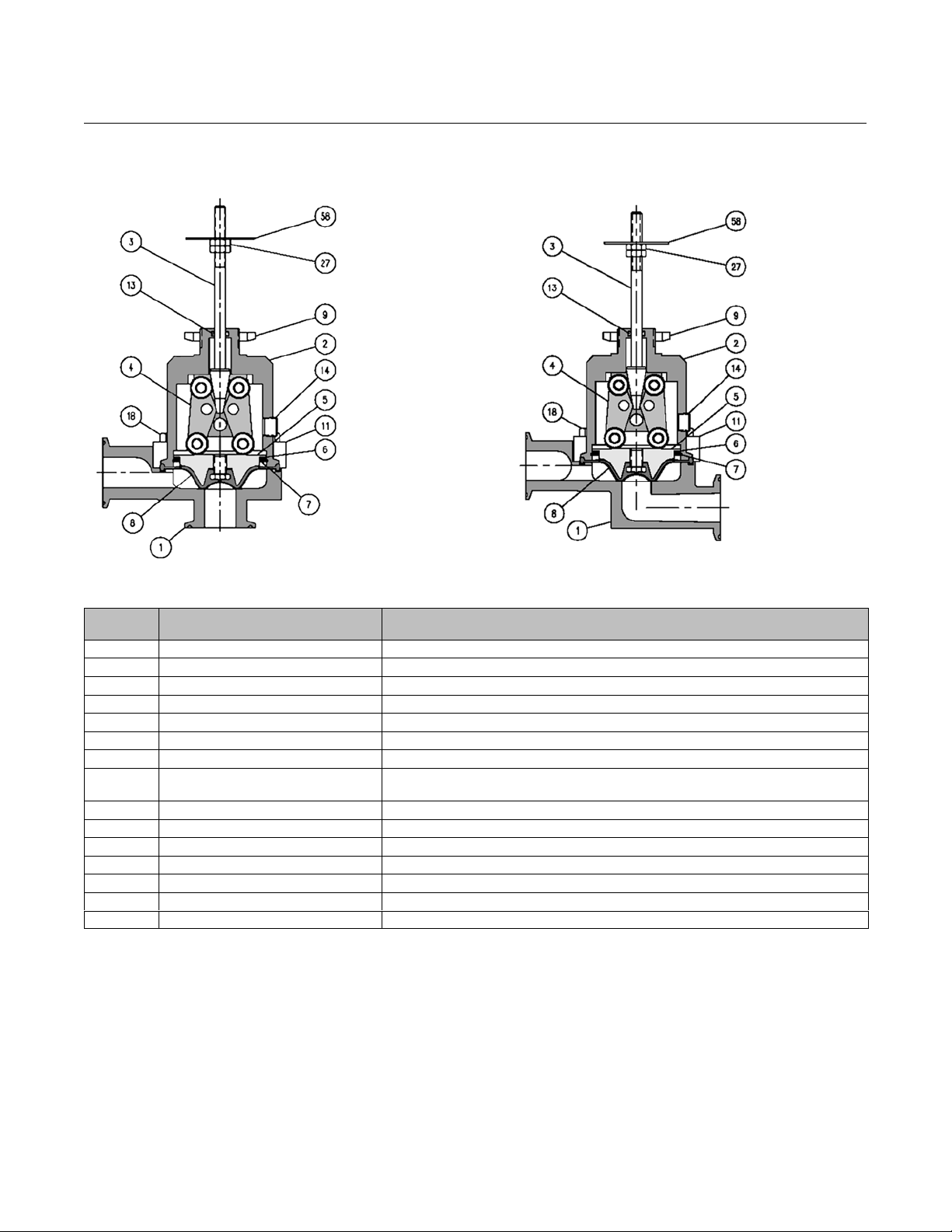

Figure 1. Baumann 84000 NPS 1 Angle Valve Body

Sub-Assembly

E1314

Figure 2. Baumann 84000 NPS 1 Inline Valve Body

Sub-Assembly

E1315

Table 1. Materials of Construction for NPS 1 Angle and Inline Valves

Key

Number

1 Valve Body ASTM A479 S31603 stainless steel, annealed

2 Bonnet ASTM A479 S30400 Annealed

3 Piston Stem Sub-assembly Stainless Steel

4 Drive Mechanism Sub-assembly Multiple (predominantly stainless steel)

5 Compressor S30300 orS30400 stainless steel

6 WaveSpring S17700 stainless steel

7 Retaining Ring S30200 stainless steel

8 Diaphragm, Closure Member

9 Drive Nut, Actuator Yoke S30400 stainless steel

11 Bonnet Flange ASTM A240 S30400 stainlesssteel

13 O-Ring, Stem FKM fluorocarbon

14 Tell Tale Port S31600 stainless steel

18 Hex Head Cap Screw Grade B8,Class 1

27 Locknuts S30400 stainless steel

58 Travel Indicator S30400 stainless steel

Description Material

PTFE face with Aramid fabric reinforced EPDM backing and S30400 stainless steel insert.

Diaphragm assembly conforms to FDA 21CFR177.1550 and USP24 Class VI standards.

2

Page 3

84000 Valve

D103343X012

Product Bulletin

52.1:84000

November 2012

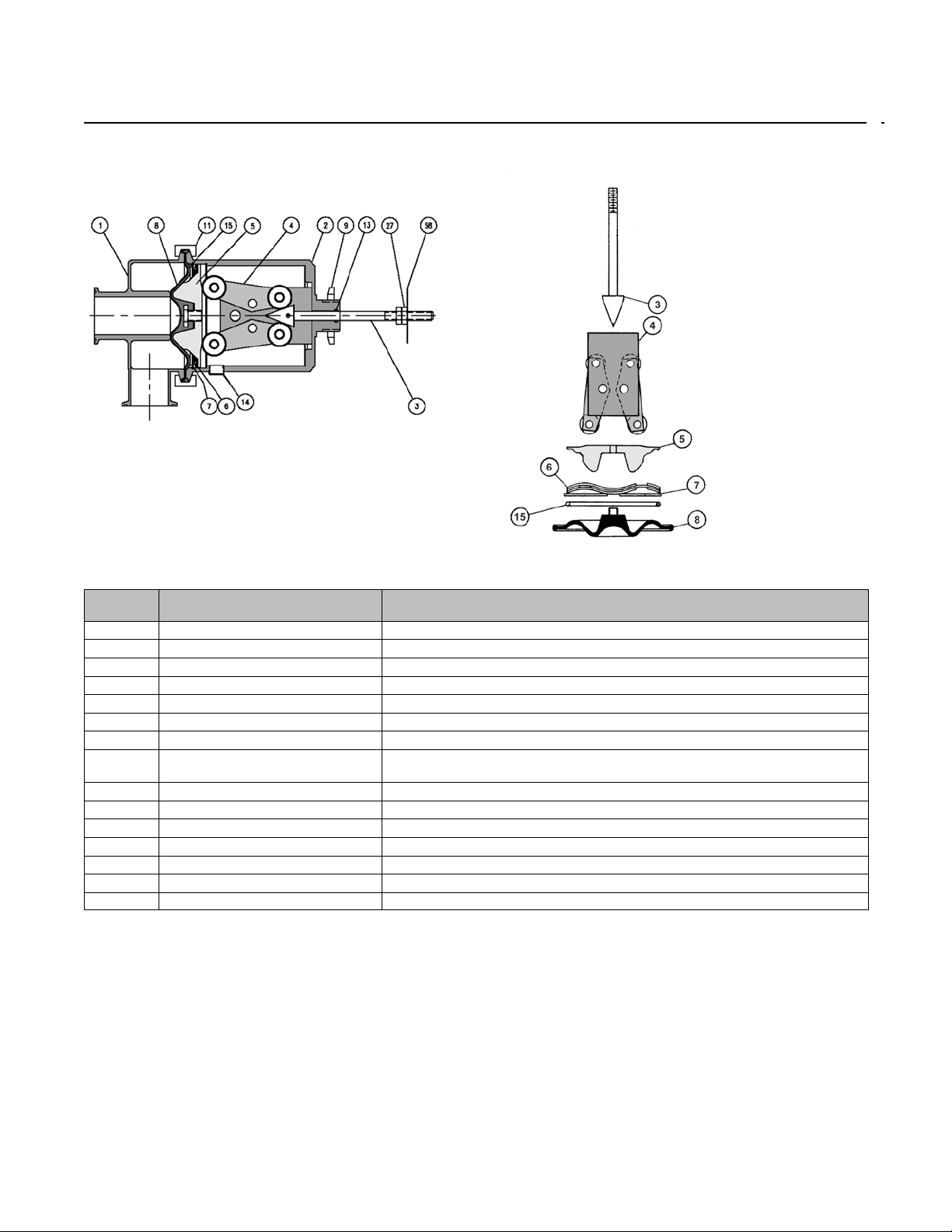

Figure 3. Baumann 84000 NPS 1-1/2 and 2 Angle

Figure 4. Baumann 84000 Linkage Mechanism

Valve Body Sub-Assembly

E1316

E1317

Table 2. Materials of Construction for NPS 1-1/2 and 2 Angle Valves

Key

Number

1 Valve Body ASTM A479 S31603 stainless steel, annealed

2 Bonnet ASTM A479 S30400 Annealed

3 Piston Stem Sub-assembly Stainless Steel

4 Drive Mechanism Sub-assembly Multiple (predominantly stainless steel)

5 Compressor S30300 orS30400 stainless steel

6 WaveSpring S17700 stainless steel

7 Retaining Ring S30200 stainless steel

8 Diaphragm, Closure Member

9 Drive Nut, Actuator Yoke S30400 stainless steel

11 Clamp S30400 stainless steel

13 O-Ring, Stem FKM fluorocarbon

14 Tell Tale Port S31600 stainless steel

15 O-Ring EPDM, conforming to FDA 21CFR 177.1550

27 Locknuts S30400 stainless steel

58 Travel Indicator S30400 stainless steel

Description Material

PTFE face with Aramid fabric reinforced EPDM backing and S30400 stainless steel insert.

Diaphragm assembly conforms to FDA 21CFR177.1550 and USP24 Class VI standards.

3

Page 4

Product Bulletin

52.1:84000

November 2012

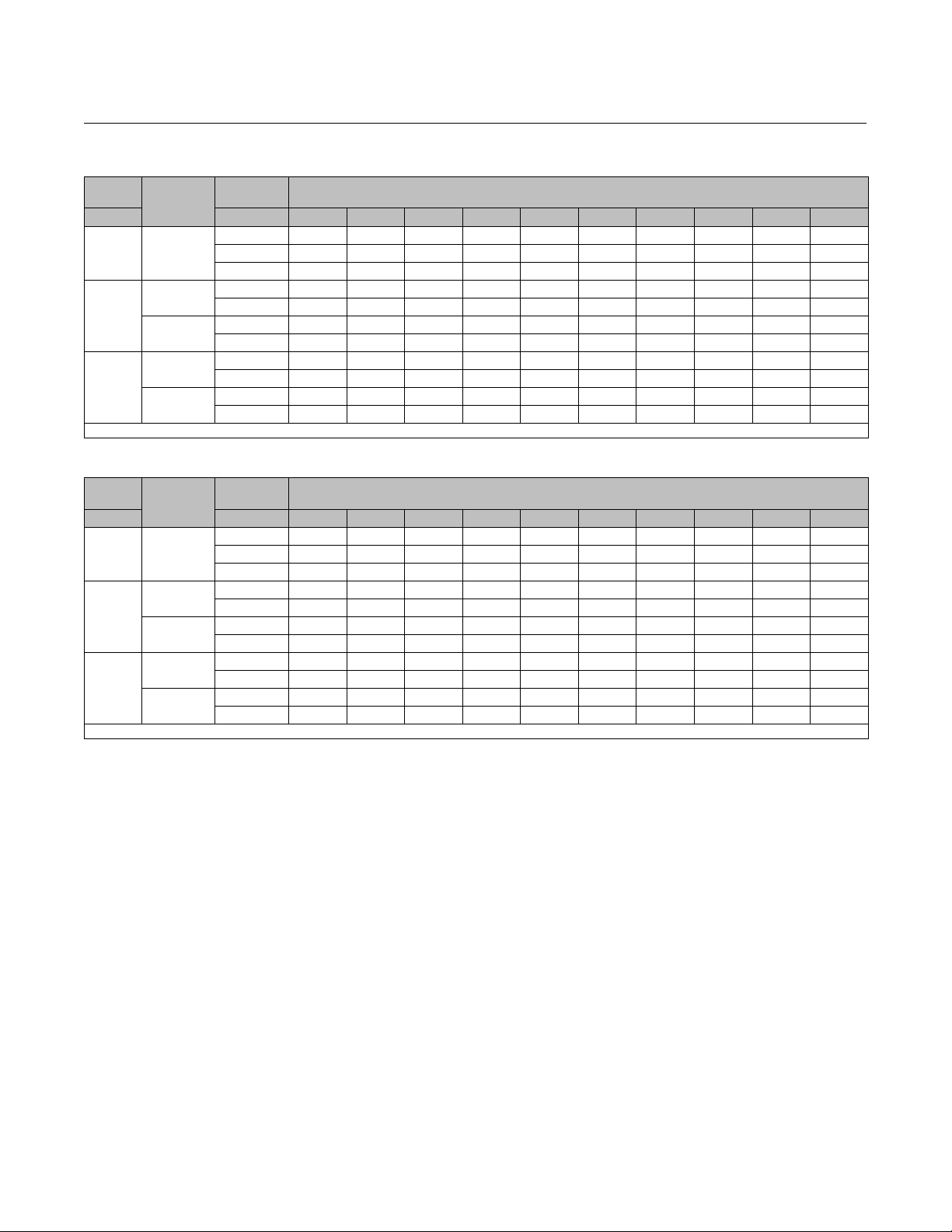

Table 3. Cv Values at Percent Plug Opening

VALVE

SIZE

NPS Inches 10 20 30 40 50 60 70 80 90 100

1

Angle &

Inline

1-1/2

Angle

2

Angle

1. Flow A to B is recommended forlow discharge pressure. Low dischargepressure being defined asnear or below atmospheric pressure.

FLOW

DIRECTION

(1)

AtoB

or

BtoA

AtoB

BtoA

AtoB

BtoA

ACTUATOR

TRAVEL

0.50 0.02 0.09 0.20 0.40 0.64 0.90 1.16 1.44 1.72 2.00

0.50 0.03 0.16 0.36 0.90 1.20 1.75 2.30 2.90 3.50 4.00

0.75 0.04 0.24 0.62 1.20 2.00 3.10 4.20 5.50 6.80 8.00

0.50 1.45 3.07 4.86 6.95 9.34 12.0 14.3 16.7 19.1 21.7

0.75 2.18 4.86 8.00 12.0 15.5 19.1 22.9 25.9 28.2 29.6

0.50 1.82 3.61 5.39 7.42 9.66 12.1 13.4 14.6 15.7 17.1

0.75 2.73 5.39 8.43 12.1 14.1 15.7 17.8 20.2 22.5 24.2

0.50 2.60 3.0 3.90 6.94 10.4 14.2 18.4 22.4 26.1 29.4

0.75 2.70 3.90 8.46 14.2 20.5 26.1 31.0 35.3 39.6 42.6

0.50 0.50 0.80 1.35 2.49 5.81 11.3 14.6 17.9 21.5 23.5

0.75 0.50 1.35 3.06 11.3 16.2 21.5 24.5 26.0 29.2 32.5

Cv VERSUS PERCENT OF AC TUATOR TRAVEL OPEN

Table 4. Kv Values at Percent Plug Opening

VALVE

SIZE

DN mm 10 20 30 40 50 60 70 80 90 100

25 Angle

&Inline

40

Angle

50

Angle

1. Flow A to B is recommended forlow discharge pressure. Low dischargepressure being defined asnear or below atmospheric pressure.

FLOW

DIRECTION

(1)

AtoB

or

BtoA

AtoB

BtoA

AtoB

BtoA

ACTUATOR

TRAVEL

12.7 0.017 0.077 0.17 0.34 0.55 0.77 0.998 1.24 1.48 1.72

12.7 0.026 0.138 0.31 0.77 1.03 1.51 1.98 2.49 3.01 3.44

19.05 0.034 0.206 0.53 1.03 1.72 2.67 3.61 4.73 5.85 6.88

12.7 1.25 2.64 4.18 5.98 8.03 10.32 12.29 14.36 16.43 18.66

19.05 1.88 4.18 6.88 10.32 13.33 16.43 19.69 22.27 24.25 25.46

12.7 1.57 3.10 4.64 6.38 8.31 10.41 11.52 12.56 13.50 14.71

19.05 2.35 4.64 7.25 10.41 12.13 13.50 15.31 17.37 19.35 20.81

12.7 2.24 3.0 3.35 5.97 8.94 12.21 15.82 19.26 22.45 25.28

19.05 2.33 3.35 7.28 12.21 17.63 22.45 26.66 30.36 34.06 36.64

12.7 0.43 0.69 1.16 2.14 4.98 9.72 12.56 15.39 18.49 20.21

19.05 0.43 1.16 2.63 9.72 13.93 18.49 21.07 22.36 25.11 27.95

Kv VERSUS PERCENT OF ACTUATOR TRAVEL OPEN

84000 Valve

D103343X012

4

Page 5

84000 Valve

D103343X012

Table 5. Technical Specifications

VALVE SIZE NPS 1 Angle & Inline NPS 1-1/2 Angle NPS 2 Angle

Installed with flow from

RATED

MAXIMUM OPERATING PRESSURE 10.34 bar (150 Psi)

MAXIMUM OPERATING TEMPERATURE 160_C (320_F)

INTERNAL BODY FINISH (WETTED INTERIOR)

Port A to B

Installed with flow from

Port B to A

TRAVEL

BONNET Bolted Clamped

ACTUATOR TYPE 32 or 54 54

RANGEABILITY 100:1

CHARACTERISTIC Modified Equal Percentage

SEAT LEAKAGE ASME/FCI 70-2, Class VI

END CONNECTIONS Sanitary (optional welded ends)

Table 6. Actuator Specifications

TYPE 32 Multi-Spring Diaphragm (Single-Acting) 54 Multi-Spring Diaphragm (Single-Acting)

NOMINAL SIZE 32in

AIR FAILURE Open or Closed

TRAVEL 12.7 to19.05 mm (0.50 or 0.75 inches)

AMBIENT TEMPERATURERANGE -29 to 82_C (-20 to 180_F)

MAXIMUM AIRPRESSURE 2.4 bar(35 psig)

DIAPHRAGM MATERIAL Nitrile / Polyester

SPRING CASES

FASTENERS Stainless Steel

YOKE

Cv 2 4 8 22 30 29 43

Kv 1.72 3.44 6.88 18.92 25.8 24.94 36.98

Cv 2 4 8 17 24 24 32

Kv 1.72 3.44 6.88 14.62 20.64 20.64 27.52

mm 12.7 12.7 19.05 12.7 19.05 12.7 19.05

inches 0.50 0.50 0.75 0.50 0.75 0.50 0.75

<30RaMicroinch/0.76RaMicron(standard)

< 20 Ra Microinch / 0.51 Ra Micron (optional - or as required)

2

J Steel, PowderEpoxy-Coated Appliance White perFDA 21 CFR 175.300

J Stainless Steel

J Ductile Iron, PowderEpoxy-Coated Appliance White per FDA 21 CFR 175.300

J Cast Stainless Steel

Product Bulletin

52.1:84000

November 2012

2

54 in

or

or

5

Page 6

Product Bulletin

52.1:84000

November 2012

Figure 5. Preferred Flow Directions for Self-Draining

84000 Valve

D103343X012

NPS 1 ANGLE VALVE BODY POSITIONED FOR

FORWARD FLOW SELF DRAINING FROM PORT A TO B

E1318

E1319

E1321

NPS 1-1/2 AND 2 ANGLE VALVE BODY POSITIONED

E1320

NPS 1-1/2 AND 2 ANGLE VALVE BODY (RECOMMENDED FOR PROCESSES

WHERE ATMOSPHERIC OR SLIGHT VACUUM IS PRESENT DOWNSTREAM

OF PORT B [PORTS A AND B MUST BE DRAINED SEPARATELY)

NPS 1 INLINE VALVE BODY POSITIONED FOR

FORWARD FLOW SELF DRAINING FROM PORT A TO B

FOR SELF DRAINING FROM PORT B TO A

6

Page 7

Product Bulletin

84000 Valve

D103343X012

Table 7. Model Numbering System

VALVE SIZE

NPS DN Inches mm Cv Kv

1

Angle

1

Inline

1-1/2

Angle

2

Angle

1. Model descriptorSA designates an angle valve body.Model descriptor SI designates an inlinevalve body.

2. Tri-Clamp end connections are standard. For optionalwelded end connections, s ubstitute (2) for (1) in the modelnumber, i.e. 54-84161SA (Tri-Clamp Ends).

54-84162SA (Welded Ends).

25

Angle

25

Inline

40

Angle

50

Angle

MODEL NUMBER

32-84021SAB 0.50 12.7 ANGLE (Port A to B) 2 1.72

32-84041SAB 0.50 12.7 ANGLE (Port A to B) 4 3.44

54-84041SAB 0.50 12.7 ANGLE (Port A to B) 4 3.44

32-84081SAB 0.75 19.05 ANGLE (Port A to B) 8 6.88

54-84081SAB 0.75 19.05 ANGLE (Port A to B) 8 6.88

32-84021SIB 0.50 12.7 ANGLE (Port A to B) 2 1.72

32-84041SIB 0.50 12.7 ANGLE (Port A to B) 4 3.44

54-84041SIB 0.50 12.7 ANGLE (Port A to B) 4 3.44

32-84081SIB 0.75 19.05 ANGLE (Port A to B) 8 6.88

54-84081SIB 0.75 19.05 ANGLE (Port A to B) 8 6.88

54-84161SAB 0.50 12.7 ANGLE (Port A to B) 22 18.92

54-84351SAB 0.75 19.05 ANGLE (Port A to B) 30 25.8

54-84161SA 0.50 12.7 ANGLE (Port B to A) 17 14.62

54-84351SA 0.75 19.05 ANGLE (Port B to A) 24 20.64

54-84251SAB 0.50 12.7 ANGLE (Port A to B) 29 24.94

54-84431SAB 0.75 19.05 ANGLE (Port A to B) 43 36.98

54-84251SA 0.50 12.7 ANGLE (Port B to A) 24 20.64

54-84431SA 0.75 19.05 ANGLE (Port B to A) 32 27.52

(1, 2)

TRAVEL

TYPE (Flow Direction)

November 2012

RATED

52.1:84000

7

Page 8

Product Bulletin

52.1:84000

November 2012

Figure 6. NPS 1 Angle and Inline Valve Body Orientations

A

E1318

NPS 1 ANGLE VALVE BODY POSITIONED FOR

FORWARD FLOW SELF DRAINING FROM PORT A TO B

B

84000 Valve

D103343X012

A

B

E1319

NPS 1 INLINE VALVE BODY POSITIONED FOR

FORWARD FLOW SELF DRAINING FROM PORT A TO B

Table 8. Allowable Pressure Drops (bar): NPS 1 Angle and NPS 1 Inline Valves

AIR-TO-OPEN ACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

DN mm bar

1. I/P transducer with 0.07 -1.2 bar (1 - 17 psig) output signal per FCI 87.2.

2. Shutoff withpositioner based on 1.4 bar (20 psi) air supply pressure.

FLOW

DIREC-

TION

25 AtoB

RATED Kv

1.72 12.7 32 0.3-1.0 7.58 8.62 8.62 0.2-0.9 6.9 8.62 8.62

3.44

6.88

TRAVEL

12.7 32 0.3-1.0 6.9 10.34 10.34 0.2-0.9 6.9 8.62 8.62

12.7 54 0.3-1.0 10.34 10.34 10.34 0.2-0.9 10.34 10.34 10.34

19.05 32 0.3-1.0 3.45 8.62 8.62 0.2-0.9 3.45 8.62 8.62

19.05 54 0.5-0.9 6.9 10.34 10.34 0.2-0.7 6.9 10.34 10.34

ACTUATOR

TYPE

Bench

Spring

Range

Signal to Actuator

0.2-1.0

bar

0.07-1.2

(1)

bar

Positioner

Table 9. Allowable Pressure Drops (psi): NPS 1 Angle and NPS 1 Inline Valves

AIR-TO-OPEN ACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

NPS Inches psig 3-15 psig 1-2 psig

1. I/P transducer with 0.07 -1.2 bar (1 - 17 psig) output signal per FCI 87.2.

2. Shutoff withpositioner based on 1.4 bar (20 psi) air supply pressure.

FLOW

DIREC-

TION

1 AtoB

RATED Cv

2.00 0.50 32 5-15 110 125 125 3-13 100 125 125

4.00

8.00

TRAVEL

0.50 32 5-15 100 150 150 3-13 100 125 125

0.50 54 5-15 150 150 150 3-13 150 150 150

0.75 32 5-15 50 125 125 3-13 50 125 125

0.75 54 7-13 100 150 150 3-10 100 150 150

ACTUATOR

TYPE

Bench

Spring

Range

Signal to Actuator

Positioner

(1)

With

(2)

bar bar

With

(2)

psig psig 3-15 psig 1-2 psig

Bench

Spring

Range

Bench

Spring

Range

Signal to Actuator

0.2-1.0

Signal to Actuator

bar

0.07-1.2

bar

(1)

Positioner

Positioner

(1)

With

(2)

bar

With

(2)

psig

8

Page 9

84000 Valve

D103343X012

Figure 7. NPS 1-1/2 and 2 Angle Valve Body

RECOMMENDED FOR PROCESSES WHERE ATMOSPHERIC OR

SLIGHT VACUUM IS PRESENT DOWNSTREAM OF PORT B.

(PORTS A AND B MUST BE DRAINED SEPARATELY)

A

Product Bulletin

52.1:84000

November 2012

E1320

B

Table 10. Allowable Pressure Drops (bar): Flow Direction A to B: NPS 1-1/2 and 2 Angle Valves

AIR-TO-OPEN ACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

FLOW

DIREC-

TION

RATED Kv

TRAVEL

ACTUATOR

TYPE

DN mm bar

18.92 12.7 54 0.3-1.0 1.99 3.99 3.99 0.2-0.9 1.99 3.99 6.96

40 AtoB

50 AtoB

1. I/P transducer with 0.07 -1.2 bar (1 - 17 psig) output signal per FCI 87.2.

2. Shutoff withpositioner based on 1.4 bar (20 psi) air supply pressure.

18.92 12.7 54 0.6-1.0 4.96 6.96 6.96 0.2-0.7 4.96 6.96 9.99

25.8 19.05 54 0.3-1.0 1.99 3.99 3.99 0.2-0.9 1.99 3.99 6.96

25.8 19.05 54 0.5-0.9 3.99 5.99 5.99 0.2-0.7 4.92 6.96 9.99

24.94 12.7 54 0.3-1.0 2.34 4.68 4.68 0.2-0.9 2.34 4.68 8.20

24.94 12.7 54 0.6-1.0 5.86 8.20 8.20 0.2-0.7 5.79 8.20 11.72

36.98 19.05 54 0.3-1.0 2.34 4.68 4.68 0.2-0.9 2.34 4.68 8.20

36.98 19.05 54 0.5-0.9 4.68 7.03 7.03 0.2-0.7 5.86 8.20 11.72

Bench

Spring

Range

Signal to Actuator

0.2-1.0

bar

0.07-1.2

(1)

bar

With

Positioner

(2)

bar bar

Bench

Spring

Range

Table 11. Allowable Pressure Drops (psi): Flow Direction A to B: NPS 1-1/2 and 2 Angle Valves

AIR-TO-OPEN ACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

FLOW

DIREC-

TION

RATED Cv

TRAVEL

ACTUATOR

TYPE

NPS Inches psig 3-15 psig 1-2 psig

22 0.50 54 5-15 29 58 58 3-13 29 58 101

1-1/2 AtoB

2 AtoB

1. I/P transducer with 0.07 -1.2 bar (1 - 17 psig) output signal per FCI 87.2.

2. Shutoff withpositioner based on 1.4 bar (20 psi) air supply pressure.

22 0.50 54 8-15 72 101 101 3-10 72 101 145

30 0.75 54 5-15 29 58 58 3-13 29 58 101

30 0.75 54 7-13 58 87 87 3-10 72 101 145

29 0.50 54 5-15 34 68 68 3-13 34 68 119

29 0.50 54 8-15 85 119 119 3-10 84 119 170

43 0.75 54 5-15 34 68 68 3-13 34 68 119

43 0.75 54 7-13 68 102 102 3-10 85 119 170

Bench

Spring

Range

Signal to Actuator

With

Positioner

(2)

(1)

psig psig 3-15 psig 1-2 psig

Bench

Spring

Range

Signal to Actuator

0.2-1.0

bar

0.07-1.2

(1)

bar

Signal to Actuator

Positioner

Positioner

(1)

With

(2)

bar

With

(2)

psig

9

Page 10

Product Bulletin

52.1:84000

November 2012

Figure 8. NPS 1-1/2 and 2 Angle Valve Body Positioned for Self Draining from Port B to A

B

84000 Valve

D103343X012

E1321

A

Table 12. Allowable Pressure Drops (bar): Flow Direction B to A : NPS 1-1/2 and 2 Angle Valves

AIR-TO-OPEN ACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

DN mm bar

1. I/P transducer with 0.07 -1.2 bar (1 - 17 psig) output signal per FCI 87.2.

2. Shutoff withpositioner based on 1.4 bar (20 psi) air supply pressure.

FLOW

DIREC-

TION

40 BtoA

50 BtoA

RATED Kv

14.62 12.7 54 0.3-1.0 5.10 10.20 10.20 0.2-0.9 5.10 10.20 17.86

14.62 12.7 54 0.6-1.0 12.76 17.86 17.86 0.2-0.7 12.76 17.86 25.58

20.64 19.05 54 0.3-1.0 5.10 10.20 10.20 0.2-0.9 5.10 10.20 17.86

20.64 19.05 54 0.5-0.9 10.20 15.31 15.31 0.2-0.7 12.76 17.86 25.58

20.64 12.7 54 0.3-1.0 2.90 5.79 5.79 0.2-0.9 2.90 5.79 10.14

20.64 12.7 54 0.6-1.0 7.24 10.14 10.14 0.2-0.7 7.24 10.14 14.48

27.52 19.05 54 0.3-1.0 2.90 5.79 5.79 0.2-0.9 2.90 5.79 10.14

27.52 19.05 54 0.5-0.9 5.79 8.69 8.69 0.2-0.7 7.24 10.14 14.48

TRAVEL

ACTUATOR

TYPE

Bench

Spring

Range

Signal to Actuator

0.2-1.0

bar

0.07-1.2

(1)

bar

With

Positioner

(2)

bar bar

Bench

Spring

Range

Table 13. Allowable Pressure Drops (psi): Flow Direction B to A: NPS 1-1/2 and 2 Angle Valves

AIR-TO-OPEN ACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

NPS Inches psig 3-15 psig 1-2 psig

1-1/2 BtoA

1. I/P transducer with 0.07 -1.2 bar (1 - 17 psig) output signal per FCI 87.2.

2. Shutoff withpositioner based on 1.4 bar (20 psi) air supply pressure.

FLOW

DIREC-

TION

2 BtoA

RATED Cv

TRAVEL

17 0.50 54 5-15 74 148 148 3-13 74 148 259

17 0.50 54 8-15 185 259 259 3-10 185 259 371

24 0.75 54 5-15 74 148 148 3-13 74 148 259

24 0.75 54 7-13 148 222 222 3-10 185 259 371

24 0.50 54 5-15 42 84 84 3-13 42 84 147

24 0.50 54 8-15 105 147 147 3-10 105 147 210

32 0.75 54 5-15 42 84 84 3-13 42 84 147

32 0.75 54 7-13 84 126 126 3-10 105 147 210

ACTUATOR

TYPE

Bench

Spring

Range

Signal to Actuator

With

Positioner

(2)

(1)

psig psig 3-15 psig 1-2 psig

Bench

Spring

Range

Signal to Actuator

0.2-1.0

Signal to Actuator

bar

0.07-1.2

(1)

bar

Positioner

Positioner

(1)

With

(2)

bar

With

(2)

psig

10

Page 11

84000 Valve

D103343X012

Figure 9. Dimensional Drawings for Baumann84000NPS1AngleandInlineValves

216 (48.5)

31 (1.24)

227

(9.0)

BAUMANN 32 ACTUATOR WITH

FIELDVUE DVC2000, TOP VIEW

Product Bulletin

52.1:84000

November 2012

249 (9.8)

216 (48.5)

85

(3.4)

40

(1.6)

84

(3.3)

84000 ANGLE VALVE BODY WITH

BAUMANN 32 ACTUATOR ATC/FO

ACTION, DUAL STOP AND FIELDVUE

DVC2000 DIGITAL VALVE CONTROLLER

E1322

127

(5.00)

166

(6.52)

85

(3.4)

32

(1.3)

148

(5.8)

84000 INLINE VALVE BODY WITH BAUMANN

32 ACTUATOR ATC/FC ACTION, DUAL STOP

AND 3660/3661 POSITIONER

Table14.ValveAssemblyandActuatorWeights

VALVE SIZE 84000 ANGLE ASSEMBLY 84000 IN-LINE ASSEMBLY ACTUATOR WEIGHTS

DN NPS kgs lbs kgs lbs TYPE kgs lbs

25 1 4.06 9.0 4.31 9.5 32 4.5 10

40 1-1/2 5.22 11.5 N/A

50 2 5.22 11.5 N/A

54 11.3 25

mm

(inch)

11

Page 12

Product Bulletin

52.1:84000

November 2012

Figure 10. Dimensional Drawing for Baumann 84000 NPS 1-1/2 and 2 Angle Valve with FIELDVUE DVC6010 Digital

Valve Controller

359 (14.5)

279 (411.0)

276

(10.9)

C

84000 Valve

D103343X012

D

G

F

E1323

Note: Actuator removal requires 115mm(4.5 inches)vertical clearance.

E

mm

(inch)

Table15.ValveAssemblyandActuatorWeights

VALVE SIZE C D E F G

DN NPS mm inch mm inch mm inch mm inch mm inch

40 1-1/2 152.4 6.0 50.8 2.00 82.55 3.25 50.39 1.984 34.44 1.356

50 2 160 6.3 50.8 2.00 88.9 3.50 63.9 2.516 47.63 1.875

Neither Emerson, Emerson Process Management,nor any of their affiliated entitiesassumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solelywith the purchaser and end user.

Baumann, Fisher, FIELDVUE, and PlantWeb are marks owned by one of the companies in the Emerson Process Management business unit of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. Wereserve the right tomodify orimprove thedesigns orspecifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2009, 2012 Fisher ControlsInternational LLC. All rights reserved.

12

Loading...

Loading...