Page 1

83000 Valve

D103342X012

Baumann™ 83000 Sanitary Angle

Control Valve

The Baumann 83000 sanitary control valve is excellent

for the control of high purity fluids or gaseous media. A

low-friction-force amplification mechanism,

comprised of a roller bearing linkage, produces

high-positioning resolution suitable for direct

operation from remote I/P signal converters.

The 83000 features a packless design and is intended

for laboratory flow rates as low as 0.001 liters per

minute (l/m) with a Cv range of 0.00001 to 1.02. This

innovative design also allows for clean-in-place (CIP)

and sanitize-in-place (SIP) procedures and is

self-draining.

Product Bulletin

52.1:83SA

December 2014

Features

Compact and light-weight design reduces installed

piping costs.

NPS 1/2 tri-clamp end connections standard with

optional welded connections.

Electropolished wetted interior finished to

≤ 30 Ra microinch (≤ 20 Ra microinch optional).

Self-draining designed for Clean-in-Place (CIP) and

Sanitize-in-Place (SIP).

Closure diaphragm is polished 316 stainless steel;

Quick-Disconnect bonnet aids closure diaphragm

replacement.

Epoxy powder-coated actuator with stainless steel

fasteners for maximum corrosion resistance.

Multi-spring field-reversible actuators with reduced

deadband permits direct operation from remote

signal devices.

W9848

83000 Sanitary Angle

Valve with Baumann 16

Actuator

Fisherr FIELDVUEt digital valve controller available

for remote calibration and diagnostics in facilities

utilizing the PlantWebt architecture.

Elastomer seals meet FDA and USP CLVI

requirements.

W9849

83000 Sanitary Angle Valve

with FIELDVUE DVC2000

Digital Valve Controller

Specifications

See table 6 for technical specifications and table 7 for

actuator specifications.

www.Fisher.com

Page 2

Product Bulletin

52.1:83SA

December 2014

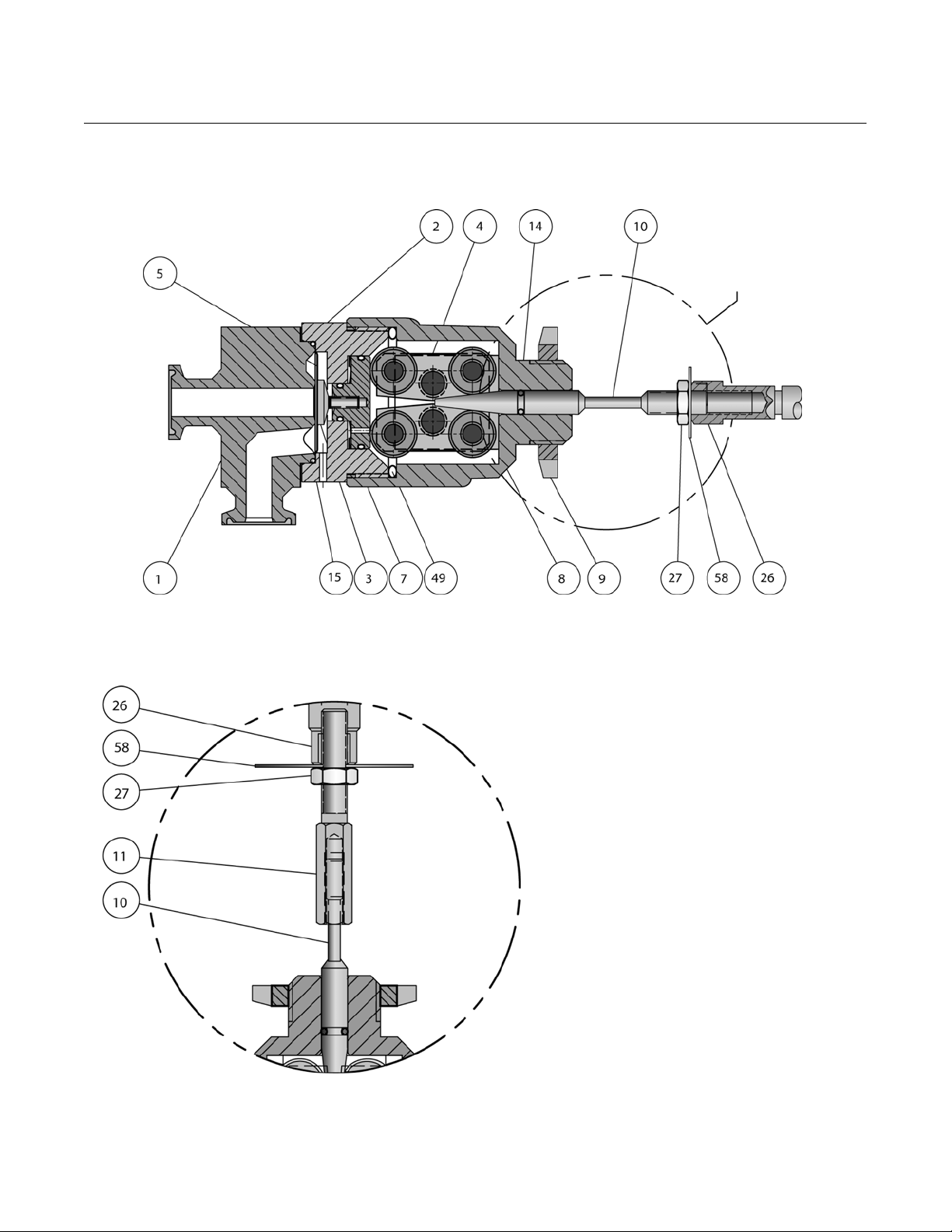

Figure 1. 83000 for Baumann 16 Actuator

83000 Valve

D103342X012

SEE DETAIL

IN FIGURE 2

E1332

Figure 2. 83000 with Stem Adaptor for Baumann 32 Actuator

E1333

2

Page 3

83000 Valve

D103342X012

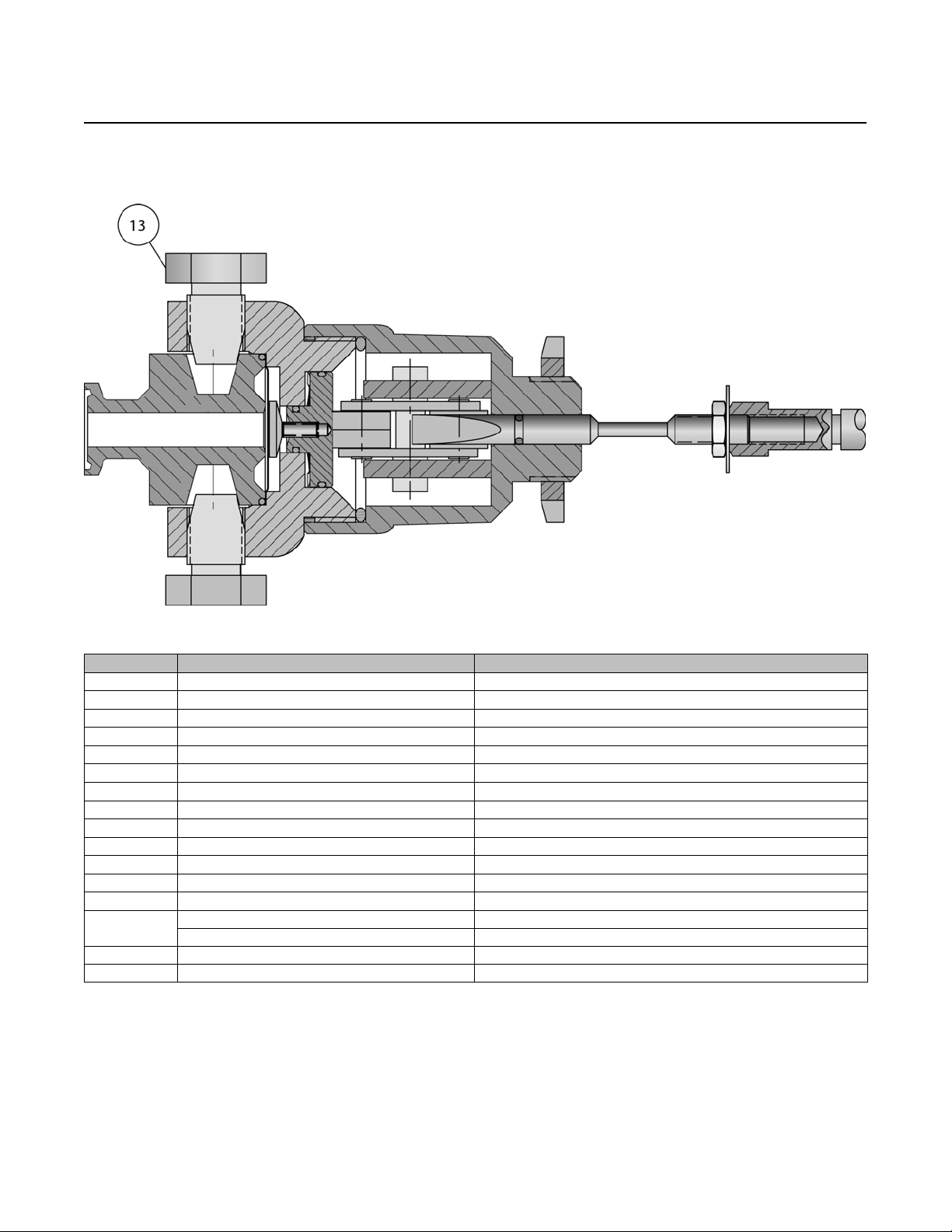

Figure 3. Baumann 83000 - Rotated View to Show Locking Bolts

Product Bulletin

52.1:83SA

December 2014

E1334

Table 1. Materials of Construction

Key Number Description Material

1 Valve Body ASME A479 S31600/S31603

2 Bonnet Yoke S30400 SST

3 Piston Subassembly S30300 SST and FKM (Fluorocarbon)

4 Bearing Cartridge Subassembly Stainless Steel and PTFE (Polytetrafluoroethylene)

5 Closure Diaphragm S31600 SST, standard / N10276 Nickel Alloy, optional

7 Wave Spring S17700 SST

8 Bonnet ASTM A743 CF8

9 Drive Nut, Yoke S30400 SST

10 Plunger ASTM A276 S31600 Condition A

11 Actuator Stem Adapter for Baumann 32 A582 S30300Stainless Steel

13 Locking Bolt (Refer to Figure 3) S21800 SST

14 O-Ring, Plunger FKM (Fluorocarbon)

15 O-Ring, Body EPDM

27

49 O-Ring FKM (Fluorocarbon)

58 Travel Indicator Disk ASTMA240 S30400

Jam Nut, Baumann 16 Actuator Stainless Steel (18-8 SST)

Jam Nut, Baumann 32 Actuator S30400 SST

3

Page 4

Product Bulletin

52.1:83SA

December 2014

Table 2. Allowable Pressure Drops

DIA-

0.177

0.381

0.304

0.381

PLUG

TRAVEL

mm

(inch)

12.7

(0.50)

0.00001 0.0001 0.0015 0.0050 0.0075 0.0094 0.0108 0.0118 0.0123 0.0129 0.014

0.00003 0.0003 0.0040 0.0127 0.0200 0.0273 0.0340 0.0393 0.0450 0.0490 0.053

0.0002 0.0002 0.0010 0.0057 0.0197 0.0440 0.0707 0.0993 0.1293 0.1573 0.182

0.0004 0.002 0.043 0.099 0.165 0.223 0.281 0.336 0.379 0.407 0.427

0.0007 0.031 0.072 0.144 0.215 0.296 0.377 0.448 0.519 0.576 0.631

0.001 0.019 0.131 0.250 0.368 0.492 0.622 0.726 0.832 0.929 1.02

Bench Range

bar psig bar psig bar psig bar psig bar psig bar psig

0.2-1.0 3-15 10 150 19 275 0.2- 0.9 3-13 10 150 19 275

5 10 20 30 40 50 60 70 80 90 100

ORIFICE

Cv Kv

0.014

0.053

0.182

0.427

0.631

1.02

0.012

0.046

0.157

0.369

0.546

0.882

1. Based on 1.38 bar (20 psig) supply.

Table 3. Flow Coefficients (Cv Values)

ORIFICE

DIA-

METER

mm

(Inch)mm(Inch)

0.686

(0.027)

1.60

(0.063)

3.81

(0.150)

3.81

(0.150)

9.40

(0.370)

9.40

(0.370)

PHRAGM

TRAVEL

(0.007)

(0.015)

(0.012)

(0.015)

AIR-TO-OPENACTION AIR-TO-CLOSE ACTION

3-15 psig

(0.2-1.0 bar)

Signal to

Actuator

Cv AT VALVE OPENING - PERCENT OF VALVE STEM TRAVEL

With

Positioner

(1)

Bench Range

3-15 psig

(0.2-1.0 bar)

Signal to

Actuator

83000 Valve

D103342X012

With

Positioner

(1)

Table 4. Flow Coefficients (Kv Values [Kv = 0.86 x Cv])

ORIFICE

DIA-

METER

mm

(Inch)mm(Inch)

0.686

(0.027)

1.60

(0.063)

3.81

(0.150)

3.81

(0.150)

9.40

(0.370)

9.40

(0.370)

4

DIA-

PHRAGM

TRAVEL

0.177

(0.007)

0.381

(0.015)

0.304

(0.012)

0.381

(0.015)

Kv AT VALVE OPENING - PERCENT OF VALVE STEM TRAVEL

5 10 20 30 40 50 60 70 80 90 100

0.0000086 0.000086 0.00129 0.0043 0.0065 0.0081 0.0093 0.0101 0.0106 0.0111 0.0117

0.000026 0.000258 0.00344 0.0109 0.0172 0.0235 0.0292 0.0338 0.0387 0.0421 0.0453

0.00017 0.000172 0.00086 0.0049 0.0169 0.0378 0.0608 0.0854 0.1112 0.1353 0.1568

0.00034 0.00172 0.03698 0.0851 0.1419 0.1918 0.2417 0.289 0.326 0.350 0.367

0.0006 0.0267 0.0619 0.124 0.185 0.2546 0.324 0.385 0.446 0.4954 0.5427

0.00086 0.0160 0.1131 0.215 0.316 0.423 0.535 0.624 0.715 0.799 0.877

Page 5

83000 Valve

D103342X012

Table 5. Flow Coefficients

ORIFICE DIAMETER DIAPHRAGM TRAVEL

mm

(Inch)

0.686

(0.027)

1.60

(0.063)

3.81

(0.150)

3.81

(0.150)

9.40

(0.370)

9.40

(0.370)

Table 6. Technical Specifications

VALVE BODY RATING 18.9 bar CWP (275 psi CWP)

NOMINAL SIZE 12.7 mm(NPS 1/2)

CONNECTIONS Tri-Clamp, Standard / Welded Ends, Optional

SEAT LEAKAGE ASME/FCI 70-2, Class IV

BONNET Quick Disconnect

CHARACTERISTIC Modified Equal Percentage

INTERNAL VALVE BODY FINISH

MAXIMUM OPERATING TEMPERATURE 177_C(350_F)

WEIGHT 1.82 kg (4 lbs)

mm

(Inch)

0.177

(0.007)

0.381

(0.015)

0.304

(0.012)

0.381

(0.015)

Product Bulletin

52.1:83SA

December 2014

F

L

0.82

0.7 0.34 0.41

0.76 0.44 0.49

0.95 0.86 0.76

≤ 30 Ra microinch, Standard / ≤ 20 Ra microinch Optional

F

0.5

0.2

d

X

T

0.55 0.56

K

C

Table 7. Actuator Specifications

(1)

TYPE

NOMINAL SIZE 103cm2(16in2)

AIR FAILURE Open or Closed (Field Reversible)

BENCH SPRINGRANGE 0.2 - 0.9 bar (3-13 psi), fail open / 0.2-1.0 bar (3-15 psi) fail closed

TRAVEL 12.7 mm(0.5 inch)

AMBIENT TEMPERATURE RANGE -29 to 71_C (-20 to 160_F)

MAXIMUM AIR PRESSURE 2.4 bar (35 psig)

DIAPHRAGM MATERIAL CR (Chloroprene), TPES (Polyester Thermoplastic)

SPRING CASES

YOKE CF8M Stainless Steel

WEIGHT 2.1 kg (4.6 lbs)

1. Baumann 32 actuator isavailable on a special order b asis. Contact your Emerson Process Management sales office.

16 Multi-Spring Diaphragm (Single Acting)

Steel, Powder Epoxy-Coated Appliance White per

FDA 21 CFR 175.300 with Stainless Steel Fasteners

5

Page 6

Product Bulletin

52.1:83SA

December 2014

83000 Valve

D103342X012

Figure 4. Valve Body Subassembly

96

E1335

(3.79)

mm

(inch)

Figure 6. 83000 with Baumann 16 Actuator and

FIELDVUE DVC6000 Digital Valve Controller

159

(46.25)

212 (8.35)

146 (5.76)

87 (3.41)

TRI-CLAMP

FITTINGS

41 (1.63)

E1336

30 (1.20)

NPS 1/2

VALVE

mm

(inch)

Figure 5. Baumann 16 Actuator with FIELDVUE

DVC2000 Digital Valve Controller

159 (6.3)

83 (3.3)

175

(6.9)

166 (6.52)

E1330

mm

(inch)

Figure 7. Baumann 16 Actuator with FIELDVUE

DVC2000 Digital Valve Controller, Top View

127

(5.01)

166 (6.52)

E1328

mm

(inch)

6

Page 7

83000 Valve

D103342X012

Figure 8. Baumann 16 Actuator with Fisher 3660/3661 Positioner and 67CFR Airset

Product Bulletin

52.1:83SA

December 2014

129 (5.1)

93 (3.7)

39

(1.6)

146

(5.76)

67CFR

E1331

159 (46.25)

Note

The Baumann 16 actuator requires 77 mm (3 inches)

vertical clearance. The Baumann 32 actuator requires 115

mm (4.5 inches) vertical clearance.

3660/3661

POSITIONER

125

(4.9)

mm

(inch)

WARNING

To prevent property damage or personal

injury, you must use an actuator support

when purchasing an actuator with a

FIELDVUE digital valve controller and

mounting sideways.

7

Page 8

Product Bulletin

52.1:83SA

December 2014

Table 8. Model Numbering System

83 SA

Actuator

Size

16 3 0.014 0.012 11 Tri-Clamp SA Angle

(1)

32

1. Contact your Emerson Process Management sales office.

83000

4 0.053 0.046 12 Welded Ends

6 0.182 0.157

7 0.427 0.369

8 0.631 0.546

9 1.02 0.882

Maximum C v

Cv Kv

End Connections Valve Body Style

83000 Valve

D103342X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumesresponsibility for the selection, use or maintenance

of any product. Responsibility forproper selection, use, and maintenance of any productremains solelywith the purchaser and end user.

Baumann, Fisher, FIELDVUE, and PlantWeb are marks owned by one ofthe companies in the Emerson Process Management business unit of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are

the property oftheir respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available uponrequest. Wereserve theright to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2009, 2014 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...