Page 1

Product Bulletin

81000 Valve

D103340X012

52.1:81MS

November 2012

Baumannt 81000 Mikroseal Control Valve

The Baumann 81000 Mikroseal control valve is

excellent for throttling of liquid or gaseous media,

particularly where wide flow variations are

encountered. Its packless design allows for

applications where leakage prone stem packings are

not tolerated.

A nearly frictionless mecha nical force-amplifying

mechanism is employed to reduce the travel of the

pneumatic or electric actuators. This allows the closure

diaphragm to move precisely against the valve orifice

to throttle or stop the passing fluid. The same nearly

frictionless mechanism, composed of stainless steel

and PTFE lined ball bearings and guide bushings,

assures very precise positioning with negligible

deadband. This permits direct operation from remote

mounted I/P (current to pneumatic) signal converters.

Easy removal of the bonnet allows for inspection and

cleaning of the valve seat and closure diaphragm while

the actuator stays attached to the bonnet and the

valve body remains in the line. During this process the

actuator stays in calibration. A backup O-ring prevents

leakage should the primary seal (diaphragm to valve

body) fail. A tell-tale connection in the bonnet yoke

can be utilized to show if the sealing diaphragm is

damaged.

W9846

81000 NPS 1/4 Angle Valve with Baumann 16 Actuator

Features

Compact and light-weight design reduces installed

piping costs

Packless construction

Epoxy powder-coated actuator cases with stainless

steel yoke and fasteners for corrosion resistance

Multi-spring, field-reversible actuator with reduced

deadband permits direct operation from remote

signal devices

Fisherr FIELDVUEt digital valve controller available

for remote calibration and diagnostics in facilities

utilizing PlantWebt architecture

www.Fisher.com

W9847

81000 NPS 1/2 Inline Valve with Baumann 16 Actuator,

and FIELDVUE DVC2000 Digital Valve Controller

Page 2

Product Bulletin

52.1:81MS

November 2012

81000 Valve

D103340X012

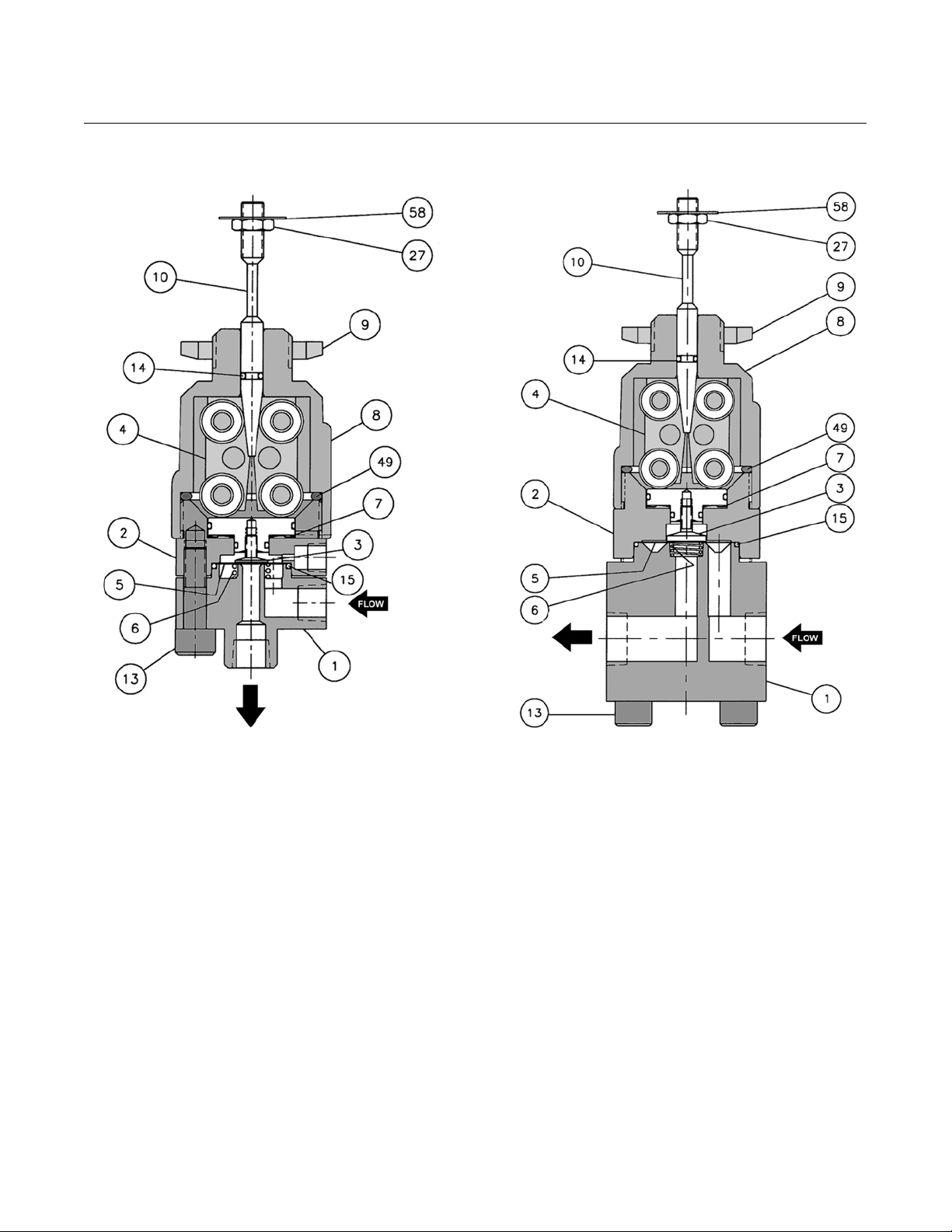

Figure 1. Baumann 81000 NPS 1/4 Angle Valve Body

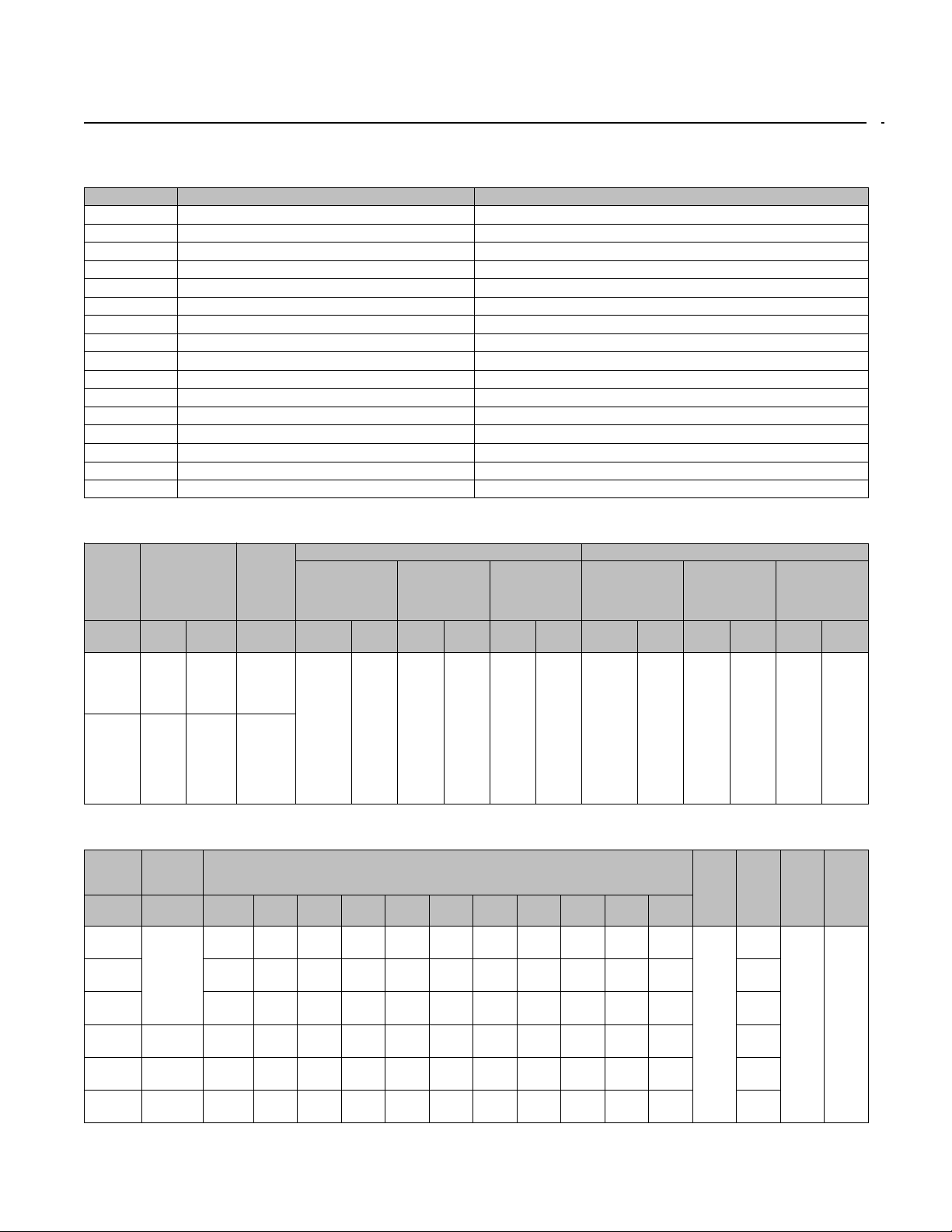

Figure 2. Baumann 81000 NPS 1/2 Inline Valve Body

E1324

Specifications

See table 4 for technical specifications and table 5 for

actuator specifications.

2

E1325

Page 3

81000 Valve

D103340X012

Table 1. Materials of Construction

Key Number Description Material

1 Valve Body S31600 SST, standard / ASTM B575 N06022, optional

2 Bonnet Yoke S31600 SST

3 Piston Subassembly S30300 SST and FKM (Fluorocarbon)

4 Bearing Cartridge Subassembly Stainless Steel and PTFE (Polytetrafluoroethylene)

5 Closure Diaphragm S31600 SST, standard / N10276 Nickel Alloy, optional

6 Seat Spring ASTM B575 N06022

7 Wave Spring S17700 SST

8 Bonnet ASTM A743 CF8

9 Drive Nut, Yoke S30400 SST

10 Plunger ASTM A276 S31600 Condition A

13 Allen head Bolts Stainless Steel (18-8 SST)

14 O-Ring, Plunger FKM (Fluorocarbon)

15 O-Ring PTFE, FDA 21 CFR 177 (Polytetrafluoroethylene)

27 Jam Nut Stainless Steel (18-8 SST)

49 O-Ring FKM (Fluorocarbon)

58 Travel Indicator Disk ASTM A240 S30400

Product Bulletin

52.1:81MS

November 2012

Table 2. Allowable Pressure Drops

AIR-TO-OPENACTION AIR-TO-CLOSE ACTION

VALVE

SIZE

NPS

(mm)

1/4

(6.35)

1/2

(12.7)

PLUG

Cv Kv

0.01

0.0009

0.03

0.10

0.30

0.01

0.0009

0.03

0.10

0.30

0.50

0.70

0.026

0.086

0.259

0.026

0.086

0.259

0.43

0.60

PLUG

TRAVEL

mm

(inch)

12.7

(0.50)

12.7

(0.50)

Bench Range

bar psig bar psig bar psig bar psig bar psig bar psig

0.2-1.0 3-15 10 150 19 275 0.2- 0.9 3-13 10 150 19 275

3-15 psig

(0.2-1.0 bar)

Signal to

Actuator

Table 3. Flow Coefficients (ASME/ISA/IEC) and ISA Sizing Factors

ORIFICE

DIA-

METER

mm

(Inch)mm(Inch)

0.635

(0.025)

1.60

(0.063)

7.92

(0.312)

7.92

(0.312)

13.2

(0.520)

13.2

(0.520)

DIA-

PHRAGM

TRAVEL

0.177

(0.007)

0.381

(0.015)

0.304

(0.012)

0.381

(0.015)

Cv AT VALVE OPENING - PERCENT OF VALVE STEM TRAVEL

5 10 20 30 40 50 60 70 80 90 100

0.00001 0.0001 0.0010 0.0024 0.0038 0.0052 0.0066 0.0076 0.0084 0.0092 0.01

0.00003 0.0003 0.002 0.005 0.009 0.013 0.017 0.021 0.024 0.027 0.03 0.50

0.0002 0.001 0.010 0.030 0.050 0.060 0.068 0.076 0.084 0.092 0.10 0.20

0.0004 0.002 0.020 0.070 0.120 0.150 0.180 0.210 0.240 0.270 0.30 0.20

0.0007 0.003 0.040 0.100 0.150 0.200 0.250 0.310 0.370 0.430 0.50 0.20

0.001 0.005 0.070 0.160 0.220 0.300 0.380 0.460 0.540 0.620 0.70 0.20

With

Positioner

Bench Range

3-15 psig

(0.2-1.0 bar)

Signal to

Actuator

F

L

0.50

0.85

F

d

With

Positioner

X

K

T

0.61 0.61

C

3

Page 4

Product Bulletin

52.1:81MS

November 2012

Table 4. Technical Specifications

VALVE BODY RATING 18.9 bar CWP (275 psi CWP)

NOMINAL SIZE 6.35 mm or 12.7 mm (NPS 1/4 or 1/2)

CONNECTIONS NPT (Flanged or Welded Ends Optional)

SEAT LEAKAGE ASME/FCI 70-2, Class IV

BONNET Bolted

CHARACTERISTIC Modified Equal Percentage

MAXIMUM OPERATING TEMPERATURE 177_C(350_F)

WEIGHTS

Table 5. Actuator Specifications

NOMINAL SIZE 103cm2(16in2)

AIR FAILURE Open or Closed (Field Reversible)

BENCH SPRING RANGE 0.2 - 0.9 bar (3-13 psi), fail open / 0.2-1.0 bar (3-15 psi) fail closed

TRAVEL 12.7 mm (0.5 inch)

AMBIENT TEMPERATURE RANGE -29 to 71_C(-20to160_F)

MAXIMUM AIR PRESSURE 2.4bar(35psig)

DIAPHRAGM MATERIAL CR (Chloroprene), TPES (Polyester Thermoplastic)

SPRING CASES

WEIGHT 2.1 kg (4.6 lbs)

6.35 mm (1/4 inch) 1.35 kg (3 lbs)

12.7 mm (1/2 inch) 1.82 kg (4 lbs)

TYPE 16 Multi-Spring Diaphragm (Single Acting)

YOKE CF8M Stainless Steel

81000 Valve

D103340X012

Steel, Powder Epoxy-Coated Appliance White per

FDA 21 CFR 175.300 with Stainless Steel Fasteners

4

Page 5

81000 Valve

(

)

D103340X012

Product Bulletin

52.1:81MS

November 2012

Figure 3. 81000 Angle Valve with Baumann 16

Actuator and FIELDVUE DVC6000 Digital Valve

Controller

159

(46.25)

1/4 NPT

24 (0.94)

54

(42.13)

E1326

1/4 NPT

mm

(inch)

145

(5.75)

81

(3.17)

Figure 4. 81000 Inline Valve with Baumann 16

Actuator and FIELDVUE DVC6000 Digital Valve

Controller

159

1/4 NPT

1/2 NPT

E1327

(46.25)

62

(2.45)

212

(8.35)

146

(5.75)

108

(4.25)

35

(1.36)

mm

inch

5

Page 6

Product Bulletin

52.1:81MS

November 2012

81000 Valve

D103340X012

Figure 5. Baumann 16 Actuator with FIELDVUE

DVC2000 Digital Valve Controller, Top View

127

(5.01)

166 (6.52)

E1328

Note: Baumann 16 actuator requires 77mm (3 inches) vertical clearance.

mm

(inch)

Figure 7. Baumann 16 Actuator with FIELDVUE

DVC2000 Digital Valve Controller

159 (6.3)

83 (3.3)

175

(6.9)

mm

E1330

Note: Baumann 16actuator requires 77mm (3 inches) vertical clearance.

166 (6.52)

(inch)

Figure 6. Baumann 16 Actuator with FIELDVUE

DVC6000 Digital Valve Controller, Top View

R235

(R9.24)

123

(4.86)

212

(8.35)

E1329

Note: Baumann 16 actuator requires 77mm (3 inches) vertical clearance.

mm

(inch)

Figure 8. Baumann 16 Actuator with Fisher

3660/3661 and 67CFR Airset

129 (5.1)

93 (3.7)

39

(1.6)

146

(5.76)

67CFR

E1331

Note: Baumann 16actuator requires 77mm (3 inches) vertical clearance.

159

(46.25)

3660/3661

POSITIONER

125

(4.9)

mm

(inch)

6

Page 7

81000 Valve

D103340X012

Table 6. Model Numbering System

16 81 2

Actuator

Size

16 3 0.01 0.009 0

81000

Maximum Cv

Cv Kv

4 0.03 0.026 3 Special H

6 0.10 0.086

7 0.30 0.259

8 0.50 0.43

9 0.70 0.60

End Connections

Screwed (NPT) /

Flangeless

Product Bulletin

52.1:81MS

November 2012

Bonnet

Construction

2 Bolted S 316 SST A Angle

Valve Body

Material

N06022

Nickel Alloy

Valve Body Style

I Inline

7

Page 8

Product Bulletin

52.1:81MS

November 2012

81000 Valve

D103340X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Baumann, Fisher, FIELDVUE, and PlantWeb are marks owned by one of the companies inthe Emerson Process Management business unit of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while everyeffort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2009, 2012 Fisher Controls InternationalLLC.Allrights reserved.

8

Loading...

Loading...