Page 1

655 Actuator

D100148X012

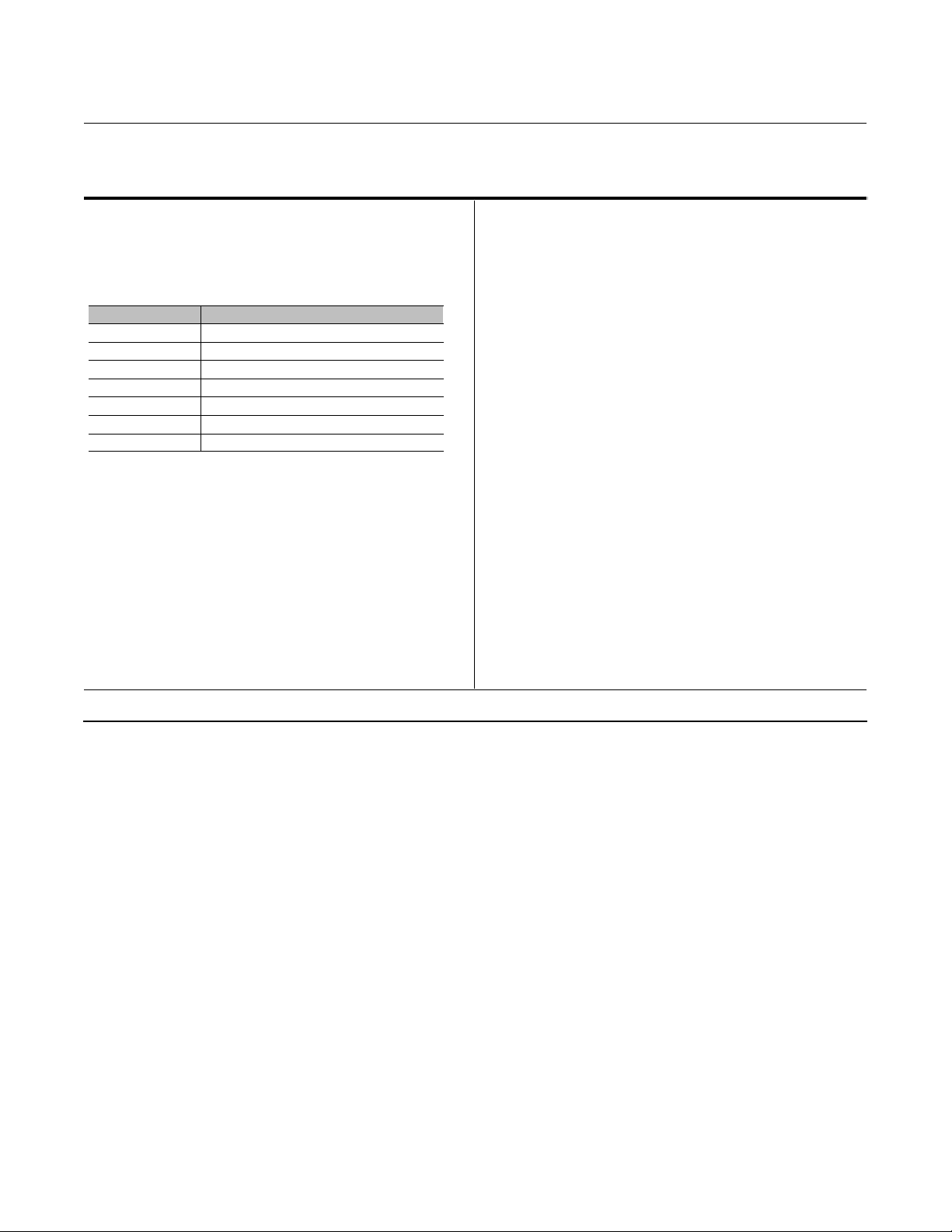

Fisherr 655 and 655R Actuators

for Self-Operated Control

Fisher 655 and 655R diaphragm actuators, in

combination with Fisher valves, provide control for a

wide variety of pressure regulation applications. The

655 is used for pressure reduction service on

push-down-to-close valves, and the 655R is primarily

for pressure relief use on push-down-to-open valves.

These actuators may be either self-operated or

remote-loaded.

Product Bulletin

61.9:655

December 2012

Features

Versatility–Typical industrial service includes

pressure control of water, steam, oil, gas, and other

fluids. Actuators can be operated by pneumatic

switches, solenoid valves, pilot valves, or remote

panel loaders for shutoff service.

Large Valve Body Selection–easy-e valves up

throughtheNPS4(NPS6forFisherEAanglevalves)

with wide choice of end connections, flow

directions, flow characteristics, valve plug designs,

and seating constructions can be specified.

Broad Actuator Spring Selection–Spring of the

proper rate is available for nearly any control valve

application. Spring selection procedure is quick and

accurate.

Severe Service Capability–Rugged yoke and casings

help provide stability and corrosion protection.

Fast Acting– Direct-operated configuration

provides faster speed of response.

W2239

Fisher 655R on Reverse-acting easy-et Valve Body

W0451-1

Fisher 655-ED Construction Details

www.Fisher.com

Page 2

Product Bulletin

61.9:655

December 2012

Specifications

655 Actuator

D100148X012

Maximum Actuator Temperature Capability

150_F with standard diaphragm material

(1)

Actuator Travel Information

Maximum Rated Travels:

Sizes 3A and 4A: 0.4375 inch plus 0.125 inch for

Actuator Sizes and Maximum Casing Ratings

Size Maximum Casing Pressure, Psig

3A, 4A 250

3B, 4B 175

32, 42 100

33, 43 65

34, 44 45

35, 45 30

36, 46 15

seating

All Other Sizes: 0.75 inch plus 0.125 inch for seating

Other Travel Information: Seetables3,1,and2

Effective Diaphragm Areas

See table 2

Actuator Construction Materials

See table 4

Valve Body Flow Coefficients

See Fisher Catalog 12

Actuator Pressure Setting Ranges

655: See table 3

655R: See table 1

Actuator Casing Connection

1/2 - 14 NPT

Actuator Options

Actuator Yoke Boss Diameters and Valve Stem

Connections

Sizes 3A-36:

J 2-1/8 inch yoke boss with J 3/8 inch

stem connection

Sizes 4A-46:

J 2-13/16 inch yoke boss with J 1/2

inch stem connection

1. Consult your Emerson Process Management sales office for fluidand temperature capabilities of nonstandard diaphragm materials.

J Travel indicator

J Casing-mounted handwheel/adjustable travel stop

J Steel upper diaphragm for sizes A and B

J PTFE diaphragm protectors

J Fluorocarbon diaphragm for high temperature

service (up to 149_C[300_F])

2

Page 3

655 Actuator

D100148X012

Product Bulletin

61.9:655

December 2012

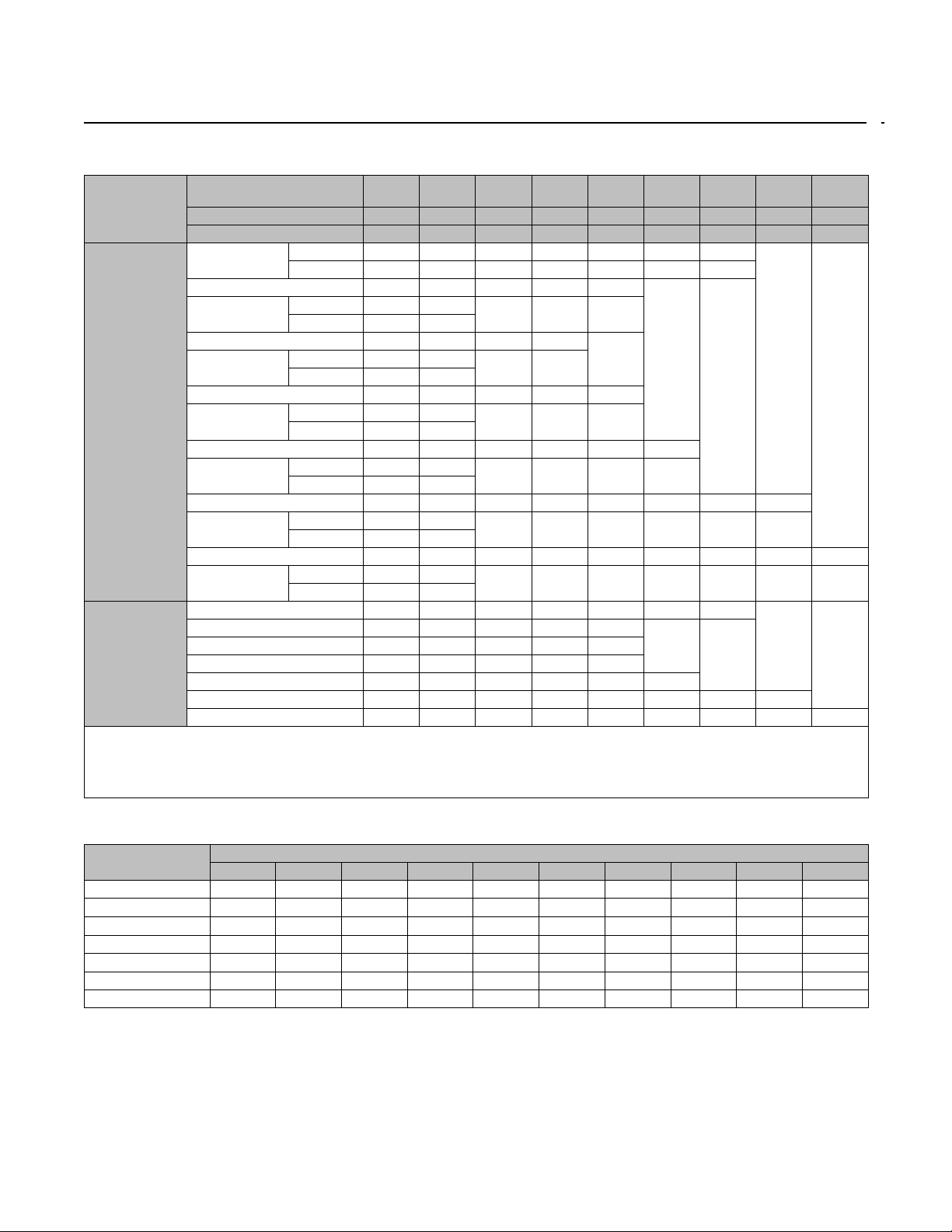

Table 1. Fisher 655R Pressures and Sensitivities at 0.4375 Inch Maximum Travel

SPRING

INFORMATION

PAR T N UMB E R

1E7933

27082

Spring Rate, Pounds per Inch 2100 1770 1470 830 612 490 368 246 123

1E7954

27082

1E7924

27082

1F7143

27092

(1)

(Relief Service)

1F1769

27092

Safe Load, Pounds 3045 2600 2200 1630 1170 1060 843 545 290

NA

(3)

(3)

(4)

(4)

(4)

(4)

(4)

(4)

(3)

Sizes 3A and 4A

Minimum NA

Maximum

(2)

Minimum, Sizes 3B and 4B 43

Maximum

(2)

Size 3B 64 64

Size 4B 89 77

Minimum, Sizes 32 and 42 26

Size 32 38 38

Size 42 53 45

Size 33 24 24

Size 43 33 28

Size 34 16 16

Size 44 23 19

Actuator

Pressure

Settings

Ranges, Psig

Maximum

(2)

Minimum, Sizes 33 and 43 16

Maximum

(2)

Minimum, Sizes 34 and 44 11

Maximum

(2)

Minimum, Sizes 35 and 45 7

Maximum

(2)

Size 35 11 11

Size 45 15 13

Minimum, Sizes 36 and 46 5

Maximum

(2)

Size 36 7.7 7.7

Size 46 10.5 9

Sizes 3A and 4A NA

Actuator

Sensitivities,

Inches of

Travel

Obtained

per Psig of

(7)

Change

1. Effects of packing box friction, unbalance & weight of valveplug not considered incalculations.

2. Greatest allowable pressure (with the value closed) that will not exceed the safe load of theactuator spring but willstill allow0.4375 inch travel.

3. This spring-actuatorsize combination not available.

4. Least pressure required (at 0.25 inch travel) to assure 1/8inch spring compression.

5. Least pressure required (at 0.25 inch travel)to assure 200 poundsof seating force.

6. Limited by adjusting screw.

7. Average for minimum and maximum pressures at zero and 0.25 inch travel.

Sizes 3Band 4B .0087 .0103 .0124 .0209 .0286

Sizes 32and 42 .013 .015 .018 .0294 NA

Size 33 and 43 .022 .026 .031 .051 .069

Sizes 34and 44 .033 .039 .046 .078 .104 .128

Sizes 35and 45 .052 .061 .076 .126 .169 .214 .278 .416

Sizes 36and 46 .076 .089 .106 .183 .250 .309 .410 .603 1.19

NA

NA

35

22

13

5.5

4.2

NA

(3)

(3)

(4)

65

(4)

43

(5)

37

(5)

146 119 85 75 57

29

(4)

19

(5)

17

(5)

64 53 38

(4)

(4)

(4)

9

18

(4)

12

(5)

38 31

11

(4)

(5)

7

24 20 14.5

(4)

7

(5)

5

NA

6.5

(3)

(5)

(6)

(5)

4

16 13 10 7.9

(4)

(4)

5

3.2

(5)

2.8

(5)

11 9 6.3 5.5

(4)

3.5

(4)

2.3

(5)

(5)

2

7.7 6.3 4.5 4

(3)

.0064 .0098 .0131 .0163 .0216

(3)

1F1768

27092

(5)

34

(3)

NA

(5)

4.1

(6)

(5)

2.5

(6)

(5)

1.8

(6)

(3)

NA

1F1767

27032

(5)

20

(3)

NA

(5)

1.5

(6)

4.2

(5)

1.1

(6)

3

(3)

NA

1F7144

27112

(3)

NA

(5)

1.3

(6)

2.8

(5)

.9

(6)

2

(3)

NA

1F7130

27112

(3)

NA

(5)

.7

(6)

1

(3)

NA

Table 2. Effective Diaphragm Area, Square I nches

ACTUATOR SIZE

0 0.125 0.1875 0.25 0.375 0.4375 0.5 0.5625 0.75 0.875

3A, 4A 10.2 9.6 9.5 9.4 9.2 9.1 8.9 8.7 7.4 6

3B, 4B 23.5 21.6 21.1 20.8 20.5 20.3 20.1 19.8 18.1 16

32, 42 40 36.4 35.2 34.2 32.6 31.8 31 30.3 28.2 26.4

33, 43 63 58 56.8 55.5 53.5 52.7 52 51.2 49.3 47.6

34, 44 93 84.8 82.8 81 78.8 77.8 77 76 73.5 72

35, 45 134 129.2 127.2 125.4 122.2 120.5 119 117.6 114.1 112

36, 46 190 181.5 179 177 173.5 172.3 171 169.8 166.5 163.5

INCHES TRAVEL DOWN FROM UPPER CASING STOP

3

Page 4

Product Bulletin

61.9:655

December 2012

655 Actuator

D100148X012

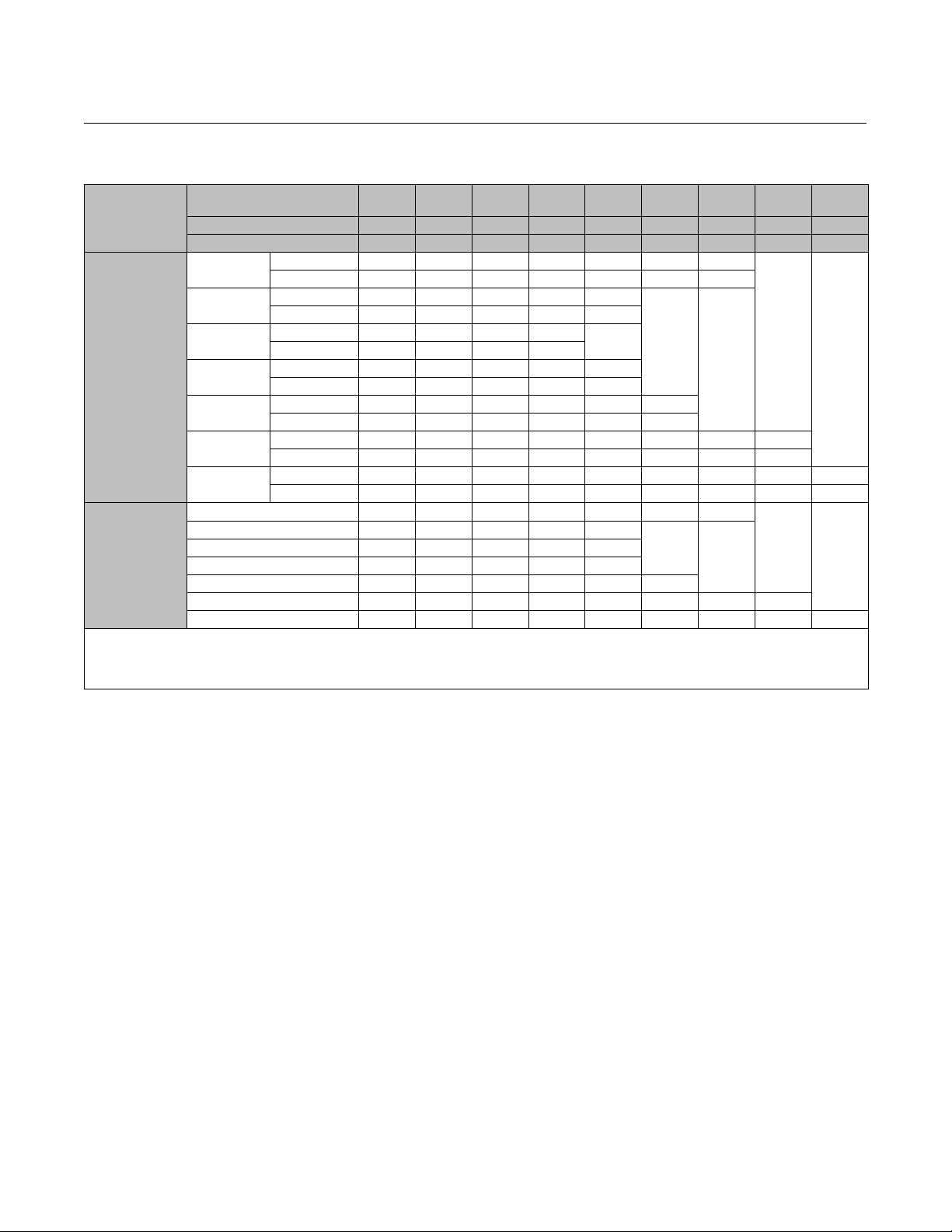

Table 3. Fisher 655 Pressures and Sensitivities at 0.4375 Inch Maximum Travel

SPRING

INFORMATION

Actuator

Pressure

Setting

Ranges, Psig

Actuator

Sensitivities,

Inches of

Travel

Obtained

per Psig of

(6)

Change

1. Effects of packing box friction, unbalance & weight of valveplug not considered incalculations.

2. Least pressure required to seat the valveand still allow 0.4375 inch travel when the pressure is released.

3. Greatest allowable pressure (at 0.25 inch travel)that will let thevalve be stroked closedwithout exceeding the safeload of the actuatorspring.

4. This spring-actuatorsize combination not available.

5. Limited by adjusting screw.

6. Average for minimum and maximum pressures at zero and 0.25 inch travels.

PART NUMBER

Spring Rate, Pounds per Inch 2100 1770 1470 830 612 490 368 246 123

Safe Load, Pounds 3045 2600 2200 1630 1170 1060 843 545 290

Sizes 3A

and 4A

Sizes 3B

and 4B

Sizes 32

and 42

Sizes 33

and 43

Sizes 34

and 44

Sizes 35

and 45

Sizes 36

and 46

Sizes 3A and 4A NA

Sizes 3B and 4B 0.0087 0.0103 0.0126 0.0217 0.029

Sizes 32 and 42 0.012 0.014 0.017 0.028 NA

Sizes 33 and 43 0.021 0.026 0.031 0.050 0.069

Sizes 34 and 44 0.032 0.037 0.045 0.076 0.104 0.132

Sizes 35 and 45 0.055 0.059 0.072 0.121 0.167 0.200 0.264 0.380

Sizes 36 and 46 0.075 0.086 0.106 0.183 0.244 0.303 0.400 0.610 1.21

Minimum

Maximum

Minimum

Maximum

Minimum

Maximum

Minimum

Maximum

Minimum

Maximum

Minimum

Maximum

Minimum

Maximum

1E7933

27082

(2)

NA

(3)

NA

(2)

(3)

(2)

(3)

(2)

(3)

(2)

(3)

27.5 23.4 20 15.5 11 8.5

(2)

(3)

17.8 15.2 13 10 7.2 5.9

(2)

(3)

12.7 10.8 9.2 7.1 5.1 4.2

1E7954

27082

(4)

NA

(4)

NA

50 42 35 20 14

107 92 78 60 43

32 26 22 12

65 55 47 36

19 16 14 7 5.2

40 34 29 22 16

13 11 9 5 3.8 2.8

8.3 7 5.8 3.3 2.4 2 1.5 1

5.8 4.9 4.1 2.3 1.7 1.3 1 0.7 0.34

(4)

NA

1E7924

27082

(4)

(4)

174 135 96 78

(4)

0.0055 0.0095 0.0121 0.0161 0.0212

1F7143

27092

78 44 32 26 19

(1)

(Reducing Service)

1F1769

27092

(4)

NA

(4)

1F1768

27092

(5)

(4)

NA

(5)

(5)

(4)

NA

1F1767

27032

(5)

59

(4)

NA

(5)

4.4

(5)

3.1

(4)

NA

1F7144

27112

(4)

NA

(5)

2.9

(5)

2.1

(4)

NA

1F7130

27112

(4)

NA

(5)

1.1

(4)

NA

Installation

These regulators may be installed in any position, as

orientation is not a problem. But for steam service, the

control line should be installed so that condensate

drains back into the diaphragm casing, thus

maintaining a water seal on the diaphragm. A strainer

(such as the Fisher 262K) is always recommended

ahead of the valve body to protect body and trim from

damaging particles.

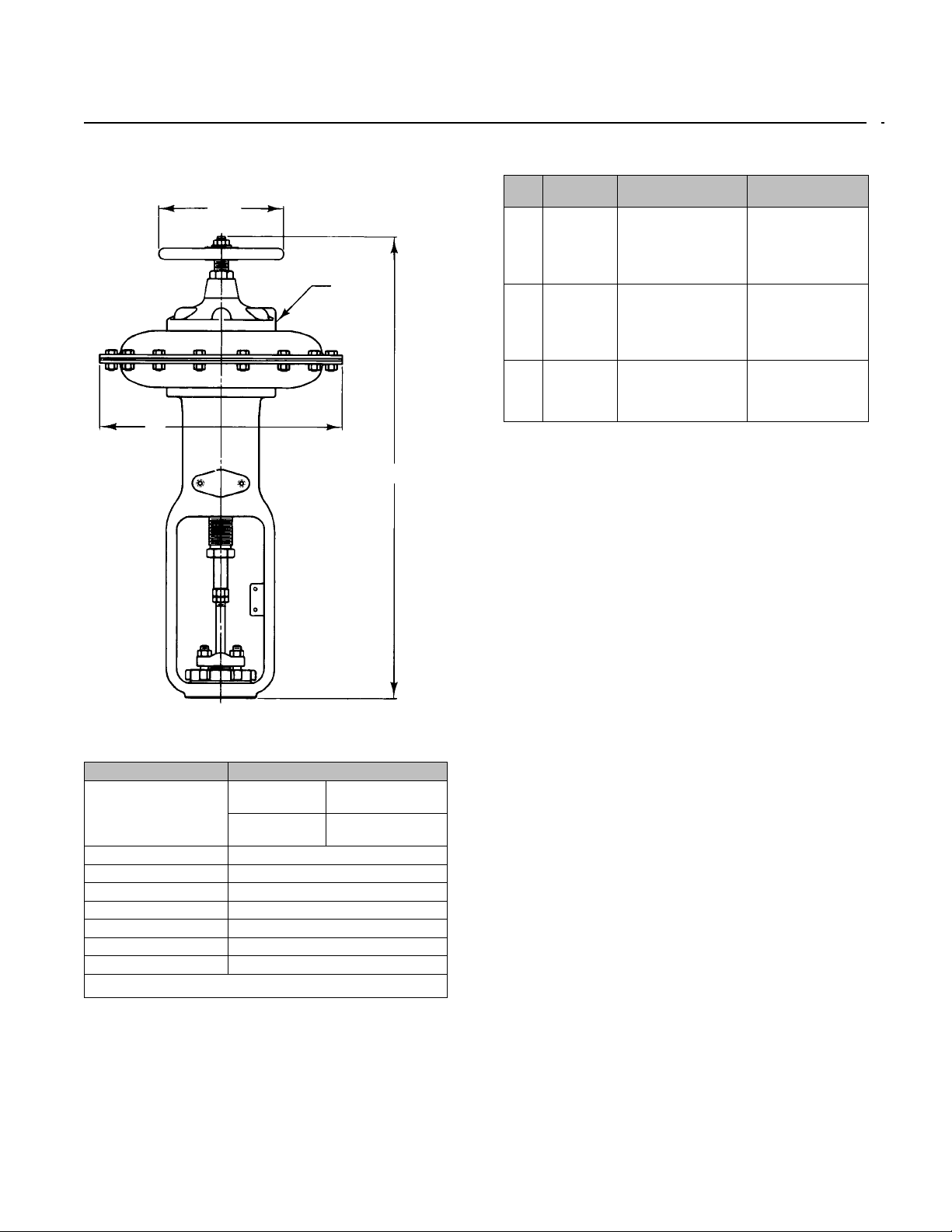

Dimensions are given in figure 1. Refer to the

appropriate instructions before installing the

regulator.

Ordering Information

When ordering, specify:

4

1. All information requested in the Ordering

Information section of the valve body bulletin.

2. Actuator type number and size

3. Actuator travel

4. Valve plug stem diameter and connection size

5. Desired regulator orientation in pipeline

6. Magnitude and type of remote loading pressure, if

applicable (for instance, 3-15 psig controller output

signal)

7. Desired actuator options

Page 5

655 Actuator

D100148X012

Product Bulletin

61.9:655

December 2012

Figure 1. Actuator Dimensions, Inches

(also see table 5)

6.75

C

1/2 - 14

NPT

Table 5. Actuator Dimension, Inches

SIZE

3A

3B

32

33

34

35

36

4A

4B

42

43

44

45

46

E

C

DIAMETER

5.88

9.00

9.88

11.38

13.12

16.00

18.62

5.88

9.00

9.88

11.38

13.12

16.00

18.62

Without Handwheel With Handwheel

17.56

18.19

17.81

17.81

18.44

19.19

19.19

19.50

20.12

19.75

19.75

20.38

21.12

21.12

22.44

24.50

23.00

23.00

23.62

24.38

24.38

24.38

26.44

24.94

24.94

25.56

26.31

26.31

Total Capability of Fisher

655-ED

The following charts (figures 2 through 11) show the

complete capability of the 655-ED, including travels

greater than 0.25 inch. Included are charts for C

and C

for the ED valves of various sizes and charts for

s

various casing sizes for the 655 actuator.

v,Cg

,

AV6711-A

A1417

Table 4. Actuator Construction Materials

Part Material

Sizes 3A, 3B, 4A,

Diaphragm casings

Yoke Cast iron standard, steel available

Spring Steel alloy

Spring seat Forged steel

Travel stop Steel

Diaphragm plate Cast iron

Diaphragm CR (Chloroprene) (standard)

Stem and adjusting screw Steel, cadmium plated

1. Consult your Emerson Process Management salesoffice for fluid and temperature

capabilities of nonstandarddiaphragm materials.

and 4B

All othersizes

Cast ironstandard,

steel available

Pressed steel,

zinc plated

(1)

Anexampleontheuseofthechartsfollows:

1. Refer to the chart showing the C

Assume your customer says his normal C

for the ED design.

v

is 37, but

v

can vary from 30 to 44 and the customer wants to

control at 110 psi. The NPS 2 will fit this quite well and

atthetopofthechartyouwillnoticethatthisrequires

a travel from 0.25 inch to 0.375 inch with the normal

travel at 0.3125 inch.

2. Next, refer to the curve on the 655-ED, A-CASING

chart of diaphragm pressure versus valve travel. Enter

the chart at 0.3125 inch valve travel and proceed up

until you intersect the 110 psi pressure. You will note

that spring drawing 1F7143 is at this intersection. You

can then readily see that when the flows vary, the

pressure will vary from approximately 118 psi to 105

psi as the valve travels from 0.25 inch to 0.375 inch.

5

Page 6

Product Bulletin

61.9:655

December 2012

Figure 2. ED Design, Liquid Flow

655 Actuator

D100148X012

1

1-1/2

2

ED

VALVE

SIZE,

NPS

2-1/2

3

0

0

0

0

0

0

0.0625 0.125

4.2 7.7 11.5

50.7 12.3

7.4

9.8 18.0 25.6

12.1 23.4 32.2

14.7 22.5

0.1875

17.4

0.25 0.3125 0.375

TRAVEL (INCHES)

14.7

22.7

29.9 37.2

33.2 41.4

43.5

17.2

27.7 32.1

53.9 65.2

18.9 20.1

44.2

49.1

0.4375

35.7

50.1

57.2

75.7

4

0

16.3

27.6

36.4

46.4

57.7

70.3 82.8

6

0

A7057

6

23.0

43.7 66.7 92.0

C

v

112.7

133.0

163.6

Page 7

655 Actuator

D100148X012

Figure 3. ED Design, Gas Flow

Product Bulletin

61.9:655

December 2012

1

1-1/2

2

ED

VALVE

SIZE,

NPS

2-1/2

0

0

0

0

0

0.0625 0.125

119

184 374

221 465 735 1005

282

264

563

0.1875

392

571

807

0.25 0.3125 0.375

TRAVEL (INCHES)

494 563

748 911 1061 1176

1274

1074 1372 1690

600

1531 1776

0.4375

619

1971

A7058

3

0

342 709

1027

1394 1760 2201

2592

4

0

460 837 1130

1465

1841

2302

2804

6

0

620 1395 2170 2945

C

g

3978

4573

5425

7

Page 8

Product Bulletin

61.9:655

December 2012

Figure 4. 655 ED, A Casing, Diaphragm Pressure versus Valve Travel

280

240

655 Actuator

D100148X012

MAX SPRINGADJ

MIN SPRING ADJ

200

160

PRESSURE

(PSIG)

120

80

40

0

SEATED

0.0625 0.125

0.1875

0.25

0.3125

0.375

SPRING

PART

NUMBER

1E7924

1E7953

1F7143

1E7923

1F1769

1F1768

(2.45 PSIG)

0.4375

TRAVEL (INCHES)

A7059

MAX, MIN CURVES POSITIONED RESPECTIVELY

8

Page 9

655 Actuator

D100148X012

Figure 5. ED Design, Steam Flow

Product Bulletin

61.9:655

December 2012

1

1-1/2

2

ED

VALVE

SIZE,

NPS

2-1/2

0

0

0

0

0

0.0625 0.125

6.0

9.2 18.7 28.6

11.1

14.1 28.2 40.4 53.7

12.8

23.3 36.8

0.1875

19.6

0.25 0.3125 0.375

TRAVEL (INCHES)

24.7

37.4

50.3

28.2

45.6 53.1

63.7 76.6 88.8

68.6

30.0

84.5

0.4375

31.0

58.8

98.6

3

4

6

A7060

0

0

0

17.1

23.0

31.0

35.5

41.9 56.5 73.3 84.6 115.1

69.8

51.4

108.5

69.7

147.3

C

s

88.0

198.9

110.1 129.6

140.2

228.7

271.3

9

Page 10

Product Bulletin

61.9:655

December 2012

Figure 6. 655 ED, B Casing, DiaphragmPressureversusValveTravel

200

175

150

655 Actuator

D100148X012

MAX SPRINGADJ

MIN SPRING ADJ

125

100

PRESSURE

(PSIG)

75

50

25

0

SEATED

0.0625 0.125

0.1875

0.25

0.3125 0.375

SPRING

PART

NUMBER

1P7888

1E7933

1E7954

1E7924

1F7143

1F1769

(1.06 PSIG)

0.4375

10

TRAVEL (INCHES)

A7061

MAX, MIN CURVES POSITIONED RESPECTIVELY

Page 11

655 Actuator

D100148X012

Figure 7. 655 ED, #20 Casing, Diaphragm Pressure versus Valve Travel

160

140

120

100

Product Bulletin

61.9:655

December 2012

MAX SPRINGADJ

MIN SPRING ADJ

PRESSURE

(PSIG)

A7062

80

60

40

20

0

SEATED

0.0625 0.125

0.1875

TRAVEL (INCHES)

0.25

0.3125 0.375

MAX, MIN CURVES POSITIONED RESPECTIVELY

SPRING

PART

NUMBER

1E7933

1E7954

1E7924

1F7143

1F1769

(0.63 PSIG)

0.4375

11

Page 12

Product Bulletin

61.9:655

December 2012

Figure 8. 655 ED, #30 Casing, Diaphragm Pressure versus Valve Travel

80

70

60

655 Actuator

D100148X012

MAX SPRING ADJ

MIN SPRING ADJ

PRESSURE

(PSIG)

50

40

30

20

10

0

SEATED

0.0625 0.125

0.1875

0.25

0.3125 0.375

SPRING

PART

NUMBER

1E7933

1E7954

1E7924

1F7143

1F1769

(0.40 PSIG)

0.4375

12

A7063

TRAVEL (INCHES)

MAX, MIN CURVES POSITIONED RESPECTIVELY

Page 13

655 Actuator

D100148X012

Figure 9. 655 ED, #40 Casing, Diaphragm Pressure versus Valve Travel

40

35

30

25

Product Bulletin

61.9:655

December 2012

MAX SPRINGADJ

MIN SPRING ADJ

SPRING

PART

NUMBER

1E7933

PRESSURE

(PSIG)

A7064

20

15

10

5

0

SEATED

0.0625 0.125

0.1875

TRAVEL (INCHES)

0.25

0.3125 0.375

MAX, MIN CURVES POSITIONED RESPECTIVELY

1E7954

1E7924

1F7143

1F1769

(0.27 PSIG)

0.4375

13

Page 14

Product Bulletin

61.9:655

December 2012

Figure 10. 655 ED, #50 Casing, Diaphragm Pressure versus Valve Travel

40

35

30

25

20

PRESSURE

(PSIG)

655 Actuator

D100148X012

MAX SPRINGADJ

MIN SPRING ADJ

SPRING

PART

NUMBER

A7065

15

10

5

0

SEATED

0.0625 0.125

0.1875

TRAVEL (INCHES)

0.25

0.3125 0.375

MAX, MIN CURVES POSITIONED RESPECTIVELY

1E7933

1E7954

1E7924

1F7143

1F1769

1F1768

1F1767

1F7144

(0.19 PSIG)

0.4375

14

Page 15

655 Actuator

D100148X012

Figure 11. 655 ED, #60 Casing, Diaphragm Pressure versus Valve Travel

20

15

Product Bulletin

61.9:655

December 2012

MAX SPRING ADJ

MIN SPRING ADJ

SPRING

PART

NUMBER

1E7933

PRESSURE

(PSIG)

A7066

10

5

0

SEATED

0.0625 0.125

0.1875

TRAVEL (INCHES)

0.25

0.3125 0.375

MAX, MIN CURVES POSITIONED RESPECTIVELY

1E7954

1E7924

1F7143

1F1769

1F1768

1F1767

1F7144

1F7130

(0.13 PSIG)

0.4375

15

Page 16

Product Bulletin

61.9:655

December 2012

655 Actuator

D100148X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for properselection, use,and maintenanceof any product remains solely with the purchaser and end user.

Fisher andeasy-e are marks owned by one ofthe companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which areavailable upon request. We reserve the right to modify or improve thedesigns or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1997, 2012 Fisher Controls International LLC. All rights reserved.

16

Loading...

Loading...