Page 1

Product Bulletin

646 Transducer

D101374X012

February 2015

Fisherr 646 Electro-Pneumatic Transducer

62.1:646

The Fisher 646 electro-pneumatic transducer uses a

converter module that converts a 4 to 20 milliampere

input signal to a proportional 0.2 to 1.0 bar (3 to

15 psig) pneumatic output signal. The converter

module uses small parts of minimum mass, which are

balanced symmetrically around a pivot point at the

center of the mass. This balanced arrangement results

in a high performance instrument that reduces

sensitivity to vibration.

An integral pneumatic relay provides the high capacity

necessary to drive pneumatic control valve/acutator

assemblies without additional boosters or positioners.

The transducer also provides stable, accurate

operation when its output is transmitted to small

volume chambers, such as a pneumatic positioner or

other pneumatic instrument. Reduced sensitivity to

vibration combined with high capacity and first order

lag characteristics make the 646 transducer ideal for

direct mounting on control valve/actuator

combinations.

Connectors and piping can be installed with each 646

transducer for diagnostic testing.

FISHER 646 ELECTRO-PNEUMATIC TRANSDUCER

WITH FISHER 657 ACTUATOR AND E VALVE

www.Fisher.com

W6783-1

W4908-1

FISHER 646 ELECTRO-PNEUMATIC TRANSDUCER

Page 2

Product Bulletin

62.1:646

February 2015

Specifications

646 Transducer

D101374X012

Input Signal

4 to 20 mA DC, constant current with 30 VDC

maximum compliance voltage

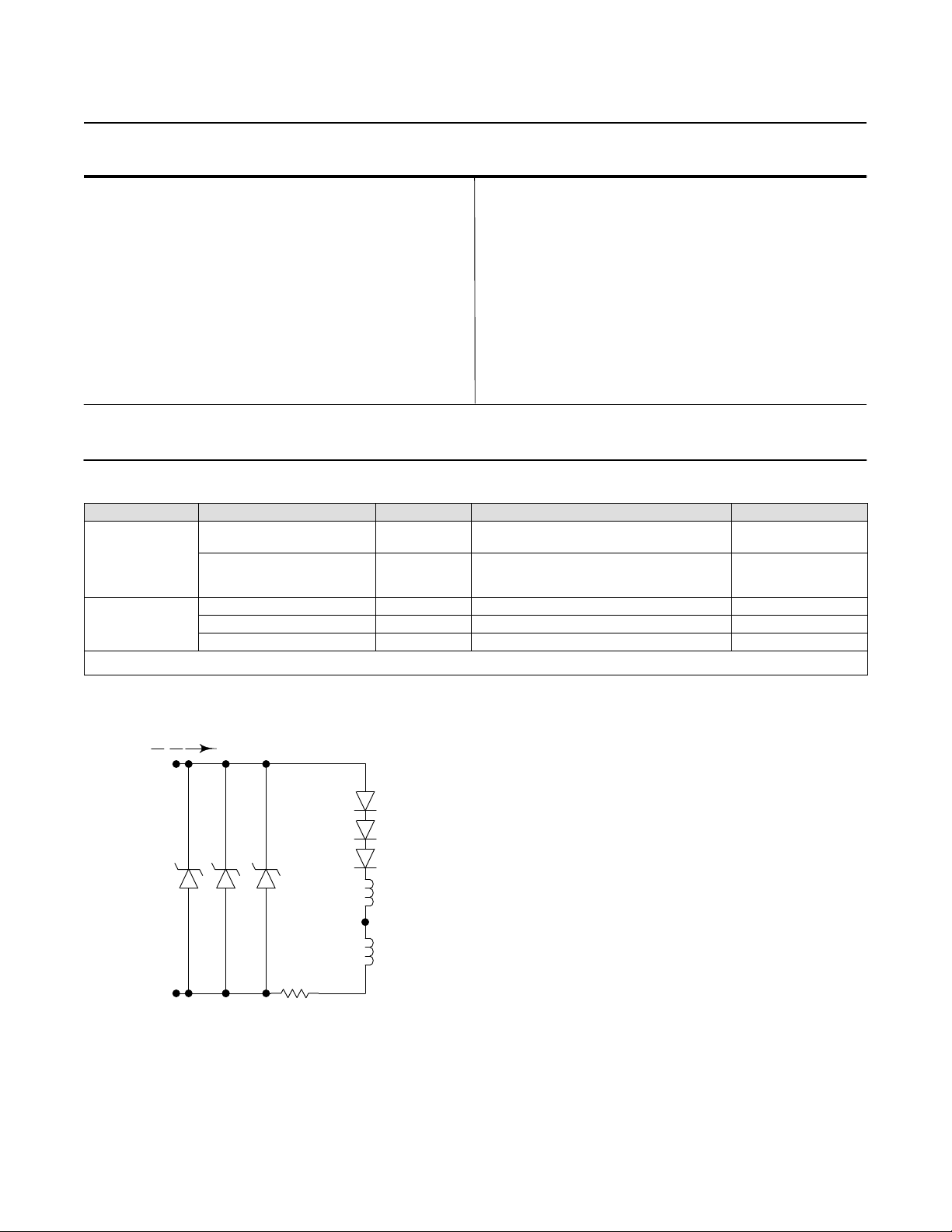

Equivalent Circuit

The 646 equivalent circuit is a series circuit consisting

of a constant voltage drop (battery) of approximately

2.1 VDC and a total resistance of 143 ohms. Input is

shunted by three 6.8 V zener diodes (see figure 1).

Output Signal

0.2 to 1.0 bar (3 to 15 psig) direct acting only

Supply Pressure

(1)

Recommended: 1.4 bar (20 psig)

Minimum: 1.4 bar (20 psig)

Maximum: 3.4 bar (50 psig)

Average Steady‐State Air Consumption

(2)(3)

0.08 m3/hr (3 scfh) at 1.4 bar (20 psi) supply pressure

Maximum Output Air Capacity

(2)

8.0 m3/hr (300 scfh) at 1.4 bar (20 psig) supply

pressure

Performance

(4)

Reference Accuracy: ±0.5% of full scale output span;

includes combined effects of hysteresis, linearity, and

deadband

Independent Linearity: ±0.5% of full scale output span

Hysteresis: 0.4% of full scale output span

Frequency Response: Gain is attenuated 3 dB at 10 Hz

with transducer output signal piped to a typical

instrument input

Temperature Effect: ±4% of full scale output span per

55_C (100_F) change

Supply Pressure Effect: 0.2% of full scale output span

per psi supply pressure change

Vibration Effect: Less than 1% of full scale output span

when tested to SAMA PMC 31.1, Condition 3

-continued-

Electromagnetic Compatibility:

Meets EN 61326-1 (First Edition)

Immunity—Industrial locations per Table 2 of

the EN 61326-1 standard. Performance is

shown in table 1 below.

Emissions—Class A

ISM equipment rating: Group 1, Class A

Operating Ambient Temperature Limits

(1)

-40 to 71_C (-40 to +160_F)

Electrical Classification

CSA— Intrinsically Safe, Explosion-proof, Type n,

Dust-Ignition proof, Div 2

FM— Intrinsically Safe, Explosion-proof, Type n,

Non-incendive, Dust-Ignition proof

ATEX— Intrinsically Safe, Flameproof, Type n

IECEx— Intrinsically Safe, Flameproof, Type n

Refer to tables 2, 3, 4, and 5 additional information.

Housing

CSA— Type 3 Encl.

FM— NEMA 3, IP54

ATEX— IP64

IECEx— IP54

Mount instrument with vent on side or bottom if

weatherproofing is a concern

Other Classifications/Certifications

CUTR— Customs Union Technical Regulations (Russia,

Kazakhstan, and Belarus)

INMETRO— National Institute of Metrology, Quality

and Technology (Brazil)

KGS— Korea Gas Safety Corporation (South Korea)

Contact your Emerson Process Management sales

office for classification/certification specific

information

Construction Materials

Housing, Cap, and Relay Body: Die cast aluminum

with less than 1% copper

2

Page 3

646 Transducer

D101374X012

Specifications (continued)

Product Bulletin

62.1:646

February 2015

Adjustments

Zero and Span: Trim potentiometers (20 turn) for

zero and span adjustments are located under the

housing cap

Mounting Position

Any position is acceptable for standard pipestand,

panel, or actuator mounting. For weatherproof

housing, mount the transducer to allow the vent to

drain.

Connections

Supply and Output Pressure: 1/4 NPT internal

connection

Vent: 1/4 NPT internal

Electrical:

J Standard 1/2 NPT or, J Optional M20 or

PG13 conduit adapter (see figure 3)

Wire Size: 18 to 22 AWG

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. The pressure and temperature limits in this document and any applicable standard or code limitation should not be exceeded.

2. Normal m

3. Average flow rate determined at 12 mA and 0.6 bar (9 psig) output.

4. Performance values are obtained using a transducer with a 4 to 20 mA dc input signal and a 0.2 to 1.0 bar (3 to 15 psig) output signal at an ambient temperature of 24_C (75_F).

3

/hour--Normal cubic meters per hour (0_C and 1.01325 bar, absolute). Scfh--Standard cubic feet per hour (60_F and 14.7 psig).

Approximate Weight (Transducer Only)

1.6 kg (3.5 pounds)

Options

Output pressure gauge

Table 1. EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level Performance Criteria

Electrostatic discharge (ESD) IEC 61000-4-2

Enclosure

I/O signal/control

Specification Limit = +/- 1% of span.

1. A = No degradation during testing. B = Temporary degradation during testing, but is self-recovering.

Radiated EM field IEC 61000-4-3

Burst (fast transients) IEC 61000-4-4 1 kV A

Surge IEC 61000-4-5 1 kV (line to ground only, each) B

Conducted RF IEC 61000-4-6 150 kHz to 80 MHz at 3 Vrms A

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

(1)

A

A

Figure 1. Equivalent Circuit

4 - 20 mA

+

6.8V 6.8V 6.8V

-

A6013

0.7V

0.7V

0.7V

60 Ohms

60 Ohms

23 Ohms

3

Page 4

Product Bulletin

62.1:646

February 2015

646 Transducer

D101374X012

Features

n Small Size—The small size and light-weight design of

the transducer facilitate mounting and provide

improved space utilization.

n Vibration Resistance—The transducer, used in a

standard valve/actuator mounted application,

exhibits an output shift of less than 1 percent of

span when tested to SAMA Standard PMC 31.1,

Condition 3.

n High Output Capability—The output volume of the

transducer is adequate to drive valve/actuator

combinations without requiring a positioner or

volume booster.

n Low Air Consumption—The transducer has low air

consumption which cuts operating costs.

n Easy Maintenance—Modular design of the converter

allows easy replacement in the field for reduced

maintenance costs.

n Superior Performance—The accuracy, linearity, and

frequency response coupled with minimal

hysteresis far exceed the requirements of most

control systems.

Figure 2. Output-Time Relationships

100

90

80

70

60

50

OUTPUT

40

30

(% OF 646 OUTPUT SPAN)

20

10

0

0 1020 3040 506070 8090100

A6815

LOADING

EXHAUSTING

TIME (%)

Installation

Refer to figure 3 for location of standard mounting

holes in the housing. Standard mounting hardware is

provided for mounting on the actuator, a pipestand, or

a panel. Field wiring connections are made to the

terminal block accessible under the housing cap.

Dimensions are shown in figure 3.

Valve Stroking Time

Figure 2 shows relative times for loading and

exhausting an actuator. Stroking time depends upon

the size of the actuator, travel, relay characteristics

and the magnitude and rate of change of the input

signal. If stroking time is critical, contact your Emerson

Process Management sales office.

4

Ordering Information

To determine what ordering information is required,

refer to the specification table. Carefully review the

description of each specification. Specify the desired

choice whenever there is a selection available. Also,

specify options that are applicable to the application.

Page 5

646 Transducer

D101374X012

Product Bulletin

62.1:646

February 2015

Figure 3. Dimensions

FISHER 67CFR

1/4-18 NPT

SUPPLY CONN

6.4

(0.25)

106.4

(4.19)

127.0

(5.00)

102.1

(4.02)

72.8

(2.86)

1/2-14 NPT

OR OPTIONAL

M20 CONDUIT CONN

OPTIONAL

GAUGE

152.4

(6.00)

79.2

(3.12)

(1.88)

47.8

CENTERLINE

OF ACTUATOR

9.7

(0.38)

EXHAUST

152.4

(6.00)

(2.25)

35

(1.38)

1/4-18 NPT

OUTPUT CONN

1/4-18 NPT

OPTIONAL OUTPUT

OR GAUGE CONN

57

CAP

REMOVAL

CLEARANCE

41.1

(1.62)

127.0

(5.00)

62.0

(2.44)

9.5

(0.38)

mm

(INCH)

38B3958-A

A6816-1

5

Page 6

Product Bulletin

62.1:646

February 2015

Table 2. Hazardous Area Classifications—CSA (Canada)

Certification Body Certification Obtained Entity Rating Temperature Code

CSA

Intrinsically Safe

Ex ia IIC T4/T5 per drawing GE28591

Ex ia Intrinsically Safe

Class I, II, Division 1 GP A,B,C,D,E,F,G T4/T5

per drawing GE28591

Explosion-proof

Ex d IIC T6

Class I, Division I, GP A,B,C,D T6

Type n

Ex nL IIC T6

Class I, Division 2, GP A,B,C,D T6

Class II, Division 1, Groups E,F,G T6

Class II, Division 2, GP F,G T6

Vmax = 30 VDC

Imax = 150 mA

Pi = 1.0 W

Ci = 0 nF

Li = 0 mH

- - - T6 (Tamb ≤ 71°C)

- - -

- - - T6 (Tamb ≤ 71°C)

Table 3. Hazardous Area Classifications—FM (United States)

Certification Body Certification Obtained Entity Rating Temperature Code

Vmax = 30 VDC

Imax = 150 mA

Pi = 1.0 W

Ci = 0 nF

Li = 0 mH

- - - T6 (Tamb ≤ 71°C)

- - - T6 (Tamb ≤ 71°C)

- - - T6 (Tamb ≤ 71°C)

FM

Intrinsically Safe

Class 1 Zone 0 AEx ia IIC T4/T5 per drawing GE28590

Class I, II, III Division 1 GP A,B,C,D,E,F,G T4/T5

per drawing GE28590

Explosion-proof

Class 1 Zone 1 AEx d IIC T6

Class I, Division I, GP A,B,C,D T6

Type n

CL 1 Zone 2 AEx nL IIC T6

Class I, Division 2, GP A,B,C,D T6

Class II, Division 1, Groups E,F,G T6

Class II, Division 2, GP F,G T6

646 Transducer

D101374X012

T4 (Tamb ≤ 71°C)

T5 (Tamb ≤ 40°C)

T6 (Tamb ≤ 71°C)

T4 (Tamb ≤ 71°C)

T5 (Tamb ≤ 40°C)

Table 4. Hazardous Area Classifications—ATEX

Certificate Certification Obtained Entity Rating Temperature Code

II 1 G & D

ATEX

Intrinsically Safe

Gas

Ex ia IIC T4/T5 Ga

Dust

Ex ia IIIC T155°C Da (Tamb

T124°C (Tamb ≤ 40°C)

II 2 G & D

Flameproof

Gas

Ex d IIC T6 Gb

Dust

Ex tb IIIC T74°C Db (T

Type n

Gas

Ex nA IIC T6 Gc

Dust

Ex tc IIIC T74°C Dc (T

amb ≤ 71°C)

II 3 G & D

amb ≤ 71°C)

≤ 71°C)

Ui = 30 VDC

Ii = 150 mA

Pi = 1.0 W

Ci = 0 nF

Li = 0 mH

- - - T6 (Tamb ≤ 71°C)

- - - - - -

- - -

T4 (Tamb ≤ 71°C)

T5 (Tamb ≤ 40°C)

T6 (Tamb ≤ 71°C)

- - -

- - -

6

Page 7

Product Bulletin

646 Transducer

D101374X012

Table 5. Hazardous Area Classifications—IECEx

Certificate Certification Obtained Entity Rating Temperature Code

Ui = 30 VDC

Ii = 150 mA

Pi = 1.0 W

Ci = 0 nF

Li = 0 mH

T4 (Tamb ≤ 71°C)

T5 (Tamb ≤ 40°C)

- - - T6 (Tamb ≤ 71°C)

- - - T6 (Tamb ≤ 71°C)

IECEx

Intrinsically Safe

Gas

Ex ia IIC T4/T5 Ga

Flameproof

Gas

Ex d IIC T6 Gb

Type n

Gas

Ex nA IIC T6 Gc

62.1:646

February 2015

7

Page 8

Product Bulletin

62.1:646

February 2015

646 Transducer

D101374X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1988, 2015 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...