Page 1

Product Bulletin

644 and 645 Pump Governors

D100185X012

December 2012

Fisherr 644 and 645 Differential Pressure

Pump Governor Actuators

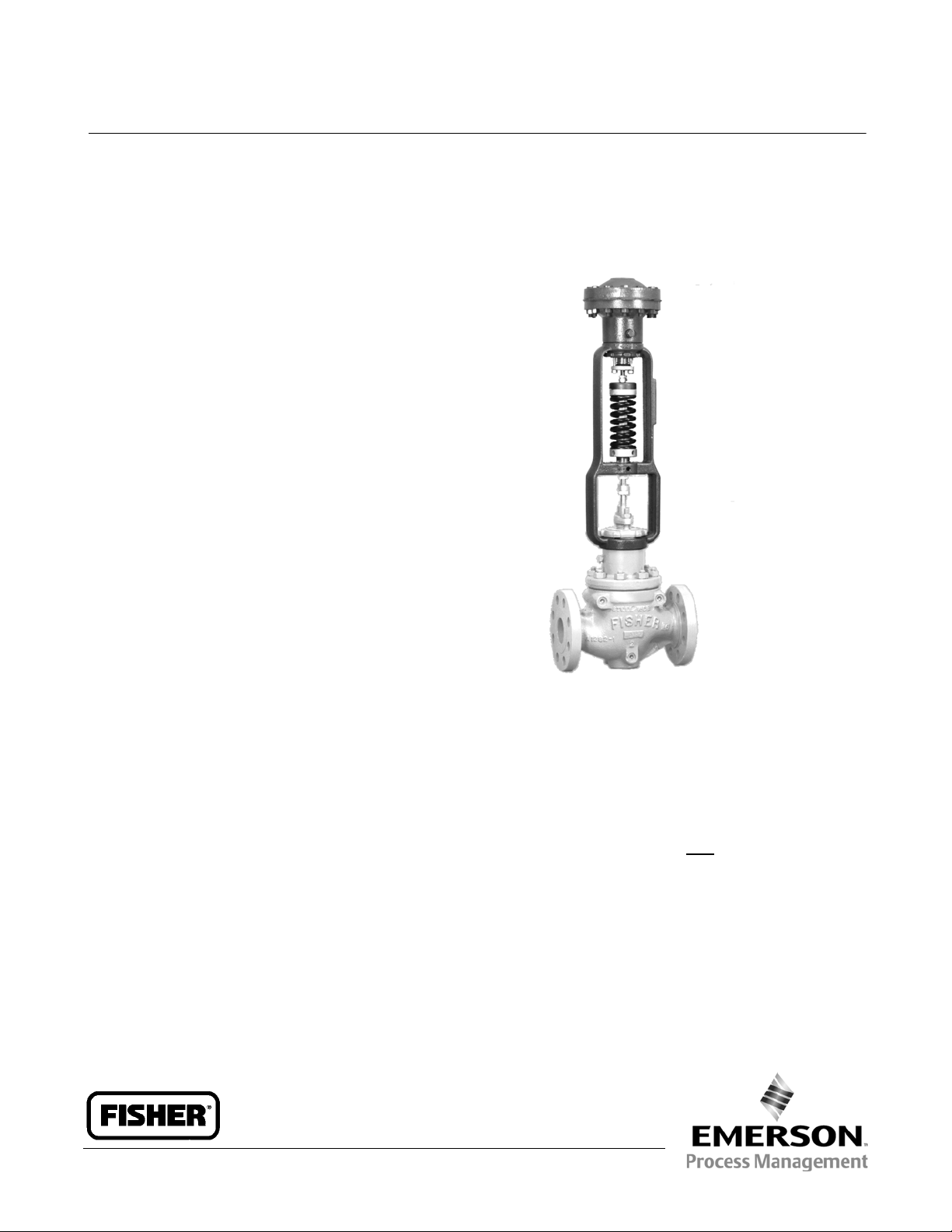

Fisher 644 and 645 actuators are used in combination

with any of several sliding-stem valves to automatically

control steam-driven boiler feedwater pumps

(reciprocating or turbine). The 644 or 645 actuator

(see figure 2), when used in combination with one of

several push-down-to-close sliding-stem valves, forms

a pump governor.

644 and 645 actuators may also be combined with

push-down-to-open valves to be used as relief

governors. Relief governors are used to divert excess

pump discharge back to the suction side of the pump.

61.9:644

Features

Rugged Construction–Steel and cast iron

construction provides long service life.

Ease of Maintenance–Few moving parts and easy

access reduce maintenance and downtime.

Ease of Adjustment–Spring adjustment is readily

accessible without removing any parts.

Fast Acting–Direct-operated configuration provides

fast speed of response.

Determining Buildup or

Droop

To determine the buildup (for relief applications) or

droop (for pressure reducing applications):

1. Find a pressure setting limit range that includes the

required pressure setting from table 1.

W2265-1

Fisher 644 ActuatorMounted on easy-et Valve Body

2. Find the sensitivity factor for the desired spring and

actuator casing combination from table 1.

3. Use the formula below to determine the buildup or

droop required for normal actuator travel.

Y

P=

X

where,

P = Buildup (for pressure relief) or Droop (for pressure

reduction), bar (psig)

Y = Normal actuator travel, mm (inches)

X = Sensitivity factor from table 1 mm/newtons

(inches/psig)

www.Fisher.com

Page 2

Product Bulletin

61.9:644

December 2012

Specifications

644 and 645 Pump Governors

D100185X012

Actuator Sizes

See table 1

Actuator Travel

Chloroprene Diaphragm: 11 mm (0.4375 inch)

maximum

Stainless Steel Diaphragm: 3 mm (0.125 inch)

maximum

Operating Principle

J Direct-acting with push-down-to-close valve

J Reverse-acting with push-down-to-open valve

Differential Pressure Ranges

See table 1

Maximum Casing Pressure

644 Actuator:

Cast-Iron Casing: 20.7 bar (300 psig)

Steel Casing: 41.4 bar (600 psig)

645 Actuator:

Cast-Iron Casing: 34.5 bar (500 psig)

Steel Casing: 69.0 bar (1000 psig)

Maximum nP Across Diaphragm

13.8 bar (200 psi)

Effective Diaphragm Area

644:

Size 1: 146 cm

Size 2: 243 cm

Size 3: 364 cm

645: 338 cm

Material Temperature Capabilities

644:

Chloroprene Diaphragm:-40 to 82_C

(-40 to 180_F)

Stainless Steel Diaphragm:

Cast-iron casing: -40 to 232_C(-40to450_F); Steel

casing: -40 to +399_C(-40to750_F)

645: -37 to 82_C(-35_ to 180_F)

Casing Pressure Connections

1/4 NPT internal

Spring Ranges and Sensitivity

See table 1

2

(8.9 inch2)

2

(14.8 inch2)

2

(22.2 inch2)

2

(20.6 inch2)

Construction Materials

Diaphragm:

644:

J Chloroprene or J Stainless steel

645: Chloroprene

Diaphragm Casing:

Diaphragm Head:

Diaphragm Rod: Stainless Steel

Packing:

J Graphite or J PTFE

J Cast iron or J Steel

J Cast iron or J Steel

Installation

Theseactuatorsmaybeinstalledinanyposition.

Typical installations are shown in figure 1. Dimensions

are shown in figure 3.

Ordering Information

Application

1. Differential pressure

2. Temperature (normal operating and maximum)

Stem Size

644: 9.5mm(3/8inch)

645: 12.7 mm (1/2 inch)

Yoke Boss Diameters

644:

J 54 mm (2-1/8 inch) or

J 71 mm (2-13/16 inch)

645: 71 mm (2-13/16 inch)

3. Required spring

Actuator

Refer to the specifications table. Review the

description to the right of each specification and in the

referenced table. Specify a choice wherever there is a

selection to be made.

Valve Body and Accessories

Refer to separate valve bulletin and bulletins covering

accessories for ordering information.

2

Page 3

644 and 645 Pump Governors

D100185X012

Figure 1. Typical Installation for Pump Governors

CONNECT TO BOILER

PRESSURE

EQUALIZING

VALVE

Product Bulletin

61.9:644

December 2012

BOILER

PRESSURE

STEAM

SUPPLY

14A2729-A

A1762-1

PUMP

GOVERNOR

SUCTION

REGULATING PUMP TO CONTROL

THE DISCHARGE PRESSURE

Table 1. Spring Information

ACTUATOR

644

645

Size 3

Casing

Size 2

Casing

Size 1

Casing

DIFFERENTIAL PRESSURERANGE SPRING RATE SENSITIVITY

Bar Psi N/mm Lbf/in mm/N In/Psi

0.3-1.2

1.2-1.9

1.9-2.8

2.8-3.8

3.8-4.7

4.7-6.9

1.0-1.7

1.7-2.4

2.4-3.2

3.2-4.1

4.1-4.3

4.3-5.9

5.9-6.8

6.8-8.2

8.2-9.7

9.7-10.7

PUMP

DISCHARGE

5-18

18-27

27-40

40-55

55-68

68-100

14-24

24-35

35-47

47-59

59-62

62-85

85-99

99-119

119-140

140-155

14A2789-A

A1763-1

56

107

107

165

107

165

43

64

86

107

129

145

221

257

310

368

PUMP

DISCHARGE

SUCTION

DIVERTING EXCESS DISCHARGE TO

CONTROL THE PRESSURE

314

609

609

940

609

940

246

368

490

612

735

830

1260

1470

1770

2100

26.1

13.5

9.0

6.2

5.4

3.7

21.0

14.0

10.5

11.0

7.1

6.2

4.1

3.5

2.9

2.5

0.0707

0.0365

0.0244

0.0168

0.0146

0.0101

0.057

0.038

0.0286

0.0299

0.0191

0.0169

0.0111

0.0095

0.0079

0.0067

RELIEF

GOVERNOR

SPRING PART NUMBER

1F945527032

1F945627032

1F945627032

1F945727042

1F945627032

1F945727042

1F714427112

1F176727032

1F176827092

1F176927092

1E792327092

1F714327092

1E795327082

1E792427082

1E795427082

1E793327082

3

Page 4

Product Bulletin

(

)

61.9:644

December 2012

644 and 645 Pump Governors

D100185X012

Figure 2. Typical Pump Governor Sectionals

W2263-1

644 ED

W2264-1

645 ED

Table 2. Dimensions

YOKE BOSS

ACTUATOR

644

DIAMETER

mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch

54712-1/8

2-13/16

SIZE 1 SIZE 2 SIZE 3 SIZE 1 SIZE 2 SIZE 3

503

19.81

548

21.56

Figure 3. Dimensions

C1/4

AH6723-A

A1742-1

E C(DIAMETER)

521

565

20.50

22.25

522

567

20.56

22.31

644

152 6.00 206 8.12 229 9.00

1/4

NPT

1/4 NPT

E

AH9149-A

A1743-1

264

(10.38)

645

NPT

1/4 NPT

66.4

(26.13)

mm

INCH

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for properselection, use, and maintenance of any product remains solely with the purchaserand end user.

Fisher andeasy-e are marks owned by one ofthe companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are theproperty oftheir respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1997, 2012 Fisher ControlsInternational LLC. All rights reserved.

4

Loading...

Loading...