Page 1

Instructional Manual

D100638X012

December 2018

Types 634 and 634M

Types 634 and 634M High-Pressure Shutoff Valves

W4128

TYPE 634M SHUTOFF VALVE WITH

STANDARD PIPE PLUGS IN BODY SIDE TAPPINGS

Figure 1. Typical Constructions

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher™ shutoff valve must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies,

Inc. instructions.

If a leak develops or if the outlet

continually vents gas, service to the

unit may be required. Failure to correct

trouble could result in a hazardous

condition. Only a qualied person shall

install or service the unit.

Call a qualied service person to service

the unit. Installation, operation and

maintenance procedures performed

W4156-1

TYPE 634 SHUTOFF VALVE WITH

OPTIONAL TANK VALVE IN UPSTREAM BODY SIDE TAPPING

by unqualied person may result

in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury.

Only a qualied person must install

or service the Types 634 and 634M

shutoff valves.

Introduction

Scope of the Manual

This manual provides installation, maintenance, and

parts information for the Types 634 and 634M highpressure shutoff valves. Refer to separate instruction

manuals for information on regulators used with these

high-pressure shutoff valves.

Product Description

Types 634 and 634M high-pressure shutoff valves

(Figure 1) serve to provide overpressure protection by

containment. The Type 634 shutoff valve with internal

registration is installed between a pressure-reducing

Page 2

Types 634 and 634M

Specications

The Specications section on this page provides the ratings and other specications for the Types 634 and 634M.

Factory specications such as type, maximum inlet pressure, maximum temperature, maximum outlet pressure,

spring range and orice size are stamped on the nameplate fastened on the regulator at the factory. The

manufacture date and original fracture disk range are printed on the disk retainer (key 3, Figure 6).

Body Size and End Connection Style

3/4 or 1 NPT internal

Maximum Inlet Pressure

(1)

1500 psig / 103 bar

Maximum Body Outlet Pressure

(1)

Type 634 Shutoff Valve: 150 psig / 10.3 bar

Type 634M Shutoff Valve: 1500 psig / 103 bar

Maximum Diaphragm Pressure

(1)

Operating: 150 psig / 10.3 bar

Emergency

(2)

: 225 psig / 15.5 bar

Outlet Pressure at which Fracture Disk Shatters

See Figure 5

Temperature Capabilities

(3)

-20

to 180°F / -29

Vent Connection

1/4 NPT internal with removable Type Y602-12

vent assembly

Downstream Pressure Registration Connection

(Type 634M Shutoff Valve Only)

1/4 NPT internal

Approximate Weight

13 lbs / 6.0 kg

1. The pressure/temperature limits in this Instruction Manual, and any applicable code or standard limitation should not be exceeded.

2. A pressure exceeding this value can cause failure of, or leakage from, pressure containing components.

3. Low temperatures may stiffen elastomers and prevent normal shutoff.

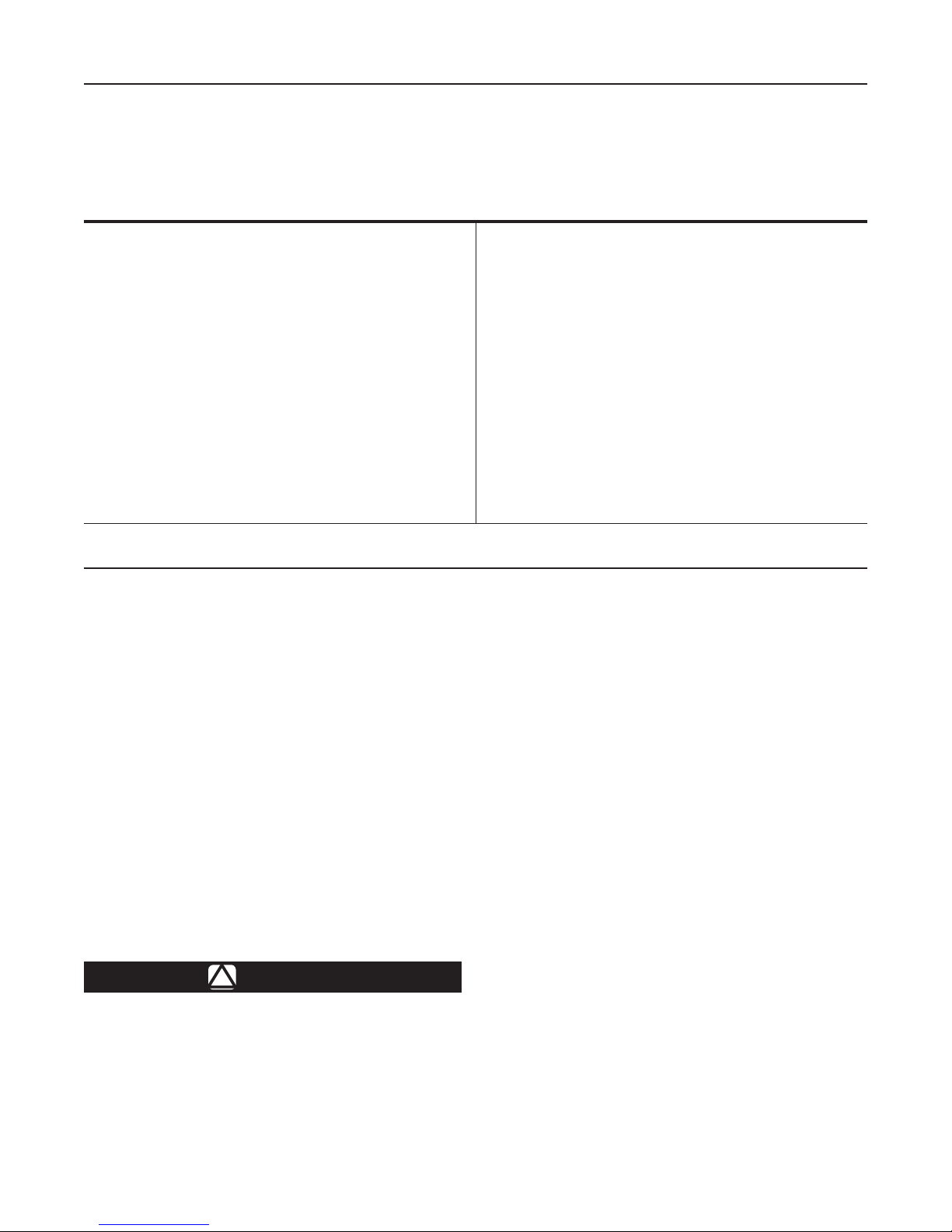

regulator and a downstream system or equipment

as shown in Figure 2. The Type 634M shutoff valve

with external registration requires a control line and is

installed upstream of a pressure-reducing regulator as

shown in Figure 3.

of accumulated gas. To avoid such

conditions, use qualified personnel

to install a high-pressure shutoff

valve where:

• Service conditions are within the

limits specied in the Specications

Principle of Operation

Regulator outlet pressure registers on the side of the

diaphragm opposite the fracture disk. An excessive

rise in outlet pressure provides enough force on the

diaphragm to drive the stem through the fracture disk.

This lets the plug close, and stay closed until upstream

and downstream pressures are relieved and a new

fracture disk is installed.

1. Before installing, inspect the shutoff valve for

section, and

• The valve is protected from

exposure to physical damage and/or

corrosive substances.

any damage and foreign material that may have

collected in the body.

2. Make certain that the body interior is clean and

Installation and Startup

All key numbers mentioned in this section appear

in Figure 6.

that piping is free from debris.

3. A Type 634 or 634M shutoff valve may be

installed in any position as long as the direction

of flow complies with the flow arrow on the side

WARNING

!

of the body (key 1). Typical positions as shown

in Figure 2 or 3 are with the disk retainer (key 3)

Installing a Type 634 or 634M highpressure shutoff valve where its

pointing down. This position eases removal of

broken fracture disk pieces.

capabilities can be exceeded or where

proper operation might be impaired

may cause personal injury, property

damage or leakage due to bursting of

pressure-containing parts or explosion

4. The Type 634 shutoff valve installation shown in

Figure 2 does not shut off inlet pressure to the

upstream reducing regulator and thus does not

provide overpressure protection to that regulator.

(1)

(3)

to 82°C

2

Page 3

Types 634 and 634M

REDUCING

REGULATOR

FRACTURE DISK

INLET PRESSURE

OUTLET PRESSURE

STEM

DIAPHRAGM

PLUG ASSEMBLY

INTERNAL

REGISTRATION

TAP

OPTIONAL TOKEN

RELIEF VALVE

VENT

TAPPING

Figure 2. Type 634 Shutoff Valve Installation

TYPE 627 PRESSURE

REDUCING REGULATOR

W4263*

DOWNSTREAM

CONTROL LINE

OPTIONAL TYPE H120

TOKEN RELIEF VALVE

TYPE 634M

SHUTOFF VALVE

Figure 4. Typical Installation Showing Token Relief Valve

Therefore, inlet pressure to the upstream

reducing regulator must not exceed the maximum

emergency outlet pressure rating of that regulator

or 1500 psig / 103 bar, whichever is less.

5. The Type 634M shutoff valve installation shown

in Figure 3 will shut off flow to the downstream

reducing regulator. Thus, inlet pressure to that

regulator is limited by its maximum allowable

inlet pressure rating or by the Type 634M

maximum inlet pressure of 1500 psig / 103 bar,

whichever is less.

PLUG ASSEMBLY

REDUCING

REGULATOR

STEM

FRACTURE DISK

INLET PRESSURE

OUTLET PRESSURE

VENT

TAPPING

DIAPHRAGM

OPTIONAL TOKEN

RELIEF VALVE

Figure 3. Type 634M Shutoff Valve Installation

6. Both types can be used along with a token

relief valve (Figure 4) to minimize unnecessary

shutoff. The relief valve is set to open before the

Type 634 or 634M shutoff valve activates. This

arrangement allows the relief valve to handle

minor overpressure problems such as gas thermal

expansion or seat leakage due to dirt moving

through the system which may move out of the

regulator during the next operating cycle. The

shutoff valve does activate if the regulator has a

major malfunction with excessive gas flow that

exceeds the token relief capacity.

WARNING

!

In case the diaphragm leaks, a Type 634

or 634M shutoff valve can vent gas from

the vent assembly (key 22, not shown)

in the upper casing (key 2). If a Type 634

or 634M shutoff valve in ammable or

hazardous gas service is installed in

an enclosed space or a conned area,

personal injury or property damage

may occur due to re or explosion of

accumulated gas. To prevent such injury

or damage, provide piping or tubing to

remove the vented gas to a safe, wellventilated area at atmospheric pressure.

CONTROL

LINE

CAUTION

To avoid a pressure surge that may

shatter the fracture disk due to impact,

start up the system slowly.

7. A self-threading vent assembly (key 22, not

shown) is screwed into the 1/4 NPT tapping of

the casing. This vent assembly may be removed

and obstruction-free piping or tubing installed

for remote venting of the casing. If kept in the

casing, the vent assembly must be pointed down

if possible or otherwise protected from blockage

such as insects, snow or freezing rain.

3

Page 4

Types 634 and 634M

FRACTURE DISK SHATTER PRESSURE TO

TYPE 634M SHUTOFF VALVE, bar

1500

1250

1000

50

7

103

100

75

INLET PRESSURE TO

TYPE 634M SHUTOFF

VALVE, psig

A3328

Type 634 Shutoff Valve

psig bar

20 to 28 1.4 to 1.9

50 to 60 3.4 to 4.1

72 to 88 5.0 to 6.1

INLET PRESSURE TO

750

A B C

500

250

0

25 50 75 1000

FRACTURE DISK SHATTER PRESSURE

OF TYPE 634M SHUTOFF VALVE, psig

TYPE 634M SHUTOFF

50

25

0

VALVE, bar

Figure 5. Fracture Disk Selection

Table 1. Fracture Disk Selection

SHATTER PRESSURE FRACTURE DISK

Type 634M Shutoff Valve Color Code Part Number

20 to 28 psig / 1.4 to 1.9 bar at 0 psig / 0 bar inlet

pressure; see curve A for other inlet pressures

50 to 60 psig / 3.4 to 4.1 bar at 0 psig / 0 bar inlet

pressure; see curve B for other inlet pressures

72 to 88 psig / 5.0 to 6.1 bar at 0 psig / 0 bar inlet

pressure; see curve C for other inlet pressures

Red 29A1936X012

Yellow 29A1936X022

White 29A1936X032

Note

If using pipe in the following step, apply

pipe compound to the pipe threads

before making the connections.

8. Install tubing or piping into the 3/4 or 1 NPT

connections of the body. With a Type 634M shutoff

valve, also install a control line into the 1/4 NPT

control line connection in the body.

CAUTION

A closed Type 634 or 634M shutoff

valve means some other component

in the system, such as a reducing

regulator, is causing overpressure.

4

The malfunctioning component and

the overpressure condition must be

corrected before the fracture disk

is replaced.

9. The downstream pressure at which the fracture

disk shatters depends on the unbalance between

inlet and downstream pressure and can be

determined from Figure 5. This shatter pressure

is non-adjustable and can only be changed if the

disk is changed (Type 634) or if either the disk or

inlet pressure is changed (Type 634M). Fracture

disks (key 4) are color coded to indicate their

shatter pressure.

10. The Type 634 shutoff valve has negligible

unbalance because downstream pressure is

essentially the same as inlet pressure during

Page 5

Types 634 and 634M

normal operation. Simply select the fracture disk

(key 4) of the appropriate color from Figure 5

according to the desired shatter pressure.

11. The Type 634M shutoff valve can have

considerable unbalance, thus causing the shatter

pressure to vary approximately 2 psig / 0.14 bar

per every 100 psig / 6.9 bar of inlet pressure

change. Select the fracture disk (key 4) of the

appropriate color from Figure 5 according to the

desired shatter pressure in combination with the

inlet pressure.

Note

The lowest pressure of the fracture disk

(key 4) chosen according to step 10

or 11 must be higher than all normal

operating pressures of the regulator

and system being protected. Regulator

pressure characteristics such as

lockup, boost and proportional band

must be considered as part of normal

operating pressures.

Maintenance

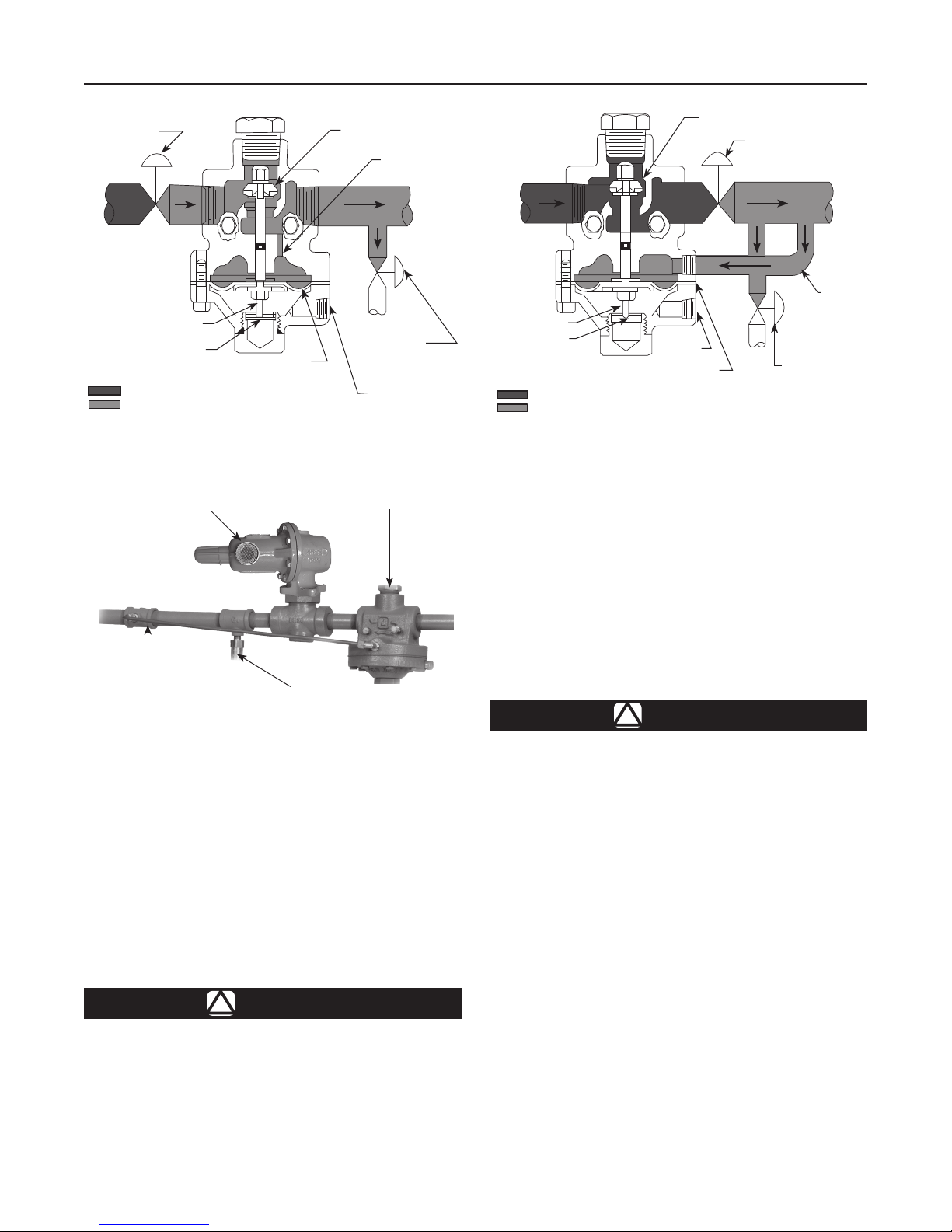

All key numbers mentioned in this section appear in

Figure 6.

Types 634 and 634M shutoff valves are normally

open. They close only when the fracture disk (key 4)

shatters. Frequency of maintenance depends upon

the severity of service conditions and the requirements

of government regulations. Parts must be replaced

as necessary. Use only Emerson-authorized

replacement parts.

Preparing for Maintenance

1. Isolate the shutoff valve from both upstream and

downstream pressure.

2. Release trapped pressure from both the inlet and

outlet ends of the body (key 1) as follows:

• Where a pipe plug (key 15) is installed in the

body side tapping, use the valves provided in the

system to bleed off pressure. Do not unscrew the

pipe plug.

• Where a tank valve (key 15, not shown) is

installed in the body side tapping, remove the

tank valve cap. Push in on the tank valve stem

until all trapped pressure bleeds out, making

sure the gas bleeds to a safe location. Then,

replace the cap.

Replacing Fracture Disk

1. Complete the procedure for preparing

for maintenance.

2. Remove the disk retainer (key 3) from the upper

casing (key 2) and snap ring (key 14) from the

disk retainer.

3. Shake any loose fragments out of the disk retainer

(key 3), and remove any remaining fragments

from the upper casing (key 2) and body cavities

so as not to hinder diaphragm (key 6) action upon

reassembly. Install a new fracture disk (key 4) and

secure it with the snap ring (key 14). Remark the

disk retainer if the replacement fracture disk has a

range different from the range of the fracture disk

originally shipped from the factory.

WARNING

!

Personal injury or equipment damage

may be caused by sudden release of

pressure or explosion of accumulated

gas. To avoid such injury or damage,

isolate the shutoff valve from system

pressure and relieve all internal pressure

before starting disassembly. Releasing

downstream pressure from a closed

Type 634 or 634M shutoff valve does not

release inlet pressure from that shutoff

valve. Since there is no longer an intact

fracture disk in a shutoff valve that has

been closed, make sure no downstream

pressure is allowed to act on the

diaphragm during maintenance.

4. If necessary, replace the O-ring (key 21) used on

the disk retainer (key 3).

5. Apply a suitable thread lubricant to the threads

of the disk retainer (key 3), and install it into the

upper casing.

6. Test for leakage after assembly.

Replacing Plug Assembly, Diaphragm

or O-rings

1. Complete the procedure for preparing

for maintenance.

2. Remove the pipe plug, cap screws, upper casing

(key 2) and hex nut (keys 2, 11, 12 and 13) from

the fracture disk (key 4) end of the stem (key 10).

5

Page 6

Types 634 and 634M

3. Remove the other special washer, diaphragm

heads (keys 5, 7 and 23), diaphragm (key 6) and

O-rings from the fracture disk (key 4) end of the

stem (key 10).

4. Slide the stem (key 10) out to gain access to the

O-ring (key 8) in its center recess.

5. Remove the special hex nut, lockwasher, plug

assembly, O-ring and special washer (keys 7, 8, 9,

16 and 17) from the plug end of the stem (key 10).

6. Inspect and replace parts as necessary.

7. Lubricate the recessed area of the stem (key 10)

with a suitable lubricant and then install the O-ring

(key 8) into the recessed area.

8. Install one special washer (key 7), O-ring (key 8),

plug assembly (key 9), lockwasher (key 16) and

special hex nut (key 17) onto the appropriate end

of the stem (key 10) as shown in Figure 6. Insert

the plug and stem assembly into the body (key 1).

9. Install the following over the fracture disk end of

the stem:

• The lower diaphragm head (key 23) with its

chamfered side facing away from the plug

assembly, followed by an O-ring (key 8);

• The diaphragm, followed by another O-ring

(key 8);

• The diaphragm head (key 5) with its chamfered

side facing toward the plug assembly;

• The other special washer (key 7);

• The other hex nut (key 12). Good assembly

practice includes tightening both hex nuts

(keys 12 and 17) to 6 to 8 ft-lbs / 8 to

11 N•m torque.

10. Apply a suitable thread sealant to the threads of

the pipe plug (key 13), and install the pipe plug

into the body (key 1).

11. Install the upper casing (key 2) so that the vent

assembly (key 22, not shown) is pointed down or

otherwise protected.

12. Install the cap screws (key 11). Before tightening

them, make sure that the plug assembly (key 9)

is closed in order to provide enough slack in

the diaphragm.

13. Tighten the cap screws (key 11) using a crisscross

bolting pattern. Good assembly practice includes

tightening the cap screws to 13 to 17 ft-lbs / 18 to

23 N•m torque.

14. Make sure that the disk retainer (key 3) and

attached parts are installed into the upper casing

according to steps 3 through 5 of the replacing

fracture disk procedure.

Parts Ordering

When corresponding with a local Sales Ofce about

Types 634 and 634M shutoff valves, include the type

number and all other pertinent information stamped

on the disk retainer and casing. Specify the elevencharacter part number when ordering from the

following Parts List.

Parts List

Key Description Part Number

Repair Kits (included are keys 4, 6, 8,

9 and 21)

With red fracture disk R634X000012

With yellow fracture disk R634X000022

With white fracture disk R634X000032

1 WCC Steel Body

3/4 NPT

Type 634 39A1091X022

Type 634M 39A0584X022

1 NPT

Type 634 39A1090X032

Type 634M 39A0585X022

2 Upper Casing

Cast iron 29A0776X012

3* Disk Retainer

Steel 19A1935X022

4* Fracture Disk, Cast iron

Red color code 29A1936X012

Yellow color code 29A1936X022

White color code 29A1936X032

5 Diaphragm Head

Plated steel 19A1937X012

6* Diaphragm

Neoprene (CR) and Nylon (PA) fabric 19A1938X012

7 Special Washer

Plated steel (2 required) 19A1940X012

8* O-ring, Nitrile (NBR) (4 required) 1D6875X0022

9* Plug Assembly

Aluminum and Nitrile (NBR) 19A1943X012

10 Stem, Stainless steel 19A1941X012

11 Cap Screw, Plated steel (8 required) 1B787724052

12 Hex Nut, Steel 1A345724122

13 Pipe Plug, Plated steel 1A794728992

14 Snap Ring 12B9220X012

15 Pipe Plug, Plated steel (2 required

with standard construction or 1 required

with Tank Valve Inlet only) 1A500828992

15 Tank Valve (not shown), Plated steel

(1 required with Tank Valve Inlet only

or 2 required with standard construction 19A1951X012

16 Lockwasher, Plated carbon steel 1C225628982

17 Special Hex Nut, Stainless steel 19A1944X012

21* O-ring, Nitrile (NBR) 10A8931X012

22 Type Y602-12 Vent Assembly (not shown)

Plastic 27A5516X012

23 Lower Diaphragm Head

Plated steel 19A6901X012

*Recommended spare part.

6

Page 7

Types 634 and 634M

15

TORQUE:

6 TO 8 FT-LBS /

8 TO 11 N•m

29A1948-DA

L3

23

6

5

8

L1

2

TORQUE:

11

13 TO 17 FT-LBS /

18 TO 23 N•m

12

L2

3

14

4

21

DETAIL OF TYPE 634 SHUTOFF VALVE

1

16

9

13

L3

TORQUE:

17

6 TO 8 FT-LBS /

8 TO 11 N•m

8

7

15

L3

23

6

5

TORQUE:

6 TO 8 FT-LBS /

12

8 TO 11 N•m

L2

29A1947-DA

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER LUBRICANT

L2 =ALUMINUM ANTI-SEIZE LUBRICANT

L3 = ZINC-BASED ANTI-SEIZE LUBRICANT

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

:

3

COMPLETE TYPE 634M SHUTOFF VALVE

Figure 6. Types 634 and 634M Assemblies

10

8

L1

2

11

TORQUE:

13 TO 17 FT-LBS /

18 TO 23 N•m

14

4

21

7

Page 8

Types 634 and 634M

Webadmin.Regulators@emerson.com

Fisher.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

D100638X012 © 1984, 2018 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 12/18.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for information purposes

only, and while effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available on request. We reserve the right to modify or improve the

designs or specications of our products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...