Page 1

Instruction Manual

Form 1243

December 2015

630 Series Regulators and Relief Valves

Introduction

Scope of Manual

This Instruction Manual provides operating, installation,

maintenance and parts information for the 630 Series

regulators and relief valves.

Description

The 630 Series consists of self-operated, spring

loaded Type 630 Big Joe® pressure regulators and

Type 630R relief valves, which are designed for

maximum inlet pressures to 1500 psig / 103 bar and

outlet pressures from 3 to 500 psig / 0.21 to 34.5 bar.

630 Series

Installation

WARNING

!

Personal injury, property damage,

equipment damage or leakage due to

escaping gas or bursting of pressurecontaining parts may result if this

regulator is overpressured or is installed

where service conditions could exceed

the limits given in Specications

section, Tables 1 through 3 or where

conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by the appropriate

code, regulation or standard) to prevent

service conditions from exceeding

those limits.

W1934

Figure 1. Spring-Loaded Type 630 Regulator

Additionally, physical damage to the

regulator could cause personal injury or

property damage due to escaping gas.

To avoid such injury or damage, install

the regulator in a safe location.

Before installing, inspect the unit for any damage and

any foreign material. The regulator or relief valve may

be mounted in any position, however, ensure that the

ow direction corresponds with the direction of the

arrow on the nameplate. Apply a good grade of pipe

compound to the male threads of the pipeline.

D100300X012

www.fisherregulators.com

Page 2

630 Series

Specications

The Specications section lists the specications for the 630 Series constructions.

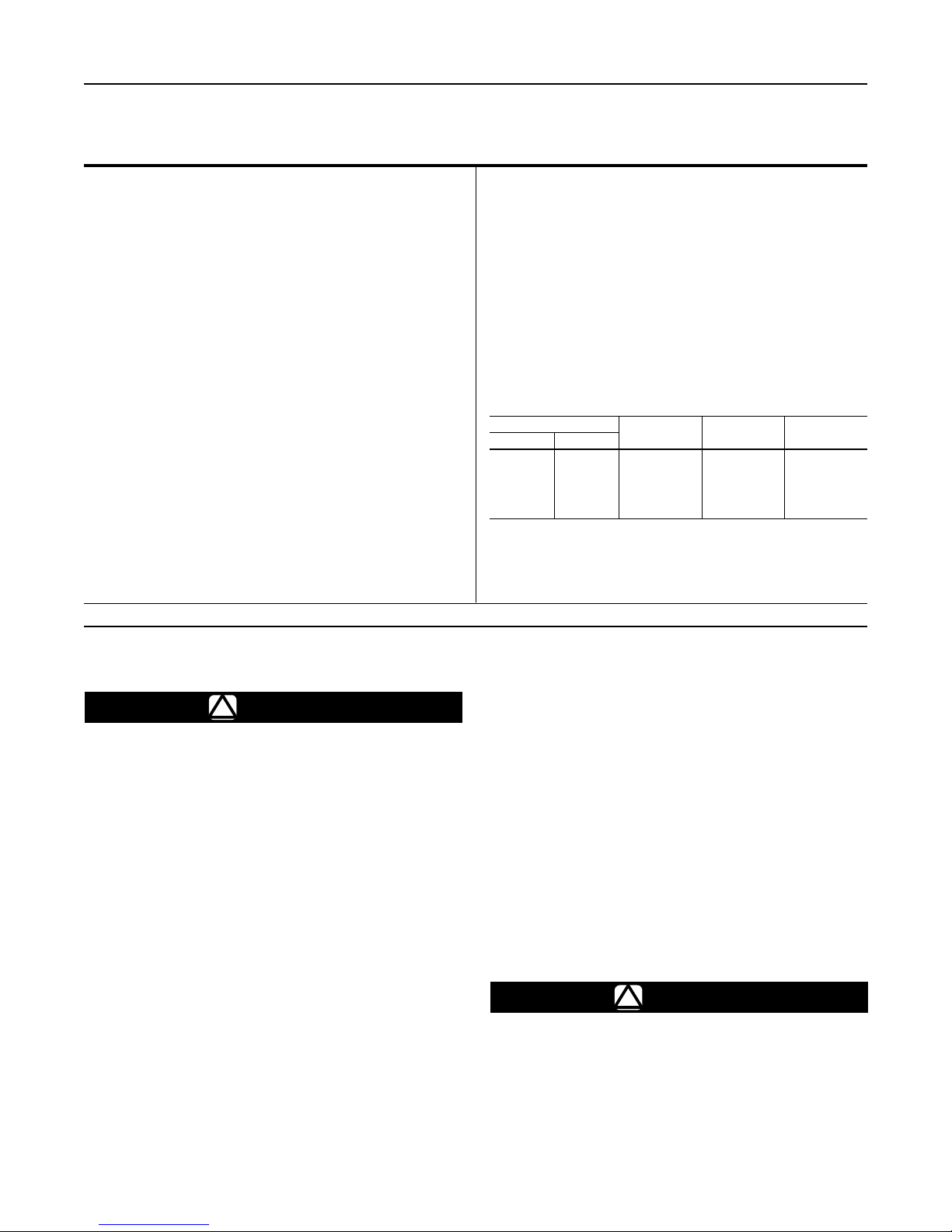

Available Congurations

Type 630: Spring-loaded reducing regulators

Type 630R: Spring-loaded relief valves

Body Size

1 and 2 in. / DN 25 and 50

End Connection Style

NPT, ASME CL150 RF, CL300 RF or CL600 RF

Maximum Allowable Inlet Pressures

(1)

Type 630 Regulators: See Table 1

Type 630R Relief Valves: See Table 3

Type 630 Outlet Pressure Ranges

(1)

3 to 500 psig / 0.21 to 34.5 bar with intermediate

values shown in Table 2

Type 630R Relief Pressure Ranges

(1)

3 to 250 psig / 0.21 to 17.2 bar

See Table 3

Maximum Allowable Outlet Pressures

(1)

See Table 2

Maximum Allowable Pressure Drops

(1)

See Table 1

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

Pressure Registration

Internal

Spring Case Vent

1/4 NPT

Material Temperature Capabilities

Standard: -20 to 180°F / -29 to 82°C

Optional: -20 to 300°F / -29 to 149°C

Orice Sizes

1/8, 3/16, 1/4, 3/8 or 1/2 in. /

3.18, 4.76, 6.35, 9.53 or 12.7 mm

Coefcients for Relief Valve Sizing

ORIFICE SIZE

In. mm

1/8

3/16

1/4

3/8

1/2

3.18

4.76

6.35

9.53

12.7

Approximate Weights

1 In. End Connection: 25 lbs / 11.3 kg

2 In. End Connection: 30 lbs / 13.6 kg

C

13.9

31.3

55.1

122.5

216.0

(1)

C

g

V

0.49

1.11

2.03

4.61

8.18

C

28.4

28.2

27.2

26.6

26.4

1

Vents

WARNING

!

When the unit is installed in an enclosed

area or indoors, escaping gas may

accumulate and be an explosion hazard.

Under these conditions the vent should

be piped away from the unit to a freely

ventilated outdoor location away from

air intakes, windows, etc. Protect all vent

openings against weather or the entrance

of any foreign material that may plug the

vent or affect operation of the regulator

or relief valve. Inspect all vent openings

periodically to be sure they are not

plugged. If the vent is in an environment

where freezing rain, ice or snow could

clog the vent, it is recommended that a

weatherproof vent be used.

Spring-loaded constructions have a screened vent

assembly (key 27, Figures 4, 5 and 6) installed in the

1/4 NPT spring case vent opening. If a remote vent

is required, remove the vent assembly and install a

remote vent line.

Overpressure Protection

As is the case with most regulators, the Type 630 springloaded regulators have outlet pressure ratings that are

lower than the inlet pressure ratings. Overpressure

protection must be provided if the actual inlet pressure

can exceed the outlet pressure rating. Overpressure

protection is also required for the loading regulator and

main regulator spring case of relief valves.

Refer to the following tables to determine pressure ratings:

1. Spring-loaded Type 630 regulators.

a. Inlet pressure and pressure drop—Table 1.

b. Outlet pressure—Table 2.

2. Spring-loaded Type 630R relief valve pressure

Table 3.

WARNING

!

Overpressuring any portion of this

equipment may cause damage to

regulator parts, leaks in the regulator

or personal injury due to bursting of

pressure-containing parts or explosion

of accumulated gas.

2

Page 3

630 Series

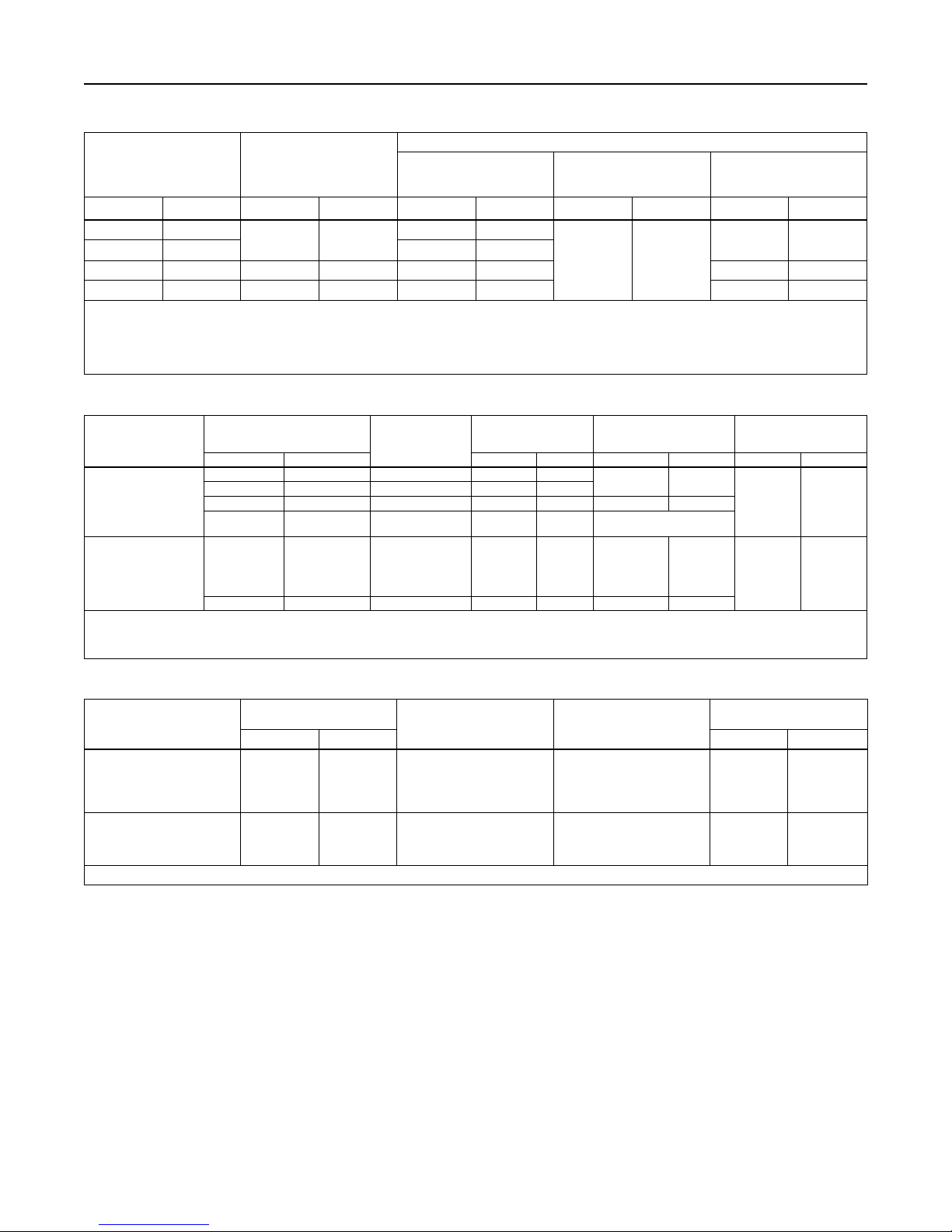

Table 1. Maximum Allowable Inlet Pressures and Pressure Drops

MAXIMUM ALLOWABLE PRESSURE DROP

ORIFICE SIZE

MAXIMUM ALLOWABLE

INLET PRESSURE

(1)

Nylon (PA)

Polytetrauoroethylene

In. mm psig bar psig bar psig bar psig bar

1/8 and 3/16 3.2 and 4.8

1/4 6.4 1000 69

1500 103

1500 103

3/8 9.5 1000 69 500 34.5 500 34.5

1/2 13 750 51.7 250 17.2 250 17.2

Note: Maximum inlet pressure not exceeded 1500 psig / 103 bar.

1. Inlet pressure must not exceed the sum of the actual outlet pressure setting and the maximum allowable pressure drop. For example, with an outlet pressure setting of 200 psig / 13.8 bar

and a 3/8 in. / 9.5 mm orice with a maximum allowable pressure drop of 500 psid / 34.5 bar d, the maximum inlet pressure is 700 psig / 48.3 bar.

2. Nitrile (NBR) valve disks are normally furnished for pressure drops to 200 psi / 13.8 bar, differential. For better erosion resistance, Nylon (PA) valve disks are normally furnished for

higher

pressure drops. Some erosion of valve disks occurs at all pressure drops due to solid particles in the ow stream. The rate of erosion is higher with large amounts of impurities in the

ow stream and with high pressure drops. Valve disks and other regulator parts must be inspected periodically for erosion and damage and must be replaced as necessary.

Table 2. Type 630 Regulator Outlet Pressure Ranges and Maximum Outlet Pressures

REGULATOR

CONSTRUCTION

Low-Pressure

High-Pressure

1. Damage to internal parts of the regulator may occur if outlet pressure exceeds the actual pressure setting by amounts greater than those shown in this column.

2. For outlet pressure settings to 25 psig / 1.72 bar only. For pressure settings over 25 psig / 1.72 bar, outlet pressure is limited by maximum emergency outlet pressure of 45 psig / 3.10 bar.

3. For outlet pressure settings to 350 psig / 24.1 bar only. For pressure settings over 350 psig / 24.1 bar, outlet pressure is limited by maximum emergency outlet pressure of 550 psig / 37.9 bar.

4. Leakage or bursting of pressure-containing parts may occur if outlet pressure exceeds these values.

OUTLET PRESSURE RANGE

psig bar psig bar psig bar psig bar

3 to 10 0.21 to 0.69 0W019227022 10 0.69

8 to 20 0.55 to 1.38 0W019127022 20 1.38

17 to 30 1.17 to 2.07 0W019027022 30 2.07 20

27 to 40 1.86 to 2.76 0Y066427022 40 2.76

27 to 50

46 to 95

90 to 150

150 to 200

200 to 275

275 to 500 19.0 to 34.5 1K370927082 500 34.5 200

1.86 to 3.45

3.17 to 6.55

6.21 to 10.3

10.3 to 13.8

13.8 to 19.0

SPRING PART

NUMBER

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

(2)

and

(PTFE) Disk

MAXIMUM OPERATING

OUTLET PRESSURE

50

95

150

200

275

Fluorocarbon (FKM) Disk Nitrile (NBR)

600 41.4

200 13.8

MAXIMUM EMERGENCY

OUTLET (CASING)

(2)

550 37.9

(2)

66 4.55

3.45

6.55

10.3

13.8

19.0

MAXIMUM OUTLET

PRESSURE

OVER SETPOINT

20 1.38

(2)

Limited by Maximum

Emergency Outlet Pressure

200 13.8

(3)

(1)

1.38

1.38

(2)

Disk

PRESSURE

(4)

Table 3. Type 630R Relief Pressure Ranges

RELIEF VALVE

CONSTRUCTION

Low-Pressure

High-Pressure

1. Leakage or bursting of pressure-containing parts may occur if inlet pressure exceeds these values.

RELIEF (INLET)

PRESSURE RANGE

psig bar psig bar

3 to 8

6 to 17

15 to 22

20 to 35

35 to 50

30 to 70

50 to 95

75 to 175

150 to 250

0.21 to 0.55

0.41 to 1.17

1.03 to 1.52

1.38 to 2.41

2.41 to 3.45

2.07 to 4.83

3.45 to 6.55

5.17 to 12.1

10.3 to 17.2

PART NUMBER

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

0W019127022

0W019027022

0Y066427022

1J146927142

To avoid overpressure, provide an

appropriate overpressure protection

device to ensure that none of the limits

listed in Specications section, Tables 1

through 3 will be exceeded.

Regulator or relief valve operation below the limits

specied in Specications section, Tables 1 through 3

does not preclude the possibility of damage from external

sources or from debris in the gas line. Inspect the

regulator for damage after any overpressure condition.

MAXIMUM ALLOWABLE

RELIEF (INLET) PRESSURE,

psig / bar

Relief Pressure Setting Plus

Maximum Allowable Buildup of

25 psig / 1.72 bar

Relief Pressure Setting Plus

Maximum Allowable Buildup of

250 psig / 17.2 bar

MAXIMUM EMERGENCY

INLET (CASING) PRESSURE

75 5.17

550 37.9

(1)

Startup

Starting up the unit consists of opening the upstream

block valve, introducing gas pressure. Use gauges to

monitor pressures during startup.

The range of allowable pressure settings is marked

on the nameplate. If a pressure setting beyond the

nameplate range is required, substitute an appropriate

spring selected from Table 5. Be sure to change the

nameplate to indicate the new pressure range.

3

Page 4

630 Series

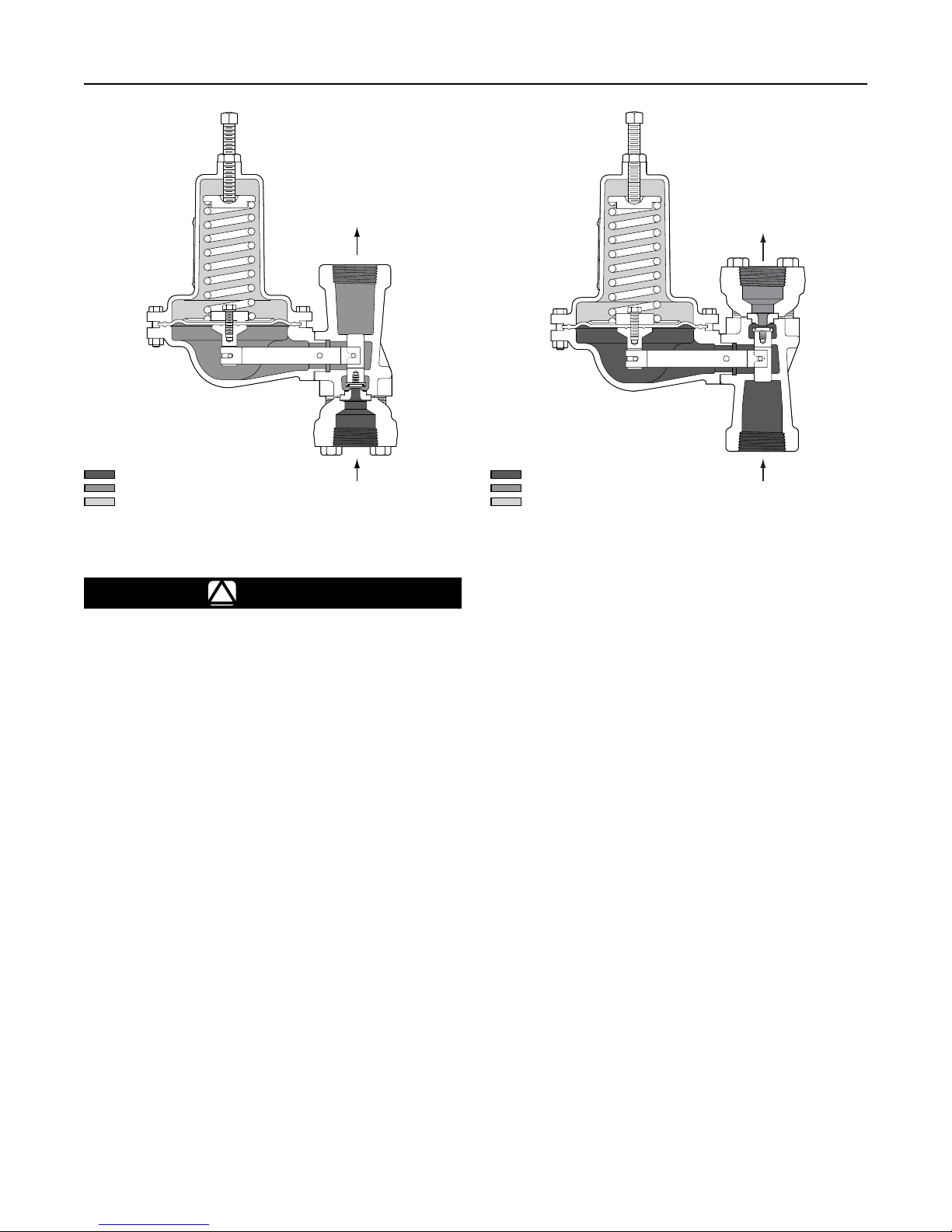

46A2976-A

A2525-1

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Type 630 Regulator Operational Schematic

WARNING

!

To avoid the consequences of overtightening the spring in spring-loaded

regulators or relief valves, consult

Table 4 and replace the adjusting screw

with one of the correct length when

replacing the spring.

Some pressure ratings are dependent upon the actual

outlet pressure settings being used. For example,

with a Type 630 regulator, outlet pressure must not

exceed the setting by more than 20 psig / 1.38 bar

for low pressure constructions or 200 psig / 13.8 bar

for high pressure constructions or damage to internal

regulator parts may occur. However, with some higher

pressure ranges, the setting plus 20 psig / 1.38 bar or

200 psig / 13.8 bar exceeds the maximum emergency

outlet (casing) pressure. Before increasing the setting,

refer to Tables 2 and 3 (as appropriate). Review the

pressure limits for the spring range being used and

be certain that the new pressure setting will not result

in an overpressure condition. Always use a pressure

gauge to monitor pressure when making adjustments.

46A2977

A2526-1

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 3. Type 630R Relief Valve Operational Schematic

Adjusting Spring-Loaded Regulators

and Relief Valves

Loosen the hex nut (key 2, Figures 4, 5 and 6) atop

the spring case. While monitoring the pressure,

rotate the adjusting screw (key 1, Figures 4, 5 and 6)

clockwise to increase set pressure or counterclockwise

to decrease it. When the unit is regulating or relieving

pressure at the desired value, tighten the hex nut.

Shutdown

Slowly close the upstream block valve.

Principle of Operation

This section describes the operation of the Type 630

regulator and the Type 630R relief valve with spring

loading. Set pressure is changed with the adjusting

screw on the regulator or relief valve. The Type 630R

relief valve uses a light spring for added stability.

Type 630 Regulators

Refer to Figure 2. In the regulator construction, outlet

pressure registers beneath the diaphragm. As long

as the outlet pressure is less than the set pressure,

spring force on the diaphragm causes the lever to hold

4

Page 5

630 Series

the valve open. When the outlet pressure exceeds the

set pressure, the diaphragm moves to compress the

spring and the lever closes the valve until the outlet

pressure returns to set pressure.

Type 630R Relief Valves

Refer to Figure 3. In the relief valve construction, inlet

pressure registers beneath the diaphragm. As long

as the inlet pressure is less than the set pressure,

spring force causes the lever to hold the valve closed.

When the inlet pressure exceeds the set pressure,

the diaphragm moves to compress the spring and the

lever opens the valve allowing inlet pressure to bleed

into the downstream line or to atmosphere until the

inlet pressure returns to set pressure.

Maintenance

Parts are subject to normal wear and must be inspected

and replaced as necessary. Frequency of inspection

depends upon severity of service conditions.

WARNING

!

To avoid personal injury or equipment

damage, isolate the regulator or

relief valve from the pressure system

and release all pressure from the

regulator or relief valve before

performing maintenance.

Except where indicated, key numbers in the following

procedures are shown in Figures 4 and 5 for the

Type 630 regulator, in Figure 6 for the Type 630R

relief valve.

Replacing Orice, Valve Disk and Lever

Note

With some piping systems it may

be possible to omit step 1 below by

removing four cap screws (key 17) and

spreading the body (key 23) and inlet

adaptor (key 18) far enough apart to

allow removal of the orice (key 20)

and Type 630 valve disk (key 21,

Figures 4 and 5) or the orice (key 20)

and the Type 630R valve seat O-ring

(key 37, Figure 6).

CAUTION

If step 1 is omitted and the body and

inlet adaptor are separated, take care to

avoid pinching ngers between the body

and the inlet adaptor.

1. Disconnect piping from inlet adaptor (key 18).

Remove four cap screws (key 17) and adaptor.

2. Remove orice (key 20) and gaskets (key 19).

3. To remove Type 630 valve disk (key 21, Figures 4

and 5) or Type 630R valve seat O-ring (key 37,

Figure 6), rst disconnect remote vent pipe (if one

is used).

4. Unscrew the two cap screws (key 31, not shown)

that secure diaphragm adaptor (key 13) to body

(key 23); remove diaphragm adaptor and attached

spring case (key 3).

5. If it is necessary to replace the lever (key 14),

drive out the pin (key 15) and slide the lever out

of the diaphragm adaptor. When replacing the

lever, make sure the slot engages the connector

assembly (key 12) and replace the pin.

6. Remove valve carrier assembly (key 22)

from body.

7. To replace seating surface:

a. For Type 630, use a 3/4 in. / 19.1 mm socket

wrench to remove and re-install valve disk and

holder assembly (key 21, Figures 4 and 5).

b. For Type 630R, unscrew machine screw (key 36,

Figure 6) and remove O-ring washer and

O-ring (keys 32 and 37, Figure 6) from O-ring

holder (key 21, Figure 6). When reassembling,

apply a good-quality gasket shellac to the

machine screw thread.

8. Use new orice gaskets (key 19) and body

gasket (key 16) when reassembling. Insert valve

carrier assembly (key 22) into the body before

re-installing the diaphragm adaptor.

Note

The spring case (key 3) must point

away from the inlet adaptor (key 18)

on Type 630 regulators as shown in

Figures 4 and 5. On Type 630R relief

valves, the spring case (key 3) must face

the same direction as the inlet adaptor

(key 18) as shown in Figure 6.

5

Page 6

630 Series

30

10

11

12

13

14

15

16

A

8

1234567

3534

9

27

9

17 18 19 20 21 22 23

0X00119-F

Figure 4. Spring-Loaded Type 630 Regulator - Low Pressure Construction

9. Be certain the lever (key 14) engages the

valve carrier.

10. Secure the diaphragm adaptor (key 13) to the body

(key 23). Fit the inlet adaptor (key 18) to the body

and install and tighten the four cap screws (key 17).

Replacing the Diaphragm

1. To relieve spring compression, loosen hex nut

(key 2, Figures 4, 5 and 6). Turn the adjusting

screw (key 1, Figures 4, 5 and 6) counterclockwise

until spring compression is relieved.

2. Disconnect remote vent line (if one is present).

3. Remove spring case (key 3) by unscrewing cap

screws and nuts (keys 9, 10 and 30).

4. Remove diaphragm (key 11) and attached parts

from the lever (key 14).

5. Unscrew cap screw (key 6) from connector

head assembly (key 12) and disassemble the

diaphragm assembly.

6. Install new diaphragm being certain that

the diaphragm is centered. Note that lowpressure constructions use a diaphragm plate

(key 8, Figure 5) on the spring case side of

the diaphragm. Install new gaskets when

replacing diaphragm.

7. When reassembling, be certain that the diaphragm

connector is engaged in the lever.

Note

Be careful not to twist the diaphragm

to lever attachment during assembly.

Twisting will cause sufcient friction to

interfere with the proper operation of

the regulator.

6

Page 7

12

12

13

13

14

14

15

15

16

16

10 11

30

10

30

11

A

A

7

6

7 6 5 43 2 1

9

9

3

9

9

4

5

12

27

27

630 Series

3435

34

35

18

17

CB2197-E

8. To ensure proper slack in the diaphragm, tighten

the spring case cap screws nger-tight only.

Compress the spring slightly with the adjusting

screw then complete the tightening of the spring

case cap screws and nuts.

23

19

20

Figure 5. Spring Loaded Type 630 Regulator - High Pressure Construction

21

22212019231817

22

Parts Ordering

The type number orice size, spring range and date of

manufacture are stamped on the nameplate. Always

provide this information in any correspondence with

your local Sales Ofce regarding replacement parts or

technical assistance.

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list. Separate kit containing all recommended

spare parts is available.

Parts List

Note

In this parts list, parts marked NACE are

intended for corrosion-resistant service

as detailed in the NACE International

Standard MR0175.

Parts Kits

Type 630 regulator kits are for low or high pressure

spring-loaded construction. Kits include neoprene

diaphragm, copper inlet gasket material (for brass

trim) or composition material (for stainless trim)

and valve disk assembly material as noted. Orice

included only where indicated. If separate orice is

required, must be ordered separately by appropriate

part number based on orice size and material.

(Included are keys 11, 16, 19, 21 and 20).

7

Page 8

630 Series

12

12

13

13

14

14

15

15

16

16

22

10

10 1130

21

20

30

11

A

A

19

23

2322 21 20 19 18 17

6

7

7 6 5 43 2 1

9

9

36

36

32

32

18

17

5

9

9

4

1

23

27

27

35

34

3435

37

37

CD3355-E

Figure 6. Spring-Loaded Type 630R Relief Valve High-Pressure Construction

Key Description Part Number

Low Pressure

Without orice

Brass/Nitrile (NBR) R630X000L12

Brass/Nylon (PA) R630X000L22

Brass/PTFE R630X000L32

Stainless steel/Nitrile (NBR) R630X000L42

Stainless steel/Nylon (PA) (standard and NACE) R630X000L52

Stainless steel/PTFE R630X000L62

With orice (key 20)

1/2 in. / 12.7 mm Brass/Nylon (PA) R630X000LA2

1/2 in. / 12.7 mm Stainless steel/Nylon (PA) R630X000LB2

High Pressure

Without orice

Brass/Nitrile (NBR) R630X000H12

Brass/Nylon (PA) R630X000H22

Brass/PTFE R630X000H32

Stainless steel/Nitrile (NBR) R630X000H42

Stainless steel/Nylon (PA) (standard and NACE) R630X000H52

Stainless steel/PTFE R630X000H62

Key Description Part Number

High Pressure (continued)

With orice (key 20)

1/8 in. / 3.18 mm Brass/Nylon (PA) R630X000HC2

1/8 in. / 3.18 mm

Stainless steel/Nylon (PA) (standard) R630X000HD2

1/8 in. / 3.18 mm

Stainless steel/Nylon (PA) (NACE) R630X00NHD2

1/4 in. / 6.35 mm Brass/Nylon (PA) R630X000HA2

1/4 in. / 6.35 mm

Stainless steel/Nylon (PA) (standard) R630X000HB2

1/4 in. / 6.35 mm

Stainless steel/Nylon (PA) (NACE) R630X00NHB2

Type 630R Relief Valve retrot kit converts

Type 630 to a Type 630R. (Included are

keys 16, 19, 20, 21, 32, 34, 35

1/2 in. / 12.7 mm Brass/Nitrile (NBR) R630RX00B12

1/2 in. / 12.7 mm Stainless steel/Nitrile (NBR) R630RX00S12

(1)

, 36 and 37)

1. Drive screw (key 35) not included in R630RX00S12 kit.

8

Page 9

630 Series

Key Description Part Number

1 Adjusting Screw, Steel See Table 4

2 Hex Nut, plated steel 1A352424122

3 Spring Case

Low-pressure

Cast iron 3C780919042

Steel 3N698122012

High-pressure

Cast iron 3C780819042

Steel 3N698322012

4 Upper Spring Seat, Zinc

Pressure range to 275 psig / 19.0 bar 16A9812X012

Pressure range over 275 psig / 19.0 bar 16A9813X012

5 Spring, steel See Table 5

6 Cap Screw, plated steel 1R817699012

7 Lower Spring Seat

Low-pressure, Steel 0W020324102

High-pressure, Zinc

Pressure range to 275 psig / 19.0 bar 0W020144022

Pressure range over 275 psig / 19.0 bar 1K371044022

8 Diaphragm Plate, Zinc-plated steel

Low-Pressure only (1 required) 0W020225072

9 Cap Screw, Zinc-plated steel

For use with steel diaphragm adaptor

For low-pressure regulator (10 required) 1C379124052

For high-pressure regulator (4 required) 1B787724052

10 Cap Screw, plated steel (for use with

cast iron diaphragm adaptor)

Low-pressure (10 required) 1A352524052

High-pressure (4 required) 1A352524052

11* Diaphragm

Neoprene (CR)

For low-pressure regulator 0W020002192

For high-pressure regulator 0W019902192

Fluorocarbon (FKM)

For low-pressure regulator (2 required) 0W0200X0022

For high-pressure regulator (2 required) 0W019902402

12 Connector Head Assembly

Aluminum trim 16A9811X012

Aluminum trim (NACE) 16A9811X032

Stainless steel trim 1P8465000B2

Stainless steel trim (NACE) 1P8465X0012

13 Diaphragm Adaptor

Low-pressure

Cast iron 0W019719012

Steel 2N698522012

Steel (NACE) 2N6985X0072

High-pressure

Cast iron 0W019819012

Steel 2N698722012

Steel (NACE) 2N6987X0042

14 Lever Assembly, Steel or Stainless steel

Low-pressure 1B2891000A2

Low-pressure (NACE) 1B2891X0032

High-pressure 1B2890000A2

High-pressure (NACE) 1B2890X0022

Key Description Part Number

15 Pin

Stainless steel 0W018835172

Stainless steel (NACE) 0W0188X0022

16* Gasket, Composition 0W018704022

17 Cap Screw, steel (4 required)

1 in. / DN 25 body 1A935924052

2 in. / DN 50 body 11A7202X022

18 Inlet Adaptor, Steel

Body

Cast Iron

1 NPT 1F479823022

2 NPT 1F479923022

Steel

1 NPT 1F479823022

1 NPT (NACE) 1F4798X0022

2 NPT 1F479923022

2 NPT (NACE) 1F4799X0022

CL150 RF

1 in. / DN 25 12A3803X012

2 in. / DN 50 27B0495X012

2 in. / DN 50 (Type 630R only) 28B6247X012

CL300 RF

1 in. / DN 25 12A3633X012

2 in. / DN 50 27B0488X012

2 in. / DN 50 (Type 630R only) 28B6248X012

CL600 RF

1 in. / DN 25 18A7701X012

2 in. / DN 50 27B0498X012

2 in. / DN 50 (Type 630R only) 28B6249X012

19* Inlet Body Gasket (2 required)

Copper, for Brass trim 0W018415042

Composition, for Stainless steel trim 0W018404022

20* Orice

Type 630

Brass

1/8 in. / 3.18 mm 0Z040014012

3/16 in. / 4.76 mm 1B219514012

1/4 in. / 6.35 mm 0W018314012

3/8 in. / 9.53 mm 0W018214012

1/2 in. / 12.7 mm 0W018114012

Stainless steel

1/8 in. / 3.18 mm 1K416635032

3/16 in. / 4.76 mm 1K416535032

1/4 in. / 6.35 mm 1K416435032

3/8 in. / 9.53 mm 1K416335032

1/2 in. / 12.7 mm 1K416235032

Stainless steel (NACE)

1/8 in. / 3.18 mm 1K4166X0012

3/16 in. / 4.76 mm 1K4165X0012

1/4 in. / 6.35 mm 1K4164X0012

3/8 in. / 9.53 mm 1K4163X0012

1/2 in. / 12.7 mm 1K4162X0012

Type 630R

Brass

1/2 in. / 12.7 mm 1B735014012

Stainless steel

1/2 in. / 12.7 mm 1B735035032

Stainless steel (NACE)

1/2 in. / 12.7 mm 1K4162X0012

*Recommended spare part.

9

Page 10

630 Series

Key Description Part Number

21* Valve Disk Assembly (Type 630 only)

For pressure ranges to 200 psig / 13.8 bar

Brass holder, Polyurethane (PU) disk 1P7351X0012

Stainless steel holder, Polyurethane (PU) disk 1P7351000A2

Brass holder, Fluorocarbon (FKM) disk 1B4500X0042

Stainless steel holder, Fluorocarbon (FKM) disk 1B4500X0012

For pressure ranges over 200 psig / 13.8 bar

Brass holder, Nitrile (NBR) disk 1B4500000A2

Stainless steel holder, Nitrile (NBR) disk 1B4500000B2

Brass holder, Nylon (PA) disk 1C1860000A2

Stainless steel holder, Nylon (PA) disk 1C1860000B2

Brass holder, PTFE disk 1C1860000C2

Stainless steel holder, Nitrile (NBR) disk 1B4500X0072

Stainless steel holder, PTFE disk 1C1860000D2

NACE construction

For pressure ranges to 200 psig / 13.8 bar

Stainless steel holder, Fluorocarbon (FKM) disk 1B4500X0082

For pressure ranges above 200 psig / 13.8 bar

Stainless steel holder, Nylon (PA) disk 1C1860000B2

Stainless steel holder, PTFE disk 1C1860000D2

Stainless steel holder, Nitrile (NBR) disk 1B4500X0072

21 O-ring Holder (Type 630R)

Brass 1D336014012

Stainless steel 1D336035032

Stainless steel (NACE) 1D3360X0012

22 Valve Carrier

Brass 0W018614022

Stainless steel 0W018635032

Stainless steel (NACE) 0W0186X0022

23 Body

Cast Iron

1 NPT 0W0209000A2

2 NPT 0W021519012

Steel

1 NPT 2N6990000A2

1 NPT (NACE) 2N6990X0092

2 NPT 2N699122012

2 NPT (NACE) 2N6991X0032

CL150 RF

1 in. / DN 25 27B3333X012

2 in. / DN 50 27B3336X012

2 in. / DN 50 (Type 630R only) 28B6244X012

CL300 RF

1 in. / DN 25 27B3334X012

2 in. / DN 50 27B3337X012

2 in. / DN 50 (Type 630R only) 28B6245X012

CL600 RF

1 in. / DN 25 27B3335X012

2 in. / DN 50 27B3338X012

2 in. / DN 50 (Type 630R only) 28B6246X012

Key Description Part Number

27 Vent Assembly, Type Y602-12 27A5516X012

30 Hex Nut, Zinc-plated steel, (used only

with Cast iron diaphragm adaptor, key 13)

Low-pressure (10 required) 1A352724122

High-pressure (4 required) 1A352724122

31 Cap Screw, plated steel (2 required)

(not shown) 1A341824052

32 O-ring Washer (For Type 630R only)

Brass 1D335914012

Stainless steel 1D335935072

Stainless steel (NACE) 1D3359X0012

33 Plug, plated steel (not shown)

For 2 in. / DN 50 bodies only 1D8293T0022

34 Nameplate, Aluminum

Type 630 1F7496X0072

Type 630R 21A5495X062

35 Drive Screw, Stainless steel (4 required) 1A368228982

36 Machine Screw

Type 630R only

Stainless steel 1A5733X0012

37* O-ring

Type 630R only

Nitrile (NBR) 1D288806992

PTFE 1F581906522

Nitrile (NBR) (NACE) 1D288806992

PTFE (NACE) 1F581906522

43 Diaphragm protector,

PTFE (not shown) (use only when specied)

High Pressure 1K881306242

Low Pressure 1K881206242

52 NACE Tag (not shown), 18-8 Stainless steel 19A6034X012

53 Tag Wire (not shown), 303 Stainless steel 1U7581X0022

*Recommended spare part.

10

Page 11

Table 4. Key 1, Adjusting Screw, Steel

630 Series

TYPE

630

630R

Spring-Loaded

Type 630

Spring-Loaded

Type 630R

TYPE

SPRING

PART NUMBER

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

1K370927082

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

Low-Pressure

High Pressure

Low-Pressure

High Pressure

ADJUSTING SCREW

PART NUMBER

1A279128982

1B212028982

1A500528982

1A500528982

1A500528982

1A500528982

1A279128982

1B212028982

1A500528982

1D336628982

1D336628982

ADJUSTING SCREW PART

NUMBER (WIRE SEAL)

1R829928992

1R830028992

1R8085T0012

1R8085T0012

1R8085T0012

1R8085T0012

1R829928992

1R830028992

1R8085T0012

1R830128992

1R830128992

Table 5. Key 5, Regulator Spring, Steel

OUTLET (OR RELIEF) PRESSURE SETTING

psig bar

3 to 10

8 to 20

17 to 30

27 to 40

27 to 50

46 to 95

90 to 150

150 to 200

200 to 275

275 to 500

3 to 8

6 to 17

15 to 22

20 to 35

35 to 50

30 to 70

50 to 95

75 to 175

150 to 250

0.21 to 0.69

0.55 to 1.38

1.17 to 2.07

1.86 to 2.76

1.86 to 3.45

3.17 to 6.55

6.21 to 10.3

10.3 to 13.8

13.8 to 19.0

19.0 to 34.5

0.21 to 0.55

0.41 to 1.17

1.03 to 1.52

1.38 to 2.41

2.41 to 3.45

2.07 to 4.83

3.45 to 6.55

5.17 to 12.1

10.3 to 17.2

LENGTH OF THREADED PORTION

SPRING PART

NUMBER

0W019227022

0W019127022

0W019027022

0Y066427022

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

1K370927082

0W019227022

0W019127022

0W019027022

0Y066427022

1J146927142

0W019127022

0W019027022

0Y066427022

1J146927142

In. mm

4

3-1/2

3

3

3

3

4

3-1/2

3

3-1/4

3-1/4

SPRING COLOR

CODE

Red Stripe

Olive Drab

Silver

Green Stripe

Red Stripe

Olive Drab

Silver

Green Stripe

Blue Stripe

Yellow Stripe

Red Stripe

Olive Drab

Silver

Green Stripe

Blue Stripe

Olive Drab

Silver

Green Stripe

Blue Stripe

102

88.9

76.2

76.2

76.2

76.2

102

88.9

76.2

82.6

82.6

11

Page 12

630 Series

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28008, France

Tel: +33 2 37 33 47 00

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 1955, 2015; All Rights Reserved

Loading...

Loading...