Page 1

Product Bulletin

546NS Transducer

D103603X012

62.1:546NS

April 2015

Fisherr 546NS Electro‐Pneumatic Transducer

The Fisher 546NS transducer receives a direct‐current

input signal and use a torque motor, nozzle‐flapper,

and pneumatic relay to convert the signal to a

proportional pneumatic output signal. Nozzle

pressure, which operates the relay, is also piped to the

torque motor feedback bellows. This provides a

comparison between input signal and nozzle pressure

and reduces errors in nozzle pressure.

The transducer can be mounted on a pneumatic

diaphragm control valve actuator to provide accurate

operation of the valve. The integrated high‐capacity

pneumatic relay eliminates the need for additional

boosters or relays for operation of control valves.

The transducer also can be used to provide stable

operation when its output signal is transmitted to

small terminal volume chambers such as control

bellows in pneumatic valve positioners.

Features

n Vibration Resistance—High natural frequency of

torque motor moving parts results in negligible

vibration influence. Meets typical seismic

requirements for nuclear service.

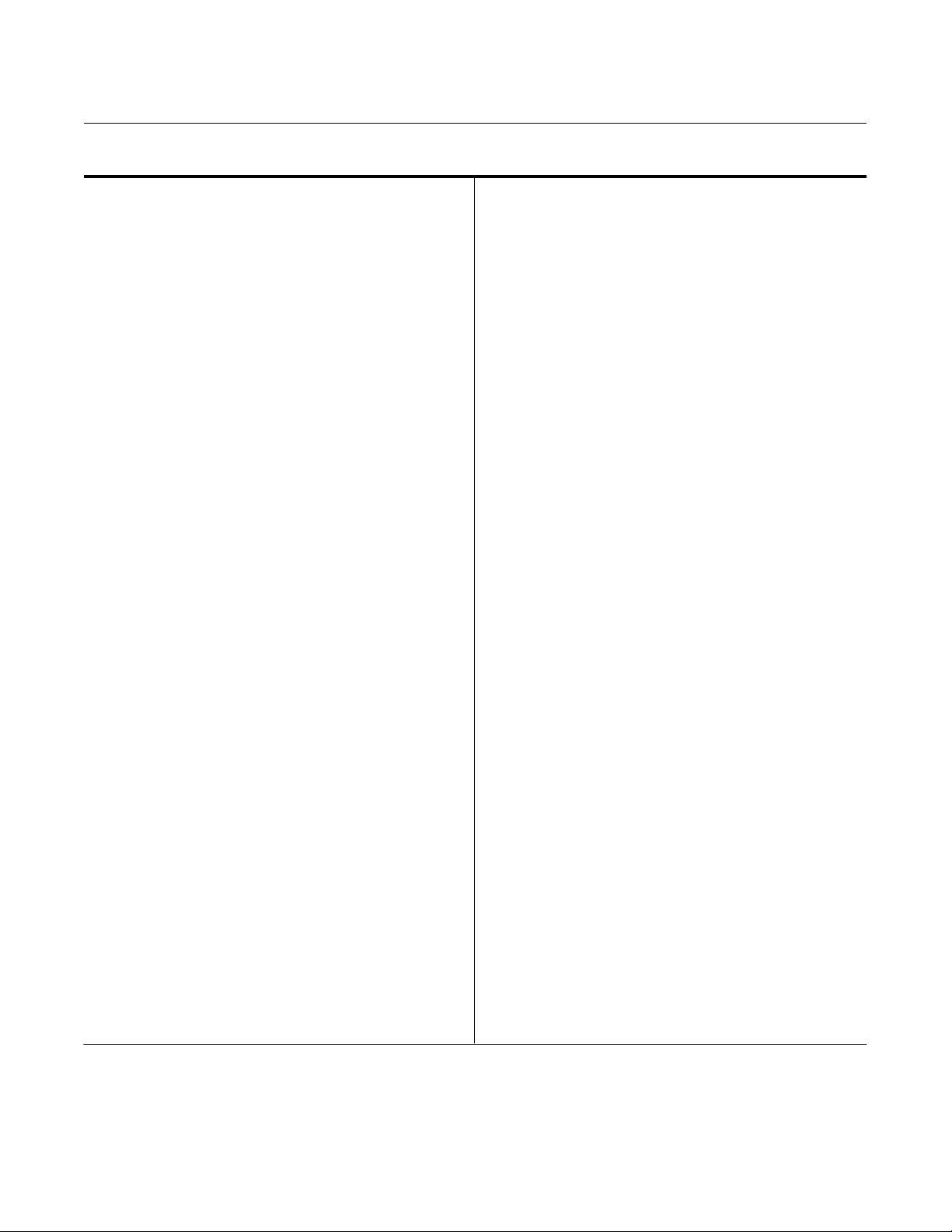

n Easy Adjustment—Screwdriver adjustments for span

and zero are conveniently located and have arrows

indicating rotation to increase settings (as shown in

figure 1).

Fisher 546NS Transducer Mounted on

657 Pneumatic Diaphragm Actuator

W2115

n Field‐Reversible Action—No additional parts

required to reverse action.

n Simple Relay Removal—Integrated pneumatic relay

is mounted outside case and can be removed

without disturbing electrical or pressure

connections or impairing explosion safety.

www.Fisher.com

Page 2

Product Bulletin

62.1:546NS

April 2015

Specifications

Available Configuration

Electro‐pneumatic signal transducer with

explosion‐proof case and cover, with EPDM

elastomers for use in elevated temperature and

radiation environments

The 546NS can be ordered

Fisher 67CFR filter regulator. The 51 mm (2 inch)

supply pressure gauge mounted on the regulator may

be

J 0 to 30 psig or J 0 to 60 psig range

Input Signals

J 4 to 20 mA DC, J 10 to 50 mA DC, or J two‐way

split range using either half of one of the standard

input signal spans

Internal Resistance of Torque Motor

4 to 20 mA DC Input Signal: 176 ±10 ohms

10 to 50 mA DC Input Signal: 90 ±10 ohms

J with or J without a

546NS Transducer

D103603X012

Performance

Actuator Loading Time: see figure 3

Reference Accuracy

Independent Linearity: ±0.50% of output signal span

Open Loop Gain: 26

Frequency Response: Gain is attenuated 3 dB at 20 Hz

with transducer output signal piped to a typical

instrument bellows with 305 mm (12 inch) of 1/4 inch

tubing

Electromagnetic Interference (EMI): Tested per IEC

61326‐1 (Edition 1.1). Meets emission levels for Class

A equipment (industrial locations) and Class B

equipment (domestic locations). Meets immunity

requirements for industrial locations (Table A.1 in the

IEC specification document). Immunity performance

shown in table 1.

Operative Ambient Temperature Limits

-40 to 66_C (-40 to 150_F)

(4)

(5)

: ±0.75% of output signal span

(1)

Output Signals

Ranges:

J 0.2 to 1.0 bar (3 to 15 psig), J 0.4 to 2.0 bar

(6 to 30 psig)

Action: Field reversible between

J reverse

Supply Pressure

(1)

J direct and

Recommended: 0.3 bar (5 psi) higher than upper

range limit of output signal

Maximum: 3.5 bar (50 psig)

Average Steady‐State Air Consumption

(2)(3)

0.44 m3/hr (16.5 scfh) at 1.4 bar (20 psi) supply

pressure

Maximum Output Air Capacity

At 1.4 bar (20 psig) Supply Pressure:

3

12.9 m

At 2.4 bar (35 psig) Supply Pressure:

18.5 m

/hr (480 scfh)

3

/hr (690 scfh)

(2)

Electrical Classification

Hazardous Area:

CSA—Explosion‐proof, Dust Ignition-proof, Div 2

FM—Explosion‐proof, Dust Ignition‐proof,

Non‐incendive

Refer to tables 2 and 3 for specific approval

information

NEMA 3R, CSA Enclosure 3

NEMA 3R mounting orientation requires vent location

to be below horizontal.

Adjustments

Zero and Span Adjustments: Screwdriver adjustments

located inside case (see figure 1)

Connections

Supply Pressure: 1/4 NPT internal located on side of

case (located on filter‐regulator if a 67CFR is mounted

to transducer)

Output Pressure: 1/4 NPT internal located on side of

case

Vent: 1/4 NPT internal with screen located on relay

Electrical: 1/2 NPT internal located on bottom of case

-continued-

2

Page 3

Product Bulletin

546NS Transducer

D103603X012

62.1:546NS

April 2015

Specifications (continued)

Construction Materials

Case and Cover: Aluminum

O‐Rings: EPDM

Flame Arrestors: Stainless steel

Supporting Bracket/Torsion Member: Stainless steel

Magnets: Alloy steel

Nozzle: Stainless steel

Feedback Bellows: Brass

Relay Body: Aluminum

Relay Restriction: Aluminum/Stainless steel

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. The pressure/temperature limits in this document and any applicable standard or code limitation should not be exceeded.

2. Normal m

3. Average flow rate determined at 12 mA and 0.6 bar (9 psig) output.

4. Performance values are obtained using a 546 transducer with a 4 to 20 mA DC input signal and a 0.2 to 1.0 bar (3 to 15 psig) or a 0.4 to 2.0 bar (6 to 30 psig) output signal. Ambient temperature

is 24_C (75_F). A transducer with other input or output signals may exceed these values.

5. Reference accuracy includes the effects of non-linearity, hysteresis, and deadband per SAMA Standard PMC 20.1-1973.

3

/hr-‐Normal cubic meters per hour (0_C and 1.01325 bar, absolute). Scfh‐‐Standard cubic feet per hour (60_F and 14.7 psia).

Relay Diaphragm: EPDM/Nomex

Relay Valve Plug and Seat Ring: Brass

Mounting

Mounting parts are available for

actuator mounting,

mounting, or

J pipestand (2 inch nominal)

J surface mounting

Approximate Weight

4.1 kg (9 lb)

R

.

J control valve

Figure 1. Zero and Span Adjustments (Cover

Removed)

W5391

SPAN ADJUSTMENT

ZERO ADJUSTMENT

Principle of Operation

Refer to figure 2, and assume that the transducer is

direct acting. As the DC milliamp signal increases, so

does the magnetic field around the coils. This results in

an increased magnetic attraction between the

armature and the pole pieces. The armature rotates

slightly clockwise to cover the nozzle, increasing

pressure in the nozzle, the upper chamber of the relay,

and the feedback bellows. Increased nozzle pressure

and increased pressure in the upper chamber of the

relay cause the relay supply port to open, increasing

the output pressure to the actuator and the control

valve. At the same time, the increased pressure in the

feedback bellows acts to move the armature back to

the equilibrium position. In this way, the new nozzle

pressure is compared to the DC input signal by the

force balance principle.

As the DC input signal decreases, magnetic attraction

is reduced and the armature rotates slightly in the

counterclockwise direction to uncover the nozzle.

Decreased nozzle pressure and decreased pressure in

the upper chamber of the relay cause the relay exhaust

port to open and allow output pressure to bleed to

atmosphere. Pressure to the control valve is reduced

until equilibrium is attained.

Reverse‐acting transducers operate in a similar

manner except that when the DC input signal

increases, pressure to the actuator and control valve

decreases.

3

Page 4

Product Bulletin

62.1:546NS

April 2015

Figure 2. Transducer Schematic

FEEDBACK

BELLOWS

546NS Transducer

D103603X012

SPAN ADJUSTMENT

(MAGNETIC SHUNT)

ZERO ADJUSTMENT

PERMANENT MAGNET

POLE PIECES

COIL

ARMATURE

TORSION ROD

EXHAUST

OUTPUT PRESSURE

NOZZLE PRESSURE

SUPPLY PRESSURE

EXHAUST PRESSURE

CP4285-A

A1505-3

OUTPUT

RELAY

VALVE PLUG

Valve Stroking Time

Figure 3 shows relative times for loading and

exhausting an actuator. Exhausting times are

nominally 25 percent of the loading times. Stroking

time depends upon the size of the actuator,travel,

relay characteristics and the magnitude and rate of

change of the input signal. If stroking time is critical,

contact your Emerson Process Management

sales office.

ARMATURE

NOZZLE

CENTER SPACER ASSEMBLY

FIXED RESTRICTION

SUPPLY

Figure 3. Output‐Time Relationships

100

90

80

70

60

50

OUTPUT

40

30

20

(% OF 546NS OUTPUT SPAN)

10

0

0 102030405060708090100

19A1361‐A

A3103

LOADING

EXHAUSTING

TIME (%)

4

Page 5

546NS Transducer

D103603X012

Product Bulletin

62.1:546NS

April 2015

Nuclear‐Service

Applications

The 546NS transducer is designed for nuclear power

applications. The 546NS construction includes

materials that provide superior performance in

elevated temperature and radiation environments.

The O‐rings are EPDM (ethylene propylene) and the

diaphragms are EPDM/Nomex. EPDM demonstrates

superior temperature capability and shelf life over

nitrile. (Use a clean, dry, oil‐free air supply with

instruments containing EPDM components. EPDM is

subject to degradation when exposed to

petroleum‐based lubricants.) The Nomex diaphragm

fabric demonstrates improved strength retention at

elevated temperature and radiation conditions.

Under the 10CFR50, Appendix B, quality assurance

program, the 546NS transducer is qualified

“commercial grade dedicated”. These can be supplied

as 10CFR, Part 21 items.

Qualification

The 546NS is qualified to meet stringent

environmental conditions encountered in nuclear

power plant containment areas. Samples were

subjected to the tests summarized below:

n Thermal Aging: accelerated service temperature of

54_C (130_F) over 10 years.

n Radiation Aging: 6 MRads Total Integrated Dose

(TID)

n Seismic Event Simulation (DBE): no natural

frequencies found between 5‐100 Hz and seismic

dwells of 8g uniaxial from 3‐40 Hz.

n LOCA/MSLB Event Simulation: saturated steam for

14 hours at 160_C ( 320_F) followed by a gradual

reduction to 83_C (182_F) over a 10 hour period.

Upon conclusion of the above tests, no loss of function

or extreme degradation was found.

Installation

Standard positions for actuator mounting and

pipestand mounting are shown on the front cover

and figure 4, respectively. Dimensions are shown in

figure 4.

Ordering Information

To determine what ordering information is required,

refer to the Specifications table. Carefully review the

information under each specification and in the

referenced table. Specify the desired choice wherever

there is a selection to be made. Always specify the type

number as identified in the Available Configurations

specification.

For transducers that are to be used in intrinsically safe

installations, specify the rating required and the

system with which the unit will be used.

When ordering actuator mounting parts, specify the

actuator type, size, travel, and diaphragm pressure

range. For all Fisher 657 and 667 actuators except size

80, specify whether actuator yoke or actuator casing

mounting is desired (yoke mounting is only available

on size 80 actuators).

For split‐range operation, specify the portion of input

signal to be used; e.g. 4 to 12 milliamps of a standard

4 to 20 milliamp signal.

For nuclear service applications, consult your Emerson

Process Management sales office for additional

information and order assistance.

5

Page 6

Product Bulletin

62.1:546NS

April 2015

Figure 4. Dimensions

546NS Transducer

D103603X012

1/4 NPT

OUTPUT

CONNECTION

51

(2.00)

CP7280-E

A1249-1

51

(2.00)

40

(1.56)

44

(1.75)

78

(3.06)

51 PIPE

(2.00)

(12.94)

(0.88)

70

(2.75)

329

22

125

(4.94)

32

(1.25)

83

(3.25)

1/2 NPT CONDUIT

CONNECTION

PIPESTAND MOUNTING

46

(1.81)

1/4 NPT SUPPLY

CONNECTION

WHEN FILTER

REGULATOR

IS FURNISHED

(2.62)

164

(6.44)

165

(6.50)

1/4 NPT SUPPLY

CONNECTION

WHEN FILTER

REGULATOR

IS NOT FURNISHED

171

(6.75)

52

(2.06)

43

(1.69)

67

37

(1.44)

6.3

(0.25)

40

(1.56)

1/4 NPT OUTPUT

CONNECTION

51

(2.00)

16

(0.62)

CP6477-E

A1248-1

40

(1.56)

44

(1.75)

(2.25)

(2.75)

70

56

329

(12.94)

78

(3.06)

8.7

(0.34)

37

(1.44)

70

(2.75)

ACTUATOR MOUNTING

125

(4.94)

32

(1.25)

(3.25)

22

(0.88)

46

(1.81)

83

164

(6.44)

1/2 NPT CONDUIT

CONNECTION

mm

(INCH)

6

Page 7

546NS Transducer

D103603X012

Product Bulletin

62.1:546NS

April 2015

Table 1. Electromagnetic Immunity Performance

Port Phenomenon Basic Standard Test Level Performance Criteria

Electrostatic discharge (ESD) IEC 61000‐4‐2

Enclosure

I/O signal/control

Specification limit = ±1% of span

1. A=No degradation during testing. B = Temporary degradation during testing, but is self‐recovering.

Radiated EM field IEC 61000‐4‐3

Rated power frequency magnetic field IEC 61000‐4‐8 60 A/m at 50 Hz A

Burst (fast transients) IEC 61000‐4‐4 1 kV A

Surge IEC 61000‐4‐5 1 kV (line to ground only, each) B

Conducted RF IEC 61000‐4‐6

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with

1 kHz AM at 80%

150 kHz to 80 MHz at 3 Vrms

with 1kHz AM at 80%

Table 2. Hazardous Area Classifications—CSA (Canada)

Certification Body Certification Obtained Temperature Code

CSA

Explosion-proof

Class I, Division 1, Group C,D

Class II, Division 1, Groups E,F,G

Class I, Division 2, Groups A,B,C,D

Class II, Division 2, Groups F,G

T5 (Tamb = 66_C)

Table 3. Hazardous Area Classifications—FM (United States)

Certification Body Certification Obtained Temperature Code

FM

Explosion-proof

Class I, Division 1, Groups C,D

Class II, Division 1, Groups E,F,G

Class I, Division 2, Groups A,B,C,D

Class II, Division 2, Groups F,G

T5 (Tamb = 60_C)

(1)

A

A

A

T5

T5

7

Page 8

Product Bulletin

62.1:546NS

April 2015

546NS Transducer

D103603X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2012, 2015 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...