Page 1

Product Bulletin

4195K Pressure Controllers

D200050X012

Fisherr 4195K Gauge Pressure Indicating

Controllers

34.5:4195K

July 2014

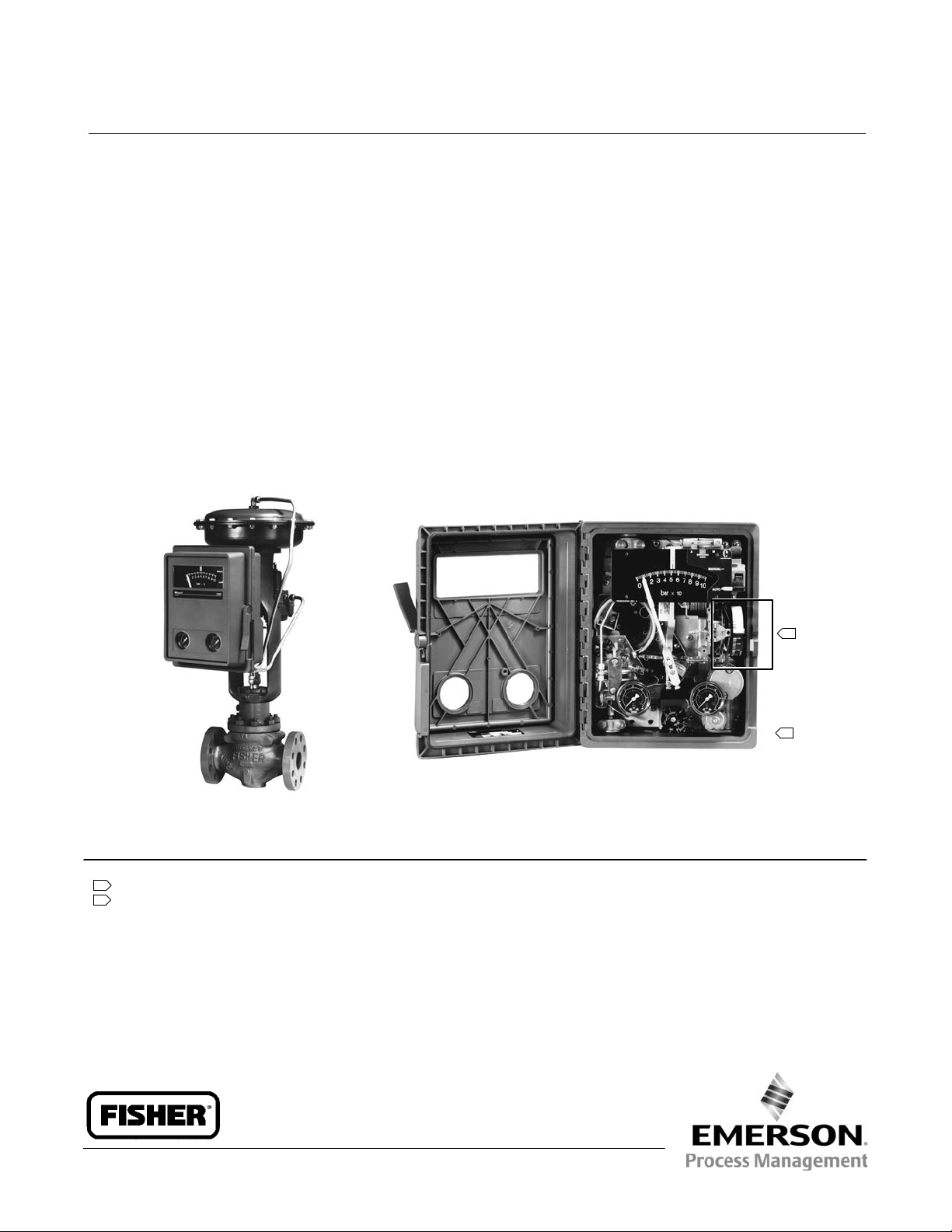

Fisher 4195K gauge pressure indicating controllers

show process pressure and set point on an

easy‐to‐read process scale. The controllers compare

process pressure with an operator‐adjusted set point

and delivers a pneumatic signal to a control element so

that process pressure changes toward the set point.

Controller types are available for proportional‐only,

proportional‐plus‐reset, proportional‐plus‐reset‐

plus‐rate, and differential gap for on‐off control. 4195K

controllers are used in industries where accurate

pressure control and process monitoring are required.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

1

W5660‐1

W5663‐1

YOKE‐MOUNTED CONTROLLER

Notes:

1 An internal cover protects the proportional band adjustment mechanism. In this photograph, the cover has been removed.

2 Controller components are indicated in figure 1.

www.Fisher.com

INTERIOR OF A FISHER 4195KBME CONTROLLER

2

Page 2

Product Bulletin

34.5:4195K

July 2014

Specifications

4195K Pressure Controllers

D200050X012

Available Configurations

See table 1

Process Sensor Range (Input Signal)

Lower and Upper Range Limits:

As shown in tables 2 and 5

Maximum Allowable Pressure:

As shown in tables 2 and 5

Process Scale

Standard scale is matched to the range of the sensing

element, with exception of receiver controllers.

(1)

Optional scales available

.

Process Connections

Standard: 1/4 NPT internal stainless steel (all input

ranges)

Optional: 1/2 NPT adaptors (see table 3)

Output Signal

Proportional, Proportional‐Plus‐Reset, or

Proportional‐Plus‐Reset‐Plus‐Rate Range:

1.0 bar (3 to 15 psig) or

Differential Gap Range:

0 to 2.4 bar (0 to 35 psig)

Action: Field‐reversible between

0.4 to 2.0 bar (6 to 30 psig)

0 to 1.4 bar (0 to 20 psig) or

direct (increasing

0.2 to

sensed pressure increases output pressure), and

reverse (increasing sensed pressure decreases

output pressure) action

Supply and Output Connections

1/4 NPT internal

Supply Pressure Requirements

(2)

See table 4

(continued)

Supply Pressure Medium

Air or natural gas

(3)

Remote Set Point Pressures

0.2 to 1.0 bar (3 to 15 psig) or 0.4 to 2.0 bar

(6 to 30 psig)

Construction Materials

See table 6

Controller Adjustments

Proportional Band: 5 to 500% of process scale span

Reset: Adjustable from 0.01 to more than 74 minutes

per repeat (from 100 to less than 0.0135 repeats per

minute)

Rate: Adjustable from 0 to 20 minutes

Differential Gap Controllers: Adjustable from 5 to

100% of process scale span

Set Point: Adjustable from 0 to 100% of the scale span

Controller Performance

Repeatability: 0.4% of output span

Dead Band: Less than 0.4% of process scale span

Typical Frequency Response: 1.5 hertz and 90 degree

phase shift with 3.05 m (10 feet) of 6.4 mm (1/4‐inch)

tubing and 1639 cm

Steady‐State Air Consumption

0.2 to 1.0 Bar (3 to 15 Psig) Output:

0.09 m

0.4 to 2.0 Bar (6 to 30 Psig) Output:

0.13 m

3

/hr (3.5 scfh)

3

/hr (5.0 scfh)

Delivery Capacity

0.2 to 1.0 Bar (3 to 15 Psig) Output:

3

6.4 m

/hr (240 scfh)

3

(100 cubic inch) volume

(4)(5)

(4)

0.4 to 2.0 Bar (6 to 30 Psig) Output:

3

9.4 m

/hr (350 scfh)

Table of Contents

Features 4.....................................

Construction Features 4.........................

Principle of Operation 8.........................

Proportional-Only Controllers 8..................

Proportional-Plus-Reset and

Proportional-Plus-Reset-Plus Rate Controllers 8..

Differential Gap Controllers 10..................

Remote Set Point Option 10....................

2

Auto/Manual Station Option 10..................

Anti-Reset Windup Option 11...................

External Feedback Option 11....................

Installation 12.................................

Ordering Information 12.........................

Application 12................................

Construction 12...............................

Page 3

4195K Pressure Controllers

D200050X012

Specifications (continued)

Exhaust Capacity

0.2 to 1.0 Bar (3 to 15 Psig) Output:

3

/hr (186 scfh)

5.0 m

0.4 to 2.0 Bar (6 to 30 Psig) Output:

3

7.9 m

/hr (295 scfh)

(4)

Product Bulletin

34.5:4195K

July 2014

Housing

Designed to NEMA 3 (Weatherproof) and IEC 529

IP54 Specifications

Operative Ambient Temperature Limits

-40 to 71C (−40 to 160F)

Hazardous Area Classification

(2)(6)

Mounting

Controller can be mounted on

wall, or pipestand

Complies with the requirements of ATEX Group II

Category 2 Gas and Dust

Approximate Weight

4.5 kg (10 pounds)

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. Consult your Emerson Process Management sales office for additional information.

2. The pressure/temperature limits in this document and any applicable code or standard should not be exceeded.

3. This product can be used with natural gas. Natural gas should not contain more than 20 ppm of H

4. Normal m

5. Without auto/manual station. With auto/manual station air consumption is 0.28 normal m

6. Also use these temperatures for transportation and storage limits.

3

/hr‐‐normal cubic meters per hour (m3/hr, 0C and 1.01325 bar, absolute). Scfh‐‐standard cubic feet per hour (ft3/hr, at 60F and 14.7 psig).

S.

2

3

/hr (10.0 scfh).

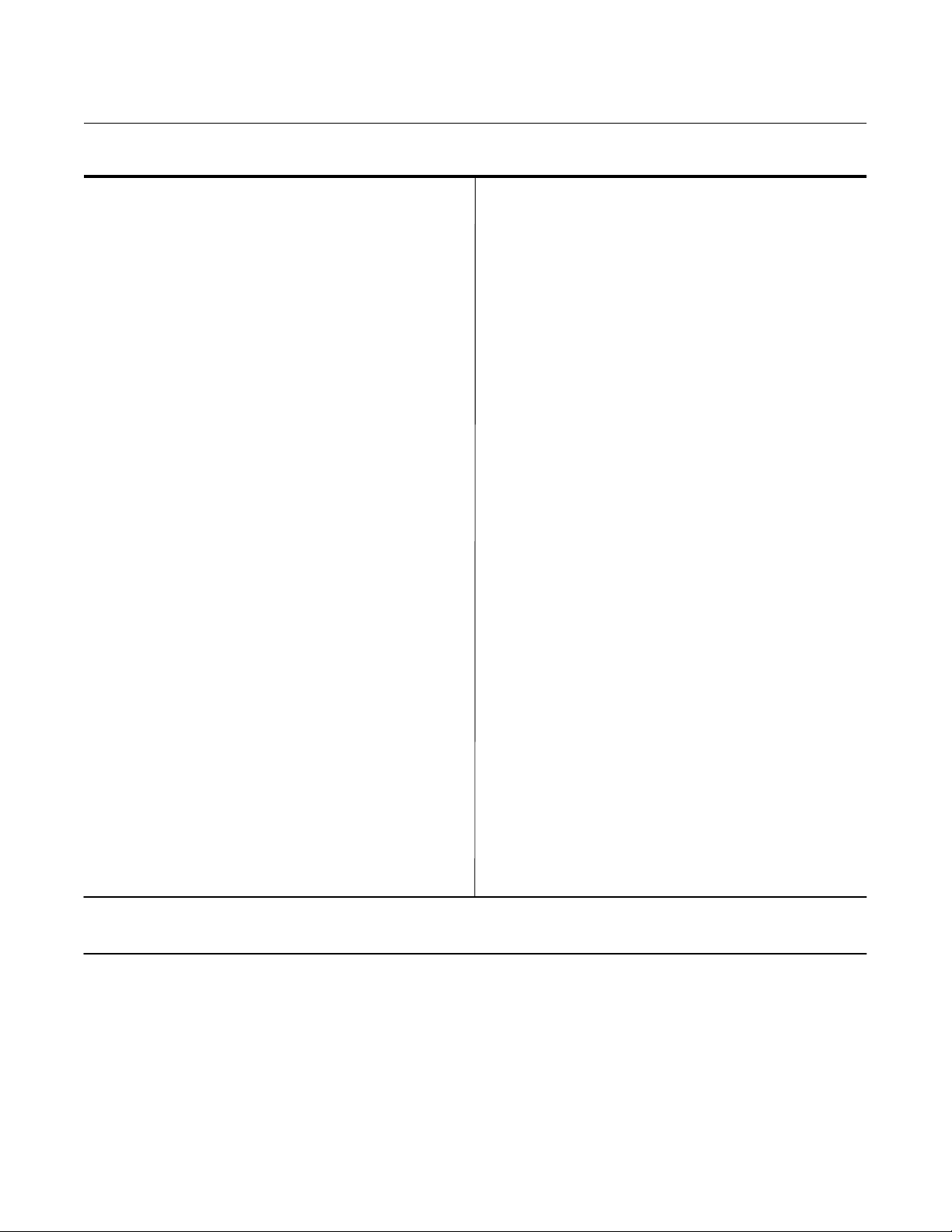

Table 1. Available Configurations

MODES OPTIONS

TYPE

NUMBER

4195KA

4195KAE

4195KAM

4195KAME

4195KB

4195KBE

4195KBF

4195KBFE

4195KBM

4195KBME

4195KBFM

4195KBFME

4195KC

4195KCE

4195KCF

4195KCFE

4195KCM

4195KCME

4195KCFM

4195KCFME

4195KS

4195KSE

4195KSM

4195KSME

1. Reverse‐acting constructions are designated by the suffix letter R in the type number.

(1)

Proportional‐

Only

X

X

X

X

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

Proportional‐

Plus‐Reset

- - -

- - -

- - -

- - X

X

X

X

X

X

X

X

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

Proportional‐

Plus‐Reset‐

Plus‐Rate

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

X

X

X

X

X

X

X

X

- - -

- - -

- - -

- - -

Differential

Gap

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

X

X

X

X

Anti‐Reset

Windup

(suffix letter F)

- - -

- - -

- - -

- - -

- - -

- - X

X

- - -

- - X

X

- - -

- - X

X

- - -

- - X

X

- - -

- - -

- - -

- - -

actuator, panel,

Remote

Set Point

(suffix letter M)

- - -

- - X

X

- - -

- - -

- - -

- - X

X

X

X

- - -

- - -

- - -

- - X

X

X

X

- - -

- - X

X

Internal Auto/

Manual Station

(suffix letter E)

- - X

- - X

- - X

- - X

- - X

- - X

- - X

- - X

- - X

- - X

- - X

- - X

3

Page 4

Product Bulletin

34.5:4195K

July 2014

4195K Pressure Controllers

D200050X012

Features

n Easy Maintenance—Simple design allows fast, easy

maintenance and minimal spare parts inventory.

n Easy Adjustment—Adjusting the set point, the zero

and span of the process pointer, and switching

between direct and reverse action are accomplished

quickly and without special tools. Additionally, the

set point and proportional band can be adjusted

with no interaction between the two adjustments.

n Application Versatility—Either a Bourdon tube or

capsular input element is available to control a wide

range of positive pressures, vacuum pressures, or

compound pressures.

n Mounting Versatility—A 4195K controller can be

mounted directly on the actuator or it can mount

on a pipestand, wall, or in a panel.

n Vibration Resistance—The simple design and low

mass of internal parts allow a 4195K controller to

withstand the vibration levels encountered in most

plant environments.

Construction Features

Simplified Relay Maintenance

A clean‐out wire provides a fast, easy means of

cleaning the relay primary orifice during service.

Pressure Protection for the Case

A rubber plug in the plastic case pops out to relieve

excessive pressure buildup inside the case.

Easy Direct/Reverse Switching

Controller action can be switched from direct to

reverse or vice versa by simply loosening the screws on

the proportional band cover and moving the cover out

to rotate the proportional band knob to the desired

action (see figure 1).

Easy Mode Conversion

Conversion from proportional to

proportional‐plus‐reset control requires the addition

of a reset valve and two pieces of tubing. Conversion

from proportional to proportional‐plus‐reset‐plus‐rate

control requires the addition of a reset/rate valve and

three pieces of tubing. Conversion from proportional

to differential gap for on/off control requires the

addition of one piece of tubing.

n High‐Visibility Display—Two red pointers on a

114 mm (4 1/2‐inch) long, white‐on‐black scale

show process pressure and deviation from set point

at a glance. Two other gauges monitor supply

pressure and output pressure.

n Low Air/Gas Consumption—The relay and nozzle

design reduces the steady-state consumption rate

to as low as 0.09 m

6 scfh requirement set for the oil and gas industry

by the US Environmental Protection Agency (New

Source Performance Standards Subpart OOOO,

EPA‐HQ‐QAR‐2010-0505).

n Corrosion Resistance—Tough, plastic housing resists

such corrosive environments as chemical plants and

the salt spray atmosphere on an offshore oil

platform. Internal constructions are available to

resist a corrosive supply pressure media.

4

3

/hr (3.5 scfh); less than the

Anti‐Reset Windup

Anti‐reset windup is available with

proportional‐plus‐reset controllers. A relief valve may

be installed to limit reset windup in either direction.

Remote Set Point

The capability to adjust the set point from a remote

location is available as an option on 4195K controllers.

Auto/Manual Capability

An optional internal auto/manual station permits

smooth, bumpless transfer between automatic control

and manual operation without disturbing the

controller output. A positive‐acting, two‐position

switch, showing either automatic or manual control

mode, is clearly visible with the controller cover

closed.

Page 5

4195K Pressure Controllers

D200050X012

Product Bulletin

34.5:4195K

July 2014

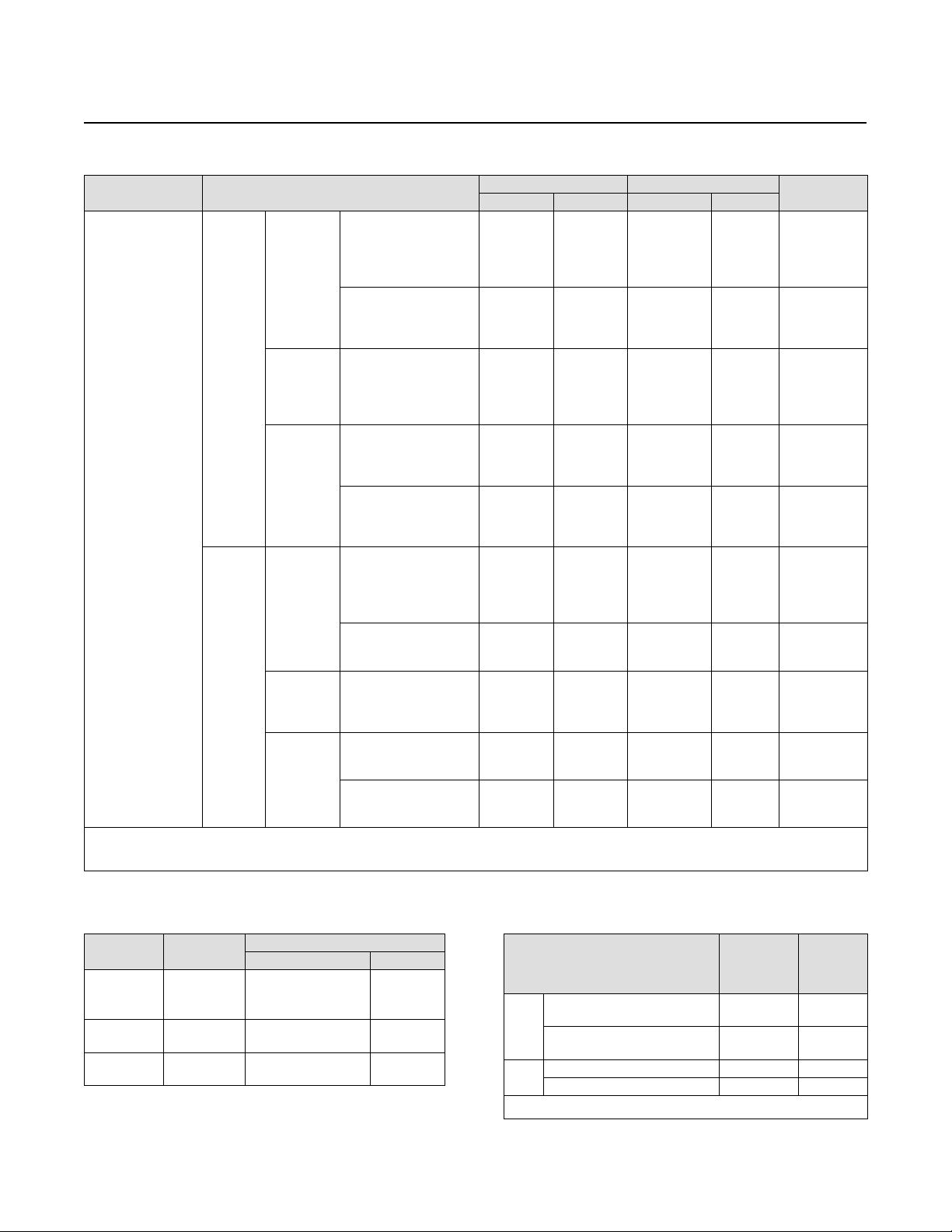

Table 2. Process Sensor (Capsular Element) Pressure Ratings

(1)

CAPSULE

MATERIAL

Metric

units

N09902

Nickel Alloy

U.S. units

1. Minimum or maximum span or any span in between may be positioned anywhere within the operating range. For example, if a 0 to 350 mbar (0 to 5 psig) sensing element is used and the

minimum span of 175 mbar (2.5 psig) is set, the process indication can be calibrated to a range of 340 mbar to 203 mbar (10 inch Hg to 6 inch Hg), 0 to 172 mbar (0 to 2.5 psig), 172 to 345

mbar (2.5 to 5 psig), 305 to 480 mbar (4.5 to 7 psig), or any value between minimum and maximum values of operating range.

2. Capsules with the travel stops set may be pressured to this value without permanent zero shift.

CAPSULAR

STANDARD RANGES

0 to 150 mbar

0 to 400 mbar

0 to 0.6 bar

Positive

pressure

Vacuum

Compound

Positive

pressure

Vacuum

Compound

0.2 to 1 bar

0 to 1 bar

0 to 1.4 bar

0 to 1.6 bar

0.4 to 2 bar

0 to 2 bar

-150 to 0 mbar

-340 to 0 mbar

-400 to 0 mbar

-0.6 to 0 bar

-1 to 0 bar

-50 to 100 mbar

-175 to 175 mbar

-150 to 250 mbar

-0.2 to 0.4 bar

-0.4 to 0.6 bar

-0.6 to 0.8 bar

-1 to 0.6 bar

-1 to 1 bar

0 to 60 inch wc

0 to 5 psig

0 to 10 psig

3 to 15 psig

0 to 15 psig

0 to 20 psig

6 to 30 psig

0 to 30 psig

-5 to 0 inch Hg

-10 to 0 inch Hg

-20 to 0 inch Hg

-30 to 0 inch Hg

-30 to 30 inch wc

-5 inch Hg to 2.5 psig

-10 inch Hg to 5 psig

-15 inch Hg to 7.5 psig

-20 inch Hg to 10 psig

-30 inch Hg to 15 psig

100 mbar

350 mbar

0.35 bar

0.4 bar

0.5 bar

0.7 bar

1 bar

0.8 bar

1 bar

85 mbar

170 mbar

350 mbar

0.35 bar

0.5 bar

100 mbar

175 mbar

350 mbar

0.35 bar

0.5 bar

0.7 bar

1 bar

1 bar

40 inch wc

2.5 psig

5 psig

6 psig

7.5 psig

10 psig

12 psig

15 psig

2.5 inch Hg

5 inch Hg

10 inch Hg

15 inch Hg

40 inch wc

2.5 psig

5 psig

7.5 psig

10 psig

15 psig

SPAN

Min Max Min Max

160 mbar

700 mbar

0.7 bar

0.8 bar

1 bar

1.4 bar

2 bar

1.6 bar

2 bar

170 mbar

340 mbar

700 mbar

0.7 bar

1 bar

160 mbar

350 mbar

700 mbar

0.7 bar

1 bar

1.4 bar

2 bar

2 bar

60 inch wc

5 psig

10 psig

12 psig

15 psig

20 psig

24 psig

30 psig

5 inch Hg

10 inch Hg

20 inch Hg

30 inch Hg

60 inch wc

5 psig

10 psig

15 psig

20 psig

30 psig

OPERATING RANGE

-350 mbar

-1 bar

-1 bar

-1 bar

-1 bar

-1 bar

-1 bar

-1 bar

-1 bar

-350 mbar

-480 mbar

-1 bar

-1 bar

-1 bar

-350 mbar

-480 mbar

-1 bar

-1 bar

-1 bar

-1 bar

-1 bar

-1 bar

-10 inch Hg

-14 inch Hg

-30 inch Hg

-30 inch Hg

-30 inch Hg

-30 inch Hg

-30 inch Hg

-30 inch Hg

-10 inch Hg

-14 inch Hg

-30 inch Hg

-30 inch Hg

-10 inch Hg

-14 inch Hg

-30 inch Hg

-30 inch Hg

-30 inch Hg

-30 inch Hg

350 mbar

1 bar

1 bar

1.4 bar

1.4 bar

1.7 bar

2.4 bar

2 bar

2.4 bar

350 mbar

480 mbar

1 bar

1 bar

1.4 bar

350 mbar

480 mbar

1 bar

1 bar

1.4 bar

1.7 bar

2.4 bar

2.4 bar

5 psig

7 psig

15 psig

20 psig

20 psig

25 psig

30 psig

35 psig

5 psig

7 psig

15 psig

20 psig

5 psig

7 psig

15 psig

20 psig

25 psig

35 psig

OPERATING

LIMIT

510 mbar

1.5 bar

1.5 bar

2 bar

2 bar

2.5 bar

3.5 bar

3 bar

3.5 bar

510 mbar

724 mbar

1.5 bar

1.5 bar

2 bar

510 mbar

724 mbar

1.5 bar

1.5 bar

2 bar

2.5 bar

3.5 bar

3.5 bar

7.5 psig

10.5 psig

22.5 psig

30 psig

30 psig

37.5 psig

45 psig

52.5 psig

7.5 psig

10.5 psig

22.5 psig

30 psig

7.5 psig

10.5 psig

22.5 psig

30 psig

37.5 psig

52.5 psig

(2)

Table 3. Optional Process Connection Adaptors

BAR INPUT

RANGE

Up to

0 to 400

0 to 400 to

0 to 600

0 to 400 to

0 to 600

PSIG INPUT

RANGE

Up to

0 to 5000

0 to 5000 to

0 to 10,000

0 to 5000 to

0 to 10,000

CONNECTION

Size Material

1/2 NPT external or

1/2 NPT internal

1/2 NPT internal stainless

1/2 NPT external stainless

steel or

stainless

steel

steel

steel

Table 4. Supply Pressure Data

Normal

Output Signal Range

0.2 to 1.0 or 0 and 1.4

(diff gap)

Bar

0.4 to 2.1 or 0 and 2.4

(diff gap)

3 to 15 or 0 and 20 (diff gap) 20 40

Psig

6 to 30 or 0 and 35 (diff gap) 35 40

1. If this pressure is exceeded, control stability may be impaired.

2. If this pressure is exceeded, damage to controller components may result.

Operating

Supply

(1)

Pressure

1.4 2.8

2.4 2.8

Maximum

Pressure

(2)

Limit

5

Page 6

Product Bulletin

34.5:4195K

July 2014

4195K Pressure Controllers

D200050X012

Table 5. Process Sensor (Bourdon Tube) Pressure Ratings and Materials

(1)

1

2

2

3.5

7

20

20

55

76

160

15

30

50

100

150

300

750

1100

2200

3700

SPAN

2

4

4

7

14

40

40

70

100

200

30

60

100

200

300

600

1000

1500

3000

5000

BOURDON TUBES

0 to 1.6

0 to 2.5

0 to 4

0 to 6

Metric units

U.S. units

1. Minimum or maximum span or any span in between may be positioned anywhere within the operating range. For example, if a 0 to 2 bar (0 to 30 psig) sensing element is used and the

minimum span of 1 bar (15 psig) is set, the process indication can be calibrated to a range of 1 to 0 bar (30 in. Hg to 0 psig), 0 to 1 bar (0 to 15 psig), 1 to 2 bar (15 to 30 psig), 2 to 3 bar

(27 to 42 psig) or any value between minimum and maximum values of operating range.

2. Travel stops should be used when the maximum or minimum process pressure will be 5% over or under the calibrated range. For example, a 0 to 2 bar (0 to 30 psig) sensing element is

calibrated for 0.7 to 2 bar (10 to 30 psig), the desired range. The minimum expected pressure is 0 psig and the maximum expected pressure is 2.8 bar (40 psig). Travel stops must be used to

prevent excessive overtravel and undertravel since the maximum allowable overpressure and underpressure is higher than 5% of the 1.4 bar (20 psig) span which is

3. Bourdon tube without travel stops may be pressured to this value without permanent zero shift.

4. Bourdon tube with travel stops set may be pressured to this value without permanent zero shift.

0 to 10

0 to 25

0 to 40

0 to 60

0 to 100

0 to 160

Psig Psig Psig In. Hg Psig Psig Standard Material

0 to 30

0 to 60

0 to 100

0 to 200

0 to 300

0 to 600

0 to 1000

0 to 1500

0 to 3000

0 to 5000

Minimum Maximum Minimum Maximum

OPERATING RANGE

Bar

-1

-1

-1

-1

-1

0

0

0

0

0

-30

-30

-30

-30

-30

0

0

0

0

0

(2)

3

6

6

10

20

60

60

90

135

270

42

84

140

280

420

840

1300

1950

3900

6000

OPERATING

(3)

LIMITS

3.3

6.6

6.6

11

22

66

66

103

155

310

48

96

160

320

480

960

1500

2250

4500

7000

(4)

STANDARD MATERIAL

S31600

(316 SST)

S31600

±70 mbar (1 psig).

Table 6. Construction Materials

Part Standard Material Optional Material

Case and cover Polyester plastic - - -

Exterior tubing Copper

Exterior fittings C36000 (brass)

Interior tubing Copper S30400 (304 stainless steel)

Bourdon tube

Nozzle S30300 (303 stainless steel) - - -

Flapper S31600 - - -

Relay springs

Relay O‐rings Nitrile - - -

Relay diaphragms Nitrile - - -

Other relay metal parts

Feedback bellows assembly C51000 (bronze) S32100 (321 stainless steel)

Supply, output gauges Brass (wetted parts only) stainless steel (wetted parts only)

Remote set point element

Capsular input element N09902 nickel alloy S31600

1. Consult your Emerson Process Management sales office for information on other materials.

(1)

S31600 (316 stainless steel)

S30200 (302 stainless steel), steel

Aluminum, stainless steel

N09902 nickel alloy

S30300

stainless steel, polyethylene

stainless steel, polyethylene

N09902 nickel alloy, N05500 nickel alloy (for NACE applications)

- - -

- - -

- - -

6

Page 7

4195K Pressure Controllers

D200050X012

Figure 1. Controller Construction Details

SET POINT INDICATOR

PROCESS PRESSURE INDICATOR

INPUT ELEMENT

3

(BOURDON TUBE)

REMOTE SET POINT

ASSEMBLY

Product Bulletin

34.5:4195K

July 2014

METAL BALL

SWITCHING

ZONE INDICATOR

LOADER KNOB

AUTO/MANUAL

SWITCH

W3679

AUTO/MANUAL STATION

W3439

PROPORTIONAL

BAND ADJUSTMENT

2

W3712‐1

INPUT ELEMENT

ZERO ADJUSTMENT

W5660‐2

SUPPLY

PRESSURE GAUGE

SET POINT

SPAN ADJUSTMENT

RESET ADJUSTMENT

(PROPORTIONAL‐PLUS‐RESET

CONTROLLERS ONLY)

ADJUSTABLE RELIEF VALVE

(ANTI‐RESET WINDUP)

OUTPUT PRESSURE GAUGE

RELAY

POINTER

SPAN ADJUSTMENT

(CAPSULAR ELEMENT)

RATE

ADJUSTMENT

W3599-1

Notes:

1 White portion of proportional band adjustment enables direct controller action; black portion enables reverse controller action.

2 For the process pointer.

3 Input element is a bourdon tube or a capsular element (as shown in inset) depending on input range. See tables 2 and 5.

FOR PROPORTIONAL‐PLUS‐

RESET‐PLUS‐RATE CONTROLLERS

1

RESET

ADJUSTMENT

7

Page 8

Product Bulletin

34.5:4195K

July 2014

4195K Pressure Controllers

D200050X012

Principle of Operation

Refer to the schematic diagrams in figures 2, 3, and 4.

Refer to table 1 for a complete description of type

number suffixes.

Proportional‐Only Controllers

(4195KA)

The input element is connected to the process pointer

and to the flapper by connecting links. As the process

pressure increases (in a direct‐acting controller), the

flapper moves toward the nozzle, restricting flow

through the nozzle and increasing nozzle pressure.

When this occurs, relay action increases the output

pressure (delivery) of the controller. Output pressure is

fed back to the proportional bellows. The action of the

proportional bellows counteracts the flapper

movement that resulted from the process pressure

change and backs the flapper away from the nozzle

until equilibrium is reached.

The set point adjustment changes the proximity of the

nozzle and flapper as does a change in process

pressure except that when the set point is changed,

the nozzle moves with respect to the flapper.

The proportional band adjustment knob positions the

nozzle on the flapper. Increasing (widening) the

proportional band moves the nozzle to a position on

the flapper where less input and more feedback

motion occurs, which decreases the gain of the

controller.

Decreasing (narrowing) the proportional band moves

the nozzle toward a position where more input and

less feedback motion occurs, which increases the gain.

The controller action is changed from direct to reverse

by turning the proportional band adjustment knob to

position the nozzle on the flapper quadrant to a point

where the direction of the flapper motion versus input

motion is reversed (see flapper detail in figure 2). With

the controller in the reverse‐acting mode, an increase

in process pressure causes a decrease in output

pressure.

controllers, output pressure is fed back to the reset

bellows as well as to the proportional bellows. In

operation, proportional‐plus‐reset controllers

minimize the offset between the process pressure and

set point.

As the process pressure increases (in a direct‐acting

controller), the flapper moves toward the nozzle,

restricting flow through the nozzle and increasing

nozzle pressure. When this occurs, relay action

increases the output pressure (delivery) of the

controller. Output pressure is fed back to the

proportional bellows and to the reset bellows.

The action of the proportional bellows quickly

counteracts the flapper movement that resulted from

the process pressure change and backs the flapper

away from the nozzle. Pressure in the reset bellows

opposes the action of the proportional bellows and

slowly moves the flapper closer to the nozzle. Thus,

when the process pressure changes, proportional

action temporarily reduces the gain of the controller

for improved stability. The process pressure then

slowly returns to set point, as pressure in both bellows

equalizes via the reset action.

The set point adjustment changes the proximity of the

nozzle and flapper as does a change in process

pressure. However, when the set point changes, the

nozzle moves with respect to the flapper.

The proportional band adjustment knob positions the

nozzle on the flapper. Increasing (widening) the

proportional band moves the nozzle to a position on

the flapper where less input and more feedback

motion occurs, which decreases the gain of the

controller. Decreasing (narrowing) the proportional

band moves the nozzle toward a position where more

input and less feedback motion occurs, which

increases the gain.

The controller action is changed from direct to reverse

by turning the proportional band adjustment knob to

position the nozzle on the flapper quadrant to a point

where the direction of the flapper motion versus input

motion is reversed. With the controller in the

reverse‐acting mode, an increase in process pressure

causes a decrease in output pressure.

Proportional‐Plus‐Reset and

Proportional‐Plus‐ Reset‐Plus‐Rate

Controllers (4195KB and KC)

The operation of proportional‐plus‐reset controllers

(4195KB) is similar to that of proportional‐only

controllers (described above). However, in 4195KB

8

A 4195KC controller also has a rate valve, which is an

adjustable restriction that momentarily increases the

controller gain to accelerate the corrective action for

slow pressure systems. A proportional‐plus‐reset‐plus‐

rate controller responds to a change in process

pressure as follows: First, the rate action delays the

proportional action just long enough to allow the

Page 9

4195K Pressure Controllers

D200050X012

Figure 2. Schematic of Fisher 4195K Controllers

Product Bulletin

34.5:4195K

July 2014

MANUAL SET POINT

ADJUSTMENT

PROCESS POINTER

REMOTE SET POINT

CONNECTED HERE

INPUT ELEMENT

CONNECTED HERE

CONNECTING

LINK

BEAM

TO

RESET

BELLOWS

TO

PROPORTIONAL

BELLOWS

RESET

VALVE

PROPORTIONAL‐PLUS‐RESET

CONTROL

SUPPLY PRESSURE

OUTPUT PRESSURE

NOZZLE PRESSURE

RESET PRESSURE

PROPORTIONAL

PRESSURE

TO RESET

TO

PROPORTIONAL

BELLOWS

BELLOWS

PROPORTIONAL

BELLOWS

FLAPPER

NOZZLE

TO NOZZLE

TO

POSITIVE

FEEDBACK

BELLOWS

(RESET BELLOWS)

TO NOZZLE

RESET BELLOWS (VENTED)

PROPORTIONAL‐ONLY

OUTPUT PRESSURE

TO FINAL CONTROL

ELEMENT

RELAY

SUPPLY

PRESSURE

TO

NOZZLE

SUPPLY PRESSURE

DIFFERENTIAL GAP CONTROL

OUTPUT PRESSURE

TO FINAL CONTROL

ELEMENT

PROPORTIONAL

BAND ADJUSTMENT

CONTROL

OUTPUT PRESSURE

TO FINAL CONTROL

ELEMENT

DIRECT ACTION

QUADRANT

SUPPLY

PRESSURE

TO

PROPORTIONAL

BELLOWS

RELAY

TO

PROPORTIONAL

BELLOWS

REVERSE ACTION

QUADRANT

FEEDBACK

LINK

FEEDBACK

MOTION

INPUT

MOTION

FLAPPER PIVOT

FLAPPER DETAIL

OUTPUT PRESSURE

TO FINAL CONTROL

ELEMENT

RELAY

TO

RESET

BELLOWS

DIFFERENTIAL RELIEF VALVE

TO

NOZZLE

RESET

VALVE

OUTPUT

RELAY

SUPPLY

PRESSURE

PROPORTIONAL‐PLUS‐RESET CONTROL

WITH ANTI‐RESET WINDUP

TO RESET

BELLOWS

TO

NOZZLE

OUTPUT

RELAY

46A9764‐C

C0756‐2

RELAY

SUPPLY

RATE VALVE

RESET VALVE

PRESSURE

PROPORTIONAL‐PLUS‐RESET‐PLUS‐RATE CONTROL

DIFFERENTIAL

RELIEF VALVE

RATE VALVE

RESET VALVE

PROPORTIONAL‐PLUS‐RESET‐PLUS‐RATE

CONTROL WITH ANTI‐RESET WINDUP

SUPPLY

PRESSURE

9

Page 10

Product Bulletin

34.5:4195K

July 2014

4195K Pressure Controllers

D200050X012

controller to respond to the change quickly with high

gain, but not long enough for the high gain to cause

instability. Then, the low gain provided by the

proportional action keeps the system stable. Finally,

reset action slowly increases the gain and returns the

process pressure toward the set point.

Differential Gap (For On‐Off Control)

Controllers (4195KS)

The operation of differential gap controllers (4195KS)

is similar to that of proportional‐only controllers

(described above). However, in 4195KS controllers, as

the process pressure increases, approaching the upper

switching point, the flapper moves toward the nozzle

(in a direct‐acting controller). This movement restricts

the flow through the nozzle and increases nozzle

pressure. When this occurs, relay action increases the

output pressure (delivery) of the controller. Output

pressure is fed back to the positive feedback bellows.

The action of the positive feedback bellows moves the

flapper closer to the nozzle, increasing nozzle

pressure, which in turn, increases the relay output.

Output pressure to the final control element switches

to full supply pressure.

switching point. On a reverse‐acting controller,

changing the proportional band adjustment will widen

or narrow the differential gap between the two

switching points by moving the position of the upper

switching point.

Remote Set Point Option

(Suffix Letter M)

The capability to adjust the controller set point from a

remote location is available for all 4195KA controllers.

With this option, a control pressure is applied to the

capsular element within the remote set point

assembly. The expansion and contraction of the

capsule moves the set point adjustment via

connecting linkage. Increasing the control pressure to

the capsule increases the set point setting, and

decreasing the control pressure reduces the set point

setting. This option is designated by the letter M in the

type number.

Auto/Manual Station Option

(Suffix Letter E)

As the process pressure decreases, approaching the

lower switching point, the flapper moves away from

the nozzle (in a direct‐acting controller) reducing

nozzle pressure. Through relay action, pressure to the

positive feedback bellows is reduced, moving the

flapper farther away from the nozzle, and further

reducing nozzle pressure. Output pressure to the final

control element switches to zero.

The set point adjustment changes the proximity of the

nozzle and flapper as does a change in process

pressure except that, when the set point is changed,

the nozzle moves with respect to the flapper. The set

point adjustment moves both the upper and lower

switching points.

The proportional band knob positions the nozzle on

the flapper. Increasing (widening) the proportional

band moves the nozzle away from the input

connection. When the proportional band adjustment

moves the nozzle across the feedback connection, the

controller action changes between direct and reverse.

On a direct‐acting controller, changing the

proportional band adjustment will widen or narrow the

differential gap between the two switching points. This

is accomplished by moving the position of the lower

A controller with the auto/manual option (designated

by the letter E in the type number) has piping on the

output side of the relay as shown in figure 3. Supply

pressure to the relay is also applied to the manual

loader. The manual loader, functioning as a regulator,

applies pressure to one side of the plastic tube and to

the auto/manual switch. Output pressure from the

relay registers on the other side of the plastic tube as

well as in the auto/manual switch.

When the auto/manual switch is in the MANUAL

position, the manual loader output is channeled

through the auto/manual switch and becomes the

controller output. When the auto/manual switch is in

the AUTO position, the relay output is channeled

through the switch to become the controller output.

Before the auto/manual switch is operated, the relay

output must equal the manual loader output to avoid

bumping the process. Adjusting the set point varies

the pressure on the left‐hand side of the plastic tube.

Adjusting the manual loader knob varies the pressure

on the right‐hand side of the plastic tube. When the

pressures are equal, the metal ball is centered in the

tube and is held in place by a small magnet. Pressure

imbalance forces the ball to one end of the tube where

it forms a seal, blocking air flow through the tube.

10

Page 11

4195K Pressure Controllers

D200050X012

Figure 3. Schematic of Auto/Manual Station

Product Bulletin

34.5:4195K

July 2014

AUTOMATIC

POSITION

OUTPUT PRESSURE

TO FINAL CONTROL

ELEMENT

RELAY OUTPUT PRESSURE

SUPPLY PRESSURE

MANUAL LOADER OUTPUT PRESSURE

48A5230‐A

A2927‐2

SUPPLY

PRESSURE

Anti‐Reset Windup Option

(Suffix Letter F)

Anti‐reset windup is available for all 4195KB and KC

controllers and is designated by the letter F in the type

number. The differential relief valve operates when the

difference between the proportional bellows pressure

and the reset bellows pressure reaches a

predetermined value. Anti‐reset windup reduces

overshoot of the process pressure that can result from

a large or prolonged deviation from set point.

External Feedback Option

External feedback is available for all 4195KB

controllers. Controllers with this option have an

external connection on the bottom of the controller

case (see figure 6). This connection breaks the positive

feedback (reset) loop inside the controller and brings it

outside (see figure 4).

The connection allows the positive feedback loops of

two controllers (primary and secondary) to be tied

together when the controllers are used in an override

application. When connected, the secondary

controller reset pressure tracks the primary controller

output pressure, minimizing reset windup in the

secondary controller.

AUTO/MANUAL

SWITCH

RELAY

Figure 4. Schematic of External Feedback Option

TO

PROPORTIONAL

BELLOWS

47A0975-A

A3342-1

PLASTIC

TUBE

METAL BALL

OUTPUT PRESSURE

TO FINAL CONTROL ELEMENT

TO RESET

BELLOWS

RESET

VALVE

EXTERNAL FEEDBACK TO

OUTPUT OF HIGH OR LOW

SELECT RELAY

SUPPLY PRESSURE

OUTPUT PRESSURE

MANUAL LOADER

MANUAL

LOADER

KNOB

MANUAL

POSITION

AUTO/MANUAL

SWITCH

TO

NOZZLE

OUTPUT

RELAY

SUPPLY

PRESSURE

NOZZLE PRESSURE

RESET PRESSURE

SELECT RELAY

OUTPUT

11

Page 12

Product Bulletin

34.5:4195K

July 2014

4195K Pressure Controllers

D200050X012

Installation

4195K gauge pressure controllers can be shipped

alone for a separate installation or for installation on a

control valve actuator. The controllers can also be

mounted on a pipe stand, on a wall, or in a panel.

When a controller is mounted on an actuator and a

positioner is not used, the controller will usually be

opposite the supply regulator as shown in figure 5. If a

positioner is used, the supply regulator can be

mounted on the actuator casing.

The controller must be installed so the vent points

down. Basic controller dimensions are shown in

figure 6. Dimensions for specific mounting

configurations are shown in figure 7.

Ordering Information

When ordering a 4195K controller, specify:

Application

1. Description of the service, such as throttling or

on‐off

2. Pressure range, composition, and temperature

of process fluid

3. Ambient temperature

Figure 5. Typical Yoke Mounting

657

ACTUATOR

4195K

CONTROLLER

67FR

FILTER

REGULATOR

MOUNTING

PLATE

W5661

Construction

Refer to the specifications and to the Construction

Features section. Carefully review each specification

and feature, indicating your choice whenever a

selection is to be made. Refer to table 1 for type

numbers; add an R to any type number if reverse

action is desired.

12

Page 13

4195K Pressure Controllers

D200050X012

Figure 6. Controller Dimensions and Connections

260

(10.25)

330

(13.00)

130

(5.13)

102

(4.00)

51

(2.00)

Product Bulletin

34.5:4195K

July 2014

5/16‐18

UNC‐2B

3 HOLES

(MOUNTING)

87

(3.44)

255

(10.04)

FRONT VIEW

1/4‐18 NPT CONTROLLER

OUTPUT CONNECTION

3

A

1

2

3

B

1/4‐18 NPT

VENT

CONNECTION

1/4‐18 NPT SUPPLY

PRESSURE CONNECTION

147

(5.80)

66

(2.56)

31

(1.22)

1/4 NPT 4 HOLES

REAR VIEW

1/4 NPT REMOTE SET

POINT CONNECTION

BOTTOM VIEW TOP VIEW

mm

(INCH)

Notes:

1 1/4-18 NPT process connection (marked A) for all bourdon tube controllers and for those capsular element controllers used in vacuum pressure applications.

2 1/4-18 NPT process connection (marked B) for capsular element controllers used in positive and compound pressure applications.

3 For the external feedback connections (4195KB controllers only), either the A or B connection is used, depending on the location of the process connection.

46A9765‐A

A2892‐4

13

Page 14

Product Bulletin

34.5:4195K

July 2014

Figure 7. Mounting Dimensions

4195K Pressure Controllers

D200050X012

92

(3.62)

TOP VIEW

HORIZONTAL PIPE

222

(8.75)

62

(2.43)

36A9757‐A

SIDE VIEW VERTICAL PIPE

PIPESTAND MOUNTING

84

(3.29)

63

(2.49)

13

(0.50)

62

(2.43)

95

(3.75)

161

(6.35)

TOP VIEW

260

(10.25)

14

B1473‐3

36A9759‐A

REAR VIEW

PANEL MOUNTING WALL MOUNTING

14R

(0.56)

236

(9.31)

306

(12.06)

13

(0.50)

36A9761‐B

152

(6.00)

62

(2.43)

13

(0.50)

REAR VIEWDIMENSIONS OF PANEL CUTOUT

mm

(INCH)

Page 15

4195K Pressure Controllers

D200050X012

Product Bulletin

34.5:4195K

July 2014

15

Page 16

Product Bulletin

34.5:4195K

July 2014

4195K Pressure Controllers

D200050X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

1987, 2014 Fisher Controls International LLC. All rights reserved.

16

Loading...

Loading...